Page 1

500 V. Analogue Insulation & Continuity Testers

M BM100/4 and BM101/4

User Guide

Guide de l’utilisateur

Gebrauchsanleitung

Guía del usuario

SAFETY WARNINGS

Safety Warnings and precautions m u s t be read and

understood before the instrument is used. They m u s t

be observed during use.

The circuit under test must be de-energised and

isolated before Insulation, Resistance, or Continuity

tests are made.

During an insulation test, the circuit must not be

touched.

After insulation tests, capacitive circuits must be

allowed to discharge before disconnecting the test

leads.

Test leads, including prods and crocodile clips must

be in good order; clean, and with no broken or

cracked insulation.

Replacement fuses must be of the correct type and

rating.

BM 100/4 Only

U.K. Safety Authorities recommend the use of fused

test leads when measuring voltage on high energy

systems.

When making a voltage measurement, the 'T est' push

must not be pressed.

NOTE

T H E I N S T R U M E N T S M U S T O N Y B E U S E D B Y S U I TA B LY T R A I N E D A N D C O M P E T E N T P E R S O N S

.

Symbols used on the instrument

Caution: Refer to accompanying notes.

Equipment protected throughout by Double Insulation

(Class II).

Equipment complies with relevant EU Directives

Page 2

Refer to Safety Warnings before using the instrument

OPERATION

Preliminary Test lead check

1. Before each use of the instrument, inspect the test leads to confirm that

their condition is good, with no damaged or broken insulation.

2. Insert the red and black test leads, terminated with the appropriate

prods or clips, to their respective ‘+’ and ‘-’ terminal sockets.

3. Short the test lead prods or clips together. Set the selector switch to ‘2 ’ .

4. Press the ‘Test’ push. Check that the instrument reads zero. If a higher

resistance reading is obtained check all connections. If the reading

remains high, suspect that the test leads may be at fault, or that the 2A

non replaceable fuse has ruptured.

Continuity Testing

1. Set the selector switch to ‘2

’, or ‘200 ’, as appropriate.

2. Connect the test leads across the isolated item / circuit under test.

3. Press and hold the ‘Test’push button; allow the needle to settle. There

is a separate scale for each range so each reading is direct. Take the

reading from the appropriate scale of the instrument.

4. Release the ‘Test’ push button and disconnect the test leads.

Insulation Testing

1. Set the selector switch to ‘200 MΩ.’

2. Connect the R e d test lead to earth, equipment frame, or cable sheath etc.

3. Connect the Black test lead to the circuit under test or cable core.

4. Confirm that Voltage is not indicated on the instrument. (BM100/4

only)

5. Press and hold the ‘Test’ push; allow needle to settle, and take the

reading from the top scale of the instrument.

6. Release the ‘Test’ push button.

7. Wait a few moments before disconnecting the test leads, to allow any

circuit capacitance to discharge. The BM100/4 will automatically

monitor the discharge on its Voltage range, indicating when it is safe to

remove the test leads.

Resistance Testing (BM101/4 only)

1. Set the selector switch to the 1MΩ resistance range.

2. Connect the test leads across the isolated item / circuit under test.

3. Press and hold the ‘Test’ push button, allow the needle to settle. Take

the reading from the 1MΩ range scale.

4. Release the ‘Test’ push button and disconnect the test leads.

Page 3

SPECIFICATION

Range:

BM100/4 BM101/4

Insulation 0,01 - 200 MΩ 0,01 - 200 MΩ

Resistance - 0,01 - 1 MΩ

Continuity (¡) 0,01 - 200 Ω 0,01 - 200 Ω

(¡¡) 0,01 - 2 Ω 0,01 - 2 Ω

Insulation Test Voltage: 500V d.c. 500V d.c.

Open Cct. Terminal Voltage:

Insulation Range <600V d.c. <600V d.c.

(>500V at 0,5MΩ) >500V at 0,5MΩ)

Resistance Range - 53V d.c.(nom.)

