Page 1

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

Operators Manual

MES34-OPS-1

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

Page 2

MES34-OPS-1

21 Feb 2014

TABLE OF CONTENTS

Page

Section 1 Definitions and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Section 2 System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Section 3 Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section 4 Normal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Section 5 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section 6 MES34 Operator’s Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

A

Page 3

MES34-OPS-1

21 Feb 2014

TABLE OF CONTENTS

B (Blank)

Page 4

SECTION 1

Definitions and Abbreviations

Contents

MES34-OPS-1

21 Feb 2014

Manual Usage....................................................................1-1

Warning, Caution And Notes .......................................1-1

Use Of Shall, Will, Should And May............................1-1

MANUAL USAGE

This technical manual only contains information

required to safely install or service an MES34 elevator

scraper system. See the CAT 631 Operator’s Safety

Manual for tractor specific system information and

operating procedures. If your system is not covered in

this manual or you are experiencing difficulties,

please contact MEGA Corp. Product Support Group

at: US toll free: 1-800-345-8889, Direct: 1-505-3452661 or visit our website at www.megacorpinc.com

for more detailed contact information.

The exact location of the hazards and description of

the hazards are reviewed in this section. All personnel

working on or operating the machine must become

familiarized with all the safety messages.

Due to the nature of these processes, ensure that all

safety information, warnings and instructions are

read and understood before any operation or any

maintenance procedures are performed. Some

procedures take place with heavy components and

at moderate heights, ensure proper safety

procedures are maintained when performing these

actions. Failure to use and maintain proper safety

equipment and procedures will cause injury, death or

damage to equipment.

Safety Messages...............................................................1-2

Abbreviations....................................................................1-3

MES34 Overview (Typical) ............................................1-4

WARNING, CAUTION AND NOTES

The following definitions are found throughout the

manual and apply as follows:

Operating procedures and techniques, which could

result in personal injury and/or loss of life if not

carefully followed.

Operating procedures and techniques, which could

result in damage to equipment if not carefully

followed.

Operating procedures and techniques that are

considered essential to emphasize.

USE OF SHALL, WILL, SHOULD AND MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a procedure is

recommended.

May - Used to indicate an acceptable or suggested

means of accomplishment.

1-1

Page 5

MES34-OPS-1

21 Feb 2014

SECTION 1

Definitions and Abbreviations

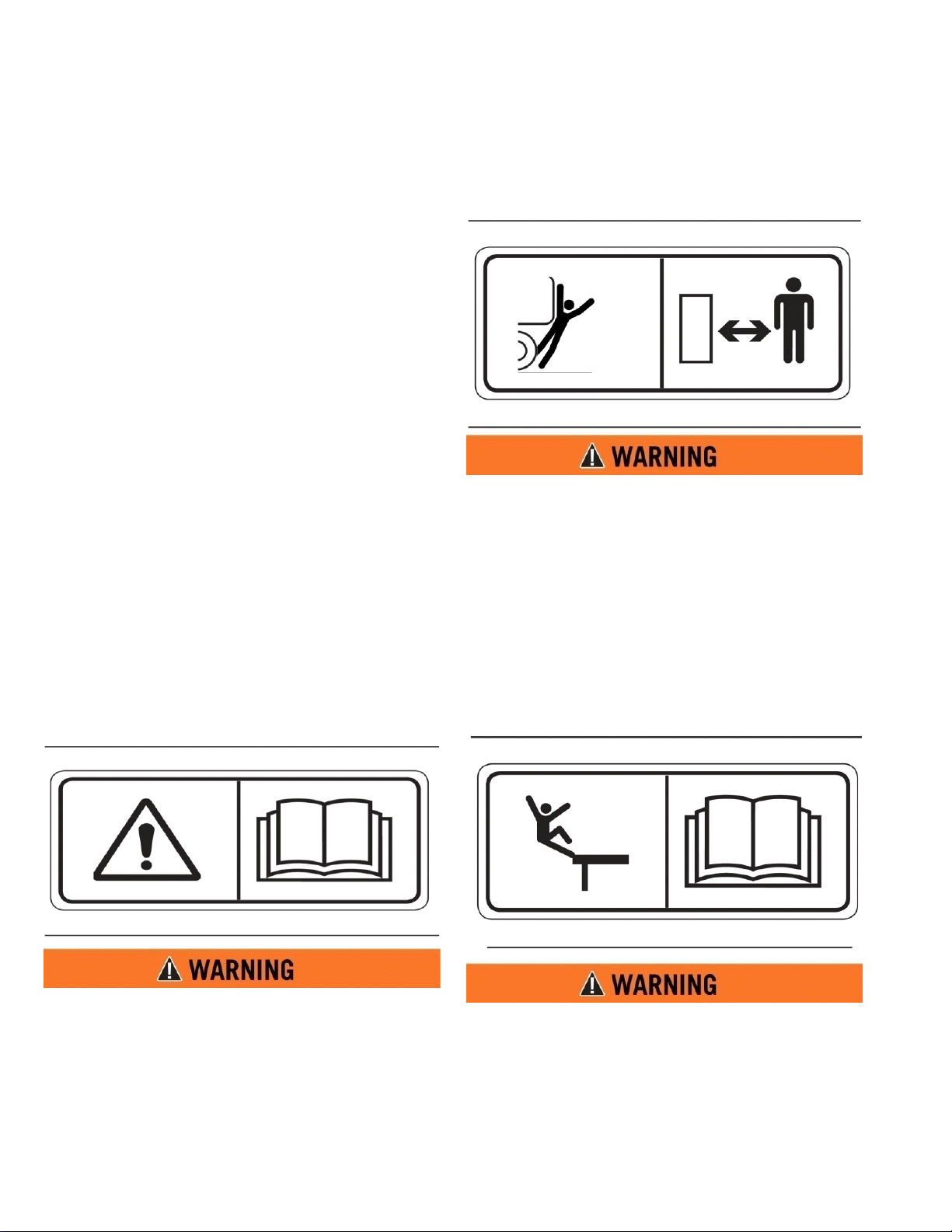

SAFETY MESSAGES

There are several specific safety messages on this

machine. The exact location of the hazards and

description of the hazards are reviewed in this

section. All personnel working on or operating the

machine must become familiarized with all the safety

messages.

Make sure that all of the safety messages are legible.

Clean the safety messages or replace the safety

messages in you cannot read the words. Replace the

illustrations if the illustrations are not legible. When

you clean the safety messages, use a cloth, water and

soap. Do not use solvent, gasoline or other harsh

chemicals to clean the safety messages. Solvents,

gasoline or harsh chemicals could loosen the

adhesive that secures the safety messages. Loose

adhesive will allow the safety messages to detach.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part that

is replaced, install a new safety message on the

replacement part.

BACKING RUNOVER HAZARD (2)

This safety label is located on the rear of the scraper

and inside the cab.

The vehicle is equipped with a back-up alarm.

Alarm must sound when operating this vehicle in

reverse. Failure to maintain a clear view in the

direction of travel could result in serious injury or

death.

DO NOT OPERATE (1)

This safety label is located on the outside of the cab.

Do not open this control box unless you read and

understand the instructions and warnings in the

Operator and Maintenance Manual. Failure to

follow instructions or heed the warnings could

result in serious injury or death.

FALL HAZARD (3)

This safety label is located at the top of the scraper.

Ensure PPE fall arrest harness is worn, adjusted

properly and attached to an anchor point when

performing maintenance on top of the MES34 or

when fall hazards are present. Failure to use PPE

when fall hazards are present may result in

serious personnel injury or death.

1-2

Page 6

SECTION 1

Definitions and Abbreviations

MES34-OPS-1

21 Feb 2014

HIGH PRESSURE MOTOR (4)

This safety label is located on the hydraulic motor.

Hydraulic motor and supply lines contain oil

under high pressure. Improper removal and

repair procedures could cause severe injury. To

remove or repair, instructions in the Maintenance

Manual must be followed.

