Page 1

AVTM246004

July 2011

Rev. 4

Instruction Manual

BITE 2 and BITE 2P

Battery Impedance

Test Equipment

(Includes AVOLink Addendum)

BITE 2: Catalog No. 246002B

BITE 2P: Catalog No. 246004

HIGH-VOLTAGE EQUIPMENT

Read this entire manual before operating.

APARATO DE ALTO VOLTAJE

Ante de operar este producto lea este manual enteramente.

M

2621 Van Buren Ave

Norristown, PA 19403-2329

610-676-8500

www.megger.com

Page 2

Page 3

BITE 2 and BITE 2P

Battery Impedance Test Equipment

Instruction Manual

Page 4

Copyright© 2003 by Megger. All rights reserved.

The information presented in this manual is believed to be adequate for the intended use of the

product. If the product or its individual instruments are used for purposes other than those specified

herein, confirmation of their validity and suitability must be obtained from Megger. Refer to the

warranty information below. Specifications are subject to change without notice.

WARRANTY

Products supplied by Megger are warranted against defects in material and workmanship for a

period of one year following shipment. Our liability is specifically limited to replacing or repairing, at

our option, defective equipment. Equipment returned to the factory for repair must be shipped

prepaid and insured. Contact your MEGGER representative for instructions and a return

authorization (RA) number. Please indicate all pertinent information, including problem symptoms.

Also specify the serial number and the catalog number of the unit. This warranty does not include

batteries, lamps or other expendable items, where the original manufacturer’s warranty shall apply.

We make no other warranty. The warranty is void in the event of abuse (failure to follow

recommended operating procedures) or failure by the customer to perform specific maintenance as

indicated in this manual.

M

2621 Van Buren Ave

Norristown, PA 19403-2329

610-676-8500 (Telephone)

610-676-8610 (Fax)

www.megger.com

email: battery@megger.com

Page 5

M

Contents

INTRODUCTION ........................................................................................................................... 1

About the BITE 2 and BITE 2P…................................................................................................ 1

How the BITE 2/2P Works........................................................................................................... 2

Applications for the BITE 2/2P....................................................................................................3

BITE 2/2P Measurements............................................................................................................. 4

Upon Receipt of the BITE 2/2P....................................................................................................4

Safety First...................................................................................................................................6

How to Use This Manual.............................................................................................................. 7

Typographic Conventions..................................................................................................... 7

SAFETY..........................................................................................................................................9

Overview ..................................................................................................................................... 9

Safety Requirements .................................................................................................................... 9

Connection to Power Source....................................................................................................... 11

Fuse Replacement ...................................................................................................................... 11

Cautions and Warnings............................................................................................................... 11

CONTROLS, CONNECTORS, INDICATORS AND MENUS...................................................... 13

Overview ................................................................................................................................... 13

BITE 2 Transmitter..............................................................................................................14

BITE 2P Transmitter ...........................................................................................................16

Receiver ..............................................................................................................................18

Receiver Keys .....................................................................................................................19

Receiver Reset Switch.........................................................................................................24

STANDARD TEST PROCEDURE................................................................................................ 25

Overview ................................................................................................................................... 25

Step One: Prepare for Testing.....................................................................................................27

Step Two: Powering-on the Receiver .......................................................................................... 28

Step Three: Scanning Test Information with the Wand (Optional)................................................ 30

If You Do Not Want to Scan Information Using the Wand ..................................................30

If You Want to Scan Information Using the Wand...............................................................30

Step Four: Setting Baseline, Warning and Fail Values................................................................ 32

Step Five: Splitting the Strap (if needed)....................................................................................33

If You Do Not Want to Split the Strap.................................................................................33

If You Want to Split the Strap..............................................................................................33

Step Six: Connecting the Receiver and the BITE 2 or BITE 2P Transmitter to the Battery.......... 35

Connecting the BITE 2 or BITE 2P Transmitter...................................................................37

Step Seven: Measuring the Cell and the Strap............................................................................. 38

Measuring the Next Section of a Sectioned Battery String ...................................................42

Step Eight: What to Do When the Test Is Complete ................................................................... 43

Reviewing a Test.................................................................................................................43

Retesting Cells and Straps ...................................................................................................44

Printing an Active Test to Review the Data (BITE 2P).........................................................44

Powering Down and Disconnecting the BITE 2/2P..................................................................... 45

AVTM246004 BITE 2/2P Rev 4 July 2011

i

Page 6

M

MODIFIED PROCEDURES FOR SPECIAL CONDITIONS.........................................................47

Overview ....................................................................................................................................47

Reversing the Current Source Leads............................................................................................ 47

Verifying the Source Current ...................................................................................................... 48

Sectioning a Battery System................................................................................................49

TRANSFERRING, PRINTING, AND DELETING TEST RESULTS ............................................55

Overview ....................................................................................................................................55

Exporting Test Results from the Receiver to a PC.......................................................................56

Printing Test Results in the BITE 2P Transmitter Printer............................................................. 58

Deleting Test Results from the Receiver...................................................................................... 59

INTERPRETING TEST RESULTS................................................................................................61

Overview ....................................................................................................................................61

Instantaneous Interpretation........................................................................................................62

Short-Term Inter pretation............................................................................................................63

Long-Term Interpretation ............................................................................................................63

Temperature Corrections.............................................................................................................64

SETTING OPTIONS...................................................................................................................... 67

Overview ....................................................................................................................................67

Turning the Receiver Backlight ON and OFF..............................................................................68

Adjusting the Receiver Screen Contrast.......................................................................................68

Selecting the Receiver Language .................................................................................................69

Setting the Receiver Clock..........................................................................................................69

Selecting the Line Frequency...................................................................................................... 71

MAINTENANCE AND TROUBLESHOOTING ...........................................................................73

Overview ....................................................................................................................................73

Cleaning and Inspecting the BITE 2 and BITE 2P.......................................................................74

Charging the Receiver................................................................................................................. 74

Replacing Batteries in the Receiver............................................................................................. 75

Maintaining the Receiver Charger in the BITE 2 and BITE 2P....................................................78

Maintaining Fuses in the BITE 2 and BITE 2P Transmitters .......................................................78

Verifying a Transmitter Fuse Problem.................................................................................79

Replacing Fuses in the BITE 2 Transmitter .........................................................................82

Replacing Fuses in the BITE 2P Transmitter ....................................................................... 85

Interpreting Error Messages........................................................................................................88

If the BITE 2 or BITE 2P Needs Repairs.....................................................................................88

OPTIONAL EQUIPMENT.............................................................................................................89

Available Options .......................................................................................................................89

APPENDIX A: TECHNICAL SPECIFICATIONS......................................................................... 91

Application................................................................................................................................. 91

Electrical.....................................................................................................................................91

BITE 2 and BITE 2P Transmitters .......................................................................................91

Receiver..............................................................................................................................92

Fuses...................................................................................................................................93

Mechanical .................................................................................................................................93

Environmental.............................................................................................................................94

Accessories - Standard................................................................................................................95

AVTM246004 BITE 2/2P Rev 4 July 2011

ii

Page 7

CONTENTS

APPENDIX B: REPLACEABLE PARTS...................................................................................... 97

Catalog Numbers 246002B and 246004...................................................................................... 97

Catalog Numbers 246002B and 246004...................................................................................... 98

How to Order Replaceable Parts for the BITE 2/2P.................................................................... 98

GLOSSARY..................................................................................................................................99

INDEX......................................................................................................................................... 101

