Page 1

User’s Guide

REF

Integrated Power Console (IPC™) System

1898001

Page 2

Symbols

EUR · USA · JPN · AUS

IPX1

EC REP

IPX7

ACC

IPX8

DEHP

STERILE

NIM

Accessory

REF

LOT

SN

REFURBISHED

!USA

On/O Button Package Contents Follow

EMC Compliance

Mark

Instructions For

Use

Do Not Oil Do Not Immerse

105345

Conforms to ANSI/AAMI ES60601-1,

Certied to CAN/CSA-C22.2 No.60601-1,

IEC/EN 60601-1

Caution: Federal law (USA) restricts this device

to sale by or on the order of a physician.

>120 VAC

ON

<120s

Fuse

Use By Date

Accessory

AC Power Type BF Applied Part Foot Pedal

Output Start/Stop Fine Irrigant

Is Approximately

Equal To

Non-Sterile Consult Instructions

Non-Sterile

Quantity

Not Greater Than

120vac

Caution

Applied Part

OFF

Duty Cycle

>180s

Catalog Number Manufacturer

Lot Number

Serial Number Ergonomically

XX° C

>X° C

BUR

EHS

Fr

Protected Against

Vertical Water Drops

Protected Against

The Eects Of

Temporary

Immersion In Water

Protected Against

The Eects Of

Temporary

Immersion In Water

RF Transmitter

(Interference May

Occur)

for Use

Stim Bur Connector

NIM Console

Connector

Electrical High

Speed Handpiece

Connector

World Wide Standard

for Medical Tubing

Diameter

Date of Manufacture Handpiece

<XX° C

Temperature

XX° C

Limitation

Outer Limits =

Transport

Inner Limits = Use

Engineered

F

R

1

2

Oscillate

Forward

Reverse

Connector

Adjustment

Left Foot Control

Unit Button /

Mode Button

Right Foot

Control Unit

Button / Control

Button

Top Foot Control

Unit Button

/ Handpiece

Button

Locked

Unlocked

Pump Head 1

Pump Head 2

Refurbished

Authorized Representative in the European

Community

Precaution: Pinch Hazard. Keep Fingers Clear

Of Rollers

PHT

Contains DEHP (di-2-ethyl hexyl phthalate)

Protective Earth

Equipotential Ground Connector

Use With

RoHS - Environmental friendly use period China (SJ/T11364-2006)

Do Not Dispose Of This Product In The

Unsorted Municipal Waste Stream. Dispose Of

This Product According to Local Regulations.

See

Recycling.Medtronic.com for Instructions On

Proper Disposal Of This Product.

If the single use symbol is on the device

label then this device is designed for single

patient use only. Do not reuse, reprocess, or

resterilize this product. Reuse, reprocessing, or

resterilization may compromise the structural

integrity of the device and/or create a risk of

contamination of the device, which could result

in patient injury, illness, or death.

Adapter

Attachment

Bone Mill

Brush

Control Unit

Dissecting Tool

Instrument Case

Lubricant/Diuser

Motor

Multi-Use Disposable Attachment

Regulator

USA Only Speed Range

<NNNN

min

For use up to

“NNNN” RPM

Page 3

Table of Contents

Symbols .......................................................................................................................................................... 2

IPC™ System .................................................................................................................................................... 4

Glossary ............................................................................................................................................................................................................................... 4

Indications for use ...........................................................................................................................................................................................................4

Device description ........................................................................................................................................................................................................... 4

Contraindications ............................................................................................................................................................................................................4

Additional IPC™ congurations ..................................................................................................................................................................................4

Warnings .............................................................................................................................................................................................................................4

Precautions .........................................................................................................................................................................................................................6

System requirements and specications ................................................................................................................................................................6

System sounds ..................................................................................................................................................................................................................7

System gures ...................................................................................................................................................................................................................8

Pre-and Post-operating instructions ...................................................................................................................................................................... 11

IPC™ components ......................................................................................................................................................................................................... 13

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity ............................................................................................... 15

Limited warranty ........................................................................................................................................................................................................... 17

For items contaminated with TSE agents ............................................................................................................................................................ 17

Endo-Scrub™ 2 .............................................................................................................................................. 18

StraightShot™ M5, StraightShot™ M4, StraightShot™ Magnum™ II, and StraightShot™ III .................... 21

Skeeter™ Ultra-Lite Oto-Tool ....................................................................................................................... 26

Indigo™ High-Speed Otologic Drill ............................................................................................................. 28

Visao™ High-Speed Drill ............................................................................................................................... 32

Troubleshooting ........................................................................................................................................... 35

Error codes .................................................................................................................................................... 37

Cleaning and sterilization ............................................................................................................................ 39

Reprocessing Instructions - Endo-Scrub™ 2 Finger Switch ........................................................................................................................... 40

Reprocessing Instructions - StraightShot™ M5, StraightShot™ M4, StraightShot™ Magnum™ II, StraightShot™ III .................. 41

Reprocessing Instructions - Skeeter™ Oto-Flex Burs ........................................................................................................................................ 43

Reprocessing Instructions - Skeeter™ Handpiece ............................................................................................................................................. 44

Reprocessing Instructions - Indigo™ High-Speed Otologic Drill ................................................................................................................. 45

Reprocessing Instructions - Indigo™ High-Speed Otologic Drill Attachments ...................................................................................... 46

Reprocessing Instructions - Visao™ Handpiece .................................................................................................................................................. 47

Reprocessing Instructions - Frontal Sinus 2mm Mini Trephine Drill ........................................................................................................... 48

Reprocessing Instructions - Medtronic Burs ....................................................................................................................................................... 49

Customer service .......................................................................................................................................... 50

Integrated Power Console (IPC™) System

Page 4

IPC™ SYSTEM

IPC™ System

Glossary

The following words and acronyms may be used in this guide.

FCU Foot Control Unit

FWD Forward - Rotation is clockwise

I.V. Intravenous

IPC™ Integrated Power Console

NIM™ Nerve Integrity Monitor - One or all of the Nerve Integrity Monitor units: NIM-Response™ 2.0, NIM-Neuro™ 2.0, NIM-

Response™ 3.0 and NIM-Neuro™ 3.0

NIM-Eclipse™ Nerve Integrity Monitor for spinal surgeries

OSC Oscillate

REV Reverse - Rotation is counter-clockwise

XPS Xomed Power System

Tool Surgical cutting device

Motor Handpiece/drill

Accessory Any compatible product that can be used with the IPC™

Attachment Any compatible product that can be secured to a handpiece

Indications for use

The IPC™ System is indicated for the incision/cutting, removal, drilling and sawing of soft and hard tissue and bone in Head & Neck/ENT

(Otologic, Neurologic, Neurotologic, Sinus, Rhinologic, Nasopharyngeal/Laryngeal), Oral/Maxillofacial and Plastic/Reconstructive/Aesthetic

surgical procedures.

Device description

The IPC™ System is a powered microdebrider, drill and saw system that will remove soft tissue, hard tissue and bone during surgical procedures.

The system consists of a power control console, foot pedal, connection cables and assorted handpieces to drive various burs, blades, drills, rasps,

cannulae and saws. It includes integrated irrigation pumps for irrigation of blades, burs and for motor coolant.

In addition to the handpieces and pumps there is a connection for continuous stimulation of the Visao™ straight burs that enables nerve

integrity monitoring during surgical procedures. The Nerve Integrity Monitor (NIM™) is a separate device that stimulates and monitors the nerve.

This system has connections that allow the NIM™ to be connected with the Visao™ handpiece and stimulating bur guard, enabling the NIM™ to

stimulate and monitor the nerve at the surgical site.

This device is intended for use by physicians trained in the procedures described.

Contraindications

None.

Additional IPC™ congurations

Additional IPC™ congurations are available. Refer to the following User’s Guides for related information.

• IPC™ POWEREASE™ System Model: 2340000 (IPC™ User’s Guide)

• Neurosurgical IPC™ System Model: EC300 (IPC™ User’s Guide CFN 175027)

Consult the appropriate User’s Guide for indications, contraindications, warnings, and component information specic to each system.

Warnings

System warnings

W1 It is important that the IPC™ system operator be familiar with the system User’s Guide, its precautions, procedures and safety issues.

W2 Do not use the IPC™ system in the presence of ammable anesthetics. Avoid potential ignition or explosion of gases.

W3 To avoid the risk of electric shock, this equipment must only be connected to a supply main with protective earth.

W4 To avoid the risk of electrical shock, achieve electrical grounding reliability with proper connections. Connect the IPC™ system to hospital

grade receptacles only.

W5 Do not attach any system component or accessory other than Medtronic approved components to the IPC™ system as this may result in

electrical shock, component damage, substandard performance, increased emissions, or decreased immunity.

1-4

Integrated Power Console (IPC™) System

Page 5

IPC™ SYSTEM

W6 Disconnect power to the IPC™ system before cleaning the unit to avoid electrical shock.

W7 This medical device complies with EN60601-1-2 safety standard for electromagnetic compatibility, requirements and test. However, if this

equipment is operated in the presence of high levels of electromagnetic interference (EMI) or highly sensitive equipment, interference may

be encountered and the user should take whatever steps are necessary to eliminate or reduce the source of the interference. Diminished

performance may lengthen operating time for the anesthetized patient.

W8 Do not operate the IPC™ system in the presence of Magnetic Resonance Imaging devices.

W9 Medical Electrical Equipment needs special Precautions regarding EMC and needs to be installed and put into service according to the EMC

information provided in this User’s Guide.

W10 The IPC™ system should not be used adjacent to or stacked with other equipment. If adjacent or stacked use is necessary, the IPC™ system

should be observed to verify normal operation in the conguration in which it will be used.

W11 Portable and mobile RF communications equipment can aect Medical Electrical Equipment.

W12 Keep NIM™ Muting Probe cable away from IPC™ system cables to prevent unintended EMG interference or muting.

W13 After each procedure, properly clean all reusable system components.

W14 All service must be performed by Medtronic qualied personnel only. Repair and/or modication to the IPC™ system by anyone other than

qualied service personnel may signicantly compromise the unit’s ability to perform eectively and/or void the equipment warranty.