ABBREVIATIONS

ft - feet

fpm - feet per minute

gpm - gallons per minute

GET - Ground Engaging Tools

KM-H - Kilometers Hour

Kg - kilograms

l - liters

lpm - liters per minute

LT - Le f t

M - meters

MES - MEGA Elevating Scraper

MPH - Miles Per Hour

PPE - Personnel Protective Equipment

psi - pounds square inch

RPM - Revolutions Per Minute

RT - Right

SQ FT - Square Feet

1-3

Page 7

MES34-OPS-1

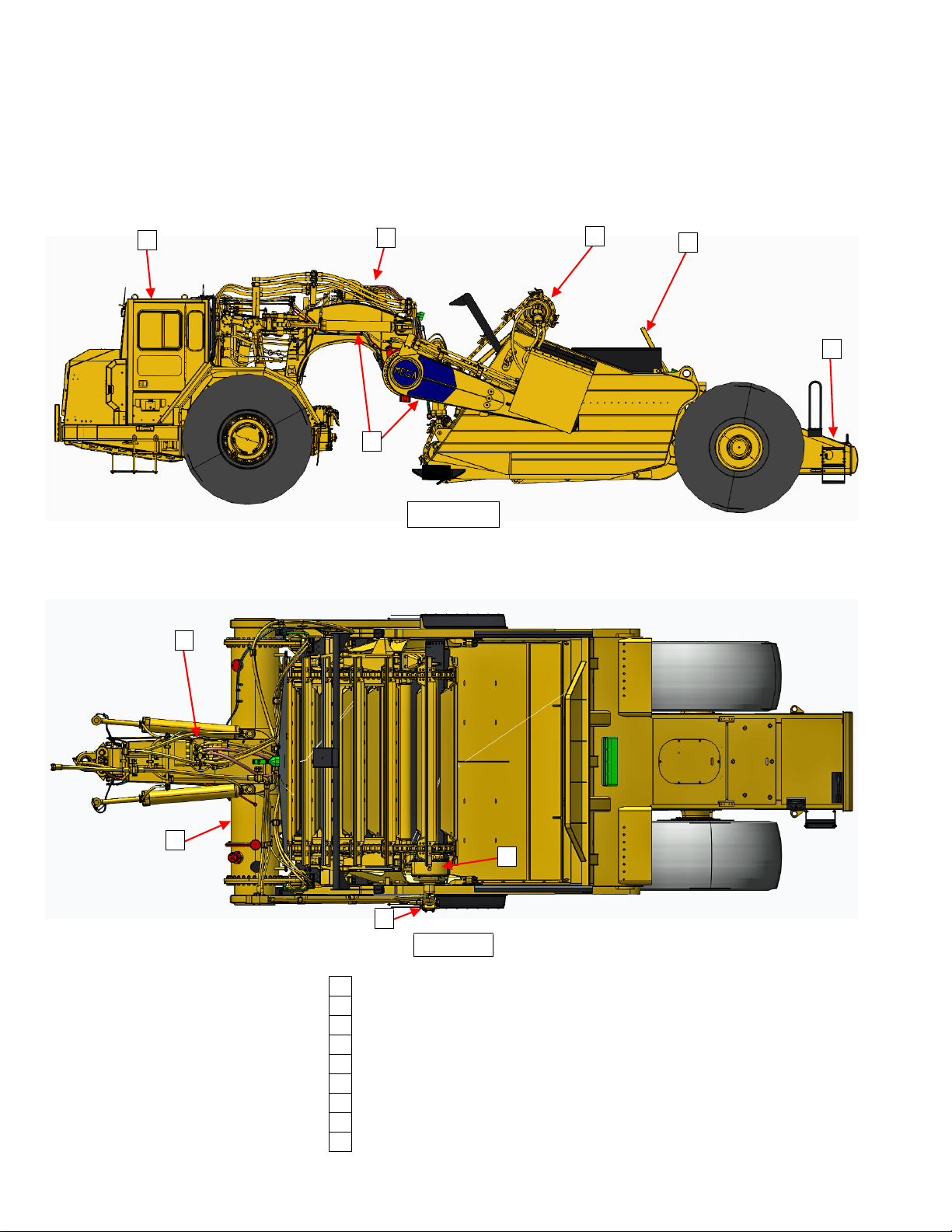

4

1

7

1

631G TRACTOR

2

DRAFT FRAME ASSEMBLY

3

ELEVATOR ASSEMBLY

4

SPILL GUARD

5

REAR BOGIE

6

ELEVATOR DRIVE MOTOR

7

SPEED DECREASER

8

FUEL TANK

9

IMPLEMENT VALVE

SIDE VIEW

TOP VIEW

9

8

5

3

2

9

6

21 Feb 2014

SECTION 1

Definitions and Abbreviations

MES34 OVERVIEW (TYPICAL)

1-4

Page 8

SECTION 2

System Description

Contents

MES34-OPS-1

21 Feb 2014

Description.........................................................................2-1

Scraper Bowl ......................................................................2-1

Rotating Floor....................................................................2-2

Elevator Assembly............................................................2-2

Rear Bogie Assembly ......................................................2-3

DESCRIPTION

The MEGA 34 cubic yard elevating scraper (MES34) is

a high production unit, designed for heavy duty

continuous load/haul/spread operations. It is capable

of performing thin, precise lifts as well as heavy

excavation with little support equipment.

This new scraper bowl is combined with a currentproduction 631G scraper tractor and wheel groups to

provide the latest in power train, operator comfort,

electronic controls and emissions compliance. The

scraper bowl assembly design has been changed

from previously fielded systems to provide increased

reliability in severe duty applications.

All scraper bowl assembly hydraulics, brakes,

electrical, controls, indicating and warning systems

are integrated into the existing 631G tractor control

groups.

The scraper bowl assembly is comprised of a scraper

bowl, rotating floor, elevator, rear bogie, wheel

groups and a draft frame assembly.

Draft Frame Assembly....................................................2-3

Electrical System ..............................................................2-4

Hydraulic System .............................................................2-4

Implement Joystick.........................................................2-5

Rear Brake System...........................................................2-6

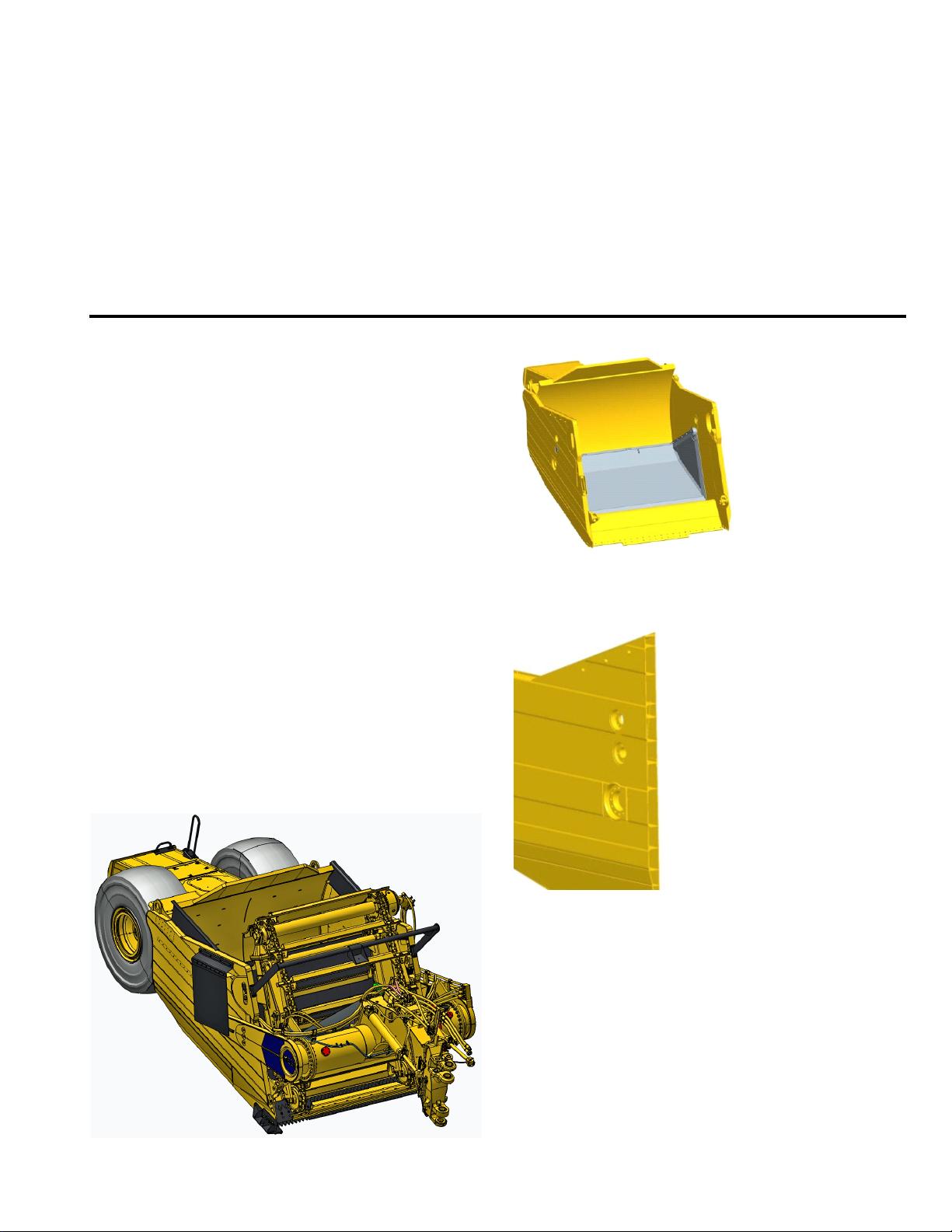

SCRAPER BOWL

The scraper bowl has

a 34 cubic yard/26

cubic meter heaped

capacity for haulage

and an adjustable full

width cutting edge

for precise cutting

and heavy excavating.

