Page 1

DCM300E Earth Leakage

Clamp Meter

afety Warnings

• Do not take measurements beyond maximum selected range.

• Take extreme care and keep hands behind the hand guard

hen taking measurements above 30 V RMS.

w

o notoperate the instrument with the battery cover removed.

•

D

• Do not operate the instrument if any part of it is damaged.

•

Do not operate the instrument in environments subject to high

temperature, damp, humidity or excessive vibration.

• Safety Warnings

instrument is used, and

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS

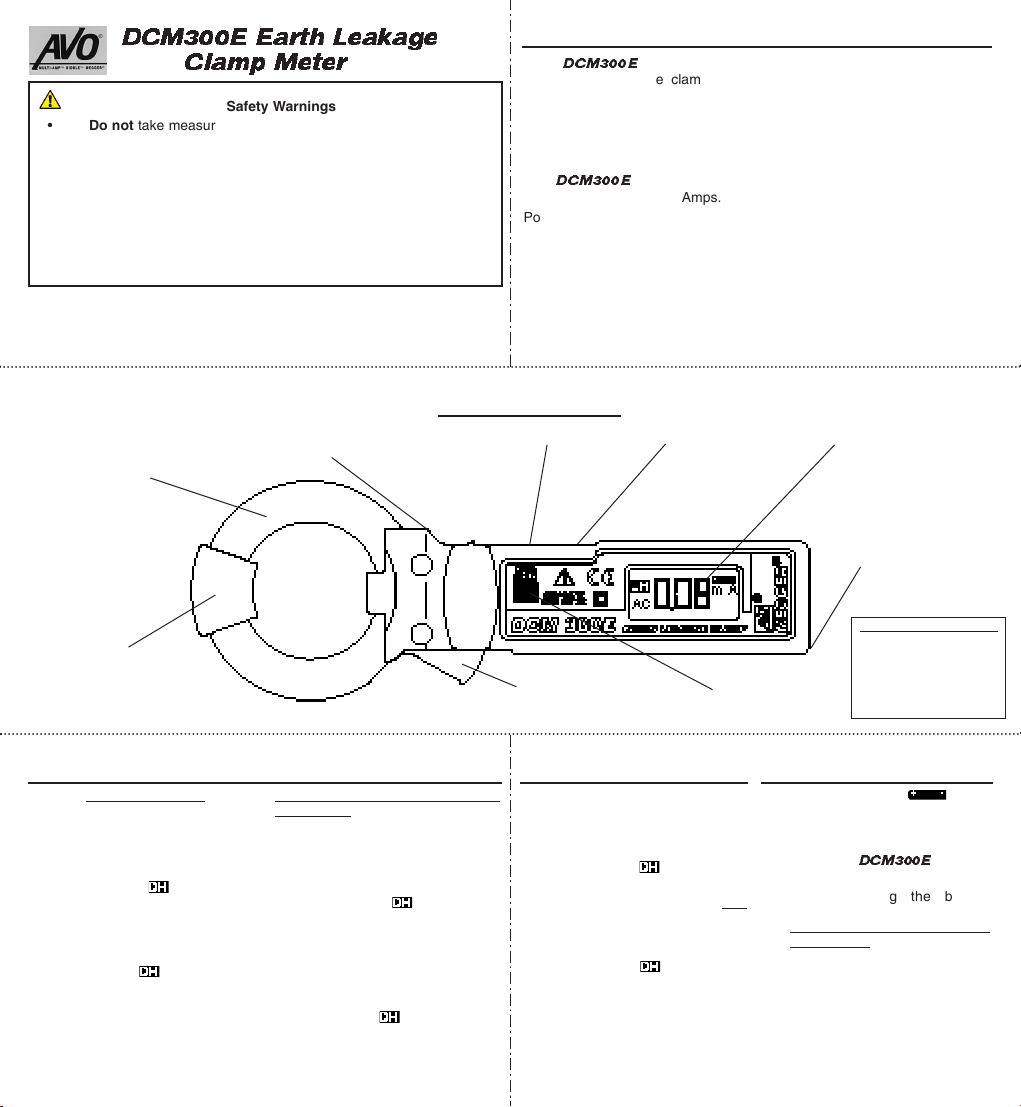

Transducer Jaws

S

must be read and understood before the

observed during use.

