Page 1

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING

Operators Manual

MCC-OPS-1

MEGA CORP.®

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190

www.megacorpinc.com

® MEGA Corp., Inc. All Rights Reserved

Page 2

MCC35-CAT735-1

A

5 Aug 2010

TABLE OF CONTENTS

Page

Section 1. Definitions and Abbreviations .………………………………………………………. 1-1

Section 2. System Description ………………………………………………………………...… 2-1

Section 3. Normal Operations …………………………………………………………………… 3-1

Section 4. Appendix (Operators Checklist) …………………………………………………… 4-1

Page 3

MCC35-CAT735-1

5 Aug 2010

TABLE OF CONTENTS

B(Blank)

Page 4

SECTION 1

Definitions and Abbreviations

Contents

Manual Usage …………………..………. 1-1

Warning, Caution & Notes ……….…...… 1-1

Shall, Will, May ……………………….. 1-1

MANUAL USAGE

This technical manual only contains

information required to safely operate the

MEGA Container Carrier (MCC) system when

installed on the CAT 735. See the CAT 735

Operators Safety and Maintenance Manual for

chassis specific system information and

operating procedures.

Only current production systems are covered in

this manual. If your system is not covered in

this manual please contact MEGA Corp.

Product Support at: 1-800-345-8889 or visit our

web site at www.megacorpinc.com for more

detailed information.

MCC35-CAT735-1

5 Aug 2010

MCC35 Overview …………………..… 1-2

Abbreviations ………………………...... 1-3

WARNING, CAUTIONS AND

NOTES

The following definitions are found throughout

the manual and apply as follows:

Operating procedures and techniques, which

could result in personal injury and/or loss of

life if not carefully followed.

Operating procedures and techniques, which

could result in damage to equipment if not

carefully followed.

Operating procedures and techniques that are

considered essential to emphasis.

USE OF SHALL, WILL AND MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a

procedure is recommended.

May - Used to indicate an acceptable or

suggested means of accomplishment.

1-1

Page 5

MCC35-CAT735-1

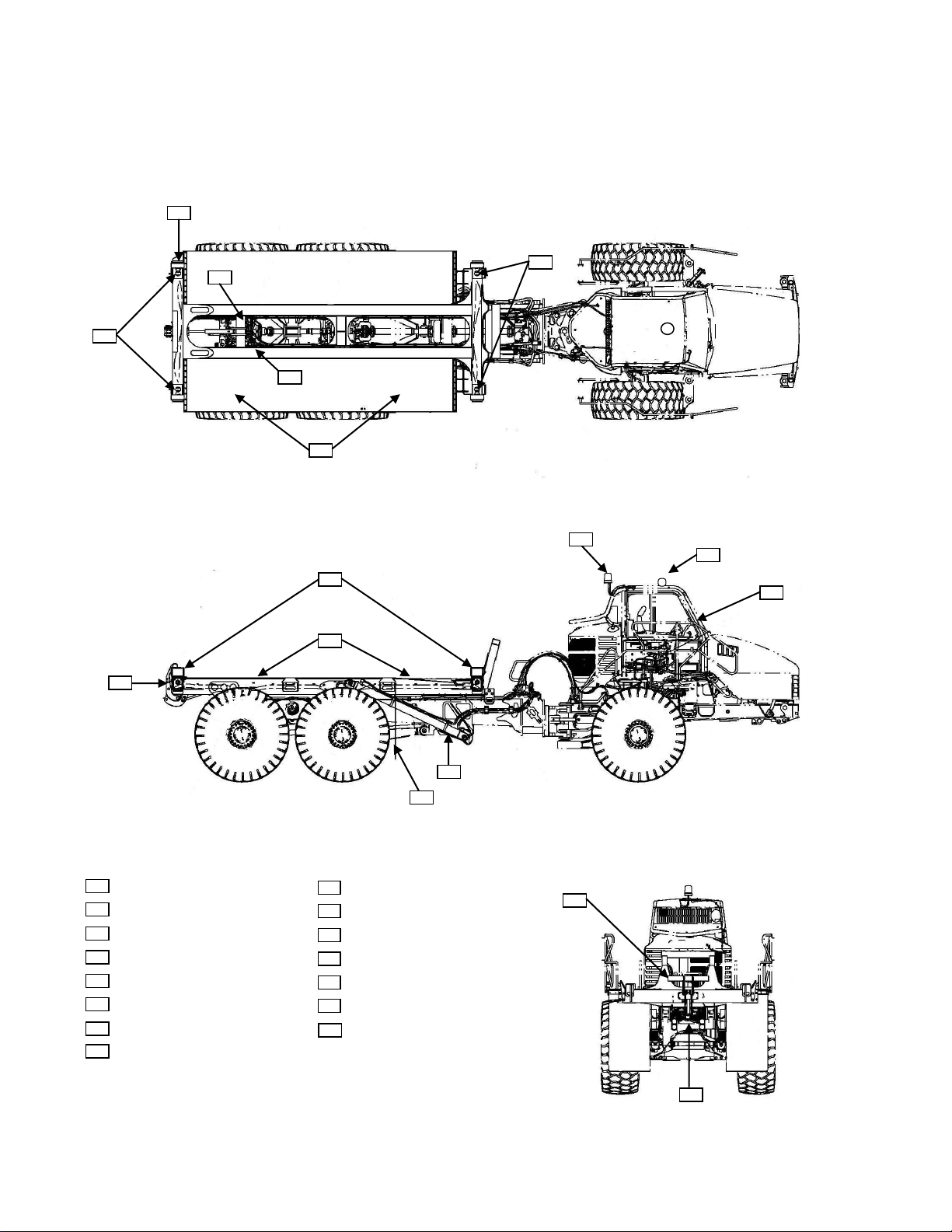

MCC35 Overview

1 2 6

3 3 8 9 4

14 7 5

12

13

11

10

15 9 10

11

12

13

14

15

Twistlock Solenoid Manifold

In-Cab Twistlock Controls

Remote Body Operation Switches

Twistlock External Status Light

Amber Flashing Beacon

Tail Lights & Accessories

Clearance Lights

1 2 3 4 5

6

7

8

Bed Assembly

Centering Guides

Twistlocks

Tailgate Restraint Assembly

Lift Cylinders

Fenders

Mud Flaps

Tailgate Operation Valve Assembly

5 Aug 2010

SECTION 1

Definitions and Abbreviations

1-2

Page 6

Definitions and Abbreviations

ABBREVIATIONS

CW – Clockwise

ECM – Electronic Control Module

ft - feet

fpm – feet per minute

IN/SQ FT – Inches per Square Feet

ISO – International Organization of

Standardization

KM-H – Kilometers Hour

Kg – kilograms

LT – Left

LWB – Long Wheel Base

M – meters

MCC – Mega Container Carrier

MPH – Miles Per Hour

OEM – Original Equipment Manufacture

PPE – Personal Protective Equipment

psi - pounds square inch

RT – Right

VDC – Volts Direct Current

MCC35-CAT735-1

5 Aug 2010

SECTION 1

1-3

Page 7

MCC35-CAT735-1

5 Aug 2010

SECTION 1

Definitions and Abbreviations

1-4(Blank)

