MEGA Corp. MMP4-1 User Manual

MMP4-1

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

Operators Manual

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

MMP4(T2)-OPS-1

4 Oct 2011

TABLE OF CONTENTS

Page

Definitions and Abbreviations ………………………………………………………… 1-1

System Description ……………………………………………………………………. 2-1

System Operation ……………………………………………………………………… 3-1

Appendix (Operators Checklist) ..…………………………………………………….. 4-1

A

MMP4(T2)-OPS-1

4 Oct 2011

TABLE OF CONTENTS

B(Blank)

SECTION 1

Definitions and Abbreviations

Contents

Manual Usage .,…………………………... 1-1

Warning, Caution & Notes ……………..… 1-1

Shall, Will, Should and May …………..…. 1-1

MANUAL USAGE

This technical manual only contains information

required to safely operate the MMP4 powered by

a CAT 3054B diesel engine. See the CAT

3054B Engine Maintenance and Operators

Safety Manual for specific vehicle system

information and maintenance procedures. The

exact location of the hazards and description of

the hazards are reviewed in this section. All

personnel working on or operating the machine

must become familiarized with all the safety

messages.

If your system is not covered in this manual or

are having difficulties please contact the MEGA

Corp. Product Support Group at:

Toll free US 1-800-345-8889

Direct 1-505-345-2661

or visit our website at www.megacorpinc.com

for more detailed contact information.

Due to the nature of these processes, ensure that

all safety information, warnings and instructions

are read and understood before any operation or

any maintenance procedures are performed. This

service function takes place with heavy

components and at moderate heights, ensure

proper safety procedures are maintained when

performing this service. Failure to use and

maintain proper safety.

MMP4(T2)-OPS-1

4 Oct 2011

Safety Messages ……………………….…. 1-2

Abbreviations …………………………….. 1-5

MMP4 T2 Overview …………….....….…. 1-6

WARNING, CAUTIONS AND NOTES

The following definitions are found throughout

the manual and apply as follows:

Operating procedures and techniques, which

could result in personal injury and/or loss of life

if not carefully followed.

Operating procedures and techniques, which

could result in damage to equipment if not

carefully followed.

Operating procedures and techniques that are

considered essential to emphasis.

USE OF SHALL, WILL, SHOULD AND

MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a procedure

is recommended.

May - Used to indicate an acceptable or

suggested means of accomplishment.

1-1

MMP4(T2)-OPS-1

4 Oct 2011

SECTION 1

Definitions and Abbreviations

SAFETY MESSAGES

There are several specific safety messages on

this machine. The exact location of the hazards

and description of the hazards are reviewed in

this section. All personnel working on or

operating the machine must become familiarized

with all the safety messages.

Make sure that all of the safety messages are

legible. Clean the safety messages or replace the

safety messages in you cannot read the words.

Replace the illustrations if the illustrations are

not legible. When you clean the safety

messages, use a cloth, water and soap. Do not

use solvent, gasoline or other harsh chemicals to

clean the safety messages. Solvents, gasoline or

harsh chemicals could loosen the adhesive that

secures the safety messages. Loose adhesive

will allow the safety messages to detach.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part

that is replaced, install a new safety message on

the replacement part.

