Page 1

WWW.MEGGER.COM

Page 2

Page 3

TABLE OF CONTENTS

Contents

Introduction .......................................................................................................... 2

Clamp-On Testing versus Fall of Potential Testing ............................................. 3

Fall of Potential Testing ................................................................................. 3

Clamp-On Testing ........................................................................................... 4

Clamp-On Ground Testing Theory and Methodology ....................................... 6

Series Circuit ................................................................................................... 6

Parallel Circuit................................................................................................. 7

Parallel-Series Circuit ...................................................................................... 7

Clamp-On Test Methodology ........................................................................ 8

Summary ....................................................................................................... 11

Ground Leakage Current Measurement ........................................................... 11

Applications .................................................................................................. 12

Utility Poles/Service Entrance or Meter .................................................. 12

Street Lighting ......................................................................................... 14

Lightning Protection ................................................................................ 14

Street Cabinets ......................................................................................... 16

Telephone Pedestals ................................................................................ 16

Cell Towers (applications with buried ground ring) .............................. 17

Pad Mounted Transformer ...................................................................... 17

Pole Mounted Transformer ..................................................................... 18

Potential Sources of Error .................................................................................. 19

Factors in Selecting a Clamp-On Ground Tester ............................................... 20

Jaw Design .................................................................................................... 20

Clamp Head Size and Shape ........................................................................ 21

Instrument Size ........................................................................................... 23

Category (CAT) Rating ................................................................................. 24

Noise Filtering............................................................................................... 25

Backlight ....................................................................................................... 25

Data Hold ...................................................................................................... 25

Ergonomics ................................................................................................... 26

Alarm Limit Function.................................................................................... 26

Result Storage............................................................................................... 26

Clamp-on Ground Testers Available from Megger .......................................... 27

Models DET14C/24C...................................................................................... 27

©2013 Megger

Guide to Clamp-on Ground Testing 1

Page 4

Introduction

Testing the quality of the grounding system has been a critical part of any

electrical maintenance program for many years. Ground electrodes are

used to provide a safe path to earth for the dissipation of fault currents,

lightning strikes, static charges and EMF/RFI signals. Over time, ground

systems deteriorate due to either environmental conditions or catastrophic

events (like lightning strikes). Alternatively, facility expansion may change

needs in the installed ground system.

The risks from ground system deterioration include potentially deadly

electrical shocks, plant-wide equipment damage, disruption in the

performance of sensitive electrical equipment, heat build-up and

eventually fire on a single piece of electrical equipment and disruption

in digital communication service. Grounding systems present a unique

challenge because they are out of site, buried beneath the soil. The

only way to ensure that the system remains capable of dissipating fault

currents is to measure its resistance periodically.

Good grounding protects people and equipment and improves the

performance of sensitive electronic equipment. The bonding to the

ground system is also a critical part of the system. Testing the quality

of grounds and bonding should be an active part of any electrical

maintenance strategy. Ground (or earth) testing is done to determine the

effectiveness of the ground system and connections to protect personnel

and equipment and ensure optimal equipment performance. Fall of

potential (and its variants) was the only method of testing ground system

integrity until the 1980s. Clamp-on, or stake-less, ground testing first

appeared in the 1980s and has gained in popularity and acceptance in the

years since its introduction.

This booklet will focus on the clamp-on method of ground testing and

is designed to give the reader a better understanding of the test method

and where it can and cannot be used. Factors that a technician may

want to consider when selecting a clamp-on ground tester will also be

addressed. Please refer to Megger’s booklet “Getting Down to Earth” for

further information on fall of potential tests and soil resistivity tests.

2 1-866-254-0962 www.megger.com

Page 5

Clamp-On Testing versus Fall of Potential Testing

Fall of Potential Testing

As mentioned, clamp-on, or stake-less, ground testing is a relatively

new method of determining the quality of a ground system. The fall of

potential method dates back to the 1930s and is based on the research

of H.B. Dwight. It is the most accurate way of measuring and confirming

ground rod resistance, but it has several major disadvantages. The basic

methodology follows. This booklet will not go into the theory or math

behind this method.

