Page 1

MMP4-2

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

Maintenance Manual

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

Page 2

MMP 4-2

5 Nov 2011

TABLE OF CONTENTS

Page

Definitions and Abbreviations ……………………………………….………………..….. 1-1

MEGA Mobile Pump (MMP 4) ...……………………………….……………………….. 2-1

Hydraulic Control System ………………………………….…………………………….. 3-1

Basic Hydraulics System …………………………………..……….………….………… 4-1

Water Pump Assembly ..…………………………..…………….……………….………. 5-1

Axle and Suspension ………………………………………….………………….………. 6-1

Frame and Booms ………..………………………………………………………….….… 7-1

Scheduled Inspections ...….…………….………………………….……………….……. 8-1

Special Inspections ………..……………………………………….………………….….. 9-1

Recommended Spare Parts ………………………………………………………….….… 10-1

Appendix ……………………………………………………………….………………... 11-1

A

Page 3

MMP 4-2

5 Nov 2011

TABLE OF CONTENTS

B(Blank)

Page 4

SECTION 1

Definitions and Abbreviations

Contents

Warning, Caution & Notes ………………. 1-1

Shall, Will, Should and May ……………. 1-1

Safety Messages ………………………… 1-2

MANUAL USAGE

This technical manual only contains

information required to safely maintain the

MMP-4 powered by a CAT 3054B diesel

engine. See the CAT 3054B Engine

Maintenance and Operators Safety Manual for

specific engine system information and

maintenance procedures. The exact location of

the hazards and description of the hazards are

reviewed in this section. All personnel

working on or operating the machine must

become familiarized with all the safety

messages.

If your system is not covered in this manual or

are having difficulties please contact the

MEGA Corp. Product Support Group at:

Toll free US 1-800-345-8889

Direct 1-505-345-2661

or visit our website at www.megacorpinc.com

for more detailed contact information.

Due to the nature of these processes, ensure

that all safety information, warnings and

instructions are read and understood before any

operation or any maintenance procedures are

performed. This service function takes place

with heavy components and at moderate

heights, ensure proper safety procedures are

maintained when performing this service.

Failure to use and maintain proper safety

MMP 4-2

5 Nov 2011

Abbreviations ………………………..… 1-5

MMP 4 General Overview …………….. 1-6

WARNING, CAUTIONS AND

NOTES

The following definitions are found throughout

the manual and apply as follows:

Operating procedures and techniques, which

could result in personal injury and/or loss of

life if not carefully followed.

Operating procedures and techniques, which

could result in damage to equipment if not

carefully followed.

Operating procedures and techniques that are

considered essential to emphasis.

USE OF SHALL, WILL, SHOULD AND

MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a

procedure is recommended.

May - Used to indicate an acceptable or

suggested means of accomplishment.

1-1

Page 5

MMP 4-2

5 Nov 2011

SECTION 1

Definitions and Abbreviations

SAFETY MESSAGES

There are several specific safety messages on

this machine. The exact location of the hazards

and description of the hazards are reviewed in

this section. All personnel working on or

operating the machine must become familiarized

with all the safety messages.

Make sure that all of the safety messages are

legible. Clean the safety messages or replace the

safety messages in you cannot read the words.

Replace the illustrations if the illustrations are

not legible. When you clean the safety

messages, use a cloth, water and soap. Do not

use solvent, gasoline or other harsh chemicals to

clean the safety messages. Solvents, gasoline or

harsh chemicals could loosen the adhesive that

secures the safety messages. Loose adhesive

will allow the safety messages to detach.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part

that is replaced, install a new safety message on

the replacement part.

Toxic Gas Hazard (1)

This safety label is located on the side of the tank

and at all water fill entrances.

Cutting or welding operation on the inside of

the tank can cause the accumulation of toxic

gases. Read and understand instructions and

warnings in the Maintenance Manual.

Failure to provide proper ventilation or

breathing apparatus while conducting these

operations may result in serious injury or

death.

Do Not Operate (2)

This safety label is located on the outside of the

front and rear control boxes. (If equipped)

Do not open this control box unless you read

and understand the instructions and warnings

in the Operator and Maintenance Manual.

Failure to follow instructions or heed the

warnings could result in serious injury or

death.

1-2

Page 6

SECTION 1

Definitions and Abbreviations

Backing Runover Hazard (3)

This safety label is located on the rear of the tank

and inside the cab.

The vehicle is equipped with a back-up alarm.

Alarm must sound when operating this

vehicle in reverse. Failure to maintain a clear

view in the direction of travel could result in

serious injury or death.

Freezing (4)

This safety label is located on the side of the

tank, at the sump drain, and on the pump.

Drain tank, fill pipe and valve in freezing

weather. Refer to the Operator and

Maintenance Manual for the procedure to

follow.

MMP4-5

5 Nov 2011

Non-Potable (5)

This safety label is located on the side of the tank

and sump drain.

Water held within tank is not potable. Do not

use tank for transport of water intended for

human or animal consumption or serious

injury or death may result.

Do Not Hoist While in Motion (6)

This safety label is located inside the cab.

Do not engage hoist cylinders while vehicle is

in motion. Before engaging hoist STOP the

vehicle. Do not engage hoisting cylinders

unless you read and understand the

instructions and warnings in the Operator or

Maintenance Manual. Failure to follow

instructions or heed the warnings will result

in injury or death.

1-3

Page 7

MMP 4-2

5 Nov 2011

SECTION 1

Definitions and Abbreviations

Fall Hazard (7)

This safety label is located at the top of the front

and rear of the tank.

Do not walk on the top of tank without fall

arrest PPE. Serious injury or death could

occur from a fall.

Rotating Shaft (8)

This safety label is located on the pump.

Do not place your hand or tools within pump

bell while pump is rotating and/or pressure

held within the motor supply hose. Refer to

the Operator and Maintenance Manual for

the procedures to operate and maintain the

pump. Failure to follow proper procedures

could result in serious injury.

High Pressure Sprayheads (9)

This safety label is located on the spraybar.

Do not operate sprayheads until all personnel

are a safe distance away from the vehicle.

High Pressure Monitor (10)

This safety label is located on top of the cab

control box.

Do not operate the monitor until all personnel

are a safe distance away from the vehicle.

1-4

Page 8

SECTION 1

Definitions and Abbreviations

High Pressure Motor (11)

This safety label is located on the hydraulic

motor.

Hydraulic motor and supply lines contain oil

under high pressure. Improper removal and

repair procedures could cause severe injury.

To remove or repair, instructions in the

Maintenance Manual must be followed.

Confined Space (12)

This safety label is located near water tank

access and fill ports.

Do not enter confined spaces without

following established site specific

procedures. Failure to follow proper safety

procedures will result in serious injury or

death.