Continuity Ranges (¡) 0,76V d.c.(nom.) 0,76V d.c.(nom)

(¡¡) 4,7V d.c.(nom.) 4,7V d.c.(nom)

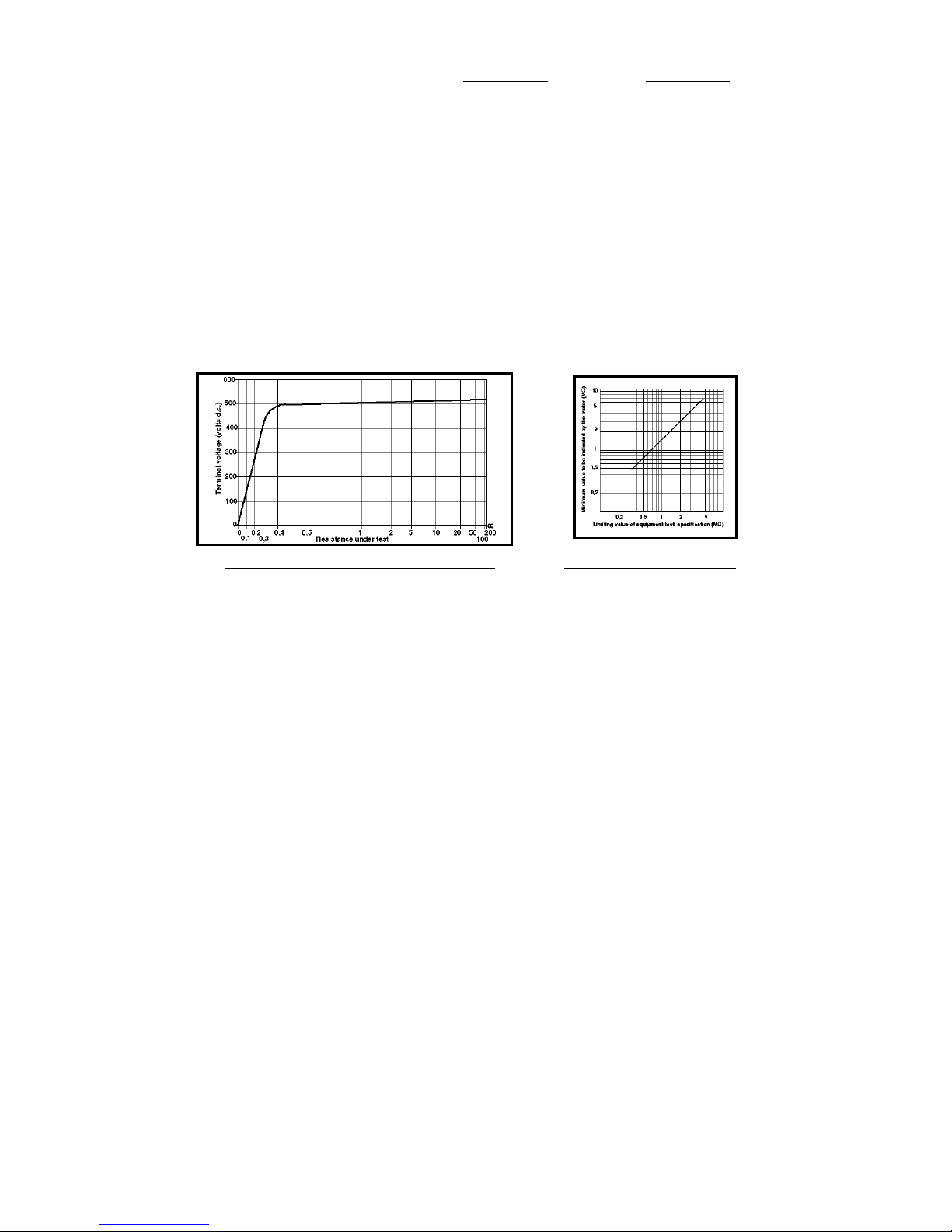

Typical Terminal Characteristics Limiting value curve

Short Cct.Terminal Current:

Insulation Range 1,6 mA 1,6 mA

Resistance Range - 325 µA

Continuity Ranges (¡) 12,3 mA 12,3 mA

(¡¡) 217 mA 217 mA

Movement: Robust Taut Band type. 250 µA F.S.D.

A.C. Voltage Measurement (BM100/4 only):

The Voltage range is automatically selected when the switch is in any

position and the ‘Test’ push button is not pressed. When connected across

the circuit under test, the BM100/4 will indicate if the circuit is energised

(a.c. or d.c.), and measure a.c.voltage up to 600 V.

Voltmeter Input Impedance: 330 kΩ

Automatic Discharge: Capacitive circuits are automatically

discharged via an internal (<500kΩ) resistor, when the ‘Test' push button

is released following an insulation test.

