Page 1

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

MEGGER is the registered Trade Mark of AVO INTERNATIONAL LIMITED. Copyright ©, AVO INTERNATIONAL LIMITED

Part No 6172-484 Edition 3 – Printed in England – 01HH

AVO INTERNATIONAL

Archcliffe Road PO Box 9007 4271 Bronze Way MEGGER SARL

Dover Valley Forge Dallas 29 Allée de Villemomble

Kent, CT17 9EN. PA 19484-9007 TX 75237-1017 93340 Le Raincy

England. U.S.A. U.S.A. Paris, France

Tel: +44 (0) 1304 502100 Tel: +1 (610) 676-8500 Tel: +1 (800) 723-2861 (U.S.A. only) Tel: +33 (1) 43.02.37.54

Fax: +44 (0) 1304 207342 Fax: +1 (610) 676-8610 Tel: +1 (214) 330-3203 (International) Fax: +33 (1) 43.02.16.24

Page 2

MEGGER

®

User Guide

Guide de l’utilisateur

B e d i e n u n g s a n l e i t u n g

I N S U L ATION MULTIMETERS

MEGGER BMM2500

Page 3

CONTENTS

2

Symbols used on the instrument are:

Risk of Electric Shock

Refer to User Guide.

Equipment protected throughout

by Double Insulation (Class II).

Equipment complies with

current EU Directives.

Equipment must

not be connected to

installations >500V.

>500V

Safety Warnings 3

General Description 4

Continuity Testing 9

Continuity Bleeper 10

Millivolt Tests 11

Capacitance Tests 12

Milliamps Tests 12

Storing Results 13

Datalogging 16

Setup Modes 18

Specification 20

Repair and Warranty 25

Page 4

3

SAFETY WARNINGS

✱ Safety Warnings and Precautions must be read and understood before the instrument is used.

They must be observed during use.

✱ The circuit under test must be de-energized and isolated before connections are made except for

voltage measurement.

✱ Circuit connections must not be touched during a test.

✱ After insulation tests, capacitive circuits must be allowed to discharge before disconnecting the

test leads.

✱ The Live Circuit Warning and Automatic Discharge are additional safety features and should not

be regarded as a substitute for normal safe working practice.

✱ Replacement fuses must be of the correct type and rating. Failure to fit the correctly rated fuse

will result in damage to the instrument in the event of an overload.

✱ Test leads, including crocodile clips, must be in good order, clean and have no broken or

cracked insulation.

✱ Ensure that hands remain behind guards of probes/clips when testing.

✱ U.K. Safety Authorities recommend the use of fused test leads when measuring voltage on high

energy systems.

NOTE

T H E I N S T R U M E N T S M U S T O N LY B E U S E D B Y S U I TA B LY T R A I N E D A N D C O M P E T E N T P E R S O N S

. U S E R S O F T H I S E Q U I P M E N T

A N D

/O R T H E I R E M P L O Y E R S A R E R E M I N D E D T H AT HE A LT H A N D SA F E T Y LE G I S L AT I O N R E Q U I R E T H E M T O C A R R Y O U T VA L I D

R I S K A S S E S S M E N T S O F A L L E L E C T R I C A L W O R K S O A S T O I D E N T I F Y P O T E N T I A L S O U R C E S O F E L E C T R I C A L D A N G E R A N D R I S K

O F E L E C T R I C A L I N J U RY S U C H A S F R O M I N A D V E RT E N T S H O R T C I R C U I T S . W H E R E T H E A S S E S S M E N T S S H O W T H AT T H E R I S K I S

S I G N I F I C A N T T H E N T H E U S E O F F U S E D T E S T L E A D S C O N S T R U C T E D I N A C C O R D A N C E W I T H T H E HSE G U I D A N C E N O T E G S 3 8

‘ EL E C T R I C A L TE S T EQ U I P M E N T F O R U S E B Y EL E C T R I C I A N S ’ S H O U L D B E U S E D .

Page 5

GENERAL DESCRIPTION

4

The MEGGER®BMM2500 Series instruments are

battery powered Insulation and Continuity testers,

with a measurement capability from 0,01Ω

Continuity to 200GΩ Insulation.

Offering multi-voltage facilities, the instruments

take full advantage of microprocessor technology

and feature a large liquid crystal display combining

digital and analogue readings. The analogue display has the benefit of indicating trends and fluctuations in readings, while the digital readout gives

direct accurate results. The display is also backlit

giving clear visibility even in low light conditions.

The BMM2500 Series instruments have the unique

capability of being able to measure voltages down

to a resolution of 0,1mV. This gives the user the

option to fit a wide variety of transducers to further

enhance the capabilities of the BMM Series instruments, eg temperature or humidity measurement.

A customised connector on the top of the instrument enables the optional M E G G E R®S P 1

Switched probe to be used for two handed probe

operation.

The 250V, 500V and 1000V ranges can be used to

test electrical installations in compliance with

BS7671 (16th Edition IEEE Wiring Regulations)

IEC364 and HD384, since each range has a 1mA

minimum test current at the minimum pass values

of insulation specified in these documents. The

100V range (BMM2580) is ideal for testing

telecommunications equipment which would be

damaged by higher voltages. The 50V range

(BMM2580) is useful for testing sensitive equipment, such as electronic components, and computer peripherals.

The BMM2500 series instruments have a current

facility which enables up to 500mA to be measured, this together with Ω, V and mV ranges

means that the instrument can realistically be used

in situations where previously a multimeter would

be needed. For higher currents an optional current

clamp is available.

Page 6

5

The BMM2500 series instruments have an

RS232 interface built in, and will allow the storage and download of results to a PC. The instruments come with all the necessary software to

download and tabulate the results. The download format is also AVO Powersuite compatible

enabling instruments to form part of an integrated test and certification system. The BMM2500

series instruments also have the capability to

data-log results over an extended time period so

that long term measurements of systems can be

taken.

Designed to IEC1010-1 the BMM2500 Series are

p rotected against connection to a 500V

Category III supply. The instruments have a basic

accuracy of ±2% at 20°C. The instruments are

waterproof and dustproof to IP54. This helps

maintain accuracy and ensures maximum reliability in harsh environments.

Page 7

OPERATION

6

Refer to Safety Warnings before using

the instrument

Testing is automatically inhibited if:

• An external voltage >25V is present when

switched to any insulation range position.

• An external voltage >10V is present on all

other ranges (excluding OFF/V/mV).

The external voltage is indicated on the display,

on insulation ranges an audible bleeper will

sound if a test is attempted.

Live Circuit Warning

When more than 25V is applied to the terminals

in the insulation ranges, the instrument defaults

to a voltmeter and gives an audible warning if a

test is attempted. On all other switch positions

except O F F / V / m V when more than 10V is

applied the default voltmeter will be activated.

Testing will be inhibited.

Voltage Testing on High Energy Systems

Use extreme care when using or measuring volt-

ages above 30V, particularly in high energy systems. Fused test leads are available as optional

accessories for local situations where increased

protection is required.

Auto-shut Off

To conserve battery life, Auto-shut Off (pre c e d e d

by a series of bleeps) operates after appro x .

1 0 minutes of instrument inactivity on insulation,

5 minutes on all other ranges. If the instrument is

switched on while holding the k e y, the Auto

s h u t - O f f time is extended to 60 minutes. To

re s t o r e operation after Auto-shut Off, select O F F

followed by the re q u i red switch position.

Note: It is recommended that the instrument is

switched to the OFF position when not in use.

Backlight

The backlight is activated by pressing the

key. The backlight will remain illuminated

for approx. one minute before automatically

switching off to conserve battery life, alternatively the key can be re-pressed.

∼

Page 8

7

Insulation

Tests (MΩ)

(See fig.1)

The insulation tests

apply a known voltage to the circ u i t

under test and

m e a s u re the re s u l ting leakage curre n t .

The circuit under

test must be completely d e - e n e r-

g i s e d and i s o l a t e d

b e f o re test connections are made.

Insulation tests are only initiated when the TEST but-

ton is pressed.

1. Set the range switch to the test voltage

required.

2. Connect the test leads, first to the instrument,

and then to the isolated item under test.

3. Press the TEST button to activate the test

voltage. Take the reading.

4. Release the TEST button at the end of the test.

( P ress the TEST button if the l t b f e a t u re is

enabled). The last reading will hold on the display.

5. Any capacitive circuits charged during a test

will automatically discharge. If significant

voltage remains the voltage warning will occur

and the voltage present displayed.

6. Remove the test leads only when no voltage is

indicated.

Locking Test Button (ltb)

When it is desired to do a long insulation test, the

test can be ‘locked on’ by pressing the XXXXX key

while the test button is held down. The warning

will appear on the display and both buttons may be

released whilst the test continues. The next press

of the test button will terminate the test.

Note: There is a short delay on the first operation

of ‘1000 V’ range, each time the range is selected.

This is to prevent accidental application of 1kV.

The MΩ range features a leakage current display.

Leakage current is the value of current that flows

during the insulation test. To view the leakage current press the XXXXX key. To view insulation resistance press the XXXXX key again.

FIG.1

∼

Page 9

8

Good procedure whilst Insulation Testing

Care must be taken when taking measurements

greater than a few GΩ. The leads must be clean

dry and in good condition. They must also not be

allowed to tangle. It is also advisable that the

switched probe SP1 is not used as the accuracy at

high value measurements is not guaranteed. The

instrument should also be clean and dry with particular attention paid to the terminals. Also attempt

to reduce any leakage that may give erroneous

results on the item under test.