NO

TE

Tactile Handguard

Mode Selector Switch (mA / A)

Features and Controls

General Description

The

DCM300E

lightweight pocket size clamp meter

esigned to measure a.c. earth

d

leakage currents. This enables earth

eakage faults to be detected and

l

located without having to isolate and

disconnect circuit wiring. Additionally,

he

t

DCM300E

circuit currents up to 300 Amps.

Powered by two LR44 or SR44 cells,

the instrument design takes full

advantage of microprocessor

technology and features a clear 3

digit LCD combining digital and bargraph analogue readings.

is a rugged

easures a.c.

m

On / Off Switch

The two position mode switch

provides 4 ranges; 30 mA, 300 mA,

0 A and 300 A, with minimum

3

resolution of 0,01 mA on the 30 mA

ange.

r

To conserve battery power,

hut offoperates after a period of

s

10 minutes of inactivity by the

instrument. The instrument can be

switched back on by selecting

and then On again.

1

⁄2

31⁄2 Digit LCD Display

Wrist Strap point

Auto

Off

Jaw Guard

Measurement of Leakage Current

Earth Conductors

1) Set the range selector switch to

the 30 /300 mA position.

2) Set the Power switch to

3) Ensure that the Data hold

switch is Off. is not

displayed.

4) Clamp the jaws around the

earth conductor.

5) If necessary, press the Data

hold switch. is displayed.

6) Take the reading from the

Digital and/or Bar-graph display

On.

.

Single phase or 3 phase

conductors

1) Set the range selector switch to

the 30 /300 mA position.

2) Set the Power switch to On.

3) Ensure that the Data hold

switch is Off. is not

displayed.

4) Clamp the jaws around the two

single phase conductors, or the

3 conductors in the case of 3

phase.

If necessary

5)

hold switch. is displayed.

6) Take the reading from the

Digital and/or Bar-graph display.

, press the Data

Battery Cover Screw

The correct size screw

must be used and

Jaw Opening Lever

Data Hold Switch

fitted to ensure battery

cover security, and

safe operation.

Measurement of Line Current Battery Replacement

1) Set the range selector switch to

the 30 /300 mA position.

2) Set the Power switch to On.

3) Ensure that the Data hold

switch is Off. is not

displayed.

4) Clamp the jaws around

conductor of the circuit under

test.

5) If necessary, press the Data

hold switch. is displayed.

6) Take the reading from the

Digital and/or Bar-graph display.

1) When the symbol

appears on the display, the two

1,5 V button cells must be

replaced.

2) Switch the

3) Loosen the small cross head

one

screw securing the battery

cover, and remove the cover.

Take care not to lose the

small screw.

4) Remove both exhausted cells

and carefully fit two new cells

into the recess. Position both

cells +ve side up.

5) Replace the battery

compartment cover and resecure with the small cross

head screw.

DCM300E

Off.

Page 2

Specification

Display: 31⁄2 digit L.C.D.

aximum Indication:

M

Over Range Indication:

ata Hold Indication:

D

Low Battery Indication:

Auto Shut-Off: Operates after approximately 10 minutes

Accuracy: 50 / 60 Hz at 23 °C ± 5 °C and 80% R H

Range Min. Resolution Accuracy

30 / 300 mA 0,1 mA ± 1,2% of reading ± 5 digits.

30 / 300A 0,01 mA 0 - 200A ± 1,2% of reading ± 5 digits.

Limitation of Circuit Voltage: Less than 600 V a.c.

Sampling Time: Digital - Approx 2 x per second.

Operating Temperature: 0˚C -40˚C, <80% RH (Non

condensation).

Storage Temperature: -10˚C -60˚C, <70% RH (Non condensation).