Accuracy (at 20°C): ± 2,5% of scale length on all ranges (e.g.± 1,9 mm

on Insulation range). Insulation range is marked with a white band (Class

1,5 as VDE 0413). Other ranges are Class 3.

Humidity: Operation: 90% R.H.max. at 20°C

Temperature Range: Operation: -5°C to + 40°C

80% R.H. max.at 35°C

Storage 95% R.H. max. at 35°C

Page 4

Storage -20°C to + 70°C

Temperature Coefficient: ±0,1% per °C

Power Supply: Single 9V Alkaline battery I.E.C. 6 LR61 type

Current consumption: 110 mA max on Insulation

40mAmax on Resistance

220 mA max on 2 Ω range

Battery life: Not less than 1800, 5 second operations on 2Ω range.

Battery Condition Test: The battery condition test position checks the

battery voltage on a simulated load, when the ‘Test’ push button is

pressed. The instrument pointer should deflect clockwise to within the

‘Battery Check’ arc on the scale. Remove the battery if the instrument is

not to be used for an extended period of time.

Battery Replacement:

For safety reasons, the battery compartment must not be opened if the

test leads are connected. To remove the battery cover, release the screw

in the centre of the cover and lever the cover upwards.

Replaceable Fuse: 500 mA, 250V. H.B.C. type (F) (20mm. x 5mm)

To check this fuse, open circuit the test leads, switch to the 200

range

and press the ‘Test’ push button. A reading of <200Ω indicates a ruptured

fuse. Located in the battery compartment, this fuse can be replaced by the

user. The replacement fuse must be of the correct type and rating.To

replace the fuse, disconnect the test leads, remove the battery cover by

releasing the screw in the centre of the cover and levering the cover

upwards. Aspare fuse is clipped onto the battery cover.

Non Replaceable Fuse: 2A - 500 V H.B.C. type (F) 50 kA. Fitted for

overall safety protection, this fuse is not replaceable by the user. No

response from the instrument to an insulation test, with the leads shorted

together is likely to mean that this fuse has ruptured. The instrument must

be returned to the manufacturer, or an approved agent for repair.

Safety: Meets the requirements for double insulation to IEC1010-1

(1995) EN61010-1 (1995) to installation Category III***, 300 V

phase to earth (ground) and 500 V phase to phase, without

the need for separately fused test leads. If required, fused test

leads are available as an optional accessory. Indicates circuit

discharge after insulation test, 600 V Category II **.

*** Relates to transient overvoltage likely to be found in fixed

installation wiring.

** Relates to transient overvoltage likely to

be found in portable equipment and appliances.

E.M.C. In accordance with IEC61326 including amendment No.1

Standards: BS 7430 (1992) - VDE 0413 (1982)

Weight: 485g

Dimensions: 175 mm x 95 mm x 57 mm.

Cleaning: Wipe disconnected instrument with a clean cloth dampened

with soapy water or Isopropyl Alcohol (IPA).

Page 5

ACCESSORIES

Supplied Part Number

Test lead set

User Guide 6172-048

Optional

Synthetic Test & carry case 6420-030

Test lead set (2 leads, 2 clips) 6220-434

Test lead set with fused prods. 6111-287

(Not recommended for continuity tests).

Publications

‘A Stitch in Time’ AVTM21-P8B

REPAIR AND WARRANTY

The instrument circuit contains static sensitive devices, and care must be taken

in handling the printed circuit board. If the protection of an instrument has been

impaired it should not be used, and be sent for repair by suitably trained and

qualified personnel. The protection is likely to be impaired if, for example, the

instrument shows visible damage, fails to perform the intended measurements,

has been subjected to prolonged storage under unfavourable conditions, or

has been exposed to severe transport stresses.

New Instruments are Guaranteed for 3 Year from the Date of Purchase

by the User.

N o t e : Any unauthorized prior repair or adjustment will automatically invalidate

Instrument Repair and Spare Parts

For service requirements for M E G G E R® Instruments contact :-

AVO INTERNATIONAL

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent, CT17 9EN Norristown, PA 19403

England U.S.A.

Tel: +44 (0) 1304 502243 Tel: +1 (610) 676-8500

Fax: +44 (0) 1304 207342 Fax: +1 (610) 643-8625

or an approved repair company.