Polarisation Index Testing

Polarization Index (P I) is the term applied to the

Dielectric Absorption Ratio when resistance values

a r e measured after 1 minute and again after 10 min-

utes. Polarization Index is then the resistance value

after 10 minutes divided by the resistance value

after 1 minute. The test can be run at any voltage.

M o re detailed information on P I Testing and value

assessment can be found in AVO International publications listed in the Accessories page.

Automatic Discharge

When the TEST button is released after an insulation test (or re-pressed if ltb feature is enabled), a

200kΩ load is automatically switched across the

terminals to discharge the item under test. Any

voltage present will be indicated on the display so

that the discharge can be monitored.

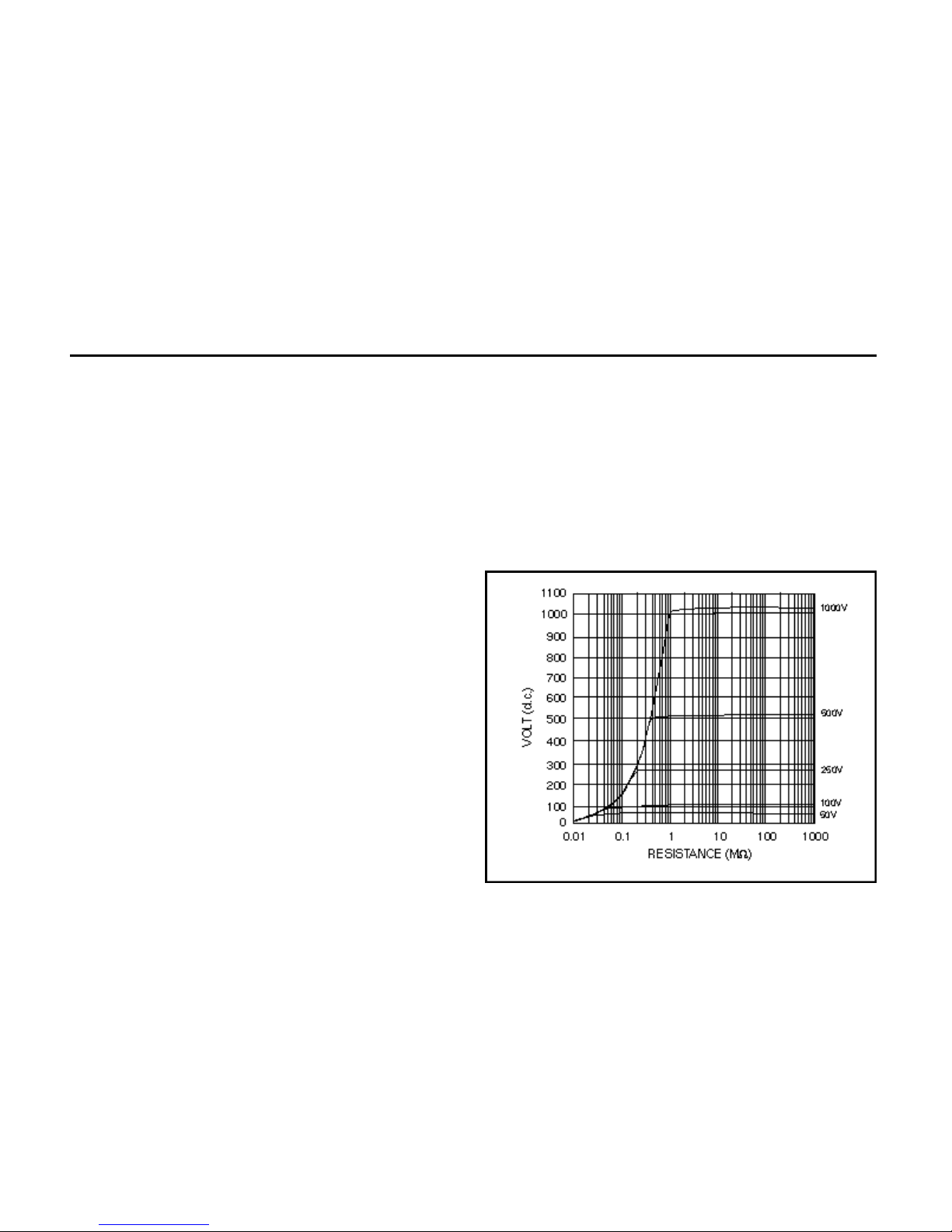

Typical Terminal Voltage Characteristics

Page 10

Continuity Testing (Ω) (See fig.2)

The continuity tests are activated when the probes

make contact of less than a few kΩ. The test operates without the need to press the TEST button.

When the test leads are removed the reading will

hold for a few seconds and then reset. To recall the

last result press the XXXXX key. This range is not

suitable for diode testing since the automatic contact detector will not be activated when connected

to a diode.

1. Set the selector switch to Ω.

2. Connect the test leads.

3. The test will activate automatically.

4. After the test probes are disconnected, the

reading will be held for a few seconds.

Zeroing of Test Lead Resistance

The resistance of the test leads can be nulled on the

continuity range (up to 9,99Ω). The null information

is retained in non-volatile memory and so will be

re m e m b e red when the instrument is switched off .

1. Select the Continuity range.

2. Short the test leads across a known good

conductor using prods.

3. When the reading has

stabilised, press the

TEST button. The

z e ro offset symbol

will appear.

4. To release the zero

offset press the test

button again.

The continuity range

f e a t u res a range lock

f a c i l i t y. To LOCK the

continuity range press the

key, the LOCK symbol will appear. To scroll

through the available ranges press the key.

To de-select the LOCK feature hold the key

down.

9

FIG.2

Page 11

10

Possible sources of error

Measurements and results can be effected by the

following:

• The impedance of operating circuits connected in parallel

• Impedance such as inductors that vary during

the measurement

• A poor connection to the circuit under test.

Continuity Bleeper

The continuity bleeper sounds continuously when

less than 5 Ω is detected. Short bleeps will sound

for resistances lower than a few kΩ and above 5Ω.

1. Set the selector switch to

2. Connect the test leads.

Display: Audible:

<5Ω continuous bleep

<3kΩ short bleep

>3kΩ no bleep

Resistance Tests (kΩ)

This is a low voltage (5 V) low current (25 µA) test

for sensitive electronic equipment. It operates in

the same way as the continuity ranges.

1. Set the selector switch to kΩ.

2. Connect the test leads.

3. The test will activate automatically.

The kΩ range features a range lock facility. To

LOCK the kΩ range press the key, the LOCK

symbol will appear. To scroll through the available

ranges press the key. To de-select the L O C K

f e a t u re hold the key down.

The resistance range is protected by a high impedance method and therefore if the instrument is

connected to a live circuit the fuse will not blow as

on the insulation, continuity and buzzer ranges.

The instrument will merely indicate the applied

over-voltage.

Diode Testing

This range can also be used for diode testing, the

positive terminal being the source of the test current. A forward biased semi-conductor junction will

typically measure 15 to 30kΩ, and a reverse junction much higher. These features together with the

small test current and wide measurement range

Page 12

∼

11

(0,01kΩ to 10000kΩ) make the resistance range

very useful for general purpose testing.

Voltage Tests (V)

If >1V a.c. or d.c. is present at the terminals the

measured voltage is indicated on the display. The

voltage display will function within specification

even if the fuse has blown.

If the voltmeter operation is in question, test the

voltmeter on a known source.

1. Set the selector switch to V.

2. Connect the test leads.

3. After a short settling time, the reading will be

displayed automatically.

To view the frequency of the a.c. V being measure d

p ress the k e y. The frequency will be displayed

in the range 16Hz-460Hz. To view a.c. V press the

key again.

Millivolt Tests(mV)

The measured a.c. or d.c. voltage is indicated on

the display.

1. Set the selector switch to mV.

2. Select either a.c. or d.c. mV using the

key.

3. Connect the test leads.

4. After a short settling time, the reading will be

displayed automatically.

Note: Live circuit warning does not function on mV

range.

Zeroing of d.c. mV (no a.c. mV zero facility)

To zero the d.c. mV range, short the leads together in the d.c. mV position, wait for the reading to

settle and then press the TEST button. Up to

9,9mV can be zeroed on the d.c. mV range. The

symbol will appear to indicate the zero has

been adjusted.

1. Select the d.c. mV range.

2. Short the test leads together.

3. When the reading has stabilised, press the

TEST button. The zero offset symbol will

appear.

4. To release the zero offset press the TEST but-

ton again.

To view the frequency of the a.c. mV being measured press the key. The frequency will be

displayed in the range 16Hz-460Hz. To view a.c.

Page 13

12

mV press the key again. For inputs less than

10mV frequency is not displayed.

Capacitance Tests (uF)

(BMM2580 only)

The measured capacitance is indicated on the display.

1. Set the selector switch to uF.

2. Connect the test leads to the circuit under test.

3. After a short settling time, the reading will be

displayed automatically.

Zeroing of uF

To zero the uF range, disconnect the leads, wait for

the reading to settle and then press the TEST but-

ton. Up to 10,0nF can be zeroed on the uF range.

The symbol will appear to indicate the zero

has been adjusted.

1. Select the uF range.

2. Disconnect the test leads from the circ u i t

under test.

3. When the reading has stabilised, press the

TEST button. The zero offset symbol will appear.

4. To release the zero offset press the test button

again.

The range is suitable for the testing of discrete

components and short low interference level signal

lines. If electrolytic capacitors are being tested

then the red lead should be connected to +ve of

the capacitor. This range is not suitable for checking capacitance of signal lines which are subject to

high levels of a.c. interference.

When the test is started – – – will show on the display, if there is excessive noise this symbol will

remain or flash indicating that there is too much

noise for a result to be reached.

