Page 1

DET2/2

Digital Earth Tester

USER GUIDE

GUIDE DE L’UTILISATEUR

GEBRAUCHSANLEITUNG

GUÍA DEL USUARIO

M

Page 2

SAFETY WARNINGS

• Special precautions are necessary when ‘live’ earths may be encountered, and isolation switches and fuses

are needed in this situation. See ‘Operation - Earth Testing Safety Precautions’.

• The earth spikes, test leads and their terminations must not be touched while the instrument is switched ‘On’.

• When working near high tension systems, rubber gloves and shoes should be worn.

• The DET2/2 must be disconnected from any external circuit while its battery cells are being charged.

• A 12 V d.c. battery must not be used as an external supply while it is still connected to the vehicle.

• Replacement fuses must be of the correct type and rating

• Before charging the DET2/2 battery ensure that the correct supply fuse is fitted and the voltage selector is

set correctly.

• Warnings and precautions must be read and understood before the instrument is used. They must be

observed during use.

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS.

NOTE

2

Page 3

Contents

Safety Warnings 2

Contents 3

General Description 4

Applications 5

Features and Controls 6

Initial Configuration 7

Setting up Test spikes 8

Earth Testing Safety Precautions 9

Operation

General Testing Procedure 11

Test condition adjustments 11

Display messages 12

Error messages 13

Battery charging 15

Measuring Techniques

Testing earth electrodes

Fall-of-Potential method 17

The 61,8% Rule 18

The Slope method 20

Method using ‘Dead’ earth 22

BS7671 (16th Edition IEE Wiring

Regulations) Requirements 23

Other methods 23

Determining ‘Touch’ potential 24

Determining ‘Step’ potential 25

Guide de l’utilisateur p43 Gebrauchsanleitung s67 Guía del usuario p91

Measuring soil resistivity -

Typical variations in soil resistivity 26

Line traverse 27

Calculation of Resistivity 27

Continuity Testing 29

Specification 30

Accessories 33

Chart for use with Slope method 35

Repair and Warranty 40

Guide de l’utilisateur 43

Gebrauchsanleitung 67

Guía del Usuario 90

Symbols used on the instrument

Caution: Refer to accompanying notes.

Equipment protected throughout by

Double Insulation (Class II)

Equipment complies with EU Directives

3

Page 4

General Description

The Megger DET2/2 is a self contained compact

portable instrument designed to measure earth

electrode resistance and perform four terminal

continuity tests. It may also make earth resistance tests

which lead to the measurement of soil resistivity.

Powered by internal rechargeable battery with an

integral charger unit, the instrument design takes full

advantage of microprocessor technology and features

a large, clear liquid crystal display to provide digital

readings. Terminals on the instrument provide an

alternative power source connection to an external 12V

battery, e.g. motor vehicle battery.

Display language can be selected from English,

French, German, Portuguese or Spanish. A range of

frequencies can be selected. DET2/2 is auto ranging,

and will indicate earth resistance in the range - 0,010 Ω

to 19,99 kΩ, with a maximum resolution of 1 mΩ. The

display warns of problems with the test conditions and

also indicates low battery voltage. This enables the

earth spikes to be re-positioned or instrument settings

to be adjusted, to achieve optimum test conditions.

The red TEST push button is pressed to switch the

instrument on, and then turned clockwise to hold it in

the On position. To switch the instrument Off, the TEST

button is turned anti - clockwise and released.

To suit prevailing lighting conditions, the LCD display

4

can be adjusted by turning the contrast knob.

Four separate membrane switches (marked with ▲ or

▼) control the measurement function and are used to

set the required language and test settings.

Test leads are not supplied with an instrument but form

part of an earth testing field accessory kit which is

available as an option. This kit also includes test spikes

(electrodes) for making temporary earth spikes.

The instrument is housed in a robust and tough case

moulded in ABS plastic. All the controls, the terminals

and the LCD display are mounted on the front panel.

DET2/2 is splash proof, and suitable for outdoor use

in most weather conditions.

Terminal ‘C2’ (‘H’) is for the connection to the remote

Current test spike.

Terminal ‘P2’ (‘S’) is for the connection to the remote

Potential test spike.

Terminal ‘P1’ (‘ES’) is for the Potential connection to

the earth electrode to be tested.

Terminal ‘C1’ (‘E’) is for the Current connection to the

earth electrode to be tested.

Page 5

Applications

The installation of satisfactory earthing systems is an

essential part of electricity supply, wiring safety and

installation economics. It is also of great importance in

many communications systems.

The primary application of the DET2/2 is in the testing

of earth electrodes, whether these take the form of a

single electrode, multiple electrodes, mesh systems,

earth plates or earth strips. All earthing arrangements

should be tested immediately after installation and at

periodic intervals thereafter.

Choice of electrode site

For an earth electrode system to perform satisfactorily

it must always have a low total resistance to earth. This

value will be influenced by the specific resistance of

the surrounding soil. This in turn depends on the

nature of the soil and its moisture content. Before

sinking an electrode or electrode system it is often

helpful to survey the surrounding area before choosing

the final position for the electrode. It is possible with

DET2/2 to obtain the resistivity of the soil over an area

and at different levels beneath the surface of the

ground. These resistivity surveys may show whether

any advantage is to be gained by driving electrodes to

a greater depth, rather than increasing the cost by

having to add further electrodes and associated cables,

in order to obtain a specified total earth system

resistance.

Earthing Systems Maintenance

After installation, checks may be made on an earthing

system to see if there is any significant change in the

resistance over a period of time or under different soil

moisture conditions, (e.g. brought about by changing

weather conditions or different seasons of the year).

Such checks will indicate if the earth electrode

resistance to earth has been exceeded by changing

soil conditions or ageing of the system.

Other Applications

For archaeological and geological purposes, an

investigation of soil structure and building remains can

be carried out at varying measured depths, by the

resistivity survey technique.

In all cases the accuracy of the instrument readings

may be taken to be higher than the changes caused by

natural variables in soil characteristics.

A further application is in continuity testing, for example

checking the resistance of conductors used in an

earthing circuit.

5

Page 6

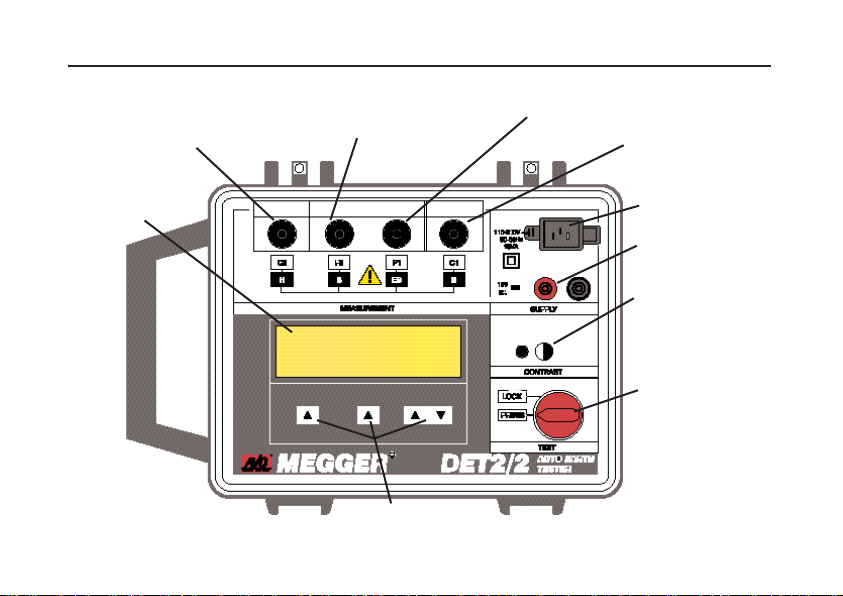

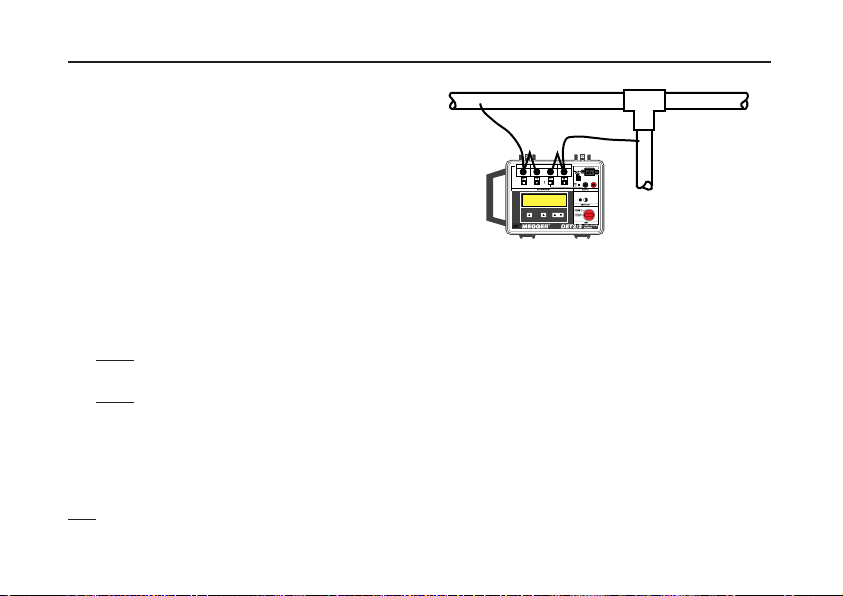

Features and Controls

To Current test spike

To Potential test spike

To electrode under test

(Potential connection)

To electrode under test

(Current connection)

31⁄2 digit L.C.D.

6

Charger socket

External 12 V d.c.

supply Terminals

Display contrast

adjustment

On / Off Test Button

(Rotate clockwise

to lock)

Test control

switches

Page 7

Initial Configuration

Default Language Setting

Select and set the display language default as follows:

1. Press the left hand key ▲ and the TEST button

together. Rotate the TEST button clockwise to the

lock position. The language options are displayed.

2. Adjust the display contrast as necessary.

3. Using the centre ▲ key, scroll through the

language options. When the required language is

highlighted with a box surround, press the left

hand ▲ key. The test frequency options are

displayed.

Default Frequency Setting

Default test frequencies are available as follows:-

108 Hz - For use when testing with interference

frequencies in the vicinity of 16 Hz.

128 Hz - For use when testing with interference

frequencies in the vicinity of 50 Hz.

135 Hz -

150 Hz - For use when testing with interference

frequencies in the vicinity of 60 Hz.

For each default value, the test frequency range can be

incremented in 0,5 Hz steps from 105 Hz to 160 Hz;

using the ▲ ▼ keys.

