Page 1

Battery

testing guide

▪ Why backup batteries are needed

▪ Battery types

▪ Failure modes

▪ Maintenance philosophies

▪ Practical battery testing

▪ Frequently asked questions

▪ Megger products overview

WWW.MEGGER.COM

Page 2

Page 3

Contents

Why backup batteries are needed ................ 4

Why test battery systems .......................................4

Why batteries fail ................................................... 4

Battery types .................................................. 5

Lead-acid overview ................................................5

Nickel-Cadmium Overview .....................................5

Battery construction and nomenclature ..................... 6

Configurations ....................................................... 6

Single post batteries .................................................... 6

Multiple post batteries ................................................ 6

Failure modes ................................................. 7

Lead-acid (flooded) failure modes ..........................7

Lead-acid (VRLA) failure modes ..............................7

Nickel-Cadmium failure modes ..............................8

Maintenance philosophies ............................ 9

How to maintain the battery ..................................... 9

Standards and common practices ........................... 9

IEEE 450 ...................................................................... 9

Inspections .............................................................. 9

Capacity test (discharge test) should be done ........... 9

IEEE 1188 .................................................................. 10

Inspections ............................................................ 10

Capacity test (capacity test) should be done ........... 10

Battery replacement criteria ................................... 10

IEEE 1106 .................................................................. 10

Inspections ............................................................ 10

Capacity test (discharge test) should be done ......... 10

Summary best way to test and evaluate your

battery ................................................................. 10

Test intervals ............................................................. 10

Practical battery testing .............................. 11

Capacity test ...........................................................11

Battery testing matrix – IEEE recommended

practices .............................................................. 11

Procedure for capacity test of vented lead acid

battery ................................................................. 12

Impedance test ....................................................... 13

Impedance theory ................................................13

Intercell connection resistance ................................... 14

Testing and electrical paths ........................................ 15

Voltage ..................................................................... 15

Specific gravity ......................................................... 15

Float current ............................................................. 16

Ripple current ........................................................... 16

Temperature .............................................................. 16

Data analysis ...........................................................17

Locating ground faults on DC systems without

sectionalizing .......................................................... 18

Overview ............................................................. 18

Current test methods ........................................... 18

A better test method ...........................................18

Frequently asked questions ........................ 19

Battery technology summary .................................. 19

Megger products overview ......................... 20

Impedance test equipment ...................................... 20

®

BITE

3 ................................................................20

®

BITE

2 and BITE®2P .............................................21

ProActiv battery database management software ...... 21

®

accessories ....................................................... 21

BITE

Capacity testing ...................................................... 23

TORKEL 820/840/860 ..........................................23

TORKEL accessories ................................................... 23

Ground fault tracing equipment .............................. 24

Battery Ground Fault Tracer (BGFT).......................24

Battery Ground-fault Locator (BGL) ...................... 24

Digital Low Resistance Ohmmeters (DLRO

Microhmmeters (MOM) ..........................................26

DLRO200 and DLRO600 ......................................26

DLRO 247000 series ............................................26

MJÖLNER 200 and MJÖLNER 600 ........................ 27

MOM200A and MOM600A .................................27

MOM690 ............................................................27

Multimeters ............................................................ 28

MMC850 Multi-conductor AC Digital

Clampmeter ........................................................28

Multimeters ......................................................... 28

Insulation Resistance Test Equipment ....................... 29

MIT400 series insulation resistance testers ............ 29

®

) and

BATTERY TESTING GUIDE

3

Page 4

Why backup

batteries are

needed

Batteries are used to ensure that critical electrical equipment

is always on. There are so many places where batteries are

used – it is nearly impossible to list them all. Some of the

applications for batteries include:

▪ Electric generating stations and substations for protection

and control of switches and relays

▪ Telephone systems to support phone service, especially

emergency services

▪ Industrial applications for protection and control

▪ Back up of computers, especially financial data

and information

▪ “Less critical” business information systems

Without battery back-up hospitals would have to close their

doors until power is restored. But even so, there are patients

on life support systems that require absolute 100% electric

power. For those patients, as it was once said, “failure is not

an option.”

Just look around to see how much electricity we use and

then to see how important batteries have become in our everyday lives. The many blackouts of 2003 around the world

show how critical electrical systems have become to sustain

our basic needs. Batteries are used extensively and without

them many of the services that we take for granted would

fail and cause innumerable problems.

Why test battery systems

There are three main reasons to test battery systems:

battery. Nonetheless, a battery, to work the way it is supposed to work must be maintained properly. A good battery

maintenance program may prevent, or at least, reduce the

costs and damage to critical equipment due to an AC mains

outage.

Even thought there are many applications for batteries,

standby batteries are installed for only two reasons:

▪ To protect and support critical equipment during

an AC outage

▪ To protect revenue streams due to the loss of service

The following discussion about failure modes focuses on

the mechanisms and types of failure and how it is possible

to nd weak cells. Below is a section containing a more

detailed discussion about testing methods and their pros

and cons.

Why batteries fail

In order for us to understand why batteries fail, unfortunately a little bit of chemistry is needed. There are two main

battery chemistries used today – lead-acid and nickel-cadmium. Other chemistries are coming, like lithium, which is

prevalent in portable battery systems, but not stationary, yet.

Volta invented the primary (non-rechargeable) battery in

1800. Planté invented the lead-acid battery in 1859 and

in 1881 Faure rst pasted lead-acid plates. With renements over the decades, it has become a critically important

back-up power source. The renements include improved

alloys, grid designs, jar and cover materials and improved

jar-to-cover and post seals. Arguably, the most revolutionary

development was the valve-regulated development. Many

similar improvements in nickel-cadmium chemistry have

been developed over the years.

▪ To insure the supported equipment is adequately backed-

up

▪ To prevent unexpected failures by tracking the battery’s

health

▪ To forewarn/predict death

And, there are three basic questions that battery users ask:

▪ What is the capacity and the condition of the battery

now?

▪ When will it need to be replaced?

▪ What can be done to improve / not reduce its life?

Batteries are complex chemical mechanisms. They have

numerous components from grids, active material, posts,

jar and cover, etc. – any one of which can fail. As with all

manufacturing processes, no matter how well they are made,

there is still some amount of black art to batteries (and all

chemical processes).

A battery is two dissimilar metallic materials in an electrolyte. In fact, you can put a penny and a nickel in half

of a grapefruit and you now have a battery. Obviously, an

industrial battery is more sophisticated than a grapefruit

4 BATTERY TESTING GUIDE

Page 5

Battery types

There are several main types of battery technologies with

subtypes:

▪ Lead-acid

▶ Flooded (wet): lead-calcium, lead-antimony

▶ Valve Regulated Lead-acid, VRLA (sealed): lead-calcium,

lead-antimony-selenium

▶ Absorbed Glass Matte (AGM)

▶ Gel

▶ Flat plate

▶ Tubular plate

▪ Nickel-cadmium

▶ Flooded

▶ Sealed

▶ Pocket plate

▶ Flat plate

Lead-acid overview

The basic lead-acid chemical reaction in a sulphuric acid

electrolyte, where the sulphate of the acid is part of the

reaction, is:

PbO

+ Pb + 2H2SO4 2PbSO4 + 2H2 + 1⁄2 O

2

The acid is depleted upon discharge and regenerated upon

recharge. Hydrogen and oxygen form during discharge and

oat charging (because oat charging is counteracting selfdischarge). In ooded batteries, they escape and water must

be periodically added. In valve-regulated, lead-acid (sealed)

batteries, the hydrogen and oxygen gases recombine to form

water. Additionally, in VRLA batteries, the acid is immobilized by an absorbed glass matte (AGM) or in a gel. The

matte is much like the bre-glass insulation used in houses.

It traps the hydrogen and oxygen formed during discharge

and allows them to migrate so that they react back to form

water. This is why VRLA never need water added compared

to ooded (wet, vented) lead-acid batteries.