The bowl cutting

edge is designed to

support a variety of Caterpillar Ground-Engaging

Tools (GET).

The scraper bowl utilizes a

cellular design in its

construction to add strength

and dent resistance to the bowl

sides. The cellular side wall

construction also provides for

mounting of several of the

moving and stationary bowl

components. These include the

rotating floor, elevator frame

mount arms, gooseneck draft

arm trunnions, bowl lift

cylinders, as well as rear bogie

assembly. Provisions are also available for optional

wear plates that increase bowl service life.

All hydraulic hoses and electrical cables for the rear

bogie functions are routed inside the right bowl wall

to the front of the bowl to eliminate the need for

component shielding. Rubber shrouds are installed

on the outer side walls to prevent wedging of

material between draft arms and outer bowl walls, in

turn protecting draft arms and trunnion ball mounts

from cracking.

2-1

Page 9

MES34-OPS-1

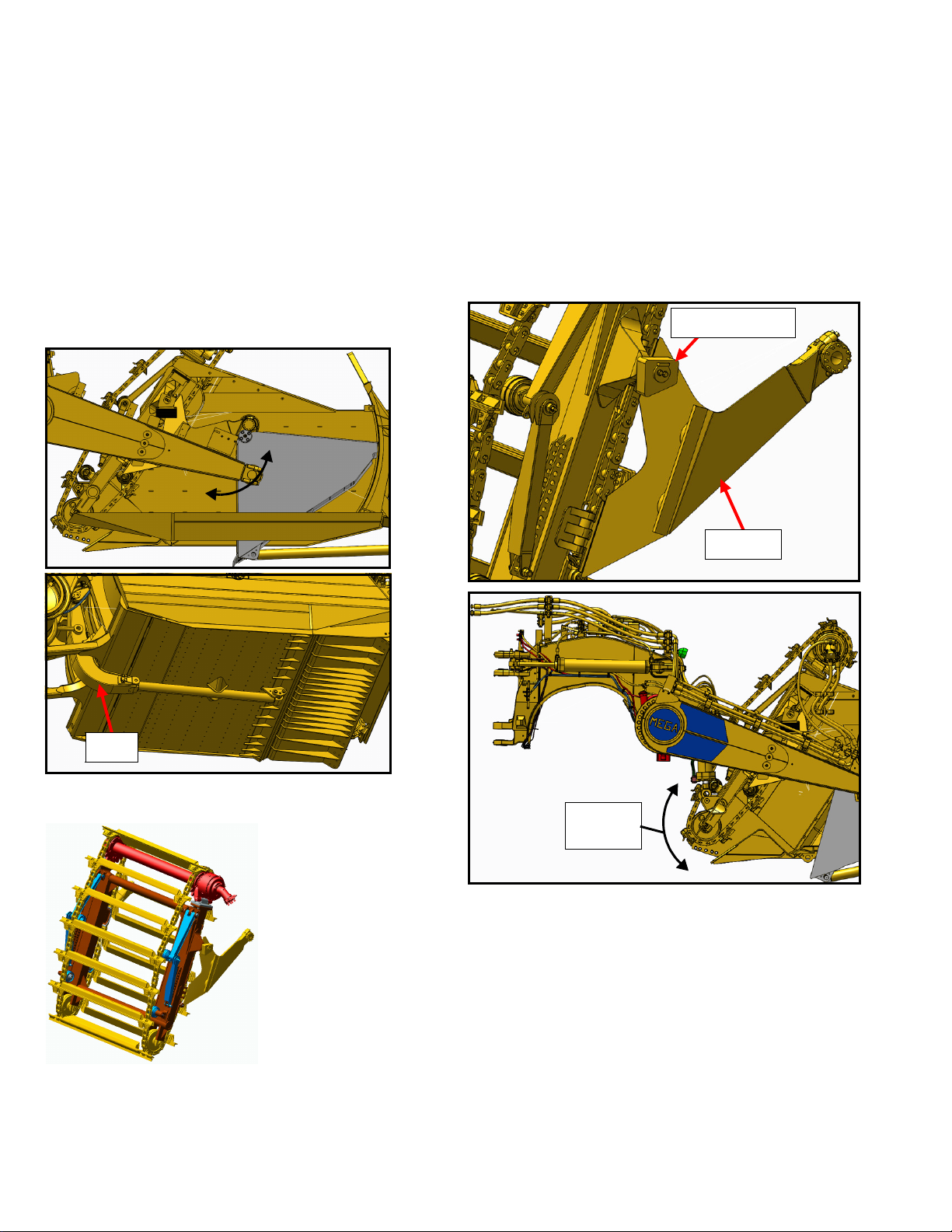

J-Link

Elevator

Swing Up

Elevator Adjusters

Draft Arm

21 Feb 2014

SECTION 2

System Description

ROTATING FLOOR

The rotating floor also utilizes a cellular design in its

construction for added strength and dent resistance.

Two large hydraulic cylinders connected to the j-link

rotate the door smoothly, allowing for precise

spreading of materials. The floor is designed with

close tolerances to the bowl for optimal material

removal, helping create a work alone piece of

machinery.

The frame incorporates draft arms which are used to

mount the assembly to the inside of the scraper

bowl. The draft arms, working in together with the

elevator adjusters, creates a mounting system that

protects the flights and cutting edge from rocks and

other large objects by swinging up, then quickly

returning back down to continue loading the bowl.