W15 Auxiliary Power Outlet with protective cover is for use with the Hydrodebrider or Bone Mill only. Consult Hydrodebrider and Bone Mill

instructions prior to use.

Component Warnings

W16 Always inspect the components before and after use for any damage or malfunction. If damage or malfunction is observed, do not use

damaged part until it is repaired or replaced. Use of damaged or malfunctioning parts can increase risk of injury.

W17 Motors and attachments may fail due to extended use and allow a component to detach and fall from the motor or attachment, causing

patient injury.

W18 Do not use an overheated device as it may cause thermal injury. Smoke and/or excessive heat may be caused by:

• Applying excessive force while cutting (e.g. side loading)

• Long operating periods (exceeding handpiece duty cycle)

• Attachment not fully locked in handpiece

• Inadequate or loss of irrigation

• Component failure or wear

W19 The handpieces will not run properly unless the attachment is in the locked or secured position.

W20 Do not change accessory with handpiece running to prevent laceration of user and cross-contamination through compromised glove.

W21 Do not place motor, attachment and tool on the patient or in an unsecured location during surgery.

W22 Do not activate foot pedal without conrming the safe position and handling of the handpiece. Accidental handpiece activation could

result in unintended tissue, bone, or nerve resection.

W23 Verify reusable device was cleaned and sterilized prior to use. If not sterilized, do not use.

W24 For warnings & precautions related to reprocessing, refer to Cleaning and sterilization instructions.

W25 This system requires insulated connectors for the StraightShot™ M4 Microdebrider, StraightShot™ Magnum™ II Microdebrider,

StraightShot™ III Microdebrider, Midas Rex™ Spine Shaver (SC1), Visao™, or Skeeter™ handpieces and the multifunction foot pedal.

W26 When using StraightShot™ microdebrider handpieces with non-rotatable tools, ensure rotation lock is engaged to prevent inadvertent

rotation. When using with optical Image Guided Surgery (IGS), engage the rotation lock prior to calibration and verication of the tip.

Disposable Warnings

W27 Tools are available for resection of soft tissue and bone for surgical procedures. Use of tools depends on the intended application and

patient needs. Sharp cutting powered tools induce bleeding and removal of signicant tissue and bone.

W28 Do not use accessory if package is opened or damaged. Broken seal oers no protection against cross-contamination.

W29 Operate the tool only after the appropriate anatomical landmarks and the intended surgical site have been conrmed. Ensure adequate

visualization when using powered accessories. Discontinue powered application in the event of lack of visualization of the surgical site.

W30 Use methods at the operative site to control bleeding that do not compromise patient safety during at-risk surgery.

W31 Always keep the cutting area of the tool away from ngers and loose clothing to prevent laceration of user and cross-contamination

through compromised glove.

W32 Excessive noise from the tool when drilling close to the cochlea or ossicular chain may cause hearing damage.

W33 Improper use of high speed burs can result in damage to the eye and/or orbit, vascular damage, nerve damage, and/or cerebral damage.

Use appropriate caution when operating this device in the vicinity of critical anatomy.

W34 Excessive pressure applied to tool may cause tool fracture. Should a tool fracture in use, extreme care must be exercised to ensure that all

fragments of the tool are retrieved and removed from the patient. Unremoved tool fragments may cause tissue damage to the patient.

W35 Do not use excessive force to pry or push bone with the attachment, tool or blade during dissection.

W36 Do not apply excessive side loading. Excessive side loading could cause angled attachments to unlock accidentally from motor.

Integrated Power Console (IPC™) System

1-5

Page 6

IPC™ SYSTEM

W37 Do not modify any system components or accessories. Use of modied components or accessories may increase risk of injury or diminish

performance of the system.

W38 Insertion of metal objects in accessory tip may cause the accessory to break leaving fragments in the wound. The fragments may be

dicult to remove, causing irritation, inammation and foreign-body response at surgical site.

W39 Bending or prying may break the accessory, causing harm to patient or sta.

W40 Inspect tools prior to and during use for signs of wear, fragmentation, eccentricities, or other defects. Replace and discard damaged tools.

Do not attempt to re-sharpen tools.

W41 Test attachments for excessive vibration at desired speed before use. Vibration may be caused by eccentricity of the tool or worn

components. Replace tool, attachment, or handpiece, or change handpiece speed.

W42 Test for wobble at desired speed prior to use. Discontinue use of accessory if tip begins to wobble and replace accessory to prevent

unintended tissue removal from patient.

W43 Powered blades should be operated in the Oscillate mode only. Operating in the Forward mode may cause damage to the blade.

W44 Do not use the burs above the speed indicated on the bur label.

W45 If an airway blade becomes clogged during use, 1-5 cc of irrigant could be aspirated by the patient before detection by the user.

W46 Do not attempt to sterilize disposable devices. The disposables are packed sterile and are intended for single use. Devices lose sterility

upon removal from packaging.

Precautions

P1 Do not kink cables. Inspect cables and pins for cracks, tears or corrosion.

P2 When using a Y-Splitter, only one multifunction foot pedal shall be active at a time.

P3 Do not connect multiple Y-Splitters.

P4 StraightShot™ handpieces are intended to operate at speeds greater than 6,000 rpm only when used with the high speed bur line.

P5 Do not use anti-fog on scope or sheath, as weeping or leaking may result.

P6 Do not use excessive force to insert the endoscope into the Endo-Scrub™ 2 sheath. this will damage the endoscope as well as the Endo-

Scrub™ 2 sheath.

P7 If the endoscope tip can be seen extending beyond the tip of the Endo-Scrub™ 2 sheath, then the sheath has been damaged. Damaged

product must be immediately discarded.

P8 Remove and discard accessories following local regulations for proper disposal of contaminated materials.

P9 When using an angled attachment, hold the handpiece assembly by the attachment so that the attachment does not inadvertently loosen

from the handpiece.

P10 Always examine operation of each tool in a handpiece before use.

P11 Powered burs and drills should be operated in the Forward mode only.

P12 To prevent damage to tools, disconnect suction tube prior to changing tool during procedure.

P13 Ensure the blade or bur is fully engaged in the microdebrider. For blades, verify the tip is fully engaged with the outer cannula prior to use.

P14 T&A blades: Gently remove the inner tube from the outer tube. The inner tube may elongate upon removal from the outer tube. If this

occurs, the inner tube may not lock properly into the handpiece or the blade may not work properly.

P15 T&A blades: Rotate the inner tube when removing and inserting it in the outer tubes to prevent damage to the internal seal. If the seal is

damaged, the blade will leak at the handpiece.

System requirements and specications

Console Specications

Functional Standards for Electrical Systems

ANSI/AAMI ES60601-1 Medical electrical equipment - Part 1: General requirements for basic safety and essential

performance

IEC 60601-1 Medical electrical equipment - Part 1: General requirements for basic safety and essential

performance

EN 60601-1 Medical electrical equipment - Part 1: General requirements for basic safety and essential

performance

IEC 60601-1-4 Medical electrical equipment - Part 1: General Requirements for Safety, Part 4: Programmable

Electrical Medical Systems

IEC 60601-1-2 Medical electrical equipment - Part 1-2: General Requirements for Safety - Collateral Standard:

Electromagnetic Compatibility - Requirements and Tests

CAN/CSA C22.2 #60601-1 Medical Electrical Equipment - Part 1: General Requirements for basic safety and essential

performance

1-6

Integrated Power Console (IPC™) System

2005, 2012

2005, 2012

2006, 2014

1996, 1999

2007, 2014

2005, 2014

Page 7

Physical Dimensions

Size 277 mm Width x 353 mm Height x 267 mm Depth

Weight 7.3 kg

Operational Environment

Temperature +10 °C to +33 °C

Humidity 30 % to 75 % RH

Barometric Pressure 700 - 1060 hPa

Transport and Storage Environment

Temperature -40 °C to +70 °C

Humidity 10 % to 95 % RH

Barometric Pressure 500 to 1060 hPa

Display / Touchscreen

Type High contrast, digital, graphic color, visible in complete darkness

Resolution Display 21 cm diagonal, resolution 480 X 640 pixels

Audio Output

Baseline Audio Sound Level 60 dBA minimum SPL (1 m)

Electrical

Input Voltage 100 V-240 V ± 10%

Frequency 50/60 Hz

Power Consumption 500 VA

Auxiliary AC output 200 VA Max.

