Page 1

Part Number M708348B092 Rev C 2017-01

KYPHON® ActivOs™ 10

Bone Cement with Hydroxyapatite

Instructions for use

Distributed by:

Medtronic Sofamor Danek USA, Inc.

1800 Pyramid Place

Menphis, TN 38132

Tel: 800 933 2635 ( In USA)

Tel: 901 396 3133 ( Outside of USA)

Fax: 901 396 0356

Manufactured in France by :

TEKNIMED S.A.S

8, rue du Corps Franc-Pommiès

65500 VIC EN BIGORRE - FRANCE

Tél. (33)5 62 96 88 38

Fax (33)5 62 96 28 72

www.teknimed.com

CAUTION: U.S. federal law restricts this device to sale by or on the order of a

physician (or properly licensed practitioner) or on the physician's prescription.

Before using this product, the operator must be thoroughly familiarized with the

directions for use, as well as the information relating to the product (description,

operating technique, brochure, etc.). The corresponding information can be

obtained from Medtronic. The operator should also be informed of the residual risk

of this product.

Implantation of KYPHON

carried out by qualified operators with in-depth knowledge and perfect command of the

specific operating techniques of Medtronic products. The operating techniques can be

acquired from the distributors.

The surgeon is responsible for any complications or harmful consequences which may

arise due to an incorrect indication or operating technique, improper use of the material

and failure to observe the safety regulations provided in the directions for use. These

complications cannot be imputed either to the manufacturer or Medtronic.

IN NO EVENT SHALL MEDTRONIC BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, CONSEQUENTIAL, OR EXEMPLARY DAMAGES ARISING OUT OF OR IN

CONNECTION WITH KYPHON® ACTIVOS™ 10 BONE CEMENT WITH

HYDROXYAPATITE, BASED UPON BREACH OF CONTRACT (INCLUDING BREACH OF

WARRANTY).

This product is a fast-setting acrylic cement for kyphoplasty and vertebroplasty procedures.

It is available in the form of an ampoule of sterile liquid and a packet of sterile powder

(liquid monomer and powder polymer).

Powder:

Polymethylmethacrylate 64.4%

Benzoyl peroxide 0.6%

Barium sulfate 25.0%

Hydroxyapatite 10.0%

Liquid:

Methyl Methacrylate 97.6%

N-N dimethyl-p-toluidine 2.4%

Hydroquinone 20 ppm

INSTRUCTIONS FOR THE PREPARATION AND CLINICAL USE OF KYPHON

Timing for the Preparation and Application of KYPHON® ActivOs™ 10 Bone Cement

The handling characteristics of bone cements are affected by operating room conditions,

including the room temperature, temperature of the cement components prior to mixing,

humidity, the geometry of the mixing apparatus, time spent mixing, and the geometry of

the delivery device. Any change in one or more of these conditions can alter the

handling characteristics of the bone cement, including the following:

- handling period - the time it takes for the bone cement to reach the doughy state (the

cement has reached the doughy state when it no longer sticks to surgical gloves)

- working period - the time the bone cement remains in the doughy state and can be

delivered

- hardening period - the time it takes for the bone cement to harden or until it can no

longer be delivered

Under specific conditions in our laboratory, KYPHON

Hydroxyapatite had a mixing and handling period of 8 minutes at a room temperature of

23°C. The bone cement remained in the doughy state for the next 11 minutes at 23°C,

to allow sufficient time for careful, minimally-invasive surgical introduction.

Lower temperatures or other changes in operating room conditions can increase the

handling, doughy (working) and hardening periods. Conversely, higher temperatures or

other changes in operating room conditions can decrease the handling, doughy (working)

and hardening periods.

Handling Characteristics of KYPHON

Hydroxyapatite at 23°C in our Laboratory

Period

Mixing

Handling

Working (doughy state)

Hardening

Note: These cumulative time periods will vary depending on temperature and other

factors. For example, the colder the environment, the longer the time necessary for

the cement to develop the required doughy consistency. Warmer temperatures

require more rapid preparation and handling. (see Figure 1) Ensure the cement's

viscosity is high enough (doughy) before delivery begins. The cement has reached

the doughy state when it no longer sticks to surgical gloves.

* These times are based on cement prepared by Medtronic. Times were obtained

from bone cement mixed in a KYPHON® Mixer and delivered through a KYPHON®

Bone Filler Device (Size 3, inner diameter = 0.114"). Times may vary when other

mixing methods, delivery devices and/or vacuum are used.