Select and set the default Frequency as follows:

1. Using the centre ▲ key, scroll through the

Frequency options. When the required Frequency

is highlighted with a box surround, press the left

hand ▲ key. The Test and Calibration mode

options are displayed. The message “Please

wait...” is displayed.

Saving the Test Parameter settings

The settings made for Test current and filtering options,

and the Frequency of the Test current may be saved for

use in subsequent tests as follows:

1. After making the settings, press and hold the ▲

Scroll key during the measuring mode. The

display lists the default selection.

2. Accept the settings and press the ▲ Yes key, or

press the ▲ No key to cancel.

Once accepted, further tests may, if desired be carried

out with different settings. The instrument will default to

the saved settings if switched Off and back On again.

7

Page 8

Setting up the Test spikes

For earth electrode testing and for earth resistivity

surveying, the instrument’s test leads are connected to

spikes inserted in the ground. The way the connections

are made depends on the type of test being undertaken

and details are given in ‘Measuring Techniques’.

Test spikes and long test leads are necessary for all

types of earth testing and the optional earth testing field

accessory kits contain the basic equipment. See

‘Accessories’.

1. Insert the Current test spike into the ground 30 to

50 metres away from the Earth electrode to to be

tested.

2. Connect this spike to the instrument terminal 'C2'

(‘H’).

3. Insert the Potential test spike into the ground

midway between the Current test spike and the

Earth electrode, and in direct line with them both.

4. Connect this spike to the instrument terminal 'P2'

(‘S’).

5. When running the test leads out to each remote

electrode, avoid laying the wires too close to each

other.

8

Page 9

Earth Testing Safety Precautions

Electrode Isolation or Duplication

It is preferable that the earth electrode to be tested is

first isolated from the circuit it is protecting, so that only

the earth is measured and not the complete system.

When this is done, the circuits and equipment must be

de-energised. If however this is not possible, the earth

electrode should be duplicated, so that when it is

disconnected for test purposes, the other one provides

the necessary circuit protection.

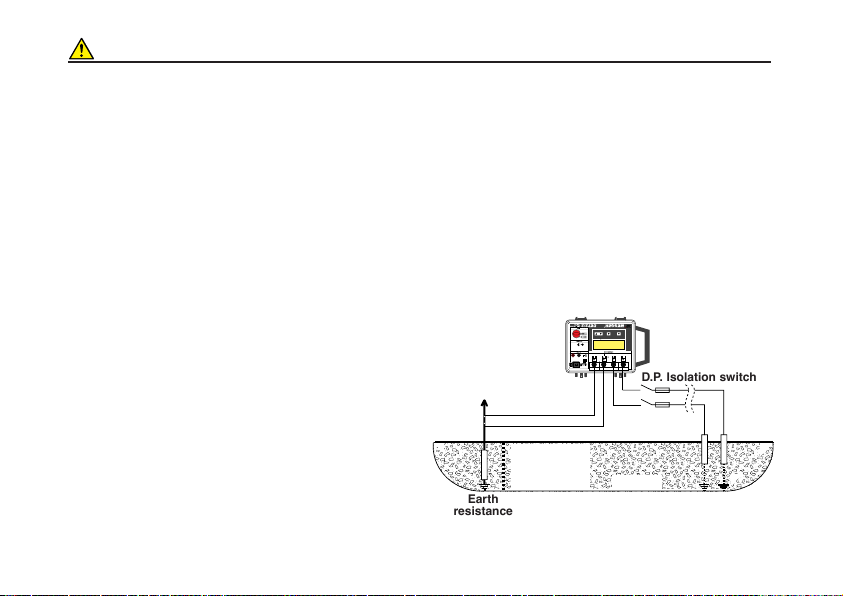

‘Live’ earth safety precautions

The DET2/2 allows earth testing to be done at a

relatively safe voltage using a maximum of a 50 V RMS

square wave at a frequency of nominally 128 Hz. In use

it is normally connected only to electrodes which are at

earth potential.

A 'Live' earth is one that carries current from the mains

supply, or could do so under fault conditions.

When working around power stations or sub stations

there is a danger that large potential gradients will

occur across the ground in the event of a phase to earth

fault. A wire which is connected to ground many metres

away will then no longer be at the same potential as

local ground, and in some cases could rise to above

1 kV. The following safety precautions are essential.

1. All persons involved must be trained and

competent in isolation and safety procedures for

the system to be worked on. They must be

clearly instructed not to touch the earth

electrode; test spikes; test leads, or their

terminations if any 'Live' earths may be

encountered. It is recommended that persons

involved wear appropriate rubber gloves, rubber

soled shoes, and stand on rubber mats.

2. The 'P2' and 'C2' terminals should be connected

through a double pole isolation switch, the rating

of which will cope with the maximum fault

voltage and current. The isolation switch must

be open whilst any personal contact is made

with the remote test spikes, or the connecting

leads, e.g. when changing their position.

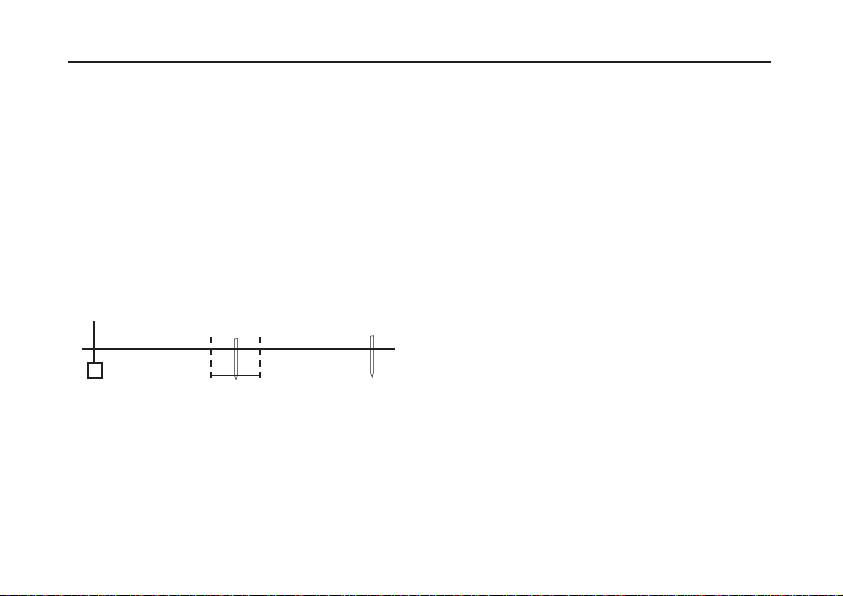

Fault

current

Voltage rise of

earthing system

under fault

conditions

Earth

resistance

A method of disconnection where fault conditions

may occur.

D.P. Isolation switch

Fuses

True earth

Remote

spikes

9

Page 10

Earth Testing Safety Precautions

If isolation switches cannot be used, the leads should

be disconnected from the instrument before remote

spikes and leads are handled. When the remote

connections have been made, the final connections

should be made to the instrument using insulated

plugs, ensuring that the Operator takes adequate and

appropriate precautions such as insulating mats,

rubber gloves etc.

If a fault occurs while a test is being made the

instrument may be damaged. Incorporating fuses

(rated at 100 mA and able to cope with the maximum

fault voltage) at the isolation switch will provide some

protection for the instrument.

Caution: When working on live sites, do not use an

external battery to power the instrument, as this would

also become live under fault conditions.

10

Page 11

Operation

It is advisable that the battery of the DET2/2 is fully

General T

charged before embarking on a test sequence. It can

be extremely inconvenient if the battery becomes too

low while a field test is in progress.

1. Firmly connect the instrument terminals to the

respective earth electrode and test spikes. See

‘Setting up the Test spikes‘ and ‘Measuring

Techniques‘.

2. Press and hold the On/Off push button, or rotate it to

the Lock position.

3. If required, carry out a Pspike test to check

continuity of the the Potential circuit.

4. The resistance value being measured is shown on

the sub display after a few moments, when the

“Please wait...” message has disappeared.

T

If the sub display message states that a true

measurement cannot be obtained, the test conditions

esting Procedure

est Condition Adjustments

can be altered to achieve optimum conditions for the

test. One or more of the following may be used:-

Test current Frequency

Using the right hand ▲ or ▼ keys, increase or decrease

the test current frequency range. See ‘Initial

Configuration and Spike set up‘.

Lo Current /Hi Current

Using the centre ▲ key, scroll through the left hand

options to select and highlight the ‘Current‘ option.

Press the left hand ▲ key to toggle between ‘Lo

Current‘ and ‘Hi Current‘. ‘Hi Current‘ assists to

overcome problems caused by high current spike

resistance. Note: Current circuit resistance is

constantly monitored during a test. If too high, a

message to this effect is displayed.

Filter

Using the centre ▲ key, scroll through the left hand

options to select and highlight the ‘Filter‘ option.

Press the left hand s key to toggle between ‘Filter off‘

and ‘Filter on‘. ‘Filter on‘ assists to reduce ‘noise‘

affecting the reading. The time taken to make a

measurement increases significantly with ‘Filter on‘.

PSpike

Using the centre ▲ key, scroll through the left hand

options to select and highlight the ‘Pspike‘ option.

Press the left hand ▲ key to automatically carry out a

11

Page 12

Operation

resistance check of the of the Potential circuit. After a

short pause, the result of this check is displayed on the

sub panel. If appropriate, the ‘Pspike‘ label then

changes to ‘Retest’, giving the option to repeat the test

after any alteration to spike position etc. has been

made. Press the centre ▲ key, now labelled ‘Measure’

to repeat the measurement.

Note: If for any reason a test is made with an open

Potential circuit, the resultant test reading will be

invalid. To confirm that connections are still in place

and to check the validity of the test, a ‘P spike‘ check

should be made before each test.

Auto Ranging

If the earth resistance being measured is low, but a

high level of ’noise’ is present, coupled with a high

Current spike resistance, the instrument will

automatically make a measurement with a lower

precision. If successful, the resistance reading will be

displayed with only 3 digits, the least significant digit

being blanked out.

Greater precision can be obtained by:-

a) Reducing spike resistance (e.g. by wetting the

ground, or by inserting the spikes deeper into the

ground).

b) Toggling to ‘Hi Current‘ option.

c) Eliminating the ‘noise’ source if possible.

12

Displa

When appropriate, messages are displayed. The

following message definitions are given:

This means that the instrument is making internal

measurements and tests before displaying the

resistance reading. The ▲ and ▼ keys remain active

and measurement conditions may be adjusted before

a reading is displayed. These messages may be

repeatedly displayed if there is a high ‘noise’ level

present, close to the frequency of the measurement,

or if the Potential circuit is incorrectly connected.