A battery has alternating positive and negative plates separated by

micro-porous rubber in ooded lead-acid, absorbed glass matte

in VRLA, gelled acid in VRLA gel batteries or plastic sheeting in

NiCd. All of the like-polarity plates are welded together and to the

appropriate post. In the case of VRLA cells, some compression of

the plate-matte-plate sandwich is exerted to maintain good contact

between them. There is also a self-resealing, pressure relief valve

(PRV) to vent gases when over-pressurization occurs.

2

Nickel-Cadmium Overview

Nickel-Cadmium chemistry is similar in some respects

to lead-acid in that there are two dissimilar metals in an

electrolyte. The basic reaction in a potassium hydroxide

(alkaline) electrolyte is:

2 NiOOH + Cd +2 H

However, in NiCd batteries the potassium hydroxide (KOH) does

not enter the reaction like sulphuric acid does in lead-acid batteries.

The construction is similar to lead-acid in that there are alternating positive and negative plates submerged in an electrolyte. Rarely

seen, but available, are sealed NiCd batteries.

O Ni(OH)2 + Cd(OH)2

2

BATTERY TESTING GUIDE

5

Page 6

Battery construction and

nomenclature

Now that we know everything there is to know about battery

chemistry, except for Tafel curves, ion diffusion, Randles

equivalent cells, etc., let’s move on to battery construction. A

battery must have several components to work properly: a jar

to hold everything and a cover, electrolyte (sulphuric acid or

potassium hydroxide solution), negative and positive plates,

top connections welding all like-polarity plates together and

then posts that are also connected to the top connections of

the like-polarity plates.

All batteries have one more negative plate than positive plate.

That is because the positive plate is the working plate and if

there isn’t a negative plate on the outside of the last positive

plate, the whole outer side of last positive plate will not have

anything with which to react and create electricity. Hence,

there is always an odd number of plates in a battery, e.g., a

100A33 battery is comprised of 33 plates with 16 positive

plates and 17 negative plates. In this example, each positive

plate is rated at 100 Ah. Multiply 16 by 100 and the capacity

at the 8-hour rate is found, namely, 1600 Ah. Europe uses a

little different calculation than the US standards.

In batteries that have higher capacities, there are frequently

four or six posts. This is to avoid overheating of the current-carrying components of the battery during high current

draws or lengthy discharges. A lead-acid battery is a series of

plates connected to top lead connected to posts. If the top

lead, posts and intercell connectors are not sufciently large

enough to safely carry the electrons, then overheating may oc-

2

cur (i

R heating) and damage the battery or in the worst cases,

damage installed electronics due to smoke or re.

To prevent plates from touching each other and shorting

the battery, there is a separator between each of the plates.

Figure 1 is a diagram of a four-post battery from the top

looking through the cover. It does not show the separators.

Configurations

Batteries come in various congurations themselves. Add to

that the many ways that they can be arranged, the number

of possible congurations is endless. Of course, voltage

plays the biggest part in a battery conguration. Batteries

have multiple posts for higher current draws. The more current needed from a battery, the bigger the connections must

be. That includes posts, intercell connectors and buss bars

and cables.

Single post batteries

Smaller battery systems are usually the simplest battery

systems and are the easiest to maintain. They usually have

single post batteries connected with solid intercell connectors. Frequently, they are quite accessible but because they

are small and can be installed in a cubby hole occasionally,

they may be quite inaccessible for testing and maintenance.

Multiple post batteries

Batteries with multiple posts per polarity start to become

interesting quickly. They are usually larger and frequently are

more critical.

Figure 1 Battery construction diagram

6 BATTERY TESTING GUIDE

Page 7

Failure modes

Lead-acid (flooded) failure

modes

▪ Positive grid corrosion

▪ Sediment (shedding) build-up

▪ Top lead corrosion

▪ Plate sulphation

▪ Hard shorts (paste lumps)

Each battery type has many failure modes, some of which

are more prevalent than others. In ooded lead-acid batteries, the predominant failure modes are listed above. Some

of them manifest themselves with use such as sediment

build-up due to excessive cycling. Others occur naturally

such as positive grid growth (oxidation). It is just a matter

of time before the battery fails. Maintenance and environmental conditions can increase or decrease the risks of

premature battery failure.

Positive grid corrosion is the expected failure mode of

ooded lead-acid batteries. The grids are lead alloys (lead-

calcium, lead-antimony, lead-antimony-selenium) that convert to lead oxide over time. Since the lead oxide is a bigger

crystal than lead metal alloy, the plate grows. The growth

rate has been well characterized and is taken into account

when designing batteries. In many battery data sheets, there

is a specication for clearance at the bottom of the jar to

allow for plate growth in accordance with its rated lifetime,

for example, 20 years.

At the designed end-of-life, the plates will have grown suf-

ciently to pop the tops off of the batteries. But excessive

cycling, temperature and over-charging can also increase the

speed of positive grid corrosion. Impedance will increase

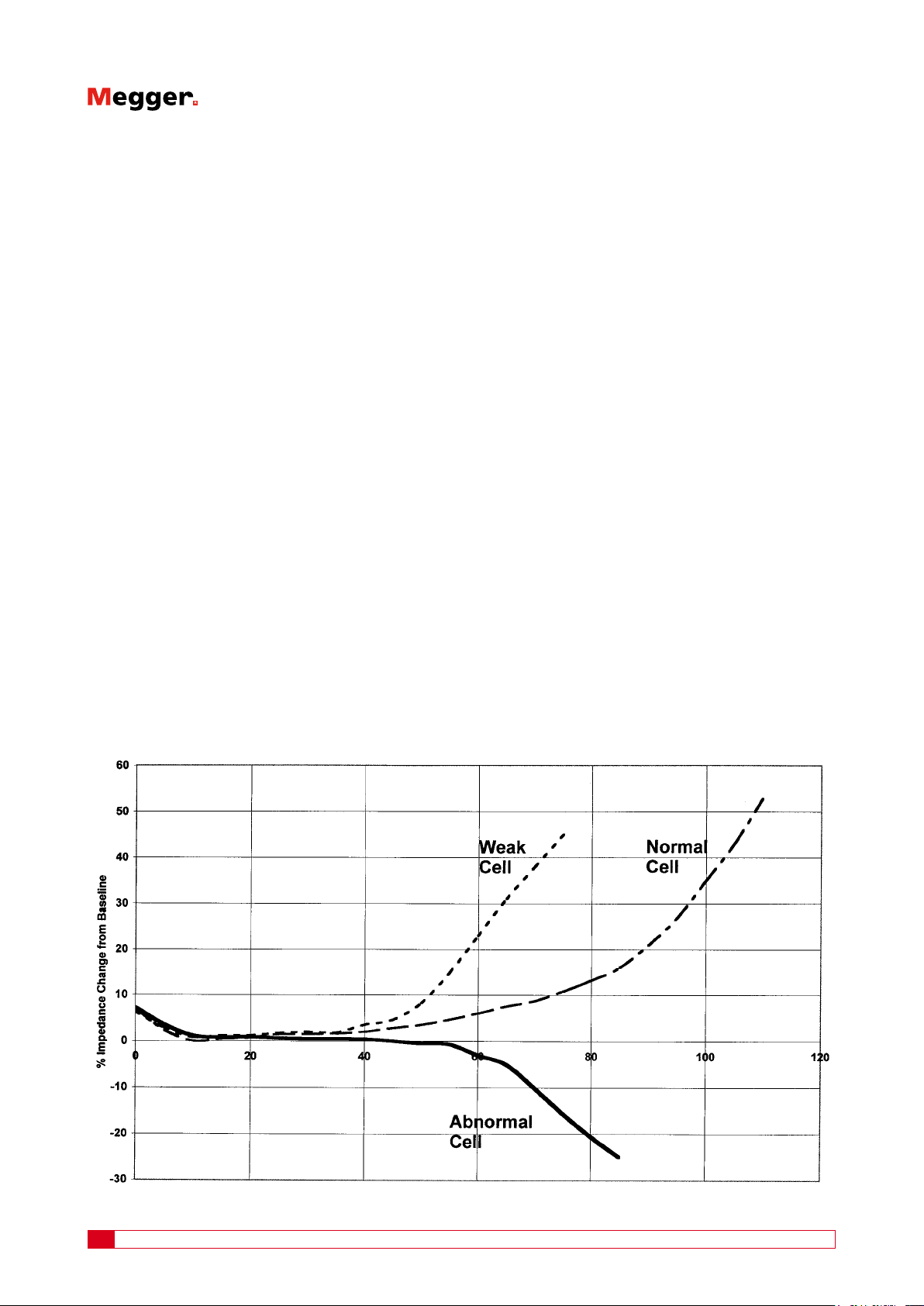

over time corresponding to the increase in electrical resistance of the grids to carry the current. Impedance will also

increase as capacity decreases as depicted in the graph in

gure 2.

