Page 1

DET2/3

Advanced Earth (Ground) Tester

User Guide

Page 2

Page 3

Contents

Safety 1

Safety warnings ...............................................................................................................................................1

Live earth safety precautions

Voltage measurement categories

...........................................................................................................................................................2

CAT IV

............................................................................................................................................................2

CAT III

............................................................................................................................................................2

CAT II

Test leads and clamps

Safety and hazard icons

Warning Icons

Warnings, Cautions and Notes

Warnings

Cautions

.............................................................................................................................................................3

Notes

..................................................................................................................................................3

.......................................................................................................................................................3

........................................................................................................................................................3

............................................................................................................................2

.....................................................................................................................2

......................................................................................................................................2

..................................................................................................................................3

.........................................................................................................................3

Introduction 4

Applications .....................................................................................................................................................4

Agricultural location.

Features

Accessories

...........................................................................................................................................................4

......................................................................................................................................................4

.....................................................................................................................................4

Overview 5

User interface ..................................................................................................................................................5

Display

Controls

Navigation control panel

Terminals

Soft keys

.............................................................................................................................................................6

...........................................................................................................................................................7

..................................................................................................................................8

.........................................................................................................................................................8

..........................................................................................................................................................9

Operation 10

Power on / off ................................................................................................................................................10

Auto off.......................................................................................................................................................10

Power options

Earth test options

Output voltage

Test frequency..............................................................................................................................................10

Noise filter

Test leads and terminal connections

Test modes

.............................................................................................................................................10

..........................................................................................................................................10

............................................................................................................................................10

...................................................................................................................................................10

...............................................................................................................11

....................................................................................................................................................11

Manual mode

Continuous graphical mode

www.megger.com

..............................................................................................................................................11

.........................................................................................................................11

DET2/3

i

Page 4

Set-up 12

Modify parameters.........................................................................................................................................12

General set-up

Graph set-up

Language set-up

...............................................................................................................................................12

.................................................................................................................................................13

............................................................................................................................................13

Earth / ground resistance 14

Test procedure .............................................................................................................................................14

Earth / ground resistivity 17

Test procedure .............................................................................................................................................17

Continuity Test 20

Test procedure .............................................................................................................................................20

Null test leads

................................................................................................................................................21

Leakage Current Test 22

Test procedure .............................................................................................................................................22

See Data management (page 33).

................................................................................................................22

Test methods and set-up 23

Fall of potential (FoP) test ...............................................................................................................................23

Four terminal test lead set-up

Four terminal ART test lead set-up

......................................................................................................................23

...............................................................................................................24

Three terminal test lead set-up

Three terminal ART test lead set-up..............................................................................................................25

Slope method (FoP)

Description

Slope four terminal test lead set-up

Slope three terminal test lead set-up

61.8% Rule (FoP)

61.8% Four terminal test lead set-up

61.8% Three terminal test lead set-up

Two terminal earth resistance test

Two clamp (stakeless) test

........................................................................................................................................25

..................................................................................................................................................25

...........................................................................................................................................29

.....................................................................................................................24

.............................................................................................................28

............................................................................................................28

...........................................................................................................29

.........................................................................................................29

..................................................................................................................30

..............................................................................................................................30

Calibration check tools 31

Instrument calibration check ..........................................................................................................................31

Checking instrument accuracy

Clamp calibration check

.......................................................................................................................31

.................................................................................................................................32

Data management 33

Save test result ...............................................................................................................................................33

To edit a record file name as...

USB connection

Single test result: download or delete

Multiple test results: download or delete

ii

.............................................................................................................................................34

.......................................................................................................................33

............................................................................................................35

........................................................................................................35

www.megger.comDET2/3

Page 5

Maintenance 36

General maintenance .....................................................................................................................................36

Cleaning

Battery

Battery status

Battery replacement.

Battery charge

12 V supply

........................................................................................................................................................36

...........................................................................................................................................................36

...............................................................................................................................................36

....................................................................................................................................37

.............................................................................................................................................38

...................................................................................................................................................38

Specifications 39

Measurement specifications ...........................................................................................................................39

Instrument specifications................................................................................................................................40

Instrument calibration check tool

Electrical specification

Mechanical specification

Clamp calibration check tool

Electrical specification

Mechanical specification

..................................................................................................................................40

..............................................................................................................................40

..................................................................................................................................41

..............................................................................................................................41

...................................................................................................................40

..........................................................................................................................41

Accessories 42

Repair and warranty 43

Calibration and repair 44

Return procedure ...........................................................................................................................................44

Approved service centres

...............................................................................................................................45

End of life 46

WEEE directive ..............................................................................................................................................46

Battery disposal

.............................................................................................................................................46

Declaration of conformity 47

Bibliography 48

Notes 49

www.megger.com

DET2/3

iii

Page 6

iv

www.megger.comDET2/3

Page 7

Safety

Safety

The safety warnings given in this document are indicative of safe practice and shall not be considered exhaustive.

Additionally, they are not intended to replace local safety procedures where the instrument is used.

Note: This User Guide uses the term ‘earth’ throughout some market areas may use the term ‘ground’.

Safety warnings

These safety warnings must be read and understood before the instrument is used. Retain for future reference.

Caution: The instrument must be operated only by suitably trained and competent persons.

If this instrument is used in a manner not specified by the manufacturer the protection of the instrument may

be impaired.

The instrument must NOT be used if any part of it is damaged.

Damaged test leads must NOT be used. Periodically inspect all test leads. Cables and connectors must be in

good order, clean and have no broken or cracked insulation. Users must exercise caution when connecting to

and disconnecting from the system under test. Do not touch any part that could be hazardous live.

Make sure that there are no hazardous voltages before connecting the instrument. Special precautions are

required when working with an untested and possibly 'live' earth. Isolation switches and fuses (not supplied)

must be used.

The instrument will indicate the presence of hazardous voltage between the P terminals. In the absence of

an indication do not assume that there are no hazardous voltages.

Do not touch the test leads or any conductive parts in the test circuit while a test is in progress.

Do not leave the instrument unattended when connected to the system under test and always disconnect the

instrument after tests have been completed.

The only clamps certified for use with the DET2/3 are the Megger MCC1010 and MVC1010, no other clamps

are to be used with this instrument. It is unsafe to use any other clamps.

This instrument contains a lithium-ion high energy battery pack.

Do not pierce, damage, disassemble or modify the battery. The battery contains safety and protection

devices, which if tampered with may cause the battery to generate heat, rupture or ignite.

If a battery is suspected to be faulty, replace it with a Megger approved battery pack. Refer to the User

Guide for instructions on how to change the battery.

If an instrument is suspected to contain a faulty battery, the battery must be removed before the

instrument is shipped.

Do not ship a faulty battery, either separately or inside an instrument.

The instrument must be set to OFF and the lid must be installed and securely closed before the instrument

is shipped.

Do not heat or dispose of the battery in a fire.

Do not subject the battery to strong impact, mechanical shock or excessive heat.

Do not short-circuit or reverse the polarity of the battery pack.

Users of this equipment and their employers are required by Health and Safety Legislation to carry out valid risk

assessments of all electrical work so as to identify potential sources of electrical danger and risk of electrical injury

such as inadvertent short circuits. Where the assessments show that the risk is significant then the use of fused

test leads may be appropriate.

www.megger.com

DET2/3

1

Page 8

Safety

Live earth safety precautions

A 'Live' earth is one that carries current from the mains supply, or could do so under fault conditions. The

following warnings apply in addition to those listed previously:

All persons involved must be trained and competent in isolation and safety procedures for the system to be

worked on. They must be clearly instructed not to touch the earth electrode, test stakes, test leads, or their

terminations, if any 'live' earths may be encountered. It is recommended that they wear appropriate rubber

gloves, rubber soled shoes, and stand on a rubber mat

The earth electrode under test should be isolated from the circuit it protects before a test is started. If this is

not possible, ART may be used to measure electrode resistance

The instrument terminals should be connected to the system under test through isolation switches. The

isolation switches must be rated to handle the likely maximum fault voltages and currents that could be

encountered at the installation.

The isolation switch must be open when any physical contact is made with the remote test stakes, or the

connecting leads, for example, when changing their position

The instrument terminals should be connected to the system under test through fuses, that are rated to

handle the likely maximum fault voltages and currents that could be encountered at the installation

Voltage measurement categories

The rated measurement connection voltage is the maximum line to earth voltage at which it is safe to connect.

CAT IV

Measurement Category IV: Equipment connected between the origin of the low-voltage Mains supply and the

Distribution Panel.

CAT III

Measurement Category III: Equipment connected between the Distribution Panel and the electrical outlets.

CAT II

Measurement Category II: Equipment connected between the electrical outlets and the User’s equipment.

Measurement equipment may be safely connected to circuits at the marked rating or lower. The connection rating

is that of the lowest rated component in the measurement circuit.

Test leads and clamps

Megger supply test leads designed for the DET2/3 which are rated correctly for the test voltage generated by this

instrument, but not all are rated for mains connection. Users must select the correct leads for their project, this

will be either low voltage type rated 50 V, 1 A or leads designed for mains environment rated at 300 V.

Caution: Measurement leads connected to this instrument must be rated at least 50 V, 1 A.

The terminals for connecting current and voltage clamps are not isolated from the measurement terminals. If the

DET2/3 is used in a CAT IV 300 V environment, the clamps and their measurement leads must be rated the same

or higher. Only the Megger MCC1010 and Megger MVC1010 are sufficiently rated, no other clamps are to be

used.

2

www.megger.comDET2/3

Page 9

Safety and hazard icons

i

This section details the various safety and hazard icons on the instruments outer case.

Icon Description

Warning: High Voltage, risk of electric shock

F

Caution: Refer to User Guide

G

Equipment complies with current EU directives

Equipment complies with current 'C tick' requirements

Do not dispose of in the normal waste stream

Warning Icons

This section details the warning icons that can show on the display.

Safety

Icon Warning Description

External Voltage Warning If an external voltage is applied between the terminals and the instrument

F

Internal Error Warning Internal Error Warning switch off and back on. Contact Megger if not

Read the User Guide Refer to the user guide if this message shows.

is set to On, the high voltage warning will flash to say that the item

under test is live and might be dangerous and the test is disabled.

The high voltage warning message will flash if more than 30 V potential

difference is applied between the voltage terminals and the current

terminals.

This warning will not show if all terminals are at the same high voltage.

Note: The warning will not operate if the instrument is set to Off.

cleared.

Warnings, Cautions and Notes

Warnings

Warnings alerts the reader to situations where a hazard to personnel can occur. They are placed before the event

to which they relate and are repeated at each applicable occasion.

Cautions

Cautions alerts the reader to situations where equipment damage may result if a process is not followed. They are

placed before the event to which they relate and are repeated at each applicable occasion.

Notes

Notes give additional information that aid the reader in the use or understanding of the equipment or subject,

they are not used when a Warning or Caution is applicable.

