autoLog

®

Autotransfusion System

Including Associated Disposables

Operator’s Manual

Caution: Federal law (USA) restricts this device to sale by or

on the order of a physician.

PROPRIETARY INFORMATION

The entire contents of this manual are copyrighted and the property of Medtronic, Inc. No part of

this book may be used or reproduced in any form or by any means, or stored in a database or

retrieval system, without the prior written authorization of Medtronic, Inc.

®

Classified by Underwriters Laboratories, Inc.

with respect to electric shock, fire and mechanical

hazards only in accordance with UL 2601-1 and CSA/CAN C22.2 no. 601.1.

®

autoLog

is a registered trademark of Medtronic, Inc.

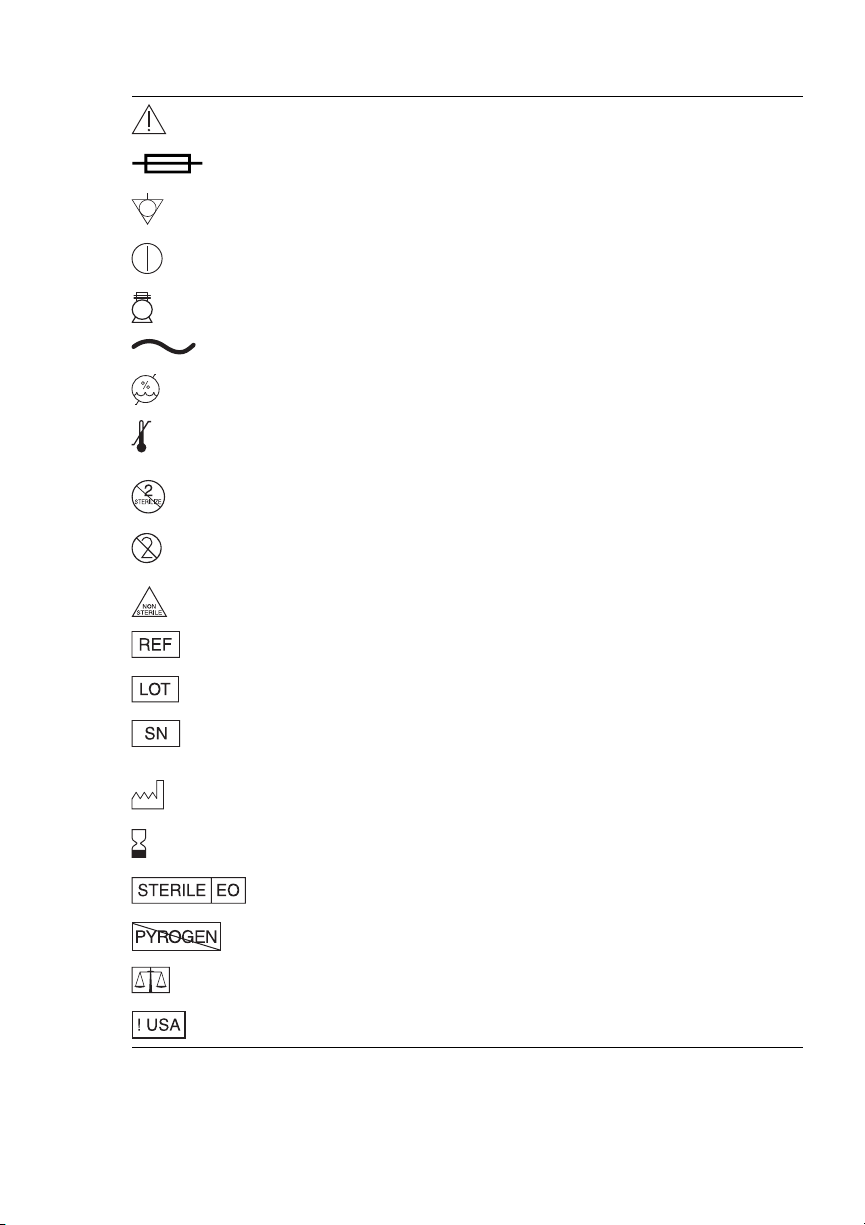

Explanation of symbols on package labeling

Attention, See Instructions for Use

Fuse

Equipotentiality

On/Off

Power - Vacuum Pump

Alternating Current

Humidity Limitation

Temperature Limitation

Do Not Resterilize

Do Not Reuse

Nonsterile

Catalog Number

Lot Number

Serial Number

Date of Manufacture

Use By

Sterilized Using Ethylene Oxide

Nonpyrogenic Fluid Path

Quantity

For US Audiences Only

Operator’s Manual 1

Conformité Européenne (European Conformity). This symbol means

that the device fully complies with European Council Directive 93/42/

EEC.

autoLog Autotransfusion System

Medical equipment with respect to electric shock, fire and mechanical

hazards only in accordance with UL2601-1 and CAN/CSA C22.2

No. 601.1.

Do not dispose of this product in the unsorted municipal waste stream.

Dispose of this product according to local regulations. See

http://recycling.medtronic.com for instructions on proper disposal of

this product.

This Way Up

Keep Dry

Fragile, Handle with Care

Corrugated Recycles

Protective Earth Ground

China RoHS Standard (SJ/T11364-2006) Electric Information Products

Pollution Control Symbol. The number represents the years the device

can be used before it must be recycled (environmental protection use

period).

Contains di(2-ethylhexyl)phthalate (DEHP)

2 Operator’s Manual

Manufacturer

Consult Instructions for Use

Authorized Representative in the European Community

Introduction

Autologous blood is blood that is derived from the same individual. Therefore, an autologous

transfusion is one in which the patient receives only his/her own blood. Autotransfusion is a