Approved Repair Companies

Anumber of independent instrument repair companies have been approved for

repair work on most

spare parts. Consult the Appointed Distributor / Agent regarding spare parts,

repair facilities and advice on the best course of action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it should be sent freight

pre-paid to the appropriate address. Acopy of the Invoice and of the packing

note should be sent simultaneously by airmail to expedite clearance through

Customs. Arepair estimate showing freight return and other charges will be

submitted to the sender, if required, before work on the instrument

c o m m e n c e s .

the Wa r r a n t y.

MEGGER

or AVO INTERNATIONAL

®

instruments, using genuine

MEGGER

®

Page 6

M

Megger Limited Archcliffe Road Dover

Kent CT17 9EN England.

T +44 (0) 1304 502 100

F +44 (0) 1304 207 342

Megger 4271 Bronze Way Dallas

TX 75237-1017 USA.

T +1 (800) 723 2861 (U.S.A. only)

T +1 (214) 333 3201 (International)

F +1 (214) 331 399

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France

T +33 (1) 30.16.08.90

F +33 (1) 34.61.23.77

Note

Users of this equipment and or their employers are reminded that Health

and Safety Legislation require them to carry out valid risk assessments

of all electrical work so as to identify potential sources of electrical

danger and risk of electrical injury such as from inadvertent short circuits.

Where the assessments show that the risk is significant then the use of

fused test leads constructed in accordance with the HSE guidance note

GS38 ‘Electrical Test Equipment for use by Electricians’should be used.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior

notice.

Megger is a registered trademark

Part No. 6172-048 V09 Printed in England 1103

Page 7

Guide de l’utilisateur

Consignes de Securité

Vous devez lire les consignes de sécurité et les

précautions et bien les comprendre avant de vous servir de

cet instrument. Respectez ces consignes et précautions lors

de l'utilisation de cet appareil.

Débranchez, désexcitez et isolez le circuit que vous comptez

tester avant d'effectuer les connexions nécessaires aux

essais d'isolement et de continuité.

Ne touchez pas aux branchements de circuits et aux

éléments métalliques exposés d'une installation ou d'un

équipement à l'essai.

Après des essais d'isolement, attendez que les circuits

capacitifs se déchargent a v a n t de débrancher les

conducteurs d'essai.

Les conducteurs d'essai, les palpeurs et les pinces crocodile

doivent être en parfait état et propres et leur isolation ne doit

pas être fissurée ou cassée.

Les fusibles de rechange doivent être du type correct et offrir

le pouvoir de coupure prévu.

BM 100/4 seulement

Les organismes officiels britanniques chargés de la sécurité

recommandent l'utilisation de conducteurs d'essai protégés

par un fusible pour mesurer la tension de circuits à forte

énergie.

Lors d’une mesure de tension, le bouton de ‘TEST‘ ne doit

pas etre enfoncé.

NOTA

L

’INSTRUMENT NE DOIT ÊTRE UTILISE QUE PAR DES PERSONNES COMPETENTES ET

FORMÉE

Vérifications préliminaires des conducteurs d’essai.

1. Avant chaque utilisation de l’instrument, examinez les conducteurs

d’essai pour vous assurer qu’ils sont en bon état et que leur isolation

n’est pas endommagée ou cassée.

2. Introduisez les conducteurs d’essai rouges et noirs qui se terminent

par des pinces ou pointes de contact de type approprié, dans les

prises femelles respectives des bornes ‘+‘ et ‘-‘.

3. Reliez l’une à l’autre les pinces ou les pointes de contact des

conducteurs d’essai puis réglez le sélecteur sur la plage ‘2

‘.

4. Appuyez sur le bouton-poussoir ‘Test‘ pour vérifier que l’instrument

affiche une valeur égale à ‘0‘. Vérifiez tous les branchements si vous

obtenez une résistance plus élevée. Si la valeur affichée reste

importante, il est probable que les conducteurs d’essai sont

défectueux ou que le fusible de 2 Aqui n’est pas remplaçable a sauté.

Page 8

Voir les Avertissement de Sécurité avant d’utiliser l’instrument

Essais d’Isolement

1.Amenez le sélecteur sur la plage ’200 M ‘.

2. Branchez les conducteurs d’essai sur l’article ou le circuit isolé à

tester.

3.Branchez le conducteur d’essai rouge à la terre: le châssis de

l’équipement ou la gaine d’un câble, etc.

