Page 1

MELCHOR GABILONDO, S.A.

Polígono Industrial Eitua, 6 / 48240 Bérriz (Vizcaya) ESPAÑA / Tel. 94 622 50 90

Intl.: 34-94 622 50 90 / Telefax: 94 622 52 78 / Intl.: 34-94 622 52 78

Teléfono Ventas: 94 622 50 30 / Telefax Ventas: 94 682 73 50

E-MAIL: interior@mega-sa.com / export@mega-sa.com

Web: www.mega.es

Page 2

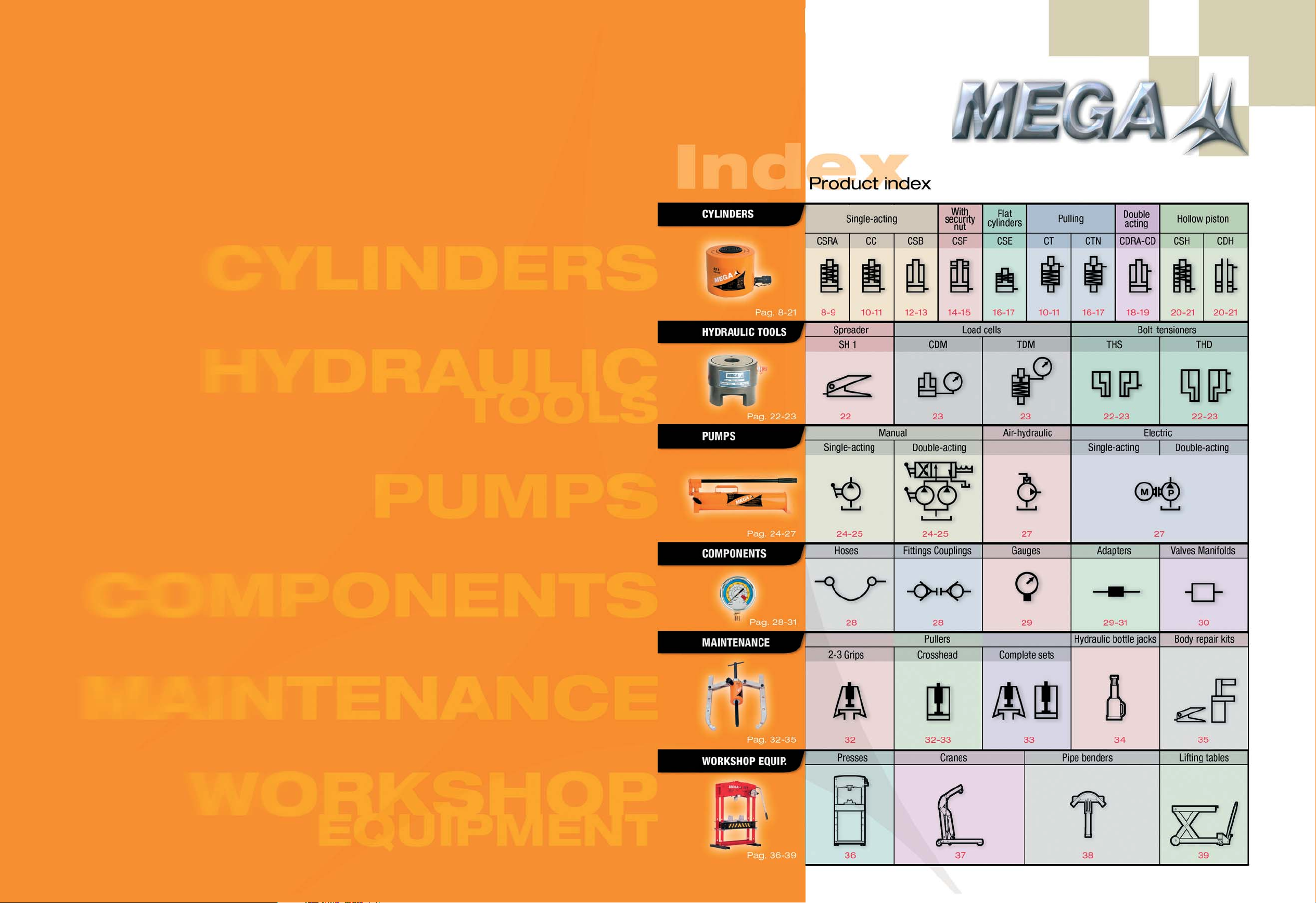

Page 3

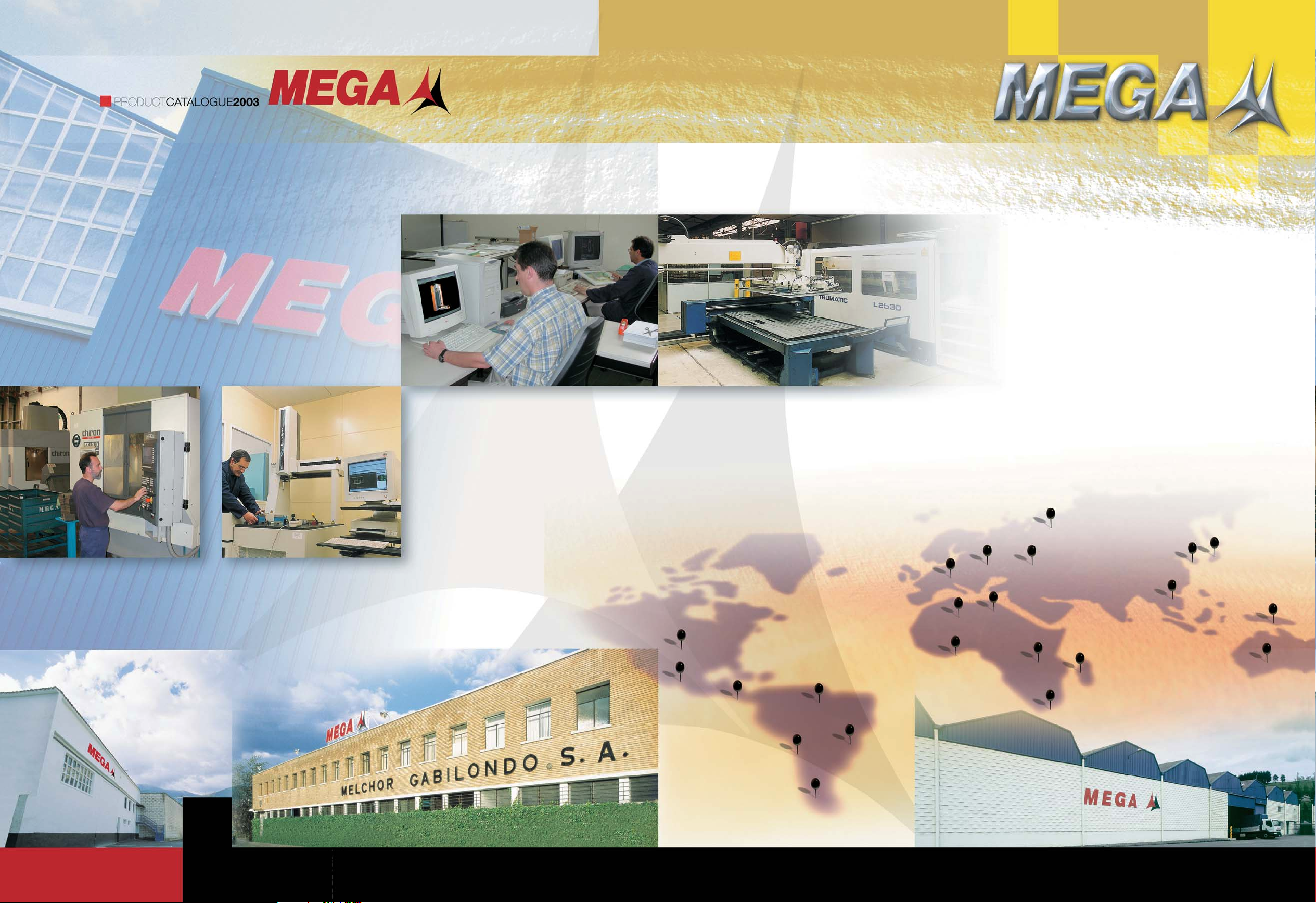

We have come a long way, but after more

than fifty years our course is still market by the

desire to achieve quality and innovation so

that we can live up to our permanent

commitment to improvement.

We maintain our innovative spirit, high standards

of quality and strict checks of material and

processes. We are making our tools more

powerful, safer, more operative and longer

lasting.

Thus we place our experience in your hands.

The high reputation of MEGA

abroad has enabled us to

consolidate a firm position on

the markets of all five

continents.

Plate laser cutting and welding

facilities. CEGAMA

Head office and factory of hydraulic components. BERRIZ Painting installation, general warehouses and despatching area. BERRIZ.

Page 4

Read carefully the safety, user and

maintenance instructions provided with

the equipment. If these basic rules are not

followed injury to the user, the hydraulic

equipment or the load to be lifted may

result.

Position the cylinder on a solid, even

and horizontal surface.

Never use the cylinder on a slope.

Keep a safe distance from the load

during operation.

Never position any part of your body under

the load.

Always secure the load with mechanical

stands.

Clean couplers before connecting and make

sure the connections are securely tightened.

Never exceed the rated capacity of the

cylinder.

It is strongly recommended the use of a

gauge to check the pressure.

Prevent hoses from sharp bending and do

not drop objects on them.

Never disconnect couplers unless the piston

is fully retracted.

Always use a safety cock to block the cylinder.

Avoid extreme heat and temperatures over

65ºC .

Never use cylinders without a saddle.

The saddle helps centre the load.

Never use excessive tightening force that

may damage the fittings. Do not use tools.

Never use extensions on hand pumps or jacks.

Use only the lever provided.

Always use a cylinder of a capacity and hydraulic stroke 25% higher than

the weight of the load to be lifted.

Use original MEGA oil.

IMPORTANT. An excess of oil will render the

pump inoperative.

