Page 1

WWW.MEGGER.COM

Reference Manual

Applications Guide

DELTA 4000

12 kV Insulation Diagnostic System

ZM-AH02E

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Page 2

Page 3

SWEDEN

Megger Sweden AB

Eldarvägen 4

Box 2970

SE-187 29 TÄBY

Sweden

T +46 8 510 195 00

F +46 8 510 195 95

seinfo@megger.com

www.megger.comEDEN

UNITED STATES

Megger

2621 Van Buren Avenue

Norristown, PA 19403

USA

T +1 610 676 8500

F +1 610 676 8610

VFCustomerSupport@megger.com

www.megger.com

ZM-AH02E

3

NOTICE OF COPYRIGHT & PROPRIETARY RIGHTS

© 2010, Megger Sweden AB. All rights reserved.

The contents of this manual are the property of Megger Sweden

AB. No part of this work may be reproduced or transmitted in

any form or by any means, except as permitted in written license

agreement with Megger Sweden AB. Megger Sweden AB has made

every reasonable attempt to ensure the completeness and accuracy

of this document. However, the information contained in this

manual is subject to change without notice, and does not represent

a commitment on the part of Megger Sweden AB. Any attached

hardware schematics and technical descriptions, or software listings

that disclose source code, are for informational purposes only.

Reproduction in whole or in part to create working hardware or

software for other than Megger Sweden AB products is strictly

prohibited, except as permitted by written license agreement with

Megger Sweden AB.

TRADEMARK NOTICES

Megger® and Programma® are trademarks registered in the U.S.

and other countries. All other brand and product names mentioned

in this document are trademarks or registered trademarks of their

respective companies.

Megger Sweden AB is certified according to ISO 9001 and 14001.

Reference Manual

Applications Guide

DELTA 4000

12 kV Insulation Diagnostic System

Page 4

4 DELTA 4000 ZM-AH02E

Contents

1 Introduction ................................................. 6

General .................................................................6

Principle of operation .............................................6

Current, capacitance and dissipation factor

relationship ............................................................ 7

Connections for UST/GST Configurations ............... 8

2 Interpretation of measurements ............. 10

Significance of capacitance and

dissipation factor .................................................10

Dissipation factor (Power factor) of typical

apparatus insulation ............................................11

Permittivity and % DF of typical insulating

materials ..............................................................11

Significance of temperature ................................. 12

Significance of humidity .......................................13

Surface leakage ...................................................13

Electrostatic interference ...................................... 14

Negative dissipation factor ................................... 14

Connected bus work, cables etc ................................ 14

3 Testing power system components ......... 16

Transformers ........................................................ 16

Introduction .............................................................. 16

Definitions ................................................................ 16

Two-winding transformers......................................... 16

Three-winding transformers ...................................... 18

Autotransformers ...................................................... 19

Transformer excitation current tests ........................... 19

Shunt reactors ........................................................... 21

Potential transformers ............................................... 21

Current transformers ................................................. 21

Voltage regulators ..................................................... 21

Dry-type transformers ............................................... 22

Bushings .............................................................. 22

Introduction .............................................................. 22

Definitions ................................................................ 22

Bushing troubles ....................................................... 24

Bushing tests ............................................................. 24

Inverted tap to center conductor test C1 (UST) .......... 26

Power and dissipation factor & capacitance test C2 ... 26

Hot collar test ........................................................... 27

Spare bushing tests ................................................... 27

Circuit breakers .................................................... 28

Introduction .............................................................. 28

Oil circuit-breakers .................................................... 28

Air-blast circuit-breakers ............................................ 30

SF

6 Circuit-breakers ................................................... 31

Vacuum circuit breakers ............................................ 32

Air magnetic circuit-breakers ..................................... 33

Oil circuit reclosers .................................................... 33

Rotating machines ............................................... 33

Cables .................................................................35

Surge (lightning) arresters .................................... 35

Introduction .............................................................. 35

Test connections ........................................................ 36

Test procedure .......................................................... 36

Test results ................................................................ 36

Liquids ................................................................. 37

Test procedure .......................................................... 37

Miscellaneous assemblies and components .......... 37

High-Voltage turns-ratio measurements ...............38

Test procedure .......................................................... 38

Temperature considerations ....................................... 38

Index ............................................................. 40

References ........................................................... 42

Appendix A

Temperature correction tables .................... 44

Page 5

ZM-AH02E DELTA 4000

5

Page 6

6 DELTA 4000 ZM-AH02E

1 INTRODUCTION

1

Introduction

Principle of operation

Most physical test objects can be accurately represented as

a two or three-terminal network. An example of a twoterminal capacitor is an apparatus bushing without any test

tap. The center conductor is one terminal and the mount-

ing ange (ground) is the second terminal. An example of

a three-terminal capacitor is an apparatus bushing which

has a power factor or capacitance tap. The center conductor is one terminal, the tap is the second terminal, and the

mounting ange (ground) is the third terminal.

It is possible to have a complex insulation system that

has four or more terminals. A direct measurement of any

capacitance component in a complex system can be made

with this test set since it has the capability for measuring

both ungrounded and grounded specimens.

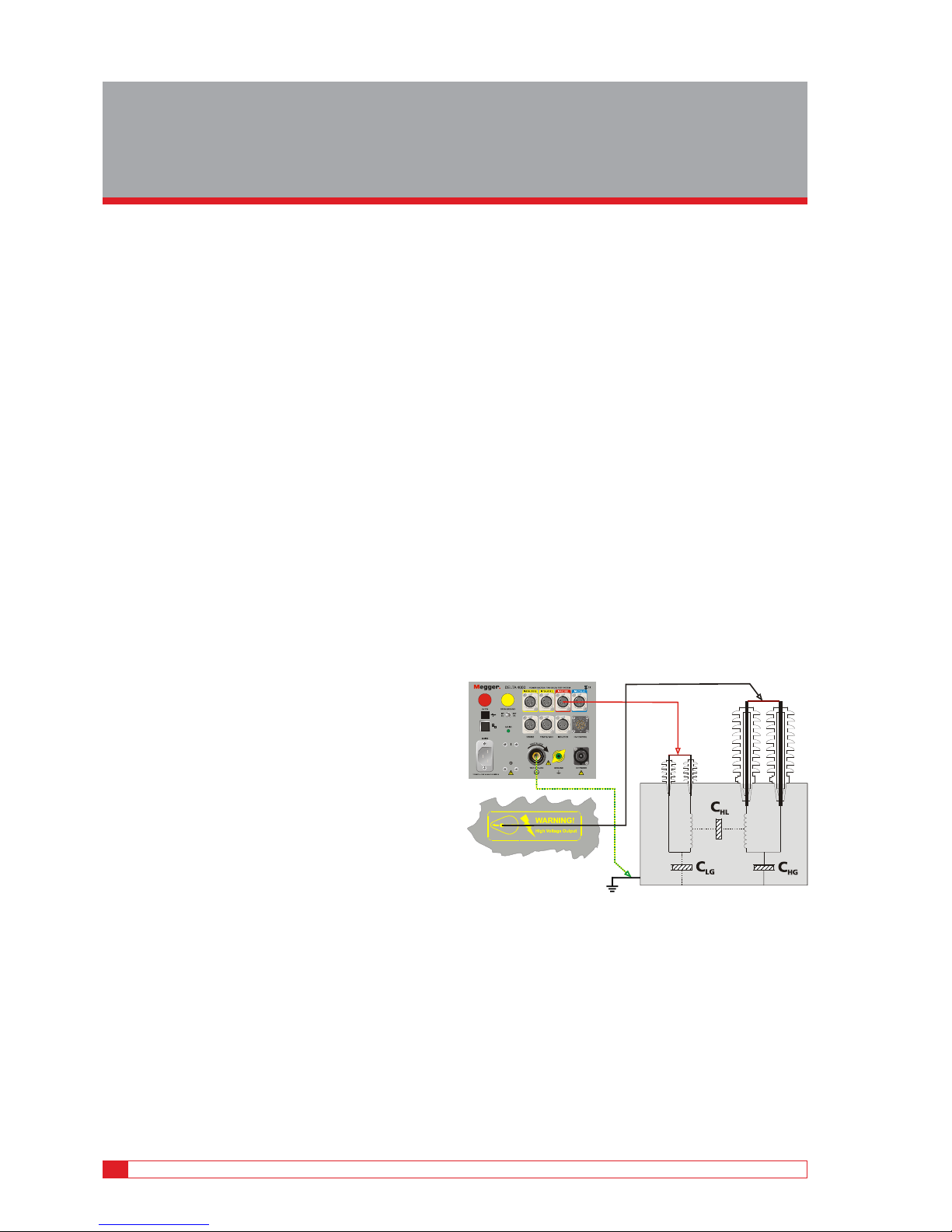

Figure 1 shows a simplied measuring circuit diagram of

the DELTA 4000 test set measuring a two-winding transformer

in UST test mode. The test voltage is connected to the HV

terminal and the current is measured at the LV terminal.

