Medrad Vistron CT Service manual

I N J E C T I O N S Y S T E M

Service Manual

VSM 600 1

TM

95403-T-140 Rev. E

System Service Manual

INJECTION SYSTEM

Catalog Number: VSM 600 1

TM

95403-T-140 Rev. E

95403-T-140 REV. D

Copyright 2009 MEDRAD, INC.

All Rights Reserved

MEDRAD

Table of Contents

MEDRADTable of Contents

Section 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Copyright Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Patents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Restricted Sale Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Address / Telephone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Statement of Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

RF Emission Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Injector Symbols and Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Introduction to Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Section 2

Maintenance and Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Recommended Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Electrical Leakage Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Ground Continuity Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Operational Checkout Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Section 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

General Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Message Code Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

“U” codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

“P” codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

“d” codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

“C” codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Other malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 7

TOC - 1

MEDRAD Vistron CT Injection System

Section 4

Disassembly and Reassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Injector Head - Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

Injector Head - Pivot Knuckle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

Injector Head - Armed Indicator Lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Injector Head - Armed Indicator Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Injector Head - Keypad Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 6

Injector Head - PC Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Injector Head - Head Extension Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 11

Injector Head - Heater/Handswitch Card (HHC) . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 12

Injector Head - Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 13

Injector Head - Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 14

Injector Head - Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 16

Injector Head - Front Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 17

Injector Head - Syringe Size Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 21

Injector Head - Syringe Sensor Card (SSB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 23

Remote Monitor - Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 25

Remote Monitor - Overlay Switchcard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 26

Remote Monitor - PC Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 28

Remote Monitor - Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 30

System Power Console (SPC) - Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 32

System Power Console (SPC) - Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 33

System Power Console (SPC) - Interface Card . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 34

Section 5

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 4

Common System Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Power Control Unit (PCU) Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 7

Power Control Unit (PCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 8

Main Processing Unit (MPU) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 10

Main Processing Unit (MPU) Block Diagram - CPU. . . . . . . . . . . . . . . . . . . . . . . . .5 - 11

Main Processing Unit (MPU) Block Diagram - Motor Control . . . . . . . . . . . . . . . . .5 - 12

Main Processing Unit (MPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 13

Display Processor Unit (DPU) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 21

Display Processor Unit (DPU) Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 22

Display Processor Unit (DPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 23

Remote Monitor (Intelligent Hand Unit - IHU) Overview . . . . . . . . . . . . . . . . . . . . .5 - 26

Remote Monitor (Intelligent Hand Unit - IHU) Block Diagram . . . . . . . . . . . . . . . . .5 - 27

Remote Monitor (Intelligent Hand Unit - IHU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 28

AutoLink Interface - ISI Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 30

AutoLink Interface - ISI Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 31

AutoLink Interface - ISI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 32

TOC - 2

Table of Contents

Section 5 (continued)

Interconnection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 34

Power Supply Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 35

Cable Wiring Diagrams

Injector Head Extension Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 36

IHU Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 36

Handswitch Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 36

AutoLink Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 36

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 36

Section 6

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

Injector Head - External Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 2

Injector Head - Internal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Injector Head - Front Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 6

Injector Head - Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 8

Remote Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 10

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

TOC - 3

MEDRAD Vistron CT Injection System

TOC - 4

Introduction

1Introduction

Copyright Notice Copyright 1999 by MEDRAD INC. All rights reserved. No part of this

manual may be reproduced in any form without prior written permis

sion of MEDRAD. Printed and assembled in the U.S.A.

Trademarks MEDRAD Vistron CTTM, Qwik-Fit Syringe®, FluiDot®, Quality for Life®,

and MEDRAD

Patents The MEDRAD Vistron CT Injector and related syringes are the subject

of the following U.S. patent numbers: 4,677,980 and 5,383,858.

Restricted Sale Federal (U.S.A.) law restricts the sale of this device on or by the order

of a physician.

®

are registered trademarks of MEDRAD Incorporated.

-

Disclaimers MEDRAD makes no warranties on the contents of this manual, and

specifically disclaims any implied warranties of merchantability or fit

ness for any purpose.

MEDRAD reserves the right to change specifications and the contents

of this manual without obligation.

External wiring modification disclaimer: MEDRAD disclaims liability

for any modifications or interfaces with other equipment which are not

in conformity with the specifications and information contained within

this manual. Such unauthorized action could jeopardize injector opera

tion, safety, or reliability.

Accessory equipment connected to the analog and digital interfaces

must be certified according to IEC 601-1 standards. Furthermore, all

configurations shall comply with the system standard IEC 601-1-1.

Anyone who connects additional equipment to the signal input or out

put, configures a medical system, and is therefore responsible that the

system complies with the requirements of the system standard IEC

601-1-1. To obtain on-site consulting or consulting references, contact

MEDRAD Service.

All drawings in this manual are for reference purposes only, and may

not reflect the construction of units produced prior to the publication of

this manual. Reproduction quality of these drawings may have been

effected by the level of reduction required. Call MEDRAD Service if

assistance in drawing interpretation is required.

-

-

-

The MEDRAD Vistron CT Injector is not for portable use.

