Page 1

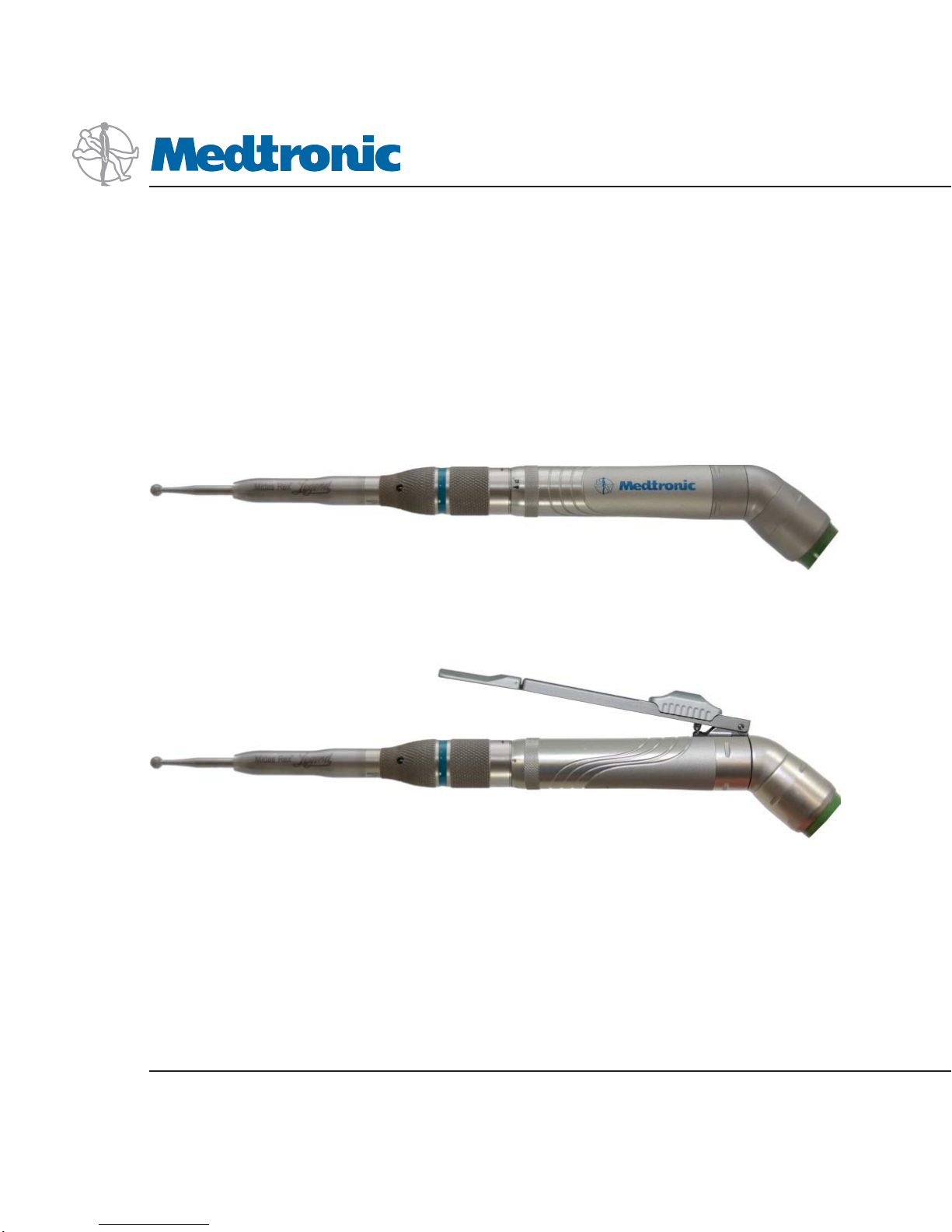

MIDAS REX® MR7

PTSC224

Pneumatic High-Speed System

Pneumatyczny system wysokoobrotowy

Pneumatický vysokorychlostní systém

Nagy sebességĦ pneumatikus rendszer

Instruction Manual

Instrukcja obsáugi

Návod

Használati útmutató

Rx Only

Page 2

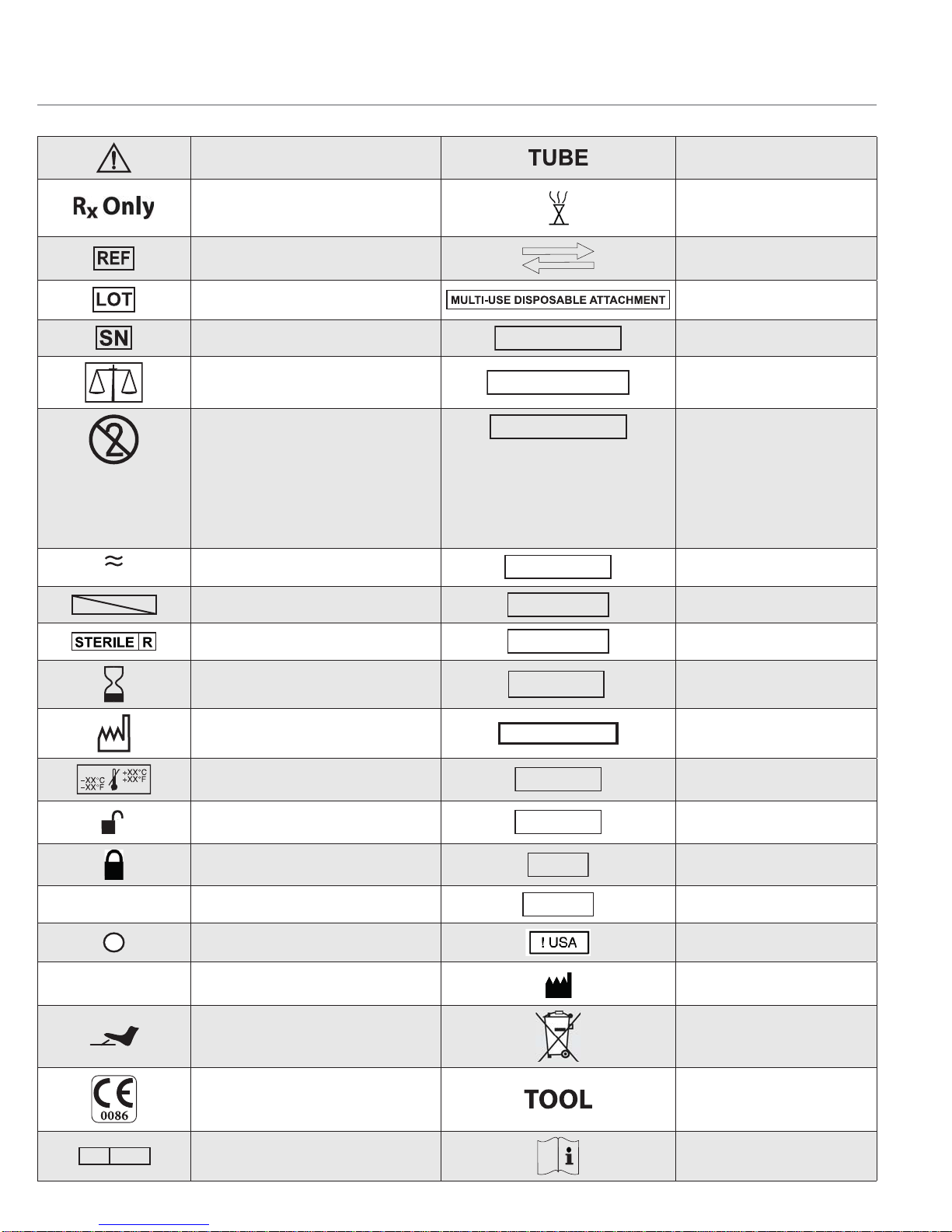

Symbols

PTSC224

The following symbols may appear within this manual, on product labeling, or on the product itself:

Attention, see Instructions for Use. Tube Control

STERILE

United States federal law restricts this

device to sale by or on the order of a

physician.

Reference Number Use with

Lot Number Multi-Use Disposable

Serial Number

Quantity

Instrument Case

Air Pressure Relief

Attachment

Instrument Case

Lubricant/Diffuser

Lubricant/Diuser

For single patient use only. Do not

re-use, re-process, or re-sterilize this

product. Re-use, re-processing or

re-sterilization may compromise the

structural integrity of the device and/

or create a risk of contamination of the

device, which could result in patient

injury, illness, or death.

Approximately equal to

Non-Sterile

Sterilized by Gamma Irradiation

Dissecting Tool

Attachment

Control Unit

Refurbished

Dissecting Tool

Attachment

Control Unit

Refurbished

+

Use by date

Accessory

Accessory

Date of manufacture

REGULATOR

Temperature Limitations

Unlock

Lock

|

On

Off USA Only

Finger-Operated Control Manufacturer

Foot-Operated Control Do not dispose to unsorted

Compliant with European Council

Directive MDD 93/42/EEC.

Bone Mill

MOTOR

Brush

Adapter

Regulator

Bone Mill

Motor

Brush

Adapter

municipal waste.

Tool Control

EC REP

Authorized Representative in the

European Community

Consult Instructions for Use

Page 3

Contents

PTSC224

General Information ...........................................................................................................................1

Indications for Use ..............................................................................................................................1

Contraindications ....................................................................................................................1

Special Notices .........................................................................................................................1

General Safety Precautions .....................................................................................................2

No Latex Policy ........................................................................................................................2

System Components ...........................................................................................................................3

Non-Disposable Components ...............................................................................................3

Disposable Components .........................................................................................................7

Legend® Dissecting Tools ........................................................................................................8

General Guidelines F

or Attachment and Tool Applications .............................................. 9

Setting up the Operating Room ..................................................................................................... 12

Power Source Requirements ............................................................................................... 12

Pneumatic Connections....................................................................................................... 12

Setting up the MR7 System ............................................................................................................. 13

Installing the Oiler Cartridge .............................................................................................. 13

Connecting the Motor ......................................................................................................... 14

Installing an Attachment and Tool ................................................................................................ 15

Straight At

tachments ............................................................................................................ 15

Specialized Attachments ...................................................................................................... 15

Activating the Motor ....................................................................................................................... 16

Disassembling the MR7 System ..................................................................................................... 17

Depressurize the System ...................................................................................................... 17

Disconnect Hoses ................................................................................................................. 17

Discard the Lubricant/Di user Cartridge ......................................................................... 17

Remove the Attachment and Tool ...................................................................................... 17

Cleaning & Sterilizing the MR7 System ........................................................................................ 18

MR7 Motor ............................................................................................................................ 18

Legend At

tachments / Tubes ............................................................................................... 19

i

Page 4

MR7 Pneumatic Control Unit / Regulator Hose /

PTSC224

Triton Adapter / Instrument Case ...................................................................................... 21

Transmissible Spongiform Encephalopathies (TSE) Return Policy............................... 21

Troubl eshooting ............................................................................................................................... 22

Refurbishing or Repairs .................................................................................................................. 25

Preventative Maintenance ............................................................................................................... 26

Limited Warran

ty ............................................................................................................................. 27

Appendix A—Specialized Attachments ........................................................................................ 28

Angled Attachments ............................................................................................................. 28

Angled Double Lock Attachments ..................................................................................... 29

Curved Bur Attachments ..................................................................................................... 30

Variable Exposure Attachments ......................................................................................... 31

Footed Attachments ............................................................................................................. 32

Rotating Footed Attachments ............................................................................................. 33

Contra-Angle Attachment (16-MF) ................................................................................... 34

Metal Cutting Attachments ................................................................................................. 35

Telescoping Attachments ..................................................................................................... 36

Perforator Driver At

tachments ........................................................................................... 37

Jacobs® Chuck Attachments ................................................................................................ 38

Bone Mill Attachment .......................................................................................................... 39

ii

Page 5

General Information

PTSC224

Read and understand this manual before use of the MR7 System.