Milliamps Tests (mA)

Because of the low source impedance associated

with current measuring this test has an added feature ensuring that when the range is first entered

the default voltmeter is visible. Testing will be inhibited if more than 25V is present at the terminals. To

start testing the TEST button should be pressed

and held down for approx. 2 seconds to activate

the mA range. Once activated, the TEST button

no longer needs to be used and the measured

value will be displayed automatically. To switch the

display between a.c. and d.c. press the

Page 14

∼

13

key.

1. Set the selector switch to mA.

2. Connect the test leads.

3. Select either a.c. or d.c. m A using the

k e y.

4. Press and hold down the TEST button for

approx. 2 seconds.

5. After a short settle time, the reading will be

displayed automatically.

To view the frequency of the a.c. mA being mea-

sured press the key. The frequency will be

displayed in the range 16Hz-460Hz. To view a.c.

mA press the key again. For inputs less than

10mA frequency is not displayed.

Storing Results on MΩ and Ω (RCL)

After an insulation test or continuity test the result

is displayed on the screen, this may be saved with

additional information. A circuit number (1-99) may

be assigned and circuits may be grouped using the

distribution board feature. In this way, when downloading to AVO PowerSuite, the results can be easily split into different test schedules. When the

results are displayed or printed, a change in the

distribution board is indicated.

Changing Distribution Boards (DB)

Before a test the distribution board number may be

changed as follows:-

1. Move the rotary selector switch to the RCL

position. The code rcl is displayed.

2. Press the key. The currently selected DB

code is displayed, e.g. d01.

3 . This number may be changed using the

and keys to display the re q u i red number.

4. The number can be accepted by pressing the

key, or aborted by pressing the EXIT button.

5. When the number is saved the code Std is

displayed (accompanied by a long bleep) to

confirm that the data has been saved.

∼

∼

Page 15

14

Testing may now continue with all subsequent

results associated with the new distribution board

number.

Storing a result

On completion and display of the measurement:-

1. Press and hold the key. After about 1

second, a bleep will be heard. For both

Continuity and Insulation, a code, as given in

the following table is displayed. This code is

used to describe the circuit tested and can

accordingly be modified by the user.

2. The code may be changed by pressing the

and keys.

3. The code may be accepted by pressing the

key, or aborted by pressing the EXIT button.

4. The circuit number is then displayed as

2 digits e.g. c01.

Note:- Many different tests may be saved under

the same circuit number.

5. The circuit number may be changed by

pressing the and keys to display

an appropriate number.

6. The number can be accepted and the

results saved by pressing the key, or the

procedure aborted by pressing the EXIT button.

7. When the result is saved, the code Std is

displayed (accompanied by a long bleep) to

confirm that the data has been saved. The

display of FULL indicates that there is no more

test storage. Approx. 300 results can be stored

in memory.

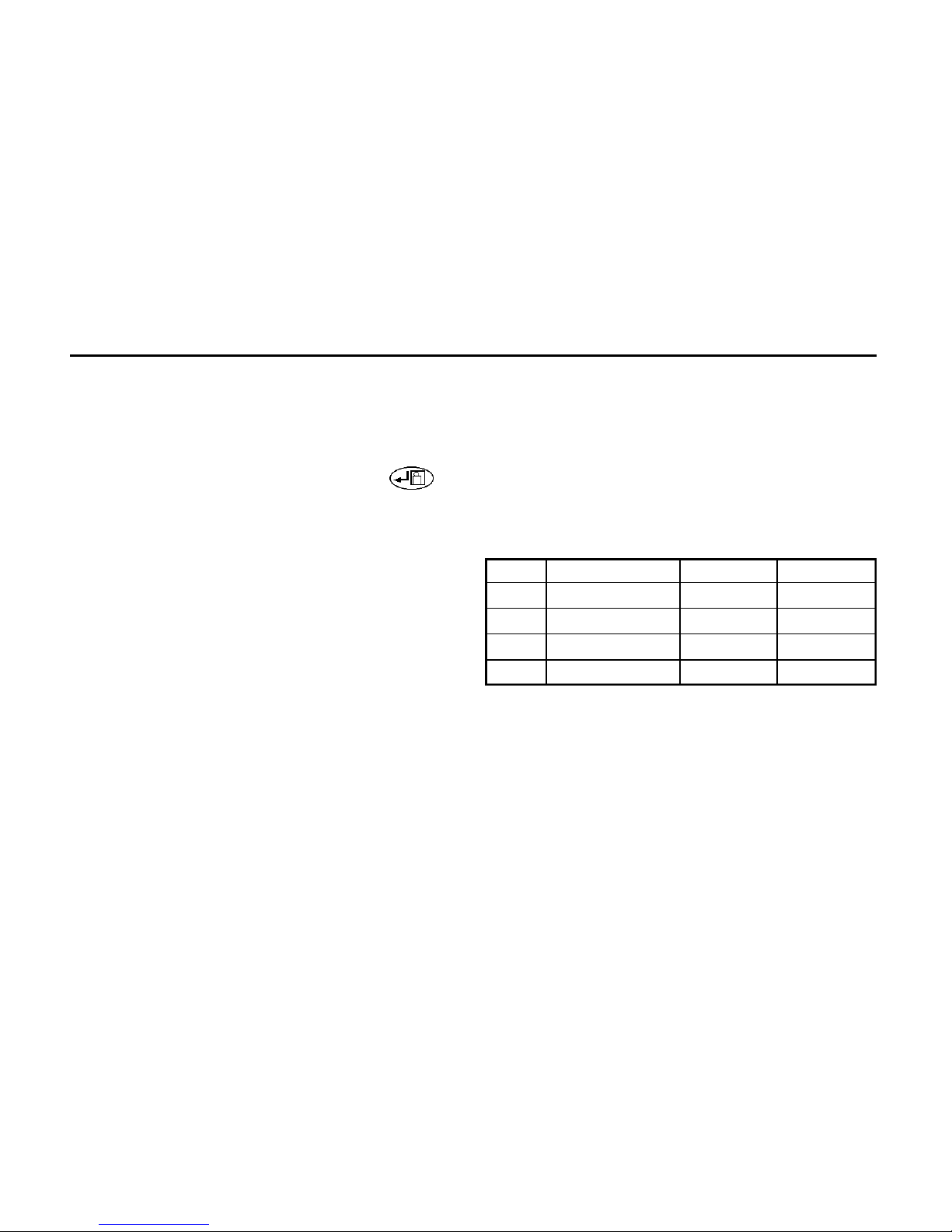

Test to be Saved Display code Meaning

Continuity r1 Single CCT

r2 Single CCT

rr1 Ring CCT

rr2 Ring CCT

rrn Ring CCT

r12 R1+R2 ReturnCCT

Insulation n_e N-PE

L_n L-N

L_E L-PE

L_L L-L

∼

∼

Page 16

15

Delete all data

1. Move the rotary selector switch to the RCL

position. The code rcl is displayed.

2. Press the and keys together. The

code dEL is displayed.

3. Confirm that the data is no longer required by

pressing the key or abort by pressing any

other key. The code rcl is displayed.

Print Results (see Setup Modes)

1. Connect printer and the instrument with a ser-

ial printer lead.

2. Move the rotary selector switch to the RCL

position. The code rcl is displayed.

3. Commence the printout by pressing the TEST

button. Abort at any time by pressing and holding the k e y . The code rc l is displayed.

Retrieve Stored Results

It is possible to view previously stored test results

by switching the rotary switch to the RCL position.

1. Move the rotary selector switch to the RCL

position. The code rcl is displayed.

2. Select the re q u i red distribution board by

pressing the and keys.

The distribution board numbers are shown in

the order that the results were stored. A long

bleep is sounded when the end of the list is

reached.

3. Press the key to list the circuit numbers

used in the currently displayed distribution

board or press the EXIT button to return to the

RCL display.

4. Select the required circuit number by pressing

the and keys. The circuit numbers

are shown in the order that the results were

stored. A long bleep is sounded when the end

of the list is reached.

5. Press the EXIT button to return to the distribution board selection screen, or press the

XXXXXkey to show the stored test codes. The

following codes are used to identify test

results:-

Code Meaning

Con Continuity Test

InS Insulation Test

6. Select the re q u i red test by pressing the

and keys. The tests are shown in

∼

∼

∼

∼

Page 17

16

the above order. Hold a key down to autorepeat. A long bleep is sounded when the end

of the list is reached.

7. Press the EXIT button to return to the circuit

number selection screen, or press the key

to scroll through the stored test results,

together with any additional connection

information.

Download to PC

The BMM series has been designed to be used

with AVO Powersuite for Windows which will

accept the test results and enable the production

of various certificates, including Periodic

Inspection and Completion. The CD supplied with

the instrument contains AVO Download Manager

Program. This enables stored and data-logged

results to be downloaded to a PC, the creation of

simple test report files which may be exported to

other applications and used to create data backups or reports/certificates. Download manager

also enables certain changes to be made to your

instrument setup such as changing the 2nd lan-

guage of the printouts. The CD contains a user

guide giving you full instructions on the use of

Download Manager.

Cable Configuration

Normally, a double-ended 9-way ‘D’ female socket

lead suitable for connecting PC to PC is required.

This lead should not exceed 3m in length. A lead is

available as an accessory, or one can be made up

as follows:–

Datalogging

Datalogging means the automatic recording of

measurements at regular intervals over an extended period, for viewing at a later time. Results are

held in the internal memory of the tester, but can

only be extracted by means of a PC connected via

the RS232 port.

Signal Insulation Tester 9-way ‘D’ 25-way ‘D’

Rx 2 3 2

Tx 3 2 3

DSR 6 4 20

GND 5 5 7

Page 18

17

Storage v. Datalogging Comparison.

