Page 1

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

OPERATORS MANUAL

MSC/MST-OPS-1

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

Page 2

MSC/MST-OPS-1

31 Dec 2013

TABLE OF CONTENTS

Page

Section 1 Definitions and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Section 2 System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Section 3 Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section 4 Normal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Section 5 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section 6 Employment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Section 7 MSC/MST Operator’s Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

A

Page 3

MSC/MST-OPS-1

31 Dec 2013

TABLE OF CONTENTS

B (Blank)

Page 4

SECTION 1

Definitions and Abbreviations

Contents

MSC/MST-OPS-1

31 Dec 2013

Manual Usage....................................................................1-1

Warning, Caution And Notes .......................................1-1

Use Of Shall, Will, Should And May............................1-1

MANUAL USAGE

This technical manual only contains information

required to safely install or service an MSC/MST. See

the appropriate Maintenance and Operators Safety

Manual for specific vehicle system information and

maintenance procedures. If your system is not

covered in this manual or you are experiencing

difficulties, please contact MEGA Corp. Product

Support Group at:

US toll free: 1-800-345-8889

Direct: 1-505-345-2661 or visit our website at

www.megacorpinc.com

information.

The exact location of the hazards and description of

the hazards are reviewed in this section. All personnel

working on or operating the machine must become

familiarized with all the safety messages.

for more detailed contact

Safety Messages...............................................................1-2

Abbreviations....................................................................1-5

MSC/MST General Overview (Typical)......................1-6

WARNING, CAUTION AND NOTES

The following definitions are found throughout the

manual and apply as follows:

Operating procedures and techniques, which could

result in personal injury and/or loss of life if not

carefully followed.

Operating procedures and techniques, which could

result in damage to equipment if not carefully

followed.

Operating procedures and techniques that are

considered essential to emphasize.

Due to the nature of these processes, ensure that all

safety information, warnings and instructions are

read and understood before any operation or any

maintenance procedures are performed. Some

procedures take place with heavy components and

at moderate heights, ensure proper safety

procedures are maintained when performing these

actions. Failure to use and maintain proper safety

equipment and procedures will cause injury, death or

damage to equipment.

USE OF SHALL, WILL, SHOULD AND MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a procedure is

recommended.

May - Used to indicate an acceptable or suggested

means of accomplishment.

1-1

Page 5

MSC/MST-OPS-1

31 Dec 2013

SECTION 1

Definitions and Abbreviations

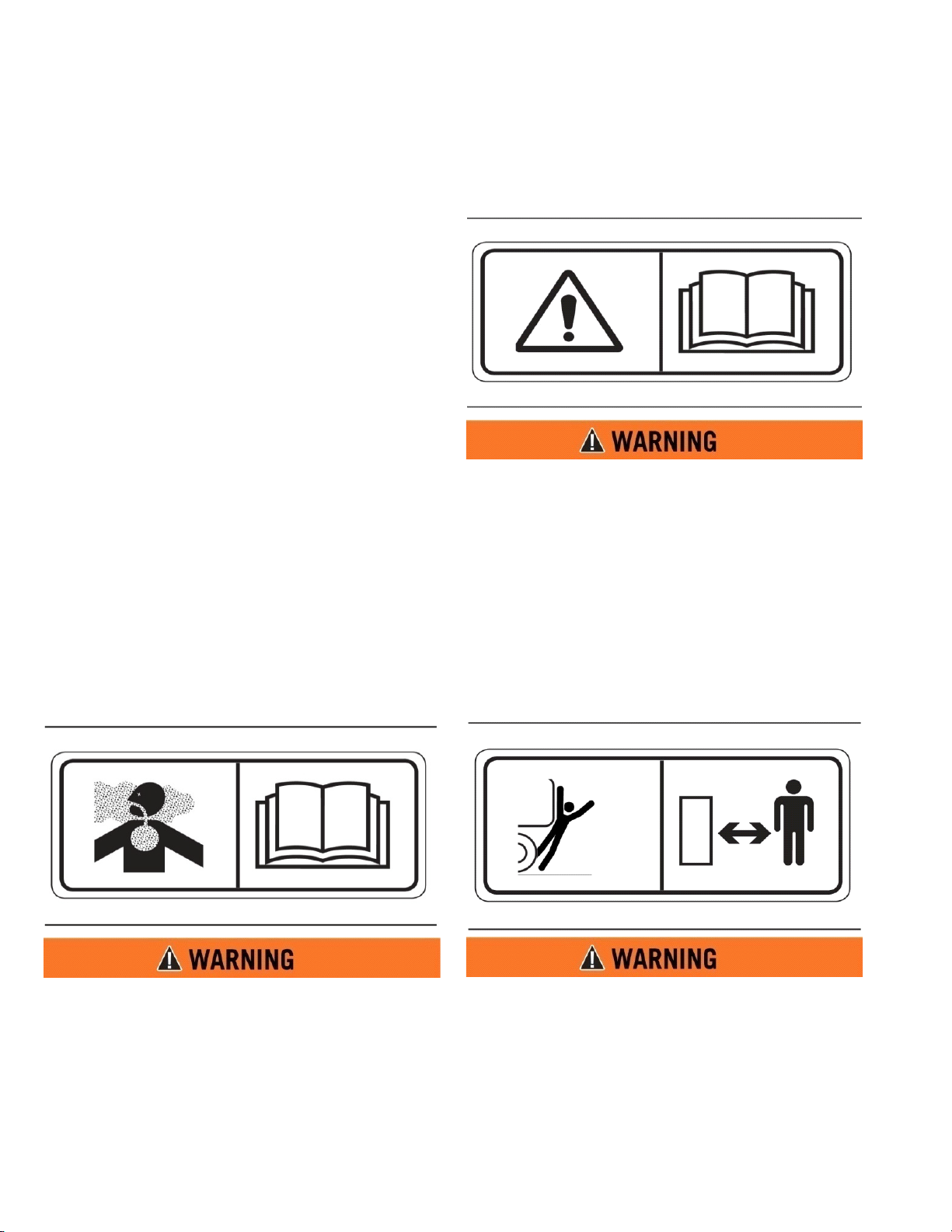

SAFETY MESSAGES

There are several specific safety messages on this

machine. The exact location of the hazards and

description of the hazards are reviewed in this

section. All personnel working on or operating the

machine must become familiarized with all the safety

messages.

Make sure that all of the safety messages are legible.

Clean the safety messages or replace the safety

messages in you cannot read the words. Replace the

illustrations if the illustrations are not legible. When

you clean the safety messages, use a cloth, water and

soap. Do not use solvent, gasoline or other harsh

chemicals to clean the safety messages. Solvents,

gasoline or harsh chemicals could loosen the

adhesive that secures the safety messages. Loose

adhesive will allow the safety messages to detach.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part that

is replaced, install a new safety message on the

replacement part.

DO NOT OPERATE (2)

This safety label is located on the outside of the front

and rear control boxes (if equipped).

Do not open this control box unless you read and

understand the instructions and warnings in the

Operator and Maintenance Manual. Failure to

follow instructions or heed the warnings could

result in serious injury or death.

TOXI C GAS HA Z ARD (1 )

This safety label is located on the side of the tank and

at all water fill entrances.

Cutting or welding operation on the inside of the

tank can cause the accumulation of toxic gases.

Read and understand instructions and warnings

in the Maintenance Manual. Failure to provide

proper ventilation or breathing apparatus while

conducting these operations may result in serious

injury or death.

BACKING RUNOVER HAZARD (3)

This safety label is located on the rear of the tank and

inside the cab.

The vehicle is equipped with a back-up alarm.

Alarm must sound when operating this vehicle in

reverse. Failure to maintain a clear view in the

direction of travel could result in serious injury or

death.

1-2

Page 6

SECTION 1

Definitions and Abbreviations

MSC/MST-OPS-1

31 Dec 2013

FREEZING (4)

This safety label is located on the side of the tank, at

the sump drain, and on the pump.

Drain tank, fill pipe and valve in freezing weather.

Refer to the Operator and Maintenance Manual

for the procedure to follow.

DO NOT HOIST WHILE IN MOTION (6)

This safety label is located inside the cab.

Do not engage hoist cylinders while vehicle is in

motion. Before engaging hoist STOP the vehicle.

Do not engage hoisting cylinders unless you read

and understand the instructions and warnings in

the Operator or Maintenance Manual. Failure to

follow instructions or heed the warnings will

result in injury or death.

NON-POTABLE (5)

This safety label is located on the side of the tank and

sump drain.

Water held within tank is not potable. Do not use

tank for transport of water intended for human or

animal consumption or serious injury or death

may result.

FALL HAZARD (7)

This safety label is located at the top of the front and

rear of the tank.

Do not walk on the top of tank without fall arrest

PPE. Serious injury or death could occur from a

fall.

1-3

Page 7

MSC/MST-OPS-1

31 Dec 2013

SECTION 1

Definitions and Abbreviations

ROTATING SHAFT (8)

This safety label is located on the pump.

Do not place your hand or tools within pump bell

while pump is rotating and/or pressure held

within the motor supply hose. Refer to the

Operator and Maintenance Manual for the

procedures to operate and maintain the pump.

Failure to follow proper procedures could result in

serious injury.

HIGH PRESSURE WATER CANNON (10)

This safety label is located on top of the cab control

box.

Do not operate the water cannon until all

personnel are a safe distance away from the

vehicle.

HIGH PRESSURE SPRAY HEADS (9)

This safety label is located on the spray bar.

Do not operate spray heads until all personnel are

a safe distance away from the vehicle.

HIGH PRESSURE MOTOR (11)

This safety label is located on the hydraulic motor.

Hydraulic motor and supply lines contain oil

under high pressure. Improper removal and

repair procedures could cause severe injury. To

remove or repair, instructions in the Maintenance

Manual must be followed.

1-4

Page 8

SECTION 1

Definitions and Abbreviations

MSC/MST-OPS-1

31 Dec 2013

CONFINED SPACE (12)

This safety label is located near the water tank access

and fill ports.

Do not enter confined spaces without following

established site specific procedures. Failure to

follow proper safety procedures will result in

serious injury or death.