They are not safety related and may be placed either before or after the associated text as required.

www.megger.com

DET2/3

3

Page 10

Introduction

Introduction

This user guide details the operational and functional details of the DET2/3 advanced earth (ground) tester.

Please read this user guide fully before attempting to use the DET2/3.

The DET2/3 automatic earth test instrument is designed to measure earth Electrode Resistance and Soil Resistivity,

with highly accurate results. It is powered by an internal rechargeable battery which has a long usage period.

The battery is recharged with an external power supply unit.

Please refer to the image opposite on page 5 for detail of the DET2/3 layout.

For personal safety and to get the maximum benefit from this instrument, make sure that the safety warnings and

instructions (Safety (page 1)) are read and understood before the instrument is used.

The list of tests and connections detailed in this user guide are not exhaustive. Refer to the booklet Getting

Down To Earth for more information.

Applications

The DET2/3 can be used on large or more complex earth systems, which include communications earth systems

and difficult test environments. It can be used to test in accordance with BS 7430 (Earthing), BS-EN-62305

(Lightning Protection), BS-EN-50122-1 (Railway Applications) and IEEE Standard 81.

Soil resistivity measurements are used to establish the optimum electrode design and site, as well as performing

archaeological and geological investigations.

Where there is doubt about a particular application, reference should be made to the advice and guidance

contained in the publication Getting Down to Earth.

Agricultural location.

The DET2/3 can be used in agricultural locations (as per IEC 61557-5) where, to comply with the standard, the

output voltage must be set to 15 V.

It can also set to 15 V when risk assessment determines that a 50 V test voltage is too high.

Note: IEC 61557-5 recommends that the output is below 25 V in agricultural locations.

Features

The DET2/3 provides accurate 1 mΩ resolution measurements of earth Electrode Resistance.

With its microprocessor controlled system it provides a flexible user-friendly approach to earth tests by the

provision of excellent error detection capabilities and full test information shown on a large colour display.

Test frequency, test voltage and filtering can be quickly and easily adjusted so that adverse conditions, which can

influence the test, can be overcome.

Resistance measurements can also be made with a switched dc signal at a variable frequency of between 10 Hz

and 200 Hz.

A wide band of test current frequencies, with a resolution of 0.5 Hz, can be used to eliminate errors caused by

noise in the earth.

The DET2/3 also includes an automatic frequency selection feature that scans for frequencies with the lowest

noise level and then runs a test at that frequency.

Accessories

A large range of accessories are available, contact Megger for details (Refer to page 42).