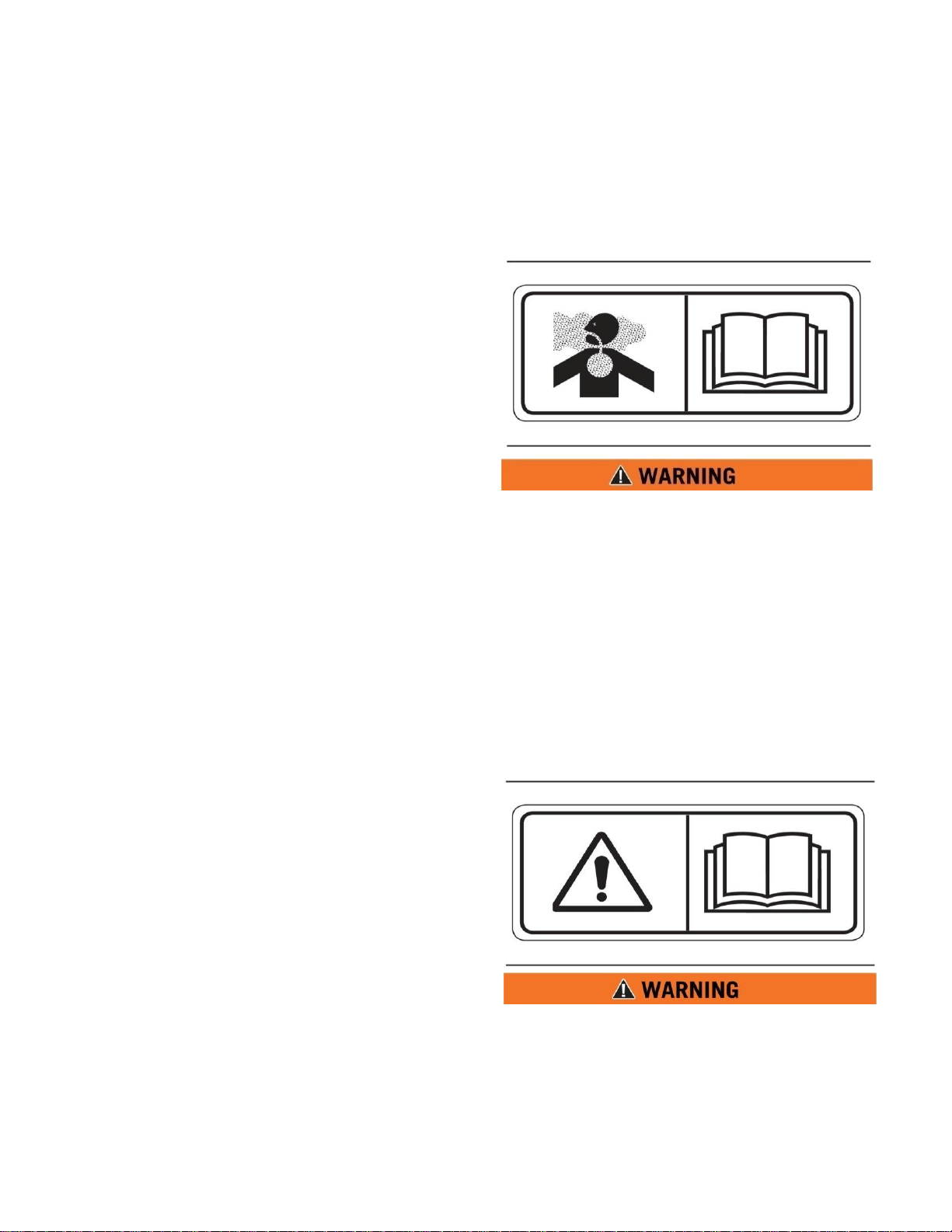

Toxic Gas Hazard (1)

This safety label is located on the side of the tank

and at all water fill entrances.

Cutting or welding operation on the inside of

the tank can cause the accumulation of toxic

gases. Read and understand instructions and

warnings in the Maintenance Manual.

Failure to provide proper ventilation or

breathing apparatus while conducting these

operations may result in serious injury or

death.

Do Not Operate (2)

This safety label is located on the outside of the

front and rear control boxes. (If equipped)

Do not open this control box unless you read

and understand the instructions and warnings

in the Operator and Maintenance Manual.

Failure to follow instructions or heed the

warnings could result in serious injury or

death.

1-2

SECTION 1

Definitions and Abbreviations

Backing Runover Hazard (3)

This safety label is located on the rear of the tank

and inside the cab.

The vehicle is equipped with a back-up alarm.

Alarm must sound when operating this

vehicle in reverse. Failure to maintain a clear

view in the direction of travel could result in

serious injury or death.

Freezing (4)

This safety label is located on the side of the

tank, at the sump drain, and on the pump.

Drain tank, fill pipe and valve in freezing

weather. Refer to the Operator and

Maintenance Manual for the procedure to

follow.

MMP4(T2)-OPS-1

4 Oct 2011

Non-Potable (5)

This safety label is located on the side of the tank

and sump drain.

Water held within tank is not potable. Do not

use tank for transport of water intended for

human or animal consumption or serious

injury or death may result.

Do Not Hoist While in Motion (6)

This safety label is located inside the cab.

Do not engage hoist cylinders while vehicle is

in motion. Before engaging hoist STOP the

vehicle. Do not engage hoisting cylinders

unless you read and understand the

instructions and warnings in the Operator or

Maintenance Manual. Failure to follow

instructions or heed the warnings will result

in injury or death.