Internal Fuse 5 x 20 mm T. L. 5 A, 250 V

Medtronic Xomed P/N 11270066

Duty Cycle for Applied Part Maximum On Time 120 Seconds

Minimum O Time 180 Seconds

IPC™ SYSTEM

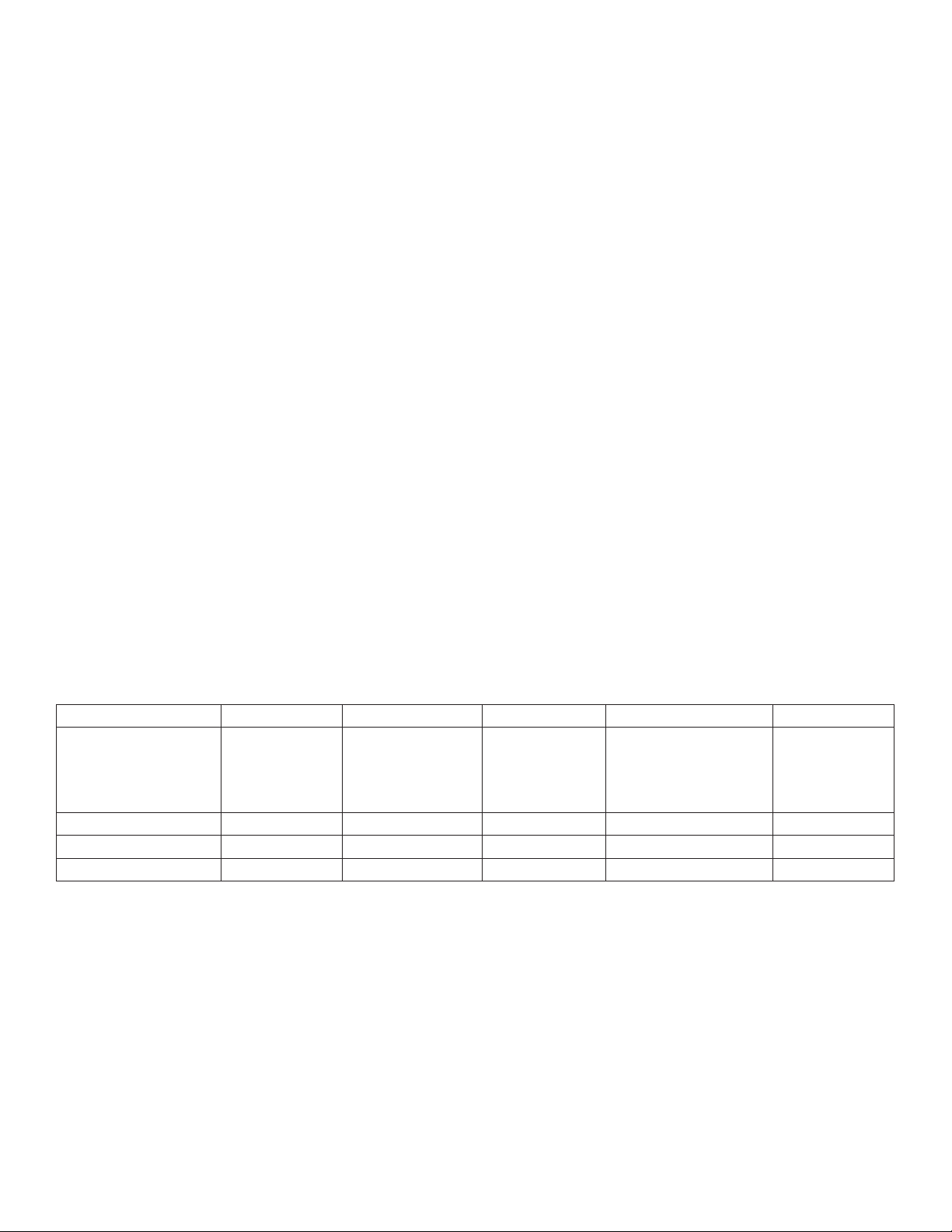

System power cords

Region Part Number Region Part Number Region Part Number

USA, Barbados, Belize,

Bolivia, Canada,

Colombia, Ecuador,

Venezuela

Standard

EA600 or 1895820

6 meter

EA650 or 1897821

United Kingdom,

Ireland, Hong Kong,

Malaysia, Singapore

EA606 Austria, Belgium, Finland,

France, Germany, Greece,

Korea, Luxembourg,

Netherlands, Norway,

Portugal, Spain, Sweden

EA602 or 1895822

China EA604 India, South Africa EA607 Switzerland EA601

Argentina EA608 Israel EA609 Denmark EA610

Australia, New Zealand EA605 Japan EA603 or 1895823 Italy, Chile EA611

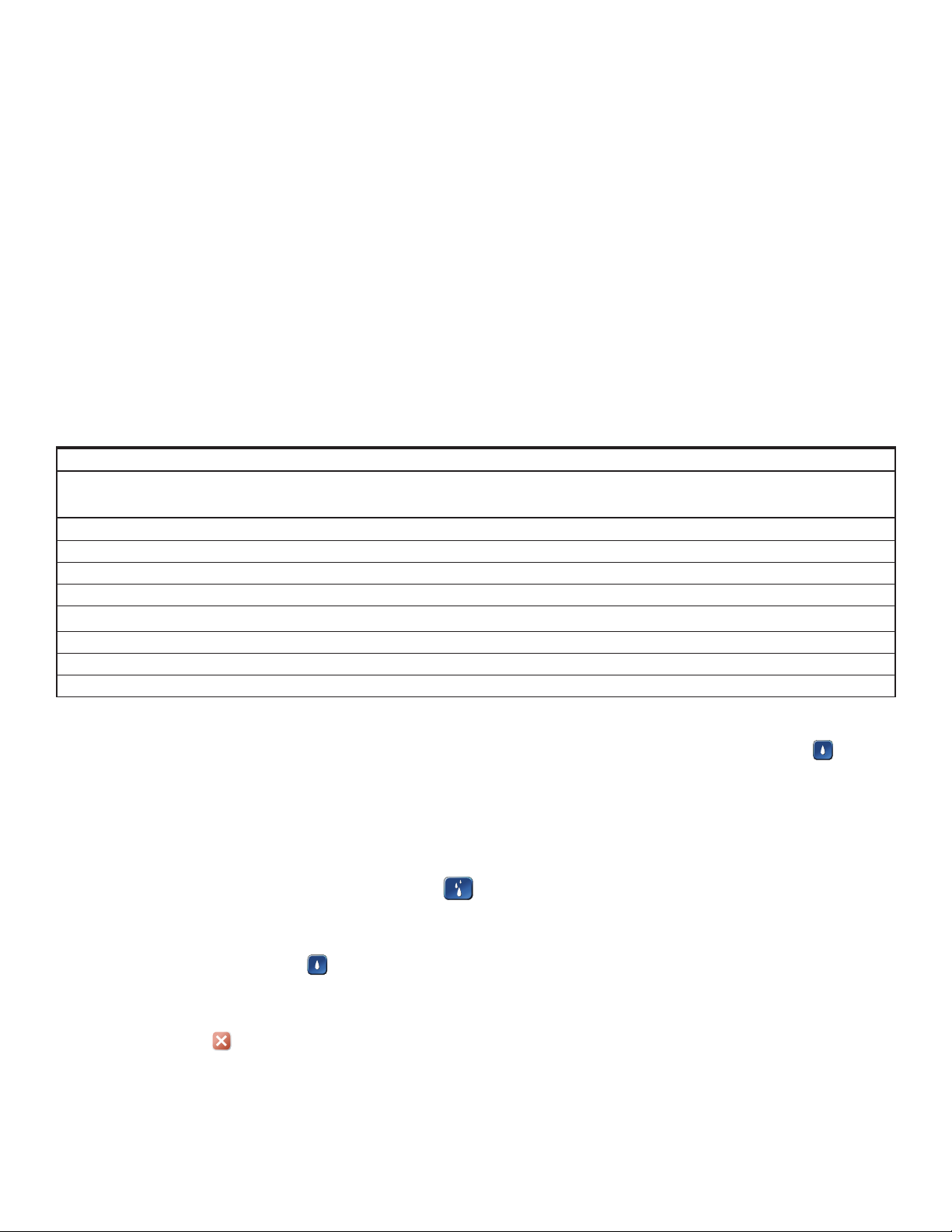

System sounds

The following tones can sound while using the IPC™ Console.

IPC™ Tone Cause(s)

1 Tone • Conrmation of change button pressed.

• Change from Forward to Oscillate.

• Change of active handpiece.

2 Tones Change from Oscillate to Forward.

3 Tones • Audible Alarm. Error detected. See screen for error message.

• Active handpiece is in Reverse and foot pedal pressed.

• First time accessory changes from Forward to Reverse.

Long Tone Change from handpiece to drill.

Integrated Power Console (IPC™) System

1-7

Page 8

IPC™ SYSTEM

12

System gures

Figure 1-1. IPC™ Console Front

1

2

3

4

5

1 Pump 1: Coolant, lens cleaning or irrigation

2 Touchscreen

3 Power on/o

4 Pump 2: Irrigation or lens cleaning

5 Console connector panel for peripheral devices

Figure 1-2. IPC™ Console Back

1

2

3

4

5

67 8

1 Pole clamp

2 Compact ash card port (Medtronic Use)

3 Manual start/stop

4 Auxiliary power outlet

5 Endo-Scrub™ 2 connector

6 Fuse access

7 Equipotential Ground Connector.

Apply potential equalization conductor.

8 Hospital grade power cord connector

1 Not applicable 4 Stimulus input from patient interface

2 Not applicable 5 Stimulus output to stim bur guard or

3 StraightShot™ M5 microdebrider,

StraightShot™ M4 microdebrider,

StraightShot™ Magnum™ II

microdebrider, StraightShot™ III

microdebrider, Visao™ drill, Indigo™

drill

1-8

Figure 1-3. IPC™ Console Connector Panel

3567 8

4

(NIM™ or NIM-Eclipse™)

POWEREASE™

6 Skeeter™ handpiece

7 Endo-Scrub™ 2 nger switch, Endo-

Scrub™ 2 foot pedal, IntelliFlow™

irrigation remote control

8 Multifunction foot pedal

Figure 1-4. Multifunction Foot Pedal & Y-Splitter

1

5

4

2

3

1

5

1 Mode button 5 Foot pedal

2 Handpiece button 6 Y-Splitter

3 Control button 7 Port 1

4 Slip-resistant foot pad 8 Port 2

6

7

8

2

4

Integrated Power Console (IPC™) System

3

Page 9

IPC™ SYSTEM

Figure 1-5. IPC™ Touchscreen

1

Speed

2

3

4

5

1 Displays active handpiece 5 Opens Help screen

2 Accessory control panel 6 Irrigation accessory panel

3 Foot pedal variable control 7 Inactive handpiece

4 Opens Pumps screen 8 Set active handpiece settings as default

Acceleration

Pump 2

Pumps

?

?

Help

Handpiece Name

+

60000

100

+

+

%

+

+

0

cc/min

EndoScrub 2

Flow

+

RPM

Prime

(Handpiece Name)

Setting

Finger

3

Control

+

+

Mode

FWD

REV

Foot

Both

PrimeOn

Figure 1-6. IPC™ Pumps Screen

Prime

Pump 1

None

None

3

Pump 2

8

None

7

6

4

1 Close Pumps screen 3 Pump 1 panel available accessories

2 Prime/Flush pump 4 Pump 2 panel available accessories

None

M4

M4

Irrigation

Irrigation

Prime

Endo-Scrub® 2

Endo-Scrub® 2

Prime

Endo-Scrub® 2

Endo-Scrub® 2

1

2

Figure 1-7. Operating Room Setup

3

2

1

10

4

9

7

8

1 Mode anesthesia equipment 6 Microscope

2 IPC™ system 7 Surgeon

3 Nursing supplies/Surgical

instruments

4 Scrub nurse 9 Anesthesiologist

5 NIM™ Monitor 10 Patient

Integrated Power Console (IPC™) System

8 Electro-Surgical unit

5

6

1-9

Page 10

IPC™ SYSTEM

Figure 1-8. IPC™ System Conguration

1

Figure 1-9. IntelliFlow™ Remote Control

1

2

2

3

11

3

4

10

9

5

6

8

7

1 Irrigation and coolant bags 7 Irrigation pole base diameter

2 Irrigation pole 8 Irrigation pole basket

3 IPC™ console 9 Power cord

4 Console connector panel 10 Pump 2

5 Accessory cables 11 Pump 1

6 Console height

1 Pause/On-O

2 Increase/Decrease Fine Adjustment

3 Increase/Decrease Coarse Adjustment OR

Select stainless steel tubing size (French size) for suction

irrigator.