MMP 4-2

5 Nov 2011

ABBREVIATIONS

BFV – Butterfly Valve

cc – Cubic Centimeters

CCW – Counter Clockwise

CW - Clockwise

fl. oz. – Fluid Ounce

FT - Feet

FPM – Feet Per Minute

GPM – Gallons Per Minute

IN/SQ FT – Inches per Square Feet

KM-H – Kilometers Per Hour

Kg – kilograms

Kpa - Kilopascals

l – liters

lpm – Liters per minute

LT – Left as viewed from the operators

position facing forward

m - meters

MPH – Miles Per Hour

MTT – Mega Truck Tank

Nm – Newton meters of torque

psi - pounds per square inch

RPM – Revolutions Per Minute

RT – Right as viewed from the operators

position facing forward

SQ FT – Square Feet

VDC – Volts, Direct Current

1-5

Page 9

MMP 4-2

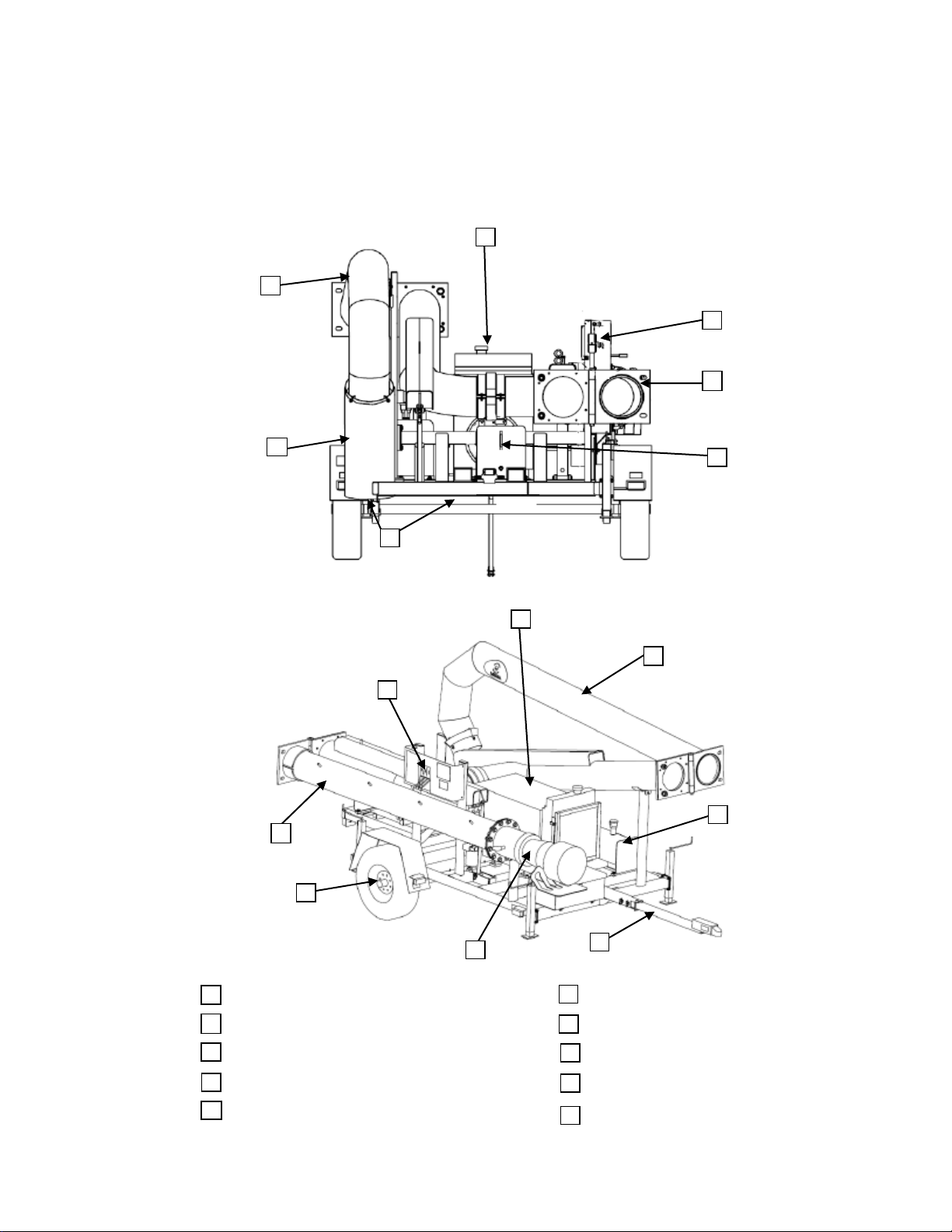

MMP 4 GENERAL OVERVIEW

DISCHARGE BOOM

5

DISCHARGE SOCK

3

1

2

4

INLET BOOM

WATER PUMP

HYDRAULIC CONTROL VALVE

6

7

HITCH ASSEMBLY

3054 CAT ENGINE ASSEMBLY

8

HYDRAULIC TANK

9

50 GALLON FUEL TANK

10

AXLE AND SUSPENSION

SIDE

VIEW

1

2

3 4 7 6 9

10

REAR

VIEW

1

2

4 5 7 8 10

5 Nov 2011

SECTION 1

Definitions and Abbreviations

1-6

Page 10

SECTION 2

MMP-4 Overview

Contents

Description ……………………………… 2-1

Inspection ……………………………..... 2-1

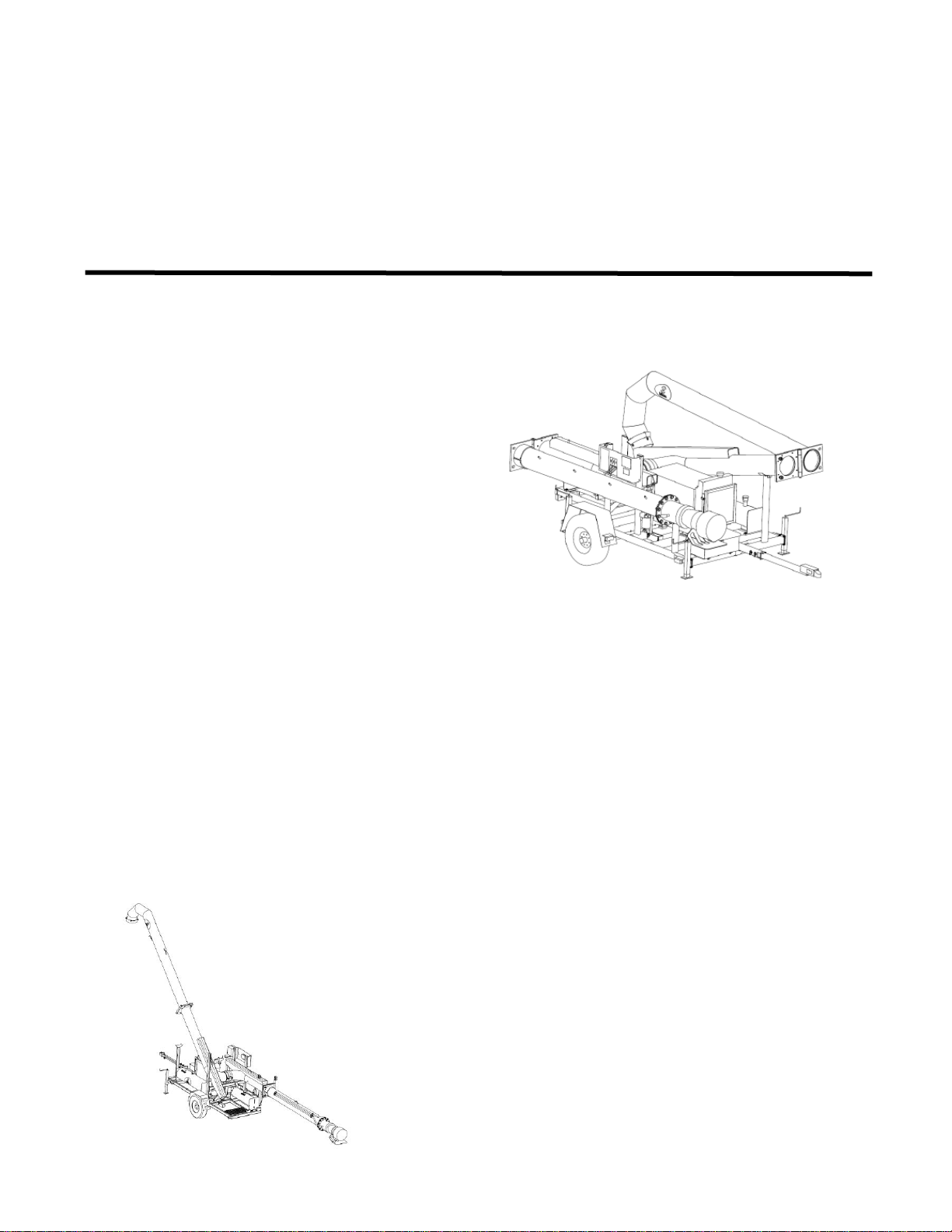

DESCRIPTION

The MEGA Mobile Pump is a towable water

lifting station. The MMP 4 may be towed by a

vehicle capable of at least a 6,000 pound (2,725

kg) towing capacity, 1,000 pound (450 kg)

tongue weight and equipped with the

appropriate weight rated Class IV trailer hitch

with a 2 5/16” ball. The MMP 4 can be

transported to a water holding pond and be set

up by 1 individual. MMP 4’s are a self

contained pumping station fitted with a

hydraulically driven 12” axial water pump that

has the potential to lift water 25’ (7.62 meters)

from pump level to fill water distribution

equipment (maximum height, 17’ [5.2 meters]

above ground level). MMP 4’s are equipped

with: hydraulically lifted inlet and discharge

booms with safety retaining chains and travel

locking devices, DOT rated lighting, 16” load

range ‘E’ on-highway trailer tires, a fold away

hitch with safety chains, a vacuum break with

an anti-siphon discharge sock on the discharge

boom, 23 gallon (87 liter) hydraulic oil tank

filled with Chevron Clarity AW 46 hydraulic

oil, a gear type hydraulic pump driven by a

Caterpillar 3054B series diesel engine and a 50

gallon (190 liter) capacity diesel fuel tank

equipped with shut off valves.

MMP 4-2

5 Nov 2011

Repair …………..............………….......... 2-2

The MMP 4 needs a minimum of 2.5’ (0.762

meters) of water above the inlet of the water

pump for proper operation.

INSPECTION

1. Inspect MMP 4 exterior paint for damage

and corrosion.

2. Inspect piping for damage and leaks.

3. Inspect frame, landing gear and suspension

for damage and missing parts.

4. Inspect engine assembly for loose, missing,

damaged or leaking parts.

5. Inspect all hydraulic hoses and couplings

for security, damage and leaking.

6. Inspect fuel, engine oil, anti freeze and

hydraulic oil for contamination and proper

level.

7. Inspect lighting, lug nuts, fenders and hitch

safety equipment for operation, damage and

missing parts.

8. Inspect electrical system for corrosion,

damage and missing parts.

2-1

Page 11

MMP 4-2

5 Nov 2011

SECTION 2

MMP-4 Overview

REPAIR

Paint

Remove corrosion, prime and paint as required.

Engine Fluid Levels and Inspections

Adjust, repair or service according to CAT

SEBU7276-01 manuals for engine service

schedule.

Leaks

1. Remove paint and corrosion from suspected

area.

2. Prep surface to be welded, weld over leak.

3. Prime and paint over weld.

4. Tighten or replace damaged or leaking

component.

Lighting

Repair as required to maintain DOT

compliance.

Missing parts

Contact MEGA Corp Parts sales for assistance.

Structure

Contact the MEGA Corp. Product Support

Group at:

Toll free US 1-800-345-8889

Direct 1-505-345-2661

or visit our website at www.megacorpinc.com

for more detailed contact information or

assistance on major structural repairs.