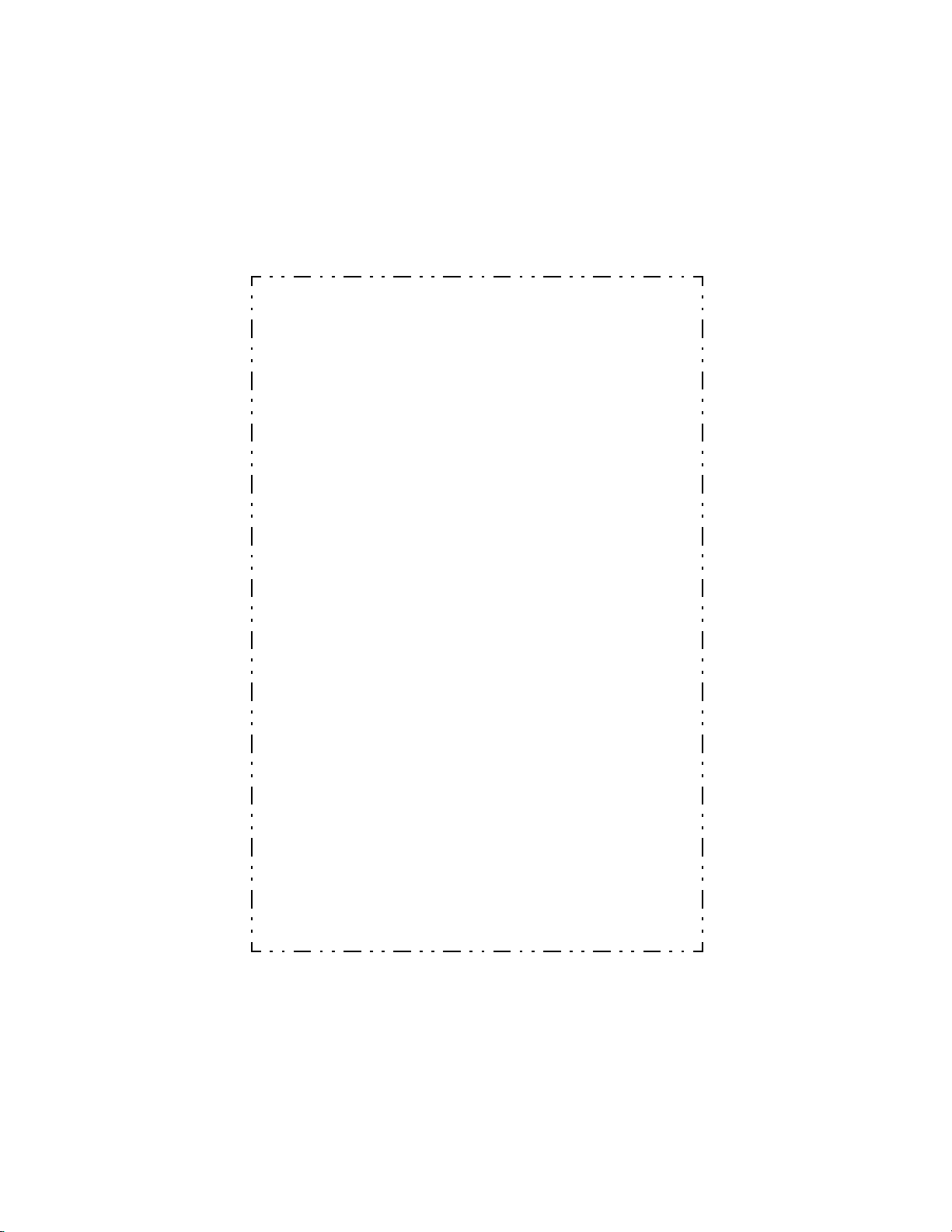

ELEVATOR ASSEMBLY

The elevator assembly

conditions and loads

materials into the

scraper bowl. The

assembly consists of an

elevator frame and

draft arms, a speed

reducer, sprockets,

chains, chain adjusters,

idlers and flights. The

upper corners of the

frame is designed with

a two piece steel casting that provides mounting for

the elevator drive system, as well as lever-type

elevator adjusters.

The flights are constructed of steel plates and

perform the actual conditioning and loading of the

materials. The flights are connected to dual drive

chains that are driven by a single high torque

hydraulic drive motor through the speed reducer.

2-2

Page 10

SECTION 2

System Description

MES34-OPS-1

21 Feb 2014

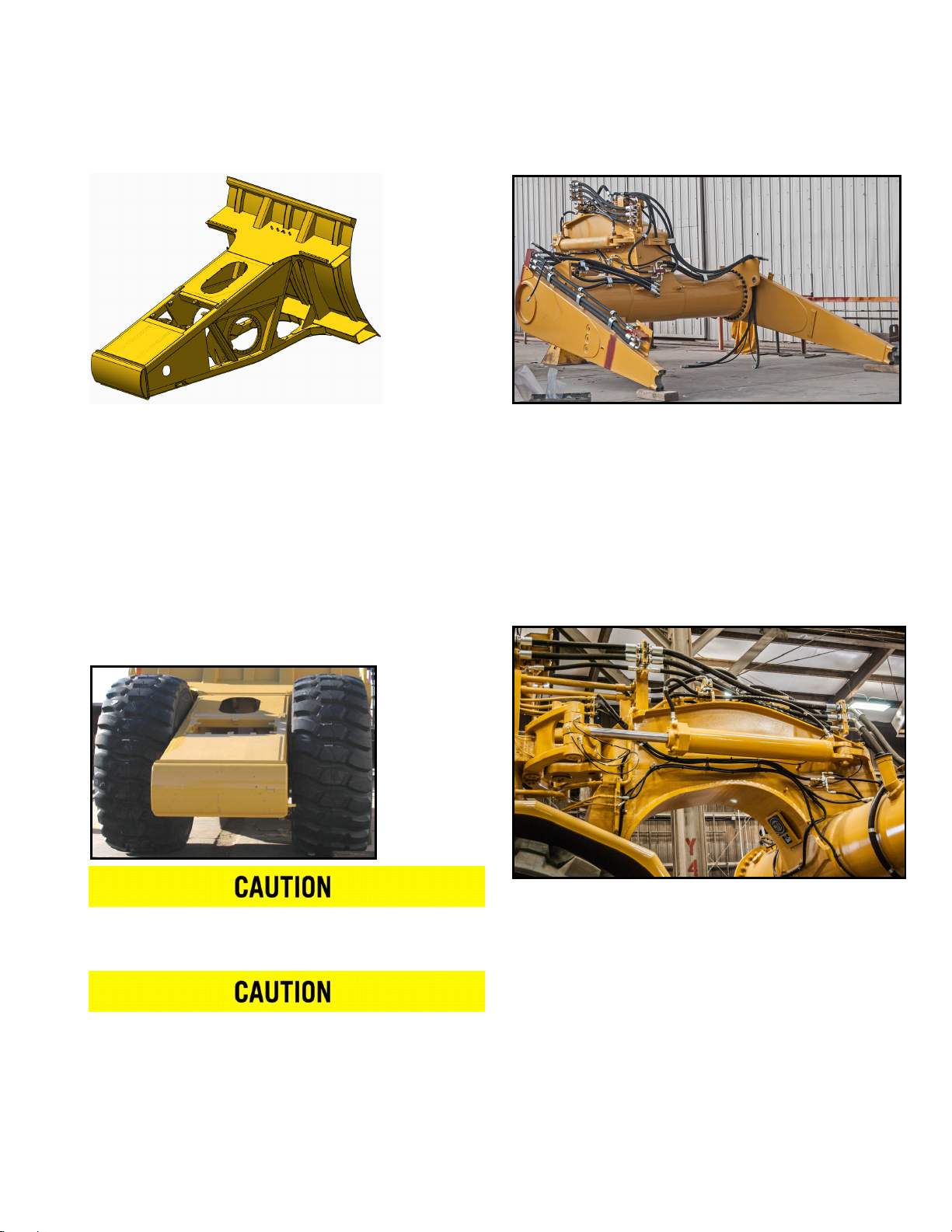

REAR BOGIE ASSEMBLY

The bogie is a structural steel tube frame and plating

that mounts to the rear wall of the scraper bowl. The

assembly provides mounting for the rear wheel

groups, rear brake system, rotating floor cylinders

and tail lights. The rear of the bogie also incorporates

a push type bumper assembly.

The rear bumper design provides a pushing point to

assist the MES34 up a grade or in poor underfoot

conditions (wet, muddy or icy haul road). The

bumper assembly is designed to be pushed straight

on by the pushing (boosting) machine.

DRAFT FRAME ASSEMBLY

The draft frame assembly is comprised of a

gooseneck, fuel tank and draft arms. This assembly,

along with two sets of hydraulic cylinders, is what

turns the unit and raises and lowers the bowl

assembly. The assembly also provides mounting for

implement control valve assembly, hydraulic

housing, electrical harnesses, protective guards and

work light.

GOOSENECK

Routine HARD bumper contacts by the pushing

(boosting) machine will cause structural fatigue and

result in reduced bogie service life.

Angled blade contact of the bumper will reduce bull

dozer blade to MES34 wheel clearance. Extreme

blade angles will cause blade/bit to wheel contact

and damage MES34 tires. MES34 and pushing

(boosting) machine operators must communicate to

ensure correct contact and maximum wheel to

blade/bit clearance is maintained.

The gooseneck is made up of vertical hitch pin and

steering cylinder castings, a ½" top plate, ¾" side

plates and a 1½" bottom plate. The vertical hitch pin

attaches to the tractor and provides the pivot point

for the steering of the unit. The back side of the

gooseneck attaches to the fuel tank to create

mounting for the draft arms.

2-3

Page 11

MES34-OPS-1

Right-Hand

Side

Left-Hand

Side

21 Feb 2014

SECTION 2

System Description

FUEL TANK

The fuel tank is constructed from a 26' mechanical

tube and two 1.5" thick flanges. The tank has a 250

gallon capacity with internal baffling to prevent

sloshing. The tank contains a fuel quantity sensor,

gravity fill port and the fast fill fuel system. The tank

also provides mounting for the draft arms,

implement control valve and the bowl lift cylinders.

