Page 1

M 210600

Insulation &

Low Resistance Tester

User Guide

SAFETY WARNINGS

✱ Safety Warnings and Precautions must be read and understood

before the instrument is used. They must be observed during use.

✱ The circuit under test must be switched off, de - energized and

isolated

before Insulation or Continuity tests are made.

✱ Circuit connections must not be touched during a test.

✱ The test button must not be pressed while connecting the test

leads or while changing ranges. (May cause ‘

Live Circuit

Warning‘ to become inoperable).

✱ The ‘Test’ button must not be pressed when making a voltage test.

✱ The Default Voltmeter, ’Live Circuit Warning‘ and Automatic

discharge

are additional safety features and should not be

regarded as a substitute for normal safe working practice.

✱ The 210600 is protected for connection to Power distribution

systems up to 300 V

Line - Ground, and 500 V Line - Line for

Installation Category

III*.

✱ It is recommended that fused test leads are used when measuring

voltage on high energy systems.

✱ After insulation tests, capacitive circuits must be allowed to

discharge

before disconnecting the test leads.

✱ Test leads, prods and alligator clips must be in good order; clean,

and with no broken or cracked insulation.

✱ Replacement fuses must be of the correct size, type and rating.

Symbols used on the instrument

Caution: risk of electric shock

Caution: refer to accompanying notes

Equipment protected throughout by Double

Insulation (Class

II)

NOTE

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT

PERSONS.

Page 2

OPERATION

Live Circuit Warning

The live circuit warning indicator will illuminate if 60 V or more is detected at

the terminals. Testing should be aborted if lit.

Default Voltage measurement

The 210600 will act as a direct reading default voltmeter (0 to 600 V

a.c./d.c.) in the ‘Standby’ mode (when switched ‘On’, and any of the

Insulation test positions is selected). The ‘Test’ push must not be pressed

when making a voltage test. Note:- The 210600 is internally fuse protected

to 500 V. For fuse protection with supplies above 500 V, use Fuse Probe Kit

FPK5.

1. Turn the instrument ‘

On’ by pressing the ‘On‘/‘Off‘ switch-button once.

2. Select any Insulation test position with the rotary selector switch. ’

V’is

displayed.

3. Carefully connect the test leads to the circuit under test.

Do not press

the ‘Test’ push.

4. Read the voltage measurement directly from the display.

5. Carefully disconnect the test leads and turn the instrument ‘

Off‘ by

pressing the ‘On‘/‘Off‘ switch-button once.

Low Resistance measurement (kΩ)

1. Turn the instrument ‘On’ by pressing the ‘On /’Off ‘switch-button once.

2. Select

kΩ with the rotary selector switch.

3. Ensure that all test leads are clean and in good condition, and connect

them to the

isolated circuit under test.

4. Press the ‘

Test’ push and read the measurement directly from the

display.

5. Disconnect the test leads and turn the instrument ‘

Off‘ by pressing the

‘On‘/‘Off‘ switch-button once.

Insulation Testing (MΩ)

Automatic circuit discharge is effective when the ‘Test‘ push is released, and

decaying voltage is displayed until the circuit is discharged.

1. Turn the instrument ‘

On’ by pressing the ‘On‘/‘Off‘ switch-button once.

2. Ensure that all test leads are clean and in good condition, and connect

them to the

isolated circuit under test.

3. Select the required test voltage with the rotary selector switch.

4. Press the ‘

Test’ push and read the measurement directly from the

display. Overrange is indicated by ‘ ’.

5. Release the ‘

Test’ push and monitor any displayed voltage to confirm

when any discharging voltage decays to zero.

6. When the circuit has discharged, disconnect the test leads and turn the

instrument ‘

Off‘ by pressing the ‘On‘/‘Off‘ switch-button once.