Voltage and current are accurately measured in amplitude

and phase and CHL capacitance, dissipation factor, power

loss etc are calculated and displayed.

Figure 1: UST-R test setup for a 2-w transformer

Dissipation factor measurements can generally be per-

formed with two different congurations, UST (Ungrounded Specimen Test) where the ground act as natural guard

or GST (Grounded Specimen Test) with or without guard.

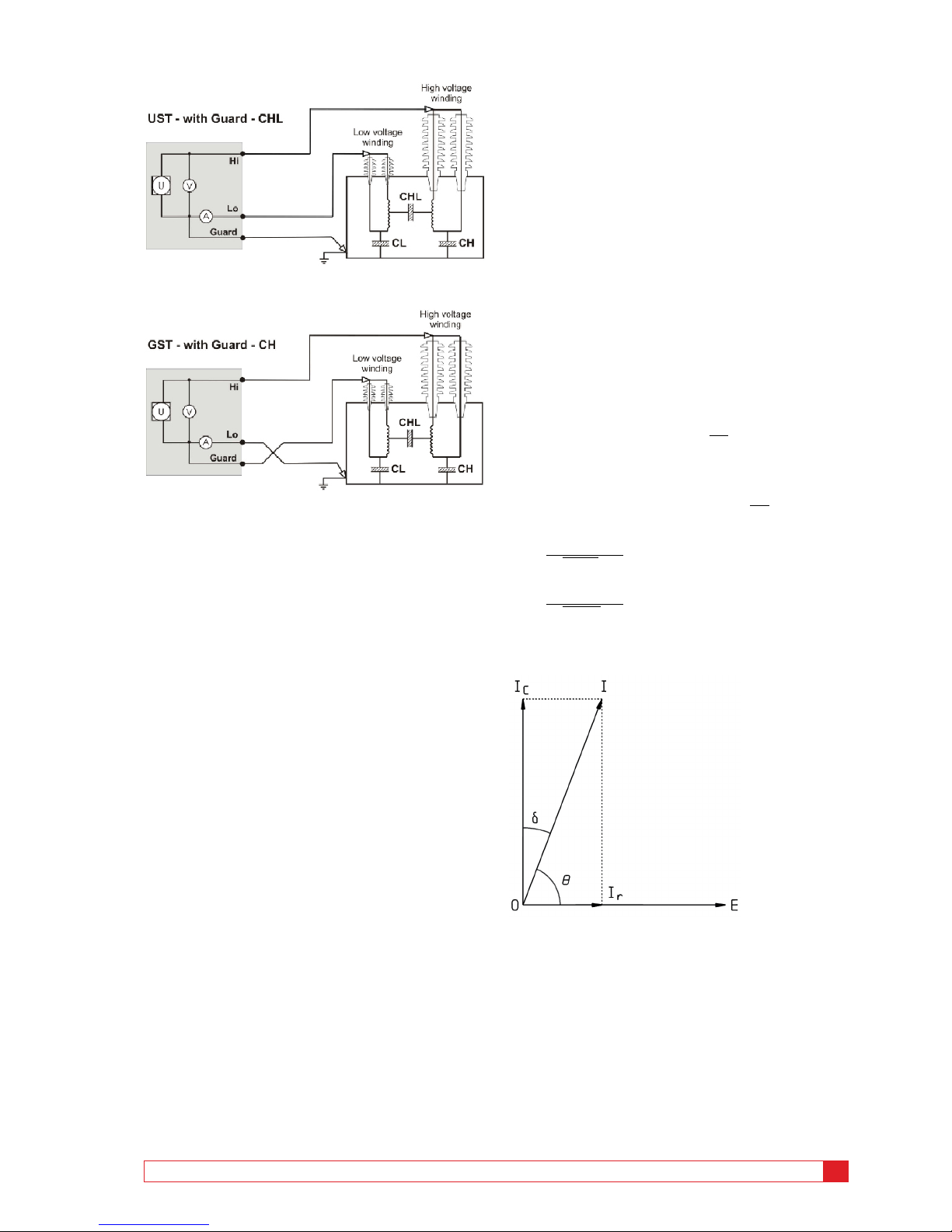

Figure 2 shows a guarded UST measurement. The current

owing through CHL is measured but the current paths

through CH and CL is guarded/grounded and not measured. Figure 3 shows a guarded GST measurement where

the CH current to ground is measured but the current

through CHL is guarded and measured.

General

The intention of this reference-application manual is to

guide the operator in the appropriate method of making

capacitance and dissipation factor/power factor measurements on power apparatus and to assist in the interpretation

of test results obtained. It is not a complete step-by-step

procedure for performing tests.

Before performing any test with this apparatus, read the

user manual and observe all safety precautions indicated.

Page 7

ZM-AH02E DELTA 4000

7

1 INTRODUCTION

Figure 2: UST connection for measuring CHL in a two-winding transformer

Figure 3: GST connection for measuring CH in a two-winding transformer

Current, capacitance and

dissipation factor relationship

In an ideal insulation system connected to an alternating

voltage source, the capacitance current Ic and the voltage

are in perfect quadrature with the current leading. In addition to the capacitance current, there appears in practice

a loss current Ir in phase with the voltage as shown in

Figure 5.

The current taken by an ideal insulation (no losses, I

r

= 0)

is a pure capacitive current leading the voltage by 90° (q =

90°). In practice, no insulation is perfect but has a certain

amount of loss and the total current I leads the voltage by

a phase angle q (q< 90°). It is more convenient to use the

dielectric-loss angle d, where d = (90° - q). For low power

factor insulation Ic and I are substantially of the same magnitude since the loss component Ir is very small.

The power factor is dened as:

Power factor= cos Θ = sin δ =

Ir

I

and the dissipation factor is dened as:

Dissipation factor = cot Θ = tan δ =

Ir

Ic

PF =

DF

•1+DF

2

DF =

PF

•1 – PF

2

The DELTA 4000 is able to display either dissipation factor

or power factor based on user’s choice.

Figure 5: Vector diagram insulation system

In cases where angle d is very small, sin d practically equals

tan d. For example, at power factor values less than 10

percent the difference will be less than 0.5 percent of reading while for power factor values less than 20 percent the

difference will be less than 2 percent of reading.

The value of I

c

will be within 99.5 percent of the value I

for power factor (sin d) values up to 10 percent and within

98 percent for power factor values up to 20 percent.

