Page 1

Page 2

Page 3

North America Headquarters

MEDRAD Service Department

One Medrad Drive

Indianola, PA 15051-0780

U.S.A.

Tel: 412-767-2400

Fax: 412-767-4120

Nihon MEDRAD KK

2-4-9, Umeda, Kita-ku,

Osaka, 530-0001

Japan

Tel: +81(0)66-133-6250

Fax:+81(0)66-344-2395

European Headquarters

MEDRAD Europe B.V.

P.O. Box 205

6190 AE Beek

The Netherlands

Tel: +31 (0) 43-3585600

Fax:+31 (0) 43-3656598

© 2009-2012 MEDRAD, INC. All rights reserved.

Reproduction of this manual is strictly prohibited without express written

consent of MEDRAD, INC.

For more information about MEDRAD products and services, please visit

www.medrad.com

Page 4

Page 5

TABLE OF CONTENTS

1 - Introduction......................................................................................................1-3

Important Safety Notice ...................................................................................................... 1-3

Certifications .......................................................................................................................1-3

Indications for Use ..............................................................................................................1-3

Contraindications ................................................................................................................ 1-3

Restricted Sale.................................................................................................................... 1-3

Required Training ...............................................................................................................1-3

Trademarks......................................................................................................................... 1-3

Disclaimers .........................................................................................................................1-3

The Equipotential Connector (EPC)....................................................................................1-4

Understanding Symbols...................................................................................................... 1-4

Warnings............................................................................................................................. 1-6

Cautions.............................................................................................................................. 1-8

2 - System Basics .................................................................................................2-9

About the Injection System ................................................................................................. 2-9

Pressure Safety Limit........................................................................................................ 2-10

Response to Occlusions ................................................................................................... 2-10

Volume and Rate Protection ............................................................................................. 2-10

Control Room Unit ............................................................................................................ 2-11

Scan Room Unit................................................................................................................2-12

Injector Head..................................................................................................................... 2-13

Battery Charger.................................................................................................................2-14

Optional Control Room Unit Accessories..........................................................................2-15

Touch Screen Calibration ................................................................................................. 2-16

Help Mode......................................................................................................................... 2-16

Setup Mode....................................................................................................................... 2-17

3 - Preparing to Inject .........................................................................................3-19

Applying Power ................................................................................................................. 3-19

Main Screen...................................................................................................................... 3-20

Battery Maintenance......................................................................................................... 3-21

Syringe and Disposable Accessory Installation ................................................................ 3-22

Retracting the Pistons................................................................................................ 3-22

Installing a Syringe .................................................................................................... 3-23

Loading a Syringe...................................................................................................... 3-25

Reinstalling a Syringe ................................................................................................ 3-27

Programming ....................................................................................................................3-28

Flow Rate and Volume ..............................................................................................3-28

Pressure Limit............................................................................................................ 3-28

Multiple Phases ......................................................................................................... 3-29

Hold and Pause Phases ............................................................................................ 3-29

Programmed Delay.................................................................................................... 3-30

Scan Delay ......................................................................................................... 3-30

Inject Delay ......................................................................................................... 3-30

Stopwatch ...........................................................................................................3-31

KVO (Keep Vein Open) ............................................................................................. 3-31

i

Page 6

MEDRAD Spectris Solaris EP MR Injection System

Storing a Protocol .............................................................................................................3-33

Recalling a Stored Protocol .............................................................................................. 3-34

4 - Arming and Injecting.....................................................................................4-35

Arming............................................................................................................................... 4-35

Single and Multi-Arm.........................................................................................................4-35

Insufficient Volume............................................................................................................4-36

Injecting............................................................................................................................. 4-36

Disarming.......................................................................................................................... 4-37

Injection History ................................................................................................................4-39

Clean Up...........................................................................................................................4-40

Appendix A: System Messages........................................................................ A-43

Type 1 Messages..............................................................................................................A-43

Type 2 Messages..............................................................................................................A-44

Type 3 Messages..............................................................................................................A-44

Appendix B: Maintenance and Checkout ....................................................... B-45

Recommended Maintenance Schedule............................................................................B-45

Inspection Procedures ......................................................................................................B-46

Cleaning Guidelines..........................................................................................................B-48

Operational Checkout .......................................................................................................B-48

Appendix C: Specifications .............................................................................. C-51

Scan Room Unit............................................................................................................... C-51

Control Room Unit ........................................................................................................... C-52

Battery Dimensions.......................................................................................................... C-52

Battery Charger................................................................................................................ C-53

Power Cords .................................................................................................................... C-53

System Capabilities ......................................................................................................... C-54

Executable Flow Rates .................................................................................................... C-54

System Performance ....................................................................................................... C-55

Forward and Reverse Controls........................................................................................ C-55

EMI/RFI............................................................................................................................ C-56

Electrical Requirements................................................................................................... C-56

Power Supply DC Output Voltage.................................................................................... C-56

Electrical Leakage............................................................................................................ C-56

Ground Continuity............................................................................................................ C-56

Environmental Specifications........................................................................................... C-56

Classifications.................................................................................................................. C-57

Appendix D: Options and Accessories............................................................ D-59

Appendix E: System Installation ...................................................................... E-61

Unpacking the Injection System........................................................................................E-62

Installation Considerations................................................................................................E-63

Fiber Optic Cable Installation............................................................................................E-65

Control Room Unit Setup..................................................................................................E-66

Handswitch Mounting........................................................................................................E-67

ii

Page 7

1 - Introduction

1 - Introduction

This manual applies to the MEDRAD Spectris Solaris® EP MR Injection

System, Catalog Number 3012011. Read all of the information contained in

this section. Understanding the information will assist you in operating the

device in a safe manner.

Important Safety Notice

This device is intended to be used by medical professionals with adequate

training and experience in magnetic resonance imaging (MRI) studies.

Certifications This device is equipped to operate at 100-240 VAC, 50/60 Hz, 180 VA

(Single), and is designed to comply with EN 60601-1/IEC 60601-1 Second/

Third Edition, and EN 60601-1-2 Second Edition and IEC 60601-1-2 Second/

Third Edition Standards.

Indications for Use This system is intended for the purposes of injecting intravenous MR contrast

media and common flushing solutions into the human vascular system for

diagnostic studies in magnetic resonance imaging (MRI) procedures.

Contraindications This device is not to be used in the arterial side of the vascular system, for

drug infusion, chemotherapy, or any other use for which the device is not

indicated. The system should not be used with a magnetic resonance imaging

scanner having a magnetic field strength greater than 3.0 Tesla.

Restricted Sale Federal (USA) law restricts this device to sale by or on the order of a

physician.

Required Training This device is intended to be used by individuals with adequate training and

experience in diagnostic image studies.

Trademarks MEDRAD, FluiDot, Qwik-Fit, Spectris Solaris, MEDRAD Radiology,

Performance for Life are federally registered trademarks of MEDRAD, INC.

The trademarks Becton Dickinson, Daiichi, NSKK, Multihance, Gadovist,

Magnevist, Optimark, Prohance, and Omniscan appear in this manual, and

are the property of their respective companies.

Disclaimers External wiring and modifications disclaimers: MEDRAD disclaims liability for

any modifications or interfaces with other equipment which are not in

conformity with the specifications and information contained within this

manual.

Accessory equipment connected to the device must be certified according to

IEC 60601-1 Second/Third Edition standard. Furthermore, all configurations

shall comply with system standard EN 60601-1/IEC 60601-1-1. Anyone who

connects additional equipment to the signal input or output part configures a

medical system and is therefore responsible that the system complies with the

requirements of the standard IEC 60601-1-1. To obtain on-site consulting or

consulting references, contact MEDRAD Service.

The MEDRAD Spectris Solaris EP MR Injection System is not intended for

portable use.

1 - 3

Page 8

MEDRAD Spectris Solaris EP MR Injection System

The Equipotential Connector (EPC)

Understanding Symbols

The Equipotential Connector (EPC) is an electrically bonded terminal on the

injector that is used as a connection point between other medical electrical

equipment. The EPC’s function is to minimize any voltage potentials

differences between all connected equipment. The EPC is not designed to be

an electrical safety ground.

The following symbols are used on the MEDRAD Spectris Solaris EP Mobile

MR Injection System and components.:

Attention, consult accompanying instructions.

Indicates that this device conforms to the requirements of the European

Medical Device Directive 93/42/EEC.

Indicates on/off switch for the Control Room Unit.

Indicates hazardous voltages.

Indicates alternating current.

Identifies a type BF applied part complying with EN 60601-1 standards.

CLASS 1

IPX1

Indicates the injection system is Class 1 medical equipment as defined by

EN 60601-1 standards.

Identifies the degree of protection against fluid as drip proof for the

Spectris Solaris EP Injector system.

Identifies connection of the handswitch.

Identifies injector head forward and reverse piston control keys.

Identifies the direction of manual knob rotation relative to plunger

movement.

Identifies the ENABLE key.

Identifies polarity of the battery pack terminals.

Indicates DC power supply.

1 - 4

Page 9

1 - Introduction

Indicates the current charge level of the system battery.

Identifies Integrated Continuous Battery Charger system activity on

Graphical User Interface. When illuminated yellow this indicates that the

Continuous Battery Charger system is present and functioning.

Indicates the AIR EXPELLED button on the injector head. When

illuminated yellow on the touch screen, also indicates that the operator has

acknowledged inspecting the fluid path for air.

Identifies the Equipotential connection.

Identifies the Earth Ground point.

IOIO

TX

RX

Identifies the Service Connection Port.

Identifies the Locking Bracket. Indicates which direction to turn Locking

Bracket knob to “lock” and “unlock” the bracket.

Identifies the Communication Cable Transmit connection.

Identifies the Communication Cable Receive connection.

Indicates design for indoor use only.

Identifies the Integrated Continuous Battery Charger System power supply

connection.

Indicates the presence of no serviceable parts.

I

Indicates the presence of AC power at the battery charger.

Identifies the Control Room Unit brightness controls.

P109

Reserved for future use.

Indicates the status of the battery charger. When a battery is properly

inserted, the LED will illuminate while charging, and extinguish when the

battery is fully charged.

Pushing Prohibited. Do not push at or above this point on the Injector.

1 - 5

Page 10

MEDRAD Spectris Solaris EP MR Injection System

This manual contains important information about use of the MEDRAD

Spectris Solaris EP MR Injection System.