4

www.megger.comDET2/3

Page 11

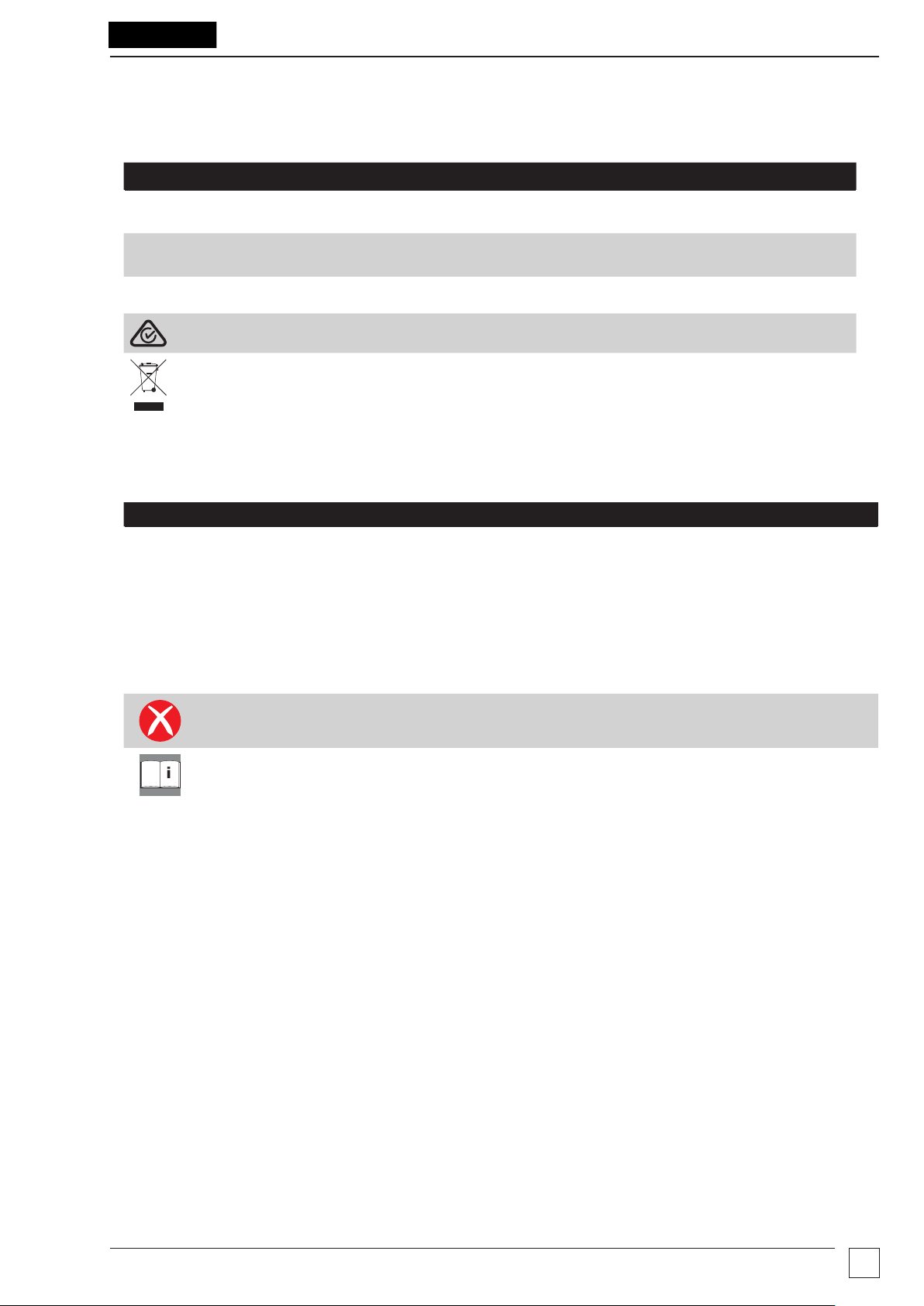

Overview

User interface

Overview

1

10

9

2

3

4

5

7

68

No. Description No. Description

1 External power / battery charge socket 6 Function switch (Controls (page 7))

2 Display 7 Navigation control panel (page 8)

3 USB: 1x Type A / 1x Type B 8 Mode switch (Controls (page 7))

4 Soft keys (page 9) 9 Save (Test Result Management (page 36))

5 Terminals (page 8) 10 External power LED (Power on / Charge (page 10))

www.megger.com

DET2/3

5

Page 12

Overview

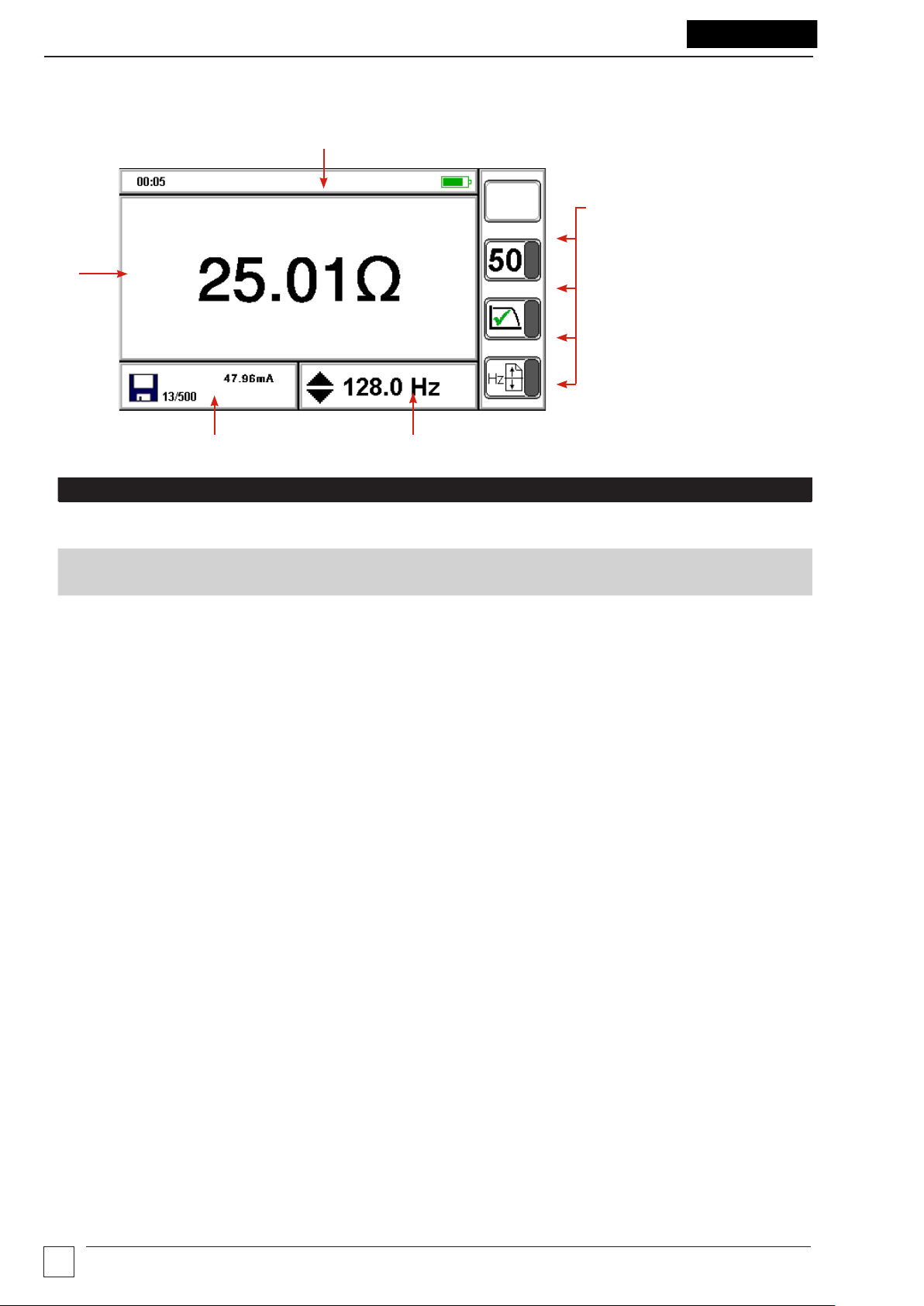

Display

2

1

3

4

4

5

No. Description No. Description

1 Status bar 4 Test mode: Secondary measurement result

Data management mode: Asset number

2 Main display / Primary measurement result 5 Test mode: Test parameters

Data management mode: Record name

3 Soft key functions

6

www.megger.comDET2/3

Page 13

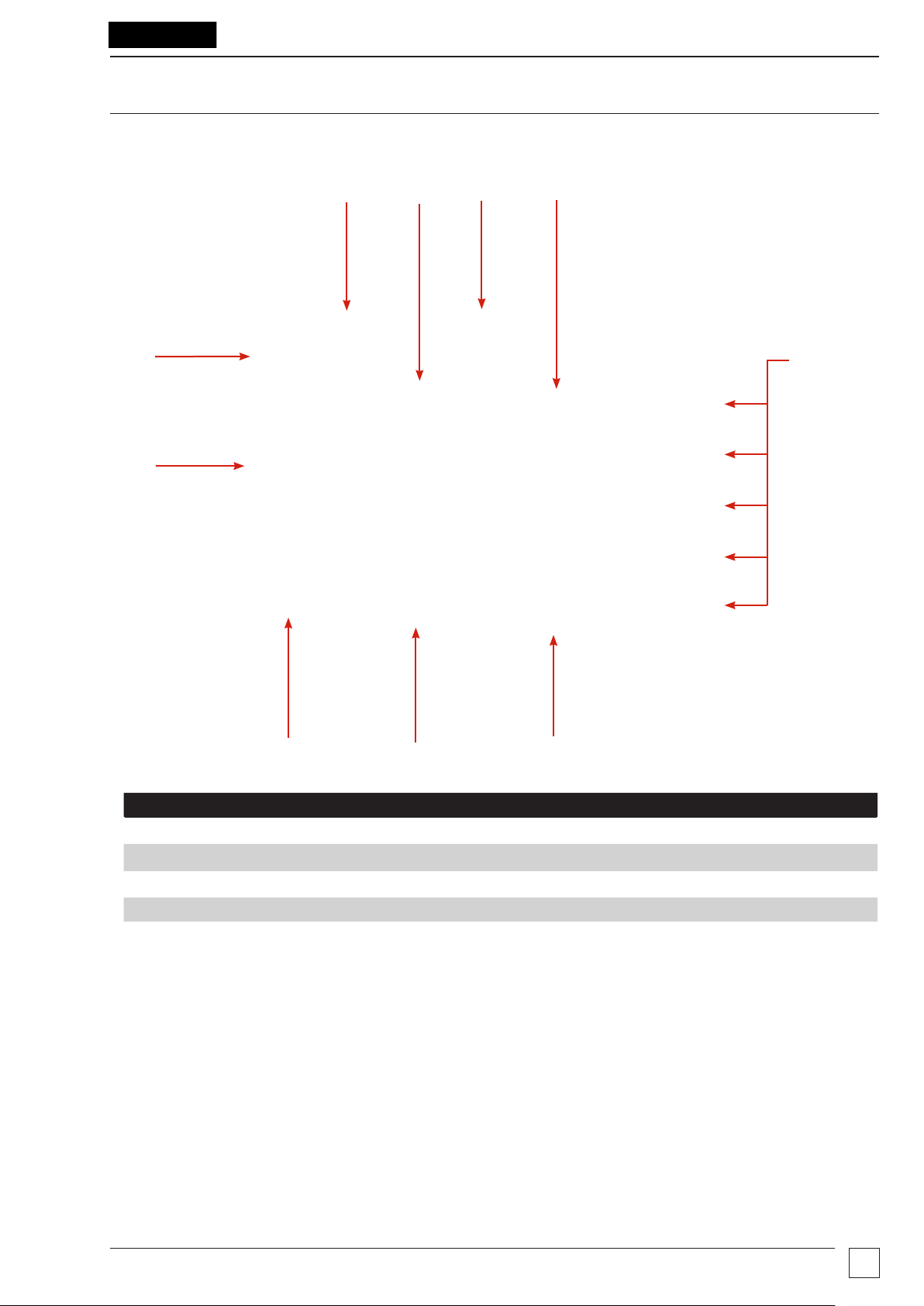

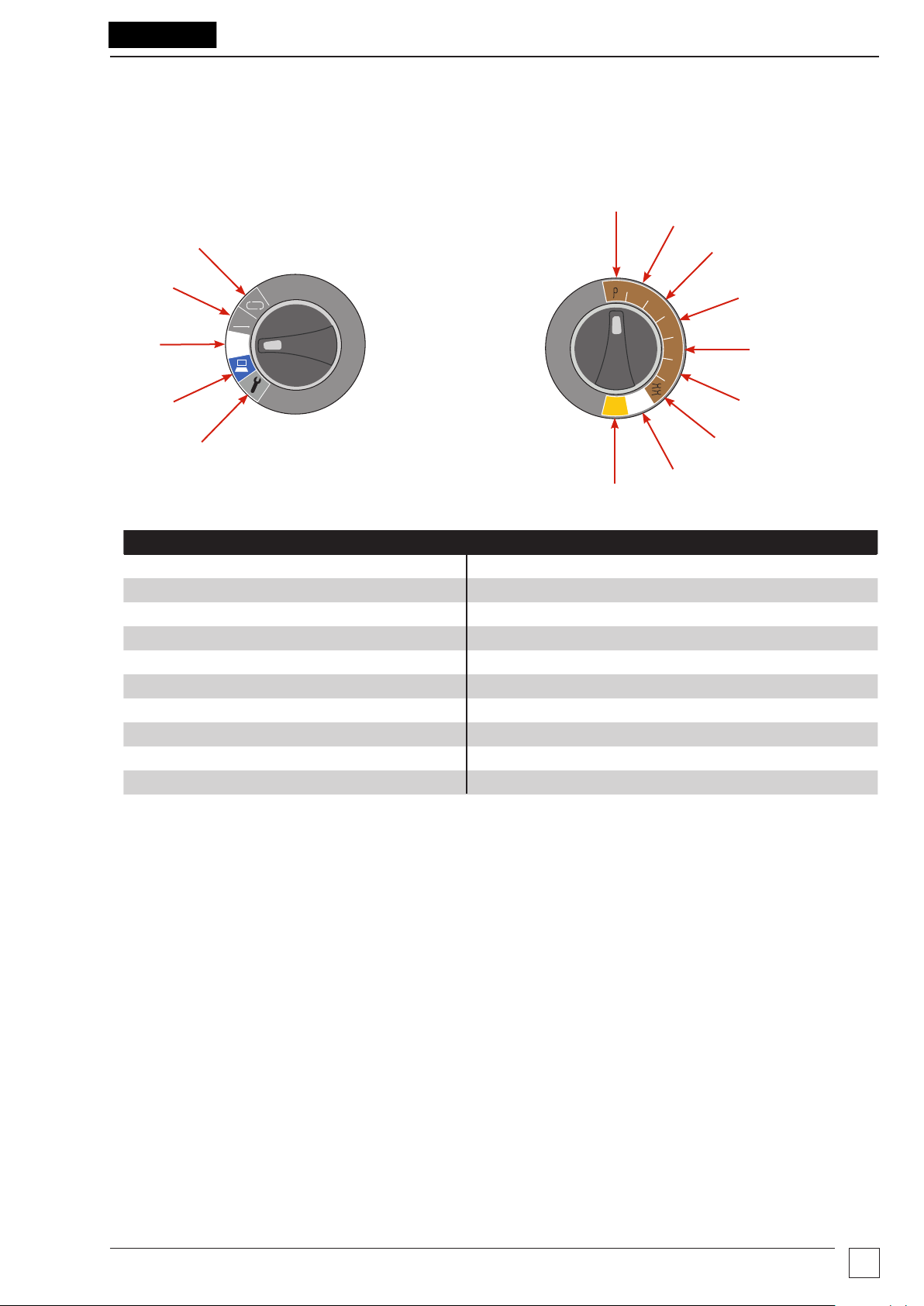

Controls

Refer to user interface (page 5).

Mode switch Function switch

1

Overview

1

2

3

2

MAN

3

4

OFF

5

No. Description No. Description

1 Continuous graphical mode (page 11) 1 ρ (Resistivity)

2 Manual mode (page 11) 2 4 Pole (ART)

3 Power on / off (page 10) 3 4 Pole

4 Test result management (page 33) 4 3 Pole (ART)

5 Set-up (page 12) 5 3 Pole

6 2 Pole

7 Dual clamp

8 A (leakage current)

9 Ω (continuity)

See Test methods and set-up (page 23).

4P

4P

3P

Ω

3P

2P

A

Ω

8

9

4

5

6

7

www.megger.com

DET2/3

7

Page 14

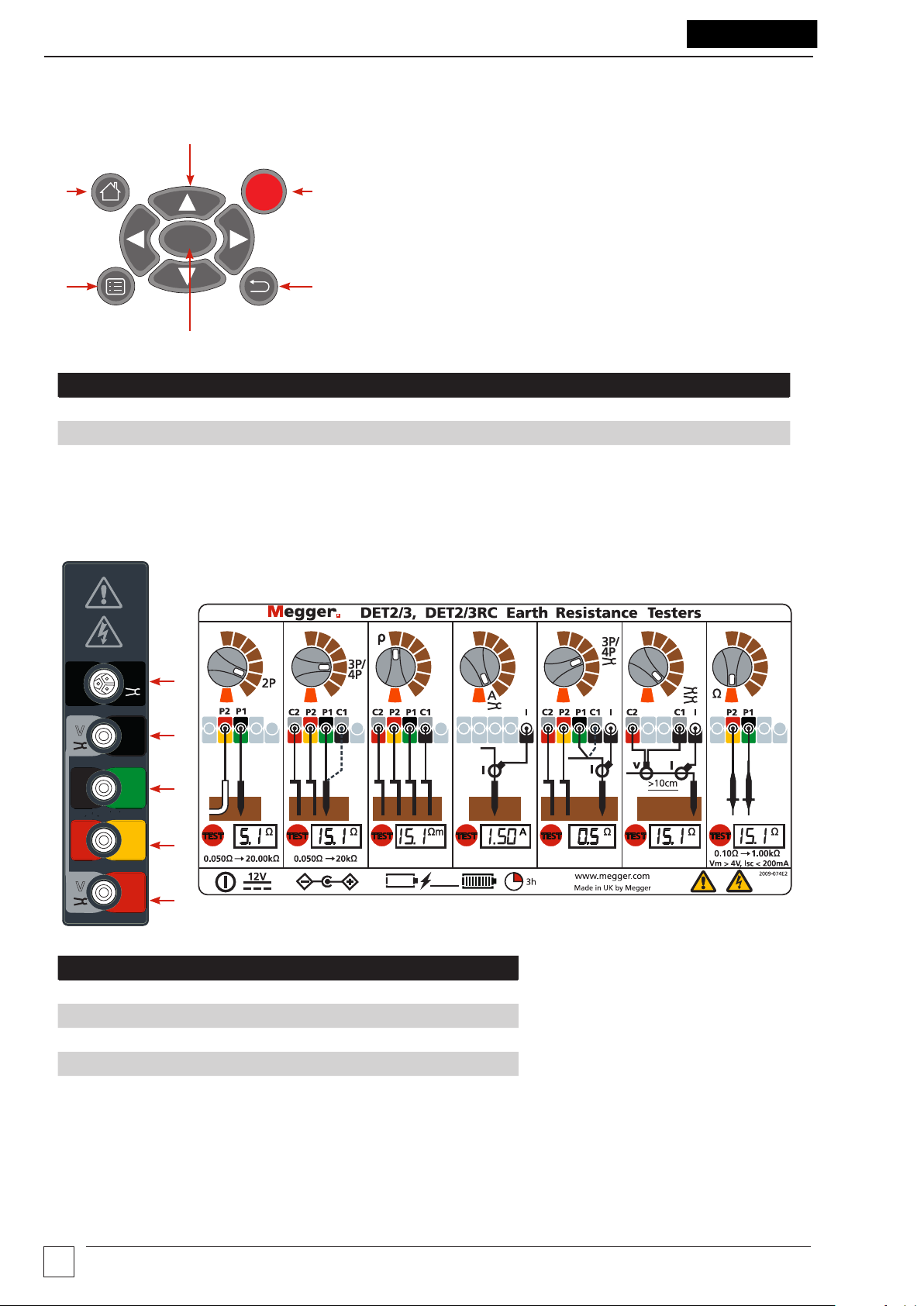

Overview

MVC1010

Navigation control panel

2

1

TEST

3

OK

6

5

No. Description No. Description

1 Home 4 Back

2 Navigation arrows 5 OK

3 Test 6 Menu

4

Terminals

See Test methods and set-up (page 23)