procedure in which the blood lost by, or removed from, a patient (autologous blood) is

subsequently returned to the patient’s circulation.

Advantages of Autotransfusion Over Allogeneic Transfusion

Because of concern over blood-related diseases, increasing numbers of physicians and patients

are focusing their attention on the risks of allogeneic transfusion, which has resulted in increased

interest in autotransfusion. There are several benefits:

■

Hepatitis risk is eliminated, as well as other blood-transmitted diseases.

■

Cross-matching errors are eliminated.

■

Use of autologous blood provides additional assurance when performing surgery on patients

with multiple red blood cell antibodies or rare blood phenotypes.

■

Valuable allogeneic blood is conserved.

Intended Use

The autoLog Autotransfusion System is intended for use in the collection, concentration,

washing, and reinfusion of autologous blood. Such areas of application may include, but are not

limited to, the following:

■

General, cardiovascular, orthopedic, vascular, plastic/reconstructive, obstetric/gynecologic

and neurosurgical surgery

■

Postoperative treatment areas

Principles of Operation

The autoLog Autotransfusion System operates by separating whole blood into its individual

components by centrifugation. Blood is an ideal biologic mixture for such a technique, because

it is a suspension of heterogeneous elements of significantly different densities and, thus, is easy

to separate. When subjected to a centrifugal force, the blood components will migrate relative to

their respective densities, with the higher density blood components moving farther from the axis

of rotation. An itemized list of recovered and removed material is shown here:

Recovered:

■

washed, packed red blood cells

Removed examples include (materials less dense than red blood cells):

■

lipids and fats

■

plasma-free hemoglobin

■

pharmacologic agents

■

activated platelets

■

irrigation solutions

■

activated clotting factors

As blood continues to enter the spinning bowl, the amassing red cell pack begins to occupy more

of the bowl volume and the excess plasma is pushed ahead of the red cells. When the total liquid

volume of the bowl has been exceeded, the excess plasma exits the bowl through the effluent

fluid outlet to the waste bag via connecting tubing.