MEDRAD urges you to read this manual carefully, become familiar with the

procedures and system functions that it describes, and follow its

recommendations to assure proper use of the system.

Labels on the system or statements in this manual preceeded by any of the

following words and/or symbols are of special significance, intended to help

you to operate the system in a safe and successful manner:

WARNING: Indicates that the information is a warning. Warnings

advise you of circumstances that could result in injury or death to the

patient or operator. Read and understand the warnings before

operating the injection system.

CAUTION: Indicates that the information is a caution. Cautions advise

you of circumstances that could result in damage to the device. Read

and understand the cautions before operating the injection system.

Note: Indicates that the information that follows is additional

important information or a tip that will help you recover

from an error or point you to related information within the

manual.

Warnings Patient injury may result from a system malfunction. If a system

malfunction occurs, immediately remove unit power (by pulling the battery

from the Scan Room Unit), and disconnect the unit from the patient. If a fault

message is displayed that cannot be corrected, and/or the system is not

operating correctly, do not use the injection system. Call MEDRAD for

assistance.

Patient injury could result from leaks or ruptures during an injection. To

prevent leaks or ruptures in the event of a blockage, use only catheters and

connectors with pressure ratings compatible with this system.

Explosion hazard. The MEDRAD Spectris Solaris EP MR Injection System is

not suitable for use in the presence of a flammable anesthetic mixture with air,

oxygen, or nitrous oxide.

Fire hazard. To avoid an electrical fire, assure the correct type of fuse is used

for replacement. The fuse must be replaced with Type F, 250 V, 2.5 A fuse by

qualified personnel only.

Electrical shock hazard. Hazardous voltages exist within system

components. Do not remove or open any enclosure.

Electrical shock hazard. Avoid fluid entry into system components. Do not

immerse any components in water or cleaning solutions. Use a damp cloth

when cleaning on or around the battery and the Integrated Continuous Battery

Charger system power supply.

Electrical shock hazard. Serious injury or death may result from exposure to

hazardous voltages existing within the system. Disconnect the Battery

Charging System from line power and remove the battery from the Scan

Room Unit before cleaning.

1 - 6

Page 11

1 - Introduction

Electrical shock hazard. Equipment must only be connected to a supply

mains with protective earth.

Ventilation hazard. To avoid a build up of hydrogen gas from the battery,

assure the room is well ventilated while battery is charging.

Improper disposal of the battery pack may result in explosion, leakage,

or personal injury. Do not open, or dispose of in a fire! Follow all local

regulations concerning the disposal of spent lead-acid based batteries, or

contact MEDRAD for assistance.

System electronic assemblies contain potentially hazardous materials.

Dispose of system components or accessories properly. Follow local

regulations for proper disposal or contact MEDRAD Service for assistance.

Unsafe operation may result from using improper accessories. Use only

accessories and options provided by MEDRAD designed for this system.

Chemical burn hazard. Always carry the battery pack firmly by the battery

pack hand grips. Damage to the housing may result in a chemical burn

hazard. Do not use if the housing is severely cracked or damaged.

Voltage hazard from worn cabling or unit disassembly. To avoid exposure

to potentially hazardous voltages, do not disassemble the injection system in

any way. Worn cabling also creates voltage hazards. If any worn or damaged

cables are detected, do not use the injection system. Contact MEDRAD for

service or replacement.

The MEDRAD Spectris Solaris EP MR Injection System is a dual syringe

system. Always ensure that the proper syringes are loaded with contrast

media and flush solution prior to the injection. Failure to properly load and

install the syringes may require the procedure to be repeated. Syringe A is

designated for contrast agent use only. Syringe B is designated for flush

solutions only.

Injury or equipment damage may result from use of tools containing

ferrous materials. Use only non-magnetic tools to install any scanner/

magnet room components.

Patient injury and/or catheter damage may result from using connector

tubing (LPCT) that is too short. Operator must consider tubing length and

stretch limitations when moving the injector or the patient.

Serious injury or death may result from syringe failure. Do not retract

pistons with connector tubing installed. Retracting the pistons with the

connector tubing installed on syringes will create a vacuum in the syringe due

to the check valve in the connector tubing. This vacuum may accelerate the

plunger rapidly toward the tip of the syringe when it is removed from the

injector causing the syringe to break.

1 - 7

Page 12

MEDRAD Spectris Solaris EP MR Injection System

Cautions Condensation may cause electrical damage to the injection system. Do

not use the system immediately after it has been brought indoors from

extreme outside temperatures. Allow the system to stabilize at room

temperature before use.

Injector may disarm or fail to operate upon exposure to high

electromagnetic fields that may be generated by radio transmitters or cellular

phones, or upon exposure to high levels of electrostatic discharge.

This injector system is in compliance to IEC-60601-1-2 / Second and

Third Edition Standards. Special precautions regarding ElectroMagnetic

Compatibility (EMC), are required for installation and use of this injector

system. Detailed EMC information can be found in the MEDRAD Injector

Service Manual - Addendum, (label number: 202559).

Damage can occur as a result of incorrect voltage. Before plugging in the

system, check the following:

• Verify that the voltage and frequency marked on the serial tag on

the back of the unit matches the voltage and frequency of the

electrical outlet.

• Verify that the Control Room Unit and the Battery Charger power

supply have the appropriate power cord plugs for the power

outlet.

Additional warnings, cautions, and notes are located throughout this manual,

where applicable.

1 - 8

Page 13

2 - System Basics

2 - System Basics

About the Injection System

The MEDRAD Spectris Solaris EP MR Injection System is a programmable,

dual syringe system, designed to accurately administer controlled doses of

intra-venous MR contrast agents and common flushing solutions to patients

undergoing a contrast enhanced MR scan.

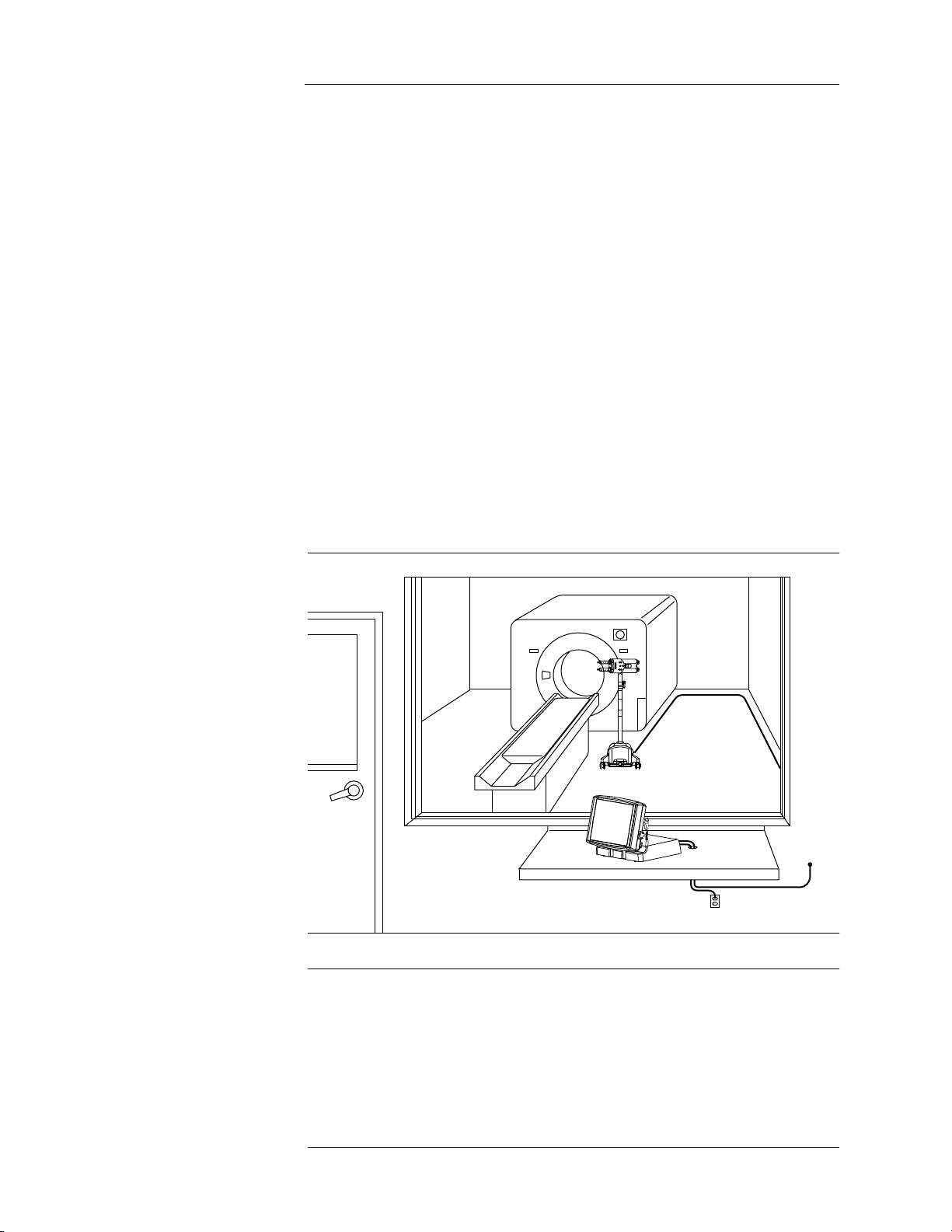

The system consists of two basic components that communicate by a direct

connection of fiber optic lines.

• The Control Room Unit houses the Touch Screen and electronic

components used to program the injection system.

• The Scan Room Unit, positioned near the magnet bore, contains

the Injector Head, system battery pack, and the mechanical

assemblies required for fluid delivery.

A battery charger is also supplied with the system, used to charge the Scan

Room Unit battery pack. For convenience, the charger can be used in the

control room, but should never be installed or operated in the scan room.

Note: Follow all institutional, local, or national safety regulations

related to routing cabling on the floor.

2 - 9

Page 14

MEDRAD Spectris Solaris EP MR Injection System

Pressure Safety Limit

Response to Occlusions

The MEDRAD Spectris Solaris EP MR Injection System is designed to allow

varied flow rates for contrast injections. By automatically reducing the flow

rate, the system can limit the pressure produced during an injection to prevent

damage or failure of any connecting devices or tubing. This feature is called

Pressure Safety Limit.

