Page 1

CoreValve™ System

Transcatheter Aortic Valve

Delivery Catheter System

Compression Loading System

Caution: Implantation of the Medtronic CoreValve™ system should be performed only by

physicians who have received Medtronic CoreValve™ training.

These devices are supplied sterile for single use only. After use, dispose of the delivery

catheter system and the compression loading system in accordance with local regulations and

hospital procedures. Do not resterilize.

Instructions for Use

Caution: Federal (USA) law restricts this device to sale by or on the order of a physician.

Page 2

Trademarks may be registered and are the property of their respective owners.

Page 3

Sterile LC: Device has been sterilized using Liquid Chemical

Sterilants according to EN/ISO 14160.

Explanation of symbols on package labeling

Use By

Consult Instructions for Use at this Website

Do Not Reuse

Do Not Resterilize

Size

Serial Number

Reorder Number

Lower Limit of Temperature

Quantity

Lot Number

Sterilized Using Ethylene Oxide

Manufactured In

Nonpyrogenic

MR Conditional

Do Not Use if Package is Damaged

Manufacturer

Date of Manufacture

For US Audiences Only

Model

1

Page 4

CoreValve™ Evolut™ bioprosthesis

1.0 Device description

The Medtronic CoreValve™ system consists of 3 components: the transcatheter aortic valve

(bioprosthesis)a, the delivery catheter system (catheter), and the compression loading system

(CLS).

1.1 Transcatheter aortic valve (bioprosthesis)

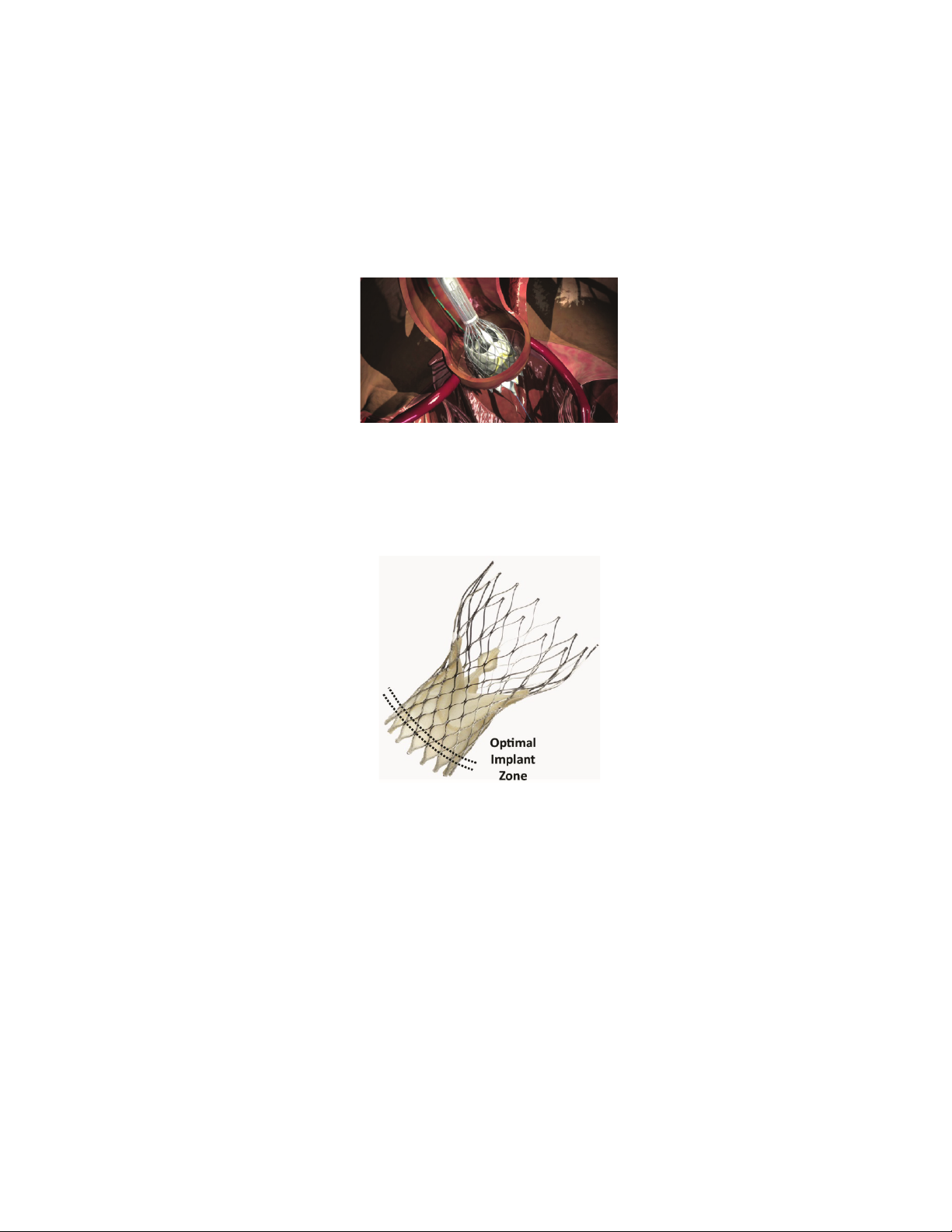

Figure 1

The bioprosthesis is manufactured by suturing 3 valve leaflets and a skirt, made from a single

layer of porcine pericardium, onto a self-expanding, multi-level, radiopaque frame made of

Nitinol. It is designed to replace the native or surgical bioprosthetic aortic heart valve without

open heart surgery and without concomitant surgical removal of the failed valve. The

bioprosthesis is processed with alpha-amino oleic acid (AOA™), which is an

antimineralization treatment derived from oleic acid, a naturally occurring long-chain fatty

acid.

The bioprosthesis is available for a range of aortic annulus and ascending aorta diameters as

shown in Table 1.

Table 1: Patient anatomical diameters

Bioprosthesis model Size Aortic annulus

diameter

MCS-P4-23-AOA-US 23 mm 17b/18 mm–20 mm ≤34 mm

CoreValve™ bioprosthesis

MCS-P3-26-AOA-US 26 mm 20 mm–23 mm ≤40 mm

MCS-P3-29-AOA-US 29 mm 23 mm–26 mm ≤43 mm

MCS-P3-31-AOA-US 31 mm 26 mm–29 mm ≤43 mm

Ascending aorta

diameter

1.2 Delivery catheter system (catheter)

The catheter with AccuTrak™ stability layer is compatible with a 0.035 in (0.889 mm)

guidewire. The distal (deployment) end of the system features an atraumatic, radiopaque tip

and a capsule that covers and maintains the bioprosthesis in a crimped position. The handle is

a

The terms “bioprosthesis” and “transcatheter aortic valve” are synonymous terms and are used interchangeably

throughout the document to refer to the CoreValve™ device.

b

17 mm for surgical bioprosthetic aortic annulus

2

Page 5

MCS-P3-26-AOA-US,

MCS-P3-31-AOA-US

located on the proximal end of the catheter and is used to load and deploy the bioprosthesis.

The handle includes a macro slider to open and close the capsule and micro knob to facilitate

precise bioprosthesis placement. The micro knob is turned counterclockwise to load the

bioprosthesis and clockwise to deploy the bioprosthesis.

The AccuTrak™ stability layer is fixed at the handle and extends down the outside of the

catheter shaft approximately 91 cm. It provides a barrier between the retractable delivery

catheter system, introducer sheath, and vessel walls, thus enabling the catheter to retract

freely and providing a more stable platform for deployment. The outer diameter of the

catheter is 15 Fr (AccuTrak™ stability layer) and 12 Fr, and the outer diameter of the valve

capsule is 18 Fr (Figure 2). The catheter can be used for femoral, subclavian/axillary, or

ascending aortic (direct aortic) access sites. The catheter is available in 2 different models

(Table 2).

Table 2: Catheter models and system compatibility

Catheter model Corresponding CLS

DCS-C4-18F-23US CLS-3000-18F-US MCS-P4-23-AOA-US

DCS-C4-18F-US CLS-3000-18F-US

1. 112.5 cm

2. 90.9 cm

3. 15 Fr

4. 12 Fr

model

Figure 2

Corresponding

bioprosthesis model(s)

MCS-P3-29-AOA-US,

5. 18 Fr

6. 7.3 cm (Model DCS-C4-18F-US); 6.9 cm (Model DCS-C4-18F-23US)

3

Page 6

1.3 Compression loading system (CLS)

The CLS compresses the bioprosthesis into the catheter. The CLS comprises the following:

Figure 3

1. Inflow tube (straight tube)

2. Outflow cone

3. Outflow cap

4. Outflow tube (tube with flared ends)

5. Inflow cone

4

Page 7

2.0 Indications

The Medtronic CoreValve™ system is indicated for relief of aortic stenosis in patients with

symptomatic heart disease due to severe native calcific aortic stenosis who are judged by a

heart team, including a cardiac surgeon, to be at intermediate or greater risk for open surgical

therapy (i.e., predicted risk of surgical mortality ≥ 3% at 30 days, based on the Society of

Thoracic Surgeons (STS) risk score and other clinical comorbidities unmeasured by the STS

risk calculator).

The Medtronic CoreValve™ system is indicated for use in patients with symptomatic heart

disease due to failure (stenosed, insufficient, or combined) of a surgical bioprosthetic aortic

valve who are judged by a heart team, including a cardiac surgeon, to be at high or greater

risk for open surgical therapy (i.e., STS predicted risk of operative mortality score ≥8% or at

a ≥15% risk of mortality at 30 days).

5

Page 8

3.0 Contraindications

The CoreValve™ system is contraindicated for patients presenting with any of the following

conditions:

• Known hypersensitivity or contraindication to aspirin, heparin (HIT/HITTS) and

bivalirudin, ticlopidine, clopidogrel, Nitinol (Titanium or Nickel), or sensitivity to

contrast media, which cannot be adequately premedicated

• Ongoing sepsis, including active endocarditis

• Preexisting mechanical heart valve in aortic position

6

Page 9

4.0 Warnings and precautions

4.1 Warnings

4.1.1 General

• Implantation of the Medtronic CoreValve™ system should be performed only by

physicians who have received Medtronic CoreValve™ training.