Sediment build-up (shedding) is a function of the amount

of cycling a battery endures. This is more often seen in UPS

batteries but can be seen elsewhere. Shedding is the sloughing off of active material from the plates, converting to

white lead sulphate. Sediment build-up is the second reason

battery manufacturers have space at the bottom of the jars

to allow for a certain amount of sediment before it buildsup to the point of shorting across the bottom of the plates

rendering the battery useless. The oat voltage will drop and

the amount of the voltage drop depends upon how hard the

short is. Shedding, in reasonable amounts, is normal.

Some battery designs have wrapped plates such that the

sediment is held against the plate and is not allowed to drop

to the bottom. Therefore, sediment does not build-up in

wrapped plate designs. The most common application of

wrapped plates is UPS batteries.

Corrosion of the top lead, which is the connection between

the plates and the posts is hard to detect even with a visual

inspection since it occurs near the top of the battery and is

hidden by the cover. The battery will surely fail due to the

high current draw when the AC mains drop off. The heat

build-up when discharging will most likely melt then crack

open and then the entire string drops off-line, resulting in a

catastrophic failure.

Plate sulphation is an electrical path problem. A thorough

visual inspection can sometimes nd traces of plate sulphation. Sulphation is the process of converting active plate

material to inactive white lead sulphate. Sulphation is due

to low charger voltage settings or incomplete recharge after

an outage. Sulphates form when the voltage is not set high

enough. Sulphation will lead to higher impedance and a

lower capacity.

Lead-acid (VRLA) failure modes

▪ Dry-out (Loss-of-Compression)

▪ Plate Sulphation (see above)

▪ Soft and Hard Shorts

▪ Post leakage

▪ Thermal run-away

▪ Positive grid corrosion (see above)

Dry-out is a phenomenon that occurs due to excessive heat

(lack of proper ventilation), over charging, which can cause

elevated internal temperatures, high ambient (room) temperatures, etc. At elevated internal temperatures, the sealed

cells will vent through the PRV. When sufcient electrolyte

is vented, the glass matte no longer is in contact with the

plates, thus increasing the internal impedance and reducing

battery capacity. In some cases, the PRV can be removed

and distilled water added (but only in worst case scenarios

and by an authorized service company since removing the

PRV may void the warranty). This failure mode is easily

detected by impedance and is one of the more common

failure modes of VRLA batteries.

Soft (a.k.a. dendritic shorts) and Hard shorts occur for a

number of reasons. Hard sorts are typically caused by paste

lumps pushing through the matte and shorting out to the

adjacent (opposite polarity) plate. Soft shorts, on the other

hand, are caused by deep discharges. When the specic

gravity of the acid gets too low, the lead will dissolve into

it. Since the liquid (and the dissolved lead) are immobilized

by the glass matte, when the battery is recharged, the lead

comes out of solution forming threads of thin lead metal,

known as dendrites inside the matte. In some cases, the lead

dendrites short through the matte to the other plate. The

oat voltage may drop slightly but impedance can nd this

failure mode easily but is a decrease in impedance, not the

typical increase as in dry-out. See gure 2, Abnormal Cell.

Thermal run-away occurs when a battery’s internal components melt-down in a self-sustaining reaction. Normally, this

phenomenon can be predicted by as much as four months

or in as little as two weeks. The impedance will increase in

BATTERY TESTING GUIDE

7

Page 8

advance of thermal run-away as does oat current. Thermal

run-away is relatively easy to avoid, simply by using temperature-compensated chargers and properly ventilating the

battery room/cabinet. Temperature-compensated chargers

reduce the charge current as the temperature increases.

Remember that heating is a function of the square of the

current. Even though thermal run-away may be avoided by

temperature-compensation chargers, the underlying cause is

still present.

Nickel-Cadmium failure modes

NiCd batteries seem to be more robust than lead-acid. They are

more expensive to purchase but the cost of ownership is similar

to lead-acid, especially if maintenance costs are used in the cost

equation. Also, the risks of catastrophic failure are considerably

lower than for VRLAs.

The failure modes of NiCd are much more limited than leadacid. Some of the more important modes are:

▪ Gradual loss of capacity

▪ Carbonation

▪ Floating effects

▪ Cycling

▪ Iron poisoning of positive plates

Gradual loss of capacity occurs from the normal aging

process. It is irreversible but is not catastrophic, not unlike

grid growth in lead-acid.

Carbonation is gradual and is reversible. Carbonation is

caused by the absorption of carbon dioxide from the air

into the potassium hydroxide electrolyte which is why it is

a gradual process. Without proper maintenance, carbonation can cause the load to not be supported, which can be

catastrophic to supported equipment. It can be reversed by

exchanging the electrolyte.

Floating effects are the gradual loss of capacity due to long

periods on oat without being cycled. This can also cause

a catastrophic failure of the supported load. However,

through routine maintenance, this can be avoided. Floating

effects are reversible by deep-cycling the battery once or

twice.

NiCd batteries, with their thicker plates, are not well-suited

for cycling applications. Shorter duration batteries generally have thinner plates to discharge faster due to a higher

surface area. Thinner plates means more plates for a given

jar size and capacity, and more surface area. Thicker plates

(in the same jar size) have less surface area.

Iron poisoning is caused by corroding plates and is irreversible.

Figure 2 Changes in impedance as a result of battery capacity

8 BATTERY TESTING GUIDE

Page 9

Maintenance

How to maintain the

philosophies

There are different philosophies and ambition levels for

maintaining and testing batteries. Some examples:

▪ Just replace batteries when they fail or die. Minimum or

no maintenance and testing.

Obviously, not testing batteries at all is the least costly with

considering only maintenance costs but the risks are great.

The consequences must be considered when evaluating

the cost-risk analysis since the risks are associated with

the equipment being supported. Batteries have a limited

lifetime and they can fail earlier than expected. Time

between outages is usually long and if outages are the

only occasions the battery shows its capability risk is high

that reduced or no back-up is available when needed.

Having batteries as back-up of important installations

without any idea of their current health spoils the whole

idea of a reliable system.

▪ Replace after a certain time. Minimum or no maintenance

and testing.

This might also be a risky approach. Batteries can

fail earlier than expected. Also it is waste of capital

if the batteries are replaced earlier than needed.

Properly maintained batteries can live longer than the

predetermined replacement time.

▪ A serious maintenance and testing program in order to

ensure the batteries are in good condition, prolong their

life and to find the optimal time for replacement .

A maintenance program including inspection, impedance

and capacity testing is the way to track the battery’s

state of health. Degradation and faults will be found

before they become serious and surprises can be avoided.

Maintenance costs are higher but this is what you have

to pay for to get the reliability you want for your back-up

system.