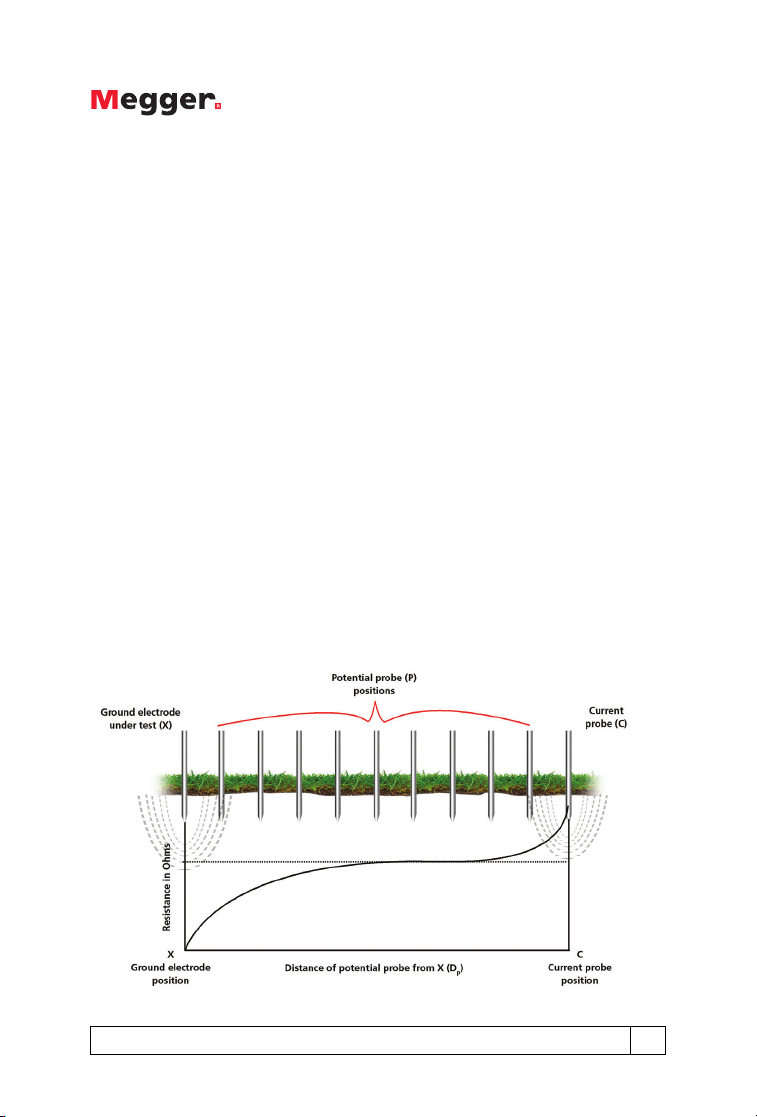

Proper fall of potential testing involves placing a current probe in the soil

at a distance from the ground electrode being tested (please note that

the ground electrode must be disconnected from the system). The actual

distance is determined by the size of the ground electrode/system. The

ground tester is then connected to the ground electrode under test, the

current probe and a potential probe. The potential probe is placed in the

soil at distances of 10%, 20%, 30%, up to 90% of the distance between

the ground electrode and the current probe and a reading is taken at

each location. The readings are then plotted against the distances and the

point where the curve flattens is the approximate resistance of the ground

electrode (see figure below).

Guide to Clamp-on Ground Testing 3

Page 6

The fall of potential method is extremely reliable, as the results can be

checked by testing at different current probe distances. This built-in proof

capability means that results do not have to be accepted on faith. The

operator has complete control of the test set-up. This method can be

used on any size ground system as long as the current probe can be

placed far enough from the ground system under test. It conforms to IEEE

81 and is IEEE approved. In an ideal world, fall of potential would be the

only method used. Unfortunately, nothing is ideal and this method has

three important disadvantages:

1. It is exceedingly time consuming and labor intensive. Temporary probes

must be placed and moved. Cables must be run. Readings must be

taken and plotted.

2. The operator must disconnect the ground electrode to make the test.

As a result, the system is not protected during the test. The ground

electrode must then be reconnected after the test, which, in addition

to being time consuming, leaves the possibility for error if it is poorly

bonded.

3. In real-world situations, space constraints can make it difficult to place

the remote probes.

Clamp-On Testing

The clamp-on ground tester is an effective and time-saving method when

used correctly because the user does not have to disconnect the ground

system to make a measurement or place probes in the ground. The theory

behind this method and the methodology itself will be covered in more

detail later in this booklet. The method is based on Ohm’s Law, where

R (resistance) = V (voltage) / I (current). The clamp includes a transmit coil,

which applies the voltage and a receive coil, which measures the current.

The instrument applies a known voltage to a complete circuit, measures

the resulting current flow and calculates the resistance (see figure on next

page).

4 1-866-254-0962 www.megger.com

Page 7

The clamp-on method requires a complete electrical circuit to measure.

The operator has no probes and therefore cannot set up the desired test

circuit. The operator must be certain that earth is included in the return

loop. The clamp-on tester measures the complete resistance of the path

(loop) that the signal is taking. All elements of the loop are measured in

series. The method assumes that only the resistance of the ground

electrode under test contributes significantly. Based on the math behind

the method (to be reviewed later), the more returns, the smaller the

contribution of extraneous elements to the reading and, therefore, the

greater the accuracy.

The major advantage of the clamp-on method is that it is quick and

easy. The ground electrode does not have to be disconnected from the

system to take the measurement and no probes need to be driven and

no cables connected. In addition, it includes the bonding and overall

connection resistance. Good grounding must be complemented by

“bonding”, having a continuous low-impedance path to ground. Fall of

potential measures only the ground electrode, not the bonding (leads

must be shifted to make a bonding test). Because the clamp-on uses the

grounding conductor as part of the return, an “open” or high resistance

bond will show up in the reading. The clamp-on ground tester also allows

Guide to Clamp-on Ground Testing 5

Page 8

the operator to measure the leakage current flowing through the system.

If an electrode has to be disconnected, the instrument will show whether

current is flowing to indicate whether it is safe to proceed.

Unfortunately, the clamp-on ground tester is often misused in applications

where it will not give an effective reading. The clamp-on method is

effective only in situations where there are multiple grounds in parallel. It

cannot be used on isolated grounds as there is no return path. Therefore,

it cannot be used for installation checks or commissioning new sites.

It also cannot be used if an alternate lower resistance return exists not

involving the soil (such as with cell towers). Unlike with fall of potential

testing, there is no way of proofing the result, meaning the results must

be taken on “faith.” The clamp-on ground tester does fill a role as one

tool that the technician could have in his “bag”, but not the only tool.