1-3

MMP4(T2)-OPS-1

4 Oct 2011

SECTION 1

Definitions and Abbreviations

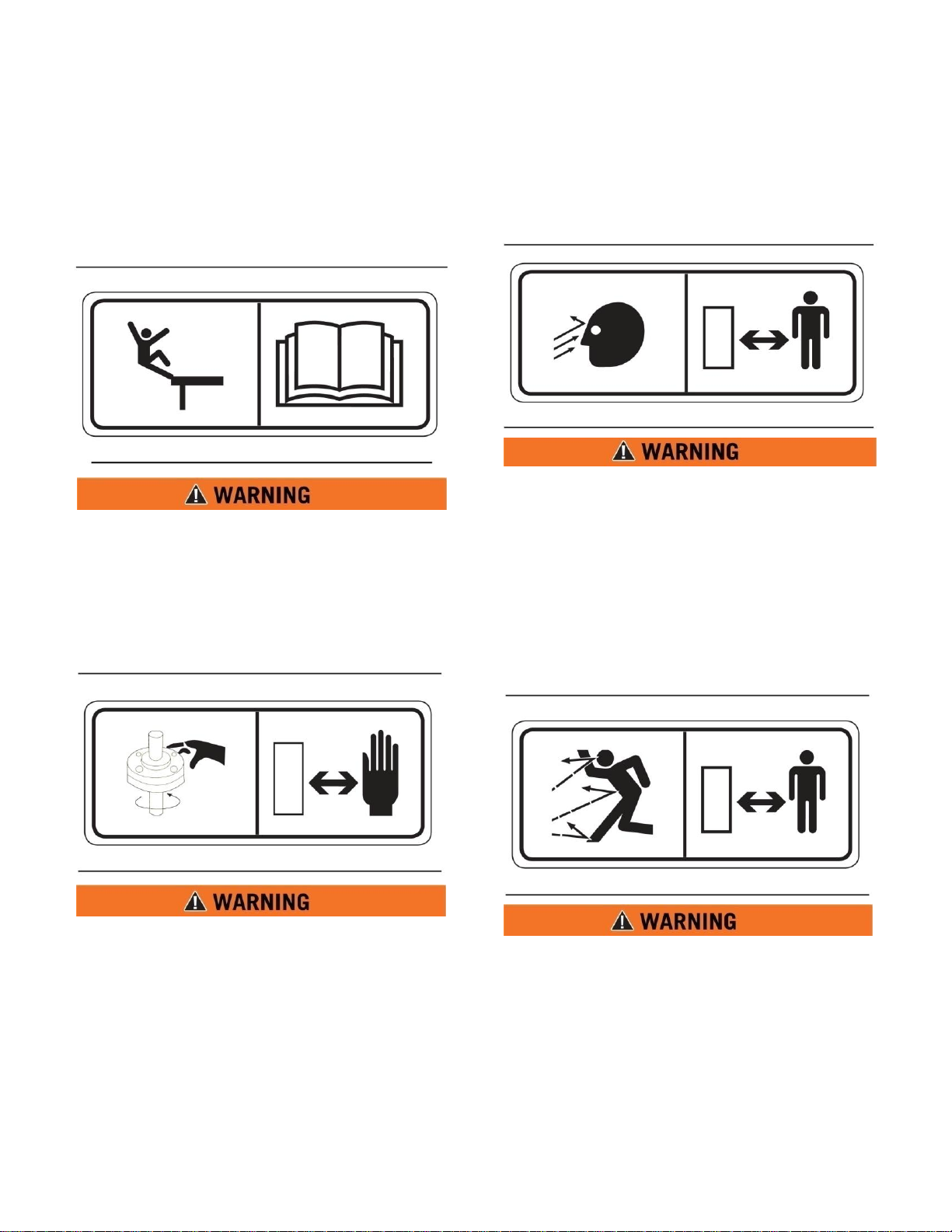

Fall Hazard (7)

This safety label is located at the top of the front

and rear of the tank.

Do not walk on the top of tank without fall

arrest PPE. Serious injury or death could

occur from a fall.

Rotating Shaft (8)

This safety label is located on the pump.

Do not place your hand or tools within pump

bell while pump is rotating and/or pressure

held within the motor supply hose. Refer to

the Operator and Maintenance Manual for

the procedures to operate and maintain the

pump. Failure to follow proper procedures

could result in serious injury.