The Midas Rex® MR7 system is designed for use by medical professionals familiar with powered surgical instrumentation.

The surgeon is responsible f

be harmful. It is strongly recommended that the surgeon and dedicated operating room personnel are knowledgeable with

the use of this equipment by being trained in Medtronic Midas Rex Hands-On Workshops or by one of the local authorized

representatives.

The MR7 system consists of the following components:

• MR7 or MR7 T

• MR7 Pneumatic Control Unit with Various Connectors

• MR7 Regulator Hose

• MR7 Lubricant/Di user Cartridge

• MR7 Triton® Adapter (optional)

• Legend® Attachments*

• Legend® Dissecting Tools*

*The MR7 syst

ouch Motor

em uses the same attachments and dissecting tools as the Legend® Pneumatic High-Speed System.

or learning the proper techniques in the use of this system, as inappropriate use may potentially

General Information

Indications for Use

The Medtronic Midas Rex MR7 System is a pneumatically operated surgical instrument system. The pneumatic motors

provide power to operate removable rotating surgical cutting tools and their accessories intended for use in neurosurgery,

including craniotomy and spinal surgery; as well as Ear, Nose and Throat (ENT), orthopedic and general surgical applications

including maxillofacial, craniofacial and sternotom

y surgeries.

Contraindications

None

Special Notices

The words warning, caution and note have special meanings in this manual, and should be carefully reviewed:

WARNING: A warning indicates that the personal safety of the patient or physician may be involved. Disregarding this

information could result in injury to the patient or physician.

CAUTION: A caution indicates that there is a risk of damaging equipment.

NOTE: A note is intended to provide additional information, which may be useful

procedure.

, but is not essential to complete the

1

Page 6

General Information

PTSC224

General Safety Precautions

WARNINGS:

• Do not use the Midas Rex MR7 System before proper cleaning and sterilization.

• Do not operate the Midas Rex MR7 System in the presence of Magnetic Resonance Imaging devices.

• Do not use damaged, faulty, or modi ed Midas Rex MR7 S

damage prior to each use:

• Check the motor’s exhaust hose for cracks or tears.

• Visually inspect attachments and tools. Do not use bent or damaged tools.

• I

nstall attachment and dissecting tool, then brie y run motor.

* Check motor for overheating and leaking lubricant.

* Check attachment for overheating.

* Check dissecting tool for ail.

• Do not operate the Midas Rex MR7 S

• Motors and attachments which fail due to extended use may allow a component to detach and fall from the motor or

attachment, and may cause patient injury.

• Heavy side loads and/or long operating periods may cause the device to overheat. If overheating occurs:

• Never place an overheated motor on the patient or draping during surgery.

• Discontinue use and rest the motor by using intermitt

sterile towel.

• If the motor is passed o , the receiver should grasp the motor by the proximal end close to the motor hose.

• T

o avoid injury to the patient or user, do not place the handpiece on the patient or in an unsecured location, when not

in use.

ystem without eye protection.

ystem components. Inspect the Midas Rex MR7 System for

ently, or wrap the motor/attachment interface with a moist

• Midas Rex MR7 motors should only be operated when the attachment is in the

If a dissecting tool package is opened, but the tool is not used or contaminated, the tool can be re-sterilized by steam

sterilization. Remove tool from all original packaging and place into an approved autoclave package. Steam sterilize as

follows:

High Vacuum Steam: 270° F (132° C) for 5 minutes

Gravity Displacement: 270° F (132° C) for 15 minutes

The re-sterilized tool must be used promptly following re-sterilization. If rust or corrosion is encountered after

re-sterilization, do not use the re-sterilized tool

.

position.

No Latex Policy

Legend and MR7 products, packaging materials, labels, package inserts, and similar items manufactured by and/or for

Medtronic Powered Surgical Solutions (MPSS) do not contain latex.

2

Page 7

System Components

PTSC224

Non-Disposable Components

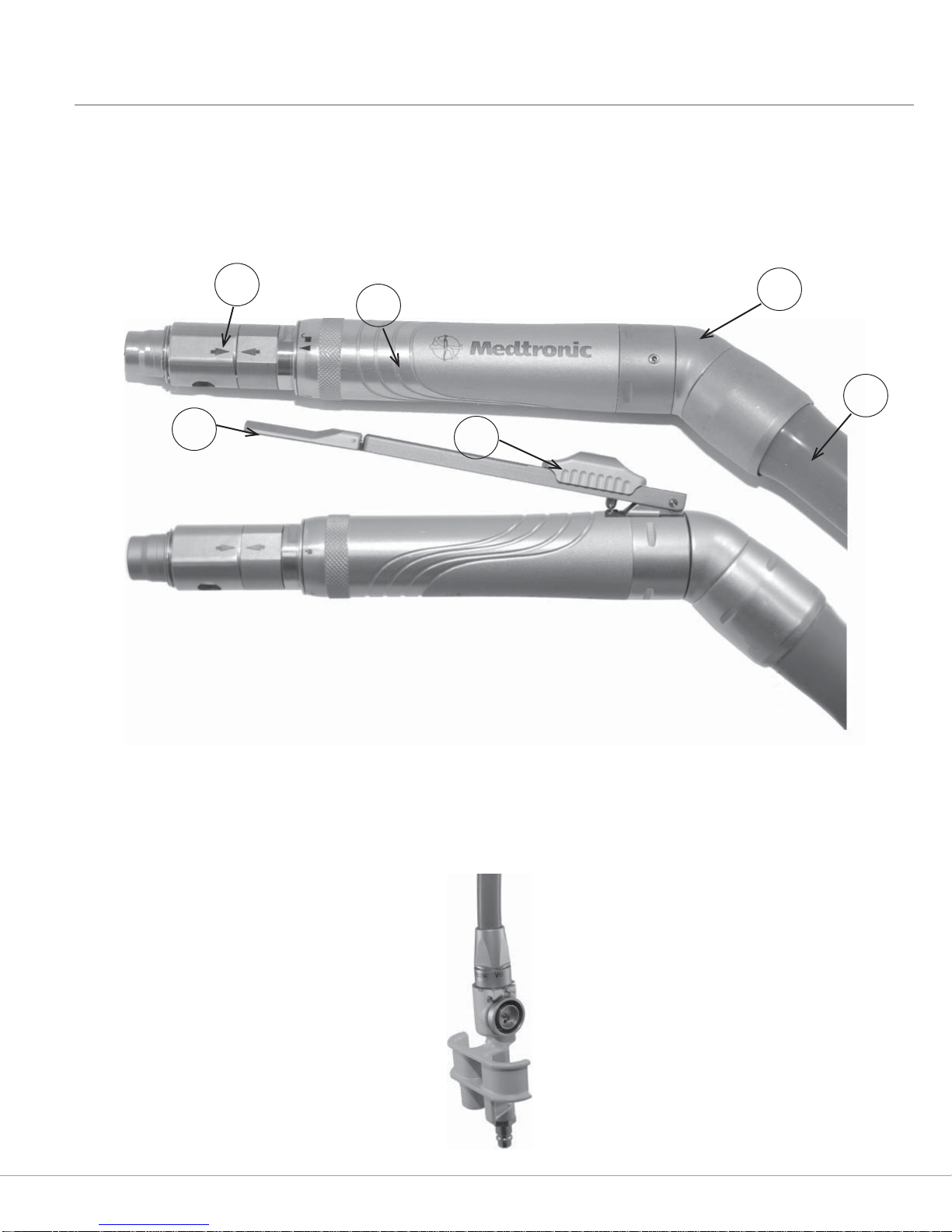

MR7 Motor

The MR7 motor is a high-speed, high-torque motor used to dissect bone and biomaterials.

Figure 1: Motor Components

System Components

1

5

1. Collet

2. Motor Case

3. Swivel

4. Hose

5. Finger Control Lever

3

2

4

6

6. Safety Slide (MR7 Touch Only)

In addition to the components listed in Figure 1, each MR7 motor has a lubricant/di user housing at the end of the motor

hose, as seen in F

igure 2.

Figure 2: Lubricant/Di user Housing

3

Page 8

System Components

PTSC224

WARNING: Use only Medtronic Midas Rex Legend or MR7

devices with an MR7 motor. Use of other devices may

cause injury or damage equipment, and will void the

manufacturer’s warranty.

Pneumatic Control Unit

The pneumatic control unit (Figure 3) provides variable

speed motor control controls through a foot pedal. It also

allows the user to switch between nger and foot control

of the motor (if applicable).

Regulator

The regulator (Figure 4) controls the delivery pressure

of compressed gas to the pneumatic control unit. The

pressure gauges monitor cylinder pressure (right gauge)

and delivery pressure (left gauge).

Note: Outlet pressure gauge accurate to +/- 12 psi.

Figure 3: Pneumatic Control Unit

Instrument Case

The instrument case (Figure 5) is used to organize

equipment.

Regulator Hose

Connects from the gas source to the pneumatic control

unit to deliver compressed gas.

Figure 4: Regulator

Figure 5: Instrument Case

4

Page 9

System Components

PTSC224

N2 DISS to Male Schrader Adapter

The N2 DISS to male Schrader adapter (Figure 6) allows

for the regulator hose to be attached to a female Schrader

in-house gas connection. A N2 DISS to female Schrader

adapter is also available f

hose to a male Schrader in-house gas connection.

or connection of the regulator

N2 DISS to Air DISS Adapter

The N2 DISS to air DISS adapter (Figure 7) allows for the

regulator hose to be attached to an Air DISS in-house gas

connection.