VERY IMPORTANT.- Never use brake fluid.

After use, retract the piston completely, clean

the equipment and keep it protected from

aggressive environment.

Repair kits are available for every item in this

calalogue.

Always indicate the reference of the item for

which the kit is intended.

Page 5

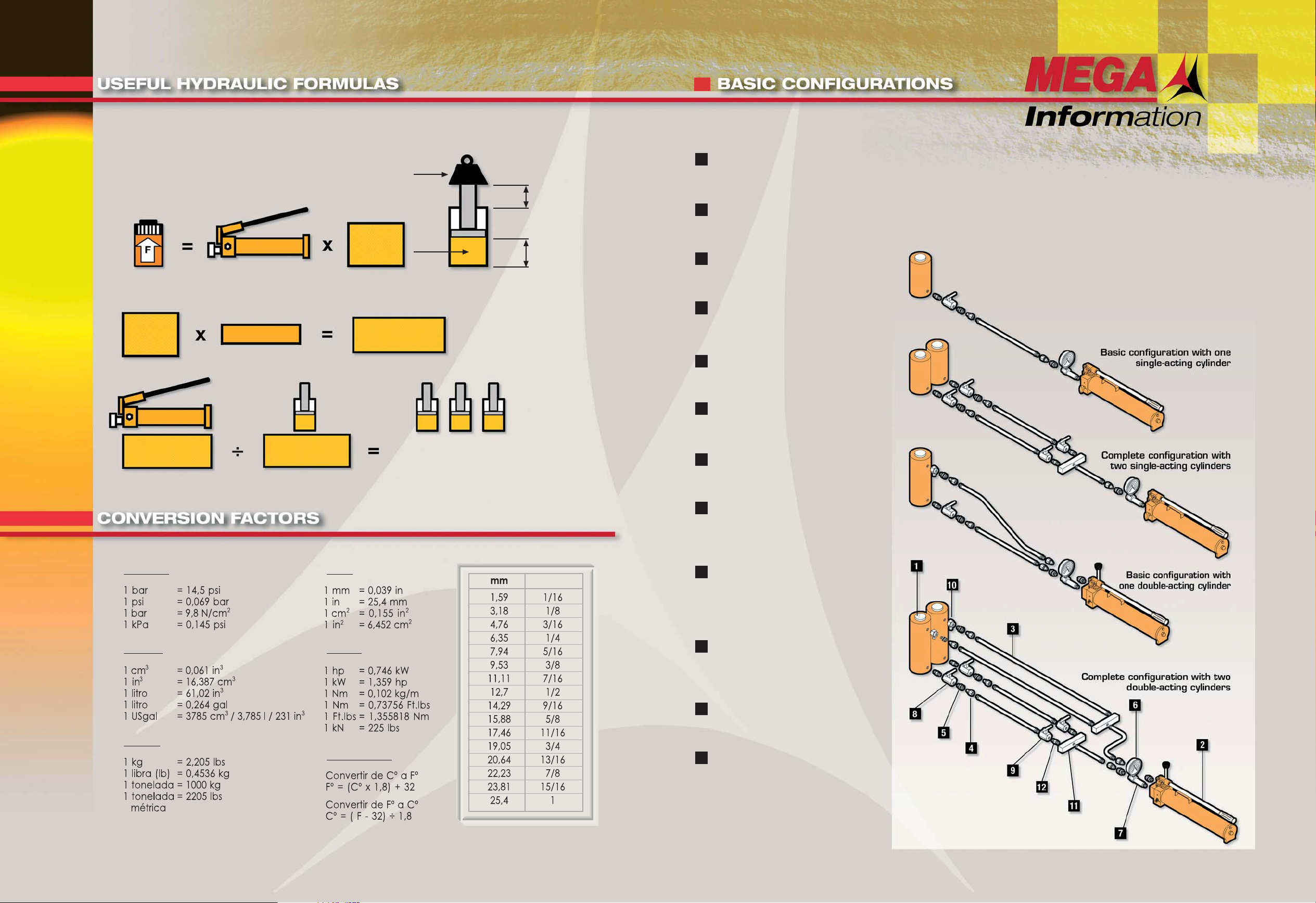

A basic hydraulic configuration consists of a single-acting cylinder, a pump

and a hose. It is really a small machine with the following components:

a) Flow generator = Pump. b) Flexible hose to transmit the oil flow from pump

to cylinder. c) Hydraulic cylinder, consisting of a chamber with inlet for the

oil and a piston to retain the oil and maintain the pressure that raises or

lowers as the oil changes within the chamber. The pressure is

created by resistance to flow. This resistance is the result

of a load. This hydraulic equipment can be used in

virtually all types of industry. From a basic pump

and cylinder set, you can build many

different system configurations by

adding components and

accessories.

1

2

3

4

5

6

7

8

9

10

11

12

Cylinder

To raise the load.

Page 8

Pump

Creates the hydraulic flow.

Page 24

Hose

Transmits the oil flow.

Page 28

A-5507-M

Male quick coupler

Page 28

A-5507-H

Female quick coupler

Page 28

Gauge

To control pressure.

Page 29

Gauge adapter

To mount the gauge.

Page 29

A-5510

Safety valve

Locks the load on raised cylinder.

Page 30

A-5509

Shutoff valve

Shuts the oil flow and locks

the load on raised cylinder.

Page 30

A-5538

Safety relief valve

Avoids accidental overpressure.

Page 30

Manifold

To distribute the oil flow.

Page 31

12 A-5511

Male connector

To connect different components.

Page 31

Capacity (kg)

Pressure (kg/cm

2

- psi)

Effective

area

(cm

2

/ in2)

Stroke

Volume of oil

(cm3/ in3)

Load

Cylinder

effective area

Stroke

Oil volume

of cylinder

Oil volume

of pump

Oil volume

of cylinder

Number of cylinders that can be used with

one pump.

With long hoses, add 35 cm

3

for each meter

used.

Basic hydraulic calculations for the correct selection of cylinders and pumps.

cm3 / in

3

cm / in

cm

2

in

2

Pressure:

Volume:

Weight:

Area:

Others:

Temperature:

Inches

Please note that the dimensions of this catalogue are exact in the metric system ( mm )

and approximate in inches.

Page 6

8 9

Mounting applications

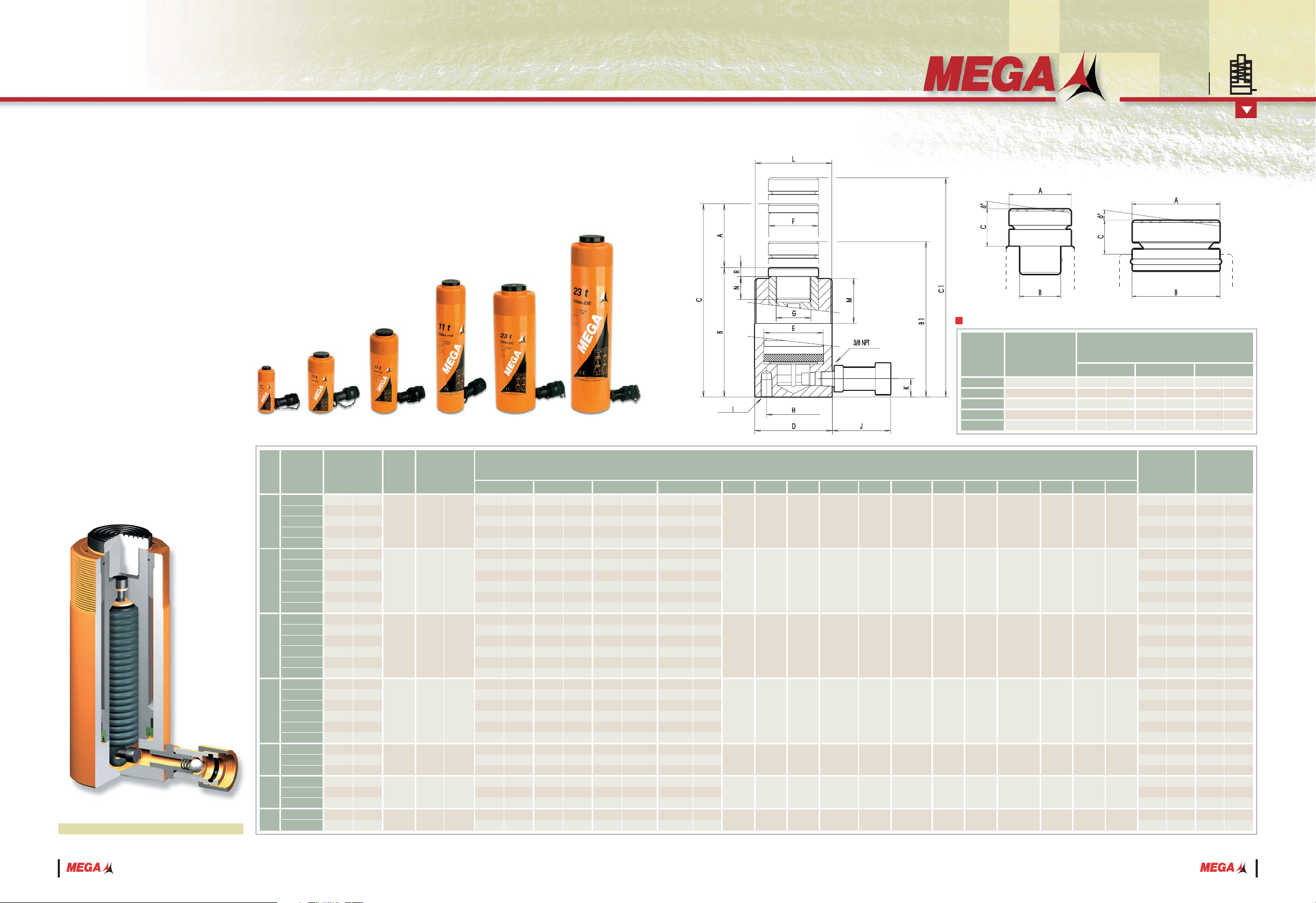

CSRA Series

HYDRAULIC CYLINDERS

Tilting saddle ( optional )

CSRA-5

CSRA-11, CSRA-16

CSRA-23, CSRA-31

CSRA-55

CSRA-93

BCSRA-5

BCSRA-11

BCSRA-23

BCSRA-55

BCSRA-93

Ref. Used with

ABC

Dimensions mm/in.