By storage, we mean the saving to memory of

results one-by-one as tests are performed. Each

result has to be individually saved after associating

it with user-selectable connection data and circuit

number, along with a previously chosen distribution board number. However, when data logging is

running, results are automatically and continuously saved to memory and no other information is

recorded.

Storage and logging are mutually exclusive functions. The instrument cannot be set up to perform

both operations at any given time. If a result is

stored, then all logged data is erased, and vice

versa. Also, only one set of logged data can be

held in memory. A new logging session will erase

the previous data. This differs in behaviour from the

storage function, in which data from successive

tests accumulates in the memory until it is full.

Another difference between storage and logging is

that the former applies only to insulation and continuity testing, whereas all types of measurement

can be logged (buzzer range excluded).

Starting a logging session

Once logging has been enabled and the interval

set up, a session of data-logging can begin. (see

Setup Modes)

1. Hold down the key and turn the rotary

switch to the desired function.

2. Release the key. The message log will

be seen. To confirm that logging is required,

p ress the display key and a confirming

message will be shown briefly.

3. Pressing EXIT will cancel logging and off will

be displayed.

If data-logging is turned on, it will commence as

soon as the test starts. That is, immediately on

volts, millivolts, ohms, kΩ and capacitance functions, or when the test button is pressed on insulation and milliamps ranges. On milliamps or millivolts functions, press theXXXXXkey if required,

after logging has started.

Stopping a logging session

While a logging session is running, it can be

stopped at any time by turning the range switch.

Any data logged up to that point will be retained.

∼

Page 19

18

Alternatively, logging can be left running and will

stop automatically a short while after the memory

becomes full.

The number of results which can be logged is

about 300, after which the message ‘full’ will be

flashed on the display for a few minutes. The

instrument will then shut down.

Other considerations

Note that the batteries may not last through the

whole logging session, depending on their condition and on the log interval which has been set. If

the batteries should fail, any results already logged

will be retained. Note also, that if the TEST button

has been set for non-latching operation, this will be

temporarily overridden during logging of insulation

results, giving a press-to-start, pre s s - t o - s t o p

action. The TEST button’s mode of operation will

return to its original setting after the logging session has finished.

Viewing logged data.

Logged results can only be retrieved via the instrument’s RS232 port, using a PC connected via a

serial cable. The disk supplied with the instrument

carries a programme capable of handling the data.

The method is similar to that for ‘downloading’

stored results. For further information see the section entitled “Download to PC”. Note that on millivolts d.c. and milliamps d.c. measurements, the

frequency result is always set to zero. On millivolts

a.c. and milliamps a.c. measurements, the frequency result is set to zero if the frequency could

not be measured.

Setup Modes

Serial Printer configuration

The printer should be set to 9600 baud, 8 bit data,

no parity and 1 stop bit. This instrument uses a

special isolated serial interface which is powered

from the PC or printer. In the unlikely event that

your PC or printer is not able to power the interface, it will be necessary to provide an additional

supply. Contact AVO Product Support for details.

Printer Setup Mode

The instrument cannot respond to a busy signal

Page 20

∼

19

given by a printer, and therefore waits at the end of

each line. This time (“Printer delay time”) and the

printer report language can be changed.

1. Press and hold the key then turn the

rotary selector switch from the OFF position to

the RCL position. The code Pdt is displayed.

2. Release the key.

To change the Printer speed

1. Toggle the key to scroll through and

display the code Pdt

2. Press the key. The current setting is

displayed.

3. Toggle the and keys until the

required setting is displayed.

4. To save the new setting, press the key.

The bleeper sounds and std is displayed. To

abort the new setting, press the EXIT button.

To select the printer language

1 . P ress the key to scroll through and dis-

play the code l n g.

2 . P ress the key. The current printer re p o r t

language is displayed as 1 (English) or 2 (as

given on the type label on the User Guide cover).

Note: Language 2 can be changed – see below.

3. Press the key until the required language

setting is displayed

4. To save the new setting, press the key.

The bleeper sounds and is Std displayed. To

abort the new setting, press the EXIT button.

Changing the Second Printer Language

Language 2 can be changed using AVO Download

Manager Program supplied with your instrument. Full

instructions are contained in the User Guide with the CD.

Data-logging

Enabling/disabling data-logging:

The factory setting is that logging is disabled and

storage is enabled.

1. Turn the range knob to ‘RCL’ while holding

down the key. Pdt will be displayed.

2. Press the key until log is showing

3. Press the key to show the current status

of the logging function, i.e on or off.

4. Pressing the key toggles the setting

between on and off.

5. Press the key to accept the setup, or the

EXIT button to quit.

Page 21

∼

20

Setting the data-logging interval.

1. While log is being displayed, press the

key. Int will appear on the display.

2. Press the key to see the value of the logging interval (in seconds)

3. Set the interval in 10 second steps with the

and keys (max. value 1990 sec-

onds, min. value 10 seconds)

4. Press the key to accept the new value,

or the EXIT button to quit.

5. Press the EXIT button again to escape from

the logging setup screens. The display will

s h o w rc l.

Using the MEGGER SP1 Switched Probe

Operation

The MEGGER SP1 is an accessory for designated

MEGGER installation test instruments. When fitted

in the specially designed connector, in place of the

existing ‘Low’ lead, the SP1 acts as a remote test

button to operate the instrument and as a ‘Low’

probe. This simplifies instrument control and twohanded probing. The SP1 is suitable for use with

MEGGER insulation test instruments up to 1kV

output test voltage.

Safety

Meets the safety requirements for double insulation to IEC1010-2-031 (1995), EN61010-2-031

(1995), IEC 1010-1 (1995), EN61010-1 (1995)

Category III* 300 V phase to earth and 500V phase

to phase. The probe is fitted with an internal, nonreplaceable fuse, to protect the user should the

probe be used accidentally in conjunction with a

testlead in the low terminal.

*Relates to transient overvoltage likely to be found

in fixed installation wiring.

Do not use the probe if any part of it is

damaged.

Battery Replacement

When the low battery symbol appears, the cells

are nearly exhausted and should be replaced as

soon as possible. Use Alkaline cells IEC LR6 (AA)

or NiCd rechargeable. To install or replace the

cells, disconnect the test leads, switch the instrument to OFF and loosen the captive screws on the

rear of the battery compartment. Remove the

cover and disconnect the battery holder from the

battery leads. Ensure that the replacement cells are

Page 22

21

fitted with the correct polarity in accordance with

the label in the battery holder. Reconnect the battery holder to the battery leads. Replace and resecure the battery compartment cover. Remove

the cells if the instrument is not going to be used

for an extended period of time.

Fuse Checking and Replacement

To check the instrument fuse, switch to an insulation range and press the TEST button. The symbol

XXXX will appear if the fuse is ruptured. To replace

the fuse, disconnect the test leads, switch the

instrument OFF and loosen the captive screws

holding the battery compartment cover in place.

Remove the cover and replace the fuse. Replace

and re-secure the battery compartment cover.

Page 23

Specification

22

(All quoted accuracies are at +20ºC.)

INSULATION RANGES

Nominal Test 250V,500V,1000V (BMM2500)

Voltage (d.c.): 50V,100V,250V,500V,1000V (BMM2580)

Test voltage accuracy: +15% maximum on open circ u i t

Short circuit curre n t : < 2 mA

Test Current on load: 1mA at min. pass value of insulation

specified in BS7671, HD384 and

IEC 364, 2mA max.

Accuracy:

(BMM2500)

Range Full Scale Accuracy

1000V 20GΩ ± 2% ± 2 digits ± 0,2% per GΩ

500V 10GΩ ± 2% ± 2 digits ± 0,4% per GΩ

250V 5GΩ ± 2% ± 2 digits ± 0,8% per GΩ

(BMM2580)

Range Full Scale Accuracy

1000V 200GΩ ± 2% ± 2 digits ± 0,2% per GΩ

500V 100GΩ ± 2% ± 2 digits ± 0,4% per GΩ

250V 50GΩ ± 2% ± 2 digits ± 0,8% per GΩ

100V 20GΩ ± 2% ± 2 digits ± 2,0% per GΩ

50V 10GΩ ± 2% ± 2 digits ± 4,0% per GΩ

Note: Above specifications only apply when high quality

silicone leads are being used.

Measuring Range:

0,01MΩ to 200GΩ (0-100GΩ on analogue scale).

EN61557 Operating range: 0,10MΩ to 1,00GΩ

Leakage Current: 10% ±3digits

CONTINUITY

Measuring Range: 0,01Ω to 99,9Ω (0 to 10Ω on

analogue scale)

EN61557 Operating range: 0,10Ω to 99,9Ω

Accuracy: ±2% ±2 digits

Open circuit voltage: 5V ±1V

Test current: 210mA ±10mA (0-2Ω)

Zero offset at probes: 0,10Ω typical

Lead resistance zeroing: Up to 9,99Ω

Noise rejection: 1V rms 50/60Hz

Buzzer: Operates at less than 5Ω

(approx).

RESISTANCE

Measuring Range: 0,01kΩ to 9,99MΩ (0 to

100MΩ on analogue scale)

Accuracy: ±3% ±2 digits

Open circuit voltage: 5V ±1V

Short circuit current: 25µA ±5 µA

Page 24

23

VOLTAGE

Measuring Range: ±1V to ±500V (0 to 1000V

on analogue scale)

Accuracy: 0-500V d.c. ±2% ±3 digit

0-500V a.c (50/60Hz) ±2% ±3 digits

0-500V 400Hz a.c. ±5% ±3 digits

Input resistance: approx 200kΩ.

