Page 1

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

Scheduled/Special

Inspections & Recommended

Support Parts

MMP4-5

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

Page 2

13 Feb 2012

TABLE OF CONTENTS

Page

Definitions & Abbreviations …………………………..……………………………………. 1-1

Scheduled Inspections …………………………………………….…………………………. 2-1

Special Inspections ……………………………………..……………………………………. 3-1

Recommended Support Parts …………………………………………..……………………. 4-1

MMP4-5

A

Page 3

B(Blank)

Page 4

SECTION 1

Definitions and Abbreviations

Contents

Warning, Cautions & Notes …..…………... 1-1

Shall, Will, Should and May ..……………. 1-1

Safety Messages ..............………………… 1-1

MMP4-5

13 Feb 2012

Abbreviations …………………………...... 1-5

Overview …………………………………. 1-7

MANUAL USAGE

This technical manual only contains parts

information required to service an MMP4

powered by a CAT 3054B diesel engine. See the

appropriate Parts Manual for specific engine

information and maintenance procedures. The

exact location of the hazards and description of

the hazards are reviewed in this section. All

personnel working on or operating the MMP4

must become familiarized with all the safety

messages.

If your system is not covered in this manual

please contact MEGA Corp. Product Support

Group at:

US toll free: 1-800-345-8889

Direct: 1-505-345-2661 or visit our website at

www.megacorpinc.com for more detailed

contact information.

See the proper manufacture specific Operation &

Maintenance, Safety Manuals and Service

Manuals for detailed chassis specific system

information and chassis specific maintenance

procedures.

Due to the nature of these processes, ensure that

all safety information, warnings and instructions

are read and understood before any operation or

any maintenance procedures are performed.

Some procedures take place with heavy

components and at moderate heights, ensure

proper safety procedures are maintained when

performing these actions. Failure to use and

maintain proper safety equipment and procedures

will cause injury, death or damage to equipment.

WARNING, CAUTION AND NOTES

The following definitions are found throughout

the manual and apply as follows:

Operating procedures and techniques, which

could result in personal injury and/or loss of life

if not carefully followed.

Operating procedures and techniques, which

could result in damage to equipment if not

carefully followed.

Operating procedures and techniques that are

considered essential to emphasize.

USE OF SHALL, WILL, SHOULD

AND MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a procedure

is recommended.

May - Used to indicate an acceptable or

suggested means of accomplishment.

1-1

Page 5

MMP4-5

13 Feb 2012

Definitions and Abbreviations

SAFETY MESSAGES

There are several specific safety messages on

this machine. The exact location of the hazards

and description of the hazards are reviewed in

this section. All personnel working on or

operating the machine must become familiarized

with all the safety messages.

Make sure that all of the safety messages are

legible. Clean the safety messages or replace the

safety messages in you cannot read the words.

Replace the illustrations if the illustrations are

not legible. When you clean the safety

messages, use a cloth, water and soap. Do not

use solvent, gasoline or other harsh chemicals to

clean the safety messages. Solvents, gasoline or

harsh chemicals could loosen the adhesive that

secures the safety messages. Loose adhesive

will allow the safety messages to detach.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part

that is replaced, install a new safety message on

the replacement part.