11

/16

7

/8

1 7/16

2 13/64

2 7/8

15

20

23

25

31

19

/32

25

/32

29

/32

1

1

7

/32

26

40

55

65

80

1 1/32

1 9/16

2 11/64

2 9/16

3 6/32

17,4

22,1

36,3

56

73,5

25

75

125

175

225

25

50

100

150

200

250

25

50

100

150

200

250

25

50

100

150

200

250

50

150

200

50

100

150

50

150

1

2

15

/16

4 15/16

6 7/8

8 7/8

1

2

3

15

/16

5 15/16

7 7/8

9 7/8

1

2

3

15

/16

5 15/16

7 7/8

9 7/8

1

2

3

15

/16

5

1 5

/16

7 7/8

9 7/8

2

5

15

/16

7 7/8

2

3

15

/16

5 15/16

2

3

15

/16

CSRA-5A

CSRA-5B

CSRA-5C

CSRA-5D

CSRA-5E

CSRA-11A

CSRA-11B

CSRA-11C

CSRA-11D

CSRA-11E

CSRA-11F

CSRA-16A

CSRA-16B

CSRA-16C

CSRA-16D

CSRA-16E

CSRA-16F

CSRA-23A

CSRA-23B

CSRA-23C

CSRA-23D

CSRA-23E

CSRA-23F

CSRA-31B

CSRA-31D

CSRA-31E

CSRA-55B

CSRA-55C

CSRA-55D

CSRA-93B

CSRA-93D

5

11

16

23

31

55

93

Rated

capacity

Ref. Stroke

Maximum

capacity

Effective area

tn

A

kN cm

2

in

2

BB1 CC1 DEF G

H

ILMNR

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

JK

B1, C1 with tilting saddle

lbs.

mm. in.

18

54

90

126

162

40

80

160

240

320

400

60

120

240

360

480

600

83

166

332

498

664

830

220

660

880

392

784

1176

664

1992

1,1

3,3

5,5

7,7

9,9

2,45

4,9

9,75

14,65

19,5

24,4

3,65

7,3

14,65

22

29,3

36,6

5,05

10,1

20,2

30,4

40,5

50,6

13,4

40,3

53,7

23,9

47,8

71,8

40,5

121,6

2,2

3,2

4,2

5,6

6,5

5,3

6,4

8,6

10,8

13,2

15,4

7,6

9,15

12,2

15,4

19

22,3

12,8

15

19,7

24,5

28,7

34,2

24,2

36,8

43

36

45,4

55,8

71,2

108,7

70

2

3

/4

70

2

3

/4

70

2

3

/4

70

2

3

/4

70

2

3

/4

70

2

3

/4

70

2 3/4

20

25

/32

20

25

/32

20

25

/32

20

25

/32

37

1 7/16

20

25

/32

47

1 27/32

1 1/2-16UN

2 1/4-14UNS

2 3/4-16UN

3 5/16-12UNS

3

5

/16-12UNS

5-12UN

6

7

/8-12UN

29

1

9

/64

27

1

1

/16

30

1

3

/16

49

1

15

/16

51

2

45

1

25

/32

50

1 31/32

16

5

/8

17

11

/16

17

11

/16

25

1

25

1

6

15

/64

6

15

/64

10

25

/64

10

25

/64

10

25

/64

2

6

/64

2

6

/64

1

/4-20UNC

5

/16-18UNC

3

/8-16UNC

1

/2-13UNC

----

1

/2-13UNC

----

40

1

9

/16

60

2 11/32

70

2

3

/4

85

3 11/32

100

3 15/16

130

5 1/64

175

6

7

/8

30

1

3

/16

45

1 49/64

55

2 11/64

65

2 9/16

75

2 61/64

100

3 15/16

130

5

1

/8

26

1

1

/32

39

1 17/32

46

1 13/16

54

2 1/8

57,15

2 1/4

80

3 6/32

105

4

9

/64

3

/4-16UNF

1-8UNC

1-8UNC

1 1/2-16UN

1 1/2-16UN

----

----

25

63

/64

40

1

9

/16

48

1

7

/8

59

2

5

/16

----

95

3 3/4

----

125

175

227

288

339

139

164

214

264

318

368

144

169

220

272

329

382

163

188

239

290

347

398

219

319

369

194

244

294

221

321

4

15

/16

6 7/8

8 15/16

11 5/16

13 11/32

5 1/2

6 7/16

9 7/16

10 3/8

12 1/2

14 1/2

5 11/16

65/8

8 11/16

10 11/16

13

16

6

7

/16

7 3/8

9 7/16

11 7/16

13 11/16

15 11/16

8 5/8

12 9/16

14 1/2

7 5/8

9 5/8

11 9/16

8 11/16

12 5/8

150

250

352

463

564

164

214

314

414

518

618

169

219

320

422

529

632

188

238

339

440

547

648

269

469

569

244

344

444

271

471

5

7

/8

9 7/8

13 7/8

18 1/4

22 3/16

6 7/16

8 7/16

12 3/8

16 5/16

20 3/8

24 5/16

6 11/16

8 5/8

12 5/8

16 5/8

20 7/8

24 7/8

7 3/8

9 3/8

13 5/16

17 5/16

21 1/2

25 1/2

10 5/8

18 7/16

22 3/8

9 5/8

13 9/16

17 1/2

10 11/16

18 9/16

135

235

337

448

549

144

194

294

394

498

598

149

199

300

402

509

612

165

215

316

417

524

625

244

444

544

219

319

419

240

440

5

5

/16

9 1/4

13 1/4

17 5/8

21 5/8

5 11/16

7 5/8

11 9/16

15 1/2

19 5/8

23 1/2

5 7/8

7 7/8

11 13/16

15 7/8

20

24

1

/64

6 1/2

8 1/2

12 7/16

16 3/8

20 5/8

14 5/8

9 5/8

17 1/2

21 3/8

8 5/8

12 9/16

16 1/2

9 7/16

17 5/16

110

160

212

273

324

119

144

194

244

298

348

124

149

200

252

309

362

140

165

216

267

324

375

194

294

344

169

219

269

190

290

4

11

/32

6 15/16

8 3/8

10 3/4

12 3/4

4 11/16

5 11/16

7 5/8

9 5/8

11 3/4

13 3/4

4 7/8

5 7/8

7 7/8

9 15/16

12 6/32

14 1/4

5 1/2

6 1/2

8 1/2

10 1/2

12 3/4

14 3/4

7 5/8

11 9/16

13 9/16

6 5/8

8 5/8

10 5/8

7 1/2

11 7/16

48,5

109,1

163

227,7

303,1

539

910,9

1

1,45

1,92

2,48

2,94

2,4

2,9

3,9

4,9

6

7

3,45

4,15

5,55

7

8,6

10,1

5,8

6,8

8,95

11,1

13

15,5

11

16,7

19,5

15,9

20,6

25,3

32,3

49,3

7,06

15,9

23,75

33,08

44,18

78,54

132,73

1,09

2,46

3,68

5,12

6,84

12,17

20,57

----

----

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a salt bath nitriding treatment

or a hard chrome plating, depending on the

model, to resist corrosion and for longer life.

With built-in bronze guide for easier sliding

of piston.

These cylinders are fitted with a removable

grooved saddle, pressure mounted or screwed

in the piston head. They are also equipped

with a high flow female quick coupler with

dust cap, ref. A-5507-H.

Carry handles on models weighing from

20 kg/44 lbs to 40 kg/88 lbs. Heavier models

are fitted with eye hooks for transport.

With mounting holes and threaded areas

protected against blows for easy coupling or

special tooling applications.