Detector Threshold: 1V

MILLIVOLTS

Measuring Range: ±0,1mV to ±1999mV

(0 to 1000mV on analogue

scale)

Accuracy:

0,1mV to 10mV d.c. or a.c. (50/60Hz) ±2% ±5 digits

10mV to 1999mV d.c. or a.c. (50/60Hz) ±2% ±3 digits

0,1mV to 10mV a.c. (16-460Hz) ±5% ±7 digits

10mV to 1999mV a.c. (16-460 Hz) ±5% ±5 digits

d.c. milliVolts zeroing: Up to 9,9mV

Input resistance: >3MΩ

CAPACITANCE

Measuring Range: 0,1nF to 9,99uF

Accuracy: ±3% ±2 digits ±0,2nF

uF zeroing: Up to 10nF

MILLI-AMPS

Measuring Range: 0,1mA to 500mA (0 to 1000mA on

analogue scale)

Accuracy:

0,1mA to 10mA d.c. or a.c. (50/60 Hz) ±2% ±5 digits

10mA to 500mA d.c. or a.c. (50/60 Hz) ±2% ±3 digits

0,1mA to 10mA a.c. (16-460 Hz) ±5% ±7 digits

10mA to 500mA a.c. (16-460 Hz) ±5% ±5 digits

FREQUENCY

Measuring range: 16Hz to 460Hz

Accuracy: ±1% ±1digit

Page 25

24

Basic and service errors for

Insulation and Resistance ranges.

The basic error is the maximum inaccuracy of the instrument under ideal conditions, whereas the service error is

the maximum inaccuracy taking into effect of battery volt-

age, temperature, interference, and system voltage and

frequency, where applicable. After determining the service

error, we can then calculate the measurement range. This

is the range of measurement over which the error in service is less than 30% of the reading. Digital instruments

are affected by the number of digits error – for example a

value 0,10Ω measured with the continuity range may give

a display in the range 0,07Ω to 0,13Ω which is a maximum

error of 30%. Therefore the measurement range measuring low resistance is 0,10Ω to 99,9Ω. When checking that

a measurement does not exceed a limit, the service error

needs to be taken into account and these tables enable

this to be done quickly and easily. These will guarantee

that the value being measured is greater than or less than

the limit value specified as appropriate.

Insulation Resistance – MΩ

Limit Min. Indicated Reading Limit Min. Indicated Reading

0,10 0,14 2,00 2,12

0,20 0,25 3,00 3,16

0,30 0,35 4,00 4,20

0,40 0,46 5,00 5,24

0,50 0,56 10,00 10,8

0,60 0,66 20,00 21,2

0,70 0,77 30,00 31,6

0,80 0,87 40,00 42,0

0,90 0,98 50,00 52,4

1,00 1,08 100,00 94,0

Continuity Resistance – Ω

Limit Max. Indicated Reading Limit Max. Indicated Reading

0,10 0,06 2,00 1,88

0,20 0,15 3,00 2,84

0,30 0,25 4,00 3,80

0,40 0,34 5,00 4,76

0,50 0,44 10,00 9,56

0,60 0,54 20,00 18,8

0,70 0,63 30,00 28,4

0,80 0,73 40,00 38,0

0,90 0,82 50,00 47,6

1,00 0,92 100,00 92,0

Page 26

25

SAFETY

The instruments meet the requirements for double insulation to IEC 1010-1 (1995), EN 61010-1 (1995) to Category

III*, 300 Volts phase to earth (ground) and 440 Volts phase

to phase, without the need for separately fused test leads.

If required, fused test leads are available as an optional

accessory.

* Relates to the transient over-voltages likely to be met in

fixed wiring installations.

Complies with the following parts of EN61557, Electrical

safety in low voltage systems up to 1000V a.c. and 1500V

d.c. – Equipment for testing, measuring or monitoring of

protective measures:-

Part 1 - General requirements

Part 2 - Insulation resistance

Part 4 - Resistance of earth connection and equi-

potential bonding

FUSE

500mA 500V, 32x 6mm Ceramic HBC 10kA minimum.

E.M.C.

The instruments meet EN61326-1

POWER SUPPLY

Battery Type: 6x1,5V Alkaline cells

IEC LR6 type or 1.2V NiCd

re-chargeable cells.

Battery Life (typical): 2100 5-sec 1kV insulation tests

3200 5-sec 500V insulation tests

4000 5-sec 250V insulation tests

2700 5-sec continuity tests

4700 5-sec kΩ tests

ENVIRONMENTAL CONDITIONS

Operating range: -5 to +40°C

Operating humidity: 90% RH at 40°C max.

Storage temperature range: -25 to +65°C

Calibration Temperature: +20°C

Maximum altitude: 2000m

Dust and water protection: IP54

Temperature coefficient: <0,1% per °C

WEIGHT: 742g

DIMENSIONS: 110mm x 220mm x 45mm

CLEANING: Wipe with a clean cloth

dampened with soapy

water or Isopropyl Alcohol

(IPA)

Page 27

26

ACCESSORIES

Supplied: Part Number

Test lead set 6220-437

Test-&-carry case 6420-112

Optional: Part Number

Fused lead set, FPK8 6111-218

Switch Test Probe SP1 6220-606

Test Record Cards (Pack of 20) 6111-216

AVO PowerSuite 6111-237

AVO NiceOne 6111-403

9-way Serial Lead 25955-025

Publications:

‘A Stitch in Time’ AVTM21-P8B

‘Testing Electrical Installations” 6172-129

Page 28

Repair and Warranty

27

The instrument circuit contains static sensitive devices,

and care must be taken in handling the printed circuit

b o a rd. If the protection of an instrument has been

impaired it should not be used, and be sent for repair by

suitably trained and qualified personnel. The protection is

likely to be impaired if, for example, the instrument shows

visible damage, fails to perform the intended measurements, has been subjected to prolonged storage under

unfavourable conditions, or has been exposed to severe

transport stresses.

New Instruments are Guaranteed for 3 Years from the

Date of Purchase by the User.

Note: Any unauthorized prior repair or adjustment will

automatically invalidate the Warranty.

Instrument Repair and Spare Parts

For service re q u i rements for MEGGER®I n s t r u m e n t s

contact:-

AVO INTERNATIONAL or AVO INTERNATIONAL

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent, CT17 9EN. Norristown, PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502243 Tel: +1 (610) 676-8579

Fax: +44 (0) 1304 207342 Fax: +1 (610) 643-8625

or an approved repair company.

Approved Repair Companies

A number of independent instrument repair companies

have been authorised for repair work on most MEGGER

instruments, using genuine MEGGER spare parts. Consult

the Appointed Distributor/Agent regarding spare parts,

repair facilities, and advice on the best course of action to

take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it

should be sent freight pre-paid to the appropriate address.

A copy of the invoice and of the packing note should be

sent simultaneously by airmail to expedite clearance

through Customs. A repair estimate showing freight return

and other charges will be submitted to the sender, if

required, before work on the instrument commences.

Page 29

28

Page 30

MEGGER

®

Guide de l’utilisateur

M U LTIMÈTRES D’ISOLAT I O N

MEGGER BMM2500

Page 31

CONTENU

30

Les symboles utilisés

sur l’instrument sont:

Attention, risque de

décharge électrique.

Attention, se reporter au

guide de l’utilisateur.

Equipement protégé dans

son ensemble par une double

isolation (Classe II).

Equipement conforme aux

Directives européennes en vigueur.

Equipement à ne

pas raccorder à des

installations >500V.

>500V

Avertissements de Securite 31

Description Generale 32

Fonctionnement 34

Tests de Continuité 37

Alarme de Continuité 38

Tests en Millivolts 39

Tests de Capacitance 40

Tests en Milliampères 41

Stocker les Rèsultats 41

Consignation de Donneés 45

Modes de Configuration 47

Specifications 51

Reparations et Garantie 56

Page 32

31

AVERTISSEMENTS DE SECURITE

★ Les avertissements et précautions de sécurité doivent être lues et comprises avant que

l’instrument soit utilisé. Ils doivent être suivis pendant l’utilisation.

★ L’alimentation du circuit testé doit être coupée et il doit être isolé avant que les connexions

soient faites, sauf pour les mesures de tension.

★ Les connexions de circuit ne doivent pas être touchées pendant un test.

★ Après les tests d’isolation, il faut laisser les circuits à condensateurs se décharger avec de

déconnecter les fils de tests.

★ L’avertissement de circuit sous tension et le déchargement automatique sont des

caractéristiques supplémentaires et ne devront pas être considérés comme des substituts à des

pratiques normales de travail en sécurité.

★ Les fusibles de remplacement doivent être du bon type et de la bonne résistance. Si l’on installe

des fusibles de résistance incorrecte, ceci causera l’endommagement de l’instrument en cas de

surcharge.

★ Les fils de test, ainsi que les pinces crocodile, doivent être en bon état, propres et de pas

présenter une isolation fendue ou cassée.

★ Les autorités de sécurité britanniques recommandent l’utilisation de fils de tests pour la mesure

de tension sur des systèmes à haute énergie.

REMARQUE

LES INSTRUMENTS DOIVENT SEULEMENT ÊTRE UTILISÉS PAR DES PERSONNES FORMÉES CONVENABLEMENT ET COMPÉTENTES.