Inability to maintain the desired flow rate while remaining below the Pressure

Safety Limit can be caused by various conditions including contrast viscosity,

catheter sizing, connector tube sizing, and stopcock restrictions. If the system

is unable, for a period of three seconds, to maintain a flow rate of at least 10%

of the programmed rate, the system will disarm due to a stall condition.

If unable to automatically achieve the required level of flow rate reduction,

thus reaching the Pressure Safety Limit, the system will terminate the

injection and move to a disarm state.

When injecting into an occlusion, a stall condition (flow rate less than 10% of

programmed rate) will result. A stall condition lasting more than 3 seconds (3

minutes for programmed rates less than 0.1 ml/sec) will result in the injection

being automatically terminated.

If an occlusion occurs during KVO (Keep Vein Open) the system will detect

the condition after 4 or less KVO boluses fail to be delivered. This will

correspond to from 1 minute with a KVO interval of 15 seconds configured, to

5 minutes with a KVO interval of 75 seconds. Refer to the Setup screen to

determine the current KVO setting.

Volume and Rate Protection

If a stall occurs due to an occlusion, and the blockage is subsequently

removed, less than 10 ml will be delivered as the pressure in the

administration set dissipates.

The following means are provided to protect against over and under volume

or rate conditions:

• Warnings displayed on the Safety screen and during the arming

sequence remind the operator to check the programmed injection

parameters prior to the system being armed.

• An onscreen indication of insufficient volume is provided whenever the

total volume programmed to be delivered is greater than the amount of

fluid in the syringe.

• Injection monitoring is performed to detect over rate or over volume

conditions due to system faults. If either of these conditions is detected,

the injection will be stopped before an additional 10 ml of fluid above

programmed volume is delivered.

2 - 10

Page 15

Control Room Unit

1

3

2

2 - System Basics

1. Handswitch

2. System Power Switch

3. Touch Screen

At rear of Touch Screen Assembly - Display Contrast Controls

2 - 11

Page 16

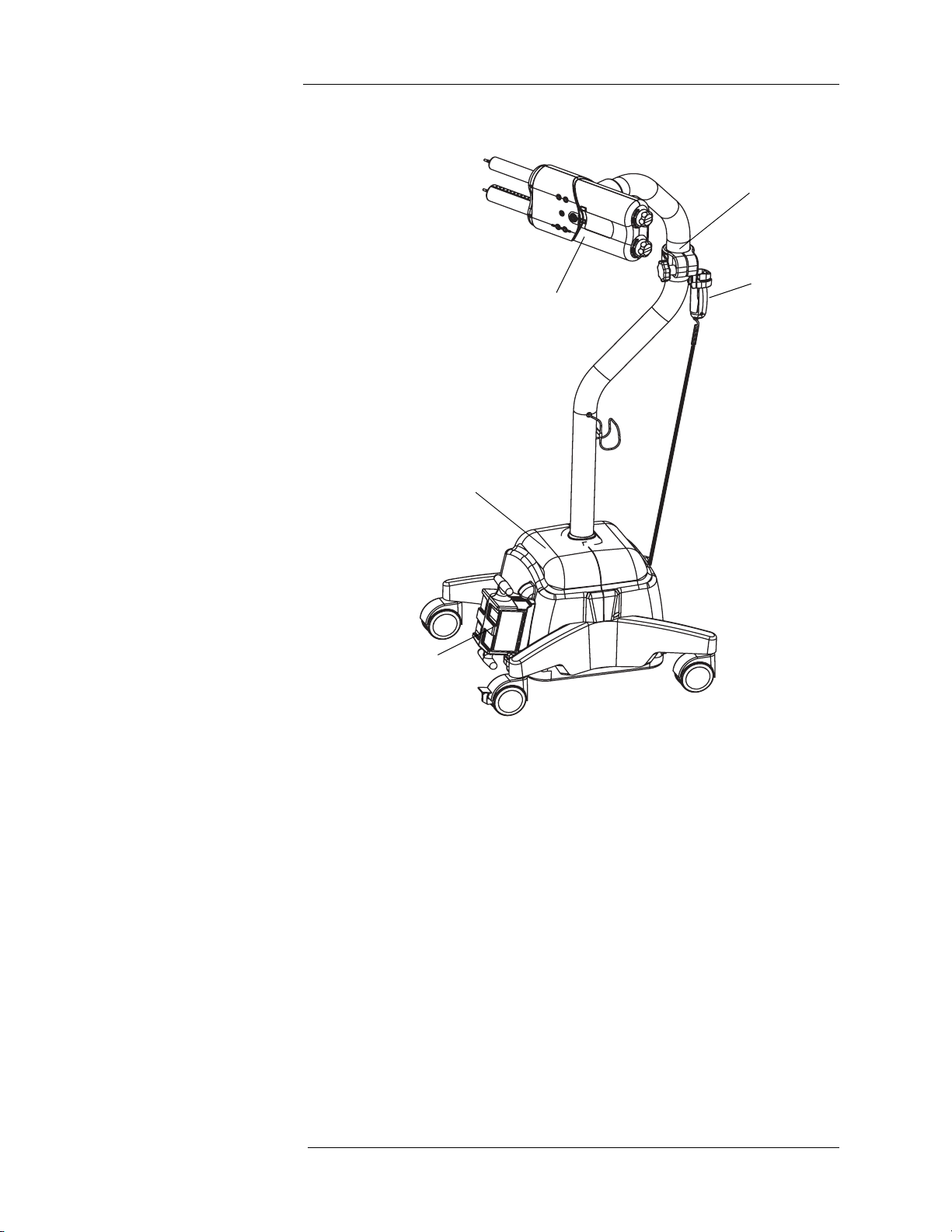

Scan Room Unit

1

3

4

2

5

MEDRAD Spectris Solaris EP MR Injection System

1. Injector Head

2. Handswitch

3. Lower Console

4. System Battery Pack

5. Middle Pivot Clamp

Not shown - Contrast Holder (optional)

2 - 12

Page 17

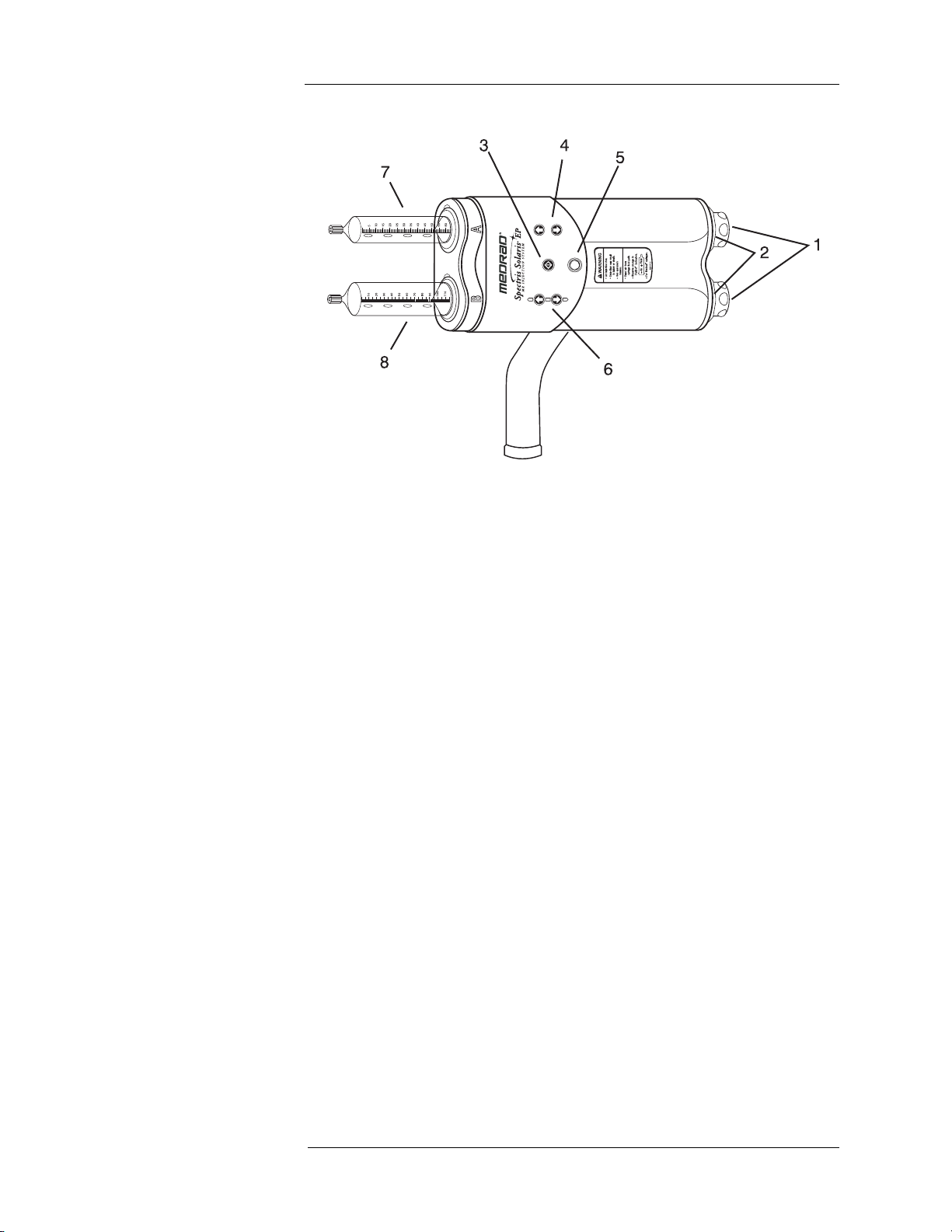

Injector Head

2 - System Basics

1. Manual piston movement knobs

2. Armed indicator lights

3. ENABLE button - Used to activate the forward/reverse controls - the

appropriate direction must be selected within 5 seconds.