ACTIVOS™ 10 BONE CEMENT WITH HYDROXYAPATITE

GENERAL INFORMATION

®

ActivOs™ 10 Bone Cement with Hydroxyapatite should only be

COMPOSITION

®

with Hydroxyapatite

®

ActivOs™ 10 Bone Cement with

®

ActivOs™ 10 Bone Cement with

Approximate Cumulative

Activity

Mix liquid and powder

Transfer into delivery system

Fill cavity in vertebral body

Wait before completing procedure

Time

From Initiation of Mixing

Through a KYPHON

Filler Device*

45 seconds - 8 minutes

®

Bone

0 - 45 seconds

8 - 19 minutes

19 - 21 minutes

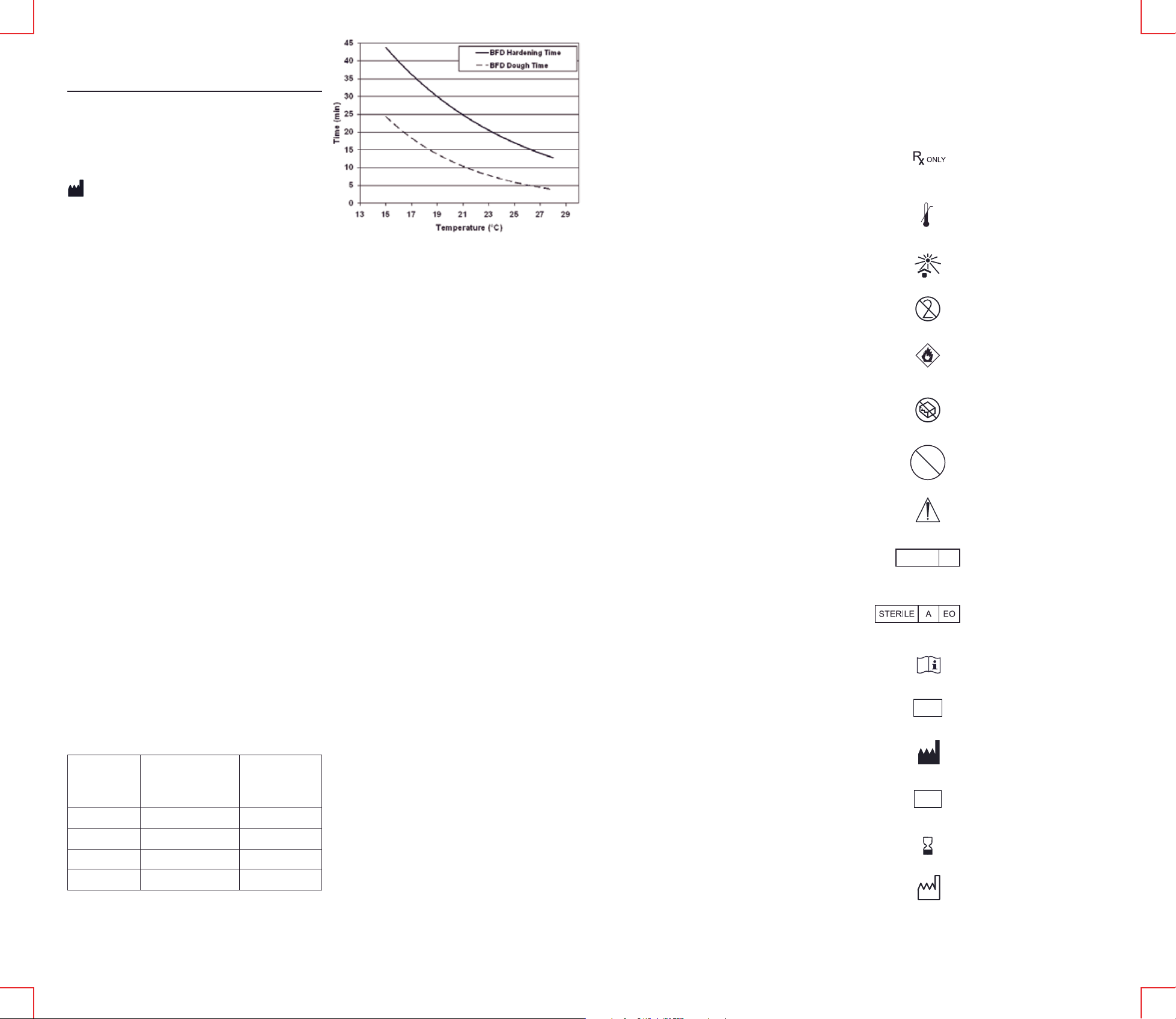

Figure 1. The effect of room temperature on the handling characteristics of KYPHON®

ActivOs™ 10 Bone Cement with Hydroxyapatite is shown in the above time vs.

temperature graph. At room temperatures of 15°C, 19°C, 23°C, and 28°C, units of

®

ActivOs™ 10 Bone Cement with Hydroxyapatite were mixed in a KYPHON®

KYPHON

Mixer and transferred to KYPHON

hardening time out of the BFD were measured, and exponential curves were fitted to

these data. The dashed curve represents BFD dough time (when cement dispensed out

of a BFD no longer sticks to a surgical glove) and the solid curve represents BFD

hardening time (when cement is too hard to dispense out of a BFD).