• The transcatheter aortic valve is to be used only in conjunction with the delivery catheter

system and the compression loading system.

• This procedure should only be performed where emergency aortic valve surgery can be

performed promptly.

• Do not use any of the Medtronic CoreValve™ system components if any of the

following has occurred:

• It has been dropped, damaged, or mishandled in any way

• The Use By date has elapsed

• Mechanical failure of the delivery catheter system and/or accessories may result in

patient complications.

4.1.2 Transcatheter aortic valve (bioprosthesis)

• Do not use the bioprosthesis if any of the following conditions is observed:

• There is any damage to the container (e.g., cracked jar or lid, leakage, broken or

missing seals)

• The serial number tag does not match the container label

• The freeze indicator in the secondary package has activated

• The storage solution does not completely cover the bioprosthesis

• Accelerated deterioration of the bioprosthesis may occur in patients presenting with an

altered calcium metabolism.

4.2 Precautions

4.2.1 General

• Do not contact any of the Medtronic CoreValve™ system components with cotton or

cotton swabs.

• Do not expose any of the Medtronic CoreValve™ system components to organic

solvents, such as alcohol.

• Do not introduce air into the catheter.

7

Page 10

• The safety and effectiveness of the Medtronic CoreValve™ system have not been

evaluated in the pediatric population.

• The safety and effectiveness of the bioprosthesis for aortic valve replacement have not

been evaluated in the following patient populations:

• Patients who do not meet the criteria for symptomatic severe native aortic stenosis

as defined below:

• Symptomatic severe high-gradient aortic stenosis: aortic valve area

≤1.0 cm2 or aortic valve area index ≤0.6 cm2/m2, a mean aortic valve

gradient ≥40 mmHg, or a peak aortic-jet velocity ≥4.0 m/s

• Symptomatic severe low-flow/low-gradient aortic stenosis: aortic valve

area ≤1.0 cm2 or aortic valve area index ≤0.6 cm2/m2; a mean aortic valve

gradient <40 mmHg; and a peak aortic-jet velocity <4.0 m/s

• Who are at low surgical risk (predicted perioperative mortality risk of <3%)

• With untreated, clinically significant coronary artery disease requiring

revascularization

• With a preexisting prosthetic heart valve with a rigid support structure in either

the mitral or pulmonic position if either the preexisting prosthetic heart valve

could affect the implantation or function of the bioprosthesis or the implantation

of the bioprosthesis could affect the function of the preexisting prosthetic heart

valve

• With cardiogenic shock manifested by low cardiac output, vasopressor

dependence, or mechanical hemodynamic support

• The safety and effectiveness of a CoreValve™ bioprosthesis implanted within a failed

preexisting transcatheter bioprosthesis have not been demonstrated.

• Implanting a CoreValve™ bioprosthesis in a degenerated surgical bioprosthesis

(transcatheter aortic valve in surgical aortic valve [TAV in SAV]) should be avoided in

the following conditions. The degenerated surgical bioprosthesis presents with a:

• Significant concomitant perivalvular leak (between the prosthesis and the native

annulus), is not securely fixed in the native annulus, or is not structurally intact

(e.g., wireform frame fracture)

• Partially detached leaflet that in the aortic position may obstruct a coronary

ostium

• Stent frame with a manufacturer’s labeled inner diameter <17 mm

• The safety and effectiveness of the bioprosthesis for aortic valve replacement have not

been evaluated in patient populations presenting with the following:

• Blood dyscrasias as defined: leukopenia (WBC <1000 cells/mm3),

thrombocytopenia (platelet count <50,000 cells/mm3), history of bleeding

diathesis or coagulopathy, or hypercoagulable states

8

Page 11

• Congenital bicuspid or unicuspid valve verified by echocardiography

• Mixed native aortic valve disease (aortic stenosis and aortic regurgitation with

predominant aortic regurgitation [3-4+])

• Moderate to severe (3-4+) or severe (4+) mitral or severe (4+) tricuspid

regurgitation

• Hypertrophic obstructive cardiomyopathy

• New or untreated echocardiographic evidence of intracardiac mass, thrombus, or

vegetation

• Native aortic annulus size <18 mm or >29 mm per the baseline diagnostic

imaging or surgical bioprosthetic aortic annulus size <17 mm or >29 mm

• Transarterial access not able to accommodate an 18 Fr sheath

• Sinus of valsalva anatomy that would prevent adequate coronary perfusion

• Moderate to severe mitral stenosis

• Severe ventricular dysfunction with left ventricular ejection fraction (LVEF)

<20% as measured by resting echocardiogram

• Symptomatic carotid or vertebral artery disease

• Severe basal septal hypertrophy with an outflow gradient

• Do not expose the bioprosthesis to solutions other than the storage and rinse solutions.

• Do not add antibiotics or any other substance to either the storage or rinse solutions. Do

not apply antibiotics or any other substance to the bioprosthesis.

• Do not allow the bioprosthesis to dry. Maintain tissue moisture with irrigation or

immersion.

• Do not attempt to repair a damaged bioprosthesis.

• Do not handle or use forceps to manipulate the bioprosthesis leaflet tissue.

• Do not deform the bioprosthesis in excess of what is experienced during crimping,

loading, and implantation.

4.2.2 Prior to use

• Exposure to glutaraldehyde may cause irritation of the skin, eyes, nose, and throat. Avoid

prolonged or repeated exposure to the vapors. Use only with adequate ventilation. If skin

contact occurs, immediately flush the affected area with water (minimum of 15 minutes).

In the event of eye contact, flush with water for a minimum of 15 minutes and seek

medical attention immediately.

• The bioprosthesis and the glutaraldehyde storage solution are sterile. The outside of the

bioprosthesis container is nonsterile and must not be placed in the sterile field.

• Damage may result from forceful handling of the catheter. Prevent kinking of the catheter

when removing it from the packaging.

9

Page 12

• This device was designed for single patient use only. Do not reuse, reprocess, or

resterilize this product. Reuse, reprocessing, or resterilization may compromise the

structural integrity of the device and/or create a risk of contamination of the device,

which could result in patient injury, illness, or death.

• The bioprosthesis size must be appropriate to fit the patient’s anatomy. Proper sizing of

the device is the responsibility of the physician. Refer to Table 1 for available sizes.

Failure to implant a device within the sizing matrix could lead to adverse effects such as

those listed in Section 5.0.

• Patients must present with access vessel diameters of ≥6 mm or an ascending aortic

(direct aortic) access site ≥60 mm from the basal plane.

• Implantation of the bioprosthesis should be avoided in patients with aortic root angulation

(angle between plane of aortic valve annulus and horizontal plane/vertebrae) of >30° for

right subclavian/axillary access or >70° for femoral and left subclavian/axillary access.

• Use caution when using the subclavian/axillary approach in patients with a patent Left

Internal Mammary Artery (LIMA) graft (for left subclavian/axillary approach only) or

patent Right Internal Mammary Artery (RIMA) graft (for right subclavian/axillary

approach only).

• For direct aortic access, ensure the access site and trajectory are free of patent RIMA or a

preexisting patent RIMA graft.

4.2.3 During use

• Adequate rinsing of the bioprosthesis with sterile saline, as described in the Instructions

for Use, is mandatory before implantation. No other solutions, drugs, chemicals, or

antibiotics should ever be added to the glutaraldehyde or rinse solutions as irreparable

damage to the leaflet tissue, which may not be apparent under visual inspection, may

result.

• During rinsing, do not touch the leaflets or squeeze the bioprosthesis.

• With the exception of attaching the bioprosthesis frame loops to the catheter tabs, do not

touch the capsule or the transition between the capsule and the catheter shaft. To protect

the capsule, handle the catheter using the catheter shaft or, during loading, the loading

tools.

• If a capsule becomes damaged during loading or the capsule fails to close, replace the

entire system (bioprosthesis, catheter, and CLS). Do not use a catheter with a damaged

capsule.

• Prevent contamination of the bioprosthesis, its storage solution, the catheter, and the CLS

with glove powder.

• After a bioprosthesis has been inserted into a patient, do not attempt to reload that

bioprosthesis on the same or any other catheter.

• During implantation, if resistance to deployment is encountered (e.g., the micro knob

starts clicking or is tight or stuck), apply upward pressure to the macro slider while

10

Page 13

turning the micro knob. If the bioprosthesis still does not deploy, remove it from the

patient and use another system.

• While the catheter is in the patient, ensure the guidewire is extending from the tip. Do not

remove the guidewire from the catheter while the catheter is inserted in the patient.

• Once deployment is initiated, retrieval of the bioprosthesis from the patient (e.g., use of

the catheter) is not recommended. Retrieval of a partially deployed valve using the

catheter may cause mechanical failure of the delivery catheter system, aortic root

damage, coronary artery damage, myocardial damage, vascular complications, prosthetic

valve dysfunction (including device malposition), embolization, stroke, and/or emergent

surgery.

• During deployment, the bioprosthesis can be advanced or withdrawn as long as annular

contact has not been made. Once annular contact is made, the bioprosthesis cannot be

advanced in the retrograde direction; if necessary, and the frame has only been deployed

≤2/3 of its length, the bioprosthesis can be withdrawn (repositioned) in the antegrade

direction. However, use caution when moving the bioprosthesis in the antegrade

direction.

• Use the handle of the delivery system to reposition the bioprosthesis. Do not use the outer

catheter sheath.

• Once deployment is complete, repositioning of the bioprosthesis (e.g., use of a snare

and/or forceps) is not recommended. Repositioning of a deployed valve may cause aortic

root damage, coronary artery damage, myocardial damage, vascular complications,

prosthetic valve dysfunction (including device malposition), embolization, stroke, and/or

emergent surgery.