Figures

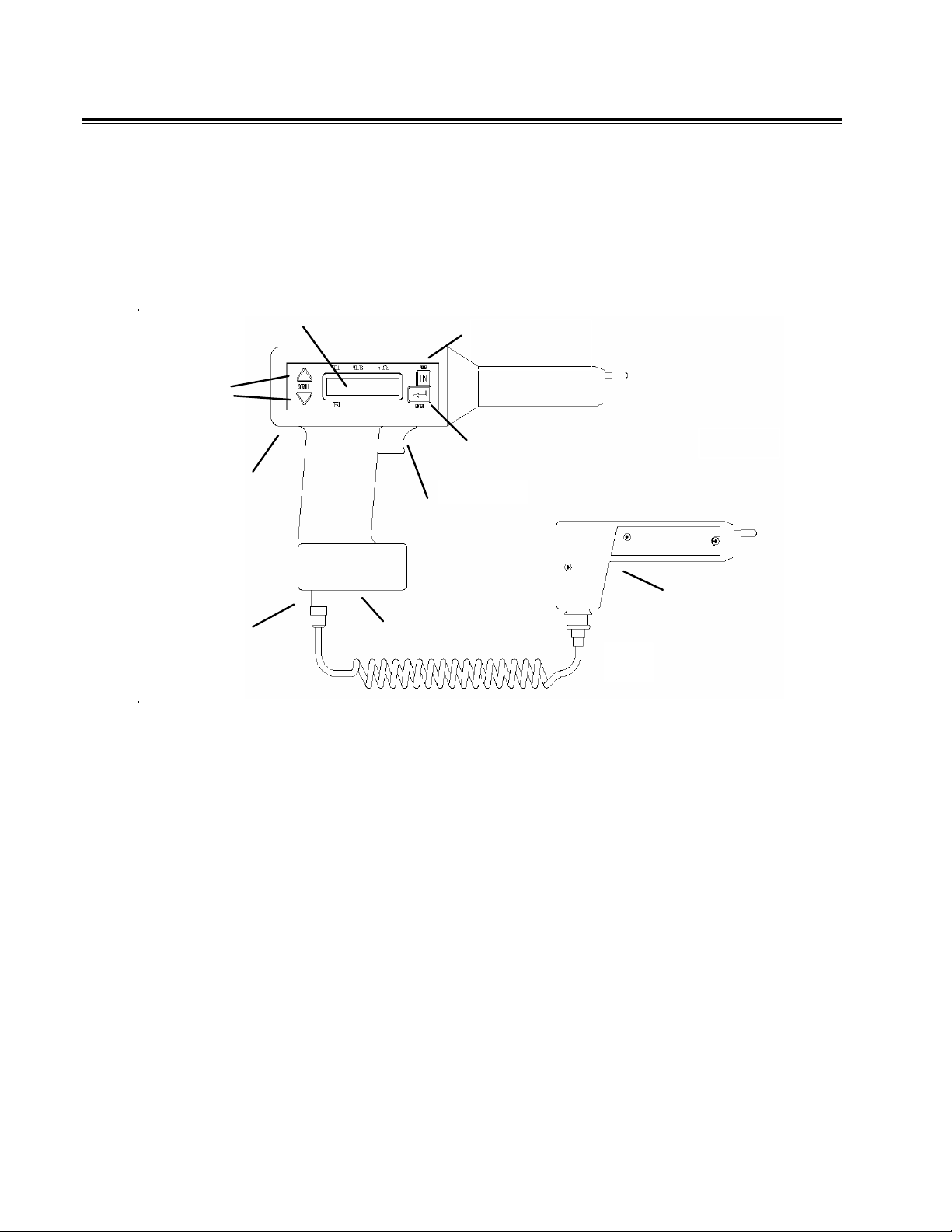

Figure 1-1: BITE 2 instrument......................................................................................................... 5

Figure 1-2: BITE 2P instrument ...................................................................................................... 6

Figure 3-1: BITE 2 transmitter ...................................................................................................... 14

Figure 3-2: BITE 2P transmitter .................................................................................................... 16

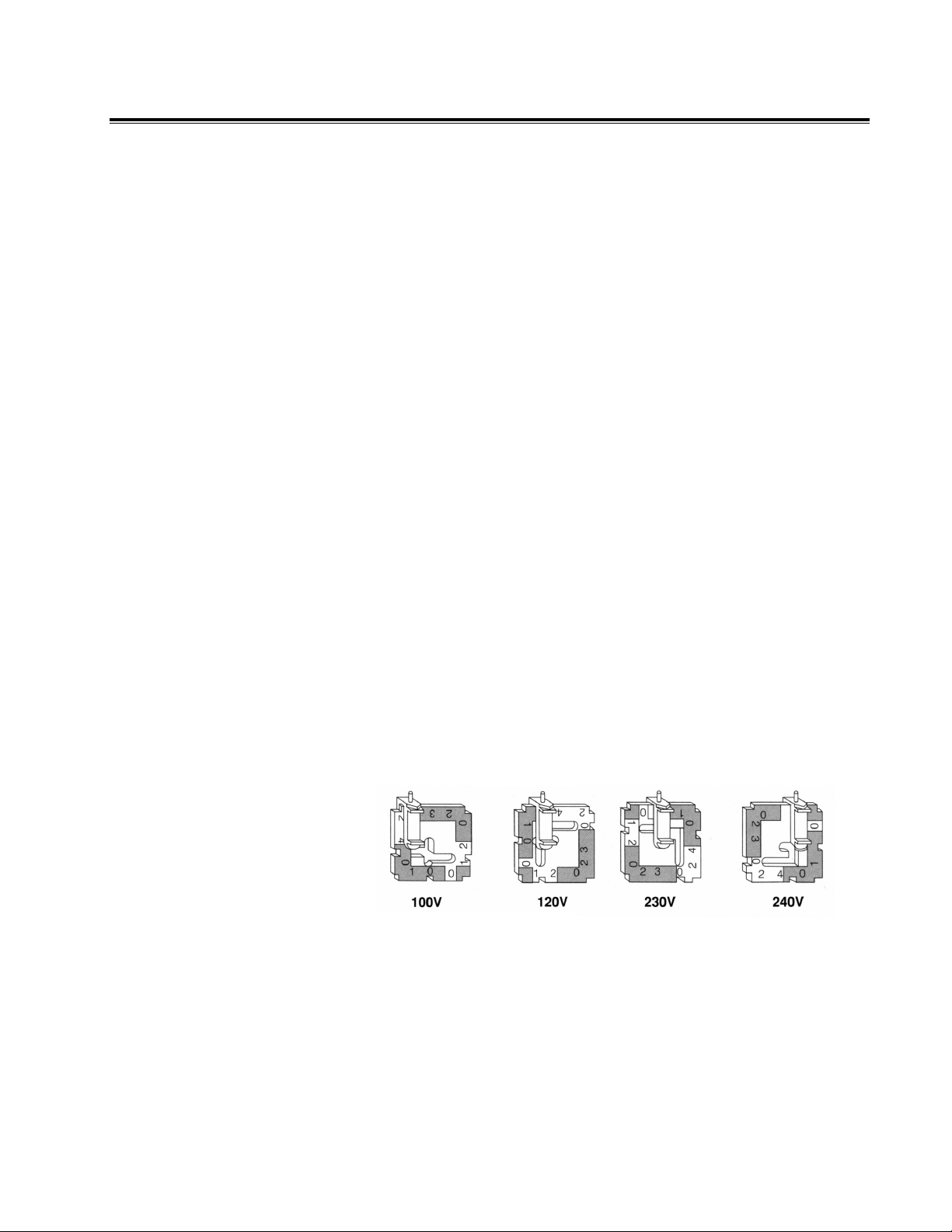

Figure 3-3: Voltage Selector Card Orientation............................................................................... 17

Figure 3-4: Receiver controls, connectors, and indicators.............................................................. 18

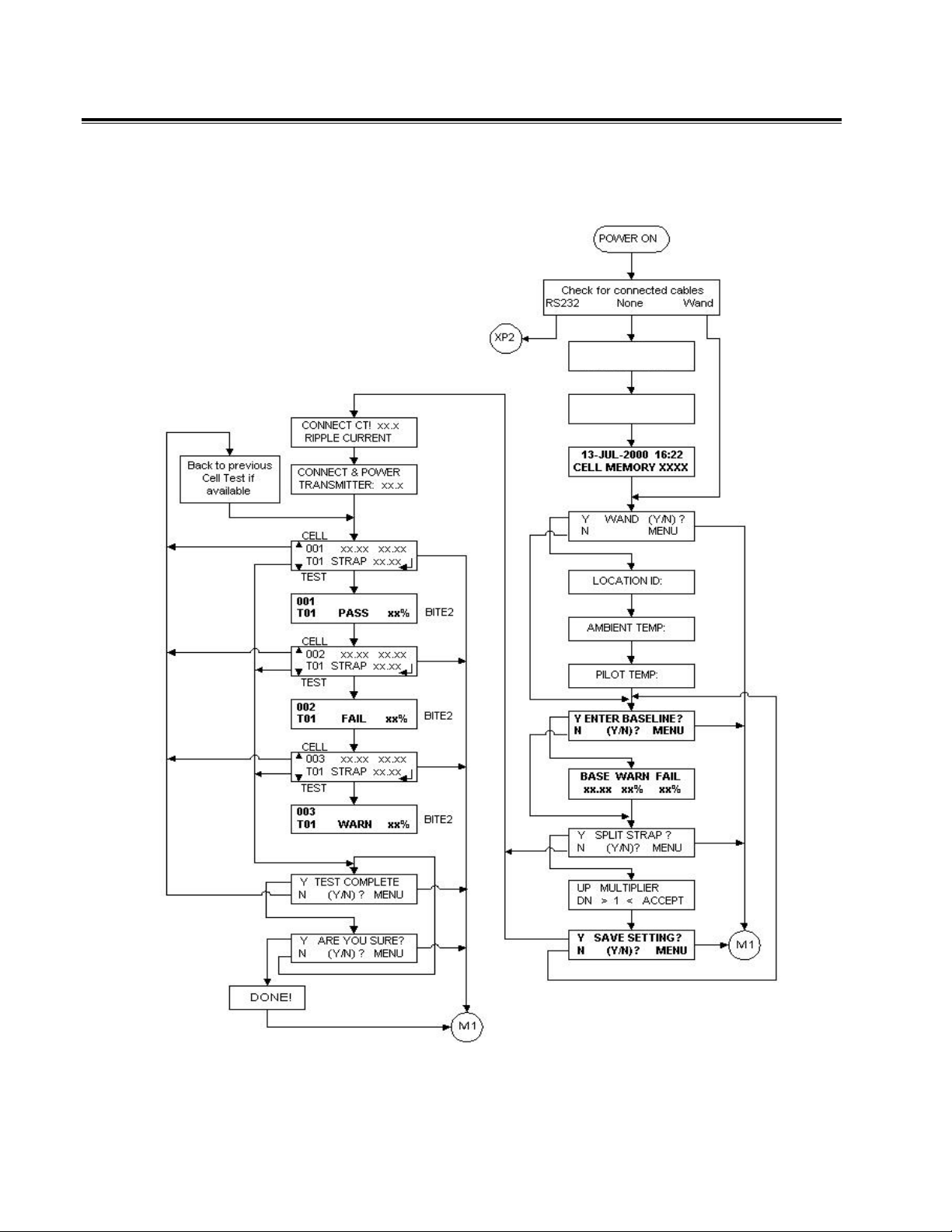

Figure 3-5: Flowchart for Receiver menus..................................................................................... 20