To rid the red cell pack of contaminants, it is washed with isotonic saline (0.9% sodium chloride

solution).

Operator’s Manual 3

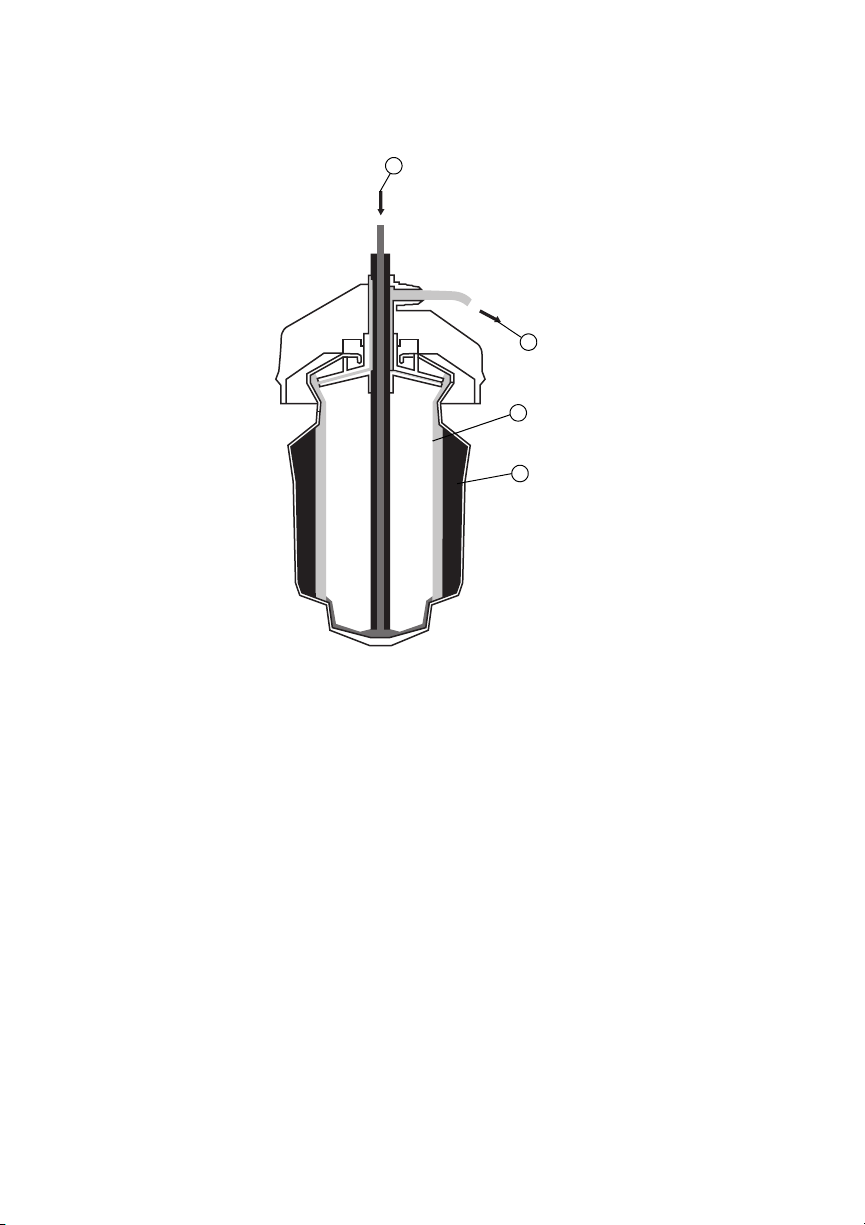

At the termination of washing, the clean, packed red cells are transferred to the holding bag. This

2

3

1

4

is accomplished by reversing the fluid pump rotation, which draws blood from the base of the

bowl and transfers it to the holding bag via the attached tubing. The blood is transferred to a

blood transfer bag and then to the patient.

4 Operator’s Manual

Figure 1.