Preparation Procedures

- Per the note above, temperature can affect the handling of the cement. Prior to use, it

is advised to keep the product at a temperature of 23 ± 1°C for a period of 24 hours.

- Prior to use, KYPHON

should be examined for damage and the presence of all required components.

- Maintain aseptic transfer surgical technique to prevent possible infection.

- Maintain strict adherence to the instructions for mixing the powder and liquid to prevent

possible dermatitis from the liquid monomer during handling.

- Assure that the inner package is undamaged, that the powder is not discolored (yellow

or brown) and the liquid is not syrupy. These conditions indicate that the product has

not been stored correctly.

- Assure that the preparation accessories are specifically compatible with the bone

cement product.

- Do not open the vial of liquid over the mixing bowl to avoid the risk of glass fragments

entering the dough.

- Never add other substances or foreign bodies to the acrylic resin. Never modify the

ratios between the liquid and solid components.

- Care should be taken in the mixing of the liquid and powder components such that the

entire contents of the vial and packet are utilized. The liquid monomer and the powder

component should be thoroughly mixed.

- The length of phases of application depends on room temperature and that of

components, but also on the degree of hygrometry in the operating room. A high

temperature reduces hardening time. A low temperature extends this time.

- Read instructions carefully prior to use.

- The operator should have specific training and experience to be thoroughly familiar with

the properties, handing characteristics, application of the product and percutaneous

cement delivery.

- Follow cement handling, mixing and preparation instructions carefully.

- It is strictly forbidden to re-sterilize products. Single use only. Sterile only if package

is unopened and undamaged.

- Monitor patients carefully for any change in blood pressure during and immediately

following the application of bone cement. Adverse patient reactions affecting the

cardiovascular system, including Bone Cement Implantation Syndrome (BCIS), have been

associated with the use of bone cements. Hypotensive reactions have occurred between

10 and 165 seconds following application of bone cement; they have lasted from 30

seconds to 5 or more minutes. Some have progressed to cardiac arrest. Patients should

be monitored carefully for any change in blood pressure during and immediately

following the application of bone cement, especially those potentially at increased risk for

peri-operative death, including elderly patients, patients with underlying cardiac or

pulmonary compromise, and patients being treated for multiple vertebral body fractures in

one procedure.

- Methyl methacrylate may cause hypersensitivity among high-risk persons, which can

result in an anaphylactic reaction.

- Due to insufficient data, the safety of this cement has not been established with regard

to pregnant women and children.

- The addition of HA has not been shown to provide any improved clinical results.

- We do not recommend using these products on patients that do not suffer from

pathological condition, such as primary or secondary osteoporosis or a tumor. This

could impair the ability of the patient to recover using conservative treatment methods.

- Established surgical principles and techniques must be strictly observed. Deep wound

infection is a serious postoperative complication that may require complete removal of

the bone cement. Deep wound infection may be latent and may not become apparent

until several years after the operation.

- Caution should be exercised to prevent excessive exposure to the concentrated fumes

of the monomer, which may irritate the respiratory tract, eyes and even the liver.

- Always check the condition of the liquid before carrying out the procedure. Do not use

the liquid component if it shows any sign of thickening or premature polymerization.

- Do not allow the liquid component to come into contact with rubber or latex gloves.

The liquid component is a powerful lipid solvent. Should contact occur, the gloves

might dissolve, causing tissue damage. Wearing two pairs of gloves may reduce the

possibility of hypersensitivity reactions.

- Do not allow personnel wearing contact lenses to be near or involved in mixing of the

bone cement.

- Use appropriate imaging techniques to verify that the instruments are correctly

positioned, that no damage has been caused to surrounding structures, and that the

injected bone cement has been correctly located. Use an imaging technique, such as

fluoroscopy, to assess the capacity of the vertebra to contain the injected bone cement.

- Avoid over-pressurizing the bone cement, as this may cause the bone cement to leak

beyond the site of its intended application. Cement leakage may cause tissue damage,

and nerve or circulatory problems, and other serious adverse events.