“Open Circuit Current Terminals”

This means that the test current flowing is low, and

implies that a resistance of >500 kΩ is present between

the test terminals. If this message remains displayed

when terminals ‘C1‘ and ‘C2‘ are shorted together, an

internal fuse has ruptured, with the possibility of other

internal damage having been caused. In this case,

return the instrument, return the instrument to the

manufacturer or an approved repair company. See

’Repair and Warranty’.

“Check connections voltage terminals”

This message is displayed when the connections to the

‘P1‘ and ‘P2‘ connections are reversed. Check and

correct as necessary.

y Messages

“Please wait...”

“Please wait... zeroing”

Page 13

“High current noise”

“High voltage noise”

These messages are displayed when the noise voltage

present is greater than the acceptable level, causing

the measurement to be invalid. Changing the test

frequency will have no effect in this instance. If

possible, eliminate the noise source, or reduce spike

resistance (e.g. by wetting the ground, or by inserting

the spikes deeper into the ground).

Further Display Messages

High level of interference or an instrument fault could

cause the display of any of the following messages:

“Invalid current”

“Invalid voltage”

“Invalid current zero”

“Invalid voltage zero”

“Current zero too big”

“Voltage zero too big”

“Noisy current zero”

“Noisy voltage zero”

Incorrect connection of the potential terminals could

cause an ‘Invalid voltage’ message.

Err

Error messages may appear on the bottom line of the

display in the event of a instrument or software fault, or

due to the existence of adverse electrical conditions. If

an error message appears, switch the DET2/2 off,

refer to ‘Repair and Warranty’ and return the

instrument to the manufacturer or approved agent,

giving details of the error message and the software

edition.

If calibration data stored in the instrument has been

incorrectly retrieved, the above message is displayed

(in English) when switching on. Switch the DET2/2

off, refer to ’Repair and Warranty’ and return the

instrument to the manufacturer or approved agent,

giving details of the error message and the software

edition.

Default language, frequency and current level are

normally retrieved when the instrument is switched on.

If unsuccessful, the above message is displayed (in

English) when switching on, with the option to “Retry”

(try reading the data again) or “Manual” (manually set

up the data again). If ‘Retry’ or ‘Manual’ is

or Messages

“Calibration data retrieval error

Refer to handbook”

“Setup data retrieval error”

13

Page 14

Operation

unsuccessful, switch the DET2/2 off, refer to ’Repair

and Warranty’ and return the instrument to the

manufacturer or approved agent, giving details of the

error message and the software edition.

14

Page 15

Battery Charging

Battery capacity

The capacity of the battery is continuously monitored

and displayed, adjacent to the battery symbol. The

indicator segments will show fully charged, or recede

as the battery is used, to indicate three quarters full,

half full or quarter full. A warning message is displayed

if the battery is unable to supply adequate test current.

Charging method

It is advisable that the battery is fully charged before

embarking on a test sequence. Charging is carried out

by external a.c. mains supply only. Charging

commences automatically as soon as the supply is

connected. Normal recharge time is 6 hours. Testing is

inhibited during charging.

Battery charging requires a supply voltage of 100 V to

130 V a.c., or

to a voltage from 130 V to 200 V will not cause harm,

but will not charge the battery, and the message

“Power Supply too low” will be displayed. Charging

time will be extended if either the power supply voltage

drops too low during the charge period or if the battery

has been excessively discharged. Charge the battery

as follows:

1. Switch the Test switch to Off.

2. Remove any connections to the 4 mm external

supply sockets.

200 V to 260 V, 50 - 60 Hz. Connection

3. Disconnect and remove the test leads.

4. Connect the mains supply to the IEC 320

connector on the top right of the instrument.

Confirm that the message “Charging On” is

displayed. Progressive and accumulated charging

times are displayed.

5. When fully charged, the charging current will

automatically reduce to ”Trickle Charge“.

Charging will automatically stop after a period of

24 hours.

Note: The battery will be prevented from charging if an

external battery is connected to the 4 mm sockets

during the charging process. An external connected

battery cannot be charged via the instrument.

15

Page 16

Battery Charging

Battery Charging Power cord plug

If the power cord plug is not suitable for your type of

socket, do not use an adaptor. You should use a

suitable alternative power cord, or if necessary, change

the plug by cutting the disconnected cord and fitting a

suitable plug.

The colour code of the cord is:-

Earth (Ground) - Yellow/Green

Neutral - Blue

Phase(Line) - Brown

If using a fused plug, a 3 amp fuse to BS 1362 should

be fitted.

Note: A plug severed from the power cord should be

destroyed, as a plug with bare connections is

hazardous in a live socket outlet.

16

Battery Charging Notes

1) Do Not leave battery in a totally discharged state.

If the instrument is idle for long periods, recharge

the battery at least every 6 months. (More

frequently if the storage temperature is >40 °C).

2) Battery charging should be carried out in a dry

environment and at temperatures in the range 0 °C

to 40°C.

3) When charging the battery indoors, the area

should be well ventilated.

Page 17

Measuring Techniques - Testing Earth Electrodes

Electrode

under test

Potential

spike

3m 3m

15m to 25m 15m to 25m

Current

spike

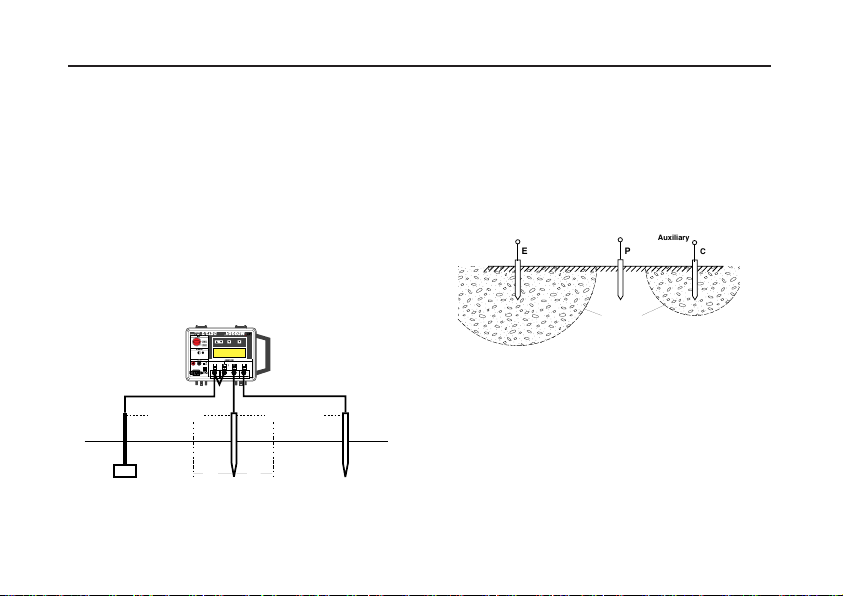

FALL-OF-POTENTIAL METHOD

This is the basic method for measuring the resistance

of earth electrode systems. However, it may only be

practical on small, single earth electrodes because of

limitation on the size of area available to perform the

tests.

Insert the Current test spike into the ground some 30 to

50 metres away from the earth electrode to be tested.

Firmly connect this spike to the instrument terminal 'C2'.

Insert the Potential test spike into the ground midway

between the Current test spike and the earth electrode.

Firmly connect this spike to the instrument terminal

'P2'.

Note:- It is important that the Current spike, the

Potential spike and the earth electrode are all in a

straight line. Also when running the test leads out to

each remote spike, it is preferable not to lay the wires

close to each other in order to minimise the effect of

mutual inductance.

Firmly connect the 'C1' and the 'P1' instrument

terminals to the earth electrode as shown.

Operate the instrument as explained in 'Basic Test

Procedure', and note the resistance obtained.

Move the potential spike 3 metres further away from the

earth electrode and make a second resistance

measurement. Then move the potential spike 3 metres

nearer the electrode (than the original position) and

make a third resistance measurement. If the three

resistance readings agree with each other, within the

required accuracy, then their average may be taken as

the resistance to earth of the electrode. If the readings

disagree beyond the required accuracy then an

alternative method should be used e.g. the 61,8% Rule

or the Slope Method etc.

Fall-of-Potential method connections.

17

Page 18

Measuring Techniques - Testing Earth Electrodes

Fall-of-Potential Method with Short 'E' Lead

Another way of making connections to the earth

electrode is to connect to the earth electrode using only

one single connection to the ‘C1’ terminal. This should

only be done if the test lead can be kept short because

its resistance will be included in the measurement.

Note:- Earth electrode test lead resistance can be

determined separately. First remove it from the the

electrode and connect to the 'C2' and 'P2' terminals.

Press the Test push button. The lead resistance can

then be deducted from the earth resistance

measurements. This procedure is not, of course,

necessary if the 'C1' and 'P1' terminals are connected

by separate test leads.

15m to 25m 15m to 25m

Electrode

under test

Fall-of-Potential method using a single lead to the

3m 3m

Potential

spike

Current

spike

earth electrode.

18

THE 61,8% RULE

To obtain an accurate reading using the Fall-ofPotential method the current spike must be correctly

sited in relation to the earth electrode. Since both

possess ‘resistance areas’, the Current spike must be

sufficiently remote to prevent these areas overlapping.

Furthermore, the Potential spike must be between

these areas. If these requirements are not met, the Fallof-Potential method may give unsatisfactory results.

Electrode

EPC

Under Test

Resistance areas associated with an earth

electrode and current spike.

Theoretically, both the Current and Potential spikes

should be at an infinite distance from the earth

electrode. However, by graphical considerations and by

actual test it can be demonstrated that:-

The ‘true’ resistance of the earth electrode is equal to

the measured value of resistance when the Potential

spike is positioned 61,8% of the distance between the

earth electrode and the Current spike, away from the

earth electrode.

Auxiliary

Potential

Electrode

Resistance Areas

(Not Overlapping)

Auxiliary

Current

Electrode

Page 19

This is the 61,8% Rule and strictly applies only when

Electrode

under test

Potential

spike

Current

spike

61,8% of EC

38,2% of EC

the earth electrode and Current and Potential spikes lie

in a straight line, when the soil is homogeneous and

when the earth electrode has a small resistance area

that can be approximated by a hemisphere. Bearing

these limitations in mind this method can be used, with

care, on small earth electrode systems consisting of a

single rod or plate etc. and on medium systems with

several rods.

Connections for the 61,8% Rule.

For most purposes the Current spike should be 30

metres to 50 metres from the centre of the earth

electrode under test. The Potential spike should be

inserted in the ground 61,8% of this distance, between

and in a straight line with, the Current spike and the

earth electrode. The distance is measured from the

earth electrode. If the earth electrode system is of

medium size containing several rods, then these

distances must be increased. The following table gives

a range of distances that agree with the rule. In the first

column ‘Maximum dimension’ is the maximum

distance across the earth electrode system to be

measured.