N2 DISS to WF4 Adapter

The N2 DISS to WF4 adapter (Figure 8) allows for the

regulator hose to be attached to a Midas Rex safety valve

regulator previously used for Midas Rex Classic or Midas

Rex III motors. The in-line oiler must be removed from the

safety valve regulator.

Motor Wrench

The motor wrench (Figure 9) is used to align arrows

on motor collet ats prior to installation of a Legend

attachment.

Figure 6: N2 DISS to Male Schrader Adapter

Figure 7: N2 DISS to Air DISS Adapter

Figure 8: N2 DISS to WF4

Adapter

Triton Adapter

The Triton adapter (Figure 10) allows the Triton handpiece

to be driven by the MR7 pneumatic control unit. It

functions much the same way as the Triton port on

the Legend pneumatic control unit, except that it is

connec

rather than being integrated into the control unit

ted between the control unit and the gas source,

Figure 9: Motor Wrench

Figure 10: Triton Adapter

5

Page 10

System Components

PTSC224

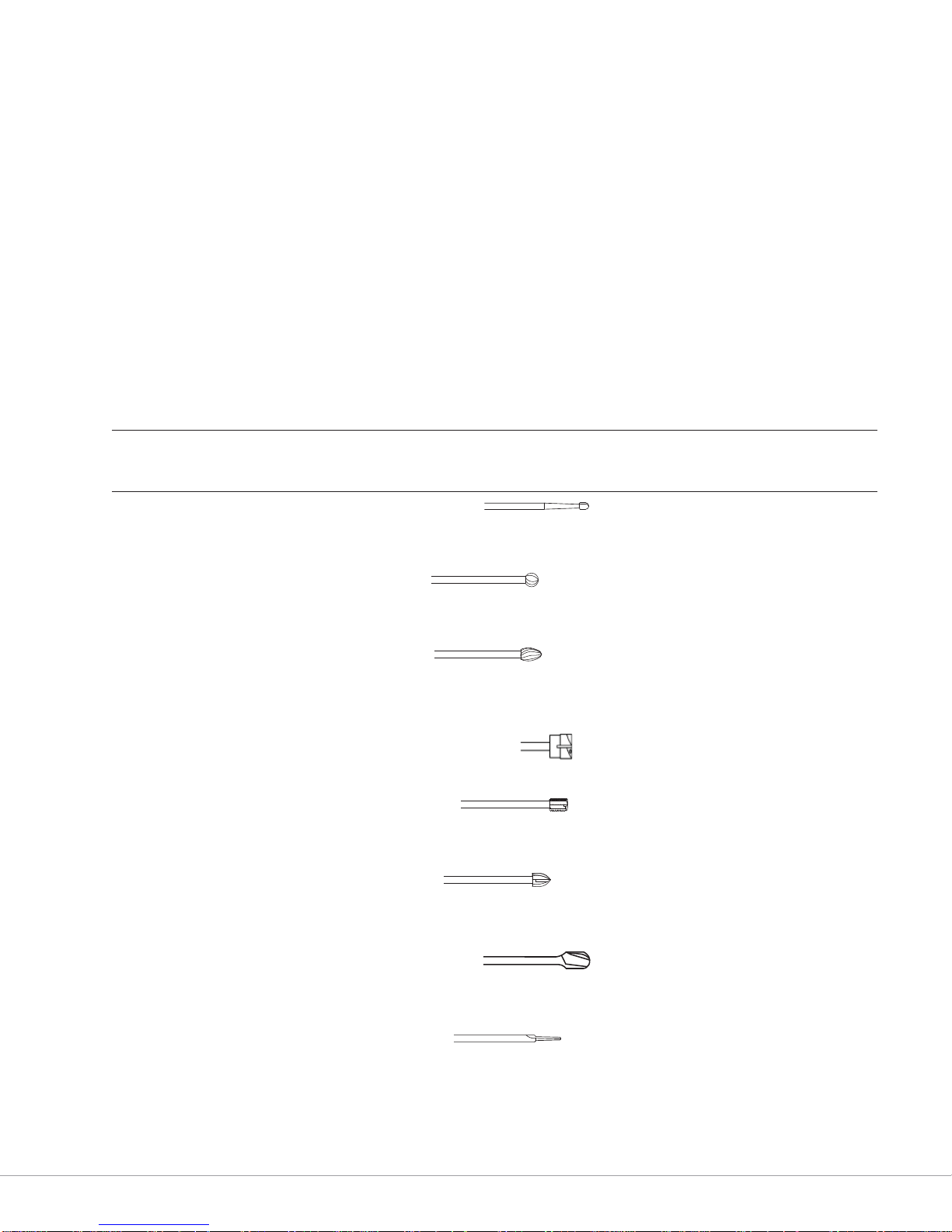

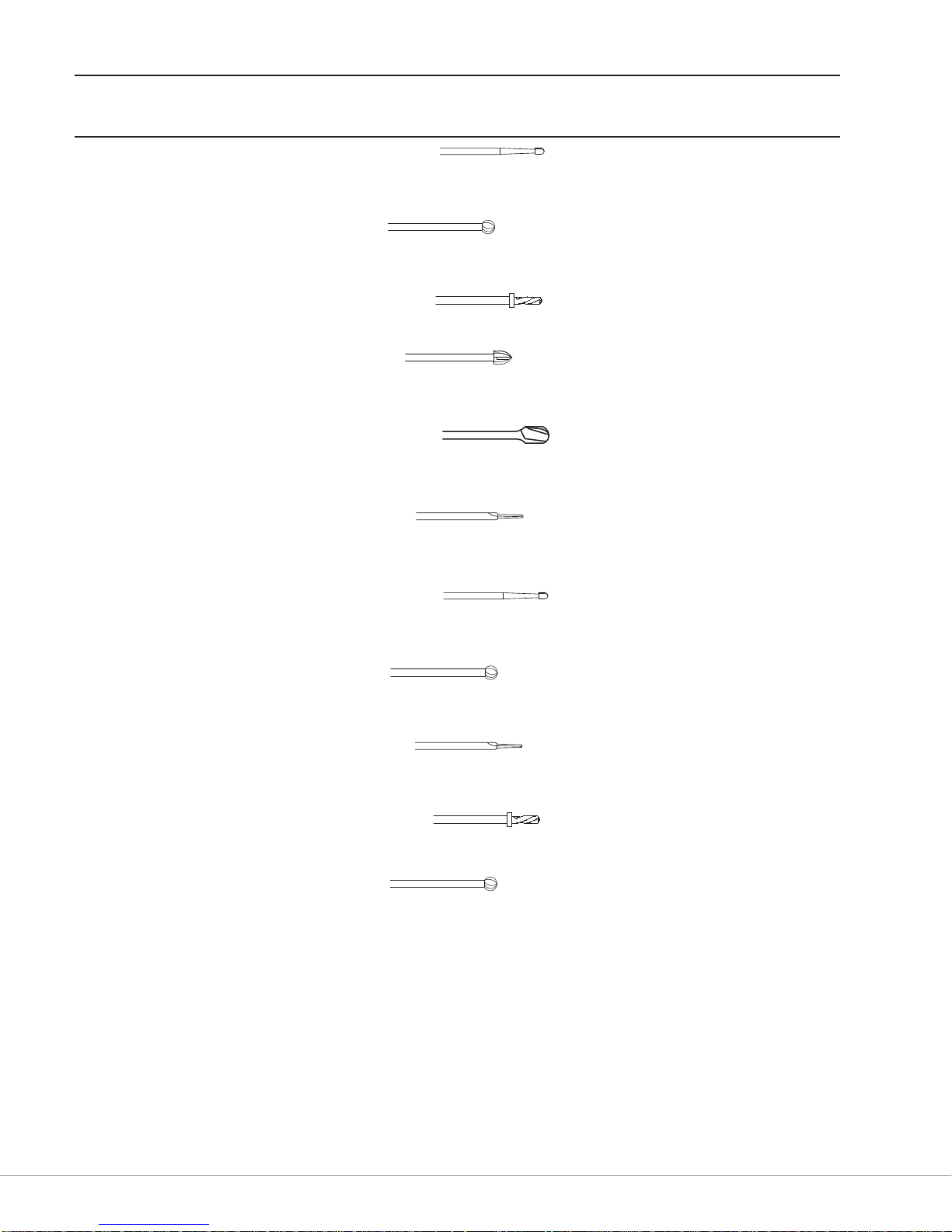

Legend Attachments

Legend motor attachments are available in various designs to facilitate a variety of surgical procedures. Attachments vary in

length, diameter, and overall design. They are marked and color-coded to correspond with their associated dissecting tools.

A few of the Legend attachments available are listed in the table below.

Attachment Example Other Details/Options

Standard Straight Attachments AS09

Standard Angled Attachments AA14

Straight Variable Exposure Attachments AVS07

Angled Variable Exposure Attachments AVA07

Fixed Footed Attachments AF01

Rotating Footed Attachments AF01R

Telescoping Attachments A

Contra-Angle Attachment AC16

Metal Cutting Attachment ASMC

Perforator Attachment AD01 Available in 800 RPM or 1000 RPM form.

5/32” Jacobs Chuck Attachment AD02

Bone Mill Attachment BM100

T10 (base)

TT12A (tube)

The telescoping attachment requires the use of the AT10

attachment base, as well as a telescoping tube. Tubes are

available in straight, cur

ved, or hooded form.

NOTE: Angled and straight attachments with the same length, mark

Curved and straight telescoping tubes with the same length, marking, and color band also share the same dissecting tool.

Example: The 14-AM straight and 14-AM angled attachments are 14 cm long, marked 14-AM and have a green color band.

All dissecting tools with the pre x 14 (14MH30) may be used in either the 14-AM straight or 14-AM angled attachment.

Be sure to match the color code and nomenclature on the Legend Dissecting Tool packaging with the color band and

nomenclature on the Legend Attachment.

ing, and color band share the same dissecting tool.

6

Page 11

Disposable Components

PTSC224

WARNING: Use only Medtronic Midas Rex Legend or

MR7 devices with an MR7 motor. Use of other devices

may cause injury or damage equipment, and will void

the manufacturer’s warranty.

Lubricant/Diffuser Cartridge

The lubricant/di user cartridge (Figure 11) provides

lubrication to the motor and lters oil from exhausted air.

Telescoping T ubes

Telescoping tubes (Figure 12) provide support to the

rotating dissecting tool. Telescoping tubes are disposable

following multiple uses and should be discarded when

heat or excessive vibration is noticed or insertion of tools

becomes di cult.