• Do not attempt to retrieve a bioprosthesis if any one of the outflow struts is protruding

from the capsule. If any one of the outflow struts has deployed from the capsule, the

bioprosthesis must be released from the catheter before the catheter can be withdrawn.

• Ensure the capsule is closed before catheter removal. If increased resistance is

encountered when removing the catheter through the introducer sheath, do not force

passage. Increased resistance may indicate a problem and forced passage may result in

damage to the device and/or harm to the patient. If the cause of resistance cannot be

determined or corrected, remove the catheter and introducer sheath as a single unit over

the guidewire, and inspect the catheter and confirm that it is complete.

• Clinical long-term durability has not been established for the bioprosthesis. Evaluate

bioprosthesis performance as needed during patient follow-up.

• Postprocedure, administer appropriate antibiotic prophylaxis as needed for patients at risk

for prosthetic valve infection and endocarditis.

• Postprocedure, administer anticoagulation and/or antiplatelet therapy per hospital

protocol.

• Excessive contrast media may cause renal failure. Preprocedure, measure the patient’s

creatinine level. During the procedure, monitor contrast media usage.

11

Page 14

• Conduct the procedure under fluoroscopy. Fluoroscopic procedures are associated with

the risk of radiation damage to the skin, which may be painful, disfiguring, and longterm.

• The safety and efficacy of a CoreValve™ bioprosthesis implanted within a transcatheter

bioprosthesis have not been demonstrated. However, in the event that a CoreValve™

bioprosthesis must be implanted within a transcatheter bioprosthesis to improve valve

function, valve size and patient anatomy must be considered before implantation of the

CoreValve™ bioprosthesis to ensure patient safety (e.g., to avoid coronary obstruction).

• In the event that valve function or sealing is impaired due to excessive calcification or

incomplete expansion, a postimplant balloon dilatation of the bioprosthesis may improve

valve function and sealing. To ensure patient safety, valve size and patient anatomy must

be considered when selecting the size of the balloon used for dilatation. The balloon size

chosen for dilatation should not exceed the diameter of the native aortic annulus or, for

surgical bioprosthetic valves, the manufacturer’s labeled inner diameter. Refer to the

specific balloon catheter manufacturer’s compliance chart to ensure that the applied

inflation pressure does not result in a balloon diameter that exceeds the indicated annulus

range for the bioprosthesis. Refer to the specific balloon catheter manufacturer’s labeling

for proper instruction on the use of balloon catheter devices. Note: Bench testing has only

been conducted to confirm compatibility with NuMED Z-MED II™ Balloon Aortic

Valvuloplasty catheters where CoreValve™ bioprosthesis device performance was

maintained after dilatation. Data on file.

4.3 Magnetic resonance imaging (MRI)

MRI may be used on the bioprosthesis only under specific conditions. See Section 6.2 MRI

safety information for more information.

12

Page 15

5.0 Potential adverse events

Potential risks associated with the implantation of the Medtronic CoreValve™ transcatheter

aortic valve may include, but are not limited to, the following:

• Death

• Cardiac arrest

• Coronary occlusion, obstruction, or vessel spasm (including acute coronary closure)

• Emergent surgery (e.g., coronary artery bypass, heart valve replacement, valve explant)

• Multi-organ failure

• Heart failure

• Myocardial infarction

• Cardiogenic shock

• Respiratory insufficiency or respiratory failure

• Cardiovascular injury (including rupture, perforation, or dissection of vessels, ventricle,

myocardium, or valvular structures that may require intervention)

• Ascending aorta trauma

• Cardiac tamponade

• Cardiac failure or low cardiac output

• Prosthetic valve dysfunction including, but not limited to, fracture; bending (out-of-round

configuration) of the valve frame; under-expansion of the valve frame; calcification;

pannus; leaflet wear, tear, prolapse, or retraction; poor valve coaptation; suture breaks or

disruption; leaks; mal-sizing (prosthesis-patient mismatch); malposition (either too high

or too low)/malplacement; regurgitation; stenosis

• Thrombosis/embolus (including valve thrombosis)

• Valve migration/valve embolization

• Ancillary device embolization

• Emergent percutaneous coronary intervention (PCI)

• Emergent balloon valvuloplasty

• Major or minor bleeding that may or may not require transfusion or intervention

(including life-threatening or disabling bleeding)

• Allergic reaction to antiplatelet agents, contrast medium, or anesthesia

• Infection (including septicemia and endocarditis)

• Stroke, transient ischemic attack (TIA), or other neurological deficits

• Permanent disability

13

Page 16

• Renal insufficiency or renal failure (including acute kidney injury)

• Mitral valve regurgitation or injury

• Tissue erosion

• Vascular access related complications (e.g., dissection, perforation, pain, bleeding,

hematoma, pseudoaneurysm, irreversible nerve injury, compartment syndrome,

arteriovenous fistula, stenosis)

• Conduction system disturbances (e.g., atrioventricular node block, left-bundle branch

block, asystole), which may require a permanent pacemaker

• Cardiac arrhythmias

• Encephalopathy

• Pulmonary edema

• Pericardial effusion

• Pleural effusion

• Myocardial ischemia

• Peripheral ischemia

• Bowel ischemia

• Heart murmur

• Hemolysis

• Cerebral infarction-asymptomatic

• Non-emergent reoperation

• Inflammation

• Fever

• Hypotension or hypertension

• Syncope

• Dyspnea

• Anemia

• Angina

• Abnormal lab values (including electrolyte imbalance)

14

Page 17

6.0 Patient information

6.1 Registration information

A patient registration form is included in each bioprosthesis package. After implantation,

please complete all requested information. The serial number is located on both the package

and the identification tag attached to the bioprosthesis. Return the original form to the

Medtronic address indicated on the form and provide the temporary identification card to the

patient prior to discharge.

Medtronic will provide an Implanted Device Identification Card to the patient. The card

contains the name and telephone number of the patient’s physician as well as information

that medical personnel would require in the event of an emergency. Patients should be

encouraged to carry this card with them at all times.

6.2 MRI safety information

Nonclinical testing and modeling have demonstrated that the Medtronic CoreValve™

bioprosthesis is MR Conditional. A patient with this device can be safely scanned in an MR

system meeting the following conditions:

• Static magnetic field of 1.5 T and 3.0 T

• Maximum spatial gradient magnetic field of 2500 gauss/cm (25 T/m)

• Maximum MR system reported, whole body averaged specific absorption rate (SAR) of

≤2.0 W/kg (Normal Operating Mode)

Based on nonclinical testing and modeling, under the scan conditions defined above, the

Medtronic CoreValve™ bioprosthesis is expected to produce a maximum in vivo

temperature rise of less than 3.6˚C after 15 minutes of continuous scanning. Based on

nonclinical data, the image artifact caused by the device will extend no greater than 7 mm

from the Medtronic CoreValve™ bioprosthesis when imaged with a gradient echo pulse

sequence and a 3.0 T MRI system.

Scanning under the conditions defined above may be performed immediately after

implantation.

The presence of other implants or medical circumstances of the patient may require lower

limits on some or all of the above parameters. For deployment of a Medtronic CoreValve™

bioprosthesis inside of a failed surgical bioprosthetic valve, consult the MRI labeling

pertaining to the failed valve for additional artifact information.

15

Page 18

7.0 How supplied

7.1 Packaging

The bioprosthesis is supplied sterile and nonpyrogenic in a sealed container made of glass

and a screw cap with a liner. The outside of the container is nonsterile and must not be

placed in the sterile field. A freeze indicator is placed inside the labeled carton. If the freeze

indicator has been activated, do not use the bioprosthesis.

The catheter is packaged in a double-pouch configuration and sterilized with ethylene oxide

gas. The catheter is sterile if the pouches are undamaged and unopened. The outer surfaces of

the outer pouch are nonsterile and must not be placed in the sterile field.

The CLS is packaged in a double-pouch configuration. The CLS is sterile if the pouches are

undamaged and unopened. The outer surfaces of the outer pouch are nonsterile and must not

be placed in the sterile field. The CLS is sterilized with ethylene oxide gas.

7.2 Storage

Store the bioprosthesis at room temperature. Avoid exposing to extreme fluctuations of

temperature. Avoid freezing. Appropriate inventory control should be maintained so that

bioprostheses with earlier Use By dates are implanted preferentially. Store the catheter and

CLS in a cool, dry environment.

16

Page 19

8.0 Additional equipment

Note: While extensive, this equipment list is not meant to cover all possible scenarios.

Transesophogeal echocardiogram (TEE) or transthoracic echocardiography (TTE) on

standby

Temporary pacer insertion

• Temporary pacemaker catheter (4 Fr or 5 Fr), per hospital protocol

• Sterile sleeve for pacemaker catheter

• Hemostatic vessel introducer sheath

• Temporary pacemaker generator

• Sterile temporary pacemaker-to-generator cable

If indicated, pulmonary artery catheter insertion

• Standard pulmonary artery catheter

• Hemostatic vessel introducer sheath

• Saline flush line connected to pressure transducer

Baseline aortography via radial, brachial, or femoral approach

• 5 Fr or 6 Fr pigtail angiographic catheter

• 6 Fr hemostatic vessel introducer sheath

• 2-port manifold with saline flush line and pressure tubing or transducer

• Power injector syringe

• Contrast media

• High-pressure power injector tubing

Predilatation of implant site

• 2-port manifold with saline flush and transducer

• 9 Fr and 18 Fr hemostatic vessel introducer sheaths

• Standard length 0.035 in (0.889 mm) straight guidewire

• Appropriate suture-mediated closure system, if applicable

• Angiographic catheter

• 0.035 in (0.889 mm) × 260 cm standard high-support guidewire to be shaped with a

pigtail loop

• Balloon valvuloplasty catheters, ≤4 cm length × 18 mm, 20 mm, 22 mm or 23 mm, and

25 mm diameters

• Inflation device or syringe and diluted 1:5 contrast media

17

Page 20

Bioprosthesis implantation

• 18 Fr hemostatic vessel introducer sheath

Standby supplies (must be available in the room)

• Pericardiocentesis tray

• 35 mm × 120 cm single loop snare

• Standard percutaneous coronary intervention (PCI) equipment

• 14 Fr and 16 Fr hemostatic vessel introducer sheaths

• Standard cardiac catheterization lab equipment

• Intra-aortic balloon pump (IABP)

18

Page 21

9.0 Instructions for use

Figure 4

1. Catheter tip

2. Capsule

3. Catheter shaft

4. Tube flush port

5. AccuTrak™ stability layer

6. Macro slider

7. Micro knob

8. Luer-lock connection flush port

9.1 Inspection and bioprosthesis loading procedure

Caution: Once the bioprosthesis is removed from its container and the catheter and CLS are

removed from their packaging, ensure all subsequent procedures are performed in a sterile

field.