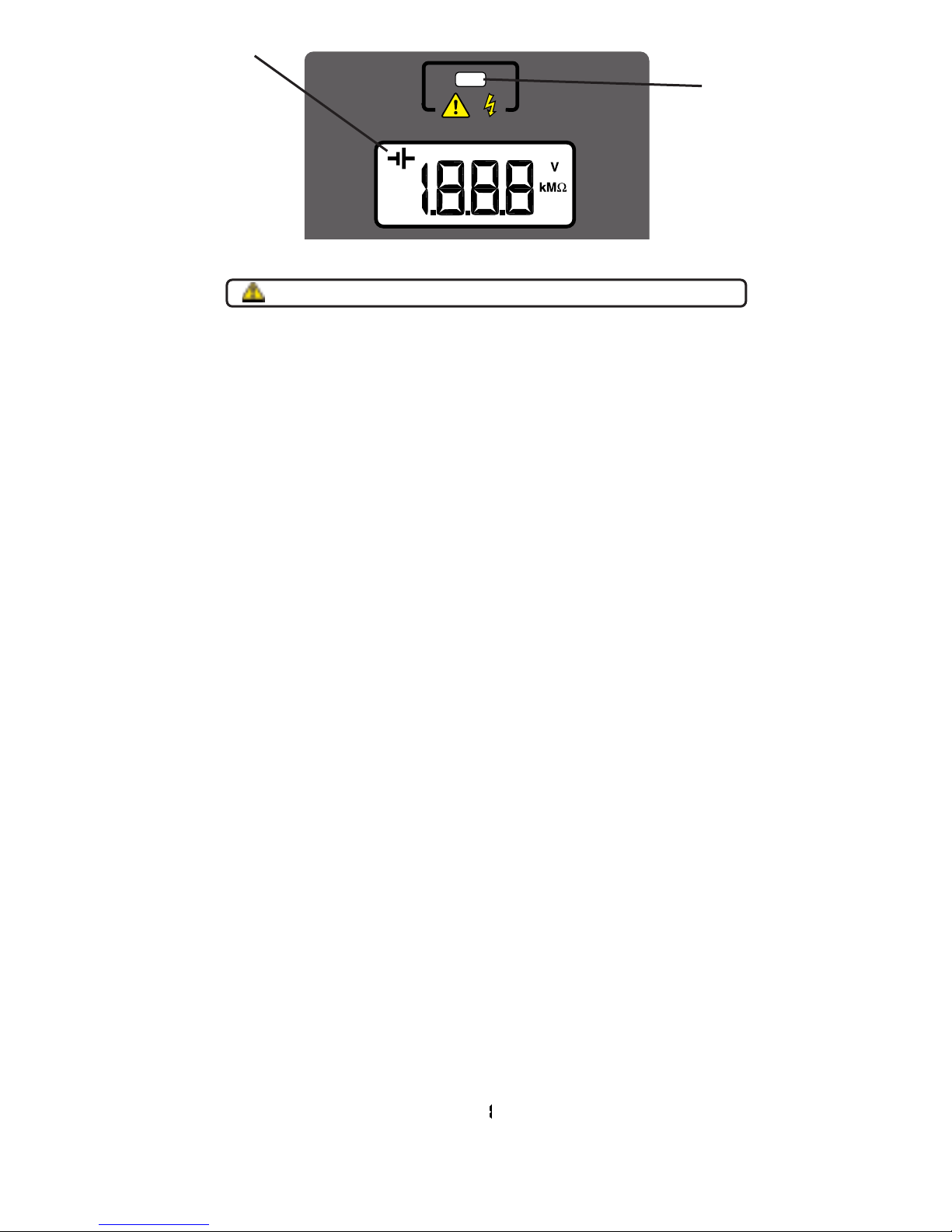

Low

Battery

Refer to Safety Warnings before using the instrument

DISPLAY FEATURES

Live

Circuit

Warning

Page 3

Using the Guard Terminal

For basic insulation tests and where there is little possibility of surface

leakage affecting the measurement, it is unnecessary to use the guard

terminal. In cable testing, there may be surface leakage paths across the

insulation between the bare cable and the external sheathing due to the

presence of moisture or dirt. Where it is required to remove the effect of this

leakage, particularly at high testing voltages, a bare wire may be bound tightly

around the insulation and connected via the third test lead to the guard

terminal ‘G’.