ABBREVIATIONS

BFV - Butterfly Valve

cc - Cubic Centimeters

CCW - Counter Clockwise

CW - Clockwise

fl. oz. - Fluid Ounce

FT - Feet

FPM - Feet Per Minute

GPM - Gallons Per Minute

IN/SQ FT - inches per Square Feet

KM-H - Kilometers Per Hour

Kg - kilograms

Kpa - Kilopascals

l - liters

lpm - Liters per minute

LT - Left as viewed from the operators

position facing forward

m - meters

MPH - Miles Per Hour

MSC/MST - Mega Scraper Conversion

Nm - Newton meters of torque

psi - pounds per square inch

RPM - Revolutions Per Minute

RT - Right as viewed from the operators

position facing forward

SQ FT - Square Feet

VDC - Volts, Direct Current

1-5

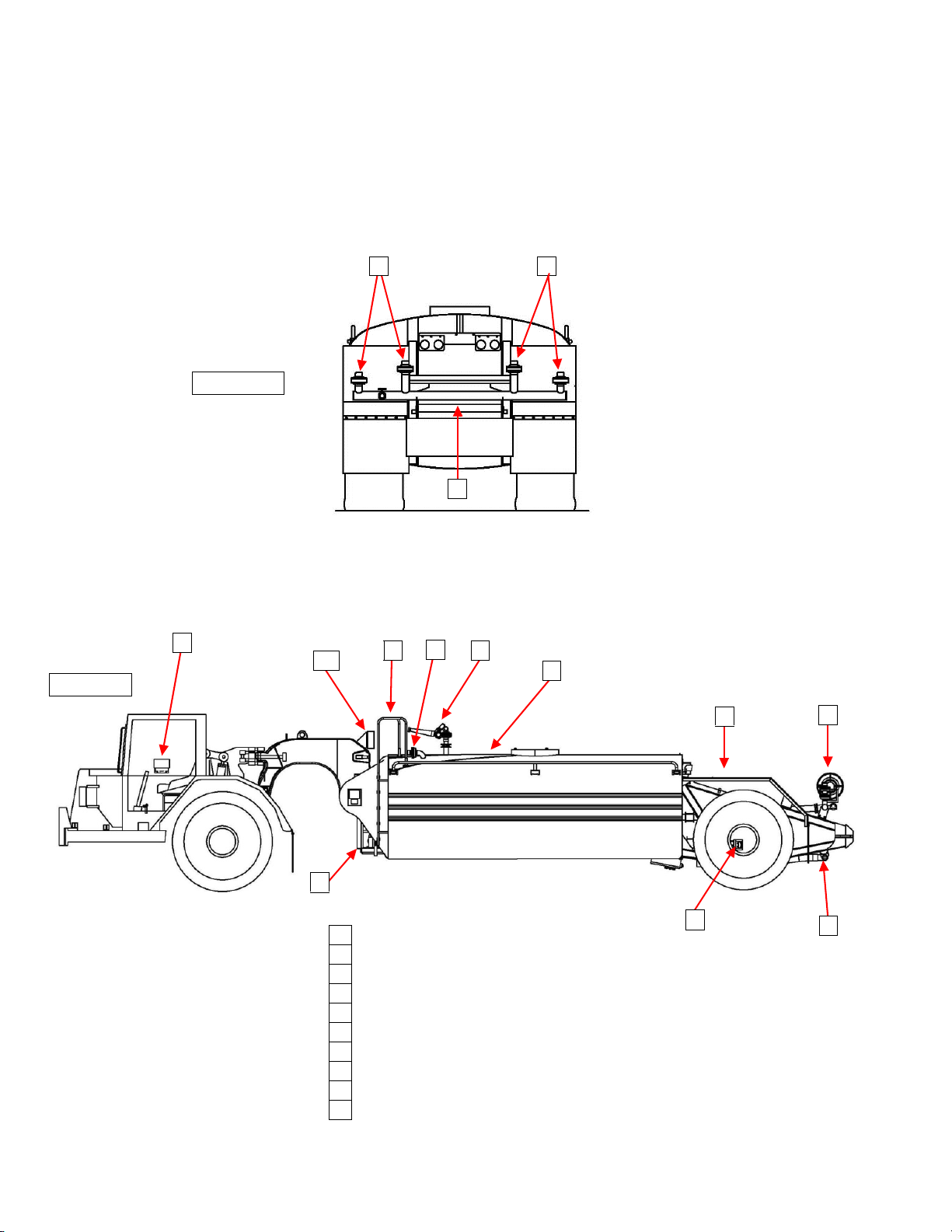

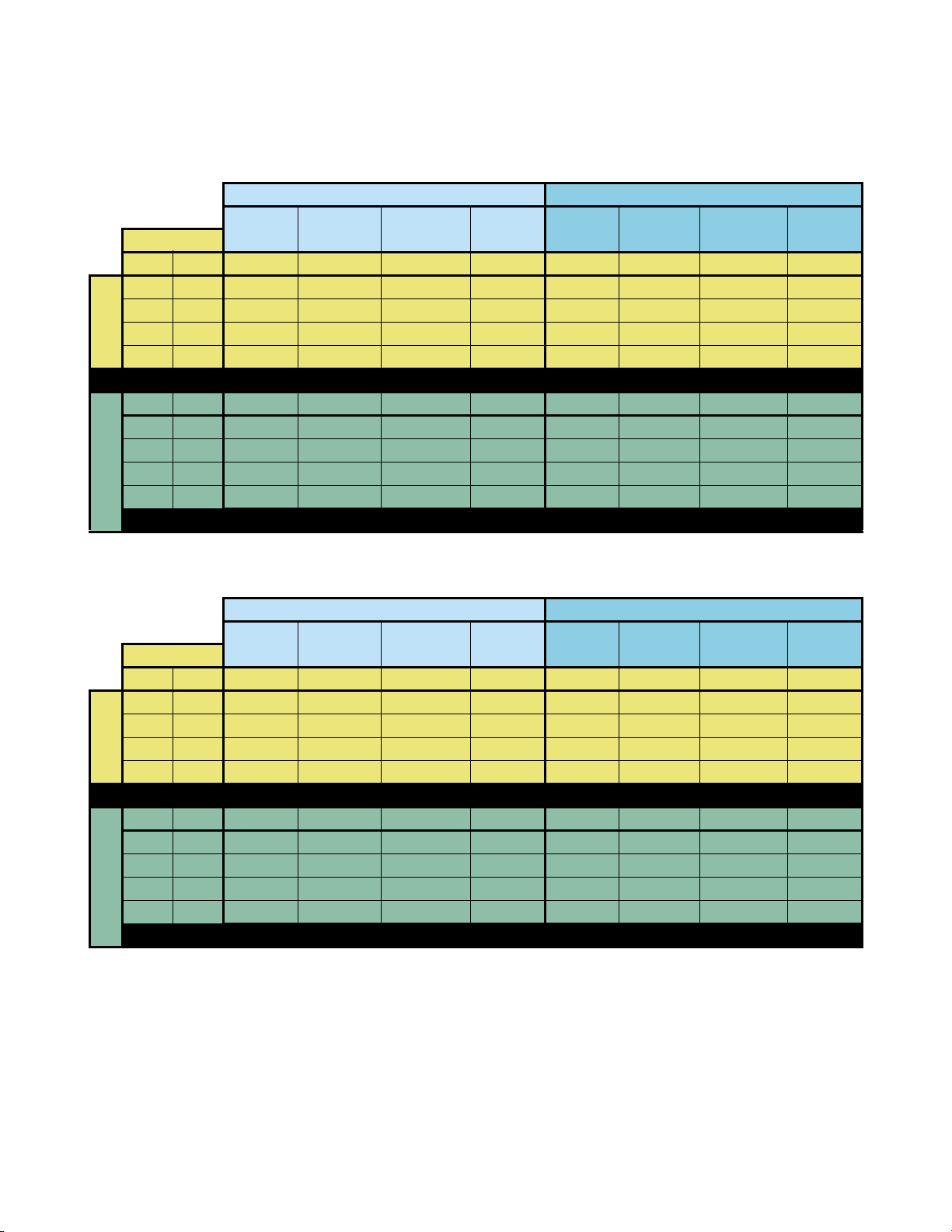

Page 9

MSC/MST-OPS-1

4

1

2

3

7

1

WATER PUMP & HYDRAULIC MOTOR

2

DUMP BAR

3

SPRAY HEADS

4

CAB CONTROLS

5

SUCTION PUMP STATION

6

HAND RAIL & WALKWAY

7

FOAM CONCENTRATE TANK

8

HOSE REEL

9

WATER CANNON

10

SOLENOID BOX

REAR VIEW

SIDE VIEW

9

3

6

10

6

8

3

5

1

31 Dec 2013

SECTION 1

Definitions and Abbreviations

MSC/MST GENERAL OVERVIEW (TYPICAL)

1-6

Page 10

SECTION 2

6

1

7

3

4

5

2

System Description

Contents

MSC/MST-OPS-1

31 Dec 2013

Water Tank (MSC/MST) ..................................................2-1

Water Pump........................................................................2-1

Hydraulic Drive Motor....................................................2-2

Cab Controls (Analog) ....................................................2-3

Cab Controls (Digital)......................................................2-5

Ground Speed Sensing (GPS) Control ......................2-9

Water Cannon System ....................................................2-11

WATER TANK (MSC/MST)

The MEGA steel water tank consists of a water tunnel,

primary floor, vertical baffles, bulkheads, outer skins,

internal piping and external piping. The tank design

is patented and known as the MEGA Anti-surge

Stabilization Tube (MAST).

The MAST is the backbone of the structure and

provides mounting for transverse baffles. The baffles

add to tank strength and dampen water surges. The

forward and rear baffles are reinforced with vertical

beams to provide mounting for the gooseneck and

rear axle bogie respectively. External and internal

piping is also used to carry water from the water

pump to spray heads, water cannon, spray bar, hose

reel, dump bar and tank drain.

Spray System.....................................................................2-12

Dump Bar............................................................................2-13

Hose Reel ............................................................................2-13

Tank Drain...........................................................................2-14

Fire Suppression System ...............................................2-14

Suction Loading (If Equipped) ....................................2-14

Braking System.................................................................2-15

M-4 WATER PUMP

M-4 Water Pump major components and their

functions are:

Early MSC/MST's may have a Berkley water pump

(B4J) installed. Contact MEGA Corp for more

information.

WATER PUMP

MSC/MST units are configured with different types of

water pumps and are based on the size of the water

tank. Typically the 5,000 - 7,000 gallon tanks are

configured with a smaller pump (4 inch inlet & 3 inch

outlet) while the 8,000 - 12,000 gallon tanks are

configured with the larger water pump (6 inch inlet &

4 inch outlet). The water pumps are very similar in

design and for the purposes of this manual the M-4 (6

inch inlet & 4 inch outlet is used to present

component information.

1. Bracket – Main frame of the pump that allows a

pump to be bolted to the tanker and provides the

means to direct mount the hydraulic drive motor.

2. Volute Case – A “snail shell” shaped case that

encloses the impeller. It is narrow at the center

and enlarges from there to the discharge area.

2-1

Page 11

MSC/MST-OPS-1

CASE DRAIN PORT

PRESSURE RETURNTEST PORTS

FLOW CONTROL CROSSOVER HOSE

31 Dec 2013

SECTION 2

System Description

3. Wear Ring – Acts as a bearing surface between

the impeller and volute case. Constructed of

bronze material.

4. Impeller – Rotating wheel attached to the shaft

that accelerates the speed of the water producing

water flow and pressure.

5. Shaft Seal – Confines grease to the inner and

outer bearing area while keeping foreign material

from entering the bearing area and seals water

inside the volute case.

6. Rope Seal – Provides a seal around the rotating

pump shaft at the volute case. Constructed of a

graphite rope material that is designed to drip

water and allow shaft lubrication.

7. Upper/Lower Bearings - Provide roller surface

for the pump shaft.