Page 8

8 DELTA 4000 ZM-AH02E

1 INTRODUCTION

Connections for UST/GST

Configurations

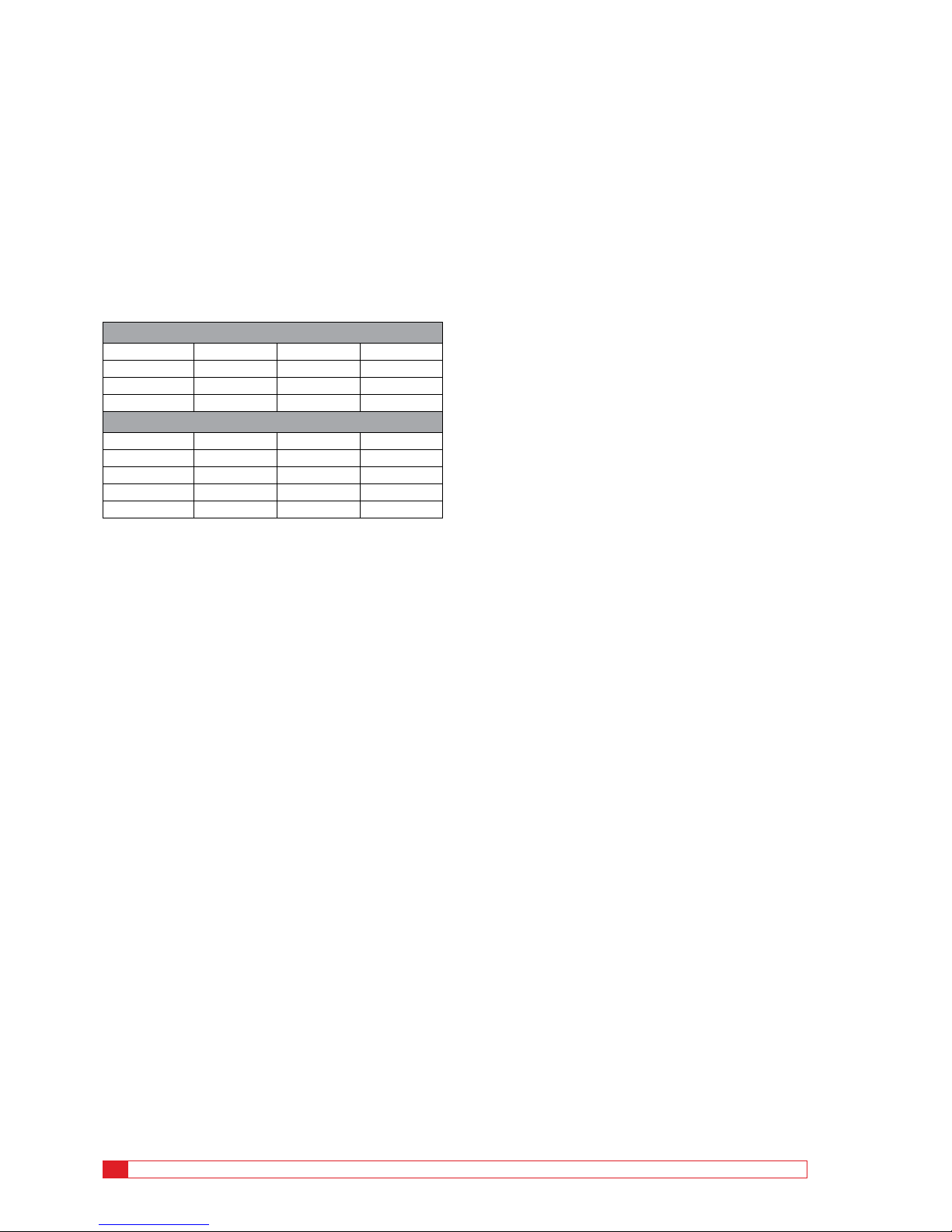

DELTA 4000 supports two basic groups of operation, GST

and UST mode. GST stands for grounded specimen test

while UST stands for ungrounded specimen test. Within

the two groups the test set can be operated in seven test

modes as summarized in Table 1.1. Measurements are

always made between the high-voltage lead and the lead/

connection in the measure column.

Table 1.1

DELTA 4000 test modes and internal measurement connections

UST: Ungrounded specimen testing

Tes t mo de Measure Ground Guard

UST- R Red Blue –

UST- B Blue Red –

UST- RB Red and Blue – –

GST: Grounded specimen testing

Tes t mo de Measure Ground Guard

GST- GND Ground Red and Blue –

GSTg-R Ground Blue Red

GSTg-B Ground Red Blue

GSTg-RB Ground – Red and Blue

In UST test mode, Ground and Guard are internally

connected. Internally the Red and Blue leads are either

connected to be measured or connected to Ground (and

Guard).

In GST test modes the current returning from Ground is

measured. Internally the Red and Blue leads are either connected to Ground or Guard to be included in or excluded

from the measurement.

Page 9

ZM-AH02E DELTA 4000

9

1 INTRODUCTION

Page 10

10 DELTA 4000 ZM-AH02E

2 INTERPRETATION OF MEASUREMENTS

in operation with consequent deterioration. Some increase

of capacitance (increase in charging current) may also be

observed above the extinction voltage because of the short

circuiting of numerous voids by the ionization process.

An increase of dissipation factor accompanied by in severe

cases possible increase of capacitance usually indicates

excessive moisture in the insulation. Increase of dissipation

factor alone may be caused by thermal deterioration or by

contamination other than water.

Unless bushing and pothead surfaces, terminal boards, etc.,

are clean and dry, measured quantities may not necessarily apply to the volume of the insulation under test. Any

leakage over terminal surfaces may add to the losses of the

insulation itself and may, if excessive, give a false indication

of its condition.

2

Interpretation of

measurements

Significance of capacitance and

dissipation factor

A large percentage of electrical apparatus failures are due

to a deteriorated condition of the insulation. Many of these

failures can be anticipated by regular application of simple

tests and with timely maintenance indicated by the tests.

An insulation system or apparatus should not be condemned until it has been completely isolated, cleaned, or

serviced and measurements compensated for temperature.

The correct interpretation of capacitance and dissipation

factor tests generally requires knowledge of the apparatus

construction and the characteristics of the particular types

of insulation used.

Changes in the normal capacitance of an insulation material

indicate such abnormal conditions as the presence of a

moisture layer, short circuits, or open circuits in the capacitance network. Dissipation factor measurements indicate

the following conditions in the insulation of a wide range

of electrical apparatus:

▪

Chemical deterioration due to time and temperature,

including certain cases of acute deterioration caused by

localized overheating.

▪

Contamination by water, carbon deposits, bad oil, dirt

and other chemicals.

▪

Severe leakage through cracks and over surfaces.

▪

Ionization.

The interpretation of measurements is usually based on

experience, recommendations of the manufacturer of the

equipment being tested, and by observing these differences:

▪

Between measurements on the same unit after successive

intervals of time.

▪

Between measurements on duplicate units or a similar

part of one unit, tested under the same conditions around

the same time, e.g., several identical transformers or one

winding of a three-phase transformer tested separately.

▪

Between measurements made at different test voltages

on one part of a unit; an increase in slope (tip-up) of a

dissipation factor versus voltage curve at a given voltage is

an indication of ionization commencing at that voltage.

An increase of dissipation factor above a typical value may

indicate conditions such as those given in the previous paragraph, any of which may be general or localized in charac-

ter. If the dissipation factor varies signicantly with voltage

down to some voltage below which it is substantially constant, then ionization is indicated. If this extinction voltage

is below the operating level, then ionization may progress

Page 11

ZM-AH02E DELTA 4000

11

2 INTERPRETATION OF MEASUREMENTS

Dissipation factor (Power

factor) of typical apparatus

insulation

Values of insulation dissipation factor for various apparatus are shown in Table 2.1. These values may be useful in

roughly indicating the range to be found in practice. Please

note that the higher values are not to be regarded as “OK”

but instead examples of “to be investigated/at risk” data.

Table 2.1

DF (PF) of typical apparatus insulation

Type apparatus % DF (PF) at 20°C

Oil-filled transformer: New, highvoltage (115 kV and up)

0.25 to 1.0

15 years old, high-voltage 0.25--

Low-voltage, distribution type 0.30-Oil circuit breakers 0.5 to 2.0

Oil-paper cables, “solid” (up to 27.6

kV) new condition

0.5 to 1.5

Oil-paper cables, high-voltage oil-filled

or pressurized

0.2 to 0.5

Rotating machine stator windings, 2.3

to 13.8 kV

2.0 to 8.0

Capacitors (discharge resistor out of

circuit)

0.2 to 0.5

Bushings: Solid or dry 3.0 to 10.0

Compound-filled, up to 15 kV 5.0 to 10.0

Compound-filled, 15 to 46 kV 2.0 to 5.0

Oil-filled, below 110 kV 1.5 to 4.0

Oil-filled, above 110 kV and con-

denser type

0.25--

In IEEE 62-1995, typical values for dissipation/power factor are given as in Table 2.2.

Table 2.2

IEEE 62-1995 power factor values

Typical power factor values @ 20°C

“New” “Old” Warning/alert limit

Power transformers, oil

insulated

0.2-0.4% 0.3-0.5% > 0.5%

Bushings

0.2-0.3% 0.3-0.5% > 0.5%

IEEE 62-1995 states; “The power factors recorded for

routine overall tests on older apparatus provide information

regarding the general condition of the ground and interwinding insulation of transformers and reactors. While the

power factors for older transformers will also be <0.5%

(20°C), power factors between 0.5% and 1.0% (20°C) may

be acceptable; however, power factors >1.0% (20°C) should

be investigated.”

Permittivity and % DF of

typical insulating materials

Typical values of permittivity (dielectric constant) k and

50/60 Hz dissipation factor of a few kinds of insulating

materials (also water and ice) are given in Table 2.3.

Table 2.3

Permittivity and dissipation factor of typical

insulating materials

Material k % DF (PF) at 20°C

Acetal resin (Delrin*) 3.7 0.5

Air 1.0 0.0

Askarels 4.2 0.4

Kraft paper, dry 2.2 0.6

Oil, transformer 2.2 0.02

Polyamide (Nomex*) 2.5 1.0

Polyester film (Mylar*) 3.0 0.3

Polyethylene 2.3 0.02-0.05

Polyamide film (Kapton*) 3.5 0.3

Polypropylene 2.2 0.05

Porcelain 7.0 2.0

Rubber 3.6 4.0

Silicone liquid 2.7 0.01

Varnished cambric, dry 4.4 1.0

Water** 80 100

Ice** 88 1.0 (0°C)

* Dupont registered trademark.

** Tests for moisture should not be made at freezing tempera-

tures because of the 100 to 1 ratio difference of % dissipation

factor between water and ice.

Page 12

12 DELTA 4000 ZM-AH02E

2 INTERPRETATION OF MEASUREMENTS

Any sudden changes in ambient temperature will increase

the measurement error since the temperature of the apparatus will lag the ambient temperature.