2-2

Page 12

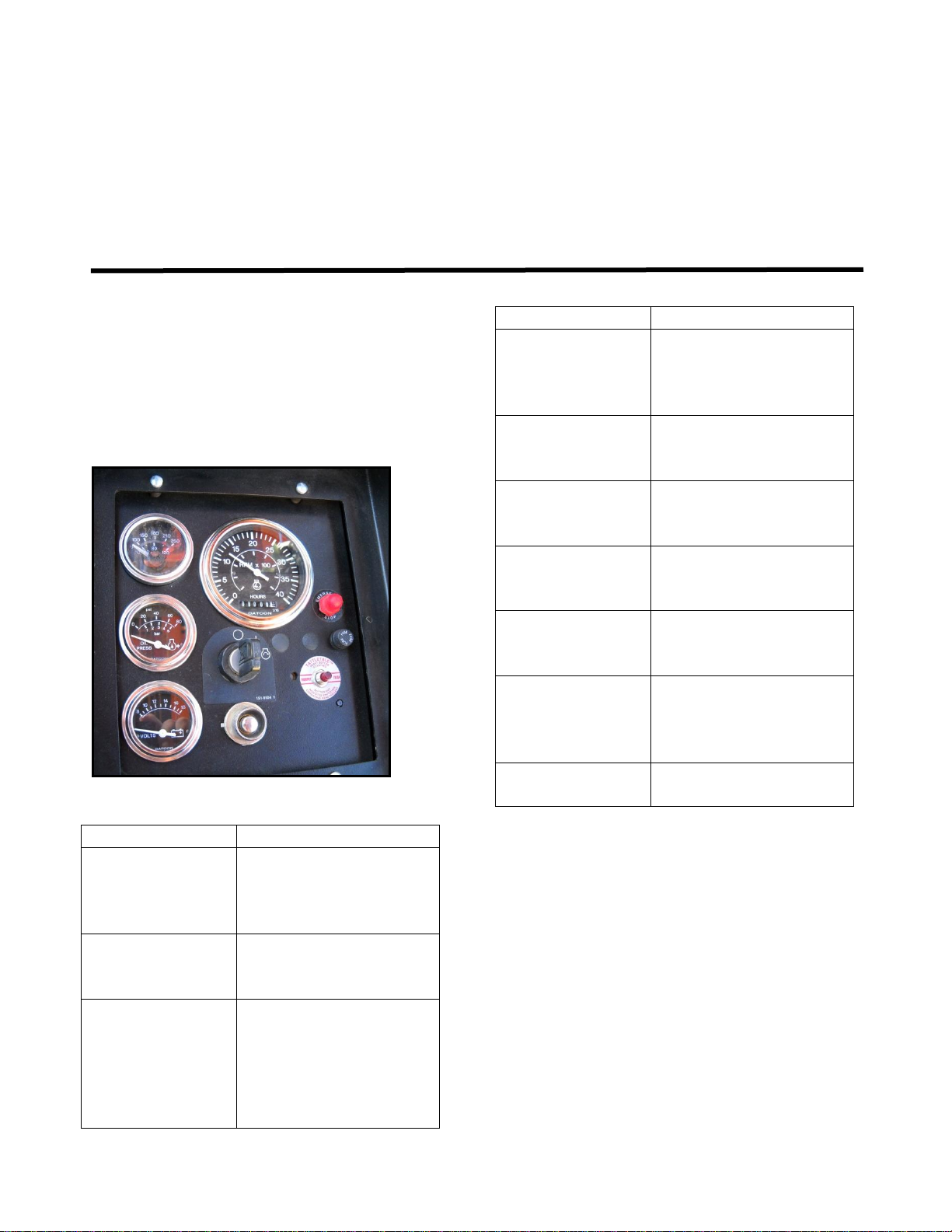

SECTION 3

Control

Function

IGNITION

SWITCH WITH

KEY

Controls engine

electrical system to start,

run and shut down

engine.

GLOW PLUG

BUTTON

Operates the cold

weather starting aid

system.

MURPHY

SWITCH

A magnetic switch that

shuts the engine down in

the event of: low engine

oil pressure and/or over

heating of the engine

cooling system.

Control

Function

SYSTEM FUSE

Protects the engine

control electrical system

in the event of an

electrical short circuit.

EMERGENCY

STOP BUTTON

Disengages the Murphy

switch to shut engine

down.

THROTTLE

CONTROL

Controls and locks

engine throttle lever to a

fixed RPM.

BATTERY

VOLTAGE

GAUGE

Displays electrical

system voltage.

ENGINE OIL

PRESSURE

GAUGE

Displays engine oil

pressure.

ENGINE

COOLANT

TEMPERATURE

GAUGE

Displays engine coolant

temperature.

ENGINE

TACHOMETER

Displays engine RPM’s.

Engine Control System

Contents

Description ……………………………. 3-1

Inspection ……………………………... 3-2

DESCRIPTION

The Engine control system consists of: A

Control box with lockable cover, Ignition

switch with key, Glow plug button, Murphy

switch, System fuse, Emergency stop button,

Throttle control, Battery voltage gauge, Engine

oil pressure gauge, Engine coolant temperature

gauge and an Engine Tachometer.

The control functions operate as follows:

MMP 4-2

5 Nov 2011

Repair …………………………………. 3-2

INSPECTION

1. Inspect control box and cabling for security,

condition and mounting.

2. Inspect switches, gauges and throttle

control for security, damage and

operational condition.

3-1

Page 13

MMP 4-2

5 Nov 2011

SECTION 3

Engine Control System

REPAIR

Switch Replacement

1. Remove power to the engine control.

2. Remove engine control face plate to gain

access to the switch.

3. Mark wiring on old switch before removal

to ensure correct wiring configuration is

maintained.

4. Remove old switch and replace with the

same type of switch.

5. Install wiring on new switch as previously

marked.

6. Install engine control face plate in control

box.

7. Apply power to the engine control and

perform functional check of the newly

installed switch.

Indicator Gauge Replacement

1. Remove power to the engine control.

2. Remove engine control face plate to gain

access to gauge and wiring.

3. Mark wiring on old gauge before removal

to ensure correct wiring configuration is

maintained.

4. Remove old gauge and replace with the

same type of gauge.

5. Install wiring on new gauge as previously

marked.

6. Install engine control face panel in control

box

7. Apply power to the engine control and

perform functional check of newly installed

indicator gauge.

Engine Tachometer Replacement

1. Remove power to the engine control.

2. Remove engine control face plate to gain

access to the backside of the tachometer.

3. Mark wiring on old tachometer before

removal to ensure correct wiring

configuration is maintained.

4. Remove old tachometer and replace with

the same type tachometer.

5. Installed wiring on new tachometer as

previously marked.

6. Install engine control plate in control box.

7. Apply power to engine control and perform

functional check of newly installed

tachometer.

Throttle Control replacement

1. Remove power to the engine and engine

Control system.

2. Loosen cable locking screw on throttle

lever on fuel injection pump.

3. Remove cable jam nut on lever side of the

fuel pump mounting bracket.

4. Remove cable jam nut on throttle adjusting

end of cable.

5. Remove cable assembly.

3-2

Page 14

SECTION 3

Engine Control System

6. Install new throttle cable assembly in

mounting bracket.

7. Thread jam nut on throttle cable adjusting

end behind mounting bracket.

8. Route throttle cable to the fuel pump cable

mounting bracket.

9. Run cable through fuel pump mounting

bracket.

10. Install jam nut on fuel pump throttle lever

side of bracket.

11. Insert throttle cable in the pivot on the

throttle lever of the fuel pump.

12. Ensure throttle cable and fuel pump throttle

lever is in the idle position.

13. Secure the throttle cable locking screw on

the new cable.

14. Ensure the new throttle cable is routed

away from moving parts.

15. Ensure throttle cable is secure.

16. Check operation of newly installed cable

for smooth operation.

MMP 4-2

5 Nov 2011

17. Ensure newly installed throttle cable allows

engine throttle lever to fully contact the

LOW idle stop.

18. Ensure the newly installed throttle cable

allows engine throttle to fully contact the

HIGH idle stop.

3-3

Page 15

MMP 4-2

5 Nov 2011

SECTION 3

Engine Control System

19. Place throttle control cable in the low idle

position.

20. Apply power to engine control box and

engine.

21. Ensure hydraulic ball valve at hydraulic

tank is OPEN.

22. Perform functional check to ensure proper

engine low and high idle RPMs. If engine

RPMs are out of specified range, check

throttle cable adjustment again and refer to

CAT SEBU7276-01 manual for correct

RPM specifications and adjustment

procedures.

3-4

Page 16

SECTION 4

Basic Hydraulics System

Contents

Description …………………………..... 4-1

Hydraulic Tank………………………….. 4-1

Hydraulic Pump………………………… 4-2

Hydraulic Control Valve……………...... 4-2

Water Pump Hydraulic Drive Motor .... 4-2

Hydraulic Cylinders ………………....... 4-3

DESCRIPTION

The MMP 4 hydraulic system originates at a

hydraulic pump coupled to a CAT 3054B

Diesel engine. The system draws hydraulic oil

from a hydraulic tank mounted at the rear of the

MMP 4 frame through a inlet screen inside of

the tank and a shut off valve on the outside of

the tank. The hydraulic pump moves the oil to

a hydraulic control valve mounted to the right

side of the unit. The control valve diverts and

regulates the oil flow and pressure through the

MMP 4 system. The Hydraulic control valve is

used to control the raising and lowering of the 2

hydraulic cylinders attached to the inlet and

discharge booms. The hydraulic control valve

also controls the hydraulic drive motor inside

of the water pump at the end of the inlet boom,

this control feature is equipped with a detent to

allow the lever to stay in the ON position

during water pump operation and is equipped

with a pressure relief valve to protect against

over pressurization of the hydraulic system.

The return hydraulic oil is passed through a

hydraulic oil filter, oil cooler then a diffuser

mounted inside of the hydraulic oil tank.