Figure 3-6: Flowchart for Receiver menus..................................................................................... 21

Figure 3-7: Flowchart for Receiver menus..................................................................................... 22

Figure 3-8: Receiver menu ............................................................................................................ 23

Figure 3-9: Receiver RESET switch.............................................................................................. 24

Figure 4-1: Receiver controls, connectors and indicators............................................................... 28

Figure 4-2: Initialization screens ................................................................................................... 29

Figure 4-3: Scanning test information............................................................................................ 31

Figure 4-4: Receiver controls, connectors, and indicators.............................................................. 35

Figure 4-5: BITE 2/2P transmitter connected to the battery ........................................................... 36

Figure 4-6: Receiver and potential probe positioned on top of battery cell terminals...................... 39

Figure 4-7: Receiver and potential probe positioned on top of battery strap terminals.................... 40

Figure 5-1: Reversing the current source leads on a single string of cells when a high

or low current message is displayed. ......................................................................... 48

Figure 5-2: Sectioning a battery system greater than 275 V........................................................... 50

Figure 5-3: Sectioning a parallel string of cells.............................................................................. 52

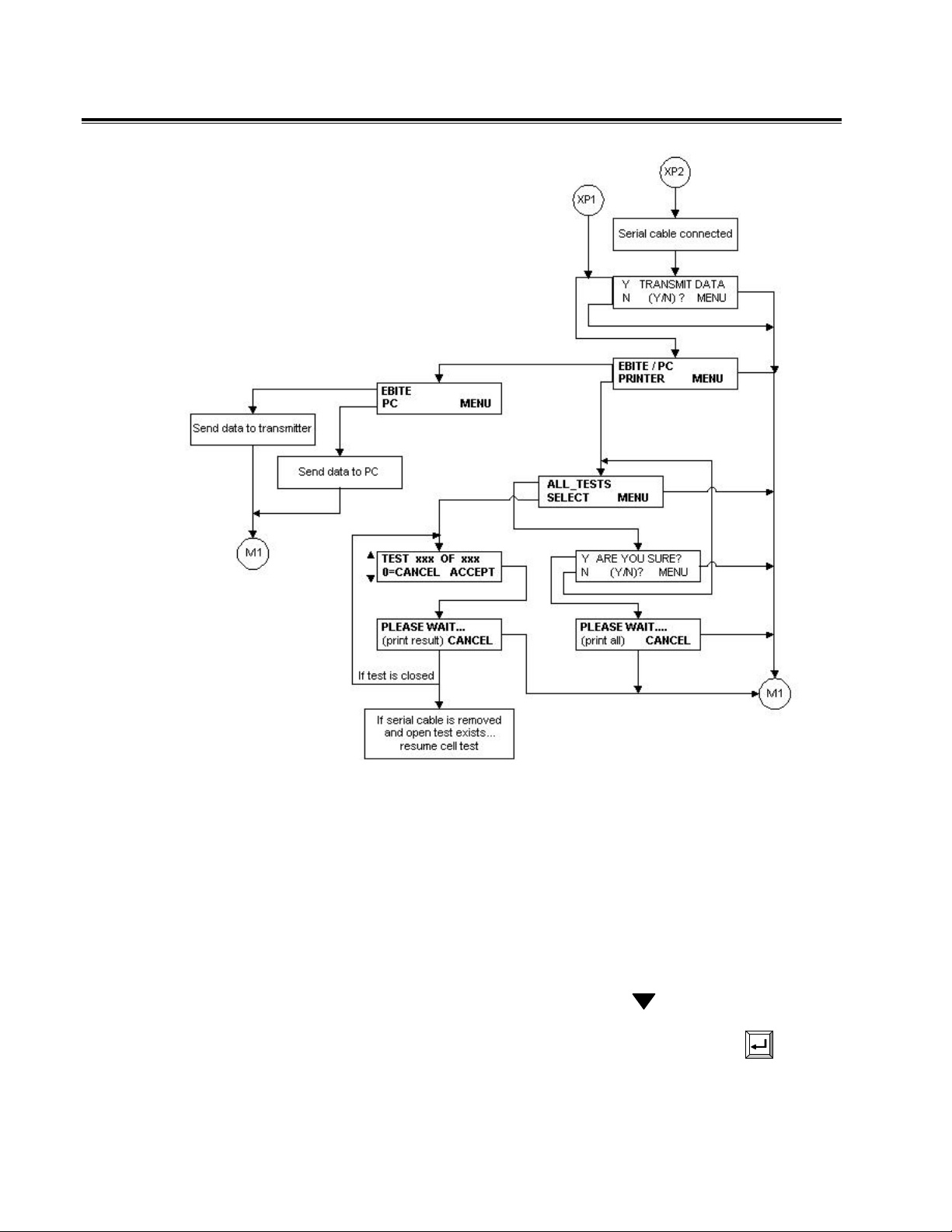

Figure 6-1: Exporting data to a PC................................................................................................57

Figure 6-2: Printing test results...................................................................................................... 58

Figure 6-3: Deleting test results from the Receiver ........................................................................ 60

Figure 7-1: Generic curve of impedance vs. cell life...................................................................... 64

Figure 9-1: RTC battery "piggybacks" the system battery.............................................................. 77

Figure 9-2: BITE 2 transmitter secondary fuses (front view) ......................................................... 83

Figure 9-3: BITE 2P transmitter secondary fuses (front view) ....................................................... 86

AVTM246004 BITE 2/2P Rev 4 July 2011

iii

Page 8

M

M

AVTM246004 BITE 2/2P Rev 4 July 2011

iv

Page 9

1

INTRODUCTION

About the BITE 2 and BITE 2P…

NOTE: Before attempting to use the BITE 2/2P, be sure that you

read and understand the safety requirements and operating

procedures contained in this manual.

M

Thank you for selecting an Megger product. This instrument

has been thoroughly tested and inspected to meet rigid

specifications before being shipped.

It is ready for use when set up and operated as described in

this manual.

The BITE 2 and BITE 2P are testing instruments used to

evaluate the condition of stationary battery strings. They

measure the complete electrical path of the battery:

• internal ac impedance of each cell/jar in the string

• dc terminal voltage of each cell/jar

• interconnection resistance

These measurements, along with other maintenance data

such as ambient and pilot cell temperatures and ac ripple

currents, help determine the condition of a battery system.

The BITE 2/2P consists of a transmitter and a receiver that

enable an operator to test for sulfating plates, post-strap

corrosion, poor internal connections and poor intercell

connections.

AVTM246004 BITE 2/2P Rev 4 July 2011

1

Page 10

M

How the BITE 2/2P Works

Average impedance values for

different types of batteries are

available from Megger.

The operator connects the current source leads from the

BITE 2/2P transmitter to a battery string so that an ac test

current is capacitively coupled through the battery. It is best

to test the battery string when it is operating at full float, that

is, a constant charge level.

Then the operator uses the receiver to measure the voltage

drop across the cell terminals. When the voltage drop across

the cell is divided by the total ac current passing through the

battery, the calculated value is impedance according to Ohm's

Law. This impedance value gives the operator an indication of

the overall condition of the cell, with high impedance typically

indicating an unhealthy cell.

Several factors influence an impedance value, for instance,

the size and type of cell, ambient and electrolyte temperature,

and state of charge. Therefore, to determine the impedance of

a healthy cell, the operator should measure a large number of

similar cells under similar conditions and then calculate the

average value. Deteriorating cells are easily identified by their

higher-than-average impedance.

The BITE 2/2P also automatically measures and records the

cell voltage and the time and date of the test. This voltage

represents individual cell float voltage while measuring an

operational string of cells.

AVTM246004 BITE 2/2P Rev 4 July 2011

The BITE 2/2P also measures intercell or strap connections

and stores them with the cell impedance values. The BITE

2/2P can measure and record all aspects of the electrical path

of the battery, including:

• location ID

• user ID

• test current

• total current

• internal cell impedance

• dc voltage

• intercell connector resistance

• specfic gravity

• time and date

2

Page 11

Applications for the BITE 2/2P

INTRODUCTION

The BITE 2/2P measures the following battery types, ranging

to 7000 Ah:

• lead-acid flooded cells

• sealed (VRLA) cells

• nickel-cadmium cells

The BITE 2/2P tests many system types, including:

• telecommunications

• substations

• UPS systems

• electrical power substations

• railroad signals and communications

• motive power batteries

• aircraft power supplies

• marine and military applications

• many others

For information about other installations that might benefit

from impedance testing, contact Megger.

AVTM246004 BITE 2/2P Rev 4 July 2011

3

Page 12

M

BITE 2/2P Measurements

Impedance readings are calibrated to 5 percent of reading over

the specified temperature range. For ac impedance, the

receiver screen presents data as ranges: 1.000, 10.00, and

100.0 mΩ. The maximum measurement is 200 mΩ.

Impedance precision (reproducibility) is 0.5%, and voltage

precision is 0.5%.

Test numbers start with number one (001) and increment

after each successful cell and strap reading. The operator

initiates data acquisition by pulling a trigger on the receiver.

The measurement range for dc voltage is from 1 to 25 V dc

with an accuracy of 1 percent of reading.

Intercell (strap) and intertier connection measurements are

made directly after the internal cell impedance measurement

when STRAP is displayed on the LCD of the receiver. This

feature provides resistance measurements in the same ranges

as the cell/module impedance.

Total current is monitored with each impedance measurement

to compute both cell and strap impedance and intercell (strap)

resistance. The operator selects filtering in a menu in the

receiver as either 50 Hz or 60 Hz depending on the line

voltage.