MCC1010

V

MVC1010

E

X

CAT IV 300V

Y

V

C1

P1

ES

P2

C2

H

I

I

E

S

1

2

3

4

5

No. Description

1 MCC1010 (used for ART, Noise current and stakeless tests)

2 MVC1010 / C1 E Voltage clamp, (current)

3 E/X / P1 ES (Potential)

4 Y / P2 S (Potential)

5 MVC1010 / C2 H Voltage clamp (current)

8

www.megger.comDET2/3

Page 15

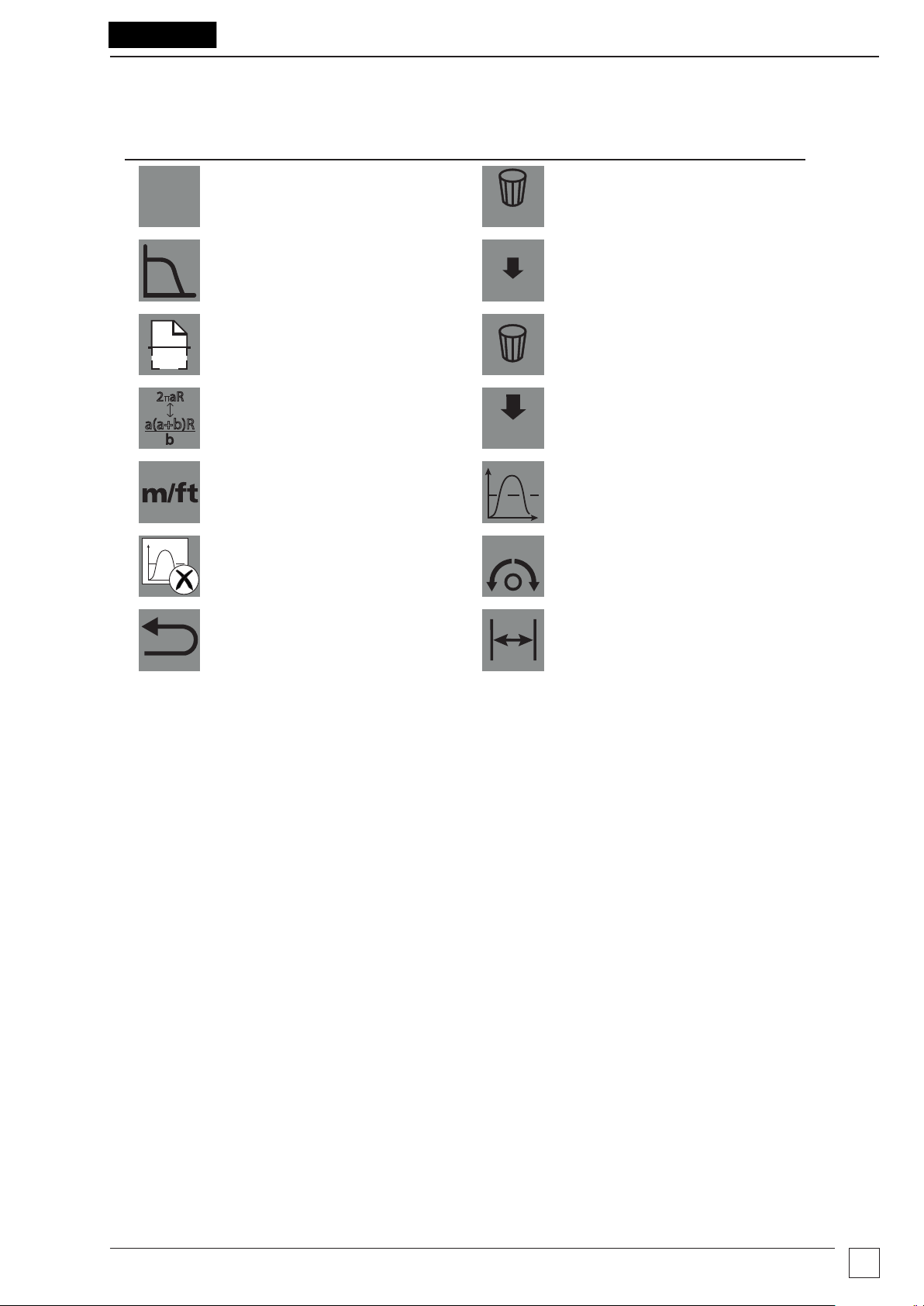

Soft keys

ALL

b

2 aR

Soft Key Description Soft Key Description

Overview

15/50V

Hz

a(a+b)R

Select 15 / 50 V

ALL

Noise filter on / off

Delete all test records

Send all test records to USB

USB

Automatic frequency Scan Delete single test record

Earth / ground resistivity test

method

Send single test record to USB

USB

Metres or feet Average

Clear

Back Resistivity spacing adjustment

NULL

Null

www.megger.com

DET2/3

9

Page 16

Operation

Operation

Before each use of the instrument, visually inspect the instrument case, test leads, stakes and connectors to

confirm their condition is good, with no damaged or broken insulation.

Power on / off

Rotate the mode switch away from Off to a mode to power up and activate the instrument

Rotate the mode switch to Off to power down the instrument.

Auto off

The instrument switches Off after a period of inactivity (user adjustable) (see General set-up (page 12)).

To start the instrument again rotate the mode switch to Off and then select a mode.

Power options

Internal battery

Mains supply: The instrument charges using the dc adapter, which will work at voltages between 100 and

240 V ac. You may continue to use the instrument while the internal battery is charging.

(See Battery charge (page 38)).

Green LED: On charge

Amber LED: External power On

12 V dc supply: Operate the instrument while connected to a 12 V dc supply. See 12 V supply (page 38).

See also Specifications (page 39).

Earth test options

Output voltage

The maximum output voltage of the instrument is ±50 V. This can be reduced to ±15 V for operation in situations

which require it. The most appropriate output voltage should be selected by the user based on local safety

procedures.

To change the output voltage

15/50V

Press

Test frequency

The instrument can either scan the usable frequency range to identify the test frequency with the lowest noise,

or the frequency set be manually set, as required.

Auto: Press

after the measurement mode is selected. The display will show the selected output voltage.

Hz

. The instrument searches for the best frequency

Manual: Press to set a frequency between 10 Hz and 200 Hz

Noise filter

Press (noise filter) to give additional noise rejection on the input signal in order to produce more stable

results, this will also extend the test duration.

10

www.megger.comDET2/3

Page 17

Operation

Test leads and terminal connections

Test lead set-up and terminal connections are described as part of the test procedure.

Important: When the instrument is connected to electrodes, make sure that all leads and cables are fully

unwound and laid out without loops.

Important: When running test leads out to each remote spike, take care not to lay them close to each other.

This is to minimise the effect of mutual inductance. Test leads must be spread out at least one metre apart.

Test modes

The instrument can operate in two modes to do a test:

Manual mode

In manual mode the test result can be shown as a single digital read out result, or as a continuously updated

digital read out result.

Continuous graphical mode

In continuous mode a continuous updated graph is displayed.

Green line: Measurement line

Black Line: Recorded average

www.megger.com

DET2/3

11

Page 18

Set-up

Set-up

This section details the instrument set-up.

Modify parameters

1. Set the Mode switch to .

2. Press

3. See instructions below for each set-up group.

Note: The set-up group screen is not active until

OK

to select a set-up group.

Setting in bold: Current setting

Setting underlined: Current selection

General set-up

1. Press to scroll through the parameters

OK

is pressed.

2. Press

3. Use to move left and right through the parameter options.

Date / Time

1. Press to modify current selected setting.

2. Press

Auto Off / Auto Dim / Brightness

1. Press to modify current selected setting.

2. Press

OK

OK

to select the highlighted parameter.

OK

to accept.

OK

to accept.

must be pressed to exit the parameter, even if no parameter was modified.

12

www.megger.comDET2/3

Page 19

Graph set-up

1. Press to scroll through the parameters.

Set-up

Graph length: 1, 5, 10, 15 min

Moving Average: 5, 10, 25, 50, 100

2. Press

3. Use to move through the options.

4. Press

OK

OK

to select the highlighted parameter.

OK

to accept.

must be pressed to exit the parameter, even if no parameter was modified.

Language set-up

Select the instrument language

1. Press to scroll through languages.

2. Press

www.megger.com

OK

to select the highlighted language.

DET2/3

13

Page 20

Earth / ground resistance

G

F

V

I

C1

E

E/X

CAT IV 300V

CAT IV 300V

CAT IV 300V

CAT IV 300V

Y

V

P1ESP2SC2

H

G

F

V

I

C1

E

E/X

CAT IV 300V

CAT IV 300V

CAT IV 300V

CAT IV 300V

Y

V

P1ESP2SC2

H

P1 P2 C2

Earth / ground resistance

Test procedure

Warning: Make sure the circuit is de-energised, before the instrument is connected for measurement.

Note: Manual or Continuous Graphical Mode (see Test modes (page 11).