Dissipation factor-temperature characteristics, as well as

dissipation factor measurements at a given temperature,

may change with deterioration or damage of insulation.

This suggests that any such change in temperature characteristics may be helpful in assessing deteriorated condi-

tions. As an example, bushings have typically a rather at

temperature correction with only slightly elevated values

at high temperatures. Generally a bushing showing highly

increased dissipation factor at elevated temperature should

be considered “at risk”.

Be careful making measurements below the freezing point

of water. A crack in an insulator, for example, is easily

detected if it contains a conducting lm of water. When

the water freezes, it becomes non-conducting, and the

defect may not be revealed by the measurement, because ice

has a volumetric resistivity approximately 100 times higher

than that of water. Moisture in oil, or in oil-impregnated

solids, has been found to be detectable in dissipation factor

measurements at temperatures far below freezing, with no

discontinuity in the measurements at the freezing point.

Insulating surfaces exposed to ambient weather conditions

may also be affected by temperature. The surface temperature of the insulation specimen should be above and never

below the ambient temperature to avoid the effects of

condensation on the exposed insulating surfaces.

Significance of temperature

Most insulation measurements have to be interpreted based

on the temperature of the specimen. The dielectric losses

of most insulation increase with temperature; however, e.g.

dry oil-impregnated paper and polyethylene of good quality

exhibit decrease of dielectric losses when temperature is

raised moderately, e.g. from 20°C to 30°C. It is also known

that the effect of temperature depends on the aging status

of the insulation. In many cases, insulations have failed due

to the cumulative effect of temperature, i.e., a rise in temperature causes a rise in dielectric loss which in turn causes

a further rise in temperature, etc (thermal runaway).

It is important to determine the dissipation factor-temperature characteristics of the insulation under test. Otherwise,

all tests of the same specimen should be made, as nearly as

practicable, at the same temperature.

To compare the dissipation factor value of tests made on

the same or similar type apparatus at different temperatures,

it is necessary to convert the value to a reference temperature base, usually 20°C (68°F). Examples of standard tables

of multipliers for use in converting dissipation factors at

test temperatures to dissipation factors at 20°C are found in

the Appendix A of this document.

In reality, temperature correction for a specic component is always individual and pending age/condition.

DELTA 4000 has a unique and patented feature for estimating the individual temperature correction (ITC). By measuring dissipation factor over frequency and using mathematical formulas and models of insulation characteristics, the

correct temperature correction can be determined from

5 to 50°C measurement temperature to 20°C reference

temperature. The input data for the calculation is dissipation factor measured from 1 to 500 Hz and the method

is principally based on Arrhenius’ law, describing how the

insulation properties are changing over temperature.

κ = κ

0

·exp(-Wa/kT)

With activation energy W

a

and Boltzmann constant k

The test temperature for apparatus such as spare bushings,

insulators, air or gas lled circuit breakers, and lightning

arresters is normally assumed to be the same as the ambient

temperature. For oil-lled circuit breakers and transformers the test temperature is assumed to be the same as the

top oil temperature or winding temperature. For installed

bushings where the lower end is immersed in oil the test

temperature lies somewhere between the oil and air temperature.

In practice, the test temperature is assumed to be the same

as the ambient temperature for bushings installed in oil-

lled circuit breakers and also for oil-lled transformers

that have been out of service for approximately 12 hours.

In transformers removed from service just prior to test,

the temperature of the oil normally exceeds the ambient

temperature. The bushing test temperature for this case can

be assumed to be the midpoint between the oil and ambient

temperatures.

Page 13

ZM-AH02E DELTA 4000

13

2 INTERPRETATION OF MEASUREMENTS

Significance of humidity

The exposed surface of bushings may, under adverse relative humidity conditions, acquire a deposit of surface mois-

ture which can have a signicant effect on surface losses

and consequently on the results of a dissipation factor test.

This is particularly true if the porcelain surface of a bush-

ing is at a temperature below ambient temperature (below

dew point), because moisture will probably condense on the

porcelain surface. Serious measurement errors may result

even at a relative humidity below 50 percent when moisture

condenses on a porcelain surface already contaminated with

industrial chemical deposits.

It is important to note that an invisible thin surface lm of

moisture forms and dissipates rapidly on materials such as

glazed porcelain which have negligible volume absorption.

Equilibrium after a sudden wide change in relative humidity is usually attained within a matter of minutes. This,

however, excludes thicker lms which result from rain, fog,

or dew point condensation.

Surface leakage errors can be minimized if dissipation

factor measurements are made under conditions where the

weather is clear and sunny and where the relative humidity does not exceed 80 percent. In general, best results are

obtained if measurements are made during late morning

through mid afternoon. Consideration should be given to

the probability of moisture being deposited by rain or fog

on equipment just prior to making any measurements.

Surface leakage

Any leakage over the insulation surfaces of the specimen

will be added to the losses in the volume insulation and may

give a false impression as to the condition of the specimen.

Even a bushing with a voltage rating much greater than the

test voltage may be contaminated enough to cause a signicant error. Surfaces of potheads, bushings, and insulators

should be clean and dry when making a measurement.

It should be noted that a straight line plot of surface resistivity against relative humidity for an uncontaminated porcelain bushing surface results in a decrease of one decade

in resistivity for a nominal 15 percent increase in relative

humidity and vice versa.

On bushings provided with a power factor or capacitance

tap, the effect of leakage current over the surface of a

porcelain bushing may be eliminated from the measurement

by testing the bushing by the ungrounded specimen test

(UST).

When testing bushings without a test tap under high

humidity conditions, numerous companies have reported

that the effects of surface leakage can be substantially

minimized by cleaning and drying the porcelain surface and

applying a very thin coat of Dow Corning #4 insulating

grease (or equal) to the entire porcelain surface. When making a hot collar test, the grease is generally only applied to

the porcelain surface on which the hot collar band is to be

located and to that of one petticoat above and one below

the hot collar band.

When testing potheads, bushings (without test tap), and

insulators under unfavorable weather conditions, the dissipation factor reading may, at times, appear to be unstable

and may vary slightly over a very short period of time. The

variation is caused by such factors as the amount of surface

exposure to sun or shade, variations in wind velocity, and

gradual changes in ambient temperature and relative humidity. Similar bushings may have appreciably different dissipation factor values for the case where one bushing is located

in the sun while the other is in the shade. A test made on

the same bushing may have a different dissipation factor

value between a morning and an afternoon reading. Due

consideration must be given to variations in readings when

tests are made under unfavorable weather conditions.

Page 14

14 DELTA 4000 ZM-AH02E

2 INTERPRETATION OF MEASUREMENTS

Negative dissipation factor

Creep currents inside an insulation system or more commonly on surfaces; create change of potential distribution

that may give increased or decreased dissipation factor, and

in some cases also negative dissipation factor. This condition is most likely to arise when making UST and GST

measurements on specimens who have a capacitance value

of a few hundred picofarad or less. Equipment such as

bushings, circuit breakers, and low loss surge arresters fall

into this category.

The error is usually accentuated if tests are made under

unfavorable weather conditions, especially a high relative

humidity which increases surface leakage.

There appears to be no clear-cut way of knowing whether

an error is signicant or what remedies should be taken to

overcome an error. A frequency sweep may give additional

information. The best advice is to avoid making measurements on equipment in locations where negative dissipation

factors are known to present a problem when unfavorable

weather conditions exist, especially high relative humidity.

Make sure the surface of porcelain bushings are clean and

dry to minimize the effects of surface leakage. Make sure all

items such as wooden ladders or nylon ropes are removed

from the equipment to be tested and are brought out of

any electrostatic interference elds that could inuence a

measurement.

Connected bus work, cables etc

A complete disconnected component is preferred when

performing dissipation factor measurements. All connected

bus work, cables, disconnect switches etc may add signicant capacitance and losses in GST measurements where

they are in parallel with the desired insulation measurement. For this reason, many test engineers will ask that the

equipment under test be totally isolated from connected

apparatus.

UST data is principally possible to measure without fully

disconnecting the test object. The capacitance from the

connected parts results only in a current to ground that is

not measured in UST test mode.

Electrostatic interference

When tests are conducted in energized substations, the

readings may be inuenced by electrostatic interference

currents resulting from the capacitive coupling between

energized lines and bus work to the test specimen. Other

sources for interference may be corona discharges (especially at high humidity) and is some cases DC uctuations

in the grounding system. Trouble from magnetic elds

encountered in high-voltage substations is very unlikely.

To counter the effects of severe electrostatic interference

on the measurement, it may be necessary to disconnect the

specimen from disconnect switches and bus work. Experience in making measurements will establish the particular

equipment locations where it is necessary to break the

connections. The related disconnect switches, leads and

bus work, if not energized, should be solidly grounded to

minimize electrostatic coupling to the test set.

