MEGA Corp. MPT User Manual

GENUINE MEGA.

MPT

MEGA PORTABLE TANK

TECHNICAL MANUAL

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

MPT12 Manual

26 Mar 2014

TABLE OF CONTENTS

Page

Section 1 Definitions and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Section 2 System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Section 3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section 4 Operation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Section 5 Maintenance and Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Section 6 Scheduled Maintenance Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Section 7 Recommended Support Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Section 8 Illustrated Parts Breakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Section 9 Appendix: Installation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-A

A

MPT12 Manual

26 Mar 2014

TABLE OF CONTENTS

B (Blank)

SECTION 1

Definitions and Abbreviations

Contents

MPT12 Manual

26 Mar 2014

Manual Usage ...................................................................1-1

Warning, Caution And Notes ......................................1-1

Use Of Shall, Will, Should And May ...........................1-1

MANUAL USAGE

This technical manual only contains information

required to safely operate and maintain the Mega

Portable Tank. If your system is not covered in this

manual please contact MEGA Corp. Product Support

at: 1-800-345-8889 or visit our website at

www.megacorpinc.com for more detailed

information.

The exact location of the hazards and description of

the hazards are reviewed in this section. All personnel

working on or operating the machine must become

familiarized with all the safety messages.

Due to the nature of these processes, ensure that all

safety information, warnings and instructions are

read and understood before any operation or any

maintenance procedures are performed. Some

procedures take place with heavy components and

at moderate heights, ensure proper safety

procedures are maintained when performing these

actions. Failure to use and maintain proper safety

equipment and procedures will cause injury, death or

damage to equipment.

Safety Messages ..............................................................1-2

Abbreviations ...................................................................1-3

MPT Overview (Typical) ................................................1-4

WARNING, CAUTION AND NOTES

The following definitions are found throughout the

manual and apply as follows:

Operating procedures and techniques, which could

result in personal injury and/or loss of life if not

carefully followed.

Operating procedures and techniques, which could

result in damage to equipment if not carefully

followed.

Operating procedures and techniques that are

considered essential to emphasize.

USE OF SHALL, WILL, SHOULD AND MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a procedure is

recommended.

May - Used to indicate an acceptable or suggested

means of accomplishment.

