USER MANUAL

Table of Contents

Safety Information……………………………………………………………………………………………. 3

Specifications…………………………………………………………………………………………………….. 4

Main Power Connection…………………………………………………………………………………..6

DMX-512 Connection…………………………………………………………………...……………...... 6

Rigging the Fixture…………………………………………………………………………………………….7

DMX Profile......................................................................................................................... 8

Main Control Menu........................................................................................................10

Cleaning & Maintenance.............................................................................................11

Parts List............................................................................................................................11

Check that the unit has not been damaged during transport

Protection Against Fire

1. Maintain a minimum of 1 foot distance from any type of flame.

3. Replace fuse only with the specified type and rating.

4. Do Not install the unit to close to a heat source.

5. Make sure cable are properly secured away from unit movement.

6. Maximum surface operating temperature 104º.

Protection Against Fire

1. Disconnect power before lamp replacement or servicing.

2. For connection to main power supply proceed to page 6.

3. This unit must be earthed. (electronically grounded)

4. Do not expose unit to rain or moisture.

Protection Against Mechanical Hazards

1. Use safety chain when hanging unit.

2. Use quality clamps or bolts when positioning unit

3. Do not open unit risk of electrical shock.

3

Specifications

Part Numbers

Fixture Lamp Flight Case

1060 - AXIS LED Spot LPHL - Phlatlight 60W P-1030DUALCASE

Mechanical Specifications

Pan: 530° Tilt: 280°

DMX Connectors: 3-pin XLR connectors

Thermal: Maximum ambient temperature 40° C

Maximum surface temperature 80° C

Fastening System: 2 clamp placement attachments

Fixture Packaged for Shipping

Size: 16.75”L x 16”W x 20.5”H

Weight: 39 lbs

Size: 20”L x 19.25”W x 22.5”H

Weight: 46 lbs

Electrical Specifications

Power supply: Auto Switch100V-240V 50/60 HZ

Power consumption: .93 amps

110 watts

Ballast: Electronic

LAMP: Phlatlight LED 60W

16.75 ”

16 ” ( with handles )

8”

3”

15.25

17.5 ”

5.25

16 ”

Electromechanical Effects

Focus: Motorized focus

Prism: 3-Facet prism rotating in both directions at different speeds

Dimmer: Electronic dimming of the lamp.