MMP 4-2

5 Nov 2011

Hydraulic Oil Filter.……………….….. 4-3

Hydraulic Oil Cooler……………….…. 4-4

Hydraulic Hoses ………………….….. 4-4

Inspection ……………………………... 4-5

Repair ……………………………….… 4-7

HYDRAULIC TANK ASSEMBLY

The hydraulic tank consists of an inlet screen,

return oil diffuser, internal baffle, shut off

valve, oil level sight gauge, reservoir cap and

breather. The system draws oil from the

bottom of the tank through an inlet screen to

pre-filter the oil. The shut off valve holds the

oil inside of the tank when servicing the

hydraulic system. The sight gauge is used as a

visual indicator of the hydraulic oil quality and

quantity. The Internal baffle allows for oil

movement with in the tank to evenly distribute

the return oil trough out the reservoir. The

return diffuser inside of the hydraulic tank just

below the normal oil level reduces the potential

for hydraulic oil foaming in the tank. The

reservoir cap and breather allow filling of the

hydraulic tank and prevent dirt and debris from

entering the hydraulic system.

4-1

Page 17

MMP 4-2

5 Nov 2011

SECTION 4

Basic Hydraulics System

HYDRAULIC PUMP

The hydraulic pump is coupled to the flywheel

end of the engine. The hydraulic pump moves

the oil through the system to generate flow and

pressure needed to operate the water pump and

boom cylinders. The pump draws oil from the

hydraulic tank and moves it to the hydraulic

control valve.

HYDRAULIC CONTROL VALVE

The hydraulic control valve directs and

regulates the hydraulic pumps oil flow. The

valve operates the boom lifting cylinders by

pressurizing the rod end of the cylinder to make

the booms move up (Cylinder retract). To

lower the booms the valve opens to allow the

oil to return to the hydraulic filter through a

metering control that controls the speed of the

cylinder movement. The hydraulic drive motor

for the water pump portion of the control valve

is equipped with a detent to allow the valve

spool to stay in an open position when the lever

is moved to the ON position for normal water

pump operation. When this lever is moved to

OFF it will shut off hydraulic oil flow to the

water pump drive motor. The hydraulic control

valve is fitted with a pressure regulator that

limits the maximum pressure of the hydraulic

system to 2,100 psi (14,450 kpa). The excess

oil flow is diverted to the hydraulic oil filter.

When the control valves are in the neutral

position, all of the hydraulic oil by-passes

through the control valve to the return

hydraulic oil filter.

WATER PUMP HYDRAULIC

DRIVE MOTOR

The hydraulic drive motor is coupled to the

water pump drive shaft inside the water pump.

The drive motor is controlled by the hydraulic

control valve, water pump spool. When the

lever is moved to the ON position the fluid is

directed to the drive motor causing the water

pump impeller to rotate, moving water up the

inlet boom.

4-2

Page 18

SECTION 4

Basic Hydraulics System

MMP 4-2

5 Nov 2011

HYDRAULIC CYLINDERS

The 2 hydraulic cylinders are used for lifting

the inlet and discharge booms to either the

‘stow/travel’ position or to the ‘fill’ position.

When the boom control lever is operated in the

‘UP’ position the pressurized oil retracts the

cylinder and lifts the boom. The speed of the

lifting is controlled by metering valves attached

to the hydraulic control valve. There are safety

chains at each cylinder to prevent any

unwanted movement in the boom when it is

filled with water and as a safety precaution in

case the control valve lever is operated

accidentally. The cylinder operates in the

boom down mode by moving the control valve

lever to the ‘DOWN’ position, the weight of

the boom makes the cylinder extend. The

speed of the downward motion is controlled by

a fluid metering valve attached to the hydraulic

cylinder that restricts the fluid exiting the

cylinder causing a slow, controlled lowering of

the booms.

HYDRAULIC FILTER

The spin on hydraulic oil filter is in the return

to tank hydraulic circuit. All hydraulic oil

passing through the system passes through the

filter prior to the hydraulic oil cooler. The

filter is rated at 400 psi (2,758 kpa) and has a

provision for the cylinder lower plumbing. The

filter is rated at 10 microns. The filter housing

has a built in bypass valve to bypass the filter

element when the inlet pressure is too high or

the filter becomes restricted.

4-3

Page 19

MMP 4-2

5 Nov 2011

SECTION 4

Basic Hydraulics System

HYDRAULIC OIL COOLER

The hydraulic oil cooler is attached to the front

of the engine radiator. The engine cooling fan

draws cool air through the oil cooler lowering

the oil temperature. The oil cooler is in the

return to tank hydraulic circuit. Built into the

oil cooler is a bypass valve that allows oil to

bypass the cooler if the return oil pressures are

too great (e.g; when the hydraulic oil is cold).

The oil cooler and engine coolant radiator are

protected by a steel mesh guard to prevent

damage to the cooler and radiator.

HYDRAULIC HOSES

The MMP-4 is equipped with hydraulic hosing

to convey the hydraulic oil pressure and flow to

components that are operated by the hydraulic

control valve. These hoses are sized according

to the volume and pressure requirements of the

component. The hydraulic drive motor for the

water pump utilizes a 1” (-16) hose to direct the

volume of oil required to turn motor that drives

the impeller of the water pump at the rated

speed. The hydraulic cylinder hoses require a

smaller volume of fluid and do not require as

large of a hose. The makeup oil requirement

for the lift cylinders (when the booms move

down) are low pressure and low volume. The

suction side of the hydraulic pump requires

suction rated hydraulic hose, this prevents the

hose from collapsing under suction loads.

4-4

Page 20

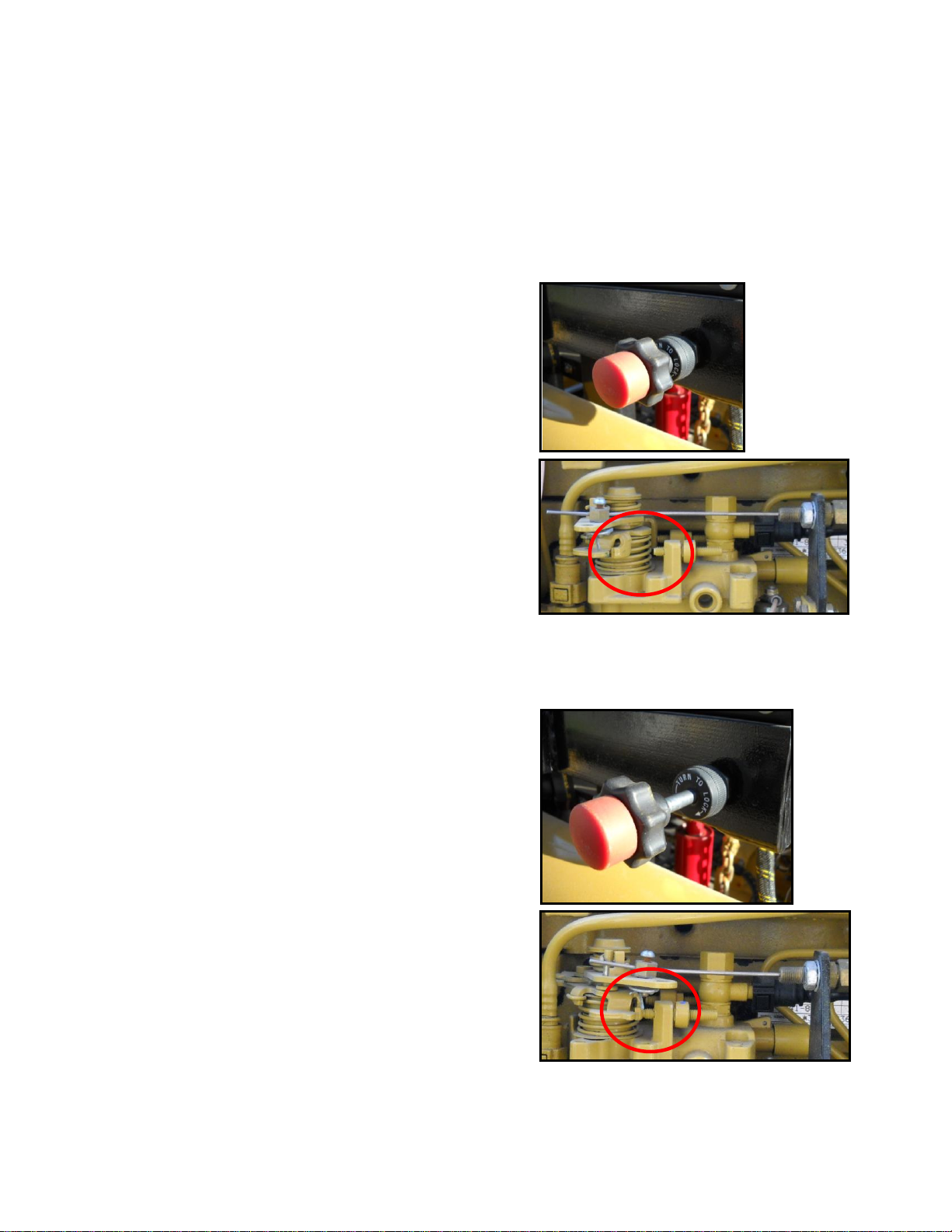

SECTION 4

OPEN

CLOSED

Basic Hydraulics System

INSPECTION

Hydraulic tank assembly

1. Inspect hydraulic oil tank for security,

damage, leaks.

2. Check hydraulic oil level and quality. The

level should be between 80% and 90% of

the level visible in the sight glass and clear.

3. Check hydraulic tank filler cap, breather

and bolt on end cover for security, damage

and leaks.

4. Check hydraulic hose fittings and shut off

valve, ensure shut off valve is open.

5. Check tank mounting bolts, ensure the bolts

are tight.