Cleaning Brushes

Cleaning brushes (Figure 13) are used to clean debris

from lumen of attachments and telescoping tubes. Sized

for an internal bore diameter of 3.2 mm, 2.4 mm or 1.2

mm in Legend Attachments and Telescoping Tubes.

System Components

Figure 11: Lubricant/Di user Cartridge

Figure 12: Telescoping Tube

NOTE: Cleaning brushes will not pass thr

contra-angle, metal cutting, perforator, or Jacobs Chuck

attachments, because they are not cannulated.

ough angled,

Figure 13: Cleaning Brushes

3.2mm

2.4mm

1.2mm

7

Page 12

System Components

PTSC224

Legend® Dissecting Tools

Legend dissecting tools are sterile cutting tools, intended for cutting bone and biomaterials.

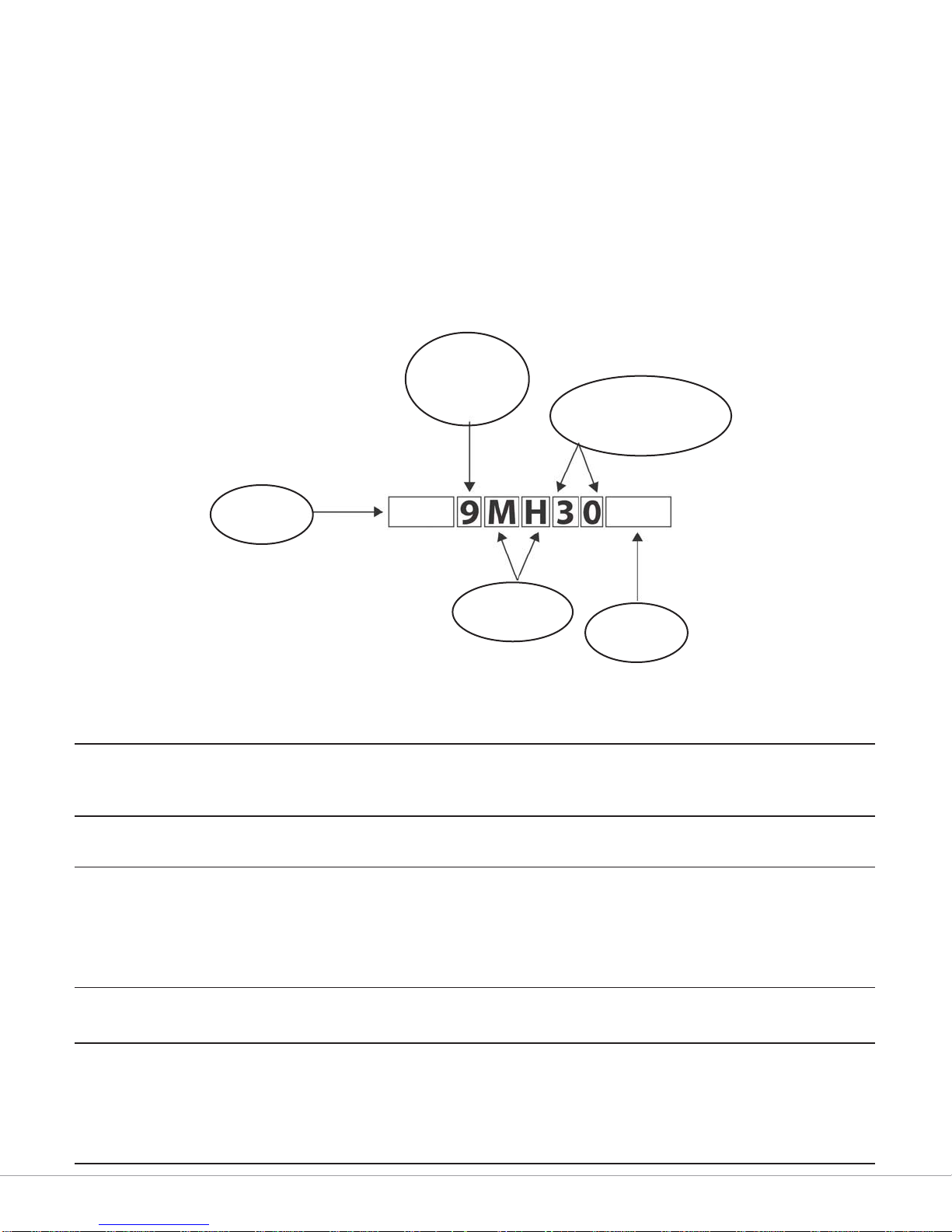

Dissecting Tool Nomenclature

Part numbers for Legend dissecting tools follow a standard naming convention, which is described in the diagram below.

A basic part number consists of the associated attachment length, the tool head shape, and the tool head diameter. Part

numbers may also include a variety of pre xes to identify speci c attachment types, as well as a variety of su xes to provide

additional information about the dissec

additional “-MN” su x.

ting tool. Tools that use a design taken from the Mednext line are designated by an

Associated

Attachment

Length

Tool

Head Diameter

(x.x millimeters)

Optional

Pre¿ x

Tool

Head Shape

Optional

Suf¿ x

Tool Number Pre¿ xes (not all inclusive)

F... For use with footed attachments

MC For use with metal cutting attachments

T For use with telescoping attachments

Tool Head Shapes (not all inclusive)

AC Acorn MH Match Head

BA Ball OV Oval

CY Cylinder RT Reverse Taper

HM Hole Maker TA Tapered

HS Hole Saw TD Twist Drill

Tool Number Suf¿ xes (note that more than one of the su xes listed may be combined in a single part number)

L Long S Spiral

D Diamond SH Short

X Extra DC Diamond Coarse

F Fine DX Diamond Extra Coarse

C Carbide MN Mednext Tool Design

8

Page 13

System Components

PTSC224

WARNINGS:

• Dissecting tools are for single-use only. Do not attempt to sterilize them. The dissecting tools are packed sterile and are

not intended for repeat use. To prevent contamination, use only once.

• Do not use an attachment and dissec

• Do not attempt to remove a tool while the motor is running.

• Do not attempt to remove a tool from an overheated motor or attachment.

• Do

not use the device if the package is opened or damaged.

ting tool combination that results in tool ail or excessive vibration.

General Guidelines For Attachment and Tool Applications

These are general guidelines for dissecting tool applications and are not an all-inclusive listing.

WARNING: Be sure to match the color code and nomenclature on the Legend Dissecting Tool packaging with the color

band and nomenclature on the Legend Attachment. Failure to do so could result in injur

sta .

Surgical

Application

Spine 8-B, 9-M, 14-AM,

Commonly

Used

Attachments

Match Head

15-A

Telescoping Match Head

Footed, Straight Tap er ed

Elongated spherical design allows controlled, delicate

dissection. For entry hole, nerve decompression, osteophyte

removal, sinus dissection, etc.

Ball

Helical cutting utes dissect bone or cement e ec

from a wide variety of approach angles. For debridement,

decortication, sinus dissection, etc.

Oval

Helical cutting utes and curved design blend acorn and ball

styles to vary dissection e ciency with appr

decortication, laminotomy, entry hole, nerve decompression,

osteophyte removal, etc.

Hole Maker/Saw

Matched sets of Hole Makers and Hole Saws are e cient and

e ective for interbody fusion.

Cylinder

E ec

tive bone sculpting and planing. For graft shaping,

debridement, corpectomy, decortication, interbody fusion,

fusion takedown, etc.

Acorn

Curved design varies dissection e ciency with varied

approach angles. F

debridement, corpectomy, decortication, fusion takedown, etc.

Elongated spherical design allows controlled, delicate

dissection. For entr

removal, sinus dissection, etc.

Slender design for precise dissection with minimal bone loss.

For transection, osteotomy, graft harvesting, bone shaping,

entr

y hole, suture hole, midface advancement, etc.

Commonly Used

Dissecting Tools

or entry hole, laminotomy, bone shaping,

y hole, nerve decompression, osteophyte

y to the patient or operating room

Suggested

Motor(s)

MR7, MR7

Touch

tively

oach angle. For

MR7, MR7

Touch

9

Page 14

System Components

PTSC224

Surgical

Application

Neurosurgical–

Cranial

General

Surgery and

Plastic Surgery

(Craniofacial/

Maxillofacial/

Sternotomy)

Ear, Nose, and

Throat (Otology,

Neurootology)

Commonly

Used

Attachments

7-6ST, 8-B, 9-M,

10-9ST, 14-AM,

15-A

Telescoping Match Head

Footed Ta pe re d

7-6ST, 8-B, 9-M,

10-9ST, 14-AM

7-6ST, 10-9ST Ball

Match Head

Elongated spherical design allows controlled, delicate

dissection. For entry hole, nerve decompression, osteophyte

removal, sinus dissection, etc.

Ball

Helical cutting ute

from a wide variety of approach angles. For debridement,

decortication, sinus dissection, etc.

Twist Drill

Helical design with stop produces a hole with a precise depth.

Ideal for plating.

A

corn

Curved design varies dissection e ciency with varied

approach angles. For entry hole, laminotomy, bone shaping,

debridement, corpectomy, decortication, fusion takedown, etc.

Elongated spherical design allo

dissection. For entry hole, nerve decompression, osteophyte

removal, sinus dissection, etc.

Slender design for precise dissection with minimal bone loss.

For transection, osteotomy, graft harvesting, bone shaping,

entr

y hole, suture hole, midface advancement, etc.

Match Head

Elongated spherical design allo

dissection. For entry hole, nerve decompression, osteophyte

removal, sinus dissection, etc.

Ball

Helical cutting utes dissect bone or cement e ectively

from a wide variety of approach angles. F

decortication, sinus dissection, etc.

Tap er ed

Slender design for precise dissection with minimal bone loss.

For transection, osteotomy, graft harvesting, bone shaping,

entry hole, suture hole, midface advancement, et

Twist Drill

Helical design with stop produces a hole with a precise depth.

Ideal for plating.

Helical cutting utes dissect bone or cement e ec

from a wide variety of approach angles. For debridement,

decortication, sinus dissection, etc.

Commonly Used

Dissecting Tools

s dissect bone or cement e ectively

ws controlled, delicate

ws controlled, delicate

or debridement,

c.

tively

Suggested

Motor(s)

MR7

MR7, MR7

Touch

MR7

10

Page 15

System Components

PTSC224

Surgical

Application

Orthopaedics 8-B, 9-M,

Biometals/

Bioceramics/

Biomaterials

Commonly

Used

Attachments

14-AM, 21-TU,

26-R, Footed,

Telescoping

Footed Ta pe re d

MC Metal Cutter

Commonly Used

Dissecting Tools

Ball

Helical cutting utes dissect bone or cement e ectively

from a wide variety of approach angles. For debridement,

decortication, sinus dissec

Tap er ed

Slender design for precise dissection with minimal bone loss.