Clamp-On Ground Testing Theory and Methodology

Understanding how and why the clamp-on method works helps in

understanding where it will and will not operate, and how to optimize its

use. As mentioned, the clamp-on test method is based on Ohm’s Law

(R = V/I). Understanding Ohm’s law and how it applies to series and

parallel circuits is the first step to understanding how and why a clamp-on

ground tester works. The following graphics will show a series circuit, a

parallel circuit and a series-parallel circuit, and the math used to determine

the total current and resistance.

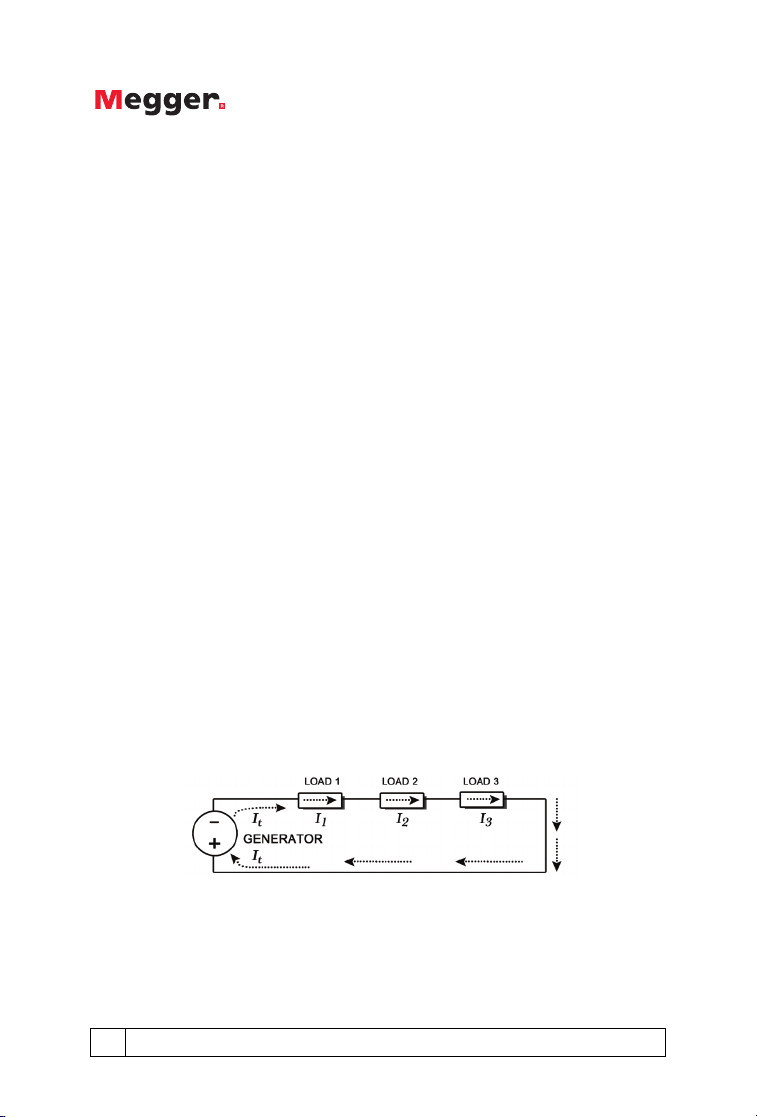

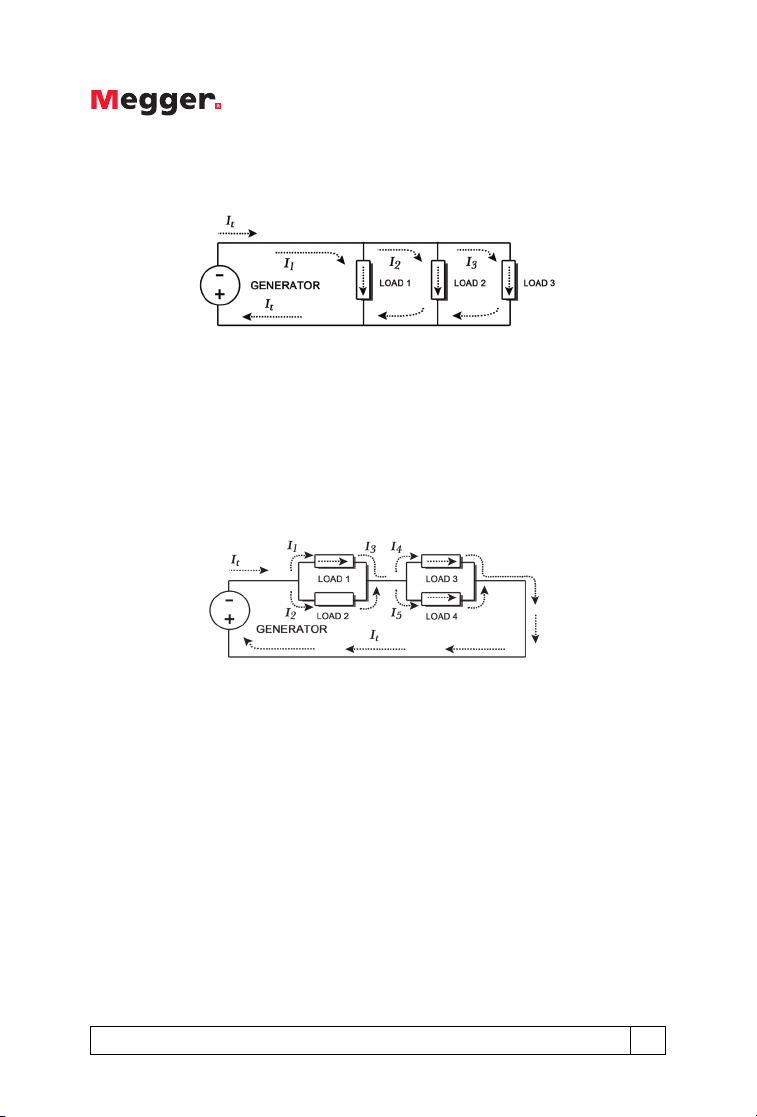

Series Circuit

In a series circuit, total current and total resistance are calculated as

follows: It = I1 = I2 = I

Rt = R1 + R2 + R

6 1-866-254-0962 www.megger.com

3

3

Page 9

Parallel Circuit

In a parallel circuit, total current and total resistance are calculated as

follows:

It = I1 + I2 + I

3

Rt = 1/ (1/R1 + 1/R2 + 1/R3)

Parallel-Series Circuit

In a parallel-series circuit, total current and total resistance are calculated