1 - 1

MEDRAD Vistron CT Injection System

Problems or

Questions

Applicability This manual applies to the VCT 600 Series MEDRAD Vistron CT Injec-

If you experience problems with the MEDRAD Vistron CT System, contact your MEDRAD authorized dealer or:

MEDRAD Service MEDRAD EUROPE B.V.

One MEDRAD Drive Postbus 3084

Indianola, PA 15051-0780 6202 NB Maastricht

USA The Netherlands

Phone: 1-412-767-2400 Phone:(31) (0) 43 3585601

1-800-MEDRAD-S FAX: (31) (0) 43 3650020

1-800-633-7237

FAX: 1-412-767-4126 Nihon MEDRAD K.K.

2-4-9 Umeda, Kita-ku,

Osaka, 530-0001

Japan

Phone:81-0-66-133-6250

Fax: 81-0-66-344-2395

tion Systems, and is referred to as the MEDRAD Vistron CT Injection

System, Vistron CT Injection System, MEDRAD Vistron CT Injector, or

Vistron CT Injector throughout this manual.

Purpose The purpose of this manual is intended to provide instructions for servic-

ing the MEDRAD Vistron CT Injection System safely and accurately. It is

intended for those qualified to service the injection system, whether they

be MEDRAD Service Personnel, Certified Laboratory Service Techni

cians or MEDRAD authorized international dealers.

Important

Safety Notice

Intended Use This device is designed specifically for the injection of intravenous con-

RF Emission

Standards

The information in this manual is intended for people with adequate

backgrounds and experience in electronics and electromechanical

devices. Any attempt to repair a sophisticated medical device such as

the injector may result in personal injury, property damage, or patient

injury.

trast media into humans for diagnostic studies in Computed Tomography

(CT) applications.

MEDRAD Vistron CT Injection Systems are equipped to operate at 100 240 VAC, 50/60 Hz, and designed to be in compliance with EN 60601 -1

(Safety), and EN 60601-1-2 (EMC/Emissions). The MEDRAD Vistron CT

Injector is classified per EN 60601-1 as a Class 1, with a Type BF

applied part. The following pictograph is displayed in recognition of this

international status:

-

1 - 2

Introduction

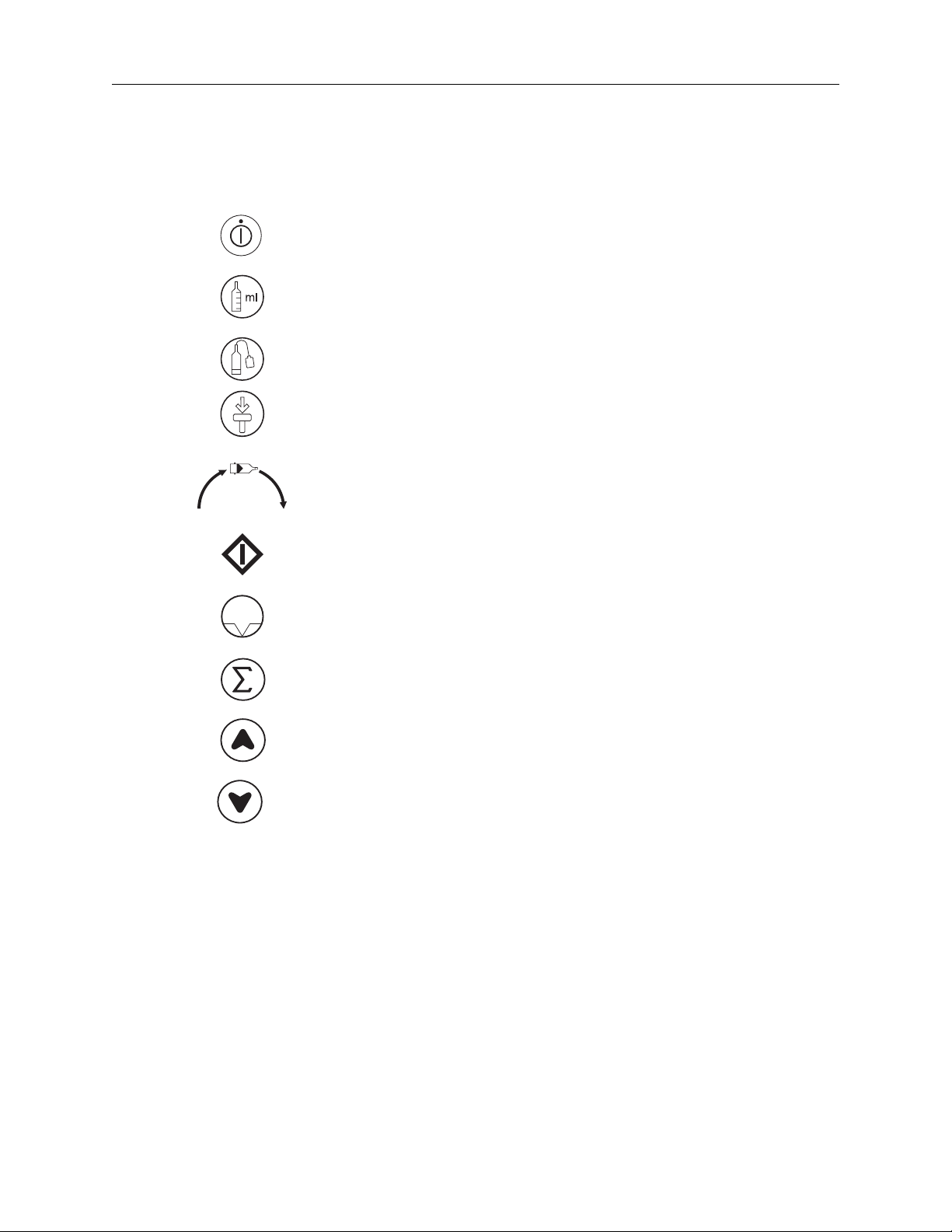

Symbols and

Descriptions

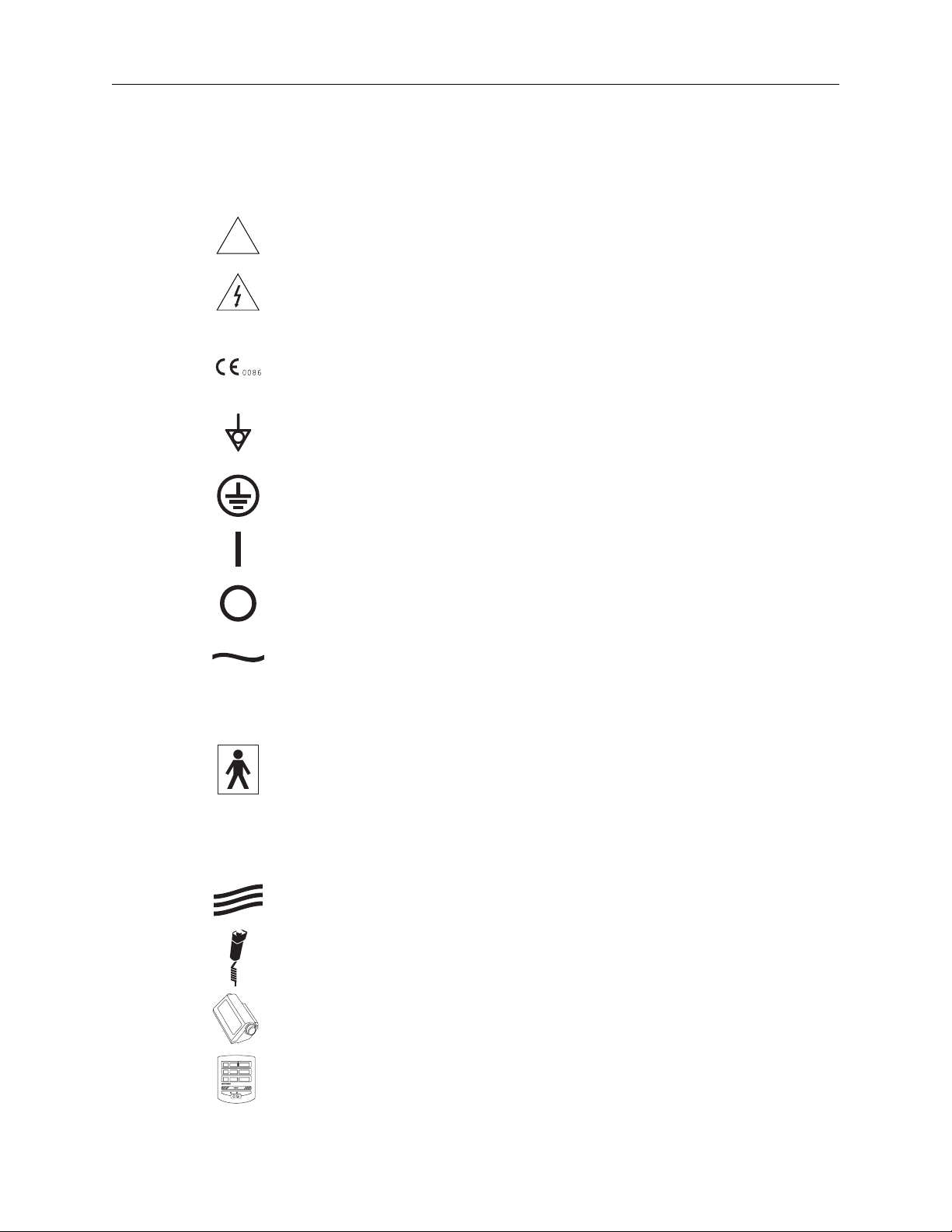

The following international symbols are used on the MEDRAD Vistron CT

Injector and throughout this manual.

!

Attention, consult accompanying instructions.

Attention, indicates hazardous voltages.

Indicates that this device conforms to the requirements of the European Medical Device Directive 93/42/EEC.

Identifies the equipotential ground.

Identifies the earth ground.

Identifies the ON switch position.

IPX1

CLASS 1

Identifies the OFF switch position.

Indicates alternating current.

Identifies the degree of protection against fluid as drip proof.

Identifies a type BF applied part complying with EN60601-1 standards.

Indicates the system is Class 1 medical equipment as defined by EN60601-1

standards

Identifies the connection on the Injector Head for the syringe heater.

Identifies connection of the remote Start/Hold Switch.

