Page 1

BM5200

5 kV Digital Insulation Tester

USER MANUAL

MANUAL DEL USUARIO

M

MANUAL DO UTILIZADOR

Page 2

Page 3

CONTENTS

Safety warnings ............................................................................................................................................................................... 3

Symbols used on instrument ............................................................................................................................................................ 4

Cleaning ................................................................................................................................................................................... 4

General description .......................................................................................................................................................................... 5

Insulation resistance test modes ................................................................................................................................................ 5

Automatic discharge ................................................................................................................................................................. 5

Lead set .................................................................................................................................................................................... 5

Instrument power ..................................................................................................................................................................... 5

Instrument safety ...................................................................................................................................................................... 5

Preparations for use ......................................................................................................................................................................... 6

Operating instructions ...................................................................................................................................................................... 7

Instrument controls and indicators ............................................................................................................................................ 7

Use of guard terminal (G) .......................................................................................................................................................... 8

Setup procedure ....................................................................................................................................................................... 8

Polarisation index (PI) ................................................................................................................................................................ 9

Timed insulation resistance ........................................................................................................................................................ 9

Preventative maintenance ................................................................................................................................................................ 9

Battery replacement .................................................................................................................................................................. 9

Technical specifications .................................................................................................................................................................. 10

Repair and warranty ....................................................................................................................................................................... 11

MANUAL DEL USUARIO ................................................................................................................................................................. 13

MANUAL DO UTILIZADOR .............................................................................................................................................................. 24

2

Page 4

G SAFETY WARNINGS

Safety warning must be observed during use:

n The circuit under test must be switched off, deenergised, isolated and checked to be safe before insulation test connections are made. Make

sure the circuit is not reenergised whilst the instrument is connected.

n Circuit connections must not be touched during an insulation test.

n After completing a test, capacitive circuits must be completely discharged before disconnecting the test leads. Capacitive charges can be

lethal.

n Tested items should be firmly shorted out with a shorting link, after discharge, until required for use. This is to guard against any stored

dielectric absorption charge subsequently being released thereby raising the voltage to potentially dangerous levels.

n The voltage indicator and automatic discharge features should be regarded as additional safety features and not a substitute for normal safe

working practice.

n It is rare, but in certain circumstances, breakdown of the circuit under test may cause the instrument to terminate the test in an uncontrolled

manner, possibly causing a loss of display while the circuit remains energised. In this event, the unit must be turned off and the circuit

discharged manually.

n Test leads, including crocodile clips, must be in good order, clean and with no broken or cracked insulation.

n The instrument should not be used if any part of it is damaged.

n Insulation testing in wet weather conditions might be hazardous. It is recommended that this instrument is not used in these circumstances.

If this is unavoidable, the user must take all necessary precautions.

n This instrument is not intrinsically safe and must not be used in hazardous atmospheres.

n If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

n Rechargeable batteries should not be used on this instrument.

NOTE

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS.

Users of this equipment and/or their employers are reminded that National Health and Safety Legislation requires them to carry out valid risk

assessments of all electrical work so as to identify potential sources of electrical danger and risk of electrical injury such as inadvertent short

circuits. Where the assessments show that the risk is significant then the use of fused test leads may be appropriate.

3

Page 5

Symbols used on this instrument

G Caution: refer to accompanying notes

F Caution: risk of electric shock

t Class II double insulated instrument

Do not dispose of in the waste stream

Equipment complies with current Australian C-Tick directives

+

Battery

Terms used in this manual

The word must is used to indicate that the instructions following should be followed under all circumstances. Failure to follow these

instructions could result in damage to the instrument and / or a hazard to the operator.

The word ‘should’ is used to indicate that the instructions indicate best practice.

Cleaning

Disconnect the instrument and wipe it with a clean cloth slightly damped with soapy water or Isopropyl alcohol (IPA).

4

Page 6

General description

BM5200 insulation tester has a digital and analogue arc display

designed for high voltage insulation resistance testing in the

maintenance and servicing of cables, rotating plant machinery,

transformers, switchgear and industrial installations.

DC insulation tests are performed at 250 V, 500 V, 1000 V, 2500

V and 5000 V. Insulation resistance measuring range is 100 kΩ to

1000 GΩ. Automatic discharge for capacitive circuits under test is

provided and decaying voltage displayed.

The guard terminal can be used to minimise the effects of surface

leakage and hence erroneous measurements when carrying out

insulation resistance tests.

Insulation resistance test modes

Three insulation resistance (IR) test modes are provided, (InS, PI, t)

and selected from any insulation range by pressing the left arrow

key depicting PI-t.

In insulation resistance test mode (InS) tests are initiated by pressing

and holding down the TEST button for two seconds. Once an

insulation test has initiated it will terminate on the next press of

the TEST button. The reading is held on screen until TEST is

pressed again or another range is selected.

A Polarisation Index (PI) mode performs a ratiometric test that

calculates the ratio of insulation resistance at ten minutes to

insulation resistance at one minute.

The timer (t) mode facilitates a single fixed duration IR test based

on the set time interval t.

5

Automatic discharge

For capacitive test objects the instrument will automatically discharge through an internal resistor and indicate voltage across

the terminals in the range 25 V to 600 V with higher voltages

indicated by ‘>600 V’. This feature will give decaying voltage

indication

following the testing of equipment possessing capacitance. When

the voltage indicator no longer shows it is safe for the user to

disconnect the test leads.

Lead set

Three recessed sockets are provided, and marked ‘+’, ‘-’ and ‘G’.

These have safety covers which open when the plugs are inserted.

When inserted into the sockets, the shrouded test lead plugs lock

into position. They are released by twisting the plug a quarter turn

and pulling out.

For this reason, only the test leads supplied or suitable Megger

replacement ones should be used.

Instrument power

The BM5200 is powered by eight 1.5 V IEC LR6/AA alkaline cells.

Rechargeable batteries should not be used on this instrument.

Instrument safety

Design safety features include:

n External voltage indication, AC or DC displayed.

n Load automatically discharged at the end of a test, and

decaying voltage displayed.

n Test leads can lock into the case to prevent accidental disconnection.

Page 7

Preparations for use

1. Unpack the shipping box and locate the BM5200 instrument,

carry case, test leads, batteries, quick start and user guides.

2. Ensure that the main range switch is in the OFF position.

3. Locate the battery compartment and open it using a PZ2

pozidrive screwdriver.

4. Remove the battery module and insert the eight 1.5 VLR6/AA

alkaline cells ensuring correct orientation according to polarity.

5. Connect the battery module to the battery lead ensuring

correct polarity.

6. Replace battery module and battery cover into the case and

replace the two screws tightening by hand only.

7. As an initial check, without any leads connected, switch

the instrument on by turning the main range switch to any

position other than OFF. Ensure that the instrument display

responds. Switch off the instrument. If the instrument display

does not respond return t to step 2, repeat the process

and check all eight battery orientations are correct.

8. If the instrument still fails to respond use a voltmeter to check

battery module voltage which should be 12 V assuming all cells

are at their rated 1.5 V.