High Pressure Sprayheads (9)

This safety label is located on the spraybar.

Do not operate sprayheads until all personnel

are a safe distance away from the vehicle.

High Pressure Monitor (10)

This safety label is located on top of the cab

control box.

Do not operate the monitor until all personnel

are a safe distance away from the vehicle.

1-4

SECTION 1

Definitions and Abbreviations

High Pressure Motor (11)

This safety label is located on the hydraulic

motor.

Hydraulic motor and supply lines contain oil

under high pressure. Improper removal and

repair procedures could cause severe injury.

To remove or repair, instructions in the

Maintenance Manual must be followed.

Confined Space (12)

This safety label is located near water tank

access and fill ports.

Do not enter confined spaces without

following established site specific

procedures. Failure to follow proper safety

procedures will result in serious injury or

death.

MMP4(T2)-OPS-1

4 Oct 2011

ABBREVIATIONS

cc – Cubic Centimeters

CCW – Counter Clockwise

CW - Clockwise

fl. oz. – Fluid Ounce

FT - Feet

FPM – Feet Per Minute

GPM – Gallons Per Minute

IN/SQ FT – Inches per Square Feet

KM-H – Kilometers Per Hour

Kg – kilograms

kPa - Kilopascals

l – liters

lpm – Liters per minute

LT – Left as viewed from the operators

position facing forward

m - meters

MPH – Miles Per Hour

MMP – MEGA Mobile Pump

Nm – Newton meters of torque

psi - pounds per square inch

RPM – Revolutions Per Minute

RT – Right as viewed from the operators

position facing forward

SQ FT – Square Feet

VDC – Volts, Direct Current

1-5

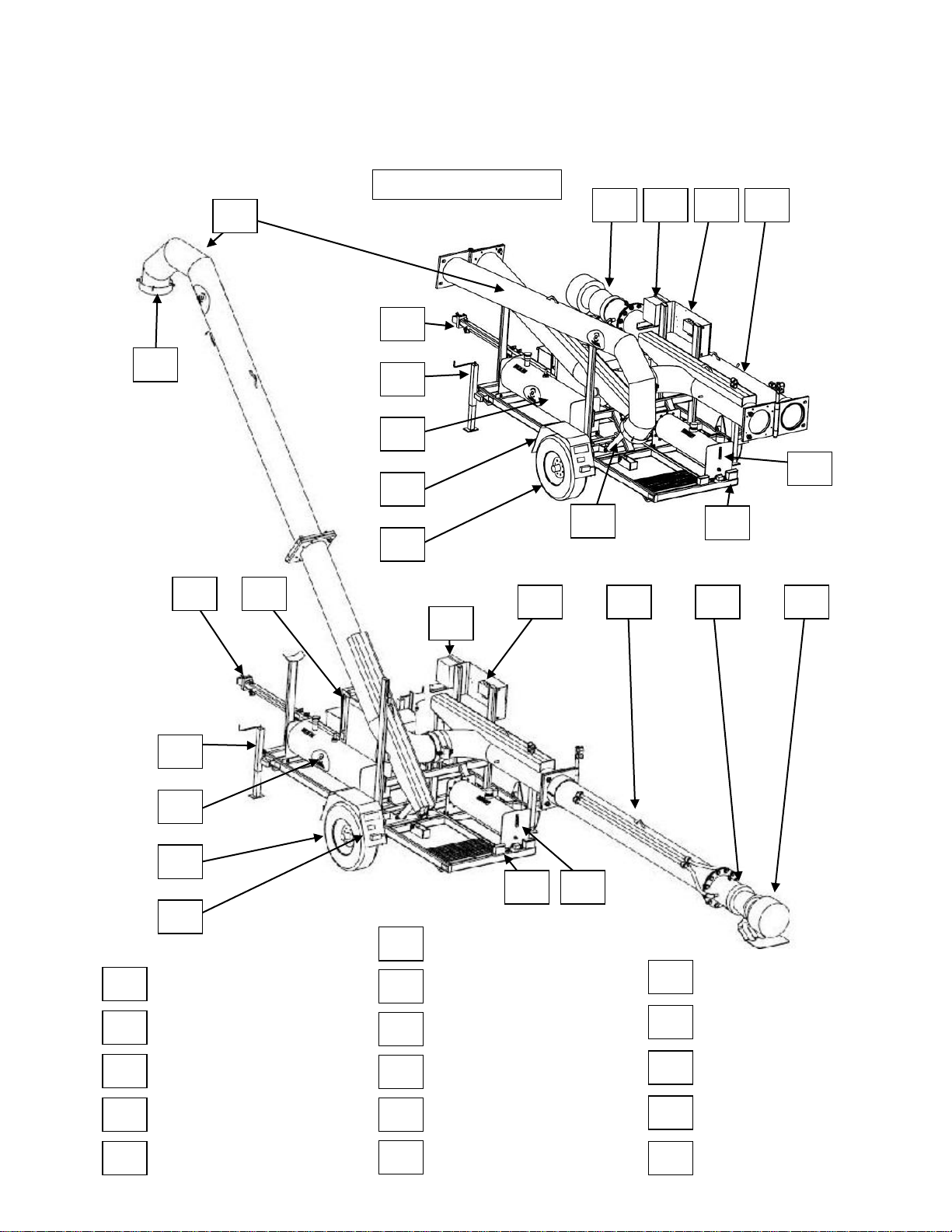

MMP4(T2)-OPS-1

1

2

3

13

16 5 15 8 7

14 6 9

10

11

4 3 8 5 16

15

6 7 10

11 1413

12 1 2 3 4

5

Discharge Boom

Vacuum Break

Tow Hitch

CAT 3054 Diesel Engine

Landing Gear (3)

6 7 8

9

10

11

Tire and Rim Assembly

Fender

5o Gallon Diesel Fuel Tank

Discharge Boom Lift Cylinder

Tail Lights

Hydraulic Oil Tank

12

13

14

16

15

Inlet Debris Screen

Axial Water Pump

Inlet Boom

Hydraulic Control Valve

Engine Control Box

MMP4 T2 Overview

4 Oct 2011

SECTION 1

Definitions and Abbreviations

1-6

SECTION 2

System Description

Contents

MMP4 Description and Usage ………… 2-1

MMP4 Frame …………………………… 2-1