Page 8

SECTION 2

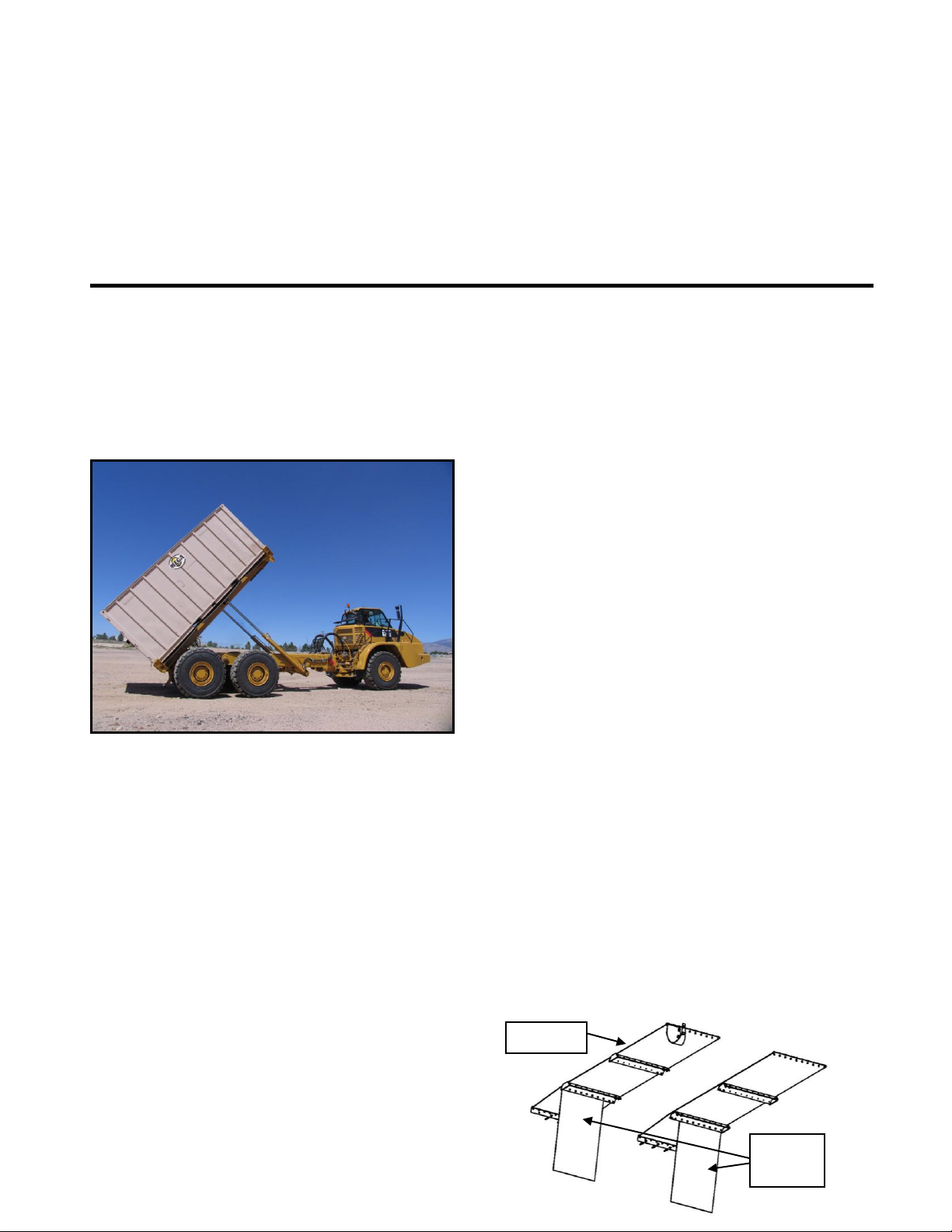

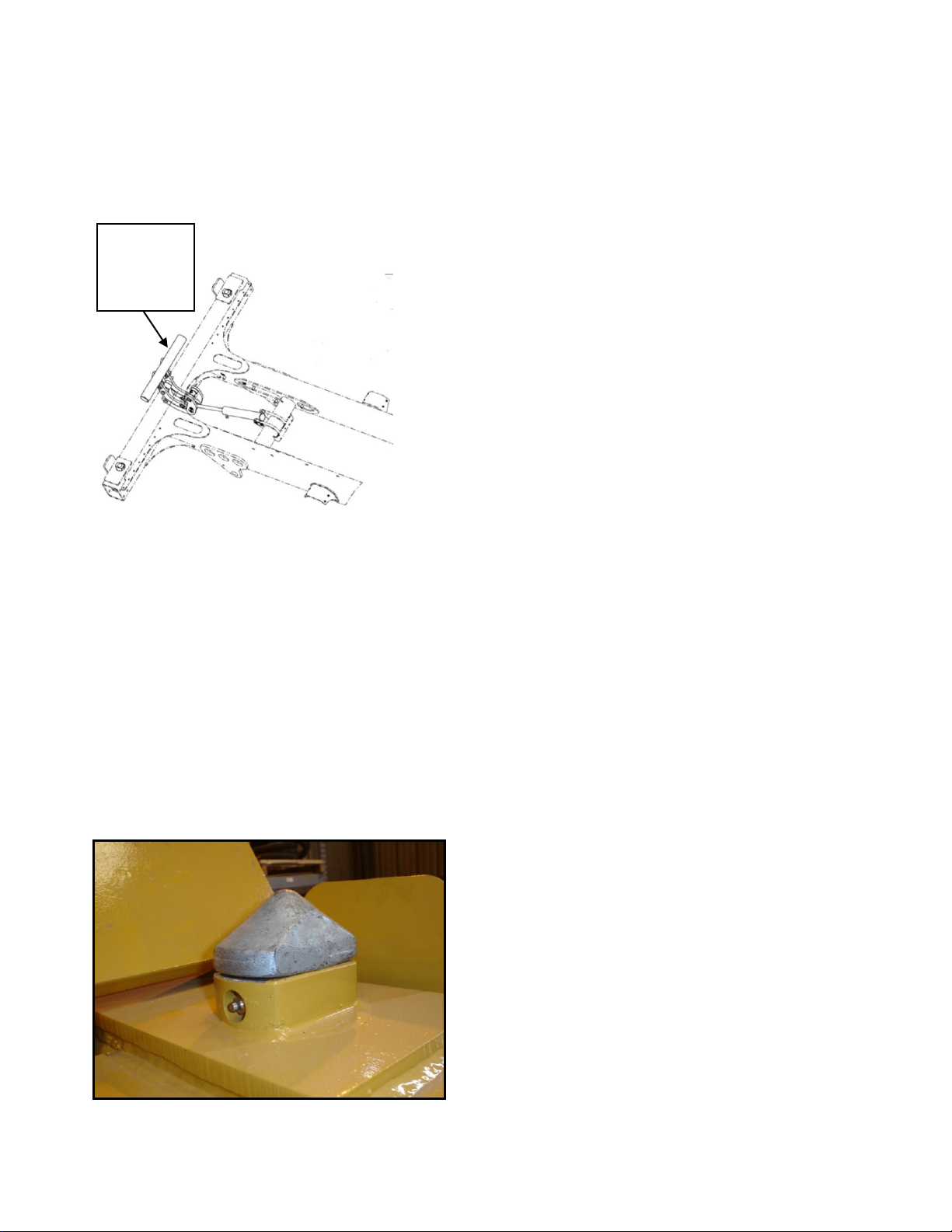

Fender

Mud

Flap

System Description

Contents

MCC35 Description and Usage …...…....... 2-1

Body Assembly ………………………….. 2-1

Hydraulics ……………………………….. 2-2

MCC35 DESCRIPTION AND USAGE

The MCC35 is designed to be attached to a long

wheel base (LWB) chassis after required chassis

reinforcements are completed. Once total

integration is completed, the assembly can be

used to mount, retain, transport, and dump a 20’

ISO container.

The MCC35 consists of a body assembly,

hydraulics and electrical systems as well as a

control system. The MCC35 is fully intergraded

with the chassis hydraulics, electrics and control

systems while adding additional in-cab controls,

lighting, and indicating/warning systems.

MCC35-CAT735-1

5 Aug 2010

Controls & Indicating System …………… 2-5

Theory of Operation ………………….….. 2-9

Lights & Accessories …………………..... 2-10

BODY ASSEMBLY

The assembly consists of a tubular frame,

fenders and mud flaps, tailgate assembly and

twistlock assemblies. The body also contains

mounting plates for hydraulic components,

sensors and accessories.

Tubular Frame

Constructed of tubular steel, cross tubes and

plating to form a frame used to carry the weight

of a loaded ISO container. The frame is secured

to the chassis by pins installed in the chassis

pivot bores and lift cylinders. The frame

incorporates container guides on each corner of

the frame to center the container over the frame

and the twistlock mechanisms. The frame also

provides for mounting of the tailgate restraint

assembly (stinger), twistlock assemblies, body

lift cylinders, body pads, body guides, fenders

and mud flap assemblies.

Fenders & Mud Flaps

The assembly is designed to protect the

container and body assembly from mud and

debris created by the drive tires. The fenders

and mud flaps assemblies are constructed of

rubber belting material and attached to

triangular metal stanchions. The stanchions are

mounted to the body assembly’s main

longitudinal beams and contain fender

tensioning devices to keep the belting just below

a loaded container.