1. Effluent Fluid Outlet

2. Plasma

3. Red Cells

4. Whole Blood Inlet

Warnings, Precautions, Contraindications, and Possible Complications

Read this Operator’s Manual completely prior to using the autoLog Autotransfusion System.

Warnings and Precautions

1. Direct Patient Reinfusion: Do not use the autoLog Autotransfusion System for direct

patient reinfusion (ie, from the machine directly into the patient) or direct patient draw (ie, from

the patient directly into the machine). Adequate safeguards do not exist to protect the

patient in these situations.

2. Reinfusion of washed red cells can be carried out by gravity or pressure infusion after

transferring processed blood to blood transfer bags. Do not directly reinfuse processed blood

from the holding bag to the patient. Directly reinfusing the blood from the holding bag exposes

the patient to the risk of possible air embolism.

3. Caution: Federal law (USA) restricts this device to sale by or on the order of a

physician. Actual performance results may vary depending on many in-use variables. It is

important to read and understand this Operator’s Manual and understand the principles of cell

washing before undertaking clinical operation of the autoLog Autotransfusion System. The

responsibility for the use of this device in all cases belongs solely to the physician ordering its

use.

4. The safe operation of all cell washing equipment requires the presence of a dedicated

operator. It is the responsibility of the hospital to ensure that the individuals assigned to this

task are well trained in the operation of the autoLog Autotransfusion System and alert to

potential problems. Never leave the machine unattended during operation as

irrecoverable damage to the blood may occur.

5. This device is intended for autotransfusion use in clinical patient care areas such as operating

rooms, intensive care, or recovery rooms. This device is NOT intended for use in blood banks

or apheresis centers, or for use where the blood bank has to handle, label, store, hold, or

otherwise process the blood for later reinfusion into the same patient.

6. The disposable components utilized with this device are for single patient use only. This

disposable was designed for single patient use only. Do not reuse, reprocess, or resterilize

this product. Reuse, reprocessing, or resterilization may compromise the structural integrity

of the device and/or create a risk of contamination of the device, which could result in patient

injury, illness, or death. Only Medtronic

with the autoLog Autotransfusion System. Maintain a sterile field at the collection site. It is

important that aseptic technique be used to minimize the possibility of contamination to the

disposables and/or the patient.

7. Due to the presence of phthalates in the product, the clinician must weigh the medical benefits

of product use against the drawbacks of phthalate exposure for male children and pregnant

or nursing women.

8. Do not attempt to reuse the disposables. Reuse may adversely affect the performance of this

system and compromise patient safety.

9. The disposables must be used immediately after the removal of the protective packaging.

Visually inspect the contents of the disposables. Should any evidence of damage to

components be found during inspection or setup, do not use the disposable and return to

Medtronic for replacement. Do not use silicone oils or greases near the disposables.

®

sterilized disposable kits are approved for patient use

#

Operator’s Manual 5

10.The disposables are sterile (ethylene oxide) and nonpyrogenic as long as package integrity

has not been violated. Do not use if the package is damaged or open. Store all disposables

in a dry place away from extremes of temperature.

11.The autoLog Autotransfusion System must not be used in the presence of flammable agents.

12.The basic concept of cell washing involves the removal of the contaminated plasma and

debris, while leaving red cells suspended in clean saline. Removal of large amounts of

plasma during autotransfusion can cause patient hypovolemia. Since platelets and

coagulation factors are contained in the plasma, this plasma removal may also reduce

coagulation factors or platelet levels below normal levels. It is also possible that inadequate

washing of salvaged blood may result in insufficient removal of anticoagulant and/or the

development of coagulopathies upon return of that blood to the patient. Therefore, careful

monitoring of the patient’s coagulation status is important to prevent complications.

13.Medtronic advises that all autologous collected blood be washed prior to reinfusion.

14.Medtronic does not have sufficient data to support the safety and efficacy of returning washed

cells from partially filled bowls and therefore cannot recommend that practice.