as follows:

It = I1 + I2 = I3 = I4 + I

5

Rt = 1/ (1/R1 + 1/R2) + 1/ (1/R3 + 1/R4)

Guide to Clamp-on Ground Testing 7

Page 10

Clamp-On Test Methodology

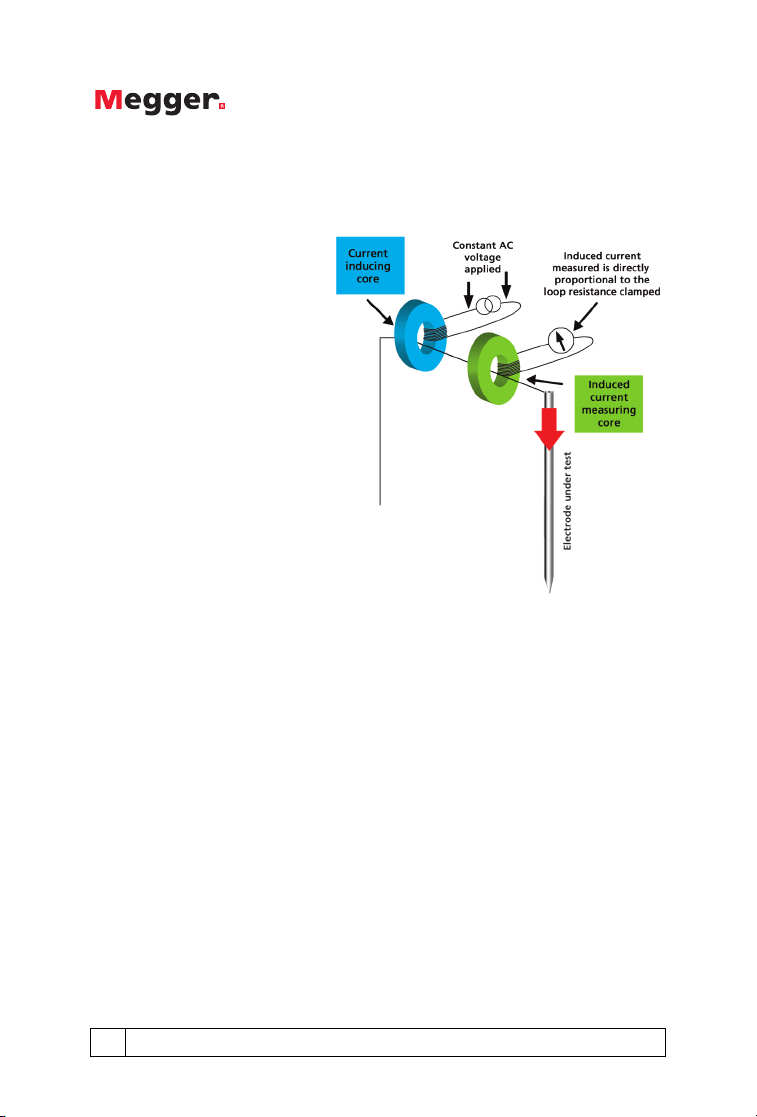

The head of a clamp-on

ground tester includes two

cores (see figure at right). One

core induces a test current

and the other measures how

much was induced. The input

or primary voltage of the

test current inducing core is

kept constant, so the current

actually induced into the test

circuit is directly proportional

to the loop resistance.

The important thing to

remember with clamp-on

testing is that clamp-on

ground testers effectively

make loop resistance

measurements. Clamp-on

measurements are loop

measurements. For the clamp-on method to work there must be a seriesparallel resistance path (and the lower the better). The more electrodes or

ground paths in the system the nearer the measurement gets to the actual

electrode under test’s true resistance. The following figure shows a pole

ground configuration, one of the most effective applications of the clampon ground tester.