2-1

Page 9

MCC35-CAT735-1

Tailgate

Restraint

Assembly

(Stinger)

5 Aug 2010

System Description

Tailgate Restraint Assembly (Stinger)

A steel tube and plate assembly that mounts and

pivots on the rear of the tubular frame. The

tailgate restraint assembly (stinger) is designed

to raise and restrain container doors in a closed

position when the body assembly is down. A

hydraulic cylinder is mounted between the

tailgate and tubular frame to raise and lower the

assembly as commanded by the hoist control

lever when the vehicle is in motion. The

assembly can also be operated from the tailgate

remote body operation switches when the

vehicle is stationary.

Twistlocks Assemblies

SECTION 2

The body assembly contains 4 twistlock

mechanisms located at each corners of the body

assembly. Each twistlock mechanism consists

of the 90° rotating block, hydraulic actuator

cylinder and a position sensor. The twistlocks

are designed to slide into the ISO container floor

receptacles as the container is lowered onto the

body assembly. Once the container is resting on

body assembly the twistlocks can then be

commanded to rotate 90° by using the in-cab

twistlock switch. The twisting action will allow

the lock to engage the container and secure the

container to the body assembly.

HYDRAULICS

The MCC35 hydraulic system uses chassis hoist

pressure for body and tailgate operation while

twistlock operation is accomplished by using

hoist pilot pressure. The MCC35 hydraulic

components consist of body lift cylinders,

tailgate control valve assembly, tailgate cylinder

counterbalance valve, tailgate cylinder, chassis

mounted accumulator, twistlock solenoid

manifold, twistlock actuators and associated

hosing.

Body Lift Cylinders

The body lift cylinders are MCC specific and

are mounted to the bed and chassis like a dump

body. Cylinders hydraulic pressure and return is

routed through the chassis hoist valve as

controlled by the in-cab hoist lever. The

supplemental ECM controls the body lifting

angle and places a mid-point stop at an

application specific angle. The mid-point stop

is set to keep the tailgate from contacting the

ejected load or ground and damaging the

tailgate door. A hoist mid-point override switch

is used to reactivate the hoist valve for raising

the body to the full load ejecting position.

2-2

Page 10

SECTION 2

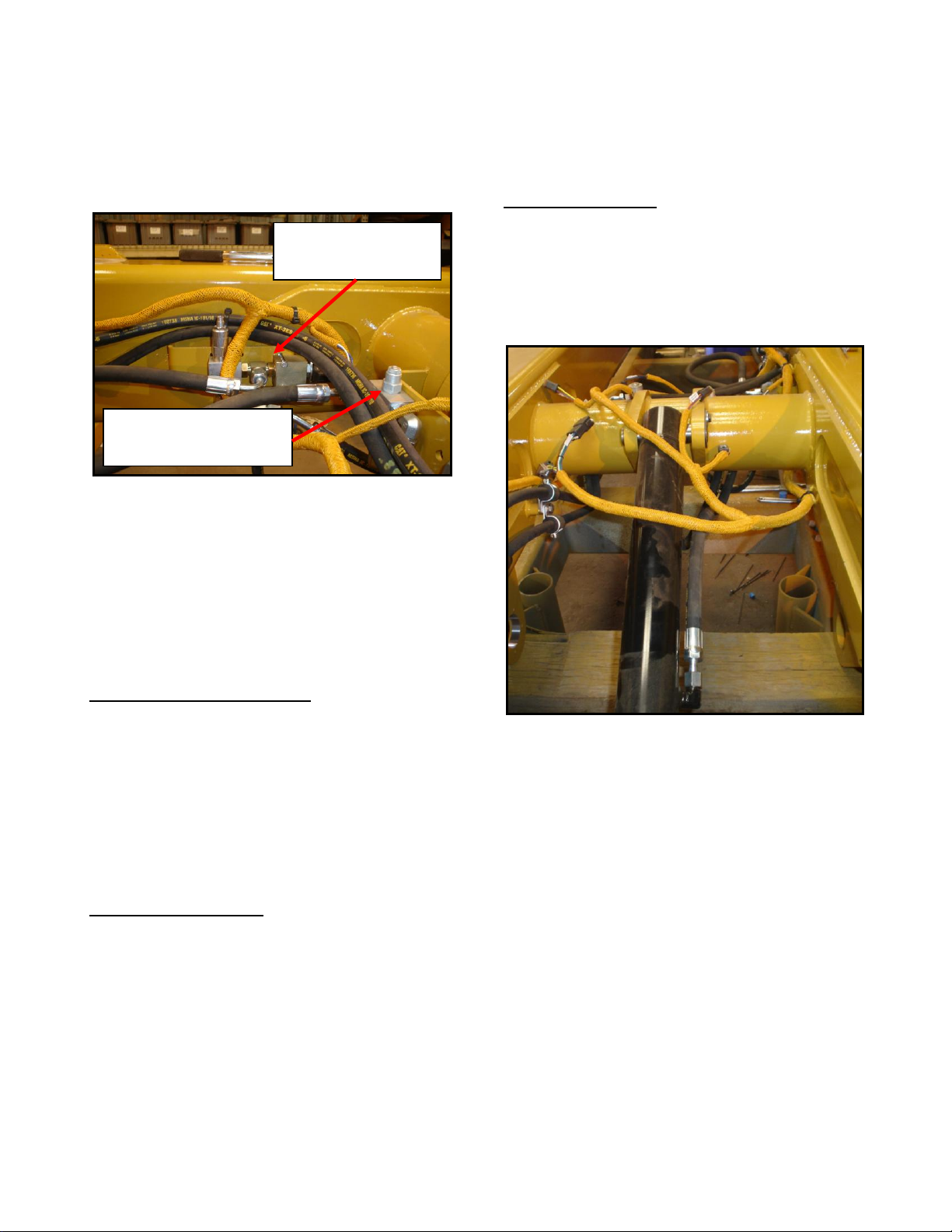

Main Solenoid

Control Valve

Counter Balance Valve

System Description

Tailgate Restraint (Stinger) Valve Assembly

The valve assembly consists of a main solenoid

control valve and a counter balance valve.

These manifolds hosed together and mounted to

the body RT main beam and cross tube

respectively. The two valve assemblies

combine to route and control hoist valve

pressure and return for the tailgate cylinder

function.

Main Solenoid Control Valve

The main solenoid control valve contains a

pressure relief and solenoid valve. The pressure

relief valve controls the clamping pressure for

the stinger to keep the tailgate door closed.

Pressure relief settings are field adjustable for

each specific type of container or load being

transported.

Counter Balance Valve

Mounted to a plate and hosed to the main

solenoid control solenoid. The valve assists in

maintaining the holding pressure for the stinger.

Pressure relief settings are field adjustable for

each specific type of container or load being

transported.

MCC35-CAT735-1

5 Aug 2010

Theory of Operation

The tailgate restraint valve assembly functions

as commanded by the remote activation

switches while the vehicle is stationary or the

hoist lever while the vehicle is in motion.

Tailgate Restraint (Stinger) Cylinder

The cylinder is connected to the body assembly

cross tube at one end and the tailgate assembly

at the other end. The cylinder receives

hydraulic pressure from the tailgate restraint

valve assembly.