1-1

MPT12 Manual

26 Mar 2014

SECTION 1

Definitions and Abbreviations

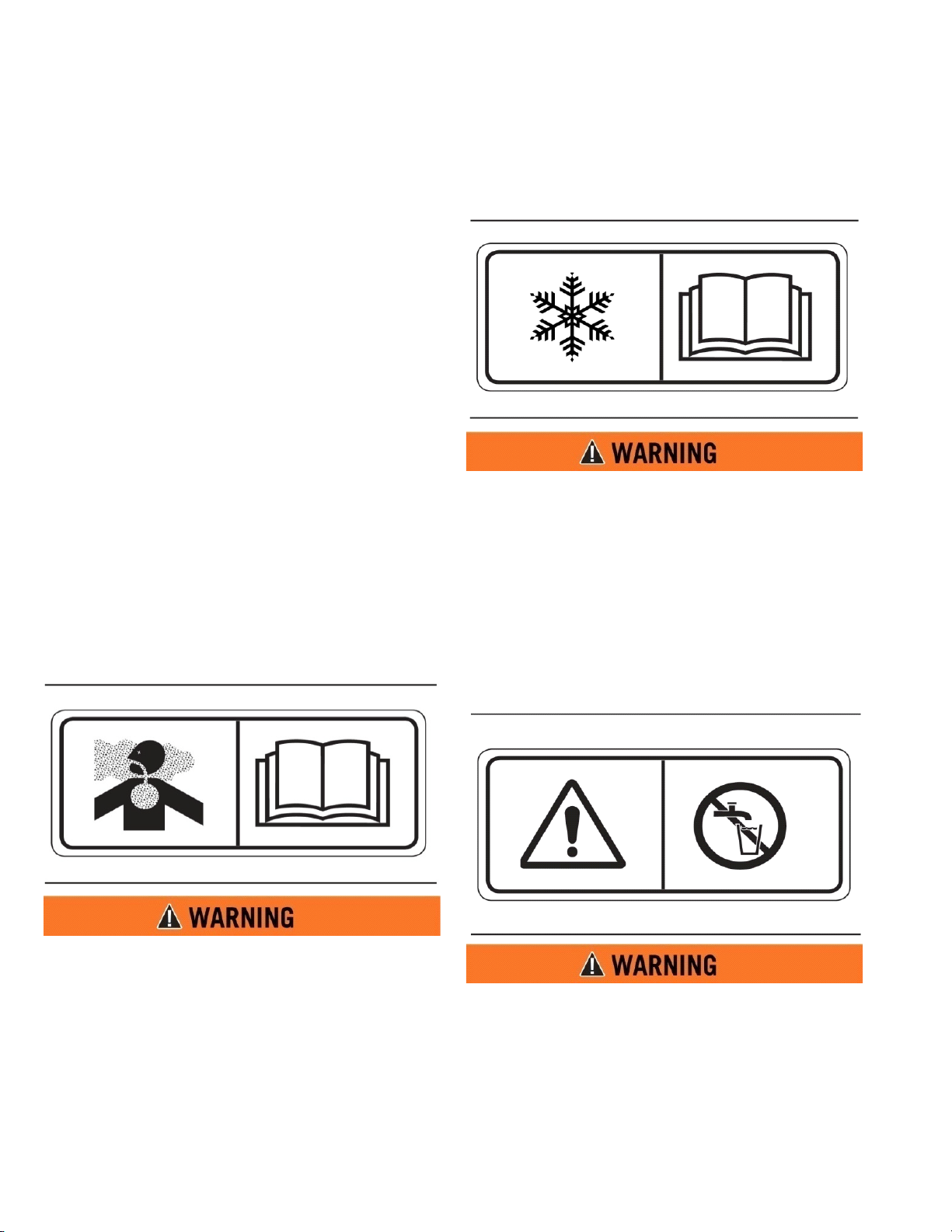

SAFETY MESSAGES

There are several specific safety messages applicable

to this machine. Some of these safety messages have

associated warning labels located on the machine.

The descriptions of the hazards and the locations (if

applicable) of their warning labels are reviewed in

this section. All personnel working on or operating

the machine must become familiarized with all the

safety messages.

Make sure that all of the safety labels are legible.

Clean or replace the safety labels if you cannot read

the words. Replace the illustrations if the illustrations

are not legible. When you clean the safety labels, use

a cloth, water and soap. Do not use solvent, gasoline

or other harsh chemicals to clean the safety labels.

Solvents, gasoline or harsh chemicals could loosen

the adhesive that secures the safety labels. Loose

adhesive will allow the safety labels to detach.

Replace any safety label that is damaged or missing.

If a safety label is attached to a part that is replaced,

install a new safety label on the replacement part.

FREEZING (2)

This safety label is located on the front of the

machine, by the discharge pipe..

Drain tank, fill pipe, and drain valve in freezing

weather. Refer to the Operator and Maintenance

Manual for the procedure to follow.

TOXIC GAS HAZ ARD ( 1)

Cutting or welding operation on the inside of the

tank can cause the accumulation of toxic gases.

Read and understand instructions and warnings

in the Maintenance Manual. Failure to provide

proper ventilation or breathing apparatus while

conducting these operations may result in serious

injury or death.

NON-POTABLE (3)

This safety label is located at the rear of the tank, near

the ladder.

Water held within tank is not potable. Do not use

tank for transport of water intended for human or

animal consumption or serious injury or death

may result.