8 1-866-254-0962 www.megger.com

Page 11

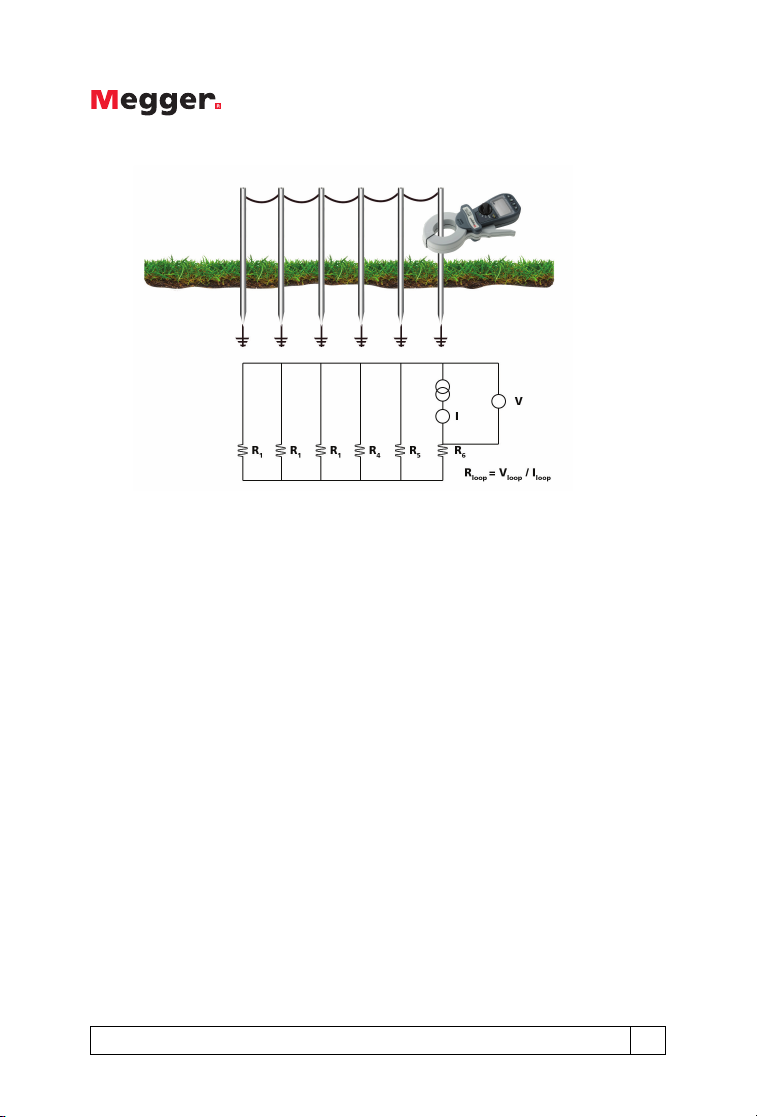

The circuit diagram for this configuration follows (based on a clamp-on

ground tester being clamped around pole 6):

The clamp-on ground tester is clamped around one of the electrodes and

then measures the resistance of the entire loop. The remaining ground

electrodes are all in parallel, and, as a group, are in series with the ground

electrode being measured. If the clamp-on tester is clamped around

pole #6, the measurement of the resistance of the entire loop would be

calculated using the following equation:

R

= R6 + (1/ (1/R1 + 1/R2 + 1/R3 + 1/R4 + 1/R5))

loop

Guide to Clamp-on Ground Testing 9

Page 12

For six similar ground electrodes with a resistance of 10Ω each, the

measurement of the total loop resistance would be:

R

= 10 + (1/ (1/10 + 1/10 + 1/10 + 1/10 + 1/10))

loop

R

= 10 + (1/ (5/10))

loop

R

= 10 + 2

loop

R

= 12Ω

loop

The measurement of the loop resistance is relatively close to the resistance

of the ground electrode being tested. If there were 60 similar ground

electrodes with a resistance of 10Ω each, the measurement of the total

loop resistance would be:

R

= 10Ω + 0.17Ω = 10.17Ω

loop

The more ground electrodes in parallel, the smaller the impact of the

resistance of the electrodes not being tested and the closer the loop

resistance is to the resistance of the electrode being tested. If the

electrode being measured has a high resistance, the test will indicate that

there is a problem. Using the six electrode example, if electrode number

6 had a resistance of 100Ω and all the other electrodes had resistances of

10Ω, the measurement of the loop resistance would be:

R

= 100 + (1/ (1/10 + 1/10 + 1/10 + 1/10 + 1/10))

loop

R

= 100 + (1/ (5/10))

loop

R

= 100 + 2

loop

R

= 102Ω

loop

In the following example, the clamp-on ground tester would indicate the

bad ground. If the 100Ω electrode was one of the electrodes not being

measured, the impact on the overall measurement would be minimal:

10 1-866-254-0962 www.megger.com

Page 13

R

= 10 + (1/ (1/10 + 1/100 + 1/10 + 1/10 + 1/10))

loop

R

= 10 + (1/ (41/100))

loop

R

= 10 + 2.44

loop

R

= 12.44Ω

loop

Please note that the measured resistance will always be higher than the

actual resistance of the ground electrode being tested. Any error present

is on the side of safety, as resistance guidelines are for maximum ground

resistance. This means that if the measured resistance is below target

level for the ground electrode, the operator can be assured that actual

resistance will also be below the target.

Summary

In summary, remember that a clamp-on ground tester measurement is a

measurement of the resistance of the entire loop. There must be a loop

resistance to measure. If there isn’t a loop to measure the operator can

create one with a temporary jumper lead. The greater the number of

parallel paths, the closer the measured value will be to the actual earth

resistance of the electrode under test. The clamp-on ground tester can

easily indicate a poor electrode whether there are a few parallel paths in

series with the measured value, or many parallel paths present.

Remember that the earth path must be in the circuit to measure ground

resistance. This caveat sounds obvious, but if you have metal structures

involved there may be a connection through that, rather than the earth

mass.