2-3

Page 11

MCC35-CAT735-1

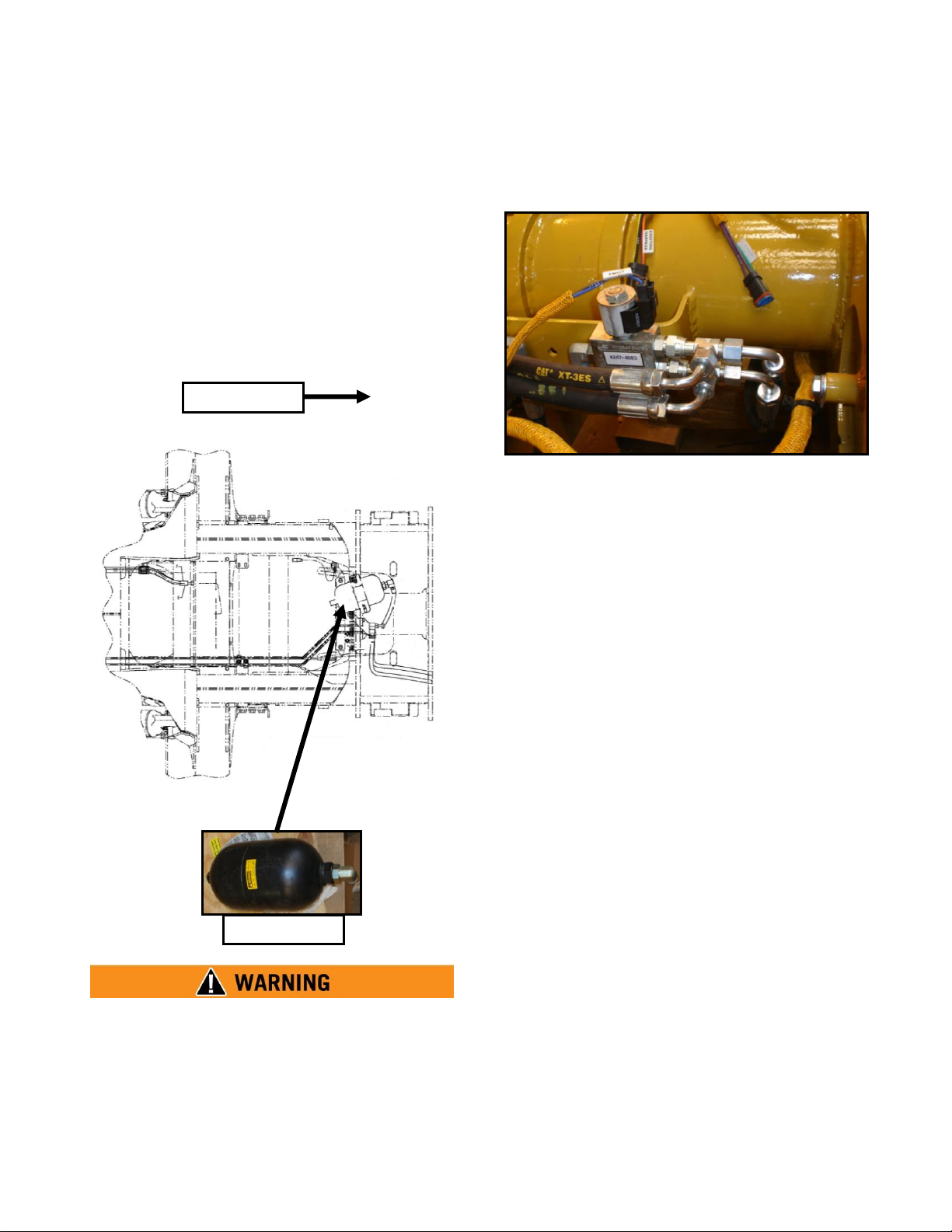

Accumulator

FORWARD

5 Aug 2010

System Description

Twistlock Hydraulic Accumulator

Mounted just to the rear of the chassis

articulation joint and is connected directly to the

hoist valve pilot pressure circuit. The

accumulator provides additional pressurized

hydraulic volume on demand for the body

twistlock manifold assembly for twistlock

operation.

Twistlock Solenoid Manifold

The hydraulic accumulator is a high pressure

charged vessel. Follow the CAT 735

Maintenance and Service Manuals for proper

charging procedures. Failure to charge this

vessel properly may result in serious personal

injury or death.

SECTION 2

Twistlock Solenoid Manifold

The manifold assembly is mounted to the body

assembly cross tube. The manifold receives

pressure from the accumulator assembly while

routing return pressure to the chassis hydraulic

tank. The manifold contains a solenoid valve to

route hydraulic pressure and return to and from

the twistlock actuators as commanded by the

twistlock controls and a pressure reducing valve

to prevent over pressurization of the twistlock

actuators.

2-4

Page 12

SECTION 2

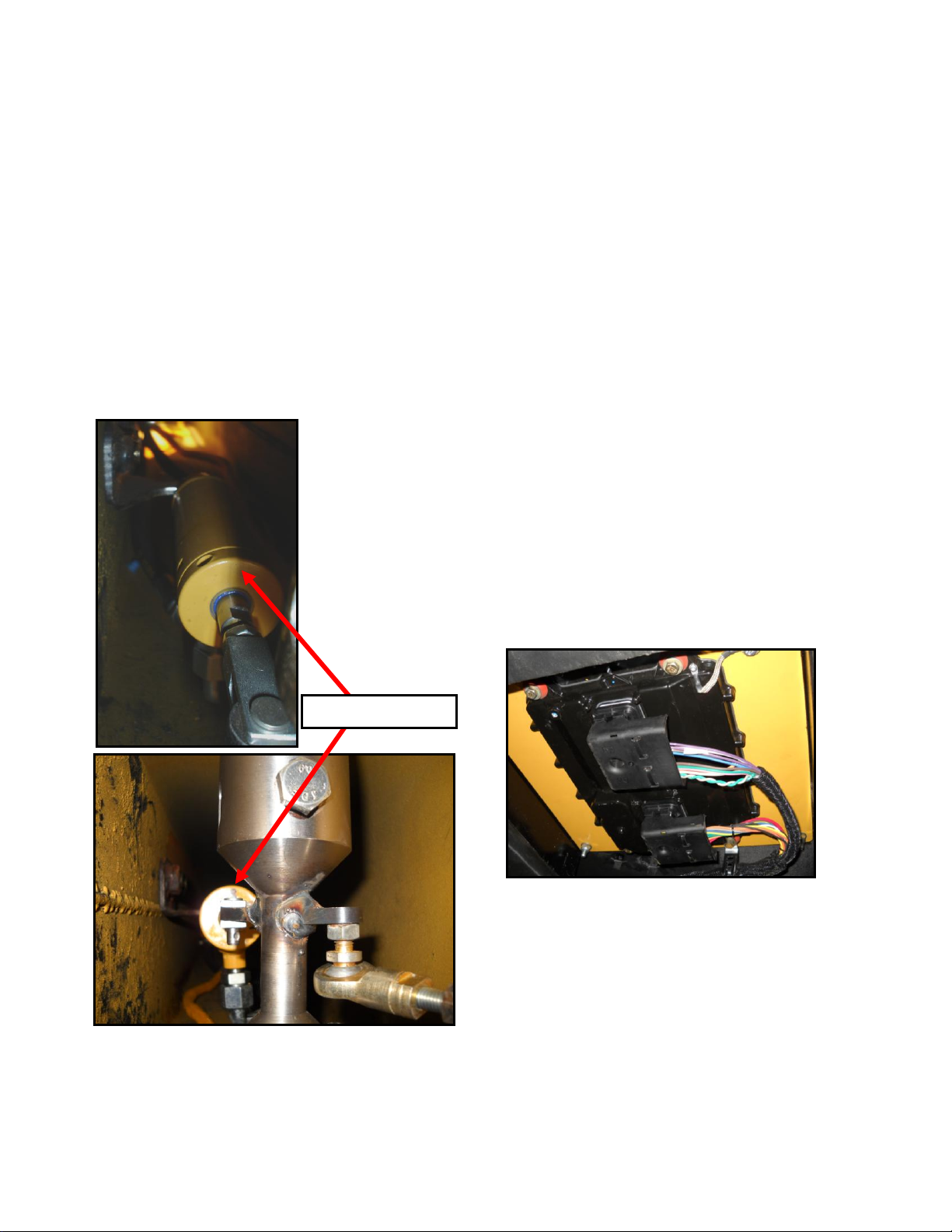

Twistlock Actuator

System Description

Twistlock Actuators

Four twistlock actuators are mounted inside the

forward and rear lateral tubes of the bed

assembly. Each actuator is connected to the

center of the twistlock and receives hydraulic

pressure from the twistlock manifold assembly

as commanded by the twistlock controls. Each

actuator is equipped with an adjustable clevis to

allow for adjustment of the twistlock head

angle.

MCC35-CAT735-1

5 Aug 2010

CONTROLS AND INDICATING

SYSTEMS

The controls required to operate the body

assembly and integrate with the existing chassis

controls are located throughout the entire

vehicle and bed assembly. The MCC35 adds

several new control components and indicators

to increase safety and reliability for the entire

system.

The control components consist of an additional

body assembly, ECM (Electronic Control

Module), hoist lever mounted midpoint override

switch, remote tailgate restraint operation

switches, tailgate restraint control fault indicator

lamp, in-cab twistlock control switch, twistlock

position sensors, twistlock position status

indicator lamp and a roof mounted twistlock

status beacon.