Cross section view

Single-acting, spring return

Page 7

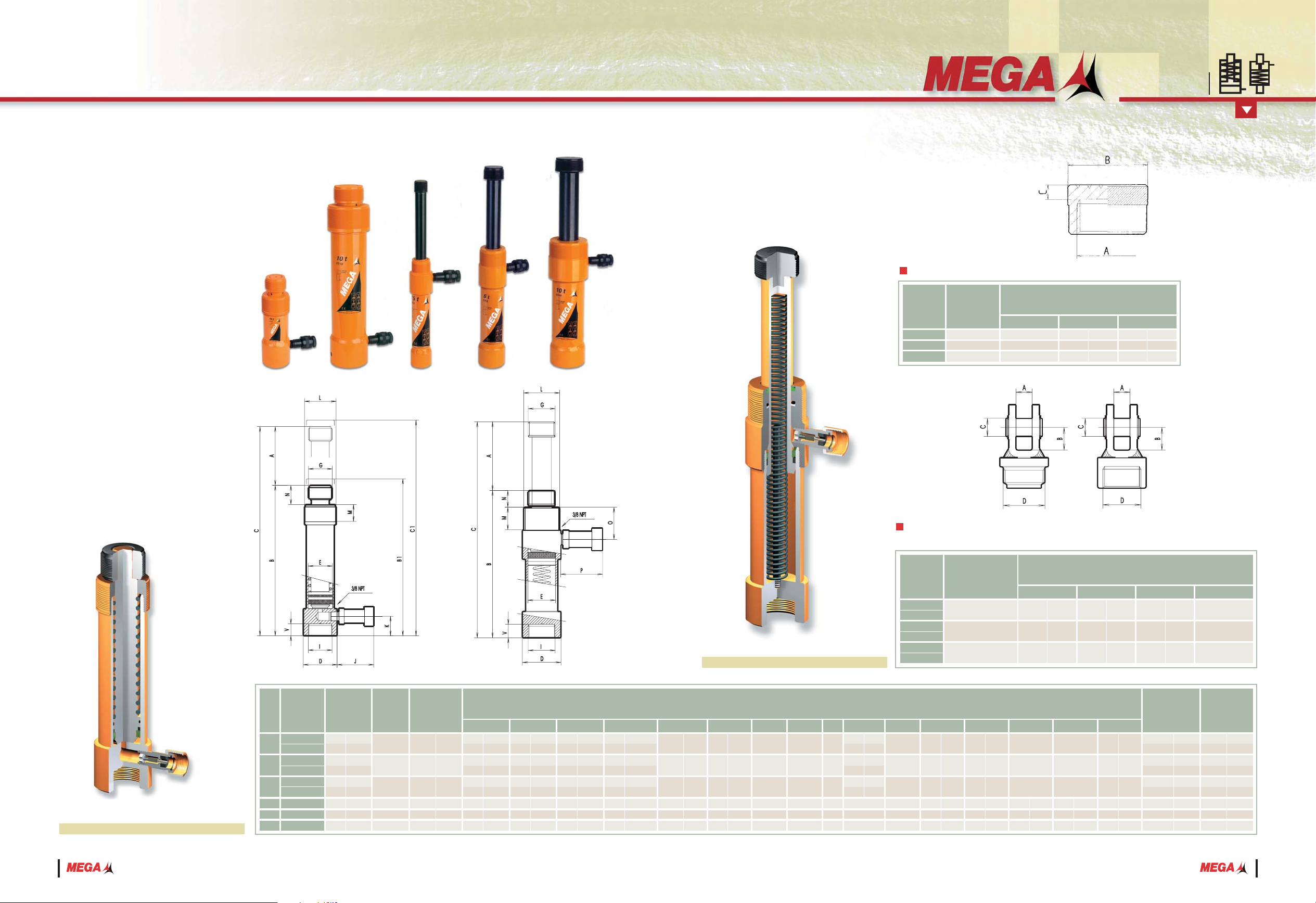

10 11

Coupling applications

CC

CT Series

HYDRAULIC CYLINDERS

CC: PUSHING

CT: PULLING

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have an induction hardening

treatment or a salt bath nitriding process

depending on the model.

Each ram is equipped with a female quick

coupler with air dust cap, ref. A-5507-H.

With mounting holes and protected

threaded areas against possible blows for

easy coupling or special tooling applications.

Unlike the pushing cylinders, the pulling

rams retract toward the base to apply

pressure.

These pushing and pulling cylinders can

be original components of the Maintenance

Kits described on page 35.

Cross section view ( CC )

CC-5 SERIES

CC-10 SERIES

CC-20 SERIES

A-5142

A-5042

A-5242

Ref. Used with

ABC

Dimensions mm/in.

1 17/64

2 7/8

2 29/32

8

10

12

5

/16

25

/64

15

/32

M26 x 2

M42 x 2,5

M60 x 2,5

32

54

74

Grooved saddle ( optional )

CC-5A

CC-5B

CC-10A

CC-10B

CC-20A

CC-20B

CT-2,5

CT-5

CT-10

5

10

20

2,5

5

10

Rated

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm2in

2

BB1 CC1 DEGIJKNOPV

cm

3

in3Kg.

Oil volume WeightDimensions mm/in.

LM

lbs.

40

92

73

196

141

368

54

103

199

2,44

5,61

4,45

11,96

8,6

22,46

3,29

6,28

12,14

3

4,9

5,3

9,6

12,1

2,2

5

8,6

17,6

M26 x 2

M42 x 2,5

M60 x 2,5

M26 x 2

M42 x 2,5

M60 x 2,5

70

2

3

/4

70

2

3

/4

70

2

3

/4

----

----

----

1,35

2,2

2,4

4,35

5,5

10

2,25

3,9

8

50

115

50

135

50

130

127

138

138

2

4

1

/2

2

5

5

/16

2

5

1

/8

5

5

7

/16

5 7/16

55

99,6

194

29,1

51,1

99

8,04

14,52

28,27

4,24

7,45

14,41

1,24

2,25

4,38

0,65

1,15

2,23

177

284

191

332

216

364

270

311

318

6

15

/16

11 3/16

7 1/2

13 1/16

8 1/2

14 5/16

10 5/8

12 1/4

12 1/2

184

292

201

342

228

376

----

----

----

7

5

/16

11 1/2

7 15/16

13 7/16

9

14

13

/16

----

----

----

227

399

241

467

266

494

397

449

456

8

15

/16

15 11/16

9 1/2

18 3/8

10 1/2

19 7/16

15 5/8

17 11/16

17 15/16

235

407

251

477

278

506

---

---

---

9

1

/4

16

9

7

/8

18 3/4

10 15/16

19 15/16

---

---

---

Stroke

A

mm. in.

M26 x 2

M42 x 2,5

M60 x 2,5

M26 x 2

M42 x 2,5

M60 x 2,5

45

60

79

45

60

79

M38 x 1,5

M56 x 2

M84 x 2

M38 x 1,5

M56 x 2

M84 x 2

----

----

----

70

70

70

2

3

/4

2 3/4

2 3/4

----

----

----

70

70

70

2

3

/4

2 3/4

2 3/4

----

----

----

33

30

38

35

44

40

1 5/

16

1 3/

16

1 1/

2

1 3/

8

1 3/

4

1 9/

16

B1, C1 with tilting saddle

1 49/64

2 11/32

3 1/8

1 49/64

2 11/32

3 1/8

32

43

60

32

43

60

1 1/4

1 11/16

2 11/32

1 1/4

1 11/16

2 3/8

22

36

48

24

35

35

7

/8

1 7/16

1 7/8

15

/16

1 3/8

1 3/8

20

26

30

21

24

27

13

/16

1 1/32

1 3/16

1 13/16

15

/16

1 1/16

18

21

23

16

21

21

11

/16

13

/16

7

/8

5

/8

13

/16

13

/16

Cross section view ( CT )

CC-5, CT-2,5 SERIES

CC-10, CT-5 SERIES

CC-20, CT-10 SERIES

A-5188

A-5189

A-5088

A-5089

A-5288

A-5289

Ref. Used with

ABC

Dimensions mm/in.

1

1

1

3

/16

20

20

20

25

/32

25

/32

25

/32

18

18

18

23

/32

23

/32

23

/32

25

25

30

D

M26 x 2

M42 x 2,5

M60 x 2,5

Attachments for pulling and

pushing pistons ( optional )

Single-acting, spring return

Page 8

12 13

General application

CSB Series

HYDRAULIC CYLINDERS

Ideal for a wide range of applications in

civil engineering, heavy fabrication,

construction, maintenance and lifting of

very heavy loads.

38

50

50

50

50

50

150

150

250

150

250

150

250

1

1

/2

2

2

2

2

2

5

15

/16

5 15/16

9 7/8

5 15/16

9 7/8

5 15/16

9 7/8

CSB-11A

CSB-23B

CSB-31B

CSB-55B

CSB-93B

CSB-200B

CSB-200D

CSB-300D

CSB-300F

CSB-400D

CSB-400F

CSB-500D

CSB-500F

11

23

31

55

93

200

300

400

500

Rated

capacity

Ref. Stroke

Maximum

capacity

Effective area

tn

A

kN cm

2

in

2

BB1 CC1 DEF R

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

JK

B1, C1 with tilting saddle

lbs.

mm. in.

60

166

220

392

664

1417

4252

6506

10843

8780

14633

10960

18265

3,66

10,1

13,4

23,9

40,5

86,5

259,6

397,2

662

536

894

669

1115

4,8

11

15,2

28,4

44

156

210

403

515

570

710

755

935

123

140

147

163

160

269

369

436

546

459

569

488

598

4

7

/8

5 1/2

5 13/16

6 7/16

6 5/16

10 5/8

14 1/2

17 3/16

21 1/2

18 1/16

22 3/8

19 3/16

23 9/16

161

190

197

213

210

319

519

586

796

609

819

638

848

6

5

/16

7 1/2

7 3/4

8 3/8

8 1/4

12 9/16

20 7/16

23 1/16

31 5/16

24

32

1

/4

25 1/8

33 3/8

147

174

175

188

180

269

469

521

731

531

741

550

760

5

13

/16

6 7/8

6 7/8

7 7/16

7 1/16

10 5/8

18 7/16

20 1/2

28 13/16

20 7/8

29 3/16

21 5/8

29 15/16

109

124

125

138

130

219

319

371

481

381

491

400

510

4

5

/16

4 7/8

4 15/16

5 7/16

5 1/8

8 5/8

12 9/16

14 9/16

18 15/16

15

19

5

/16

15 3/4

20 1/16

109,1

227,7

303,1

539

910,9

1945,8

2976,5

4017,1

5014

2,2

5

6,9

12,9

20

70,8

95,3

183

234

259

322

343

424

15,9

33,18

44,18

78,54

132,73

283,52

433,73

585,35

730,6

2,46

5,14

6,84

12,17

20,57

43,95

67,24

90,75

113,27

2 11/32

3 3/8

3 15/16

5 1/8

6 7/16

9 9/16

11 7/8

13 3/4

15 7/16

60

85

100

130

163

242

302

349

392

1 49/64

2 9/16

2 61/64

3 15/16

5 1/8

7 1/2

9 1/4

10 5/8

12

45

65

75

100

130

190

235

270

305

1

17

/32

2 1/8

2 1/4

3 6/32

4 9/64

5 15/16

6 11/16

8 1/4

9 7/16

39

54

57,15

80

105

150

170

210

240

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

70

70

70

70

70

70

70

70

70

15

/16

15

/16

15

/16

15

/16

15

/16

2 7/16

3 1/16

3 7/16

3 9/16

23

23

23

23

23

62

78

88

91

5

/64

5

/64

5

/64

5

/64

5

/64

3

/16

3

/16

3

/16

3

/16

2

2

2

2

2

5

5

5

5

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a salt bath nitriding

treatment or a hard chrome plating,

depending on the model, to resist corrosion

and for longer life.