15.Blood may be salvaged from body cavities, joint spaces, and other operative sites or trauma

sites only if there is no clinical evidence of sepsis, malignancy, or wound contamination.

16.Never transfuse blood that is suspected of having high hemolysis.

®1

17.Make sure no water or other irrigation, such as Betadine

, is aspirated into the

autotransfusion system at any time, as this will hemolyze the red cells. Use an adequately

sized suction tip to minimize hemolysis.

18.When using a hard-shell cardiotomy or blood collection reservoir, vacuum levels should not

exceed 150 mm Hg.

19.Do not use any hot solutions over 42°C (108°F), since high heat can destroy red cells.

20.To avoid overheating the centrifuge, which could cause hemolysis, do not use the autoLog

Autotransfusion System at temperatures higher than 30°C (86°F).

21.Plastic materials used in the autoLog Autotransfusion System and its disposable kits may be

sensitive to chemicals (such as solvents and certain detergents). Under certain adverse

conditions, exposure to these chemicals (including vapors) may cause the plastics to fail or

malfunction.

22.Treat all blood and fluids using universal bloodborne pathogen precautions.

23.In the unlikely event of a power loss or other failure during the wash portion of the cycle, a

lower than normal hematocrit will result. The blood should be tested for hematocrit so that the

operator knows what is being given to the patient.

24.Do not restrict the flow in any tubing line. If a tubing line is inadvertently clamped or kinked

during operation, pressure may build up in the centrifuge bowl causing failure or leakage.

Always check the entire disposable kit to confirm that all tubing is free of any kinks, twists or

flat areas. Double check the pump head and wash kit to ensure that all components are in the

proper flow direction.

25.The standard waste bag for the autoLog Autotransfusion System holds approximately 10 L.

Periodically check the waste bag volume and empty as required. The waste bag may be

emptied at any time; however, a small amount of fluid (100–200 mL) should be left in the bag

to provide for proper expansion during filling and emptying. Avoid the introduction of room air

into the waste bag. A full waste bag will cause back pressure and bowl leaks to occur.

1

Betadine® is a registered trademark of Purdue Frederick Company.

6 Operator’s Manual

26.The AABB Standards for Perioperative Blood Collection and Administration (Third Edition,

2007), Reference Standard 5.1.8A, recommends the expiration period for blood recovered

interoperatively with processing be stored at room temperature no longer than 4 hours from

the time of collection. Interoperative blood collected with processing can be stored for

24 hours at 1°C and 6°C, if the storage is begun within 4 hours of completion of processing.

The transfusion of shed blood collected under postoperative or post-traumatic conditions

shall begin within 6 hours of initiating the collection. In the unlikely event of power failure,

these guidelines should be strictly adhered to. If the blood is less than 4 hours old, it is

permissible to continue processing and transfuse the blood to the patient.

27.Medtronic recommends the use of a blood transfusion filter between the reinfusion container

and the patient in compliance with The AABB Standards for Perioperative Blood Collection

and Administration (Third Edition, 2007), Reference Standard 5.4.5.1, which states,

“Perioperative products intended for transfusion shall be transfused through a filter designed

to retain particles that are potentially harmful to the patient.”

28.Inside the autoLog Autotransfusion System cabinet there are various electrical components

and wiring. Physical contact with any of these components while the unit is plugged in could

result in severe electrical shock. Always turn off and unplug the unit prior to working inside

the cabinet or changing any fuses. For continued protection against risk of fire, replace fuses

only with the same type and rating. Internal grounding is provided for safety.

29.Although this system was tested for EMC compliance and passed, the potential exists that, in

some situations, the autoLog Autotransfusion System and other devices might

electromagnetically interfere with each other. Take steps to minimize this possibility.

