Page 1

PERFORMER™CPB

c

Page 2

Page 3

PERFORMER™CPB

An Advanced Extracorporeal Circulatory Support System

Operator’s Manual

Distributed Exclusively

by Medtronic, Inc.

Manufactured by

RanD S.r.l.

Medolla (MO) Italy

c

Page 4

Page 5

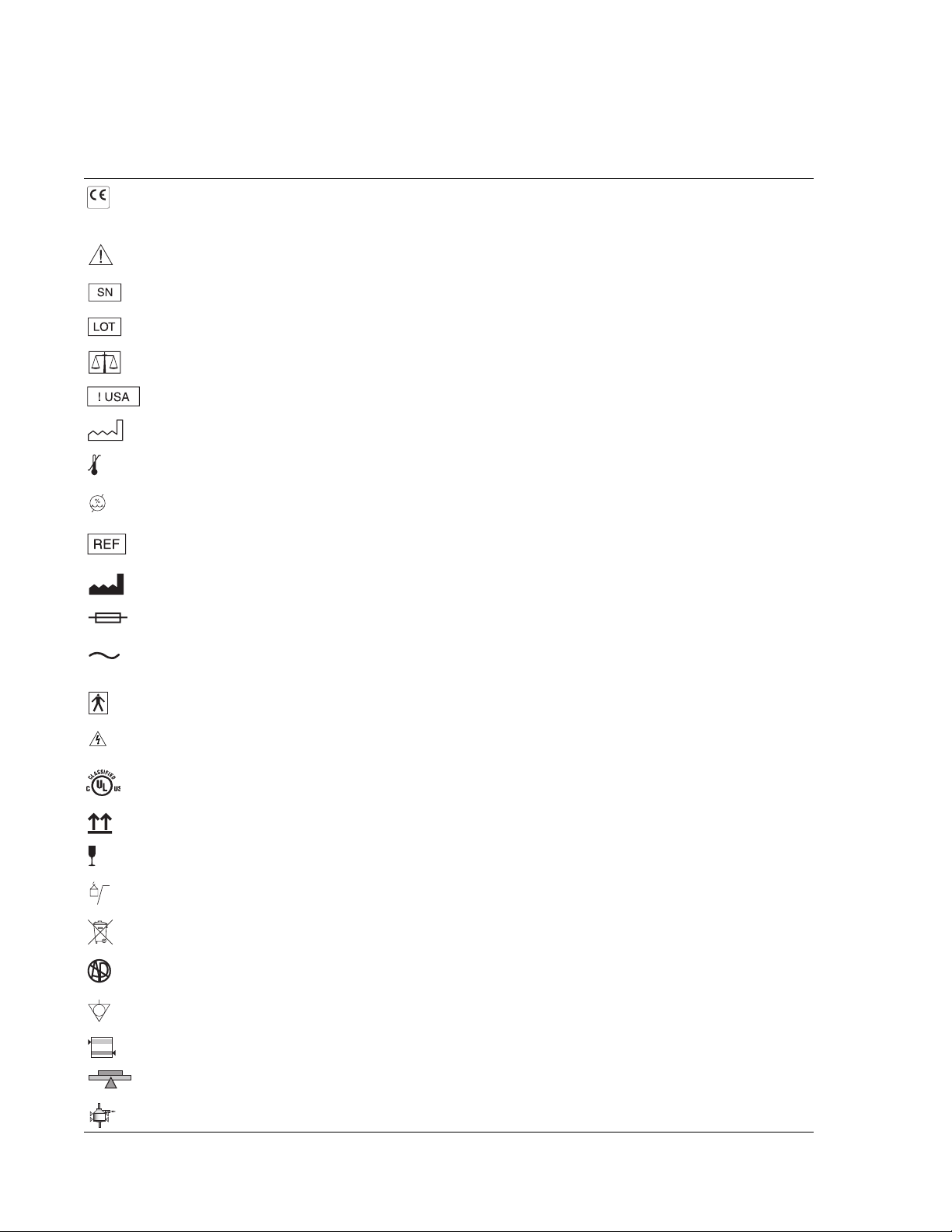

Explanation of symbols on package labeling

Refer to the package label to see which symbols apply to this product

0123

Conformité Européenne (European Conformity). This symbol means that the device fully

complies with European Council Directive MDD 93/42/EEC (14 June 1993, concerning

medical devices) and amendments.

Caution, Consult Accompanying Documents

Serial Number

Lot Number

Quantity

For US Audiences Only

Date of Manufacture

Temperature Limitation

Humidity Limitation

Catalog Number

Manufacturer

Fuse

Alternating Current

Type BF Equipment

High Voltage

Medical equipment with respect to electrical shock fire, and mechanical hazards only in

accordance with UL 60601-1/CAN/CSA C22.2 No. 601.1, IEC 60601-2-16 71NL.

This Way Up

Fragile, Handle with Care

xx Kg

MAX

Maximum Weight

Do not dispose of this product in the unsorted municipal waste stream.

Danger: Risk of explosion if used in the presence of flammable anesthetics.

Equipotentiality

Level Sensor

Remote Tube Clamp

VARD

Operator’s Manual i

Page 6

Bio-Pump

Flowmeter/ABD

Class II (Double Insulated) Equipment

Open Here

Warning, Crushing Hazard: Finger

Pneumatic Pressure Range

Atmospheric Limitation

ii Operator’s Manual

Page 7

Table of Contents

1 Introduction 1-1

System Description 1-2

System Overview 1-2

Indications for Use 1-5

Contraindications 1-5

Warnings 1-5

Cautions 1-9

2Safety2-1

Safety Standards 2-2

Disposables and Accessories 2-2

Main Power Supply Failure 2-2

Electromagnetic Disturbance 2-3

Elimination of the Disposable Material 2-3

End of Life Disposition 2-3

Calibration 2-3

Technical Documentation 2-3

Replacing Fuses 2-3

Equipotential Connection 2-4

Battery Pack Disposal 2-4

3 Technical Specifications 3-1

General Data 3-2

Technical Features 3-3

Electromagnetic Emissions and Immunity Declarations 3-6

Monitoring System for Hematocrit, Temperature and O

Temperature Probes 3-11

Battery Supply System (UPS) 3-11

IEC 60601-2-16 Compliance Chart 3-12

Saturation 3-10

2

4 Installation 4-1

Installation 4-2

Installation Checklist and Commissioning 4-3

5 Instructions for Use 5-1

Console 5-2

Roller Pump, Roller Inserts, Tube Inserts, and Tubing 5-6

System Configuration 5-16

System Start-up 5-35

Main Run Screen 5-41

Timers 5-46

Cardioplegia 5-49

AAR Controller - Venous Air Removal Device (Resting Heart mode only) 5-58

Air Detection 5-63

Operator’s Manual iii

Page 8

Table of Contents

Level Sensing System (Bio-Pump CPB mode only) 5-67

AutoClamp System (Bio-Pump CPB mode only) 5-73

Pressure Mode Selection 5-84

Venous Saturation and Hematocrit Monitoring 5-90

Options Menu Screen 5-94

Servo (Resting Heart mode only) 5-104

Preparing for Cardiopulmonary Bypass Checklist 5-109

Initiating Extracorporeal Support Checklist 5-112

6 Cleaning and Maintenance 6-1

Cleaning 6-2

Maintenance 6-2

7 Troubleshooting 7-1

General Information 7-2

Emergency Procedures 7-4

Alarms 7-20

Alerts 7-27

8 Warranty 8-1

IMPORTANT NOTICE - LIMITED WARRANTY 8-2

IMPORTANT NOTICE - LIMITED WARRANTY 8-3

A Index A-1

iv Operator’s Manual

Page 9

PERFORMER™ CPB 0

Operator’s Manual

Page 10

Page 11

System Description 1-2

System Overview 1-2

Indications for Use 1-5

Contraindications 1-5

Warnings 1-5

Cautions 1-9

Introduction

1

1

Operator’s Manual 1-1

Page 12

Chapter 1

System Description

System Description

The Performer™ CPB System, hereafter referred to as the Performer CPB, is an

electromechanical extracorporeal support device used during cardiopulmonary

bypass procedures. It is an integrated console that can provide total circulatory

support of the cardiopulmonary system using the Medtronic

Blood Pump, hereafter referred to as the Bio-Pump.

System Overview

®

Bio-Pump® Centrifugal

Total extracorporeal support of the cardiovascular system is accomplished by using

the Bio-Pump

Performer CPB for generating arterial flow up to 10.0 liters per minute (L/min).