Ground Leakage Current Measurement

In addition to measuring the loop resistance, a clamp-on ground tester

should also have the ability to measure ground leakage current. Operator

safety is the most important reason to measure leakage current. If the

tester indicates leakage current, the operator knows that the circuit is live

and that he/she should not contact it without the proper precautions.

Beyond the safety aspect, the leakage current measurement can indicate

if there is a load imbalance on the system. If the loads are balanced,

Guide to Clamp-on Ground Testing 11

Page 14

there will not be any current flowing. If a 3-phase system has been split

and different pieces of equipment are being run off different phases,

there is the potential for an imbalance. The system will try to compensate

and dump the imbalance on the ground system. This situation results in

wasting energy (and money) and stressing the ground system. Leakage

current flow may also result from gradually deteriorating insulation that is

not bad enough to trip the breaker. Whatever the cause, the presence of

leakage current indicates that further action should be taken.

Applications

As with any type of testing, it is critical that the operator understand

the apparatus (in this case, the ground system) that is being tested. The

clamp-on measurement works in many situations, but is not applicable

in certain configurations. In this section, we will look at various types of

applications and outline whether the clamp-on method is viable or not.

Utility Poles/Service Entrance or Meter

The more parallel earths in series with the electrode under test, the nearer

the measurement will be to the actual earth resistance value. Utility poles

(see below) are an ideal application for the clamp-on method.

12 1-866-254-0962 www.megger.com

Page 15

The earth systems on utility poles have many parallel ground connections

making this a perfect location for using the clamp-on method. Each

pole has a ground electrode to maintain fault and lightning protection,

and pole mounted transformers have two electrodes on star configured

systems. It is important that these electrodes are checked. The overall

earth value of such systems typically needs to be less than 0.3 – 0.5Ω,

while each electrode typically needs to be below 10 – 20Ω to be effective.

Another related application is to test the ground electrode resistance on a

service entrance or meter (see graphic below). Here, there is the possibility

of multiple earth paths, two electrodes, or maybe connection to a water

pipe, so take care to identify the best positions to make a measurement.

Sometimes it is best to clamp the electrode itself below where the earth

connections are made.

Guide to Clamp-on Ground Testing 13

Page 16

Street Lighting

A similar application to utility pole electrodes is street lighting. The cable

running to each street light’s electrode may be clamped, but remember to

clamp the correct side of the grounding conductor as shown below.

Lightning Protection

Another ideal application for the clamp-on test method is to test ground

electrodes on lightning protection. Lightning protection on any building

is only as effective as the quality of its grounding. Electrodes are normally

placed at each corner of a building with extra electrodes between on

larger buildings. The conductors used are typically copper tapes up to 50

mm wide. The following figure shows a typical lightning protection circuit

where a clamp-on ground tester is clamped around the electrode.

14 1-866-254-0962 www.megger.com

Page 17

In many cases this is difficult because the electrode is buried in a small pit.

In addition, many lightning protection down tapes are fitted with

removable links to allow the application of a two-wire continuity test.

These removable links, often referred to as ‘jug handles’, are time

consuming to remove, but make ideal locations to use a clamp-on tester.

The clamp-on tester will measure the whole loop, including all of the

connections and tape bonds, just the same as a two wire test.

Many lightning protection systems on factory buildings, especially in

European countries, use lightning receptors mounted at regular intervals

on the roof. These receptors are all interconnected as shown in the

following figure. This approach further decreases the series resistance of

the parallel earth path, meaning the measured value is even closer to the

true earth resistance of an electrode under test.

Remember there could be other connections to the lightning protection

system. The user must remember to clamp around the tape below all

connections. Otherwise the ground electrode will be tested in parallel

to any other paths to earth. There may be connections to external

metal work such as metal balconies and hand rails. These must also

be above the point where the clamp-on tester is clamped. Remember

the importance of a visual inspection as well. With the price of copper,

grounding tapes can be cut and stolen. Depending where the tape is cut,

and how the system is linked, the instrument could return a good, but

false, reading.

Guide to Clamp-on Ground Testing 15

Page 18

Street Cabinets

Another application is to test the

ground electrode installed inside

primary cross-connection points,

sometime called street cabinet/

flexibility points (see figure below).

These electrodes typically need to be

below 25Ω to maintain reliability. In

this application there may not be more

than two parallel earth paths in series

with the electrode. However, based

on the math, if the clamp-on ground

tester provides a measurement below

25Ω, then the electrode must certainly

be below 25Ω.

Telephone Pedestals

Telephone pedestal ground

electrodes can be tested

using the clamp-on method.

Cable sheaths are all

connected to a ground bar,

which in turn is connected

to the ground electrode.

The clamp-on can be placed

around the cable connecting

the ground bar to the

electrode to perform a test. If

access is difficult a temporary

extension cable can be fitted

to facilitate fitting on the

clamp-on tester.

16 1-866-254-0962 www.megger.com

Page 19

Cell Towers (applications with buried ground ring)

A ground resistance measurement cannot be made if the rods are

linked together by a ring that is buried beneath the soil. This type of

configuration, which is common in cell towers, allows access somewhere

above the ring. Cell towers are grounded at the base, with each guy wire

grounded and all of them connected together in a ring of grounds.