With built-in bronze guide for easier sliding

of piston.

These cylinders are fitted with a removable

grooved saddle, pressure mounted or

screwed in the piston head. They are also

equipped with a female quick coupler

with dust cap, ref. A-5507-H.

Carry handles on models weighing from

20 kg/44 lbs to 40 kg/88 lbs Heavier

models are fitted with eye hooks for

transport.

Cross section view

Tilting saddle ( optional )

CSB-11

CSB-23

CSB-31

CSB-55

CSB-93

CSB-200

CSB-300

CSB-400

CSB-500

BCSB-11

BCSB-23

BCSB-31

BCSRA-55

BCSRA-93

BCSB-200

BCSB-300

BCSB-400

BCSB-500

Ref. Used with

ABC

Dimensions mm/in.

1 1/16

1 17/32

1 17/32

2 13/64

2 7/8

4 7/8

5 1/8

6 5/16

7 3/32

14

16

22

25

31

50

65

78

88

35

/64

5

/8

55

/64

1

1

7

/32

2

2

9

/16

3 5/64

3 15/32

40

55

55

65

80

138

155

185

205

1

9

/16

2 11/64

2 11/64

2 9/16

3 6/32

5 7/16

6 1/64

7 9/32

8 1/16

27

39

39

56

73,5

124

130

160

180

Single-acting, load return

Page 9

14 15

With security lock nut

CSF Series

HYDRAULIC CYLINDERS

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a salt bath nitriding

treatment to resist corrosion.

With built-in bronze guide for easier sliding

of piston.

These cylinders are fitted with a removable

grooved saddle, pressure mounted or

screwed in the piston head. They are also

equipped with a high flow female quick

coupler with dust cap, ref. A-5507-H.

Carry handles on models weighing from 20

kg/44 lbs to 40 kg/88 lbs Heavier models

are fitted with eye hooks for transport.

The mechanical lock of load is effected by

a safety lock nut at the piston extension

desired.

Particularly recommended for foundations

support in construction, bridge building

and maintenance of heavy machinery in

public works or steel industry, specially

when load must be kept on hold for long

periods.

The safety lock nut allows disconnection

of the pump and ensure total safety

conditions when operating under the load.

Cross section view

With tilting saddle ( optional )

CSF-31 SERIES

CSF-55 SERIES

CSF-93 SERIES

CSF-200 SERIES

CSF-300 SERIES

CSF-400 SERIES

CSF-500 SERIES

BCSB-31

BCSRA-55

BCSRA-93

BCSB-200

BCSB-300

BCSB-400

BCSB-500

Ref. Used with

ABC

Dimensions mm/in.

1 17/32

2 13/64

2 7/8

4 7/8

5 1/8

6 5/16

7 3/32

22

25

31

50

65

78

88

55

/64

1

1

7

/32

2

2

9

/16

3 5/64

3 15/32

55

65

80

138

155

185

205

2 11/64

2 9/16

3 6/32

5 7/16

6 1/64

7 9/32

8 1/16

39

56

73,5

124

130

160

180

150

150

150

150

150

250

150

250

150

250

5

15

/16

5 15/16

5 15/16

5 15/16

5 15/16

9 7/8

5 15/16

9 7/8

5 15/16

9 7/8

CSF-31D

CSF-55D

CSF-93D

CSF-200D

CSF-300D

CSF-300F

CSF-400D

CSF-400F

CSF-500D

CSF-500F

31

55

93

200

300

400

500

Nominal

capacity

Ref. Stroke

Maximum

capacity

Effective area

tn

A

kN cm

2

in

2

BB1 CC1 DEF R

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

JK

B1, C1 with tilting saddle

lbs.

mm. in.

660

1176

1992

4252

6506

10843

8780

14633

10960

18265

40,3

71,8

121,6

259,6

397,2

662

536

894

669

1115

294

318

356

424

500

610

528

638

563

673

11

9

/16

12 1/2

14

16

11

/16

19 11/16

24

20

3

/4

25 1/8

22 3/16

26 1/2

444

468

506

574

650

860

678

888

713

923

17

1

/2

18 7/16

19 15/16

22 5/8

25 5/8

33 7/8

26 11/16

35

28

1

/16

36 5/16

422

443

476

524

585

795

600

810

625

835

16

5

/8

17 7/16

18 3/4

20 5/8

23

31

5

/16

23 5/8

31 7/8

24 5/8

32 7/8

272

293

326

374

435

545

450

560

475

585

10

11

/16

11 1/2

12 13/16

14 3/4

17 1/8

21 7/16

17 11/16

22

18

11

/16

23

303,1

539

910,9

1945,8

2976,5

4017,1

5014

14,5

27,2

56,4

125

222

269

315

383

427

515

44,18

78,54

132,73

283,52

433,73

585,35

730,6

6,84

12,17

20,57

43,95

67,24

90,75

113,27

3

15

/16

5 1/8

6 7/8

9 9/16

11 7/8

13 3/4

15 7/16

100

130

175

242

302

349

392

2

61

/64

3 15/16

5 1/8

7 1/2

9 1/4

10 5/8

12

75

100

130

190

235

270

305

TR 2

1

/4 x 5

TR 80 x 5

TR 105 x 5

TR 160

x 5

TR 180 x 5

TR 220 x 5

TR 260 x 5

2

3

/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

70

70

70

70

70

70

70

15

/16

15

/16

1 27/32

2 7/16

3 1/16

3 7/16

3 9/16

23

23

47

62

78

88

91

5

/64

5

/64

5

/64

3

/16

3

/16

3

/16

3

/16

2

2

2

5

5

5

5

32

60

125

275

490

593

695

845

940

1135

Single-acting, load return

Page 10

16 17

Flat cylinders

CSE Series

HYDRAULIC CYLINDERS

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a salt bath nitriding treatment

to resist corrosion.

Grooved piston ends make optional grooved

saddle unnecessary.

All are equipped with high flow female quick

couplers with dust cap, ref A-5507-H, except

model CSE-5 fitted with a female quick coupler,

ref. A-5506-H.

With mounting holes in the base.

These CSE cylinders have been designed

to combine minimum collapsed height with

optimum stroke.

They are suitable for lifting, clamping,

levelling or positioning jobs where space is

tight.

The spring return piston allows easy removal

from working place.

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a hard chrome plating

treatment to resist corrosion.

Equipped with high flow female quick coupler

with dust cap, ref. A-5507-H and carrying handle.

Designed for pulling and tensioning

applications, they can be used in those

operations where two heavy pieces have to be

put one near the other.

They are normally used in industrial assembling,

testing, welding operations of plates or heavy

steel frame works.

They are fitted with clevis eyes on both ends

which are linked to attachments welded onto

the plates to join or weld.

AB

C

X

D W

P

O

3/8 PNT

E

F

127

150

150

5

5

15

/16

5 15/16

CTN-10

CTN-30

CTN-50

10

30

50

Nominal

capacity

Ref. Stroke

Maximum

capacity

Effective area

tn

A

kN cm

2

in

2

BC DEF0PW

X

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

lbs.

mm. in.

183

725

1085

11,15

44,3

66,2

21,1

48,6

81,4

625

775

920

24

9

/16

30 1/2

36 7/32

60

100

125

2

11

/32

3 15/16

4 15/16

85

125

155

3

11

/32

4 15/16

6 1/8

18 11/16

24 9/16

30 5/16

9,6

22,1

37

98,95

331,8

497,2

14,42

48,34

72,45

2,23

7,49

11,23

475

625

770

42

62

80

1

21

/32

2 7/16

3 6/32

35

40

44

1

3

/8

1 9/16

1 3/4

70

70

70

2

3

/4

2 3/4

2 3/4

40

50

60

1

9

/16

2

2

11

/32

75

100

150

2

15

/16

3 15/16

5 15/16

CSE-5

CSE-11

CSE-23

CSE-31

CSE-55

CSE-93

5

11

23

31

55

93

Nominal

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm

2

in

2

BCD TU

cm

3in3

Kg.

Oil volume WeightDimensioes mm/in.

lbs.

5

18

37

53

125

212

0,77

2,8

5,73

8,2

19,4

32,8

1,65

3,85

7,05

10,5

20,7

37,9

0,75

1,75

3,2

4,8

9,4

17,2

1

/4

7

/16

7

/16

15

/32

5

/8

5

/8

7,06

15,9

33,08

44,18

78,54

132,73

1,09

2,46

5,12

6,84

12,17

20,57

1 3/8

1 3/4

2 1/8

2 11/32

2 27/32

3 15/32

1 19/32

2 3/16

2 9/16

2 27/32

3 15/32

4 3/32

60

79

98

115

147

180

2

11

/32

3 1/8

3 7/8

4 17/32

5 25/32

7 3/32

Stroke

A

mm. in.

13

/16

1 1/64

1 9/16

1 13/16

2 7/16

3 1/8

7

/8

1 5/16

1 7/16

1 3/4

2 5/16

2 15/16

48,5

109,1

227,7

303,1

539

910,9

20

28

40

47

62

80

22

34

37

44

58

75

6,5

11

11

12

16

16

34

44,5

54

60

72

88

40,5

55,5

65

72

88

104

EFHIJ

K

RS

30

45

65

75

100

130

1

3

/16

1 49/64

2 9/16

2 61/64

3 15/16

5 1/64

1 1/32

1 17/32

2 1/8

2 1/4

3 6/32

4 9/64

1 3/32

1 29/64

2

2

3

/64

2 3/4

3

7

/32

1

/4

23

/64

23

/64

7

/16

9

/16

2 11/32

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

11

/16

15

/16

15

/16

15

/16

15

/16

15

/16

3

/64

3

/64

3

/64

3

/64

3

/64

3

/64

1 5/8

2 13/64

3 1/8

3 11/16

4 7/8

6 5/16

26

39

54

57,15

80

105

28

37

50

52

70

76

5,5

6,6

9

9

11

14

60

70

70

70

70

70

17

23

23

23

23

23

41

56

80

94

124

160

1

1

1

1

1

1

Cross section view

CTN Series

Pulling cylinders

HYDRAULIC CYLINDERS

Single-acting, spring-return

Single-acting, spring return

Page 11

18 19

Double-acting cylinders

CDRA

CD Series

HYDRAULIC CYLINDERS

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a salt bath nitriding treatment

or a hard chrome plating, depending on the

model, to resist corrosion and for longer life.