Bio-Pump flow is achieved by adjusting the pump speed RPM knob on the front panel

of the Performer CPB console. Flow measurement is accomplished using a reusable

ultrasonic flow transducer that is noninvasively attached to the arterial line of the

extracorporeal circuit. The detected flow is displayed on the front panel of the console

(red LED) and on the Main Run Screen of the Central Information Display (CID). The

pump speed RPM knob has a minimum RPM mechanical stop, or detent, that

prevents an unintentional reduction of RPM below 2000. The user must press down

on the detent lever while turning the knob counterclockwise to purposefully reduce the

RPM below 2000. The minimum RPM detent lever does not affect increasing the

RPM.

Integral to the Performer CPB are four roller pumps, each with an independent

Start/Stop button, a 3-turn roller speed control knob and a LCD for monitoring flow or

RPM. The roller pumps are indicated for moving fluids through an extracorporeal

circuit that incorporates a flexible tube. The roller pumps are not indicated for use in

supporting flow through arterial circuits.

Two small roller pumps (PM4 and PM3) generate low flow for cardioplegia delivery,

hemoconcentration, or other auxiliary applications. PM4 is a deep-well pump capable

of accommodating two tubes of same or different dimensions and is capable of a

maximum flow of 1.1 L/min. PM3 accommodates one tube and is capable of a

maximum flow of 0.6 L/min. PM3 and PM4 can be configured via the CID so that both

pumps operate in tandem, with PM4 designated as the master pump and PM3

designated as the slave pump. The master pump Start/Stop button and pump speed

RPM knob operate both pumps.

®

Centrifugal Blood Pump. The Bio-Pump is the exclusive device on the

Two large roller pumps (PM1 and PM2) generate flow for cardiotomy suction, left heart

venting, or auxiliary application. PM1 is a low torque/high speed roller pump with a

maximum flow capacity of 3.7 L/min. PM2 is a high torque/mid-flow roller pump with

a maximum flow capacity of 1.5 L/min.

The interchangeable roller pump inserts are factory calibrated for providing optimal

occlusion for standard sizes of polyvinyl chloride (PVC) tubing available for medical

use. Factory-calibrated roller pump inserts are also available when using 2 tubes in a

single raceway.

The Performer CPB provides perfusion monitoring via:

1-2 Operator’s Manual

Pressure monitoring transducers for up to 8 pressures including venous line,

arterial line, cardioplegia delivery, AAR suction, vent line, sucker line, syringe, and

one user-defined.

Page 13

Introduction

System Overview

Temperature monitoring using YSI™1 Series 400 probes for 8 temperatures

including venous line, arterial line, cardioplegia delivery, and the remainder user

defined.

Flow monitoring for the arterial line using a reusable Transonic

™2

ultrasonic flow

probe, which noninvasively connects directly to the arterial line tubing. This flow

probe also serves to detect backflow in the arterial circuit. Flow data combined

with patient body surface area entered in the CID also provides for continuous

monitoring of cardiac index.

Oxygen saturation and hematocrit monitoring using an opto-electric sensor,

which couples with a dedicated disposable cuvette that is integrated into the

extracorporeal circuit. This data, in combination with the information obtained

from the flow transducer, is used to calculate and display oxygen consumption on

the CID.

Timers for pump time, clamp time, and cardioplegia delivery times and intervals.

The CID enables the user to interact with the Performer CPB equipment. It consists

of a 30.73 cm (12.1 in) color graphic display (256 colors, 800 x 600 pixel) in

combination with a touch screen system to activate the various functions represented

on the screen. The display is divided into well-defined zones for the individual

perfusion modes and uses unique graphic pictures and icons to display information.

Critical information areas are always visible. The touch screen display allows the

user to:

■

display all desired perfusion parameters

■

input patient information

■

configure pump responses to activation of safety devices and events that occur

during bypass

■

set safety alert and alarm limits

■

display graphical trending of data

■

select cardioplegia delivery modes

■

read message alarms and warnings

■

select audible alert and alarm tones

The CID and the console incorporate distinct visual and audible cues intended to

elevate the user's awareness when a safety sensor is activated and when

user-defined or default operational limits of a system are exceeded. The Performer

CPB enables the user to configure integrated safety links between the following safety

sensors and the Bio-Pump and the roller pumps:

■

Air Bubble Detection (ABD) of macro-air in the arterial circuit is integral to the

ultrasonic flow monitoring system. The system can be configured by the user to

cause the Bio-Pump to either Stop or Coast in response to this sensor being

activated and prevent transmission of air to the patient. The user can also

configure this safety link to not change the Bio-Pump function, but only produce

visual and audible alarm cues.

■

Air bubble detection of macro-air in the cardioplegia circuit, using an ultrasonic

transducer mounted to the side of the console that couples directly to the

cardioplegia delivery tubing. The user can configure the cardioplegia delivery

pump (PM4) to either Stop or Pause in response to this event and prevent

transmission of air to the heart. The user can also configure this safety link to not

change the roller pump function but only produce visual and audible alarm cues.

1

YSI™ is a registered trademark of YSI Incorporated.

2

Transonic™ is a registered trademark of Transonic Systems Inc. Corporation.

Operator’s Manual 1-3

Page 14

Chapter 1

System Overview

■

Active Air Removal (AAR) technology integral to the Performer CPB is used in

conjunction with a dedicated disposable Venous Air Removal Device (VARD) for

venous air sensing and automatic removal. This prevents air entering the venous

line from reaching the Bio-Pump and potentially being transmitted to the patient.

The Active Air Removal (AAR) technology with the VARD is only utilized when

operating the Resting Heart mode.

■

Level Detection utilizes a pair of level sensors to monitor changes in fluid or blood

volume in reservoirs. The system can be configured by the user to cause the

Bio-Pump to either Stop or Coast in response to a level sensor being activated,

preventing emptying the reservoir and transmitting air into the circuit. The user

can also configure this safety link to not change the Bio-Pump function, but only

produce visual and audible alarm cues. The level detection system is only utilized

when operating in the Bio-Pump CPB mode.

■

An AutoClamp System utilizes a pneumatically-powered Remote Tube Clamp

(RTC) that is placed on the arterial line and serves to prevent retrograde flow from

the aorta into the venous reservoir if the Bio-Pump run mode changes. When the

Bio-Pump enters either the STOP or COAST mode, or the pump speed is

manually reduced to 2000 RPM, there exists the potential for arterial retrograde

flow and entrainment of air into the arterial line from around the aortic cannulation

site. This poses a hazard to the patient if the pump is restarted before air is

removed. The AutoClamp System can be configured to automatically clamp the

arterial line when the Bio-Pump speed changes, prevent retrograde flow and

thereby prevent the potential to entrainment air around the aortic cannulation site.

The AutoClamp System is only utilized when operating in the Bio-Pump CPB

mode.

■

Pressure transducers enable user-defined alert and alarm limits for arterial line

pressures, venous line pressures, cardioplegia pressures, as well as the

individual roller pump pressures.

The Performer CPB provides an uninterruptible power supply (UPS) that will provide

battery power to operate the system for a minimum of 30 minutes with a fully loaded

system (see page 5-44) in the absence of line power.

Additional user conveniences include:

■

Cardioplegia delivery configuration options to select automatic shut off of the

cardioplegia pump to user-defined volume or time delivery parameters and a

user-defined option for two-pump blood and drug proportioning from 0:1 (pure

drug) to 15:1.

■

Graphic trending of flow, cardiac index, venous saturation, hematocrit, pressure,

and temperature data.

■

Capability to auto-regulate the speed of the Bio-Pump to maintain a desired

venous line pressure. This function is particularly useful when operating the

Medtronic

®

Resting Heart™ System and optimizing the relationship between

blood flow and left heart emptying.

■

An integrated printer to generate hard copy records.

■

A removable data storage card that allows perfusion and system information to be

stored electronically and then later formatted for generating reports.

■

Electric powered height adjustment for optimal operation, transport, and storage.

1-4 Operator’s Manual

Page 15

Indications for Use

The Medtronic® Performer™ CPB Advanced Extracorporeal Circulatory Support

System is indicated for use up to 6 hours in the extracorporeal circulation of fluids for

cardiopulmonary bypass procedures, when used by a qualified medical professional

who is experienced in the operation of this or similar equipment.

The Bio-Pump

an extracorporeal perfusion circuit for extracorporeal circulatory support for periods

appropriate to cardiopulmonary bypass (up to 6 hours).

Contraindications

The device is not designed, sold, or intended for use except as indicated.

The centrifugal pump is contraindicated for use as a cardiotomy suction device.

Warnings

Introduction

Indications for Use

®

Centrifugal Blood Pump is indicated for use in pumping blood through

General

■

The user must read and understand all information in the Operator's Manual prior

to use. Failure to read and follow all instructions, or failure to observe all stated

warnings, could cause serious injury or death to the patient.

■

Only trained and qualified medical personnel should operate and monitor the

Perfor mer CPB.

■

Use the system and any attached devices according to the manufacturer's

instructions and good medical practice.