DRAFT ARMS

HYDRAULIC SYSTEM

The hydraulic power used to operate all scraper bowl

functions comes from several components mounted

on the tractor and bowl assembly. These components

consist of an auger pump, elevator drive motor,

implement pump, implement control value

assembly, bowl lift cylinders and floor cylinders.

AUGER PUMP (VARIABLE PISTON)

The pump is mounted on the tractor transmission

accessory section and provides hydraulic power to

the elevator drive motor. The pump is a variable

displacement type pump with hydraulic output

being controlled by the tractor ECM.

The draft arms connect the draft frame to the bowl.

They are constructed from steel plates, mechanical

tube and cast steel trunnion bearings. The arms

connect at the trunnions and create a pivot point

between the draft frame and the bowl for raising and

lowering the cutting edge of the bowl.

ELECTRICAL SYSTEM

The electrical system of the scraper bowl assembly is

fully integrated with the existing tractor systems.

These sub systems consist of all tail braking and turn

signal lights, implement controls and all brake

indicating and warning systems.

The tractor ECM will maintain the operators selected

elevator speed within a desired range. This is

accomplished by ECM resident software designed to

control pump output based on a selected elevator

speed. See CAT Operator and Maintenance manuals

for more information.

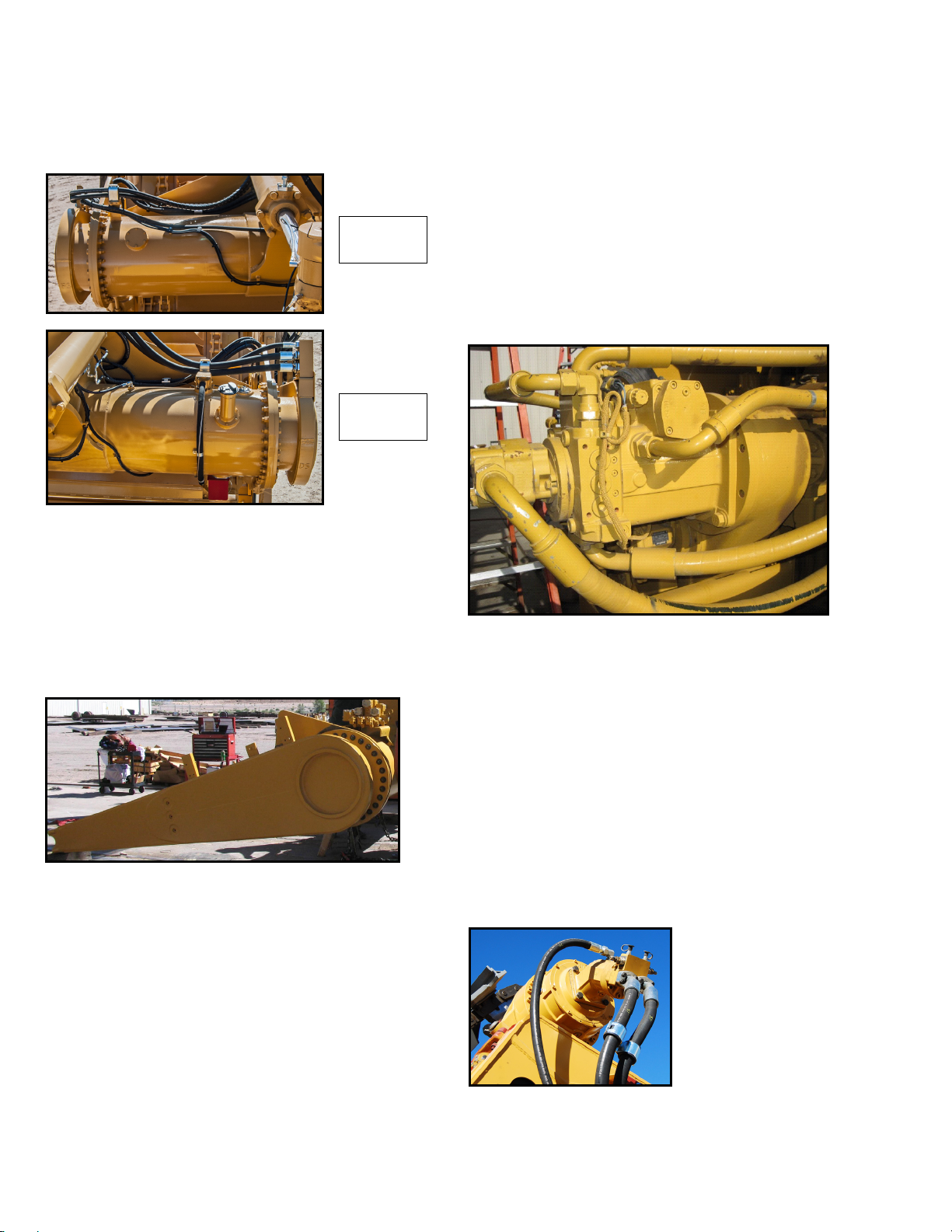

ELEVATOR DRIVE MOTOR

The drive motor is

powered hydraulically

by the auger pump as

commanded by the

implement joystick

thumb switch. The

motor is mounted to the

speed reducer that

drives the elevator upper sprocket assembly.

2-4

Page 12

SECTION 2

Floor Cylinders

J-link

Floor Cylinders

Implement

Joystick

1

System Description

MES34-OPS-1

21 Feb 2014

IMPLEMENT PUMP

The multi-section gear type pump mounted on the

tractor transmission accessory section. The pump

provides hydraulic power to the implement valve

assembly to operate floor and bowl lift systems as

commanded by the implement stick.