Shutter: Electronic strobe of lamp 9 flash per second

4

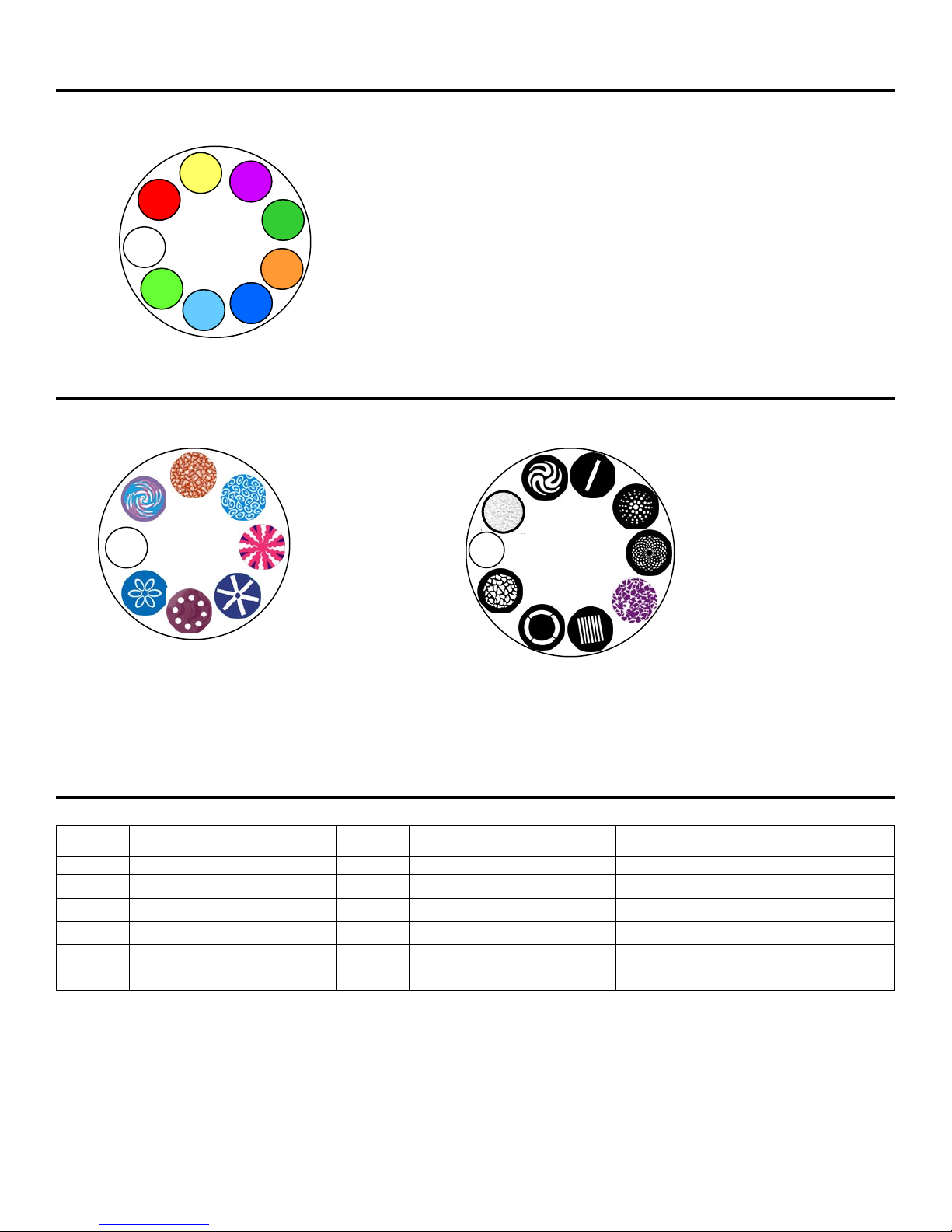

Color

Gobo’s

Rotating Gobo Wheel

1: Open

2: Red

3: Yellow

4: Purple

5: Green

6: Orange

7: Blue

8: Light Blue

9: Light Green

1: Open

2: Gobo 1

3: Gobo 2

4: Gobo 3

5: Gobo 4

6: Gobo 5

7: Gobo 6

8: Gobo 7

Static Gobo Wheel

1: Open

2: Gobo 8

3: Gobo 9

4: Gobo 10

5: Gobo 11

6: Gobo 12

7: Gobo 13

8: Gobo 14

9: Gobo 15

10: Gobo 16

Dichroic Glass Gobo: Diameter 25 mm Image 20 mm Thickness 2 mm max

DMX Channels

Channel Function Channel Function Channel Function

1 Pan 7 Static Gobo Wheel 13 Shutter / Strobe

2 Pan Fine 8 Rotating Gobo Wheel 14 Control

3 Tilt 9 Gobo Rotation

4 Tilt Fine 10 Prism / Prism Rotation

5 Pan/Tilt Speed 11 Focus

6 Control 12 Dimmer

5

Main Power Connection

Caution!

1. Do not connect fixture to a dimmer system.

2. This unit must be earthed. (electronically grounded)

3. Replace fuse only with the specified type and rating.

This device is equipped with a auto switching power supply that will allow you to work from 100V-240V 50/60Hz

The occupation of the connection-cable is as follows:

Cable (USA) Cable (EU) Pin 110V

Black Brown

White

Green

Light Blue

Yellow/Green

110V

Connection

N

Live

Neutral

Ground

L

L

N

220V

Connection

220V

L

L

N

L

L

N

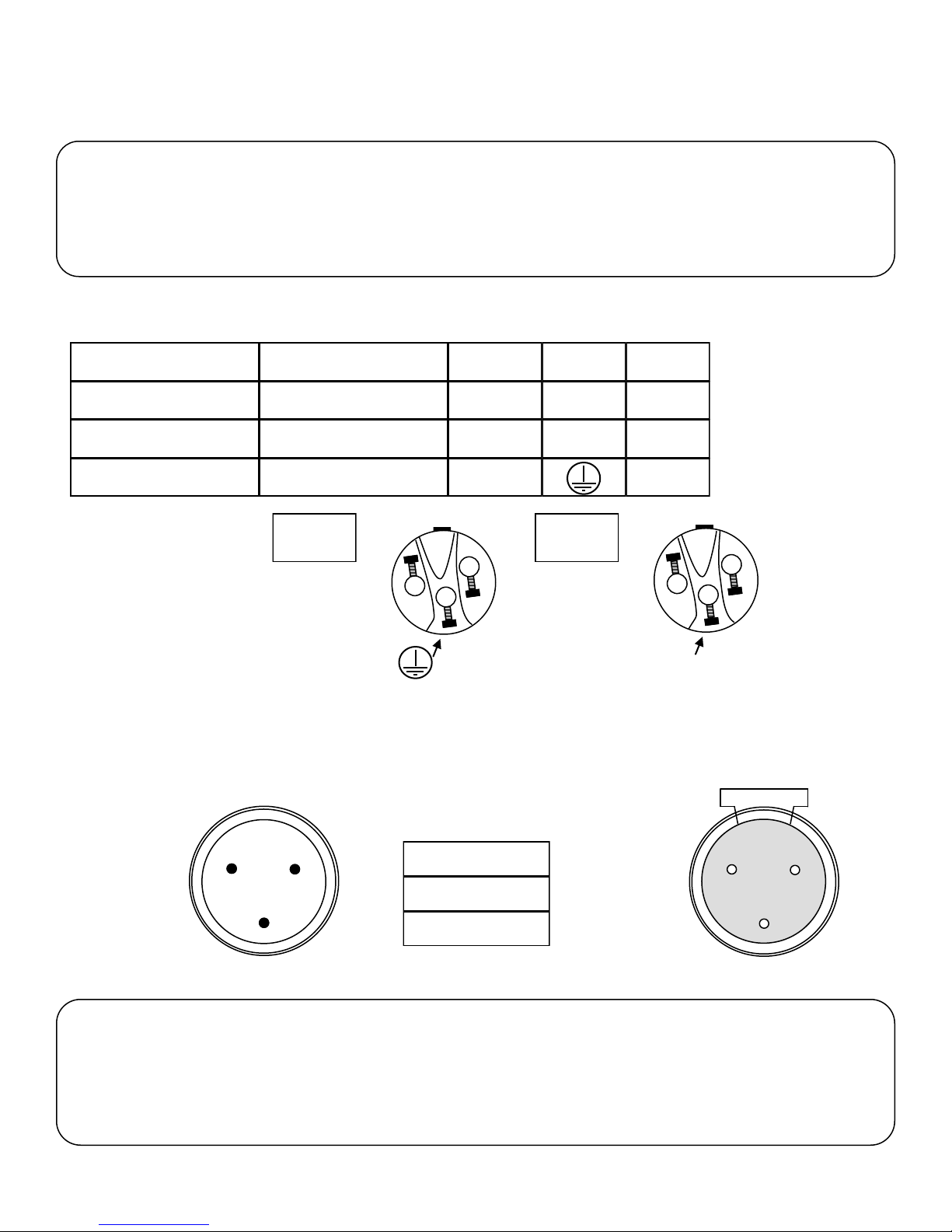

DMX-512 Connection

The fixture is equipped with 3 pin XLR Sockets for DMX input and output. The sockets are wired in parallel. Only use a shielded

twisted pair cable designed for RS-485 and 3 pin XLR plugs and connectors in order to connect the controller with the fixture or

the fixture with another.

DMX—input

DMX—output

2

1

3

Caution!

At the last fixture the DMX signal needs to be terminated with a terminator. Solder a 120

Ohm resistor between the (-) and the (+) signal into a 3 pin XLR plug and plug it in to the

last fixture on the signal run. Pre-manufactured terminator plugs are available for

purchase from your Mega-Lite dealer (HOS-DMXT).