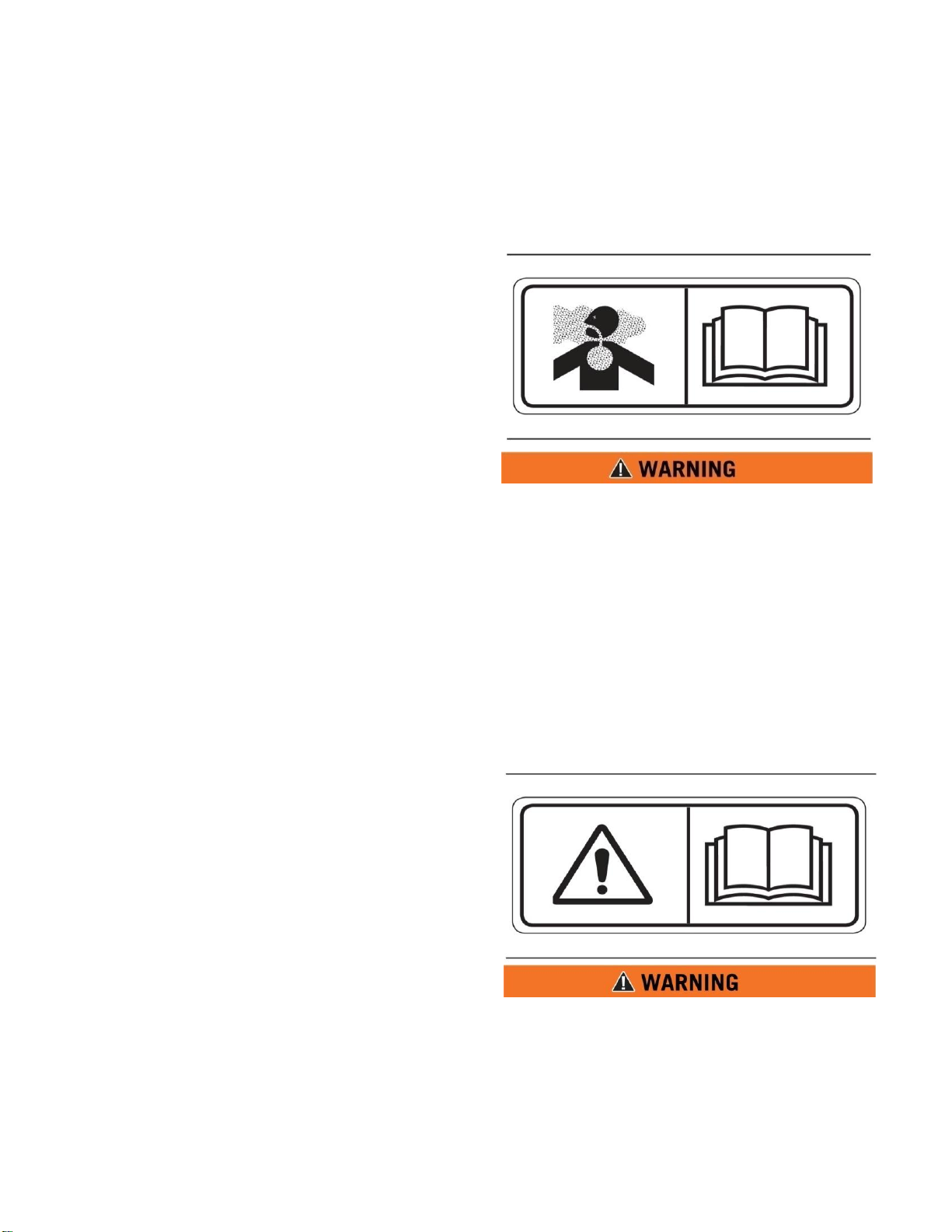

SECTION 1

Toxic Gas Hazard (1)

This safety label is located on the side of the tank

and at all water fill entrances.

Cutting or welding operation on the inside of

the tank can cause the accumulation of toxic

gases. Read and understand instructions and

warnings in the Maintenance Manual.

Failure to provide proper ventilation or

breathing apparatus while conducting these

operations may result in serious injury or

death.

Do Not Operate (2)

This safety label is located on the outside of the

front and rear control boxes. (If equipped)

Do not open this control box unless you read

and understand the instructions and warnings

in the Operator and Maintenance Manual.

Failure to follow instructions or heed the

warnings could result in serious injury or

death.