Maximum

dimension

in metres

5

10

20

Distance to Potential

spike in metres from

centre of earth

system

62

93

124

Distance to Current

spike in metres from

centre of earth

system

100

150

200

For greater accuracy an average reading can be

calculated by moving the current spike, say 10 metres,

towards and then away from its first position and

making further resistance measurements. (Remember

that the Potential spike must also be moved in

accordance with the 61,8% Rule). The average of the

three readings can then be calculated.

19

Page 20

Measuring Techniques - Testing Earth Electrodes

P

C

Electrode

under test

EC

Position of Electrode P

measured from E

Arbitrary position

of Earth electrode

0,2 EC 0,4 EC

0,6 EC

Position of

C electrode

Earth

resistance

curve

R3

R2

R1

Resistance

20

THE SLOPE METHOD

This method is more applicable to larger earth

electrode systems or where the position of the centre of

the earthing system is not known or inaccessible (e.g.

if the system is beneath the floor of a building). The

Slope method can also be used if the area available for

siting the earth electrodes is restricted. It can be tried if

the previous methods prove unsatisfactory and

generally yields results of greater accuracy than those

methods.

Connections for the Slope method

The equipment is set up as shown. The remote Current

spike is placed 50 metres or more from the earth

electrode system to be measured and connected to the

'C2' terminal. The Potential spike is inserted at a

number of positions consecutively, between the earth

system and the Current spike, and connected to the

'P2' terminal. The test spikes and the earth system

should all be in a straight line.

The 'C1' and 'P1' terminals are connected separately

to some point on the earth electrode system.

The earth resistance is measured at each separate

position of the Potential spike and the resistance curve

is plotted from the results. At least six readings are

needed. Drawing the curve will show up any incorrect

points which may be either rechecked or ignored.

Example Resistance curve from Slope method

tests.

Page 21

Suppose the distance from the earth electrode system

to the current spike is EC. From the curve equivalent

resistance readings to Potential positions 0,2EC, 0,4EC

and 0,6 EC can be found. These are called R1, R2 and

R3 respectively.

Calculate the slope coefficient μ, where

μ = (

which is a measure of the change of slope of the earth

resistance curve.

From the table commencing on page 36 obtain the

value of Pt / Ec for this value of μ.

Ptis the distance to the Potential electrode at the

position where the ‘true’ resistance would be

measured.

Multiply the value of Pt / Ec by Ec to obtain the distance

Pt.

From the curve read off the value of resistance that

corresponds to this value of Pt. The value obtained is

the earth electrode system's resistance.

Note:- (i) If the value of μ obtained is not covered in

the table then the current spike will have to be moved

further away from the earthing system.

R3-R2

(R2-R1)

)

(ii) If it is necessary, further sets of test results can be

obtained with different values of EC, or different

directions of the line of EC. From the results obtained of

the resistance for various values of the distance EC.

Example of possible results from several Slope

method tests.

This shows how the resistance is decreasing as the

distance chosen for EC is increased.

The curve indicates that the distances chosen for EC in

tests (1) and (2) were not large enough, and that those

chosen in tests (3) and (4) were preferable because

they would give the more correct value of the earth

resistance.

(iii) It is unreasonable to expect a total accuracy of

more than 5%. This will usually be adequate, bearing in

mind that this sort of variation occurs with varying soil

moisture conditions or non-homogeneous soils.

21

Page 22

Measuring Techniques - Testing Earth Electrodes

E

Electrode

under test

METHOD USING A ‘DEAD’ EARTH

The techniques using test spikes explained earlier are

the preferred methods of earth testing. In congested

areas it may not be possible to find suitable sites for the

test spikes, nor sufficient space to run the test leads. In

such cases a low resistance conductive water main

may be available. This is referred to as a ‘dead’ earth.

Great care must be taken before deciding to adopt this

method and its use is not to be encouraged. Before

employing this method, the user must be quite sure that

no part of the ‘dead‘ earth installation contains plastic or

other non-metallic materials.

1) Short together terminals ‘P1’ and ‘C1’.

2) Short together terminals ‘P2’ and ‘C2’.

2) Firmly

connect a test lead to ‘C1‘ and ’P1‘ and the

other test lead to ‘P2‘ and ‘C2‘.

3) Firmly

connect the free ends of the test leads

to the ‘dead’ earth, and to the electrode under test.

4) Press the Test push, and take a reading in

the normal way.

This test will give give the combined resistance to earth

of the two earths in series. If that of the ‘dead‘ earth is

negligible then the reading may be taken as that of the

electrode under test .

22

The resistance of the two test leads can be found by

firmly joining their free ends together, pressing the Test

push and taking the reading in the usual way. Test lead

resistance can then be subtracted from the original

reading, to obtain the combined resistance of the earth

electrode and the ‘dead’ earth.

In congested urban areas, the Star-Delta method is the

preferable. This method is explained along with other

methods referred to, in ‘Getting Down to Earth’ (see

‘Accessories‘ - Publications).

‘Dead’ earth testing

Page 23

BS7671(16th Edition wiring regulations)

requirements

Regulation 713-11 of BS7671 specifies that the

resistance of earth electrodes must be measured. The

accompanying Guidance Notes describe a method of

test that is very similar to the Fall-of-Potential method.

If the maximum deviation from the average of the three

readings is better than 5% then the average can be

taken as the earth electrode resistance. If the deviation

exceeds 5% then the current spike should be moved

further away from the electrodes and the tests

repeated.

Other Methods

There are other methods of earth electrode testing

among which are the Four Potential, Intersecting Curves

and Star Delta methods. Megger Limited publications

explain these test methods and give other helpful

information about earth testing. See ‘Accessories‘ -

Publications.

E

6m

P

6m

Test spike positions for BS7671 testing

C

23

Page 24

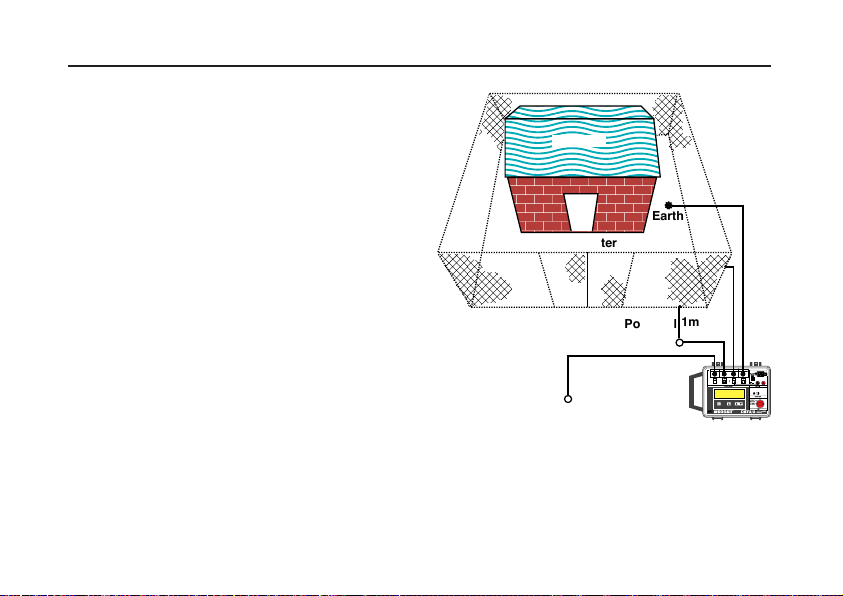

Measuring Techniques - Testing Earth Electrodes

Earth

1m

Potential

spike

Current

spike

Earthed Perimeter Fence

SUBSTATION

Determining ‘Touch’ Potential

‘Touch’ potential is the potential difference a person

would experience across his body if he were, for

example, standing on the ground outside the earthed

perimeter fence of a substation and touching the fence

at the time a fault occurred.

Firmly connect the instrument as follows:-

1) Terminal 'C1' to the substation earth.

2) Terminal 'C2' to the Current spike inserted in the

ground some distance away.

3) Terminal 'P1' to the structure being tested e.g. the

perimeter fence.

4) Terminal 'P2' to the Potential spike inserted in the

ground 1 metre away from the perimeter fence

adjacent to the point where a person might stand.

5) Press the Test push, and take a reading in

the normal way. This is the effective resistance

between the point of test on the fence and the

Potential spike as seen by the test current.

The maximum value of the current that would flow in

the earth when a fault to earth occurred at the

substation must be known. The maximum fault current

has to be calculated from the parameters associated

with the substation ratings involved. From Ohms Law

(V = I x R), the Touch potential can be calculated.

24

Determining 'Touch' potential.

Page 25

Determining ‘Step’ potential

Earth

Current

spike

SUBSTATION

1m

A

B

‘Step’ potential is the potential difference a person

would experience between his feet as he walked across

the ground in which a fault current was flowing.

Firmly connect the instrument as follows :-

1) Terminal 'C1' to the substation earth.

2) Terminal 'C2' to the Current spike inserted in the

ground some distance away.

3) Firmly connect the 'P1' and 'P2' terminals to test

spikes inserted in the ground 1 metre apart, (or the

length of a step) at positions A and B respectively.

A is nearest to the substation earth.

4) Press the Test push, and take a reading in

the normal way.

Record the resistance indicated. This is the effective

resistance across the positions A and B, as seen by the

test current.

The maximum value of the current that would flow in

the earth when a fault to earth occurred at the

substation must again be known. From Ohms Law the

‘Step potential’ can be calculated.

Determining ‘Step’ potential

25

Page 26

Measuring Techniques - Measuring Soil Resistivity

Typical variations in soil resistivity

The resistance to earth of an earth electrode is

influenced by the resistivity of the surrounding soil. The

resistivity depends upon the nature of the soil and its

moisture content and can vary enormously as seen in

the table below:-

Material

Ashes

Coke

Peat

Garden earth - 50% moisture

Garden earth - 20% moisture

Clay soil - 40% moisture

Clay soil - 20% moisture

London clay

Very dry clay

Sand - 90% moisture

Sand - normal moisture

Chalk

Consolidated

Sedimentary rocks

Specific

resistance

in Ω-cms

20 - 800

4500 - 20000

400 - 2000

5000 - 15000

13000

300000 - 800000

5000 - 15000

1000 - 50000

350

1400

4800

770

3300

Information

source

Higgs

Ruppel

Ruppel

Ruppel

Ruppel

Broughton

Edge & Laby

26

Because it is impossible to forecast the resistivity of the

soil with any degree of accuracy it is important to

measure the resistance of an earth electrode when it is

first laid down and thereafter at periodic intervals.

Before sinking an electrode into the ground for a new

installation it is often advantageous to make a

preliminary survey of the soil resistivity of the

surrounding site. This will enable decisions to be made

on the best position for the electrode(s) and to decide

whether any advantage can be gained by driving rods

to a greater depth. Such a survey may produce

considerable savings in electrode and installation costs

incurred trying to achieve a required resistance.