Body Assembly ECM

The unit is located under the floor of the cab

under the operator’s seat. This additional ECM

is integrated to existing chassis ECMs with

cable harnesses and loaded with a MCC35

specific software flash file.

The ECM controls and monitors hoist lever

position, hoist lever override switch, remote

body operation switch panel, bed position

sensor, in-cab twistlock switch, twistlock

position sensors, twistlock status indicating

beacon, transmission and hoist valve.

2-5

Page 13

MCC35-CAT735-1

Body Midpoint

Override

Switch

5 Aug 2010

Hoist Control Lever Handle

A modified hoist lever handle replaced the

existing handle to provide a midpoint override

switch capable of disabling the ECM

commanded hoist raise stop signal. The hoist

lever still performs normal hoist functions of

RAISE, HOLD, FLOAT and LOWER as

described in the CAT Operators Safety Manual

with the exception of hoist raise automatic

midpoint stop feature as described below and in

the Body Assembly ECM. The hoist lever will

also allow tailgate functions to occur

automatically at the beginning of a raise

function (tailgate down to unrestrain container

doors) and at the end of a body lower function

(tailgate up to retain container doors) only when

the vehicle is in forward motion above 7 mph.

SECTION 2

System Description

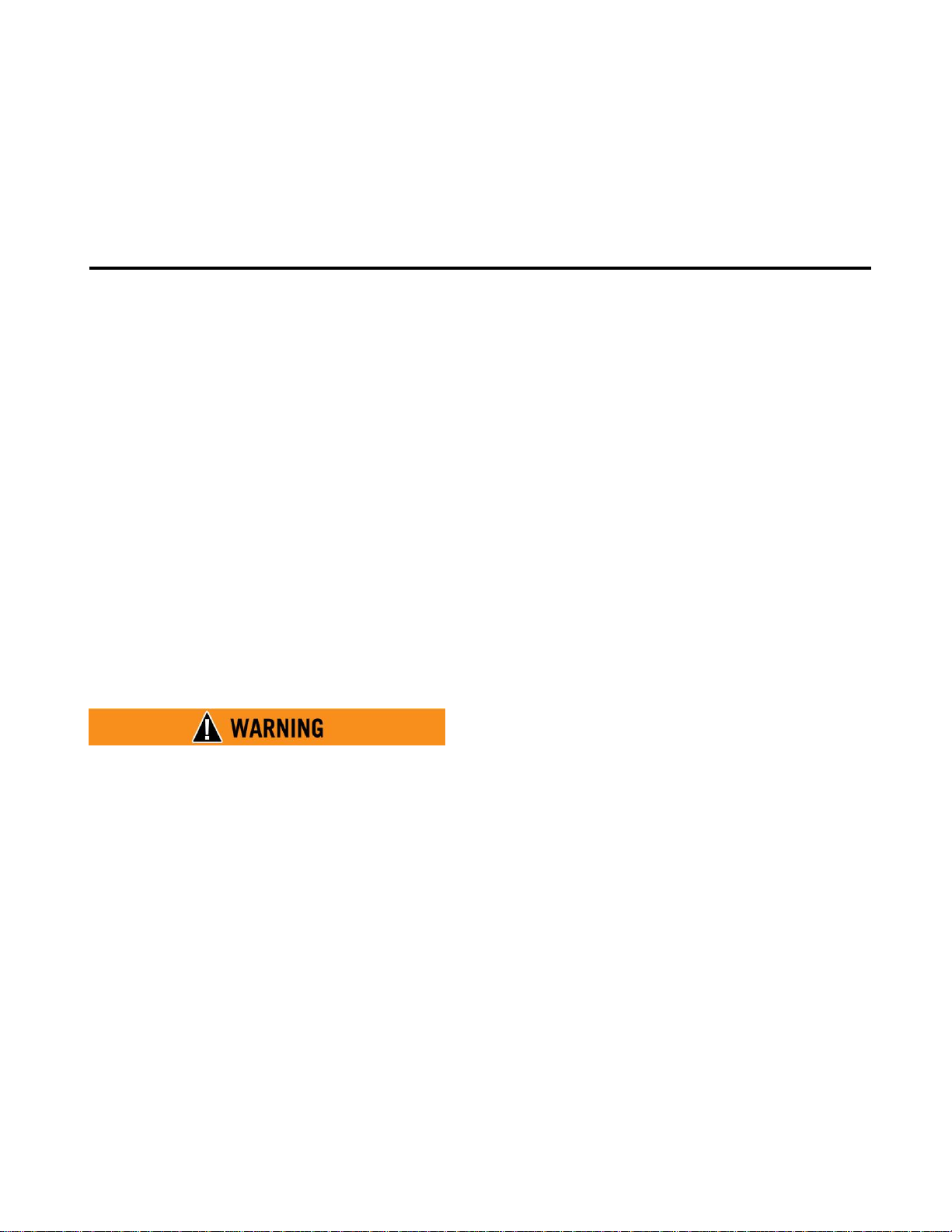

Tailgate Remote Operation Switches

The panel is mounted on the left rear tube of the

body assembly just below the amber marker

light. The panel contains 2 switches normally

used to lower the tailgate and relieve pressure

on the container doors or to raise the stinger to

secure the tailgate for transport. These switches

will only function if the stinger fault indicator

lamp is extinguished, the hoist lever is in

FLOAT, twistlocks are in the full ENGAGED

position and the vehicle is stationary.

The OPEN switches may also be used for

limited body lift function. This function is

limited by the additional ECM as programmed.

This will prevent the body from raising above

the preset angle when the stinger OPEN switch

is depressed. If the body does RAISE the ECM

will command the hoist valve to return to the

FLOAT position and the body will lower.

2-6

Page 14

Body Position Sensor

LIGHT

STATUS

OFF

All twistlocks are DISENGAGED

FLASHING

One or several twistlocks are

transiting or a fault exists.

ON

All twistlocks are ENGAGED.

Body Position

Sensor

Twistlock

Switch

Twistlock

Indicator Light

Stinger Control Fault

Indicator Lamp

The sensor is mounted to the body assembly left

rear pivot mount. The position sensor is

connected to the chassis by an adjustable link

and provides the ECMs with angular body

positioning for automatic body raise stop

feature, in-cab body up indicator light and gear

limit functions.

In-Cab Twistlock Switch and Indicator Light

The switch and indicator light are mounted in

the existing instrument cluster. The switch

MCC35-CAT735-1

5 Aug 2010

SECTION 2

System Description

commands the twistlock solenoid manifold to

route pressure to the twistlock cylinders. The

indicator light provides the operator with an incab status of the twistlocks as follows:

In-Cab Stinger Control Fault Light

The light is mounted in the dash just to the right

of the twistlock switch. Indicates a fault exists

in the tailgate system remote switches or

circuitry.

2-7

Page 15

MCC35-CAT735-1

Blue Twistlock

Status Beacon

5 Aug 2010

Twistlock Sensors

Each twistlock sensor is mounted inside the

tubular frame and attached to its respective

twistlock by a bellcrank and adjustable clevis.

The sensor provides individual twistlock

position information to the body assembly

ECM. It is the body assembly ECM that

commands the in-cab twistlock light indications

after processing all sensor information.