Step Manual Mode Continuous Graphical Mode

OR

1

15 m to 25 m 15 m to 25 m

P1 P2 C2

15 m to 25 m 15 m to 25 m

Connect pins / stakes Connect pins / stakes

Note:

Set up test leads and stakes as required by each test (do not connect the test leads to the instrument):

Test Test Method Set-up

4P / 4P ART

3P / 3P ART

4P / 4P ART

3P / 3P ART

4P / 4P ART

3P / 3P ART

Fall of potential

Fall of potential

Fall of potential

Slope method

Slope method

61.8% rule

61.8% rule

Four terminal test lead set-up (page 23)

Three terminal test lead set-up (page 24)

Three terminal ART test lead set-up (page 24)

Slope four terminal test lead set-up (page 27)

Slope three terminal test lead set-up (page 28)

61.8% Four terminal test lead set-up (page 29)

61.8% Three terminal test lead set-up (page 29)

2P Two terminal earth resistance test (page 29)

2 Clamp Two clamp (stakeless) test (page 30)

4P

4P

3P

2

Ω

Ω

3P

2P

A

4P

4P

3P

Ω

3P

2P

A

Ω

Set the function Set the function

MAN

3

OFF

MAN

OFF

Set the mode Set the mode

14

www.megger.comDET2/3

Page 21

Earth / ground resistance

P2

P1

P2

C2

Manual mode Continuous graphical mode

CAT IV 300V

E/X

V

Y

CAT IV 300V

CAT IV 300V

P1

ES

P2

SC2H

C1

E

G

F

I

CAT IV 300V

V

OR

CAT IV 300V

CAT IV 300V

E/X

V

Y

CAT IV 300V

CAT IV 300V

P1

ES

P2

SC2H

C1

E

V

4

61.8% of EC 38.2% of EC

P1

C2

61.8% of EC 38.2% of EC

Connect test leads to instrument Connect test leads to instrument

5 Set test parameters Set test parameters

Note:

15/50V

15 or 50 test voltage

Manually select a frequency

Hz

Automatically select a frequency

Noise filter on or off

6 Start test Start test

Press

TEST

Press and hold

TEST

Press

TEST

7

until padlock icon appears

G

F

I

: Stop the current data stream and restart the graph.

: Activate / deactivate the average display

: Go back to test settings (the Ready screen)

8

End Test

9

Test ends

Press to stop

TEST

End Test

Press to stop

TEST

www.megger.com

DET2/3

15

Page 22

Earth / ground resistance

Manual mode Continuous graphical mode

10

11

Press / Repeat test

See Data management (page 33).

Repeat test if required. While the test result is shown, test parameters can be modified for the next test. If

required test parameters can be repeated.

OR

Press / Repeat test

16

www.megger.comDET2/3

Page 23

Earth / ground resistivity

C1

CAT IV 300V

P1

P2

C2

E

ES

S

H

I

V

E

X

Y

V

MVC1010 MVC1010

MCC1010

I

C1

CAT IV 300V

P1

P2

C2

E

ES

S

H

I

V

E

X

Y

V

MVC1010 MVC1010

MCC1010

I

a(a+b)R

b

2 aR

Earth / ground resistivity

Test procedure

Setup test

P1 (ES) C2 (H)P2 (S)

a a a

Wenner

1 Connect pins / stakes

P1 (ES) C2 (H)P2 (S)

a ab

Schlumberger

Note: Set up the test leads and stakes as required by the selected test method (on screen).

Do not connect the test leads to the instrument.

or

2 Set function to ρ

Set the mode

3

Manual or Continuous

(see Test modes (page 11).

4 Select test method

Set test measurements

4P

4P

A

Ω

MAN

OFF

Wenner or Schlumberger

Adjust parameters

Metres or Feet

3P

Ω

3P

2P

www.megger.com

DET2/3

17

Page 24

Earth / ground resistivity

Resistivity

The DET2/3 can measure and calculate resistivity using the Wenner or Schlumberger methods. These are very

similar, both involving placing four pins / stakes into the earth / ground. These only penetrate the soil by a short

distance.

MVC1010 MVC1010

Y

V

C2

P2

H

S

C1 (E) P1 (ES) C2 (H)P2 (S)

a a a

The Wenner method is the most common with the pins / stakes equally spaced in a line. The resistivity is

calculated in the equation:

ρ

X

E

CAT IV 300V

ES

P1

E

= 2πaR

V

MCC1010

C1

I

I

MVC1010 MVC1010

Y

V

C2

P2

H

S

C1 (E) P1 (ES) C2 (H)P2 (S)

a ab

CAT IV 300V

V

X

E

MCC1010

C1

ES

P1

E

I

I

The Schlumberger method has the potential pins / stakes closer together, with a<2b. The resistivity is calculated

in the equation:

ρ

=

5

Press

OK

a(a+b)

π

b

R

MVC1010 MVC1010

Y

V

C2

P2

H

S

CAT IV 300V

V

X

E

MCC1010

C1

ES

P1

E

I

I

6 Connect test leads to instrument

C1 (E) P1 (ES) C2 (H)P2 (S)

7 Set test parameters

18

15/50V

voltage

15 or 50 test

Set a frequency

Hz

Automatically

find a frequency

Noise Filter On

or Off

www.megger.comDET2/3

Page 25

8

Note:

Start test

Manual mode Continuous graphical mode

OR

Press and hold

TEST

Press

TEST

until padlock icon

appears

: Stop the current data stream and restart the graph.

: Activate / deactivate the average display

: Go back to test settings (the Ready screen)

Earth / ground resistivity

Press

TEST

9

End Test

10

Test ends

Press to stop

11

12

Press

/ Repeat test

Note: See Data management (page 33).

Repeat test if required. While the test result is shown, test parameters can be modified for the next

test, if required.

TEST

End Test

Press to stop

TEST

Press / Repeat test

www.megger.com

DET2/3

19

Page 26

Continuity Test

Continuity Test

Warning: Make sure the circuit is de-energised, before the instrument is connected for measurement.

Note: To remove any test lead resistance in the test result, Null the test leads (see Null test leads (page 21)).

Test procedure

1

Set function to Ω

2 Set the mode

3 Connect test leads to instrument

MAN

OFF

MVC1010 MVC1010

X

Y

V

CAT IV 300V

C2

ES

P2

H

S

4P

4P

3P

Ω

3P

2P

A

Ω

V

E

MCC1010

C1

P1

E

I

I

Start test

Manual mode Continuous graphical mode

4

Press to start

TEST

OR

Press

TEST

Clear: Stop the current data stream and restart the graph.

Average: Activate / deactivate the average display.

End test

5

Press to stop

TEST

Press

TEST

20

www.megger.comDET2/3

Page 27

Continuity Test

Manual mode Continuous graphical mode

6

Press

See Data management (page 33).

Note: Press Save at any time to save the current reading.

OR

Null test leads

Note: Test must be running to be able to Null the test leads.

The Null function only works when the measured resistance is less than 10 Ω.

Press

1. Put the two test lead tips firmly together.

2. Press .

When the test result shows, press again to activate / de-activate the Null process:

Null active: Result is minus the test lead resistance.

The Null function is active while results are continuously updated or when results update is stopped.

Null de-active: Result includes test lead resistance.

If the measured resistance is below zero, while Null is active, the result will show that it is too low to measure

(the instrument will not show negative resistance values).

www.megger.com

DET2/3

21

Page 28

Leakage Current Test

Leakage Current Test

Test procedure

1 Connect MCC1010

2 Set function to A

3 Set the mode

MAN

OFF

4P

4P

3P

Ω

3P

2P

A

Ω

4 Place MCC1010 around

conductor to be tested

Manual mode

5

Press to start

TEST

Note:

Clear: Stop the current data stream and restart the graph.

Average: Activate / deactivate the average display.

6

Press to stop

TEST

Start Test

OR

End Test

MVC1010 MVC1010

X

Y

V

E

CAT IV 300V

C2

ES

P2

H

P1

S

E

Continuous graphical mode

Press

TEST

Press

TEST

V

MCC1010

C1

I

I

7

8

See Data management (page 33).

22

Press

Press

www.megger.comDET2/3

Page 29

Test methods and set-up

P1 P2 C2

Test methods and set-up

The test methods detailed in this section is not exhaustive, see the booklet 'Getting Down To Earth' for more

information on other tests and methods.

Key to images in this section:

P: Potential spike

C: Current spike

E: Electrode

Fall of potential (FoP) test

Important: The current stake / pin, potential stake / pin and earth electrode must be placed in a straight line.

Important: When running test leads out to each remote stake / pin, take care not to lay them close to each

other. This is to minimise the effect of mutual inductance.

Four terminal test lead set-up

1. Insert the current stake / pin into the earth 30 to 50 metres away from the earth electrode to be tested.

2. Insert the potential stake / pin into the earth midway between the current test spike and the earth electrode.

3. Firmly connect terminal C1 and P1 to the earth electrode as shown.

4. Move the potential stake / pin three metres further away from the earth electrode and make a second

resistance measurement.

5. Move the potential stake / pin three metres nearer the electrode (than the original position) and make a third

resistance measurement.

If the three resistance readings are similar (within the required accuracy) then their average can be taken as the

resistance to earth of the electrode.

V

CAT IV 300V

CAT IV 300V

P2

S

C2

H

15 m to 25 m 15 m to 25 m

Y

CAT IV 300V

ES

P1

E/X

CAT IV 300V

E

V

C1

I

F

G

www.megger.com

DET2/3

23

Page 30

Test methods and set-up

100%

Four terminal ART test lead set-up

MVC1010 MVC1010

V

C2

H

Three terminal test lead set-up

V

CAT IV 300V

CAT IV 300V

C2

H

CAT IV 300V

ES

P2

S

P1

MCC1010

C1

E

I

I

V

X

Y

E

C1 (E)

P2 (S)

C2 (H)

P1 (ES)

62%

E/X

P1

CAT IV 300V

E

V

C1

I

F

G

Y

CAT IV 300V

ES

P2

S

15 m to 25 m 15 m to 25 m

P1 P2 C2

Important: The current stake / pin, potential spike and earth / ground electrode must be placed in a straight line.

Important: When running test leads out to each remote stake / pin, take care not to lay them close to each

other. This is to minimise the effect of mutual inductance.

Determine the earth electrode test lead resistance

The earth electrode test lead resistance can be determined separately.

1. Remove the test lead from the earth electrode and connect to the C2 and P2 terminals.

2. Press test.

The lead resistance can then be deducted from the earth resistance measurements.

This procedure is not required if the C1 and P1 terminals are connected by separate test leads.

Note: The result for a three terminal test will include the resistance of the test lead used to connect to the earth

electrode under test. The resistance can be measured by connecting the lead to the P1(X) and P2(Y) terminals,

selecting a 2P test and pressing the test button. This lead resistance can be subtracted from the earth resistance

measurements.

24

www.megger.comDET2/3

Page 31

Three terminal ART test lead set-up

Test methods and set-up

C2 (H)

MVC1010 MVC1010

Y

V

C2

H

CAT IV 300V

P2

S

P2 (S)

X

E

ES

P1

100%

V

MCC1010

C1

E

I

I

P1 (ES)

62%

Slope method (FoP)

Description

Extract from the technical guide Getting Down to Earth:

It has been shown that the true earth resistance of an electrode system is obtained when the temporary potential

P is positioned at a distance from the electrical centre of the system equal to 61.8% of the distance from the

electrical centre to the temporary current probe. This principle is used in the technique called 'Intersecting Curves'

explained in Getting Down to Earth. It becomes apparent that the method is complex in nature and requires

some trial and error calculations.