HYDRAULIC DRIVE MOTOR

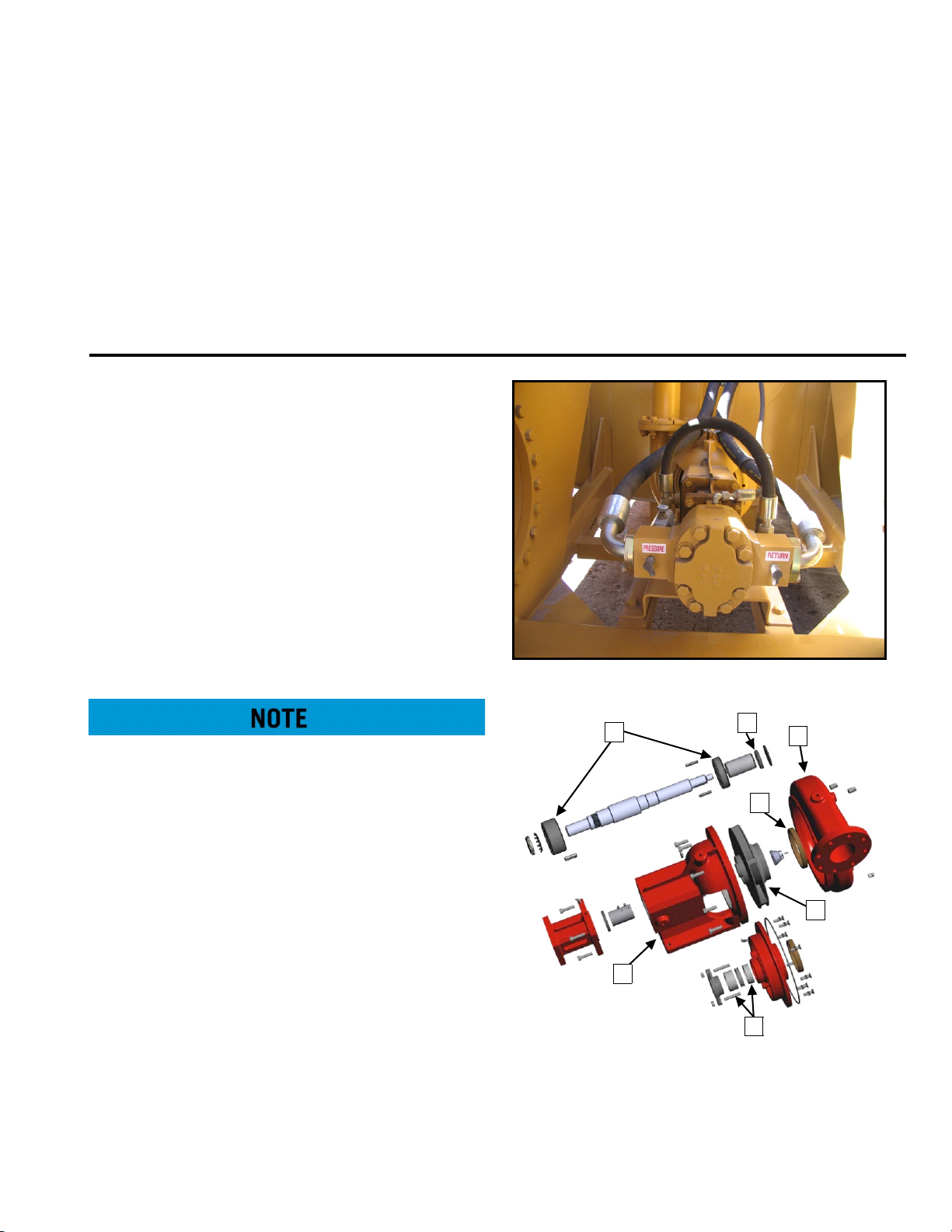

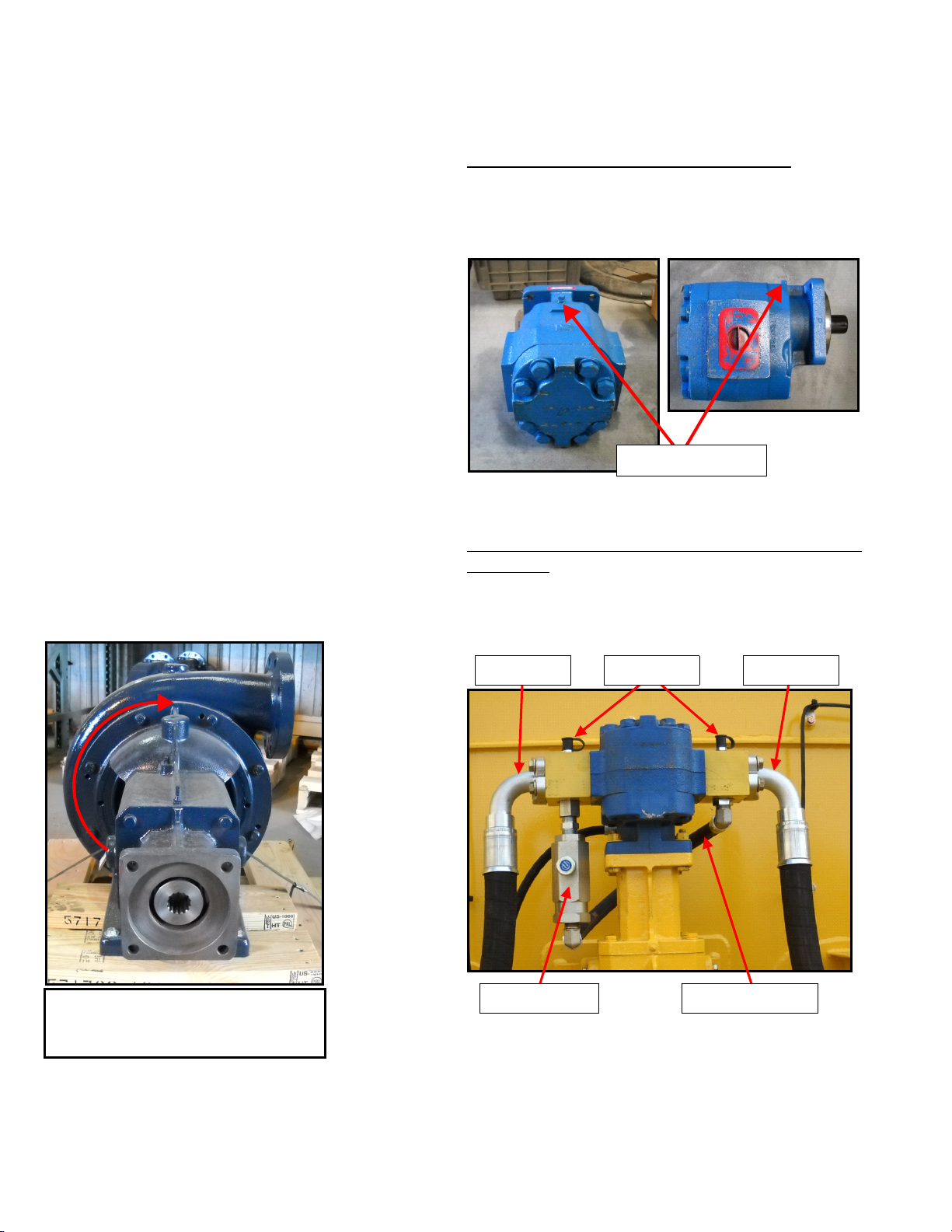

M-4 PUMP DRIVE MOTOR AND CROSSOVER

ASSEMBLY

The M-4 pump rotates clockwise as viewed from the

drive end of the assembly.

Hydraulic Drive Motor Port Identification

The hydraulic drive motor requires hydraulic flow

from a valve to the motor pressure port, return oil

flow to the hydraulic reservoir and a free to tank case

drain.

Hydraulic Drive Motor Speed Control (Crossover

Assembly)

The hydraulic drive motor speed control (Crossover

Assembly) consists of a flow control valve, 2 hydraulic

manifolds, crossover hose and test ports.

Clockwise rotation as viewed from

the drive end of the water pump

assembly.

The hydraulic drive motor may be installed in 4

different orientations depending on the water pump

location or application.

2-2

Page 12

SECTION 2

ADJUSTING

KNOB

System Description

MSC/MST-OPS-1

31 Dec 2013

Hydraulic Flow Control Valve

The hydraulic flow control is directional. The arrow on

the body indicates the direction of oil flow to meter

the bypassing oil. The adjusting knob on the valve

will allow adjustment of the oil flow to bypass the

drive motor, up to135 LPM (35 GPM) or up to 700

RPMs (RPM increase/decrease will vary depending on

the size of hydraulic drive motor the unit is equipped

with). If the flow control is reversed, the flow control

adjusting knob will not function and the full flow

capacity of the valve will bypass. This can result in

water pump rpm being below specifications with no

adjustment capability of the adjusting knob. By

turning the adjusting knob clockwise the hydraulic

oil that is bypassing will be reduced, increasing the

speed of the water pump. Turning the knob counterclockwise will increase the volume oil being

bypassed reducing the water pump speed. The flow

control valve is typically mounted on the PRESSURE

manifold of the hydraulic drive motor.

HYDRAULIC DRIVE MOTOR ACTIVATION

The hydraulic drive motor on MSC/MST's are typically

driven by the chassis implement hydraulic system.

The activation can be controlled by the following;

Pilot Operated Diversion Valve - A remote

mounted diversion valve that receives an electric

signal from the cab control pump switch to activate a

pilot control to move a spool within the diversion

valve redirecting the hydraulic oil to flow to the water

pump drive motor. Typically this type of valve is

installed between the hoist pump and the hoist

valve.

Existing Mechanically Operated Implement

Valve - Typically used on early model trucks with a

pneumatic system. This system is operated by the

existing cab control lever. When the lever is moved

to move a spool valve which divert hydraulic oil to

the water pump drive motor.

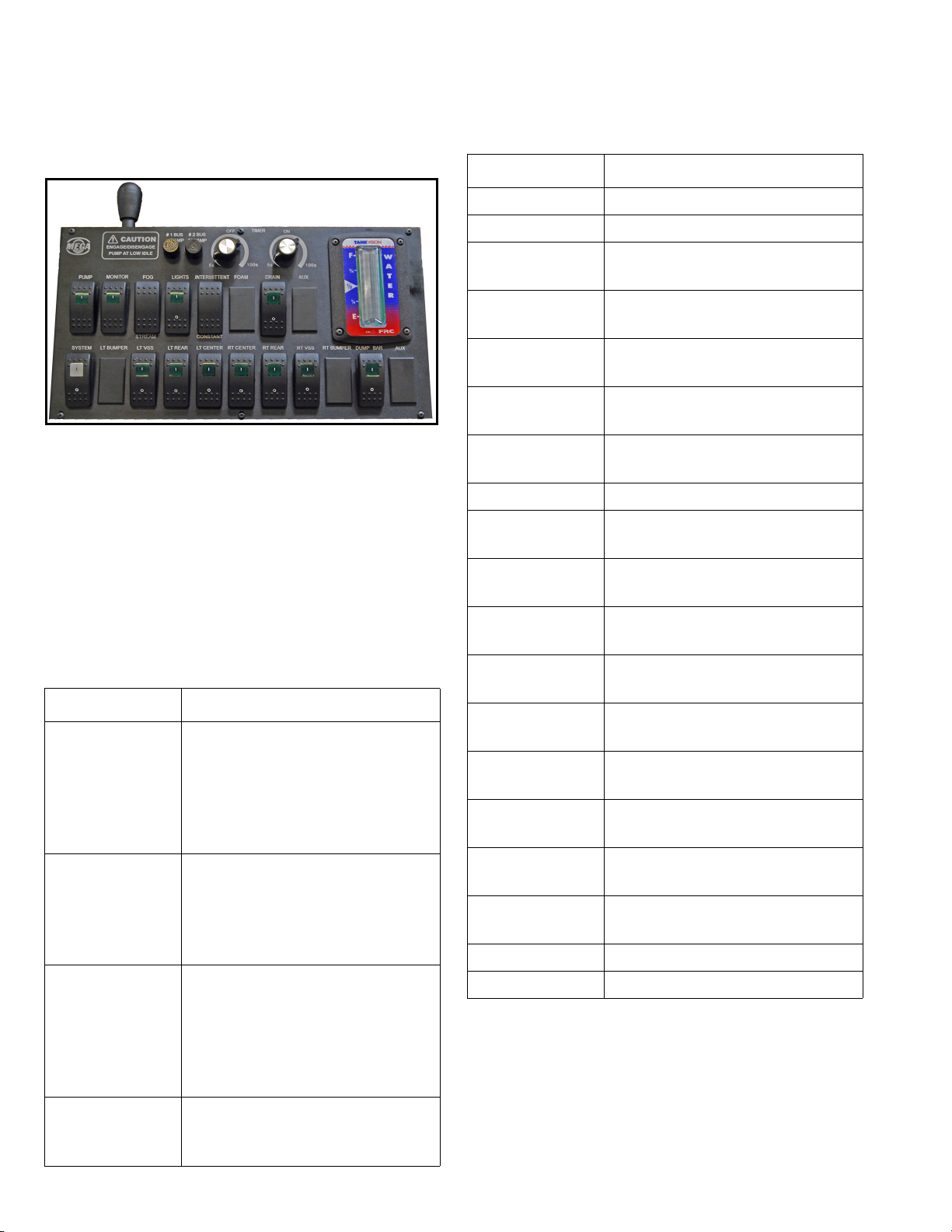

CAB CONTROLS (ANALOG)

MSC/MST units can be configured with a manual

pneumatic, electro-pneumatic or electro-hydraulic

control system.