■

The system is qualified only for durations appropriate to cardiopulmonary bypass

procedures. It has not been qualified, either through in-vitro, in-vivo, or clinical

studies, for use beyond 6 hours.

■

The Performer CPB enables the user to change the configuration of the default

factory settings. Reconfiguration in regards to how components respond to events

and assurance that users are properly trained to operate the Perfusion Screens

must be appropriately controlled by the user institution. Failure to establish such

controls may result in user error that could result in patient injury or death.

■

Following standard practices for electronic devices, closely monitor the system

when exposure to intense electrical noise or fluctuating line voltage occurs.

Strong electromagnetic fields emitted from other equipment in the operating room

(OR) (internal and external defibrillators, electrocautery devices, etc) or

fluctuations in the alternating current (AC) power line voltage may compromise

performance or damage the equipment.

■

Portable and mobile radio frequency (RF) communication devices may affect the

operation of this system. (See “Electromagnetic Emissions and Immunity

Declarations” on page 3-6.)

■

A standby Bio-Console® Extracorporeal Blood Pumping Console should be

available during cardiopulmonary bypass procedures.

■

Maintain a minimum Bio-Pump speed or clamp the pump outlet line to prevent

backflow.

■

Do not kink the VARD sensor cable.

Operator’s Manual 1-5

Page 16

Chapter 1

Warnings

■

Do not allow fluids to come into contact with the cable connections.

■

To prevent backflow of the patient's blood when the pump outlet tubing is open,

establish and maintain a minimum pump speed that overcomes line and patient

resistance. Failure to do this could allow retrograde flow and exsanguinate the

patient.

■

All gaseous bubbles have the potential for gaseous emboli and must be dealt with

carefully. Use of Safety Devices (Arterial Line Air Bubble Detector, VARD, Level

Detection, AutoClamp) and Safety Systems (Bio-Pump Backflow Alert) is

recommended to aid in the detection and elimination of gaseous bubbles in the

extracorporeal circuit.

■

When handcrank operation of a roller pump is necessary due to a failure of the

motor or motor controller, the roller pump digital display may remain illuminated.

Any RPM/flow values that are being displayed will not correlate to the manual

RPMs or flow generated using the handcrank.

■

A fluid isolator is necessary in the pressure monitoring line to prevent contact of

sterile fluid path with the instrument and damage to the instrument and pressure

system.

■

Do not bypass the fluid isolator/filter in the pressure lines for the pressure

connectors (PR1 through PR8, ALP, and VLP) or fluid could enter the transducer

and damage internal components.

■

Do not introduce fluid into the male pressure luer connections on the console.

■

Do not connect the external temperature probes in conjunction with

electrocautery usage; this may compromise the temperature values measuring.

■

The device has been designed and tested in conformity with the Electro-Magnetic

Compatibility standard EN60601-1-2 (2003). It is advisable, however, to avoid its

use in the presence of electromagnetic fields or other equipment causing

interference (eg, cellular phones). Special information regarding installation, use,

and precautions are described in “Electromagnetic Emissions and Immunity

Declarations” on page 3-6.

■

The utilization of other manufacturers' probes (eg, flow and temperature) may

jeopardize the performance of the device and, as a consequence, the

measurement reliability.

■

The equipment is not protected against defibrillator discharges.

AAR Controller

AutoClamp System

1-6 Operator’s Manual

■

Do not operate the Active Air Removal (AAR) system with device or components

other than the Medtronic

®

Resting Heart™ Module. There are no safety or

performance data known to Medtronic that establish compatibility of any other

manufacturer's device or components with the AAR system. Any substitution of

components becomes the responsibility of the user. Such substitution will void

Medtronic's warranty and the user will bear full responsibility for any adverse

consequences stemming from such use.

■

Do not use the integrated AAR Controller until proper operating conditions are

verified. Prior to each use, it is the responsibility of the user to determine that the

system is in proper operating condition as described in this manual.

■

To prevent backflow of the patient's blood when the pump outlet tubing is open,

establish and maintain a minimum pump speed that overcomes line and patient

resistance. Use the AutoClamp System on the arterial line. Failure to do this could

allow retrograde flow and introduce air into the arterial circuit.

Page 17

Introduction

Warnings

■

Prior to configuring the Arterial AutoClamp to CLOSE when the Bio-Pump enters

the COAST mode, it is the user's responsibility to test their extracorporeal circuit

and confirm the conduct of perfusion at their institution does not generate arterial

backflow when the Bio-Pump enters the COAST mode or the Bio-Pump speed is

manually reduced to the “detent” position.

■

If the Bio-Pump enters the Coast Mode in response to the “AIR DETECTED BY

ABD” alarm, pump RPM will remain at 2000 and will not automatically ramp up

after the air is no longer detected by the ABD or after the ABD is turned off. Flow

can only be resumed manually after careful assurance that air has been

completely removed from the arterial circuit.

■

If the Bio-Pump enters the Coast Mode in response to the “AIR DETECTED BY

ABD” alarm and the AutoClamp is configured to CLOSE, the AutoClamp will not

automatically OPEN after Bio-Pump flow is resumed. The user must manually

press the AutoClamp button on the Main Run Screen to open the clamp after

careful assurance there will be forward flow.

■

The Self Test must be performed prior to each use of the device. If the AutoClamp

System does not operate as described during the Self Test, do not use the

AutoClamp System. Contact Medtronic Service.

■

Resume flow only after careful assurance there is no air in the arterial circuit.

■

Ensure the air pressure to the AutoClamp System is within the range specified in

Chapter 3.

Battery/UPS

■

If a partially charged battery is used, there may be less than 30 minutes of battery

power available.

■

When the Uninterruptable Power Supply (UPS) converts the system to battery

power, ALL pumps, pump functions, safety systems, alerts, alarms, monitors,

controls, the Pinch Valve and the Central Information Display (CID) are active and

function the same as when the system is on AC power.

Main Power Switch

■

Ensure that the Main Power switch is off before storage, inspection, cleaning, and

preparation for use to disable both the battery power and wall AC power.

Central Information Display (CID)

■

If the CID fails during a procedure, the Performer CPB can be operated through

the local controls for the roller pumps and the Bio-Pump.

■

If the CID fails during a procedure, the sensors that have safety connections with

the Bio-Pump will remain enabled. The sensors that detect and measure blood

flow, Arterial Line Pressure (ALP), Venous Line Pressure (VLP), Venous

Saturation (SvO2), Hematocrit (Hct), Revolutions Per Minute (RPM), and

Cardioplegia Pressure can be displayed by scrolling through the Liquid Crystal

Display (LCD) display on the Bio-Pump control panel on the front of the console.

■

If the CID fails during a procedure, DO NOT turn the system power off as this will

cause all settings and device assignments to be lost.

■

The CID must be in the Home Screen for data to be downloaded into the

CompactFlash

allow a minimum of 10 seconds for the data download to complete before

removing the CompactFlash

®3

memory card. After the CID is changed to the Home Screen,

®

memory card.

3

CompactFlash® is a registered trademark of SanDisk Corporation.

Operator’s Manual 1-7

Page 18

Chapter 1

Warnings

Tubing

Roller Pump

■

Using the Pre-Cardiopulmonary Bypass Parameters Screen with the

alpha-numeric keyboard during the conduct of cardiopulmonary bypass will cover

essential perfusion and cardioplegia delivery information screens. Enter data

prior to initiating bypass. Do not use during bypass.

■

Tubing must not be reversed in the roller pump as air embolism may occur.

■

Use only tubing of the material and sizes specified for this system.

■

Set the roller pump to the Stop Mode before installing tubing.

■

The roller pump safety cover interlocks are not enabled until after the Resting

Heart™ Screen is opened. Ensure that the roller pump safety covers remain

closed during the Power On Self-Test (POST).

■

The roller pump safety cover interlocks are not enabled until after the Resting

Heart™ Screen is opened. Ensure that the roller pump safety covers remain

closed when in the Emergency Mode.

■

The roller pump safety cover interlocks are not enabled until after the Resting

Heart™ Screen is opened. Ensure the roller pump safety covers remain closed if

roller pump function is required before enabling the Resting Heart™ Screen.

Handcrank

■

If handcrank operation is necessary due to the loss of AC and battery power, flow

detection and safety systems are inoperable. Closely monitor the circuit to prevent

introduction of air.

Bio-Pump

■

If air enters the Bio-Pump, stop perfusion as gaseous emboli may be introduced

into the patient.

■

If the Bio-Pump stops, immediately clamp the arterial line and venous line. Check

for air in the arterial line that may have resulted from backflow. If air is visible,

remove from the arterial circuit before resuming bypass.