Identifies connection of the injector head cable.

Identifies connection of the remote monitor.

1 - 3

MEDRAD Vistron CT Injection System

Symbols and

Descriptions (cont.)

Identifies the Standby key.

Identifies the Fill Select key.

Identifies the Autofill key.

Identifies the Retract key.

Identifies rotation direction on the Manual Knob for manually moving the piston. Clockwise is forward movement.

J302

Identifies the START key.

Identifies the HOLD key.

Identifies the SUMMARY key.

Identifies the UP Arrow key. Use to increase values when programming

Identifies the DOWN Arrow key. Use to decrease values when programming

Identifies the AutoLink connector.

1 - 4

Introduction

INTRODUCTION TO

WARNINGS / CAUTIONS

This manual contains important information about safe servicing of the

MEDRAD Vistron CT Injection System.

MEDRAD urges the service technician to read this manual carefully,

become familiar with the procedures and system functions that it

describes, and follow its recommendations to assure proper servicing

of the system.

Warning labels on the MEDRAD Vistron CT system or Warning statements in this manual preceeded by any of the following words and/or

symbols are of special significance:

WARNING: Indicates a potentially hazardous situation. If

!

not avoided, this could result in death or serious injury.

WARNING: Indicates electrical hazards which could result

in death or serious injury.

CAUTION: Indicates potential hazards or unsafe practices

!

which could cause product, system, or property damage.

NOTE: Indicates helpful information is being offered.

1 - 5

MEDRAD Vistron CT Injection System

WARNINGS Injury may result from exposure to hazardous voltages

existing within the system. The system should be opened

and serviced by qualified service personnel only. Disconnect

the system from line power before cleaning or attempting to

perform any maintenance.

Explosion hazard in the presence of flammables. Do not

!

!

use the system in the presence of anesthetic gases and

equipment.

Patient or operator injury can occur from use of worn

power cords or control cables. Examine power cords and

cables for cuts, frays, or any other visible damage. Do not

use the system if any of the cords or cables show signs of

damage. Any damaged or worn connection cables or power

cords should be replaced.

Patient or operator injury can occur from a falling injector head or pedestal. Do not move the head, pedestal, or

counterpoise system by pulling on the injector head or

cabling. Move the injector by grasping the center of the ped

estal or vertical arm on the counterpoise.

-

Unsafe operation may result from using improper acces-

!

sories and replacement parts. Use only accessories,

options, and parts provided by MEDRAD, and designed for

this system.

1 - 6

Introduction

CAUTIONS

Damage may occur as a result of failure to follow electro-

!

!

!

!

static discharge (ESD) protection practices. ESD protection

practices must be followed when servicing any component of

this system.

Damage could result from improperly handled components. Before touching any of the circuit cards in the system,

discharge yourself to grounded metal. If memory components

are to be shipped, place the components in conductive carriers

(as supplied through MEDRAD).

Damage can occur as a result of incorrect voltages. Check

the voltage and frequency marked on the back of the Power

Supply. Ensure that the outlet providing power to the injector

supplies a voltage, frequency, and volt-ampere rating within

the range specified on the unit.

Environmental damage may result from improper disposal

of system components or accessories. Electronic assem

blies contain potentially hazardous materials. Follow all local

regulations for the recycling or disposal of electronic assem

blies, or contact MEDRAD Service for assistance.

-

-

Damage can occur as a result of abrupt interruption or

!

!

!

!

application of supplies. To avoid damage to sensitive circuits

on the boards, disconnect the power cord before removing or

replacing PC boards.

Allow system temperature to stabilize before use. To avoid

damage to sensitive electronic circuits, allow the system to sta

bilize to room temperature before servicing when exposed to

extreme temperature changes.

Perform regular preventive maintenance. To ensure that

your MEDRAD Vistron CT System remains properly calibrated,

and that all primary and backup circuits are functioning prop

erly, regular preventive maintenance is recommended. An

annual preventive maintenance package is not included in the

new machine warranty. Contact your local MEDRAD Service

Representative for details.

Damage may result from improper or careless cleaning

methods. While cleaning any outside portion of the system,

avoid allowing any water to seep inside system components.

NOTE: All relevant guidelines for institutional, local, or

national safety recommendations related to cable routing

and installation should be followed.

-

-

1 - 7

MEDRAD Vistron CT Injection System

CAUTIONS

(cont.)

!

!

The injector may disarm or fail to operate when exposed to

high magnetic fields. Do not use radio transmitters, cellular

phones, or devices generating electrostatic discharge in the

vicinity of this system.

Condensation may cause electrical damage to the injector.

Do not use the injector immediately after it has been brought

indoors from extreme outside temperatures. Allow the injector

he stabilize at room temperature before use.

1 - 8

Maintenance and Checkout

Maintenance and

2

Checkout Procedures

This section contains recommended procedures for maintenance, and

an operational checkout of the

Routine maintenance and inspection will:

• Ensure continued performance of the injection system

• Reduce the possibility of equipment malfunction

MEDRAD Vistron CT Injection System.