The best testing scheme is the balance between maintenance

costs and risks of losing the battery and the supported

equipment. For example, in some transmission substations,

there is upwards of $10 million per hour owing through

them. What is the cost of not maintaining battery systems

in those substations? A $3000 battery is fairly insignicant

compared to the millions of dollars in lost revenues. Each

company is different and must individually weigh the costrisk of battery maintenance.

battery

Standards and common

practices

There are a number of standards and company practices for

battery testing. Usually they comprise inspections (observa-

tions, actions and measurements done under normal oat

condition) and capacity tests. Most well-known are the

IEEE standards:

▪ IEEE 450 for flooded lead-acid

▪ IEEE 1188 for sealed lead-acid

▪ IEEE 1106 for nickel-cadmium

IEEE 450

IEEE 450, “IEEE Recommended Practice for Maintenance, Testing and Replacement of Vented Lead-acid Batteries for Stationary Applications” describes the frequency

and type of measurements that need to be taken to validate

the condition of the battery. The standard covers Inspections, Capacity test, Corrective actions, Battery replacement

criteria etc.

Below is a summarized description for the maintenance, for

the full instructions see the IEEE450 standards.

Inspections

▪ Monthly inspection include appearance and

measurements of string voltage, ripple voltage, ripple

current, charger output current and voltage, ambient

temperature, voltage and electrolyte temperature at pilot

cells, battery float charging current or specific gravity at

pilot cells, unintentional battery grounds etc.

▪ Quarterly inspections include same measurements as

monthly inspection and in addition, voltage of each cell,

specific gravity of 10% of the cells of the battery and float

charging current, temperature of a representative sample

of 10% or more of the battery cells.

▪ Once a year a quarterly inspection should be extended

with, specific gravity of all cells of the battery, temperature

of each cell, cell-to-cell and terminal connection resistance

are performed on the entire string.

Capacity test (discharge test) should be done

▪ At the installation (acceptance test)

▪ Within the first two years of service

▪ Periodically. Intervals should not be greater than 25% of

the expected service life.

BATTERY TESTING GUIDE

9

Page 10

▪ Annually when the battery shows signs of degradation or

has reached 85% of the expected service life. Degradation

is indicated when the battery capacity drops more than

10% from its capacity on the previous capacity test or is

below 90% of manufacturers rating. If the battery has

reached 85% of service life, delivers 100% or greater of

the manufacturer's rated capacity and has no signs of

degradation it can be tested at two-year Intervals until it

shows signs of degradations.

IEEE 1188

IEEE 1188, “IEEE Recommended Practice for Maintenance, Testing and Replacement of Valve-Regulated

Lead-Acid Batteries for Stationary Applications” denes the

recommended tests and frequency.

Below is a summarized description for the maintenance, for

the full instructions see the IEEE1188 standards.

Inspections

▪ Monthly inspection include battery terminal float voltage,

charger output current and voltage, ambient temperature,

visual inspection and DC float current per string.

▪ Quarterly same measurements as for monthly inspection

shall be done and additionally cell/unit impedance value,

temperature of negative terminal of each cell and voltage

of each cell. For applications with a discharge rate of one

hour or less, resistance of 10% of the intercell connections

shall be measured.

▪ Semi-Annual same measurements as for quarterly

inspection shall be done and additionally a check and

record of voltage of each cell/unit, cell/unit internal ohmic

values, temperature of the negative terminal of each cell/

unit of battery.

▪ Yearly and Initial above measurements should be taken

and in addition, cell-to-cell and terminal connection

resistance of entire battery and AC ripple current and/or

voltage imposed on the battery.

Capacity test (capacity test) should be done

▪ At the installation (acceptance test)

▪ Periodically. Intervals should not be greater than 25% of

the expected service life or two years, whichever is less.

▪ Where impedance values has changed significantly

between readings or physically changes has occurred

▪ Annually when the battery shows signs of degradation or

has reached 85% of the expected service life. Degradation

is indicated when the battery capacity drops more than

10% from its capacity on the previous capacity test or is

below 90% of manufacturers rating.

IEEE 1106

IEEE 1106, “IEEE Recommended Practice for Installation,

Maintenance, Testing and Replacement of Vented Nickel-Cadmium Batteries for Stationary Applications”.

Below is a summarized description for the maintenance, for

the full instructions see the IEEE1106 standards.

Inspections

▪ Inspection at least once per quarter include battery

terminal float voltage, appearance, charger output current

and voltage, pilot-cell electrolyte temperature.

▪ Semi-annually general inspection and measurement of

voltage of each cell shall be done.

Capacity test (discharge test) should be done

▪ Within the first two years of service

▪ At 5-year intervals until the battery shows signs of

excessive capacity loss.

▪ Annually at excessive capacity loss

Summary best way to test and

evaluate your battery

Test intervals

1. Make a capacity test when the battery is new as part of

the acceptance test.

2. Make an impedance test at the same time to establish

baseline values for the battery.

3. Repeat the above within 2 years for warranty purpose.

4. Make an impedance test every year on ooded cells and

quarterly on VRLA cells.

5. Make capacity tests at least for every 25% of expected

service life.

6. Make capacity test annually when the battery has

reached 85% of expected service life or if the capacity

has dropped more than 10% since the previous test or is

below 90% of the manufacturers rating.

7. Make a capacity test if the Impedance value has changed

signicantly.

8. Follow a given practice (preferably from the IEEE

standard) for all temperature, voltage, gravity measure-

ments etc. and ll in a report. This will be a great help

for trending and for fault tracing.

Battery replacement criteria

Both IEEE 450 and IEEE 1188 recommend replacing the

battery if its capacity is below 80% of manufacturer’s rating.

Maximum time for replacement is one year. Physical characteristics such as plate condition or abnormally high cell

temperatures are often determinants for complete battery or

individual cell replacements.

10 BATTERY TESTING GUIDE

Page 11

Practical battery

testing

The Battery testing matrix below may help guide even the

most skilled battery testing technician and will help simplify

the recommended practices.

The following is a description of some of the tests or maintenance parameters.

Capacity test

Capacity test is the only way to get an accurate value on the

actual capacity of the battery. While used regularly it can be

used for tracking the battery’s health and actual capacity and

estimating remaining life of the battery. When the battery is

new its capacity might be slightly lower than specied. This

is normal.

There are rated capacity values available from the manufacturer. All batteries have tables telling the discharge current

for a specied time and down to a specic end of discharge

voltage. Table below is an example from a battery manufacturer

End

Volt.

Model

/Cell

DCU/DU-9 100 52 34 26 21 18 15 12 10

1.75

DCU/DU-11 120 66 41 30 25 21 18 15 13

DCU/DU-13 150 78 50 38 31 27 23 19 16

Common test times are 5 or 8 hours and common end of discharge voltage for a lead acid cell is 1.75 or 1.80 V.

During the test it is measured how much capacity (current

x time expressed in Ah) the battery can deliver before the

terminal voltage drops to the end of discharge voltage x

number of cells. The current shall be maintained at a constant value. It is recommended to select a test time that is

approximately the same as the battery’s duty cycle. Common

test times are 5 or 8 hours and common end of discharge

voltage for a lead acid cell is 1.75 or 1.80 V. It is recommended to use the same testing time during the battery’s

Nominal rates at 25º C (77º F)

8 h

Amperes (includes connector voltage drop

Ah

Ratings

1 h 2 h 3 h 4 h 5 h 6 h 8 h 10 h

Battery testing matrix – IEEE recommended practices

Instrument

Parameter

Capacity

Internal ohmic value

Intercell connection

resistance

Voltage of each

cell / pilot cell

Spec. grav. and temp.

of each cell / pilot cell

Corrosion at Terminals

DC Float Current

Unintentional Battery

Grounds

Battery ripple current

Charger AC ripple.

Current and Voltage

Cycling of Ni / Cd

batteries

Structural integrity of

rack / cabinet

Spectrum Analyzer

Bite3 Bite2 DLROs MOM/

Mjölner

▪ ▪

▪ ▪ ▪ ▪

▪ ▪ ▪

▪ ▪ ▪

▪ ▪ ▪

▪ ▪ ▪

▪

DCMs BMM80 M5091 BGFT BGL DMA35 TORKEL Visual

▪ ▪ ▪ ▪

▪ ▪

▪

▪

▪

▪

BATTERY TESTING GUIDE

11

Page 12

lifetime. This will improve accuracy when trending how battery’s capacity changes.