1-2

Page 6

SECTION 1

Definitions and Abbreviations

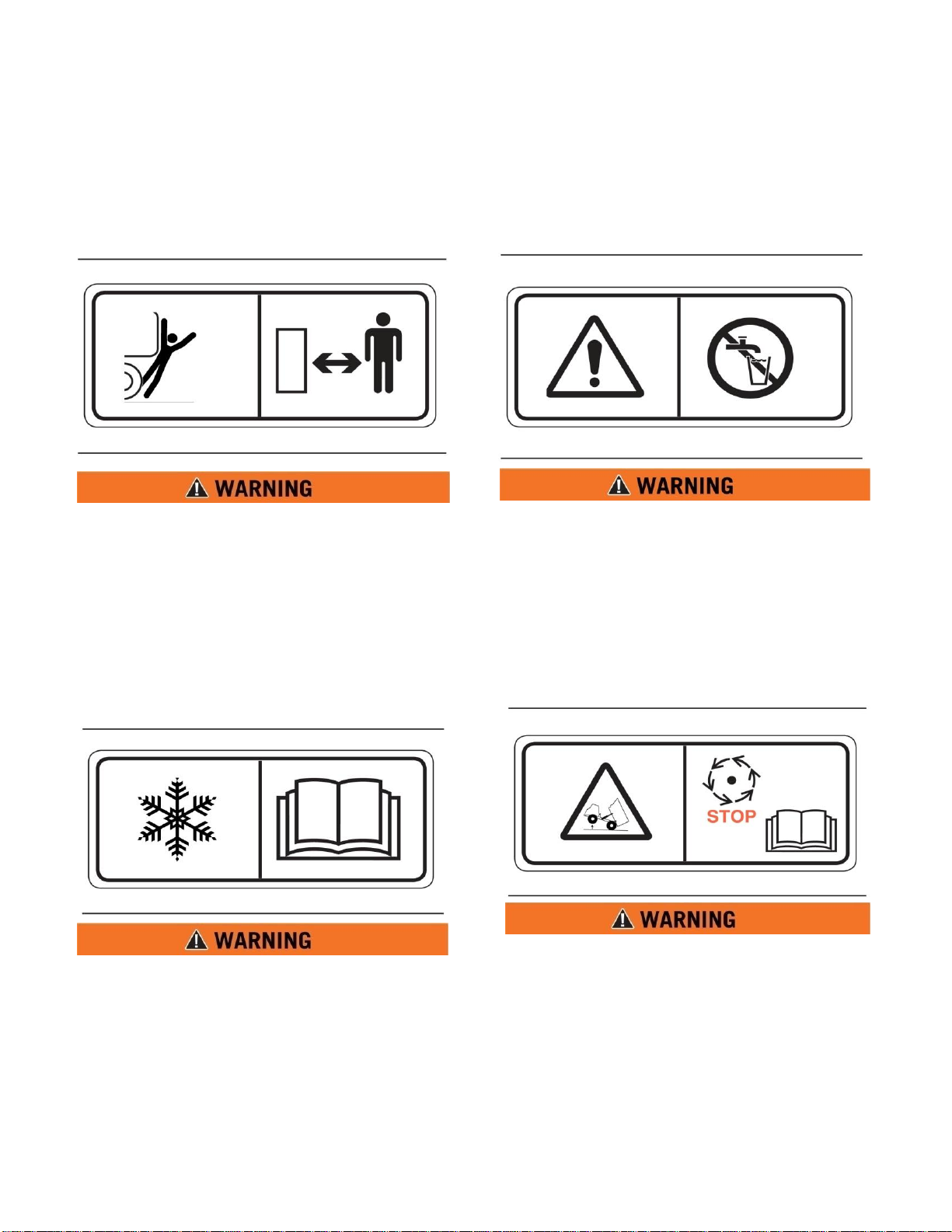

Backing Runover Hazard (3)

This safety label is located on the rear of the tank

and inside the cab.

The vehicle is equipped with a back-up alarm.

Alarm must sound when operating this

vehicle in reverse. Failure to maintain a clear

view in the direction of travel could result in

serious injury or death.

Freezing (4)

This safety label is located on the side of the

tank, at the sump drain, and on the pump.

Drain tank, fill pipe and valve in freezing

weather. Refer to the Operator and

Maintenance Manual for the procedure to

follow.

MMP4-5

13 Feb 2012

Non-Potable (5)

This safety label is located on the side of the tank

and sump drain.

Water held within tank is not potable. Do not

use tank for transport of water intended for

human or animal consumption or serious

injury or death may result.

Do Not Hoist While in Motion (6)

This safety label is located inside the cab.

Do not engage hoist cylinders while vehicle is

in motion. Before engaging hoist STOP the

vehicle. Do not engage hoisting cylinders

unless you read and understand the

instructions and warnings in the Operator or

Maintenance Manual. Failure to follow

instructions or heed the warnings will result

in injury or death.