MMP 4-2

5 Nov 2011

Hydraulic Pump

1. Inspect hydraulic pump, adapter and hosing

for vibrations, unusual noises, security,

damage and leaks.

Hydraulic Control Valve

1. Check hydraulic control valve mounting for

security, damage and leaks.

2. Check control valve levers for ease of

operation, security, damage and missing

parts.

3. Check control valve fittings and metering

valves for security, damage and leaks.

4. Check pressure regulator for proper relief

pressure (2,100 psi/14,450 kpa), security

and leaks.

4-5

Page 21

MMP 4-2

5 Nov 2011

SECTION 4

Basic Hydraulics System

Water Pump Hydraulic Drive Motor

1. Check water pump drive motor fittings for

security, damage and leaks.

2. Check for an oily film on water surface

(indications of hydraulic oil leak below the

surface of the water). If water pump is

submerged.

3. Check for oil residue inside of the inlet to

the water pump. If water pump is in the

travel position.

Hydraulic Cylinders

1. Check hydraulic cylinders for security,

damage and leaks.

2. Check hydraulic cylinder safety chains for

security, missing parts and damage.

3. Check hydraulic hoses and metering valves

for security, damage and leaks.

4. Check for proper operation and alignment.

Hydraulic filter assembly

1. Inspect hydraulic oil filter mounting for

security and damage.

2. Check hydraulic filter for leaks and

damage.

3. Check hydraulic filter assembly hose fitting

adapters for security and leaks.

Hydraulic Oil Cooler assembly

1. Check hydraulic oil cooler and radiator

guard for security and damage.

2. Check hydraulic oil cooler and fittings for

leaks.

3. Check hydraulic oil cooler for blockage and

debris that may interfere with proper

cooling of oil passing through cooler

assembly.

4-6

Page 22

SECTION 4

Basic Hydraulics System

REPAIR

Hydraulic tank assembly

1. Repair, secure or adjust as required.

Hydraulic Pump

1. Repair or replace as required.

Hydraulic Control Valve

1. Repair, adjust or replace as required.

2. To set hydraulic relief pressure, install a 0 –

3,000 psi (0 – 21,000 kpa) pressure gauge

on the test fitting located on the retract hose

(RAISE) for the inlet boom cylinder.

3. With the engine operating at high idle,

operate the inlet boom UP lever and

observe the reading on the pressure gauge.

MMP 4-2

5 Nov 2011

4. If the hydraulic oil pressure is not within

the specifications, adjust the pressure

regulator cartridge as follows:

a. To increase the pressure, loosen the

lock nut on the regulator stem and

screw in the stem clockwise (CW) until

the pressure is at 2,100 psi (14,450

kpa), tighten lock nut on stem.

b. To reduce the pressure, loosen the lock

nut on the regulator stem and unscrew

the stem counter clockwise (CCW) until

the proper pressure is obtained, tighten

lock nut on stem.

c. Recheck hydraulic pressure.

d. Shut unit off.

e. Remove pressure gauge from test port.

4-7

Page 23

MMP 4-2

Set Screw

Index Marks

5 Nov 2011

SECTION 4

Basic Hydraulics System

Water Pump Hydraulic Drive Motor

1. Repair or replace as required.

Hydraulic Cylinders

1. Repair or replace as required.

Hydraulic Cylinder Speed Control Valve

1. If the hydraulic boom cylinders raise too

slowly or lower too fast, check the

adjustment as follows;

a. Loosen set screw on knob.

b. Fully seat the flow control on the

hydraulic control valve for the cylinder

with the travel speed that needs

adjustment.

c. Rotate adjustment knob CW to fully

seat needle.

d. Rotate knob 1 full turn CCW.

e. Raise boom, check speed to ensure

speed is desired, if speed is too fast turn

knob CW 1 index mark, if the speed is

too slow turn knob CCW 1 index mark

at a time until desired speed is achieved.

f. Tighten set screw.

Hydraulic Filter Assembly

1. Repair or replace as required.

Hydraulic Oil Cooler Assembly

1. If cooling fins are dirty or plugged with

debris, remove, replace or clean cooler as

required.

2. Tighten or replace leaking or damage

adapter fittings as required.

3. Replace radiator guard if damage is present.

Hydraulic Hoses

1. Remove and replace damaged hose

assembly if damage to outer covering is

present or leaks are present.

2. Replace hose assembly if hose end is

unserviceable due to leaks or damage.

4-8

Page 24

SECTION 5

Water Pump Assembly

Contents

Description ………………………......... 5-1

Hydraulic Drive Motor …………...…… 5-1

Inspection and Service ...………………. 5-2

DESCRIPTION

The water pump assembly is comprised of;

hydraulic drive motor, water pump housing,

impeller, shaft and bearings and an inlet screen.

The water pump assembly uses hydraulic oil

flow produced by the engine driven hydraulic

oil pump to turn the hydraulic drive motor

which is directly coupled to the water pump

impeller. Water pump speed is controlled by

the hydraulic control valve and pressure relief

cartridge which diverts the oil flow to the inlet

port (pressure) of the hydraulic drive motor to

the return oil hose for the hydraulic system.

The pressure relief cartridge diverts excessive

oil pressure directly to the hydraulic return

hose, returning back to the hydraulic oil to the

tank for system protection.

MMP 4-2

5 Nov 2011

Parts Breakdown of Water Pump ..…….... 5-5 Repair ………………………………... 1-1

Disassembly .............................................. 5-7

Assembly ................................................... 5-8

HYDRAULIC DRIVE MOTOR

A gear-type hydraulic motor mounted inside

the water pump assembly. The hydraulic motor

receives hydraulic oil flow from the hydraulic

system controlled by the hydraulic control

valve at 1,900 - 2,800 PSI (13,000 – 19,300

kpa) and flow rates up to 35 GPM (135 lpm)

for operation. The hydraulic motor is coupled

directly to the water pump shaft and rotates in a

clockwise (CW) direction as viewed from the

inlet of the pump. The speed and volume of the

water pump is dependent on the engine RPMs,

[e.g: higher engine RPMs yields a higher

output volume of water].

5-1

Page 25

MMP 4-2

Proper Hydraulic Oil Level

5 Nov 2011

SECTION 5

Water Pump Assembly

INSPECTION

DAILY

1. Check for excessive vibration and noise.

2. Check water pump for security and leaks.

3. Check and adjust fluid levels.

4. Check hydraulic system for security and

leaks.

250 hours

1. Remove water pump from inlet boom.

2. Check water pump drive motor for security,

damage and signs of leakage.

3. Check water pump bearing oil level.

4. Check water pump bearing oil for

contamination.

5. Grease water pump suction bowl reservoir.

6. Check water pump trash screen for

blockage, security and damage.

7. Check impeller for damage.

500 hours

1. Perform all 250 hour inspections and

repairs.

2. Change oil in the 2 water pump bearing

reservoirs.

3. Check water pump housing for damage and

security.

SERVICE

1. Park unit on level ground, lower and secure

stabilizing jacks to make unit stable for

maintenance.

Ensure the MMP4 is properly positioned

and configured before maintenance is

performed. Units not configured properly

or stabilized, may rollover and cause

serious personal injury or death.

2. Remove all electrical and hydraulic power

to make the unit safe for maintenance.

Ensure the MMP4 is made safe for

maintenance. Performing maintenance on a

unit with hydraulic and electrical power

applied may result in serious personal

injury or death.

3. Ensure the use of only clean, compatible

hydraulic oil. The hydraulic system must

have a filter rated at 10 micron filtration.

4. When disconnecting and reconnecting the

hydraulic hoses to the pump, ensure the

fittings are kept clean.

5. Hydraulic fluid levels must be maintained

at 80% to 90% of the level shown in the

sight glass. Check level daily.

5-2

Page 26

SECTION 5

Oil Level Check Plugs on

Axial Water Pump

Water Pump Assembly

6. Check hydraulic fluid for excessive

bubbles, foaming and water contamination

daily.

7. Use hydraulic oils with anti-wear additives

such as these recommended oils or their

equivalent:

Pennzoil AW46 Hydraulic Oil

Texaco Rando HDAZ

Shell Tellas Hydraulic Oils

Mobil D.T.E. 20 Series

Chevron EP Hydraulic Oils

Exxon Univis N Hydraulic Oils

When using this equipment in

environmentally sensitive areas the use of

bio-degradable or non-hazardous oils such

as: Chevron Clarity, Exxon Univis Bio 40

or Mobil EAL 224H are recommended.

8. Remove Item 40 on Figure 1 to gain access

to the bearing housing reservoir fill plug

(Item 34 in Figure 1) and item 23 on the

discharge bowl, with the water pump in a

vertical position.

The water pump must be removed from the

boom and set in a vertical position on the

inlet end when performing this action. Any

other position will result in incorrect

servicing and improper component oil level

will decrease the service life of the water

pump, shaft and bearings.

There are 2 bearing fluid reservoirs in the

MMP4 water pump housing.

MMP 4-2

5 Nov 2011

9. Check oil in the 2 bearing housings every

250 operating hours.

10. Slight dark discoloration of the oil in the

bearing housing is normal. This is due to

the wearing of the carbon face seal.

11. Presence of water or emulsified oil in the

bearing housing indicates immediate need

for seal replacement and inspection of

bearing. If this condition is present, refer to

MMP 4 Disassembly Instructions.

12. Change oil in the bearing housing every

500 operating hours or semi annually which

ever occurs first if no contamination or

fluid loss is present. Use clean nondetergent 10W, 20W oil, AW32 or AW46

hydraulic oil.

13. The level should be at the spill point of the

fill plug. DO NOT OVERFILL

If there is a difficulty in checking these

fluid levels, ensure that FSB-9 (Water

Pump Lube Level Modification) has been

completed.