The measurement difculty which is encountered when

testing in the presence of interference depends not only

upon the severity of the interference eld but also on the

capacitance and dissipation factor of the specimen. Unfavorable weather conditions such as high relative humidity,

fog, overcast sky, and high wind velocity will increase the

severity and variability of the interference eld. The lower

the specimen capacitance and its dissipation factor, the

greater the difculty is to perform accurate measurements.

It is also possible that a negative dissipation factor reading

may be obtained so it is necessary to observe the polarity

sign for each reading. Specically, it has been found that

some difculty may be expected when measuring capaci-

tance by the GST test method in high interference switchyards when the capacitance value is less than 100 pF. This

difculty may be minimized considerably by:

▪

Using the maximum voltage of the test set if possible.

▪

Disconnecting and grounding as much bus work as

possible from the specimen terminals.

▪

Making measurements on a day when the weather

is sunny and clear, the relative humidity is less than

80 percent, the wind velocity is low, and the surface

temperature of exposed insulation is above the ambient

temperature.

Tests made by the UST method are less susceptible to interference pickup than are tests made by the GST method.

In the UST test method, the capacitive coupled pickup

current in the high-voltage circuit ows directly to ground

after having passed through the high-voltage winding of

the power supply transformer. In the GST test method the

same pickup current, after passing through the high-voltage

transformer winding, must pass through one of the bridge

transformer-ratio measuring arms before reaching ground.

Page 15

ZM-AH02E DELTA 4000

15

2 INTERPRETATION OF MEASUREMENTS

Page 16

16 DELTA 4000 ZM-AH02E

3 TESTING POWER SYSTEM COMPONENTS

▪

Autotransformer: A transformer in which at least two

windings have a common section.

▪

Excitation Current (No-Load Current): The current which

flows in any winding used to excite the transformer when

all other windings are open-circuited.

▪

Tap (in a transformer): A connection brought out of a

winding at some point between its extremities, to permit

changing the voltage, or current, ratio.

▪

Delta Connection: So connected that the windings of a

three-phase transformer (or the windings for the same

rated voltage of single-phase transformers associated in

a three- phase bank) are connected in series to form a

closed circuit.

▪

Y (or Wye) Connection: So connected that one end of

each of the windings of a polyphase transformer (or of

each of the windings for the same rated voltage of singlephase transformers associated in a polyphase bank) is

connected to a common point (the neutral point) and

other end to its appropriate line terminal.

▪

Zigzag Connection: A polyphase transformer with

Y-connected windings, each one of which is made up of

parts in which phase-displaced voltages are induced.

▪

Tertiary Winding: The third winding of the transformer

and often provides the substation service voltage, or in

the case of a wye-wye connected transformer, it prevents

severe distortion of the line-to-neutral voltages.

The following equipment and tests will be discussed in this

guide:

▪

Two-Winding Transformers

▪

Three-Winding Transformers

▪

Autotransformer

▪

Transformer Excitation Current Tests

▪

Shunt Reactors

▪

Potential Transformers

▪

Current Transformers

▪

Voltage Regulators

▪

Dry-Type Transformers

Two-winding transformers

Two-winding transformer measurement is described in

Figure 10.

3

Testing power system

components

Transformers

Introduction

The transformer is probably one of the most useful electrical devices ever invented. It can raise or lower the voltage

or current in an ac circuit, it can isolate circuits from each

other, and it can increase or decrease the apparent value

of a capacitor, an inductor, or a resistor. Furthermore, the

transformer enables us to transmit electrical energy over

great distances and to distribute it safely in factories and

homes. Transformers are extensively used in electric power

systems to transfer power by electromagnetic induction between circuits at the same frequency, usually with changed

values of voltage and current.

Dissipation/Power factor testing is an effective method to

detect and help isolate conditions such as moisture, carbonization, and contamination in bushings, windings and liquid

insulation. In addition to power factor testing, transformer

excitation current measurements will help detect winding

and core problems.

The voltage rating of each winding under test must be considered and the test voltage selected accordingly. If neutral

bushings are involved, their voltage rating must be considered in selecting the test voltage. Measurements should be

made between each inter-winding combination (or set of

three-phase windings in a three-phase transformer) with all

other windings grounded to the tank (UST test). Measurements should also be made between each winding (or set of

three-phase windings) and ground with all other windings

guarded (GST test with guard).

In a two-winding transformer, a measurement should

also be made between each winding and ground with the

remaining winding grounded (GST-GND test). For a

three-winding transformer, a measurement should also be

made between each winding and ground with one remaining winding guarded and the second remaining winding

grounded (GSTg test). This special test is used to isolate the

inter-windings. A nal measurement should be made be-

tween all windings connected together and the ground tank.

It is also desirable to test samples of the liquid insulation.

Definitions

▪

Step-Down Transformer: A transformer in which the

power transfer is from the higher voltage source circuit to

a lower voltage circuit.

▪

Step-Up transformer: A transformer in which the power

transfer is from the lower voltage source circuit to a

higher voltage circuit.

Page 17

ZM-AH02E DELTA 4000

17

3 TESTING POWER SYSTEM COMPONENTS

Figure 10: Two-Winding Transformer Test

Test connections

For all transformer testing, including spare transformers,

ensure the following safety conditions are observed:

Test connections are dened in table 3.1.

Table 3.1

Two-winding transformer test connections

Tes t No .

Insulation tested

Low voltage

lead configuration

Tes t

lead

connections to

wind-

ings

Remarks

Tes t mo de

Measure

Ground

Guard

High voltage

Red

Blue

1

CHG+

CHL

GSTGND

Red &

Blue

H L – L Grounded

2 CHG GSTg-RB

Red &

Blue

H L – L Guarded

3 CHL UST- R Red Blue H L –

4 CHL – Test 1 minus Test 2 – – –

Calculated

intercheck

5

CLG +

CHL

GSTGND

Red &

Blue

L H –

H Grounded

6 CLG GSTg-RB

Red &

Blue

L H – H Guarded

7 CLH UST-RB Red Blue L H –

8 LH – Test 5 minus Test 6 – – –

Calculated

intercheck

Equivalent circuit

Note: Short each winding on itself.

Measurement Inter-checks (Calculated)

Capacitance Watts

C

4

= C1 - C

2

W4 = W1 - W

2

C8 = C5 - C

6

W8 = W5 - W

6

Note: Subscripts are test numbers

H

High-voltage winding

L

Low-voltage winding

G

Ground

1] The transformer must be taken out of service and

isolated from the power system.

2] Ensure the transformer is properly grounded to the

system ground.

3] Before applying any voltage on the transformer

make sure that all bushing current transformers

are shorted out.

4] Never perform electrical tests of any kind on a unit

under vacuum. Flashovers can occur at voltages as

low as 250 volts.

5] If the transformer is equipped with a load tap

changer, set the unit to some step off of neutral.

Some load tap changers are designed with arrester

type elements that are not effectively shorted out

in the neutral position even with all the bushings

shorted.

6] Connect a ground wire from the test set to the

transformer ground.

7] Short all bushings of each winding including the

neutral of a wye-connected winding. The neutral

ground must also be removed. The shorting wire

must not be allowed to sag.

8] Connect the high voltage lead to the high side

bushings for tests 1, 2, and 3. Ensure that the high

voltage cable extends out away from the bushing.

9] Connect the red low voltage lead to the low volt-

age bushings.

10] For tests 5, 6 and 7, connect the high voltage lead

from the test set to the low voltage bushings of

the transformer and the red low voltage lead from

the test set to the high voltage bushings.

11] Individual tests should be performed on each bush-

ing. Bushings equipped with a potential/test tap

should have the UST test performed and the GST

on those without test taps.

Hot collar tests can if necessary be performed on

both types.

Page 18

18 DELTA 4000 ZM-AH02E

3 TESTING POWER SYSTEM COMPONENTS

8] Correct the power factor readings of the trans-

former to 20°C using individual temperature correction or standard tables

9] Identify each set of readings of the transformer

bushings with a serial number. Record manufacture, type or model and other nameplate ratings.

Especially be aware to record nameplate C

1

capacitance and power factor values if available. Correct

the power factor readings on the bushings to 20°C

Test results

Power factor results should always be compared to manufacturers’ tests, or to prior test results if available. It is impossible to set maximum power factor limits within which

all transformers are acceptable, but units with readings

above 0.5% at 20°C should be investigated.

Oil-lled service-aged transformers may have slightly

higher results and should be trended to identify signicant

changes.

Bushings, if in poor condition, may have their losses

masked by normal losses in the winding insulation Therefore, separate tests should be applied to them.