■

If the Bio-Pump enters the Coast Mode in response to the “AIR DETECTED BY

ABD” alarm, pump flow will remain at 0.5 L/min and will NOT automatically ramp

up after the air is no longer detected by the ABD or after the ABD is turned off.

Flow can only be resumed manually after careful assurance that air has been

completely removed from the arterial circuit.

Power On Self-Test (POST)

■

Bypassing the POST when a system has failed may cause error messages or

malfunction during use.

■

If the POST repeatedly produces a FAILED indication, contact a Medtronic

service representative.

Air Bubble Detector (ABD)

■

A gray icon (with a red X) for the Arterial Line Air Bubble Detector icon indicates

the sensor is DISABLED and will not generate an alarm if air enters the arterial

circuit.

1-8 Operator’s Manual

Page 19

Cautions

Introduction

Cautions

■

The Air Bubble Detector (ABD) sensor must be positioned at a sufficient distance

from the patient to allow the air detection system sufficient time to respond before

air can reach the patient.

■

The ABD sensor latch must be completely closed to secure the sensors to the

tubing.

■

The ABD sensor must be positioned so the cable is between the tubing and the

floor.

■

The performance of the ABD must be verified before each use.

■

A gray icon (with a red X) for the Cardioplegia (CPG) Air Bubble Detector icon

indicates the sensor is DISABLED and will not generate an alarm if air enters the

cardioplegia circuit.

■

Do not use sharp instruments on the CID, Bio-Pump control panel scroll arrows,

or the roller pump Start/Stop button as these may damage the device. Restrict

touching the screen with fingers only.

■

Installing the Bio-Pump with the motor revolving may damage the Bio-Pump.

■

When assembling the Bio-Pump Centrifugal Blood Pump, Model BPX-80, for use

with the Performer CPB, do not use alcohol or alcohol-based fluids. Do not expose

to chemical agents as they may affect the integrity of these devices. Anesthesia

solutions such as FORANE

4

are known to degrade polycarbonate plastics. Avoid

contact of these solutions with the BPX-80 Bio-Pump.

■

Using the Bio-Pump beyond labeled recommendations may result in failure of the

centrifugal blood pump, reduced pumping capacity, leaks, excessive blood

trauma, and degradation or corrosion of blood contact materials, which may pass

through the blood to the patient.

■

Refer to the instructions included with the Medtronic® Resting Heart™ System or

specific manufacturers’ disposable circuits.

■

Maintain a minimum pump speed or clamp the circuit's arterial line to prevent

arterial backflow.

■

If the pressurized gas fails or the air hose is disconnected, the Remote Tube

Clamp (RTC) will close.

■

Do not drop the O2Sat/Hct sensors as shock may damage the sensor.

■

Do not adjust the occlusion setting on the roller pump insert; doing so will void the

warranty.

■

Ensure the castor brakes are engaged before use.

■

When transporting the machine, reduce the equipment’s height to the lowest

position to avoid tipping.

■

Only ship the Performer CPB in a Medtronic-approved crate. Contact your service

personnel for the correct procedure.

■

After each use, clean the device as per the instructions on page 6-2 and ensure

all components are in proper working condition.

4

FORANE® is a registered trademark of ATOFINA.

Operator’s Manual 1-9

Page 20

Chapter 1

Cautions

1-10 Operator’s Manual

Page 21

Safety Standards 2-2

Disposables and Accessories 2-2

Main Power Supply Failure 2-2

Electromagnetic Disturbance 2-3

Elimination of the Disposable Material 2-3

End of Life Disposition 2-3

Calibration 2-3

Technical Documentation 2-3

Safety

2

2

Replacing Fuses 2-3

Equipotential Connection 2-4

Battery Pack Disposal 2-4

Operator’s Manual 2-1

Page 22

Chapter 2

Safety Standards

ATTENTION: The Performer CPB must be operated only by skilled personnel trained

for this task and in conformity to the present Operator’s Manual.

Safety Standards

The Performer CPB equipment complies with the essential requirements of the

Directive on Medical Devices 93/42 EEC (CE 0123)

The Performer CPB equipment also complies with the following international

standards:

Manufacturing safety, electrical safety:

■

■

■

■

Functional safety:

■

■

■

■

IEC 60513

IEC 60529

EN 60601-1

EN 60601-1-1 (2003)

ISO 14971

EN 60601-1-4

EN 60601-1-4/A1 (2000)

EN 60601-2-16

Electromagnetic compatibility:

■

EN 60601-1-2 (2003)

Disposables and Accessories

Use only disposables and accessories approved by Medtronic for use with the

Instrument. The use of other manufacturers' disposables and accessories has not

been validated by Medtronic and will void the warranty on the Instrument and may

jeopardize the functionality of the Instrument, possibly compromising patient safety.

Used accessories and parts may be used with the Instrument only when their

suitability for use has been established and certified, from the technical safety point

of view, by a person or entity authorized by Medtronic to test their performance with

the Instrument.

Main Power Supply Failure

In case of a main supply failure, fully-charged backup battery will allow treatment with

a fully loaded system to continue for a minimum of 30 minutes (see page 5-44).

2-2 Operator’s Manual

Page 23

Electromagnetic Disturbance

The Performer CPB has been designed and tested to comply with the requirements

and tests of the electro-magnetic compatibility standard EN60601-1-2 (2003). It is

advisable, however, to avoid its use in the presence of strong electromagnetic fields

radiated from other equipment in the operating room (ie, defibrillators and

electrocautery devices) that may cause interference.

Special information regarding installation, use, and precautions are described in

“Electromagnetic Emissions and Immunity Declarations” on page 3-6.

The use of any accessory, probes, or cables other than those specified in this

document, including replacement parts, may result in either increased emissions or

decreased immunity of the Performer CPB.

Elimination of the Disposable Material

The disposables used in each treatment shall be disposed of using specific containers

and in conformity with local norms.

Safety

Electromagnetic Disturbance

End of Life Disposition

Do not dispose of this product in the unsorted municipal waste stream. Follow local

regulations for proper disposal. Please refer to Medtronic web site

http://recycling.medtronic.com for proper disposal guidance to ensure compliance

with the European Union’s Waste Electrical and Electronic Equipment (WEEE)

Directive.

Calibration

The calibration shall be performed only by authorized personnel.

Technical Documentation

The Service Manual, with electrical schemes, calibration procedures, and component

lists, will be provided upon request, for exclusive use by authorized, trained personnel.

Replacing Fuses

No auto-restoring fuses are present on the Performer CPB equipment; only internal

and external non-restoring fuses.

The replacement of a malfunctioning internal fuse(s) must be performed by

authorized, trained personnel.

The replacement of a malfunctioning external fuse(s) must be performed by using the

correct fuse(s) type as indicated by the external label and by the manufacturer (see

“General Data” on page 3-2).

Operator’s Manual 2-3

Page 24

Chapter 2

Equipotential Connection

Equipotential Connection

Specific connection for the potential equalization is available on the Performer CPB in

case the local regulations require “potential compensation” by means of connection

to the potential compensation network.

The potential equalization connection is also recommended if other pieces of

equipment are used in combination with the Performer CPB.

Battery Pack Disposal

The life of the rechargeable battery packs is foreseen up to 4 years (depending on the

number of charge/discharge cycles and on correct use). After this period, battery

replacement and disposal is provided by authorized, trained personnel.

2-4 Operator’s Manual

Page 25

Technical Specifications

General Data 3-2

Technical Features 3-3

Electromagnetic Emissions and Immunity Declarations 3-6

Monitoring System for Hematocrit, Temperature and O2

Saturation 3-10

Temperature Probes 3-11

Battery Supply System (UPS) 3-11

IEC 60601-2-16 Compliance Chart 3-12

3

3

Operator’s Manual 3-1

Page 26

Chapter 3

General Data

General Data

STATEMENT OF CONFORMITY AND CLASSIFICATION

The equipment is a Class IIB active medical device in conformity with Annex IX of the

European Council Directive MDD 93/42/EEC on Medical Devices.

The equipment is CE marked according to the Annex 2.3 of the European Council

Directive MDD 93/42/EEC on Medical Devices.

Electrical Data

Classification (as for EN60601-1) Class I, type BF

Operation Mode Continuous

Voltage 100 to 240 VAC ± 10%

Frequency 50 to 60 Hz ± 10%

Current max. 6 A (100 to 120V)

max. 3 A (220 to 240V)

Power absorption max. 600 VA

Earth leakage current < 300 µA

Patient leakage current < 100 µA

Potential equalization Connector available

External fuses (type 5 x 20) 2x F6.3A/250V (100 to 120V)

2x F3.15A/250V (220 to 240V)

Power Cord “Hospital Grade” type

Max. 3 m length

10A, 125V (North America)

10A, 250V (Europe)

Ingress Protection

(IP code as for IEC 60529)

Environmental Operating Conditions

Temperature +10°C to +40°C

Relative humidity 30% to 75% (noncondensing)

Atmospheric pressure 700 to 1060 mBar

Transport and Storage Conditions

Temperature -20°C to +60°C

IP 21: protected against solid foreign objects of

12 mm diameter and greater; protected against

drop water.