A low current cutoff alarm is maintained at 3 A, and the

maximum current allowed is 15 A. The LCD displays

"Hi_A" to warn of an ac current over-range and "Lo_A" for

current below 3 A.

Upon Receipt of the BITE 2/2P

AVTM246004 BITE 2/2P Rev 4 July 2011

Check the equipment received against the packing list to

ensure that all materials are present. Notify Megger of any

shortage (tel: 610-676-8500).

The BITE 2 instrument is shown in Figure 1-1. The BITE 2

includes the following components and accessories:

• transmitter with built-in receiver battery charger

• receiver

4

Page 13

INTRODUCTION

• current source leads

• clamp-on current sensor (CT) with a 6-ft extension

cable

• canvas carrying case for leads

• instruction manual

• null modem cable

Figure 1-1: BITE 2 instrument

The BITE 2P instrument is shown in Figure 1-2. The BITE 2P

includes the following components and accessories:

• transmitter with built-in printer and receiver battery

charger

• receiver

• current source leads

• clamp-on current sensor (CT) with a 6-ft extension

cable

• instruction manual

• null modem cable

AVTM246004 BITE 2/2P Rev 4 July 2011

5

Page 14

M

Figure 1-2: BITE 2P instrument

Safety First

AVTM246004 BITE 2/2P Rev 4 July 2011

Be sure to read the safety information in Chapter 2

thoroughly and observe all safety precautions and

recommendations.

6

Page 15

How to Use This Manual

Typographic

Conventions

INTRODUCTION

Cautions alert you to possible

damage to equipment.

G

Warnings alert you to

conditions that are potentially

hazardous to people.

F

• Figures and tables are numbered in sequence by

section.

• Numbered lists show procedural steps.

• Bullets list items and options.

• Buttons represent elements on the BITE 2/2P control

panel.

CAUTION

Never allow water to enter the case of the BITE 2/2P.

WARNING

Always power off and disconnect the BITE 2/2P before

cleaning it.

Notes provide important

information.

Margin notes offer extra

information and assistance.

AVTM246004 BITE 2/2P Rev 4 July 2011

NOTE: If you do not want to test the strap, pull the trigger and go

directly to Step Six.

7

Page 16

M

M

AVTM246004 BITE 2/2P Rev 4 July 2011

8

Page 17

M

2

SAFETY

Overview

The BITE 2 and BITE 2P and their recommended

operating procedures have been designed with careful

attention to safety. However, it is not possible to eliminate

all hazards from electrical test equipment or to foresee

every possible hazard that may occur. The user not only

must follow the safety precautions contained in this

manual, but also must carefully consider all safety

aspects of the operation before proceeding.

Safety Requirements

Any use of electricity inherently involves some degree of

safety hazard. While Megger has made every effort to

reduce the hazard, the operator must assume

responsibility for his or her own safety. Any work on

batteries is hazardous and requires constant attention to

safety. You should guard particularly against the

possibility of acid spills, explosion, and electrical shock.

The BITE 2/2P test instrument has been designed to the

IEC-1010-1 safety standard. Observe all industry

standard safety rules for testing batteries.

• The BITE 2/2P transmitter is designed for connection

to energized systems. Keep the BITE 2/2P

transmitter S1 power switch set to O (OFF) or turn off

the Current On/Off switch when connecting or

disconnecting to the battery. Always wear rubber

gloves during these operations.

• Always connect the source leads to the BITE 2/2P

before connecting to the battery under test.

AVTM246004 BITE 2/2P Rev 4 July 2011

9

Page 18

M

• Always remove the instrument test leads from the

battery under test when not in use.

• The purpose of this equipment is limited to use as

described in this manual. Do not use the equipment

or its accessories for any purpose other than

specifically described.

• To avoid electric shock hazard, operating personnel

must not remove the protective instrument covers.

Component replacement and internal adjustments

must be made by qualified service personnel only.

• Do not operate in an explosive atmosphere. Explosive

gases such as hydrogen can be present around

batteries. A properly vented battery environment is

considered safe, but it is the responsibility of the

operator to verify conditions before using the

BITE 2/2P.

• Wear protective clothing and eye protection to guard

against skin and eye damage from battery acid or in

the event of short-circuit sparking.

Replacement leads can be obtained

from Megger.

• Ensure that test leads and probes are in good

condition, clean, and free of broken or cracked

insulation.

• Observe all cautions and warnings in this manual and

on the equipment.

• This instrument is to be used only by suitably trained

personnel who are familiar with the hazards involved

in testing high voltage dc systems.

• Safety is the responsibility of the operator.

AVTM246004 BITE 2/2P Rev 4 July 2011

10

Page 19

Connection to Power Source

SAFETY

The BITE 2/2P test instruments operate from a singlephase power source. The three-wire power cord requires a

two-pole, three-terminal, live, neutral, and ground type

connector. The voltage to ground from either pole of the

power source must be 100 – 240 volts (50-60 Hz)

nominal. Do NOT exceed 264 V max.

Before connecting to the ac power source, determine that

the instrument rating matches the voltage of the power

source and has a suitable two-pole, three-terminal

grounding type connector.

The power input plug must be inserted only into a mating

receptacle with a ground contact. Do not bypass the

grounding connection. Any interruption of the grounding

connection can create an electric shock hazard. Make

sure that the receptacle is properly wired before inserting

the plug.

Depending on whether the test set is supplied with a

black, white and green input supply cord or a brown,

blue and green/yellow supply cord, the black or brown

cord lead must be connected to the live pole and the

white or blue cord lead must be connected to the neutral

pole of an approved power input plug. The green or

green/yellow ground lead of the input supply cord must

be connected to the protective ground (earth) contact of

the input plug.

Fuse Replacement

See "Maintaining Fuses in the BITE 2

and BITE 2P Transmitters" on page

78 for detailed instructions on fuse

replacement.

Refer fuse replacement to qualified personnel only. To

avoid electric shock and fire hazard, use only the fuse

specified (see Appendix B), which is identical with respect

to type, voltage rating, and current rating.

Cautions and Warnings

This manual provides cautions and warnings where

applicable, and these safety features should be strictly

observed.

AVTM246004 BITE 2/2P Rev 4 July 2011

11

Page 20

M

M

AVTM246004 BITE 2/2P Rev 4 July 2011

12

Page 21

M

3

CONTROLS, CONNECTORS, INDICATORS AND

MENUS

Overview

This chapter explains the locations and functions of the

controls, connectors, indicators and menus for the

BITE 2/BITE 2P transmitter and receiver. The first section

covers the BITE 2 transmitter, the second covers the BITE

2P transmitter, and the third covers the receiver.

AVTM246004 BITE 2/2P Rev 4 July 2011

13

Page 22

M

J3 J2

F1

BITE 2 Transmitter

Current On/Off Switch

Figure 3-1 shows a front view of the BITE 2 transmitter.

Over Voltage

Current Ready

Control Panel

Digital Meter

J1

Power Switch

Receiver Charger On/Off Indicator

Receiver Charger On/Off Indicator

Figure 3-1: BITE 2 transmitter

Digital Meter—ac source current digital indicator with a

scale of 0 to 15 A.

Power Switch—The power switch is pressed to turn the

transmitter on and off. The power switch is marked with |

(for ON) and O (for OFF).

Current On/Off Switch—The current on/off switch is

pressed to start or stop the flow of the test current to the

battery.

AVTM246004 BITE 2/2P Rev 4 July 2011

14

Page 23

CONTROLS, CONNECTORS, INDICATORS AND MENUS

Receiver Charger On/Off Indicator—LED illuminates when

the receiver is plugged into the receiver and the charger is

energized. It also indicates the state-of-charge of the receiver

battery. While the battery is charging, the LED remains

constant; when the battery is fully charged, the LED blinks.

Indicator Lamps:

CURRENT READY—Illuminates after the coupling

capacitors in the transmitter are charged to the bus

voltage. A delay timer allows current flow to the

battery under test.

POWER—Illuminates whenever the Power Switch is in

the | (ON) position and the unit is powered by 120 V

(230 V) ac line voltage

OVER VOLTAGE—Indicates that the voltage across the

current source leads is greater than 275 V dc. (The

READY light will go out and the current flow to the

battery will stop when an over-voltage condition

occurs.)

Transmitter

Connector Panel

Power module—The transmitter power module comprises

the following components:

J1 receptacle—The standard power cord supplied with

the instrument is inserted into this 120 V/60 Hz (230

V/50 Hz) receptacle for ac power.

F1 Fuse carrier/voltage selector—The fuse carrier is

removed as needed to replace fuses. The arrow located on

the connector panel directly to the left of the J1 receptacle

should point to the indicator on the fuse carrier that

corresponds to the proper voltage (120 V or 230 V). See

Figure 3-3.

J2 connector—The transmitter current source leads are

connected from this connector to the battery under test.

J3 connector—The receiver battery is charged from this

connector to J3 on the receiver to charge its battery.

AVTM246004 BITE 2/2P Rev 4 July 2011

15

Page 24

M

Receiver Charger

Bin

J3

Switch

BITE 2P Transmitter

Figure 3-2 shows a front view of the BITE 2P transmitter.

Printer

Storage

Current Ready

Over Voltage

Control Panel

Digital

J2

F1

Power

Module

J1

Power

J4

Current On/Off Switch

Figure 3-2: BITE 2P transmitter

Digital Meter—ac source current indicator with a scale of 0

to 15 A.

