Page 1

M

CFL510F

Cable Fault Locator

USER MANUAL

Page 2

GSAFETY WARNINGS

Although this tester does not generate any hazardous voltages, circuits to which it can be connected could be

dangerous due to electric shock hazard or due to arcing (initiated by short circuit). While every effort has been

made by the manufacturer to reduce the hazard, the

user must assume responsibility for ensuring his, or her

own safety.

For use on energised systems rated up to 300 V Installation Category III* the fused clip set Megger Part

Number 6111-218, must be used.

* Relates to the transient over voltages likely to be met in fixed wiring installations.

4mm plug to BNC Adaptor:

This 4mm plug to BNC adapter is intended for use with telecomm network cables only, it is not designed or

intended for direct connection to an energised mains supply. However, in normal use it may be subject to telecom

network voltages (TNV) as defined by IEC 60950 3rd edition (1999-04).

The BNC plug and socket are, by necessity, accessible. The outer sheath for this connector is normally at SELV

levels, however under single fault conditions it may carry hazardous voltages. The operator must therefore verify

that the accessible plug or socket is at SELV levels prior to touching, or alternatively wear appropriate insulated

gloves.

■ The instrument should not be used if any part of it is damaged.

■ Test leads, probes and crocodile clips must be in good order, clean and with no broken or cracked

insulation.

■ Check that all lead connections are correct before making a test.

■ A Fused Lead Set must be used to connect to energised live systems. Refer to the accessories section for options.

■ Disconnect the test leads before accessing the battery compartment.

■ Refer to operating instructions for further explanation and precautions.

■ Safety Warnings and Precautions must be read and understood before the instrument is used.

They must be observed during use.

2

NOTE

THE INSTRUMENTS MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS.

Page 3

CONTENTS

3

GSafety Warnings 3

Introduction 5

General description

Battery replacement

User Controls and Display 8

Layout and functions

Operation 10

General Testing procedure

Line Feed

Connection to cable under test

Measuring distance to fault

Menu

TX Null

Velocity Factor

Pulse widths

Techniques to improve accuracy

Care and Maintenance 15

Specifications 16

Symbols used on the instrument are:

G Caution: Refer to accompanying notes.

F Equipment protected throughout by

double or reinforced insulation.

t Instrument flash tested to 3.7kV rms.

c Equipment complies with current EU

directives.

Page 4

INTRODUCTION

Thank you for purchasing the CFL510F cable fault

locator. Before attempting use of your new

instrument please take the time to read this user

guide, ultimately this will save you time, advise you

of any precautions you need to take and could

prevent damage to yourself and the instrument.

The CFL510F is an advanced instrument capable of

identifying a wide range of cable faults. The

instrument uses a technique called Pulse Echo (also

known as Time Domain Reflectometry or TDR). A

pulse is launched into a cable from one end. This can

be on either a pair of conductors, or a conductor and

the screen. The pulse travels down the cable at a

velocity determined by the insulation between the

conductors and this resistance to the flow of the

pulse is characterised as impedance for the cable.

Any changes in cable impedance will cause a

proportion of the pulse to be reflected.

The pulse velocity is normally described as a fraction

of the speed of light and is called the Velocity Factor.

By measuring the time between the transmitted pulse

and the reception of the reflected pulse, and

multiplying this by the speed of light and the velocity

factor, the actual distance to the reflection point can

be established.

Reflections are caused by changes in the cables

characteristic impedance, such as poor joints or

discontinuities. Faults showing an impedance higher

than that of the cables normal impedance will cause

a reflection of the same polarity, i.e.positive, whilst

faults with an impedance lower than that of the cable

will cause an inverse negative going reflection.

Matched cable terminations absorb all the pulse

hence no “end of cable” reflection will occur, the

cable appearing endless. Open or short circuits will

reflect all the pulse and a large reflection will be

displayed. At an open or short circuit all the

transmitted energy is reflected and the CFL510F will

not ‘see’ the cable beyond that fault.

As a pulse travels down a cable, the size and shape

of that pulse is gradually attenuated by the cable. The

pulse reduces in amplitude and becomes more

elongated or stretched. The level of attenuation (or

losses) is determined by the cable type, the condition

of the cable and any connections along its length.