Typical 135 lpm (35 gpm) Adjustable

Hydraulic Flow Control

MANUAL PNEUMATIC

Multi-function control box mounted in the cab to

control all water tank functions. Spray system head

and auxiliary functions are controlled by using

manual pneumatic levers, accessory switches and

embedded joystick. The cab control requires 24 VDC

power to operate.

2-3

Page 13

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

ELECTRO-PNEUMATIC]

Multi-function control box that is mounted in the

vehicle cab to control all water tank functions.

Controls are available for the water cannon,

intermittent spray, water pump, work lights, foam

suppression, adjustable nozzle, system, spray heads,

spray bar, gravity dump bar, and tank drain valve. The

control box also provides indications of tanker water

level and a system fuse holder. The cab controls

requires 24 VDC vehicle power to operate.

The control functions operate as follows:

Control Function

Joystick Sends command signals to the

logic box (electric water cannon)

or hydraulic control valve assembly (hydraulic water cannon) to

move the water cannon left,

right, up and down.

TIMER ON Sets ON time (variable adjust-

ment 5-100 sec) of selected spray

heads and dump bar when the

timer switch is in the intermittent

position

TIMER OFF Sets OFF time (variable adjust-

ment 5-100 sec) between timer

cycles of selected spray heads

and dump bar when the timer

switch is in the intermittent position.

Control Function

MONITOR Opens the water cannon BFV.

LIGHTS Provides power to work lights.

FOAM Open or closes the foam concen-

trate tank in-line control valve.

INTERMITTENT/

CONSTANT

AUX Reserved for specialized func-

ADJUSTABLE

NOZZLE

AUX Reserved for specialized func-

WATER LEVEL Indicates tank water level.

SYSTEM Provides power for all cab control

LT BUMPER Opens or closes left front bumper

LT VSS Opens or closes left vertical side

LT REAR Opens or closes left rear spray

LT CENTER Opens or closes left center rear

RT CENTER Opens or closes right center rear

RT REAR Opens or closes right center rear

RT VSS Opens or closes right vertical side

RT BUMPER Opens or closes right front

DUMP BAR Opens or closes dump bar BFV.

DRAIN Opens or closes tank drain BFV.

Activates or deactivates system

timer function.

tions.

Adjusts water cannon nozzle

from FOG/FAN to STREAM.

tions.

functions.

spray head.

spray head.

head.

spray head.

spray head.

spray head.

spray head.

bumper spray head.

PUMP Routes vehicle hydraulic system

pressure and flow to the water

pump hydraulic drive motor.

2-4

Page 14

SECTION 2

Master

Switch Box

Joystick Box

System Description

MSC/MST-OPS-1

31 Dec 2013

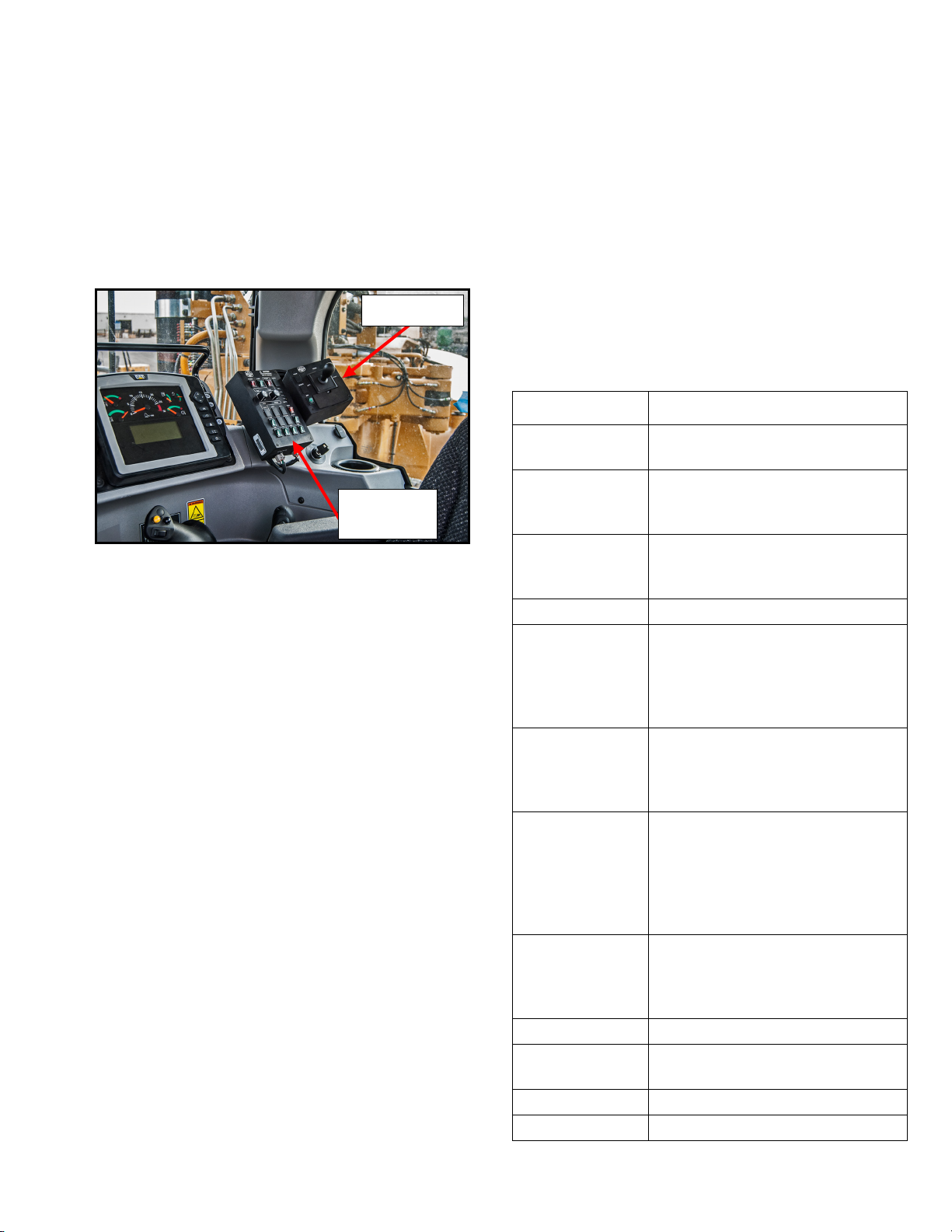

CAB CONTROLS (DIGITAL)

MSC/MST units with fully hydraulic systems MUST be

configured with the Mega Digital Spray Control

System (DiSCS).

ELECTRO-HYDRAULIC SYSTEM (CAT 621H/K only)

This system is designated as a Digital Spray Control

System (DiSCS). The system is comprised of control

boxes, logic controllers, sensors, and cabling. It is a

multi-function control system with a separate

joystick box that is mounted in the vehicle cab. These

two boxes control all water tank functions. The

master switch box operates the water pump, spray

heads, intermittent spray, work lights, hose reel,

dump bar, suction loading, and tank drain valve. The

master switch box also provides indications of tanker

water level and water pump protection features. The

remote mounted joystick box operates the water

cannon, adjustable nozzle and foam suppression. The

cab controls require 12/24 VDC vehicle power to

operate.

ABBREVIATIONS AND DEFINITIONS

AUX1 – Auxiliary or additional optional function

BFV – Butterfly Valve

DMPBAR – Dump bar for heavy spray of water close

to ground. Can be either a gravity or pressure

dump bar (pressure dump bar requires water

pump activation to operate).

DRAIN – Drain (gravity or pressure) for evacuation of

water from tank, mounted typically at the rear

of the tank.

KPH – Kilometers per hour

LT VSS – Left Vertical Side Spray

LTC – Left Center Spray Head

LTR – Left Rear Outer Spray Head

MPH – Mile per hour

RAMP – Ramping Control feature. Rate of increase or

decrease in speed of water flow during PUMP

engagement or disengagement

RT VSS – Right Vertical Side Spray

RTC – Right Center Spray Head

RTR – Right Rear Outer Spray Head

The master switch box control functions operate as

follows:

Control Function

POWER Provides power for all cab control

functions.

PUMP Routes vehicle hydraulic system

pressure and flow to the water pump

hydraulic drive motor.

INTMNT Intermittent setting.

Activates or deactivates system

timer function.

LIGHTS Provides power to work lights.

t ON

(Intermittent

timer—manual

mode)

RATE

(GPS Auto Mode)

t OFF

(Intermittent

timer—manual

mode)

SPEED

(GPS Auto Mode)

WATER LEVEL Indicates tank water level.

AUTO Controls activation of GPS Auto

AUX 1 Reserved for user-added option.

AUX 2 Reserved for specialized function.

Sets ON time of selected spray heads

when the timer switch is in the intermittent (INTMNT) position.

Scale: adjustable from 5 seconds to

30 seconds.

Increases or decreases amount of

water dispersed during a cycle when

AUTO switch is on (see extended

description).

Sets OFF time between timer cycles

of selected spray heads when the

timer switch is in the intermittent

(INTMNT) position.

Scale: adjustable from 5 seconds to

30 seconds.

Sets desired ground speed for maximum flow (OPEN continuously) of

selected spray heads (see extended

description).

mode.

2-5

Page 15

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

Control Function

HOSE Controls activation of hose reel func-

tion ONLY.

SUCTION LOAD Controls activation of suction load

station ONLY.

LT VSS Opens or closes left vertical side

spray head.

DRAIN Opens or closes tank drain BFV.

DUMP BAR Opens or closes dump bar BFV.

RT VSS Opens or closes right vertical side

spray head.

LT REAR Opens or closes left rear spray head.

LT CENTER Opens or closes left center rear spray

head.

RT CENTER Opens or closes right center rear

spray head.

RT REAR Opens or closes right rear spray

head.