Power Switch—The power switch is pressed to turn the

transmitter on and off. The power switch is marked with a |

(for ON) and an O (for OFF).

Current On/Off Switch—The current on/off switch is

pressed to start or stop the flow of the test current to the

battery.

AVTM246004 BITE 2/2P Rev 4 July 2011

16

Page 25

CONTROLS, CONNECTORS, INDICATORS AND MENUS

Indicator Lamps:

Note: Use only the 120V or

240V setting. The 100V and

230V will blow fuses.

RECEIVER CHARGER ON/OFF—Illuminates when the

receiver is plugged into J4 and the receiver charger is

energized. It also indicates the state-of-charge of the receiver

battery.

CURRENT READY—Illuminates after the coupling capacitors

in the transmitter have been charged to the bus voltage. A

delay timer allows current flow to the battery under test.

OVER VOLTAGE—Indicates that the voltage across the

current source leads is greater than 275 V dc. (When an

over-voltage condition occurs, the CURRENT READY light will

go out and the current will stop being applied to the battery.)

J1 receptacle—The standard power cord supplied with the

instrument is inserted into this 120 V (230 V) receptacle for ac

power.

F1 Fuse carrier/voltage selector—The fuse carrier is

removed as needed to replace fuses.

To change selected voltage: open fuse cover, using small blade

screwdriver or similar tool. Pull voltage selector card straight

out of housing, using indicator pin. Orient indicator pin to

point up when desired voltage is readable at bottom. Insert

voltage selector card into housing with printed side of card

facing forward toward IEC connector and edge containing the

desired voltage first. Replace cover, and verify that indicator

pin shows the desired voltage.

Figure 3-3: Voltage Selector Card Orientation

J2 connector—The transmitter current source leads are

connected from this connector to the battery under test.

J3 connector—The printer cable from the receiver is

connected to print test data.

J4 connector—The receiver battery is charged from the on

the BITE 2P transmitter when the J4 connector on the

transmitter is connected to the J3 connector on the receiver.

AVTM246004 BITE 2/2P Rev 4 July 2011

17

Page 26

M

POWER ON

ENTER Key

7-

Pin

4-Pin

Potential

3-Pin

TRIGGER

UP and

Receiver

The receiver is a universal device that can be used with the

entire BITE product family. Figure 3-4 shows a front view of

the receiver.

DOWN

ARROW

Keys

Connector

Connector

LCD

Switch

Probe

Connector

Figure 3-4: Receiver controls, connectors, and indicators

POWER ON switch—The POWER ON switch is pressed to

power on the receiver. However, it is important to note that

this switch does not power off the receiver. You must choose

POWER DOWN from Menu 1.

LCD—The graphics-type LCD displays menu choices and

receiver-related information. (See the following subsection,

“Receiver Keys,” for information about keys associated with

the screen.)

Potential probe—The potential probe is used in conjunction

with the receiver to take cell impedance, voltage, and strap

resistance measurements.

Trigger—The trigger is pulled to perform functions on the

receiver, including entering test information.

AVTM246004 BITE 2/2P Rev 4 July 2011

18

Page 27

CONTROLS, CONNECTORS, INDICATORS AND MENUS

7-pin connector—The 7-pin connector is used to insert one

of the following: RS-232 communication cable, bar-code wand

(optional), potential probe or printer.

Receiver Keys

4-pin connector—The 4-pin connector is used to connect the

current sensor (CT).

3-pin connector—The 3-pin connector is used to connect the

battery charger.

Buzzer—The buzzer prompts the user to input data. It also

sounds under certain error conditions.

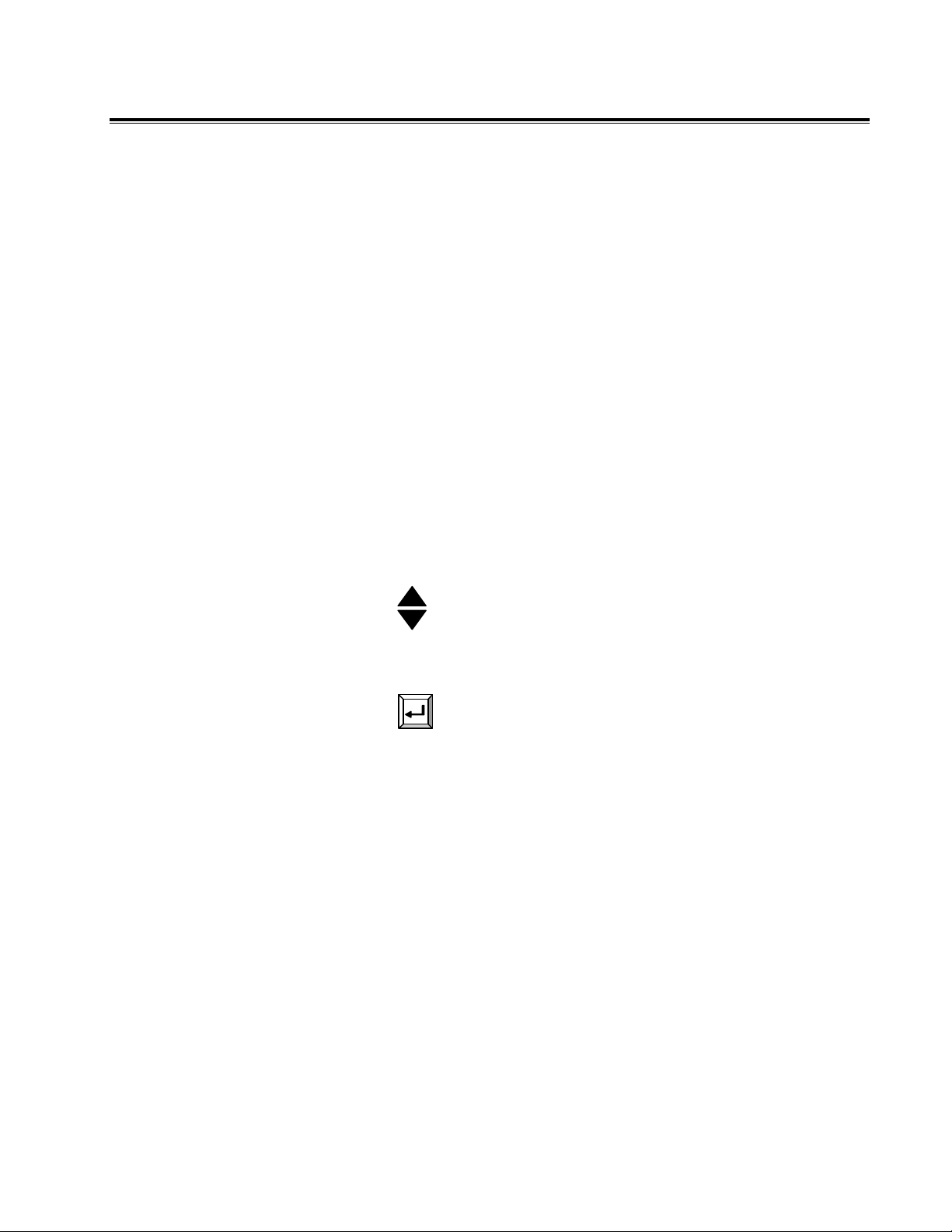

There are three keys located on the receiver that are used to

operate the receiver and to navigate through the menus and

displays on the LCD screen:

The UP ARROW and DOWN ARROW keys are

used to select information displayed next to

these keys on the screen. These keys are also

used to scroll up and down through receiver

screens.

The ENTER key is used to access receiver

menus, which are shown in Figure 3-6

through Figure 3-7.

AVTM246004 BITE 2/2P Rev 4 July 2011

19

Page 28

M

Test Menu Structure

Megger

COPYRIGHT 2000

RELEASE 2.0

Figure 3-5: Flowchart for Receiver menus

AVTM246004 BITE 2/2P Rev 4 July 2011

20

Page 29

CONTROLS, CONNECTORS, INDICATORS AND MENUS

Main Menu Structure

AVTM246004 BITE 2/2P Rev 4 July 2011

Figure 3-6: Flowchart for Receiver menus (cont'd)

21

Page 30

M

Print Menu Structure

Figure 3-7: Flowchart for Receiver menus (cont’d)

Example of How to Use

the Receiver Keys

AVTM246004 BITE 2/2P Rev 4 July 2011

1. Suppose that the following Menu is displayed on the

screen as shown in Figure 3-6.

2. To select EXPORT DATA, press .

3. However, to move from menu to menu, press .

22

Page 31

CONTROLS, CONNECTORS, INDICATORS AND MENUS

Y TEST COMPLETE

N (Y/N)? MENU

Figure 3-8: Receiver menu

AVTM246004 BITE 2/2P Rev 4 July 2011

23

Page 32

M

Receiver Reset

Switch

The RESET switch (see Figure 3-9), located on the receiver

back panel, is only for Megger authorized calibration and

repair. Activating the RESET switch de-energizes the

receiver. Never use the RESET switch. It will result in

permanent loss of data and loss of calibration.

RESET Switch

Figure 3-9: Receiver RESET switch

AVTM246004 BITE 2/2P Rev 4 July 2011

24

Page 33

M

4

STANDARD TEST PROCEDURE

Overview

The testing procedure explained in this chapter represents a

generic application of the BITE 2/2P. Actual test scenarios

may differ with each application. Contact Megger if you need

additional information about a specific test procedure.