Maintenance General maintenance of the MEDRAD Vistron CT injection system

should consist of four primary procedures: Inspection, cleaning, elec

trical leakage and ground continuity checks, and operational checkout. This section contains guidelines and recommended methods for

each of these procedures:

1. Inspection: This first step should encompass inspection of the

entire system, looking for obvious signs of damage, such as;

cracks in the housing, frayed or worn cables, and contrast media

spills which may have leaked into the system.

-

2. Cleaning: This procedure involves the thorough cleaning of all

system components to remove any deposits of contrast medium. If

any substances have leaked into any part of the system, the sub

assembly should be disassembled and thoroughly cleaned.

3. Electrical Leakage / Ground Continuity Checks: To ensure the

safety of the patient and hospital personnel in injection system

operations.

4. Operational Checkout: A complete functional performance checkout of the injection system.

-

2 - 1

MEDRAD Vistron CT Injection System

Recommended

Maintenance

Schedule

Your MEDRAD Vistron CT Injection System must be properly main-

tained to ensure that it is in peak operating condition. Your individual

maintenance system and schedule depends upon how your injection

system is used; the type of procedures performed, and frequency of

use. The following maintenance schedule is recommended for the

system:

Daily:

The piston rod should be thoroughly cleaned after each use. Before

use each day, the system should be cleaned and inspected, using the

procedures outlined in this section. Ensure that all system safety and

warning labels are in place and are legible.

Monthly:

Once a month, the entire system should be thoroughly inspected and

cleaned, and an Operational Checkout should be performed.

Annually:

Once per year, both Electrical Leakage and Ground Continuity checks

should be performed.

NOTE: Local regulations or hospital protocol may require

electrical leakage checks at more frequent inter

vals. If this applies, local regulations for leakage

must be followed.

-

MEDRAD also recommends that a complete system calibration and per-

formance checkout, by a qualified MEDRAD Service Representative or

authorized dealer, be performed once a year. Cont

Service, or your local

In the United States, Canada, and Europe, the MEDRAD Service

Department offers Preventive Maintenance Programs. These annual

programs greatly assist in maintaining accuracy and reliability, and

can also extend the life of the system. Contact

In Europe, contact your local MEDRAD office or your local authorized

dealer for further information. Refer to the Introduction Section of this

manual for address, telephone and FAX information.

NOTE: Failures which occur due to lack of proper mainte-

nance will not be covered under warranty.

MEDRAD office for complete details.

act MEDRAD Factory

MEDRAD for details.

2 - 2

Maintenance and Checkout

Inspection

Procedures

Injector Head /

Control Panel

The following procedures are recommended for daily inspection of all

components in the M

are detected, either repair the system, or call M

not use the system until the problem is corrected.

1. Inspect the housing for any damage or cracks that could allow

fluid to leak inside, or weaken the structural integrity of the unit.

2. Examine the handswitch and cable: Look for cuts, cracks, or worn

spots in the cable; look for cracks and loose parts in the switch

and housing. Ensure that the switch operates without sticking.

3. Inspect all cables connected to the unit: Look for cuts, cracks,

worn spots or other obvious damage to the cables. Ensure that all

connectors are properly seated.

4. Inspect for contrast media build-up in the syringe interface area.

Follow the cleaning procedures outlined in this section.

5. Verify proper operation of all LED displays.

EDRAD Vistron CT Injection system. If any defects

EDRAD for service. Do

Syringe Heater 1. Ensure that the device is warm to the touch.

2. Ensure that the LED indicator is not illuminated or flashing.

3. Inspect the cable and connector for cracks, worn areas, or other

obvious damage.

System Power

Console

1. Inspect all cables connected to the unit: Look for cuts, cracks, or

worn spots, or other obvious damage. Ensure that all connectors

are properly seated.

2 - 3

MEDRAD Vistron CT Injection System

Remote Monitor 1. Inspect the housing for any damage or cracks that could allow

fluid to leak inside, or weaken the structural integrity of the unit.

2. Inspect the cable connected to the Remote Monitor: Look for cuts,

cracks, or worn spots in the cables; look for loose pins or strain

reliefs on the connectors. Ensure that the connector is properly

seated.

3. Inspect all parts of the wall mounting bracket for cracks or other

defects that would weaken the assembly. Ensure that the bracket

remains firmly attached to the wall.

Pedestal Mounts 1. Inspect the stand, base, and support arm for cracks and other

defects that could weaken the structure.

2. Ensure that all mounting bolts and screws are secure.

3. Ensure that the casters roll smoothly, with no binding or scraping.

CS Mounting

Systems

4. Ensure that all locking mechanisms on the casters are functional.

5. If applicable, verify that the vertical height adjustment of the column shaft moves freely, without binding or scraping.

6. Inspect the injector head pivots. The head and stand arm must

pivot freely. The injector head should rotate no more than 180

o

The stand pivot should not rotate more that 350

.

o

.

1. Inspect all parts of the arm and mounting system for cracks and

other defects that would weaken the system.

2. Ensure that the mounting system is securely assembled, with no

loose parts. The arm should be stable with the head installed.

3. Ensure that the arm moves smoothly in all directions, with no binding or scraping.

4. Verify that all cabling is tied back and does not interfere with the

movement of the supporting parts or the injector head.