If the battery reaches the end of discharge voltage at the

same time as the specied test time the battery’s actual

capacity is 100% of the rated capacity. If it reaches the end

of discharge at 80% (8 h) or before of the specied 10 h it

is shall be replaced. See gure 3.

Procedure for capacity test of

vented lead acid battery

1. Verify that the battery has had an equalizing charge if

specied by the manufacturer

2. Check all battery connections and ensure all resistance

readings are correct

3. Record specic gravity of every cell

4. Record the oat voltage of every cell

5. Record the temperature of every sixth cell in order to

get an average temperature

6. Record the battery terminal oat voltage

7. Disconnect the charger from the battery

8. Start the discharge. The discharge current should be

corrected for the temperature obtained at point 5 (not if

capacity is corrected afterwards) and maintained during

the entire test.

9. Record the voltage of every cell and the battery terminal

voltage in the beginning of the discharge test

10. Record the voltage of every cell and the battery terminal

voltage one or several times at specied intervals when

the test is running

11. Maintain the discharge until the battery terminal voltage

has decreased to the specied end of discharge voltage

(for instance 1.75 x number of cells)

12. Record the voltage of every cell and the battery terminal

voltage at the end of the test. The cell voltages at the

end of the test have special importance since weak cells

are indicated here.

13. Calculate the actual battery capacity

It is important to measure the individual cell voltages. This

has to be made a couple of times during the test. Most

important is to measure the cells at the end of the discharge

test in order to nd the weak cells.

It is also very important that the time OR the current during

a discharge test is adjusted for the temperature of the battery. A cold battery will give less Ah than a warm. Temperature correction factors and methods are described in the

IEEE standards.

Manufacturers can also specify their batteries at constant

power discharge. This is used where the load has voltage

regulators. Then the current will increase when the voltage drops. Procedure for testing these batteries is the same

but the load equipment must be able to discharge with a

constant power.

Batteries can also be tested at a shorter time than their duty

cycle, for instance at 1 hour. Then the current rate has to be

increased. Advantage is that less capacity is drained from

the battery (valid for lead-acid) and it requires less time to

recharge it. Also less man-hour is needed for the test. Contact your battery manufacturer for more information. At

higher rates it is more important to supervise the battery’s

temperature.

Between load tests, impedance measurement is an excellent

tool for assessing the condition of batteries. Furthermore, it is

recommended that an impedance test be performed just prior to

any load test to improve the correlation between capacity and

impedance.

Figure 3 If the battery reaches the end of discharge at 80%

(8 h) or before of the specified 10 h it is shall be replaced.

12 BATTERY TESTING GUIDE

Figure 4 Replacement of battery is recommended when the

capacity is 80% of rated.

Page 13

Impedance test

Impedance, an internal ohmic test, is resistance in AC terms.

With regard to DC battery systems, impedance indicates

the condition of batteries. Since it tests the condition of

the entire electrical path of a battery from terminal plate to

terminal plate, impedance can nd weaknesses in cells and

intercell connectors easily and reliably.

Basically, impedance test is determined by applying an AC

current signal, measuring the AC voltage drop across the

cell or intercell connector and calculating the impedance

using Ohm’s Law. In practice, not only is the AC voltage

drop measured but so is the AC current. The AC current

is measured because of other AC currents in a battery that

are additive (subtractive). Other AC currents are present

from the charger system. The test is performed by applying

an AC test signal to the terminal plates. Then measure both

the total AC current in the string and the voltage drop of

each unit in the string by measuring each cell and intercell

connector consecutively until the entire string is measured.

The impedance is calculated, displayed and stored. As the

cells age, the internal impedance increases as depicted in

gure 2. By measuring impedance, the condition of each

cell in the string can be measured and trended to determine

when to replace a cell or the string which helps in planning

for budgetary needs.

The impedance test is a true four-wire, Kelvin-type measurement that provides excellent reliability and highly reproducible data on which to base sound decisions with regard

to battery maintenance and replacement. Impedance is able

to nd weak cells so that proactive maintenance can be

performed. After all, the battery is a cost but it is supporting

a critical load or revenue stream. If a single cell goes open

then the entire string goes off line and the load is no longer

supported. Therefore, it is important to nd the weak cells

before they cause a major failure.

The graph in gure 5 shows the effect of decreasing capacity on impedance. There is a strong correlation between

impedance and capacity so that weak cells are ably and

reliably found in sufcient time to take remedial action. The

graph shows the reorganized impedance data in ascending

order with each cell’s corresponding load test end voltage.

(Impedance in milliohms coincidentally is the same scale as

the voltage, 0 to 2.5). This view, that is ascending impedance/descending voltage, groups the weak cells on the right

side of the graph to nd them easily.

Impedance theory

A battery is not simply resistive. There is also a capacitive

term. After all, a battery is a capacitor, a storage device, and

resistors cannot store electricity. gure 6 shows an electrical

circuit, known as the Randles Equivalent Circuit, that depicts a battery in simple terms. There are those who would

have people believe that the capacitive term is not necessary

and that the resistance is the only part that needs measuring.

Impedance measures both the DC resistance (the real

component in impedance) and the reactance (the imaginary components in impedance). Only by measuring both

can the capacitive term start to be understood. The other

argument used against impedance is that frequency is a

variable in the reactance part of the impedance equation.

That is true except that since Megger uses a xed frequency,

namely 50 or 60 Hz depending upon geography, it is always

Figure 5 Ascending impedance with corresponding end voltage

BATTERY TESTING GUIDE

13

Page 14

the same. This variable, 2πω, now becomes a constant and,

therefore, frequency does not affect the nal result in any

way. The only parts that affect the nal result are the parts

that vary within the battery, namely resistance and capacitance, which paint the whole capacity/condition picture.

In the diagram shown in gure 6, Rm is the metallic resistance, Re is the electrolyte resistance, Rct is the charge

transfer resistance, Wi is the Warburg impedance and Cdl is

the capacitance of the double layer. Rm includes all of the

metallic components one post to the other post, i.e., post,

top lead and grids and to a certain degree, the paste. Re

is the resistance of the electrolyte which doesn’t vary that

much on a bulk basis. But at the microscopic level in the

pores of the paste, it can be signicant. Rct is the resistance

of the exchange of ions from the acid to the paste. If the

paste is sulphated, then Rct increases or if that portion of

the paste is not mechanically (electrically) attached to the

grid so that electrons cannot ow out of the cell. Warburg

impedance is essentially insignicant and is a function of

the specic gravity. Cdl is what probably makes the most

important contribution to battery capacity. By only measuring DC resistance, capacitance, an important part of the

cell, is ignored. Impedance measures both DC resistance

and capacitance.

A battery is complex and has more than one electrochemical process occurring at any given time, e.g., ion diffusion,

charge transfer, etc. The capacity decreases during a discharge due to the conversion of active material and depletion of the acid. Also, as the plates sulphate, the resistance

of the charge transfer increases since the sulphate is less

conductive than the active material. (See discussion about

the differences between the thickness of the plates in longduration versus short-duration batteries.)

Intercell connection resistance

Intercell connection resistance is the other half of the battery. A battery is comprised of cells connected in a series

path. If any one component fails the entire series connection fails. Many times batteries fail, not because of weak

cells, but due to weak intercell connections, especially on

lead posts which can cold-ow. Generally, hardware should

be tightened to the low end of the torque scale that is recommended by the battery manufacturer. But torque wrenches are a mechanical means to verify low electrical resistance.