The BITE 2/2P is used to test battery strings while the dc

Using the BITE 2/2P to test a battery string involves the

NOTE: Before performing tests on any battery system, read,

understand, and observe all safety precautions as outlined in

Chapter 2 “Safety”, which starts on page 9 of this manual.

system is at float potential. It can store up to 2040 cell/jar

records in up to 300 tests. The transmitter can provide test

current for battery strings of up to 275 V dc.

NOTE: If the battery under test is greater than 275 V dc, the

string must be tested in sections. Refer to "Sectioning a

Battery System" on page 49 for information on sectioning a

battery.

following steps:

1. Perform pretest activities such as recording information

about the test site, visually inspecting the condition of the

battery, and recording the temperature.

2. Power on the receiver and follow menus.

AVTM246004 BITE 2/2P Rev 4 July 2011

3. Scan test information with the bar-code wand (optional).

4. Split the strap (if needed).

25

Page 34

M

5. Connect the BITE current source leads to the battery and

then power on the transmitter.

F

6. Measure the cell impedance, voltage, and strap resistance.

7. Perform post-test activities such as transferring data,

reviewing and deleting data, and powering down and

disconnecting the transmitter.

The detailed procedures needed to perform these steps are

explained in the following subsections.

WARNING

Before attempting to use the BITE2 or 2P to perform a

test, be sure that you first read and understand the safety

requirements and operating procedures contained in this

manual. When using the BITE 2/2P, strictly observe all

safety precautions.

Operating Note

Do not perform a test while the battery is under a heavy

charge or discharge. If the battery under test has been

recently subjected to boost charging, a waiting period of 72

hours is recommended before performing an ac impedance

test or any other test. If the ac mains are out and the battery

is discharging to support the load, then unreliable impedance

measurements may be obtained. Relative impedance values

are affected by charge and discharge status, cell age, and

ambient temperature.

AVTM246004 BITE 2/2P Rev 4 July 2011

26

Page 35

Step One: Prepare for Testing

STANDARD TEST PROCEDURE

Record information about the test site, visually inspect the

condition of the battery, and record the ambient temperature.

1. Record the installation date and the location and type of

cells being tested. You can record the information at the

battery test site on a data sheet or on the top of the paper

fed from the built-in printer or scanned into memory.

If the battery is to be measured while on standby, ensure

that the charger associated with the battery is supplying

normal float current and that the battery is not in a

discharged condition.

The best reproducible test information occurs when the

battery is operating at recommended float voltage. See

Operating Note on page 26.

2. Perform a visual check of all cells and connections.

For flooded cells, use a flashlight and mirror (if necessary)

and check for plate corrosion and other internal defects.

Record and correct all problems encountered before testing

impedance.

NOTE: For valve-regulated

(sealed) cells, measure the

temperature of the negative

post of the cell.

For VRLA cells, visually inspect for leaking or weeping

posts, bulging cells, terminal corrosion and general

installation condition. Record and correct all problems

encountered before testing impedance.

For NiCd cells, visually inspect each cell and intercell

connector for general condition. Check electrolyte levels.

Record and correct all problems encountered before testing

impedance.

Changes in cell temperature or ambient (room) temperature may

affect cell impedance.

3. Record the cell temperature.

4. Record the ambient temperature.

After you have successfully performed these pretest activities,

you are ready to power on the receiver. The following

subsection contains the appropriate procedures.

AVTM246004 BITE 2/2P Rev 4 July 2011

27

Page 36

M

Step Two: Powering-on the Receiver

After you successfully perform the pretest activities described

Step One, you are ready to power on the receiver.

UP and

DOWN

ARROW

Keys

3-Pin

Connector

7-Pin

Connector

LCD

4-Pin

Connector

POWER ON

Switch

ENTER Key

TRIGGER

Potential

Probe

Figure 4-1: Receiver controls, connectors and indicators

AVTM246004 BITE 2/2P Rev 4 July 2011

1. Make sure the receiver charger is disconnected from the

receiver.

NOTE: Do not use the receiver to perform tests while the

charger is connected to the receiver.

2. Connect the potential probe cable assembly to the 7-pin

connector on the receiver.

3. Press the POWER ON switch on the receiver.

The receiver powers on and displays several initialization

screens.

28

Page 37

STANDARD TEST PROCEDURE

POWER ON

Check for connected cables

RS232 None Wand

Megger

COPYRIGHT 2000

RELEASE 2.0

Figure 4-2: Initialization screens

NOTE: If the receiver is not sufficiently charged, a low battery

message is displayed to alert you. You can work for a short time

on a low battery; however, you should charge the receiver as soon

as possible to ensure that your work is not disrupted because of

low battery power.

NOTE: If the available memory in the receiver is low (that is, if

there is not much space left to store test information), a message

is displayed to alert you. In this case, prior to testing you may

want to export previous test results to a PC and then delete all or

some of those test results from the receiver. Doing so will make

more memory available for the test you are about to perform.

After initializing, the receiver displays a screen that prompts

you to decide whether you want to scan bar-coded

information related to the test. The following subsection

contains the appropriate procedures.

AVTM246004 BITE 2/2P Rev 4 July 2011

29

Page 38

M

Step Three: Scanning Test Information with the Wand (Optional)

Refer to page 89 for additional

information about bar coding.

If you connect the wand before

powering on the receiver, the

receiver automatically prompts

you to scan the location ID.

If You Do Not Want

to Scan Information

Using the Wand

After initialization, the screen on the receiver prompts you to

decide whether you want to scan the test location ID, ambient

temperature, and pilot cell temperature using preprinted bar

codes provided by Megger.

Y WAND (Y/N)?

N MENU

If you choose to use the wand, the scanned information is

stored in the receiver along with the results of the test. It is

important to note that the wand is optional and, although it

provides a quick and convenient way of recording information,

it is not needed to perform a test.

If you do not have a wand or you do not want to scan

information about this test, press on the receiver. The

key corresponds to the N (for NO) and instructs the receiver

to bypass the scanning procedures.

If You Want to Scan

Information Using

the Wand

The UP ARROW key

corresponds to the Y (for yes).

AVTM246004 BITE 2/2P Rev 4 July 2011

The receiver then prompts you to decide whether you want to

split the strap. Proceed to Step Five: Splitting the Strap on

page 33.

If you have a wand and you want to scan information about

this test:

1. Press on the receiver.

The receiver prompts you to connect the wand.

CONNECT WAND!

30

Page 39

STANDARD TEST PROCEDURE

2. Using the wand adapter cable, insert the wand into the

7-pin connector on the receiver. (See Figure 4-1 on

page 28 for the location of the 7-pin connector.)

If these indications do not

occur, the receiver has not

saved the information.

The receiver prompts you to begin scanning the test

information. For information on creating bar-code labels,

refer to the documentation provided with the wand.

Figure 4-3: Scanning test information

3. Scan the location ID. Then scan Enter. The receiver

buzzer should sound and the wand LED should light each

time you scan information with the wand.

4. Scan the ambient temperature. Then scan Enter.

5. Scan the pilot cell temperature. Then scan Enter.

You are finished scanning information. The receiver prompts

you to disconnect the wand.

DISCONNECT WAND:

........WAITING........

6. Disconnect the wand from the 7-pin connector on the

receiver.

The receiver now prompts you to set baseline, warn and fail

values for the test.

AVTM246004 BITE 2/2P Rev 4 July 2011

31

Page 40

M

Step Four: Setting Baseline, Warning and Fail Values

The BITE 2/2P now lets you set baseline, warning and fail

impedance values when conducting a test. Then, after

displaying the cell or strap measurements, the BITE 2/2P

receiver screen will indicate PASS, FAIL or WARN and will

display the measured value as a percentage of the baseline

value.

After you finish wanding information, the receiver will display

the following menu:

Y ENTER BASELINE?

N (Y/N) MENU

If you do not want to set baseline, warn and fail values, press

(for NO). The receiver screen will ask whether you want to

split the strap. Go to "Step Five: Splitting the Strap below.

If you want to enter baseline, warn and fail values, press

(for YES).

BASE WARN FAIL

XX.XX XX% XX%

Use the to scroll through the digits until the desired

1.

digit is displayed.

2.

Press

.

3. Repeat for each digit and the decimal point until the

desired baseline, warn and fail values are displayed.

AVTM246004 BITE 2/2P Rev 4 July 2011

32

Page 41

Step Five: Splitting the Strap (if needed)

STANDARD TEST PROCEDURE

If You Do Not Want

to Split the Strap

After the Wand Menu and Enter Baseline menu, the receiver

displays a screen that asks whether you want to split the

strap.

You need to split the strap if the strap you want to measure

consists of more cables or intercell connectors than the

diameter of the clamp-on current sensor (CT) can handle.

Y SPLIT STRAP

N (Y/N)? MENU

NOTE: Splitting a strap may not split the current equally. Verify

that the current is split fairly evenly between the straps. If the

current split is not even, then try to find another location where

the current is more evenly split.

If You Want to Split

the Strap

If you do not want to split the strap, simply press (for NO)

on the receiver, which instructs the receiver not to split the

strap.

You are prompted to connect the CT to the strap. Proceed to

“Step Six: Connecting the Receiver and the BITE 2 or BITE 2P

Transmitter to the Battery” on page 35.

If you want to split the strap:

1. Press on the receiver to enter Y (for YES).

The receiver prompts you to enter a multiplier, which is a

numeric value that the receiver uses to determine the

measurement of the entire strap.

UP MULTIPLIER

DN >1_< ACCEPT

AVTM246004 BITE 2/2P Rev 4 July 2011

33

Page 42

M

For example, suppose that the strap you want to measure

consists of four cables, but you can get the standard CT

around only two of them. You would need to enter a multiplier

of 2.