1-3

Page 7

MMP4-5

13 Feb 2012

Definitions and Abbreviations

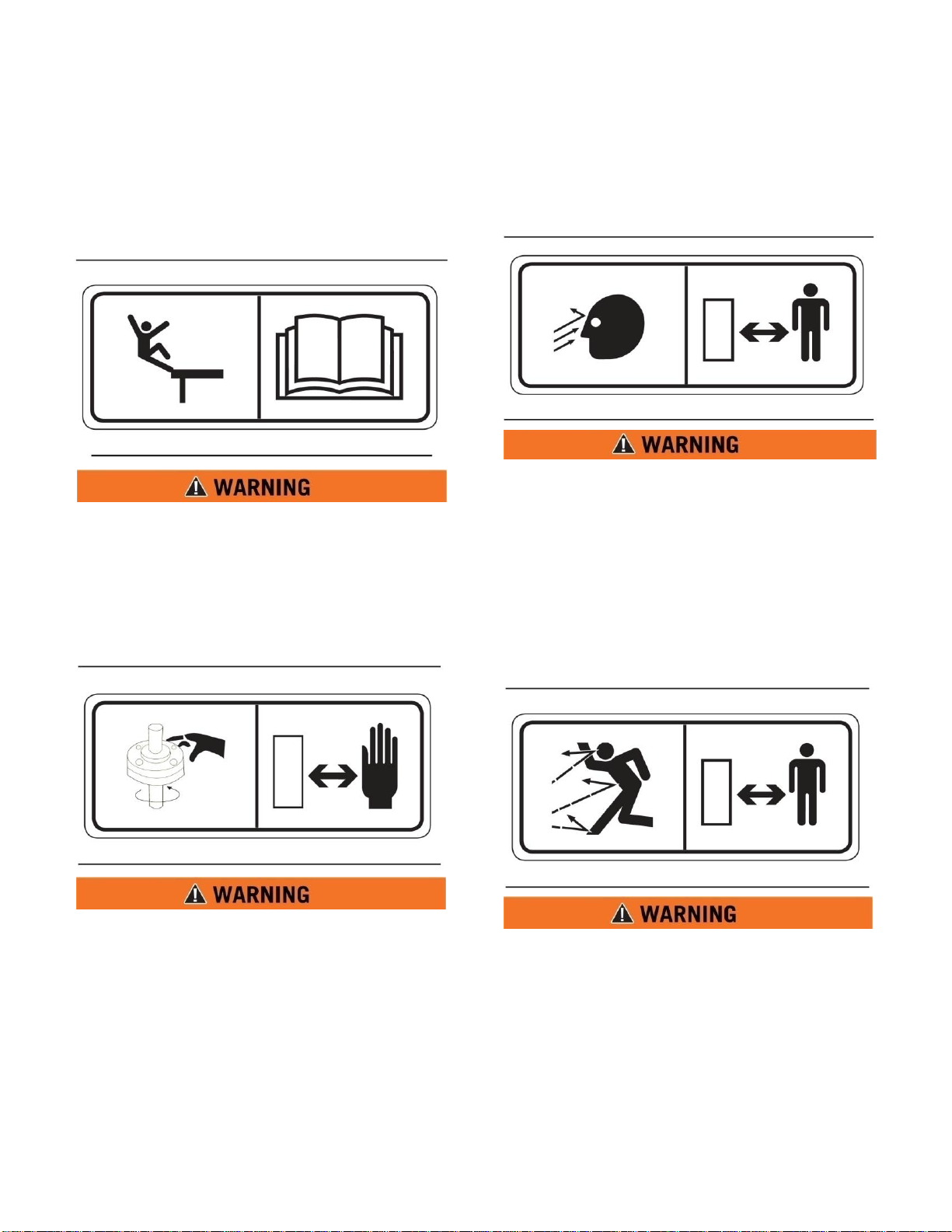

Fall Hazard (7)

This safety label is located at the top of the front

and rear of the tank.

Do not walk on the top of tank without fall

arrest PPE. Serious injury or death could

occur from a fall.

Rotating Shaft (8)

This safety label is located on the pump.

Do not place your hand or tools within pump

bell while pump is rotating and/or pressure

held within the motor supply hose. Refer to

the Operator and Maintenance Manual for

the procedures to operate and maintain the

pump. Failure to follow proper procedures

could result in serious injury.

SECTION 1

High Pressure Sprayheads (9)

This safety label is located on the spraybar.

Do not operate sprayheads until all personnel

are a safe distance away from the vehicle.

High Pressure Monitor (10)

This safety label is located on top of the cab

control box.

Do not operate the monitor until all personnel

are a safe distance away from the vehicle.

1-4

Page 8

SECTION 1

Definitions and Abbreviations

High Pressure Motor (11)

This safety label is located on the hydraulic

motor.

Hydraulic motor and supply lines contain oil

under high pressure. Improper removal and

repair procedures could cause severe injury.

To remove or repair, instructions in the

Maintenance Manual must be followed.

Confined Space (12)

This safety label is located near water tank

access and fill ports.

Do not enter confined spaces without

following established site specific

procedures. Failure to follow proper safety

procedures will result in serious injury or

death.