Increased power factor values, in comparison with a previous test or tests on identical apparatus, may indicate some

general condition such as contaminated oil. An increase in

both power factor and capacitance indicates that contamination is likely to be water. When the insulating liquid is be-

ing ltered or otherwise treated, repeated measurements on

windings and liquid will usually show whether good general

conditions are being restored.

Oil oxidation and consequent sludging conditions have a

marked effect on the power factors of transformer wind-

ings. After such a condition has been remedied, (ushing

down or other treatment) power factor measurements are

valuable in determining if the sludge removal has been effective.

Measurements on individual windings may vary due to differences in insulation materials and arrangements.

However, large differences may indicate localized deterioration or damage. Careful consideration of the measurements

on different combinations of windings should show in

which particular path the trouble lies; for example, if a measurement between two windings has a high power factor,

and the measurements between each winding and ground,

with the remaining winding guarded, gives a normal reading, then the trouble lies between the windings, perhaps in

an insulating cylinder.

Three-winding transformers

Testing of three-winding transformers is performed in

the same manner as two-winding transformers with the

additional tests of the tertiary winding. In some cases

transformers are constructed so that the inter-windings are

shielded by a grounded electrostatic shield or a concentricwinding arrangement. This could provide test results that

capacitance is almost non-existent or even a negative power

factor. The transformer manufacturer should be contacted

12]

Transformer windings must remain shorted for all

bushing tests. Windings not energized must be

grounded.

13] For transformers that have wye-wye configuration,

and the neutrals internally cannot be separated,

1-3 and 5-7 cannot be measured. In this case short

the high voltage bushings and the low voltage

bushings together and perform a GST test. Test

voltage should be suitable for the rating of the

low voltage winding.

Test procedure

For all power factor testing, the more information you

record at the time of testing will ensure the best comparison of results at the next routine test. Test data should be

compared to the nameplate data. If nameplate or factory

readings are not available, compare the results of prior

tests on the same transformer or results of similar tests on

similar transformers. If at all possible, power factor and

capacitance readings should be taken on all new transformers for future benchmarking.

Field measurements of power-factor and capacitance can

differ from measurements made under the controlled

conditions in the factory. Therefore, the power-factor and

capacitance should be measured at the time of installation

and used as a base to compare future measurements. Power

factor testing is extremely sensitive to weather conditions.

Tests should be conducted in favorable conditions whenever possible. All tests are performed at 10kV. If these values

exceed the rating of the winding, test at or slightly below

the rating.

1]

Follow the test sequence of the Two-Winding

Transformers Test Connections. Tests 1, 2 and 3 can

be completed without a lead change.

2] Test 4 is a calculation subtracting the capacitance

and watts results in test 2 from test 1. The results

should compare with the UST measurement for the

C

HL

insulation

3] Reverse the test leads for tests 5, 6 and 7. Test volt-

age should be at a level suitable for the secondary

winding of the transformer.

4] Test 8 is a calculation by subtracting test 6 from

test 5. Results should compare with the UST measurement in test 7 for the C

HL

insulation.

5] Enter all the nameplate information of the trans-

former. Note any special or unusual test connections or conditions.

6] Enter ambient temperature and relative humidity

and a general indication of weather conditions at

the time of the test.

7] Enter the insulation temperature (top oil or wind-

ing temperature)

Page 19

ZM-AH02E DELTA 4000

19

3 TESTING POWER SYSTEM COMPONENTS

to verify the existence of a shield or a concentric-winding

arrangement.

Three-winding transformer test connections are described

in Table 3.2.

Table 3.2

Three-winding transformer test connections

Tes t No .

Insulation tested

Low voltage lead

configuration

Test lead

connections to

windings

Remarks

Tes t mo de

Measure

Ground

Guard

High voltage

Red

Blue

1

CHG+

CHL

GSTg-B Red Blue H L T

L Grounded

T Guarded

2 CHG

GSTg-

RB

Red &

Blue

H L T

L & T

Guarded

3 CHL UST-R Red Blue H L T T Grounded

4 CHL – Test 1 minus Test 2 – – –

Calculated

intercheck

5

CLG +

CLT

GSTg-

BR

Blue Red L H T

T Grounded

H Guarded

6 CLG

GSTg-

RB

Red &

Blue

L H T

T & H

Guarded

7 CLT UST- RB Blue Red L H T H Grounded

8 CLT – Test 5 minus Test 6 – – –

Calculated

intercheck

9

CTG +

CHT

GSTg-B Red Blue T H L

H Grounded

L Guarded

10 CTG

GSTg-

RB

Red &

Blue

T H L

H & L

Guarded

11 CHT UST-R Red Blue T H L L Grounded

12 CHT – Test 9 minus Test 10 – – –

Calculated

intercheck

Equivalent Circuit

Note: Short each winding on

itself.

Measurement Interchecks (Calculated)

Capacitance Watts

C

4

= C1 - C

2

W4 = W1 - W

2

C8 = C5 - C

6

W8 = W5 - W

6

C12 = C9 - C

10

W12 = W9 - W

10

Note: Subscripts are test num-

bers

H High-voltage winding

L Low-voltage winding

T Tertiary winding

G Ground

Autotransformers

In the design of an autotransformer, the secondary winding

is actually part of the primary winding. For a given power

output, an autotransformer is smaller and cheaper than a

conventional transformer. This is particularly true if the

ratio of the incoming line voltage to outgoing line voltage

lies between 0.5 and 2.

Autotransformers may have a tertiary winding. If so, both

primary and secondary bushings are shorted together and

the tertiary bushings are shorted to each other. The autotransformer is then tested as a two winding transformer.

Individual tests should be performed on each bushing if

they are equipped with a test tap.

If the autotransformer does not have a tertiary winding,

short the high voltage bushings and the low voltage bushings together and perform a GST test. Test voltage should

be suitable for the rating of the low voltage winding

Transformer excitation current tests

Transformer excitation current tests are helpful in determining possible winding or core problems in transformers,

even when ratio and winding resistance tests appear normal.

Excitation tests should be conducted routinely along with

power factor testing.

Test connections

Test connection described in table 3.3.

Page 20

20 DELTA 4000 ZM-AH02E

3 TESTING POWER SYSTEM COMPONENTS

Table 3.3

Transformer excitation current test connections

Single phase

Measure Test lead connections

Terminal symbol High voltage Red Ground

H1-H2 H1 H2 –

H2-H1 H2 H1 –

Three phase high side “Y”

Measures Test lead connections

Terminal symbol High voltage Red Ground

H1-H0 H1 H0 –

H2-H0 H2 H0 –

H3-H0 H3 H0 –

Three phase high side “∆“

Measures Test lead connections

Terminal symbol High voltage Red Ground

H1-H2 H1 H2 H3

H2-H3 H2 H3 H1

H3-H1 H3 H1 H2

▪

Transformer excitation current tests are performed on the

high voltage winding to minimize the excitation current.

Problems in the low voltage windings will still be detected

by this method.

▪

The secondary windings are left floating with the

exception of a wye or zig-zag secondary. In this case

the neutral bushing remains grounded as it is in normal

service. Refer to the user manual for test connections for

Single Phase, Three Phase High Side Wye and Three Phase

High Side Delta transformers.

▪

Single Phase: The transformer is energized from the phase

to neutral bushings (ANSI: H1-H2). Test connections can

be reversed for additional data, but test results should be

the same. H2 may also be designated as H0.

▪

Wye – Wye: Observe that the ground wire is removed

from the high voltage side neutral bushing for testing,

but remains connected on the low voltage side neutral

bushing.

Test procedure

▪

Test voltages should be as high as possible, but limited

to 10 kV, without exceeding the rating of the line-to-line

voltages on delta connected transformers and line-toground on wye connected transformers. Also note that in

many cases the maximum applied voltage is limited by the

maximum current output

▪

Test voltage must always be the same as prior tests if any

comparisons are made.

▪

All transformer excitation current tests are conducted in

the UST test mode (normally UST-R, using Red low voltage

lead).

▪

For routine testing, transformers with load tap changers

should have tests performed in at least one raise and one

lower position off of neutral. The no-load tap changer

should be in the normal in service position.

▪

For new transformers, excitation tests should be

performed in every tap position for both the load and noload tap changers.

▪

The more information that is recorded at the time of

testing will ensure the best comparison of results at the

next routine test.

▪

Temperature corrections are not applied to transformer

excitation current tests.

Test results

Compare test results to previous tests on the same transformer, or to manufacturers’ data if available. Tests can also

be compared to similar type units. It is essential that identical test voltages be used for repeat tests on a transformer.

Fluctuation in the test voltage will produce inconsistent

current readings. Three phase transformers should have the

individual windings energized at both ends if the original

test appears abnormal.

Transformer excitation current tests on the high voltage

winding should detect problems in the secondary winding

if they exist. Winding resistance testing in addition to the

excitation tests could be helpful in isolating either a core or

winding defect.