With built-in bronze guide for easier sliding

of piston.

Fitted with a relief safety valve, ref. A-5538

on the piston retract side, to prevent accidental

overpressure.

These cylinders are fitted with a removable

grooved saddle, pressure mounted or screwed

in the piston head. Are also equipped with

a high flow female quick coupler with dust

cap, ref. A-5507-H.

Carry handles on models weighing from

20 kg/44 lbs to 40 kg/88 lbs. Heavier models

are fitted with eye hooks for transport.

With mounting holes and threaded areas

protected against blows for easy coupling or

special tooling applications.

The hydraulic force being applied in both

directions, these cylinders are very solid and

used where a precision operation is required

to move or position loads accurately on the

assembly place. Widely demanded in public

works and big structure manufacture.

*E= Pushing

*T= Pulling

Cross section view

CDRA-9

CDRA-23, CDRA-31

CDRA-55

CDRA-93

CD-200

CD-300

CD-400

CD-500

BCSRA-11

BCSRA-23

BCDRA-55

BCDRA-93

BCSB-200

BCSB-300

BCSB-400

BCSB-500

Ref. Used with

ABC

Dimensions mm/in.

7

/8

1 7/16

57

/64

21

/32

4 7/8

5 1/8

6 5/16

7 3/32

20

23

40

46

50

65

78

88

25

/32

29

/32

1 9/16

1 13/16

2

2

9

/16

3 5/64

3 15/32

40

55

65

80

138

155

185

205

1

9

/16

2 11/64

2 9/16

3 6/32

5 7/16

6 1/64

7 9/32

8 1/16

22,1

36,3

22,7

42,2

124

130

160

180

Tilting saddle ( optional )

Hydraulic return

CDRA-9D

CDRA-23D

CDRA-31D

CDRA-55D

CDRA-55F

CDRA-93D

CDRA-93F

CD-200D

CD-200F

CD-300D

CD-300F

CD-400D

CD-400F

CD-500D

CD-500F

9

23

31

55

93

200

300

400

500

Nominal

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm

2

in

2

BB1 CC1 DEFG

J

KNOPR

cm

3

in

3

Oil volume WeightDimensions mm/in.

LM

lbs.

5,8

10,4

19,8

28,2

37

60,3

77,3

135

173

210

261

301

373

388

476

150

150

150

150

250

150

250

150

250

150

250

150

250

150

250

5 15/16

5 15/16

5 15/16

5 5/16

9 7/8

5 5/16

9 7/8

5 5/16

9 7/8

5 5/16

9 7/8

5 5/16

9 7/8

5 5/16

9 7/8

285

315

338

321

421

355

455

356

456

412

512

417

517

439

539

11 3/16

12 7/16

13 5/16

12 5/8

16 9/16

14

17

7

/8

14

17

7

/8

16 7/32

20 6/32

16 13/32

20 11/32

17 9/32

21 7/32

305

338

363

361

461

401

501

406

506

477

577

495

595

527

627

435

465

488

471

671

505

705

506

706

562

762

567

767

589

789

17 1/8

18 5/16

19 7/32

18 17/32

26 13/32

19 7/8

27 3/4

19 15/16

27 3/4

19 15/16

30

22

5

/16

30 3/16

23 3/16

31 1/16

455

488

513

511

711

551

751

556

756

627

827

645

845

677

877

Stroke

A

mm. in.

60

85

100

130

175

242

302

349

392

B1, C1 with tilting saddle

12,56

4,62

33,18

10,28

44,18

18,55

78,54

28,28

132,73

46,14

283,52

433,73

585,35

730,6

E

T

E

T

E

T

E

T

E

T

E

E

E

E

86,24

31,72

227,7

70,54

303,1

127,3

539

194,07

910,9

316,6

1945,8

----

2976,5

----

4017,1

----

5014

----

E

T

E

T

E

T

E

T

E

T

E

T

E

T

E

T

E

T

1,94

0,71

5,12

1,6

6,84

2,87

12,17

4,38

20,57

7,15

43,95

67,24

90,75

113,27

E

T

E

T

E

T

E

T

E

T

E

E

E

E

12

13

5

/16

14 9/32

14 7/32

18 9/64

15 3/4

19 3/4

16

10

1

/8

18 3/4

22 11/16

19 1/2

23 7/16

20 3/4

24 11/16

17 15/16

19 7/32

20 3/16

20 1/64

28

21

11

/16

29 9/16

21 7/8

29 3/4

24 11/16

32 9/16

25 3/8

33 1/4

26 5/8

34 1/2

2 11/32

3 3/8

3 15/16

5 1/8

6 7/8

9 9/16

11 7/8

13 3/4

15 7/16

40

65

75

100

130

190

235

270

305

1

37

/64

2 9/16

2 61/64

3 15/16

5 1/8

7 1/2

9 1/4

10 5/8

12

1

1

/4

2 1/8

2 1/4

3 6/32

4 9/64

5 15/16

6 11/16

8 1/4

9 7/16

1 - 8 UNC

1

1

/2 - 16 UN

1

1

/2 - 16 UN

1 - 12 UNF

1

3

/4 - 12 UN

----

----

----

----

70

70

70

70

70

70

70

70

70

2

3

/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

23

23

37

23

47

62

78

84

90

15

/16

15

/16

1 7/16

15

/16

1 27/32

2 7/16

3 1/16

3 5/16

3 17/32

2 1/4 - 14 UNS

3

5

/16 - 12 UNS

3

5

/16 - 12 UNS

5 - 12 UN

6

7

/8 - 12 UN

----

----

----

----

----

----

----

----

27

49

49

45

50

1

1

/16

1 15/16

1 15/16

1 3/4

2

----

----

----

----

17

25

25

38

50

11

/16

1

1

1

1

/2

2

47

70

75

65

70

65

82

90

92

1

7

/8

2 3/4

2 7/8

2 9/16

2 3/4

2 9/16

3 1/4

3 9/16

3 5/8

113

113

113

113

113

113

113

113

113

4

7

/16

4 7/16

4 7/16

4 7/16

4 7/16

4 7/16

4 7/16

4 7/16

4 7/16

6

10

10

15

15

5

5

5

5

E

T

E

T

E

T

E

T

E

T

E

T

E

T

E

E

E

E

E

E

E

E

11,6

3,23

30,5

9,46

40,6

17,1

71,8

26

120

43,1

121,6

42,2

202,5

70,5

260

432,7

397

662

525

87,4

670

115

Kg.

15

/64

25

/64

25

/64

19

/32

19

/32

3

/16

3

/16

3

/16

3

/16

E

T

E

T

E

T

E

T

E

T

E

T

E

T

E

E

E

E

E

E

E

E

12,7

22,9

43,5

62

81,4

132,6

170

297

380

462

574

662

820

853

1047

31,8

54

57,15

80

105

150

170

210

240

190

53

500

155

665

280

1175

425

1965

707

1992

692

3318

1154

4253

7088

6506

10845

8590

14315

10960

18265

Page 12

20 21

CSH: Single-acting, spring return

CDH: Double-acting, hydraulic return

CSH

CDH Series

HYDRAULIC CYLINDERS

CSH: SINGLE-ACTING

CDH: DOUBLE-ACTING

Working pressure: 700 kg/cm2/10.000 psi.

All pistons have a salt bath nitriding treatment

to resist corrosion.

With built-in bronze guide for easier sliding

of piston.

These cylinders are fitted with a removable

saddle, and are also equipped with a high

flow female quick coupler with dust cap, ref.

A-5507-H.

Carry handles on models weighing from

20 kg/44 lbs to 40 kg/88 lbs. Heavier models

are fitted with eye hooks for transport.

With mounting holes and threaded areas for

easy coupling or special tooling applications.

Fitted with a relief safety valve, ref. A-5538,on

the piston retract side, to prevent accidental

overpressure.

Hollow piston cylinders

The hollow cylinders can be used for general

applications of pushing or lifting forces.

Additionally, they feature a centre-hole

piston which allows the insertion of a rod

or screw, attachable to the threaded saddle,

that travels through the cylinder for pulling

or pushing operations.

Ideal for tensioning, extracting, gear and

pin removal etc.

CSH-12

CSH-20

CSH-30

CSH-60

CSH-90

CDH-30

CDH-60

CDH-90

12

20

30

60

90

30

60

90

Nominal

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm

2

in

2

BCD PQ

cm

3in3

Kg.

Oil volume WeightDimensions mm/in.

lbs.

74

140

270

640

1010

638

1265

1995

4,5

8,5

16,5

39

61,6

39

77,2

121,8

8,3

17,6

28,6

58,5

143

42,2

72

163

3,8

8

13

26,6

65

19,2

32,7

74

1 5/8

1 7/8

2 1/2

3

3

5

15

/16

5 15/16

5 15/16

18,03

28,86

42,51

84,34

133

42,51

84,34

133

2,8

4,5

6,6

13

20,6

6,6

13

20,6

5 11/16

6 3/4

7 7/8

9 5/8

10 11/16

11 11/16

11 7/8

12 3/16

7 5/16

8 11/16

10 3/8

12 5/8

13 11/16

17 9/16

17 13/16

18 1/64

70

95

110

155

200

110

155

200

2

3

/4

3 3/4

4 5/16

6 1/8

7 7/8

4 5/16

6 1/8

7 7/8

Stroke

A

mm. in.