6

Page 8

Operating instructions

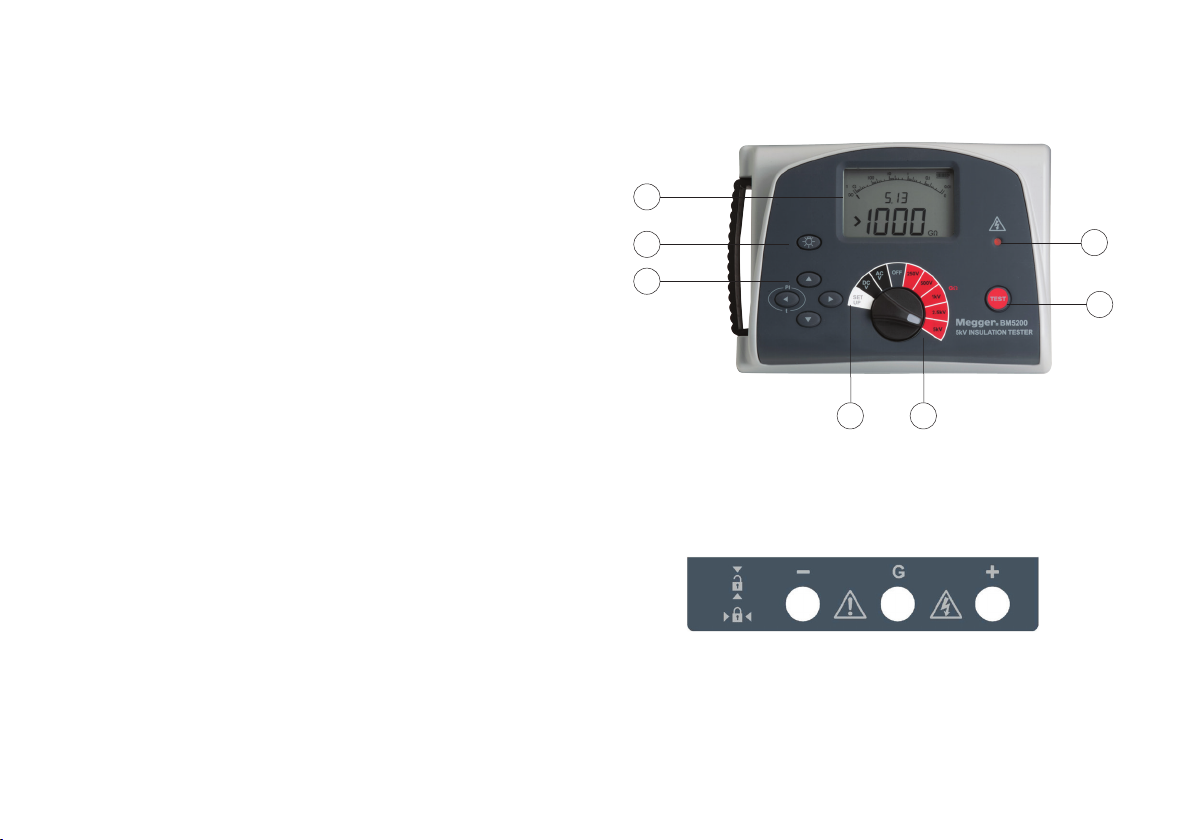

Instrument controls and indicators

1. Backlit LCD display with analogue arc and dual 3-digit display.

2. Backlight on/off switch

3. Four arrow buttons, PI-t function on left arrow button

4. Main range switch Setup functions plus AC and DC voltmeter

(25 V to 600 V)

5. Main range switch with DC insulation tests at 250 V, 500 V,

1000 V, 2500 V and 5000 V.

6. TEST button to initiate and terminate insulation tests

7. Warning High Voltage (HV) indicator

1

2

3

7

6

Before switching on the BM5200 the test leads should be

connected to the instrument.

There are three test terminals marked +, - and G. These terminals

are designed to accept only the test leads supplied. Shutters across

the terminals prevent accidental ingress of dirt and other objects.

Test leads lock in the terminals to prevent accidental removal

during a test, rotate the plug until the locking action is engaged.

Terminal plugs can be removed by rotating through a quarter turn.

At the end of a test ensure that the voltage has decreased to a

safe value, i.e. <50 V, before removing the test leads. Reactive

loads may take some time to dissipate stored energy through the

instrument’s internal discharge resistors.

7

4

5

The BM5200 is turned on by rotating the main range switch to

insulation test, voltage test or setup function.

The terminals are located on a panel to the rear of the instrument

and marked +, - and G meaning Guard terminal.

Page 9

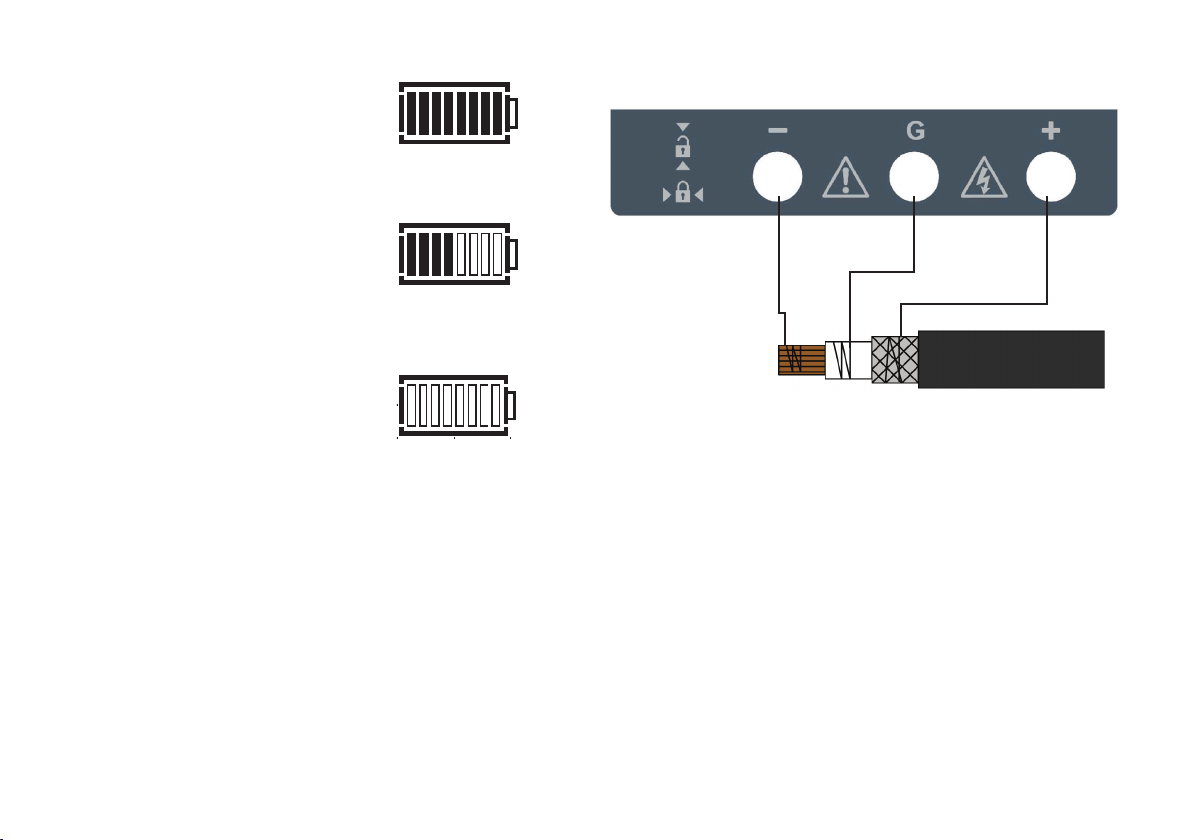

The battery level indicator is

located at the top right of the

display and contains four pairs of

segments depicting charge level.