The guard terminal is at the same potential as the negative terminal. Since the

leakage resistance is effectively in parallel with the resistance to be

measured, the use of the guard causes the current flowing through surface

leakage to be diverted from the measuring circuit. The instrument therefore

reads the leakage of the insulator, ignoring leakage across its surface.

SPECIFICATION

Insulation Ranges

Measuring Ranges: 0 - 1.999MΩ at all test voltages

19.99 MΩ at all test voltages

199.9 MΩ at all test voltages

1999 MΩ at 500 V and 1000 V d.c. test voltages

Fully auto - ranging at all voltages

Test Voltages (d.c.): 100 V; 250 V; 500 V; 1kV

Test V. Accuracy: ±5% at open circuit

Short Cct. Current: 1.2 mA nominal

Accuracy (73.4°F ± 3.6˚F): <500 MΩ: ± 3% ±2 digits

500 MΩ to 1999 MΩ: ± 5% ±2 digits

Temp. Co-efficient: <500 MΩ: ≤86˚F, ±0.06% per °F, >86˚F ± 0.14% per ˚F

500 MΩ to 1999 MΩ: ≤86˚F ± 0.11% per ˚F, >86˚F,

±0.28% per °F,

Hum Rejection: Within twice the normal accuracy if the noise current

does not exceed 1 mA for the 1 kV range, or 0.5 mA

for the other ranges and is within 45 Hz to 65 Hz.

Low resistance Range

Measuring Range: 0 - 1.999 kΩ

19.99 kΩ

Open Cct. Voltage: 4.3 V nominal

Accuracy (73.4°F ± 3.6˚F):± 2% of reading ± 1digit

1100

1000

900

800

700

600

500

400

300

200

100

0

0.01

0.1

1

10

100

1000

10000

100000

Terminal Characteristics

Leakage path

to ‘+’ve

terminal

to ‘G’

terminal

to ‘-’ve

terminal

Tightly bound bare wire

Page 4

M

Archcliffe Road

Dover

Kent CT17 9EN Tel: +44 (0) 1304 502100

England Fax: +44 (0) 1304 207342

PO Box 9007

Valley Forge

PA 19484-9007 Tel: +1 (610) 676-8500

U.S.A. Fax: +1 (610) 676-8610

4271 Bronze Way

Dallas

TX 75237-1017 Tel: +1 (800) 723-2861 (U.S.A. only)

U.S.A. Tel: +1 (214) 330-3203 (International)

Fax: +1 (214) 337-3038

110 Milner Avenue, Unit 1

Scarborough

ON M1S 3R2 Tel: +1 (800) 567-0286

Canada Fax: +1 (416) 298-0848

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark.

Part No. 6172-373 - Edition 4 - Printed in England - 11HH

www.megger.com

Page 5

Short Cct. Current: 2.75 mA nominal

Temp. Coefficient: ±0.06% per °F

Default Voltage measurement

Range: 0 - 600 V a.c. / d.c. (effective on Insulation ranges

with ‘Test’ push not pressed)

Input impedance: 300 kΩ to 1 MΩ depending on input voltage

Discharge Rate: A 1 µF capacitor will discharge to a safe level in ≤ 2 s

Accuracy: ±2% of reading ± 1 digit d.c. or a.c. at 45 Hz to 65 Hz

Temp. Coefficient: ±0.06% per °F

General Specifications

Overload rating: The 210600 is protected for connection to Power

distribution systems up to 300 V Line - Ground, and

500 V Line - Line for Installation Category III*.

Temp. Range:

Operating: 23°F to 122°F

Storage: 4°F to 158°F

Humidity:

Operating: 70% RH at 68°F, 60% RH at 95°F, 50% RH at 104°F

for measurements <200 MΩ

Storage: 95% RH at 95°F

Display: 31⁄2 digit L.C.D. Maximum reading 1999

Automatic Discharge: Capacitive circuits are automatically discharged when

the ‘Test‘ push is released following an insulation test

Power Supply: 6 x 1.5 V AA( Alkaline) type cells

Battery life: Typically 2100 x 5 second operations (worst case)

Note:- Battery cells should not be left in an instrument which may remain

unused for extended periods of time.