It is far better to actually perform an electrical test using an

appropriate instrument. It is a low electrical resistance that

is desired. This test should be performed before the battery

is commissioned. Proper intercell connections are necessary

to ensure that discharge rates can be met. The instrument

of choice is a DLRO® or a MOM which can easily verify

that all connections have been made properly. It can even

nd minor errors before the battery is commissioned, preventing possible causes of failure or damage to supported

equipment.

Testing intercell connection resistance performs two functions:

▪ Validates intercell connection resistance

▪ Finds possible gross errors with top lead internal to the cell

By following IEEE Recommended Practices, intercell connection resistance can be validated. Those recommended

practices specify that the variation of intercell connection

resistance be less than ten percent. This translates into 7

micro-ohms on a 70-micro-ohm intercell connection resis-

tance. This method can even nd a washer stuck between

the post and the intercell connector whereas torquing will

not. They also specify that ten percent of the intercell connectors be measured quarterly and all intercell connectors

annually.

In multiple post batteries, it is possible to nd those rare

gross errors in a cell’s top lead. (See multiple post bat-

tery diagram in gure 1). On multiple-post cells, measure

straight across both connections, then measure diagonally

to check for balance in the cell and connections. Measuring only straight across does not adequately test for either

intercell connection resistance or for gross top lead defects.

This is due to the parallel circuits for the current.

The graph in gure 7 shows the data obtained from an actual 24-cell telephone (CO) battery The peak at connector

#12 (cell 12 to 13) is an intertier cable connection. Con-

nector #3 was out of specication and it was determined

that one of the two bolts was not properly torqued. It was

retorqued and retested. It came within ten percent of the

string average after retorquing.

The negative plates (odd-numbered plates #1 through 15)

are all connected through negative top lead which is connected to both negative posts. Positive plates (even-numbered) are connected to each other through positive top

lead which is connected to both positive posts. There are

two intercell connectors between neg post 1 and pos post 1

and between neg post 2 and pos post 2.

The higher the current draw the more critical is the proper

sizing of current-carrying components both internal to the

Figure 6 Randles equivalent circuit

14 BATTERY TESTING GUIDE

Figure 7 Intercell connection resistance bar graph

Page 15

cell and external. UPS batteries are usually designed for

a high rate discharge lasting typically only 15-20 minutes.

However, a telecommunications CO battery may have only

a 500 Amp draw but can discharge for up to eight hours. So

either combination can have disastrous effects due to improperly sized and maintained cells and intercell connectors.

Testing and electrical paths

In order to properly test a multiple post cell, one must un-

derstand its construction. Based on the diagram in gure 1,

it can be seen that there are two parallel paths for the test

current to travel. If the test leads are placed on neg post 1

and pos post 1, the two parallel paths are (1) directly from

neg post 1 to pos post 1 through their intercell connectors

and (2) neg post 1 down to the top lead, up to neg post 2

and across the intercell connectors to pos post 2 down to

the pos top lead and back up to pos post 1.The two paths

are parallel circuits and hence indistinguishable. If one bolt

is loose, there isn’t any way to determine that since the test

current will follow the path of least resistance. The better method to measure intercell connection resistance is to

measure diagonally from neg post 1 to pos post 2 and again

from neg post 2 to pos post 1. Compare the two readings

for highest condence. Admittedly, diagonal measurements

are still parallel but the comparison becomes more interest-

ing due to the increased inuence of top lead and loose

hardware. Diagonal measurements do not allow for a direct

connection from post to post. In the case of six-post cells,

measure diagonally across the farthest posts in both directions.

Voltage

Float voltage has traditionally been the mainstay of any

testing procedure. What is voltage? Voltage is the difference,

electrically speaking, between the lead and the lead oxide

on the plates or between the nickel and the cadmium. The

charger is the item that keeps them charged. The sum of all

of the cell voltages must be equal to the charger setting (except for cable losses.) This implies then that voltage merely

indicates the state-of-charge (SOC) of the cells. There is

no indication of a cell’s state-of-health (SOH). A normal

cell voltage doesn’t indicate anything except that the cell is

fully charged. An abnormal cell voltage, however, does tell

you something about the condition of the cell. A low cell

voltage can indicate a shorted cell but only when the volt-

age nally drops to about 2.03. If a cell is low then other

cells must be higher in voltage due to the charger setting.

Remember that the sum of all cell voltages must equal the

charger setting. Those cells that are higher are counteracting the low cell and generally speaking the higher cells are in

better condition because they can tolerate the higher voltage. But those cells are being overcharged which over-heats

them and accelerates grid corrosion and water losses.

Let’s say for the moment that the low voltage cell is not yet

at 2.03, it is at 2.13 V. At 2.13 V it is not low enough to ag

a concern but it is degrading. It may or may not be able to

support the load when an outage occurs. Impedance is able

to nd that weak cell sooner than voltage. In this case, impedance will decrease since it is an impending short circuit.

A similar example can be found in VRLA when it comes to

dry-out or loss-of-compression. Voltage will not nd this

condition until it is far later in the battery’s life, until it is too

late. Impedance nds this condition much earlier so that

remedial action can be performed.

So don’t confuse fully charged with full capacity.

As said above, cell voltage divergence can be caused by a

number of factors and one way to solve this problem could

be to make an equalization charge. In an equalization charge

procedure, the entire battery is charged at a higher (than

normal) voltage for several hours to balance the voltage in

all the cells. The procedure can lead to heating and possibly

water loss. It is recommended to follow the manufacturer’s

procedure to avoid damaging the battery.

Specific gravity

Specic gravity is the measure of the sulphate in the acid of

a lead-acid battery. It is also the measure of the potassium

hydroxide electrolyte in nickel-cadmium battery but since

the potassium hydroxide electrolyte isn’t used in the chemical reaction, it is not necessary to measure it periodically.

Specic gravity traditionally has not provided much value

in determining impending battery failure. In fact, it changes

very little after the initial 3 to 6 months of a battery’s life.

This initial change is due to the completion of the formation process, which converts inactive paste material into

active material by reacting with the sulphuric acid. A low

specic gravity may mean that the charger voltage is set too

low causing plate sulphation to occur.

In a lead-acid battery the sulphate is a closed system in that

the sulphate must be either on the plates or in the acid.

If the battery is fully charged then the sulphate must be

in the acid. If the battery is discharged, the sulphate is on

the plates. The end result is that specic gravity is a mirror

image of voltage and thus state-of-charge. Specic grav-

ity readings should be taken when things are amiss in the

battery to obtain as much information about the battery as

possible.

Different battery applications and geographies have varying

specic gravities to accommodate rates, temperature, etc.

Following is a table that describes some applications and

their specic gravities.

Specific gravities and their applications

Specific gravity Percent acid Application

1.170 25 Tropical stationary

1.215 30 Standard stationary

1.250 35 UPS/high rate

1.280 38 Automotive

1.300 40 VRLA stationary

1.320 42 Motive power

1.400 50 Torpedo

BATTERY TESTING GUIDE

15

Page 16

Float current

Another leg of the Ohm’s Law triangle is current. The

charger voltage is used to keep a battery charged but voltage

is really the vehicle to get current into the battery (or out

of it during discharge). It is current that converts the lead

sulphate back to active material on the grids.

There are two types of DC current on a battery: recharge

current which is the current applied to recharge a battery

after a discharge and oat current which is the current used

to maintain a battery in a fully charged state. If there is a

difference between the charger setting and the battery’s

voltage, that difference will cause a current to ow. When

the battery is fully charged

the oat current which counteracts the self-discharge of

the battery (<1% per week). Since the voltage differential

between the charger and the battery is small, the oat current is small. When there is a large voltage difference such

as after a discharge the current is high and is limited by the

charger until the voltage difference becomes less. When the

current is on the plateau in the graph below, this is called

current limit. When the voltage differential becomes less,

the charge current is reduced as depicted on the downward

sloping charge current line on the graph shown in gure 8.

The charge voltage is the voltage of the battery, not the

charger setting which is why it is increasing.