IMPLEMENT CONTROL VALVE ASSEMBLY

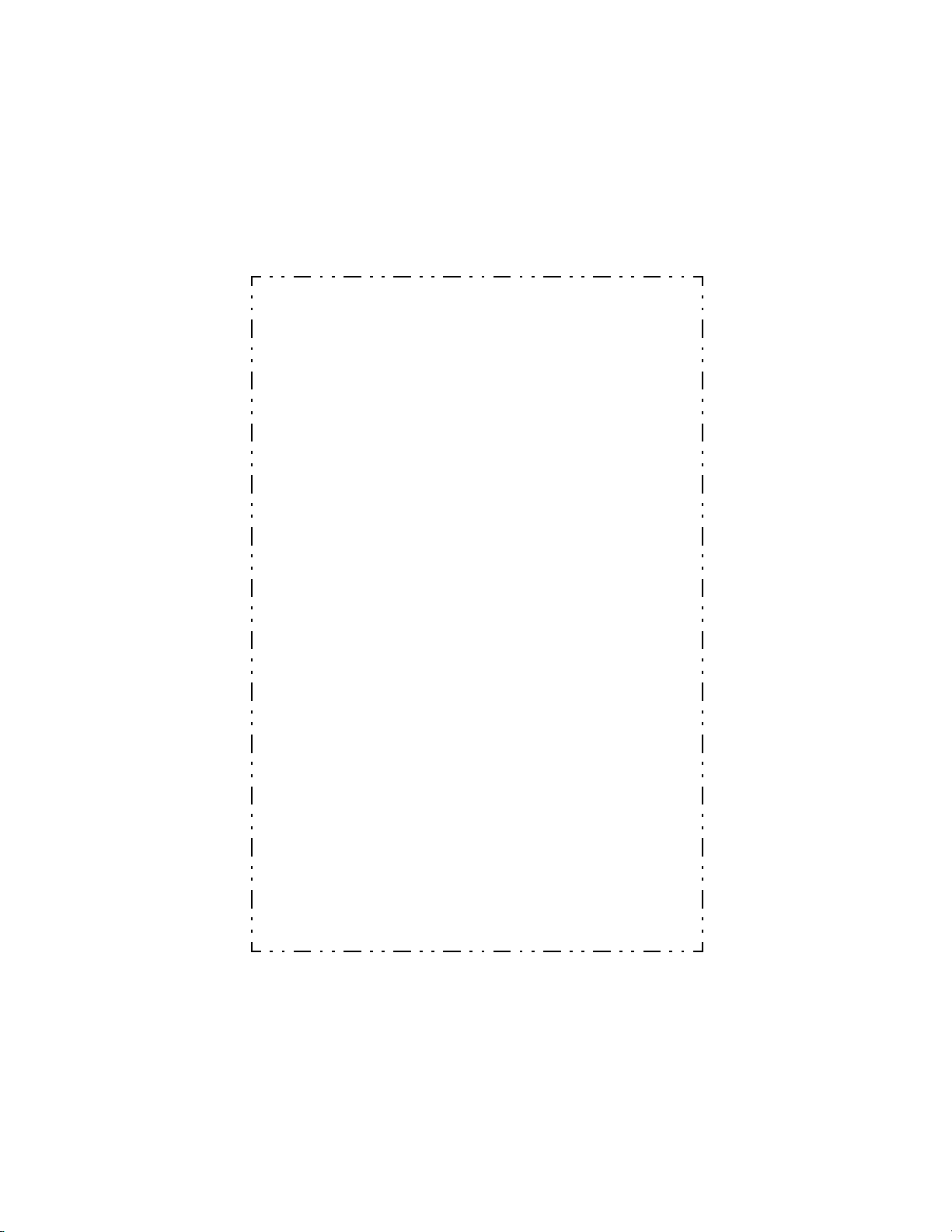

The implement control valve is

mounted to the fuel tank and

provides hydraulic control for

bowl, rotating floor and

elevator functions as

commanded by the implement

joystick. It also contains several

pressure sensors to provide

feedback for rotating floor auto

functions.

BOWL LIFT CYLINDERS

The two bowl hydraulic cylinders

work together to raise and lower

the bowl assembly. The cylinders

are attached to the draft tube and

lower bowl edge. The cylinders

receive hydraulic pressure from the

implement control valve as

commanded by the implement

control stick.

IMPLEMENT JOYSTICK

The joystick is located on the right side console and

provides controls for elevator, bowl, cushion hitch

and differential lock functions. See the CAT Operators

manuals for specific information pertaining to

cushion hitch and differential lock functions.

FLOOR CYLINDERS

The two hydraulic cylinders work together to open or

close the bowl floor assembly. The cylinders are

attached to the J-link and the rear bogie.

Implement Joystick function are as follows:

Bowl Control (Joystick)

•Forward & Hold

•Rear & Hold

– lowers bowl.

– raises bowl.

• Releasing the joystick from a commanded

position will hold the bowl in the current

position.

2-5

Page 13

MES34-OPS-1

23

45

6

21 Feb 2014

SECTION 2

System Description

Floor Control (Joystick)

•Left & Hold

•Right & Release

– opens floor fully.

– auto closes floor.

• Auto close can be interrupted by

commanding floor open and release.

Elevator Control (Thumb-switch)

•Left

•Right

– elevator rotates to load.

– elevator rotates to unload.

• Speed increases the further the thumb-switch

is moved from center.

• If a different elevator direction is desired with

“cruise control” on, elevator will delay for

about 3 seconds before reversing direction.

Transmission Hold (Outer Push Button)

st

•1

Push & Release – prevents the

transmission from shifting.

When the transmission hold is engaged, an

indicator light will illuminate on the front

dash.

nd

•2

Push & Release – normal shifting is

resumed.

REAR BRAKE SYSTEM

The MES rear brake system is integrated with the

existing 631G tractor parking, service and emergency

brakes. All three systems are activated with the

existing brake controls located in the tractor cab. See

the CAT 631G Operator and Service Manual for

additional tractor brake information.

The MES rear brake system consists of a wheel group,

two additional air tanks, pneumatic manifold

assembly, pneumatic brake relay valve, brake pods,

solenoid valve, pressure switch, pressure sending

unit and hosing.

AIR TANKS

The MES is equipped

with two air tanks

mounted in the rear

bogie that store 100150 psi air. The tanks

are interconnected and

receive pressurized air

from the tractor

primary air tank that is mounted under the tractor

cab. Each tank is equipped with drain port to remove

moisture from the brake system.

Cushion Hitch (Inner Push Button)

st

•1

•2

Elevator On/Off/Resume (Trigger Switch)

• Pull bottom of trigger

Push & Release – enables cushion hitch.

nd

Push & Release – disables cushion hitch.

– engages “cruise

control” and holds existing elevator direction

and speed selected by thumb switch. If speed

and direction was previously set, pulling the

trigger will reestablish previous settings.

• Push top of trigger

– disengages “cruise

control”.

TANK PRESSURE SENDING UNIT

A 24 VDC pressure sending unit

is mounted on the rear bogie

and is wired into the existing

tractor brake pressure indicating

and warning systems. The

sending unit provides air

pressure sensing for the tractor

air brake sensing in the tractor

cab. The sending unit also

provides a signal to the brake low pressure warning

system that sounds an audible warning tone when

brake supply pressure drops below allowable limits.

2-6

Page 14

SECTION 2

System Description

MES34-OPS-1

21 Feb 2014

PNEUMATIC MANIFOLD ASSEMBLY

A pneumatic manifold mounted in the rear bogie

used to route pneumatic pressure for service, parking

and emergency brake operation. The manifold also

provides mounting for a check valve, parking brake/

emergency solenoid and parking brake pressure

switch.

CHECK VALVE

A spring operated valve allowing air flow in only one

direction. The valve is located with the pneumatic

manifold assembly in the rear bogie.

PARKING/EMERGENCY BRAKE SOLENOID

A 24 VDC electrical solenoid that opens or closes to

control the parking or emergency brake function.

The solenoid valve responds to electrical signals as

commanded by the parking or emergency brake in

the tractor cab. The solenoid valve will open to bleed

off parking/emergency brake release pressure from

the brake pods. This release of air pressure will cause

the parking/emergency brakes to be applied.

PARKING BRAKE PRESSURE SWITCH

A 24 VDC pressure switch used to

illuminate the parking brake warning

light in the tractor cab. The sensor will

turn on the parking brake warning

light when parking brake release

pressure drops below allowable

limits.

SERVICE BRAKE RELAY VALVE

A pneumatic relay valve that controls and routes air

tank activation pressure to both brake pods. The relay

controls air pressure applied to the brake pods as

commanded by a pneumatic signal pressure by

activating the service brake pedal located in the

tractor cab.

BRAKE PODS

A pneumatic cylinder

designed to extend or

retract and apply service,

parking or emergency

brakes. The pods are

mounted to the MES rear

bogie and are connected

to the wheel group brake activation lever. The pod

contains a coil spring and responds to pressure

received from the brake relay valve as commanded

by service brake pedal. The pod will also apply

parking or emergency brakes when one side of the

cylinder is depressurized when commanded by the

activation of the parking or emergency brakes. Loss

of pneumatic pressure allows the brake pod coil

spring to extend the rod end.

PARKING BRAKE THEORY OF OPERATION

The parking brake is applied by activating the

parking brake switch in the tractor cab. Once the

switch is moved to the park position an electrical

signal is sent to the parking brake solenoid valve

mounted on the rear bogie pneumatic manifold. The

sent signal will open the solenoid valve allowing

pneumatic pressure to decrease from one side of the

brake pod. The brake pod coil spring can now

overcome air pressure and extend the brake pod rod

end attached to the wheel group brake lever and

apply the brakes. Once parking brake pneumatic

pressure drops below allowable limits, the parking

brake pressure switch mounted on the pneumatic

manifold will close and illuminate the parking brake

warning light in the cab of the tractor.

The parking brake is released by activating the

parking brake switch. Once the switch is moved an

electric signal is sent to close the parking brake

solenoid valve. The valve closing will allow

pneumatic pressure from the pneumatic manifold to

be routed to the brake pod. This pressure increase

will eventually overcome the brake pod coil spring

and retract the brake pod cylinder rod end attached

to the brake pod releasing the brakes. As pressure

increases above allowable limits, the parking brake

pressure switch will turn off the parking brake

warning light in the tractor cab once pressure is

above allowable limits.

2-7

Page 15

MES34-OPS-1

21 Feb 2014

SECTION 2

System Description

SERVICE BRAKE THEORY OF OPERATION

The service brake is applied by pressing down on the

service brake pedal in the tractor cab. Pressing down

on the pedal will send a pneumatic pressure signal to

the service brake relay valve mounted on the rear

bogie. The sent signal will release pneumatic

pressure from the brake pod chamber allowing the

pod coil spring to extend the rod end and apply

service brakes.