The joystick box functions operate as follows:

Control Function

Joystick

(L EFT-RIGHT-UPDOWN)

FOAM Open or closes the foam concentrate

NOZZLE Adjusts water cannon nozzle from

BFV Opens or closes the water cannon

Sends command signals to the

hydraulic control valve assembly to

move the water cannon.

tank in-line control valve.

FOG to STREAM.

butterfly valve.

Cab control power is then activated by turning the

cab control POWER switch ON while logic controllers

are switched on when the chassis ignition switch is

turned ON.

The spray system will function normally when cab

control power is applied (cab control POWER switch

ON) and sufficient water level (water level EMPTY

light not flashing) is present. Activation of a specific

function is accomplished by depressing the selected

function switch on the master switch box or joystick

box.

Depressing the switch sends a signal to the logic

control panel in the solenoid box to activate a given

function. The logic control then receives the signal

and provides an output command to the given coil or

function.

Once the logic control panel output is processed, the

logic control sends a feedback signal back to the cab

control box to illuminate the LED on the selected

function switch. If the switch LED does not illuminate,

a malfunction may exist in the logic control, wiring

harness or cab control box.

If a function switch is depressed with no

corresponding switch LED, check to ensure system

power switch is ON and the water level empty LED is

not flashing. If the switch LED is not illuminated, a

malfunction may exist.

BASIC SYSTEM THEORY OF OPERATION

Spray system power is provided by chassis 12/24 volt

DC power. Power is routed to cab controllers and

logic control panels by turning on the switched

power via the ignition key switch.

When the chassis ignition switch is turned ON, the

master switch box will undergo a functional self-test.

During this process, ALL LEDs will first turn ON, then

off. While this is occurring, the water level indicator

lights will initially register a FULL tank, and will then

decrease down to EMPTY. The EMPTY light will blink,

and then the water level indicator will count up to

register the current water level of the tank.

If the selected function switch LED illuminates and

the component on the water tanker is not

functioning, the component (water-way valve, spray

head or water cannon) may have malfunctioned.

As functions are turned on and off, the water pump

switch will remain illuminated unless all spray system

functions (water-way valves, spray heads or water

cannon) are turned off. The logic control will

automatically turn the water pump off if all valves are

closed to prevent over-temp of the water pump

volute case. As the water level of the tank drops and

the EMPTY LED begins to flash, the logic controls will

deactivate the water pump to prevent cavitation or

dry running of the water pump.

2-6

Page 16

SECTION 2

System Description

MSC/MST-OPS-1

31 Dec 2013

WATER PUMP PROTECTION FEATURES

Soft Start and Stop

from sudden starts and stops whenever the pump is

turned ON or OFF via the switch or any auto/logic

control feature. This is accomplished by the logic

control system slowly commanding the appropriate

proportional hydraulic control valve to open or close

slowly to prevent hard starts or stops that can reduce

water pump service life.

Low Water Protection

automatically turned off by the logic control system

when a low water condition is detected. The logic

control system monitors tank water level and

commands the water pump to turn off when a

predetermined low water condition is noted. This

prevents the water pump from running in a dry sump

that will over-heat shaft seals due to lack of water.

Continued use will damage the shaft seals.

No-Flow Conditions

automatically turned off after about 100 seconds,

whenever all water discharge valves are closed. The

logic control system monitors all discharge valves

and begins a TIME OUT cycle to turn off the water

pump after about 100 seconds. Any time a discharge

valve is opened during the timing cycle, the clock is

reset. This feature prevents the water from heating

up due to the water pump impeller spinning in a

sump with no flow. The heating of the static water

will also heat the water pump causing deterioration

of grease and premature bearing failure.

– The water pump is protected

– The water pump is

– The water pump is

MASTER SWITCH BOX EXTENDED FUNCTION

DESCRIPTIONS

POWER – Turns POWER ON and OFF to cab controls

and digital controllers.

PUMP – Sends request for pump engagement/

disengagement to the digital control processor. The

digital controllers will activate the hydraulic circuit to

slowly ramp-up or ramp-down the water pump.

The water pump switch will flash whenever the

switch is on and the following conditions apply:

• Low water condition is sensed (EMPTY LED is

flashing).

• No flow condition is sensed (for about 100

seconds, no waterway valves are open)

Engaging/disengaging the water pump above LOW

IDLE will result in water pump component damage

and reduced service life.

INTMNT (Intermittent Function)

Intermittent spray function sends request for

adjustable timing of spray head and dump bar as

commanded by the tON and tOFF dials.

Intermittent will only operate if at least 1 discharge

function (spray head or dump bar) switch is

activated. Water discharge can be stopped at any

time when in INTMNT mode by turning discharge

function switches OFF. The timer will continue to

cycle even if no water is being sprayed

2-7

Page 17

MSC/MST-OPS-1

3s - 15s

min

max

15s - 30s

3 o’clock

3 o’clock

31 Dec 2013

SECTION 2

System Description

The tON and tOFF adjusting knobs command timing

as follows:

• t ON – Adjusts spray head ON time.

• t OFF – Adjusts spray head OFF time.

The relationship between dial rotation and ON/OFF

time is as follows:

– min to 3 o’clock position: 3 sec to 15 sec

– 3 o’clock to max position: 15 sec to 30 sec

The above time ON/OFF scale applies to firmware

versions 3.7.0 and above. For firmware versions 3.6.x

and below, the range is 5 seconds to 30 seconds,

scaled linearly across the rotation of the dial.

The intermittent function will turn selected spray

head or dump bar on and off. Duration of tON and

tOFF cycle times are selected by setting the

appropriate dials on the master switch box. When the

INTMNT switch is ON and functions are selected, the

operator will observe different switch LEDs

conditions to indicate operation within the tON and

tOFF cycles. When a selected function switch (spray

head or dump bar) is operating during an ON cycle,

the selected function switch LED will be illuminated

as well as the INTMNT switch LED. When the INTMNT

cycles automatically to an OFF cycle, INTMNT switch

and function switch LEDs will extinguish. As the ON

cycle is about ready to engage, the INTMNT switch

LED will flash 3 times at the end of the OFF cycle to

indicate the selected spray functions are about to be

turned ON. These light conditions will change back

and forth until intermittent or function switches are

turned off.

Water Level Indicator – Indicates tank water level as

sensed by the water level pressure

sensor in the rear of the water

tank. When the red EMPTY LED

light flashes, the tank is at

minimum water level. This low

level signal is also sent to the logic

control to automatically rampdown the water pump to prevent

component damage. Water pump

operation can only be restored if

sufficient water is in tank to

extinguish the EMPTY light.

In order to re-activate the water pump after lowwater shut-off, first fill the water tank with sufficient

water capacity to permit pump operation. Then turn

the PUMP and POWER switches OFF. Cycle the chassis

ignition key OFF/ON. Wait for the Master Switch Box

to complete its lights check. Then, if the water level

gauge reads above EMPTY, turn the POWER and the

PUMP switches on.

Certain terrains and water level fluctuations may

allow low water protection to capture a low water

level condition, causing the pump ramp-down. If

conditions allow water pump activation after water

level/terrain fluctuations have ceased, then the water

pump may be re-activated by following the steps in

the previous note.

Pressure Discharge Function Descriptions:

Spray Heads – Control opening or closing of the

associated valve when selected, or automatically

controlled when INTMNT function is selected.

Dump Bar (Pressure) – Controls opening or closing

of the BFV when selected, or automatically controlled

when INTMNT function is selected.

Suction Load - Allows continuous hydraulic water

pump drive circuit flow during a low water level

condition. Also disables use of any other master

switch box waterway valve

2-8

Page 18

SECTION 2

Joystick Box Functions

System Description

AUX FUNCTIONS

AUX 1 – Sends request for operation of auxiliary

functions or additional non-standard options of spray

system. This function is unique to a specific tank

serial number.

AUX 2 (Suction Load Station) – If equipped, sends a

request to the hydraulic water pump drive circuit to

allow suction load pump drive motor operation

during a low water level condition while also

disabling the timed-out function. When turned ON,

the AUX2 switch LED will flash rapidly and all

pressure discharge functions are disabled.

HOSE – Allows continuous water pump operation for

hose reel use while also disabling the use of any

other master switch box waterway valves.

Ensure all discharge function switches are OFF when

using HOSE function. Activating the HOSE switch

requests all discharge function to turn OFF (All Spray

heads, Water Cannon BFV, Drain, Dump Bar and

FOAM).

Non-Pressure Discharge Function Descriptions:

Dump Bar (Gravity) – Controls opening and closing

of the BFV when selected, or automatically controlled

when the INTMNT function is selected.

JOYSTICK BOX EXTENDED FUNCTION

DESCRIPTIONS

The joystick box houses logic controls for the joystick

and the FOAM, NOZZLE, and BFV switches. These

switches and the joystick control requests for water

cannon operation.

MSC/MST-OPS-1

31 Dec 2013

BFV – Sends request to open or close butterfly valve.

The butterfly valve controls water flow to the Water

Cannon. Activating the BFV switch requests the water

PUMP to stay ON with NO other pressure discharge

functions activated providing, sufficient water is in

tank to allow command to be sent.

JOYSTICK – Sends requests for rotation and

elevation motion for water cannon operation.

GROUND SPEED SENSING (GPS) CONTROL

The MEGA ground speed sensing control system is an

independent and self-contained GPS unit and

antenna that provides speed information to the

existing Mega Digitally Integrated Spray Control

System (DiSCS). The DiSCS’s logic control uses the

ground speed signal to automatically cycle and pulse

spray heads to obtain a desired lay-down of water

regardless of ground speed. The system contains

controls to adjust maximum water discharge speed

as well as actual rate of flow. This automatic control

reduces water usage and prevents over-watering of

haul roads and intersections.

FOAM – Sends request for FOAM agent valve to open

or close.

NOZZLE – Sends request for adjustable nozzle on

water cannon to move from FAN/FOG to STREAM

spray patterns.

The system will automatically close all discharge

functions (spray heads) below 5 KPH/3 MPH to

prevent puddling of water at intersections. The

system also opens selected discharge functions

when accelerating above 5KPH/3 MPH.

2-9

Page 19

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

The system warns the operator of all malfunctioning

system functions and provides full manual control of

all spray system functions in the event of an AUTO

mode failure. All automatic system protection

features of low water level conditions, no-flow

conditions and water pump soft start/stop feature

still operate normally in the AUTO mode.

GPS EXTENDED FUNCTION DESCRIPTIONS

SPEED – Above what vehicle speed the command is

sent for maximum flow of all selected discharge

functions (spray heads). Below this vehicle speed,

timed cycles and/or reduced water volume flow

occur.

The scale for the SPEED function is 0 KPH/0 MPH (Full

LEFT) to 48 KPH/30 MPH (Full RIGHT).

When vehicle speed goes below the set SPEED,

application rate of water discharged will be either

pulse the requested discharge functions and/or

reducing the number of discharge functions based

on the RATE selected.

IF vehicle speed is GREATER than set SPEED the RATE

has little or no effect on water discharge. Typically all

requested pressure discharge functions are ON and

no timing cycle.

AUTO – This function has priority over intermittent

mode. The intermittent light will illuminate steadily

when operating conditions are met and AUTO is ON.

AUTO enables vehicle speed signal from the GPS

module to activate the speed sensing mode, and

operates the spray system based on RATE and SPEED

adjustments. Pulse will begin when the AUTO

function requests reduced volume.