NOUS RAPPELONS AUX UTILISATEURS DE L’ÉQUIPEMENT ET/OU À LEURS EMPLOYEURS QUE LES LOIS SUR LA SANTÉ ET LA

SÉCURITÉ EXIGENT QU’ILS EFFECTUENT DES ÉVALUATIONS DE RISQUE VALIDES DE TOUT MATÉRIEL ÉLECTRIQUE AFIN

D’IDENTIFIER TOUTE SOURCE POTENTIELLE D’UN DANGER ÉLECTRIQUE ET DE RISQUE DE BLESSURE D’ORIGINE ÉLECTRIQUE

TELLE QUE LES COURT-CIRCUITS. LÀ OÙ LES ÉTUDES MONTRENT QUE LE RISQUE EST SIGNIFICATIF, ALORS LES FILS DE TESTS À

FUSIBLES CONFORMÉMENT À LA NOTE DE RECOMMANDATION HSE GS38 SUR L’ “EQUIPEMENT DE TEST ÉLECTRIQUE POUR UNE

UTILISATION PAR DES ÉLECTRICIENS” DOIVENT ÊTRE UTILISÉS.

Page 33

DESCRIPTION GENERALE

32

Les instruments de la série BMM2500 MEGGER

sont des testeurs de continuité et d’isolation

alimentés par batteries, avec une capacité de

mesure d’une continuité de 0,01Ω à une isolation

de 200GΩ.

Présentant des fonctions multi-voltage, les

instruments utilisent pleinement la technologie des

microprocesseurs et un grand écran à cristaux

liquides associant les affichages analogique et

numérique. L’affichage analogique a l’avantage

d’indiquer des tendances et des variations de

mesures, tandis que l’affichage numérique fournit

des résultats directs précis. L’écran est à fond

lumineux, ce qui donne une visibilité claire même

dans des conditions de basse luminosité.

Les instruments de la série BMM2500 ont la

capacité unique de pouvoir mesurer des tensions à

une précision de 0,1mV. Ceci donne à l’utilisateur

la possibilité d’installer une large gamme de

transducteurs pour développer davantage les

capacités des instruments de la série BMM, par

exemple les mesures de température ou

d’humidité.

Un connecteur personnalisé sur le dessus de

l’instrument permet le recours à une sonde à

commutateur optionnelle MEGGER SP1 pour une

utilisation de sonde à deux mains.

Les gammes à 250V, 500V et 1000V peuvent être

utilisées pour tester des installations électriques

conformes aux normes britanniques BS7671

(Réglementation sur les installations électriques

IEEE, 16ème édition) IEC364 et HD384, dans la

m e s u re où chaque gamme a une intensité

minimum de 1mA aux valeurs de passage

minimales d’isolation définie dans ces documents.

La gamme à 100V (BMM2580) est idéale pour

tester les équipements de télécommunications qui

seraient endommagés par des tensions plus

élevées. La gamme à 50V (BMM2500) est utile

pour tester les équipements sensibles, tels que

des composants électroniques et des

périphériques informatiques.

Les instruments de la série BMM2500 ont une

fonction intensité qui per-met de mesurer jusqu’à

500mA. Ceci, associé aux gammes Ω, V et mV,

signifie que l’instrument peut être utilisé de

Page 34

33

m a n i è re réaliste dans des situations où,

auparavant, un multimètre aurait été nécessaire.

Pour des intensités plus élevées, un limiteur de

courant est disponible en option.

Les instruments de la série BMM2500 ont une

interface RS232 intégrée, et permettront le

stockage et le déchargement de résultats vers un

PC. Les instruments sont livrés avec le logiciel

nécessaire pour décharger les résultats et les

mettre en tableau. Le format de déchargement est

aussi compatible avec AVO PowerSuite, ce qui

permet aux instruments de faire partie d’un

système de certification et de tests intégré. Les

instruments de la série BMM2500 ont également la

capacité d’enregistrer les résultats sur un long laps

de temps de sorte qu’on peut réaliser des mesures

à long terme des systèmes.

Conçue suivant les normes IEC1010-1, la série

BMM2500 est protégée contre la connexion à une

alimentation de Catégorie III à 500V. Les

instruments ont une précision de base de ±2% à

20°C. Les instruments sont étanches et ne

prennent pas la poussière conformément à IP54.

Ceci facilite le maintien de la précision et assure

une fiabilité maximale dans des environnements

difficiles.

Page 35

FONCTIONNEMENT

34

Se reporter aux avertissements de

sécurité avant d’utiliser l’instrument.

Les tests sont automatiquement bloqués si:

• Une tension externe >25V est présente lorsque

l’équipement est mis dans toute position de la

gamme d’isolation.

• Une tension externe >10V est observée sur toutes

les autres gammes (sauf ARRET/V/mV/RCL).

La tension externe est indiquée sur l’écran et sur

des gammes d’isolation un signal sonore retentit si

on tente d’effectuer un test.

Avertissement de circuit sous tension

Lorsque l’on applique plus de 25V aux bornes dans

les gammes d’isolation, l’instrument devient par

défaut un voltmètre et émet un avertissement

s o n o re si un test est tenté. Dans toutes les autre s

positions du commutateur sauf A R R E T/V/m V/R C L ,

lorsque l’on applique plus de 10V le voltmètre par

défaut sera activé. Les tests sont bloqués.

Tests de tension sur des systèmes à haute énergie

Prêter une attention extrême lors de l’utilisation ou

de la mesure de tensions de plus de 30V,

p a r t i c u l i è rement dans des systèmes à haute

é n e rgie. Des fils de tests à fusibles sont

disponibles en tant qu’accessoires optionnels pour

des situations locales dans lesquelles une

protection plus élevée est nécessaire.

Arrêt automatique

Pour préserver la durée de vie des batteries, un

arrêt automatique (précédé d’une série de

tonalités) se déclenche après environ 10 minutes

d’inactivité de l’instrument en mode isolation, 5

minutes sur toutes les autres gammes. Si

l’instrument est allumé en appuyant sur la touche

XXXXX, la période avant l’arrêt automatique est

prolongée de 60 minutes. Pour rallumer après un

Arrêt automatique, sélectionner ARRET suivi de la

position du commutateur nécessaire.

R e m a r q u e : Nous recommandons que l’instrument

soit mis en position Arrêt lorsqu’il n’est pas en serv i c e .

Fond éclairé

L’éclairage en fond est activé en appuyant sur la

touche XXXX .

Le fond éclairé fond restera allumé

environ une minute avant de s’éteindre automatiquement

pour préserver la durée de vie de la batterie. Il est

également possible de ré appuyer sur la touche

XXXXX.

∼

Page 36

35

Tests d’isolation

(MΩ) (voir fig. 1)

Les tests d’isolation

appliquent une

tension connue à un

c i rcuit testé et

m e s u rent l’intensité

de fuite qui en résulte.

Le circuit testé doit

ê t re complètement

d é s a c t i v é et i s o l é

avec que les

connexions de tests

soient faites.

Les tests d’isolation ne sont lancés que lorsque l’on

appuie sur le bouton T E S T.

1. Placer le commutateur de gamme sur la

tension de test nécessaire.

2. Connecter les fils de test, d’abord à l’instrument,

et ensuite à l’élément isolé à tester.

3. Appuyer sur le bouton TEST pour activer la

tension de test, relever la mesure lue.

4. Relâcher le bouton de TEST à la fin du test. La

dernière lecture restera sur l’écran.

5. Tous les circuits à condensateurs charg é s

pendant un test se décharg e ro n t

automatiquement. Si des tensions significatives

persistent, l’alarme de tension se déclenchera et

les tensions relevées s’aff i c h e ro n t .

6. R e t i rer les fils de test seulement lorsque

aucune tension n’est indiquée.

Blocage du Bouton de tests (ltb)

Lorsque l’on souhaite effectuer un long test

d’isolation, le test peut être “bloqué” en appuyant sur

la touche X X X X X tout en maintenant le bouton de

test enfoncé. L’ a v e r t i s s e m e n t apparaîtra sur

l’écran et les deux boutons pourront être re l â c h é s

pendant que le test se poursuit. Appuyer sur le

bouton de test une fois de plus terminera le test.

Remarque: Il y a un court délai lors de la première

utilisation de la gamme ‘1000V’, à chaque fois que

la gamme est sélectionnée. Ceci vise à d’empêcher

l’application accidentelle d’1KV.

La gamme MΩ présente un affichage d’intensité de

fuite. L’intensité de fuite est la valeur du courant

qui circule pendant le test d’isolation. Pour

visualiser l’intensité de fuite, appuyer sur la touche

XXXX. Pour visualiser la résistance d’isolation,

FIG.1

∼

Page 37

36

appuyer de nouveau sur la touche XXXXX.

Bonne procédure pendant la réalisation de

tests d’isolations

Il faut faire attention lors de la prise de mesure s

s u p é r i e u res à quelques GΩ. Les fils doivent être pro p re s ,

secs et en bon état. Il faut aussi leur empêcher de

s ’ e n c h e v ê t re r. Nous recommandons également que la

sonde à commutateur SP1 ne soit pas utilisée, puisque

la précision pour des mesures à valeur élevée n’est pas

garantie. L’instrument devrait également être pro p re et

sec en apportant une attention particulière aux born e s .

Essayer également de réduire une fuite qui pourrait

donner des résultats erronés sur des éléments testés.

Tests de l’indice de polarisation

L’indice de polarisation (IP) est un terme appliqué au

rapport d’absorption diélectrique lorsque les valeurs de

résistance sont mesurées après 1 minute puis de

nouveau après 10 minutes. L’indice de polarisation est

alors la valeur de résistance après 10 minutes divisée par

la valeur de résistance après 1 minute. Le test peut être

e ffectué pour n’importe quelle tension. Des informations

plus détaillées sur les tests d’IP et l’analyse des valeurs

sont disponibles dans les publications intern a t i o n a l e s

AVO énumérées dans les pages d’accessoire s .