- Leaks may also occur during the injection if the instruments are in a vein or if there

are undetected micro-fractures.

- If bone cement is detected outside the vertebral body or in the circulatory system

during the procedures, stop the injection immediately.

- Inadequate fixation or unanticipated postoperative events may affect the cement / bone

interface and may lead to micromotion between the cement and bone surface. A layer

of fibrous tissue may then develop between the cement and the bone, and loosening of

the bone cement may occur leading to failure. Long-term regular supervision is

therefore recommended for all patients.

- The final polymerization stage occurs in situ and is an exothermic reaction with

considerable liberation of heat. According to ISO 5833 standard, the temperature can

reach 95°C. The released heat may damage bone or other tissues surrounding the

implant. Maintain patient's position until the polymerization process has been completed,

so as to obtain proper fixation. An additional 1 to 2 hours or more may be necessary,

depending on the patient's medical condition and the operator.

- The long term effects of the bone cement in the spine have not been established.

- Difficulty in swallowing and blistering of the throat, alleged to be an allergic reaction to

the use of bone cement, have also been reported.

- DO NOT mix more than one vial of liquid and one packet of powder together at any

one time. Never modify the ratios between the liquid and solid components. Doing so

could affect bone cement properties, including handling characteristics.

- Modifying the polymerization time by either warming or cooling the bone cement and/or

associated delivery devices has not been tested and could affect bone cement

properties, including handling characteristics.

®

Bone Filler Devices (BFD, size 3). Dough time and

®

ActivOs™ 10 Bone Cement with Hydroxyapatite packaging

WARNINGS

- Only physicians thoroughly trained in the surgical use of bone cement and balloon

kyphoplasty should use KYPHON® ActivOs™ 10 Bone Cement with Hydroxyapatite. The

operator should have specific training and be familiar with the properties, handling

characteristics, and application of the bone cement and adhere to the instructions for use.

- Adverse events may occur whenever you fail to comply with the instruction leaflet.

- The handling characteristics of bone cements are affected by operating room conditions,

including the room temperature, temperature of the cement components prior to mixing,

humidity, the geometry of the mixing apparatus, time spent mixing, and the geometry of

the delivery device. Any change in one or more of these conditions can alter the

handling characteristics of the bone cement, including the following:

- handling period - the time it takes for the bone cement to reach the doughy state

(the cement has reached the doughy state when it no longer sticks to surgical gloves)

- working period - the time the bone cement remains in the doughy state and can be delivered

- hardening period - the time it takes for the bone cement to harden or until it can no

longer be delivered

- During the application of KYPHON® ActivOs™ 10 Bone Cement with Hydroxyapatite,

radiological control is essential so that the operator can follow the progress of the filling

and stop the procedure if the slightest leakage of cement is detected.

- A thorough preoperative check-up of the patient must be carried out prior to the operation.

- Make sure the operating room is properly ventilated to eliminate monomer fumes as

much as possible. The monomer is a volatile and flammable liquid. Ignition of

monomer fumes caused by the use of electrocautery devices in surgical sites near

freshly implanted bone cement has been reported.

- The insertion of a foreign body into the tissues increases the normal risk of infection

associated with surgery during the postoperative period.

KYPHON® ActivOs™ 10 Bone Cement with Hydroxyapatite is indicated for the fixation of

pathological fractures of the vertebral body using vertebroplasty or kyphoplasty procedures.

Painful vertebral compression fractures of the vertebral body may result from osteoporosis,

benign lesions (hemangioma), or malignant lesions (metastatic cancers, myeloma).

- Cases of active or incompletely treated infection

- Coagulation disorders, or severe cardiopulmonary disease

- Spinal stenosis (>20% by retropulsed fragments)

- Compromised of the vertebral fractures due to posterior involvement

- Non-pathological, acute traumatic fractures of the vertebra

- Vertebral plana (collapse>90%)

- Compromise of the vertebral body or the walls of the pedicles

- Unstable vertebral fractures due to posterior involvement

- Hypersensitivity to one of the constituents of the product.

Serious adverse events, some with fatal outcome, associated with the use of acrylic bone

cements include:

- cardiac arrest

- cerebrovascular accident

- myocardial infarction

- pulmonary embolism

- cardiac embolism

Although the majority of these adverse events present early within the post-operative

period, there have been some reports of diagnoses beyond a year or more after the

procedure.