The limit of how far you can see is determined by

the point beyond which you will not be able to see

or distinguish a reflection. To help identify small

reflections, especially at greater distance the CFL510F

has an adjustable gain setting. By increasing the gain

small reflections become more obvious.

The CFL510F can be used on any cable consisting of

at least two insulated metallic elements, one of which

may be the armouring or screen of the cable. The

CFL510F has internal matching networks to allow

testing of 25, 50, 75 and 100 cables. (These typically

correspond to power, coaxial data and data/telecoms

4

Page 5

cable). By selecting the CFL510F impedance closest to

that of the cable under test, maximum power can be

transmitted into the cable allowing long cables to be

tested.

The velocity factor of the CFL510F must be adjusted

to match that of the cable under test, allowing an

accurate distance measurement to be read directly

from the instrument. Where the VF of a cable is not

known, but the length is, the cursor can be set to the

end of the cable and the VF on the CFL510F adjusted

until the correct cable length is displayed.

Other configuration settings include changing the

distance units between metres and feet, changing the

propagation velocity units between a ratio and a

distance per microsecond. Display contrast is fully

adjustable to compensate for all viewing conditions. A

backlight aids viewing in low ambient light

conditions.

The instrument can be powered by manganese-alkali,

nickel-cadmium or nickel-metal-hydride batteries. All

cells must be of the same type.

5

Page 6

When the low battery symbol appears in the

display window the cells are nearly exhausted and

should be replaced as soon as possible. Use alkaline

cells IEC LR6 (AA) 1.5V or 1.2V rechargeable cells

only.

To install or replace the cells, switch the instrument

off. Disconnect the test leads, loosen the battery

cover retaining screws and remove the cover. Lift out

and disconnect the battery holder.

Replace the cells, ensuring that correct polarity is

observed (shown on the battery holder).

Incorrect battery cell polarity can cause electrolyte

leakage resulting in damage to the instrument

Refitting the battery holder is the reverse of removing

it.

BATTERY FITTING AND REPLACEMENT

6

Page 7

7

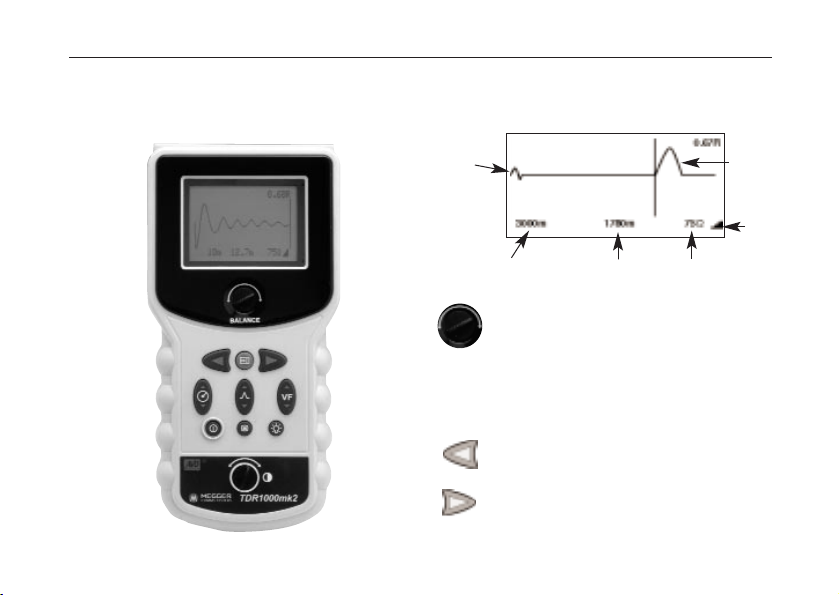

USER CONTROLS AND DISPLAY

The controls of the CFL510F have been arranged such

that the instrument is easy to learn and use. The

instrument controls consist of the following

Instrument Display:

The display shows the user the current settings of the

instrument and the reflected energy trace from the

cable connected.