Déchargement automatique

Lorsque le bouton de TEST est relâché après un

test d’isolation (ou renfoncé si la fonction ltb est

activée), une charge de 200kΩ est automatiquement transférée à travers les bornes pour

d é c h a rger l’élément sous test. Toute tension

présente sera indiquée sur l’écran de sorte que le

déchargement puisse être contrôlé.

Caractéristiques normales de tension aux born e s

Page 38

37

Tests de continuité (Ω) (voir fig.2)

Les tests de continuité sont activés lorsque les sondes

e n t rent en contact à moins de quelques kΩ. Le test

fonctionne sans avoir besoin d’appuyer sur le bouton

T E S T. Lorsque les fils de test sont retirés, l’affichage se

maintient pendant quelques secondes puis est remis à

z é ro. Pour re t r ouver le dernier résultat, appuyer sur la

touche X X X X X. Cette gamme n’est pas adaptée aux tests

de diodes puisque le détecteur de contact automatique

ne sera pas activé lors de la connexion avec une diode.

1. Mettre le commutateur de sélection sur Ω.

2. Connecter les fils de tests.

3. Le test se déclenchera automatiquement.

4. Une fois que les sondes de tests sont

déconnectées, l’affichage se maintient

quelques secondes.

Mise à zéro de la résistance des fils de tests

La résistance des fils de tests peut être mise à zéro sur la

gamme de continuité (jusqu’à 9,99Ω). L’information de

mise à zéro est conservée dans la mémoire non-volatile et

sera donc sauvegardée lorsque l’instrument sera éteint.

1. Sélectionner la gamme continuité.

2. Court-circuiter les fils de test à travers un bon

conducteur en utilisant les poussoirs.

3. Lorsque la lecture sera stabilisée, appuyer sur

le bouton de T E S T. Le symbole de

compensation à zéro va apparaître.

4. Pour libérer la compensation du zéro, appuyer

de nouveau sur le bouton TEST.

La gamme de continuité comprend une fonction de

blocage de gamme. Pour BLOQUER la gamme de

continuité, appuyer sur la touche X X X X X, le

symbole de BLOCAGE X va apparaître. Pour faire

défiler les gammes disponibles, appuyer sur la

FIG.2

Page 39

38

touche XXXXX. Pour désengager la fonction de

BLOCAGE, maintenir la touche XXXXX enfoncée.

Sources possibles d’erreur

Les mesures et les résultats peuvent être affectés

par:

• L’impédance de circuits en fonctionnement

connectés en parallèle

• L’impédance telle que celle des inducteurs qui

varie pendant les mesures

• Une mauvaise connexion au circuit testé.

Alarme de continuité

L’alarme de continuité sonne en continu lorsqu’elle

détecte moins de 5Ω. Des bips courts retentissent

pour des résistances inférieures à quelques kΩ ou

supérieures à 5Ω.

1. Placer le commutateur de sélection sur

2. Connecter les fils de tests.

Affichage: Signal sonore:

<5Ω bip continu

<3kΩ bip court

>3kΩ pas de signal

Tests de résistance (kΩ)

C’est un test à basse tension (5V) et à basse

intensité (25µA) pour un équipement électronique

sensible. Il fonctionne de la même manière que les

gammes de continuité.

1. Placer le commutateur de sélection sur kΩ.

2. Connecter les fils de tests.

3. Le test se lancera automatiquement.

La gamme KΩ comprend une fonction de blocage

de gamme. Pour BLOQUER la gamme kΩ,

appuyer sur la touche X X X , le symbole de

BLOCAGE X apparaît. Pour faire défiler les

gammes disponibles, appuyer sur la touche

X X X X X. Pour désengager la fonction de

BLOCAGE, maintenir la touche XXXXX enfoncée.

La gamme de résistance est protégée par une

méthode à haute impédance, donc si l’instrument

est connecté à un circuit sous tension, le fusible ne

grillera pas comme sur les gammes d’isolation, de

continuité et de sonnerie. L’instrument indiquera

simplement la surtension appliquée.

Page 40

39

Tests de diode

Cette gamme peut également être utilisée pour

tester des diodes, la borne positive étant la source

du courant de test. Le symbole de diode apparaîtra

si la tension présente entre les bornes est dans les

limites de jonction du semi-conducteur. Les

caractéristiques ainsi que la petite intensité de test

et la large gamme de mesure (de 0,01KΩ à

10000kΩ) rendent la gamme de résistance très

utile pour des tests à des fins générales.

Tests de tension (V)

Si un courant alternatif ou continu de >1V est

observé aux bornes, la tension mesurée est

indiquée sur l’écran. L’ a ffichage de tension

fonctionnera conformément aux spécifications

même si le fusible grille. Si le fonctionnement du

voltmètre est en question, tester le voltmètre sur

une source connue.

1. Mettre le commutateur de sélection sur V.

2. Connecter les fils de tests.

3. Après un bref instant de mise au point, la

lecture apparaîtra automatiquement.

Pour visualiser la fréquence du courant alternatif

en cours de mesure, appuyer sur la touche XXXXX.

La fréquence s’affichera dans la fourchette 16Hz460Hz. Pour visualiser la tension du courant

alternatif appuyer sur la touche XXXX de nouveau.

Tests en millivolts (mV)

La tension de courant alternatif ou continu est

indiquée sur l’écran.

1. Placer le commutateur de sélection sur mV.

2. Sélectionner mV c.a ou c.c en utilisant la

touche XXXXX.

3. Connecter les fils de tests.

4. Après un bref instant de mise au point, la

lecture apparaîtra automatiquement.

Remarque: L’avertissement de circuit sous tension

ne fonctionne pas sur la gamme de mV.

Mise à zéro des mV en courant continu (pas de

fonction de mise à zéro des mV en courant

alternatif)

Pour re m e t t re la gamme de mV en courant continu à

z é ro, raccorder les fils ensemble dans la position mV

courant continu, attendre que la lecture s’établisse

puis appuyer sur le bouton T E S T. On peut re m e t t re

à zéro jusqu’à 9,9mV sur la gamme de mV en

courant continu. Le symbole X X X X X apparaîtra pour

∼

Page 41

40

indiquer que le zéro a été réglé.

1. Sélectionner la gamme de mV en courant

continu.

2. Raccorder les fils de tests ensemble.

3. Lorsque l’affichage s’est stabilisé, appuyer sur

le bouton de T E S T. Le symbole de

compensation du zéro apparaîtra.

4. Pour libérer la compensation du zéro, appuyer

sur le bouton TEST.

Pour visualiser la fréquence du courant alternatif mV

mesuré, appuyer sur la touche X X X X X. La fréquence

sera affichée dans la fourchette 16Hz-460Hz. Pour

visualiser les mV du courant alternatif, appuyer de

nouveau sur la touche X X X X X. Pour des entrées

i n f é r i e u res à 10mV, la fréquence ne s’affiche pas.

Tests de capacitance (uF)

(seulement BMM2580)

La capacitance mesurée est indiquée sur l’écran.

1. Placer le commutateur de sélection sur uF.

2. Connecter les fils de tests au circuit testé.

3. Après un bref instant de mise au point, la

lecture apparaîtra automatiquement.

Mise à zéro de uF

Pour mettre la gamme uF à zéro, déconnecter les

fils, attendre que l’affichage se stabilise et appuyer

sur le bouton de T E S T. Jusqu’à 10,0uF peuvent être

mis à zéro sur la gamme uF. Le symbole

s ’ a ffichera pour indiquer que le zéro a été réglé.

1. Sélectionner la gamme uF.

2. Déconnecter les fils de tests du circuit testé.

3. Une fois l’affichage stabilisé, appuyer sur le

bouton de T E S T. Le symbole de

compensation du zéro apparaîtra.

4. Pour libérer la compensation du zéro, appuyer

de nouveau sur le bouton de TEST.

La gamme est adaptée aux tests de composants

d i s c rets et de lignes de signaux courts à niveau

d ’ i n t e r f é rences faible. Si des condensateurs

é l e c t rolytiques sont testés, le fil rouge doit être

connecté à +ve sur le condensateur. La gamme n’est

pas adaptée à la vérification de capacitance de

lignes de signaux soumises à des niveaux

d ’ i n t e r f é rence en courant alternatif élevés.

Lorsque le test commence – – – s’affiche sur

l’écran, s’il y a un bruit excessif, ce symbole

Page 42

41

restera ou clignotera pour indiquer qu’il y a trop de

bruit pour pouvoir atteindre un résultat.

Tests en milliampères (mA)

En raison de la faible impédance de sourc e

associée à la mesure de d’intensité, ce test a une

fonction supplémentaire, assurant que quand vous

entrez pour la première fois dans la gamme, le

voltmètre par défaut est visible. Les tests sont

bloqués si l’on trouve plus de 25V aux bornes.

Pour commencer les tests, il faut appuyer sur le

bouton de TEST et le maintenir enfoncé pendant

environ 2 secondes pour activer la gamme mA.

Une fois activé, le bouton de TEST ne doit plus

obligatoirement être utilisé et la valeur mesurée

s ’ a ffichera automatiquement. Pour passer de

l’affichage des courants alternatifs aux courants

continus, appuyer sur la touche XXXXX.

1. Placer le commutateur de sélection sur mA.

2. Connecter les fils de tests.

3. Appuyer sur et maintenir enfoncé le bouton de

TEST pendant environ 2 secondes.

4. Sélectionner les mA soit en c.a. soit en c.c.

avec la touche XXXXX.

5. Après un bref instant de mise au point, la

lecture apparaîtra automatiquement.

Pour visualiser la fréquence du courant alternatif

mesuré en mA, appuyer sur la touche XXXXX. La

fréquence s’affichera dans la fourchette 16Hz460Hz. Pour visualiser les mA en courant alternatif

appuyer de nouveau sur la touche XXXXX. Pour

des entrées inférieures à 10mA, la fréquence n’est

pas affichée.