4. Syringe A forward/reverse controls

5. AIR EXPELLED button/indicator

6. Syringe B forward/reverse controls

7. Syringe A: Contrast agent

8. Syringe B: Flush solution

2 - 13

Page 18

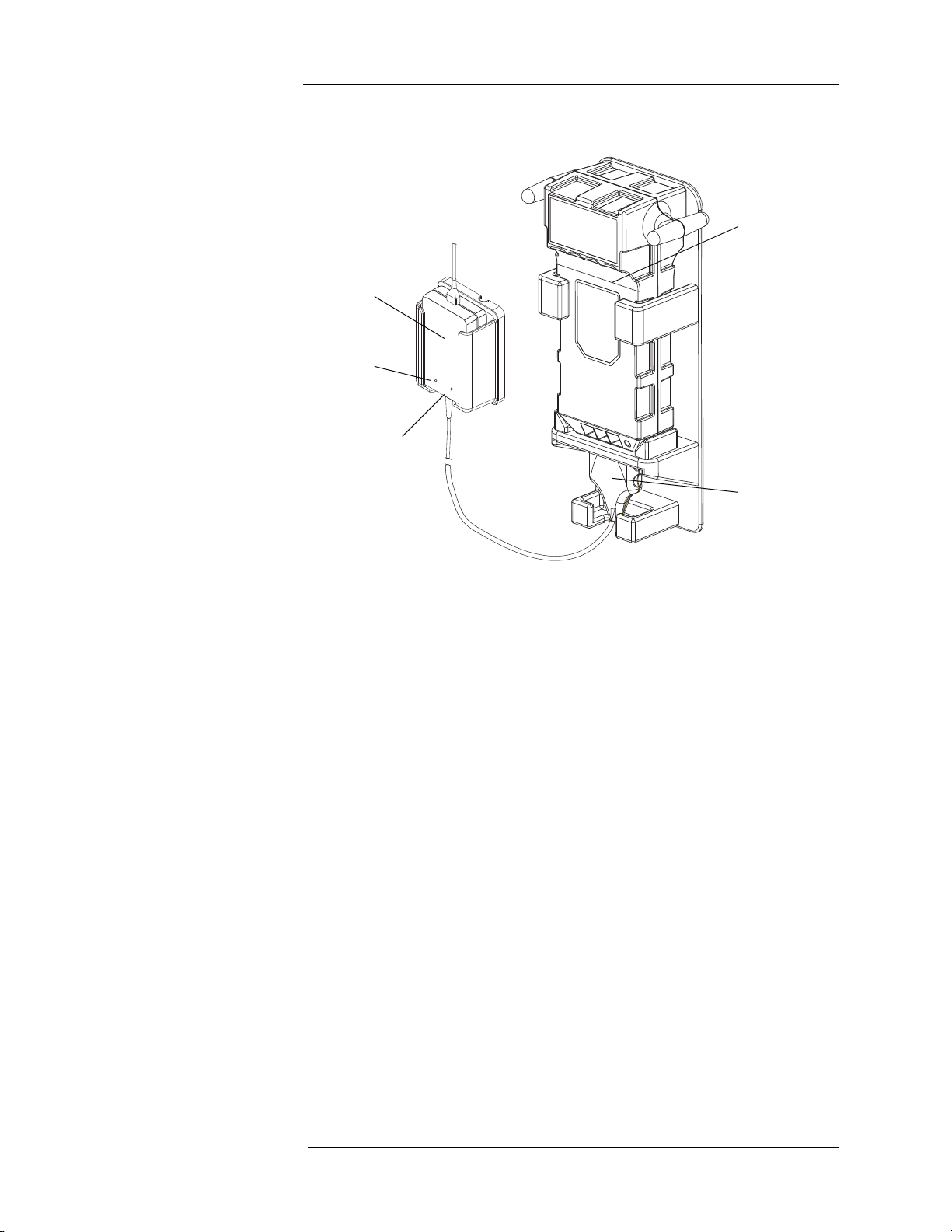

Battery Charger

1

3

4

5

2

MEDRAD Spectris Solaris EP MR Injection System

1. Battery Pack

2. Battery Charging Unit

3. Charging Indicator - Amber

4. Power Indicator - Green

5. Battery Charger Head

2 - 14

Page 19

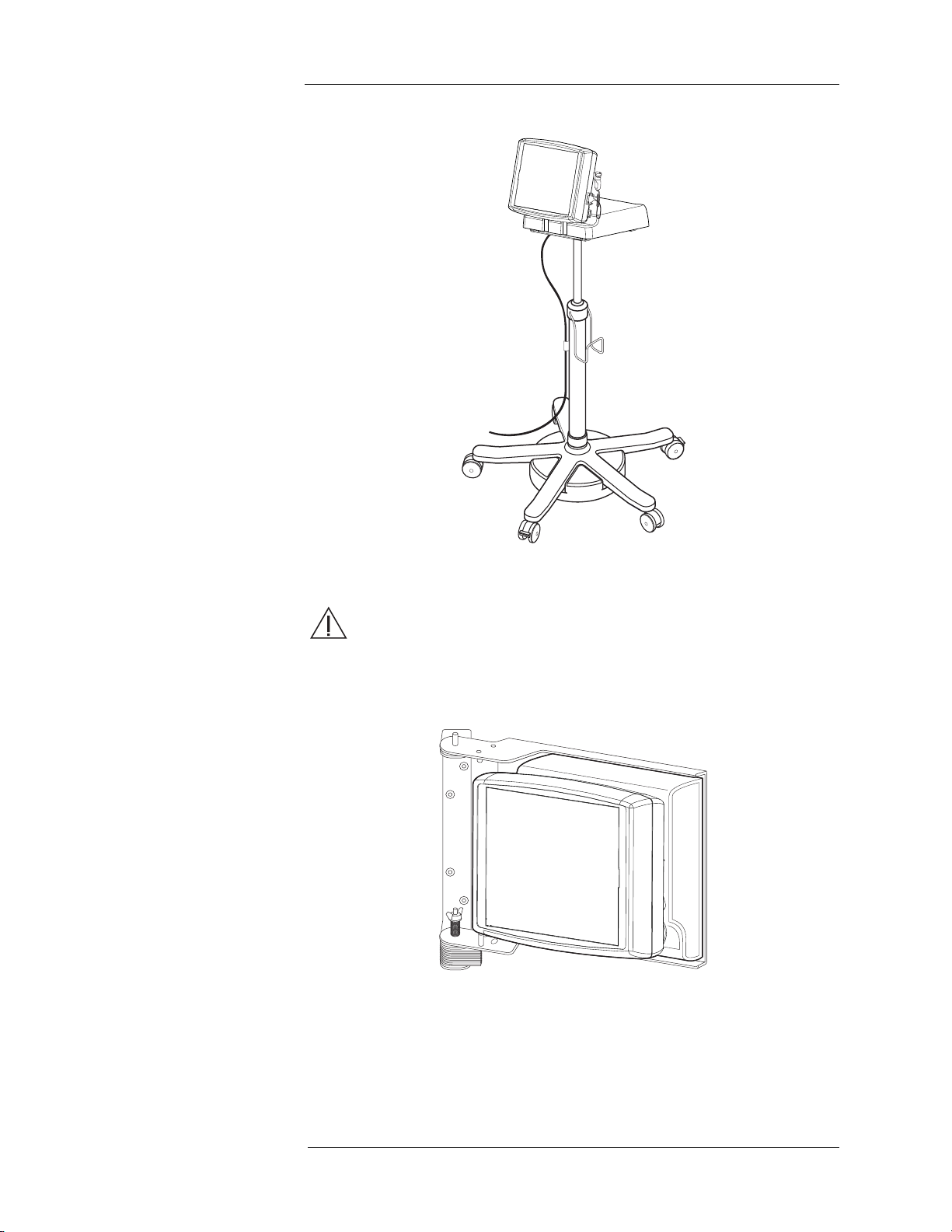

Optional Control Room Unit Accessories

2 - System Basics

Adjustable Height Pedestal

WARNING: Injury or equipment damage may result if the

adjustable height pedestal is taken into the scanner room. Do not

take the adjustable height pedestal in the scanner room. It

contains ferrous material that could be attracted toward the magnet.

Wall Mounting Bracket

Note: These accessories contain ferrous material and are

designed to be used in the Control Room only. Do not

install or operate in the Scan Room.

2 - 15

Page 20

MEDRAD Spectris Solaris EP MR Injection System

Touch Screen Calibration

To enter Touch Screen Calibration mode, simultaneously press both the

Contrast UP and DOWN keys on the rear of the touch screen housing. A

series of screens with instructions to press the appropriate calibration circles

will appear.

CAUTION: Do not touch the screen with a sharp object in order to

perform the calibration.

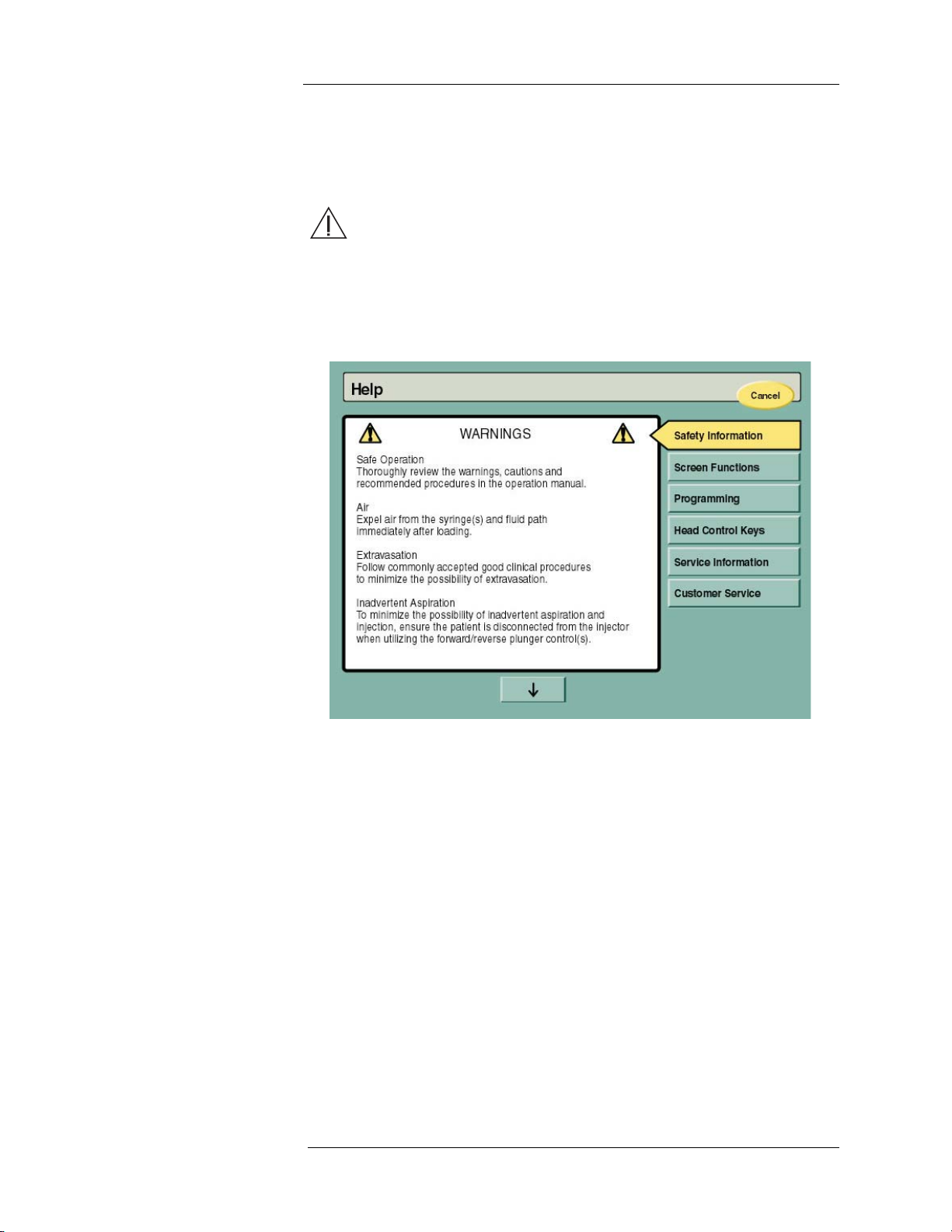

Help Mode The Help screen can be accessed by pressing the HELP button on the lower