Test results on three phase transformers, especially wyeconnected windings, could produce high but similar readings on two phases compared to the third phase. This is

Page 21

ZM-AH02E DELTA 4000

21

3 TESTING POWER SYSTEM COMPONENTS

the result of the low phase being wound around the center

leg of a three-legged core. The reluctance of the magnetic

circuit is less for the center leg of the core resulting in a

lower charging current.

Shunt reactors

When electrical energy is transmitted at extra high voltages,

special problems arise that require the installation of large

compensating devices to regulate the over-voltage conditions and to guarantee stability. Among these devices are

shunt reactors. Shunt reactors are composed of a large coil

placed inside a tank and immersed in oil. They can be single

phase units or three phases in one tank. In both cases each

phase has its own neutral bushing.

Test connections

▪

For all tests, the line and neutral bushings for

corresponding phases must remain shorted.

Test procedure

▪

Record test results on the test form for Miscellaneous

Equipment Capacitance and Power Factor Tests.

▪

Test voltages are at 10kV. If 10kV exceeds the insulation

rating, test at or slightly below the insulation rating.

▪

For single phase units only one overall ground test is

performed in the GST mode.

Test results

Power factor and capacitance results should be recorded in

the same manner as for oil lled power transformers. Temperature correction should be to the top oil temperature.

Compare test results to previous tests or tests on similar

units. Additional bushing tests should be performed if test

results are suspect.

Potential transformers

Potential transformers are installed on power systems for

the purpose of stepping down the voltage for the operation

of instruments such as Volt-meters, Watt-meters and relays

for various protective purposes. Typically the secondary

voltage of potential transformers is 120 V, so power factor

testing is performed on the primary winding. Potential

transformers are typically single phase with either single or

two bushing primaries. Single bushing primaries have one

end of the high voltage winding connected to ground. Secondary windings are normally three wire and dual identical

secondary windings are common.

Test connections

Ensure that the potential transformer is disconnected from

the primary source before testing begins.

1]

Remove any fusing on the secondary circuits to

prevent any type of back-feeding to the secondary.

2] Ground one leg of each secondary winding for all

tests on two primary bushing transformers, for

dual secondary transformers it is typically X1 and

Y1.

3] Ensure that the case of the potential transformer

is securely grounded to a system ground before

testing begins, this also includes testing of spare

transformers.

Test procedure

Ensure the test set is securely grounded.

1]

Record all tests results. Power factor tests should

be corrected to ambient temperature.

2] Compare test results to prior tests on the same or

similar equipment.

Current transformers

Current transformers are used for stepping down primary

current for Ampere-meters, Watt-meters and for relaying.

Typical secondary current rating is 5 A. Current transformers have ratings for high voltage and extra high voltage

application. The higher voltage classications can be oiled

lled, dry type or porcelain construction. Tests on two

bushing primary currents transformers are performed

by shorting the primary winding, grounding all secondary windings and test in the GST mode. Some current

transformers in the high voltage classications have test

taps similar to bushings. Tests can be performed on units

equipped with a test tap for the C1 insulation and the C2

tap insulation. Assure that the unit under test is grounded

before testing. Record all test results and correct the power

factor readings to the ambient temperature at the time of

the test.

Voltage regulators

Regulators are generally induction or step-by- step. The

induction regulator is a special type of transformer, built

like an induction motor with a coil-wound secondary, which

is used for varying the voltage delivered to a synchronous

converter or an ac feeder system. The step-by-step regulator

is a stationary transformer provided with a large number of

secondary taps and equipped with a switching mechanism

for joining any desired pair of these taps to the delivery

circuit. Voltage regulators may be single or three phase.

Single phase regulators consist of three bushings identied

as S (Source), L (Load) and SL (Neutral). The windings in

the regulator cannot be effectively separated, so one overall

power factor test is performed. All the bushings are shorted

together and tested in the GST-GND test mode.

Tests should be conducted with the tap changer moved to

some position off of neutral. Additional Hot Collar tests

may be conducted on bushings of suspect units. Excitation

tests may also be performed by energizing terminal L with

the high voltage lead and the low voltage lead on SL in the

UST position. Terminal S should be left oating. Power

factor results should be corrected to top oil temperature on

regulators just taken out of service. Ambient temperature

should be used for those that have been out of service for

any length of time. Power factor results should be compare

to previous tests on the same equipment or similar tests on

similar units.

Page 22

22 DELTA 4000 ZM-AH02E

3 TESTING POWER SYSTEM COMPONENTS

Dry-type transformers

Testing notes

Test voltages should be limited to line-to-ground ratings

of the transformer windings. Insulation power factor tests

should be made from windings to ground and between

windings. Temperature at the time of testing should be at

or near 20°C. ANSI/IEEE C57.12.91 - 1997 recommends

correcting results other than 20°C. However, there is very

little data available for temperature correction of dry-type

transformers. Repeat tests should be performed as near as

possible, in the same conditions as the original test.

Higher overall power factor results may be expected on drytype transformers. The majority of test results for power

factor is found to be below 2.0%, but can range up to 10%.

The insulation materials necessary for dry-type construction, must meet the thermal and stress requirements.

If power factor results appear to be unacceptable, an additional Tip-Up Test can be performed if a 10kV test set

is used. This test can be performed to evaluate whether

moisture or corona is present in the insulation system.

The applied test voltage is varied starting at about 1kV and

increased in intervals up to 10 kV or the line-to-ground rating of the winding insulation. If the power factor does not

change as the test voltage is increased, moisture is suspected

to be the probable cause. If the power factor increases as

the voltage is increased, carbonization of the insulation or

ionization of voids is the cause.

Note DELTA 4000 has a specific feature where the

test set recognizes voltage dependence and

will automatically indicate a non-linear behavior and by this indicate to the user to perform

a tip-up test

Bushings

Introduction

Bushings provide an insulated path for energized conductors to enter grounded electrical power apparatus. Bushings

are a critical part of the electrical system that transforms

and switches ac voltages ranging from a few hundred volts

to several thousand volts. Bushings not only handle high

electrical stress, they could be subjected to mechanical

stresses, afliated with connectors and bus support, as well.

Although a bushing may be thought of as somewhat of a

simple device, its deterioration could have severe consequences.

All modern bushings rated 23 kV and higher have a power

factor or a capacitance tap which permits dissipation factor

testing of the bushing while it is in place on the apparatus

without disconnecting any leads to the bushing. The dissipation factor is measured by the ungrounded specimen

test (UST) which eliminates the inuence of transformer

winding insulation, breaker arc-interrupters, or support

structures which are connected to the bushing terminal.

Figure 11 shows the test connections between the test set

and bushing when using the UST test mode.

1]

Connect test ground to apparatus ground.

2] Connect the high-voltage lead to the terminal at

the top of the bushing and the low-voltage lead

(red) to the power factor tap.

3] Ground the apparatus tank. The tap is normally

grounded through a spring and it is necessary,

when making measurements, to remove the

plug which seals and grounds the tap. Use the

UST measure red, ground blue test mode setting

(UST-R).

The UST test also can be used for making measurements

on bushings which have provisions for ange isolation. The

normal method of isolating the ange from the apparatus

cover is to use insulating gaskets between the ange and

cover and insulating bushings on all but one of the bolts

securing the mounting ange to the cover. During normal

operation, the ange is grounded by a single metal bolt;

however, when testing the bushing, this bolt is removed.

The measurement is identical to that when testing bushings

which have a power factor tap except that the low-voltage

lead, red in this case, is connected to the isolated bushing

ange.

Definitions

Bushing voltage tap

A connection to one of the conducting layers of a capacitance graded bushing providing a capacitance voltage divid-

er. Note: additional equipment can be designed, connected

to this tap and calibrated to indicate the voltage applied to

the bushing. This tap can also be used for measurement of

power factor and capacitance values.

Page 23

ZM-AH02E DELTA 4000

23

3 TESTING POWER SYSTEM COMPONENTS

Bushing test tap

A connection to one of the conducting layers of a capacitance graded bushing for measurement of power factor and

capacitance values.

Capacitance (of bushing)

(1) the main capacitance, c1, of a bushing is the capacitance

between the high-voltage conductor and the voltage tap or

test tap.

(2) the tap capacitance, c

2, of a capacitance graded bushing

is the capacitance between the voltage tap and mounting

ange (ground).

(3) the capacitance, c, of a bushing without a voltage or test

tap is the capacitance between the high-voltage conductor

and the mounting ange (ground).

Capacitance graded bushing

A bushing in which metallic or non-metallic conducting

layers are arranged within the insulating material for the

purpose of controlling the distribution of the electric eld

of the bushing, both axially and radially.