4. Branchez le conducteur d’essai noir sur le circuit testé ou sur le

conducteur de câble.

5. Confirmez que l’instrument n’affiche pas une tension (BM100/4

uniquement).

6. Appuyez sur le bouton-poussoir ‘Test‘. Maintenez la pression sur ce

bouton. Attendez que l’aiguille se stabilise puis effectuez une mesure

en utilisant l’échelle supérieure de l’instrument.

7.Relâchez le bouton-poussoir ‘Test‘.

8. Attendez quelques instants avant de débrancher les conducteurs

d’essai afin de permettre à la capacitance du circuit de se décharger.

L’appareil BM100/4 contrôle automatiquement la décharge sur la

plage de tension et vous indique le moment où vous pouvez retirer

sans danger les conducteurs d’essai.

Essais de Continuité

1. Amenez le sélecteur sur la plage ‘2

‘ ou ‘200 ‘, suivant les cas.

2.Branchez les conducteurs d’essai aux bornes du circuit testé.

3.Appuyez sur le bouton-poussoir ‘Test‘. Maintenez la pression sur ce

bouton. Attendez que l’aiguille se stabilise. Il y a une échelle séparée

pour chaque plage. Par conséquent, la lecture est directe. Notez la

valeur affichée sur l’échelle appropriée de l’instrument.

4. Relâchez le bouton-poussoir ‘Test‘ puis débranchez les conducteurs

d’essai.

Essais de Résistance (modèle BM101/4 uniquement)

1.Amenez le sélecteur sur la plage de résistance de 1 M

.

2. Branchez les conducteurs d’essai aux bornes du circuit testé.

3. Appuyez sur le bouton-poussoir ‘Test‘. Maintenez la pression sur ce

bouton. Attendez que l’aiguille se stabilise. Notez la valeur affichée sur

l’échelle de la plage de 1 M .

4. Relâchez le bouton-poussoir ‘Test‘ puis débranchez les conducteurs

d’essai.

Essais de Tension (Modèle BM 100/4 uniquement)

La plage de tension est automatiquement sélectionnée, quelle que soit la

position occupée par le sélecteur, tant que vous n’appuyez pas sur le

bouton-poussoir ‘Test‘. L’organisme officiel de sécurité de Grande-

Bretagne recommande d’utiliser, pour ce type d’activités, des conducteurs

d’essai protégés par des fusibles.

1. Branchez les conducteurs d’essai aux bornes du circuit testé.

2. L’instrument indique que ce circuit est excité et la tension présente

Page 9

Gebrauchsanleitung

Hinweise zur Betriebssicherheit

Die S i c h e r h e i t s h i n w e i s e und Vo r s i c h t s m a ß n a h m e n

müssen vor Einsatz des Geräts gelesen und verstanden

worden sein und während des Einsatzes beachtet werden.

Der zu prüfende Schaltkreis muß vor Herstellen d e r

Verbindungen zum Prüfen der Isolation oder des Durchgangs

abgeschaltet, energielos gemacht und isoliert werden.

Während des Prüfens dürfen Schaltkreisanschlüsse und

freiliegende Metallteile einer Installation oder Anlage nicht

berührt werden.

Nach den Isolationsprüfungen und v o r Abschluß der

Meßkabel muß kapazitiven Schaltkreisen Gelegenheit

gegeben werden, sich vollständig zu entladen.

Meßkabel, Sonden und Krokodilklemmen müssen in gutem

Zustand und sauber sein und dürfen keine gebrochene oder

gespaltene Isolierung haben.

Sicherungen müssen durch solche vom richtigen Typ und

Nennwert ersetzt werden.

Nur BM 100/4

Die britischen Sicherheitsbehörden empfehlen die

Verwendung von abgesicherten Meßkabeln beim Messen

von Spannungen an hochenergetischen Systemen.

Bei Spannungsmessung Testtaste nicht drücken.

ANMERKUNG

DIESES INSTRUMENT DÜRFEN NUR VON AUSREICHEND GESCHULTEN UND

KOMPETENTEN PERSONEN BEDIENT WERDEN

Vorbereitende Prüfung der Meßkabel

1. Vor jedem Einsatz des Meßinstruments müssen die Meßkabel geprüft

werden, um zu gewährleisten, daß sie sich in gutem Zustand befinden

und die Isolierung weder beschädigt noch gebrochen ist.