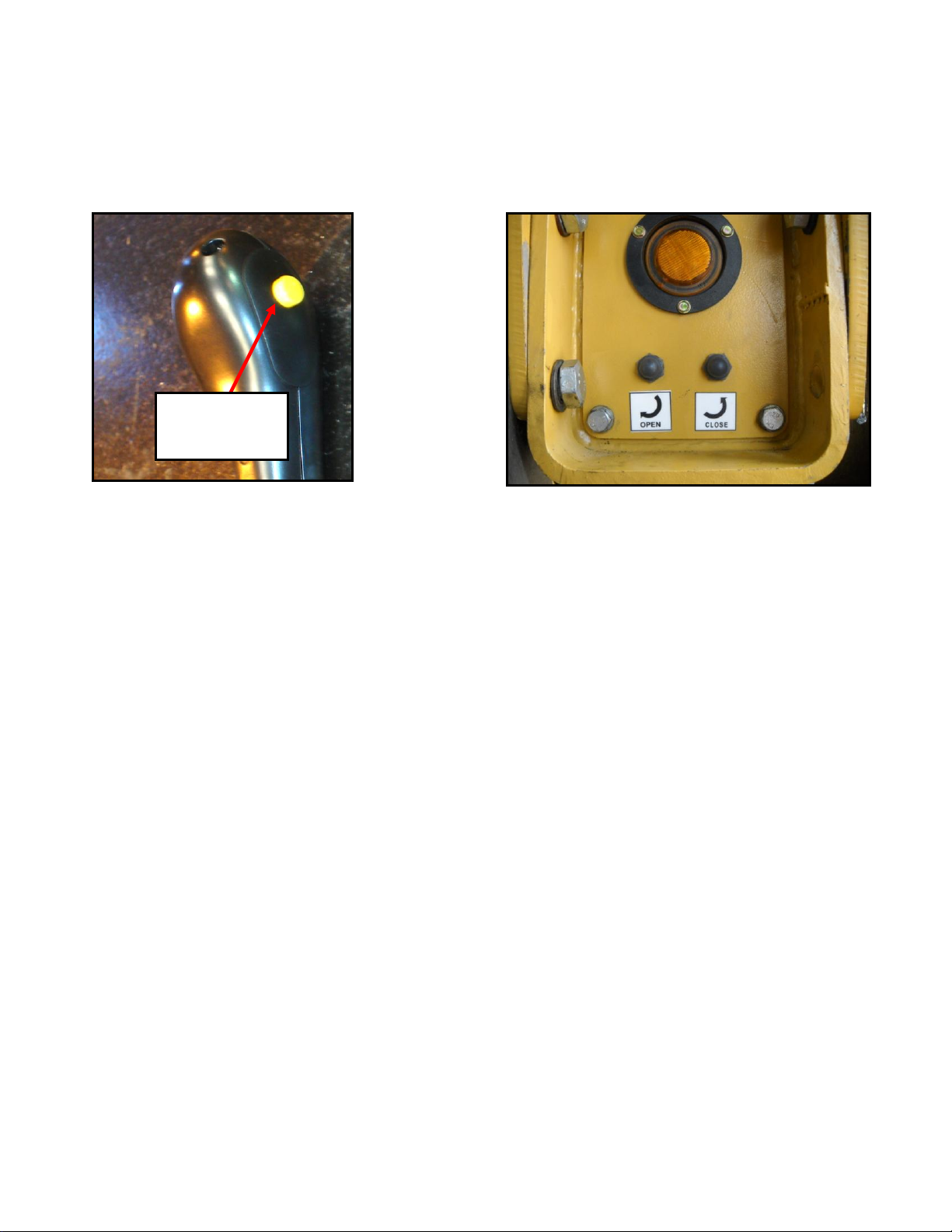

External Twistlock Status Beacon

The blue twistlock status beacon assembly is

mounted to the top of the chassis cab and is

controlled by the additional ECM. The blue

beacon will only flash when all twistlocks are

DISENGAGED, indicating to the crane operator

it is safe to remove the container from the bed

assembly.

SECTION 2

System Description

THEORY OF OPERATION

The bed assembly, controls systems, indicators

and components operate as follows:

LOCKING THE CONTAINER TO THE

BODY ASSEMBLY

Once a container is lowered to the body

assembly the container must be secured to the

body for transportation and dumping. Initially

the external twistlock status beacon is ON and

in-cab twistlock status lights are OFF. The

operator then activates the in-cab twistlock

switch that in turn sends a lock signal to the

body assembly ECM. The ECM then

commands the twistlock solenoid to provide

hydraulic pilot pressure to all twistlock

actuators. Hydraulic pressure will begin to

rotate all twistlocks and twistlock sensors to a

position that will require the ECM to turn OFF

the twistlock external status light. Once all

twistlocks are in an ENGAGED position, the

ECM will illuminate the in-cab twistlock status

light. If the twistlock light does not illuminate

and a fault exists, the twistlock fault light will

illuminate.

RAISING THE BED ASSEMBLY FOR

DUMPING

The operator moves the hoist control lever from

FLOAT to RAISE. The chassis ECM will

command the hoist valve to route pressure to the

tailgate operation valve assembly. The solenoid

control valve will provide pressure to the

tailgate hydraulic cylinder and lower (OPEN)

the tailgate to unsecure the container doors.

Once the tailgate restraint (stinger) is fully

lowered, hydraulic pressure is routed to the lift

cylinders and the bed begins to RAISE. The incab body position light will illuminate and the

chassis is restricted to 1st gear.

When the bed reaches a predetermined dump

angle, as sensed by the bed position sensor, the

body assembly ECM will command the hoist

valve to stop supplying pressure to the lift

2-8

Page 16

SECTION 2

System Description

cylinders and the hoist valve will default to

HOLD. The operator will position the hoist

lever to HOLD. The midpoint stop value is set

prevent the tailgate of the container from

contacting the ejected load or the ground. This

safety feature will prevent damage to the body

assembly and the tailgate.

If the load is not fully ejected from the container

the operator may raise the bed further. This is

accomplished by positioning the hoist lever to

the HOLD position, depress and hold the

midpoint override switch and move the hoist

lever to the RAISE position then release the

override switch. The body will continue to raise

to the upper limit angle value as programmed

into the ECM software.

The midpoint stop and the upper raise limit

angles can be programmed as specified by the

type of container and the end users

requirements.

LOWERING THE BED ASSEMBY

The operator moves the hoist control lever to

LOWER position. The chassis ECM commands

the hoist valve to provide pressure to the lift

cylinders and the bed begins to lower. Once the

bed assembly is down operators should position

the hoist lever to FLOAT. Once the container

doors are closed manually, the operator should

depress the stinger CLOSE button from the

remote switches to command the stinger to raise

and restrain the tailgate. The stinger can also be

operated by the hoist control lever when the

vehicle is moving forward at 7 mph or greater

and the hoist lever is placed in the LOWER

position. This action will allow hoist valve

LOWER oil pressure through the stinger

activation control valve and CLOSE the stinger.

When the stinger is in the full CLOSE position

the operator can move the hoist lever to the

FLOAT position.

MCC35-CAT735-1

5 Aug 2010

RAISING (CLOSING) OR LOWERING

(OPENING) THE TAILGATE RESTRAINT

WITH THE REMOTE BED OPERATION

SWITCHES

The remote switches control the hoist valve

control to operate the stinger from the ground at

the rear of the machine. The hoist lever must be

in the FLOAT position, twistlocks ENGAGED,

all fault indicators OFF for this control to

operate.

LIGHTS & ACCESSORIES

The MCC35 is equipped with several different

lighting systems and accessories. They consist

of relocated chassis tail lights and accessories,

an amber flashing beacon and body assembly

clearance lights.

Tail Light & Accessory Assembly

The tail lights and other accessories are

removed from the rear of the chassis and

relocated on the MCC35 rear mounting plate.

These lights and accessories consist of tail light

modules, backup alarm and work/reverse lights.

The relocation of all lights and accessories

provides and unobstructed view of all light

systems with the MCC35 installed and loaded

with a container. The light and accessories

operate as defined in the CAT 735 Operators

Safety and Maintenance Manual.

2-9

Page 17

MCC35-CAT735-1

Amber Light-

Key ON Beacon

5 Aug 2010

System Description

Amber Flashing Beacon

Mounted to the top of the MCC35 cab and is

activated when the vehicle key switched power

is ON. This beacon serves as an anti-collision

device indication the vehicle is under power and

in service.

Clearance Lights

An amber colored light mounted on each end of

the body assembly tube cap. The lights operate

on 24 VDC and are on when the chassis running

lights or parking lights are on.

SECTION 2

2-10

Page 18

SECTION 3

Normal Operations

Contents

Description …………..…………………… 3-1

Before Operations …..………………….... 3-1

DESCRIPTION

This section provides normal bed operation

procedures for the MCC 35 on the CAT 735

LWB chassis only. These procedures are in

addition to and do not replace existing CAT

735 requirements. Refer to the CAT 735

Operations and Maintenance manual for other

specific CAT 735 operation instructions,

warnings and hazards. The MCC35 specific

operating procedures are also found in checklist

form located in the appendix and designed to

be used in the cab.

BEFORE OPERATIONS

These procedures are used to perform a walkaround inspection of the MCC35 system before

use or the beginning of a shift. This inspection

requirement is in addition to and does not

replace the vehicle manufacture’s inspections.

Ensure all safety information, warnings and

instructions are read and understood before any

operation or maintenance procedures are

performed. Ensure proper safety procedures

are used when operations the MCC35. Failure

to use proper safety procedures and equipment

may cause serious personnel injury or death.