3-2 Operator’s Manual

Relative humidity 10% to 90% (noncondensing)

Atmospheric pressure 700 to 1060 mBar

Interface

External Motor Drive (Bio-Pump) 10-pin LEMO

VARD Sensor 10-pin LEMO

®1

(EGG.3B.310.CLL)

®

(EGG.1B.310.CLL)

Page 27

Flow Probe / ABD 15-pin D-SUB

Level Sensors 7-pin LEMO

Auto Clamp 8-pin LEMO

Serial interface RS232 / RS485

(5 KV opto-isolated)

Dimensions and Weight

WxDxH 500 x 560 x 1000 - 1400 mm

Weight Approximately 90 kg

1

LEMO® is a registered trademark of LEMO USA, Inc.

Technical Features

9-pin D-SUB

Technical Specifications

®

(EGG.1B.307.CLL)

®

(EGG.2B.308.CLL)

Technical Features

Pump PM1

Unidirectional peristaltic pump with manual

operating system

■

Flows

Up to 3.7 L/min (9.5 mm (3/8 in) pump segment)

■

Up to 3.7 L/min (6.4 mm (1/4 in) and

6.4 mm (1/4 in) pump segments)

■

Up to 1.8 L/min (6.4 mm (1/4 in) pump segment)

Maximum tolerance ± 10%

Pressure range within tolerance -150 to +500 mm Hg

Protection system

■

Feedback with rotation signal detected on the

encoder.

■

Open-cover sensor (and subsequent pump

blockage).

Pump PM2 Unidirectional peristaltic pump with manual

operating system

■

Flows

Up to 1.5 L/min (9.5 mm (3/8 in) pump segment)

■

Up to 1.5 L/min (6.4 mm (1/4 in) and

6.4 mm (1/4 in) pump segments)

■

Up to 0.8 L/min (6.4 mm (1/4 in) pump segment)

Maximum tolerance ± 10%

Pressure range within tolerance -150 to +500 mm Hg

Protection system

■

Feedback with rotation signal detected on the

encoder.

■

Open-cover sensor (and subsequent pump

blockage).

Pump PM3 Unidirectional peristaltic pump with manual

operating system

■

Flows

Up to 0.6 L/min (6.4 mm (1/4 in) pump segment)

■

Up to 0.16 L/min (3.2 mm (1/8 in) pump

segment)

Maximum tolerance ± 10%

Pressure range within tolerance -150 to +500 mm Hg

Operator’s Manual 3-3

Page 28

Chapter 3

Technical Features

Protection system

■

Feedback with rotation signal detected on the

encoder.

■

Open-cover sensor (and subsequent pump

blockage).

Pump PM4 Unidirectional peristaltic pump with manual

operating system

■

Flows

Up to 1.1 L/min (6.4 mm (1/4 in) and

6.4 mm (1/4 in) pump segments)

■

Up to 0.7 L/min (6.4 mm (1/4 in) and 3.2 mm (1/8

in) pump segments)

■

Up to 0.6 L/min (6.4 mm (1/4 in) pump segment)

Maximum tolerance ± 10%

Pressure range within tolerance -150 to +500 mm Hg

Protection system

■

Feedback with rotation signal detected on the

encoder.

■

Open-cover sensor (and subsequent pump

blockage).

Pressures (PR1, PR2, PR3, PR4,

Electronic measurement by means of sensors

PR7, PR8)

Operating range -500 to 500 mm Hg

Maximum tolerance ± 5 mm Hg from -200 to 500 mm Hg

± 10 mm Hg from -500 to -200 mm Hg

Protection system Test at time T1 (start-up self-tests)

Pressures (VLP, ALP) Electronic measurement by means of sensors

Operating range -500 to +750 mm Hg

Maximum tolerance ± 5 mm Hg from -200 to 500 mm Hg

± 10 mm Hg from -500 to -200 mm Hg and

from 500 to 750 mm Hg

Protection system Test at time T1 (start-up self-tests)

Note: The VLP and ALP pressure inputs have redundant protective pressure transducers.

Flow Meter Ultrasonic transit-time type

Tubing 9.5 mm (3/8 in) ID x 2.4 mm (3/32 in)

6.4 mm (1/4 in) ID x 1.2 mm (1/16 in) (Not yet

implemented.)

Accuracy ± 10% (1.0 to 7.0 L/min)

± 20% (-0.15 to 1.0 L/min)

Flow range 9.5 mm (3/8 in) ID x 2.4 mm (3/32 in) ➝ 1.0 to 7.0

L/min

6.4 mm (1/4 in) ID x 1.2 mm (1/16 in) (Not yet

implemented.)

Air Bubble Detector (ABD)

Sensitivity Single bubble 0.1 mL (5000 Micron) to 0.3 mL of air

at 7.0 L/min flow, 37°C, blood

3-4 Operator’s Manual

Page 29

Technical Specifications

Technical Features

Cardioplegia Air Sensors Ultrasound detection system

Sensitivity 0.5 mL bubble volume at 500 mL/min

Safety system Automatic: self-test performed every 10 minutes

during the therapy

Fluid-In-Line Sensors (FIL) Ultrasound detection system

Sensitivity Able to detect presence of fluid in suction line

UPS System Uninterruptable Power Supply

Inlet voltage 24 V

Outlet voltage 24 V

Nominal current 6 A

Autonomy Minimum 30 min. (with fully loaded system - see

Buffer Battery Pack

Type 2x12V - 9 A/h

Recharging time 6 hours

Replacement 4 years max.

Buzzer Sound buzzer for alarms

Type Uninterrupted sound

Current 0.3 to 8.3 mA

Sound level > 60 dB a 1 m

Frequency 2500 Hz

External Communication Interface

Format Master-Slave Binary Communication

Cable RS-485/USB

Communication parameters:

Baud Rate

Bits Number

Parity

Stop Bit

Transmission Interval 1 second or greater

page page 5-44)

57800

8

Null

1

Printer Fixed-head thermal printer

Columns 52 … 104 (according to the character set)

Printing speed 3.5 cm/sec

Lines/sec 10

Character set extended ASCII

Paper width 111.5 mm

Power supply 24 V DC

Consumption 3.5 A max

Operator’s Manual 3-5

Page 30

Chapter 3

Electromagnetic Emissions and Immunity Declarations

Memory Card

Ty p e C o m pa c t F l a s h

®

Card International Association (PCMCIA) adapter

with Personal Computer Memory

Heater

Weighing System

Syringe Pump

Reservoir Level Detection System (optional)

Type Capacitive

Reservoir Wall Thickness 1-3.5 mm (wall thickness for hard shell reservoir)

Number of Sensors 2

AutoClamp System (optional)

Ty p e P n e um a t i c

Clamp Force 14.5 Kg (32 lbs)

Tubing 9.5 mm (3/8 in) ID x 2.4 mm (3/32 in) PVC

Air Pressure Required 379 - 689 kPa (55 - 100psi)

Not yet implemented.

Not yet implemented.

Not yet implemented.

Electromagnetic Emissions and Immunity Declarations

Emissions Declaration

The Performer CPB equipment is intended for use in the electromagnetic environment

specified in the table below. The customer or the user of the Performer CPB

equipment should ensure that it is used in such an environment.

Emission test Compliance Electromagnetic environment-guidance

RF Emissions

CISPR 11

RF Emissions

CISPR 11

Harmonic

emissions

IEC 61000-3-2

Voltage fluctuation /

flicker emissions

IEC 61000-3-3

Immunity Declaration

The Performer CPB equipment is intended for use in the electromagnetic environment

specified in the following tables. The customer or the user of the Performer CPB

equipment should ensure that it is used in such an environment.

Tabl e 3-1 . Electromagnetic Emissions for all Equipment and Systems

Group 1 The Performer CPB equipment generates

Class A

Class A The Performer CPB equipment is suitable

Complies

(Reference EN60601-1-2)

radio frequency (RF) energy only as a

byproduct of its internal function. Therefore,

its RF emissions are very low and are not

likely to cause any interference in nearby

electronic equipment.

for use in all establishments other than

domestic and those directly connected to

the public low-voltage power supply

network that supplies buildings used for

domestic purposes.