Low Battery Indicator: The low battery indicator symbol will appear

when the battery cells are exhausted.

Battery Replacement: The rear cover must not be opened if the test leads

are connected. To remove the rear cover, release the screw at the bottom of

the cover and lift the cover upwards.To avoid the possibility of shock, do not

press the ‘Test‘ push when changing batteries.

Fuses: 2 x 500 mA 500 V (F) H.B.C.10 kA min 11⁄4“ x 1⁄4“

To check the

+ve fuse, short the +ve and -ve test leads and press the ‘Test’

push. An ‘ ’ reading indicates that the

+ve fuse has ruptured.

Fuse Replacement: Held in screw type holders located in the base of the

instrument. Use a flat blade screwdriver to release the center part of each

fuse holder. Remove the fuses and test each in turn. Replace with fuse(s) of

the correct type, size and rating.

Weight: 2.2 lb (including batteries)

Dimensions: 7” x 5” x 5”

Cleaning: Wipe disconnected instrument with a clean cloth dampened with

soapy water or Isopropyl Alcohol (IPA)

*Relates to transient overvoltage likely to be found in fixed installation wiring.

0.5A(F) 500V

HBC(10 kA)

Guard fuse

Positive fuse

Page 6

ACCESSORIES

Supplied Part Number

User Guide 6172-373

Battery - 6 x 1.5 V AA(Alkaline) type

Test Record Card (5 supplied)

Optional

Carrying case 217740

Fuses 500 mA, 500 V (F) H.B.C. (pack of 5) 6121-289

Fused probe kit FPK4 6111-287

Test lead set comprising:-

1 black, 1 red, 1 green test lead, with alligator clips 6220-436

Test Record cards (Pack of 20) 6111-216

Publication - ‘A Stitch in Time’ AVTM21-P8B

REPAIR AND WARRANTY

The instrument contains static sensitive devices, and care must be taken in

handling the printed circuit board. If an instrument’s protection has been

impaired it should not be used, but sent for repair by suitably trained and

qualified personnel. The protection is likely to be impaired if for example; it

shows visible damage; fails to perform the intended measurements; has been

subjected to prolonged storage under unfavourable conditions, or has been

subjected to severe transport stresses.

NEW INSTRUMENTS ARE GUARANTEED FOR 1 YEAR

FROM THE DATE OF PURCHASE BY THE USER.

Note:

Any unauthorized prior repair or adjustment will automatically invalidate

the Warranty.

INSTRUMENT REPAIR AND SPARE PARTS

For service requirements for Megger Instruments contact :-

Megger Limited or Megger

Valley Forge Corporate Center Archcliffe Road

2621 Van Buren Avenue Dover

Norristown, PA 19403 Kent, CT17 9EN

U.S.A. England

Tel: +1 (610) 676-8579 Tel: +44 (0) 1304 502243

Fax: +1 (610) 676-8625 Fax: +44 (0) 1304 207342

or an approved repair company.

Approved Repair Companies

A number of independent instrument repair companies have been authorised

for repair work on most Megger instruments, using genuine Megger spare

parts. Consult the Appointed Distributor / Agent regarding spare parts, repair

facilities, and advice on the best course of action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it should be sent

freight pre-paid to the appropriate address. Acopy of the invoice and of the

packing note should be sent simultaneously by airmail to expedite clearance

through Customs. Arepair estimate showing freight return and other charges

will be submitted to the sender, if required, before work on the instrument

commences.

MeterCenter

2046 West Peninsula Circle

Chandler, AZ 85248

Telephone (480) 659-8351 Toll Free (800) 230-6008 Fax (480) 659-8361

Loading...

Loading...