4 7/16

4 7/16

4 7/16

49

/64

1 3/64

1 19/64

2 1/64

3 1/64

1 19/64

2 1/64

3 1/64

119,3

196,6

291,7

578,8

867

291,7

578,8

880

113

113

113

19,5

26,5

33

53,5

79

33

53,5

79

145

172

200

245

272

296

302

310

186

220

263

321

348

446

452

460

EFGHI

J

KN

2 11/64

2 3/4

3 3/8

4 15/16

6 1/2

3 3/8

4 15/16

6 1/2

1 23/64

2

2

7

/16

3 45/64

5 3/64

2 7/16

3 45/64

5 3/64

2

3

1

/4

3 5/8

5 1/8

----

3

5

/8

5 1/8

----

5

/16 - 18 UNC

3

/8 - 16 UNC

3

/8 - 16 UNC

1

/2 - 13 UNC

----

3

/8 - 16 UNC

1

/2 - 13 UNC

----

2

3

/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

2 3/4

25

/32

25

/32

25

/32

25

/32

1 1/2

25

/32

25

/32

1 1/2

25

/32

25

/32

7

/8

1

1

3

/16

7

/8

1

1

3

/16

38,5

50,5

62

94

128

62

94

128

M29 x 1,5

M37 x 1,5

M46 x 1,5

M72 x 1,5

M104 x 1,5

M46 x 1,5

M72 x 1,5

M104 x 1,5

50,8

82,6

92,1

130,2

---92,1

130,2

----

70

70

70

70

70

70

70

70

20

20

22

25

30

22

25

30

20

20

20

20

38

20

20

38

41

48

63

76

76

150

150

150

55

70

85,72

125

165,1

85,72

125

165,1

O

1 27/32

1 7/8

2

47

48

50

----

----

----

----

----

----

----

----

----

----

Cross section view ( CSH)

CSH-12

CSH-20

CSH-30, CDH-30

CSH-60, CDH-60

CSH-90, CDH-90

BRCSH-12

BMCSH-12

BRCSH-20

BMCSH-20

BRCSH-30

BMCSH-30

BRCSH-60

BMCSH-60

BMCSH-90

Ref. Used with

ABC

Dimensions mm/in.

1 6/64

1 25/64

1 3/4

2 49/64

27,2

35,2

44,2

70,2

M29 x 15

M37 x 1,5

M46 x 1,5

M72 x 1,5

M104 x 1,5

D

3

/4 - 16 UNF

----

1 - 8 UNC

----

1

1

/4 - 7 UNC

----

1

5

/8 - 5 1/2 UNS

----

----

38

50

61

93

127

1

1

/2

2

2

13

/32

3 21/32

5

28

30

32

37

42

1

1

/64

1 3/16

1 1/4

1 29/64

1 21/32

Threaded saddle ( optional )

Grooved saddle ( optional )

Cross section view ( CDH )

Page 13

22 23

Load cells

HYDRAULIC TOOLS

SH-1

Spring return

Capacity: 1 t

Weight: 3,5kg / 7,7lbs

Fitted with female quick coupler, ref. A-5506-H.

Widely used for spreading operations in tight

spaces where a high force is required.

This hydraulic tool is a component of the

Maintenance Kits described on page 35.

TDM-10 - 10t

Tension load cell

Designed for measuring applications

and pull test.

Precision: ± 2,5%.

CDM-10 - 10t

Compression load cell

Widely used as a load cell in presses,

clamps etc.

Precision: ± 2,5%.

The THD bolt tensioners feature same

characteristics as those of the THS series,

although they have a double cylinder for

use where space is tight.

Spread cylinder

Working pressure: 1.500 kg/cm2/21.430

psi.

A bolt tensioner is a hydraulic hollow

cylinder with an internally threaded

piston which is attached into a bolt.

The application of a hydraulic force to

the cylinder stretches the bolt.

The nut can be then tightened with

the aid of a rod inserted in a hole

previously drilled on the nut.

The supporting ring of the bolt

tensioner has an opening for an easier

tightening operation.

2

3

/8

3

1

/8

(9

/14)

611/16

SH1

TDM

CDM Series

THS

THD Series

Hydraulic bolt tensioners

HYDRAULIC TOOLS

WeightDimensions mm/in.

8

5

/16

8

5

/16

8

5

/16

8

5

/16

10

25

/64

10

25

/64

THS-20

THS-22

THS-24

THS-27

THS-30

THS-33

THS-36

THS-39

THS-42

THS-45

THS-48

THS-52

THS-56

THS-60

THS-64

THS-68

THS-72

THS-76

THS-80

THS-85

THS-90

THS-95

THS-100

Ref. Stroke

Maximum

capacity

Effective

area

A

kN cm2in2ADmm. in.

20

22

24

27

30

33

36

39

42

45

48

52

56

60

64

68

72

76

80

85

90

95

100

321,3

692,45

1302,2

2057,6

2642

3638,2

21,85

3,38

47,12

7,3

88,56

13,73

139,92

21,7

179,66

27,85

247,4

38,35

13

/16

7

/8

15

/16

1 1/16

1 3/16

1 5/16

1 7/16

1 9/16

1 11/16

1 13/16

1 15/16

2 3/64

2 7/32

2 3/8

2 9/16

2 11/16

2 13/16

3

3

3

/16

3 3/8

3 9/16

3 3/4

3 15/16

Metric

thread

M-20

M-22

M-24

M-27

M-30

M-33

M-36

M-39

M-42

M-45

M-48

M-52

M-56

M-60

M-64

M-68

M-72

M-76

M-80

M-85

M-90

M-95

M-100

77

3

3

/64

112

4

13

/32

153

6

1

/32

198

7

13

/16

227

8

15

/16

263

10

3

/8

A1

72

2

13

/16

100

3

15

/16

136

5

3

/8

187

7

3

/8

208

8

3

/16

245

9

5

/8

54

2

1

/8

77

3

1

/32

102

4

1

/64

131

5

6

/32

152

6

185

7

9

/32

23

29

/32

30

1

3

/16

40

1

9

/16

52

2

3

/64

58

2

5

/16

70

2

3

/4

HH1

27

1

1

/16

40

1

9

/16

54

2

1

/8

74

2

15

/16

85

3

3

/8

102

4

1

/64

L

90

3

9

/16

104

4

3

/32

128

5

3

/64

160

6

5

/16

186

7

5

/16

216

8

1

/2

U

Kg. lbs.

5,5

4,4

4

3,5

13,2

12,1

11

9,9

28,6

27,5

25,3

23,1

57,3

55,1

53

50,7

48,5

82,6

79,3

76

125

121

116

2,5

2

1,8

1,6

6

5,5

5

4,5

13

12,5

11,5

10,5

26

25

24

23

22

37,5

36

34,5

57

55

53

WeightDimensions mm/in.

8

5

/16

8

5

/16

8

5

/16

8

5

/16

10

25

/64

THD-20

THD-22

THD-24

THD-27

THD-30

THD-33

THD-36

THD-39

THD-42

THD-45

THD-48

THD-52

THD-56

THD-60

THD-64

THD-68

THD-72

THD-76

THD-80

THD-85

Ref. Stroke

Maximum

capacity

Effective

area

A

kN cm2in2ADmm. in.

20

22

24

27

30

33

36

39

42

45

48

52

56

60

64

68

72

76

80

85

365,14

779,4

1495,6

2099

2858,5

24,83

3,85

53

8,21

101,7

15,76

142,73

22,12

194,38

30,13

13

/16

7

/8

15

/16

1 1/16

1 3/16

1 5/16

1 7/16

1 9/16

1 11/16

1 13/16

1 15/16

2 3/64

2 7/32

2 3/8

2 9/16

2 11/16

2 13/16

3

3

3

/16

3 3/8

Metric

thread

M-20

M-22

M-24

M-27

M-30

M-33

M-36

M-39

M-42

M-45

M-48

M-52

M-56

M-60

M-64

M-68

M-72

M-76

M-80

M-85

65

2

9

/16

95

3

3

/4

130

5

1

/64

160

6

19

/64

188

7

3

/8

A1

–

–

–

–

–

52

2

3

/64

75

2

15

/16

96

3

3

/4

130

5

1

/8

152

6

HH1

–

–

–

–

–

L

227

8

15

/16

269

10

19

/32

308

12

1

/8

386

15

3

/16

423

16

5

/8

U

Kg. lbs.

11

10

8,8

7,7

24,2

22

21

19,4

53

49,6

46,3

43

88,2

83,8

79

77

72,7

132

125

119

5

4,5

4

3,5

11

10

9,5

8,8

24

22,5

21

19,5

40

38

36

35

33

60

57

54

23

29

/32

30

1

3

/16

40

1

9

/16

52

2

3

/64

58

2

5

/16

(3

1

/

8

)

(11

1

/

4

)

(2

3

/

8

)

THS: Single cylinder / THD: Double cylinder

Page 14

24 25

BM

BK

BMD Series

HYDRAULIC PUMPS

BM-04, BM-1, BM-2 and BMPA-1

All are single acting, one-speed hand pumps, and can be used as a portable hydraulic tool or in a fixed position.

They can operate both in a horizontal or vertical position. In this case, the pump head should be placed downwards.

Their light weight and small oil volume make them a very useful pump where a quick action is required.

They are fitted with a safety relief valve, factory rated at the maximum working pressure.

BM-3, BMAP-3, BM-6 and BM-12

Single-acting, two-speed hand pumps. The two-stage automatic system allows the operation of both pistons

for a quick approach of the cylinder to load.

The larger pump piston cuts out when the cylinder activated by the pump is under high pressure.

All fitted with a safety relief valve, factory rated at the maximum working pressure.

BK-05, BK-09

Vertical hand pumps. Single and two-speed.

Fitted with holes in the pump base to be used as a fixed hydraulic tool.

BM-04

BM-1

BM-2

BMAP-1

BK-05

BKD-09

BM-3

BMAP-3

BM-6

BM-12

BMD-3

BMD-6

BMD-12

Ref.

Oil flow per

stroke

cm3in

3

AB C

Kg.

WeightDimensions mm/in.

lbs.