Near or below 4.8 KPH/3 MPH, AUTO will switch to

INTERMITTENT mode and discharge functions may

operate continuously or ramp down the water pump

to OFF. When vehicle speed rises above 4.8 KPH/3

MPH, AUTO will resume control of the system.

RATE – Is the distance traveled/time for spray head

ON cycle.

•Knob turned counterclockwise reduces ON

distance/ ON time

• Knob turned clockwise increases ON distance/

ON time

Reduced Volume Mode – Reduction in discharge

volume by reducing the number of spray heads

requested to activate.

• If 4 rear spray heads are requested, reduced

volume allows only the 2 outer spray heads to

turn ON and the 2 center spray heads are OFF.

• If 3 rear spray heads are requested 1 spray head

will be OFF, typically the center head adjacent to

the outer head requested.

• If 2 spray heads are requested 1 spray head will

be OFF typically the center spray head unless no

center spray heads are requested, then NO spray

heads will be OFF.

Pulsing – Reference to Pulse Width Modulation or

ON/OFF cycle.

2-10

Page 20

SECTION 2

System Description

MSC/MST-OPS-1

31 Dec 2013

WATER CANNON SYSTEM

The system is comprised of a water cannon (hydraulic

or electric), hydraulic control valve assembly or logic

box, butterfly valve assembly, nozzle and controls.

WATER CANNON (Hydraulic)

cannon is threaded to a flanged pipe that mounts

directly above the BFV. The water cannon also

provides mounting for a variety of different nozzles.

HYDRAULIC CONTROL VALVE ASSEMBLY

the cab control box. A pressure relief valve is

incorporated in the manifold block to protect the

water cannon system against any over pressurization

conditions. The assembly is mounted to the tank

lower flange and receives hydraulic pressure from the

vehicle hydraulic pump.

A metal waterway that directs

a stream of water in both

elevation (up-down) and

rotation (right-left). Hydraulic

motors move the waterway

based upon hydraulic flow

from the hydraulic control

valve assembly as

commanded by the cab

control joystick. The water

The assembly contains three

hydraulic solenoid valves that

direct hydraulic pressure to

the hydraulic motors on the

water cannon and BFV

cylinder as commanded by

WATER CANNON (ELECTRIC)

A metal waterway that directs a

stream of water in both

elevation (up-down) and

rotation (right-left). 24 VDC

electric motors move the

waterway based upon filtered

electronic signals from the logic

box as commanded by the cab

control joystick. The water

cannon is threaded to a flanged pipe that mounts

directly above the BFV. The water cannon also

provides mounting for a variety of different nozzles.

ELECTRO-PNEUMATIC BFV ASSEMBLY

An electro-pneumatic valve that

controls the flow of water to the

water cannon. A 24 volt DC

solenoid receives commands

from a cab control MONITOR /

BFV switch through the logic

box to route pressurized air to

an air chamber which opens or closes a 3” valve. The

assembly is clamped between upper and lower pipe

flanges.

WATER CANNON NOZZLES AND STREAM SHAPERS

Smooth Bore Nozzle

A cone shaped 1.5” diameter nozzle

that directs water flow. The nozzle

has a built in stream shaper that

smooths water flow to increase water

stream distance.

HYDRAULIC BFV ASSEMBLY ASSEMBLY

A hydraulically operated

valve that opens or closes

to control water flow to

the water cannon. The

hydraulic cylinder receives

hydraulic pressure from

the hydraulic control valve

or solenoid control box assembly as commanded by

the cab control water cannon switch. The assembly is

clamped between upper and lower pipe flanges.

Smooth Bore (Stackable)

A segmented cone shaped nozzle

that directs water flow. The nozzle

opening is adjusted by removing

segments to acquire the most

efficient nozzle opening for a given

water pump operating pressure.

Nozzle segment diameters are 1?”,

1½”, 1¾” and 2”. The nozzle requires

and in-line stream shaper to increase

water stream distance.

2-11

Page 21

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

In-Line Stream Shaper

A performance enhancer that is

mounted between the water

cannon outlet and the selected

straight bore nozzle. The stream

shaper pathway is a honeycomb

style channel designed to

efficiently shape a water stream

to maximum water stream

distance.

Manual Adjustable Nozzle

Fog/Stream:

allows the operator to manually adjust selected

water stream patterns from fog to stream. Some

nozzles are configured for fire suppression foam

eduction.

Fan/Stream:

allows the operator to manually adjust selected

water stream patterns from flat fan to stream. The flat

fan pattern orientation is adjustable from horizontal

to vertical by reorienting the nozzle on the water

cannon.

Remote Adjustable Nozzle (Electric/Hydraulic)

A modified straight bore nozzle that

A modified straight bore nozzle that

Fan/Stream

A modified straight bore nozzle that allows the

operator to remotely adjust selected water stream

patters from flat fan to stream from the cab control.

The nozzle inner or outer barrel is moved by an

electric actuator to obtain the fan or stream pattern.

The flat fan pattern orientation is adjustable from

horizontal to vertical by reorienting the nozzle on the

water cannon.

SPRAY SYSTEM

The spray head system consists of 4, 6 or 8 hydraulic

or pneumatic actuated spray heads, cab controls,

solenoid control box assembly, and hydraulic or

pneumatic hosing.

PNEUMATIC SPRAY HEAD

A two piece aluminum valve

body and adjustable ring

mounted to a water supply

header pipe. The upper

portion of the valve body is

an air chamber with a

diaphragm and guide disk

assembly attached to the bottom. The air chamber

receives pressurized air from the solenoid control box

as commanded by the cab control switch. When the

upper portion of the valve body is pressurized the

guide disk will seal the opening on the lower portion

of the valve and stop water flow.

A modified straight bore nozzle that allows the

operator to remotely adjust selected water stream

patterns from fog to stream from the cab control. The

nozzle inner or outer barrel is moved by an electric or

hydraulic actuator to obtain the fog or stream

pattern. Some nozzles are configured for fire

suppression foam eduction.

When the cab control system is OFF and the water

pump is OFF the air chamber incorporates a spring

that will apply pressure to the guide disk assembly

and seal the opening on the lower portion of the

valve and stop flow. When air pressure is removed

from the upper portion of the valve body when the

water pump is ON and the cab control switch ON,

pressurized water from the header pipe will unseat

the guide disk and water will flow from the lower

portion of valve.

2-12

Page 22

SECTION 2

1/4” Opening

3/8” Opening

Pneumatic

Hydraulic

System Description

MSC/MST-OPS-1

31 Dec 2013

HYDRAULIC SPRAY HEAD

A two piece aluminum valve

body, hydraulic cylinder and

adjustable ring mounted to a

water supply header pipe. The

upper portion of the valve body

contains a hydraulic cylinder

that receives hydraulic pressure

from the system solenoid control box as commanded

by the cab control switch. When the hydraulic

cylinder on the upper portion of the valve body is

pressurized the cylinder extends to contact the guide

disk and seal the opening on the lower portion of the

valve and stop water flow. When the cab control

system is OFF and the water pump is OFF the upper

valve body incorporates a spring to apply pressure to

the guide disk to seal the opening on the lower

portion of the valve and stop flow. When the spray

head switch is turned on hydraulic pressure retracts

the hydraulic cylinder and pressurized water from the

header pipe will unseat the guide disk and water will

flow from the lower portion of valve.

SOLENOID CONTROL BOX

The control box assembly is mounted to the forward

bulkhead or the rear of the gooseneck of the MSC/

MST. The assembly contains pneumatic or hydraulic

solenoid valves that direct pneumatic or hydraulic

pressure to the spray head as commanded by the cab

control box. The solenoids receive pneumatic

pressure from the vehicle or hydraulic pressure from

water pump oil circuit and 24 VDC power from the

cab control box.

DUMP BAR

Spray Head Adjustable Rings

The adjustable ring is used to control fan width and

water flow. The ring may be loosened and rotated to

expose more or less of the lower valve opening to

control water fan width from 15° to 90°. The ring also

may be used rotated to a 1/4” or 3/8” slot (as shown

below) to increase or decrease overall water flow. The

greater the opening, the greater the water flow.

A spray bar that contains several rows of 3/8” drain

holes to dispense water. A hydraulically operated BFV

controls the water supply to the dump bar. The BFV is

controlled electrically from the cab control box and is

actuated by a hydraulic cylinder. The actuators

receive hydraulic pressure from the solenoid control

box assembly. Dump bars can be either gravity or

pressure fed.

HOSE REEL

A reel assembly that is

located on the bottom aft

end of the water tank fitted

with a 1” or 1.5” diameter

reinforced rubber hose and

a fire fighting style nozzle.

The hose reel assembly

receives pressurized water

from the pressurized

manifold on the back of the tank to operate.

2-13

Page 23

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

TANK DRAIN

A hydraulic BFV attached to the water tank pressure

pipe is used to drain water from the water tank. The

BFV is controlled electrically from the cab control box

and is actuated by a hydraulic actuator. The actuators

receive hydraulic pressure from the solenoid control

box assembly. Tank drains can be either gravity or

pressure fed.

FIRE SUPPRESSION SYSTEM

A system that consists of a 120 or 60 gallon stainless

steel holding tank, an electric or pneumatic actuated

shut-off valve, in-cab control switch, hosing and a

foam eduction nozzle mounted to the water cannon.

FOAM EDUCTION NOZZLE

A manual or remote

adjustable (fog/stream)

nozzle is attached to the

water cannon waterway. The

nozzle inner housing uses

high pressure water to create

a venture effect that will

create a suction force,

pulling foam concentrate from the holding tank.

Once foam concentrate is flowing, the nozzle

proportions foam concentrate, water and air to

produce finished foam. The nozzle can be adjusted to

allow control of foam solution at a rate of 1%, 3% or

6%. Rate adjustment is obtained by replacing a

removable disk.

SUCTION LOADING (IF EQUIPPED)

FOAM CONCENTRATE TANK

A stainless steel tank

mounted in the forward

upper portion of the water

tank. The holding tank

contains a supply tube that

extends to the bottom of the

tank and connected to a

flexible hose at the top of the tank and then routed to

the foam agent shut-off valve. The tank also contains

a pressure/vacuum cap which keeps foreign matter

out of the tank while providing for pressure relief and

air displacement during temperature changes.

ELECTRIC/PNEUMATIC SHUT-OFF VALVE

The in-line shut-off valve is mounted on the foam

tank upper lip and is controlled by the in-cab control

FOAM switch. The shut-off valve is actuated by either

an electric or pneumatic actuator that is controlled

by the in-cab control switch. Once the shut-off valve

is opened, foam concentrate will flow from the

holding tank to the water cannon nozzle if the water

cannon and water pump switches are ON.

A second water pump mounted typically to the water

pump sump at the rear of the MAC. The suction

loading station is equipped with a manual diversion

valve that will switch the hydraulic oil flow from the

main discharge pump drive motor to the suction

loading pump drive motor. When oil is diverted to

the suction loading drive motor, it can pull water

from a holding pond and fill the MAC. The suction

loading option includes lengths of 4” suction hose

equipped with quick couplers and a check valve inlet

foot with a debris screen. The suction hoses are

typically stored in tubes either built into the MAC or a

hanging tube arrangement.

2-14

Page 24

SECTION 2

System Description

MSC/MST-OPS-1

31 Dec 2013

BRAKING SYSTEM

MSC/MST PRIME MOVERS

See the prime mover Operator and Service Manual

for brake system information.

MSC/MST 611/615

See the CAT 611/615 Operator and Service Manual

for brake system information.