Tx Null: This rotary control allows the user

to match the internal balance circuit of the

CLF510F to that of the cable under test. When

correctly adjusted the majority of the displayed

transmitted pulse can be nulled out, allowing

cable features close to the start of the cable to

be identified. Refer to section TX Null for

further details.

Cursor Left: Moves the ‘distance’ cursor to

the left. Auto repeats if held down.

Cursor Right: Moves the ‘distance’ cursor to

the right. Auto repeats if held down

Transmission

pulse

Range

Distance to cursor

Impedance

Gain

Reflection

Page 8

Find key: Automatically moves the cursor to

the first potential fault (change of impedance).

Power: Pressing this button will turn the

instrument on or off depending on its current

state.

Range: A bi-directional button allowing range

adjustment from 10m (30ft) to 3km (10 000ft)

in 6 steps. The bi-directional feature allows

ranges to be selected forward and backward,

without having to scroll through all the ranges

in one direction

Gain: This control is used to increase or

decrease the gain of the instrument. This helps

the user identify faults over the entire cable

length.

Velocity Factor: Adjusts the Velocity Factor

(VF) of the instrument to match that of the

cable under test.

IMPORTANT: The VF value must match the VF of

the cable under test to give an accurate distance

measurement.

Menu: Allows the user to change the units of

measurement for Distance, Velocity Factor,

Impedance and Test Rate. Refer to menu

section later in this text.

Backlight: Pressing this button will toggle the

backlight on and off. The backlight will

automatically switch off after 1 minute

Contrast: Allows the user to manually correct

the display contrast to suit local ambient

lighting conditions.

Output Sockets: 4mm shrouded sockets designed to

accept the leads supplied with the instrument.

Battery cover: Located on the back of the

instrument and provides the user with access to the

battery compartment. The cover must not be removed

while the instrument is switched on or connected to a

cable. The instrument must not be operated with the

cover open.

USER CONTROLS AND DISPLAY

8

Page 9

9

OPERATION

General Testing procedure

Ensure the correct test leads are firmly fitted into the

sockets of the instrument.

Switch on the instrument. The CFL510F will display

the start screen for a couple of seconds, followed by

a trace. The instrument will be set to the range and

velocity factor last used. If these settings are different

for the cable under test (C.U.T) then use the

RANGE

and VF keys to set the correct values. Refer also to

‘Velocity factor’ later in this text.

Connection to Cable Under Test

Connect the test lead to the cable under test.

Connection may be made to a live system with a

voltage to earth (ground) less than 300V with an

installation (over voltage) category of III or lower.

This means that the instrument may be connected to

any fixed wiring of a building installation, but not to

primary supply circuits such as overhead cables.

A Fused Lead Set must be used to connect to

energised live systems. Refer to the accessories

section for options.

When selecting 25 cable impedance, an internal

50Hz/60Hz filter is automatically switched in.

Measuring distance to fault

Ensure that the whole length of the cable can be

seen on the display, and that the range selected is

correct.

Find key

The Find key searches for the furthest major

change of impedance. This may be a fault or the end

of the cable if this is a short or open circuit.

When found the event is displayed and the cursor

placed on the leading edge. The gain, zoom and

cursor position may need to be adjusted for accurate

measurement. Note that Find does not adjust the

TxNull or Velocity Factor.

To enable ‘difficult to see’ faults to be identified, the

gain of the instrument can be adjusted. With the gain

at minimum small changes of cable impedance may

be overlooked. By increasing the gain the fault

becomes more obvious.

If no faults are obvious, adjust the gain until any

major reflections appear. Open and short circuits

should easily be identified. Partial faults can be less

obvious.

If no significant reflections can be seen use the “TX

Null” to minimise the effect of the output pulse on

any potential “near end” faults (refer to section on TX

Null).

Page 10

In the event of no reflections being visible, increase

gain until any reflection can be easily identified.

(If no reflections can be seen, try shorting or earthing

the far end of the cable to ensure that you are

“seeing” the whole length of the cable).

The cursor can also be moved using the LEFT and

RIGHT cursor keys. Move the cursor to the beginning

of the reflection. The distance to the fault can then be

directly read from the display.

NOTE: The distance calculation is performed using

the velocity factor set in the CFL510F. If this velocity

factor is not correct for the circuit under test, the

displayed distance will be incorrect.