Battery level indication of 50% of

battery life.

Battery level indication of a flat

battery.

Use of guard terminal (G)

For basic insulation resistance tests where there is little possibility

of surface leakage affecting the measurement, it is not necessary

to use the guard terminal i.e. if the insulator is clean and there

are unlikely to be any adverse current paths. However in cable

testing for example, there may be surface leakage paths across

the insulation between the bare cable and the external sheathing

due to the presence of moisture or dirt. To obtain an accurate

measurement, particularly at high testing voltages, a bare wire

may be bound tightly around the insulation and connected via the

third test lead to the guard terminal ‘G’.

As illustrated in the diagram, the guard terminal is at the same

potential as the negative terminal. Since the leakage resistance

is effectively in parallel with the resistance to be measured, the

use of the guard causes the current flowing through surface

leakage to be diverted from the measuring circuit. The instrument

therefore reads the leakage of the insulator, ignoring leakage

across its surface.

Setup procedure

The setup function is used to set the internal timer (t). Default

value is set at 1 minute and can be adjusted using the up and

down arrows. When the desired time setting is displayed the PI-t

(left

arrow) key is pressed and a beep confirms the new setting.

8

Page 10

Polarisation index (PI)

Polarisation Index (PI) test performs a test that calculates the

ratio of insulation resistance at ten minutes, IR

resistance at one minute, IR

indication of insulation polarisation when subjected to high

voltage DC. A high PI value indicates a high degree of insulation

polarisation and therefore good insulation condition. Generally the

PI value should be two or above.

Polarisation occurs at different rates ranging from minutes to

several hours which led the IEEE to create a ratiometric PI test. The

IEEE standard 43-2000, “Recommended Practice for Testing

Insulation Resistance of Rotating Machinery,” limits the use of PI

test on winding systems to those with IR

MΩ.

Timed insulation resistance

The timed IR test is a test that automatically terminates after a

user adjustable time (t). Users can select SETUP on the range

switch and adjust timer (t) using up and down arrow buttons to

set the desired time followed by a single press of the PI-t (left

arrow) button. Default time (t) is set at one minute because

IR1min is frequently referred to in international standards.

. This test provides a simple

1min

1min

to insulation

10 min

being less than 5000

Preventative maintenance

No user serviceable parts

There are no user serviceable parts in the BM5200 except for the

batteries.

If an instrument’s protection has been impaired it should not be

used, but sent for repair by suitably trained and qualified personnel.

The protection is likely to be impaired if for example, it shows

visible damage, fails to perform the intended measurements,

has been subjected to prolonged storage under unfavourable

conditions, or has been subjected to severe transport stresses.

Battery replacement

G WARNING

The battery contacts are not isolated from the test leads.

Remove the test leads from the instrument before opening

the battery compartment.

The cells are housed in a battery compartment in the base of the

instrument. To change the cells, use a PZ2 pozidrive screwdriver to

remove the battery cover securing screws and lift off the battery

compartment cover. Observing the correct polarity as marked on

the battery housing, install 8 replacement IEC LR6 (AA) cells.

Replace and secure the battery compartment cover on completion.

9

Page 11

Technical specifications

The following specifications apply at 20 °C unless otherwise

stated:

Electrical specifications

Insulation range 0.1 MΩ to 1 TΩ

Nominal test voltages 250 V, 500 V, 1000 V, 2500 V,

5000 V

Terminal voltage accuracy <1000 V 0 to 10% of nominal

test voltage

≥100 V 0 to +5% of nominal

test voltage

Insulation accuracy Up to 1 GΩ: All ranges ±5%

±2 digits

Over 1 GΩ:

5000 V ±5% ±0.04% per GΩ

2500 V ±5% ±0.08% per GΩ

1000 V ±5% ±0.2% per GΩ

500 V ±5% ±0.4% per GΩ

250 V ±5% ±0.8% per GΩ

Short circuit current 1.4 mA ±0.5 mA

Maximum load capacitance 5 μF

Voltmeter accuracy (DC or AC) 3% ±3 V

Frequency measurement 45 Hz to 65 Hz

Frequency accuracy ±2 Hz

Voltage range (DC or AC) 25 to 600 V AC or DC

Power supply 8 x LR6/AA batteries

Battery life 5 hours @ 5 kV into 100 MΩ

with AA Alkaline LR6

Guard 2% error guarding 5 MΩ leakage

on 100 MΩ load

Environmental specifications

Operating temperature range -20 ºC to +55 ºC

Operating humidity 90% RH, 0 ºC - 40 ºC

70% RH, 40 ºC - 55 ºC

Storage temperature -30 ºC to +65 ºC

Insulation protection IP40

Maximum Altitude 2000 m

Service error with stated environmental limits is twice intrinsic

error

Safety protection

Insulation CAT III 600 V - applicable standard IEC 61010-1:2001

Measurement Category III is applicable to test and measuring

circuits connected to the distribution part of the building’s lowvoltage mains installation. This part of the installation is expected

to have a minimum of two levels of over-current protective devices

between the transformer and possible connecting points.

EMC

The product conforms to IEC 61326-1:2005

Dimensions (W x H x D) 220 mm x 115 mm x 163 mm

Weight 1.45 kg

10

Page 12

Accessories

Replacement 3m x 3 leadset 1002-531

Repair and warranty

This instrument is not repairable. Should the instrument fail during the warranty period the instrument will be replaced by Megger.

New instruments are Guaranteed for 1 Year from the date of purchase by the User.

Note: Any unauthorised prior repair or adjustment will automatically invalidate the warranty.

This product contains no repairable parts and if defective it should be returned to your supplier in its original packaging or packed so

that it is protected from damage during transit.

11

Page 13

M

BM5200

Probador Digital de Aislamiento 5 kV

MANUAL DEL USUARIO

12

Page 14

CONTENIDO

Advertencias de seguridad ........................................................................................................................................................... 14

Símbolos usados en el instrumento ............................................................................................................................................... 15

Limpieza ................................................................................................................................................................................ 15

Descripción general ....................................................................................................................................................................... 16

Modos de prueba de la resistencia de aislamiento .................................................................................................................. 16

Descarga automática .............................................................................................................................................................. 16

Juego de cables ...................................................................................................................................................................... 16

Potencia del instrumento ........................................................................................................................................................ 16

Seguridad del instrumento .................................................................................................................................................... 17

Instrucciones de operación ............................................................................................................................................................ 17

Controles e indicadores del instrumento .......................................................................................................................................18

Instrument controls and indicators .......................................................................................................................................... 18

Uso del terminal de protección (G) .......................................................................................................................................... 19

Procedimiento de configuración ........................................................................................................................................................... 19

Índice de polarización (PI) ....................................................................................................................................................... 20

Resistencia sincronizada de aislamiento .................................................................................................................................. 20

Mantenimiento preventivo ............................................................................................................................................................ 20

Reemplazo de la batería ......................................................................................................................................................... 20

Especificación técnica ................................................................................................................................................................... 21

Reparación y garantía .................................................................................................................................................................. 22

13

Page 15

G ADVERTENCIAS DE SEGURIDAD

Advertencias de seguridad deben ser observadas durante el uso:

n El circuito bajo prueba debe ser apagado, descargado, aislado y verificado para la seguridad antes que las conexiones de la prueba sean hechas.