Power OFF

1. Chocks – Set As Required

2. Vehicle Parking Brake – ON

3. Gear Selector Lever – N (Neutral)

4. In Cab Controls – Set As Required

5. Cab Mounted Indicator Beacons –

Security and Damage

MCC35-CAT735-1

5 Aug 2010

Operations ………..……………………… 3-2

After Operations ………………………… 3-4

6. MCC35 Accumulator – Security

Damage and Leaks

7. LT Body Lift Cylinder – Security,

Damage, Leaks and Lubrication

8. LT Side Body Assembly, Centering

Guides, Twistlocks, Lights, Fender and

Mud Flap – Security, Damage and

Lubrication.

9. LT Pivot Pin – Security, Damage and

Lubrication

10. Body Position Sensor – Security and

Damage

11. Remote Bed Operation Switches –

Condition, Security and Damage.

12. Tailgate Assembly – Security, Damage,

Leaks and Lubrication.

13. Twistlock Mechanisms – Security,

Damage, Operation and Lubrication.

14. Tail Light and Accessories – Security

and Damage

15. Hydraulic Sequencing and Twistlock

Manifolds – Security, Damage and

Leaks.

16. RT Pivot Pins – Security, Damage and

Lubrication

17. RT Side Body Assembly, Centering

Guides, Twistlocks, Lights, Fender and

Mud Flap – Security, Damage and

Lubrication.

3-1

Page 19

MCC35-CAT735-1

5 Aug 2010

Normal Operations

18. RT Pivot Pin – Security, Damage and

Lubrication.

19. RT Body Lift Cylinder – Security,

Damage and Leaks

20. Hydraulic Tank – Serviced as Required

Power ON Engine ON

1. Vehicle – Start

2. Twistlock Switch – DISENGAGE

3. Twistlock In-Cab Light – OFF

4. Twistlock External Beacon – ON

5. Amber Beacon – ON

6. Twistlock Switch – ENGAGE

7. Twistlock In-Cab Light – ON

8. Twistlock External Beacon - OFF

9. MCC35 Bed Raise/Lower Operations –

CHECKED FOR PROPER

OPERATION. Ensure all bed and

tailgate functions operate properly using

the hoist lever. Check bed-up position

light, raise auto stop and raise override

function properly.

10. Remote Bed Operation Switches –

CHECKED FOR PROPER

OPERATION. Ensure both remote

switches and tailgate function properly.

SECTION 3

OPERATIONS

The procedures to follow are used to safely

operate the body system for container loading,

dumping, and container unloading.

Under certain operating conditions, the

combination of hydraulic oil for the brake

system in conjunction with the hoist system

may create a slight pressure differential across

the piston heads in the hoist cylinders. If the

hoist lever is left in the FLOAT position with

this pressure differential present, the bed will

gradually return the body over the center of

balance of the pivots and the body will lower

onto the chassis. Proper use of the RAISE,

HOLD, LOWER and FLOAT positions of the

hoist control is important for the correct

operation of the machine or damage to the

machine may result.

CONTAINER LOADING

1. Body Assembly – DOWN. Ensure bed

position light is OFF.

2. Tailgate – DOWN. Use hoist lever or

remote switches to position the tailgate.

3. Hoist Lever – FLOAT

4. Twistlock Switch – DISENGAGE

5. Twistlock In-Cab Light – OFF

6. Twistlock External Beacon - ON

7. Position Vehicle – As Required for

Loading

8. Gear Selector Lever – N (Neutral)

9. Parking Brake - As Required

3-2

Page 20

Normal Operations

10. Container - LOADED

11. Hoist Lever – FLOAT

The body must be in the FLOAT position

when driving the machine. If the hoist

control lever is in any position except

FLOAT, the transmission will remain in

FIRST gear. Normal gear shifting will not

take place until the hoist control lever is

moved to the FLOAT position.

12. Twistlock Switch – ENGAGE

13. Twistlock In-Cab Light – ON

If the twistlock indicator lamp is flashing,

move the twistlock activation switch to the

DISENGAGE position and wait for the

indicator lamp to remain OFF. Then move

the switch to the ENGAGE position and

wait for the lamp to be illuminated. If after

cycling the activation switch does not

illuminate the light discontinue use of the

MCC35.

14. Twistlock External Beacon – OFF

15. Tailgate – CLOSE. Use remote

switches to position the tailgate.

Any restraining devices (e.g. chains, straps)

used on container doors for transport must

be removed after tailgate is positioned

against container door prior to dumping

operations.

16. Parking Brake – OFF

17. Gear Selector Lever – As Required

MCC35-CAT735-1

5 Aug 2010

SECTION 3

18. Move away from loading area.

CONTAINER DUMPING

1. Vehicle - Position for container

dumping.

2. Gear Selector Lever – As Required

3. Parking Brake – As Required

4. Tailgate – DOWN. Use hoist lever or

remote switches to position the tailgate.

Any restraining devices (e.g. chains, straps)

used on container doors for transport must

be removed after tailgate is positioned

against container door prior to dumping

operations.

5. Hoist Lever – RAISE. Hold in the raise

position until the bed stops

automatically.

6. Hoist Lever & Override Switch – As

Required. Use the override system as

required to dump the entire load.

7. Hoist Lever – LOWER. Ensure the bed

assembly is fully lowered and the bed

position light extinguishes.

If required, install restraining devices (e.g.

chains, straps) to keep container doors

closed for transport before the tailgate is

raised.

8. Tailgate – UP. Use remote switches to

position the tailgate.

3-3

Page 21

MCC35-CAT735-1

5 Aug 2010

9. Hoist Lever – FLOAT

The body must be in the FLOAT position

when driving the machine. If the hoist

control lever is in any position except

FLOAT, the transmission will remain in

FIRST gear. Normal gear shifting will not

take place until the hoist control lever is

moved to the FLOAT position.

10. Parking Brake – As Required

11. Gear Selector Lever – As Required

12. Vehicle – Exit dumping area

CONTAINER UNLOADING

1. Body Assembly – DOWN. Ensure bed

position light is off.

2. Tailgate – DOWN. Use hoist lever or

remote switches to position the tailgate.

3. Hoist Lever – FLOAT

4. Position Vehicle – As Required for

Unloading

5. Gear Selector Lever – N (Neutral)

6. Parking Brake - As Required

7. Twistlock Switch – DISENGAGE

8. Twistlock In-Cab Light – OFF

9. Twistlock external status beacon (Blue)

- ON

10. Container - UNLOAD

11. Twistlock Switch – As Required

SECTION 3

Normal Operations

12. Depart unloading area.

AFTER OPERTIONS

Perform this inspection at the end of the day or

end of a shift.

1. Paring Brake – ON

2. Gear Selector Lever – As Required

3. Vehicle – Shutdown

4. Hoist Lever As Required

5. Twistlock Switch – As Required

6. LT Side Bed Assembly and Components –

Security, Damage and Leaks

7. Rear Bed Assembly and Accessories –

Security, Damage and Leaks

8. RT Side Bed Assembly and Components –

Security, Damage and Leaks

9. Hydraulic Tank - Serviced

3-4

Page 22

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

MCC35

OPERATORS

CHECKLIST

5 Aug 2010

SECTION 4

Appendix

4-1

Page 23

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

TABLE OF CONTENTS

Title Page

1. BEFORE OPERATIONS ………… N-2

A. Power OFF …………......…… N-2

B. Power ON and Engine ON ….. N-4

2. OPERATIONS ……………………. N-5

A. Container Loading …..……… N-6

B. Container Dumping ….…..… N-9

C. Unloading Container ..……… N-11

3. AFTER OPERATIONS ………..… N-7

N-1

5 Aug 2010

SECTION 4

Appendix

4-2

Page 24

SECTION 4

MCC35-CAT735(CL)-1

5 Aug 2010

BEFORE OPERATIONS

These procedures are used to perform a walk-around

inspection of the MCC35 system before use or the

beginning of a shift. This inspection requirement is in

addition to and does not replace the vehicle manufacture’s

inspections.

Ensure all safety information, warnings and instructions

are read and understood before any operation or

maintenance procedures are performed. Ensure proper

safety procedures are used when operations the MCC35.

Failure to use proper safety procedures and equipment

may cause serious personnel injury or death.