1. Shield

2. Signal (-)

3. Signal (+)

6

2

1

3

Rigging the fixture

Caution!

1. The installations must be carried out by an authorized dealer or trained professional.

2. Unit may cause severe injures if you have doubts concerning the safety do not install.

3. Unit is to be 24inches away from flammable materials (decoration material)

4. Use high quality installation equipment to hang unit.

When rigging a unit it is very important that you follow common safety procedures. Rigging requires extensive experience including but not limited to calculating working loads, material being used and periodic safety inspections. If you lack these qualifications, do not attempt the installation yourself, instead use a professional structural rigger.

When rigging the unit always be secured with a secondary safety attachment. The installation location of the projector has got to

be built in the way that it can hold 10 times the weight for 1 hour with out any harming. Installation should be checked at least

one time a year by a skilled person.

7

Axis LED Spot DMX Profile

DMX Channel Function Description Value

1 Pan Pan Course 0-255

2 Pan Fine Pan Fine 0-255

3 Tilt Tilt Course 0-255

4 Tilt Fine Tilt fine 0-255

5 Pan/Tilt Speed

Slow 171-255

6 Colors

Forward Rainbow Effect (fast to slow) 161-255

7 Static

Gobo Wheel

Gobo Wheel rotation slow to fast 225-255

Gobo 9 with variable gobo shaking 100-114

Gobo 8 with variable gobo shaking 115-129

Gobo 7 with variable gobo shaking 130-144

Gobo 6 with variable gobo shaking 145-159

Gobo 5 with variable gobo shaking 160-174

Gobo 4 with variable gobo shaking 175-189

Gobo 3 with variable gobo shaking 190-204

Gobo 2 with variable gobo shaking 205-219

Gobo 1 with variable gobo shaking 220-224

Fast 0-84

Mid 85-170

Open 0-16

Red 17-33

Yellow 34-50

UV Filter 51-67

Green 68-84

Orange 85-101

Blue 102-118

Light Blue 119-135

Light Green 136-152

Open 0-9

Gobo 1 10-19

Gobo 2 20-29

Gobo 3 30-39

Gobo 4 40-49

Gobo 5 50-59

Gobo 6 60-69

Gobo 7 70-79

Gobo 8 80-89

Gobo 9 90-99

8

8 Rotating

Gobo

Gobo 7 with variable gobo shaking 80-99

Gobo 6 with variable gobo shaking 100-119

Gobo 5 with variable gobo shaking 120-139

Gobo 4 with variable gobo shaking 140-159

Gobo 3 with variable gobo shaking 160-179

Gobo 2 with variable gobo shaking 180-199

Gobo 1 with variable gobo shaking 200-219

Open 0-9

Gobo 1 10-19

Gobo 2 20-29

Gobo 3 30-39

Gobo 4 40-49

Gobo 5 50-59

Gobo 6 60-69

Gobo 7 70-79

Gobo Wheel rotation slow to fast 220-255

9 Gobo Rotation

Clockwise rotation (slow to fast) 41-158

Counter Clockwise rotation (slow to fast) 159-255

No Function 0

Gobo indexing 1-40

No Function 0

10 Prism Rotation

Clockworks rotation (fast to slow) 5-127

Engaged prism 1-4

No Rotation 128-132

Counter Clockworks rotation (fast to slow) 133-255

11 Focus Focus 0-255

12 Dimmer Dimmer 0% to 100% 0-255

13 Shutter/

Strobe

Strobe (slow to fast) 64-95

Pulse strobe (slow to fast) 128-158

Random Strobe (slow to fast) 192-223

Close 0-31

Open 32-63

Open 96-127

Open 159-191

Open 224-255

14 Control

No Function 0-199

Reset (hold for 3 sec) 200-219

No Function 220-255

9

Main Control Menu

The control board on the fixture base is your interface to access and control

all the functions on the unit. Its digital display gives you a code view of the

options and functions. The following will explain each function and its options.