9.1.1 Inspection prior to use

1. Before removing the bioprosthesis, catheter, or CLS from its primary packaging,

carefully inspect the packaging for any evidence of damage that could compromise

the sterility or integrity of the device (e.g., cracked jar or lid, leakage, broken or

missing seals, torn or punctured pouch).

Caution: Do not use the product if there is evidence of damage.

2. Inspect the temperature indicator located within the packaging for the bioprosthesis to

ensure it has not been activated.

Caution: Do not use the bioprosthesis if the temperature indicator has been activated.

9.1.2 Preparation of the catheter

3. Wipe the length of the catheter with a moist (saline) gauze.

4. Use the micro knob and macro slider on the handle to open and close the catheter

(Figure 4).

19

Page 22

5. Attach a stopcock to the first flush port. Attach a 10 mL syringe filled with saline to

the stopcock on the first flush port and flush. Repeat step for the second flush port on

the catheter (Figure 5).

Figure 5

6. Verify no catheter leakage is observed during any of the flushing steps. If leakage is

observed, use a new system.

7. Attach a 10 mL syringe filled with saline to the third flush port on the handle on the

catheter (Figure 6) and flush.

Figure 6

8. Fill a loading bath with cold, sterile saline (0°C to 8°C [32°F to 46°F]), and place the

CLS components in the bath.

9.1.3 Bioprosthesis rinsing procedure

9. Fill each of 3 rinsing bowls with approximately 500 mL of fresh, sterile saline at

ambient temperature (15°C to 25°C [59°F to 77°F]).

10. Confirm the integrity of the primary bioprosthesis container. Open the container and

remove the bioprosthesis by carefully grasping one of the frame loops. Let any

remaining solution drain from the bioprosthesis completely.

Caution: The bioprosthesis should not be handled or manipulated with sharp or

pointed objects. Use atraumatic blunt-tipped forceps only. Do not use the forceps to

grasp the tissue portion of the bioprosthesis.

Note: Retain the container with the original solution. It may be needed to store and

return a rejected bioprosthesis.

11. Compare the serial number on the container with the serial number on the tag

attached to the bioprosthesis.

Caution: If the serial numbers do not match, Do not use the bioprosthesis.

20

Page 23

12. Carefully remove the serial number tag from the bioprosthesis and retain the tag.

Ensure that the suture that was used to secure the serial number tag to the

bioprosthesis is completely removed from the bioprosthesis.

13. Immerse the entire bioprosthesis in a sterile rinsing bowl.

14. Gently agitate the bioprosthesis by hand for 2 minutes to remove the glutaraldehyde

from the bioprosthesis.

15. Repeat steps 13 and 14 in each of the 2 remaining rinsing bowls to ensure complete

removal of glutaraldehyde from the bioprosthesis.

16. Leave the bioprosthesis submerged in sterile saline until it is ready to be loaded.

9.1.4 Bioprosthesis loading procedure

Caution: Rapid capsule advancement can contribute to difficulties with loading the valve.

Slowly advancing the capsule helps facilitate successful loading.

Caution: With the exception of attaching the bioprosthesis frame loops to the catheter tabs,

do not touch the capsule or the transition between the capsule and the catheter shaft. To

protect the capsule, handle the catheter using the catheter shaft or, during loading, the loading

tools.

Note: If a capsule becomes damaged during loading or the capsule fails to close, replace the

entire system (bioprosthesis, catheter, and CLS). Do not use a catheter with a damaged

capsule.

Perform the bioprosthesis loading procedure while the bioprosthesis, CLS, capsule, and

catheter tip are immersed in cold, sterile saline (0°C to 8°C [32°F to 46°F]).

17. To open the capsule, activate the macro slider and slide back.

18. Submerge and cool the bioprosthesis in a bath filled with cold, sterile saline.

19. Advance the outflow tube (tube with flared ends) over the catheter shaft toward the

handle (Figure 7).

Figure 7

20. Gently squeeze the outflow part of the cold bioprosthesis frame and insert it into the

outflow cone (Figure 8).

Note: As applicable, all subsequent bioprosthesis loading steps should be performed

under chilled (0°C to 8°C [32°F to 46°F]) saline.

21

Page 24

Figure 8

21. Slowly continue to insert the frame into the outflow cone.

22. Once the bioprosthesis is fully inserted, secure the outflow cap onto the outflow cone

(Figure 9).

Figure 9

23. Carefully insert the inflow tube (straight tube) into the outflow cap (Figure 10).

Figure 10

24. Gently continue to advance the inflow tube until the bioprosthesis frame loops begin

to separate.

25. Insert the distal catheter tip into the inflow tube (Figure 11).

Figure 11

Note: The distal end of the catheter (Figure 11) may look slightly different from the

figures in Section 9.0. The functionality of the catheter is the same.

26. Carefully withdraw the inflow tube and attach the exposed frame loops to the catheter

tabs (Figure 12).

22

Page 25

Figure 12

27. Rotate the micro knob to advance the capsule to cover the bioprosthesis frame loops

and the top of the outflow struts (Figure 13).

Note: Ensure that the capsule has covered all of the outflow struts and the

bioprosthesis frame loops are securely attached to the catheter tabs.

Figure 13

28. Advance the outflow tube over the radiopaque marker band of the capsule prior to

advancing the capsule further (Figure 14).

Figure 14

29. Remove the outflow cap and inflow tube from the outflow cone (Figure 15).

Figure 15

30. Move the outflow cone away from the bioprosthesis over the catheter toward the

handle.

31. Advance the inflow cone over the bioprosthesis using the outflow tube (Figure 16).

23

Page 26

Figure 16

Note: Ensure the bioprosthesis frame axis is visually aligned (coaxial) with the inflow

cone axis during the insertion of the bioprosthesis into the inflow cone (Figure 17).

Complete the insertion of the bioprosthesis into the inflow cone in one uninterrupted

movement.

Figure 17

1. Inflow cone axis

2. Bioprosthesis frame axis

32. Continue to advance the bioprosthesis into the inflow cone until the outflow tube

contacts the inside of the inflow cone (Figure 18).

Figure 18

33. Visually inspect the bioprosthesis within the inflow cone to verify there is no crease

or infold in the frame beyond the second node from the inflow end. Ensure inspection

is performed circumferentially around the entire bioprosthesis.

Caution: If a crease or infold greater than 2 nodes long is noticed, do not use the

bioprosthesis or catheter. Prepare a new bioprosthesis to load into a new catheter.

24

Page 27

Figure 19

Figure 20

34. Hold the inflow cone against the outflow tube while slowly advancing the capsule

over the bioprosthesis until the capsule comes within approximately 5 mm of the

catheter tip (Figure 21). If the micro knob clicks, apply upward pressure to the macro

slider and continue turning the micro knob (Figure 22).

Figure 21 Figure 22

35. With the catheter tip submerged in cold saline, flush both tube flush ports with saline.

36. Slowly advance the capsule over the bioprosthesis until the capsule contacts the

catheter tip.

37. If the micro knob has fully advanced the capsule and a small gap remains between the

end of the capsule and the catheter tip, stabilize the handle with one hand; position the

other hand on the blue catheter shaft and gently advance the capsule manually to

close the gap between the capsule and the catheter tip (Figure 23).

Figure 23

38. Remove the outflow cone and outflow tube from the catheter (Figure 24).

Figure 24

25

Page 28

39. Conduct a final visual inspection of the loaded bioprosthesis to make sure the frame is

free of creases or infolds beyond the second node from the inflow end. Ensure

inspection is performed circumferentially around the entire bioprosthesis.

Caution: If a crease or infold greater than 2 nodes long is noticed, do not use the

bioprosthesis or catheter. Prepare a new bioprosthesis to load into a new catheter.

Figure 25

40. Leave the loaded bioprosthesis submerged in cold saline until implantation.

Figure 26

9.2 Bioprosthesis implantation

9.2.1 Vascular access

Note: Vascular access should be achieved per hospital protocol (either percutaneously or via

surgical cutdown).

Note: The primary access artery will be used to introduce the CoreValve™ system and, if

predilatation is performed, the balloon catheter; the secondary access artery will be used to

introduce the reference pigtail.

1. Establish a central venous line. Insert a 4 Fr or 5 Fr temporary pacemaker catheter via

the right internal jugular vein (or other appropriate access vessel) per hospital

protocol.

2. Insert a 6 Fr introducer sheath into the secondary access artery.

3. Insert an 18 Fr introducer sheath into the primary access artery.

4. Administer anticoagulant according to hospital protocol. If heparin is administered as

an anticoagulant, check the activated clotting time (ACT) after initial bolus of heparin

and recheck every 30 minutes thereafter. Maintain ACT ≥250 seconds.

Note: Anticoagulant may be administered at any time prior to this point, but avoid

delaying beyond this point.