3-6 Operator’s Manual

Page 31

Technical Specifications

Electromagnetic Emissions and Immunity Declarations

Tabl e 3-2. Electromagnetic Immunity for all Equipment and Systems

(Reference EN60601-1-2)

Immunity test IEC 60601 Test level Compliance level Electromagnetic

environment-guidance

Electrostatic

discharge

(ESD)

IEC 61000-4-2

Electrical fast

transient/ burst

(ESD)

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruption, and

voltage variations

on power supply

input lines

IEC 61000-4-11

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

±6 kV contact

±8 kV in air

±2 kV for power supply

lines

Complies to the test

level

Complies to the test

level

±1 kV for input/output

lines

±1 kV differential mode

±2 kV common mode

<5% U

T

(>95% dip in UT)

Complies to the test

level

Complies to the test

level

for 0.5 cycle

40% U

T

(60% dip in UT)

for 5 cycle

70% U

T

(30% dip in UT)

for 25 cycle

<5% U

T

(>95% dip in UT)

for 5 sec

3 A/m Complies to the test

level

Floor should be wood,

concrete, or ceramic tile. If

floors are covered with

synthetic material, the

relative humidity must be

at least 30%.

Main power quality must

be that of a typical

commercial or hospital

environment.

Main power quality must

be that of a typical

commercial or hospital

environment.

Main power quality must

be that of a typical

commercial or hospital

environment.

Note: In consideration of

the possibility of

continuous functional

operation during main

power interruption, the

Performer CPB equipment

is provided with an

Uninterruptible Power

Supply (UPS) with battery.

Power frequency (50/60

Hz) magnetic field must

be at levels characteristic

of a typical location in a

typical commercial or

hospital environment.

Note: U

is the AC main voltage prior to application of the test level.

T

Operator’s Manual 3-7

Page 32

Chapter 3

Electromagnetic Emissions and Immunity Declarations

Tabl e 3-3. Electromagnetic Immunity for Life Supporting Equipment and Systems

(Reference EN60601-1-2)

Immunity test IEC 60601 Test level Compliance

level

Electromagnetic

environment-guidance

Follow the recommended

separation distance calculated

from the equation applicable to the

frequency of the transmitter when

using portable and mobile RF

communication equipment in

close proximity to any part of the

Performer CPB equipment,

including cables.

Recommended separation

distance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

Outside ISM bands

a

10 Vrms

150 kHz to 80 MHz

in ISM bands

a

10 V/m

80 MHz to 2.5 GHz

3Vrms d= 1,2√ P

6Vrms d= 2√ P

10 V/m

d= 1.2√ P 80 MHz to 800 MHz

d= 2.3

√ P 800 MHz to 2.5 GHz

Where P is the maximum output

power rating of the transmitter in

watts (W) according to the

transmitter manufacturer and d is

the recommended separation

distance in meters (m)

Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site surveyc,

should be less than the

compliance level in each

frequency range

Interference may occur in the

vicinity of equipment marked with

the following symbol:

b

.

d

.

a

b

3-8 Operator’s Manual

1. At 80 MHz and 800 MHz, the higher frequency range applies.

2. These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects, and people.

The ISM (Industrial, Scientific and Medical) bands between 150 kHz and 80 MHz are 6,765 MHz to 6,795

MHz; 13,553 MHz to 13,567 MHz; 26,957 MHz to 27,283; and 40.66 MHz to 40.70 MHz.

The compliance levels in the ISM frequency bands 150 kHz and 80 MHz and in the frequency range 80

MHz to 2.5 GHz are intended to decrease the likelihood that mobile/portable communication equipment

could cause interference if it is inadvertently brought into patient areas. For this reason, an additional

factor of 10/3 is used in calculating the recommended separation distance for transmitters in these

frequency ranges.

Page 33

Technical Specifications

Electromagnetic Emissions and Immunity Declarations

c

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones, land

mobile radios, amateur radios, AM and FM radio broadcast, and TV broadcast cannot be predicted

theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an

electromagnetic site survey should be considered. If the measured field strength in the location in which

the Performer CPB equipment is used exceeds the applicable RF compliance level above, the Performer

CPB equipment should be observed to verify normal operation. If abnormal performance is observed,

additional measures may be necessary, such as reorienting or relocating the Performer CPB equipment.

d

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

Recommended Separation Distance Between Portable and Mobile RF Communication Equipment and Performer CPB Equipment

The Performer CPB equipment is intended for use in an electromagnetic environment

in which radiated RF disturbance is controlled. The customer or user of the

Performer CPB equipment can help prevent electromagnetic interference by

distancing the portable and mobile RF communication equipment (transmitters) as far

away as possible from the Performer CPB as recommended in Table 3-4, according

to the maximum output power of the communication equipment.

Tabl e 3-4 . Recommended separation distance between portable and mobile RF

communication equipment and the Equipment or System for Life-Supporting Equipment and

Rated maximum

output power of

transmitter

W

150 kHz to 80

MHz outside ISM

bands

d= 1.2

Systems (Reference EN60601-1-2)

Separation distance according to frequency of transmitter

m

√ P

150 kHz to 80

MHz in ISM

bands

d= 2√ P

80 MHz to 800

MHz

d= 1.2√ P

800 MHz to 2.5

GHz

d= 2.3√ P

0.01 0.12 0.20 0.12 0.23

0.1 0.380.630.380.73

11.221.22.3

10 3.8 6.3 3.8 7.3

100 12 20 12 23

For transmitters rated at the maximum output power not listed above, the recommended

separation distance d in meters (m) can be determined by using the equation applicable to

the frequency of the transmitter, where P is the maximum output power rating of the

transmitter in watt (W) according to the transmitter manufacturer.

Note 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range

applies.

Note 2: The ISM (Industrial, Scientific and Medical) bands between 150 kHz and 80 MHz are

6,765 MHz to 6,795 MHz; 13,553 MHz to 13,567 MHz; 26,957 MHz to 27,283; and 40.66

MHz to 40.70 MHz.

Note 3: An additional factor of 10/3 is used in calculating the recommended separation

distance for transmitters in the ISM frequency bands between 150 kHz and 80 MHz and in

the frequency range 80 MHz to 2.5 GHz to decrease the likelihood that mobile/portable

communication equipment could cause interference if it is inadvertently brought into patient

areas.

Note 4: These guidelines may not apply in all situations. Electromagnetic propagation is

affected by adsorption and reflection from structures, objects, and people.

Operator’s Manual 3-9

Page 34

Chapter 3

Monitoring System for Hematocrit, Temperature and O

Saturation

2

Monitoring System for Hematocrit, Temperature and O2 Saturation

The Performer CPB equipment has an integrated device, called the

Hematocrit-Temperature-Saturation (HTS) Module, that allows the user to measure:

■

blood oxygen saturation in blood (Sat O2)

■

red blood cell concentration (hematocrit) in blood (Hct)

■

temperature of 8 external locations, detected by as many thermistor probes,

connected with the device by means of a standard “jack” connection

O2 Sat/Hct

Caution: The oxygen saturation and hematocrit monitoring system is not intended to

substitute for regular patient observation and laboratory testing. Prior to any

therapeutic treatment, the oxygen saturation and hematocrit should be determined by

laboratory methods.

Warning: Do not connect the external temperature probes in conjunction with

electrocautery.

Warning: The device must be used only with thermistor temperature probes, as

indicated by the manufacturer.

Warning: The device has been designed in conformity with the IEC 60601-1-2 norm.

It is advisable, however, to avoid its use in the presence of electromagnetic fields or

other equipment causing interference (eg, cellular phones).

Warning: In case of electromagnetic interferences, the temperature values detected

by the external probes and indicated on the main display may undergo transitory

variations. However, this is not an alarming condition for the patient since the

temperature signals are not employed in the temperature control feedback. In the

subsequent measurements, the user shall carefully evaluate the value(s) reliability in

relation to the real conditions before proceeding with whatever action or control

system modification.

Electrical Data

Voltage 5 V DC

Current 0.2 A

3-10 Operator’s Manual

Patient's leakage current < 0.001 mA

Performance

Sat O

operating range 40 to 99%

2

Sat O

accuracy ± 4% (with In-Vivo Offset, see page 5-92)

2

Hct operating range 15 to 50%

Page 35

Hct accuracy ± 4% (with In-Vivo Offset, see page 5-92)

Temperature Range +2°C to +45°C

Temperature Accuracy ± 0.5°C

Temperature Probes

The manufacturer guarantees the proper functioning of the HTS device for the

temperature measurement only when the following probe type is used (thermistor

probe):

Type Model Re-usable / Disposable

YSI Series 400 Re-usable

Warning: The utilization of other manufacturers' probes may jeopardize the

performance of the device and, as a consequence, the measurement reliability.

The performance and precision of the reusable probes indicated in the previous table

will continue if the following recommendations are followed:

Technical Specifications

Temperature Probes

High Temperature

Life

Mechanic Stresses

Disinfection

Warning: A periodical maintenance/control of the multiple-use probes detecting

efficacy is recommended every 3 months.