MMP4-5

13 Feb 2012

ABBREVIATIONS

BFV – Butterfly Valve

cc – Cubic Centimeters

CCW – Counter Clockwise

CW - Clockwise

fl. oz. – Fluid Ounce

FT - Feet

FPM – Feet Per Minute

GPM – Gallons Per Minute

IN/SQ FT – Inches per Square Feet

KM-H – Kilometers Per Hour

Kg – kilograms

Kpa - Kilopascals

l – liters

lpm – Liters per minute

LT – Left as viewed from the operators

position

facing forward

m - meters

MPH – Miles Per Hour

MTT – Mega Truck Tank

Nm – Newton meters of torque

psi - pounds per square inch

RPM – Revolutions Per Minute

RT – Right as viewed from the operators

position facing forward

SQ FT – Square Feet

VDC – Volts, Direct Current

1-5

Page 9

MMP4-5

13 Feb 2012

SECTION 1

Definitions and Abbreviations

1-6(Blank)

Page 10

Definitions and Abbreviations

1

Discharge Boom

13

Water Pump, Axial, 12”

2

Hinge Pin (2 required)

14

Intake Guard Plate

3

Flange Gasket (2 required)

15

Battery Box

4

Jack Stand (3 required)

16

Hitch Pins, 1” (2 required)

5

Hydraulic Control Valve with handles

17

Coupler, 2 5/16”

6

Control Valve mounting plate

18

Water Pump Gasket, 12”

7

Victaulic Coupling, 12”

19

CAT 3054 Engine assembly

8

Intake Boom

20

Guard, Radiator

9

Tail Light (2 required)

21

Fuel Tank Assembly

10

Fender (1 Right hand)(1 Left Hand)

22

Tire and Rim Assembly

11

Marker Light (2 Red)(4 Amber)

23

Axle Assembly

12

Filter, Hydraulic, 400 psi

MMP 4 GENERAL OVERVIEW

MMP 4 Basic View

MMP4-5

13 Feb 2012

SECTION 1

1-7

Page 11

MMP4-5

1

Discharge sock, tapered

7

Hydraulic Tank Assembly

2

Cylinder, Discharge Boom

8

Cylinder, Inlet Boom

3

Hitch Pin, 1”, Boom Lock (2 required)

9

Marker Light, (2 Red)(4 Amber)

4

Boom, Safety Chain (2 required)

10

Tail Light, (2 required)

5

Safety Chain, Hitch (2 required)

11

Victaulic Coupling, 12”

6

Hydraulic Oil Level Gauge

12

Hydraulic Control Valve with Handles

MMP 4 Basic Rear View

13 Feb 2012

SECTION 1

Definitions and Abbreviations

1-8

Page 12

MMP4-5

FREQUENCY

STEP

FRAME

DAILY

WEEKLY

250 HOURS

OR SEMI

ANNUALLY

500 HOURS

OR

ANNUALLY

1000

HOURS

2000

HOURS

1

Check Frame, Landing gears, Hitch

Assembly and Fenders for cracks and

security.

X

2

Check Axle, Springs, U-Bolts, Spring

mounting hardware for cracks, security and

missing parts.

X

3

Check Safety Chains and restraining

hardware for security and missing parts.

X

4

Check Lug nut torque (80 - 90 ft/lbs), Tire

Pressure and Condition.

BEFORE EVERY MOVEMENT OF MMP4 TRAILER

5

Check Lighting, Hitch assembly, Brakes,

Wheel seals, Hitch Pins, Boom securing

devices, Coupling device and safety Chains.

BEFORE EVERY MOVEMENT OF MMP4 TRAILER

6

Replace Wheel Bearing Lube.

X

STEP

CAT 3054 ENGINE

Refer to the Caterpillar SEBU7276-01 3054B Industrial Engine Manual for Caterpillar

Engine specific maintenance guidelines and parts.

1

Check Engine Oil Level, Engine Fuel Level

and Coolant Level.

X

2

Change Engine Oil and Filter

X

13 Feb 2012

SECTION 2

Scheduled Inspections

Contents

Description ……………………………. 2-1

Frame …..….………….……………….. 2-1

3054B Engine ……..………………..…. 2-1

.

DESCRIPTION

This section establishes scheduled maintenance inspections of a MMP4 powered by a CAT 3054B

diesel engine at the designated frequencies. Performing these inspections will identify potential system

discrepancies and allow preventative maintenance to be performed before a component or system is

rendered totally inoperative.