9.2.2 Crossing the valve

5. Advance the graduated pigtail catheter to the ascending aorta and position the distal

tip in the noncoronary cusp of the aortic valve.

6. Identify the ideal annular viewing plane using contrast injections at various

angiographic angles.

Note: It is recommended that a dedicated individual prepare and operate the contrast

injector.

26

Page 29

7. Insert an angiographic catheter over a standard J-tip guidewire into the primary access

sheath and advance to the ascending aorta.

8. Exchange the J-tip guidewire for a 0.035 in (0.889 mm) straight-tip guidewire.

Advance the straight-tip guidewire across the aortic valve into the left ventricle (LV).

9. After crossing the aortic valve with the guidewire, advance the angiographic catheter

into the LV.

10. Exchange the straight-tip guidewire for an exchange-length J-tip guidewire.

11. Exchange the angiographic catheter for a 6 Fr pigtail catheter.

12. Remove the guidewire and connect the catheter to the transducer. Using both

catheters, record the aortic pressure gradient.

13. Using a right anterior oblique (RAO) projection, advance the previously pigtail-

shaped, 0.035 in (0.889 mm) high-support guidewire through the pigtail catheter and

position in the apex of the LV.

14. Remove the pigtail catheter while maintaining guidewire position in the LV.

9.2.3 Predilatation of the implant site

Note: The need for predilatation of the native valve is determined by the heart team.

Information for failed surgical bioprostheses: Balloon predilatation of a stenotic surgical

aortic bioprosthesis has not been evaluated. In cases where there is severe stenosis,

predilatation of the surgical aortic bioprosthesis may be done at the discretion of the heart

team and the steps used are identical to native valve predilatation.

15. Insert the valvuloplasty balloon through the 18 Fr introducer sheath and advance it to

the ascending aorta.

16. Reposition the angiographic equipment to the ideal viewing plane. Position the

valvuloplasty balloon across the valve, while maintaining strict fluoroscopic

surveillance of the distal tip of the guidewire in the LV.

17. Perform balloon valvuloplasty per hospital protocol and remove the valvuloplasty

balloon while maintaining guidewire position across the aortic valve.

9.2.4 Deployment

18. Insert the device over the 0.035 in (0.889 mm) guidewire and into the introducer

sheath with the macro slider facing upward. Advance the device while maintaining

strict fluoroscopic surveillance of the guidewire in the LV.

19. When crossing the aortic arch, it is critical that the guidewire is controlled to prevent

it from moving forward. Without proper management of the distal tip of the

guidewire, the guidewire could move forward and cause trauma to the LV.

20. Advance the device through the valve. Perform an angiogram to confirm that the

pigtail catheter is in position within the noncoronary cusp of the aortic root.

Fluoroscopically identify the appropriate landmarks.

27

Page 30

Figure 27

21. Note the radiopaque bands (Figure 28). Follow the diagrams in Figure 29 and

Figure 32 for the optimal placement of the bioprosthesis. The bioprosthesis should be

placed so that the skirt is within the aortic annulus (approximately 4 mm to 6 mm

below the annulus). In native anatomy, the annulus is defined as the angiographic

floor of the aortic root. For surgical bioprostheses, consider the features of the valve

when determining the optimal placement.

Figure 28 Figure 29

22. After attaining optimal catheter position, slowly turn the micro knob and begin to

deploy the bioprosthesis. As the inflow aspect of the bioprosthesis starts to flare

outward, monitor bioprosthesis position under fluoroscopy.

Caution: During implantation, if resistance to deployment is encountered (e.g., the

micro knob starts clicking or is tight or stuck), apply mild upward pressure to the

macro slider while turning the micro knob (Figure 22). If the bioprosthesis still does

not deploy, remove it from the patient and use another system.

Figure 30

23. Perform an angiogram. Once annular contact is made, the bioprosthesis should not be

advanced into a lower position.

28

Page 31

Note: The force required to move the bioprosthesis into a higher position becomes

noticeably greater once annular contact is made.

24. Continue deploying rapidly to the 2/3 deployment point; stop turning the micro knob.

Note: Shortly after annular contact, the blood pressure will be reduced until the

2/3 deployment point, when the bioprosthesis leaflets are exposed and are

functioning.

Figure 31

25. Perform an angiogram to assess the location of the bioprosthesis. Refer to Figure 29

and Figure 32 for the optimal placement of the bioprosthesis skirt within the aortic

annulus (approximately 4 mm to 6 mm below the annulus).

Figure 32

26. If the bioprosthesis is positioned low, slight repositioning of a partially deployed

bioprosthesis (≤2/3 of the bioprosthesis length) can be achieved by carefully

withdrawing the catheter.

27. When satisfactory position is achieved, withdraw the reference pigtail catheter to the

ascending aorta. Continue to turn the micro knob until both frame loops disengage.

Use orthogonal views under fluoroscopy to confirm that the frame loops have

detached from the catheter tabs. If a frame loop is still attached to a catheter tab, do

not pull on the catheter. Under fluoroscopy, advance the catheter slightly and, if

necessary, gently rotate the handle clockwise (<180°) and then counterclockwise

(<180°) to disengage the loop from the catheter tab.

29

Page 32

9.2.5 Postdeployment

28. Under fluoroscopic guidance, confirm that the catheter tip is coaxial with the inflow

portion of the bioprosthesis.

29. Withdraw the catheter to the aorta, while maintaining guidewire position.

Note: For transfemoral access, withdraw the catheter until the catheter tip is

positioned in the descending aorta. For direct aortic access and subclavian access,

withdraw the catheter until the catheter tip is close to the distal tip of the introducer

sheath.

30. Close the capsule and remove the catheter through the 18 Fr introducer sheath.

Note: If the capsule does not close properly, gently rotate the catheter clockwise

(<180°) and then counterclockwise (<180°) until the capsule closes.

Caution: Ensure the capsule is closed before catheter removal. If increased resistance

is encountered when removing the catheter through the introducer sheath, do not

force passage. Increased resistance may indicate a problem and forced passage may

result in damage to the device and/or harm to the patient. If the cause of resistance

cannot be determined or corrected, remove the catheter and introducer sheath as a

single unit over the guidewire, and inspect the catheter and confirm that it is

complete.

31. Dispose of the device in accordance with local regulations and hospital procedures.

32. Advance a 6 Fr pigtail catheter over the guidewire into the LV.

33. Remove the guidewire and connect the pigtail catheter to the transducer.

34. Using both pigtail catheters, record aortic pressure gradient.

35. Remove the 6 Fr pigtail over a standard, J-tip guidewire.

36. Perform a postimplant aortogram with the reference pigtail to ensure coronary

patency and assess aortic regurgitations.

Note: In the event that valve function or sealing is impaired due to excessive

calcification or incomplete expansion, a postimplant balloon dilatation of the

bioprosthesis may improve valve function and sealing. To ensure patient safety, valve

size and patient anatomy must be considered when selecting the size of the balloon

used for dilatation. The balloon size chosen for dilatation should not exceed the

diameter of the native aortic annulus or, for surgical bioprosthetic valves, the

manufacturer’s labeled inner diameter. Refer to the specific balloon catheter

manufacturer’s compliance chart to ensure that the applied inflation pressure does not

result in a balloon diameter that exceeds the indicated annulus range for the

bioprosthesis. Refer to the specific balloon catheter manufacturer’s labeling for

proper instruction on the use of balloon catheter devices. Note: Bench testing has only

been conducted to confirm compatibility with NuMED Z-MED II™ Balloon Aortic

Valvuloplasty catheters where CoreValve™ bioprosthesis device performance was

maintained after dilatation. Data on file.

30

Page 33

37. Remove the 18 Fr introducer sheath and complete the puncture site closure per

hospital protocol.

38. Perform contrast angiography to verify the absence of any vascular complications.

39. Remove the reference pigtail catheter over a standard guidewire. Remove the 6 Fr

introducer and close the access site per hospital protocol.

40. Administer anticoagulation and/or antiplatelet therapy as required according to

hospital protocol.

31

Page 34

10.0 Return of explanted bioprostheses

Medtronic is interested in obtaining recovered bioprostheses. Specific pathological studies of

the explanted bioprosthesis will be conducted under the direction of a consulting pathologist.

A written summary of the findings will be returned to the physician. To obtain a product

return kit, contact a Medtronic distribution center or a Medtronic Representative. If a kit is

not available, place the explanted bioprosthesis in a container of glutaraldehyde or 10%

buffered formalin immediately after excision. For further instructions on the return of an

explanted device, contact a Medtronic Representative.

32

Page 35

11.0 Summary of clinical study

The Medtronic CoreValve™ U.S. Pivotal Trial was designed and executed to evaluate the

safety and effectiveness of the CoreValve™ system to treat symptomatic severe aortic

stenosis in subjects necessitating aortic valve replacement. The trial was divided into

2 cohorts—patients who were determined by a heart team to be at high risk for surgery

(predicted operative mortality of ≥15% [and predicted operative mortality or serious,

irreversible morbidity risk of <50%]) or those who were determined to be at extreme risk for

surgery (irreversible morbidity risk of ≥50% at 30 days). Section 11.2 presents the results of

the High Risk cohort, and Section 11.3 presents the results of the Extreme Risk cohort.

The Medtronic CoreValve™ SURTAVI Trial was designed and executed to evaluate the

safety and efficacy of transcatheter aortic valve implantation (TAVR) in subjects with severe,

symptomatic aortic stenosis (AS) at intermediate surgical risk (heart team agreement of

predicted risk of operative mortality is ≥3% and <15% at 30 days) by randomizing subjects

to either surgical aortic valve replacement (SAVR) or TAVR. Section 11.1 presents the

results of the SURTAVI Trial.