The receiver would then multiply the reading you take by two

so that the proper test results are computed for all four

cables.

Pressing increases the

multiplier. Pressing

decreases the multiplier.

Saving the settings saves the

baseline, warn and fail values

and the multiplier.

2. Press or to specify the correct multiplier.

3. When the multiplier you want to use is displayed, press

to accept the multiplier value.

The receiver screen asks if you want to save settings

Y SAVE SETTING?

N (Y/N) MENU

Press (for YES) or for (NO). Proceed to Step Six.

AVTM246004 BITE 2/2P Rev 4 July 2011

34

Page 43

STANDARD TEST PROCEDURE

Step Six: Connecting the Receiver and the BITE 2 or BITE 2P

Transmitter to the Battery

WARNING!

To avoid electric shock, always wear rubber gloves when

F

making connection to battery systems. Voltages to

ground in excess of 270 V dc are possible.

UP and

DOWN

ARROW

Keys

3-Pin

Connector

LCD

1. The receiver screen prompts you to connect the CT.

CONNECT CT! XX.X

RIPPLE CURRENT

2. Connect the plug of the CT to the 4-pin connector on the

receiver. Figure 4-4 shows the location of the 4-pin

connector.

POWER ON

Switch

ENTER Key

TRIGGER

7-Pin

Connector

Figure 4-4: Receiver controls, connectors, and indicators

AVTM246004 BITE 2/2P Rev 4 July 2011

4-Pin

Connector

Potential

Probe

35

Page 44

M

If you are splitting the strap,

keep in mind the multiplier you

specified. When the CT is

connected, the receiver displays

a measurement of the system

ripple current.

3. Position the clamp-on end of the CT around a convenient

intertier or intercell connection on the battery so that the

current you are going to measure will be within the loop

created by the current source leads from the

transmitter and the battery string.

NOTE: Loads, parallel strings, and charging equipment can

create parallel paths for the measurement current. Therefore,

place the standard 2 in. CT at a location that verifies the source

measurement current for the cells under test. Do not place the CT

around the current source lead. This may not represent the

current flowing through the battery string.

4. Pull the receiver trigger to advance the receiver and store

the ripple-current reading.

5. Next, the receiver screen prompts you to begin connecting

the BITE 2/2P transmitter to the battery.

CONNECT & POWER

TRANSMITTER: XX.X

Source leads from

transmitter connected

to terminal plate

Red

Source leads from

transmitter connected

to terminal plate

To ac power

Black

Figure 4-5: BITE 2/2P transmitter connected to the battery

AVTM246004 BITE 2/2P Rev 4 July 2011

36

Page 45

STANDARD TEST PROCEDURE

Connecting the

BITE 2 or BITE 2P

Transmitter

1. Make sure that the transmitter power switch is in the O

(OFF) position.

See Figure 3-1 for the position

of the J2 connector.

Be sure to make the

connections to the battery

terminal plate and not to

intercell connection hardware.

G

2. Insert the plug of the current source leads into the

transmitter connector marked J2. Then rotate the plug

collar clockwise to tighten it.

3. Connect the current source leads to the end positive and

negative terminal plates of the battery.

CAUTION

You can use the BITE 2 transmitter to provide test current for

measurements on each cell/module for a battery string of up

to 275 V dc. If the battery under test exceeds this limit, section

the battery into portions that are less than 275 V dc. For

information on sectioning a battery, refer to "Sectioning a

Battery System" on page 49.

.

BITE 2: The transmitter

CURRENT READY lamp

illuminates when the unit is

operating and applying current.

BITE 2P: The transmitter

Power LED illuminates when

the unit is on.

AVTM246004 BITE 2/2P Rev 4 July 2011

4. Insert the power cord into the J1 power receptacle on the

transmitter. Then plug the power cord into a 120 V

(230 V) outlet, as appropriate.

5. Power on the transmitter by pressing the power switch to

the | (ON) position.

6. Press the current On/Off switch to energize the current

source. There is a delay while the coupling capacitors are

charged to the bus voltage. Then the CURRENT READY

lamp lights.

7. Observe the current reading displayed on the receiver

screen.

8. Pull the receiver trigger to advance the receiver and

store the source current reading.

37

Page 46

M

The receiver displays the first test screen, which prompts you

to measure the first cell. Proceed to “Step Seven: Measuring

the Cell and the Strap.”

Operating Note

If there are less than 3 A flowing within the string of cells

selected, the receiver displays a message indicating low

current (Lo_A). This ensures proper current magnitude for

accurate measurement since the total current includes both

current from the BITE 2/2P and any ac ripple current

produced by the battery charger. If significant ripple current

is present and out of phase with the applied source current, a

low current condition may occur. If this happens, first turn off

the BITE 2/2P transmitter, then reverse the polarity of the

current source leads to bring the two currents in phase. For

the majority of applications, this will not present any

difficulty. (Refer to Chapter 5 for more information.)

Step Seven: Measuring the Cell and the Strap

CAUTION

G

Do not exceed 25 V dc, the maximum voltage allowed

between the receiver and the potential probe.

The twisting action of the probe

tips as the handle is pushed

down cleans the point of

contact and provides a better

test connection. See Figure 4-6.

AVTM246004 BITE 2/2P Rev 4 July 2011

After the transmitter is connected to the battery and is

powered on, the receiver displays the first test screen.

CELL VOLTS mΩ

001 XX.XX XX.XX

T01

The digits displayed in the upper left corner of the screen

(001) indicate that you are ready to test the first cell. The

digits in the lower left corner indicate the number of the active

test (for example, T01 for test one, T02 for test two, and so

on).

To begin testing the first cell in the string:

1. Position the receiver on the positive terminal and the

potential probe on the negative terminal of the cell/jar,

and then press down.

38

Page 47

STANDARD TEST PROCEDURE

NOTE: The reason the receiver should be positioned on the

positive terminal is to obtain a positive float voltage of the cell.

Then a cell that has gone into “cell reversal” becomes very

evident when it displays a negative float voltage.

Current Source Lead

Current Source Lead

from Transmitter

connected to negative

terminal plate

Black

from Transmitter

connected to positive

terminal plate

Red

Figure 4-6: Receiver and potential probe positioned

on top of battery cell terminals

The measurements are stored

in the receiver.

2. View the cell terminal voltage and ac impedance values

that are displayed on the receiver screen.

A sample screen is shown below.

CELL VOLTS mΩ

001 13.43 23.33

T01

3. When the voltage and impedance values displayed on the

screen stabilize, pull the trigger on the receiver to store

the reading.

If you have entered baseline, warn and fail values, the

screen will display either PASS, WARN or FAIL and a

percentage of baseline.

001

T01 PASS XX%

AVTM246004 BITE 2/2P Rev 4 July 2011

39

Page 48

M

terminal negative

If you do not want to test the

strap, pull the trigger and go

directly to Step Eight.

Current Source

Lead from

Transmitter

connected to

plate

The receiver LCD now displays the word STRAP, which

prompts you to test the strap that is associated with the

cell you just tested.

CELL VOLTS mΩ

001 13.43 23.33

T01 STRAP 0.112

4. Position the receiver and potential probe on top of the

battery strap terminals, and then press the probes down.

See the sample placement shown in Figure 4-7.

Current Source

Lead from

Transmitter

connected to

terminal positive

plate

Black

Red

Figure 4-7: Receiver and potential probe positioned

on top of battery strap terminals

AVTM246004 BITE 2/2P Rev 4 July 2011

40

Page 49

STANDARD TEST PROCEDURE

If you are testing a sectioned

battery string and want to test

the next section, refer to the

following subsection,

“Measuring the Next Section of

a Sectioned Battery String,” for

the appropriate procedures.

5. When the strap value displayed on the screen stabilizes,

pull the trigger on the receiver to store the reading.

The measurements are stored in the receiver.

The receiver now displays the digits 002 in the top left corner

of the test screen. This means that you are ready to test

cell #2.

6. Continue to measure the other cells and straps in the

string.

7. After the last cell, the receiver expects a strap result.

Short the receiver and potential probe together and pull

the trigger. This saves the last cell’s data or else it will be

lost.

8. When you are finished measuring all the cells and straps,

press on the receiver to complete the test.

The receiver prompts you to confirm that the test is complete.

Y TEST COMPLETE

N (Y/N)? MENU

Review the test information that

is stored in the receiver. You

can scroll through the results

and, if needed, retest individual

cells and straps. Refer to

"Reviewing a Test” on page

43.

9. Press on the receiver to enter Y (for YES).

The receiver prompts you again to confirm that the test is

complete.

Y ARE YOU SURE

N (Y/N)? MENU

10. Press on the receiver to enter Y (for YES).

The receiver displays a screen to indicate that the test is

complete.

DONE!

For instructions on what to do following the test, see "Step

Eight: What to Do When the Test Is Complete” on page 43.

AVTM246004 BITE 2/2P Rev 4 July 2011

41

Page 50

M

Measuring the Next

Section of a

Sectioned Battery

String

F

If you have finished testing the first section of a sectioned

battery string and want to measure the next section:

1. Press the Current ON/OFF switch on the BITE 2/2P

transmitter.

This blocks the current from being applied to the battery

while the transmitter powers down.

2. Connect the current source leads to the next battery

section.

NOTE: If you are interrupted and need to leave the site

unexpectedly, simply shut down the receiver and transmitter.

The receiver will “remember” where you left off when you

return to finish the test.