right corner of the Main screen. Besides safety information, the Help screen

displays a variety of topics as displayed below.

2 - 16

Page 21

2 - System Basics

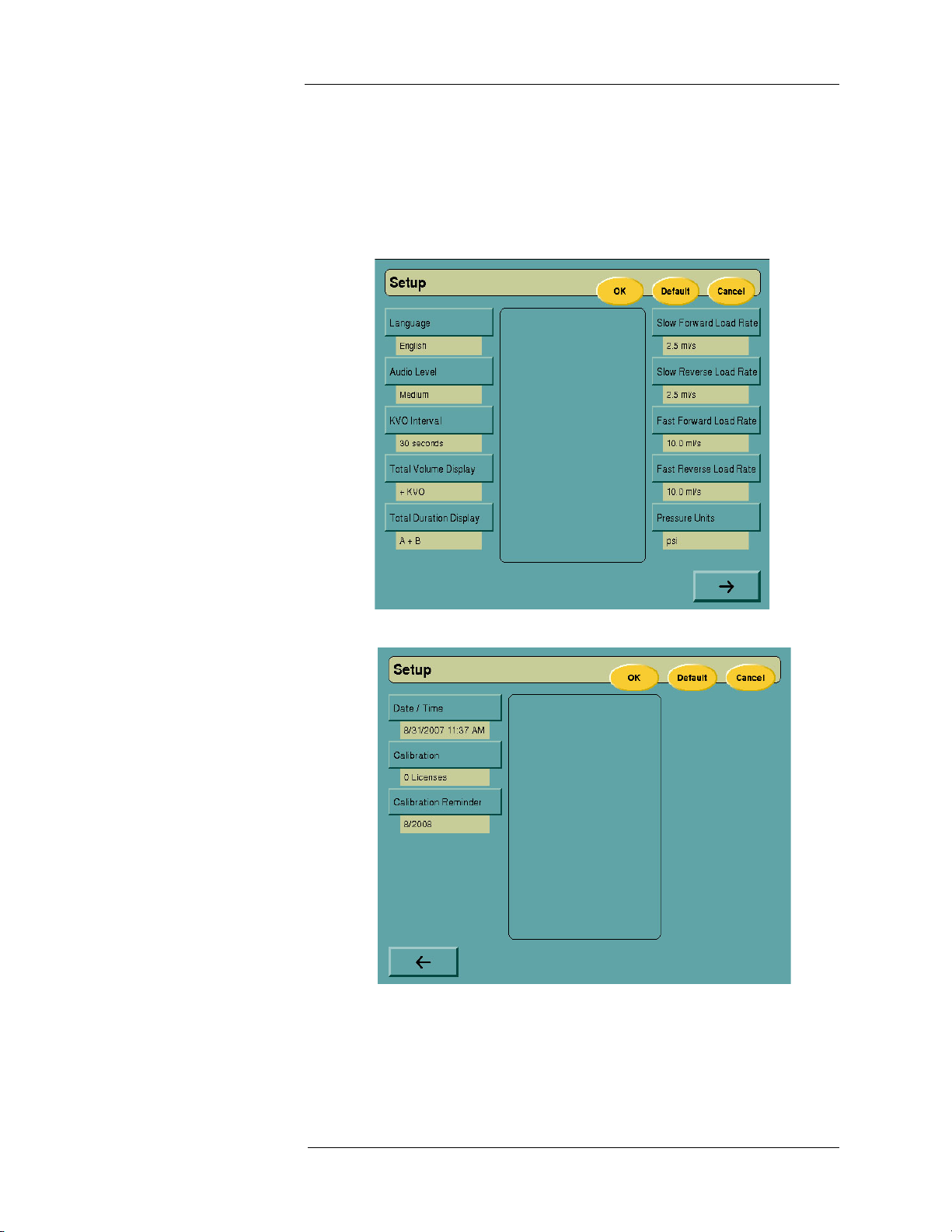

Setup Mode The Setup screen can be accessed by pressing the SETUP button at the

lower right corner of the Main screen. The Setup screen allows user

configurable options and preferences to be selected, along with setting of

date and time parameters.

Select the appropriate option, then choose from the available selections in the

display window. Select the DEFAULT key to return all options to original

factory settings.

The system provides a calibration and maintenance reminder. This reminder

will be displayed on the System Logo screen at each startup, beginning 30

days before the system is due to be recalibrated. The duration of time from

one calibration to the next is programmed during system installation or by

selecting the Calibration Reminder key and entering the correct due date.

2 - 17

Page 22

MEDRAD Spectris Solaris EP MR Injection System

2 - 18

Page 23

3 - Preparing to Inject

3 - Preparing to Inject

Applying Power Place the power switch located on the right side of the Control Room Unit in

the ON position. The System Logo screen will appear while the system

performs a series of self diagnostic tests.

Note: Do not touch the screen or activate any controls while

self diagnostics are in progress. If this occurs, diagnostic

tests will interpret this activity as a hardware failure and

halt the system. The system must then be powered

down/up to reset the error.

After diagnostics have successfully completed, the System Logo screen will

be replaced by the Safety screen

After reading the Safety screen, press CONTINUE to view the Main screen.

Apply power to the Scan Room Unit by inserting the battery into the

receptacle on the bottom of the Scan Room Unit. Upon power up of the CRU

and SRU, verify that the indicators, lamps, and speaker are operational.

Note: The Control Room Unit can be programmed for an

injection without power applied at the Scan Room Unit.

3 - 19

Page 24

MEDRAD Spectris Solaris EP MR Injection System

Main Screen The Main screen is entered from the Safety screen after power-up. The Main

screen is used during programming, arming, and injecting, with applicable

screen controls made visible based on the task currently being performed.

3 - 20

Page 25

3 - Preparing to Inject

Battery Maintenance WARNING: Explosion Hazard. Serious injury or death may result

from improper use of the battery charger. The battery charger,

MEDRAD Catalog Number 3012424, is intended for use in a well

ventilated area, with the injection system battery, MEDRAD Catalog

Number 3012070, only. Do not use the charger with non-rechargeable

batteries.

When the Main screen appears, check the status of the system battery in the

lower left corner of the screen. The battery icon will contain three horizontal

bars when indicating full charge, two when indicating medium charge, one for

low charge, and no indicators in the icon when the battery is fully depleted,

not connected, or communication is not detected between the Control Room

and Scan Room Units.

If the depleted battery is not replaced when only one bar is displayed, the

system will complete any injection that is in progress. However, the system

may not initiate a single or multi arm injection, the forward and reverse

controls on the injector head may not function and system communications

may be lost.

Each battery pack should last for 4 to 6 typical injections using a 20 minute

KVO, or approximately 5 hours in an idle state before requiring a recharge.

Monitor battery status per injection and on a daily basis. Each battery is

capable of being recharged approximately 300 times. When the life of a

battery pack becomes shortened, noticeably sustaining fewer injections per

charge, this signals that battery life is expiring and the battery pack should be

replaced. Call MEDRAD Service for battery pack replacement.

To charge the battery, place the 3-pronged, charging head into the battery,

then connect the charger to AC power. A green LED on the charger indicates

that AC power is applied. An amber LED indicates that the battery is charging.

The amber LED will turn off when full charge is reached. Battery charge time

is approximately 5 hours.

3 - 21

Page 26

MEDRAD Spectris Solaris EP MR Injection System

Syringe and Disposable Accessory Installation

Retracting the Pistons

Fully retract each piston by using the reverse switches on the injector head.

Note: When using the reverse switches, first press the Enable

switch; then within 5 seconds, press the reverse

switch(es). Both pistons may be reversed simultaneously.

The forward and reverse switches have dual speed capabilities:

When the switches are partially depressed, the pistons will move slowly.

When fully depressed, the pistons will move quickly. Forward and reverse

piston speeds are fully configurable (1 to 10 ml/sec) in the Setup mode.

The manual knobs may also be used to move the pistons in the forward or

reverse direction. Turn the knobs clockwise to advance the piston,

counterclockwise to retract.

3 - 22

Page 27

Installing a Syringe WARNINGS:

Patient or operator injury may result if damaged components are

used. Do not use damaged components. Visually inspect all

components before use.

Patient infection may result from the use of non-sterile

components. Maintain sterility of all disposable components. Do not

store pre-loaded syringes.

The use of single-use disposable devices on more than one

patient is a biological hazard. Do not reuse single-use disposable

components.

Patient injury could result if the syringe is not properly engaged.

Ensure the alignment marks on the syringe and injector head are

properly aligned, and the piston and plunger are interlocked. Improper

engagement may cause syringe damage or under-volume delivery.

CAUTION: Improperly engaged syringes may leak or be

damaged. Ensure proper engagement of syringe and injector. Syringe

and injector engagement points must align.

3 - Preparing to Inject

Note: Syringe A is intended for contrast media, and Syringe B

is intended for flushing solution only.

1. Align the flanges on the syringe with the notches in the injector head.

(The syringe is keyed to properly fit in only one way.)