MSC/MST 613

See the CAT 613 Operator and Service Manual for

braking system information

MSC/MST 621H/K

See the CAT 621H/K Operator and Service Manual for

braking system information.

For further information contact MEGA Corp. Product

Support Group at:

US toll free: 1-800-345-8889

Direct: 1-505-345-2661 or visit our website at

www.megacorpinc.com for more detailed contact

information.

AIR TANKS

The MSC/MST is equipped with two 8 inch x 32 inch

air cylinder mounted to the MSC/MST rear bogie that

store 110-130 psi air. The cylinders receive

pressurized air from the tractor primary air tank

mounted under the tractor cab.

TANK PRESSURE SENDING UNIT

A 24 VDC pressure sending unit is mounted to the

rear MSC/MST air tank and is wired into existing

tractor brake pressure indicating and warning

systems. The sending unit provides air pressure

sensing for the tractor air pressure gauge mounted in

the dash. The sending unit also provides a signal to

the brake low pressure warning system that sounds

an audible warning tone when brake supply pressure

drops below allowable limits.

MSC/MST 621G & 631G

The MSC/MST rear brake system is integrated with

the existing tractor parking, service and emergency

brakes. All three systems are activated with the

existing brake controls located in the tractor cab. See

the CAT 621G and 631G operator and service manual

for additional tractor brake information.

The MSC/MST rear brake system consists of a wheel

group, two additionally air tanks, pneumatic

manifold assembly, pneumatic brake relay valve,

brake pods, solenoid valve, pressure switch, pressure

sending unit and hosing.

PNEUMATIC MANIFOLD ASSEMBLY

A pneumatic

manifold mounted

in the rear bogie

used to route air

pressure for service,

parking and

emergency brake

operation. The

manifold also

provides mounting for a check valve, parking brake/

emergency solenoid valve and parking brake

pressure switch.

CHECK VALVES

A spring operated valve allowing air flow in a

predetermined direction. A one-way check valve is

located at the MSC/MST rear air tank tractor air

supply in. A double-check valve is located on the

pneumatic manifold.

2-15

Page 25

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

PARKING /EMERGENCY BRAKE SOLENOID

brake pods. This release of air pressure will cause the

parking/emergency brakes to be applied.

PARKING BRAKE PRESSURE SWITCH

A 24 VDC electrical solenoid that

opens or closes to control the

parking or emergency brake

function. The solenoid valve

responds to electrical signals as

commanded by the parking or

emergency brake in the tractor

cab. The solenoid valve will open to

bleed off parking/emergency

brake release pressure from the

A 24 VDC pressure switch used

to illuminate the parking brake

warning light in the tractor cab.

The sensor will turn on the

parking brake warning light

when parking brake release

pressure drops below allowable

limits.

BRAKE PODS

A pneumatic cylinder designed to extend or retract

and apply service, parking or emergency brakes. The

pods are mounted to the MSC/MST rear bogie and

are connected to the wheel group brake activation

lever. The pod contains a coil spring and responds to

pressure received from the brake relay valve as

commanded by service brake pedal. The pod will also

apply parking or emergency brakes when one side of

the cylinder is depressurized when commanded by

the activation of the parking or emergency brakes.

Lose of pneumatic pressure allows the brake pod coil

spring to extend the rod end.

SERVICE BRAKE RELAY VALVE

generated by activating the service brake pedal

located in the tractor cab.

A pneumatic relay that

controls and routes air

tank activation pressure

to both brake pods. The

relay controls air

pressure applied to the

brake pods as

commanded by a

pneumatic signal

THEORY OF OPERATION

Parking Brake

The parking brake is applied by activating the

parking brake switch in the tractor cab. Once the

switch is moved to the park position an electrical

signal is sent to the parking brake solenoid valve

mounted on the rear bogie pneumatic manifold.

The sent signal will open the solenoid valve allowing

pneumatic pressure to decrease from one side of the

brake pod. The brake pod coil spring can now

overcome air pressure and extend the brake pod rod

end attached to the wheel group brake lever and

apply the brakes. Once parking brake pneumatic

pressure drops below allowable limits, the parking

brake pressure switch mounted on the pneumatic

manifold will close and illuminate the parking brake

warning light in the cab of the tractor.

The parking brake is released by activating the

parking brake switch. Once the switch is moved an

electric signal is sent to close the parking brake

solenoid valve. The valve closing will allow

2-16

Page 26

SECTION 2

System Description

pneumatic pressure from the pneumatic manifold to

be routed to the brake pod. This pressure increase

will eventually overcome the brake pod coil spring

and retract the brake pod cylinder rod end attached

to the brake pod releasing the brakes. As pressure

increases above allowable limits, the parking brake

pressure switch will turn off the parking brake

warning light in the tractor cab once pressure is

above allowable limits.

Service Brake

The service brake is applied by pressing down on the

service brake pedal in the tractor cab. Pressing down

on the pedal will send a pneumatic pressure signal to

the service brake relay valve mounted on the rear

bogie. The sent signal will release pneumatic

pressure from the brake pod chamber allowing the

pod coil spring to extend the rod end and apply

service brakes.

MSC/MST-OPS-1

31 Dec 2013

The service brake is released by releasing the brake

pedal. Once the pedal released a pneumatic signal is

received by the brake relay to increase air pressure to

the brake pod. As pneumatic pressure increases the

force of the brake pod coil spring is overcome and

the service brake is released.

Emergency Brake

The emergency brake theory of operation is the same

as the parking brake except for the means of

activation. Activation is accomplished by using the

emergency brake foot switch located on the floor of

the tractor cab just left of the service brake pedal.

2-17

Page 27

MSC/MST-OPS-1

31 Dec 2013

SECTION 2

System Description

2-18 (Blank)

Page 28

SECTION 3

Limitations

Contents

Water Pump.......................................................................3-1

WATER PUMP

The following cautions are operational limitations of

Mega water pumps. Failure to heed these cautions

may result in reduced pump life and severe water

pump damage.

MSC/MST-OPS-1

31 Dec 2013

Water pump RPM must not exceed the specifications

listed below with engine at HIGH IDLE. Failure to

ensure water pump speed is at or below

specifications will result in reduced spray system

component service life.

Do not operate the water pump in a dry sump.

Operating the water pump with a dry sump will result

in water pump component damage and reduced

service life.

Engaging/disengaging the water pump above LOW

IDLE may result in water pump component damage

and reduced service life.

Limit water pump operation to 2.5 minutes when in a

no-flow condition (not flowing water through spray

heads, dump bar, water cannon, drain valve or hose

reel). Water pump operation in a no flow condition

will cause overheating of the water pump and

damage to the shaft bearings and seals.

PUMP MODEL RPM

M-3 PUMP 2350 ± 50

M-4 PUMP 1,900 ± 50

M-4B PUMP 2,000 ± 50

If water pump RPM is to out of the desired range,

adjust the water pump hydraulic drive motor flow

control valve to obtain specified RPM.

The suction loading pump has a maximum vertical

lift capability of 8-10 feet. Attempting to pump water

into the tank from a reservoir that is more than 8-10

feet below the pump station will result in reduced

suction loading performance.

Avoid any sudden stoppage of water pump e.g.;

disengaging water pump above LOW IDLE. Stopping

water pump suddenly above LOW IDLE will result in

shaft, impeller and drive motor damage.

3-1

Page 29

MSC/MST-OPS-1

31 Dec 2013

SECTION 3

Limitations

3-2 (Blank)

Page 30

SECTION 4

Normal Operations

Contents

MSC/MST-OPS-1

31 Dec 2013

Description.........................................................................4-1

Before Operations............................................................4-1

Operations..........................................................................4-1

DESCRIPTION

This section provides the vehicle operator with step

by step operating procedures for the installed

MSC/MST system. The information is separated into

before operations, operations, and after operations. A

pocket size checklist of all listed procedures is also

provided in the Appendix for use in the vehicle cab.

BEFORE OPERATIONS

These procedures are used to perform a walk-around

inspection of the MEGA water tanker system before

use or the beginning of a shift. This inspection is in

addition to and does not replace the vehicle

manufacturer’s inspection requirements.

1. Chocks – As Required

2. Vehicle Parking Brake – ON

3. Cab Control Switches – SET OFF

4. Bumper Spray Heads – SECURED & SET

5. Vehicle Hydraulic Tank – SERVICED

After Operations...............................................................4-5

Cold Weather Operation And Storage .....................4-5

10. Tank Drain Petcocks – CLOSED

11. Spray Heads – SECURED & SET

12. Water Pump Assembly – CHECKED

a. Water Pump – Check to ensure volute case

drain valve is closed.

b. Water pump and drive motor for evidence of

overheating.

13. Hose Reel – CHECKED

OPERATIONS

Use these procedures to safely operate the standard

and optional systems installed on the MEGA water

tanker.

Limit water pump operation to 2.5 minutes when in a

no-flow condition (not flowing water through spray

heads, dump bar, water cannon, drain valve or hose

reel). Water pump operation in a no flow condition

will cause overheating of the water pump and

damage to the shaft bearings and seals.

6. Gooseneck Lines & Hoses – CHECKED & SECURED

7. Solenoid Control Box – CHECKED AND SECURED

8. Water Cannon – CHECKED & SECURED

a. Nozzle – Check for security and kinking of

foam concentrate supply line.

9. (If Equipped) Foam Concentrate Level –

CHECKED. At least 1” from the top of the foam

tank.

Ensure PPE fall arrest harness is worn, adjusted

properly and attached to an anchor point. Failure

to use PPE properly may result in personnel injury

or death.

SPRAY HEAD SYSTEM

Operating more than 4 spray heads simultaneously

will greatly reduce the width and flow of active spray

heads.

1. Cab Control SYSTEM/POWER Switch – ON

2. INTERMITTENT TIMER – SET

a. TIMER ON/OFF Dials – SET

b. INTERMITTENT Switch – SET

3. PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

4-1

Page 31

MSC/MST-OPS-1

31 Dec 2013

SECTION 4

Normal Operations

4. Individual Spray Heads – SELECTED

Once operations are complete:

5. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

6. Cab Control SYSTEM/POWER Switch – OFF

GPS AUTO MODE

1. Cab Control POWER Switch – ON

2. PUMP Switch ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

3. PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

4. DUMP Bar Switch – ON

Once operations are complete:

5. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

6. Cab Control SYSTEM/POWER Switch – OFF

WATER CANNON

1. Cab Control SYSTEM/POWER Switch – ON

3. AUTO – SET AS REQUIRED

a. RATE and SPEED Dials – SET

b. AUTO Switch – ON

4. Individual Spray Head Switches – ON

Once operations are complete:

5. Individual Spray Head Switches – OFF

6. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

7. Cab Control POWER Switch - OFF

DUMP BAR

1. Cab Control SYSTEM/POWER Switch – ON

2. INTERMITTENT – SET AS REQUIRED

a. TIMER ON/OFF Dials – SET

b. INTERMITTENT Switch – SET

2. PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

3. Water Cannon – Pointed in a safe direction.

4. MONITOR/BFV Switch – ON

5. Water Cannon Joystick – As Required.

6. MONITOR/BFV Switch – OFF

Once operations are complete:

7. Water Cannon Nozzle - STOW

Manual and remote adjustable nozzles must be

stowed pointing vertically to reduce wear on

water cannon joints. Leaving the nozzle in any

other position will cause increased wear on water

cannon joints and result in premature joint

failure.