Opposite are shown two typical trace displays. The

top shows an open circuit at 2000m away; the second

a short circuit at 2000m away.

OPERATION

10

Page 11

Instrument Features

Menu

The Menu key allows the user to change the units of

measurement for Distance, Velocity factor, Impedance

and Test Rate.

By pressing the

Menu key the CFL510F will display:

To select a function use the GAIN key to scroll up or

down the menu.

To change the units us the LEFT or RIGHT cursor

keys.

OPERATION

11

Available options Description Options

Distance Unit The Units in which the distance to m (metres) or ft(feet).

fault is displayed.

VF Format CFL510F velocity factor RATIO, m/us or ft/us

(which should be adjusted to match

the cable under test)

Impedance Output impedance of the CFL510F 25/50 75/100

Test Rate Refresh rate 1/second or 3/second

Distance Unit m

VF Format RATIO

Impedance 75Ω

Test rate 1s

Page 12

TX Null

Without the “TX Null” control, the transmitted pulse

would be visible at the beginning of the trace,

swamping any reflections within the pulse length (the

dead zone). The ‘TX Null’ circuit matches the

characteristic impedance of the cable under test to

produce an equivalent pulse. Subtracting this

equivalent pulse from the transmitted pulse effectively

removes the dead zone from the display and allows

“near end” reflections to be seen.

NOTE: In some cases, it may not be possible to

completely null the transmitted pulse.

Velocity Factor

The velocity factor is used by the instrument to

convert the measured time for a pulse to be reflected,

into a distance. It can be displayed as a ratio of the

speed of light (eg 0.660 = 66% of the speed of light),

or as a distance per microsecond in ft/us or m/us.

If the exact length of cable is known and the

reflection from the cable end is visible then an

accurate velocity factor can be determined:

■ Locate the reflection caused by the end of the

known length of cable with the instrument set on

the shortest possible range to see the end of the

cable.

■ Locate the start of this reflection as described in

the Operation section of this manual.

■ Adjust the velocity factor until the correct cable

length is shown.

■ Note the VF value for future reference.

The measurement of the distance to the fault can

now be made with more confidence. The ability of

the instrument to accurately measure the distance to a

cable feature relies on the velocity factor being

correct. Any errors in the velocity factor are directly

related to distance measurement errors.

OPERATION

12

Page 13

OPERATION

13

Pulse Widths

As the RANGE and IMPEDANCE matching of the

CFL510F are adjusted so the duration of the

transmitted pulse changes. The pulse widths range

from 7ns to 3µs to overcome signal attenuation and

enable the instrument to see further down a length of

cable. The greater the range selected on the CFL510F,

the wider the transmitted pulse.

The accuracy of the “Distance to fault” is not affected

by the length of the pulse. However, if two or more

features exist close together (excluding open or short

circuits), then the second or subsequent feature may

be partially masked by the reflection from the first

fault. Hence, for potential multiple features, the

instrument should be used with the shortest suitable

range, and so the smallest pulse width, that can see

both features.

For output pulse characteristics, refer to output pulse

data in the CFL510F Specification at the end of this

guide.

Techniques

To improve on the accuracy of the measurement,

numerous techniques can be used, depending on the

situation encountered. Not every situation can be

described, but the following points are effective and

the most common and easily implemented methods.

Test the cable from both ends

When fault finding a cable it is good practice to take

measurements from both ends. Particularly in the case

of open circuit faults, when the true end of the cable

is not visible. If the measurement is made from both

ends, then the combined answer should equal the

expected length of the cable. Even when the true end

of the cable is visible on the display, the reflections

after the fault may be too obscure to analyse clearly.

In this case, measurement from both ends yields a

clearer picture as well as improved accuracy.

It is also good practice to follow the cable route with

a cable tracer, as not all cable runs will be straight. It

can save a great deal of time if the exact route of the

cable is known as faults are often found at these

points and can be accredited to third party

intervention.

Care and Maintenance

Other than replacing the batteries, the instrument has

no user serviceable parts. In case of failure it should

be returned to your supplier or an approved

Megger Limited repair agent.