1-10

Integrated Power Console (IPC™) System

Page 11

IPC™ SYSTEM

Pre-and Post-operating instructions

The following are general IPC™ pre- and post-operating instructions. Refer to other sections of this IFU for operating instructions specic to

individual handpieces or accessories.

When the system arrives

• Verify the contents of the box match the packing slip. If incomplete or damaged, notify Medtronic Customer Service.

• If container is damaged, or cushioning material shows stress, notify carrier and Medtronic Customer Service. Keep shipping materials for

carrier inspection.

• Save the cartons and packing material. If the instrument is to be shipped the shipping package will provide proper protection.

Set up the IPC™

Refer the related topics for detailed instruction.

1. Install pump cartridges or irrigation tubing.

2. Prepare IPC™ for use.

3. Calibrate touchscreen, if necessary.

4. Change system settings, if necessary.

5. Set up and prime pumps.

6. Conrm system operation.

7. Press the manual start/stop button on the back of the console (Figure 1-2) and verify you can start/stop the handpiece, irrigation and/or

coolant ow.

Install the pump cartridges or irrigation tubing

1. Locate the correct pump and lift up the lock (Figure 1-10).

Pump 1: Coolant, lens cleaning or irrigation

Pump 2: Irrigation

Note: The number on the pump must match the number on the cartridge (either 1/1

or 2/2). If the cartridge does not have a pump designator number, use the Pump Setup

Screen to install the pump cartridge.

2. Insert the pump cartridge.

3. Snap the pump lock shut.

Note: Ensure the pump cartridge does not crimp the tubing.

Figure 1-10. Install Pump Cartridge

1

2

3

Prepare IPC™ for use

1. Verify Operation Room set up (Figure 1-7). The surgeon may have preferences to the location and visibility.

2. Verify the wheels are locked on the IPC™ cart.

3. Inspect all components for damage and determine if the system is ready for use.

4. Mount the IPC™ and irrigation/coolant bags on the I.V. pole (Figure 1-8).

Notes:

• Mount irrigant and coolant bags above the IPC™ to ensure adequate ow.

• It is recommended to use an irrigation pole with minimum base diameter of 53 cm and to mount all items as low as possible to increase

stability during use.

• For transport or uneven oor conditions greater than 10 degrees, maximum height to mount the console is 38 cm if irrigation and coolant

bags are at fully extended pole height.

5. Plug the IPC™ into the power source. Position the IPC™ so that it does not obstruct the power source for the purpose of disconnecting the

Main voltage by the power cord.

6. Locate the correct foot pedal or accessory connection port on the connector panel (Figure 1-3), align the mark on the connector to the mark

on the console, and then insert the connector.

7. Connect suction, cooling and/or irrigation tubing.

8. Turn on the IPC™ and verify the system passes the self-test and the accessory screen appears on the IPC™ monitor.

Note: If the IPC™ does not detect a handpiece or foot pedal the Connect Handpiece/Connect Foot Switch screen appears. Do the following:

• Verify the cable is connected to the correct connection port.

• Press [OK] in the Connect Handpiece/Connect Foot Switch message window to continue use of the IPC™ without the handpiece or foot

pedal.

Calibrate touchscreen

Note: This step is optional.

1. Turn on the IPC™ console.

2. When the system starts, on the Splash screen, press [Settings].

3. On the Settings screen, press Touch Screen Calibration and follow the screen prompts.

Integrated Power Console (IPC™) System

1-11

Page 12

IPC™ SYSTEM

Change system settings

Note: During surgery, system settings can be overwritten.

1. Turn on the IPC™ console.

2. While the system starts, on the Splash screen, press [Settings].

3. To change the language, press the appropriate language.

4. To change the default settings, press [Default].

• On the Default screen, press the Forward or Backward arrow to change the accessory.

• Make changes to the default settings.

• To conrm system settings and return to the Splash screen, press [OK].

5. For accessories with audible tones, press the REV Audible Tones button to control the following:

• The system delivers one set of reverse beeps when the Reverse mode is activated.

• The system delivers one set of reverse beeps the rst time the drill is used in Reverse mode after the Reverse mode has been activated.

6. To conrm system settings and continue to the IPC™ touchscreen, press [OK].

7. To restore settings to factory default, press [Restore].

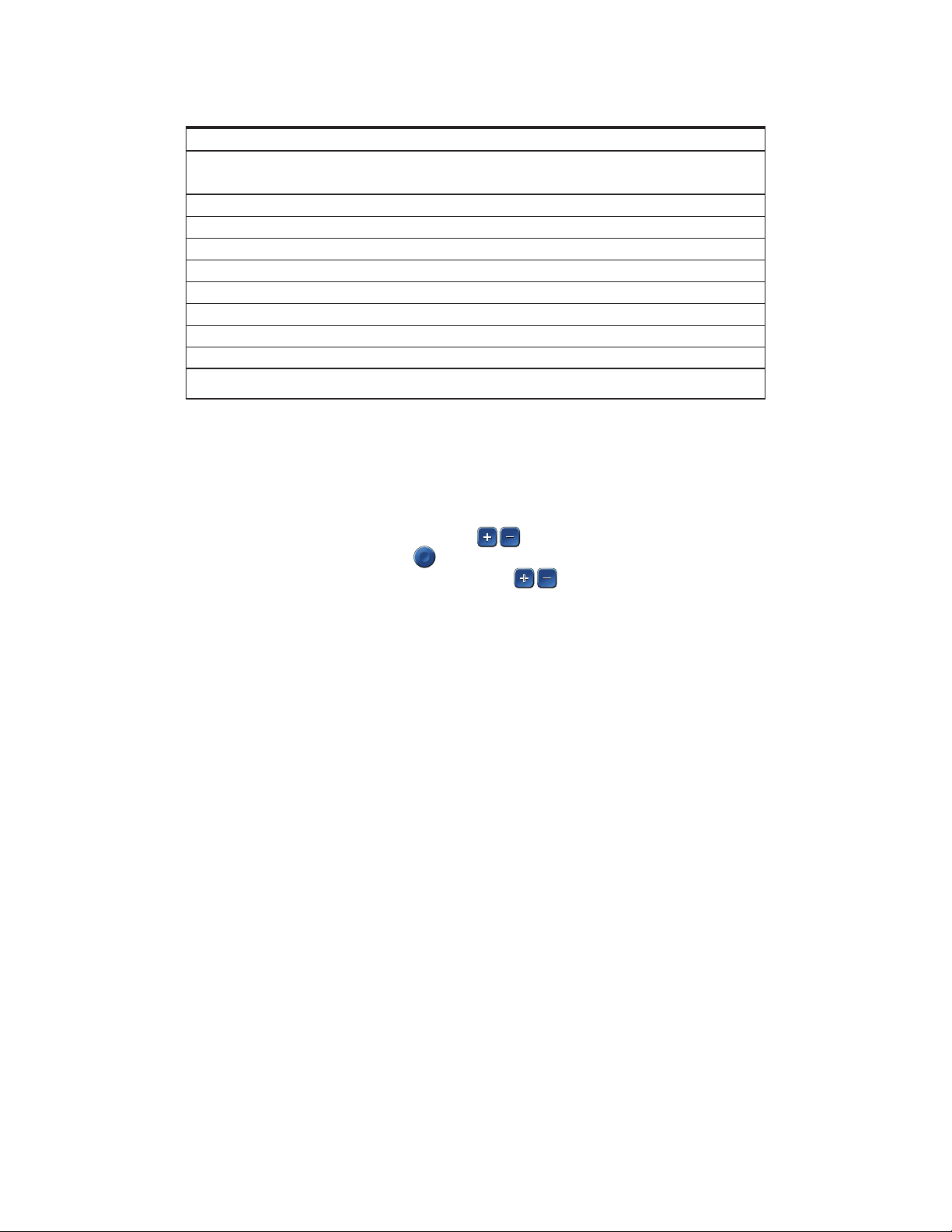

Handpiece default settings

The system conguration is dependent on the handpiece(s) connected to the console. The following table denes the default congurations,

default settings (X) and default options (O).

Note: During use, update the default settings for the active handpiece by pressing the Set active handpiece settings as default settings

button (Figure 1-5).

Table 1. IPC™ Touchscreen Default Congurations

Speed Mode or Mode Select Switch

Handpiece rpm cpm % Forward Oscillate Reverse Acceleration Deceleration Size Flow Irrigation Control

Visao™ 80000 X O 30

Indigo™ 52000 X O 30

StraightShot™ M5 5000 O X 05

StraightShot™ M4 5000 O X 05

StraightShot™ III, Magnum™ II 5000 O X 30

Skeeter™ 16000 X O v 0

Endo-Scrub™ 2 3

Suction Irrigator 8 50 %

Set up and prime pumps

• The IPC™ turns on pump 1 and/or 2 long enough to purge air out of the tubing set(s) the rst time the prime button is pressed.

• The IPC™ resets the prime feature when you turn IPC™ power O and On.

• After you prime the pump, the prime button and functionality become ush functionality.

1. Connect tubing from an IPC™ cartridge to irrigation or coolant port on an accessory.

2. On the irrigation tubing, turn the clamp to OPEN.

3. If an accessory uses the clear drip chamber (Visao™), ll the clear drip chamber with coolant. To ll, squeeze and release the chamber until

full.

4. On the IPC™ touchscreen (Figure 1-5), press the pumps button.

Note: The IPC™ pumps screen is also available from the Connect Handpiece/Connect Foot Switch screen which the system displays during

IPC™ preparation for use if a handpiece or foot switch is not detected by the system.