Power OFF

1. Chocks – Set As Required

2. Vehicle Parking Brake – ON

3. Gear Selector Lever – N (Neutral)

4. In Cab Controls – Set As Required

N-2

Appendix

MCC35-CAT735(CL)-1

MCC35-CAT735-1

5 Aug 2010

4-3

Page 25

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

5. Cab Mounted Indicator Beacons –Security and

Damage

6. MCC35 Accumulator – Security Damage and Leaks

7. LT Body Lift Cylinder – Security, Damage, Leaks and

Lubrication

8. LT Side Body Assembly, Centering Guides,

Twistlocks, Lights, Fender and Mud Flap – Security,

Damage and Lubrication.

9. LT Pivot Pin – Security, Damage and Lubrication

10. Body Position Sensor – Security and Damage

11. Remote Bed Operation Switches – Condition, Security

and Damage.

12. Tailgate Assembly – Security, Damage, Leaks and

Lubrication

13. Twistlock Mechanisms – Security, Damage, Function

and Lubrication

14. Tail Light and Accessories – Security and Damage

N-3

5 Aug 2010

SECTION 4

Appendix

4-4

Page 26

SECTION 4

MCC35-CAT735(CL)-1

5 Aug 2010

15. Hydraulic Sequencing and Twistlock Manifolds –

Security, Damage and Leaks.

16. RT Pivot Pins – Security, Damage and Lubrication

17. RT Side Body Assembly, Centering Guides,

Twistlocks, Lights, Fender and Mud Flap – Security,

Damage and Lubrication.

18. RT Pivot Pin – Security, Damage and Lubrication.

19. RT Body Lift Cylinder – Security, Damage and

Leaks

20. Hydraulic Tank – Serviced as Required

Power ON Engine ON

1. Vehicle – Start

2. Twistlock Switch – DISENGAGE

3. Twistlock In-Cab Light – OFF

4. Twistlock External Status Beacon – ON

5. Amber Beacon – ON

N-4

Appendix

MCC35-CAT735-1

5 Aug 2010

4-5

Page 27

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

6. Twistlock Switch – ENGAGE

7. Twistlock In-Cab Light – ON

8. Twistlock External Status Beacon - OFF

9. MCC35 Bed Raise/Lower Operations – CHECKED

FOR PROPER OPERATION. Ensure all bed and

tailgate functions operate properly using the hoist

lever. Check bed-up position light, raise auto stop

and raise override function properly.

10. Remote Bed Operation Switches – CHECKED FOR

PROPER OPERATION. Ensure both remote

switches and tailgate function properly.

OPERATIONS

The procedures to follow are used to safely

operate the body system for container loading,

dumping, and container unloading.

N-5

5 Aug 2010

SECTION 4

Appendix

4-6

Page 28

MCC35-CAT735(CL)-1

5 Aug 2010

Under certain operating conditions, the combination

of hydraulic oil for the brake system in conjunction

with the hoist system may create a slight pressure

differential across the piston heads in the hoist

cylinders. If the hoist lever is left in the FLOAT

position with this pressure differential present, the bed

will gradually return the body over the center of

balance of the pivots and the body will lower onto the

chassis. Proper use of the RAISE, HOLD, LOWER

and FLOAT positions of the hoist control is

important for the correct operation of the machine or

damage to the machine may result.

CONTAINER LOADING

1. Body Assembly – DOWN. Ensure bed position light

is OFF.

2. Tailgate – DOWN. Use hoist lever or remote

switches to position the tailgate.

3. Hoist Lever – FLOAT

4. Twistlock Switch – DISENGAGE

N-6

MCC35-CAT735-1

5 Aug 2010

SECTION 4

Appendix

4-7

Page 29

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

5. Twistlock In-Cab Light – OFF

6. Twistlock External Status Beacon - ON

7. Position Vehicle – As Required for Loading

8. Gear Selector Lever – N (Neutral)

9. Parking Brake - As Required

10. Container - LOADED

11. Twistlock Switch – ENGAGE

12. Twistlock In-Cab Light – ON

13. Twistlock External Status Beacon - OFF

If the twistlock indicator lamp remains illuminated or

is flashing, move the twistlock activation switch to the

DISENGAGE position and wait for the indicator lamp

to remain constant. Then move the switch to the

ENGAGE position and wait for the lamp to be

extinguished. If after cycling the activation switch

does not extinguish the light discontinue use of the

MCC35.

N-7

5 Aug 2010

SECTION 4

Appendix

4-8

Page 30

MCC35-CAT735(CL)-1

5 Aug 2010

14. Tailgate – UP. Use hoist lever or remote switches to

position the tailgate.

Any restraining devices (e.g. chains, straps) used on

container doors for transport must be removed after

tailgate is positioned against container door prior to

dumping operations.

15. Hoist Lever – FLOAT

The body must be in the FLOAT position when

driving the machine. If the hoist control lever is in any

position except FLOAT, the transmission will remain

in FIRST gear. Normal gear shifting will not take

place until the hoist control lever is moved to the

FLOAT position.

16. Parking Brake – OFF

17. Gear Selector Lever – As Required

18. Move away from loading area.

N-8

MCC35-CAT735-1

5 Aug 2010

SECTION 4

Appendix

4-9

Page 31

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

CONTAINER DUMPING

1. Vehicle - Position for container dumping.

2. Gear Selector Lever – As Required

3. Parking Brake – As Required

4. Tailgate – DOWN. Use hoist lever or remote

switches to position the tailgate.

Any restraining devices (e.g. chains, straps) used on

container doors for transport must be removed after

tailgate is positioned against container door prior to

dumping operations.

5. Hoist Lever – RAISE. Hold in the raise position

until the bed stops automatically.

6. Hoist Lever & Override Switch – As Required. Use

the override system as required to dump the entire

load.

N-9

5 Aug 2010

SECTION 4

Appendix

4-10

Page 32

SECTION 4

MCC35-CAT735(CL)-1

5 Aug 2010

7. Hoist Lever – LOWER. Ensure the bed assembly is

fully lowered and the bed position light extinguishes.

If required, install restraining devices (e.g. chains,

straps) to keep container doors closed for transport

before the tailgate is raised.

8. Tailgate – UP. Use hoist lever or remote switches to

position the tailgate.

9. Hoist Lever – FLOAT

The body must be in the FLOAT position when

driving the machine. If the hoist control lever is in

any position except FLOAT, the transmission will

remain in FIRST gear. Normal gear shifting will not

take place until the hoist control lever is moved to the

FLOAT position.

10. Parking Brake – As Required

11. Gear Selector Lever – As Required

N-10

MCC35-CAT735-1

5 Aug 2010

Appendix

4-11

Page 33

MCC35-CAT735-1

MCC35-CAT735(CL)-1

5 Aug 2010

12. Vehicle – Exit dumping area

CONTAINER UNLOADING

1. Body Assembly – DOWN. Ensure bed position light

is off.

2. Tailgate – DOWN. Use hoist lever or remote

switches to position the tailgate.

3. Hoist Lever – FLOAT

4. Position Vehicle – As Required for Unloading

5. Gear Selector Lever – N (Neutral)

6. Parking Brake - As Required

7. Twistlock Switch – DISENGAGE

8. Twistlock In-Cab Light – OFF

9. Twistlock Status Beacon - ON

10. Container - UNLOAD

11. Twistlock Switch – As Required

12. Twistlock In-Cab Light – As Required

N-11

5 Aug 2010

SECTION 4

Appendix

4-12

Page 34

SECTION 4

MCC35-CAT735(CL)-1

5 Aug 2010

13. Depart unloading area.

AFTER OPERTIONS

Perform this inspection at the end of the day or end of a

shift.

1. Paring Brake – ON

2. Gear Selector Lever – As Required

3. Vehicle – Shutdown

4. Hoist Lever As Required

5. Twistlock Switch – As Required

6. LT Side Bed Assembly and Components – Security,

Damage and Leaks

7. Rear Bed Assembly and Accessories – Security, Damage

and Leaks

8. RT Side Bed Assembly and Components – Security,

Damage and Leaks

9. Hydraulic Tank - Serviced

N-12

Appendix

MCC35-CAT735-1

5 Aug 2010

4-13

Page 35

MCC35-CAT735-1

5 Aug 2010

SECTION 4

Appendix

4-14(Blank)

Loading...

Loading...