Cleaning the instrument should only be done by

wiping with a clean cloth dampened with soapy

water or Isopropyl Alcohol (IPA).

Page 14

Except where otherwise stated, this specification

applies at an ambient temperature of 20C.

General

Ranges: 10m, 30m, 100m, 300m, 1000m, 3000m

(30ft, 100ft, 300ft, 1000ft, 3000ft, 10000ft)

Accuracy: 1% of range pixel at 0.67VF

[

Note- The measurement accuracy is for the indicated

cursor position only and is conditional on the velocity

factor being correct.]

Resolution: 1% of range.

Input Protection: This instrument complies with

IEC61010-1 for connection to

live systems up to 300V CAT

III. Fused leads must be used

if the voltage between the

terminals exceeds 300V.

Output pulse: 5 volts peak to peak into

open circuit. Pulse widths determined by range and

cable impedance:

25Ω 50Ω 75Ω 100Ω

10m

7ns 7ns 7ns 7ns

30m 20ns 20ns 20ns 20ns

100m 100ns 60ns 100ns 100ns

300m 300ns 120ns 170ns 300ns

1000m 1000ns 520ns 680ns 1000ns

3000m 3000ns 2020ns 2340ns 3000ns

Gain: Set for each range with four

user selectable steps.

Velocity Factor: Variable from 0.01 to 0.99

in steps of 0.01

Impedance matching: 25, 50, 75, 100

Tx Null: 0 to 120

Refresh Rate: Selectable from the menu.

Once per second or three

times a second.

Power Down: Automatic after 5 minutes with

no key press.

OPERATION

14

Page 15

SPECIFICATIONS

15

Backlight: Stays on for 1 minute when activated.

Batteries: Six LR6 (AA) type batteries, Manganese-

alkali or nickel-cadmium or nickel-metalhydride cells

Nominal voltage:

9V for Alkali or 7.2V for NiCad.

Battery consumption:

100mA nominal, 140mA with backlight.

(20/30 hours continuous use depending

on backlight use)

Safety: This instrument complies with IEC61010-1

for connection to live systems up to 300V

CAT III. Fused leads must be used if the

voltage between the terminals exceeds

300V.

EMC: Complies with Electromagnetic

Compatibility Specifications

(Light industrial) BS EN 61326-1, with a

minimum performance of ‘B’ for all

immunity tests.

Mechanical

The instrument is designed for use

indoors or outdoors and is rated to IP54.

Case Dimensions: 230 mm long (9 inches)

115 mm wide (4.5 inches)

48 mm deep (2 inches)

Instrument weight: 0.6kg (1.32lbs)

Case material: ABS

Connectors: Two 4mm-safety terminals.

Test Lead: 2 metres long consisting of

2 x 4mm shrouded connector

to miniature crocodile clips

Display: 128 64 pixel Graphics LCD.

Environmental: Operational Temperature:

-15C to +50C (5F to 122F)

Storage Temperature:

-20C to 70C (-4F to158F)

Page 16

ORDERING INFORMATION

16

CFL510F

Included Accessories

Test & Carry case with strap 6420-125

Miniature Clip Test Lead Set 6231-652

User Guide 6172-659

Optional Accessories

Fused prod and clip set 6111-218

For use on energised systems rated up to 300V CATIII use the fused prod and clip set Megger

Part Number 6111-218, must be used.

Page 17

17

Page 18

18

Page 19

Page 20

M

Megger Limited

Archcliffe Road, Dover

Kent CT17 9EN England

T (0) 1 304 502101

F (0) 1 304 207342

Megger

4271 Bronze Way, Dallas, Texas

75237-1088 USA

T 1 800 723 2861

T 1 214 333 3201

F 1 214 331 7399

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France

T +33 (1) 30.16.08.90

F +33 (1) 34.61.23.77

OTHER TECHNICAL SALES OFFICES

Toronto CANADA, Sydney AUSTRALIA, Madrid SPAIN, Mumbai India and the Kingdom of BAHRAIN.

Megger products are distributed in 146 countries worldwide.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

Part No. 6172-660 V03 Printed in England 1103

www.megger.com

Loading...

Loading...