5. On the IPC™ pumps screen (Figure 1-6), select the accessory for each pump.

6. For each pump, press the prime button and verify the following:

• Pump(s) run until air is completely purged from tubing.

• Small amount of lubricant ows at the tip of the irrigation device.

• Pump(s) turns o.

7. Press the close button.

1-12

Integrated Power Console (IPC™) System

Page 13

IPC™ SYSTEM

+

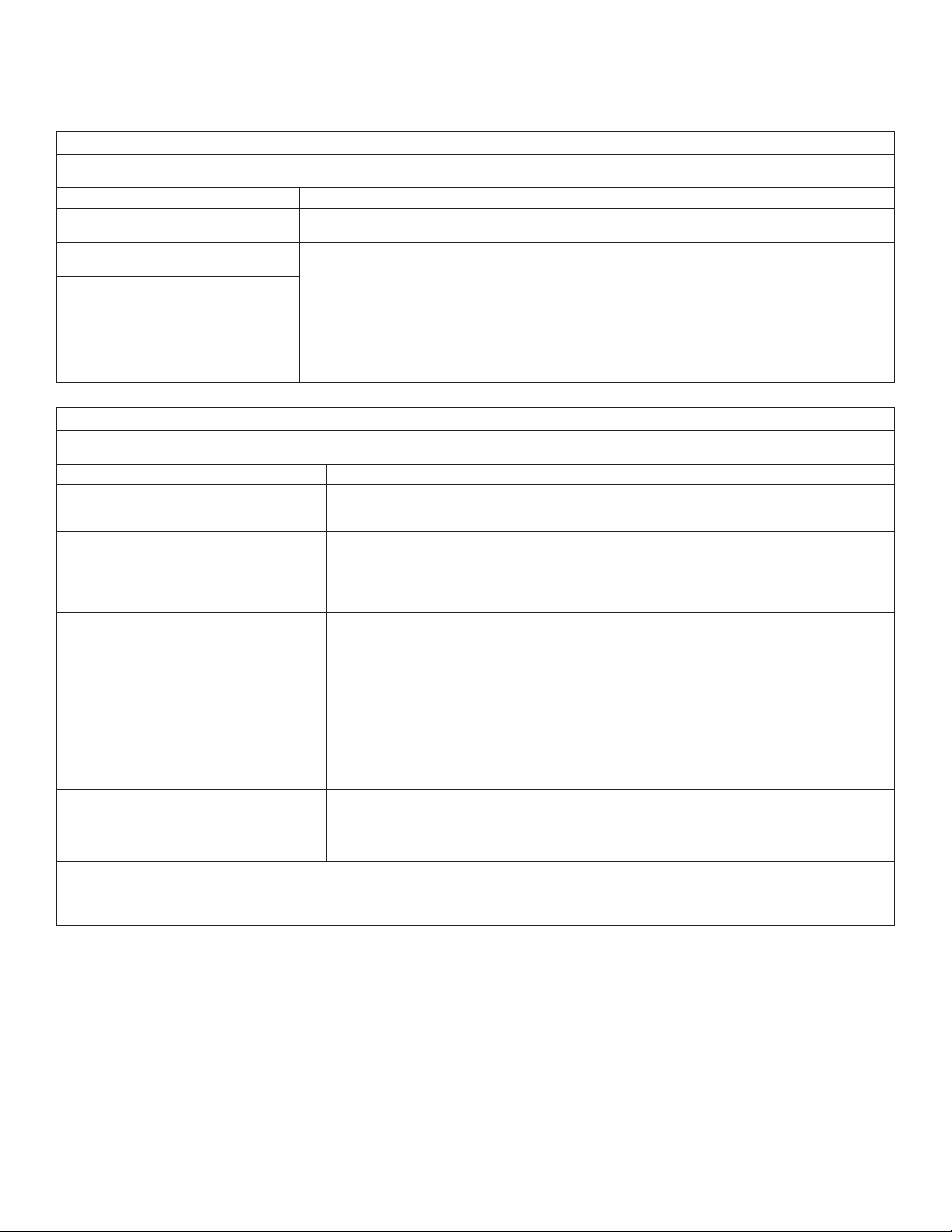

Pump default congurations

The pump conguration is dependent on the handpiece(s) connected to the console. The following table denes the pump default settings (X)

and default options (O).

Table 2. IPC™ Pumps Screen Default Congurations

Pump 1 Pump 2 Endo-Scrub™ 2 Suction Irrigator

Handpiece Cooling Irrigation Irrigation Pump 1 Pump 2 Pump 1 Pump 2

Visao™ X X O O

Indigo™ O X O O O O

StraightShot™ M5 O X* X O

StraightShot™ M4 O X* X O

StraightShot™ III, Magum II O X* X O

Skeeter™ O O O O

Endo-Scrub™ 2 X O X O

Suction Irrigator O O O O

* When the IPC™ detects both the StraightShot™ M4 or StraightShot™ M5 and the Legend EHS Stylus Touch handpiece, by default, the system sets

pump 2 as a “shared” irrigation pump. You must manually connect the irrigation tubing to the active handpiece.

Conrm system operation

1. Conrm the irrigation pedal starts handpiece and irrigation ow. Verify the speed changes from white to yellow in the Speed box on the

touchscreen.

2. Conrm the foot pedal buttons operate. Refer to Multifunction foot pedal for details.

3. On the touchscreen, verify you can do all of the following:

• Adjust Speed: In the Speed box, press the plus and minus buttons.

• Change Modes: In a Mode box, press any mode button.

• Adjust Flow Rate: In the Irrigation box, press the plus and minus buttons.

+

+

+

Disassemble the IPC™

1. Remove irrigation tubing or cartridge from IPC™ pump.

Note: Before removing the tubing from the pump, adjust the clamp on the intravenous tubing to the CLOSED position to prevent excessive

drainage of irrigant from the intravenous bag.

2. Disconnect components and cables. To disconnect non-silicone multi-pin cables from the console, push the cable toward the console and

then pull out by the lock ring.

Note: Silicone insulated multi-pin and single pin cable connectors do not have a lock ring. Remove these types of cable connectors straight

from the connector panel.

3. After disconnecting insulated connectors from the console, connectors that have debris under the insulator must be cleaned according to

Cleaning and Sterilization instructions. If debris is still present after cleaning and sterilization, return for warranty servicing.

4. See Cleaning and sterilization section of this User’s Guide for instructions.

IPC™ components

Auxiliary power to console

• The auxiliary power outlet is available for use with the Hydrodebrider™ and Bone Mill consoles only.

• The auxiliary power outlet is for use at grid voltage ≤120 VAC only.

Multifunction foot pedal

You can use the multifunction foot pedal (Figure 1-4) to start/stop the handpiece, control handpiece speed, handpiece selection and mode of

operation. Refer to the Multifunction foot pedal controls topic for each handpiece for specic use and control.

Y-Splitter

Y-Splitter (Figure 1-4) allows using a maximum of two multifunction foot pedals connected to a single IPC™. In this conguration, the Y-Splitter

shall be connected to the IPC™, and the multifunction foot pedal(s) shall be connected to the Y-Splitter. When connecting a single foot pedal to

the Y-Splitter, you may connect to either Port 1 or 2.

Integrated Power Console (IPC™) System

1-13

Page 14

IPC™ SYSTEM

IntelliFlow™ irrigation remote control

Use the IntelliFlow™ irrigation remote control (Figure 1-9) to start/stop and change irrigation ow while in the sterile eld.

If you are using handpiece irrigation:

• To pause irrigation ow, press the Pause/On-O button.

• To adjust ow rate, press the Fine Adjustment or Coarse Adjustment Increase/Decrease button.

If you are using the Suction Irrigator:

• To pause or turn on/o the Suction Irrigator, press the Pause/On-O button.

• To adjust ow rate, press the Fine Adjustment Increase/Decrease button.

• To select the stainless steel tubing size (French size), press the Stainless Steel Tubing Size button.

1-14

Integrated Power Console (IPC™) System

Page 15

IPC™ SYSTEM

Electromagnetic compatability

Environment of Intended Use: Professional healthcare facility environment

Guidance and manufacturer’s declaration – electromagnetic emissions

The IPC™ System is intended for use in the electromagnetic environment specied below. The customer or the user of the IPC™ System should assure that it is used in such an

environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic

emissions

IEC 61000-3-2

Voltage

uctuations/icker

emissions

IEC 6100-3-3

The IPC™ System is intended for use in the electromagnetic environment specied below. The customer or the user of the IPC™ System should assure that it is used in such an

environment.

Immunity test IEC 60601-1-2 test level Compliance level Elec tromagnetic environment - guidance

Electrostatic

discharge (ESD) IEC

61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

Power frequency

(50/60 Hz)

magnetic eld

IEC 61000-4-8

NOTES:

1. UT is the mains voltage prior to application of the test level.

2. When the console is powered and connected to the footswtich, application of -15KV air discharge onto the footswitch buttons may cause the console to freeze. Power cycle the

console to re-establish normal operation.

Group 1 The IPC™ System uses RF energy only for its internal function. Therefore, its RF emissions are very low and are not likely to cause

Class A The IPC™ Systems suitable for use in all establishments, ther than domestic and those directly connected to the public low-

Class A

Complies

any interference in nearby electronic equipment.

voltage power supply network that supplies buildings used for domestic purposes.

Guidance and manufacturer’s declaration – electromagnetic immunities - part I

± 8 kV contact

± 15 kV air

± 2 kV for power supply lines

± 1 kV for input/output lines

± 1 kV line to line

± 2 kV line to earth

0% UT (100% dip in UT)

for 0.5 cycle at 0°, 45°, 90°, 135°,

180°, 225°, 270°, and 315°

0% UT (100% dip in UT)

for 1 cycle at 0°

40% UT (60% dip in UT) for

5 cycles

70% UT (30% dip in UT) for 0.5 sec

0% UT (100% dip in UT) for 5 sec

30 A/m 30 A/m Power frequency magnetic elds should be at levels characteristic of a typical location

± 8 kV contact

± 15 kV air

± 2 kV for power supply lines

± 1 kV for input/output lines

± 1 kV line to line

± 2 kV line to earth

0% UT (100% dip in UT)

for 0.5 cycle at 0°, 45°, 90°, 135°,

180°, 225°, 270°, and 315°

0% UT (100% dip in UT)

for 1 cycle at 0°

40% UT (60% dip in UT) for

5 cycles

70% UT (30% dip in UT) for 0.5 sec

0% UT (100% dip in UT) for 5 sec

The relative humidity should be at least 5% Note-1.