Asegúrese que el circuito no esté recargado mientras el instrumento sea conectado.

n Las conexiones del circuito no deben ser tocadas durante la prueba de aislamiento.

n Despues de completar la prueba, los circuitos de capacitivos deben estar completamente descargados antes de desconectar los cables de prueba. Las

cargas capacitivas puede ser mortales.

n Los objetos probados deben estar firmemente en corto, después de su descarga, hasta ser requeridos para su uso. Esto es para proteger contra

cualquier carga eléctrica almacenada que sea liberada posteriormente levantando el voltaje a niveles potencialmente peligrosos.

n El indicador de voltaje y las características automáticas de descarga deben ser considerados como característica adicional de seguridad y no un

sustituto de la práctica de seguridad laboral.

n Es raro, pero en ciertas circunstancias, una avería del circuito bajo prueba podría causar que el instrumento termine la prueba de una manera

incontrolable, causando posiblemente una pérdida de pantalla mientras el circuito se mantiene cargándose. En este evento, la unidad debe ser

apagada y el circuito debe ser cargado manualmente.

n Los cables de prueba, incluyendo las breves, deben estar en buena condición, limpios y sin un aislamiento roto o rajado.

n El instrumento no debe ser usado si alguna parte está dañada.

n La prueba de aislamiento en condiciones climáticas húmedas podría ser peligrosa. Se recomienda que este instrumento no sea usado en estas

circunstancias. Si esto es inevitable, el usuario debe tomar todas las precauciones necesarias.

n Este instrumento no es intrínsicamente seguro y no debe ser usado en atmósferas peligrosas.

n Si este equipo es usado en una manera no especificada por el fabricante, la protección proporcionada por el equipo puede ser perjudicada.

n Las baterías recargables no deben ser usadas en este instrumento.

NOTA

EL INSTRUMENTO DEBE SER USADO SOLO POR PERSONAS CONVENIENTEMENTE ENTRENADAS Y COMPETENTES.

A los usuarios de este equipo y/o a sus empleados se les recuerda que la legislación nacional de salud y seguridad requiere

que ellos realicen evaluaciones válidas de riesgos de todo trabajo eléctrico para identificar las fuentes potenciales de un

peligro eléctrico y el riesgo de lesiones eléctricas tales como cortocircuitos inadvertidos. Cuando las evaluaciones muestren

que el riesgo es significante entonces el uso conjunto de los cables de prueba podría ser apropiado.

14

Page 16

Símbolos usados en este instrumento

G Advertencia: refiérase a las notas que se incluyen

F Advertencia: riesgo de un eléctrico

t Clase II instrumento de doble aislamiento

No desheche en el servicio de desperdicios

El equipo cumple con las presentes directivas C-Tick australianas

+

Batería

Términos usados en este manual

La palabra debe se usa para indicar que las instrucciones que siguen deben ser seguidas bajo todas circunstancias. La falta de seguir

estas instrucciones podría resultar en daño al instrumento y/o un peligro al operador.

La palabra “puede” es usada para indicar que las instrucciones indican la mejor practica.

Limpieza

Desconecte el instrumento y límpielo con un paño limpio ligeramente húmedo con agua jabonosa o alcohol isopropilo (IPA).

15

Page 17

Descripción general

El probador de aislamiento BM5200 tiene una forma de arco

digital y análogo diseñado para la prueba de la resistencia de

aislamiento de alto voltaje en el mantenimiento y servicio de cables,

maquinaria giratoria de planta, transformadores, dispositivo de

distribución e instalaciones industriales.

Las pruebas de aislamiento DC son realizados a 250 V, 500 V,

1000 V, 2500 V y 5000 V. El rango de medición de la resistencia

de aislamiento es de 100 kQ a 1000 GΩ. La descarga automática

para los circuitos capacitivos bajo prueba se provee y la caída de

voltaje.

La terminal de protección puede ser usada para minimizar los

efectos de la fuga superficial y las medidas erróneas cuando se

realicen pruebas de resistencia de aislamiento.

Modos de prueba de la resistencia de aislamiento

Se proporcionan tres modos de prueba de la resistencia de

aislamiento, (InS, PI, t) y seleccionados de cualquier rango de

aislamiento al presionar la flecha izquierda con PI-t.

En los modos de prueba de la resistencia de aislamiento, las

pruebas son iniciadas al presionar y sostener el boton TEST

(prueba) por dos segundos. Una vez que la prueba de aislamiento

se ha iniciado, se terminara al presionarse nuevamente el botón

TEST (prueba). La lectura se mantiene en la pantalla hasta que el

botón TEST es presionado otra vez u otro rango sea seleccionado.

El modo del índice de polarización (PI) realiza una prueba

radiométrica que calcula la tasa de resistencia de aislamiento a los

diez minutos a la resistencia de aislamiento a un minuto.

El modo sincronizado (t) facilita una prueba única de duración fija

IR basado en un intervalo de tiempo fijo t.

Descarga automática

Para los objetos de prueba capacitiva, el instrumento descargará

automáticamente a través de un resistor interno e indicará el

voltaje a través de los terminales en el rango de 25 V a 600 V con

voltajes altos indicados por ‘>600 V’. Esta característica dará una

indicación de una caída de voltaje siguiendo la prueba del equipo

que posee capacitancia. Cuando el indicador de voltaje ya no

se muestra, es seguro para el usuario desconectar los cables de

prueba.

Juego de cables

Se suministra tres zócalos con entradas y marcados ‘+’, ‘-‘ y ‘G’.

Estos tienen tapas de seguridad que se abren cuando los enchufes

se introducen. Cuando se introducen en los zócalos, los enchufes

cubiertos de los cables de prueba se aseguran en posición. Se

sueltan al girar un cuarto el enchufe y jalar.

Por esta razón, solo los cables de prueba suministrados o repuestos

convenientes de Megger deberán ser usados.

16

Page 18

Potencia del instrumento

El BM5200 es operado con ocho baterías alkalinas 1.5 V IEC

LR6/AA

Seguridad del instrumento

Las características del diseño de seguridad incluyen:

n Indicador externo del voltaje, AC o DC en pantalla.

n Activa automáticamente la descarga al final de la prueba y la

caída de voltaje.

n Los cables de prueba pueden asegurarse en el estuche para

prevenir una desconexion accidental.

Preparación para su uso

1. Abra el paquete y ubique el instrumento BM5200, el estuche,

los cables de prueba, baterías, y las guías del usuario y de

inicio.

2. Asegúrese que el interruptor principal esté en posición de

apagado.

3. Localice el compartimento de la batería y ábrala usando un

destornillador PZ2 pozidrive.

4. Retire el módulo de baterías e introduzca las ocho baterías

alka linas 1.5 VLR6/AA asegurando la orientación correcta de

acuerdo a su polaridad.

5. Conecte el módulo de baterías al cable de la batería asegu

rando la polaridad correcta.

6. Regrese el módulo de baterías y su cubierta dentro de su

estuche y ponga los dos tornillos ajustándolos solo con la

mano.