2 - 4

NOTE: All relevant guidelines for institutional, local, or

national safety recommendations related to cable

routing and installation should be followed.

Maintenance and Checkout

Cleaning

Procedure

Deposits of contrast media can interfere with proper operation of the

Medrad Vistron CT Injection System. The following guidelines should be

followed when removing deposits, or cleaning any portion of the system.

WARNING: Injury may result from exposure to hazardous voltages existing within the system. Disconnect the

system from line power before cleaning or attempting to per

form any maintenance.

CAUTION: Improper or careless cleaning methods may

!

• If contrast medium has leaked inside any component of the system,

the effected subassembly should be disassembled and cleaned.

This cleaning procedure can be done in the field by trained Medrad

Service personnel, or returned to Medrad Factory Service. If the

cleaning will be performed in the field, do not disturb any internal wir

ing or components.

result in equipment damage. Do not soak or immerse any

part of the injection system in water. While cleaning any out

side portion of the system, avoid allowing any water to leak

inside system components.

-

-

-

• Care must be taken not to get water or cleaning solutions inside any

system components. Do not use strong industrial cleaning agents or

solvents such as acetone. Warm water and a mild disinfectant such

as antibacterial hand soap are all that is required.

• To clean the syringe interface area of the injector head, fully retract

the piston. Using a paper towel moistened with warm water or a mild

disinfectant, gently wipe the inner syringe installation area. Do not

insert any sharp instruments into this area during the cleaning pro

cess.

• The 100 ml syringe adaptor plate and piston extensions may be

removed and soaked or submerged in water or mild cleaning solu

tion. Ensure that the adaptor plate is completely dry before installing

onto the injector head.

• Check all System Safety and Warning Labels for legibility. Ensure

that the labels are not damaged or missing.

WARNING: Injury may result from exposure to hazardous voltages existing within the system. Ensure that the

system is completely dry before connecting to the power

source and applying power.

-

-

2 - 5

MEDRAD Vistron CT Injection System

Electrical

Leakage

Check

To ensure safe operation of the Medrad Vistron CT Injection System,

an electrical leakage check must be part of regular maintenance.

Use a commercial leakage tester such as one of the following:

MANUFACTURER MODEL

Bio-Tek Instruments, Inc. Model 601 PRO

Electrical Safety Analyzer

Bender Unimet 1000 ST

Bapco IEC601L

1. With the AC ground open, power applied, and the line at normal,

leakage should be less than 100 micro amps at 110V, or 300 micro

amps at 220V.

2. With the AC ground open, power applied and the line reversed,

leakage should be less than 100 micro amps at 110V, or 300 micro

amps at 220V.

3. Disconnect the leakage test device.

Ground

Continuity

Check

Operational

Checkout

A ground continuity check must also be part of regular maintenance of

the Medrad Vistron CT system.

1. Disconnect the system from the power source.

2. Using an ohm meter, measure the resistance between the ground

terminal on the power cord and the Power Supply housing. The

resistance measured must be less than 0.2 ohms.

A basic functional checkout of the Medrad Vistron CT Injection System should be included as part of regular maintenance. Verifying

proper operation of the injection system will help in detection of any

problems that may not be noticed in day to day operation. The follow

ing procedure represents a suggested series of activities which

encompass typical operation of the system. Read the following proce

dure carefully before beginning the checkout. If problems are

detected, refer to the General Troubleshooting Procedures found in

Section 3.

NOTE: Any problems detected during this or any other

procedure should be corrected before using the

injection system in patient procedures.

-

-

2 - 6

Maintenance and Checkout

System Labels Ensure that all system safety and warning labels are in place and legible.

Power Up Apply power to the injector. Verify that the injector beeps and that all indi-

cators on the injector head and remote monitor illuminate. After the injector

completes the diagnostic tests, use the Enable key and the Forward/

Reverse motion controls to fully advance and reverse the piston.

Programming 1. Enter the following protocol. Verify that all of the increment/decrement

keys function properly.

Flow Rate Volume

Phase 1: 9.9 ml/sec 40 ml

Phase 2: 6.5 30

Phase 3: 3.0 20

Phase 4: 1.0 10

Pressure Limit: 200 psi

2. Press the Summary key to verify that the total and maximum values

display on the control panel.

3. Install a 125 or 200 ml Qwik-Fit syringe.

4. Fully advance the piston plunger.

5. Use Fill Select to select 100 ml.

6. Use the Autofill key to reverse the piston plunger to the 100 ml posi-

tion.

7. ARM in the Single Injection mode. Start the injection by pressing the

Start key on the injector head.

8. Verify that the Scan Delay timer beeps during the last 10 seconds of

the countdown, and when the countdown completes.

9. During one of the phases, press the Hold key to pause the injection for

at least 10 seconds. Press the Hold key again to resume the injection.

10. Verify that the injection progresses and completes normally.

11. Remove the syringe and press the Retract key to fully retract the piston.

12. Use the Disarm/Reset key to delete the entire protocol.

2 - 7

MEDRAD Vistron CT Injection System

13. Enter the following protocol (with a Scan Delay of 15 seconds):

Phase 1: 2.0 ml/sec 45 ml

Pressure Limit: 200 psi

14. Reinstall the syringe and arm in the Multi Injection mode.

15. Press the remote Start switch to start the injection.

16. Verify that the injection completes successfully and that the injector

remains armed.