11.1 Intermediate Risk trial (SURTAVI)

The Surgical Replacement and Transcatheter Aortic Valve Implantation (SURTAVI) trial is

a prospective, randomized, unblinded, multi-center investigational study. The purpose of this

trial is to investigate the safety and efficacy of transcatheter aortic valve implantation

(TAVR) in subjects with severe, symptomatic aortic stenosis (AS) at intermediate surgical

risk by randomizing subjects to either surgical aortic valve replacement (SAVR) or TAVR.

A total of 1746 subjects were randomized in this study (879 subjects were randomized to

TAVR and 867 subjects were randomized to surgical aortic valve replacement [SAVR]) at

87 activated centers. Severe aortic stenosis was defined as an aortic valve area of ≤0.8 cm2 or

aortic valve area index ≤0.5 cm2, a mean aortic valve gradient of >40 mmHg or jet velocity

>4 m/sec. The primary objective of the study was to demonstrate that the safety and

effectiveness of the Medtronic CoreValve™ system (TAVR), as measured by all-cause

mortality or disabling stroke at 24 months, is non-inferior to surgical aortic valve

replacement (SAVR) in the treatment of symptomatic severe aortic stenosis in subjects who

have a predicted intermediate risk for aortic valve surgery.

Of the 879 subjects randomized to TAVR, 864 received an attempted implant and comprise

the primary analysis cohort (the modified intention-to-treat [mITT] cohort) TAVR set, while

796 of the 867 randomized to SAVR received an attempted implant and comprise the mITT

SAVR cohort. The implanted population (863 TAVR and 794 SAVR) consists of all subjects

who were implanted with a valve. Of the 863 subjects in the Implanted TAVR group, 724

were attempted with the CoreValve™ system, 139 with the CoreValve™ Evolut™ R system.

The following data summarize the results from the SURTAVI trial.

11.1.1 Patient population

The demographics of the study population are shown in Table 3. The treatment arms were

generally well balanced (i.e., no statistically significant differences were identified between

the treatment arms) with respect to age, gender, baseline NYHA classification, and aggregate

33

Page 36

Age (years)

79.9 ± 6.2 (864)

79.7 ± 6.1 (796)

(-0.37, 0.81)

Male

57.6% (498/864)

55.0% (438/796)

(-2.15%, 7.37%)

NYHA Class

II

39.8% (344/864)

41.8% (333/796)

(-6.71%, 2.72%)

III

54.6% (472/864)

51.6% (411/796)

(-1.80%, 7.78%)

IV

5.6% (48/864)

6.5% (52/796)

(-3.30%, 1.31%)

STS Score (risk of

mortality, %)

Logistic EuroScore (%)

11.9 ± 7.6 (864)

11.6 ± 8.0 (795)

(-0.44, 1.06)

Coronary artery disease

62.6% (541/864)

64.2% (511/796)

(-6.20%, 3.05%)

Previous MI

14.5% (125/864)

13.9% (111/796)

(-2.84%, 3.88%)

Previous reintervention

Coronary artery bypass

surgery

Percutaneous coronary

intervention

Cerebrovascular disease

17.5% (151/864)

16.3% (130/796)

(-2.47%, 4.73%)

Peripheral vascular

disease

Prior stroke

6.6% (57/864)

7.2% (57/796)

(-3.04%, 1.87%)

Chronic lung

disease/COPD

Home oxygen

2.1% (18/864)

2.6% (21/795)

(-2.09%, 0.92%)

Creatinine level >2 mg/dl

1.6% (14/864)

2.1% (17/796)

(-1.90%, 0.81%)

Atrial fibrillation/atrial

flutter

Permanent pacemaker

implantation

History of hypertension

92.7% (801/864)

90.3% (719/796)

(-0.30%, 5.10%)

Cirrhosis of the liver

0.5% (4/863)

0.6% (5/795)

(-0.99%, 0.60%)

Echocardiographic findings—Implanted Population

Effective orifice area

(cm2)

Mean gradient (mmHg)

47.2 ± 14.3 (856)

47.8 ± 13.8 (786)

(-2.03, 0.70)

1

Continuous measures - Mean ± SD (Total no.); categorical measures - % (no./Total no.)

BCI: Bayesian credible interval

indicators of surgical risk (STS score and EuroSCORE). Most the subjects were in NYHA

class II and III.

Table 3: Subject Demographics and Clinical Characteristics – mITT Set

Demographics and

Baseline

Characteristics

Summary Statistics1

Difference

TAVR SAVR

(TAVR – SAVR)

(95% BCI)2

4.4 ± 1.5 (864) 4.5 ± 1.6 (796) (-0.28, 0.03)

16.0% (138/864) 17.2% (137/796) (-4.83%, 2.34%)

21.3% (184/864) 21.2% (169/796) (-3.88%, 3.99%)

30.8% (266/864) 29.9% (238/796) (-3.54%, 5.29%)

35.4% (305/862) 33.5% (267/796) (-2.74%, 6.39%)

28.1% (243/864) 26.5% (211/796) (-2.68%, 5.89%)

9.7% (84/864) 9.0% (72/796) (-2.14%, 3.47%)

0.8 ± 0.2 (790) 0.8 ± 0.2 (727) (-0.01, 0.03)

2

34

Page 37

Number of Index Procedures

863

Total delivery catheter in the body time (min)

15.0 ± 15.9

Type of Anesthesia

General

75.7% (653/863)

Conscious Sedation

24.3% (210/863)

Respiratory Support Required

69.8% (602/863)

Access Site

Femoral

93.2% (804/863)

Percutaneous

81.3% (654/804)

Surgical cut-down

18.7% (150/804)

Iliac

0.5% (4/863)

Percutaneous

75.0% (3/4)

Surgical cut-down

25.0% (1/4)

Subclavian axillary

2.3% (20/863)

Direct Aortic

4.1% (35/863)

Other

0.0% (0/863)

Total Time in Cath Lab or OR (min)

190.8 ± 61.3

Total Procedure Time (min)

52.3 ± 32.7

Pre-TAVR balloon valvuloplasty performed

47.2% (407/863)

Post-TAVR balloon valvuloplasty performed

29.0% (250/863)

1

Continuous measures - Mean ± SD; categorical measures - % (no./Total no.). Data include subjects with the

index procedure defined as the first procedure that the delivery catheter is introduced.

11.1.2 Procedure data

As shown in Table 4, total time the delivery catheter was in the body was approximately

15 minutes. A majority of TAVR subjects were administered general anesthesia while the

remaining subjects underwent the procedure with conscious sedation. A substantial majority

of the subjects (greater than 90%) has the valve delivered via iliofemoral access and

percutaneous access was more common than surgical cut-down. Balloon predilatation was

performed in approximately half of the subjects and postdilatation was performed in

approximately 30%.

Table 4: Procedural Data Summary for TAVR Subjects – mITT Set

Summary Statistics1

Assessment

N=864

11.1.3 Safety and effectiveness results

11.1.3.1 Primary safety and effectiveness endpoint

The primary objective was to demonstrate that the safety and effectiveness of TAVR using

the Medtronic CoreValve™ and CoreValve™ Evolut™ R systems, as measured by the allcause mortality or disabling stroke rate during a fixed follow-up of 24 months, is non-inferior

to SAVR in the treatment of symptomatic severe aortic stenosis in subjects who were

determined by the heart team to be at intermediate surgical risk.

The “early win” assessment of the primary endpoint included all subjects in the mITT

population (N = 1660). The median of the posterior distribution for the primary endpoint

35

Page 38

Posterior Median (95% BCI)

12.6% (10.2%, 15.3%)

14.0% (11.4%, 17.0%)

Difference (TAVR-SAVR) Posterior

Median (95% BCI)

Primary Objective – Non-Inferiority

Posterior Probability

,.

data

> 0.9999

Posterior Threshold for Non-Inferiority

0.971

Non-inferiority test

Passed

event rate was 12.6% for the TAVR arm and 14.0% for the SAVR arm, with a median of the

posterior distribution of the difference in the primary endpoint event rate (TAVR – SAVR) of

-1.4% and a 95% Bayesian credible interval (BCI) of (-5.2%, 2.3%), as summarized in

Table 5. The posterior probability of non-inferiority with a margin of 7% was > 0.9999,

which is greater than the pre-specified threshold of 0.971, thus the primary endpoint noninferiority could be concluded.

Table 5: Primary Endpoint: All-Cause Mortality or Disabling Stroke at 24 Months -

mITT Set

TAVR

N=864

-1.4% (-5.2%, 2.3%)

SAVR

N=796

Figure 33 shows K-M rates of all-cause mortality or disabling stroke in the mITT set for both

treatment arms up to 24 months follow-up.

36

Page 39

Figure 33: Primary Endpoint: All-Cause Mortality or Disabling Stroke Kaplan-Meier

Event Rate – mITT Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion.

11.1.3.2 Key secondary safety and effectiveness endpoints

Hierarchical testing of secondary endpoints

Hypothesis testing was performed on pre-specified secondary endpoints using a hierarchical

test procedure, as shown in Table 6. TAVR was found to be non-inferior to SAVR within the

pre-specified non-inferiority margins in terms of mean gradient and EOA at 12 months, the

NYHA functional classification change from baseline to 12 months, and the KCCQ score

change from baseline to 30 days. TAVR was determined to be superior to SAVR with respect

to length of index procedure hospital stay, the mean pressure gradient at 12 months, EOA at

12 months, and the KCCQ score change from baseline to 30-days.

TAVR was not found to be superior to SAVR with respect to days alive and out of hospital at

12 months. The remaining secondary endpoints were not tested.

37

Page 40

#1 Mean

months

#2 EOA at 12

months

2.2 ± 0.6

(545)

1.8 ± 0.6

(455)

#3 NYHA

months)

#4 KCCQ

baseline)

#5 Length of

hospital stay

#6 Mean

months

#7 EOA at 12

months

2.2 ± 0.6

(545)

1.8 ± 0.6

(455)

#8 KCCQ

baseline)

Note: The Implanted population was used for the mean gradient and EOA, and the mITT population for the rest.