5-3

Page 27

MMP 4-2

5 Nov 2011

SECTION 5

Water Pump Assembly

14. Use a liquid pipe sealant to seal and

reinstall pipe plugs in bearing housings and

water pump housings.

The use of a high strength thread sealant

may make it difficult to remove plugs at the

next service interval. A Liquid Teflon pipe

sealant is recommended.

15. Lube suction bowl bushing at (Item 15 in

Figure 1), every 250 operating hours or

semi annually which ever occurs first.

(Mystic 5496 Marine Grease or equivalent)

1 each - 3/8” NPT grease fitting may be

required to perform this operation.

More frequent service intervals may be

required if the quality of the water being

transferred is of poor quality containing:

salts, dirt, sediments or other contaminants.

5-4

Page 28

SECTION 5

Figure 1: MMP 4 Water Pump

40

30

22

20

Water Pump Assembly

MMP 4-2

5 Nov 2011

5-5

Page 29

MMP 4-2

Item

Part number

Description

Item

Part number

Description

1

303910-01

Hydraulic Motor

21

303910-20

Lower Seal

2

303910-02

Discharge pipe with

flange

22

303910-21

Discharge Bowl

Assembly

3

303910-03

Grommet

23

303910-22

Pipe Plug

4

303910-04

1" Elbow

24

303910-23

Shaft

5

303910-05

Pipe

25

303910-24

Snap-Ring

6

303910-06

Shaft collar

26

303910-25

Upper Seal

7

303910-07

Bearing Housing

27

303910-26

Bearing

8

303910-08

Bolt

28

303910-27

Snap-Ring

9

(Not used on this model)

29

303910-28

Snap-Ring

10

303910-09

Bushing Lower

Discharge Bowl

30

303910-29

Coupler (male) 1"

11

303910-10

Bolt

30

303910-30

Coupler (female) 1"

12

303910-11

Bushing Suction Bowl

31

303910-31

O-Ring

13

303910-12

Suction Bowl

32

(Not used on this model)

14

303910-13

Screw 3/8" x 1-1/2" Sq.

Head Set Screw

33

303910-32

Bolt

15

303910-14

Pipe Plug

34

303910-33

Plug Bearing Housing

16

303910-15

Strainer Assembly

35

303910-34

O-Ring

17

303910-16

Snap-Ring

36

303910-35

Swivel Union (Optional)

2 req.

18

303910-17

Thrust Collar

37

303910-36

Discharge Flange

(Optional)

19

303910-18

Key

20

303910-19

Impeller

40

Pipe Plug

Table 1: MMP 4 Water Pump Parts Break Down

5 Nov 2011

SECTION 5

Water Pump Assembly

5-6

Page 30

SECTION 5

Water Pump Assembly

DISASSEMBLY

Removal of the water pump assembly from the

inlet boom is necessary to properly service or

repair the water pump. The water pump

assembly is heavy (greater than 200 pounds or

91 kg). Use proper lifting devices and

techniques for this operation to preclude

personnel injury or death.

1. Place MMP4 on a firm hard packed, level

work surface.

2. Set and secure 3 landing gear legs.

3. Remove electrical power from unit.

4. Disconnect and cap hydraulic hoses from

water pump drive motor fittings.

5. Remove water pump from inlet boom.

6. Remove strainer by loosening (4) screws

(Item 14).

To inspect impeller (Item 20) remove (8)

bolts (Item 11) holding suction bowl

(Item13) to discharge bowl (Item 22).

7. Remove suction bowl and check impeller

and suction bowl face for excessive wear.

Replace if obvious wear is present or if

pump performance is poor.

8. To inspect hydraulic motor (Item 1) upper

bearing (Item 27) and upper seal (Item 26),

use the following procedure:

9. Remove hydraulic pipes (Item 5) from

drive motor.

MMP 4-2

5 Nov 2011

10. Remove (8) bolts (Item 8) holding

discharge bowl to discharge pipe (Item 2).

11. Remove discharge pipe assembly.

Remove (4) bolts (Item 33) holding

hydraulic motor to bearing housing (Item

7).

12. Remove and inspect hydraulic motor.

13. Inspect motor O-Ring (Item 31) and replace

if necessary.

14. Drain oil from bearing housing by tilting

unit on side and removing drain plug (Item

s 23, 34 and 40). Inspect condition of oil.

If oil is low or is emulsified with water, the

upper seal should be replaced (Item 26).

15. Remove snap ring (Item 29) near end of

shaft (Item 24).

16. Remove shaft collar (Item 6) by loosening

set screws on collar by inserting the

appropriate Allen wrench through the oil

plug hole in the bearing housing.

17. Remove bearing housing by lifting straight

up (bearing will remain in housing).

18. Remove snap ring (Item 28) and slide

bearing (Item 27) out of housing. Inspect

for rough spots and replace if necessary.

19. Inspect lower O-Ring (Item 35) and upper

shaft seal for damage or wear, replace if

necessary.

5-7

Page 31

MMP 4-2

5 Nov 2011

SECTION 5

Water Pump Assembly

20. Remove upper shaft seal and retainer (Item

26) by sliding off shaft.

21. To remove impeller, shaft and lower seal,

use the following procedure:

22. Remove snap ring (Item 17) from end of

impeller (Item 20).

23. Push and hold drive end of shaft (Item 24)

toward discharge bowl (Item 22).

24. Slide impeller back and remove split thrust

collar (Item 18) from shaft.

25. Slide impeller forward to remove.

26. Remove shaft key (Item 19) and gently

slide shaft out of discharge bowl toward

drive end.

27. Inspect lower shaft seal (Item 21) and

replace if necessary.

28. Inspect shaft and bronze discharge bowl

bushing (Item 10) and replace if worn.

(Moderate wear [e.g: shiny areas or ridges

not more than .010" (0.254 mm) deep] on

shaft are acceptable, the upper bearing takes

most of the loading).

29. Inspect bushing (Item 12) in suction bowl

(Item 13) and replace if worn.

ASSEMBLY:

1. Assembly is performed in reverse order of

disassembly:

2. Ensure O-Rings are properly installed in

grooves (Items 31 and 35).

Use only clean grease when assembling

new seal on shaft and when installing new

seal seat in bearing housing. Apply a light

film of clean oil to seal faces when

assembling to prevent scratching surfaces.

(Extreme care and cleanliness must be used

when installing shaft seals to prevent

possible component damage). Failure to

keep items clean and use clean grease to

perform this function may result in seal,

bearing or shaft damage.

The following is the required filling

procedure for the bearing reservoirs when

the pump is in a vertical position resting on

the inlet end:

3. Fill suction bowl bushing area to bottom of

bushing with waterproof grease.

4. Fill oil hole (1/2" plug) in discharge bowl

(Item 22) to spill point (pump in vertical

position) with clean hydraulic oil. Refer to

line 5 above for oil specifications.

5. Fill oil hole (1/4" plug) in upper bearing

housing (Item 7) to spill point with clean

hydraulic oil. Refer to line 5 for above for

oil specifications.

5-8

Page 32

SECTION 5

RETURN

PRESSURE

Water Pump Assembly

6. Use anti-seize compound on all threaded

fasteners when re-assembling pump.

DO NOT USE ANTI-SEIZE ON SEALS

OR BEARINGS. If an anti-seize

compound is used in this application

bearing and/or seal failure will result.

7. Ensure pressure and return pipes are

connected to proper ports on the hydraulic

motor.

8. Install strainer to pump inlet, tightening (4)

retaining bolts (Item 14).

9. Inspect mounting gasket for damage,

replace as necessary.

10. Install pump assembly to suction pipe,

tighten fasteners.

11. Hook up hydraulic hoses.

12. Check hydraulic fluid level, adjust level as

required.

13. Check to ensure hydraulic pump inlet valve

is OPEN.

MMP 4-2

5 Nov 2011

14. Run unit, engage water pump control,

ensure proper rotation of water pump and

no leaks are present.

Motor rotation is counter-clockwise looking

from discharge end of pump.

15. Shut unit off and recheck hydraulic fluid

level, at 80% to 90% of the level shown in

the sight glass, adjust level as required.

5-9

Page 33

MMP 4-2

5 Nov 2011

SECTION 5

Water Pump Assembly

5-10(Blank)

Page 34

SECTION 6

Axle and Suspension

Contents

Description …………………………….. 6-1

Service ..………………….…………….. 6-1

DESCRIPTION

The MMP-4 is equipped with a 6,000 lb (2,725

kg) rated single axle utilizing a double eye leaf

spring suspension. The springs are attached to

the frame by welded spring hangers. The axle

is attached to the springs by U-bolts with weld

on axle mounts. Mounted to the axle hubs by 8

lug nuts are load range E tire and rim

assemblies. Each tire and rim assembly is

protected by a steel fender that contains a front

amber marker lamp and rear red marker lamp

assembly. Current production models are not

equipped with brakes.

SERVICE

1. Park MMP-4 on firm level ground, lower

forward landing gears, raise hitch, uncouple

MMP-4 from tow vehicle.

2. Lower rear landing gear until the MMP-4 is

stabile.

3. With a jack of adequate capacity raise 1 tire

in the air high enough to remove the tire.

MMP 4-2

5 Nov 2011

Inspection ……………………………….. 6-2

Repair .......................……………..….….. 6-2

4. Place a jack stand under axle to prevent

axle from falling.

Do not lift the axle for the center, place jack

under the U-bolts towards the axle end.