4-2

Page 32

Normal Operations

8. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

9. Cab Control SYSTEM/POWER Switch – OFF

FIRE SUPPRESSION SYSTEM

1. Cab Control SYSTEM/POWER Switch – ON

2. PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

3. Water Cannon – Pointed in a safe direction.

MSC/MST-OPS-1

31 Dec 2013

SECTION 4

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

12. Cab Control SYSTEM/POWER Switch – OFF

13. Vehicle – Wash or fresh water rinse areas exposed

to the foam spray.

TANK DRAIN

1. Cab Control SYSTEM/POWER Switch – ON

2. PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

4. FOAM Switch – ON

5. MONITOR/BFV Switch – ON

6. Water Cannon Joystick – As Required.

Once operations are complete:

7. FOAM Switch – OFF

8. Water Cannon – Flow water through the water

cannon nozzle with the FOAM switch off to flush

foam from the nozzle.

9. MONITOR/BFV Switch – OFF

10. Water Cannon Nozzle – STOW

Manual and remote adjustable nozzles must be

stowed pointing vertically to reduce wear on

water cannon joints. Leaving the nozzle in any

other position will cause increased wear on water

cannon joints and result in premature joint

failure.

11. PUMP Switch – OFF

3. DRAIN Switch – ON

4. Water Level – Drain to desired level.

Do not operate the water pump in a dry sump.

Dry running operation will cause water pump

failure.

Once operations are complete:

5. DRAIN Switch – OFF

6. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

7. Cab Control SYSTEM/POWER Switch – OFF

HOSE REEL

1. Hose Nozzle – CLOSED

2. Hose – Deploy desired length.

4-3

Page 33

MSC/MST-OPS-1

OPEN

CLOSED

CLOSED

OPEN

31 Dec 2013

SECTION 4

Normal Operations

3. Gate Valve – OPEN

4. Cab Control SYSTEM/POWER Switch – ON

5. PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

6. Vehicle RPM – SET

7. Hose Nozzle – OPEN as desired.

Once operations are complete:

8. Hose Nozzle – CLOSE

9. Vehicle RPM – LOW IDLE

10. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

6. Position all butterfly valves as indicated in the

following pictures and in the order as follows:

a. SUMP VALVE - CLOSE

b. SUCTION VALVE - OPEN

c. SPRAY BAR VALVE - CLOSE

d. TANK FILL VALVE - OPEN

11. (If Equipped) Cab Control SYSTEM/POWER

Switch- OFF

12. Gate Valve – CLOSED

13. Hose – Reel in and stow hose nozzle.

SUCTION LOAD STATION

1. Place vehicle near water holding pond.

2. Secure vehicle and make unit safe for exiting cab.

3. Foot Valve – Serviceable

4. Suction Hoses – Inspect suction hoses for

serviceability. Ensure suction hoses are

connected properly to each other and the suction

load inlet to prevent air leaks while in use.

5. Suction Hoses – Immerse in water supply.

The suction loading pump has a maximum

vertical lift capability of 8-10 feet. Attempting to

pump water into the tank from a reservoir that is

more than 8-10 feet below the pump station will

result in reduced suction loading performance.

Opening and closing valves in this sequence

allows the water in the suction loading sump

built inside of the tank to flood the water pump

and suction hose. This will allow water pump to

lift water from pond.

7. Ensure water pump and suction hoses are full of

water before operating pump.

Operating the water pump in a dry sump will

result in shaft seal damage.

4-4

Page 34

SECTION 4

Normal Operations

MSC/MST-OPS-1

31 Dec 2013

8. Ensure foot valve remains submerged in water.

9. Start chassis engine.

10. At LOW IDLE turn SYSTEM/POWER switch ON.

11. (DiSCS Only) AUX2 - ON

12. Turn PUMP Switch – ON

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

13. Increase engine RPM to HIGH IDLE.

When unit is full of water

14. Reduce engine RPM to LOW IDLE.

3. Chocks – As Required

4. Bumper Spray Heads – SECURED & SET

5. Gooseneck Hoses & Lines – CHECKED & SECURED

6. Solenoid Control Box – CHECKED

7. Water Cannon – CHECKED & SECURED

8. Vehicle Hydraulic Tank - CHECKED AS REQUIRED

9. Tank Drain Petcocks – As Required.

10. Tank Lines and Hoses – SECURED

11. Spray Heads – SECURED & SET

12. Water Pump – CHECKED

a. Water Pump – Check for damage and volute

case drain valve set as required.

15. PUMP Switch – OFF

Engaging/disengaging the water pump above

LOW IDLE may result in water pump component

damage and reduced service life.

16. AUX2 - OFF

17. SYSTEM/POWER Switch OFF.

18. Turn engine OFF.

19. Disconnect, drain and stow suction hoses.

AFTER OPERATIONS

These procedures are used to perform a walk-around

inspection after using the MEGA water tanker

systems. This inspection is in addition to and does

not replace the vehicle manufacturer’s inspection

requirements.

1. Vehicle parking brake – ON

2. Cab Control Switches – SET OFF

13. Hose Reel – CHECKED

COLD WEATHER OPERATION AND STORAGE

Ice will cause serious damage to water pump, spray

heads, butterfly valves, water-to-oil cooler, and the

water cannon if water is allowed to freeze in the

volute case, water piping, or on top of a closed

butterfly valve. Ensure all water is drained from

system when the temperatures are expected to fall

below 4.4°C (40°F) for any period of time. Failure to

ensure all systems are drained and free from standing

water will result in shaft, operator, diaphragm, drive

motor, water pump, or butterfly valve damage when

operation is attempted with ice in the housings.

To ensure all water is drained from tank check the

following:

1. Park unit on a slight nose up angle to allow water

to flow to the rear of the tank.

2. Drain the tank using an appropriate method until

the Water Level Gauge reads EMPTY.

4-5

Page 35

MSC/MST-OPS-1

31 Dec 2013

SECTION 4

Normal Operations

3. Open all drain petcocks (water pump, spray bars,

etc.).

4. Remove water pump sump cover.

5. Start engine.

6. Cab Control SYSTEM/POWER Switch – ON

7. MONITOR/BFV Switch – ON

8. DUMP BAR Switch – ON

9. DRAIN Switch – ON

10. Water Cannon Nozzle – Pointed fully DOWN

11. Turn engine off.

12. Cab Control SYSTEM/POWER Switch – OFF

13. Hose Reel – DRAIN

a. Hose – UNWIND

b. Nozzle – Fully OPEN

c. Gate Valve – OPEN

d. Allow water to drain.

e. Hose – REWIND

f. Gate Valve – CLOSED

g. NOZZLE – CLOSED

7. Individual Spray Head Switches – OFF

8. DUMP BAR Switch – OFF

9. DRAIN Switch – OFF

10. MONITOR/BFV Switch – OFF

11. Turn engine off.

12. Cab Control SYSTEM/POWER Switch – OFF

14. Check to ensure all water has drained from tank.

TO REACTIVATE UNIT:

1. Lubricate water pump bearings as instructed in -2

technical manual.

2. Inspect tank interior to ensure it is clean, if the

tank is coated, ensure coating integrity, clean or

repair as required.

3. Install sump cover with new gasket.

4. Close all drain valves and petcocks.

5. Start engine.

6. Control SYSTEM/POWER Switch – ON

4-6

Page 36

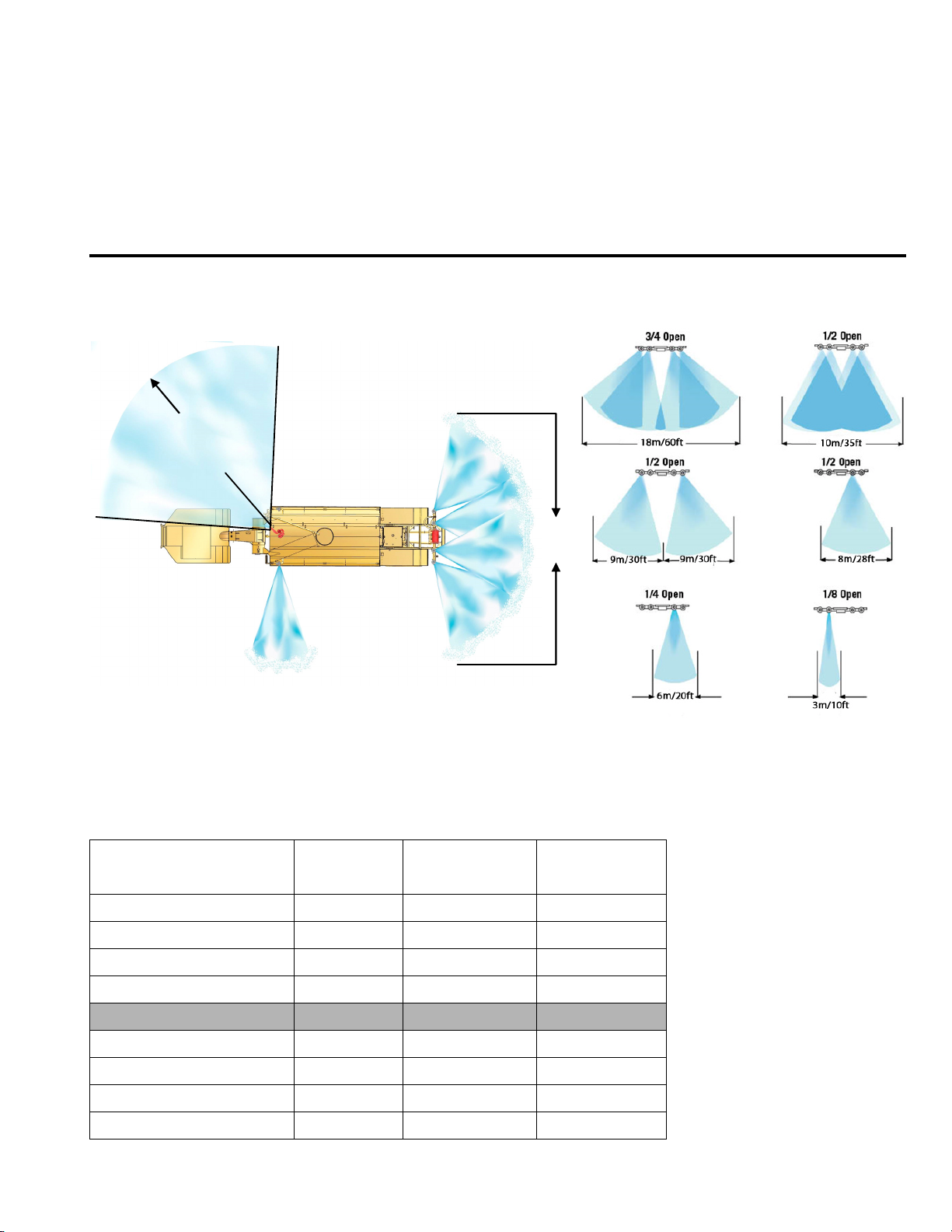

SECTION 5

36 - 57 meters

120 - 190 feet

90 degrees

60 feet

18 meters

Performance

Contents

MSC/MST-OPS-1

31 Dec 2013

Spray Pattern and Reach .............................................5-1

Typical Spray System Duration ..................................5-1

Precision Watering ........................................................5-2

Fire Suppression System .............................................5-7

SPRAY PATTERN AND REACH (TYPICAL 9’ SPRAY BAR)