7. Como revisión inicial, sin los cables conectados, encienda el

instrumento girando el interruptor principal a cualquie

posición diferente a apagado. Asegúrese que la pantalla del

instrumento funcione. Apague el instrumento. Si la pantalla del

instrumento no responde, vuelva al paso 2, repita el proceso y

verifique que las orientaciones de las ocho baterías estén

correctas.

8. Si el instrumento todavía falla en responder use un voltímetro

para revisar el voltaje del módulo de baterías el cual debe ser

12 V asumiendo que todas las pilas estén a su nivel 1.5 V.

17

Page 19

Instrucciones de operación

Controles e indicadores del instrumento

1. Pantalla retroiluminada LCD con arco análogo y pantalla doble

de 3 dígitos.

2. Interruptor iluminado de encedido y apagado.

3. Cuatro botones de flechas, función PI-t en el botón con la

flecha a la izquierda

4. Funciones de instalación del interruptor principal más voltímetro

AC y DC (25 V a 600 V)

5. Interruptor principal con prueba de aislamiento DC a 250 V,

500 V, 1000 V, 2500 V y 5000 V.

6. Botón TEST para iniciar y terminar las pruebas de aislamiento.

7. Indicador de advertencia de alto voltaje (HV)

Antes de encender el BM5200 los cables de prueba deben estar

conectados al instrumento.

Hay tres terminales de pruebas marcadas +, - y G. Estos terminales

están diseñados para aceptar solo los cables de prueba suministradas.

Las protecciones de los terminales previenen el ingreso accidental de

polvo y otros objetos. El bloqueo de los conectores en los bornes

sirven para prevenir de extracciones accidentales durante una

prueba y se activan girando el tapón mediante una rotación a

través con un cuarto de vuelta.

Al final de una prueba debe asegurarse que la tensión ha

disminuido a un valor seguro, por ejemplo <50 V antes de retirar

los conectores. Las cargas reactivas pueden tardar cierto tiempo

en descargarse.

1

2

3

4

5

7

6

El BM5200 se enciende girando el interruptor principal a la prueba

de aislamiento, prueba de voltaje o función de iniciación.

Los bornes están localizados en la parte trasera del equipo y está

indicada con el signo + y -. El símbolo G significa borne protegido.

18

Page 20

El indicador del nivel de la batería está

localizado en la parte superior derecha

de la pantalla y contiene cuatro pares

de segmentos que muestran el nivel de

cargado.

La indicación del nivel de cargado a un

50% de la vida de la batería.

La indicación del nivel de una batería

baja.

Uso del terminal de protección (G)

Para pruebas básicas de la resistencia de aislamiento dond hay una

pequeña posibilidad de fuga superficial que afecte la medición,

no es necesario usar el terminal de protección. Por ejemplo, si

el aislador está limpio y es poco probable tener alguna corriente

adversa. Sin embargo en prueba de cableado por ejemplo, podría

haber fugas superficiales en el aislamiento entre el cable pelado y

el revestimiento externo debido a la presencia de húmeda o polvo.

Para obtener una medición exacta, particularmente en pruebas

de altos voltajes, un alambre pelado podría sujetarse duramente

alrededor del aislamiento y conectarse via el tercer cable de

prueba al terminal de protección ‘G”.

19

Como se ilustra en el diagrama, el terminal de protección está al

mismo potencial como el terminal negativo. Como la resistencia

de fuga está efectivamente en paralelo con la resistencia a ser

medida, el uso de la protección causa que la corriente en la

fuga superficial sea desviada del circuito medido. El instrumento

entonces lee la fuga del aislador, ignorando la fuga en la

superficie.

Procedimiento de configuración

La función de configuración se usa para configurar el temporizador

interno (t). El valor por defecto es de 1 minuto y se puede ajustar

con las flechas hacia arriba y hacia abajo. Cuando aparezca la

configuración de tiempo deseada se presiona la tecla Pl-t (flecha

izquierda) y un pitido confirmará la nueva configuración.

Page 21

Índice de polarización (PI)

La prueba de índice de polarización (PI) realiza una prueba métrica

de relación que calcula la tasa de resistencia de aislamiento a los

diez minutos, IR

IR

.

1min

Esta prueba suministra una indicación simple de polarización de

aislamiento cuando está sujeta a un alto voltaje DC. Un valor alto

PI indica un alto grado de polarización de aislamiento y por lo

tanto una buena condición de aislamiento. Generalmente el valor

de PI debe ser dos o más.

La polarización ocurre a ritmos diferentes que van desde minutos

a varias horas que lleva al IEEE crear una prueba radiométrica PI.

El normal IEEE 43-2000, “Práctica recomendada para la prueba de

resistencia de aislamiento de maquinaria rotativa,” limita el uso

de la prueba PI a sistemas de bobinas a aquellas con IR

menos de 5000 MΩ.

Resistencia sincronizada de aislamiento

La prueba sincronizada IR es una prueba que automáticamente

termina a un tiempo ajustable del usuario (t). Los usuarios pueden

seleccionar SETUP (configuración) en el rango del interruptor y

ajustar el reloj (t) usando los botones de flechas de arriba y abajo

para fijar el tiempo deseado seguido con la presión del botón de

flecha a la izquierda PI-t. El tiempo pre-determinado (t) está fijado

a un minuto porque IR 1 min es con frecuencia referido a normas

internacionales.

a la resistencia de aislamiento a un minuto,

10min

1min

siendo

Mantenimiento preventivo

No hay partes de repuesto al usuario

No hay partes de repuesto al usuario en el BM5200 con excepción

de las baterías.

Si la protección de un instrumento ha sido deteriorada, no

debe ser usado pero envíado para reparación por personal

convenientemente entrenado y calificado. La protección está

probablemente deteriorada si por ejemplo, muestra daños

visibles, falla en realizar la medida prevista, ha sido sujeta a un

almacenamiento prolongado bajo condiciones desfavorables, o ha

sido sujeto a un severo mal transporte.

Reemplazo de las baterias

G Advertencia

Los contactos de las baterías no están aislados de los cables de

prueba. Quite los cables de prueba del instrumento antes de

abrir el compartimento de la batería.

Las pilas están alojadas en un compartimento de baterías en la

base del instrumento. Para cambiar las pilas, use un desarmador

pozidrive PZ2 para quitar la cubierta de la batería asegurando los

tornillos y levante la cubierta del compartimento de la batería.

Observe la polaridad correcta como está marcada en la estructura,

instale 8 pilas IEC LR6 (AA).

Vuelva a colocar la cubierta del compartimento de la batería y

asegúrela a su cierre.