Ensure jack stands of proper capacity is

used to secure the axle prior to removing

the tire assembly. Failure to properly lift

and secure the MMP-4 properly may result

in an unstable load, over loading of the jack

or damaging an MMP-4 component causing

damage to the MMP-4.

5. Lower the landing gear to re-stabilize the

MMP-4.

MMP-4 must be stable and secure on

adequate capacity jack stands and the jack

removed prior to servicing the hub

assembly. Failure to secure and ensure the

MMP-4 is stable and secure will result in

serious personal injury or death if the unit

falls.

6. Semi-annually (every 6 months), remove

rubber plug at the center of the wheel

bearing cap.

6-1

Page 35

MMP 4-2

5 Nov 2011

SECTION 6

Axle and Suspension

7. Pump grease into the grease fitting in the

spindle end with a manual type grease gun

only.

Do not mix Lithium, Calcium, Sodium or

Barium complex greases due to possible

compatibility problems. When changing

from one type of grease to another, it is

necessary to disassemble the wheel bearing

and ensure all grease is removed prior to repacking or servicing the wheel bearing.

Failure to ensure greases are not mixed may

result in wheel bearing, axle end, hub,

MMP-4 or tow vehicle damage.

8. Rotate wheel while pumping grease into

fitting.

9. Continue to pump grease until clean grease

is extruded through the outer bearing.

10. Rotate wheel while pumping grease into

fitting.

11. Clean old grease from around the bearing

cap.

12. Install the rubber plug in the grease cap.

13. Repeat on the other wheel bearing.

Manual wheel bearing greasing is only a

semi-annual service point. Failure to

perform annual wheel bearing service and

inspection may result in damage to the axle,

wheel bearings or MMP-4 if not preformed.

INSPECTION

1. Inspect axle for cracking, damage and

security.

2. Inspect springs for worn eye bushings, bent,

loose or broken shackles, mounts and bolts,

sagging or broken leafs, loose or damaged

U-bolts.

3. Check for loose wheel bearings.

4. Inspect lug nuts to ensure all are present

and torque properly to 80 to 90 ft/lbs (110

to 125 Nm).

5. Inspect for wheel seal leakage.

6. Inspect tires for inflation to 80 psi (550

kpa), cracking, uneven wear, tread and side

wall damage.

7. Inspect fender assembly for security and

damage.

REPAIR

1. Axle tube, replace as required.

2. Damaged springs or mounting hardware,

replace as required.

3. Worn spring eye bushings, loose spring

bolts and damaged or worn shackles,

replace as required.

4. Fender damage, repair as required.

5. Tire for wear or damage, replace as

required.

6-2

Page 36

Axle and Suspension

Thickener Type

Lithium Complex

Dropping Point

215°C (419°F)

Minimum

Consistency

NLGI No. 2

Additives

EP, Corrosion &

Oxidation Inhibitors

Viscosity Index

80 Minimum

Nut Locking Tab

6. Wheel bearings:

a. Secure MMP-4 with jack stands and

wheel chocks.

b. Jack up 1 tire and secure axle.

c. Remove tire and rim assembly.

d. Remove wheel bearing grease cap.

e. Remove cotter pin or bend clear the nut

locking tab.

f. Remove spindle nut by turning nut

CCW.

g. Remove hub assembly.

h. Inspect hub for damaged threads,

missing or damaged studs. Replace as

required.

i. Inspect grease seal for damage (e.g;

tears, cracks, leaks and distortion).

j. To remove grease seal; pry out of hub

with a long handled screwdriver.

k. Clean and inspect wheel bearings and

bearing races for corrosion, pitting,

wear, heat discoloration and

free/smooth movement. Replace as

required.

MMP 4-2

5 Nov 2011

SECTION 6

Never spin the wheel bearing with

compressed air. The bearing may be

damaged, causing the bearing explode

causing severe personal injury or death.

REASSEMBLY

1. Pack wheel bearings with a premium,

water resistant, high speed wheel

bearing grease.

2. Apply a light coat of grease on the

bearing races.

Recommended Wheel Bearing

Lubrication Specifications are as

follows;

3. Install inner wheel bearing in hub.

4. Install new grease seal in hub using a

small hammer or proper seal installation

tool.

5. Install hub on spindle.

6. Install outer wheel bearing onto the

spindle.

7. Install bearing retaining washer and

spindle nut.

6-3

Page 37

MMP 4-2

5 Nov 2011

Axle and Suspension

8. Tighten spindle nut to 50 ft/lbs (68

Nm).

9. Loosen nut to remove the torque. Do

not rotate the hub

10. Finger tighten until just snug.

11. Install and secure cotter pin or nut

locking tab.

12. Install wheel bearing grease cap.

13. Install tire and rim assembly.

14. Tighten lug nut using a cross tightening

sequence to 15 to 20 ft/lbs (20 to 27

Nm).

Use an anti-seize compound on the

threads of the lug studs. This will

prevent galling and seizure of the lug

nut to the stud.

15. Final torque lug nuts to 80 to 90 ft/lbs

(110 to 125 Nm).

16. Remove jack stands and lower wheel to

ground.

Re-torqueing of lug nuts is required

after initial 50 miles (80 km) of travel

and then again after 200 miles (320 km)

of travel. Failure to ensure proper lug

nut torque may result in tire, wheel or

hub failure that will cause damage to

MMP-4 and tow vehicle.

SECTION 6

6-4

Page 38

SECTION 7

Frame and Booms

Contents

Description …………………………….. 7-1

Inspection ……………………………… 7-1

DESCRIPTION

The MMP-4 frame is constructed from steel

tubing welded together to form a rigid mounting

platform that the components of the MMP-4 are

attached to. The frame is equipped with 3

adjustable stabilizing jacks, a movable hitch,

mounting pads for the diesel engine, hydraulic

and fuel tanks, travel lock mounts for the inlet

and discharge booms, safety chain lock anchors,

hydraulic cylinder mounts, suspension mounts,

mounting structures for the boom pivot and

hydraulic control valve mounting, fenders and

lighting.

INSPECTION

1. Inspect frame for damage and missing parts.

2. Inspect all welds for cracks, rust or damage.

3. Inspect hitch assembly and coupling for

security, serviceability, damage and missing

parts.

MMP 4-2

5 Nov 2011

Repair …………………………………… 7-4

4. Inspect battery box for security and damage.

5. Inspect landing gear/stabilizer legs for

security, serviceability and damage.

6. Inspect engine mounting bolts for security.

7-1

Page 39

MMP 4-2

5 Nov 2011

SECTION 7

Frame and Booms

7. Inspect discharge boom, travel locks and

mounts for security and damage.

8. Inspect fenders for security and damage.

9. Inspect lighting for security, damage and

function.

10. Inspect boom mounting, pivot point, travel

locks and Victaulic coupling for lubrication,

security, damage and leaks.

7-2

Page 40

SECTION 7

Frame and Booms

11. Inspect fuel tank for mounting security and

damage, fuel level, fuel level gauge and

filler cap serviceability and damage, fuel

shut off valve for security, damage and

leaks.

12. Inspect inlet boom, travel locks and

mounting for lubrication, security, damage

and serviceability.

13. Inspect hinge pins, flanges gaskets for

lubrication, security, wear and damage.

MMP 4-2

5 Nov 2011

13. Inspect hydraulic control valve and mount

for security, damage, leaks and missing

parts.

14. Inspect suspension spring mounts for

security, damage and wear.

7-3

Page 41

MMP 4-2

5 Nov 2011

SECTION 7

Frame and Booms

15. Inspect hydraulic cylinder mounting for

lubrication, security, cracks, damage, worn

pins, and missing parts.

16. Inspect safety chains and safety chain locks

for security, damage and missing parts.

REPAIR

1. Replace damaged or missing parts as

required.

2. If frame damage is noted, or you have a

question about the MMP4 contact:

MEGA Corp. Product Support Group at:

Toll free US 1-800-345-8889

Direct 1-505-345-2661

www.megacorpinc.com for more contact

information or repair options and

procedures.

3. Adjust, secure or replace parts as required.

7-4

Page 42

MMP 4-2

FREQUENCY

STEP

FRAME AND

SUSPENSION

DAILY

BEFORE

TRANSPORT

FIRST

50

MILES

FIRST 200

MILES

SEMI-

ANNUALLY

ANNUALLY

1

Check frame and

suspension for cracks,

damaged or missing

components.

Repair or replace as

required.

X

2

Verify lug nut torque.

(80 to 90 ft/lbs or 110 to

125 Nm)

Re-Torque as

required.

X X

X

3

Check tires and wheel

for security, damage,

inflation (80 psi or 550

kpa) and missing parts.

Repair as required.

X

4

Service wheel bearings

with grease.

X

5

Remove and repack

wheel bearings.

X

6

Check travel locking

components for

serviceability, damage,

proper installation and

missing parts.

Repair as required.

X

5 Nov 2011

SECTION 8

Scheduled Inspections

DESCRIPTION

This section establishes scheduled maintenance inspections of the MMP-4 at designated frequencies.

Performing these inspections will identify potential system discrepancies and allow preventative

maintenance to be performed before a component or system is rendered totally inoperative.

** NOTE: Units operated in extremely low quality water environments may require more frequent

inspections.

8-1

Page 43

MMP 4-2

FREQUENCY

STEP

FRAME AND

SUSPENSION

DAILY

BEFORE

TRANSPORT

FIRST 50

MILES

FIRST 200

MILES

SEMI-

ANNUALLY

ANNUALLY

7

Check lighting system.

Repair as required.

X

8

Check hitch assembly

for security, damage,

proper installation and

missing parts.

Repair as required.

X

9

Check landing gear for

security, damage and

operation.

Repair as required.