2. Insert the syringe.

3. Twist 1/4 turn clockwise until the syringe snaps into place. (Graduations

will be facing the front of the injector head.)

3 - 23

Page 28

MEDRAD Spectris Solaris EP MR Injection System

Fig. 1 Empty

Fig. 2 Filled

WARNING: Air embolism can cause patient injury or death. Expel

all trapped air from the syringe(s), connectors, tubing, and catheterover-needle before injecting.

Note: Do not hit or tap the syringe to remove air bubbles.

To reduce the volume and size of air bubbles drawn into the syringe during

loading, a MEDRAD Fluid Dispensing Device (FDD or “spike”) is

recommended. Air removal from the syringe(s) will be much more difficult if a

small diameter tube, such as a catheter-over-needle, needle, or a tube longer

than 10 inches (25 cm), is used for loading.

Operator vigilance and care, coupled with a set procedure, is essential to

minimizing the possibility of an air embolism. The injector head should be

pointed upward during loading, enabling any air to accumulate at the syringe

tip and to be expelled. The injector head should be pointed downward during

an injection, enabling any small air bubbles which could still be in the fluid to

float to the rear of the syringe(s).

To help avoid air injection, MEDRAD syringes are equipped with FluiDot indicators. These FluiDot indicators should be observed as part of an arming pro-

cedure. When the FluiDot is viewed through an empty syringe, the dots

appear as small narrow ellipses as illustrated below in figure 1. However,

when viewed through a full syringe, the dots become larger, almost round (or

wider than round) as illustrated below in figure 2.

FluiDot indicators must be viewed in a properly illuminated environment, with

a light source behind the operator providing enough light to permit easy

viewing.

To minimize air embolization risks, ensure that one operator is designated the

responsibility of filling the syringe(s). Do not change operators during the

procedure. If an operator change must occur, ensure that the new operator

verifies that the fluid path is purged of air.

WARNING: If a blockage occurs, disposable components with a

lower pressure rating may leak or rupture. Use only catheter and

connectors with ratings that are compatible with the MEDRAD

Spectris Solaris EP MR Injection System.

During installation of the low pressure connector tubing (LPCT) with Tconnector to the syringe(s), and before arming, manually advance the syringe

plunger(s) to provide a very slow flow of fluid at the connection. An absence of

flow is an obvious indication of air or a blockage in the fluid path.

3 - 24

Page 29

Loading a Syringe WARNIN GS:

1. Position the injector head so that the syringes are

pointing upward.

2. Fully advance each piston plunger. The plungers

may be advanced simultaneously after pressing

ENABLE.

3. Attach a sterile filling device (spike or Female-toFemale Adaptor - MEDRAD Catalog Number FFA

50) onto the tip of the syringe. If loading contrast

media and/or saline from a bag or bottle, use a

spike. If loading contrast media from a pre-filled

syringe, use an FFA 50.

A. If using a spike, open the bottle(s) of contrast

and/or bag(s) of flushing solution, then draw the

contents (contrast for syringe A; flush for syringe B)

into the syringe(s) by depressing ENABLE, and

then the reverse load button for each syringe.

B. If using the FFA 50, attach it to the tip of syringe

A, then attach the pre-filled syringe to the FFA

50. Draw the contents from the prefilled syringe

into syringe A by pressing ENABLE, then the

reverse load button.

4. With the filling device still attached, advance the

plunger to expel any air that may remain in the top

of the syringe; then, if necessary, draw more fluid

into the syringe to replace fluid loss.

5. Remove the filling device and expel any air bubbles

from the syringes.

Remove all trapped air from the syringe, connector tubing, and

catheter-over-needle before connecting the patient to the injector.

Syringe sterility will be compromised, and patient infection may

result, if the plunger is removed from the syringe. Do not remove the

plunger to fill the syringe.

Bacterial contamination can occur if syringes are used to store

contrast media. Use loaded syringes immediately. Do not store loaded

syringes for later use. Discard any unused syringes.

Note: The presence of rounded FluiDot indicators does not

indicate the total absence of air bubbles in the syringe tip.

Note: FluiDot indicators must be viewed in a properly

illuminated environment, with a light source behind the

operator providing enough light to permit easy viewing.

3 - Preparing to Inject

3 - 25

Page 30

MEDRAD Spectris Solaris EP MR Injection System

6. Attach the long end of the T-connector to

syringe B.

7. While the injector head is still in a vertical

position, attach the short section of the Tconnector to syringe A.

8. Starting with syringe A, then syringe B,

prime the T-connector, then fill the

connector tubing with the appropriate

fluid. Ensure that all air is expelled from

the entire length of the tubing.

Saline Flush Contrast

Note: A MEDRAD SSIT 96VLD low pressure connector tube

(LPCT) holds approximately 7 ml of fluid. If syringe B is

used to flush, use at least 8 ml of flush to deliver this

volume to the patient.

Note: If the connector tube is filled with saline, contrast will be

delivered to the patient with a delay dependent on the

flow rate selected for syringe A.

Note: When the connector tube is filled with contrast the

volume remaining displayed on the protocol screen is

approximately 7 ml less than what was loaded into the

syringe.

9. Tilt the injector head downward before attaching to the vascular entry

device in the patient. After attaching the connector tube to the vascular

entry device verify that the connector luer fittings are secured. The

injector head must be maintained in this position during the injection.

WARNINGS:

Patient injury could result from movement of the Scan Room Unit

after the patient is connected to the fluid path. Lock the casters at

the base of the unit and the Middle Pivot Clamp to prevent unintended

movement.

Patient injury and/or catheter damage may result from using

connector tubing (LPCT) that is too short. Operator must consider

tubing length and stretch limitations when moving the injector or the

patient.

10. Secure the Scan Room Unit by locking the casters and the Middle Pivot

Clamp, then verify that all air has been expelled from the fluid path by

carefully inspecting all tubing and syringe(s). Acknowledge that the

inspection has occurred by pressing the AIR REMOVED confirmation

button/indicator on the injector head. The Air Removed Indicator will then

illuminate yellow on the touch screen.

Note: Reverse movement of the pistons after the AIR

EXPELLED button has been pressed will cancel the Air

Expelled status. Re-check the fluid path for air, then

press the AIR EXPELLED button again to continue.

3 - 26

Page 31

3 - Preparing to Inject

1. Insert the end of the syringe in

the horizontal cutouts in the

injector head.

2. Advance the piston until it is

past the plunger feet and the

piston/plunger interlock.

3. Rotate the syringe 1/4 turn

clockwise until the syringe

locks and alignment marks are

positioned.

4. Proceed as normal by

aspirating and dislodging any

air bubbles.

Reinstalling a Syringe

WARNING: Patient injury could result if the syringe is not

properly engaged. Ensure the alignment marks on the syringe and

injector head are properly aligned, and the piston and plunger are

interlocked. Improper engagement may cause syringe damage or

under-volume delivery.

If you remove a syringe from the injector, and then wish to reinstall it, perform

the following steps:

Note: If bubbles appear in the syringe DO NOT hit the syringe

to remove them. Reverse the plunger 3 to 5 ml, then rock

the head on the pivot to gather and accumulate the small

bubbles. Expel the remaining air.

3 - 27

Page 32

MEDRAD Spectris Solaris EP MR Injection System

Programming

If a program has not been previously entered or stored on the Main screen

when the unit is powered up, the Main screen will display default settings; 1.0

ml/s flow rate and 1.0 ml volume, KVO off and No Delay.

Flow Rate and Volume

Begin programming by selecting any programmable block, such as FLOW

RATE or VOLUME. When a programmable block on the screen is touched, a

keypad will be displayed to permit the selection of numeric values. The

numeric keypad is displayed when a Flow Rate, Volume or Delay value is

selected. The keypad window will also display the appropriate programmable

range for the parameter selected. To lock in values, press ENTER. Press <<

to edit a selection, or CANCEL to eliminate a selection if an error is made.

Pressure Limit The pressure limit can be programmed by choosing a value between 100-325

PSI up to the greater of the syringes’ maximum pressure.

3 - 28

Page 33

3 - Preparing to Inject

Multiple Phases If appropriate, select a second phase for the injection protocol by pressing the

triangle block below the first phase of the injection. The Phase Type selector

will appear in order to select the function of the new phase.

Hold and Pause Phases

A Hold or Pause phase can be programmed into a multi-phase injection. A

Pause phase will stop the total injection process for a preprogrammed length

of time, while the Hold phase will stop the injection until input from the

operator resumes the injection. A Hold phase can be maintained for up to 20

minutes, at which time the system will disarm.

After selecting the phase type, continue programming by entering Flow Rate

and Volume values for the new phase.

3 - 29

Page 34

MEDRAD Spectris Solaris EP MR Injection System

Programmed Delay After entering Flow Rate and Volume parameters, press SET in the Delay

Timer field to select the delay type (Scan Delay, Inject Delay, Stopwatch, or

No Delay.)

Note: There is no direct interface between the scanner and the

injector. The scanner cannot trigger the injector, nor can

the injector trigger the scanner.

Scan Delay Scan Delay time will elapse in the timer block on the screen. The time

remaining before the scan should be activated will decrement in one second

intervals. (The scan delay countdown will continue through multiple arm

injections.) When countdown is complete, the system will emit 5 beeps.

Inject Delay Inject Delay will also countdown in one second intervals, commencing when

the handswitch is pressed. The clock will display, in one second decrements,

the time remaining before the injection will begin. When inject delay is chosen

and the handswitch is pressed, the injection will automatically occur unless

the injector is disarmed. When countdown is complete, the system will emit 5

beeps and the injection will automatically begin.

If Hold is activated during an inject delay or a scan delay, the timer will stop

during the hold interval and resume when the handswitch is pressed.

For scan or inject delays that are longer than 3 minutes, the unit will beep 30

seconds before the delay is to terminate, then will beep every second from 5

seconds through 1 second before the delay is due to terminate.

3 - 30

Page 35

3 - Preparing to Inject

15 seconds

20 seconds

30 seconds (default)

45 seconds

60 seconds

75 seconds

Stopwatch The Stopwatch function initiates an incremental count of elapsed time from

initial fluid injection.

After selecting the delay type, enter the delay duration on the numeric keypad.

To lock in values, press ENTER. Press CANCEL to eliminate a selection if an

error is made.