Page 27

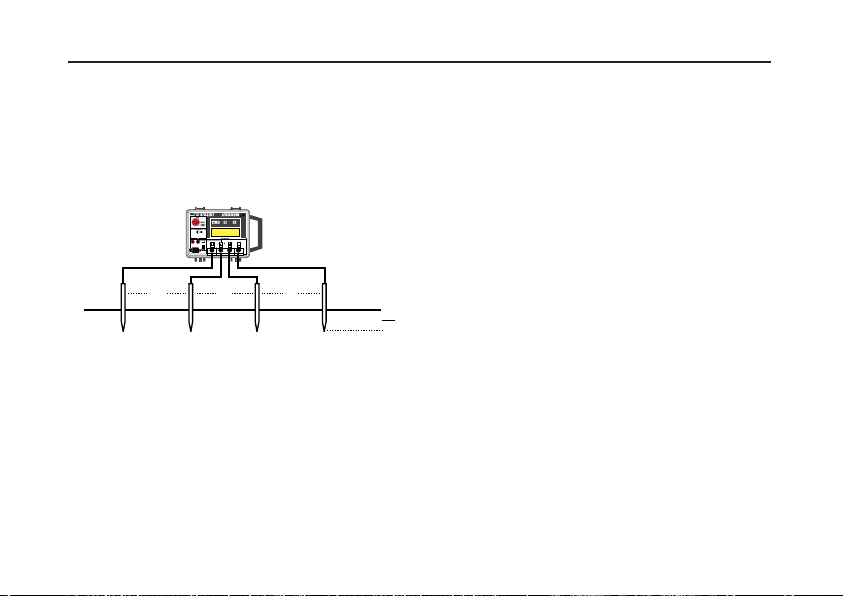

Line Traverse

a

a

a

P1

a

20

The most common method of measuring soil resistivity

is often referred to as the line traverse. Four test spikes

are inserted into the ground in a straight line at equal

distances 'a' and to a depth of not more than 1/20 of 'a'.

The instrument is connected to the test spikes as

shown.

Soil resistivity measurement.

The instrument is operated and the measurement

made in the normal way. The resistivity may be

calculated from the formula given opposite or from the

nomogram overleaf. This is the average soil resistivity

to a depth 'a'.

The four test spikes are then re-positioned for further

tests along a different line. If both the spacing 'a' and

the depth a/20 are maintained, a directly comparable

reading will be obtained each time, and thus regions of

lowest resistivity can be located over a given area (at

the constant depth 'a').

Re-spacing the test spikes at separations 'b', 'c', 'd', etc

will yield results from which a profile of the resistivity at

new depthsb/20, c/20, d/20,etc.can be obtained.

If the same line for the test spikes is maintained, but the

separation of them is progressively widened, resistivity

values at various depths can be obtained. By this

means depth surveys may be made.

More details can be found in the Megger Limited

publications. See ‘Accessories‘.

Calculation of resistivity

Assuming that the tests were carried out in

homogeneous soil the resistivity is given by the

formula:-

ρ = 2πaR

where ‘R’ is the resistance measured in ohms, ‘a’ is the

test spike spacing in metres and ‘ρ’ is the resistivity in

ohm-metres.

For non-homogeneous soils the formula will give an

apparent resistivity which is very approximately the

average value to a depth equal to the test spike spacing

'a'.

27

Page 28

Measuring Techniques - Measuring Soil Resistivity

Resistivity calculation Nomogram

28

Page 29

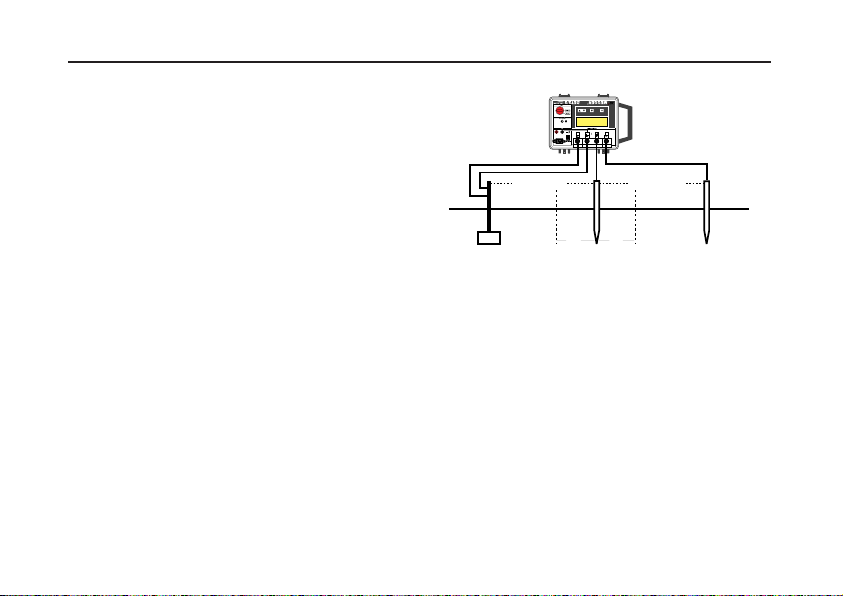

Measuring Techniques - Continuity Testing

DET 2/2 can be used to measure metallic resistances

of low inductance or capacitance. To test the continuity

of conduit or other earth conductors the instrument can

be connected as shown. Ensure that the circuit is deenergised, before connecting the instrument for

measurement.

Note:- Due to the inherent high accuracy of the

instrument and the low continuity resistance to be

measured, contact resistance between the test lead

clips and the conduit becomes a factor in the measured

value. Contact resistance should therefore be kept as

low as possible.

1) Firmly short together terminals ‘P2’ and ‘C2’.

2) Firmly short together terminals ‘P1’ and ‘C1’.

3) Firmly

4) Firmly

5) Press the Test push, and take a reading in the

The resistance of the two test leads can be found by

firmly joining their free ends together, pressing the

T

est push and taking the reading in the usual way. Test

lead resistance can then be subtracted from the original

reading, to give a ‘true’ value of continuity resistance.

connect a test lead to ‘P2 and C2’,and the

other test lead to ‘P1’ and ‘C1’.

connect the free ends of the test leads

across the isolated circuit under test.

normal way.

Continuity testing.

29

Page 30

Specification

Earth Resistance Ranges: 0,010 Ω to 19,99 kΩ (Auto-ranging) 1 mΩ resolution

Accuracy (23°C ±2°C): ±0,5% of reading ±2 digits. Service error ±5% of reading ±2 digits ±10 mΩ

Test Frequency: 105 Hz to 160 Hz reversing d.c. (50 Hz environments default to 128 Hz,

Test Current: 50 mA max. (selectable high and low levels)

Max Output Voltage: < 50 V r.m.s.

Interference: Typically 40 V pk to pk (50 Hz, 60 Hz, sinusoidal nature)

Max. Current spike

(Loop) Resistance: Range (R

Max. Potential Spike Resistance: Range (R

30

(meets VDE service error over 50 mΩ)

60 Hz environments default to 150 Hz). Set in steps of 0,5 Hz

) High current (Rp) Low current (Rc)

0,010 Ω - 0,499 Ω 5 kΩ 1 kΩ

E

0,500 Ω - 1,999 Ω 5 kΩ 3 kΩ

2,000 Ω - 19,99 Ω 10 kΩ 5 kΩ

20,000 Ω - 199,9 Ω 50 kΩ 20 kΩ

200, 0 Ω - upwards 50 kΩ 50 kΩ

) High current (Rp) Low current (Rp)

E

0,010 Ω - 0,499 Ω 1 kΩ 10 kΩ 1 kΩ 10 kΩ

0,500 Ω - 1,999 Ω 1 kΩ 20 kΩ 1 kΩ 10 kΩ

2,000 Ω - 19,99 Ω 1 kΩ 20 kΩ 1 kΩ 10 kΩ

20,000 Ω - 199,9 Ω 200 x R

200, 0 Ω - upwards 50 kΩ total 50 kΩ total

(Rp1) (Rp2)(R

E 20 kΩ 200 x RE 20 kΩ

) (Rp2)

p1

Page 31

Display: Alpha numeric LCD (130 mm x 35 mm) giving test information and a large

(20 mm) 3

1

⁄2 digitLCD, maximum reading 1999

Instrument Protection: Meets the general requirements of IP54

Temperature Effect: <±0,1%/°C over the temperature range -10°C to +40°C

Temperature Range: Operating: -10°C to +40 °C

Storage: -20°C to +60°C

Humidity: Operating: 90% RH max. at 40°C

Flash Test: 3 kV a.c.

Voltage Withstand: In the event of a system fault the instrument will withstand 240 V a.c.

applied between any two terminals.

Compliance with Standards: BS 7430 (1992) BS7671 (1992) NFC 15-100

VDE 0413 Part 7 (1982) IEC364

Power Supply: (i) Internal rechargeable sealed lead acid cells 12 V nominal, 2,6 Ah

capacity. Battery voltage range over which basic accuracy is

maintained, 11,0 V to 13,5 V.

Battery life: Typically 5 Hours continuous use

Battery charging time: 6 hours max. (from completely exhausted).

Charging supply required: 100 V to 130 V or 200 V to 260 V a.c. 50 Hz/60 Hz.

Power consumption: 25 VA

31

Page 32

Specification

Note: When the battery is charging, fast transients can cause the display to go blank. This will not normally affect

the charging operation.

Fuses (Non replaceable):

Mains supply protection: 200 mA (T) ceramic HBC 20 mm x 5 mm to IEC 127/3

Battery protection: 2 A (T) ceramic HBC 20 mm x 5 mm to IEC 127/3

Battery in-line protection: 3,15 A (T) ceramic HBC 20 mm x 5 mm IEC 127/3

External 12 V supply protection: 2 A (T) ceramic HBC 20 mm x 5 mm IEC 127/3

Output current protection: 80 mA (F) glass 20 mm x 5 mm

Fuse (Replaceable):

Mains power cord fused plug: 3 Amp fuse to BS 1362

Safety: Meets the requirements for safety to IEC 61010-1

E.M.C: In accordance with IEC61326-1

Operational uncertainties: Visit www.megger.com

Dimensions: 344 mm x 245 mm x 158 mm

Weight: 5 kg

Cleaning: Wipe the disconnected instrument with a clean cloth dampened with

32

(ii) External 12 V d.c. source

soapy water or Isopropyl Alcohol (IPA).

Page 33

VDE 0413 part 7 specification stipulates that these

instructions should contain a table or diagram showing

the maximum value which the instrument must indicate

in certain conditions. An earth test being performed on

any electrode system would normally be carried out to

a particular specification. Therefore, even at the iworst

accuracy of the instrument, the reading is never above

the limiting value required by the particular

specification in question.