20

Page 22

Especificaciones técnicas

Las siguientes especificaciones se aplican a 20 °C a menos que

algo diferente se indique:

Especificaciones eléctricas

Rango del aislamiento 0.1 MΩ a 1 TΩ

Voltajes nominales de prueba 250 V, 500 V, 1000 V, 2500 V,

5000 V

Exactitud terminal de voltaje <1000 V 0 a +10% del voltaje

nominal de prueba

≥100 V 0 to +5% del voltaje

nominal de prueba

Exactitud de aislamiento hasta 1 GΩ:

Todos los rangos ±5% ±2 dígitos

Por encima 1 GΩ: 5000 V ±5% ±0.04% por GΩ

2500 V ±5% ±0.08% por GΩ

1000 V ±5% ±0.2% por GΩ

500 V ±5% ±0.4% por GΩ

250 V ±5% ±0.8% por GΩ

Presente corto circuito 1.4 mA ± 0.5 mA

Máxima capacitancia de carga 5 μF

Exactitud del voltímetro (DC o AC) 3% ±3 V

Medición de frecuencia 45 Hz a 65 Hz

Exactitud de frecuencia ±2 Hz

Rango de voltaje (DC o AC) 25 a 600 V AC o DC

Protección con error de 2% protegiendo 5 MΩ derrame en una

carga de 100 MΩ

Especificaciones ambientales

Rango de temperatura de operación

-20 ºC a +55 ºC

Humedad de operación 90% RH, 0 ºC - 40 ºC

70% RH, 40 ºC - 55 ºC

Temperatura de almacenamiento -30 ºC a +65 ºC

Protección del aislamiento IP40

Altitud máxima 2000 m

Error en el servicio con límites ambientales establecidos es un

error intrínseco doble

Protección de seguridad

Aislamiento CAT III 600 V - IEC61010-1:2001 estándar aplicable

La medición de la categoría III es aplicable a la prueba y a la

medición de los circuitos conectados a la instalación de la red

a bajo voltaje de la parte de distribución del edificio. Esta parte

de instalación se espera que tenga un nínimo de dos niveles de

dispositivos protectivos de sobrecorriente entre el transformador y

puntos posibles de conexión.

Fuente de alimentación 8 x LR6/AA baterías

Duración de batería 5 horas @ 5 kV en 100 MΩ con

AA Alkalina LR6

21

Page 23

EMC

El producto se ajusta a IEC 61326

Dimensiones (Ancho x Alto x Largo)

220 mm x 115 mm x 163 mm

Peso 1.45 kg

Accesorios

Cables de repuesto 3 m x 3 1002-531

Reparación y garantía

Este instrumento no puede repararse. En caso de fallas dentro del período de garantía, el instrumento será sustituido por Megger.

Los nuevos instrumentos están garantizados por 1 año desde la fecha de compra por el usuario.

Nota: Cualquier reparación previa no autorizada o ajuste invalidará automáticamente la garantía.

Este producto contiene partes no reparables y si está defectuoso debe ser devuelto a su proveedor en la envoltura original o empaquetado

de manera que esté protegido de daños durante tránsito.

22

Page 24

23

Page 25

M

BM5200

Provador Digital de Isolamento 5 kV

MANUAL DO UTILIZADOR

24

Page 26

ÍNDICE

Avisos de segurança ....................................................................................................................................................................... 26

Os símbolos usados no instrumento ............................................................................................................................................... 27

Limpeza .................................................................................................................................................................................. 27

Descrição geral .............................................................................................................................................................................. 28

Modos de teste da resistência de isolamento .......................................................................................................................... 28

Descarga automática ............................................................................................................................................................... 28

Conjunto de cabos .................................................................................................................................................................. 28

Potência do Instrumento ......................................................................................................................................................... 28

Segurança do instrumento ..................................................................................................................................................... 28

Preparação para uso ...................................................................................................................................................................... 29

Instruções de uso ........................................................................................................................................................................... 29

Controles e indicadores do instrumento ................................................................................................................................. 29

Utilização do terminal de proteção (G) .................................................................................................................................... 30

Índice de polarização (PI) ......................................................................................................................................................... 31

Resistência de isolamento cronometrada ................................................................................................................................. 31

Procedimento de configuração ................................................................................................................................................ 31

Manutenção preventiva ................................................................................................................................................................. 32

Substituição das pilhas ............................................................................................................................................................ 32

Especificações técnicas ................................................................................................................................................................... 32

Reparação e garantia ..................................................................................................................................................................... 34

25

Page 27

G AVISOS DE SEGURANÇA

O aviso de segurança deve ser observado durante a utilização:

n O circuito sob teste deve estar desligado, desativado, isolado e controlado para ser seguro, antes que as conexões de teste de isolamento

sejam feitas. Certifique-se que o circuito não está reativado enquanto o instrumento está ligado.

n As conexões do circuito não devem ser tocadas durante um teste de isolamento.

n Depois de completar um teste, os circuitos capacitivos devem estar totalmente descarregados antes de desconectar os cabos de teste. As des

cargas capacitivas podem ser mortais.

n Os objetos provados devem estar firmemente em curto-circuito, com uma ligaçação de curto-circuito, após a descarga, até à utilização. Isto

é para proteger contra qualquer absorção dielétrica armazenada, que seja posteriormente liberada, aumentando assim, a tensão a níveis po

tencialmente perigosos.

n O indicador de tensão, e as características de descarga automática, devem ser consideradas como recursos de segurança adicionais, e não

um substituto para a prática normal de segurança no trabalho.

n É raro, mas em certas circunstâncias, uma avaria do circuito sob teste pode fazer com que o instrumento termine o teste numa maneira

descontrolada, possívelmente causando uma perda de visor, enquanto o circuito continua energizado. Neste caso, o aparelho deve ser

desligado e o circuito descarregado manualmente.

n Os cabos de teste, incluindo os clipes de crocodilo, devem estar em boas condições, limpos e sem isolamento quebrado ou rachado.

n O instrumento não deve ser usado se qualquer parte estiver danificada.

n Testes de isolamento em condições chuvosas podem ser perigosos. Recomenda-se que este instrumento não seja utilizado nessas circunstâncias.

Se isso fôr inevitável, o utilizador deve tomar todas as precauções necessárias.

n Este instrumento não é intrinsecamente seguro e não deve ser utilizado em atmosferas perigrosas.

n Se este equipamento é usado numa maneira não especificado pelo fabricante, a proteção fornecida pelo equipamento pode ser comprometida.

n As baterias recarregáveis não devem ser utilizadas neste instrumento.

NOTA

O INSTRUMENTO DEVE SER UTILIZADO ÚNICAMENTE POR PESSOAS COMPETENTES E DEVIDAMENTE TREINADAS.

Aos utilizadores deste equipamento e/ou aos seus empregadores faz-se lembrar de que a Legislação Nacional de Saúde e Segurança obriga-os

a realizar avaliações válidas de risco de todos os trabalhos eléctricos, de modo a identificar potenciais fontes de perigo elétrico, e o risco de

lesões elétricas, tais como curto-circuitos acidentais. Quando as avaliações mostram que o risco é significativo, a utilização de cabos de teste

acoplados pode ser apropriada.

26

Page 28

Os símbolos utilizados neste instrumento

G Cuidado: verifique as notas explicativas incluidas

F Cuidado: risco de choque elétrico

t Classe II instrumento de isolamento duplo

Não descarte no serviço de resíduos

O equipamento está em conformidade com as actuais directivas C-Tick Australianas

+

Pilha

Termos usados neste manual

A palavra deve é usada para indicar que as instruções seguintes devem ser seguidas em todas as circunstâncias. O não cumprimento

destas instruções pode resultar em danos no instrumento e/ou perigo para o utilizador.

A palavra ‘deve’ é usada para indicar que as instruções indicam a melhor prática.

Limpeza

Desligue o aparelho e limpe-o com um pano limpo, levemente umedecido com água e sabão ou álcool isopropílico (IPA).