If the operator clamps around the head of one of the guy wire grounds,

the test current will simply complete the circuit in the ground ring and not

through the soil. The test current circulates through the conductor that

connects the individual elements (ground rods) that comprise the ring. As

such, the clamp-on ground tester will not be measuring the quality of the

ground system. The reading will actually be a reading of the resistance

of the “loop”. This measurement does allow the operator to verify the

connections beneath the soil.

Guide to Clamp-on Ground Testing 17

Page 20

Pad Mounted Transformer

Pad-mounted transformer ground electrodes can be verified using

the clamp-on method. However, sometimes there are a number of

connections to the same electrode so the user may have to clamp around

the electrode itself below the connections. Should all these connections

be to a large buried ground mat this measurement would then become

a continuity measurement because the test loop will not include an earth

path.

Pole Mounted Transformer

Remember the first of the two golden

rules of clamp-on testing, “there must

be a loop resistance to measure.”

There are some occasions with utility

poles where that loop does not exist,

at least not where you want it to be

anyway. The figure below illustrates a

system with a star-delta transformer

mounted on a pole with two sets of

electrodes.

Neither set of electrodes are connected

to an overhead earth cable. One

is connected to the metal case of

18 1-866-254-0962 www.megger.com

Page 21

the transformer, and the other is connected to the star point of the LV

secondary winding. The danger here is that the loop measured could

be between the two sets of electrodes, with part of the loop being the

resistance of the wood pole, resulting in a high measurement. This could

mislead the user into believing there is a problem when in fact there isn’t

one.

In contrast, in the graphic below, there is a connection to local distribution

and its local ground system. This means we now have an earth loop to

measure and a measurement may be taken. However, remember the

resistance measurement taken is a combination of the two earths in

series. A measurement of 40Ω will not mean each electrode system is

below 25Ω of course, one could be 10Ω and the other 30Ω. If the

measurement is, for example, 10Ω then we know we are going to be

okay.

Potential Sources of Error

If used correctly, the clamp-on test will give reliable measurements as long

as the operator uses a good quality instrument. To highlight and forewarn

users here are some potential sources of error:

Guide to Clamp-on Ground Testing 19

Page 22

We have already discussed one potential source of error; that the user

might not understand the circuit under test. Remember that there must

be a loop resistance to measure and that the earth path must be in the

circuit to measure earth resistance. The example with the pole-mounted

transformer discussed previously is a prime example of an application

where the earth path was not in the circuit.

There are two other key sources of error that the user must understand:

1. Dirt Trapped in the Clamp Head: Dirt trapped between the closing

gap in the head will modify the magnetic circuit. Magnetic flux will

bleed over between the inducing core and the measuring core. The

result will be a false low reading which in some cases could result in

a poor electrode being measured as being good. Many instruments

use interlocking laminations or teeth as they are sometimes referred

to. These can trap the dirt and are difficult to clean. They are also

easily damaged. Damaged teeth will either result in poor, inaccurate

measurements, or render the instrument useless.

2. Noise Current Affecting the Measurement: Testing in noisy

environments can result in high levels of noise current flowing down

the electrode under test. This can cause readings to vary, making them

difficult to interpret, or if the current is too high, make measurement

impossible.

Factors in Selecting a Clamp-On Ground Tester

The most common reason for users not being able to use the clamp-on

ground tester is poor access. Often cable or tape sizes are too large for

the clamp or the instrument design and size make it difficult to fit in tight

spaces. This section will cover the factors that a user should consider

before buying a clamp-on ground tester. In addition to access, we will

look at safety and performance factors.

Jaw Design

There are two ways to design the jaws of the clamp on a clamp-on

ground tester. The easier way to get the jaws to mate properly is to use

interlocking teeth on the core ends. The more complex way, from an

20 1-866-254-0962 www.megger.com

Page 23

engineering standpoint, is to use flat core ends. This latter approach,

when implemented, provides greater measurement integrity and

instrument reliability.

Interlocking teeth Flat jaws

As mentioned in the section on potential sources of error on the previous

page, dirt trapped between the closing gap in the clamp head can result

in erroneous readings. Clamp-on ground testers are used outdoors in

environments that are often dusty and dirty. They are exposed to materials

that can end up on the core ends of the jaws. With flat core ends, the

surfaces can be cleaned easily. This same material tends to get stuck in the

interlocking teeth and is very hard to remove.

The interlocking teeth are also delicate and relatively easy to damage

or shift out of alignment. Damaged teeth cause the instrument to give

inaccurate readings or can cause the instrument to not work at all. Often,

an instrument with damaged teeth must be scrapped.

When considering a clamp-on ground tester, make sure to look at the

clamp head and jaw mating surfaces.

Clamp Head Size and Shape

Ground electrodes come in different shapes and sizes and can be

positioned in difficult-to-access locations. The clamp head size and shape

should be considered when choosing an instrument. Clamp-on ground

testers have different head shapes (round, oval or elliptical), opening sizes

and thicknesses.

Guide to Clamp-on Ground Testing 21

Page 24

An elliptical shaped head can allow much easier access to ground

electrodes in recessed wells.

A larger inner area allows for clamping around larger ground rods or

ground tapes (some of which can have a width of 50 mm). With a smaller

internal opening on the instrument, the larger ground tape must be cut

and a thinner copper bar welded in between to allow the instrument to

make a measurement.

22 1-866-254-0962 www.megger.com

Page 25

Some ground electrodes are secured quite close to the building wall or

utility pole, making it difficult to clamp the head around the rod. The

thicker the head, the more difficult this process is. A thinner head is

preferable, if performance is not compromised.