Mains power quality should be that of a typical commercial or hospital environment.

Mains power quality should be that of a typical commercial or hospital environment.

Mains power quality should be that of a typical commercial or hospital environment.

If the user of the IPC™ System requires continued operation during power mains

interruptions, it is recommended that the IPC™ System be powered from an

uninterruptible power supply or a battery.

in a typical commercial or hospital environment.

Integrated Power Console (IPC™) System

1-15

Page 16

IPC™ SYSTEM

Guidance and manufacturer’s declaration – electromagnetic immunities - part II

The IPC™ System is intended for use in the electromagnetic environment specied below. The customer or the user of the IPC™ System should assure that it is used in such an

environment.

Immunity test IEC 60601-1-2 test

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

NOTE: These guidelines may not apply in all situations. Electromagnetic propagation is aected by absorption and reection from structures, objects and people.

level

3 Vrms

150 kHz to 80 MHz

6 Vrms

150 kHz to 80 MHz

in ISM bands and

amateur radio bands

3 V/m

80 MHz to 2.7 GHz

9–28 V/m

Spot frequencies

385 MHz–5.785 GHz

Pulse modulation

Compliance level Electromagnetic environment - guidance

3 Vrms

150 kHz to 80 MHz

6 Vrms

150 kHz to 80 MHz

in ISM bands and

amateur radio bands

3 V/m

80 MHz to 2.7 GHz

9–28 V/m

Spot frequencies

385 MHz–5.785 GHz

Pulse modulation

Portable RF communications equipment (including peripherals such as antenna cables and external antennas)

should be used no closer than 30cm (12 inches) to any part of the IPC™ System, including cables specied by

the manufacturer. Othewise, degradation of the performance of this equipment may result.

Portable and mobile RF communications equipment should be used no closer to any part of the IPC™ System

including cables, than the recommended separation distance calculated from the equation applicable to the

frequency of the transmitter.

Recommended separation distance

where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer, E is the immunity test levels in volt per meter (V/m), and d is the recommended separation

distance in meters (m).

Interference may occur in the vicinity of equipment marked with the following symbol:

d = (6/E) √P

Recommended separation distances between

portable and mobile RF communications equipment and the IPC™ System

The IPC™ System is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the IPC™ System can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the IPC™ System as recommended

below, according to the maximum output power of the communications equipment.

Rated

maximum

output

power of

transmitter

P(W)

0.01 0.03 0.03 0.07 0.03 0.03 0.03 0.07

0.1 0.07 0.07 0.21 0.07 0.07 0.07 0.21

1 0.22 0.22 0.67 0.22 0.22 0.22 0.67

10 0.7 0.7 2.12 0.7 0.7 0.7 2.12

100 2.2 2.2 6.7 2.2 2.2 2.2 6.7

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in metres (m) can be determined using the equation applicable to the

frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE: These guidelines may not apply in all situations. Electromagnetic propagation is aected by absorption and reection from structures, objects and people.

380 MHz–390MHz

d = 0.22√P

430 MHz–470MHz

d = 0.22√P

Separation distance according to frequency of transmitter m

704 MHz–787MHz

d = 0.67√P

800 MHz–960MHz

d = 0.22√P

1.7 GHz–1.99GHz

d = 0.22√P

2.4 GHz–2.57GHz

d = 0.22√P

5.1 GHz–5.8GHz

d = 0.67√P

1-16

Integrated Power Console (IPC™) System

Page 17

IPC™ SYSTEM

Limited warranty

A. This Limited Warranty provides the following assurance for the customer who purchases a Medtronic IPC™ System. This Limited Warranty is

extended only to the buyer purchasing the IPC™ System directly from Medtronic or from its aliate or its authorized distributor or representative. The IPC™ System includes the console, motor or handpiece, foot control, motor cables, instrumentation cases and trays (hereafter referred

to as System Components), straight and angled motor attachments (hereinafter referred to as “Attachments”), bur guards and telescoping

tubes (hereinafter referred to as Semi-reusable Components) and dissecting tools, irrigation and coolant tubing, and Intelliow remote control

(hereinafter referred to as Single Use Components) and jointly referred to as the IPC™ System, unless specically noted.

i. Should a System Component fail to function to Medtronic’s published specications during the term of this Limited Warranty (one [1] year

from the date of sale of a new System Component or ninety [90] days from the date of sale of a refurbished or used System Component),

Medtronic will either repair or replace the Motor Component or any portion thereof.

ii. Should an Attachment fail to function to Medtronic’s published specications during the term of this Limited Warranty (ninety [90] days

from the date of sale of a new Attachment), Medtronic will either repair or replace the Attachment or any portion thereof.

iii. Should a Semi-reusable Component fail to function to Medtronic’s published specications during the term of this Limited Warranty (thirty

[30] days from the date of sale of a new Semi-reusable Component), Medtronic will replace the Semi-reusable Component or any portion

thereof.

iv. Should a Single Use Component fail to function to Medtronic’s published specications prior to its “use by” date Medtronic will replace the

Single Use Component.

B. To qualify for this Limited Warranty, the following conditions must be met:

i. The Product must be used on or before its “Use By” or “Use Before” date, if applicable.

ii. The Product must be used in accordance with its labeling and may not be altered or subjected to misuse, abuse, accident or improper

handling.

iii. Medtronic must be notied in writing within thirty (30) days following discovery of a defect.

iv. The Product must be returned to Medtronic within thirty (30) days of Medtronic receiving notice as provided for in (3) above.

v. Upon examination of the Product by Medtronic, Medtronic shall have determined that: (i) the Product was not repaired or altered by any-

one other than Medtronic or its authorized representative, (ii) the Product was not operated under conditions other than normal use, and

(iii) the prescribed periodic maintenance and services, if applicable, have been performed on the Product.

C. This Limited Warranty is limited to its express terms. THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED

WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Medtronic be liable for any consequential, incidental, prospective or other similar damage resulting from a defect, failure, or

malfunction of the IPC™ System, whether a claim for such damage is based upon the warranty, contract, negligence or otherwise.

D. The exclusions and limitations set out above are not intended to, and should not be construed so as to, contravene mandatory provisions of

applicable law. Users may benet from statutory warranty rights under legislation governing the sale of consumer goods. If any part or term of

this Limited Warranty is held by any court of competent jurisdiction to be illegal, unenforceable, or in conict with applicable law, the validity

of the remaining portion of the Limited Warranty shall not be aected, and all rights and obligations shall be construed and enforced as if this

Limited Warranty did not contain the particular part or term held to be invalid.

For items contaminated with TSE agents

Medtronic recommends incineration of devices that have directly or indirectly contacted patients suspected or conrmed with prions or a

Transmissible Spongiform Encephalopathy (TSE) such as Crutzfeldt-Jakob disease (CJD).

Integrated Power Console (IPC™) System

1-17

Page 18

ENDOSCRUB™ 2

(5)

Endo-Scrub™ 2

Device description

The system can be used to clear the end of a rigid rod endoscope in order to maintain good visualization of endoscopic procedures without

having to remove the scope from the surgical site.

Indications for use

The device is indicated for use during routine diagnostic procedures and during endoscopic sinus surgery with standard mechanical

instruments.

The IPC™ System incorporates Endo-Scrub™ 2 functionality by using irrigation pump number one (1) and controlling operation with the touch

screen and an external foot pedal or nger switch.

DO NOT use the Endo-Scrub™ 2 for infusion, for disinfection or sterilization of an endoscope, or for suction removal of blood and debris.

Use the Endo-Scrub™ 2 sheath only with an endoscope listed on the sheath product label, as malfunction or poor performance could result.

Figure 2-1. Endo-Scrub™ 2 Finger Switch Figure 2-2. Endo-Scrub™ 2 Foot Pedal

(1)

(2)

1 Finger switch 4 Light connection

2 Endo-Scrub™ 2 sheath 5 Finger Switch cable

3 Irrigation connection

(3)

(4)

Endo-Scrub™ 2 assembly

1. Inspect the endoscope to ensure that it is in good condition. Imperfections will prevent complete retraction of irrigant. The scope lens should

be free of ne pits, microcracks, or rough seals. The endoscope barrel should be free of mineral deposits or other encrustation.

2. Wet interior insertion port of the plastic sheath hub and outer surface of the endoscope shaft prior to assembly. Wetting both surfaces of

each item allows for easier positioning.

3. Slowly, slide the approved endoscope into the Endo-Scrub™ 2 sheath (Figure 2-3). The endoscope tip MUST NOT extend past the sheath end

as irrigation run-in will occur.

Note: Do not force the endoscope fully into the plastic hub. The sheath may be damaged beyond use if the endoscope is pushed fully into

the plastic hub.

4. Connect the irrigation tubing and a light source (Figure 2-4).

Figure 2-3. Endo-Scrub™ 2 Assembly Figure 2-4. Endo-Scrub™ 2 Assembly

Endo-Scrub™ 2 nger switch assembly

If using the Endo-Scrub™ 2 nger switch, complete the following:

1. Slide the nger switch onto the Endo-Scrub™ 2 sheath (Figure 4-1). Align the cutout section of the ring with the luer connector of the tubing

set. The nger switch is properly installed when the cutout section of the ring is rmly seated against the luer connector.

2. Activate the pump by pressing the actuator button located on the nger switch.

1-18

Integrated Power Console (IPC™) System

Page 19

ENDOSCRUB™ 2

Endo-Scrub™ 2 activation

1. To activate the Endo-Scrub™ 2 wash cycle, press and release the nger switch or multifunction foot pedal.

2. To initiate a continuous ow of irrigant, press and hold the nger switch or multifunction foot pedal.

Note: Do not use the Endo-Scrub™ 2 as a suction device. If blood or debris are suctioned into the sheath, it may be necessary to briskly ush

out the empty sheath by using a syringe lled with sterile normal saline solution.