Float current will vary with battery size. The larger the

battery is, the more oat current it will take to keep it fully

charged. Float current can increase for a couple of reasons:

ground faults on oating battery systems and internal battery faults. Ground faults are discussed later. As a battery’s

internal impedance increases, it takes more current to pass

through that higher impedance. The increase in oat current

can be an indicator of battery faults. In lieu of measuring

oat current, many of the same conditions are found with

impedance.

In VRLA batteries, oat current

of battery problems, namely thermal runaway. Thermal runaway is the result of a battery problem, not the cause. Some

of the causes that can lead to thermal runaway are shorted

cells, ground faults, dry-out, excessive charging and insuf-

Figure 8 Constant-voltage Constant-current charge characteristics

[1]

, the only current owing is

[2,3]

seems to be an indicator

cient heat removal. This process takes anywhere from two

weeks to four months to occur once the oat current starts

its increase. By measuring oat current, it may be possible

to avoid catastrophic failure of the battery and damage to

connected and nearby equipment. Impedance will nd many

of these same errors.

Ripple current

Batteries, as DC devices, prefer to have only DC imposed

on them. The charger’s job is to convert AC into DC but

no charger is 100% efcient. Frequently, lters are added

to chargers to remove the AC current from the DC output.

The AC current on the DC is called ripple current. Battery

manufacturers have stated that more than about 5 A rms

of ripple for every 100 Ah of battery capacity can lead to

premature failure due to internal heating. Ripple voltage is

not a concern since it is the heating effect of the ripple cur-

rent that damages batteries. The 5% ripple current gure is

a rough estimate and depends also on the ambient temperature. Ripple current can increase slowly as the electronic

components in the charger age. Also if a diode goes bad,

the ripple current can increase more dramatically leading to

heating and premature death without anyone knowing it. Although impedance is not a measure of ripple current, ripple

current is measured because of the way Megger designs its

impedance instruments.

There is anecdotal evidence

[4]

that low frequency ripple

(<10Hz) may charge and discharge a battery on a microscale. More research is necessary to prove this hypothesis.

Excessive cycling can lead to premature death of a battery

regardless of the reasons for the cycling, be they outages,

testing or maybe micro-cycling. One thing is true: the lower

the AC is on the battery system, the less the damage is that

can occur. VRLA batteries seem to be more sensitive to

ripple current than their ooded counterparts. It is then

advisable to lter their chargers for ripple current/voltage.

Temperature

It is well known that low temperatures slow up the internal

chemical reactions in any battery; the degrees of reduced

performance vary according to the technology. For example,

at temperatures around freezing, a VRLA may need capacity

compensation of 20%. The lead-calcium cell using 1.215

specic gravity acid will require a doubling of capacity,

while the Ni-Cd will need about 18% increased capacity.

At the other end of the temperature range, high temperature is the killer of all batteries. There will be no surprise

to nd out that this impact varies from one technology to

another. Lead acid at 95˚F will experience a 50% shortened

life, while Ni-Cd will have a 16-18% shortening of life.

By applying what Arrhenius learned about chemical reactions, for every 18º F (10º C) increase in battery tem-

[1] Cole, Bruce, et al., Operational Characteristics of VRLA Batteries Configured in Parallel Strings, GNB Technologies

[2] Brown, AJ, An Innovative Digital Flat Current Measurement Technique - Part Two, Proceedings of BattConn® 2000

[3] Boisvert, Eric, Using Float Charging Current Measurements to Prevent Thermal Runaway on VRLA Batteries, Multitel

[4] Ruhlmann, T., Monitoring of Valve Regulated Lead Acid Batteries, Proceedings of BattConn® 2000

16 BATTERY TESTING GUIDE

Page 17

perature, battery life is halved, battery life can start to be

managed. The increased temperature causes faster positive

grid corrosion as well as other failure modes. By holding a

lead-acid battery at a temperature of 95º F (35º C) instead

of the designed 77º F (25º C), a 20-year battery will last

only ten years, a ten-year battery only ve years and so on.

Increase the temperature by another 18º F to 113º F (45º C),

a 20-year battery will last only ve years!

A battery is rarely held at a certain temperature for its entire

life. A more realistic scenario is for a battery to heat during

the day and cool down at night with higher average temperatures in the summer and lower average temperatures

in winter. It is unfortunate but cooling the battery off to

below 77º F (25º C) will not gain back the life that was lost.

Once the positive grid corrodes, it cannot be converted

back again. Furthermore, positive grid corrosion occurs at

all temperatures, it is merely a matter of speed of the corrosion rate. The end result is to control, as best as possible

(back to cost versus risk), the temperature of the batteries in

the network.

IEEE 450, Annex H offers a method for calculating the

impact of high temperatures on a lead acid battery.

Data analysis

The essence of any testing methodology is how to interpret

the data to make some sense of it all. The same is true of

battery testing. If the data are to be hand-written and led

or if a printout from an instrument is reviewed then led,

then there is no useful analysis except if there is an emergency at that very moment. The real value in battery testing

lies in the trending of data to determine if problems are

imminent or a little farther out. Trending of battery data,

especially impedance and capacity, is an excellent tool for

budgetary planning. By watching the batteries degrade over

time, a decision can be made as to when to replace a battery.

With trending, emergency replacements decrease dramatically.

The rst time a battery’s impedance is tested can cause concern because there is no baseline. In these cases, it is good

to compare each cell against every other cell in the string.

Weak cells stand out. It is these cells which require further

investigation. The table below provides a guideline depending upon the length of time batteries have been tested.

Single Test Trending

% Deviation

from String

Avg

Lead-acid,

Flooded

Lead-acid, VRLA,

AGM

Lead-acid, VRLA,

Gel

NiCd, Flooded 15 10 100

NiCd, Sealed 15 5 80

5 2 20

10 3 50

10 3 50

Cell’s %

Change from

Last Test

Cell’s %

Change

Overall

BATTERY TESTING GUIDE

17

Page 18

Locating ground faults

on DC systems without

sectionalizing

Overview

The main objective of a battery system is to provide standby and emergency power to operate industrial, consumer,

commercial or protective devices. Some of these devices

include emergency lighting units, uninterruptible power

supplies, continuous process systems, operating controls,

switchgear components and protective relays.

In emergency situations, it is essential that these devices be

in proper operating condition. Failure of a DC system or

the battery can result in operational failure of the devices

connected to that system. System failure can lead to loss of

revenue, damage to equipment and/or injured personnel.

It is a common situation for a oating DC system to develop grounds within it. When a battery system is partially

or completely grounded, a short circuit is formed across the

battery and consequently may cause the protective device to

fail to operate when needed.

ground resistance on that feeder. Faults can be traced easily

regardless of the number of distribution panels or circuits

because the “tracer” is merely following the strength of the

AC signal. System integrity is maintained because it is an online AC test and is designed to prevent system trips.

After injection of a low-frequency AC waveform, a resistive

fault on a branch of the battery system will be indicated by

a low-resistance value. For example, if the total resistance

of a battery system showed 10 kΩ, this would indicate a

resistive fault on the battery system. The resistive fault can

be located by clamping on each individual circuit until a

resistive value of 10 kΩ is found.

It is easy to see that this method can be adapted in a straight

forward manner to locate multiple faults by using the theory

of parallel paths. For example, if the total system resistance

indicates 1 kΩ and an individual branch indicates 10 kΩ

resistive fault, the user would know that the system has a

second fault because the total system resistance and the

branch resistance do not match. By using the AC injection

method, ground faults on ungrounded DC systems is easy,

straight-forward and safe.

Current test methods

Traditionally utilities and industrial complexes have gone

to great lengths to nd ground faults within their battery

systems. However, locating these battery grounds proves to

be a very elusive and time-consuming process. The current

ground-fault location method involves sectionalizing, or

interruption, of DC branches to isolate the ground fault.