Cast insulation bushing

A bushing in which the internal insulation consists of a

solid cast material with or without an inorganic ller.

Composite bushing

A bushing in which the internal insulation consists of several coaxial layers of different insulation materials.

Compound-filled bushing

A bushing in which the radial space between the internal in-

sulation (or conductor where no internal insulation is used)

and the inside surface of the insulating envelope is lled

with insulating compound

Creep distance

The distance measured along the external contour of the

insulating envelope which separates the metal part operat-

ing at line voltage and the metal ange at ground voltage.

Insulating envelope

An envelope of inorganic or organic material such as a ceramic or cast resin placed around the energized conductor

and insulating material.

Internal insulation

Insulating material provided in a radial direction around

the energized conductor in order to insulate it from ground

voltage.

Major insulation

The insulating material providing the dielectric, which is

necessary to maintain proper isolation between the energized conductor and ground voltage. It consists of internal

insulation and the insulating envelope(s).

Oil-filled bushing

A bushing in which the radial space between the inside

surface of the insulating envelope and the internal insula-

tion (or conductor where no internal insulation is used) is

lled with oil.

Oil-impregnated paper insulated bushing

A bushing in which the internal insulation consists of a

core wound from paper and subsequently impregnated with

oil. The core is contained in an insulating envelope, the

space between the core and the insulating envelope being

lled with oil.

Resin-bonded paper-insulated bushing

A bushing in which the internal insulation consists of a

core wound from resin coated paper. During the winding

process, each paper layer is bonded to the previous layer

by its resin coating and the bonding is achieved by curing

the resin. Note: a resin bond paper-insulated bushing may

be provided with an insulating envelope, in which case the

intervening space may be lled with another insulating

medium.

Resin impregnated paper-insulated bushing

A bushing in which the internal insulation consists of a

core wound from untreated paper and subsequently impregnated with a curable resin.

Solid bushing

A bushing in which the major insulation is provided by a

ceramic or analogous material

Non-condenser bushings

Non-condenser bushings include the following designs:

solid porcelain, gas-lled hollow shell bushings (porcelain

or epoxy shells). Solid porcelain bushings were used exclu-

sively in early electrical systems, but it became apparent that

there was a voltage limit to the application of these solid

porcelain bushings. Solid porcelain bushings were utilized

up through 23kV, but after that point alternative insulation

mediums had to be employed. The next step in bushing construction used other materials between the metal

conductor and the solid porcelain shell. Some of the early

materials included oil, asphalt, & air. These designs worked

well, but given the ever increasing voltages of the world’s

developing electrical systems, it became apparent that ever

increasing diameter bushings would be required. These

large diameter bushings were impractical for an industry

determined to construct smaller apparatus. A new solution

had to be found. That solution was condenser bushings.

Today, our new sf6 gas breakers are equipped with hollow

shell bushings, constructed of either porcelain or epoxy,

which are lled with sf6 gas.

Condenser bushings

The major goal of condenser designed bushings is to

reduce the physical size of the bushing. This compaction allows not only for a smaller bushing, but also a smaller host

apparatus (i.e. oil circuit breaker or transformer).

Condenser bushings allowed for this compaction by placing the foil condenser layers at varying intervals during the

winding of the paper core, which resulted in uniform voltage stress distribution axially throughout the bushing. Additionally, varying the lengths of the foil layers provided even

voltage distribution along the upper and lower ends of the

bushing. The incorporation of condenser layers in bushings

provided both radial and axial voltage stress control, which

resulted in smaller compact bushings. The condenser layers

Page 24

24 DELTA 4000 ZM-AH02E

3 TESTING POWER SYSTEM COMPONENTS

are basically a series of concentric capacitors between the

center conductor and ground. This design is employed on

a wide range of voltage levels, up to and including 765kV.

Modern condenser bushings are usually equipped with test

taps. Bushings rated 115 kV and above usually have voltage taps, bushings rated below 115kV have test taps. The

availability of either a voltage tap or a test tap allows for the

testing of the main insulation c1. The test tap is normally

designed to withstand only about 500 volts while a voltage

tap may have a normal rating of 2.5 to 5 kV. This voltage is

only a concern when performing the c2 (tap insulation test)

or the inverted ungrounded specimen test (UST), both of

which will be discussed later in this guide. Before applying a

test voltage to the tap, the maximum safe test voltage must

be known and observed. An excessive voltage may puncture the insulation and render the tap useless. If absolutely

no information is available on the tap test voltage, do not

exceed 500 volts.

Bushing troubles

Operating records show that about 90 percent of all preventable bushing failures are caused by moisture entering

the bushing through leaky gaskets or other openings. Close

periodic inspection to nd leaks and make repairs as needed

will prevent most outages due to bushing failures. Such an

external inspection requires little time and expense and will

be well worth the effort. High-voltage bushings, if allowed

to deteriorate, may explode with considerable violence and

cause extensive damages to adjacent equipment.

Flashovers may be caused by deposits of dirt on the bushings, particularly in areas where there are contaminants

such as salts or conducting dusts in the air. These deposits

should be removed by periodic cleaning.

Table 3.9 lists the common causes of bushing troubles and

the inspection methods used to detect them.

Table 3.9

Bushing troubles

Trouble Possible results Methods of detection

Cracked

porcelain

Moisture enters

Oil and/or gas leaks

Filler leaks out

Visual inspection

Power factor/Tan delta test

Hot-collar test

Deterioration of

cemented

joints

Moisture enters

Oil and/or gas leaks

Filler leaks out

Visual inspection

Power factor/Tan delta test

Hot-collar test

Gasket leaks

Moisture enters

Oil and/or gas leaks

Filler leaks out

Visual inspection

Power factor/Tan delta test

Hot-collar test

Hot-wire test for moisture

Insulation resistance

Moisture in

insulation

Moisture enters

Power factor/Tan delta test

Hot-collar test

Solder seal

leaks

Moisture enters

Filler leaks out

Visual inspection

Power factor/Tan delta test

Hot-collar test

Broken

connection

between

ground

sleeve and

flange

Sparking in apparatus

tank or within bushing

Discolored oil

Power factor/Tan delta test

DGA

Voids in

compound

Internal corona

Visual inspection

Power factor/Tan delta test

Hot-collar test

Oil migration

Filler contamination

Visual inspection

Power factor/Tan delta test

Hot-collar test

No oil

Oil leaks out

Moisture enters

Visual inspection

Power factor/Tan delta test

Hot-collar test

Displaced

grading

shield

Internal sparking

discolors oil

Hot-collar test

DGA

Electrical

flashover

Cracked or broken

porcelain

Complete failure

Visual inspection

Hot-collar test

Lightning

Cracked or broken

porcelain

Complete failure

Visual inspection

Test surge arresters

Corona

Internal breakdown

Radio interference

Treeing along surface

of paper or internal

surface

Power factor/Tan delta test

Hot-collar test

Hot-wire test

Thermographic scanning

DGA

Shortcircuited

condenser

sections

Increased capacitance

Reduced voltage at

capacitance tap

Adds internal stress to

insulation

Power factor/Tan delta test

Voltage test at capacitance

tap

Capacitance test

Darkened oil

Radio interference

Poor test results

Power factor/Tan delta test

Hot-collar test

Bushing tests

Power and dissipation factor & capacitance test

C1 for main insulation

The voltage or test tap allows for testing the main bushing

insulation while it is in place in the apparatus without disconnecting any leads from the bushing. The main insulation

is the condenser core between the center conductor and

the tap layer. The test is conducted in the UST test mode

which eliminates the losses going to grounded portions of

the bushing. The UST method measures only the bushing

Page 25

ZM-AH02E DELTA 4000

25

3 TESTING POWER SYSTEM COMPONENTS

and is not appreciably affected by conditions external to the

bushing.

Test connections (UST)

Figure 11: UST-R, test on transformer bushing

Connect a ground wire from the test set to the host apparatus for the bushing under test.

1]

Connect the high voltage lead from the test set to

the center conductor of the bushing. If the bushing

under test is in a transformer, jumper all the bushings of the same winding. Also jumper the bushings of the other windings and connect them to

ground. Make sure the bare connector on the high

voltage lead extends away from the bushing under

test to avoid contact with the bushing porcelain.

2] Connect the low voltage lead from the test set to

the test tap. Test tap accessibility will differ with

the bushings’ style and rating. Some test taps are

terminated in a miniature bushing mounted on

the grounded mounting flange of the bushing.

The tap is grounded in normal service by a screw

cap on the miniature bushing housing. By removing the screw cap the tap terminal is available to

perform the tests. Most taps are readily accessible,

but a special probe is necessary to make contact

with the tap in certain bushing designs.

3] The tap housing may contain a small amount of oil

or compound. Care must be taken when removing the screw cap to catch the oil. Be sure the oil is

replaced after testing is completed.