For transection, osteotomy, graft harvesting, bone shaping,

entry hole, suture hole, midface advancement, etc.

Acorn

Curved design varies dissec

approach angles. For entry hole, laminotomy, bone shaping,

debridement, corpectomy, decortication, fusion takedown, etc.

Cylinder

E ective bone sculpting and planing. For graft shaping,

debridement, corpec

fusion takedown, etc.

Slender design for precise dissection with minimal bone loss.

For transection, osteotomy, graft harvesting, bone shaping,

entr

y hole, suture hole, midface advancement, etc.

Cutting utes or diamond wheel design remove metals,

ceramics and other biomaterials e ec

of approach angles. For cutting rods, pins, plates, implants,

screws, etc.

tion, etc.

tion e ciency with varied

tomy, decortication, interbody fusion,

tively from a variety

Suggested

Motor(s)

MR7, MR7

Touch

MR7, MR7

Touch

11

Page 16

Setting up the Operating Room

PTSC224

Setting up the Operating Room

Power Source Requirements

Required Operating

(Dynamic) Pressure

80–120 psi 100 psi 12 cubic feet/min. Nitrogen or Dry-Filtered

5.5–8.3 bar 6.9 bar 340 liters/min.

CAUTION: Do not run the motor at an operating pressure above or below the required operating pressure range. Operating

pressure belo

may damage or reduce the life of the motor.

w 80 psi (5.5 bar) may not provide proper lubrication to the motor. Operating pressure above 120 psi (8.3 bar)

Nominal Operating

(Dynamic) Pressure

Approximate Flow Rate

Required

Gas Type

Compressed Air

Pneumatic Connections

Figure 14: Gas Connection Options

1. Regulator Hose (N2 DISS)

2. N2 DISS to Air DISS Adapter Gas Source

3. N2 DISS to Male Schrader Adapter Gas Source

4. Gas Source (N2 DISS)

5. Regulator

6. DISS/WF4 Adapter

7. Regulator

CAUTION: If you are using the Midas Rex Safety Valve Regulator instead of the Legend Regulator, you must replace the

in-line oiler with the DISS/WF4 adapter before use.

12

Page 17

Setting up the MR7 System

PTSC224

Setting up the MR7 System

Installing the Oiler Cartridge

WARNING: Do not use the MR7 system with the Midas

Rex in-line oiler. The MR7 motor is su ciently lubricated

by the lubricant/di user on the motor hose, and will be

over-lubricated if the Midas Rex in-line oiler is used.

1. Set the non-running (static) pressure to 80–120 psi

(5.5–8.3 bar) at the gas source. Operating (dynamic)

pressure may be adjust

2. Hold the lubricant/di user cartridge perpendicular

to the housing (F

circular tting onto the housing’s circular receptacle

(Figure 16), breaking the foil seal.

3. Rotate the cartridge down until it clicks into plac

4. Verify that the

with the notch on the housing (Figure 17).

WARNINGS:

• Failure to properly secure the lubricant/di user

cartridge may cause injury to operator and/or

operating room sta .

• Do not attempt to remo

cartridge while the system is pressurized.

symbol on the cartridge is lined up

ed later.

igure 15), and press the cartridge’s

e.

ve the lubricant/di user

Figure 15: Aligning the Lubricant/Di user Cartridge with the

Housing

Figure 16: Pressing the Cartridge onto the Housing

CAUTIONS:

• Do not use an MR7 motor without a lubricant/

di user installed.

• Do not use a lubricant/di user cartridge for more

than one hour of drill time.

• Do

• Do not attempt to re ll a used lubricant/di user

• Do not use a lubricant/di user cartridge if it appears

not re-use a lubricant/di user cartridge. It is a

single-use product.

cartridge.

to be damaged

, or if the inner foil seal is punctured.

Figure 17: Correctly I

nstalled Lubricant/Di user Cartridge

13

Page 18

Setting up the MR7 System

PTSC224

Connecting the Motor

Connect the motor hose to the motor port on the top of

the pneumatic control unit, by swinging the port cover

to the side and pressing the end of the hose into the port

(Figure18).

ARNING: Do not pinch, kink, obstruct, cut, tear, or step

W

on the motor/exhaust hose. This may cause the hose to

burst, potentially injuring the patient or user.

NOTES:

• If using the MR7 Touch motor, slide the contr

on the pneumatic control unit to the position

(Figure 19). This will automatically depress and lock

the foot pedal. The control will not lock into the

position unless the motor hose is connected into the

motor port. When the motor hose is removed from

the motor port, the foot pedal will return to normal

position.

• If using the Triton Power Surgical Instrumentation

Syst

em in conjunction with the MR7 motor, use the

optional Triton adapter to connect the Triton hose.

Refer to the documentation accompanying the

adapter for connection instructions.

ol slide

Figure 18: Connecting the Motor Hose to the Motor Port

• The motor’s exhaust hose may have an oily lm

on the external sur

temperature di erentials following sterilization.

Wipe the exhaust hose with a sterile cloth prior to

use. If motor continues to have oil on the exhaust

hose, return the motor to MPSS f

WARNING: To avoid injury to the patient or user, do not

use the pneumatic control unit to operate systems other

than the MR7, Legend

Prior to installation of a Legend attachment and

dissecting tool, ensure that the arrows on the motor

collet ats are aligned (Figure 20). If the arrows are not

aligned,

closest to the motor case until its arrow is aligned with

the arrow on the other collet at.

WARNING: To avoid injury when using the MR7 Touch

motor

installing the attachment and tool.

use the motor wrench to turn the collet at

, ensure the safety slide is in the “O” position before

face from pressure and/or

or refurbishing.

, and Triton systems.

Figure 19: Finger/Foot Control Slide

Figure 20: Aligning the collet ats

14

Page 19

Installing an Attachment and Tool

PTSC224

Installing an Attachment and Tool

WARNING: Dissecting tool utes are sharp and may

perforate surgical gloves. Tools may be grasped with a

hemostat to aid in installation and removal.

Straight Attachments

Installation:

1. Slide the attachment over the motor collet, aligning

the triangular markers (Figure 21). You will feel and

hear the attachment click into place when it is fully

seated.

2. Insert the dissecting tool into the attachment with a

slight rotational motion (F

hear the tool click into place when it is fully seated in

the attachment.

3. Turn the attachment to the

case (Figure 23). Gently pull on the shaft of the

dissecting tool to verify proper installation.

Removal:

Removal is the reverse of installation.

igure 22). You will feel and

position on the motor

Figure 21: Sliding the Attachment over the Motor Collet

Figure 22: Inserting the Dissecting Tool into the Attachment

Specialized Attachments

See Appendix A—Specialized Attachments for installation

and removal instructions for other attachments.

Figure 23: Attachment in the Locked Position

15

Page 20

Activating the Motor

PTSC224

Activating the Motor

NOTE: In order to activate the MR7 Touch motor, the safety slide on the nger control switch must be in the | position, and

the control slide on the foot control must be in the

motor is connected to the motor port.

1. Activate the motor by pressing on the foot control pedal (Figure 24), or by pressing on the nger control lever (MR7

Touch motor only).

2. Adjust operating pressure as needed at the compressed gas source until supply pressure gauge on pneumatic contr

unit reads within a range of 80–120 psi (5.5–8.3 bar) as required. Operating pressure (with motor running) will decrease

slightly from the non-running (static) pressure setting when the motor is ac

Foot Control Pedal

position. The control slide will not lock in the position unless a

ol

tivated.

Figure 24: Foot Control Pedal

Air Pressure Gauge

Control Slide

Figure 25: MR7 Finger Control Switch

Finger Control Lever

WARNINGS:

• Do not use excessive force to pry or push bone with the attachment or tool during dissection. This could cause the tool

to break and cause injur

• Use adequate irrigation during dissection, to prevent thermal necrosis.

• MR7 motors should only be operated when the attachment is in the

y to the patient or operating room sta .

position.

NOTE: To decrease pressure, turn down the in-house compressed gas source or loosen the pressure handle on the

regulator. Push down on the pressure relief at the pneumatic control unit to exhaust excess pressure in the hoses. T

re-adjust pressure as needed.

16

hen

Page 21

Disassembling the MR7 System

PTSC224

Depressurize the System

1. Turn o the compressed gas at the source.

2. Press the pressure relief button on the pneumatic control unit, to release remaining gas.

Disassembling the MR7 System

WARNING: Do not disassemble equipment before the gas is released fr

om control unit.

Disconnect Hoses

Release the motor hose from the control unit, by holding the hose rmly and pressing the motor port connection button.

Figure 26: Motor Port Connection and Pressure Relief Buttons

Motor Port Connection Button

Pressure Relief Button

Discard the Lubricant/Diffuser Cartridge

Remove the lubricant/di user cartridge from the housing and discard it.

CAUTION: Do not re-use a lubricant/di user cartridge. It is a single-use product.

Remove the Attachment and Tool

1. Follow the applicable removal instructions in the Installing an Attachment and Tool section of this manual to remove the

attachment and tool from the motor.

WARNING: Dissecting tool utes are sharp and may perforate surgical gloves. Tools may be grasped with a hemostat to aid

in installation and removal.

2. Discard used dissecting tools in an appropriate container.

17

Page 22

Cleaning & Sterilizing the MR7 System

PTSC224

Cleaning & Sterilizing the MR7 System

MR7 Motor

Warnings and

Precautions

Limitations Verify functionality prior to re-use.

INSTRUCTIONS

Point of Use No particular requirements. Follow hospital procedures.

Containment and

Transportation

Preparation for

Decontamination

Cleaning:

Automated

(Do NOT use ultrasonic

washer)

Cleaning: ManualWipe all external surfac

Disinfection No particular requirements. Follow hospital procedures.

Packaging For sterilization, place devices in instrument tray. Devices may be unwrapped, or wrapped with up to two layers of 1-ply

Sterilization

(Temperatures are

minimum required,

times are minimum

required)

Do not soak/submerge MR7 devices.

Do not use ultrasound to clean MR7 devices.

Do not use chlorine based or corrosive cleaning agents such as bleach, lye, acetone, sodium hypochlorite/bleach, sodium

h

ydroxide, formic acid, or solutions containing glutaraldehyde.

The use of a washer-disinfector for cleaning may cause a pre-mature degradation in performance.