Table 6: Secondary Endpoints: Hierarchical Testing

Secondary

Endpoint

Non-inferiority testing

gradient at 12

change

(baseline – 12

summary

score change

(30 day –

Superiority testing

index

procedure

TAVR

Mean ±

SD (N)

8.3 ± 4.0

(590)

1.3 ± 0.8

(604)

18.4 ±

22.8

(819)

5.8 ± 4.9

(863)

SAVR

Mean ± SD

(N)

11.7 ± 5.6

(500)

1.3 ± 0.8

(508)

5.9 ± 27.0

(700)

9.8 ± 8.0

(795)

Difference

(TAVR-SAVR)

(95% BCI)

(-4.0, -2.8) 1.00 0.95 Passed

(0.3, 0.5) 1.00 0.95 Passed

(-0.1, 0.1) 1.00 0.95 Passed

(10.0, 15.1) 1.00 0.95 Passed

(-4.7, -3.4) 1.00 0.975 Passed

Posterior

Probability

Pr(HA | data)

Threshold

Test

Result

gradient at 12

summary

score change

(30 day –

8.3 ± 4.0

(590)

18.4 ±

22.8

(819)

11.7 ± 5.6

(500)

5.9 ± 27.0

(700)

(-4.0, -2.8) 1.00 0.975 Passed

(0.3, 0.5) 1.00 0.975 Passed

(10.0, 15.1) 1.00 0.975 Passed

11.1.3.3 Additional effectiveness data

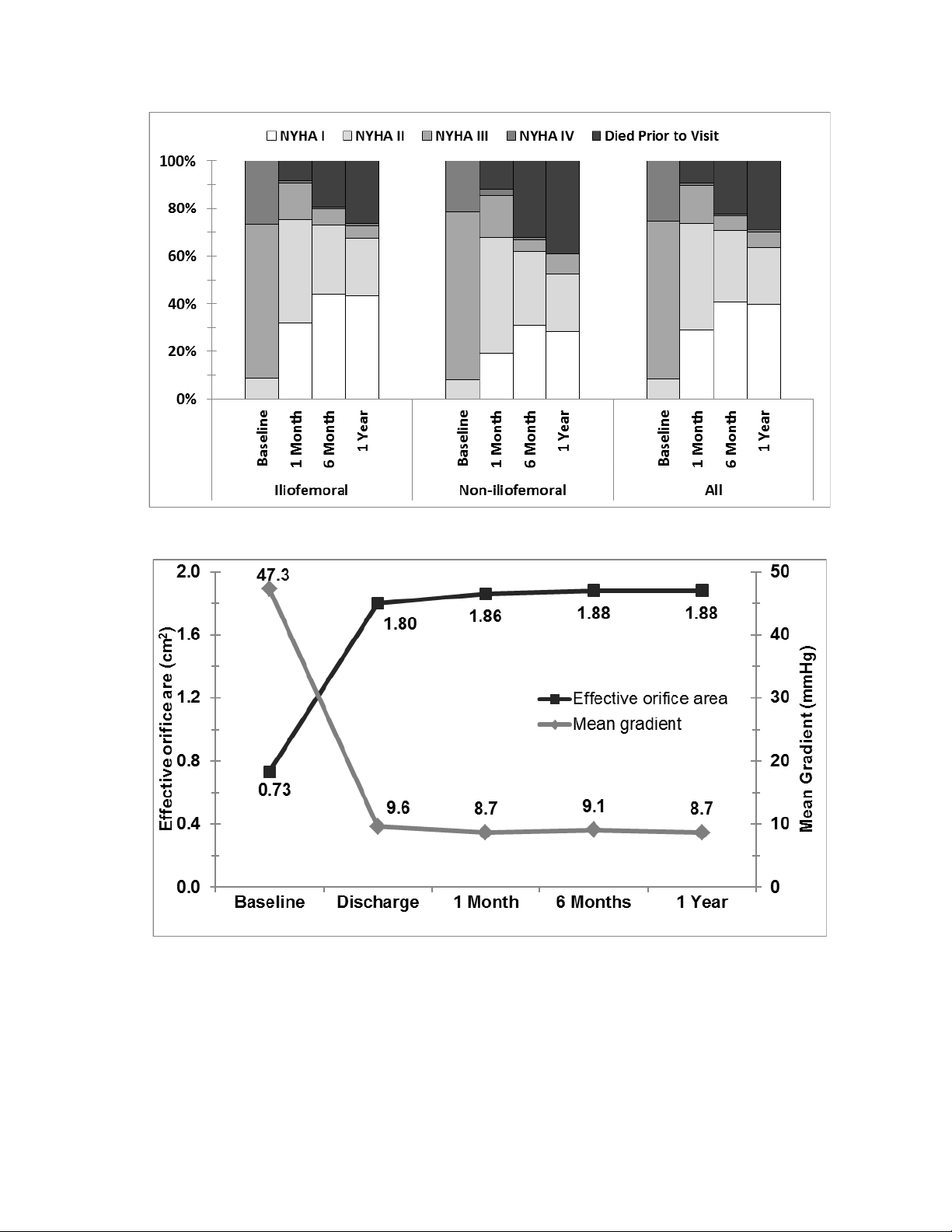

Valve performance

Effective orifice area (EOA) and mean gradient for TAVR and SAVR subjects are shown in

Figure 34 and Figure 35.

38

Page 41

Figure 34: TAVR and SAVR EOA by Visit (Implanted Population)

Note: Line plot with mean and standard deviation.

Figure 35: TAVR and SAVR Mean Gradient by Visit (Implanted Population)

Note: Line plot with mean and standard deviation.

Figure 36 shows total aortic regurgitation (AR) severity over time for both treatment arms.

Figure 37 shows paravalvular aortic regurgitation.

39

Page 42

Figure 36: TAVR and SAVR Total Aortic Regurgitation by Visit (Implanted Population)

Note: Values < 1.0% are not labeled.

Figure 37: Paravalvular Aortic Regurgitation by Visit (Implanted Population)

Note: Values < 1.0% are not labeled.

40

Page 43

NYHA functional class

NYHA functional classification was evaluated for subjects at each interval for the TAVR and

SAVR treatment arms. NYHA classification data for subjects at each interval are shown in

Figure 38.

Figure 38: TAVR and SAVR NYHA Classification by Visit (mITT Population)

Note: Values < 1.0% are not labeled.

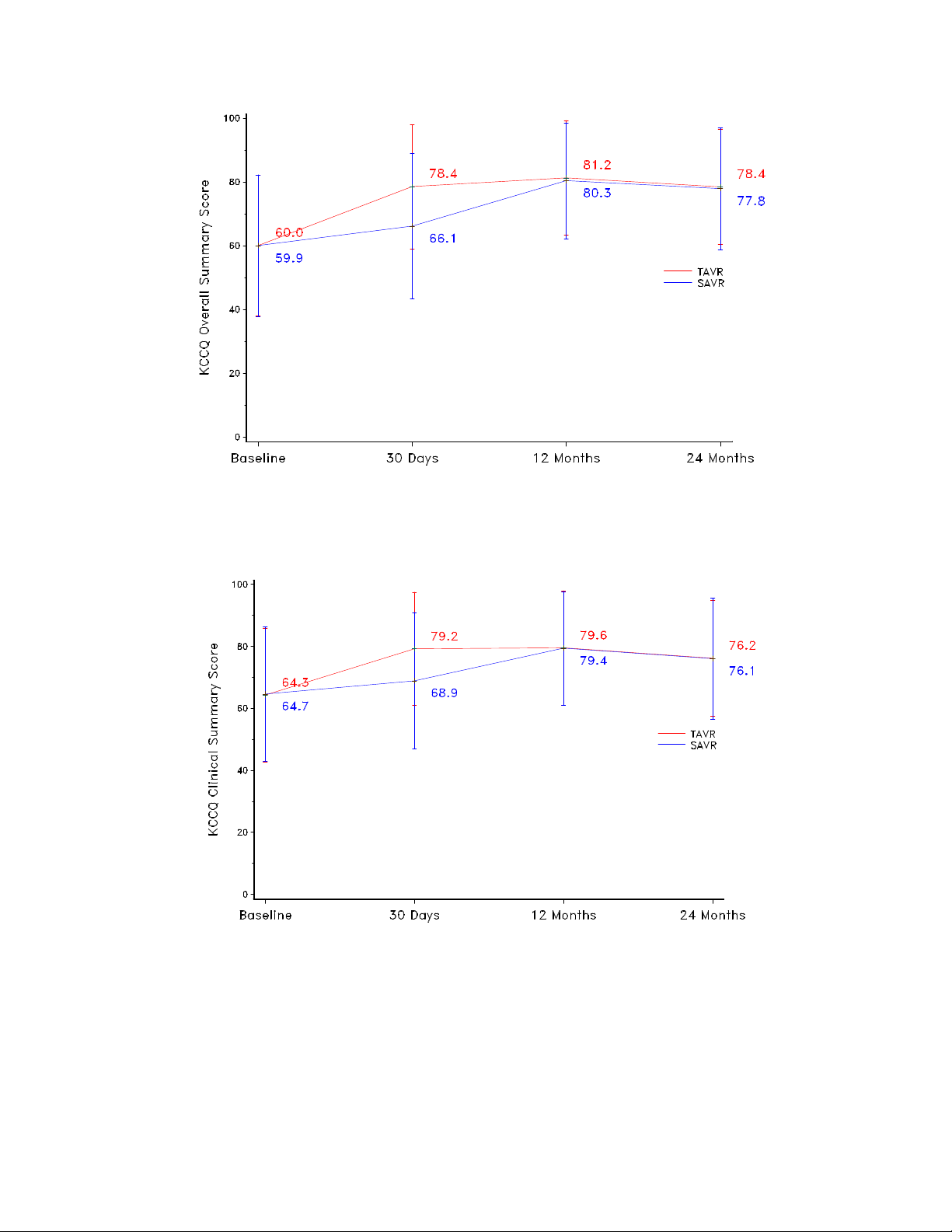

Health status/QoL change

QoL was measured using the Kansas City Cardiomyopathy Questionnaire (KCCQ), the SF36 Health Status Questionnaire, and the EuroQoL (EQ-5D) measure.