The table overleaf shows the maximum reading which

shall be indicated by the instrument (at its maximum

error) to ensure that the maximum value of the earth

resistance given in the relevant earth electrode test

specification is met.

Note: The decimal point position in the Maximum

Resistance value column is correct for resistance

readings < 2 Ω. For the 2 Ω to 20 Ω column and the >

20 Ω column, the decimal point should be moved

accordingly. For maximum readings in excess of 200 Ω

use the right hand column and adjust the decimal point

accordingly.

The table gives the maximum reading that would be

allowed for a known maximum resistance value,

assuming the instrument is used as specified.

If a maximum resistance is known, this value is found

from the left hand column. The maximum reading to be

given by the instrument is found by reading across to

the appropriate of the three right hand columns,

depending upon the range of the value to be measured.

For example If 10 Ω is the value of the maximum

resistance, since this is less than 20 Ω, the centre

column of the three right hand columns is used. This

shows that a reading of less than 9,49 Ω will ensure

that, allowing for instrument tolerances, the measured

resistance will be less than 10 Ω.

A maximum value may be given to a measurement by

using the table in reverse. For example, a reading of

1,545 Ω would give a maximum limit to the resistance

value of between 1,600 Ω and 1,650 Ω. Interpolation

can be used to increase the accuracy if required.

Note: This table can only be used for readings from a

DET2/2.

33

Page 34

Specification

Maximum

Resistance

Value

0,050 -0,036 0,100 -0,083 0,150 -0,131 0,200 18,80,179 1,88

0,250 23,60,226 2,35

0,300 28,30,274 2,83

0,350 33,10,321 3,30

0,400 37,90,369 3,78

0,450 42,60,417 4,26

0,500 47,40,464 4,73

0,550 52,10,512 5,21

0,600 56,90,560 5,68

0,650 61,70,607 6,16

0,700 66,40,655 6,64

0,750 71,20,702 7,11

0,800 76,00,750 7,59

0,850 80,70,798 8,07

0,900 85,50,845 8,54

0,950 90,20,983 9,02

1,000 95,00,940 9,49

1,050 99,80,988 9,97

34

Maximum Reading Maximum

< 2

2 to 20

> 20

Resistance

Value

1,100 104,51,036 10,45

1,150 109,31,083 10,92

1,200 114,01,131 11,40

1,250 118,81,179 11,88

1,300 123,61,226 12,35

1,350 128,31,274 12,83

1,400 133,11,321 13,30

1,450 137,91,369 13,78

1,500 142,61,417 14,26

1,550 147,41,464 14,73

1,600 152,11,512 15,21

1,650 156,91,560 15,69

1,700 161,71,607 16,16

1,750 166,41,655 16,64

1,800 171,21,702 17,11

1,850 176,01,750 17,59

1,900 180,71,798 18,07

1,950 185,41,845 18,54

2,000 190,21,893 19,02

2,050 195,01,940 19,50

21,00 199,81,988 19,97

Maximum Reading

< 2

2 to 20

> 20

Page 35

Accessories

SUPPLIED Part Number

User Guide 6171-428

Battery charging Power cord

OPTIONAL

Publications

‘Getting Down to Earth’ AVTM25-TA

Four Terminal Earth Testing kit 6310 - 755

Carrying bag containing:Club hammer, 4 x spikes, two spike

extractors, 3m (x2) cable and 30m,

50m of cable on winders.

Four Terminal Compact Earth 6210 - 161

Testing kit

Compact carrying bag containing:2 x push in spikes, 3m, 15m, 30,

and 50m of cable on cable tidy.

Three Terminal Compact Earth 6210 - 160

Testing Kit

Compact carrying bag containing:2 x push spikes, 3m, 15m and 30m

of cable on a cable tidy.

U.S. OPTIONS Cat. Number

Standard Accessory kit 250579

Canvas case containing:2 x 20 in rods, leads

(25,50 &100 ft)

Deluxe Accessory kit 250581

Padded case to hold instrument,

2 x 20 in rods, leads

(25,50 &100 ft)

Soil Resistivity kit 250586

Padded case to hold instrument,

44 x 20 in rods and test leads

(4 x 50ft )

35

Page 36

Chart for use with the Slope Method

Values of P

μ 0123456789

0.40 0.6432 0.6431 0.6429 0.6428 0.6426 0.6425 0.6423 0.6422 0.6420 0.642

0.41 0.6418 0.6417 0.6415 0.6414 0.6412 0.6411 0.641 0.6408 0.6407 0.6405

0.42 0.6404 0.6403 0.6401 0.64 0.6398 0.6397 0.6395 0.6394 0.6393 0.6391

0.43 0.639 0.6388 0.6387 0.6385 0.6384 0.6383 0.6381 0.638 0.6378 0.6377

0.44 0.6375 0.6374 0.6372 0.6371 0.637 0.6368 0.6367 0.6365 0.6364 0.6362

0.45 0.6361 0.6359 0.6358 0.6357 0.6355 0.6354 0.6352 0.6351 0.6349 0.6348

0.46 0.6346 0.6345 0.6344 0.6342 0.6341 0.6339 0.6338 0.6336 0.6335 0.6333

0.47 0.6332 0.633 0.6329 0.6328 0.6326 0.6325 0.6323 0.6322 0.632 0.6319

0.48 0.6317 0.6316 0.6314 0.6313 0.6311 0.631 0.6308 0.6307 0.6306 0.6304

0.49 0.6303 0.6301 0.63 0.6298 0.6297 0.6295 0.6294 0.6292 0.6291 0.6289

0.50 0.6288 0.6286 0.6285 0.6283 0.6282 0.628 0.6279 0.6277 0.6276 0.6274

0.51 0.6273 0.6271 0.627 0.6268 0.6267 0.6266 0.6264 0.6263 0.6261 0.626

0.52 0.6258 0.6257 0.6255 0.6254 0.6252 0.6251 0.6249 0.6248 0.6246 0.6245

0.53 0.6243 0.6242 0.624 0.6239 0.6237 0.6235 0.6234 0.6232 0.6231 0.6229

0.54 0.6228 0.6226 0.6225 0.6223 0.6222 0.622 0.6219 0.6217 0.6216 0.6214

0.55 0.6213 0.6211 0.621 0.6208 0.6207 0.6205 0.6204 0.6202 0.6201 0.6199

0.56 0.6198 0.6196 0.6194 0.6193 0.6191 0.619 0.6188 0.6187 0.6185 0.6184

0.57 0.6182 0.6181 0.6179 0.6178 0.6176 0.6174 0.6173 0.6171 0.617 0.6168

0.58 0.6167 0.6165 0.6164 0.6162 0.6161 0.6159 0.6157 0.6156 0.6154 0.6153

0.59 0.6151 0.615 0.6148 0.6147 0.6145 0.6143 0.6142 0.614 0.6139 0.6137

0.60 0.6136 0.6134 0.6133 0.6131 0.6129 0.6128 0.6126 0.6125 0.6123 0.6122

0.61 0.612 0.6118 0.6117 0.6115 0.6114 0.6112 0.6111 0.6109 0.6107 0.6106

0.62 0.6104 0.6103 0.6101 0.6099 0.6098 0.6096 0.6095 0.6093 0.6092 0.609

0.63 0.6088 0.6087 0.6085 0.6084 0.6082 0.608 0.6079 0.6077 0.6076 0.6074

36

t / EC

for Values of μ

Page 37

μ 0123456789

0.64 0.6072 0.6071 0.6069 0.6068 0.6066 0.6064 0.6063 0.6061 0.606 0.6058

0.65 0.6056 0.6055 0.6053 0.6052 0.605 0.6048 0.6047 0.6045 0.6043 0.6042

0.66 0.604 0.6039 0.6037 0.6035 0.6034 0.6032 0.6031 0.6029 0.6027 0.6026

0.67 0.6024 0.6022 0.6021 0.6019 0.6017 0.6016 0.6014 0.6013 0.6011 0.6009

0.68 0.6008 0.6006 0.6004 0.6003 0.6001 0.5999 0.5998 0.5996 0.5994 0.5993

0.69 0.5991 0.599 0.5988 0.5986 0.5985 0.5983 0.5981 0.598 0.5978 0.5976

0.70 0.5975 0.5973 0.5971 0.597 0.5968 0.5966 0.5965 0.5963 0.5961 0.596

0.71 0.5958 0.5956 0.5955 0.5953 0.5951 0.595 0.5948 0.5946 0.5945 0.5943

0.72 0.5941 0.594 0.5938 0.5936 0.5934 0.5933 0.5931 0.5929 0.5928 0.5926

0.73 0.5924 0.5923 0.5921 0.5919 0.5918 0.5916 0.5914 0.5912 0.5911 0.5909

0.74 0.5907 0.5906 0.5904 0.5902 0.5901 0.5899 0.5897 0.5895 0.5894 0.5892

0.75 0.589 0.5889 0.5887 0.5885 0.5883 0.5882 0.588 0.5878 0.5876 0.5875

0.76 0.5873 0.5871 0.587 0.5868 0.5866 0.5864 0.5863 0.5861 0.5859 0.5857

0.77 0.5856 0.5854 0.5852 0.585 0.5849 0.5847 0.5845 0.5843 0.5842 0.584

0.78 0.5838 0.5836 0.5835 0.5833 0.5831 0.5829 0.5828 0.5826 0.5824 0.5822

0.79 0.5821 0.5819 0.5817 0.5815 0.5813 0.5812 0.581 0.5808 0.5806 0.5805

0.80 0.5803 0.5801 0.5799 0.5797 0.5796 0.5794 0.5792 0.579 0.5789 0.5787

0.81 0.5785 0.5783 0.5781 0.578 0.5778 0.5776 0.5774 0.5772 0.5771 0.5769

0.82 0.5767 0.5765 0.5763 0.5762 0.576 0.5758 0.5756 0.5754 0.5752 0.5751

0.83 0.5749 0.5747 0.5745 0.5743 0.5742 0.574 0.5738 0.5736 0.5734 0.5732

0.84 0.5731 0.5729 0.5727 0.5725 0.5723 0.5721 0.572 0.5718 0.5716 0.5714

0.85 0.5712 0.571 0.5708 0.5707 0.5705 0.5703 0.5701 0.5699 0.5697 0.5695

0.86 0.5694 0.5692 0.569 0.5688 0.5686 0.5684 0.5682 0.568 0.5679 0.5677

0.87 0.5675 0.5673 0.5671 0.5669 0.5667 0.5665 0.5664 0.5662 0.566 0.5658

0.88 0.5656 0.5654 0.5652 0.565 0.5648 0.5646 0.5645 0.5643 0.5641 0.5639

0.89 0.5637 0.5635 0.5633 0.5631 0.5629 0.5627 0.5625 0.5624 0.5622 0.562

37

Page 38

Chart for use with the Slope Method (continued)