Stocker les résultats en MΩ et Ω (RCL)

Après un test d’isolation ou de continuité, le résultat

est affiché sur l’écran, il peut être sauvegardé avec

des informations supplémentaires. Un numéro de

c i rcuit (de 1 à 99) peut être attribué et les circ u i t s

peuvent être groupés en utilisant la fonction de

tableau de distribution. De cette façon, lors d’un

t é l é c h a rgement vers AVO PowerSuite, les résultats

peuvent facilement être divisés en plusieurs

p rogrammes de tests diff é rents. Lorsque les

résultats sont affichés ou imprimés, un changement

de tableau de distribution est indiqué.

Changement de tableaux de distribution (TD)

Avant un test, vous pouvez modifier le numéro de

tableau de distribution de la façon suivante:

∼

∼

Page 43

42

1. Tourner le sélecteur rotatif sur la position RCL.

Le code rcl s’affiche.

2. Appuyer sur la touche XXXXX. Le code TD

actuellement sélectionné s’affiche, par

exemple 01.

3 . Ce numéro peut être modifié à l’aide des

touches X X X X X et X X X X X pour afficher le

n u m é ro voulu.

4. Le numéro peut être confirmé en appuyant sur

la touche XXXXX, ou annulé en appuyant sur le

bouton QUITTER (EXIT).

5. Lorsque le numéro est sauvegardé le code Std

s ’ a ffiche (accompagné par un long signal

sonore) confirmant que les données ont été

sauvegardées.

Les tests peuvent maintenant continuer avec tous

les résultants associés par la suite avec le nouveau

numéro de tableau de distribution.

Stocker un résultat

A l’achèvement et à l’affichage de la mesure:

1. Appuyer sur et maintenir enfoncée la touche

XXXXX. Après environ 1 seconde, un signal

sonore retentira. Aussi bien pour la continuité

que pour l’isolation, un code, tel que donné

dans le tableau ci-après s’affiche. Ce code est

utilisé pour décrire le circuit testé et peut de ce

fait être modifié par l’utilisateur.

2. Le code peut être modifié en appuyant sur les

touches XXXXX et XXXXX.

3. Le code peut être confirmé en appuyant sur la

touche XXXXX, ou annulé en appuyant sur le

bouton QUITTER.

4. Le numéro de circuit s’affiche sous la forme de

2 chiffres par exemple c01.

Remarque: De nombreux tests différents peuvent

être sauvegardés sous le même numéro de circuit.

5. Le numéro de circuit peut être modifié en

appuyant sur les touches XXXXX et XXXXX

pour afficher le numéro qui convient.

6. Le numéro peut être confirmé et les résultats

peuvent être sauvegardés en appuyant sur la

touche X X X X X, ou la pro c é d u re peut être

annulée en appuyant sur le bouton QUITTER.

7. Lorsque le résultat est sauvegardé, le code Std

s ’ a ffiche (accompagné d’un long signal

sonore) confirmant que les données ont été

s a u v e g a rdées. L’ a ffichage PLEIN (FULL)

indique qu’il n’y a plus de place pour stocker

∼

∼

∼

Page 44

43

les tests. Environ 300 résultats peuvent être

sauvegardés dans la mémoire.

Tests à sauvegarder Code d’affichage Signification

Continuité r1 Circuit CCT simple

r2 Circuit CCT simple

rr1 Circuit en anneau CCT

rr2 Circuit en anneau CCT

rrn Circuit en anneau CCT

r12 Circuit CCT de retour R1+R2

Isolation n_e N-PE (e=terre)

L_n L-N

L_E L-PE

L_L L-L

Effacer toutes les données

1. Déplacer le commutateur de sélection rotatif

en position RCL. Le code rcl s’affiche.

2. Appuyer sur les touches XXXXX et XXXXX en

même temps. Le code dEL s’affiche.

3. Confirmer que les données ne sont plus

nécessaires en appuyant sur la touche XXXXX

ou annuler en appuyant sur toute autre touche.

Le code rcl s’affiche.

Imprimer les résultats (voir modes de configuration)

1. Connecter l’imprimante et l’instrument avec un

câble d’imprimante en série.

2. Déplacer le commutateur de sélection rotatif

sur la position RCL. Le code rcl s’affiche.

3. Commencer l’impression en appuyant sur le

bouton de TEST. Annuler n’importe quand en

appuyant et en maintenant enfoncée la touche

XXXXX. Le code rcl s’affiche.

Retrouver des résultats sauvegardés

Il est possible de visualiser des résultats de tests

précédemment enregistrés en déplaçant le

commutateur rotatif sur la position RCL.

1. Déplacer le commutateur de sélection rotatif

sur la position RCL. Le code rcl s’affiche.

2. Sélectionner le tableau de distribution

nécessaire en appuyant sur les touches XXXXX

et X X X X X. Les numéros des tableaux de

distribution sont présentés dans l’ordre suivant

lequel les résultats ont été sauvegardés. Un

long signal sonore retentit lorsque l’on atteint

la fin de la liste.

3 . Appuyer sur la touche X X X X X pour lister les

n u m é ros de circuits utilisés dans le tableau de

distribution actuellement affiché ou appuyer sur

le bouton QUITTER pour re t o u rner à l’écran RCL.

4. Sélectionner le numéro de circuit en appuyant

∼

∼

Page 45

44

sur les touches XXXXX et XXXXX. Les numéros

de circuits sont présentés dans l’ordre suivant

lequel les résultats ont été sauvegardés. Un

long signal sonore retentit lorsque la la fin de la

liste est atteinte.

5. Appuyer sur le bouton QUITTER pour retourner

à l’écran de sélection des tableaux de

distribution, ou appuyer sur la touche XXXXX

pour afficher les codes de tests enregistrés.

Les codes suivants sont utilisés pour identifier

les résultats des tests:

Code Signification

Con Test de continuité

InS Test d’isolation

6. Sélectionner le test voulu en appuyant sur les

touches X X X X X et X X X X X. Les tests sont

présentés dans l’ord re ci-dessus. Un long

signal sonore retentit lorsque vous atteignez la

fin de la liste.

7. Appuyer sur le bouton QUITTER pour retourner

sur l’écran de sélection du numéro de circuit,

ou appuyer sur la touche XXXXX pour faire

défiler les résultats de tests stockés, ainsi que

toute autre information de connexion.

Télécharger sur un PC

La série BMM a été conçue pour être utilisée avec

AVO Powersuite pour Windows qui acceptera les

résultats de tests et permettra la production de

certificats divers, parmi lesquels l’Inspection

périodique et le certificat d’Achèvement. Le CD fourn i

avec l’instrument contient le programme AV O .

Dowload Manager. Ceci permet le téléchargement de

résultats stockés et des données enregistrées vers un

PC, la création de rapports de tests simples qui

peuvent être exportés vers d’autres applications et

utilisés pour créer des sauvegardes ou des rapports

et certificats. Ce gestionnaire de télécharg e m e n t

permet également de faire certaines modifications de

v o t r e instrument telles que le changement de la

deuxième langue des impressions. Le CD contient un

guide d’utilisation donnant des instructions complètes

sur l’utilisation du gestionnaire de télécharg e m e n t .

Configuration du câble

Normalement, un fil à double prise femelle “D” à 9

voies adapté à la connexion de deux PC est

nécessaire. Ce câble ne devrait pas dépasser 3m

de long. Un câble est disponible comme

accessoire ou peut être fabriqué comme suit:

∼

∼

Page 46

45

Consignation de données

La consignation des données signifie l’enre g i s t re m e n t

automatique de mesures à intervalles réguliers sur

une longue période, pour une visualisation ultérieure .

Les résultats sont conservés dans une mémoire

i n t e rne du testeur, mais ne peuvent être extraits que

par un PC connecté à travers le port RS232.

Comparaison entre stockage et consignation

des données.

Par stockage, nous entendons la sauvegarde en

mémoire des résultats un par un au fur et à mesure

que les tests sont effectués. Chaque résultat doit

être individuellement sauvegardé après avoir été

associé avec des données de connexion

sélectionnables par l’utilisateur et un numéro de

circuit, en même temps que le numéro de tableau

de distribution choisi précédemment. Cependant,

lorsque la consignation de données est en cours,

les résultats sont sauvegardés automatiquement et

de manière continue dans la mémoire et aucune

autre information n’est enregistrée.

Le stockage et la consignation sont des fonctions

r é c i p roquement exclusives. L’instrument ne peut être

réglé pour effectuer les deux opérations en un même

instant donné. Si un résultat est stocké, alors toutes

les données consignées sont effacées, et vice versa.

De plus, seul un ensemble de données consignées

peut être maintenu en mémoire. Une nouvelle

session de consignation effacera les données

précédentes. Ceci diff è re du comportement de la

fonction de stockage, dans laquelle les données des

tests successifs s’accumulent dans la mémoire

jusqu’à ce qu’elle soit pleine. Une autre diff é re n c e

e n t re le stockage et la consignation est que le

p remier s’applique seulement aux tests d’isolation et

de continuité, tandis que tous les types de mesure s

peuvent être consignés (à part la gamme d’alarme).

Commencer une session de consignation

Une fois que la consignation a été activée et que

l’intervalle a été défini, une session de

S i g n a l Testeur d’isolation ‘D’ à 9 voies ‘D’ à 25 voies

Rx 2 3 2

Tx 3 2 3

DSR 6 4 20

GND 5 5 7

Page 47

46

consignation de données peut commencer (voir

modes de configuration):