1-2

SECTION 1

Definitions and Abbreviations

MPT12 Manual

26 Mar 2014

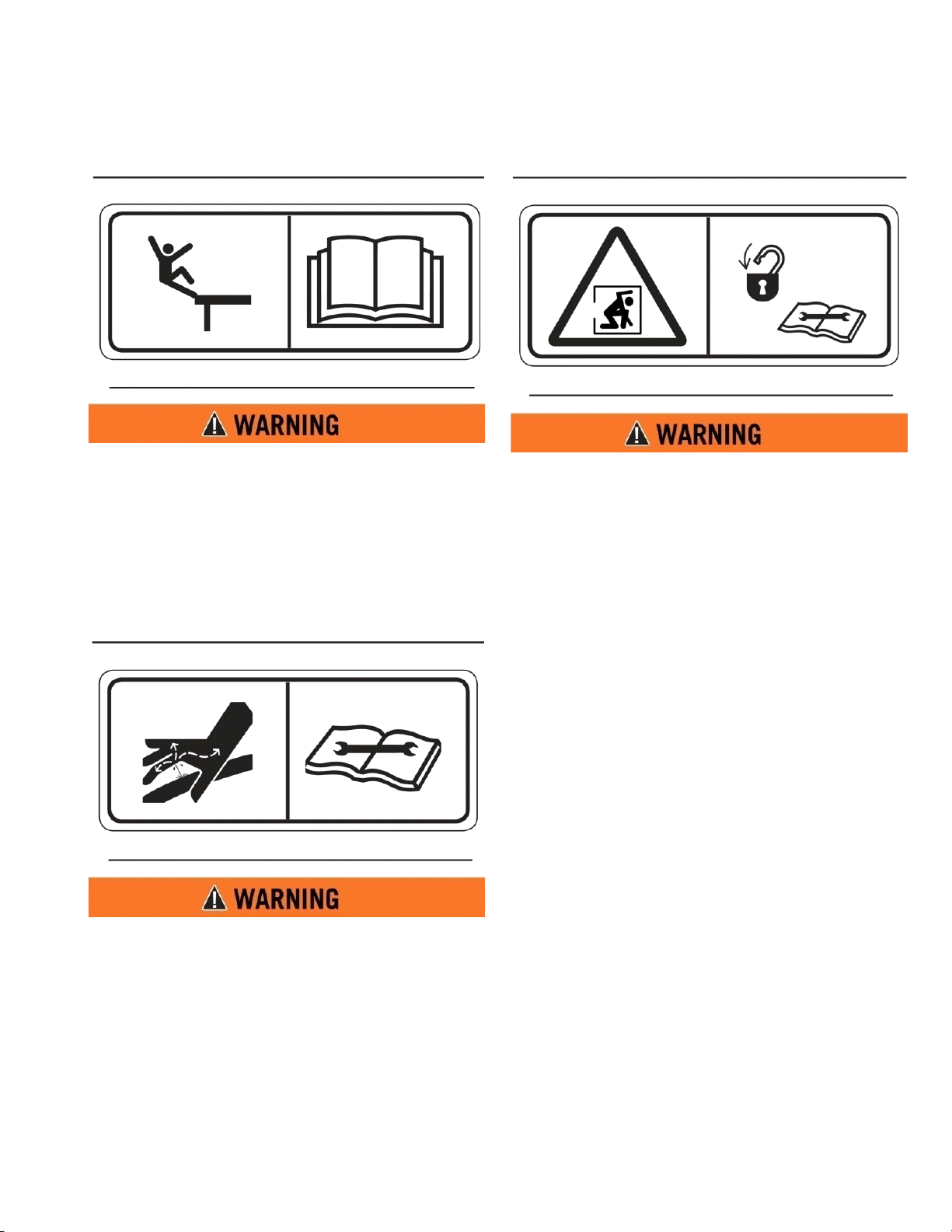

FALL HAZARD (4)

Do not walk on the top of tank without fall arrest

PPE. Serious injury or death could occur from a

fall.

HIGH PRESSURE MOTOR (5)