KVO (Keep Vein Open)

The KVO function delivers small boluses of fluid from syringe B at

configurable intervals. KVO can run during:

• Programming

• Pre and post injection

• Between multiple injections

• During Pause and Hold

The delivery interval can be selected in the Setup mode, which is accessed

using the Setup button on the Main Screen.

After an initial KVO pulse of 2 ml, KVO delivery intervals include 0.25 ml

pulsed every:

3 - 31

Page 36

MEDRAD Spectris Solaris EP MR Injection System

The KVO field displays the time available to support

KVO based on the configured interval and the volume

remaining in syringe B less any volume programmed

from syringe B in the protocol.

Starting KVO:

On the Main Screen, press START in the KVO field to initiate KVO. When

KVO is running, “KVO” will appear, and the KVO Injecting arrows will flash in

the Syringe B touch screen indicator.

KVO will function during Pause, Hold and/or inject delay periods. KVO will

resume post-injection until no fluid remains in syringe B, or until STOP KVO is

pressed in the Injection Complete window.

Note: Volume displayed in the Volume Delivered window can

be configured in the Setup mode to include the total KVO

volume delivered in addition to volume delivered by the

programmed injection.

KVO may be stopped at any time by pressing STOP in the KVO field, or by

pressing any injector head control button (this will also disarm the system and

terminate any injection in progress). Other actions that disarm the injector,

such as syringe removal, disarm button press and injection stall, will also stop

KVO.

KVO and Occlusions

If an occlusion occurs during KVO the system will detect the condition after 4

or less KVO boluses fail to be delivered. This will correspond to from 1 minute

with a KVO interval of 15 seconds configured, to 5 minutes with a KVO interval of 75 seconds. Refer to the Setup screen to determine the current KVO

setting.

:

3 - 32

Page 37

3 - Preparing to Inject

Storing a Protocol To store a protocol for future use, press the STORE button on the upper right

corner of the Main screen.

An alpha-numeric keypad will appear with a flashing cursor in the title block.

Type in a title of up to 20 characters, including spaces. Use the arrow key to

backspace, individually erasing characters, and the CLEAR key to clear a

string of text. When title entry is completed, press ENTER.

To exit the Store screen without making changes, press the CANCEL button

in the upper right corner.

3 - 33

Page 38

MEDRAD Spectris Solaris EP MR Injection System

Recalling a Stored Protocol

To access program memory, press RECALL on the Main screen.

Select a previously stored injection protocol by pressing one of the names on

either side of the screen. Key parameters of the selected injection will be

displayed in the center of the screen. Once selected, the protocol can be

deleted by selecting DELETE at the upper right corner of the screen, or

brought to the Main screen by selecting OK.

3 - 34

Page 39

4 - Arming and Injecting

4 - Arming and Injecting

Before beginning the arming process, ensure that the casters on the Scan

Room Unit are locked, verify that all air has been expelled from the fluid path,

and that the programmed parameters are correct. Carefully inspect all tubing

and syringe(s), then acknowledge that the inspection has occurred by

pressing the AIR EXPELLED button/indicator on the injector head. A yellow

illuminated Air Expelled Indicator on the touch screen confirms that the button

has been pressed.

WARNINGS:

Air embolization can cause death or serious injury to the patient.

Do not connect a patient to the injector until all trapped air has been

cleared from the syringe and fluid path.

Patient injury could result from high flow rate venous injections.

Use extreme care when selecting flow rate and duration. Before

arming the injector, verify that high flow rate injection parameters have

not been unintentionally programmed.

Patient injury could result from inadvertent aspiration. To

minimize the possibility of inadvertent aspiriation and injection, ensure

the patient is disconnected from the injector when utilizing the forward/

reverse plunger control(s).

Extravasation can cause injury to the patient. Follow commonly

accepted good clinical procedures to minimize the possibility of

extravasation.

Arming To begin the arming and injecting process, press ARM on the Main screen. If

necessary, changes can be made to programmed injection parameters after

the arming sequence is complete. Select the required parameter, then enter

the correct value with the on-screen keypad. Pressure safety limit programmed by the user is indicated to the user and cannot be changed when

the injector is armed.

Note: If the AIR EXPELLED button on the injector head has not

been pressed, the system will request user confirmation

that air has been expelled before proceeding.

Single and MultiArm

Select either a Single or Multiple arming sequence by pressing either SINGLE

or MULTI. (The default is Single arm.)

A single arm injection will perform the protocol once, then disarm.

A multi-arm injection allows the protocol to be repeated, creating a series of

injections. After the protocol is completed, the system will automatically rearm in preparation for the protocol to be repeated. Each injection in the series

must be started with the handswitch.

4 - 35

Page 40

MEDRAD Spectris Solaris EP MR Injection System

Insufficient Volume If an insufficient volume condition occurs during a multi arm sequence, the

system will remain armed to permit the injection of the remaining volume.

However, the screen will update to display only the phases that are

achievable with the volume that remains. In a single arm sequence, the

screen will update when arming occurs to display only the phases that are

achievable.

While the system is armed, pressing DISARM or activating any injector head

controls will return the system to the idle state.

Injecting After the system has been armed, press the handswitch to begin the injection.

Additional presses of the handswitch will alternately “hold” and resume the

injection. The maximum duration for Hold is 20 minutes. If the maximum hold

time is exceeded the injection will abort automatically.

If an inject delay has been programmed, pressing the handswitch will

activate the countdown timer. The programmed injection will automatically

begin when the timer counts down to zero. If the handswitch is pressed during

an inject delay, the countdown timer will stop counting until the switch is

pressed again, or the Hold time is exceeded.

If a scan delay is programmed, the scan delay countdown and the injection

will start simultaneously. During the injection, additional presses of the hand

switch will alternately “hold” and resume the injection and the scan delay

timer.

If KVO is running: KVO will function during Pause, Hold and/or inject delay

periods as long as sufficient fluid remains in syringe B to complete the

programmed injection. KVO will run post-injection until no fluid remains in

syringe B, or until STOP KVO is pressed in the Injection Complete window. To

stop KVO the operator can also press any injector head control buttons.

If a Hold phase is entered, parameters for the remaining portion of the

injection protocol can be altered.

4 - 36

Page 41

4 - Arming and Injecting

On the Injecting Screen:

• As each phase is activated, the phase parameters will be highlighted to

display injection progress.

• The Duration window will also increment to display elapsed time.

• The Delivered window will increment as the injection proceeds to display

volume delivery (including KVO volume, if selected in Setup mode).

• The Volume Remaining display will decrement.

• The Programmed pressure limit and the current pressure will be indicated

on the display. If a pressure limit condition occurs, it will indicate on the

display.

• If KVO is selected, the time available for KVO will decrement in the KVO

Time Remaining window while KVO is active. (During an injection, KVO

will stop and the time display will not count-down.)

On the Injector Head

• While injecting, indicator lamps on the back of the injector head will be

illuminated (white for syringe A, blue for syringe B). The appropriate

lamps will be lit solid while injecting, and flash while either Armed or on

Hold.

• If multi-arm is selected, the indicator lamps will flash when the system

rearms.

• During KVO the blue indicator lamp for syringe B is illuminated.

• AIR EXPELLED Indicator is illuminated.

:

Disarming Pressing DISARM, activating any injector head controls, or touching any

portion of the touch screen while the system is injecting, will cause the system

to disarm.

The Hold mode can be entered at any time during an injection by pressing the

handswitch. The system will remain in this state until the handswitch is

pressed a second time, or the maximum hold time of 20 minutes is exceeded.

4 - 37

Page 42

MEDRAD Spectris Solaris EP MR Injection System

Note: A MEDRAD SSIT 96VLD low pressure connector tube

(LPCT) holds approximately 7 ml of fluid. If syringe B is

used to flush, use at least 8 ml of flush to deliver this

volume to the patient.

Note: If the connector tube is filled with saline, contrast will be

delivered to the patient with a delay dependent on the

flow rate selected for syringe A.

Note: When the connector tube is filled with contrast, the

volume remaining displayed on the screen is

approximately 7 ml less than what is present in the

system.

When an injection (single or all multi-arm sequences) is completed, the

following window, with a brief summary of the injection parameters, will be

displayed.

4 - 38

Page 43

4 - Arming and Injecting

Injection History To review injection parameters used in a procedure, along with actual

achieved values for the injection, press the HISTORY button on the Main

screen.

The Injection History screen displays an injection summary block containing

the following data:

• Time and Date Started

• Programmed Flow Rate

• Programmed Volume

• Programmed Protocol

• Total Fluid (plus KVO)

• Delay Type

• Delay Duration

• Pressure Limit Programmed

• Peak Pressure

• Pressure Limit Status (YES/NO)

• Premature Termination Status (YES/NO)

The system maintains status information of the 20 most recent injections,

sorted by date and time.

To delete any injection protocol history from the system, press DELETE while

the protocol is selected. To scroll to the next page of protocols, press the

ARROW key. To exit the Injection History screen, press CANCEL.

4 - 39

Page 44

MEDRAD Spectris Solaris EP MR Injection System

Clean Up Note: Do not resterilize or reuse any disposable items.

When cleaning the injector, remove and discard all used disposable items.

(Syringes should be removed without retracting the pistons.) It is not

necessary to remove the connector tubing when removing and discarding

syringes.

WARNING:

Serious injury may result from syringe failure. Do not retract

pistons with connector tubing installed.

• Disconnect the Control Room Unit from line power and remove

the battery from the Scan Room Unit before cleaning.

• Avoid fluid entry into system components. Do not immerse any

components in water or cleaning solution.

• Do not remove any covers or disassemble the injector.

Periodically inspect for loose or frayed cables, loose covers,

cracks, dents, or loose hardware. Contact MEDRAD Service for

repairs.

• Retracting the pistons with the connector tubing installed on

syringes will create a vacuum in the syringe due to the check

valve in the connector tubing. This vacuum may accelerate the

plunger rapidly toward the tip of the syringe when it is removed

from the injector causing the syringe to break.

CAUTIONS:

System malfunction may be caused by failure to perform regular

maintenance. Regular preventive maintenance is recommended to

ensure that the system stays calibrated and functions properly. Refer

to Appendix B of this manual or contact MEDRAD for additional

information.

Do not expose system components to excessive amounts of

water or cleaning solutions. Wipe components with a soft cloth or

paper towel dampened with cleaning solution.

Do not use strong cleaning agents and solvents. Warm water and

a mild disinfectant are all that is required. Do not use strong industrial

cleaning solvents such as acetone.