The KCCQ overall and clinical summary scores for the two treatment arms are shown in

Figure 39 and Figure 40, respectively.

41

Page 44

Figure 39: KCCQ Overall Summary Scores

Note: Line plot with mean and standard deviation.

Figure 40: KCCQ Clinical Summary Scores

Note: Line plot with mean and standard deviation.

The SF-36 physical and mental component summary scores for the two treatment arms are

shown in Figure 41 and Figure 42, respectively.

42

Page 45

Figure 41: SF-36 Physical Component Summary Scores

Note: Line plot with mean and standard deviation.

Figure 42: SF-36 Mental Component Summary Scores

Note: Line plot with mean and standard deviation.

The EQ-5D index scores for the two treatment arms are shown in Figure 43.

43

Page 46

2.8%

29)

3.8%

8.1%

8.7%

12.3%

13.8%

101)

2.1%

18)

1.6%

6.8%

6.9%

11.2%

11.5%

2.0%

17)

1.6%

4.8%

5.5%

7.5%

7.8%

0.0%

(0, 0)

0.0%

(0, 0)

0.0%

(0, 0)

0.1%

(1, 1)

0.0%

(0, 0)

0.1%

(1, 1)

Non-cardiovascular

0.1%

0.0%

2.1%

1.4%

4.0%

4.0%

Figure 43: EQ5D Index Scores

Note: Line plot with mean and standard deviation.

11.1.3.4 Additional safety data

Adverse events that occurred in the PMA clinical study

Procedural safety and safety during follow-up were evaluated for both TAVR and SAVR

within the SURTAVI trial. Kaplan-Meier (K-M) rates of some key CEC-adjudicated events

are presented in Table 7.

Table 7: All Adverse Events (0-24 Months) -mITT Set

Events Summary Statistics1

0-30 Days 0-12 Months 0-24 Months

TAVR SAVR TAVR SAVR TAVR SAVR

All-cause mortality or

disabling stroke

All-cause mortality

(24,

(18,

(30, 33)

(13, 13)

(66, 74)

(55, 55)

(66, 79)

(51, 51)

(87, 97)

(77, 77)

(87,

(70, 70)

Cardiovascular

Valve-related2

(17,

(13, 13)

44

(39, 39)

(41, 41)

(52, 52)

(51, 51)

Page 47

(1, 1)

(0, 0)

(16, 16)

(10, 10)

(25, 25)

(19, 19)

0.8%

(7, 7)

0.1%

(1, 1)

2.1%

(17, 19)

0.4%

(3, 3)

2.6%

(20, 22)

0.4%

(3, 3)

3.3%

29)

5.4%

5.3%

6.7%

6.3%

8.0%

1.2%

11)

2.4%

2.2%

3.4%

2.4%

4.1%

2.1%

18)

3.0%

3.1%

3.3%

4.1%

4.0%

5.7%

51)

5.9%

7.1%

7.8%

8.0%

8.4%

5.9%

55)

1.0%

6.3%

1.0%

6.3%

1.0%

Acute kidney injury - Stage

3

0.7%

(6, 6)

1.3%

(10, 10)

0.7%

(6, 6)

1.3%

(10, 10)

0.7%

(6, 6)

1.3%

(10, 10)

0.8%

(7, 7)

0.9%

(7, 7)

1.9%

(15, 15)

1.4%

(11, 11)

2.6%

(18, 18)

1.9%

(13, 13)

2.8%

26)

4.1%

8.4%

7.4%

13.2%

9.0%

28.1%

217)

6.8%

31.3%

9.0%

34.6%

10.3%

25.6%

220)

6.5%

28.5%

8.6%

31.5%

9.8%

1

Kaplan-Meier rate (# patients, # events).

Subjects with pacemaker or ICD at baseline are included. Not adjudicated by CEC.

Events Summary Statistics1

Reintervention

0-30 Days 0-12 Months 0-24 Months

TAVR SAVR TAVR SAVR TAVR SAVR

All stroke

Disabling stroke

Non-disabling stroke

Life threatening/disabling

bleeding

Major vascular

complication

MI

Aortic valve hospitalization

Permanent pacemaker

implantation3

(28,

(10,

(18,

(49,

(51,

(24,

(217,

(43, 45)

(19, 20)

(24, 25)

(47, 47)

(8, 8)

(32, 34)

(48, 48)

(44, 45)

(18, 19)

(26, 26)

(60, 66)

(54, 59)

(68, 104)

(239, 241)

(52, 55)

(26, 28)

(26, 27)

(60, 61)

(8, 8)

(55, 68)

(62, 64)

(48, 50)

(19, 20)

(30, 30)

(64, 72)

(54, 59)

(90, 134)

(253, 257)

(58, 61)

(29, 31)

(29, 30)

(63, 65)

(8, 8)

(62, 85)

(67, 70)

Permanent pacemaker

implantation4

2

Valve-related death is any death caused by structural or non-structural valve dysfunction or aortic valve

re-intervention.

3

Subjects with pacemaker or ICD at baseline are not included. Not adjudicated by CEC.

4

(220,

(51, 51)

(242, 244)

11.1.4 Additional study observations

11.1.4.1 Pre-specified analyses

The primary endpoint was examined for treatment arm differences in outcome between the

stratified randomization designation (revascularization or no revascularization) and gender.

45

(66, 68)

(256, 260)

(71, 74)

Page 48

All-cause mortality or disabling stroke stratified by need for revascularization

– mITT set

Figure 44 and Figure 45 present the all-cause mortality or disabling stroke analysis stratified

by need for coronary revascularization for the mITT set.

Figure 44: All-Cause Mortality or Disabling Stroke for Subjects with Need for

Revascularization – mITT Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference between the two subgroups.

46

Page 49

Figure 45: All-Cause Mortality or Disabling Stroke for Subjects without Need for

Revascularization – mITT Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference between the two subgroups.

All-cause mortality or disabling stroke analyzed by gender – mITT set

Figure 46 and Figure 47 present all-cause mortality or disabling stroke analyzed by gender

for the mITT set.

47

Page 50

Figure 46: All-Cause Mortality or Disabling Stroke at 24 Months for Male Subjects -

mITT Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference between the two subgroups.

48

Page 51

Figure 47: All-Cause Mortality or Disabling Stroke at 24 Months for Female Subjects –

mITT Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference between the two subgroups.

11.1.4.2 All-cause mortality by severity of aortic regurgitation

A sub-group analysis was performed to investigate the relationship between all-cause

mortality and severity of aortic regurgitation at discharge. Two sub-groups of subjects with

none/trace and mild/moderate/severe total AR as assessed at discharge were analyzed.

The results from the analysis with 2 subgroups are shown for the TAVR treatment arm in

Figure 48.

49

Page 52

Figure 48: All-Cause Mortality by Severity of Aortic Regurgitation (2 Groups) – TAVR

Implanted Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference between the two subgroups.

11.1.4.3 All-cause mortality by conduction disturbance requiring a permanent pacemaker post-TAVR

An analysis was performed for implanted TAVR subjects to investigate the relationship

between all-cause mortality and permanent pacemaker implantation (PPI) through 30 days

post TAVR (Figure 49). Similar rates between subjects without a PPI and subjects with a

new PPI indicate that new-onset conduction disturbance and resultant PPI was not

significantly associated with mortality in this study.

50

Page 53

Figure 49: All-Cause Mortality by New Permanent Pacemaker – TAVR Implanted Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference among the three subgroups.

All-cause mortality by patient prosthesis mismatch

The site reported aortic annular perimeters were comparable between the two treatment arms

(TAVR: 78.3 ± 7.2 mm vs. SAVR: 78.4 ± 7.1 mm). Patient prosthesis mismatch (PPM) is

defined as an indexed EOA of 0.85-0.65 cm2/m2 (moderate) and <0.65 cm2/m2 (severe) for

subjects with a BMI <30 kg/cm2, or 0.70-0.60 cm2/m2 (moderate) and <0.60 cm2/m2 (severe)

for subjects with a BMI ≥30 kg/cm2. Figure 50 and Figure 51 present the prevalence of PPM

at 12 months in the two treatment arms by valve size. The majority of SAVR patients

received a labeled valve size of ≤23 mm, and smaller valve sizes generally had more

prevalent PPM. In comparison, PPM was less prevalent in the TAVR arm.

The K-M curves for all-cause mortality by PPM grade (none, moderate, and severe) are

shown in Figure 52 and Figure 53 for the TAVR and SAVR arm, respectively.

51

Page 54

Figure 50: Prevalence of PPM at 12 Months in the TAVR Arm by Valve Size

Figure 51: Prevalence of PPM at 12 Months in the SAVR Arm by Valve Size

52

Page 55

Figure 52: All-Cause Mortality by PPM - TAVR Implanted Population

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference among the three subgroups.

53

Page 56

Figure 53: All-Cause Mortality by PPM - SAVR Implanted Set

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical

conclusion. The trial was not powered to assess the difference among the three subgroups.

54

Page 57

11.2 High Risk cohort

The CoreValve™ U.S. Pivotal Trial High Risk cohort was a prospective, randomized,

unblinded, multi-center investigational study. Patients were stratified by intended access site

(iliofemoral or non-iliofemoral) prior to randomization to ensure patients were allocated to

each comparison group proportionately. Prior to randomization, patients were first evaluated

for iliofemoral access. If patients were not eligible for iliofemoral access due to their

inadequate vasculature or peripheral vascular disease, they were then considered for noniliofemoral access. Patients were then individually evaluated for subclavian or direct aortic

access.

The purpose of the study was to evaluate the safety and effectiveness of the Medtronic