Allow an adequate cooling period after st

Use ONLY nylon cleaning brushes. Non-nylon cleaning brushes leave residue that may prevent the tool from being secured

properly in the handpiece.

It is recommended that devices are reprocessed as soon as is practical following use.

No particular requirements. F

Review the washer-disinfector warning above, before using this cleaning method. Remove devices from instrument trays

before placing into washer baskets. Orient devices following recommendations of the washer/disinfector manufacturers. Verify

that devices are visually clean after automated cleaning.

Recommended Washer Cycle

Pre-Wash: Cold tap water, 2 min.

Wash: 66oC, 5 min. using a neutral enzymatic detergent, pH 6.0–8.0

Rinse: Hot tap water, 1 min.

enzymatic detergent, pH 6.0–8.0.

Brush motor case and collet with a nylon brush dampened with a neutral enz

be sure to brush under the nger control lever.

Rinse motor thoroughly under running water, collet end pointed down. Dry collet and motor with lint free towel.

Verify that device

polypropylene wrap

Steam Sterilization:

Cycle:

Temperature:

Time:

Drying:

s are visually clean after manual cleaning.

ollow hospital procedures.

es of the motor and hose, and wipe inner surface of oiler housing with a cloth dampened with a neutral

Gravity

132°C

25 min.

15 minutes

eam sterilization.

Pre-vac

132°C

4 min.

15 minute

ymatic detergent. If using the MR7 Touch motor,

Pre-vac (FR/WHO)

134°C

18 min.

s

20 minutes

Pre-vac (UK)

134°C

3 min.

10 minutes

*Items contaminated with Transmissible Spongiform Encephalopathies (TSE) agents may be decontaminated using steam

autoclave at a temperature of 134–137°C f

referenced in NHS Estates HTM 2010 parts 4 & 6: Appendix 2, Items Contaminated With TSE Agents and WHO Infection Control

Guidelines for Transmissible Spongiform Encephalopathies. Medtr

suspected or con rmed with a TSE diagnosis be incinerated.

STERRAD Sterilization: Do not use low temperature hydrogen peroxide gas plasma sterilization due to lumen internal diameter

and length restrictions.

100% EtO Sterilization Parameters:

Preconditioning: 51–59°C, 70 ±5% relative humidity, 30 min.

Temperature: 51–59°C

Relative humidity: 70 ±5%

Ethylene oxide concentration: 725 ± 25mg/L

Gas exposure time (full-cycle): 4 hours

Aeration: 18 hours at 51–59°C

Steris: Do not use liquid perac

18

or a single cycle of 18 minutes or repeated for a total of six 3-minute cycles as

onic recommends that all products used on a patient

etic acid sterilization due to immersion procedure.

Page 23

Cleaning & Sterilizing the MR7 System

PTSC224

Maintenance,

Inspection and Testing

Storage Store with other sterile devices.

Inspect devices for any damage before and after each use. If damage is observed, do not use the device until it is repaired.

After cleaning and sterilization, verify functionality prior to re-use.

NOTE: The instructions provided above have been validated by the manufacturer as being CAPABLE of preparing the

product for re-use. It remains the responsibility of the processor to ensure that the reprocessing as actually performed,

using equipment, materials and personnel in the reprocessing facility, achieves the desired result. This normally requires

validation and routine monitoring of the pr

ocess.

Legend Attachments / Tubes

Warnings and

Precautions

Limitations Verify functionality prior to re-use.

INSTRUCTIONS

Point of Use No particular requirements.

Containment and

Transportation

Preparation for

Decontamination

Cleaning:

Automated

(Do NOT use ultrasonic

washer)

Cleaning: ManualW

Disinfection No particular requirements Follow hospital procedures.

Packaging F

Do not soak/submerge Legend devices.

Do not use ultrasound to clean Legend devices.

Do not use chlorine based or corrosive cleaning agents such as bleach, lye, acetone, sodium hypochlorite/bleach, sodium

hydroxide, formic acid, or solutions containing glutaraldehyde.

The use of a washer-disinfector for cleaning may cause a pre-mature degradation in performance.

Allow an adequate cooling period after st

Use ONLY nylon cleaning brushes. Non-nylon cleaning brushes leave residue that may prevent the tool from being secured

properly in the handpiece.

It is recommended that devices are reprocessed as soon as is practical following use.

No particular requirements. F

Review the washer-disinfector warning above, before using this cleaning method. Manually rinse attachments/tubes under

tap water

before placing into washer baskets. Orient devices following recommendations of the washer/disinfector manufacturers.

Recommended Washer Cycle

Pre-Wash: Cold tap water, 2 min.

Wash: 66°C, 5 min. using a neutral enzymatic detergent, pH 6.0–8.0

Rinse: Hot tap water, 1 min.

Immerse the head of Contra-Angle attachments in surgical instrument cleaning solution and run the motor for 1 minute.

Other attachments and tubes may be mechanically agitated in cleaning solution, but not soaked or immersed.

A nylon brush dampened with a surgical instrument cleaning solution may be used to clean the external sur

connecting surfaces of the attachments and tubes.

Straight attachments, footed attachments and telescoping straight tubes have special cleaning brushes sized to the

attachment’s or telescoping tube’s internal diamet

the attachment or telescoping tube from rear to front to loosen and remove debris trapped inside.

Move any moveable parts back and forth to allow solution to thoroughly clean attachment, e.g., sleeve on footed attachment,

perforator attachment.

Rinse thoroughly with tap water.

Thoroughly dry attachments. An air gun may be used to blow moisture out from rear to front of attachment.

Using an aerosol spray lubricant (such as Pana Spray), per

polypropylene wrap.

, until no visible soil is noticed, before placing them into the automatic washer. Remove devices from instrument trays

ipe all attachments and telescoping tubes with a cloth, dampened with a surgical instrument cleaning solution.

Holding the can approximately 10–15 cm (3–6 in.) away from the attachment, spray all components that move, rotate, or

slide with three quick squirts.

Articulate movable components to ensure proper lubrication.

Remove excess lubricant with a clean cloth.

or sterilization, place devices in instrument tray. Devices may be unwrapped, or wrapped with up to two layers of 1-ply

ollow hospital procedures.

eam sterilization.

faces and internal

er. Push the brush wet with surgical instrument cleaning solution through

form the following steps to lubricate attachments:

19

Page 24

Cleaning & Sterilizing the MR7 System

PTSC224

Sterilization

(Temperatures are

minimum required,

times are minimum

required)

Maintenance,

Inspection and Testing

Storage Store with other st

Steam Sterilization:

Cycle:

Temperature:

Time:

Drying:

*Items contaminated with TSE agents may be decontaminated using steam autoclave at a temperature of 134–137°C for a

single cycle of 18 minutes or repeated for a total of six 3-minute cycles as referenced in NHS Estates HTM 2010 parts 4 & 6:

Appendix 2, Items Contaminated W

Encephalopathies. Medtronic recommends that all products used on a patient suspected or con rmed with a T

be incinerated.

STERRAD Sterilization: Do not use low temperature hydrogen peroxide gas plasma sterilization due to lumen internal diameter

and length restrictions.

100% EtO Sterilization Parameters:

Preconditioning: 51–59°C, 70 ±5% relative humidity

Temperature: 51–59°C

Relative Humidity: 70 ±5%

Ethylene oxide concentration: 725 ± 25mg/L

Gas exposure time (full-cycle): 4 hours

Aeration: 18 hours at 51–59°C

Steris: Do not use liquid peracetic acid sterilization due to immersion pr

Inspect devices for any damage before and after each use. If damage is observed, do not use the device until it is repaired.

Verify functionality prior to re-use.

Gravity

132°C

25 min.

15 minutes

erile devices.

Pre-vac

132°C

4 min.

15 minutes

ith TSE Agents and WHO Infection Control Guidelines for Transmissible Spongiform

, 30 min.

Pre-vac (FR/WHO)*

134°C

18 min.

20 minutes

ocedure.

Pre-vac (UK)*

134°C

3 min.

10 minute

s

SE diagnosis

NOTE: The instructions provided above have been validated by the manufacturer as being CAPABLE of preparing the

product for re-use. It remains the responsibility of the processor to ensure that the reprocessing as actually performed,

using equipment, materials and personnel in the reprocessing facility, achieves the desired result. This normally requires

validation and routine monitoring of the process.

20

Page 25

Cleaning & Sterilizing the MR7 System

PTSC224

MR7 Pneumatic Control Unit / Regulator Hose / Triton Adapter /

Instrument Case

Warnings and

Precautions

Limitations Verify functionality prior to re-use.

INSTRUCTIONS

Point of Use No particular requirements. Follow hospital procedures.

Containment and

Transportation

Preparation for

Decontamination

Cleaning:

Automated

(Do NOT use ultrasonic

washer)

Cleaning: ManualWipe the pneumatic control unit, regulator hose, Triton adapter,

Disinfection No particular requirements. Follow hospital procedures.

Packaging No particular requirements. F

Sterilization Do not sterilize pneumatic control unit, regulator hose, or Triton adapter.

Maintenance,

Inspection and Testing

Storage Do not store with sterile devices.

Do not soak/submerge MR7 devices.

Do not use ultrasound to clean MR7 devices.

Do not use chlorine based or corrosive cleaning agents such as bleach, lye, acetone, sodium hypochlorite/bleach, sodium

hydroxide, formic acid, or solutions containing glutaraldehyde.

Do not sterilize the MR7 pneumatic control unit, regulator hose, or Triton adapter.

It is recommended that devices are reprocessed as soon as is practical following use.

No particular requirements. F

Not validated.

instrument cleaning solution after each use.

Inspect devices for any damage before and after each use. If damage is observed, do not use the device until it is repaired.

Verify functionality prior to re-use.

ollow hospital procedures.

and instrument case with a cloth dampened with surgical

ollow hospital procedures.

NOTE: The instructions provided above have been validated by the manufacturer as being CAPABLE of preparing the

product for re-use. It remains the responsibility of the processor to ensure that the repr

ocessing as actually performed,

using equipment, materials and personnel in the reprocessing facility, achieves the desired result. This normally requires

validation and routine monitoring of the process.

Transmissible Spongiform Encephalopathies (TSE) Return Policy

Medtronic Powered Surgical Solutions (MPSS) will not authorize or accept the return of MPSS products that directly contact

patients or is contaminated with a patient’s body uids who is suspected or con rmed with a Transmissible Spongiform

Encephalopathies / Creutzfeldt-Jakob Disease (TSE/CJD) diagnosis. Futhermore, MPSS recommends that all MPSS products

used on a patient con rmed with a TSE diagnosis be incinerated. Contact your Sales Representative for replacement of

product incinerated under this policy or for temporary equipment while original equipment is quarantined. Contact MPSS

Regulatory A airs Department for additional inf

patient suspected of a TSE/CJD diagnosis must be incinerated.