Other reported adverse events relevant to the anatomy being treated with acrylic bone

cements for vertebroplasty and kyphoplasty include:

- Leakage of the bone cement beyond the site of its intended application with introduction

into the vascular system resulting in embolism of the lung and/or heart or other clinical

sequelae.

- deep or superficial wound infection

- fistula

- hematoma

- hemorrhage

- heterotopic new bone formation

- extravasation of bone cement potentially resulting in but not limited to:

- compression or irritation of nerve structures, such as the spinal cord or nerve roots,

causing radiculopathy, parasthesia, paraplegia or paralysis

- introduction into the vascular system resulting in embolism or other clinical sequelae

- intradiscal leakage

- pyrexia due to allergy to bone cement

- short-term conduction irregularities

- thrombophlebitis

- transitory fall in blood pressure

- migration of hardened bone cement bolus

Other reported adverse events include:

- pneumonia

- intercostal neuralgia,

- collapse of the vertebra adjacent to the one injected due to an osteoporotic disease

- pneumothorax

- fracture of a pedicle

- rib fracture in patients with diffuse osteopenia due to the significant downward force

exerted during needle insertion.

The liquid in the ampoule is sterilized by ultra-filtration, and the ampoule's blister pack is sterilized

using ethylene oxide. The powder in a double pouch is sterilized using gamma irradiation.

Before using, check the protective wrapping carefully to ensure that it has not suffered

any damage which could compromise its sterility.

When removing the product from its wrapping be sure to follow asepsis rules.

The cement is supplied sterile, ready for use in the operating room.

It is strictly forbidden to re-sterilize the product. Single use only.

Sterile only if package is unopened and undamaged.

Do not use after the expiry date.

- Percutaneous vertebroplasty or kyphoplasty procedures should only be performed in

medical settings in which emergency decompressive surgery is available.

- Adverse reactions affecting the cardiovascular system have been attributed to acrylic

cement. Recent data indicate that the monomer undergoes rapid hydrolysis into

methacrylic acid, and that a significant fraction of the circulating methacrylate is present

in the form of free acid rather than methyl ester. Correlation between changes in

circulating concentrations of methyl methacrylate/methacrylic acid and changes in blood

pressure has not been established.

- The doctor is responsible for any complication or harmful consequences, which may

result from an erroneous indication or operating technique, from inappropriate use of the

material (including re-use), or non-observation of the safety instructions that figure in the

directions for use.

- Additives (such as antibiotics) are not to be mixed with the bone cement, as this will

alter cement properties.

The patient should be informed by the doctor of the potential consequences of the factors

mentioned in the following paragraphs: contraindications and adverse events, that is,

those liable to hinder the success of the operation, as well as possible complications

which may arise. The patient should also be informed of the measures to be taken to

diminish the possible consequences of these factors.

Designation Powder (g) Liquid (g)

®

KYPHON

ActivOs™ 10 Bone Cement with Hydroxyapatite 21g 9.2g

The cement should be stored unopened in its original packaging, in a dry, clean place

away from the light, at a maximum temperature of 25°C.

-Allow the cement to harden before disposal with other medical waste. Comply with local

regulations in force relating to medical waste for safe handling and disposal of the cement.

-Regarding separate disposal of the liquid or of the powder, comply with local regulations

in force relating to handling and disposal of the cement.

PRECAUTIONS FOR USE

INDICATIONS FOR USE

CONTRAINDICATIONS

ADVERSE EVENTS

STERILIZATION

IMPORTANT PHYSICIAN INFORMATION

PATIENT INFORMATION

PACKAGING AND STORAGE

RECOMMENDATIONS FOR DISPOSAL

For further information, please contact Customer Service, Medtronic Sofamor Danek USA,

Inc., 1800 Pyramid Place, Menphis, Tennessee, 38132, Telephone: 800 933 2635 ( in

U.S.A), 901 396 3133 ( outside of U.S.A), Fax: 901 396 0356

© 2015 Medtronic Sofamor Danek USA, Inc. All rights reserved.

REQUESTS FOR INFORMATION

CAUTION: U.S. Federal Law restricts

this device to sale by or on the order of

a physician (or properly licensed practitioner).

Upper limit of temperature

Keep away from sunlight

Do not reuse

Flammable product

Do not use if package

is damaged

2

STERILIZE

Do not resterilize

Caution

STERILE R

Sterilized using irradiation

Product compound,

using alternative way of sterilization

Consult instructions for use

REF

Catalog number

Manufacturer

LOT

Batch code

Use by date YYYY-MMM-DD

Date of manufacture YYYY-MM-DD

Réf. : TF410407 ind 3 / 01-2017

Loading...

Loading...