A further technique was evolved and is described below. It is easier to use and has been shown to give

satisfactory results, both in theoretical and practical cases and when the soil is nonhomogenous. It is called the

Slope Method.

To apply the Slope Method:

1. Choose a convenient rod E to which the Earth Tester can be connected. E is one of many parallel rods

forming the complex earth system.

2. Insert the current probe at a distance (DC) from E (DC is normally two to three times the maximum dimension

of the system).

3. Insert potential probes at distances equal to 20% of DC, 40% of DC and 60% DC.

See examples in step 4.

4. Measure the earth resistance using each potential probe in turn. Let these resistance values be R1, R2 and R3

respectively.

Examples:

R1 = 0.2 x DC

R2 = 0.4 x DC

R3 = 0.6 x D

C

5. Calculate the value of:

R3 - R

µ =

R2 - R

2

1

The resultant is called μ and represents the change of slope of the resistance / distance curve.

6. Refer to Table 1: Values of DP / DC for various values of µ (page 27) to find the corresponding value of

DP/DC for μ.

www.megger.com

DET2/3

25

Page 32

Test methods and set-up

7. Since DC (distance to the current probe) is already known, calculate a new DP (distance of the potential probe)

then insert the potential probe at this new distance from E.

DP= DP/DC x D

C

Now measure the earth resistance by placing the potential probe at this new distance DP. This measurement is

known as the 'true' resistance.

8. Repeat the whole process for a larger value of DC. If the 'true' resistance decreases appreciably as DC is

increased, it is necessary to increase the distance of DC still further. After making a number of tests and

plotting the 'true' resistance, the curve will begin to show less of a decrease and will indicate more stable

readings. It is at this point the resistance of the earthing system is noted.

Note: As with other earth testing techniques, some experimentation may be necessary to ascertain if the practical

result is as accurate as the theory appears to indicate.

The Slope Method has been designed to eliminate the need for impractically long leads by the ability to

interpolate the correct distance along the combined resistance curve, i.e. the curve of the current probe’s

resistance superimposed upon that of the tested grid, without sufficient spacing to produce the characteristic 'flat

portion' between.

One particular observation on the Slope Method is that if the calculation of μ is greater than that given in the

table, the distance C must be increased.

Secondly, before the measured values for R

, R2 and R3 can be accepted with a degree of confidence, it is

1

recommended that a curve be plotted which will identify any localized effects and eliminate uncharacteristic

readings from the calculations. Thirdly, it is also suggested that the test be repeated in different directions and

with different spacings. The various results should exhibit a reasonable degree of agreement.

26

www.megger.comDET2/3

Page 33

Table 1: Values of DP / DC for various values of µ

Test methods and set-up

µ DP / D

C

µ DP / D

C

µ DP / D

0.40 0.643 0.80 0.580 1.20 0.494

0.41 0.642 0.81 0.579 1.21 0.491

0.42 0.640 0.82 0.577 1.22 0.488

0.43 0.639 0.83 0.575 1.23 0.486

0.44 0.637 0.84 0.573 1.24 0.483

0.45 0.636 0.85 0.571 1.25 0.480

0.46 0.635 0.86 0.569 1.26 0.477

0.47 0.633 0.87 0.567 1.27 0.474

0.48 0.632 0.88 0.566 1.28 0.471

0.49 0.630 0.89 0.564 1.29 0.468

0.50 0.629 0.90 0.562 1.30 0.465

0.51 0.627 0.91 0.560 1.31 0.462

0.52 0.626 0.92 0.558 1.32 0.458

0.53 0.624 0.93 0.556 1.33 0.455

0.54 0.623 0.94 0.554 1.34 0.452

0.55 0.621 0.95 0.552 1.35 0.448

0.56 0.620 0.96 0.550 1.36 0.445

0.57 0.618 0.97 0.548 1.37 0.441

0.58 0.617 0.98 0.546 1.38 0.438

0.59 0.615 0.99 0.544 1.39 0.434

C

0.60 0.614 1.00 0.542 1.40 0.431

0.61 0.612 1.01 0.539 1.41 0.427

0.62 0.610 1.02 0.537 1.42 0.423

0.63 0.609 1.03 0.535 1.43 0.418

0.64 0.607 1.04 0.533 1.44 0.414

0.65 0.606 1.05 0.531 1.45 0.410

0.66 0.604 1.06 0.528 1.46 0.406

0.67 0.602 1.07 0.526 1.47 0.401

0.68 0.601 1.08 0.524 1.48 0.397

0.69 0.599 1.09 0.522 1.49 0.393

0.70 0.597 1.10 0.519 1.50 0.389

0.71 0.596 1.11 0.517 1.51 0.384

0.72 0.594 1.12 0.514 1.52 0.379

0.73 0.592 1.13 0.512 1.53 0.374

0.74 0.591 1.14 0.509 1.54 0.369

0.75 0.589 1.15 0.507 1.55 0.364

0.76 0.587 1.16 0.504 1.56 0.358

0.77 0.585 1.17 0.502 1.57 0.352

0.78 0.584 1.18 0.499 1.58 0.347

0.79 0.582 1.19 0.497 1.59 0.341

www.megger.com

DET2/3

27

Page 34

Test methods and set-up

Slope four terminal test lead set-up

V

CAT IV 300V

C2

H

P1 P2 C2

CAT IV 300V

a

Y

P2

S

Slope three terminal test lead set-up

V

CAT IV 300V

CAT IV 300V

P2

S

C2

H

CAT IV 300V

Y

ES

CAT IV 300V

ES

E/X

P1

> 50 m

E/X

P1

CAT IV 300V

E

CAT IV 300V

V

C1

I

aa

V

E

C1

aaa

I

F

F

G

aa

G

> 50 m

aa

aaa

P2

a

P1

aa

C2

28

www.megger.comDET2/3

Page 35

61.8% Rule (FoP)

P1

61.8% Four terminal test lead set-up

Test methods and set-up

V

CAT IV 300V

C2

H

61.8% of EC 38.2% of EC

P1

CAT IV 300V

S

P2

Y

CAT IV 300V

ES

61.8% Three terminal test lead set-up

CAT IV 300V

H

V

C2

CAT IV 300V

S

Y

P2

E/X

P1

CAT IV 300V

ES

CAT IV 300V

E

P1

E/X

V

C1

CAT IV 300V

G

F

I

P2

V

C1

E

F

I

C2

G

www.megger.com

100%

P2 C2

DET2/3

29

Page 36

Test methods and set-up

Two terminal earth resistance test

Warning: Make sure the circuit is de-energised, before the instrument is connected for measurement.

This will measure the resistance between the P1(X) and P2(Y) terminals using an ac test voltage. This method may

not be suitable for continuity and bonding tests (refer to local regulations).

Note: The test voltage used for the two pole resistance test is ac and may not be suitable for all continuity tests

(see local regulations).

Note: If the earth noise voltage is above 50 V peak to peak (18 Vrms), the display will show a warning triangle

and an excessive noise voltage indicator.

Set up the test leads and stakes as required (do not connect the test leads to the instrument):

P1 (E)

MVC1010 MVC1010

Y

V

C2

H

CAT IV 300V

P2

S

V

X

E

ES

P1

MCC1010

C1

E

I

I

P2 (H)

Two clamp (stakeless) test

The two clamp (stakeless) test uses both the MVC1010 and MCC1010 to obtain a measurement for the electrode

under test.

MVC1010 MVC1010

Y

V

C2

H

CAT IV 300V

P2

S

V

X

E

ES

P1

MCC1010

C1

E

I

I

30

www.megger.comDET2/3

Page 37

Calibration check tools

Calibration check tools

The instrument's calibration should be checked, before and after each test, against the calibration check tool.

Instrument calibration check

1. Make sure that the mode switch is set to Off.

2. Connect the instrument as shown:

MVC1010 MVC1010

Y

V

C2

H

CAT IV 300V

P2

S

V

X

E

ES

P1

MCC1010

C1

E

I

I

Calibration

adaptor

3. Set the function switch to 2P, 3P or 4P.

4. Start a test:

Press and release TEST.

The instrument completes pre-measurement checks.

The resistance is shown and should match the value written on the calibration check tool.

Checking instrument accuracy

Instrument accuracy: 0.5% (+ 2 digits). At 25 Ω is this gives an allowed measurement range of +/- 0.145 Ω.

Calibration check tool accuracy: 0.1%. At 25 Ω this gives an allowed variation of 0.025 Ω.

Therefore a test, which uses the 4 pole position, will produce the following bands:

25 + 0.145 + 0.025 = 25.17 (a figure greater than this is out of specification)

25 + 0.145 – 0.025 = 25.12 (a figure between 25.12 and 25.17 is possibly out of specification)

25 – 0.145 + 0.025 = 24.88 (a figure between 24.88 and 25.12 is in specification)

25 – 0.145 – 0.025 = 24.83 (a figure less than this is out of specification)

www.megger.com

DET2/3

31

Page 38

Calibration check tools

Clamp calibration check

1. Make sure that the mode switch is set to Off.

2. Connect the instrument as shown:

MVC1010 MVC1010

Y

V

H

CAT IV 300V

C2

P2

S

V

X

E

ES

P1

Dual Clamp calibration

check

Hold clamps against

these faces

MCC1010

C1

E

I

I

3. Close the MCC1010 around one loop of the clamp calibration check tool.

4. Close the MVC1010 around the other loop of the clamp calibration check tool.

5. Make sure that there is a minimum separation of 100 mm between the MCC1010 and MVC1010.

6. Set the function switch to

.

7. Start a test:

Press and release TEST.

The instrument completes pre-measurement checks.

The two-clamp resistance is shown and should match the value written on the clamp calibration check tool.

Note: Make sure that the MCC1010 and MVC1010 jaw mating surfaces are free of dust and contamination and

that they make a good contact with each other when the jaws are closed.

32

www.megger.comDET2/3

Page 39

Data management

Data management

Use test result management mode of view saved test results and transfer saved test results to USB drive or PC.

Test result data is saved in two formats:

As a Data File: Data saved from manual or guided mode saved as a single data file.

As a Graph File: Data saved from continuous mode saved as a graph of a complete test.