Sectionalizing disables the system protection and has been

known to cause inadvertent line and generator tripping. For

this reason, many utilities have banned sectionalizing. Until

more recently, though, this had been the only method available to locate ground faults.

A better test method

Developments have led to a better test method; injecting a

low-frequency AC signal and using that AC signal to locate

the ground in the DC system. This method can be performed without sectionalizing the DC system and it reduces

the fault locating time from days to hours. Furthermore, it

allows for system protection to be present at all times.

The AC injection method measures single or multiple

ground faults by rst injecting a low-frequency, 20 Hz AC

signal between the station ground and the battery system.

Second, the resulting current is then measured by using a clamp-on sensing current transformer. From this,

the resistance value can be calculated using the in-phase

component of the circulating current, thus rejecting the

effect of capacitive loads. Therefore, if the signal is injected

at the battery terminal and the clamp-on CT is connected

to the outgoing lead, the instrument will measure the total

ground resistance present on the battery system. If the CT

is clamped on a feeder, then the instrument will measure the

18 BATTERY TESTING GUIDE

Page 19

Frequently asked

questions

What does float voltage of a cell tell me?

Float voltage indicates that the charger is working, that

is, state-of-charge. It does not indicate the state-of-health

(condition) of the cell. It indicates that the cell is fully

charged, but don’t confuse fully charged with full capac-

ity. There have been many times that the oat voltage is

within acceptable limits and the battery fails. A low oat

voltage may indicate that there is a short in the cell. This

is evident by a oat voltage at about 2.06 or below for

lead-acid (if the charger is set for 2.17 V per cell)

In some cases, a cell oats considerably higher than the

average. This may be caused by the high oat voltage cell

compensating for another cell that is weak and is oating low. It is possible that one cell oats much higher to

compensate for several cells oating a little low. The total

of all cells’ voltages must equal the charger setting.

What are the recommended maintenance practices for the

different types of batteries?

IEEE Recommended (Maintenance) Practices cover the

three main types of batteries: Flooded Lead-acid (IEEE

450), Valve-Regulated Lead-acid (IEEE 1188) and NickelCadmium (IEEE 1106). Generally speaking, maintenance

is essential to ensure adequate back-up time. There are

differing levels of maintenance and varying maintenance

intervals depending upon the battery type, site criticality

and site conditions. For example, if a site has an elevated

ambient temperature, then the batteries will age more

quickly implying more frequent maintenance visits and

more frequent battery replacements.

How important is intercell connection resistance?

Our experience has found that many battery failures are

due to loose intercell connections that heat up and melt

open rather than from cell failure. Whether a cell is weak

or an intercell connector is loose, one bad apple does

spoil the whole bushel.

When lead acid batteries are frequently cycled, the negative

terminal may cold ow, thus loosening the connection.

The proper sequence of measuring multiple post batteries is critical. Not all instruments provide valid intercell

connection resistances due to their method of testing.

Megger instruments provide valid data.

How often should impedance readings be taken?

The frequency of impedance readings varies with battery

type, site conditions and previous maintenance practices.

IEEE 1188 Recommended Practices suggests that a baseline shall be taken six months after battery has been in

operation and then semi-annual quarterly. With that said,

Megger recommends that VRLA batteries are measured

quarterly due to their unpredictable nature and semi-annually for NiCd and ooded lead-acid. Impedance reading should also be taken prior to every capacity test.

At what point should I stop changing cells and replace the

entire battery?

In shorter strings (less than 40 cells/jars), the entire

should be replaced when three to ve units have been

replaced. In longer strings, a similar percentage that is

replaced is the criterion.

How can I predict when I need to change a cell?

Even though there is not a perfect mathematical correlation between battery capacity and impedance (or

any other battery test except a load test), the amount of

increase in impedance is a strong indicator of battery

health. Megger has found that a 20 percent increase in im-

pedance for ooded lead-acid generally correlates to 80%

battery capacity. In VRLA, that increase is closer to 50%

from the battery’s initial impedance or from the manufacturer’s baseline values.

Will capacity testing destroy my battery?

The battery system is designed to provide back-up power

during all outages that appear during its lifetime. Performing a capacity test is nothing else than simulating one

outage but in a controlled way. Batteries can normally be

deep discharged (discharged to manufacturer’s end-of

discharge voltage) 100 - 1000 times depending on type

of battery. Using a few of these cycles has no real impact

on the battery’s lifetime. On the other hand there is no

reason to test more frequently than recommended by the

standards.

Can I make a discharge test while my battery is still connected

to the load (on-line)?

Yes it is possible to do. Megger has test equipment that

automatically senses and regulate the discharge current

even when the batteries are connected to the ordinary

load. Most users choose to make a 80% discharge test

when on-line in order to still have some backup time at

the end of the test.

What are some common failure modes?

Failure mode depends upon the type of battery, the site

conditions, application and other parameters. Please refer

the summary on pages 7-8 or to the “Battery Failure

Modes,” which can be found on the Megger website.

Look under the Battery Test Equipment product section.

In the upper right-hand column under “Documents click

for Application Guides, Articles and FAQs.

Battery technology summary

As you can see, there is a lot to a battery. It is a complex

electro-chemical device. There is much more information

available that goes further into the details of Tafel curves

and depolarization but that is beyond this scope. Essentially, batteries need maintenance and care to get the most of

them which is the main reason people spend so much on

batteries – to support far more expensive equipment and

to ensure continuous revenue streams.

BATTERY TESTING GUIDE

19

Page 20

Megger products

Impedance test equip-

overview

Megger offers solutions to ensure system performance with

its comprehensive line of Battery Test Equipment, Low

Resistance Ohmmeters and Micro-ohmmeters, Insulation

Testers, and Multimeters.

An overview of the various products available is described

below. For more information on these and many other Megger products, please contact us at (800) 723-2861,

(214) 333-3201. Visit our web site www.megger.com for the

most up-to-date news, product and service information.

ment

Regardless of whether you are testing ooded lead-acid,

VRLA or Ni-Cd cells, Megger has the right equipment for

your battery maintenance requirements. The products and

associated accessories provides meaningful data on bat-

tery health without signicant expense or any reduction in

remaining battery capacity.

Interruption in service can cause disaster to supported

equipment and facilities. Consequently, a dependable backup

power system is critical so that when AC mains fail, costly

service interruptions can be avoided. The battery impedance

test helps to identify weak cells before they cause problems.

Taking the battery off-line for testing is time consuming and

adds risk to the process. This process is unnecessary with

the on-line testing capabilities of the Megger family of battery test products. The highly repeatable instruments help

reduce downtime.

BITE® 3

20 BATTERY TESTING GUIDE

▪ Determines the condition of lead-acid batteries up to

2000 Ah

▪ On-line testing with Pass/Warning/Fail calculations

▪ Measures impedance, intercell connection resistance, cell

voltage

▪ Windows CE¨ Operating System with more than 16 MB of

memory

▪ Measures float and ripple currents

The BITE 3 is a compact, battery-operated, instrument with

powerful on-board data analysis tools. It is the rst of its

kind instrument in that the ProActiv can download all previous data to provide the best in on-site data analysis like no

other instrument of its kind. The menus are easy to navigate with a bright, backlit LCD. The data display includes

the normal numeric arrangement but adds two graphical

displays to help analyze weak cells.

Page 21

BITE® 2 and BITE®2P

switchgear components, protective relays and continuous

process systems. Failure of a battery system within environments such as utilities, hospitals or manufacturing plants can

result in operational failure of the devices connected to it.

ProActiv assists the user to avoid battery failures, budget for

future battery string and cell replacements, and plan battery

change outs in an orderly manner.

ProActiv utilizes a standard MS Access database format. It

allows the user to organize and manage battery data such as

voltages, impedance, intercell connection resistance, ripple

current, specic gravity, IR thermographs and more.

▪ Determines the condition of lead-acid and nickel-cadmium

batteries up to 7000 Ah

▪ On-board Pass/Warning/Fail indications

▪ On-line testing