Connect Endo-Scrub™ 2 to IPC™ console

1. Locate the Endo-Scrub™ 2 connector cover on the back of the IPC™ console (Figure 1-2).

2. Insert a small screwdriver in the notch on the cable connector cover and pull.

3. Connect the control switch cable to the cable connector.

4. Connect the Endo-Scrub™ 2 nger switch (Figure 2-1) or the multifunction foot pedal (Figure 2-2) to the console (Figure 2-5).

Endo-Scrub™ 2 touchscreen controls

To set or adjust Endo-Scrub™ 2 controls, on the IPC™ touchscreen, in the Flow section of the Endo-Scrub™ control box (Figure 2-6), do the

following:

• To enable the Endo-Scrub™ 2 , press the On/O check-box.

• To adjust the ow rate, press the plus button to increase ow rate or the minus button to decrease ow rate.

• To prime the pump, press the prime button.

Figure 2-5. IPC™ Endo-Scrub™ 2 Connection Port Figure 2-6. IPC™ Endo-Scrub™ 2 Touchscreen

(1)

1 Finger switch or foot pedal connection port

Endo-Scrub™ 2 in standalone mode

The Endo-Scrub™ 2 can operate as a standalone device by changing the IPC™ system defaults.

1. On the Defaults menu (Figure 2-7), in the Stand Alone section, select Endo-Scrub™ and then press [OK].

2. On the Handpiece Connection screen (Figure 2-8), in the Endo-Scrub™ box, press [OK].

Figure 2-7. IPC™ General System Default

Menu

Figure 2-8. Handpiece Connection Screen

Integrated Power Console (IPC™) System

1-19

Page 20

ENDOSCRUB™ 2

Endo-Scrub™ 2 cleaning and sterilization instructions

Refer to document 68E4005 in the Cleaning and Sterilization section.

Endo-Scrub™ 2 foot pedal cleaning

If debris is found under the foot pedal boot, return for warranty service.

Do not immerse or sterilize the foot pedal unit.

Do not use alcohol, other solvents or abrasive cleaners.

1. Wipe down the Endo-Scrub™ 2 foot pedal with a cloth dampened with a neutral enzymatic detergent, pH 6.0-8.0 or phenol based

disinfectant.

2. Dry the unit with a clean, non-abrasive cloth.

1-20

Integrated Power Console (IPC™) System

Page 21

STRAIGHTSHOT™ M5, STRAIGHTSHOT™ M4, STRAIGHTSHOT™ MAGNUM™ II, AND STRAIGHTSHOT™ III

12 3

2

StraightShot™ M5, StraightShot™ M4, StraightShot™ Magnum™ II, and StraightShot™ III

Device description

The StraightShot™ M5 Microdebrider handpiece is an accessory to the IPC™ system and uses a cannulated motor that provides a suction path

through the motor. The handpiece can operate at speeds of 30,000 rpm forward and 7500 rpm oscillate. The higher forward operating speeding

allows the handpiece to support high speed burs.

The StraightShot™ M4 Microdebrider, features a nger wheel that enables the user to rotate the cutting tip of specially designed straight and

curved rotatable blades. It is also compatible with non-rotating blades and burs. It includes a locking mechanism to prevent inadvertent rotation

of non-rotating blades. The lightweight design combines high power and precision performance and can operate in forward mode of 12000 rpm

for bur operation and 5000 rpm in oscillate for blade operation. The StraightShot™ M4 also provides irrigation tubing management grooves to

keep tubing out of the surgeon’s way during a procedure.

Note: The StraightShot™ III and the StraightShot™ Magnum™ II are not for sale in the United States.

The IPC™ incorporates the microdebrider at pump 2. Control operation of the microdebrider with the IPC™ touchscreen and the multifunction

foot pedal.

When the IPC™ detects both the StraightShot™ M4 or StraightShot™ M5 and the Legend EHS Stylus handpieces, the system defaults Pump 2 to

the Shared conguration. You must manually move the irrigation tubing from the inactive to the active handpiece. Use the pumps screen to

override the Shared default by selecting the StraightShot™ M4 or the Legend EHS Stylus for Pump 1. Refer to “Set up and Prime Pumps” for more

information.

Figure 3-1. StraightShot™ M5 Handpiece Figure 3-2. StraightShot™ Magnum™ II and III Handpiece

1

45

1 Finger wheel 4 Finger wheel lock 1 Suction barb 2 Locking collar

2 Irrigation tubing groove 5 Locking collar

3 Suction barb

StraightShot™ M4 and StraightShot™ M5 blade or bur assembly

1. Insert the tool aligning the tabs with the notches (Figure 3-3). Orientate the irrigation barb to the left or right side.

Note: The StraightShot™ M4 and the StraightShot™ M5 use a four-tab alignment system.

• For rotating straight blades, orient the irrigation barb at the 3 o’clock position for right-handed surgeons and 9 o’clock for left-handed

surgeons.

• For rotating curved blades, orient the irrigation barb at 3 o’clock.

• For rotatable blades, adjust the nger wheel with small back-and-forth motions until the blade is engaged.

2. Press the locking collar (Figure 3-4).

3. Release the locking collar.

Note: If the collar does not return to full out position adjust the nger wheel with small back-and-forth motions until collar pops out.

4. Pull on the blade or the bur to ensure engagement and visually check to make sure the distal tip of the inner blade is in contact with the

distal tip of the outer cannula (Figure 3-5).

Figure 3-3. Blade or Bur Assembly Figure 3-4. Blade or Bur Assembly Figure 3-5. Blade or Bur Assembly

Integrated Power Console (IPC™) System

1-21

Page 22

STRAIGHTSHOT™ M5, STRAIGHTSHOT™ M4, STRAIGHTSHOT™ MAGNUM™ II, AND STRAIGHTSHOT™ III

12

StraightShot™ M4 and StraightShot™ M5 suction and irrigation tube assembly

1. Attach a suction tube to the suction source and an irrigation tube on the irrigation barb (Figure 3-6).

2. Secure suction and irrigation in the irrigation groove on the handpiece (Figure 3-7).

Figure 3-6. Suction and Irrigation Assembly Figure 3-7. Suction and Irrigation Assembly

StraightShot™ Magnum™ II and StraightShot™ III blade and bur assembly

1. Press the collet and insert blade in collet (Figure 3-8).

2. Release the collet (Figure 3-8).

3. Pull on the tool to ensure engagement and check distal tip of inner blade is in contact with the distal tip of the outer cannula.

StraightShot™ Magnum™ II and StraightShot™ III suction and irrigation assembly

1. Attach a suction tube to the suction source and an irrigation tube on the irrigation barb (Figure 3-9).

2. Secure suction and irrigation tubing with tubing clips.

Figure 3-8. StraightShot™ II and III Blade and Bur Assembly Figure 3-9. StraightShot™ II and III Suction and Irrigation

Assembly

Connect StraightShot™ to IPC™ console

Locate the StraightShot™ connection port on the connector panel (Figure 3-10) and insert the connector.

Note: To insert multi-pin connectors (indicated by a silver or red mark on the connector), align the mark on the connector to the mark on the

console, then insert the connector.

Figure 3-10. IPC™ Connection Ports

1-22

1 Handpiece connection port

2 Multifunction foot pedal connection port

Integrated Power Console (IPC™) System

Page 23

STRAIGHTSHOT™ M5, STRAIGHTSHOT™ M4, STRAIGHTSHOT™ MAGNUM™ II, AND STRAIGHTSHOT™ III

StraightShot™ touchscreen controls

Note: The StraightShot™ Magnum™ II and StraightShot™ III handpiece screens feature the same controls as those shown on the StraightShot™

M4 touchscreen.

Note: When you stop the blade, one of the following occurs:

• If the IPC™ button is visible on the touchscreen, the inner blade returns to the same position it began.

• If the XPS button is visible on the touchscreen, the inner blade stops the current position.

To set or adjust StraightShot™ controls, on the IPC™ touchscreen, in the StraightShot™ Handpiece control box (Figure 3-11, 3-12), do the

following:

• To change rotation mode, select OSC (oscillating) or FWD (forward).

Note: The system displays the default Oscillating or Forward mode speed.

• To adjust speed for the StraightShot™ M4, StraightShot™ Magnum™ II, and StraightShot™ III, in the Speed control box, press the plus to

increase speed or the minus button to decrease speed.

Forward Mode: Default, 12000 rpm; variable adjustment from 50 to 12000 rpm.

Oscillate Mode: Default, 5000 rpm; variable adjustment from 50 to 5000 rpm.

• To adjust speed for the StraightShot™ M5, in the Speed control box, press the plus to increase speed or the minus button to decrease speed.

Forward Mode: Default, 12000 rpm; variable adjustment from 50 to 30000 rpm.

Oscillate Mode: Default, 5000 rpm; variable adjustment from 50 to 7500 rpm.

• To adjust the irrigation ow rate, in the Pump control box, press the plus button to increase ow rate or the minus button to decrease ow

rate. If intermittent ow is available, pressing the plus or minus button progresses the system through intermittent and continuous ow. The

system displays Intermittent when in intermittent ow mode.

Forward Mode: Default, 30 cc per minute.

Oscillate Mode: Default, 5 cc per minute.

Note: To adjust ow rate, you can use the touchscreen or the IntelliFlow Irrigation remote control.

• To rotate outer blade, use the nger wheel (Figure 3-1).

• In oscillating mode only, you can use the Blade Position control box to do any of the following:

Note: The motion indicator indicates rotation direction of the blade.

To enable the multifunction foot pedal to change rotation displacement, press the delta button.

To rotate inner blade in small increments, press the counter-clockwise buttons.

Figure 3-11. StraightShot™ M4 Touchscreen Figure 3-12. StraightShot™ M5 Touchscreen

Integrated Power Console (IPC™) System

1-23

Page 24

STRAIGHTSHOT™ M5, STRAIGHTSHOT™ M4, STRAIGHTSHOT™ MAGNUM™ II, AND STRAIGHTSHOT™ III

1

24

Microdebrider blade control

Note: Periodically submerse blade tip in sterile water, with suction on, to keep blades clear during the procedure.

• To rotate the outer blade (Figure 3-13), use the nger wheel (Figure 3-1).

• To rotate the inner blade, use the Blade Position control box on the IPC™ touchscreen. Refer to the related accessory Controls topic for further

information.