Hydraulics ……………………………….. 2-1

MMP4 DESCRIPTION AND USAGE

The MMP4 is designed to be towed behind a

typical ¾ ton or 1 ton capacity pickup truck.

The MMP4 can be transported over the road to

just about any water holding pond area used for

filling water distribution equipment.

The MMP4 can be set up, made ready for

operation and reconfigured for transport by 1

person and simple hand tools. The MMP4’s

primary usage is to lift water from a water

holding pond and discharge the water into the

fill port on water haulage equipment. The

MMP4 is equipped with a Diesel engine with

an integrated hydraulic pump and oil cooler, 50

gallon (190 liter) diesel fuel tank, 32 gallon (87

liter) hydraulic oil reservoir, 3 circuit hydraulic

control valve, DOT rated lighting, 6,000 pound

(2,725 kg) capacity axle and tire combination, 3

point stabilizing jacking system, hydraulically

operated inlet and discharge boos, 12” axial

hydraulic drive water pump and a folding hitch

assembly. The MMP4 is capable of lifting

water approximately 25’ (7.62 meters) with a

discharge port approximately 17’ (5.2 meters)

above ground level.

MMP4(T2)-OPS-1

4 Oct 2011

Axial Water Pump ………………………. 2-2

Engine Control Box ……………………... 2-2

MMP4 FRAME

The MMP4 frame is the back bone of the unit,

manufactured using rectangular tubing.

Attached to the frame is the 6,000 lbs (2,725

kg) capacity axle assembly, boom supporting

structures, hydraulic and fuel tanks, engine

assembly including a battery and tool storage

box, a fold away hitch assembly, rear walk

way, fenders and DOT rated lighting.

HYDRAULICS

The hydraulic system of the MMP4 consists of

an engine mounted hydraulic pump, 35 gallon

(135 liter) hydraulic oil tank equipped with an

inlet screen, return oil diffuser, external shut off

valve, oil level sight glass and a breather

equipped filler cap. The balance of the

hydraulic system is designed with a 10 micron

rated return oil filter, 3 spool hydraulic control

valve with pressure regulation capability, a

hydraulic oil cooler equipped with a bypass

valve to protect against hydraulic shock when

the oil is cold, hydraulically driven submergible

12” axial water pump, hydraulic cylinders to

lift the inlet and discharge booms.

2-1

Loading...

Loading...