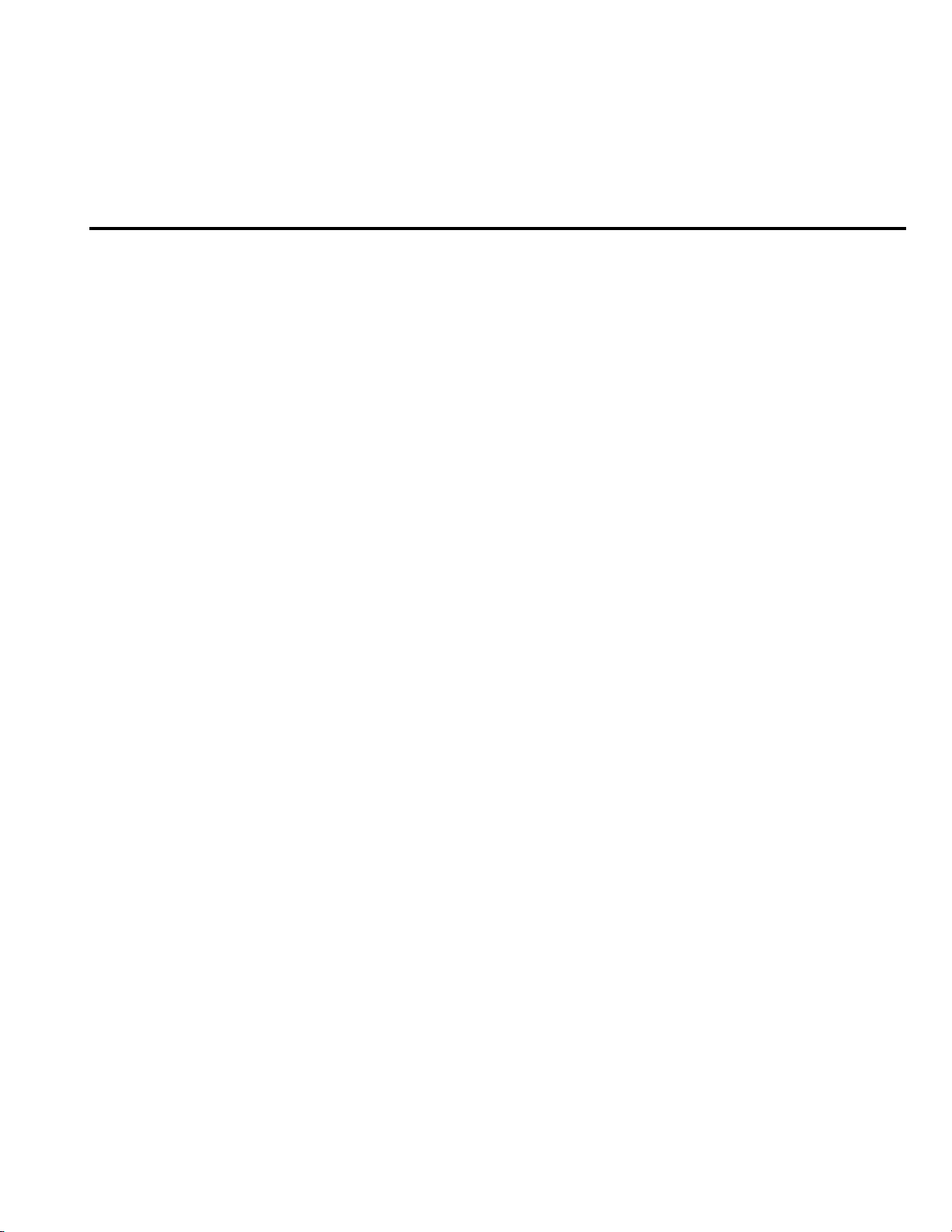

CONFINED SPACE (6)

Do not enter confined spaces without following

established site specific procedures. Failure to

follow proper safety procedures will result in

serious injury or death.

ABBREVIATIONS

BFV - Butterfly Valve

CCW - Counterclockwise

CW - Clockwise

FIP - Fault Isolation Procedures

Ft-lbs - Foot Pounds of Torque

GPM - Gallons per Minute

IPB - Illustrated Parts Breakdown

LT - Left (as viewed from the rear of the

vehicle looking forward)

MPT - Mega Portable Tank

n-m - Newton Meters of Torque

PSI - Pounds per Square Inch

RT - Right (as viewed from the rear of the

vehicle looking forward)

RPM - Revolutions per minute

Hydraulic motor and supply lines contain oil

under high pressure. Improper removal and

repair procedures could cause severe injury. To

remove or repair, instructions in the Maintenance

Manual must be followed.

1-3

MPT12 Manual

8

1

5

2

4

6

1

HYDRAULIC CYLINDERS

2

ENGINE & HYDRAULIC PUMP

3

LEVER CONTROL SYSTEM

4

FILL PIPE

5

FILL PIPE VALVE

6

ACCESS LADDER

7

TOOL BOX

8

DISCHARGE TUBE

9

D.O.T. LIGHTS

10

HYDRAULIC TANK

REAR VIEW

SIDE VIEW

1

1

3

7

5

4

6

9 9

9

10

10

26 Mar 2014

SECTION 1

Definitions and Abbreviations

MPT OVERVIEW (TYPICAL)

1-4

SECTION 2

System Description

Contents

MPT12 Manual

26 Mar 2014

Description.........................................................................2-1

MPT Tank .............................................................................2-1