2. Verbinden Sie die Stifte oder Klemmen des roten und des schwarze

Meßkabels mit der Plus- bzw. Minusbuchse.

3. Verbinden Sie die Stifte oder Klemmen der Meßkabel miteinander und

schalten Sie den Wählschalter auf ‘2

4 Drücken Sie die Taste “Test” und prüfen Sie, ob das Meßinstrument

‘0‘ anzeigt. Prüfen Sie alle Verbindungen, wenn das Instrument einen

höheren Widerstandswert anzeigt. Falls der Wert hoch bleibt, können

Sie davon ausgehen, daß die Meßkabel fehlerhaft sind oder die nicht

auswechselbare Sicherung von 2 Amp durchgebrannt ist.

‘.

Page 10

Wenden Sie sich vor dem Einsatz des

Instruments an sie Sicherheitshinweise

Isolationsprüfung

1. Schalten Sie den Wählschalter auf ‘200 M ‘.

2. Verbinden Sie die Meßkabel mit dem zu prüfenden Teil bzw. Schaltkreis.

3. Verbinden Sie das rote Meßkabel mit dem Erdungspol, dem

Geräterahmen oder der Kabelabschirmung usw.

4. Verbinden Sie das schwarze Meßkabel mit dem zu prüfenden

Schaltkreis oder der Kabelseele.

5.Achten Sie darauf, daß das Meßinstrument keine Spannung anzeigt

(nur BM 100/4).

6.Halten Sie die Taste “Test” gedrückt, warten Sie, bis der Zeiger sich

beruhigt hat und lesen Sie den auf der obersten Skala angezeigten

Wert ab.

7. Lassen Sie die Taste ‘Test‘ los.

8. Warten Sie einige Sekunden, bevor Sie die Meßkabel abklemmen,

damit sich eventuell verbliebene Leiterkapazität entladen

kann. BM100/4 überwacht die Entladung automatisch im

Spannungsbereich und zeigt damit an, wenn die Meßkabel gefahrlos

abgeklemmt werden können.

Durchgangsprüfung

1. Schalten Sie den Wählschalter je nach Einsatzzweck auf ‘2

‘ oder

‘200 M ‘.

2. Verbinden Sie die Meßkabel mit dem Eingang bzw. Ausgang des zu

prüfenden Schaltkreises.

3. Halten Sie die Taste ‘Test‘ gedrückt und warten Sie, bis der Zeiger sich

beruhigt hat. Für jeden Bereich steht eine gesonderte Skala zur

Verfügung, so daß die Werte direkt abgelesen werden können. Lesen

Sie den Wert in der entsprechenden Skala des Meßinstruments ab.

4. Lassen Sie die Taste ‘Test‘ los und trennen Sie die Meßkabel.

Widerstandsprüfung (nur BM 101/4)

1. Schalten Sie den Wählschalter auf den Widerstandsbereich von 1 M

.

2. Verbinden Sie die Meßkabel mit dem Eingang bzw. Ausgang des zu

prüfenden Schaltkreises.

3.Halten Sie die Taste ‘Test‘ gedrückt und warten Sie, bis der Zeiger sich

beruhigt hat. Lesen Sie den Wert von der Skala ‘1 M ‘ ab.

4. Lassen Sie die Taste ‘Test‘ los und trennen Sie die Meßkabel.

Spannungsprüfung (nur BM 100/4)

Wenn die Taste ‘Test‘ nicht gedrückt ist, wird der Spannungsbereich in

jeder Schalterstellung automatisch gewählt. Die britischen

Sicherheitsbehörden empfehlen für diesen Zweck die Verwendung von

abgesicherten Meßkabeln.

1. Verbinden Sie die Meßkabel mit dem Eingang bzw. Ausgang des zu

prüfenden Schaltkreises.

2. Das Meßinstrument zeigt an, ob der Schaltkreis erregt ist, und auf der

inneren Skala wird der vorliegende Spannungspegel (bis zu 600 V

Wechselspannung) angezeigt.

Page 11

Guía del usuario

Avisos de Seguridad

Deberán leerse y comprenderse las precauciones y los

avisos de seguridad antes de usar el instrumento. También

deberán observarse durante su uso.

El circuito bajo prueba debe desconectarse, desenergizarse

y aislarse antes de hacerse las conexiones, cuando se llevan

a cabo pruebas de continuidad y aislamiento.