** NOTE: MMP4’s operated in extremely low quality water environments may require more frequent

inspections.

Hydraulic System ……………………... 2-2

Control System ………………..………. 2-3

2-1

Page 13

MMP4-5

FREQUENCY

STEP

HYDRAULIC SYSTEM

DAILY

WEEKLY

250 HOURS

OR SEMI

ANNUALLY

500 HOURS

OR

ANNUALLY

1000

HOURS

2000

HOURS

1

Check Hydraulic Oil Level.

X

2

Change Hydraulic Oil Filter.

X

3

Change Hydraulic Oil.

X

4

Check Water Pump Lube Reservoirs.

X

5

Grease Suction Bowl Reservoir..

X

6

Check Hydraulic Hoses and Fittings for

Security and Leaks.

X

7

Change Oil in Both water Pump Oil

Reservoirs.

X

8

Check For Hydraulic Oil Leaks

X

9

Check For Water Leaks

X

10

Check Hydraulic Pump for Security and

Leaks.

X

13 Feb 2012

SECTION 2

Scheduled Inspections

2-2

Page 14

MMP4-5

FREQUENCY

STEP

CONTROL SYSTEM

DAILY

WEEKLY

250 HOURS

OR SEMI

ANNUALLY

500 HOURS

OR

ANNUALLY

1000

HOURS

2000

HOURS

1

Check MURPHY Switch for proper

Operation.

X

2

Check Throttle control for Proper Engine

RPM’s.

X

3

Check Hydraulic Control Valve For proper

Operation and Leaks.

X

4

Check Boom Safety Chains for Security and

Function.

X

5

Check Hydraulic Cylinders for Security,

Operation and Leaks.

X

6

Check Main Hydraulic Relief Pressure

Setting. (2000 psi)

X

7

Lube Boom Hinge Pins and Hydraulic

Cylinder Pins.

X

8

Inspect Boom Hinge Flange Gaskets for

Leaks and Damage.

X

9

Check Inlet and Discharge Tubing for

Damage and leaks, to include Discharge

Sock and Victaulic Coupling.

X

13 Feb 2012

SECTION 2

Scheduled Inspections

2-3

Page 15

MMP4-5

13 Feb 2012

SECTION 2

Scheduled Inspections

2-4(Blank

Page 16

MMP4-5

13 Feb 2012

SECTION 3

Special Inspections

Contents

Description ……………………………. 3-1 Storage/Winterization …………………. 3-1

DESCRIPTION

This section contains special inspection

requirements for a specific system after use, an

unusual event or storage.

STORAGE/WINTERIZATION

Entering

1. Remove any exterior dirt, grease and grime

that may trap moisture.

2. Flush all water suction and discharge tubes

(e.g. water pump,).

3. Ensure all water is drained from the tubes

and water pump.

4. Ensure all covers/caps for fluid reservoirs

are in proper operating condition and are

secured to the openings.

5. Fill Fuel tank to capacity, shut fuel shut off

valves at bottom of fuel tank.

6. Check tires for proper inflation.

7. Check Boom retaining hardware, ensure it

is operational and secure.

8. Lubricate all grease points (e.g. Hinge pins,

cylinder pins water pump suction bowl).

9. Check battery fluid level and charge.

10. Disconnect battery cables from battery.

11. Service all engine systems per CAT

SEBU7276-01 service manual.

12. If possible, shelter entire unit from the

elements.

Removing

1. Remove all covers and seals from all

fill/discharge openings and components.

2. Inspect piping for debris that may damage

unit that water will be pumped into.

3. Check to ensure all water pump reservoirs

are filled to the correct level and the fluid is

not contaminated.

4. Remove any exterior dirt, grease and grime

and treat any corrosion.

5. Service all Engine systems per CAT

SEBU7276-01 service manual.

6. Check all fluid levels for condition and

level, replace or adjust as necessary.

7. Check Braking system (if equipped) repair

as necessary.

8. Check safety chains for damage.

9. Check lighting system for proper operation,

repair as necessary.

10. Clean and connect battery cables to battery.

11. Perform ‘Daily’ maintenance checks, repair

as necessary.

12. Perform a full functional check of all MMP

control systems.

3-1

Page 17

MMP4-5

13 Feb 2012

SECTION 3

Special Inspections

3-2(Blank)

Page 18

MMP4-5

A. AXIAL WATER PUMP GROUP, 303910

PART DESCRIPTION

PART NO.