17. Use the remote monitor the start another injection. Verify that the

Scan Delay timer on the remote monitor beeps during the last 10

seconds of the countdown and when the countdown is complete.

18. Verify that the injection completes successfully, and that the injector remains armed.

Flow Rate Volume

19. Disarm the injector by pressing the Disarm key on the

remote monitor.

20. Remove power from the unit.

AutoLink Check 1. Enter an injection protocol in which the injector will start and stop

the CT scanner. Verify that the scanner will start and stop in

response to the injector scanner relay signal.

2. Enter an injection protocol in which the CT scanner will start and

disarm the injector. Verify that the injector will start and disarm in

response to the AutoLink control on the CT scanner.

2 - 8

3 Troubleshooting

Troubleshooting

System Malfunction

Codes

General

Troubleshooting

Guidelines

Conditions can occur which will prevent the injection system from being

armed, or even interrupt an injection that is in progress. These conditions

may be operator induced or caused by a system malfunction. Error Codes

which inform the user of these conditions are displayed on the control

panel.

Consider the following guidelines before troubleshooting any condition.

These guidelines may help in resolving the condition quickly: Remember,

try the simple things first.

CAUTION: Damage may occur as a result of failure to follow electrostatic discharge (ESD) protection practices.

!

ESD protection practices must be followed when servicing any

component of this system.

CAUTION: Damage could result from improperly handled

components. Before touching any of the circuit cards in the

!

system, discharge yourself to grounded metal. If memory com

ponents are to be shipped, place the components in conductive

carriers (as supplied through MEDRAD).

CAUTION: Disconnect the power cord before removing or

replacing PC boards. Sensitive circuits on the boards can be

!

damaged by abrupt interruption or application of supplies.

-

• Try removing power for one minute. Allow the system to reset completely, then reapply power and retry. The condition could be intermittent, or caused by a voltage transient. If the condition persists,

continue troubleshooting.

• To verify the existence of a condition, attempt to re-create the problem.

Follow the Checkout Procedure outlined in Section 2 of this manual to

check for proper (or improper) operation of the system.

• Some faults can be caused by a noisy electrical environment. If these

conditions persist, contact MEDRAD Factory Service* for further assis

tance.

* Indicates contact MEDRAD Factory Service or an Authorized Dealer.

3 - 1

-

MEDRAD Vistron CT Injection System

Message Codes [U] Message Codes

Identify conditions which require attention. These messages will clear

the control panel within 5 seconds (press any key to clear the message

after 2 seconds). The [U] code list is on page 3 - 3.

[P] Message Codes

Identify conditions which require action. These messages will clear the

control panel when the operator responds to the condition which caused

the message to appear. The [P] code list is on page 3 - 4.

[d] Message Codes

Identify conditions which cause the system to disarm. These messages

will clear the control panel within 5 seconds (press any key to clear the

message after 2 seconds) when the condition which causes them to

appear is corrected. The [d] code list is on page 3 - 4.

[C] Message Codes

identify errors that require additional attention. These errors fall into two

categories: errors that may be operator correctable, and errors that indi

cate the activation of an injector safety back-up system. The [C] message code list and troubleshooting instructions begin on page 3 - 5.

-

3 - 2

Troubleshooting

[U] Codes Display Description

U103 Cannot continue with injector head operation - Invalid

piston or manual knob movement detected.

U110 Cannot arm - Total Volume of the protocol exceeds syringe

capacity. Attach a larger syringe or adjust volume.

U121 Cannot continue injector head operation - Syringe or

adapter is not fully engaged. This message will also appear

if the Retract key is pressed while a syringe is engaged.

U122 Cannot continue injector head operation - Syringe or

adapter plate has been installed.

U131 Cannot activate Autofill. Press Enable/Forward Motion

control or use manual knob to extend piston fully (0 - 1 ml

syringe volume).

U132 100 ml Systems: Cannot activate Autofill - 100 ml adapter

is attached.

Non-100 ml systems: A system failure occurred. Disconnect the patient and contact MEDRAD Service*.

U133 Cannot activate Autofill - The system has detected a pre-

filled syringe attached.

U141 Cannot continue with injector head operation - Operator

pressed a control panel key or Start switch.

U153 Cannot Arm - ISI Injector Start Input/Disarm Control is

active (J302 pins 20 and 25 are shorted).

U161 Cannot program Duration before programming Volume.

U162 Cannot change phases with an invalid or incomplete phase.

U171 Cannot arm with an incomplete or invalid phase.

U172 Cannot arm - Scroll to highest phase before proceeding.

U175 Cannot arm - Syringe volume is 0 ml.

U321 Arming - System diagnostics in progress. Press any key to

interrupt process.

3 - 3

MEDRAD Vistron CT Injection System

[P] Codes Display Description

P100 Is air expelled from syringe and fluid path? Press

Disarm/Reset key to cancel or Arm/Yes to continue.

P123 100 ml syringe adapter is detected. Press Inject Mode key

to confirm that an adapter plate has been installed.