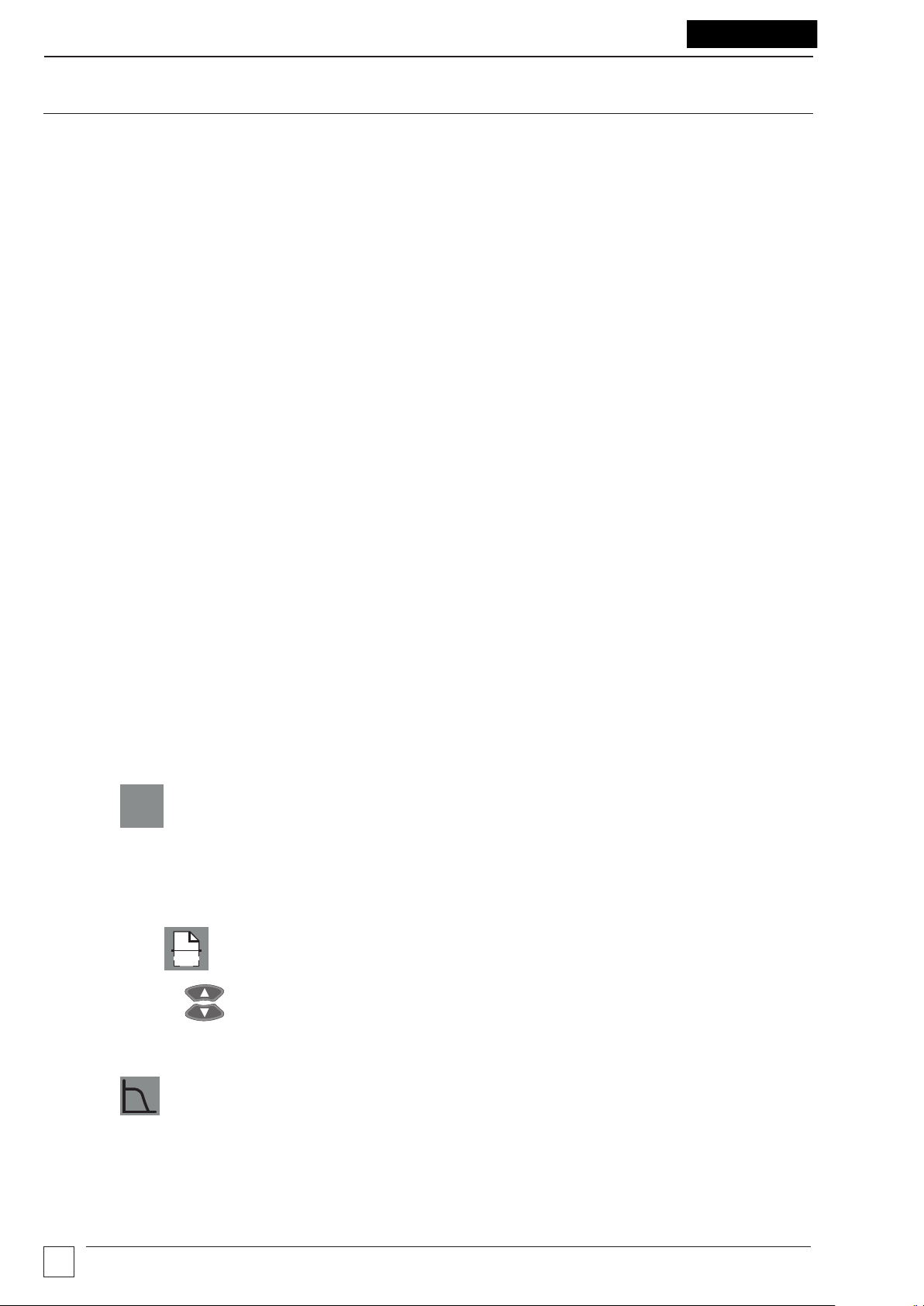

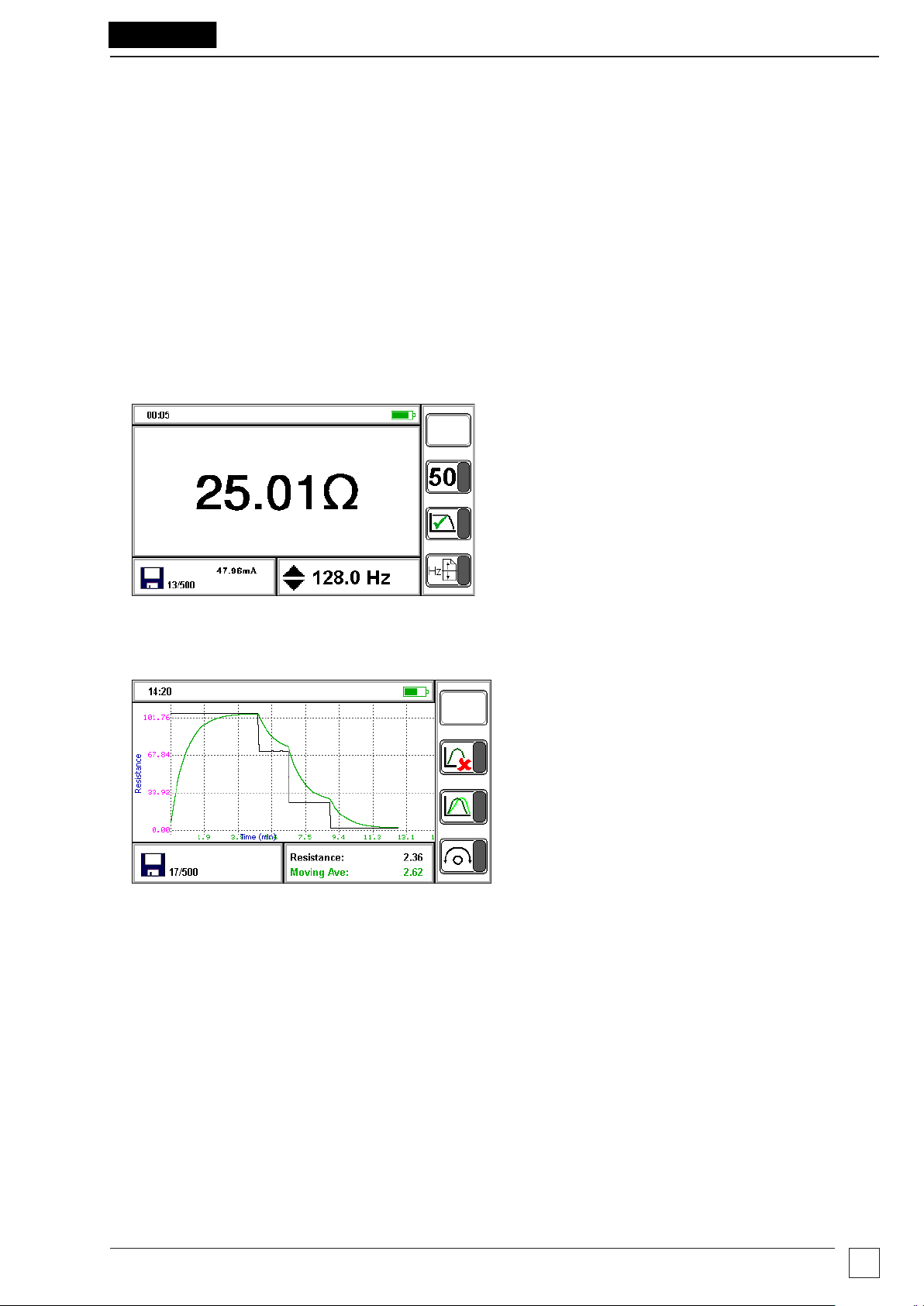

Data file records Graph file records

Up to 500 test records can be saved (data and graph files). A test record is either:

Manual mode: A single test record, several saved records may be required to complete a test.

Continuous mode: A single test record as a graph file.

Note: A pop-up error dialogue box will show when the memory is full to tell the user to clear some space.

Save test result

1. Press when the save icon is displayed.

The test is assigned a record number.

To edit a record file name as...

1. Set the mode switch to

2. Press

3. Press

4. Press

(Red bar visible)

5. Press to select a test result

www.megger.com

to select or

OK

OK

to select record name

DET2/3

33

Page 40

Data management

6. Press

(Red bar visible)

7. Press

8. Enter a test result three digit number.

Keyboard show - use arrow keys to navigate.

9. Press to save and return.

OK

Data file: Test001.tab.

Graph file: Graph001.tab.

to move to Asset ID.

OK

.

The save icon will display when save function is available.

Press save button and a record number will display.

Note: In continuous graphical mode save can be pressed at any time.

USB connection

A USB type socket is provided for this purpose on the top of the DET2/3. The position is clearly marked with a

USB symbol.

34

www.megger.comDET2/3

Page 41

Single test result: download or delete

ALL

Connect a USB memory device to the instrument.

1. Set the mode switch to

2. Select or

Data management

3. Press

4. Press

OK

OK

to select record number

(Red bar visible)

5. Press

to select a test result:

Download a single test record Delete a single test record

Press

The selected test record is downloaded (copied)

USB

Press

The selected test record is deleted

to the connected device

Multiple test results: download or delete

6. Select or .

7. Press

OK

.

Download all test records Delete all test records

Press

The selected test records are downloaded

USB

.

Press

All saved test records are deleted

(copied) to the connected device

www.megger.com

DET2/3

35

Page 42

Maintenance

Maintenance

General maintenance

Test leads should be checked before use for damage and continuity.

Ensure the unit is kept clean and dry after use.

Close all covers and flaps when not in use.

Cleaning

1. If connected, disconnect from mains power.

2. Wipe the Instrument with a clean cloth dampened with either water or isopropyl alcohol (IPA).

Battery

Caution: Old batteries must be disposed of in accordance with local regulations.

Caution: Always set the instrument to Off and remove test leads before battery is removed and

installed. Only use approved batteries supplied by Megger.

Approved batteries (see Specifications (page 39)).

To help maintain the health, reliability and longevity of the installed battery:

Make sure that the battery is fully charged before the instrument is used

Keep the battery charged up whenever possible while in use. Li-Ion batteries prefer frequent top-ups and

should never be left in a flat state for extended periods as this can cause permanent damage

If the battery is to be stored for extended periods maintain a charge of 40%, allow for some discharge and

maintenance of the protection circuit.

Store the battery in a cool, dry place. Li-ion batteries can get stressed when exposed to heat which can

reduce its life. See Specifications (page 39).

Battery status

Battery charging

Battery charged Battery low, 0%-5%, flashing

Battery down to 6%-26%

Battery discharging Battery faulty/error, flashing

When running from the battery, the above will indicate the current state of charge (the icon will be filled

proportionally to the state of charge). When the battery is charging, it will show an animation that starts with the

current state of charge and fills the indicator to 100 %, then repeats. Once the battery is full, the animation will

stop. If the charger is connected (and on), but unable to charge the battery, the icon will flash.

Capacity and typical charge life 10 hours max.

36

www.megger.comDET2/3

Page 43

Battery replacement.

Maintenance

1

2

3

7

4

5

6

Warning: Disconnect all leads before removing case.

Caution: Protect the face and switches of the instrument when turning it upside-down.

Note: Replace with Megger approved battery, part number 1002-552 only.

1. Remove lid by opening to approximately 70° and sliding right.

2. Switch the instrument Off.

3. Disconnect all leads .

4. Invert the lower case and rest the front panel on a soft surface so as not to damage the keypad.

5. Remove 4 fixing screws (1) and lift off the case.

6. Undo 4 fixing screws (2), remove battery cover (3).

7. Disconnect battery connector (4) and lift foam strips (7) to release the battery lead.

8. Remove battery (5).

9. Connect new battery to connector (5).

10. Install new battery ensuring correct orientation and that lead is correctly routed in slot (6). Secure lead using

foam strips (7).