Working

pressure

kg/cm

2

psi

Effective oil

volume

cm

3

in

3

cm3in

3

C’ D G J J’ L M NFH

8,5

8,5

8,5

8,5

8,5

8,5

I

11

/32

11

/32

11

/32

11

/32

11

/32

11

/32

10000

10000

10000

21430

10000

10000

10000

21430

10000

10000

10000

10000

10000

700

700

700

1500

700

700

700

1500

700

700

700

700

700

400

1250

2000

1250

650

1100

3000

3000

6000

12000

3000

6000

12000

–

–

–

–

–

0,5

1,15

1,1

1,15

1,15

1,15

1,15

1,15

24,4

76,3

122

76,3

39,7

67,1

183

183

366

732

183

366

732

–

–

–

–

–

8

19

18

19

19

19

19

19

18 1/64

23 7/32

22 7/16

23 7/32

24 5/8

24 5/8

27 9/16

27 9/16

27 9/16

27 9/16

27 9/16

27 9/16

27 9/16

5

5

1

/4

6 1/64

5 5/8

7 3/32

8 15/16

5 5/16

5 5/16

6 5/8

11 7/16

5 3/4

6 5/8

11 7/16

137

155

175

155

144

233

185

185

185

185

185

185

185

5

13

/32

6 1/64

6 7/8

6 1/64

5 11/16

9 3/16

7 9/32

7 9/32

7 9/32

7 9/32

7 9/32

7 9/32

7 9/32

460

590

570

590

625

625

700

700

700

700

730

730

730

127

133

155

142

180

228

135

135

168

290

146

168

290

0,15

0,15

0,15

0,06

0,15

0,15

0,15

0,07

0,15

0,15

0,15

0,15

0,15

2,5

2,5

2,5

1

2,5

2,5

2,5

1,15

2,5

2,5

2,5

2,5

2,5

17

5

/16

24

14

13

/16

24

24

24

23

7

/16

23 7/16

23 7/16

23 7/16

23 7/16

23 7/16

23 7/16

440

610

630

610

610

610

595

595

595

595

595

595

595

1 3/16

1 3/16

1 3/16

1 3/16

5 1/2

5 1/2

2 5/8

2 5/8

2 5/8

2 5/8

4 15/16

4 15/16

4 15/16

30

30

30

30

140

140

67

67

67

67

125

125

125

3

/8-18NPT

3

/8-18NPT

3

/8-18NPT

1

/4-19GAS

3

/8-18NPT

3

/8-18NPT

3

/8-18NPT

1

/4-19GAS

3

/8-18NPT

3

/8-18NPT

3

/8-18NPT

3

/8-18NPT

3

/8-18NPT

–

–

–

–

–

–

3 6/32

3 6/32

5 1/8

–

3 6/32

5 1/8

–

–

–

–

–

–

–

80

80

130

–

80

130

–

–

–

–

–

–

–

23 7/8

23 7/8

–

–

23 7/8

–

–

–

–

–

–

–

–

607

607

–

–

607

–

–

400

600

600

600

600

600

665

665

665

665

665

665

665

97

104

140

112

–

–

110

110

110

110

110

110

110

3 13/16

4 1/64

5 1/2

4 7/16

–

–

4

5

/16

4 5/16

4 5/16

4 5/16

4 5/16

4 5/16

4 5/16

33

33

33

33

–

–

12

12

10

10

12

10

10

1 5/16

1 5/16

1 5/16

1 5/16

–

–

15

/32

15

/32

25

/64

25

/64

15

/32

25

/64

25

/64

M8x1,25

M8x1,25

M6x1

–

M8x1,25

M6x1

–

9,4

14,8

26,5

15,9

15,4

20,9

30,9

30,9

44,1

55,1

37,5

50,7

61,7

4,25

6,7

12

7,2

7

9,5

14

14

20

25

17

23

28

15 3/4

23 5/8

23 5/8

23 5/8

23 5/8

23 5/8

26 3/16

26 3/16

26 3/16

26 3/16

26 3/16

26 3/16

26 3/16

–

–

–

–

–

–

3 6/32

3 6/32

6 1/2

11 7/16

3 6/32

6 1/2

11 7/16

–

–

–

–

–

–

80

80

165

290

80

165

290

2

3 6/32

3 9/16

3 6/32

3 3/4

3 3/4

2 9/16

2 9/16

–

–

2 9/16

–

–

50

80

90

80

96

96

65

65

–

–

65

–

–

1st stage 2nd stage

Single-acting hand pumps

Vertical pump

Double-acting hydraulic hand pumps

BMD-3, BMD-6 and BMD-12

These are double acting and two-speed hand pumps.

They all feature same technical advantages as the single acting one-speed pumps.

With a safety relief valve, factory rated at the maximum working capacity.

Hydraulic diagram

Hydraulic diagram

Hydraulic diagram

Hydraulic diagram

Page 15

26 27

NS

NAP

BKN Series

HYDRAULIC PUMPS

NS-1, NS-21, NS-22 and NAP-3

Single-acting, one-speed air pumps.

Air driven pumps for operation where electric power is not available or dangerous.

With safety relief valve, factory rated at the maximum working pressure.

Once the NS-1, NS-21 and NS-22 air pumps are connected to the air line, press down on the back section of pedal for operation. Descent

or pressure release is effected by pressing down on the front section.

Weight

Dimensions mm/in.

BES-5

BES-10

BES-20

BES-30

BED-10

BED-20

BED-30

Ref.

Effective oil

volume

l. Gal. kWkg/cm2psi.

443

485

615

625

485

615

625

1,32

2,65

5,3

7,95

2,65

5,3

7,95

17 7/

16

19 3/

32

24 3/

16

24 5/

8

19 3/

32

24 3/

16

24 5/

8

Working

pressure

700

700

700

700

700

700

700

A B C Kg. lbs.

79

106

161

210

106

161

210

36

48

73

95

48

73

95

10000

10000

10000

10000

10000

10000

10000

5

10

20

30

10

20

30

250

255

325

365

255

325

365

9

7

/

8

10

12

3

/

4

14 3/

8

10

12

3

/

4

14 3/

8

215

285

325

365

285

325

365

8

1

/

2

11 1/

4

12 3/

4

14 3/

11

1

/

4

12 3/

4

14 3/

8

48,8

67

128

128

67

1,28

1,28

0,8

1,1

2,1

2,1

1,1

2,1

2,1

1390

1400

1390

1390

1400

1390

1390

0,552

0,736

1,472

1,472

0,736

1,472

1,472

Power

Oil flow

l/min in3/min

30,5

42,7

79,3

79,3

42,7

79,3

79,3

0,5

0,7

1,3

1,3

0,7

1,3

1,3

l/min in3/min

1st stage 2nd stage

R.p.m.

BKN-09

Manual and air powered pump.

The pneumatic operation allows for a

faster movement of the piston.

The manual operation is required for

precision pressing jobs or when

compressed air supply is not available.

Recommended air pressure:

7-10 kg/cm2. / 100-140 psi

Minimum air flow:

270 l./min. / 59,39 gpm

INDISPENSABLE

Important. It is recommended the

use of an air filter-regulator-lubricator

unit with these pumps to resist

corrosion and for longer life.

WeightDimensions mm/in.

NS-1

NS-21

NS-22

NAP-3

BKN-09

Ref.

Effective oil

volume

cm3in3cm3/min

kg/cm2psi.

150

150

150

120

407

30,5

76,3

61

183

67,1

5 7/8

5 7/8

5 7/8

4 3/4

16

Working

pressure

700

700

225

1500

700

A B C Kg. lbs.

15,5

17,6

16,7

33

18

7

8

7,6

15

8,2

10000

10000

3215

21430

10000

500

1250

1000

3000

1100

120

120

120

120

140

4

3

/4

4 3/4

4 3/4

4 3/4

5 1/2

440

697

606

800

193

17

5

/16

27 7/16

23 7/8

31 1/2

7 5/8

–

–

–

–

0,15

–

–

–

–

2,5

3,05

3,05

9,45

2,6

3,05

50

50

155

43

50

Oil flow

Oil flow per

stroke

in3/min

cm3in

3

BES

BED Series

HYDRAULIC PUMPS

Air hydraulic pumps Single-acting

Electric pumps

BES: single-acting

BED: double-acting

Oil to cylinder

Oil from cylinder

Oil

Air

Pressure

booster

BES-5, BES-10, BES-20 and BES-30: SINGLE-ACTING

BED-5,BED-10, BED-20 and BED-30: DOUBLE ACTING

They have a two-stage, radial pump that provides a working pressure of 700 kg/cm2/10.000

psi.

The first stage allows a quick approach of piston to load and the second stage gives the

effective working pressure.

With precision made components, electric power provides improved operation for applications

requiring high pressure.

With safety relief valve, factory rated at the maximum working pressure. For a continuous

operation, pressure should not exceed 560 kg/cm

2

/8.000 psi.

Frequency: 50 Hz.: 220/380 V - 1,5 kW - 2 HP - 1400 rpm.

Frequency: 60 Hz.: 265/460 V - 1,7 kW - 2,3 HP - 1700 rpm.

Hydraulic diagram

Page 16

The high flow quick couplers allow a fast and safe connection of the different components in the hydraulic applications.

They consist of two halves, oil tight, called male and female, and have dust caps to prevent entry of dirt.

Supplied according to the reference on the chart.

28 29

ACCESSORIES

The references MAP and MCE are high pressure

flexible hoses made of a polyester eslastomer tube,

reinforced with a braid of polyaramid yarn, a polyester

interlay, a single braid of carbon steel wire and an

outer polyurethane cover.

Minimum burst pressure: 2.800 kg/cm

2

/ 40.000 psi

MAPS-1,5 flexible hose is made of an inner

polyethylene tube (POM ), with four spiral steel wire

braids and a polyamide cover.

Minimum burst pressure: 4.400 kg/cm

2

/ 63.800 psi

As an option, the 1,5 m hoses are supplied with a

quick coupler included.