(100 ml configurations only)

P124 100 ml syringe adapter is not detected. Press Inject Mode

key to confirm that adapter plate has been removed.

(100 ml configurations only)

P123, 124 (Non-100 ml configurations)

A system failure occurred. Disconnect patient and contact

MEDRAD Service.

P125 Cannot continue self diagnostics with syringe attached.

Remove syringe to continue.

P151 AutoLink available? Press Inject Mode key to confirm that

the system is interfaced with the scanner.

P152 AutoLink not available? Press Inject Mode key to confirm

that the system is not interfaced with the scanner.

[d] Codes Display Description

d101 System disarmed - Control panel key or Disarm/Reset key

was pressed.

d108 System disarmed - Injector stalled.

d115 System disarmed - Hold time exceeded 10 minutes.

3 - 4

d116 System disarmed - Start switch was inserted or removed.

d117 System disarmed - Manual knob was rotated.

d118 System disarmed - Syringe or adapter was detached.

d119 System disarmed - Backlash timer expired. Syringe pres-

sure was greater than backlash pressure.

d120 System disarmed - AutoLink Start/Disarm input (J302 pins

20 and 25) opened during an injection.

Troubleshooting

[C] Codes

C500 Check Remote Start/Hold Switch

This error code typically indicates a problem with the remote start

switch (VHS 600) connected at J102. If a remote start switch is not

present, contact MEDRAD Service. If one is present, take the following

steps to attempt to return the injector to service:

1. Check the remote start switch connection at the head to assure the

connector is fully seated. If the connection is loose, remove and

reattach the connector.

2. Press the Standby key on the injector head to reset the system.

3. Disconnect the patient and perform a trial injection using the

remote Start/Hold switch. If the system performs correctly, return

the system to use.

4. If the error code reappears, remove the Start/Hold switch from the

injector head.

5. Press the Standby key, and perform another trial injection, using

the Start/Hold switch on the injector head. If the system performs

correctly, contact MEDRAD Service for a replacement remote

Start/Hold switch.

6. If the error persists, contact MEDRAD Service.

C510 Check Remote Monitor

This error code typically indicates a problem with the Remote Monitor

(VRM 600). If a Remote Monitor is not present, contact MEDRAD Ser

vice*. If a Remote Monitor is present, take the following steps to

attempt to return the injector to operating status:

1. Check the remote monitor connection at the system power console

to assure the connector is fully seated. If the connection is loose,

turn off the AC power at the system power console, remove and

reattach the connector.

2. Turn on the AC power to the system, or press the Standby key on

the injector head.

-

3. Disconnect the patient and perform a trial injection using the Start/

Hold key on the remote monitor. Observe the remote monitor dis

plays during the injection. If the system performs correctly, return

the system to use.

-

3 - 5

MEDRAD Vistron CT Injection System

4. If the error code reappears, turn off the AC power and disconnect

the remote monitor from the system power console.

5. Apply the AC power and perform another trial injection using the

Start/Hold key on the injector head. If the system performs

correctly, contact MEDRAD Service* for a replacement remote

monitor.

6. If the error persists, contact MEDRAD Service*.

Error codes C520, C530 and C540 indicate that the safety back-up

subsystems in the Vistron CT injector have detected a pressure

(C520), volume (C530), or flow rate (C540) in excess of the specifica

tion limits for the programmed value. Disconnect the patient immediately and examine the patient for injury. Contact MEDRAD Service*

before using the system again.

C520 System Pressure Exceeded Pressure Limit

-

This may occur as a result of injecting into a blockage or a small catheter/needle with the maximum pressure limit selected. Check the fluid

path for blockages, then press the Standby key to restart the injector.

If no blockage exists, reduce the flow rate or pressure limit according

to the instructions of the physician.

C530 Injected Volume Exceeded Programmed Value

C540 Flow Rate Exceeded Programmed Value

C560 Head Overlay Failure Detected

This error indicates that an overlay key press was detected during

power-up or arming when none should have been present. This may

have been due to an accidental key press from the operator, or a fault

in the overlay itself. Restart the system by pressing the Standby key,

and do not press any keys until self diagnostics are complete. If the

error code is displayed again, Contact MEDRAD Service*.

3 - 6

Troubleshooting

C570 A Failure Occurred in the AutoLink Interface

This error may occur when the interface cable and circuit are being

tested. This condition can be caused by a loose or improper connec

tion. Verify the connection of the cable at the power supply and scanner. If all cable connections are secure and this code persists,

disconnect the interface cable and contact MEDRAD Service. The

injection system will function, but AutoLink will not be operational.

C599 System Error, Call MEDRAD Service*

A C599 error indicates that a failure has occurred within the system.

Disconnect the patient, and contact MEDRAD Service*.

OTHER MALFUNCTIONS

If after pressing the Standby key to power up the system the injector

head or remote monitor displays are blank:

-

• Check the power cord, all cables, and connections.

• Verify that the Main Power switch on the System Power

Console is in the ON position

• If the problem persists, call MEDRAD Service*.

Failure of individual displays or keys, damage to system components,

or any other misoperation should also be brought to the attention of

MEDRAD Service*.

3 - 7

Loading...

Loading...