MODE

DMX

ENTER

DOWN

UP

MODE

ENTER

UP

DOWN

DMX Address

0-512

Color Control

Reverse Pan Reverse Tilt

Demo Mode Reset

DMX Address

Use the up/down keys to select the required DMX start channel. Press Enter to confirm or Mode to exit and return to main

menu. The display will flash if there is no DMX signal been received from the console.

Color Control

This function allows you to chose from Bi-Color placement or Fixed Color placement. Use the up/down keys to select, Y to select

bi-color mode or N to select fixed color mode . Press Enter to confirm or Mode exit and return to the main menu.

Reverse Pan

This function allows you to invert the Pan direction. Use the up/down keys to select, Y to invert pan and N not to invert the pan.

Press Enter to confirm or Mode exit and return to the main menu.

Reverse Tilt

This function allows you to invert the Tilt direction. Use the up/down keys to select, Y to invert tilt and N not to invert the tilt.

Press Enter to confirm or Mode exit and return to the main menu.

Demo Mode

This option allows you to turn on the demo mode. Use the up/down keys to select, Y to turn on demo mode and N not to turn off

the demo mode. Press Enter to confirm or Mode exit and return to the mail menu.

Reset

This option allows you to reset the fixture and re-home all the motor setting. Use the up/down keys to select, Y to Reset and N

not to reset the fixture. (note: after you reset the fixture you must also set it to N to stop resetting or it will continue to reset)

Press Enter to confirm or Mode exit and return to the main menu.

9

Cleaning and maintenance

Installation Maintenance: The operator has to make sure that the unit is operating safely and has the installations and electron-

ics checked by an expert every 2 years.

The following points have to be considered during the inspection:

1) All screws used for installing the device or part of the device have to be tightly connected and must not be corroded.

2) There must not be any deformations on the housing, fixation and installation spots (ceiling, suspension, trussing).

3) Mechanically moved parts like axles and other must not show any traces of wearing and must not rotate with unbalances.

4) The electronic power supply cables must not show any damages, material fatigue (e.g. porous cables) or sediments. Further

instructions depending on the installation spot and usage have to be adhered by a skilled installer and any safety problems

have to be removed.

Disconnect from mains before starting maintenance operation!

Caution Danger to life!

We recommend a frequent cleaning of the device. Please use a moist, lint free cloth. Never use alcohol or solvents!

1) The objective lens will require periodic cleaning on usage and environment. Environment with foggers will require more periodic cleaning as fog fluid tends to build up residues, reducing the light output.

2) The cooling-fans should be cleaned monthly. DO NOT blow high pressure air into fans as incorrect rotation can damage the

fans operation.

3) The gobos, dichroic color filters and internal lenses may be cleaned with soft brush using soapy water.

4) The interior of the fixture should be cleaned using a vacuum.

5) We recommend proper lubrication of the motor wheel. The quantity of the oil must not be excessive in order to avoid oil run

outs when motor wheel rotates

Note: There is no serviceable parts inside the device except for the fuse. Maintenance and service operations are to be carried

out by authorized dealers.

Replacing the fuse: Only replace the fuse with the same type and rating.

Replacing the power cable: If the power cable of this device becomes damaged, it has to be replaced by authorized dealers only

In order to avoid hazards.

Should you have further questions , please contact your dealer.

Parts List

9051 Dual Axis 250or Axis LED Spot Case

1060-MPCB Main PCB Card

1060-DC Driver Card

1060-LD Lamp Driver Card

1060-DIS Display Card

1060-FAN Fan 3X3

1060-SFAN Fan 2.5X2.5

LPHL Phlatlight LED Lamp

1060-PRISM Prism

1060-QRM Quick Release Mount Set

1060-PS Power supply

1060-PL Primary Lens

1030-ARMB Arm Body Set

1030-DISB Display Body Set

1030-HEADB Head Body Set

1060-MC Motor Color

1060-MRG Motor Rotating Gobo

1060-MGR Motor Gobo Rotator

1060-MFG Motor Fixed Gobo

10

Ph 210-684-2600 Fax 210-855-6279

www.mega-lite.com / info@mega-lite.com

Mega-Lite

5718 Kenwick St

San Antonio, TX 78238

Loading...

Loading...