Note: For all body fluid spills, follow institutional

decontamination procedures.

Note: If contrast medium has leaked inside any component of

the system, the affected subassembly should be

disassembled and cleaned by MEDRAD Service

personnel or returned to MEDRAD Factory Service.

4 - 40

Page 45

4 - Arming and Injecting

Scan Room Unit Using a soft non-abrasive cloth, warm water, and a mild disinfectant, carefully

clean the assembly, paying particular attention to the following:

• Injector Head

• Syringe Piston Plunger

• Syringe Interface

• SRU Lower Console covers

To clean the injector head, piston, and syringe interface

1. Fully advance the piston.

2. Remove the battery from the Scan Room Unit.

3. Place the injector head in a vertical position.

4. Clean the piston with a soft cloth or paper towel dampened with cleaning

solution.

5. Thoroughly dry the piston with a paper towel.

6. Re-install the system battery, then fully retract the piston.

7. Remove the battery from the Scan Room Unit again.

8. Clean the inner area of the syringe interface with a soft cloth or paper

towel dampened with cleaning solution.

9. Wipe the injector head case and control panel with a soft cloth or paper

towel dampened with cleaning solution.

10. Thoroughly dry the injector head case and control panel with a paper

towel.

:

Control Room Unit CAUTION: Do not spray cleaning solutions directly onto the

touch screen. To prevent damage, wipe the touch screen with a soft

non-abrasive cloth or paper towel dampened with cleaning solution.

4 - 41

Page 46

MEDRAD Spectris Solaris EP MR Injection System

4 - 42

Page 47

Appendix A: System Messages

Appendix A: System Messages

The system will display messages on the screen as conditions or events

occur. There are three basic types of messages:

WARNING: Patient injury may result from a system malfunction.

If a system malfunction occurs, immediately remove Scan Room Unit

power (by pulling the battery from the head stand), and disconnect the

system from the patient. If a fault message is displayed that cannot be

corrected, and/or the system is not operating correctly, do not use the

injection system. Call MEDRAD for assistance.

Type 1 Messages Type 1 messages are messages which provide information regarding the

current status of the system, and will clear automatically from the screen.

These messages are typically displayed in the lower right corner of the

screen.

A - 43

Page 48

MEDRAD Spectris Solaris EP MR Injection System

A

System Error Detected

Immediately disconnect the patient from the injector.

Record the code below and contact MEDRAD Service.

Refer to the operation manual or www.Medrad.com for contact information.

Symcode = HSW

Errnum = -2600

Type 2 Messages Type 2 messages are messages that convey information that must be

explicitly acknowledged before proceeding. The message is displayed within

a yellow dialog box - a button (or buttons) must be pressed to acknowledge

and remove the message from the screen.

Type 3 Messages Type 3 messages are system malfunction messages which require power to

be removed from the system. Some Type 3 messages provide suggestions to

prevent the condition from recurring. If the condition cannot be corrected,

record the code and number from the lower left corner of the dialog box, then

call MEDRAD Service for assistance.

A - 44

Page 49

Appendix B: Maintenance and Checkout

Appendix B: Maintenance and

Checkout

This section contains recommended procedures for maintenance, and an

operational checkout of the MEDRAD Spectris Solaris EP MR Injection

System. Routine maintenance and inspection will:

• Ensure continued performance of the injection system

• Reduce the possibility of equipment malfunction

Recommended Maintenance Schedule

Your MEDRAD Spectris Solaris EP MR Injection System must be properly

maintained to ensure that it is in peak operating condition. Your individual

maintenance system and schedule depends upon how your injection system

is used, the type of procedures performed, and frequency of use. The

following maintenance schedule is recommended for the system:

Daily:

The piston rod should be thoroughly cleaned after each use. Before use each

day, the system should be cleaned and inspected, using the procedures

outlined in this section. Ensure that all system safety and warning labels are in

place and are legible.

Monthly:

Once a month, the entire system should be thoroughly inspected and

cleaned, and an Operational Checkout should be performed.

Annually:

As part of an annual maintenance program performed by a qualified

MEDRAD Service Representative or authorized dealer, both Electrical

Leakage and Ground Continuity checks should be performed.

NOTE: Local regulations or hospital protocol may require

electrical leakage checks at more frequent intervals. If

this applies, local regulations for leakage must be

followed.

MEDRAD also recommends that a complete system calibration and

performance checkout be performed annually. Contact MEDRAD Factory

Service, or your local MEDRAD office for complete details.

In the United States, Canada, and Europe, the MEDRAD Service Department

offers Preventive Maintenance Programs. These annual programs greatly

assist in maintaining accuracy and reliability, and can also extend the life of

the system. Contact MEDRAD for details. In Europe, contact your local

MEDRAD office or your local authorized dealer for further information. Refer

to the back of the title page of this manual for address, telephone and FAX

information.

B - 45

Page 50

MEDRAD Spectris Solaris EP MR Injection System

NOTE: Failures which occur due to lack of proper maintenance

will not be covered under warranty.

MEDRAD Service MEDRAD Service will make available upon request:

• Circuit diagrams, component parts lists, or other information that will

assist qualified technicians to repair components classified as repairable.

• On-site consulting or consulting references upon request.

Inspection Procedures

The following procedures are recommended for daily inspection of all

components in the MEDRAD Spectris Solaris EP MR Injection System. If any

defects are detected, either repair the system, or call MEDRAD for service.

Do not use the system until the problem is corrected.

Scan Room Unit 1. Inspect the housing for any damage or cracks that could allow fluid to leak

inside, or weaken the structural integrity of the unit.

2. Inspect all cables connected to the unit: Look for cuts, cracks, worn spots

or other obvious damage to the cables. Ensure that all connectors are

properly seated.

3. Inspect for contrast media build-up in the syringe interface area. Follow

the cleaning guidelines outlined in this section.

4. Inspect the stand, base, and support arm for cracks and other defects that

could weaken the structure.

5. Ensure that all mounting bolts and screws are secure.

6. Ensure that all locking mechanisms on the casters are functional.

7. Inspect the pivot points. The head and support arm must pivot freely. The

injector head should rotate on the support arm no more than 330

support arm should not rotate on the center post more than 350

NOTE: All relevant guidelines for institutional, local, or national

safety recommendations related to cable routing and

installation should be followed.

o

o

.

. The

Control Room Unit 1. Inspect all cables connected to the unit: Look for cuts, cracks, or worn

spots, or other obvious damage. Ensure that all connectors are properly

seated.

2. Inspect the housing for any damage or cracks that could allow fluid to leak

inside, or weaken the structural integrity of the unit.

B - 46

Page 51

Appendix B: Maintenance and Checkout

Wall Mount Bracket 1. Inspect all parts of the bracket for cracks and other defects that would

weaken the assembly.

2. Ensure that the bracket is securely attached to the wall.

3. Ensure that all cables are secured to the display control unit and do not

interfere with the movement of the mounting bracket.

Height Adjustable

Pedestal

1. Inspect the stand, base and support arm for cracks and other defects that

could weaken the structure.

2. Ensure all mounting bolts and screws are secure.

3. Ensure that the casters roll smoothly with no binding or scraping.

4. Ensure all locking mechanisms on the casters are functional.

5. Verify that the vertical height adjustment of the column shaft moves freely

without binding or scraping.

Battery Charger 1. Inspect all cables connected to the unit: Look for cuts, cracks, or worn

spots, or other obvious damage. Ensure that all connectors are properly

seated.

2. Inspect the housing for any damage or cracks that could allow fluid to leak

inside, or weaken the structural integrity of the unit.

3. Inspect all parts of the wall mounting bracket for cracks or other defects

that would weaken the assembly. If applicable, ensure that the bracket

remains firmly attached to the wall.

Communication Link 1. Inspect the cables for cuts, cracks or worn spots. Ensure that the

connectors are properly seated.

B - 47

Page 52

MEDRAD Spectris Solaris EP MR Injection System

Cleaning Guidelines

Deposits of contrast media can interfere with proper operation of the

MEDRAD Spectris Solaris EP MR Injection System. The following guidelines

should be followed when removing deposits, or cleaning any portion of the

system.

WARNING: Serious injury or death may result from exposure to

hazardous voltages existing within the system. Disconnect the

system from line power before cleaning or attempting to perform any

maintenance. Ensure that the system is completely dry before

connecting to the power source and applying power.

CAUTION: Improper or careless cleaning methods may result in

equipment damage. Do not soak or immerse any part of the injection

system in water. While cleaning any outside portion of the system,

avoid allowing any water to leak inside system components.

• If contrast medium has leaked inside any component of the system, the

affected subassembly should be disassembled and cleaned. This

cleaning procedure can be done in the field by trained MEDRAD Service

personnel, or returned to MEDRAD Service. If the cleaning will be

performed in the field, do not disturb any internal wiring or components.

• Care must be taken not to get water or cleaning solutions inside any

system components. Do not use strong industrial cleaning agents or

solvents such as acetone. Warm water and a mild disinfectant such as

antibacterial hand soap are all that is required.

• To clean the syringe interface area of the injector head, fully retract the

piston. Using a paper towel moistened with warm water or a mild

disinfectant, gently wipe the inner syringe installation area. Do not insert

any sharp instruments into this area during the cleaning process.

• Check all System Safety and Warning Labels for legibility. Ensure that the

labels are not damaged or missing.

Operational Checkout

A basic functional checkout of the MEDRAD Spectris Solaris EP MR Injection

System should be included as part of regular maintenance. Verifying proper

operation of the injection system will help in detection of any problems that

may not be noticed in day to day operation. The following procedure

represents a suggested series of activities which encompass typical operation

of the system. Read the following procedure carefully before beginning the

checkout. If problems are detected, contact MEDRAD Service.

NOTE: Any problems detected during this or any other

procedure should be corrected before using the injection

system in patient procedures.

B - 48

Page 53

Appendix B: Maintenance and Checkout

System Labels Ensure that all system safety and warning labels are in place and legible.

Power Up Apply power to the system. Verify that the Safety screen is displayed after

system diagnostics occur. Press OK to acknowledge the messages on the

Safety screen. Upon power up of the CRU and SRU, verify that the indicators,

lamps, and speaker are operational.

Programming After the Main screen is displayed, verify that the following controls are

functioning properly.

At the rear of the Control Room Unit, Press the Lighten Display Contrast