μ 0123456789

0.90 0.5618 0.5616 0.5614 0.5612 0.561 0.5608 0.5606 0.5604 0.5602 0.56

0.91 0.5598 0.5596 0.5595 0.5593 0.5591 0.5589 0.5587 0.5585 0.5583 0.5581

0.92 0.5579 0.5577 0.5575 0.5573 0.5571 0.5569 0.5567 0.5565 0.5563 0.5561

0.93 0.5559 0.5557 0.5555 0.5553 0.5551 0.5549 0.5547 0.5545 0.5543 0.5541

0.94 0.5539 0.5537 0.5535 0.5533 0.5531 0.5529 0.5527 0.5525 0.5523 0.5521

0.95 0.5519 0.5517 0.5515 0.5513 0.5511 0.5509 0.5507 0.5505 0.5503 0.5501

0.96 0.5499 0.5497 0.5495 0.5493 0.5491 0.5489 0.5487 0.5485 0.5483 0.5481

0.97 0.5479 0.5476 0.5474 0.5472 0.547 0.5468 0.5466 0.5464 0.5462 0.546

0.98 0.5458 0.5456 0.5454 0.5452 0.545 0.5447 0.5445 0.5443 0.5441 0.5439

0.99 0.5437 0.5435 0.5433 0.5431 0.5429 0.5427 0.5424 0.5422 0.542 0.5418

1.00 0.5416 0.5414 0.5412 0.541 0.5408 0.5405 0.5403 0.5401 0.5399 0.5397

1.01 0.5395 0.5393 0.539 0.5388 0.5386 0.5384 0.5382 0.538 0.5378 0.5375

1.02 0.5373 0.5371 0.5369 0.5367 0.5365 0.5362 0.536 0.5358 0.5356 0.5354

1.03 0.5352 0.5349 0.5347 0.5345 0.5343 0.5341 0.5338 0.5336 0.5334 0.5332

1.04 0.533 0.5327 0.5325 0.5323 0.5321 0.5319 0.5316 0.5314 0.5312 0.531

1.05 0.5307 0.5305 0.5303 0.5301 0.5298 0.5296 0.5294 0.5292 0.529 0.5287

1.06 0.5285 0.5283 0.5281 0.5278 0.5276 0.5274 0.5271 0.5269 0.5267 0.5265

1.07 0.5262 0.526 0.5258 0.5256 0.5253 0.5251 0.5249 0.5246 0.5244 0.5242

1.08 0.5239 0.5237 0.5235 0.5233 0.523 0.5228 0.5226 0.5223 0.5221 0.5219

1.09 0.5216 0.5214 0.5212 0.5209 0.5207 0.5205 0.5202 0.52 0.5197 0.5195

1.10 0.5193 0.519 0.5188 0.5186 0.5183 0.5181 0.5179 0.5176 0.5174 0.5171

1.11 0.5169 0.5167 0.5164 0.5162 0.5159 0.5157 0.5155 0.5152 0.515 0.5147

1.12 0.5145 0.5143 0.514 0.5138 0.5135 0.5133 0.513 0.5128 0.5126 0.5123

1.13 0.5121 0.5118 0.5116 0.5113 0.5111 0.5108 0.5106 0.5103 0.5101 0.5099

1.14 0.5096 0.5094 0.5091 0.5089 0.5086 0.5084 0.5081 0.5079 0.5076 0.5074

1.15 0.5071 0.5069 0.5066 0.5064 0.5061 0.5059 0.5056 0.5053 0.5051 0.5048

38

Page 39

μ 0123456789

1.16 0.5046 0.5043 0.5041 0.5038 0.5036 0.5033 0.5031 0.5028 0.5025 0.5023

1.17 0.502 0.5018 0.5015 0.5013 0.501 0.5007 0.5005 0.5002 0.5 0.4997

1.18 0.4994 0.4992 0.4989 0.4987 0.4984 0.4981 0.4979 0.4976 0.4973 0.4971

1.19 0.4968 0.4965 0.4963 0.496 0.4957 0.4955 0.4952 0.4949 0.4947 0.4944

1.20 0.4941 0.4939 0.4936 0.4933 0.4931 0.4928 0.4925 0.4923 0.492 0.4917

1.21 0.4914 0.4912 0.4909 0.4906 0.4903 0.4901 0.4898 0.4895 0.4892 0.489

1.22 0.4887 0.4884 0.4881 0.4879 0.4876 0.4873 0.487 0.4868 0.4865 0.4862

1.23 0.4859 0.4856 0.4854 0.4851 0.4848 0.4845 0.4842 0.4839 0.4837 0.4834

1.24 0.4831 0.4828 0.4825 0.4822 0.4819 0.4817 0.4814 0.4811 0.4808 0.4805

1.25 0.4802 0.4799 0.4796 0.4794 0.4791 0.4788 0.4785 0.4782 0.4779 0.4776

1.26 0.4773 0.477 0.4767 0.4764 0.4761 0.4758 0.4755 0.4752 0.475 0.4747

1.27 0.4744 0.4741 0.4738 0.4735 0.4732 0.4729 0.4726 0.4723 0.472 0.4717

1.28 0.4714 0.4711 0.4707 0.4704 0.4701 0.4698 0.4695 0.4692 0.4689 0.4686

1.29 0.4683 0.468 0.4677 0.4674 0.4671 0.4668 0.4664 0.4661 0.4658 0.4655

1.30 0.4652 0.4649 0.4646 0.4643 0.4639 0.4636 0.4633 0.463 0.4627 0.4624

1.31 0.462 0.4617 0.4614 0.4611 0.4608 0.4604 0.4601 0.4598 0.4595 0.4592

1.32 0.4588 0.4585 0.4582 0.4579 0.4575 0.4572 0.4569 0.4566 0.4562 0.4559

1.33 0.4556 0.4552 0.4549 0.4546 0.4542 0.4539 0.4536 0.4532 0.4529 0.4526

1.34 0.4522 0.4519 0.4516 0.4512 0.4509 0.4506 0.4502 0.4499 0.4495 0.4492

1.35 0.4489 0.4485 0.4482 0.4478 0.4475 0.4471 0.4468 0.4464 0.4461 0.4458

1.36 0.4454 0.4451 0.4447 0.4444 0.444 0.4437 0.4433 0.443 0.4426 0.4422

1.37 0.4419 0.4415 0.4412 0.4408 0.4405 0.4401 0.4398 0.4394 0.439 0.4387

1.38 0.4383 0.4379 0.4376 0.4372 0.4369 0.4365 0.4361 0.4358 0.4354 0.435

1.39 0.4347 0.4343 0.4339 0.4335 0.4332 0.4328 0.4324 0.4321 0.4317 0.4313

1.40 0.4309 0.4306 0.4302 0.4298 0.4294 0.429 0.4287 0.4283 0.4279 0.4275

1.41 0.4271 0.4267 0.4264 0.426 0.4256 0.4252 0.4248 0.4244 0.424 0.4236

39

Page 40

Chart for use with the Slope Method (continued)

μ 0123456789

1.42 0.4232 0.4228 0.4225 0.4221 0.4217 0.4213 0.4209 0.4205 0.4201 0.4197

1.43 0.4193 0.4189 0.4185 0.4181 0.4177 0.4173 0.4168 0.4164 0.416 0.4156

1.44 0.4152 0.4148 0.4144 0.414 0.4136 0.4131 0.4127 0.4123 0.4119 0.4115

1.45 0.4111 0.4106 0.4102 0.4098 0.4094 0.409 0.4085 0.4081 0.4077 0.4072

1.46 0.4068 0.4064 0.406 0.4055 0.4051 0.4047 0.4042 0.4038 0.4034 0.4029

1.47 0.4025 0.402 0.4016 0.4012 0.4007 0.4003 0.3998 0.3994 0.3989 0.3985

1.48 0.398 0.3976 0.3971 0.3967 0.3962 0.3958 0.3953 0.3949 0.3944 0.3939

1.49 0.3935 0.393 0.3925 0.3921 0.3916 0.3912 0.3907 0.3902 0.3897 0.3893

1.50 0.3888 0.3883 0.3878 0.3874 0.3869 0.3864 0.3859 0.3855 0.385 0.3845

1.51 0.384 0.3835 0.383 0.3825 0.3821 0.3816 0.3811 0.3806 0.3801 0.3796

1.52 0.3791 0.3786 0.3781 0.3776 0.3771 0.3766 0.3761 0.3756 0.3751 0.3745

1.53 0.374 0.3735 0.373 0.3725 0.372 0.3715 0.3709 0.3704 0.3699 0.3694

1.54 0.3688 0.3683 0.3678 0.3673 0.3667 0.3662 0.3657 0.3651 0.3646 0.364

1.55 0.3635 0.363 0.3624 0.3619 0.3613 0.3608 0.3602 0.3597 0.3591 0.3586

1.56 0.358 0.3574 0.3569 0.3563 0.3558 0.3552 0.3546 0.354 0.3535 0.3529

1.57 0.3523 0.3518 0.3512 0.3506 0.35 0.3494 0.3488 0.3483 0.3477 0.3471

1.58 0.3465 0.3459 0.3453 0.3447 0.3441 0.3435 0.3429 0.3423 0.3417 0.3411

1.59 0.3405 0.3399 0.3392 0.3386 0.338 0.3374 0.3368 0.3361 0.3355 0.3349

40

Page 41

Repair and Warranty

The instrument circuit contains static sensitive devices,

and care must be taken in handling the printed circuit

board. If the protection of an instrument has been

impaired it should not be used, and be sent for repair by

suitably trained and qualified personnel. The protection is

likely to be impaired if, for example, the instrument shows

visible damage, fails to perform the intended

measurements, has been subjected to prolonged storage

under unfavourable conditions, or has been exposed to

severe transport stresses.

New Instruments are Guaranteed for 1 Year from the

Date of Purchase by the User.

Note: Any unauthorized prior repair or adjustment will

automatically invalidate the Warranty.

Instrument Repair and Spare Parts

For service requirements for Megger Instruments contact

Megger Limited or Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown

England PA 19403 U.S.A.

Tel: +44 (0)1304 502243 Tel: +1 (610) 676-8579

Fax: +44 (0)1304 207342 Fax: +1 (610) 676-8625

or an approved repair company.

Approved Repair Companies

A number of independent instrument repair

companies have been approved for repair work on most

Megger instruments, using genuine Megger spare parts.

Consult the Appointed Distributor/Agent regarding spare

parts, repair facilities and advice on the best course of

action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it

should be sent, freight pre-paid, to the appropriate

address. A copy of the Invoice and of the packing note

should be sent simultaneously by airmail to expedite

clearance through Customs. A repair estimate showing

freight return and other charges will be submitted to the

sender, if required, before work on the instrument

commences.