27

Page 29

Descrição geral

O provador de isolamento BM5200 tem um visor digital e arco

analógico desenhado para testar a resistência de isolamento de

alta tensão na manutenção e reparação de cabos, máquinas

rotativas instaladas, transformadores, interruptores e instalações

industriais.

Os testes de isolamento DC são realizados a 250 V, 500 V, 1000 V,

2500 V e 5000 V. A faixa de medição da resistência de isolamento

é de 100 kΩ a 1000 GΩ. A descarga automática para circuitos

capacitivos em teste é fornecida e a tensão decadente é exibida.

O terminal de proteção pode ser usado para minimizar os efeitos

da fuga de superfície e, portanto, as medidas erradas aquando da

realização de testes de resistência de isolamento.

Modos de teste da resistência de isolamento

São fornecidos três modos de teste da resistência de isolamente

(IR), (InS, PI, t) e selecionados a partir de qualquer faixa

de isolamento, pressionando a tecla em seta na esquerda

representando PI-t.

Em modo de teste da resistência de isolamento (InS) os testes

são iniciados pressionando e segurando o botão TEST (teste)

durante dois segundos. Uma vez que um teste de isolamento

tenha começado, terminará na próxima pressão do botão de TEST

(teste). A leitura é mantida no visor até que o TEST é pressionado

novamente ou outra faixa seja selecionada.

Um modo de Indice de Polarização (PI) realiza um teste ratiometric

que calcula a relação entre a resistência de isolamento a dez

minutos à resistência de isolamento a um minuto.

O modo de cronômetro (t) facilita um teste único de duração fixa

IR com base no intervalo de tempo estabelecido t.

Descarga automática

Para objetos de teste capacitivo o instrumento descarregará automaticamente através de um resistor interno e indicará a tensão

através dos terminais na faixa de 25 V e 600 V com tensões mais

altas indicadas por ‘> 600 V ‘. Esta caracteristica dará uma indicação

de uma descida de tensão após o teste do equipamento que possui

capacitância. Quando o indicador de tensão já não aparece, é

seguro para o utilizador desligar os cabos de teste.

Conjunto de cabos

São fornecidas três tomadas com recesso, e marcadas ‘+’, ‘-’ e ‘G’.

Estas têm tampas de segurança que se abrem quando as fichas

estão inseridas. Quando inseridas nas tomadas, os cabos cobertos

das fichas de teste ficam seguros na posição. Eles são libertos

torcendo a ficha um quarto de volta e puxando para fora.

Por esta razão, apenas os cabos de teste fornecidos ou os

substitutos adequados da Megger devem ser usados.

Energia para o instrumento

O BM5200 é alimentado por oito pilhas alcalinas 1,5 V IEC LR6/

AA.

As baterias recarregáveis não devem ser utilizadas neste instrumento.

Segurança do instrumento

As características do desenho de segurança incluem:

n Indicação de tensão externa, AC ou DC exibida.

28

Page 30

n A carga é automaticamente descarregada no final de um teste,

e a tensão decadente é exibida.

n Os cabos de teste podem ficar seguros na caixa para evitar descon

exão acidental.

Preparações para utilização

1. Abra a caixa e localize o instrumento BM5200, bolsa de trans

porte, cabos de teste, pilhas, e guias de início rápido e do

utilizador.

2. Certifique-se que a faixa do interruptor principal está na

posição OFF.

3. Localize o compartimento das pilhas e abra-o usando uma

chave de fendas PZ2 pozidrive.

4. Remova o módulo das pilhas e introduza as oito pilhas alcalinas

1,5 VLR6/AA, assegurando-se da orientação correta de acordo

com a sua polaridade.

5. Ligue o módulo das pilhas ao cabo das pilhas assegurando-se

que a polaridade está correta.

6. Reponha o módulo e a tampa das pilhas na caixa e recoloque

os dois parafusos apertando sòmente à mão.

7. Como verificação inicial, sem quaisquer cabos conectados,

ligue o instrumento girando a faixa do interruptor principal

para qualquer outra posição além de OFF. Certifique-se que o

visor do instrumento funciona. Desligue o instrumento. Se o

visor do instrumento não responder, retorne à etapa 2, repita o

processo e verifique que todas as orientações das oito pilhas

estão corretas.

8. Se o instrumento ainda não responder, use um voltímetro para

verificar a voltagem do módulo das pilhas que deverá ser de

29

Instruções de utilização

Controles e indicadores do instrumento

1. Visor em contraluz LCD com arco analógico duplo de 3 dígitos.

2. Interruptor iluminado de ligar/desligar

3. Quatro botões de setas, a função PI-t no botão de seta à

esquerda

4. Organização das funções do interruptor principal mais

voltímetro AC e DC (25 V e 600 V)

5. Faixa do interruptor principal com testes de isolamento DC a

250 V, 500 V, 1000 V, 2500 V e 5000 V.

6. Botão TEST para iniciar e terminar os testes de isolamento

7. Indicador de aviso de Alta Tensão (HV),

Antes de ligar o BM5200 os cabos de teste devem estar

conectados ao instrumento.

Existem três terminais de teste marcados +, - e G. Estes terminais

são desenhados para aceitar apenas as cabos de teste fornecidos.

Obturadores nos terminais evitam a entrada acidental de sujidade

e outros objetos. Os cabos de teste trancam no terminal, para

evitar que se desliguem acidentalmente durante o teste. Este

bloqueio consegue-se rodando a fixa até ativar o mecanismo de

engrenagem. Ficha pode ser removida rodando novamente de

volta.

NO final do teste certificar que a voltagem foi descarregada e que

passou para valores de segurança, i.e. <50 V, antes de remover os

cabos de teste. Cargas reativas podem levar algum tempo a

dissipar a energia acumulada, através dos componentes internos

de descarga residual.

Page 31

O indicador do nível das pilhas está

localizado no canto superior direito

do ecrã e contém quatro pares de

segmentos que mostram o nível

de carga.

1

2

3

4

5

7

6

O BM5200 liga-se girando a faixa do interruptor principal para

teste de isolamento, teste de tensão ou função de configuração.

Os terminais são trancados no painel situado na traseira do

equipamento e sinalizado com sinal “+”, - “G” significa terminal

protegido.

Indicação do nível de 50% de vida

útil da pilha.

Indicação do nível de uma

bateria descarregada.

Utilização do terminal de proteção (G)

Para os testes de resistência de isolamento de base, onde há

pouca possibilidade de fuga de superfície que afecte a medição,

não é necessário usar o terminal de proteção, isto é, se o isolador

está limpo e que não seja provável haver caminhos de corrente

adversos. No entanto, por exemplo, no teste de cabo, pode

haver fugas de superfície através do isolamento, entre o cabo

descoberto e o

invólucro externo, devido à presença de humidade ou sujidade.

Para obter uma medida precisa, especialmente em testes de alta

tensão, um arame descoberto pode ser ligado firmemente em

torno do isolamento e conectado, por via do terceiro cabo de

teste, ao terminal de proteção ‘G’.