The service brake is released by releasing the brake

pedal. Once the pedal released a pneumatic signal is

received by the brake relay to increase air pressure to

the brake pod. As pneumatic pressure increases the

force of the brake pod coil spring is overcome and

the service brake is released.

EMERGENCY BRAKE THEORY OF OPERATION

The emergency brake theory of operation is the same

as the parking brake except for the means of

activation. Activation is accomplished by using the

emergency brake foot switch located on the floor of

the tractor cab just left of the service brake pedal.

2-8

Page 16

SECTION 3

Limitations

Contents

MES34-OPS-1

21 Feb 2014

Gross Vehicle Weight .....................................................3-1

Operator’s Seat.................................................................3-1

GROSS VEHICLE WEIGHT

Do not exceed 195,656 lbs/80,80495 GVW.

OPERATOR’S SEAT

When you operate the machine in very rough ground

conditions or at travel speeds not suitable for the

ground conditions, this may result in excessive seat

vertical travel with impact of the suspension against

the travel stops, which may cause injury. Do not

operate the machine on ground conditions and at

travel speeds that could result in the seat suspension

travel stops being contacted. In order to minimize

impact loading on the operator, properly adjust the

seat controls based upon your weight and based

upon your height. Refer to the 631G Operation and

Maintenance Manual, "Seat" for more information.

Engine & Transmission.................................................. 3-1

ENGINE & TRANSMISSION

Do not allow the engine to overspeed when you go

downhill. Do not disengage the transmission while

you are travelling downhill. If equipped, use the

retarder control to reduce engine overspeed when

you are going downhill. If your machine is not

equipped with a retarder control, use the service

brake control to reduce engine overspeed when you

are going downhill. Never coast the machine.

3-1

Page 17

MES34-OPS-1

21 Feb 2014

SECTION 3

Limitations

3-2 (Blank)

Page 18

SECTION 4

MES34

Empty Weight = 113,456 LBS/46,475 KG

Loaded Weight = 195,656 LBS/80,495 KG

Normal Operations

Contents

MES34-OPS-1

21 Feb 2014

Description.........................................................................4-1

Weights and Dimensions ..............................................4-1

Before Operations............................................................4-2

DESCRIPTION

This section provides the vehicle operator with step

by step procedures used to operate the MES34

system only. See the CAT631(G) Operators' manual

for specific tractor operations and system details.

WEIGHTS AND DIMENSIONS

Operations..........................................................................4-2

After Operations...............................................................4-4

The MES34 normal operating procedures mirror the

established CAT format of operations. The

procedures are separated into before operations,

operations and after operations. A pocket size

checklist of all MES34 procedures is contained in the

Appendix for use in the vehicle cab.

4-1

Page 19

MES34-OPS-1

21 Feb 2014

SECTION 4

Normal Operations

BEFORE OPERATIONS

These procedures are used to perform a walk-around

inspection of the MES34 before use or beginning of

the shift. This inspection is in addition to and does

not replace the CAT 631G tractor inspection

requirements found in the 631G Operation &

Maintenance Manuals.

1. Chocks – As Required

2. Vehicle Parking Brake – ON

3. Gear Selector Lever – “N” Neutral

4. Cab Control Switches – SET AS REQUIRED

5. Cab Windows – DAMAGE AND CLEANLINESS

6. LH Tractor – DAMAGE, SECURITY AND LEAKS.

7. Front of Tractor – DAMAGE, SECURITY AND

LEAKS.

18. Brake Air Tanks - DRAIN VALVES CLOSED

19. LH Exterior Bowl Structure, Mud Flaps and Draft

Arm – DAMAGE AND SECURITY

20. Elevator Drive Motor and Speed Reducer –

DAMAGE, SECURITY AND LEAKS

OPERATIONS

Use these procedures to safely operate the standard

and optional systems installed on the MES34.

1. Check for adequate clearance around the

machine.

Before you maneuver the machine, make sure

that no personnel are between the machine and

attachments. Pinch points and attachments will

cause serious injury or death.

8. Machine Kill Switch – OFF

9. Hydraulic Reservoir Level – CHECKED

10. Machine Lock-out Switch - ON

11. RH Tractor – DAMAGE, SECURITY AND LEAKS

12. King Pin, Transmission and Gooseneck –

DAMAGE, SECURITY, SERVICING AND LEAKS

13. Fuel Tank, Gooseneck, Implement Valve

Assembly and Hosing – DAMAGE, SECURITY AND

LEAKS

14. Bowl Cutting Edge, Lift Cylinders and Hosing –

DAMAGE, SECURITY AND LEAKS

15. Elevator Assembly, Floor Assembly and Bowl

Interior – DAMAGE AND SECURITY

16. RH Exterior Bowl Structure, Mud Flaps and Draft

Arm – DAMAGE AND SECURITY

17. Rear Bogie, Tires and Floor Cylinders – DAMAGE,

SECURITY AND LEAKS

2. Mirrors – ADJUST

3. Engine - START

4. Operators Seat – ADJUST

Only operate the machine while you are in a seat

with a fastened seat belt. Only operate the

controls while the engine is running.

5. Steering Column – ADJUSTED

6. Seat Belts – FASTNED

7. Bowl – RAISE

8. Cushion Hitch – ENGAGE AS REQUIRED

Actuation of the cushion-hitch or steering control

can cause movement in the hitch area, reducing

clearances suddenly. Personal injury or death can

result from hitch movement if a person is in the

hitch area.

4-2

Page 20

SECTION 4

Normal Operations

MES34-OPS-1

21 Feb 2014

9. Service Brake Pedal – DEPRESS To prevent

machine from moving

10. Parking Brake – RELEASE

11. Transmission Control Lever – MOVE TO DESIRED

DIRECTION AND APPROPRIATE GEAR SPEED

For operator comfort and maximum service life of

power train components, deceleration and/or

braking is recommended before any directional

shifts are made.

12. Service Brake – RELEASE

13. Throttle Pedal – DEPRESS UNTIL DESIRED ENGINE

SPEED IS ACHIEVED

14. Drive the machine forward in order to have the

best visibility and the best control.

the area is clear before you operate the machine

in the REVERSE position.

The cushion-hitch should be turned on at all

times except when you are loading materials or

when you are dumping materials. When the

cushion-hitch is turned OFF, depth of cuts will be

more even and material will spread more

smoothly during unloading. This will help you to

achieve faster cycle times.

The elevator does not need to be running when

you are unloading fine material.

Reduce engine speed when you maneuver in

tight quarters or when you are going over a hill.

15. While you operate the machine slowly in an open

area, check for proper operation of all controls

and all protective devices.

When you operate the machine in very rough

ground conditions or at travel speeds not suitable

for the ground conditions, this may result in

excessive seat vertical travel with impact of the

suspension against the travel stops, which may

cause injury. Do not operate the machine on

ground conditions and at travel speeds that

could result in the seat suspension travel stops

being contacted. In order to minimize impact

loading on the operator, properly adjust the seat

controls based upon your weight and based

upon your height. Refer to the 631G Operation

and Maintenance Manual, "Seat" for more

information.

Select the appropriate travel speed before you

begin to drive the machine downhill. Do not shift

the transmission control while you are going

downhill.

When you drive the machine downhill, use the

same gear speed that would be used to drive the

machine uphill.

Do not operate the machine when the parking

brake is applied.

Loading the machine in a straight line is

preferred.

Do not overload the bowl.

There is restricted visibility to the area directly

behind the machine. Failure to make sure the

area is clear could result in injury or death. Use a

second person on the ground to make sure that

Do not operate the machine without normal air

pressure.

4-3

Page 21

MES34-OPS-1

21 Feb 2014

SECTION 4

Normal Operations

Do not allow the engine to overspeed when you

go downhill. Do not disengage the transmission

while you are travelling downhill. If equipped, use

the retarder control to reduce engine overspeed

when you are going downhill. If your machine is

not equipped with a retarder control, use the

service brake control to reduce engine overspeed

when you are going downhill. Never coast the

machine.

AFTER OPERATIONS

Perform these procedures after the end of the shift or

end of the day. These steps are in addition to and do

not replace the CAT631G after operation

requirements established in the Operation and

Maintenance Manual.

9. Lock all vandalism covers and all compartments.

1. Machine – STOPPED

2. Parking Brake – APPLIED

3. Gear Shift Lever - NEUTRAL

4. Engine – OFF

5. Inspect the engine compartment for debris.

Clean out any debris in order to avoid a fire

hazard.