Battery Supply System (UPS)

The Performer CPB is equipped with a battery Uninterruptible Power Supply (UPS)

system that provides the low voltage supply (24V) if the main power supply fails, thus

allowing treatment to continue.

Note: When the Uninterruptable Power Supply (UPS) converts the system to battery

power, ALL pumps, pump functions, safety systems, alerts, alarms, monitors,

controls, the Pinch Valve and the Central Information Display (CID) are active and

function the same as when the system is on AC power.

■

Do not expose the probe to temperatures higher than

100°C.

■

Only expose the probes to temperatures in the range

of 80°C and 100°C for short periods of time.

Prolong the life of the cable by frequently sprinkling it with

talcum powder, especially after disinfection.

Ensure that the cable is not subject to excessive

mechanical stress like traction, squeezing, or kinking.

For proper disinfection of the multiple-use probes, refer to

the instructions supplied by the manufacturer inside the

packaging.

In case of a main supply failure, fully-charged battery backup will allow treatment with

a fully loaded system to continue for a minimum of 30 minutes (see page 5-44.)

Operator’s Manual 3-11

Page 36

Chapter 3

IEC 60601-2-16 Compliance Chart

Recharging of the battery pack is performed by means of a special circuit located in

the base, therefore allowing the battery pack to get completely recharged when the

equipment is turned on and is operated by the main power supply.

It takes approximately 6 hours to completely recharge a fully depleted battery pack.

IEC 60601-2-16 Compliance Chart

REQUIREMENT REFERENCE RESULT-REMARK

1. Description of the Installation

Procedure

2. Syringe Pump Specification N/A; this device is not

3. Blood Pump accuracy and

specification; range, pressure

accuracy

4. Protective system description

of the dialysis fluid

composition

5. Protective system description

of the dialysis fluid

temperature

6. Protective system description

of the ultra-filtration

7. Protective system description

of the extracorporeal blood

loss to the environment

8. Protective system description

of the blood leak

(51.101) N/A; there is no dialysis fluid

(51.102) N/A; there is no dialysis fluid

(51.103) N/A; there is no ultra-filtration

(51.104.1) N/A; the perfusionist is

(51.104.2) N/A; the perfusionist is

See IFU page 4-2.

implemented at this time.

See IFU page 3-3 to page 3-4.

processing with this device.

processing with this device.

processing system with this

device.

continually in view of the device

during use.

continually in view of the device

during use.

3-12 Operator’s Manual

9. Protective system description

of the blood loss due to the

coagulation

(51.104.3) See IFU page 5-90. If the

circulating hematocrit falls below

20%, the Protective System

activates distinct audible and

visual cues to warn the user. In

case the blood pump stops

during Perfusion Mode or in case

the blood pump is stopped

inadvertently, after 60 seconds

the Protective System activates

distinct audible and visual

alarms.

Page 37

Technical Specifications

IEC 60601-2-16 Compliance Chart

10. Protective system description

of the Arterial Pressure

11. Protective system description

and sensitivity of the Air

Infusion prevention

12. Protective system description

of the Buffer-free HDF

13. Over-ride time of the

Protective System

(51.105) See IFU page 5-84. When the

arterial pressure alert limit is

exceeded, the Protective System

activates distinct audible and

visual cues to warn the user.

When the arterial pressure alarm

limit is exceeded, the Protective

System activates distinct audible

and visual cues to warn the user

and immediately stops the blood

pump.

(51.106) For the system description, see

IFU page 5-63. For the system

sensitivity, see IFU page

page 3-4. When air is detected

by an Air Bubble Detector (ABD),

the Protective System activates

distinct audible and visual alarm

cues to warn the user and

immediately stops the blood

pump.

(51.111) N/A; there is no Buffer-free HDF

preparation with this device.

(51.108) See IFU page 7-2. An over-ride

of the Protective System will

activate continuous visual and

audible “alert” cues.

See IFU page 5-66. The audible

alarm cue can be temporarily

muted. If the Protective System is

not corrected and reset within

one minute, the audible alarm

cue will automatically resume.

14. Audible alarm time period (51.107) See IFU page 5-66. The audible

15. Sound pressure level of

audible alarm source.

16. Contact material with dialysis

fluid

(51.107) See IFU page 5-30. Except for

(51.107) N/A; there is no dialysis fluid

alarm cue can be temporarily

muted. If the Protective System is

not corrected and reset within

one minute, the audible alarm

cue will automatically resume.

the VARD Alarm, the sound level

(volume) for alarms is not

settable.

processing with this device.

Operator’s Manual 3-13

Page 38

Chapter 3

IEC 60601-2-16 Compliance Chart

3-14 Operator’s Manual

Page 39

Installation 4-2

Installation Checklist and Commissioning 4-3

Installation

4

4

Operator’s Manual 4-1

Page 40

Chapter 4

Installation

Installation

All installation and verification procedures shall be performed in the presence of

authorized, service personnel.

Installation

■

After unpacking the equipment, verify its integrity and the presence of the

necessary accessories.

■

Do not install the equipment near areas at risk of explosion or where flammable

anaesthetic gases are used.

■

Do not turn on the equipment if any physical anomalies are noticed that could

jeopardize the correct functioning of the equipment. Contact a Medtronic service

technician.

■

Do not use adapters or extension cords on the main power cable. If necessary,

replace the equipment plug with one that is consistent with the available power

supply system.

Grounding

■

Since the Performer CPB is a Class I device per IEC 60601-1 (Clause 14), it must

be connected to a properly grounded power source.

■

The grounding reliability of the power source must be accomplished in

accordance with the effective local regulation and the IEC 60601-1 harmonized

standard (Clauses 18, 58: Protective earthing, functional earthing and potential

equalization).

■

The hospital/clinic’s electrical environment department should be contacted for

any clarification or questions.

Potential Equalization Line

If other pieces of equipment are present, the use of the specific connection for the

potential equalization is recommended.

Power Supply

The equipment must be operated from the type of power indicated on the identification

data label.

■

Vol ta ge AC 100/240

■

Frequency 50/60 Hz

Liquid/Foreign Matter Penetration

The equipment is protected from liquid/foreign matter penetration according to the

IEC 60529 standard definition: protection class of the Performer CPB is IP 21.

Turn in g O n

Operate the equipment only when it has reached room temperature.

Intended use

The Performer CPB equipment is intended exclusively for hospital use.

The Performer CPB equipment is NOT for domestic use.

4-2 Operator’s Manual

Page 41

Installation Checklist and Commissioning

VISUAL INSPECTION

Integrity of external components; check for damages due to transport

Identification data label, stickers, warning labels

Main Power Supply voltage, plug model, cable and fair-leads

Movement of rotating parts

Accessories and documentation

FUNCTIONAL INSPECTION

Height regulation device

Braking device

Central Information Display

■

Configuration Mode

■

Touch Screen alignment

■

Perfusion Mode

Installation

Installation Checklist and Commissioning

Bio-Pump Control Panel and Display

Roller Pump Control Panels and Displays

Pressure Sensors

■

PR1, PR2, PR3, PR4, VLP, ALP, PR7, PR8

■

Test Measurement at 0 mm Hg

■

Test Measurement at +450 mm Hg

■

Test Measurement at -450 mm Hg

HTS Module

■

Temperature

■

O2 Sat / Hematocrit

Bio-Pump

Flow Probe / Air Bubble Detector

VARD Ultrasonic Sensors

Cardioplegia Air Bubble Detector

FIL Sensor

Roller Pumps

AAR Solenoid Pinch-Valve

Printer

Battery Pack charge level and UPS

AutoClamp System (optional)

Reservoir Level Detection System (optional)

System Mode Simulation

Operator’s Manual 4-3

Page 42

Chapter 4

Installation Checklist and Commissioning

ELECTRICAL SAFETY CHECK PER IEC EN 60601-1 REGULATIONS

Protective earth resistance

Earth leakage current NC

Housing leakage current NC

Leakage current with main voltage on A.P.

Patient leakage current (A.P.) NC

4-4 Operator’s Manual

Page 43

Instructions for Use

Console 5-2

Roller Pump, Roller Inserts, Tube Inserts, and Tubing 5-6

System Configuration 5-16

System Start-up 5-35

Main Run Screen 5-41

Timers 5-46

Cardioplegia 5-49

AAR Controller - Venous Air Removal Device (Resting Heart mode

only) 5-58

5

5

Air Detection 5-63

Level Sensing System (Bio-Pump CPB mode only) 5-67

AutoClamp System (Bio-Pump CPB mode only) 5-73

Pressure Mode Selection 5-84

Venous Saturation and Hematocrit Monitoring 5-90

Options Menu Screen 5-94

Servo (Resting Heart mode only) 5-104

Preparing for Cardiopulmonary Bypass Checklist 5-109

Initiating Extracorporeal Support Checklist 5-112

Operator’s Manual 5-1

Page 44

Chapter 5

Console

Console

External Operational Controls

4

5

6

2

3

1

Figure 5-1. Performer CPB Controls

1. Power Cord: Connects the system to the appropriate wall electrical (AC) power

supply.