41

Page 42

42

Page 43

M

DET2/2

Contrôleur de masse numérique

Guide de l’utilisateur

43

Page 44

AVERTISSEMENTS RELATIFS A LA SECURITE

• Des précautions spéciales doivent être prises lorsque des masses ‘sous tension’ peuvent être recontrées, et

dans ce cas des interrupteurs d’isolement et des fusibles sont nécessaires. Voir ‘Exploitation - Contrôle de

masse - Précautions de sécurité’.

• Les piquets de mise à la masse, les câbles d’essai et leurs terminaisons ne doivent pas être touchés lorsque

l’instrument est en ‘Marche’.

• Des gants et des chaussures en caoutchouc doivent être portés lors du travail prés de circuits à haute tension.

• L’instrument DET2/2 doit être débranché de tout circuit extérieur pendant le changement de ses batteries.

• Une batterie de 12 V c.c. ne doit pas être utilisée comme alimentation extérieure si elle est encore connectée

au véhicle.

• Les fusibles de remplacement doivent être du type et de la puissance corrects.

• Avant de charger la batterie du DET2/2 vérifier que le fusible d’alimentation correct est installé, et que

• Les Avertissements et les Précautions doivent être lus et compris avant d’utiliser l’instrument. Ils doivent

être observés pendant l’usage.

L’INSTRUMENT NE DOIT PAS ETRE UTILISE QUE PAR DES PERSONNES COMPETENTES AYANT RECU LA FORMATION APPROPRIEE

REMARQUE

44

Page 45

Table des matière

Avertissements relatifs à la sécurité 44

Table des matières 45

Description générale 46

Applications 47

Caractéristiques et commandes 48

Configuration initiale 49

Mise en place des piquets d’essai 50

Précautions de sécurité de contrôle de masse 51

Exploitation

Procédure générale d’essai 53

Ajustements des conditions d’essai 53

Messages de l’affichage 54

Messages d’erreur 55

Charge de la batterie 56

Essai de continuité 58

Spécifications 59

Accessoires 64

Réparations et Garantie 65

User Guide p2 Gebrauchsanleitung s67 Guía del usuario p91

Symboles utilisés sur cet instrument

Attention: Consultez les notes

jointes.

Equipement protegé par un isolement

double ou renforcé (Classe II).

Cet équipement respecte les

directives en viguer de l’UE.

45

Page 46

Description générale

Le Megger DET2/2 est un instrument portable compact et

autonome destiné à mesurer la résistance des électrodes

de mise à la masse et à effectuer quatre essais de

continuité de bornes.

Alimenté par une batterie rechargeable interne avec

chargeur incorporé, l’instrument bénéficie pleinement de la

technologie du microprocesseur et les lectures numériques

sont fournies par un affichage à cristaux liquides clair et

largement dimensionné. L’instrument est en outre doté de

bornes permettant un branchement sur une alimentation

extérieure de 12 volts, comme par exemple une batterie de

véhicule.

La langue d’affichage peut être choisie entre l’anglais, le

français, l’allemand, le portugais ou l’espagnol. Toute une

gamme de fréquences peuvent être sélectionnées. Le

DET2/2 sélectionne automatiquement la gamme et

indiquera une résistance de masse dans la gamme 0,010 Ω

à 19,99 kΩ avec une résolution maximum de 1 mΩ.

L’affichage signale les problèmes relatifs aux conditions

d’essai ainsi qu’une basse tension de batterie. Ceci permet

de repositionner les piquets de mise à la masse ou d’ajuster

les réglages de l’instrument de manière à obtenir les

conditions d’essai optimales.

Le bouton poussoir rouge TEST est appuyé pour mettre

l’instrument en service, puis tourné dans le sens des

aiguilles d’une montre pour le maintenir en position Marche.

Pour arrêter l’instrument, tourner le bouton TEST dans le

46

sens inverse des aiguilles d’une montre et le relâcher.

L’affichage LCD peut être ajusté en tournant le bouton de

contrôle pour convenir aux conditions d’éclairage ambiant.

Quatre touches à membrane (marquées ▲ ou ▼)

contrôlent la fonction de mesure et sont utilisées pour

choisir la langue requise et les réglages d’essai.

Les câbles d’essai ne sont pas fournis avec l’instrument,

mais font partie d’un kit d’accessoire de contrôle de mise à

la masse, disponible en option. Le kit comprend en outre

des piquets d’essai (électrodes) pour réaliser des piquets

de mise à la masse temporaires.

L’instrument est fourni dans une valise robuste et durable,

moulée en plastique ABS. Toutes les commandes, les

bornes et l’affichage LCD sont montés sur le panneau

avant. Le DET2/2 est étanche aux éclaboussements, et

peut donc être utilisé à l’extérieur dans la plupart des

conditions atmosphériques.

La borne ‘C2’ (‘H’) est la connexion pour le piquet d’essai

de courant éloignée.

La borne ‘P2’ (‘S’) est la connexion pour le piquet d’essai de

potentiel éloignée.

La borne ‘P1’ (‘ES’) est pour la connexion du potentiel pour

l’électrode de masse à tester.

La borne ‘C1’ (‘E’) est pour la connexion du courant pour

l’électrode de masse à tester.

Page 47

Applications

L’installation de systèmes de mise à la masse satisfaisants

est un élément clé de l’alimentation électrique, de la

sécurité du câblage et de l’économie des installations. Elle

a également une importance unique dans de nombreux

systèmes de communication.

L’application principale du DET2/2 est le contrôle des

électrodes de mise à la masse, qu’il s’agisse d’électrode

simple, d’électrodes multiples, de grillages, de plaques ou

de bandes de mise à la masse. Tous les systèmes de mise

à la masse doivent être testés immédiatement après leur

installation, puis à des intervalles réguliers.

Choix de l’emplacement de l’électrode.

Pour qu’un système d’électrode de mise à la masse

fonctionne de façon satisfaisant, il doit toujours avoir une

faible résistance totale à la masse. Cette résistance sera

influencée par la résistance spécifique du sol environnant,

qui est elle-même fonction de la nature du sol et de son

humidité. Avant d’implanter une électrode ou un système

d’électrode, il est souvent utile d’étudier la zone

d’implantation avant de choisir la position finale de

l’électrode. L’instrument DET2/2 permet d’étudier la

résistivité du sol sur une zone particulière et à différentes

profondeurs. Ces études de résistivité peuvent indiquer si

des avantages existent en enfonçant les électrodes plus

profondément au lieu d’augmenter les coûts en ajoutant

d’autres électrodes et leurs câbles afin d’obtenir une

résistance totale de masse spécifiée.

Entretien des systèmes de mise à la masse

Après leur installation, les systèmes de mise à la masse

doivent être vérifiés pour détecter tout changement de la

résistance dans le temps, ou dans des conditions

d’humidité différentes (causées par exemple par les

conditions climatiques variables ou à différentes saisons

de l’année). De tels contrôles indiqueront si la résistance

à la masse des électrodes a été dépassée à cause du

changement des conditions du sol ou du vieillissement du

système.

Autres applications

La technique d’étude de résistivité peut être utilisé à des

fins archéologiques ou géologiques en étudiant la structure

du sol et des ruines de bâtiments à diverses profondeurs

mesurées.

Dans tous les cas, la précision des lectures de l’instrument

sera toujours supérieure aux changements causés par les

paramètres naturels variables des caractéristiques du sol.

Une autre application concerne les essais de continuité,

par exemple pour vérifier la résistance des conducteurs

utilisés dans un circuit de mise à la masse.

47

Page 48

Caractéristiques et commandes

Vers piquet d’essai

de courant

Vers piquet d’essai

de potentiel

Vers électrode à tester

(connexion de potentiel)

Vers électrode à tester

(connexion de courant)

Affichage LCD

à 3 chiffres 1⁄2

48

Prise de chargeur

Bornes d’alimentation

12V c.c. extérieure

Réglage de contraste

de l’affichage

Bouton Test Marche/Arrêt

(tourner dans le sens des

aiguilles d’une montre pour le

verrouiller)

Interrupteurs de

contrôle d’essai

Page 49

Configuration initiale

Réglage du langage par défaut

Choisissez et réglez le langage d’affichage par défaut

comme suit :

1. Appuyez simultanément sur la touche gauche s et sur

le bouton TEST. Tournez le bouton TEST dans le

sens des aiguilles d’une montre pour le verrouiller.

Les options de langage sont affichées.

2. Si nécessaire, ajustez le contraste de l’affichage.

3. A l’aide de la touche centrale ▲, faites défiler les

options de langage. Lorsque le langage requis est mis

en évidence par un cadre, appuyez sur la touche

gauche ▲. Les options de fréquence d’essai sont

alors affichées.

Réglage de la fréquence par défaut

Les fréquences par défaut suivantes sont disponibles :

108 Hz - Pour effectuer des essais avec des

fréquences parasites de l’ordre de 16 Hz.

128 Hz - Pour effectuer des essais avec des

fréquences parasites de l’ordre de 50 Hz.

135 Hz 150 Hz - Pour effectuer des essais avec des

fréquences parasites de l’ordre de 60 Hz.

Pour chaque valeur par défaut, la plage de fréquences

d’essai peut être augmentée en incréments de 0,5 Hz

entre 105 Hz et 160 Hz, en utilisant les touches s et t .

Sélectionnez et réglez la fréquence par défaut comme suit :

1. A l’aide de la touche centrale ▲, faites défiler les

options de fréquence. Lorsque la fréquence requise est

mise en évidence par un cadre, appuyez sur la touche

gauche s . Les options du mode essai et étalonnage sont

alors affichées. Le message “Attendre SVP...” est affiché.

Sauvegarde des réglages des paramètres d’essai

Les réglages du courant d’essai et des options de filtrage,

ainsi que la fréquence du courant d’essai peuvent être

sauvegardés pour utilisation dans d’autres essais comme

suit :

1. Une fois que les réglages sont effectués, appuyez et

maintenez appuyée la touche s pendant le mode de

mesure. L’affichage donne une liste des sélections par

défaut.

2. Acceptez les réglages et appuyez sur la touche ▲

Oui, ou appuyez sur la touche ▲ Non pour annuler.

Une fois les réglages acceptés, d’autres essais peuvent

être effectués avec des réglages différents. L’instrument

reviendra aux réglages sauvegardés par défaut en

coupant et en remettant l’alimentation en service.

49

Page 50

Mise en place des piquets d’essai

Pour les essais d’électrodes de mise à la masse et pour les

études de résistivité du sol, les câbles d’essai de

l’instrument sont connectés à des piquets enfoncés dans le