If TSE/CJD is excluded as a diagnosis, the quarantined reusable equipment may be returned f

cleaning, decontamination and sterilization. Hospital personnel should contact their infection control personnel for current

procedures and policy for reusable equipment processing when suspect of contamination with Creutzfeldt-Jakob Disease

(CJD) or other Transmissible Spongiform Encephalopathies (TSE).

Reusable devices that have been used on patients with suspected Creutzfeldt-Jakob Disease (CJD

Spongiform Encephalopathies (TSE) should be quarantined and not reused until diagnosis is con rmed or excluded.

Reusable devices should be quarantined after having been cleaned, decontaminated, sterilized and packed in a ridged

sealed container until nal diagnosis.

ormation regarding TSE contamination. MPSS dissecting tools used on a

or use after appropriate

) or other Transmissible

21

Page 26

Trou bleshooting

PTSC224

Troubleshooting

NOTE: All Legend and MR7 devices returned for servicing or refurbishing should be properly cleaned and sterilized prior to

shipping.

Motor not Running or Low on Power:

Possible Cause Solution

Hoses not properly connected. Make sure all connections are secure.

Operating pressure inadequate. Check gas supply pressure gauge. Increase pressure

Attachment not pr

Foot pedal on pneumatic control unit not functioning

pr

operly.

Motor stalls. Manually spin the dissecting tool, then activate the

according to compressed gas requirements, if necessary.

operly installed and locked onto the motor. Remove and re-install attachment and tool to ensure

proper installation and locking of attachment onto

motor.

Check for obstructions under the foot pedal. If foot pedal

continues to fail, return the pneumatic control unit to

MPSS to be refurbished.

motor. If the motor continues to stall, return it to MPSS to

be refurbished.

Motor Continues to Run:

Possible Cause Solution

Pneumatic control unit is not functioning properly. Depressurize the system and return the pneumatic

control unit to MPSS to be refurbished.

Finger control is not functioning properly. Return motor to MPSS to be refurbished.

Pneumatic contr

ol unit is locked in the nger control position. Move the nger control lever to the foot control position.

System Makes an Abnormal Noise:

Possible Cause Solution

Inadequate lubrication. Check for proper installation of the lubricant/di user

cartridge. If the problem persists, replace the cartridge.

If replacing the cartridge doesn’t x the problem, return

the motor to MPSS f

Motor’s exhaust hose is damaged, or internal pressure hose is

detached.

Worn bearings.Switch attachments to det

Attachment not properly installed and locked onto the motor. Remove and reinstall attachment and tool to ensure

Safety relief valve has been activated by high air pressure.Ensure that air operating/dynamic air pressure is no

Depressurize the system and return the motor to MPSS

to be refurbished.

are failing in the motor or in the attachment. Return the

failing component to MPSS to be refurbished.

proper installation and locking of the attachment onto

the motor.

higher than 120 psi.

or refurbishing.

ermine whether the bearings

22

Page 27

Trou bleshooting

PTSC224

Motor is Too Hot to Touch/Hold:

Possible Cause Solution

Inadequate cool down period following sterilization. Motor must be allowed to cool down following steam

sterilization.

Inadequate lubrication. Check for proper installation of the lubricant/di user

cartridge.

Attachment transferring heat to the motor

Heavy side loading during dissec

Inadequate irrigation. Ensure adequate irrigation to surgical site during bone

tion. Discontinue use and rest the motor by using it

. Switch attachments to determine whether the heat is

being generated by the motor or the attachment. Return

the failing component to MPSS for refurbishing.

intermittently or wrap the motor with a moist sterile

towel. If overheating continues, return the motor to

MPSS for refurbishing.

dissection.

Attachment Will not Properly Seat on the Motor:

Possible Cause Solution

Motor collet ats are not aligned. Use the Legend motor wrench to rotate the at closest to

the motor case until its marker is aligned with the marker

on the at farthest away fr

om the motor case.

Tool is Dif¿ cult to Remove from Attachment:

Possible Cause Solution

Aging of attachment. Return to MPSS to be refurbished, or purchase new

Improper cleaning.

Use of reprocessed tools.

Use of an unauthorized refurbisher.

equipment.

16-MF Contra-Angle Attachment is Overheating:

Possible Cause Solution

The Contra-Angle attachment operates by a set of internal

gears to engage the drive shaft. It is normal for some heat to

be generated approximately 2cm from the distal end of the

attachment and at the right of the angle head.

Verify pressure setting of 80 psi (5.5 bar).

If

heat continues or is excessive, return the attachment to

MPSS to be refurbished or purchase new equipment.

Perforator is Running too Slow:

Possible Cause Solution

Pressure set incorrectly. Check the pressure setting at the foot control.

23

Page 28

Trou bleshooting

PTSC224

Dissecting Tool Flails:

Possible Cause Solution

A non-Legend dissecting tool is being used. Replace with a Legend dissecting tool.

Worn attachment or tube bearings.Try another attachment or tube to isolate the location

Attachment/tube and tool are not compatible. Match color code on the dissecting tool packaging to the

Motor is damaged. Return motor to MPSS to be refurbished.

Dissec

at certain speeds.

Dissecting Tool Vibrates Excessively:

Possible Cause Solution

Dissecting tool’s size and geometry may create excessive

vibration at certain speeds.

ting tool’s size and geometry may contribute to ailing

of the problem. If the attachment is failing, return it to

MPSS. I

f the tube is failing, dispose of it and use a new

tube.

color code on the attachment/tube.

Adjust the speed by changing the pressure setting or

fo

ot/ nger control. Do not use if ailing persists. Change

dissecting tools.

Adjust the speed by changing the pressure setting or

foot/ nger control. Change dissecting tools.

Dissecting Tool Will not Seat Properly in the Motor or Attachment Collet:

Possible Cause Solution

Debris in collet of attachment or motor. Clean the attachment or motor thoroughly according

to the instructions in this manual. If cleaning does not

correct the problem, return the attachment or motor to

MPSS to be refurbished.

A non-Legend dissec

ting tool is being used. Replace with a Legend dissecting tool.

Smoke is Generated by the Attachment or Motor:

Possible Cause Solution

Attachment is not in the locked position. Make sure the attachment is in the locked position.

24

Page 29

Refurbishing or Repairs

PTSC224

Refurbishing or Repairs

When the MR7 System requires servicing or refurbishing, contact Medtronic Powered Surgical Solutions Repair Services for

a return authorization and instructions for returning the equipment. Medtronic Powered Surgical Solutions provides quality

assured service by factory-trained personnel who will utilize genuine Midas Rex Legend parts as required. All items being

returned for servicing or refurbishing should be properly cleaned and st

Contact:

Medtronic Powered Surgical Solutions Repair Services:

(800) 335-9557 or (817) 788-6440

mmrcustomerservice@medtronic.com

Peak performance, reliability and maximum service life from your MR7 System may be assured by using only those Midas

Rex Legend products for your MR7 System that are manufactured by and sold through Medtronic Powered Surgical

Solutions, Fort Worth, Texas. While Medtronic Powered Surgical Solutions guarantees complete compatibility among its

products within a speci c product line, the dissecting tools are designed for single-use only, and Medtronic disclaims any

responsibility when reprocessed dissecting tools are used. If you would like more information about the patient and product

risks associated with reprocessed tools, please contact the number or e-mail address list

Due to safety and environmental concerns, Medtronic Powered Surgical Solutions requests the return of pneumatic high

speed motors for proper disposal at the end of the product life cycles.

erilized prior to shipping.

ed above.

25

Page 30

Preventative Maintenance

PTSC224

Preventative Maintenance

The Midas Rex MR7 System Preventive Maintenance Manual has been developed to assist you in getting the greatest

ownership value from your MR7 System, while helping to maximize its performance, safety and reliability. The scheduled

preventive maintenance/serv

preventive maintenance manual for the speci c steps necessary to maintain the MR7 System.

ice program is in addition to the required routine cleaning after each use. Please refer to the

26

Page 31

Limited Warranty

PTSC224

A. This Limited Warranty provides the following assurance to the purchaser of a Medtronic Midas Rex® MR7 Pneumatic

High Speed System. This Limited Warranty is extended only to the buyer purchasing the MR7 System directly from

Medtronic or from its a liate or its authorized distributor or representative. The Midas Rex® MR7 Pneumatic High

Speed System includes the motor, foot control, instrumentation cases and trays (hereafter referred to as Syst

Components), straight and angled motor attachments (hereinafter referred to as “Attachments”), telescoping tubes

(hereinafter referred to as Semi-reusable Components) and dissecting tools and other accessories not listed above

and jointly referred to as MR7 Pneumatic High Speed System, unless speci cally noted.

(1) Should a System Component fail to function to Medtronic’s published speci cations during the term of

this Limited Warranty (one year fr

date of sale of a refurbished or used System Component), Medtr

Component or any portion thereof.

(2) Should an Attachment fail to function to Medtronic’s published speci cations during the term of this

Limited Warranty (90 days from the date of sale of a new Attachment), Medtronic will either repair or

replace the Attachment or any portion thereof.

(3) Should a Semi-reusable Component fail to function to Medtronic’s published speci cations during

the term of this Limited Warranty (30 days fr

Medtronic will replace the Semi-reusable Component or any portion thereof

(4) Should a Single Use Component fail to function to Medtronic’s published speci cations prior to its “use

by” date Medtronic will replace the Single Use Component.

B. To qualify for this Limited Warranty, these conditions must be met:

(1) The Product must be used on or before its “Use By” or “Use Before” date, if applicable.

(2) The Product must be used in accordance with its labeling and may not be altered or subjected to misuse,

abuse, ac

(3) Medtronic must be noti ed in writing within thirty (30) days following discovery of a defect.

(4) The Product must be returned to Medtronic within thirty (30) days of Medtronic receiving notice as

pr

(5) Upon examination of the Product by Medtronic, Medtronic shall have determined that: (i) the Product was

not repaired or altered by anyone other than Medtronic or its authorized representative, (ii) the P

was not operated under conditions other than normal use, and (iii) the prescribed periodic maintenance

and services, if applicable, have been performed on the Product

C. This Limited Warranty is limited to its express terms. THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. In no event shall Medtronic be liable for any

consequential, incidental

MR7 System, whether a claim for such damage is based upon the warranty, contract, negligence or otherwise.