6. Remove all flammable debris from the front

bottom guard through the access doors in order

to reduce a fire hazard. Discard the debris

properly.

7. Turn the key for the battery disconnect switch to

the OFF position. When the machine is left for an

extended period of one month or longer, you

should remove the key. This will help to prevent a

battery short circuit. Removing the key will also

help to protect the battery from vandalism and

from the current draw that is made by certain

components.

8. Perform a walk around inspection of the entire

machine looking for damage, security, leaks and

servicing.

4-4

Page 22

SECTION 5

Performance

Contents

MES34-OPS-1

21 Feb 2014

Description........................................................................5-1

Gradeability/Speed/Rimpull .......................................5-1

DESCRIPTION

This section contains MES34 performance data.

GRADEABILITY/SPEED/RIMPULL

631G Gross Weight

37.25R35 Tire

Retarding ...........................................................................5-2

Figure 5-1: Gradeability/Speed/Rimpull

5-1

Page 23

MES34-OPS-1

21 Feb 2014

SECTION 5

Performance

RETARDING

631 Gross Weight

Figure 5-2: Retarding

5-2

Page 24

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

MES34

OPERATOR’S

CHECKLIST

6-1

Page 25

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

TABLE OF CONTENTS

Title Page

1. BEFORE OPERATIONS . . . . . . . . . . . . . . . . . . . N-2

2. OPERATIONS

3. AFTER OPERATIONS. . . . . . . . . . . . . . . . . . . . . N-14

6-2

N-1

Page 26

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

BEFORE OPERATIONS

These procedures are used to perform a walk-around

inspection of the MES34 before use or beginning of

the shift. This inspection is in addition to and does

not replace the CAT 631G tractor inspection

requirements found in the 631G Operation &

Maintenance Manuals.

MES34-OPS-1

21 Feb 2014

1. Chocks – As Required

2. Vehicle Parking Brake – ON

3. Gear Selector Lever – “N” Neutral

4. Cab Control Switches – SET AS REQUIRED

5. Cab Windows – DAMAGE AND CLEANLINESS

6. LH Tractor – DAMAGE, SECURITY AND LEAKS.

7. Front of Tractor – DAMAGE, SECURITY AND

LEAKS.

8. Machine Kill Switch – OFF

9. Hydraulic Reservoir Level – CHECKED

10. Machine Lock-out Switch - ON

N-2

6-3

Page 27

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

11. RH Tractor – DAMAGE, SECURITY AND LEAKS

12. King Pin, Transmission and Gooseneck –

DAMAGE, SECURITY, SERVICING AND LEAKS

13. Fuel Tank, Gooseneck, Implement Valve

Assembly and Hosing – DAMAGE, SECURITY AND

LEAKS

14. Bowl Cutting Edge, Lift Cylinders and Hosing –

DAMAGE, SECURITY AND LEAKS

15. Elevator Assembly, Floor Assembly and Bowl

Interior – DAMAGE AND SECURITY

16. RH Exterior Bowl Structure, Mud Flaps and Draft

Arm – DAMAGE AND SECURITY

17. Rear Bogie, Tires and Floor Cylinders – DAMAGE,

SECURITY AND LEAKS

18. Brake Air Tanks - DRAIN VALVES CLOSED

19. LH Exterior Bowl Structure, Mud Flaps and Draft

Arm – DAMAGE AND SECURITY

20. Elevator Drive Motor and Speed Reducer –

DAMAGE, SECURITY AND LEAKS

N-3

6-4

Page 28

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

OPERATIONS

Use these procedures to safely operate the standard

and optional systems installed on the MES34.

1. Check for adequate clearance around the

machine.

Before you maneuver the machine, make sure

that no personnel are between the machine and

attachments. Pinch points and attachments will

cause serious injury or death.

MES34-OPS-1

21 Feb 2014

2. Mirrors – ADJUST

3. Engine - START

4. Operators Seat – ADJUST

Only operate the machine while you are in a seat

with a fastened seat belt. Only operate the

controls while the engine is running.

5. Steering Column – ADJUSTED

6. Seat Belts – FASTENED

7. Bowl – RAISE

N-4

6-5

Page 29

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

8. Cushion Hitch – ENGAGE AS REQUIRED

Actuation of the cushion-hitch or steering

control can cause movement in the hitch area,

reducing clearances suddenly. Personal injury or

death can result from hitch movement if a person

is in the hitch area.

9. Service Brake Pedal – DEPRESS To prevent

machine from moving

10. Parking Brake – RELEASE

11. Transmission Control Lever – MOVE TO DESIRED

DIRECTION AND APPROPRIATE GEAR SPEED

For operator comfort and maximum service life

of power train components, deceleration and/or

braking is recommended before any directional

shifts are made.

12. Service Brake – RELEASE

13. Throttle Pedal – DEPRESS UNTIL DESIRED ENGINE

SPEED IS ACHIEVED

N-5

6-6

Page 30

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

14. Drive the machine forward in order to have the

best visibility and the best control.

15. While you operate the machine slowly in an open

area, check for proper operation of all controls

and all protective devices.

MES34-OPS-1

21 Feb 2014

When you operate the machine in very rough

ground conditions or at travel speeds not

suitable for the ground conditions, this may

result in excessive seat vertical travel with impact

of the suspension against the travel stops, which

may cause injury. Do not operate the machine on

ground conditions and at travel speeds that

could result in the seat suspension travel stops

being contacted. In order to minimize impact

loading on the operator, properly adjust the seat

controls based upon your weight and based

upon your height. Refer to the 631G Operation

and Maintenance Manual, "Seat" for more

information.

There is restricted visibility to the area directly

behind the machine. Failure to make sure the

area is clear could result in injury or death. Use a

second person on the ground to make sure that

N-6

6-7

Page 31

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

the area is clear before you operate the machine

in the REVERSE position.

The cushion-hitch should be turned on at all

times except when you are loading materials or

when you are dumping materials. When the

cushion-hitch is turned OFF, depth of cuts will be

more even and material will spread more

smoothly during unloading. This will help you to

achieve faster cycle times.

The elevator does not need to be running when

you are unloading fine material.

Reduce engine speed when you maneuver in

tight quarters or when you are going over a hill.

Select the appropriate travel speed before you

begin to drive the machine downhill. Do not shift

the transmission control while you are going

downhill.

N-7

6-8

Page 32

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

When you drive the machine downhill, use the

same gear speed that would be used to drive the

machine uphill.

Do not operate the machine when the parking

brake is applied.

MES34-OPS-1

21 Feb 2014

Loading the machine in a straight line is

preferred.

Do not overload the bowl.

Do not operate the machine without normal air

pressure.

Do not allow the engine to overspeed when you

go downhill. Do not disengage the transmission

while you are travelling downhill. If equipped,

use the retarder control to reduce engine

overspeed when you are going downhill. If your

N-8

6-9

Page 33

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

machine is not equipped with a retarder control,

use the service brake control to reduce engine

overspeed when you are going downhill. Never

coast the machine.

AFTER OPERATIONS

Perform these procedures after the end of the shift

or end of the day. These steps are in addition to and

do not replace the CAT631G after operation

requirements established in the Operation and

Maintenance Manual.

1. Machine – STOPPED

2. Parking Brake – APPLIED

3. Gear Shift Lever - NEUTRAL

4. Engine – OFF

5. Inspect the engine compartment for debris.

Clean out any debris in order to avoid a fire

hazard.

6. Remove all flammable debris from the front

bottom guard through the access doors in order

to reduce a fire hazard. Discard the debris

properly.

N-9

6-10

Page 34

SECTION 6

Appendix

MES34-OPS(CL)-1

21 Feb 2014

7. Turn the key for the battery disconnect switch to

the OFF position. When the machine is left for an

extended period of one month or longer, you

should remove the key. This will help to prevent a

battery short circuit. Removing the key will also

help to protect the battery from vandalism and

from the current draw that is made by certain

components.

MES34-OPS-1

21 Feb 2014

8. Perform a walk around inspection of the entire

machine looking for damage, security, leaks and

servicing.

9. Lock all vandalism covers and all compartments.

N-10

6-11

Page 35

MES34-OPS-1

21 Feb 2014

SECTION 6

Appendix

6-12 (Blank)

Loading...

Loading...