2. Fuse/Circuit Breakers: For service personnel use only. The replacement of a

malfunctioning external fuse(s) must be performed by using the correct fuse(s)

type indicated by the external label and by the manufacturer (see “General Data”

on page page 3-2).

3. Grounding Equalization Post: When local regulations require “potential

compensation,” connect a cable from the potential compensation network to this

grounding equalization post.

4. Main Power Switch: Press the top of the Main Power switch to turn the system

on. The displays next to the pump controls will illuminate and an audible start-up

tone will sound. To turn off AC power, press the bottom of the Main Power switch.

5. Console Up and Down Switches: Press and release the Up switch to elevate

the console on its pedestal to the maximum “up” limit. Press and release the

Down switch to lower the console on its pedestal to the maximum “down” limit.

The user may stop console up or down movement at any time by pressing and

releasing the respective Up or Down switch once the desired height is reached.

7

Note: The press-and-release function of the console Up/Down switches are disabled

after leaving the Home Screen and entering an operational mode (Resting Heart or

Bio-Pump CPB). To adjust the height while in an operational mode, the user must

press and hold the respective Up or Down switch until the desired height is reached.

5-2 Operator’s Manual

6. Castor Brake and Unbrake Switches: The console is mounted on 4 castors.

The two rear castors are in permanent front-to-back alignment, but the two front

castors swivel 360 degrees. Press the Castor Brake switch to prevent the

console from rolling. Press the Castor Unbrake switch to release the brakes and

enable movement of the console.

Page 45

7. Batteries: Integrated batteries provide uninterruptible battery backup for the

entire system in the event wall power is lost. Fully-charged batteries will power

the system for a minimum of 30 minutes with a fully loaded system (see

page 5-44).

Front Panel - Controls and Displays

1

Instructions for Use

Console

2

3

4

5

6

7

8

9

10

11

12

Figure 5-2. Console Front Panel

1. CID (Closed): Incorporates graphic menus and buttons for the user-selectable

options, provides enabling or disabling of components and safety devices,

provides visual and audible signals during alert and alarm conditions, monitors

system functions during use, and displays information pertinent to patient

physiology during extracorporeal procedures.

2. Bio-Pump Control Panel with Backup Displays: Incorporates a pump speed

RPM knob, LED flow display, and two backup LCD displays. (See Figure 5-4.)

3. Roller Pump Control Panel and Display for PM1: Incorporates a Start/Stop

button to enable/disable the pump motor, a 3-turn potentiometer knob to control

RPM, an LCD to indicate motor on/off status, pump flow, or RPM information,

and pump identification information.

4. Large Roller Pump PM1: Configured for suction or left heart venting. Maximum

flow capacity is 3.7 L/min. Accommodates the following tube sizes:

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in)

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in) and 6.4 mm (1/4 in) x 1.2 mm (1/16 in)

(Two tubes)

■

9.5 mm (3/8 in) x 2.4 mm (3/32 in) (PVC)

5. External Communication Interface: RS-485/USB port to connect the

Performer CPB to a perfusion data collection system.

Operator’s Manual 5-3

Page 46

Chapter 5

Console

6. Small Roller Pump PM4: Configured for delivery of cardioplegia. Maximum flow

capacity is 1.1 L/min. Accommodates the following tube sizes:

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in) and 6.4 mm (1/4 in) x 1.2 mm (1/16 in)

(Two tubes)

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in) and 3.2 mm (1/8 in) x 1.2 mm (1/16 in)

(4:1 Cardioplegia)

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in)

7. Roller Pump Control and Display for PM4: Incorporates a Start/Stop button to

enable/disable the pump motor, a 3-turn potentiometer knob to control RPM, an

LCD display to indicate motor on/off status, pump flow, or RPM information, and

pump identification information.

8. Small Roller Pump PM3: Configured to be used either as a cardioplegia slave

pump in conjunction with PM4, or as a free pump (examples: hemoconcentrator,

aortic root vent). Maximum flow capacity is 0.6 L/min. Accommodates the

following tube sizes:

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in)

■

3.2 mm (1/8 in) x 1.2 mm (1/16 in)

9. Roller Pump Control and Display for PM3: Incorporates a Start/Stop button to

enable/disable the pump motor, a 3-turn potentiometer knob to control RPM, an

LCD to indicate motor on/off status, pump flow, or RPM information, and pump

identification information.

10. Large Roller Pump PM2: Configured for suction or left heart venting. Maximum

flow capacity is 1.5 L/min. Accommodates the following tube sizes:

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in)

■

6.4 mm (1/4 in) x 1.2 mm (1/16 in) and 6.4 mm (1/4 in) x 1.2 mm (1/16 in)

(Two tubes)

■

9.5 mm (3/8 in) x 2.4 mm (3/32 in) (PVC)

11. Roller Pump Control and Display for PM2: Incorporates a Start/Stop button to

enable/disable the pump motor, a 3-turn potentiometer knob to control RPM, an

LCD to indicate motor on/off status, pump flow, or RPM information, and pump

identification information.

12. PR1 Pressure Transducer Port: Connects to a pressure monitoring line with

fluid isolator when pressure-limiting safety responses are required with roller

pump PM1.

System Status LEDs (Green, Yellow, and Red)

At the top of the CID, but outside the touch screen, are three colored lights that are

associated with the operation status of the system. These lights serve as an additional

visual cue for the user when a change in an alarm, alert, or system status occurs.

1

Figure 5-3. System Status LEDs

5-4 Operator’s Manual

2

3

Page 47

1. When the green lights are illuminated, all safety devices are engaged and all

systems are functioning normally.

2. When the yellow lights are illuminated, there is either a system status change, a

safety device is not engaged, or the Alert Mode of a safety device is activated.

3. When the red lights are illuminated, the Alarm Mode of a safety device is

activated.

Bio-Pump Control Panel

Instructions for Use

Console

4

3

1

2

Figure 5-4. Bio-Pump Control Panel

1. Pump Speed RPM Knob

■

Turn the knob clockwise to control the external drive motor speed from 0 to

approximately 4500 RPM.

■

Completely rotate the knob counterclockwise to below 0 RPM and “click” to

turn the drive motor off.

■

The knob provides for a minimum RPM detent button. This is a mechanical

stop that prevents an unintentional reduction of RPM below 2000. Press down

on the detent lever while turning the knob counterclockwise to reduce the

RPM below 2000.

■

The minimum RPM detent button does not affect increasing the RPM.

2. Flow Display

■

Displays the Bio-Pump flow rate in liters per minute (L/min). This is an

additional display for the Bio-Pump flow value that is also shown on the Main

Run Screen of the CID.

■

The LED will display flow from 0.00 to 9.99 L/min.

Note: In the event the CID fails, the front panel Bio-Pump flow display will continue to

function and display blood flow detected by the ultrasonic blood flow transducer.

3. Backup LCDs

■

Two LCDs display 6 user-selected hemodynamic or metabolic parameters.

■

The LCDs provide additional displays of essential parameters viewed on the

CID.

Note: In the event the CID fails, the LCDs will continue to function and enable

selection and display of the listed parameters. (See “Emergency Procedures” on

page 7-4.)

4. Scroll Arrows

Operator’s Manual 5-5

Page 48

Chapter 5

Roller Pump, Roller Inserts, Tube Inserts, and Tubing

The scroll arrows allow selection/viewing of the following parameters in each of

the backup LCDs (only in the Emergency Mode):

■

Revolutions Per Minute (RPM)

■

Arterial Line Pressure (ALP)

■

Venous Line Pressure (VLP) (Resting Heart mode only)

■

Cardioplegia Pressure (CPG)

■

Venous Oxygen Saturation (SO2)

■

Hematocrit (Hct)

Roller Pump, Roller Inserts, Tube Inserts, and Tubing

Roller Pumps

Roller pumps are indicated for moving fluids through a flexible tube. As each roller

passes through the pump raceway, it occludes the tube and displaces the fluid in the

tube in the direction of rotation.

Each pump only rotates in a clockwise direction.

Uses include, but are not limited to, propulsion of arterial blood and myocardial

preservation solutions, and extraction of fluids from the thorax or vascular chambers.

The Performer CPB comes with two (2) large roller pumps with a maximum flow

potential of 3.7 L/min (PM1) or 1.5 L/min (PM2) and two (2) small roller pumps with a

maximum flow capacity of 1.1 L/min (PM4) or 0.64 L/min (PM3).

3 5 6

2

1