Before selecting an instrument, the user should consider the size

and location of the ground electrodes to be tested and compare this

information with the specifications of the instruments being considered.

If the user is unsure of what future requirements might be, he/she should

err on the side of there being larger ground rods/tapes to test in the

future.

Instrument Size

The early clamp-on ground tester

models were quite long. In recent years,

technology has allowed manufacturers to

make these instruments shorter. Why is

shorter better? A shorter instrument will

allow better access in difficult locations,

especially in recessed wells.

Guide to Clamp-on Ground Testing 23

Page 26

Category (CAT) Rating

The CAT rating of a test instrument defines where in the electrical supply

chain the instrument can be safely used. This is usually printed on the

instrument across the test connections and appears as CATII, CATIII or

CATIV. CATI is generally no longer used as it has no practical application.

The CAT rating defines the level of transient (spike or surge) the

instrument has been designed to withstand. These transients vary in size

and duration depending on the source of the transient. The transient

riding on a high-energy supply is more dangerous than a transient on an

isolated cable as it can deliver larger currents when a fault occurs (a spike

on steroids, for example).

A transient may be several kV in amplitude but its duration is typically

very short, maybe only 50 microseconds. On its own the transient will

cause little damage. However, when it occurs on top of the normal

mains sinusoidal supply voltage it can start an arc, which continues until

the end of the cycle. In the case of a CAT IV system the available short

circuit current can be in excess of 1000 amps. This generates hundreds

of kilowatts of heat in a small space for a few milliseconds, creating a big

bang, possibly causing burns, fire or explosion.

Instruments designed with the correct category rating have sufficient

clearance between critical parts to prevent an arc from creating the initial

breakdown when a transient occurs. The electrical supply can be broken

down into categories from CATI to CATIV as shown below:

24 1-866-254-0962 www.megger.com

Page 27

As most ground electrode testing takes place outside, users should

consider buying an instrument rated to CATIV 600 V.

Noise Filtering

As mentioned, testing in electrically noisy environments can result in

high levels of electrical noise current flowing down the electrode under

test. This situation can cause the readings to vary, making them difficult

to read. If the current is too high, it can make measurement impossible.

If the user is going to measure ground resistance in an electrically noisy

environment like a switch yard, he/she should look at clamp-on ground

testers that include noise filtering functions. The instrument should detect

the presence of noise and indicate it to the user. Noise filtering increases

noise immunity (usually with a slight increase in measurement time).

Backlight

Ground tests are not always made in the sunlight or in clear weather. As

an example, measurements are often made in low light environments like

cable basements. If the user may be working in such an environment, he/

she should consider an instrument that includes backlight capability.

Data Hold

Depending on the location of the ground electrode, the instrument’s

screen may not always be visible when taking a reading. In this situation,

the user cannot see the reading being taken by the instrument. Including

a hold function on the instrument allows the user to freeze the reading

and then view it when the screen is again visible. Accessing a data hold

button can be difficult during a test and activating it at the time that

the reading settles requires guesswork. Instruments with intelligent data

hold capability allow the user to activate the data hold function before

clamping around the ground electrode. The unit then automatically

captures the reading once it settles and indicates that the measurement is

done by an audible sound.

Guide to Clamp-on Ground Testing 25

Page 28

Ergonomics

Clamp-on ground testers can be used to make many

measurements in a single day (think about the pole

ground application). It is important to consider the

instrument’s ergonomic features, especially in relation to

opening the jaw. The trigger design should be easy and

comfortable to operate. If it is too small, it will require

more force to open (as there is less leverage) and have a

greater chance of the fingers slipping off, causing the jaw

to snap shut.

Alarm Limit Function

The ability to set audible and visual alarm limits can be quite useful,

especially for inexperienced users. Limit alarms should be able to be set for

both resistance and current. A current alarm is an operator safety feature.

Result Storage

Result storage is another capability that the user should consider before

buying an instrument. Traditionally, ground tester results are written

down manually. Buying an instrument that stores the results can save time

and prevent recording errors. Accuracy is improved if the results are time

and date stamped.

26 1-866-254-0962 www.megger.com

Page 29

Clamp-on Ground Testers Available

from Megger

Models DET14C/24C

The DET14C and DET24C are advanced

clamp-on ground resistance testers that

set new standards pertaining to access,

performance, features, simplicity of

operation and safety. Designed with

flat core ends, they prevent dirt buildup, ensuring measurement integrity and

improved reliability over products with

interlocking teeth. Other enhancements

include safety to CATIV 600V, a builtin filter function for electrically noisy

environments, time and date stamped

stored test results and ultra long battery life.

Guide to Clamp-on Ground Testing 27

Page 30

NOTES

28 1-866-254-0962 www.megger.com

Page 31

Page 32

Megger makes high quality instruments for

the following electrical testing applications:

n Insulation Testing

n Relay Testing

n Oil Testing

n Circuit Breaker Testing

n Power Quality Analysis

n Low Resistance Testing

n Battery Testing

n Watthour Meter Testing

n Transformer Testing

n Cable Fault Locating

n Power Factor Testing

n Hi Pot Testing

Megger manufactures electrical test and maintenance

instruments for electrical power, process manufacturing,

building wiring, engineering services and communications.

Visit our website for local assistance worldwide at

www.megger.com.

UNITED STATES

Megger Valley Forge

2621 Van Buren Avenue

Norristown, PA 19403

866-254-0962

CLAMPONGuide_en_V01

Loading...

Loading...