Self-Raising System .........................................................2-1

DESCRIPTION

The Mega Portable Tank (MPT) is a 12,000 gallon

platform or stand tank designed for towing with a

fifth-wheel on-highway tractor. The Mega MPT is

used to rapidly fill water distribution equipment to

maximize productivity. All Mega MPTs are selferecting by use of an engine-driven hydraulic pump

and hoist cylinders with pin locks. Mega MPTs have a

12 inch diameter discharge pipe capable of filling a

5,000 gallon tank in approximately 2 minutes. The

MPT can be filled from a municipal water source or

with other water pumping equipment. The 3” fill pipe

is equipped with an automatic shut off to prevent

overfilling.

Water Discharge System ............................................... 2-2

Axle .......................................................................................2-2

MPT TANK

The MPT tank is 2.59m (8.5 ft) in diameter, 11.13m

(36.5 ft.) in length, and has a capacity of 45.42 L

(12,000 gallons). The corners of the tank are

reinforced to provide sturdy connection to supports.

An access ladder leading to the top of the tank is

located at the rear of the trailer, and a ladder is

located inside of the tank. An 8” diameter float is

located inside of the tank for automatic fill shut-off

when the tank is full.

SELF-RAISING SYSTEM

The MPT’s self-raising system incorporates dual

hydraulic cylinders and a 6.5 horsepower engine with

a hydraulic pump.

HYDRAULIC CYLINDERS

The MPT is designed to comply with all Department

of Transportation requirements, and is available in

custom colors and with special signage as specified

by the customer. For more information, please

contact the Mega Sales Department at 1-800-3458889, or contact your local dealer.

Dual 127mm (5 inch) diameter double-acting

hydraulic cylinders that allow the tank to be raised for

connection to a tractor. The frame can be lifted with

the same cylinders after tractor hook-up is complete.

2-1

MPT12 Manual

26 Mar 2014

SECTION 2

System Description

ENGINE

A 6.5 horsepower engine and hydraulic pump that is

mounted on the base of the MPT. The engine is

equipped with a handle for removal and storage after

the tank has been locked in the raised position. Quick

disconnects for the lines to the hydraulic pump are

located on the structure for storage of the hydraulic

hoses after the motor/pump package is removed.

WATER DISCHARGE SYSTEM

The MPT’s water discharge system includes a 10 inch

diameter discharge pipe with a flow rate of

approximately 2,000 gal/min, a shut-off valve with a

constant force wheel to ensure positive closure, a

weight and pulley system to secure the chain while

positioning the tanker beneath the discharge pipe

spout, and a canvas discharge sock for the discharge

pipe spout.

PIN HANDLER

The Mega Pin Handler is a tool that allows a person to

install and remove all six (6) MPT hitch pins while

standing at ground level, eliminating the need for a

ladder and saving time in the process.

AXLE

The heavy-duty utility axle has a 25,000 lb. capacity

with an oil-lubricated bearing and auto slack

adjusters. It is the highest strength axle tube

generally available for utility vehicle axles. The

materials used allow for a stiffer and stronger axle

beam with no camber required.

The axle utilizes electro-hydraulic air braking. The

backing plate of the hydraulic brake mounts onto the

piloted axle brake flange, allowing the brakes to

perform at their optimum effectiveness.

2-2

SECTION 3

Commissioning

Contents

Description.........................................................................3-1

DESCRIPTION

The following section details the test procedure steps

required for inspection of the stand tank prior to

placing the stand tank into service. If you are having

difficulties with these procedures, please contact The

MEGA Corp. Product Support Group at: U.S. Toll Free

1-800-345-8889 or Direct 1-505-345-2661 or visit our

website at www.megacorpinc.com for more contact

information.

1. Check hydraulic oil level.

MPT12 Manual

26 Mar 2014

2. Check oil level in wheel hubs.

3. Check engine oil & fuel.

4. Start engine.

5. Remove locking pins.

6. Raise tank until pin hoist clears top pinhole.

7. Lower tank& replace locking pins.

8. Butterfly in closed position.

9. Fill with water.

10. Pull up on float, adjust valve until water flow

shuts off

11. Fill tank to check operation of float.

12. Drain water back into main supply.

13. Tie down float, toolbox, and hydraulic tank cap.

3-1

Loading...

Loading...