30

Page 32

Como ilustrado no diagrama, o terminal de proteção está ao

mesmo potencial que o terminal negativo. Uma vez que a

resistência de fuga está efetivamente em paralelo com a

resistência a ser medida, o uso da proteção faz com que a

corrente, que flui através de fugas de superfície, seja desviada

do circuito de medição. O instrumento, portanto, lê a fuga do

isolador, ignorando fugas na sua superfície

Procedimento de configuração

A função de configuração é usada para definir o marcador de

tempo interno (t). O valor padrão é de 1 minuto e pode ser

ajustado usando as setas para cima e para baixo. Quando o ajuste

do tempo desejado é mostrado, a tecla PI-t (seta para a esquerda)

é pressionada e um sinal sonoro confirma a nova configuração.

31

Índice de Polarização (PI)

O teste de Índice de Polarização (PI) realiza um teste da razão

métrica que calcula a relação entre a resistência de isolamento

a dez minutos, IR

minuto, IR

1min

.

Este teste fornece uma indicação simples de polarização de

isolamento quando submetido a alta tensão DC. Um valor elevado

PI indica um alto grau de polarização de isolamento e, portanto,

uma boa condição de isolamento. Geralmente o valor de PI deve

ser de dois ou mais.

A polarização ocorre a taxas diferentes, que variam de minutos

a várias horas, o que levou a IEEE a criar um teste ratiometric PI.

O padrão 43-2000 IEEE, “Práticas Recomendadas para Testes

de Resistência de Isolamento de Máquinas Rotativas”, limita a

utilização do teste de PI em sistemas de bobinagem aos que IR

seja inferior a 5000 MΩ.

Resistência de isolamento cronometrada

O teste cronometrado IR é um teste que termina automaticamente

depois do tempo ajustável (t) pelo utilizador. Os utilizadores

podem selecionar SETUP (configuração)na faixa do interruptor e

ajustar o cronômetro (t), utilizando teclas de seta de para cima

e para baixo, para definir o tempo desejado, seguido por uma

simples pressão do botão PI-t (seta à esquerda). O tempo padrão

(t) está fixado a um minuto, porque IR1min é frequentemente

referido nas normas internacionais.

min e a resistência de isolamento a um

10min

1min

Page 33

Manutenção preventiva

Não há peças reparáveis pelo utilizador

Não existem peças reparáveis pelo utilizador no BM5200, exceto

as pilhas.

Se a proteção de um instrumento foi danificada, não deve ser

usado, mas enviado para reparação por pessoal devidamente

treinado e qualificado. A proteção é susceptível de estar

danificada se, por exemplo, mostra danos visíveis, não executa as

medidas previstas, foi submetido a armazenamento prolongado

em condições

desfavoráveis, ou que tenha sido submetido a condições

deficientes durante o transporte.

Substituição das pilhas

G AVISO

Os contatos das pilhas não estão isoladas dos cabos de teste.

Retire os cabos de teste do instrumento antes de abrir o

compartimento das pilhas.

As pilhas estão alojadas num compartimento na base do

instrumento. Para trocar as pilhas, use uma chave de fendas PZ2

pozidrive para remover os parafusos que seguram a tampa e retire

a tampa do compartimento das pilhas. Verificando a polaridade

correta indicada no compartimento das pilhas, instale 8 pilhas de

substituição IEC LR6 (AA).

Ao concluir, aparafuse a tampa do compartimento das pilhas.

Especificações técnicas

As especificações seguintes aplicam-se a 20 ° C, salvo indicação

em contrário:

Especificações elétricas

Faixa de isolamento 0,1 MΩ a 1 MΩ TΩ

Tensões nominais de teste 250 V, 500 V, 1000 V, 2500 V,

5000 V

Precisão do terminal de tensão <1000 V 0 a +10% da tensão

nominal de teste

≥100 V 0 a +5% da tensão

nominal de teste

Precisão do isolamento

Até 1 GΩ: Todas as faixas ±5%

±2 dígitos

Mais de 1 GΩ:

5000 V ±5% ± 0,04% por GΩ

2,500 V ±5% ± 0,08% por GΩ

1000 V ±5% ± 0,2% por GΩ

500 V ±5% ± 0,4% por GΩ

250 V ±5% ± 0,8% por GΩ

Corrente de curto-circuito 1,4 mA ± 0,5 mA

Capacidade máxima de carga 5 μF

Precisão do voltímetro (DC ou AC) 3% ±3 V

Medição de frequência 45 Hz a 65 Hz

Precisão da frequência ±2 Hz

Faixa de tensão (DC ou AC) 25 a 600 V AC ou DC

32

Page 34

Fonte de alimentação 8 x pilhas LR6/AA

Duração da pilha com Proteção 5 horas a 5 kV em 100 MΩ

AA alcalinas LR6

2% de erro na proteção de fugas

de 5 MΩ em carga de 100 MΩ

Especificações ambientais

Faixa de temperatura de operação

-20 ºC a +55 ºC

Umidade de operação 90% RH, 0 ºC - 40 ºC

70% RH, 40 ºC - 55 ºC

Temperatura de armazenamento -30 ºC a +65 ºC

Protecção dei solamento IP40

Altitude Máxima 2000 m

O erro de serviço com limites ambientais estabelecidos é o dobro

do erro intrínseco

Protecção de segurança

Isolamento CAT III 600 V - IEC61010-1:2001

A medição de Categoria III, é aplicável para testar os circuitos

de medição, ligados aos canais da instalação eléctrica de baixa

tensão, no local de distribuição do edifício,. Esta parte da

instalação, deverá ter um mínimo de dois níveis de dispositivos

de protecção de excesso de corrente, entre o transformador e os

possíveis pontos de conexão.

Dimensões (Ancho x Alto x Largo)

220 mm x 115 mm x 163 mm

Peso 1.45 kg

EMC

O produto está em conformidade com IEC 61326

33

Page 35

Acessórios

Cabo de substituição leva 3 x 3m

Reparação e garantia

Este equipamento não é reparável. Se o equipamento falhou durante o período de garantia, o mesmo será substituído pela Megger.

Instrumentos novos estão garantidos por 1 ano a contar da data da compra pelo utilizador.

Nota: Qualquer reparação ou ajuste prévios não autorizados invalidam automaticamente a garantia.

Este produto não contém peças reparáveis e em caso de defeito deverá ser devolvido ao seu fornecedor na embalagem original ou

acondicionado de modo que seja protegido de danos durante o transporte.

34

Page 36

M

Megger Limited

Archcliffe Road, Dover

Kent CT17 9EN England

T +44 (0)1 304 502101

F +44 (0)1 304 207342

E uksales@megger.com

Megger

Valley Forge Corporate Centre

2621 Van Buren Avenue

Norristown, PA 19403 USA

T +1 610 676 8500

F +1 610-676-8610

E ussales@megger.com

Megger

501 Crystal Paradise Mall

Off Veera Desai Road

Andheri(w), Mumbai - 400053

Maharashtra

India

T +91 22 26740468

F +91 22 26740465

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

Printed in the UK

Part No. BM5200--2001-444_UG_en-es-pt_V06

www.megger.com

Megger Sweden AB

Eldarvägen 4

Box 2970

SE-187 29 TÄBY

Sweden

T +46 8 510 195 00

F +46 8 510 195 95

Megger Pty Limited

Unit 26 9 Hudson Avenue

Castle Hill

Sydney NSW 2125 Australia

T +61 (0)2 9659 2005

F +61 (0)2 9659 2201

E ausales@megger.com

Loading...

Loading...