Warning: Do not reconnect any test leads until the battery cover is fitted.

1. Refit battery cover (3) and secure using 4 screws (2) to torque 20 cNm.

2. Refit case and secure using 4 screws (1) to torque 40 cNm.

3. Turn instrument upright and refit lid.

Note: The battery must be disposed of according to local environmental regulations.

www.megger.com

DET2/3

37

Page 44

Maintenance

Battery charge

Note: Make sure the ambient temperature is correct to charge a battery (see Specifications (page 39)).

When the battery status indicator shows the battery is nearly discharged or is discharged, recharge the battery as

detailed below.

The DET2/3 can be used while the battery is on charge. The instrument will charge faster when switched off.

A charge cycle on a fully discharged battery takes approximately four hours (see the Battery status (page 36)).

1. Switch the instrument Off.

2. Disconnect the instrument from all electrical circuits.

3. Open the external power socket rubber door.

4. Connect the ac / dc adaptor (amber LED shows for two seconds then changes to green (charging)).

5. When fully charged the LED shows steady amber (power connected - battery charged).

6. Once the charge cycle has started the instrument can be used as normal.

12 V supply

When the battery status indicator shows the battery is nearly discharged or is discharged, use the power supply

provided with the instrument to recharge the battery. The instrument will function normally with the power

supply in use. Use only the power supply provided by Megger; other supplies may introduce noise into the

measurement, affecting accuracy and instrument stability.

Note: The LED indicating the instrument is connected to an external 12 V supply will go amber if the charger is

connected (and on), but unable to charge.

The instrument will now operate on the 12 V dc supply.

38

www.megger.comDET2/3

Page 45

Specifications

Specifications

Only values with tolerance or limits are guaranteed data. Parameters without tolerances are for information only.

Measurement specifications

2, 3 and 4 terminal resistance

Range 0.001 Ω to 20.00 kΩ Auto range

Accuracy

3P

2P

Operational uncertainty ±2% of reading ±2 digits

4 and 3 terminal ART (selective) resistance

Range 0.01 Ω to 10.00 kΩ auto range

Accuracy ±5% accuracy (±3 digits) at 23°C ±2°C

Stakeless resistance

Range 0.01 Ω to 200 Ω

Accuracy ±7% (±3 digits)

Test to standards BS 7430 (Earthing)

Test frequency 2P, 3P & 4P

resistivity

Test frequency dual clamp,

3p ART & 4P ART

Test current 50 mA max.

Maximum output voltage 50 V rms

Maximum interference 50 V peak to peak

Continuity

Range 0.01 Ω to 1 kΩ (3 digits)

Accuracy ±3% (±2 digits)

Test Current Up to 205 mA

Lead Null < 10 Ω

Leakage current

Range 0.00 A to 2.00 A at 5% (+3 digits)

Accuracy ±5% (±3 digits)

at 23 °C ±0.5% of reading ±2 digits

±10 mΩ

±20 mΩ

Meets IEC61557 operational uncertainty requirement with readings over 10 mΩ

when spike resistances are below 100 Ω

±5% of reading ±2 digits ±10 mΩ

Meets IEC61557 operational uncertainty requirement with readings over 50 mΩ

BS 62305 (Lightning)

IEEE Standard 81

10 Hz to 200 Hz (steps of 0.5 Hz)

70 Hz to 200 Hz (steps of 0.5 Hz)

www.megger.com

DET2/3

39

Page 46

Specifications

Instrument specifications

Display Backlit, colour, WQVGA display 5.25 in

Operating temperature From -10 to 40 °C (14 to 104 °F)

Operating humidity 90% RH max at 40 °C

Storage temperature From -20 to 60 °C (4 to 140 °F)

Temperature coefficient < ±0.1% per °C over operating Temp.

Environmental protection IP54 operational (lid open)

IP65 storage (lid closed)

Altitude: Up to 2000 m above sea-level.

Measurement connection rating CAT IV 300 V (clamp terminals not isolated from measurement terminals)

Measurement output rating ±50 V 1 A, ac or dc.

Power supply Internal Li-ion battery (rechargeable / replaceable)

External 100 to 240 V ac, 50 - 60 Hz (with adaptor)

External 18V dc supply (65 W)

Battery life 10 h. max. (typically)

Battery charge time Fast recharge to 50%, 3 h for 100%.

Ambient temperature

(battery charge)

Safety Meets IEC 61010

EMC Meets IEC 61326

Dimensions 315 x 285 x 181 mm

Weight 4.8 kg (10.6 lb)

PC data download USB 2.0

Data Management Internal 500 record storage

USB Host Send data to pen drive

Resistivity calculation Wenner

Tests 2P, 3P, ART (Selective), 4P, Stakeless (clamp) modes

Real time clock Yes

RoHS compliant Yes

0 - 40 ºC

(13.8 x 11.2 x 7.1 in)

Schlumberger

Instrument calibration check tool

Electrical specification

Resistance 25 Ω ±0.1%

Mechanical specification

Dimensions 60 x 55 x 25 mm (2.5 x 2.25 x 1 in)

Weight 0.1 kg (0.2 lb) approximately

40

www.megger.comDET2/3

Page 47

Clamp calibration check tool

Electrical specification

Resistance 25 Ω ±0.1%

Mechanical specification

Operating temperature -10 °C to 50 °C (14 °F to 122 °F)

0% to 85% RH at +35 °C (95 °F)

Storage temperature -20 °C to 70 °C (-4 °F to 158 °F)

Dimensions 111 x 216 x 45 mm (4.4 x 8.5 x 1.8 in)

Weight 0.1 kg (0.2 lb) approximately

Specifications

www.megger.com

DET2/3

41

Page 48

Accessories

Accessories

Warning: Use only Megger approved test leads and accessories with this instrument.

Item Part Number

Cable reel kit ETK30 1010-176

Cable reel kit ETK50 1010-177

Cable reel kit ETK100 1010-178

Cable reel kit ETK50C 1010-179

Cable reel kit ETK100C 1010-180

Clamp MCC1010 1010-516

Clamp MVC1010 1010-518

12 V dc power lead 1004-183

Terminal adapter, detachable retro-fit for C1, P1, P2, C2 connectors 6220-803

Power supply 18 V >3.5 A 1010-793

42

www.megger.comDET2/3

Page 49

Repair and warranty

Repair and warranty

If an instrument’s protection has been impaired it should not be used, but sent for repair by suitably trained

and qualified personnel. The protection is likely to be impaired if for example, it shows visible damage, fails to

perform the intended measurements, has been subjected to prolonged storage under unfavourable conditions, or

has been subjected to severe transport stresses.

New instruments are guaranteed for one year from the date of purchase by the user.

Note: Any unauthorized prior repair or adjustment will automatically invalidate the warranty and calibration.

Note: No user repair is possible beyond that which is described within this manual, i.e. battery replacement and

cleaning. Any attempt to disassemble or repair beyond this point will invalidate any warranty on the item.

www.megger.com

DET2/3

43

Page 50

Calibration and repair

Calibration and repair

Megger operate fully traceable calibration and repair facilities to make sure your instrument continues to provide

the high standard of performance and workmanship that is expected. These facilities are complemented by a

worldwide network of approved repair and calibration companies, which offer excellent in-service care for your

Megger products.

For service requirements for Megger Instruments contact:

Megger Limited

Archcliffe Road

Dover

Kent

CT17 9EN

England

Tel: +44 (0) 1304 502 243

Fax: +44 (0) 1304 207 342

or Megger

Valley Forge Corporate Centre

2621 Van Buren Avenue

Norristown

PA 19403

U.S.A.

Tel: +1 610 676 8579

Fax: +1 610 676 8625

Return procedure

Warning: This instrument contains a lithium ion high energy battery pack.

UK and USA Service Centres

1. When an instrument requires recalibration, or in the event of a repair being necessary, a Returns Authorisation

(RA) number must first be obtained from one of the addresses shown above.

The following information is to be provided to enable the Service Department to prepare in advance for

receipt of your instrument and to provide the best possible service to you:

Model (for example, DET2/3)

Serial number (found on the underside of the case or on the calibration certificate)

Reason for return (for example, calibration required, or repair)

Details of the fault if the instrument is to be repaired

2. Make a note of the RA number. A returns label can be emailed or faxed to you if required.

3. Pack the instrument carefully to prevent damage in transit.

4. Before the instrument is sent to Megger, freight paid, make sure that the returns label is attached, or that the

RA number is clearly marked on the outside of the package and on any correspondence.

Copies of the original purchase invoice and packing note should be sent simultaneously by airmail to expedite

clearance through customs. In the case of instruments which require repair outside the warranty period, an

immediate quotation can be provided when obtaining the RA number.

5. Track the progress on line at www.megger.com.

44

www.megger.comDET2/3

Page 51

Calibration and repair

Approved service centres

A list of Approved Service Centres can be obtained from the UK address above, or from Megger’s website at

www.megger.com

www.megger.com

DET2/3

45

Page 52

End of life

End of life

WEEE directive

The crossed out wheeled bin symbol placed on Megger products is a reminder not to dispose of the product at

the end of its life with general waste.

Megger is registered in the UK as a Producer of Electrical and Electronic Equipment (registration No.: WEE/

HE0146QT).

For further information about disposal of the product consult your local Megger company or distributor or visit

your local Megger website.

Battery disposal

The crossed out wheeled bin symbol placed on a battery is a reminder not to dispose of batteries with general

waste at the end of their life.

This instrument contains a rechargeable Li-ion battery, which is located under the battery cover at the bottom of

the instrument. To remove the Li-ion battery follow the instructions in Battery (page 36).

A spent Li-ion battery is classified as an Industrial Battery. For disposal in the UK contact Megger Ltd.

For disposal of batteries in other parts of the EU contact your local Megger branch or distributor.

Megger is registered in the UK as a producer of batteries (registration No.: BPRN00142).

For Further information see www.megger.com

46

www.megger.comDET2/3

Page 53

Declaration of conformity

Declaration of conformity

Hereby, Megger Instruments Limited declares that radio equipment manufactured by Megger Instruments

Limited described in this user guide is in compliance with Directive 2014/53/EU. Other equipment manufactured

by Megger Instruments Limited described in this user guide is in compliance with Directives 2014/30/EU and

2014/35/EU where they apply.

The full text of Megger Instruments EU declarations of conformity are available at the following internet address:

megger.com/eu-dofc

www.megger.com

DET2/3

47

Page 54

Bibliography

Bibliography

Getting Down to Earth, published by and available from Megger, Pt. No.: 21500-072.

48

www.megger.comDET2/3

Page 55

Notes

Notes

www.megger.com

DET2/3

49

Page 56

Megger Limited

Archcliffe Road

Dover

Kent

CT17 9EN

ENGLAND

T +44 (0)1 304 502101

F +44 (0)1 304 207342

Megger GmbH

Obere Zeil 2 61440