D. The exclusions and limitations set out above are not intended to, and should not be construed so as to, contravene

mandatory provisions of applicable law. Users may bene t from statutory warranty rights under legislation

governing the sale of consumer goods. If any part or term of this Limited Warranty is held by any court of

competent jurisdiction to be illegal, unenforceable, or in con ict with applicable law,

portion of the Limited Warranty shall not be a ected, and all rights and obligations shall be construed and enforced

as if this Limited Warranty did not contain the particular part or term held to be invalid.

cident or improper handling.

ovided for in (3) above.

, prospective or other similar damage resulting from a defect, failure, or malfunction of the

om the date of sale of a new System Component or 90 days from the

onic will either repair or replace the Motor

om the date of sale of a new Semi-reusable Component),

.

the validity of the remaining

Limited Warranty

em

roduct

27

Page 32

Appendix A—Specialized Attachments

PTSC224

Appendix A—Specialized Attachments

Angled Attachments

Installation:

1. Slide the attachment over the motor collet, aligning

the triangular markers (Figure 27). You will feel and

hear the attachment click into place when it is fully

seated.

2. Turn the attachment to the

case (Figure 28).

3. With the “ tool lock” in the position, insert the

dissecting tool into the attachment with a slight

rotational motion (Figure 29). You will feel and hear

the tool click into place when it is fully seated.

4. Turn the tool lock to the

pull on the shaft of the dissecting tool to verify

proper installation.

NOTE: A dissecting tool may be installed in the

attachment before the angled attachment is placed on

the motor.

CAUTION: Hold the handpiec

attachment, so that the attachment does not

inadvertently loosen from the handpiece.

position on the motor

position (Figure 30). Gently

e assembly by the

Figure 27: Sliding the Attachment over the Motor Collet

Figure 28: Attachment in the Locked Position

Removal:

Removal is the reverse of installation.

Figure 29: Inserting the Dissecting Tool into the Attachment

Figure 30: Tool Lock in the Locked P

osition

28

Page 33

Appendix A—Specialized Attachments

PTSC224

Angled Double Lock Attachments

Installation:

1. Slide the attachment over the motor collet, aligning

the triangular markers.

2. Pull the attachment towards the motor and turn the

attachment to the

3. With the “ tool lock” in the position, insert the

dissecting tool into the attachment with a slight

rotational motion. You will feel the tool click into

place when it is fully seated.

4. Turn the tool lock to the

the shaft of the dissecting tool to verify proper

installation.

5. On Variable Exposure Attachments, use the TUBE

adjustment ring to adjust the exposure of the

dissecting tool. With the tool pointing away fr

you, turn the ring to the right to increase the length

of the tube, thereby decreasing the exposure of the

tool. Turn the ring to the left to decrease the length

of the tube, thereby increasing the exposure of the

tool

.

position.

position. Gently pull on

om

Figure 31: Installing the attachment.

Figure 32: Inserting the Dissecting Tool into the Attachment

Removal:

1. To remove the attachment, hold the motor in the

palm of your hand, and push the sleeve on the

attachment distally while turning the attachment to

the

position.

2. Release the sleeve and remove the attachment.

Figure 33: Removing the Attachment

29

Page 34

Appendix A—Specialized Attachments

PTSC224

Curved Bur Attachments

WARNINGS:

• Use adequate irrigation and keep the cooling sleeve

soaked during dissection. Inadequate irrigation may

cause thermal necrosis.

• Do not modify the bur. Bending or prying may break

the bur, causing harm to the patient or operating

oom sta .

r

• Excessive pressure applied to the bur may cause bur

damage. If this occurs, use extreme care to ensure

that all fragments of the bur are remo

patient.

• Disposable devices are for single-use only. Do

not attempt to sterilize disposable devices. The

disposables are packed sterile and are not intended

for repeat use. T

once.

• Test for bur wobble (eccentricity) at the desired

speed prior touse. Select a new bur or reduce speed

if wobble is observed prior to use or during the

procedure. Bur wobble may cause patient injur

CAUTIONS:

• Curved burs are not designed for variable tool

exposure. Do not attempt to adjust tool exposure, as

this may damage the device.

o prevent contamination, use only

ved from the

y.

Cooling the Bur

1. Prior to initial use, soak the cooling sleeve by dipping

it into a cup of saline or DI water, as shown below.

Wetting of the cooling sleeve prior to cutting

2. During use, maintain copious irrigation of the cooling

sleeve and bur tip by dribbling saline or DI water

along the entire length of the cooling sleeve and bur

tip.

Operation

1. Activate the motor and gently press the curved bur

against the bone to begin dissection.

2. Use a light sweeping motion to continue removing

bone.

Removal

1. Turn both AT10 (V01) locking rings to the position

and pull the bur out of the attachment.

2. Discard the curved bur, according to hospital

procedures.

Reuse and Cleaning

Do not reuse.

• When operating or t

bur is properly inserted and locked into AT10

attachment.

esting the motor, ensure the

Installation

1. Turn the tube locking ring and the tool locking ring

on the AT10 (V01) Telescoping Attachment into the

position.

2. Slide the curved bur into the AT10 (V01), until the

hub is fully seated.

3. Gently press on the head of the dissecting tool to

lock it into place. You will hear a click when the

curved bur is fully seated.

4. Turn both locking rings to the

AT10 (V01).

5. Gently pull on the curved bur to verify proper

installation.

6. Refer to your motor’s Instruction Manual for

information on setting up the AT10 (V01) attachment

and motor.

7. Brie y run the motor with the curved bur installed,

checking for bur w

If either occurs, perform the corrective actions

described in the Troubleshooting section of these

instructions.

obble or excessive vibration.

position on the

Sterility

Each bur is gamma-sterilized and is not intended for

repeated use. Do not attempt to re-sterilize.

Cutting Time

Continuous cutting for extended periods may cause the

device to heat to an uncomfortable temperature. To avoid

this, limit cutting to the recommended times below:

Maximum

Continuous

Cutting Time

1 & 2 mm burs 2 minutes 12 minutes

3 & 4 mm burs 3 minutes 12 minutes

Maximum Total

Cutting Time

30

Page 35

Variable Exposure Attachments

PTSC224

CAUTION: The Legend Variable Exposure attachments

can be distinguished from standard attachments by

the dual color bands on the attachment. Match the

color band on the attachment to the color code on the

ting tool packaging.

dissec

WARNINGS:

• Surgeons should familiarize themselves with the

performance of dissecting tools before use, and

should explore the e ect of various levels of tool

exposure on dissection stability.

excessive chatter, vibration, or movement, decrease

the tool exposure.

• Dissecting tool size and geometry may contribute

to excessive vibration at certain speeds. I

decrease speed by adjusting the foot/ nger control,

or by changing the operating pressure or console

speed setting. If necessary, use a di erent dissecting

tool.

If the tool exhibits

ncrease or

Appendix A—Specialized Attachments

Figure 34: Adjusting Tool Exposure

Installation:

1. Refer to the appropriate section of this manual on

installing xed or angled attachments.

2. After installation, use the TUBE adjustment ring to

adjust the exposure of the dissecting tool (Figure 34).

With the tool pointing away fr

ring to the right to increase the length of the tube,

thereby decreasing the exposure of the tool. Turn the

ring to the left to decrease the length of the tube,

thereby increasing the exposure of the tool

WARNING: Do not use the Variable Exposure

Attachment if the TUBE adjustment ring spins freely

or fails to click into plac

exposure may change without warning.

CAUTION: Make sure that the tool lock (angled

attachments only) and the attachment lock are still in the

position after each adjustment of the tool exposure.

Attempting to increase the exposure too far may result

in the attachment becoming unlocked. Accidentally

turning the tool lock may result in reduced speed and/or

overheating of the attachment.

WARNING: Do not use the end of the tube as a depth

gauge or depth stop.

e with each adjustment, as the

om you, turn the

.

Removal:

1. Removal is the reverse of installation.

2. When cleaning, clean the attachment completely,

rst without adjusting the tube length, then with the

tube fully extended, and with the tube fully retrac

ted.

31

Page 36

Appendix A—Specialized Attachments

PTSC224

Footed Attachments

Installation:

1. Insert the dissecting tool into the motor collet with a

slight rotational motion (Figure 35). You will feel and

hear the tool click into place when it is fully seated.

2. Slide the footed attachment over the dissecting

tool

, onto the motor, aligning the triangular markers

(Figure 36).

3. Pull the footed attachment towards the motor and

turn the attachment to the

Removal:

1. To remove the Legend footed attachment, hold

the motor in the palm of your hand, and push the

sleeve on the attachment distally while turning the

attachment to the position (Figure 38).

WARNING: Remove Legend Footed Attachments

cautiously and slowly per instructions to avoid injury to

the operator.

2. Release the sleeve and remove the attachment.

3. Pull the dissecting tool out of the motor collet and

discard

the tool.

position (Figure 37).

Figure 35: Inserting the Tool into the Collet

Figure 36: Sliding the Attachment onto the Motor

Figure 37: Attachment in the Locked Position

32

Figure 38: Removing the Attachment

Page 37

Appendix A—Specialized Attachments

PTSC224

Rotating Footed Attachments

NOTE: Rotating and xed footed attachments with the

same length, marking, and color band share the same

dissecting tools.

Installation:

1. Insert the dissecting tool into the motor collet with a

slight rotational motion (Figure 39). You will feel and

hear the tool click into place when it is fully seated.

2. Slide the attachment over the dissecting tool and

onto the motor

(Figure 40). You will feel and hear the attachment

click into place when it is fully seated.

3. Turn the attachment to the

NOTE: The footed end of the attachment now has 360˚

of unrestricted rotation.

Removal:

Removal is the reverse of installation.

, aligning the triangular markers

position (Figure 41).

Figure 39: Inserting the Tool into the Collet

Figure 40: Sliding the Attachment onto the Motor

Figure 41: Attachment in the Locked Position

33

Page 38

Appendix A—Specialized Attachments

PTSC224

Contra-Angle Attachment (16-MF)

CAUTION: Do not run the 16-MF attachment with

operating pressure above 80 psi (5.5 bar). This may

cause over-heating and damage to internal gears of

attachment.

Installation:

1. Decrease the pressure at the compressed gas source

to 80 psi (5.5 bar).

2. Adjust the pressure as needed by lowering it at the

gas source, then push down the pressure relief on

the pneumatic contr

pressure in the hoses.

3. Slide the attachment over the motor collet, aligning

the triangular markers (Figure 42). You will feel and

hear the attachment click into plac

seated.

4. Turn the attachment to the position (Figure 43).

5. Turn the attachment head lever to the open position

(Figure 44).

6. Insert the dissecting tool and return the lever to the

closed position. Gently pull on the dissecting tool

shaft to verify pr

ol unit to exhaust the excess

e when it is fully