WARNING

Do not remove the BITE 2/2P transmitter current source

leads from the battery until the BITE 2/2P transmitter is

powered off. Always disconnect the current source leads

from the battery before removing them from the J2

connector on the transmitter. Do not leave the BITE 2/2P

connected to the battery when not in use.

AVTM246004 BITE 2/2P Rev 4 July 2011

3. Press the Current On/Off switch on the BITE 2/2P

transmitter.

After the CURRENT READY light illuminates, the current is

applied to the battery and you can continue testing.

Test the section. Repeat the procedure as needed, depending

on the number of sections in the battery string.

42

Page 51

STANDARD TEST PROCEDURE

Step Eight: What to Do When the Test Is Complete

Reviewing a Test

You can perform the following operations after a test is

complete:

1. Export test results to a PC. You can then use the PC to

view or print the test results. (Refer to Chapter 6.)

2. Print test results on the BITE 2P transmitter printer.

3. Delete the test information from the receiver.

4. Start a new test. (Return to "Step One: Prepare for

Testing" page 27.)

5. Power down and disconnect the transmitter. You will

need to do this if you are finished using the BITE 2/2P

for this testing session. (See "Powering Down and

Disconnecting the BITE 2/2P" on page 45).

At any time while you are performing a test, you can review

the results of the active test that are already stored in the

receiver.

AVTM246004 BITE 2/2P Rev 4 July 2011

1. To review the current test, press on the receiver to

scroll back through the active test screens.

2. Press to scroll forward through the active test screens.

You may print the active test results on the BITE 2P

transmitter printer for review. Please note that there are no

statistics or bar graphs printed for the active test. See

"Printing an Active Test to Review the Data (BITE 2P)" on

page 44.

43

Page 52

M

Retesting Cells and

Straps

You cannot review a test after it

has been completed. (Refer to

"Step Seven: Measuring the Cell

and the Strap," #'s 6,7, and 8,

for a description of completing a

test.)

If needed, you can retest any of the cells or straps in the

current test.

1. Navigate through the test screens until information about

the cell or strap you want to retest is displayed.

2. Pull the trigger.

The receiver enters into test mode.

001 XX.XX XX.XX

T01

3. Position the receiver and potential probe on top of the

battery cell terminals, and then press down.

4. When the voltage and impedance values displayed on the

LCD stabilize, pull the trigger to store the readings.

See the sample placement

shown in Figure 4-7 on page 40.

Printing an Active

Test to Review the

Data (BITE 2P)

AVTM246004 BITE 2/2P Rev 4 July 2011

5. When the strap values displayed on the screen stabilize,

pull the trigger to store the reading.

NOTE: Both measurements must be taken.

6. To return to testing, scroll forward to the next cell.

7. To retest another cell/strap, repeat steps 1-5.

To print the test data of the string for which you are taking

measurements, disconnect the potential probe and connect

the printer cable to J3. The LCD will display the following

screen.

44

Page 53

STANDARD TEST PROCEDURE

(EXPORT DATA)

Y TRANSMIT DATA

N (Y/N?) MENU

1. Press for TRANSMIT. The screen will display the

following screen.

EBITE/PC

PRINTER MENU

2. Press for PRINTER then SELECT. You will be

prompted to enter the test number. During printing the

following screen will appear:

ALLTESTS

SELECT

3. Press until the active test number is displayed. In this

example, six is the active test.

TEST 001 OF 006

O = CANCEL ACCEPT

4. Reconnect the potential probe to resume testing. The

measurement screen is displayed again.

Powering Down and Disconnecting the BITE 2/2P

AVTM246004 BITE 2/2P Rev 4 July 2011

Before you power down and disconnect the BITE 2/2P

transmitter, first power down and disconnect the receiver.

Then power down and disconnect the transmitter. Carefully

follow these steps:

1. To power down the receiver, press the

receiver until the LCD displays the following:

POWER DOWN

EXPORT DATA MENU

45

key on the

Page 54

M

2. Press on the receiver to choose POWER DOWN.

The receiver prompts you to confirm your decision.

Y ARE YOU SURE?

N (Y/N)? MENU

3. Press on the receiver to enter Y (YES). The receiver

powers down.

4. Disconnect the CT from the battery and the receiver.

You can now power down the transmitter.

5. To power down the BITE 2/2P transmitter, press the

Current ON/OFF switch to disconnect the current

source. Then press the transmitter power switch to the

O (OFF) position.

WARNING

F

Remember to recharge the

receiver battery. Refer to

"Charging the Receiver" on page

74 for detailed procedures.

G

Do not remove the BITE 2/2P transmitter current source

leads from the battery until the BITE 2/2P transmitter is

powered down. Always disconnect the current source

leads from the battery before removing them from the J2

connector on the transmitter.

6. Remove the current source leads from the battery.

7. Remove the current source leads from the J2 connector

on the transmitter.

8. Unplug the power cable and then disconnect it from the

J1 receptacle on the transmitter.

CAUTION

Do not leave the BITE 2/2P connected to the battery when

not in use.

AVTM246004 BITE 2/2P Rev 4 July 2011

46

Page 55

M

5

MODIFIED PROCEDURES FOR SPECIAL

CONDITIONS

Overview

This chapter explains how to perform alternative test

procedures, including reversing the current source leads

and sectioning battery systems to correct high or low current

situations.

This chapter also describes optional equipment that can be

used with the BITE 2 and BITE 2P test instruments.

Reversing the Current Source Leads

If the transmitter displays a high or low current message,

you need to modify the test procedure. See the following

subsections for alternative test procedures.

Figure 5-1 shows a battery system with a single string of

cells. If a high or low current message is displayed on the

receiver after you connect the current source leads to a

similar battery configuration, try reversing the polarity of the

current source leads. Doing so shifts the test current by 180

degrees and offsets the effect of the system ripple current in

the receiver. This helps ensure sufficient test current in the

section of the battery string to enable computation of cell

impedance or strap resistance.

AVTM246004 BITE 2/2P Rev 4 July 2011

47

Page 56

M

From transmitter

(current source

leads)

J2

Figure 5-1: Reversing the current source leads on a single string of cells

when a high or low current message is displayed.

Verifying the Source Current

This temporarily “disconnects”

the transmitter and blocks the

current from going to the

battery.

AVTM246004 BITE 2/2P Rev 4 July 2011

A low current indication on the transmitter’s analog or

digital meter can be caused by high resistance in the cell

string. To verify whether the magnitude of the source current

is within the required limits (3-15 A):

1. Press the Current switch on the BITE 2/2P transmitter

to the ( (OFF) position.

2. Disconnect the current source leads from the battery.

3. Connect the current source lead clips together and

restart current flow by pressing the BITE 2/2P

transmitter Current On/Off switch to the (ON) position.

48

Page 57

MODIFIED PROCEDURES FOR SPECIAL CONDITIONS

WARNING

Do not remove the BITE 2/2P transmitter current source

leads from the battery until the transmitter is powered

F

off. Always disconnect the current source leads from the

battery before removing them from the J2 connector on

the transmitter. Do not leave the BITE 2/2P connected to

the battery when not in use.

The wire for the current source

lead set extends from only one

side of each pair of jaws.

Sectioning a Battery

System

Sectioning a Battery

System Greater than

275 Volts

If the LCD displays "Lo_A", refer to page 88 under

"Maintenance and Troubleshooting."

Section the battery system by connecting the current source

leads across individual sections of the string to isolate highresistance or open cells and straps. (See "Sectioning a

Battery System” below for the correct procedures.)

To test certain battery systems with the BITE 2/2P, you must

measure individual sections, one at a time. Examples are

included in the following subsections.

The nonpolarized coupling capacitor in the BITE 2/2P

current source is limited to 275 V. This restricts the current

source applied across battery systems of 275 V dc and

higher.

AVTM246004 BITE 2/2P Rev 4 July 2011

If the battery system to be tested is greater than 275 V, you

must test the system in sections that are 275 V or less. It is

recommended that you section the battery in equally-sized

sections.

Figure 5-2 shows a 600 V dc UPS system in which the source

current leads are connected across a 200 V section of the

battery string.

49

Page 58

M

J2

Not to

exceed

250 V dc

From transmitter

(current source

leads)

B

A

Figure 5-2: Sectioning a battery system greater than 275 V

The potential between the current source leads (red at A

and black B) in Figure 5-1 cannot exceed 275 V. To section

the string:

1. Place the current source leads (at points A and B) in the

string so that the potential does not exceed 275 V.

2. Test the cells located between connections A and B.

3. When you are finished testing the cells, press the Current

switch on the transmitter to the O (OFF) position.

NOTE: If you have to move the transmitter to test the next

section, you may need to power down and disconnect the

transmitter. (See "Powering Down and Disconnecting the BITE

2/2P" on page 45.)

4. Remove the current source leads from the battery. Then

move them to the next section to be tested (not to exceed

275 V).

AVTM246004 BITE 2/2P Rev 4 July 2011

50

Page 59

MODIFIED PROCEDURES FOR SPECIAL CONDITIONS

WARNING

Do not remove the BITE 2/2P transmitter current source

leads from the battery until the BITE 2/2P transmitter

F

current is de-energized. Always disconnect the current

source leads from the battery before removing them

from the J2 connector on the transmitter. Do not leave

the BITE 2/2P connected to the battery when not in use.

Sectioning a Battery

System with Parallel

Strings

5. Press the Current On/Off switch.

The current is applied to the battery and you can

continue testing.

6. Test the section.

Repeat the procedure, as needed, depending on the

number of sections in the battery string.

Figure 5-3 shows how to start sectioning a battery system

with parallel strings of cells. To test this string, you must