Multifunction foot pedal controls

By default, press each button on the foot pedal for at least 100 ms for the selection to become active. Use the IPC™ touch screen Settings screen

to change the default value.

To use the multifunction foot pedal (Figure 3-14) to control the handpiece do the following:

• To select forward or oscillate mode, press the mode button.

• To start or adjust the speed of a handpiece in variable mode, press the foot pedal.

• To rotate the inner blade (60 or 180), press the control button.

• To change the handpiece, press the handpiece button.

Figure 3-13. Blade Dissection Figure 3-14. Multifunction Foot Pedal & Y-Splitter

1

5

4

2

1

5

3

1 Suction ow in through inner blade irrigation ow between inner and outer blades 1 Mode button 5 Foot pedal

2 Outer blade 2 Handpiece button 6 Y-Splitter

3 Inner blade 3 Control button 7 Port 1

4 Outer sleeve 4 Slip-resistant food pad 8 Port 2

6

3

7

8

2

4

Cleaning and sterilization instructions

Refer to document 68E3282 in the Cleaning and Sterilization section.

StraightShot™ M4 technical specications

StraightShot™ M4 1898200T

Size 14.3 cm Length x 1.8 cm Width (1898200T)

Weight 228 g 1898200T

Speed 50-5000 rpm oscillate

50-12000 rpm forward

Duty Cycle for Applied Part The StraightShot™ M4 handpiece under full load is rated for intermittent operation per the following:

Maximum On Time: 60 seconds

Minimum O Time: 30 seconds

3

1-24

Integrated Power Console (IPC™) System

Page 25

STRAIGHTSHOT™ M5, STRAIGHTSHOT™ M4, STRAIGHTSHOT™ MAGNUM™ II, AND STRAIGHTSHOT™ III

StraightShot™ M5 technical specications

StraightShot™ M5 1899200

Size 12.5 cm Length x 2.0 cm Width (1899200)

Weight 203 g 1899200

Speed 50-7500 rpm oscillate

50-30000 rpm forward

Duty Cycle for Applied Part The StraightShot™ M5 handpiece under full load is rated for intermittent operation per the following:

Maximum On Time: 60 seconds

Minimum O Time: 30 seconds

StraightShot™ Magnum™ II and StraightShot™ III technical specications

StraightShot™ Magnum™ II 1897200

StraightShot™ III 1897201

Size 17 cm Length x 1.6 cm Width (1897200/1897201)

Weight 240 g 1897200, 1897201

254 g 1897200T

Speed 50-5000 rpm oscillate

50-12000 rpm forward

Duty Cycle for Applied Part Under full load is rated for intermittent operation per the following:

Maximum On Time: 60 seconds

Minimum O Time: 30 seconds

Integrated Power Console (IPC™) System

1-25

Page 26

SKEETER™ ULTRALITE OTOTOOL

4

Skeeter™ Ultra-Lite Oto-Tool

Device description

The Skeeter™ handpiece and burs may be used with the IPC™ via direct connection with the Skeeter™ handpiece connector. The lightweight

Skeeter™ Ultra-Lite Oto-Tool Handpiece weighs 57 grams. The drill shaft diameter is approximately 2mm and is angled approximately 15 degrees

from the plane of the handpiece. The shaft angulation and small diameter maximize visualization of the surgical eld during drill use.

The Skeeter™ is used with the Oto-Flex bur. The Oto-Flex bur, designed for use with the Skeeter™, are composed of a exible stainless steel shaft

with a bur and a PTFE bearing at one end, and the handpiece engagement at the other. The inside of the PTFE bearing is lightly coated with

silicone spray to reduce operating friction.

Oto-Flex bur color coding

For identication of size, all Oto-Flex Burs are color coded. Diamond burs are further dierentiated from carbide burs by a white band on the

shaft of each diamond bur. A color code chart is provided in the base of the Oto-Tool System sterilization case. The bur size identication color

codes are as follows:

Color Bur Size Color Bur Size Color Bur Size

Violet 0.5 mm Yellow 0.8 mm Brown 1.8 mm

Blue 0.6 mm Orange 1.0 mm Red 2.3 mm

Green 0.7 mm Gray 1.4 mm Black Specialty

Skeeter™ assembly

1. Press the bur release button (Figure 4-1).

2. Load the desired bur for the procedure into the handpiece by inserting the bur shaft through the distal end of the handpiece with a slight

twisting motion while simultaneously pressing the bur release button.

3. The bur is locked into place when a “click” is noted. Locking of the bur should be checked prior to use by rmly pulling on the bur after the

“click” is noted.

4. Tug the bur to ensure it ts securely in the handpiece.

5. To remove the bur from the handpiece, press the bur release button on the handpiece and pull the bur out.

Connect Skeeter™ to IPC™ console

On the IPC™ Console, locate the Skeeter™ accessory connection port on the connector panel (Figure 4-2), align the mark on the connector to the

mark on the console, then insert the connector.

The Skeeter™ does not use irrigation. By default, the system sets both pumps to None.

Control the operation of the Skeeter™ with the IPC™ touchscreen and the multifunction foot pedal.

Figure 4-1. Skeeter™ Handpiece Assembly Figure 4-2. IPC™ Connection Port

3

2

1

(1) (2)

5

1 Bur at distal end 4 Bur shaft 1 Skeeter™ handpiece connection port

2 Bur color code 5 Bur release button 2 Multifunction foot pedal connection port

3 PTFE bearing

1-26

Integrated Power Console (IPC™) System

Page 27

SKEETER™ ULTRALITE OTOTOOL

Skeeter™ touchscreen controls

To set or adjust Skeeter™ controls, on the IPC™ touchscreen, in the Skeeter™ control box (Figure 4-3), do the following:

• To change rotation mode, in the Mode control box, select FWD (forward) or REV (reverse).

• To adjust speed, in the Speed control box, press the plus button to increase speed or the minus button to decrease speed.

Default, 16000 rpm; variable adjustment from 1000 to 16000 rpm.

Skeeter™ multifunction foot pedal controls

By default, press each button on the foot pedal for at least 100 ms for the selection to become active. Use the IPC™ touch screen Settings screen

to change the default value.

To use the multifunction foot pedal (Figure 4-4) to control the handpiece do the following:

• To select Forward or Reverse mode, press the mode button.

• To start or adjust the speed of a handpiece in variable mode, press the foot pedal.

• To toggle between the start/stop mode and variable speed mode, press the control button.

• To change the handpiece, press the handpiece button.

Figure 4-3. Skeeter™ Touchscreen Figure 4-4. Multifunction Foot pedal and Y-Splitter

Skeeter

Speed

16000

RPM

+

+

Mode

FWD

REV

1

5

4

2

1

6

3

7

8

2

1 Mode button 5 Foot pedal

2 Handpiece button 6 Y-Splitter

3 Control button 7 Port 1

4 Slip-resistant food pad 8 Port 2

Skeeter™ cleaning and sterilization instructions

Refer to documents 68E3968 and 68E3969 in the Cleaning and Sterilization section.

Skeeter™ technical specications

Skeeter™ 3055601

Size 17 cm Length x 1.6 cm Diameter

Weight 57 g

Speed 1000-16000 rpm forward/reverse

Duty Cycle for Applied Part Continuous run

Storage Temperature -40 C to +70 C

Humidity 10 % to 100 % RH

Barometric Pressure 500 to 1060 hPa

3

5

4

Integrated Power Console (IPC™) System

1-27

Page 28

INDIGO™ HIGHSPEED OTOLOGIC DRILL

1 Correct Alignment

Indigo™ High-Speed Otologic Drill

Device description

The Indigo™ High-speed Otologic drill is a small, compact high-speed, high-torque, reversible electric drill that can be used to dissect bone and

biomaterial at variable speeds from 200 to 60000 rpm. The cable cannot be removed from the drill.

The Indigo™ drill is designed to work only with Medtronic burs and Indigo™ attachments. The use of other burs and attachments may result in

sub-standard performance and will void the manufacturer’s warranty.

Indigo™ drill straight attachment assembly

1. Verify the alignment marks on the motor collet are in alignment (Figure 6-1).

Note: If the marks are misaligned, turn the collet until the marks are aligned.

2. Slide the attachment over the motor collet (Figure 6-2) so that the alignment mark on the attachment aligns with the alignment mark

(unlocked symbol) on the motor collet.

3. Insert the bur with a slight twisting motion until you feel it seat into position.

4. Turn the attachment so the alignment mark aligns with the locked symbol on the motor collet. You will hear two clicks while rotating the

attachment.

5. To ensure a secure t, gently pull the tool.

Note: The Indigo™ motor will not run correctly unless the attachment is in the locked position.

Indigo™ drill angled attachment assembly

1. Verify the alignment marks on the motor collet are in alignment (Figure 6-1).

Note: If the marks are misaligned, turn the collet until the marks are aligned.

2. Slide the attachment over the motor collet (Figure 6-3) so that the alignment mark on the attachment aligns with the alignment mark

(unlocked symbol) on the motor collet.

3. Turn the attachment so the alignment mark aligns with the locked symbol on the motor collet. You will hear two clicks while rotating the

attachment.

4. Verify the alignment marks on the tool lock ring align with the unlocked symbol on the attachment.

5. Insert the bur with a slight twisting motion until you feel it seat into position.

6. Turn the lock ring so the alignment mark aligns with the locked symbol on the attachment. You will hear two clicks while rotating the

attachment.

7. To ensure a secure t, gently pull the tool.

Note: The Indigo™ motor will not run correctly unless the attachment and lock ring is in the locked position.

Figure 6-1. Indigo™ Alignment

Indigo™

High-Speed Otologic Drill

23

6 Incorrect Alignment

Indigo™

High-Speed Otologic Drill

1 Correct Alignment 4 Indigo™ Motor

2 Stationary Collet 5 Cable

3 Rotating Collet 6 Incorrect Alignment

4

5

1-28

Integrated Power Console (IPC™) System

Page 29

Figure 6-2. Indigo™ Straight Attachment Assembly Figure 6-3. Indigo™ Angled Attachment Assembly

12

Indigo™

High-Speed Otologic Drill

Indigo™

Indigo™

High-Speed Otologic Drill

High-Speed Otologic Drill

1

1 Tool Lock Ring