Las conexiones de circuitos y la estructura metálica expuesta

de una instalación o un equipo bajo prueba no deben

tocarse.

Después de las pruebas de aislamiento, debe dejarse que se

descarguen los circuitos capacitivos antes de desconectar

los conductores de prueba.

Los conductores de prueba, sondas y pinzas cocodrilo

deberán estar en buen estado, limpias y con su aislamiento

intacto.

Los fusibles de repuesto deben ser del identicos en tipo y

valor o los originales.

Solo BM 100/4

Las Autoridades Británicas de la Seguridad recomiendan

el uso de conectores de prueba con fusible cuando se midan

tensiones en sistemas de alta energía.

Cuando se realizo une medido de tension, el boton de test

no debe estar pulsado.

NOTA

LOS INSTRUMENTOS SOLO DEBERAN UTILIZARLOS PERSONAS COMPETENTE

CAPACITADAS Y COMPETENTES

Comprobación del cable de prueba preliminar

1. Antes de utilizar cada instrumento, inspeccione los cables de prueba

para confirmar que su condición es buena y que su aislamiento no

está dañado o roto.

2. Introduzca los cables de prueba rojo y negro, terminados con las

puntas de contacto o pinzas adecuadas, a sus respectivos enchufes

terminales ‘+’ y ‘-’.

3. Conecte las puntas de contacto o pinzas del cable de prueba juntas y

regule el interruptor selector a ‘2

‘.

4. Pulse el botón pulsador ‘Test’ (Prueba) y compruebe que el

instrumento lea ‘0‘. Compruebe todas las conexiones si se obtiene una

lectura de resistencia superior. Si la lectura permanece alta, deberá

pensar que los cables de prueba tienen un fallo o que ha habido un

corte en el fusible no sustituible de 2A.

Page 12

Consultar los avisos de seguridad antes de usar el instrumento

Comprobación del aislamiento

1. Regule el interruptor selector a ‘200 M ‘.

2. Conecte los cables de prueba a la pieza aislada / circuito bajo

prueba.

3. Conecte el cable de prueba Rojo en masa; el bastidor del equipo o

revestimiento del cable, etc.

4. Conecte el cable de prueba Negro al circuito bajo prueba o alma del

cable.

5. Confirme que no se indica la Tensión en el instrumento (sólo

BM100/4).

6. Pulse y mantenga apretado el botón pulsador ‘Test’ . Deje que a aguja

se pare y tome la lectura en la escala superior del instrumento.

7. Suelte el botón pulsador ‘Test’.

8. Espere unos segundos antes de desconectar los cables de prueba

para permitir la descarga de cualquier circuito de capacitancia. El

BM100/4 supervisará automáticamente la descarga en su gama de

Tensión, mostrando por tanto el momento en el que no existe peligro

para sacar los cables de prueba.

Comprobación de continuidad

1. Regule el interruptor selector a ‘2

‘ ó ‘200 ‘, según proceda.

2. Conecte los cables de prueba por el circuito bajo prueba.

3. Pulse y mantenga apretado el botón pulsador ‘Test’. Deje que la aguja

se pare. Hay una escala distinta para cada rango, de manera que cada

lectura es directa. Tome nota de la lectura en la escala adecuada al

instrumento.

4. Suelte el botón pulsador ‘Test’ y desconecte los cables de prueba.

Comprobación de la resistencia (sólo BM101/4)

1. Regule el interruptor selector al rango de resistencia 1M

.

2. Conecte los cables de prueba por el circuito bajo prueba.

3. Pulse y mantenga apretado el botón pulsador ‘Test’. Deje que la aguja

se pare y tome la lectura en la escala del rango 1M .

4. Suelte el botón pulsador ‘Test’ y desconecte los cables de prueba.

Comprobación de la tensión (sólo BM100/4)

La gama de tensión se selecciona automáticamente cuando el interruptor

se encuentra en cualquier posición y NO se ha pulsado el botón pulsador

‘Test’. Las autoridades sobre seguridad del Reino Unido han

recomendado el uso de cables de prueba protegidos por fusibles para

este uso.

1. Conecte los cables de prueba por el circuito bajo prueba.

2. El instrumento indicará si el circuito está activado y el nivel de tensión

existente en ese momento (máximo de 600V C.A.) aparecerá en la

escala inferior.

Loading...

Loading...