QTY

1. Gasket, 12”

304174

2

2. Grommet

303910-03

2

3. Thrush Collar

303910-17

1

4. Lower Seal

303910-20

1

5. Upper Seal

303910-25

1

6. O-Ring, Bearing, (Lower)

303910-31

2

7. O-Ring, Hydraulic Motor, (Upper)

303910-35

2

B. HYDRAULIC GROUP

PART DESCRIPTION

PART NO.

QTY

1. Cylinder, 12”, Discharge Boom

303923

1

2. Cylinder, 20”, Inlet Boom

303924

1

3. Filter, Hydraulic, 400 psi

304704

2

4. Cap, Hydraulic Tank

302624

1

5. Gauge, Hydraulic Oil Level

304094

1

6. Gasket, Hydraulic Oil Tank

304116

1

7. Oil, Hydraulic, Clarity (35 Gallon Capacity)

Call MEGA

Corp Product

Support for

assistance

35 gal

13 Feb 2012

SECTION 4

Recommended Support Parts

Contents

Description …………………………… 4-1

Axial Water Pump Group ……………. 4-1

Hydraulic Group ……………………… 4-1

Water Piping Group ………………….. 4-2

DESCRIPTION

This section contains a listing of recommended support parts that should be available in the supply

warehouse. Once parts are issued from warehouse stock ensure depleted quantities are replenished to

keep the recommended support parts package at 100%.

The tables are categorized by specific sub system of the MMP. DO NOT FORGET that all MMP’s are

not configured the same and there are some variations in systems due to changes in equipment and

actual production dates. Ensure MMP serial numbers and actual component part numbers are checked

before ordering any parts.

Frame and Suspension Group ………... 4-2

CAT 3054B Group ………………..….. 4-2

Lighting Group ……………………….. 4-3

Notes ………………………………..… 4-4

4-1

Page 19

MMP4-5

C. WATER PIPING (BOOM) GROUP

PART DESCRIPTION

PART NO.

QTY

1. Sock, Down spout, tapered

304196

2

2. Tie Down Strap, 2”

304291

1

3. Pin, Hinge pivot

037627-05

1

4. Neoprene gasket, Boom flange

304117

2

5. Pin, Hitch, 1”

303935

2

6. Chain, 3/8”

355028

6 ft

7. Shackle, 3/8”

355020

4

D. FRAME AND SUSPENSION GROUP

PART DESCRIPTION

PART NO.

QTY

1. Wheel and Tire Assembly

303933

1

2. Hitch pin, 1”

303935

2

3. Chain, 3/8”

355028

4 ft

4. Shackle, 3/8”

355020

2

5. Bearing, Wheel, Inner

304157

2

6. Bearing, Wheel, Outer

304158

2

7. Seal, Wheel Bearing

304159

2

8. Jack stand

037708

1

9. Hitch, 2 5/16 Ball Coupler

304231

1

E. CAT 3054B ENGINE SUPPORT PARTS GROUP

REFER TO SEBU7276-01 INDUSTRIAL ENGINE MANUAL FOR SPECIFIC PARTS AND SERVICE

INFORMATION

PART DESCRIPTION

PART NO.

QTY

1. Filter, Engine Oil

304192

1

2. Filter, Element, Fuel

304188

1

3. Filter, Element, Fuel/Water Separator

304190

1

4. Filter, Element, Air, Primary

304186

1

5. Filter, Element, Air, Secondary

304187

1

6. Seal, Filter, Fuel

304189

1

7. Seal, Filter, Water Separator Base

304191

1

8. Gauge, Fuel Tank

304515

1

9. Cap, Fuel Tank

304091

1

10. Petcock, ¼”

300296

2

13 Feb 2012

SECTION 4

Recommended Support Parts

4-2

Page 20

MMP4-5

F. LIGHTING GROUP

PART DESCRIPTION

PART NO.

QTY

1. Light, Stop/Tail/Turn

302607

2

2. Light, Clearance, Amber

302974

2

3. Light, Clearance, Red

302975

2

4. Light, license plate

304124

1

5. Wiring Harness

304119

1

13 Feb 2012

SECTION 4

Recommended Support Parts

NOTES

4-3

Page 21

MMP4-5

13 Feb 2012

SECTION 4

Recommended Support Parts

NOTES

4-4

Loading...

Loading...