X

10

Check pipe work to

include: the Victaulic

coupling, boom flanges

and gaskets, cylinder

mounting and pivot

points for security,

damage, leaks,

serviceability and

missing parts.

Repair as required.

X

11

Check hydraulic tank

mounting bolts for

security, damage and

missing parts.

Repair as required.

X

12

Check fuel tank

mounting bolts for

security, damage and

missing parts.

Repair as required.

X

13

Check engine mounting

bolts for security,

damage and missing

parts.

Repair as required.

X

5 Nov 2011

SECTION 8

Scheduled Inspections

8-2

Page 44

MMP 4-2

FREQUENCY

STEP

FRAME AND

SUSPENSION

DAILY

BEFORE

TRANSPORT

FIRST 50

MILES

FIRST 200

MILES

SEMI-

ANNUALLY

ANNUALLY

14

Check battery box and

contents for security,

damage and missing

parts.

Repair as required.

X

15

Check safety chains,

safety chain mounting

and safety chain

locking pins for

security, damage and

missing parts.

Repair as required.

X

5 Nov 2011

SECTION 8

Scheduled Inspections

8-3

Page 45

MMP 4-2

FREQUENCY

STEP

HYDRAULIC SYSTEM

DAILY

250

Hours

500

Hours

1000

Hours

1

Check hydraulic oil for proper

level, clarity, foaming and signs of

contamination.

Repair, adjust or replace as

required.

X

2

Check hydraulic control valve for

security, damage, function and

leaks.

Repair as required.

X

3

Check hydraulic pump for

security, damage and leaks.

Repair as required.

X

4

Check hydraulic oil cooler for

security, damage and leaks.

Repair as required.

X

5

Check hydraulic hosing for

security, damage and leaks.

Repair as required.

X

6

Check hydraulic cylinders and flow

controls for security, damage and

leaks.

Repair as required.

X

7

Check hydraulic oil filter for

security, damage and leaks.

Repair as required

X

8

Check hydraulic pressure

regulator for function and pressure

setting (2,100 psi or 14,450 kpa).

Adjust or repair as required.

X

9

Drain and refill hydraulic reservoir

and replace hydraulic filter

element.

X

10

Check hydraulic pump drive

coupling for wear, security and

damage.

Repair as required.

X

5 Nov 2011

SECTION 8

Scheduled Inspections

8-4

Page 46

SECTION 8

FREQUENCY

STEP

WATER PUMP

ASSEMBLY

DAILY

250 Hours

500 Hours

1

Check water pump for security, damage,

obstructions and operation.

Repair as required.

X

2

Check water pump trash screen for

security, obstructions and damage.

Repair as required.

X

3

Check for excessive vibrations and noise.

Repair as required.

X

4

Remove water pump assembly from inlet

boom and check for:

Hydraulic drive motor security,

damage and leaks.

Bearing oil reservoir levels.

Bearing oil reservoirs for

contamination.

Impeller damage.

Water pump housing bolts for

security, damage and missing parts.

Repair, adjust or replace as required.

X

5

Grease water pump suction bowl bearing.

X

6

Remove water pump from inlet boom and

change bearing reservoir oil.

X

Scheduled Inspections

MMP 4-2

5 Nov 2011

8-5

Page 47

MMP 4-2

FREQUENCY

STEP

ENGINE AND

ENGINE CONTROLS

DAILY

250 Hours

500 Hours

1

Refer to the correct engine Operation

and Maintenance Manual for required

service intervals and procedures.

Follow and perform all required service

procedures, operations, conditions and

schedules.

X

2

Check and ensure all engine control

functions are in proper working order.

Repair as required.

X

3

Check all engine safety guards for

security, damage and missing parts.

Repair as required.

X

4

Check engine start battery and cables for

security, damage, corrosion, water level

(if required) and condition.

Repair as required.

X

5

Check engine throttle control for

security, damage and proper operation.

Repair as required.

X

6

Check engine control box for security,

damage and proper operation.

Repair as required.

X

7

Check engine MURPHY Safety switch

for security, damage and proper

operation.

Repair as required.

X

8

Check engine muffler and intake system

for security, damage, and condition.

Repair as required.

X

9

Check diesel fuel level to ensure proper

level to allow unit to run for daily

operation.

Refill as required.

X

10

Check engine control cable for security

and damage.

Repair as required.

X

5 Nov 2011

SECTION 8

Scheduled Inspections

8-6

Page 48

SECTION 9

Special Inspections

DESCRIPTION

This section contains special inspection

requirements for a specific system after use, an

unusual event or storage.

STORAGE/WINTERIZATION

Entering

1. Remove any exterior dirt, grease and grime

that may trap moisture.

2. Flush all water suction and discharge tubes

(e.g. water pump,).

3. Ensure all water is drained from the tubes

and water pump.

4. Ensure all covers/caps for fluid reservoirs

are in proper operating condition and are

secured to the openings.

5. Fill Fuel tank to capacity, close fuel shut off

valves at bottom of fuel tank.

6. Check tires for proper inflation.

7. Check Boom retaining hardware, ensure it

is operational and secure.

8. Lubricate all grease points (e.g. Hinge pins,

cylinder pins water pump suction bowl).

9. Check battery fluid level and charge.

10. Disconnect battery cables from battery.

11. Service all engine systems per CAT

SEBU7276-01 service manual.

12. If possible, shelter entire unit from the

elements.

MMP4 - 2

5 Nov 2011

Removing

1. Remove all covers and seals from all

fill/discharge openings and components.

2. Inspect piping for debris that may damage

unit that water will be pumped into.

3. Check to ensure all water pump reservoirs

are filled to the correct level and the fluid is

not contaminated.

4. Remove any exterior dirt, grease and grime

and treat any corrosion.

5. Service all Engine systems per CAT

SEBU7276-01 service manual.

6. Check all fluid levels for condition and

level, replace or adjust as necessary.

7. Check Braking system (if equipped) repair

as necessary.

8. Check safety chains for damage.

9. Check lighting system for proper operation,

repair as necessary.

10. Clean and connect battery cables to battery.

11. Perform all ‘Daily’ maintenance checks,

repair as necessary.

12. Perform a full functional check of all MMP

control systems.

9-1

Page 49

MMP4 - 2

5 Nov 2011

SECTION 9

Special Inspections

9-2(Blank)

Page 50

MMP4 - 2

A. AXIAL WATER PUMP GROUP, 303910

PART DESCRIPTION

PART NO.

QTY

1. Gasket, 12”

304174

2

2. Grommet

303910-03

2

3. Thrush Collar

303910-17

1

4. Lower Seal

303910-20

1

5. Upper Seal

303910-25

1

6. O-Ring, Bearing, (Lower)

303910-31

2

7. O-Ring, Hydraulic Motor, (Upper)

303910-35

2

B. HYDRAULIC GROUP

PART DESCRIPTION

PART NO.

QTY

1. Cylinder, 12”, Discharge Boom

303923

1

2. Cylinder, 20”, Inlet Boom

303924

1

3. Filter, Hydraulic, 400 psi

304704

2

4. Oil, Hydraulic, Clarity (35 Gallon Capacity)

USE LOCAL

SUPPLIER

35 gal

C. WATER PIPING (BOOM) GROUP

PART DESCRIPTION

PART NO.

QTY

1. Sock, Down spout, tapered

304196

2

2. Tie Down Strap, 2”

304291

1

3. Pin, Hinge pivot

037627-05

1

4. Neoprene gasket, Boom flange

304117

2

5. Pin, Hitch, 1”

303935

2

6. Chain, 3/8”, GR 70, 6 ft.

038453-11

1

7. Shackle, 3/8”

355020

4

5 Nov 2011

SECTION 10

Recommended Support Parts

DESCRIPTION

This section contains a listing of recommended support parts that should be available in the supply

warehouse. Once parts are issued from warehouse stock ensure depleted quantities are replenished to

keep the recommended support parts package at 100%.

The tables are categorized by specific sub system of the MMP. DO NOT FORGET that all MMP’s are

not configured the same and there are some variations in systems due to changes in equipment and

actual production dates. Ensure MMP serial numbers and actual component part numbers are checked

before ordering any parts.

10-1

Page 51

MMP4 - 2

D. FRAME AND SUSPENSION GROUP

PART DESCRIPTION

PART NO.

QTY

1. Wheel and Tire Assembly

303933

1

2. Hitch pin, 1”

303935

2

3. Chain, 3/8”, GR 70, 2.4 ft

038453-13

1

4. Shackle, 3/8”

355020

2

5. Bearing, Wheel, Inner

304157

2

6. Bearing, Wheel, Outer

304158

2

7. Seal, Wheel Bearing

304159

2

8. Jack stand

037708

1

E. CAT 3054B ENGINE SUPPORT PARTS GROUP

REFER TO SEBU7276-01 INDUSTRIAL ENGINE MANUAL FOR SPECIFIC PARTS AND SERVICE

INFORMATION

PART DESCRIPTION

PART NO.

QTY

1. Filter, Engine Oil

304192

1

2. Filter, Element, Fuel

304188

1

3. Filter, Element, Fuel/Water Separator

304190

1

4. Filter, Element, Air, Primary

304186

1

5. Filter, Element, Air, Secondary

304187

1

6. Seal, Filter, Fuel

304189

1

7. Seal, Filter, Water Separator Base

304191

1

5 Nov 2011

SECTION 10

Recommended Support Parts

10-2

Page 52

MMP4 - 2

5 Nov 2011

SECTION 10

Recommended Support Parts

NOTES

10-3

Page 53

MMP 4-2

5 Nov 2011

SECTION 10

Recommended Support Parts

10-4(Blank)

Loading...

Loading...