Power Source: 2 x 1,5 V Button battery type LR44

Power Consumption: Approx 5 mW.

Battery Life: Typically 50 hours.

Flash Test: 3700 V a.c. / 1 minute max (Between CT

Safety: Meets the requirements for double insulation to IEC 1010-2-032,

IEC1010-1 (1995), EN 61010-1 (1995) installation Category II*,

600 Volts phase to earth, Category III** 300 V phase to earth,

500 Volts phase to phase.

E.M.C: The instrument meets EN 50081-1 and EN 50082-1 (1992).

Jaw Opening Capability: 40 mm diameter.

Dimensions: 64 mm x 176 mm x 23 mm

Weight: Approximately 125 gm.

Cleaning: Wipe with a clean cloth damped with soapy water or Isopropyl

Alcohol (IPA).

* Relates to transient overvoltage likely to be found in portable equipment

and appliances.

** Relates to transient overvoltage likely to be found in fixed installation

wiring.

200.

3

2.5 V ~ 2,7 V

f instrument inactivity.

o

non condensing.

200 - 250A - 3,0% of reading ± 5 digits.

250 - 300A ± 5,0% of reading ± 5 digits.

Analogue - Approx 12 x per second.

or SR44.

core and housing).

Repair and Warranty

he instrument circuit contains static sensitive devices, and care must be

T

taken in handling the printed circuit board. If the protection of an instrument

as been impaired it should not be used, and be sent for repair by suitably

h

trained and qualified personnel. The protection is likely to be impaired if, for

example, the instrument shows visible damage, fails to perform the intended

easurements, has been subjected to prolonged storage under

m

unfavourable conditions, or has been exposed to severe transport stresses.

New Instruments are Guaranteed for 1 Year from the Date of Purchase

Any unauthorized prior repair or adjustment will automatically

Note:

invalidate the Warranty.

Instrument Repair and Spare Parts

For service requirements for

AVO INTERNATIONAL or AVO INTERNATIONAL

Archcliffe Road 510 Township Line Road

Dover Bluebell

Kent, CT17 9EN PA 19422-2795

England U.S.A.

Tel: +44 (0) 1304 502243 Tel: +1 (215) 646-9200

Fax: +44 (0) 1304 207342 Fax: +1 (215) 643-7215

or an approved repair company.

Approved Repair Companies

A number of independent instrument repair companies have been approved

for repair work on most

spare parts. Consult the Appointed Distributor / Agent regarding spare parts,

repair facilities and advice on the best course of action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it should be sent

freight pre-paid to the appropriate address. A copy of the Invoice and of the

packing note should be sent simultaneously by airmail to expedite clearance

through Customs. A repair estimate showing freight return and other

charges will be submitted to the sender, if required, before work on the

instrument commences.

Symbols used on the instrument:

Caution: Refer to accompanying notes.

Equipment protected hroughout by Double Insulation (Class

Equipment complies with EU Directives

by the User.

MEGGER®Instruments contact :-

MEGGER® instruments, using genuine

MEGGER

II).

®

AVO

Archcliffe Road 510 Township Line Road 561 S.Westmoreland Road

Dover Bluebell Dallas

Kent, CT17 9EN.

England. U.S.A. U.S.A.

Tel: +44 (0) 1304 502100 Tel: +1 (215) 646-9200 Tel: +1 (8oo) 723-2861 (U.S.A. only)

Fax: +44 (0) 1304 207342 Fax: +1 (215) 643-2670 Tel: +1 (214) 330-3203 (International)

The company reserves the right to change the specification or design without prior notice

MEGGER

is the registered Trade Mark of AVO INTERNATIONAL LIMITED. This data uses the comma as the decimal marker to align with general European usage

Copyright © AVO INTERNATIONAL LIMITED. Part No. 6172-172 Edition 1 - 11BB

INTERNATIONAL

19422-2795 TX 75237-1017

A

P

Fax: +1 (214) 337-3038

Loading...

Loading...