30.The autoLog Autotransfusion System includes a centrifuge that rotates at 10,000 rpm. Parts

that turn at high speeds may be dangerous. Safety rules related to the use of centrifuges must

be followed. Do not open the centrifuge or remove the bowl before it comes to a complete

stop.

31.Current leakage is a primary indicator of electrical shock hazard to personnel making contact

with any exposed portion of the equipment. Each autoLog Autotransfusion System is checked

during the final quality inspection to verify that current leakage is less than 100 µA. Have

current leakage checked at least yearly, or as required by the operating facility’s biomedical

engineering department, or other qualified service technician. In addition, particular attention

should be given to checking the current leakage and insulation after an event such as a fluid

spill or major voltage surge in the power source has occurred, or after any machine repair.

32.Maintain the autoLog Autotransfusion System in good working order and calibrate it on a

regular basis.

Transportation of Device

1. To avoid potential damage during transit, use the autoLog Autotransfusion System’s original

shipping packaging.

2. Never lay the autoLog Autotransfusion System on its side as this can damage the centrifuge.

3. Be careful not to move the autoLog Autotransfusion System by the IV pole. Over time this can

cause the top panel of the machine to loosen and cause permanent damage.

Contraindications and Complications

1. The use of citrate-based anticoagulant in patients with impaired liver function may require

additional monitoring and may, in certain circumstances, be contraindicated. Improperly

processed red cells may contain residual citrate-based solution which, in excess quantities,

could cause citrate toxicity, depression of serum calcium, or bleeding tendencies.

Operator’s Manual 7

2. Gross contamination and/or septic procedures.

3. Surgery within the malignant area that may allow dissemination of

tumor/malignant cells, if aspirated, into the autotransfusion system.

4. Caesarean sections (presence of amniotic fluid).

5. Presence of high concentrations of prostatic fluid.

6. Contamination of salvaged blood with drugs not intended for intravenous administration.

®2

7. Collagen-based hemostatic agents, such as Gelfoam

, should not be used in combination

with any autotransfusion system. In their presence, temporarily discontinue salvage during

the time the agent is being used. After the agent has been given time to initiate hemostasis

in the wound, irrigate the area copiously with saline and aspirate to non-autotransfusion

collection containers before autologous blood salvage is continued. Failure to flush the area

thoroughly could result in the hemostatic agent being drawn into the collected blood. This

could result in coagulation of the collection blood or possible disseminated intravascular

coagulopathy (DIC) complications in the patient.

8. Coagulopathy.

9. Morbidity and mortality in autotransfusion, as in allogeneic transfusions, are directly related

to the volume of blood infused, if plasma and platelets are not concurrently transfused.

2

Gelfoam® is a registered trademark of Pharmacia & Upjohn Company.

8 Operator’s Manual

Device Description and Specifications

Features and Specifications

Note: Technical data, features, and options referenced in this manual are based on the latest

information available at the time of printing. Medtronic reserves the right to change specifications

without notice.

Electrical Classification:

Class I, Ordinary, Continuous Operation

Power:

Voltage: 110 – 120 / 220 – 240 V~

Frequency: 50 – 60 Hz

Phase: Single

Current: 1.6 / 0.8 A (depending upon voltage selection)

Fuses: 4 A / 250 V~ / T

Power Cord: 2 wires plus ground (earth) connector

3 prong hospital grade (USA only)

Speed and Flow Rate Specifications:

Centrifuge: 0 – 10,000 rpm (± 5%)

Pump: 0 – 600 mL/min (± 5%)

Vacuum: 150 – 200 mm Hg

Dimensions:

Width: 33 cm (13 in)

Height: 75 cm (30 in)

Depth: 22 cm (9 in)

Weight:

32 kg (70 lb)

Temperature Limit:

Operational: 10°C – 30°C (50°F – 86°F)

Storage: 5°C – 50°C (41°F – 122°F)

Humidity Range:

Operational: 10 – 95% noncondensing

Storage: 10 – 95% noncondensing

Operator’s Manual 9