Page 1

READ BEFORE USING

Operation Manual

Page 2

Page 3

1 Information .......................................................................................................................1 - 1

1.1 Important Safety Notice..................................................................................................................................... 1 - 1

1.2 Disclaimers ....................................................................................................................................................... 1 - 1

1.3 Training Information .......................................................................................................................................... 1 - 1

2 About This Manual...........................................................................................................2 - 3

2.1 Intended Use..................................................................................................................................................... 2 - 3

2.2 Contraindications .............................................................................................................................................. 2 - 3

2.3 Certifications..................................................................................................................................................... 2 - 3

2.3.1 Safety Certifications................................................................................................................................ 2 - 3

2.3.2 EMC Certifications .................................................................................................................................. 2 - 3

2.4 Additional Information Regarding Compliance to IEC 60601-1-2/2007............................................................... 2 - 4

2.5 Restricted Sales ................................................................................................................................................ 2 - 7

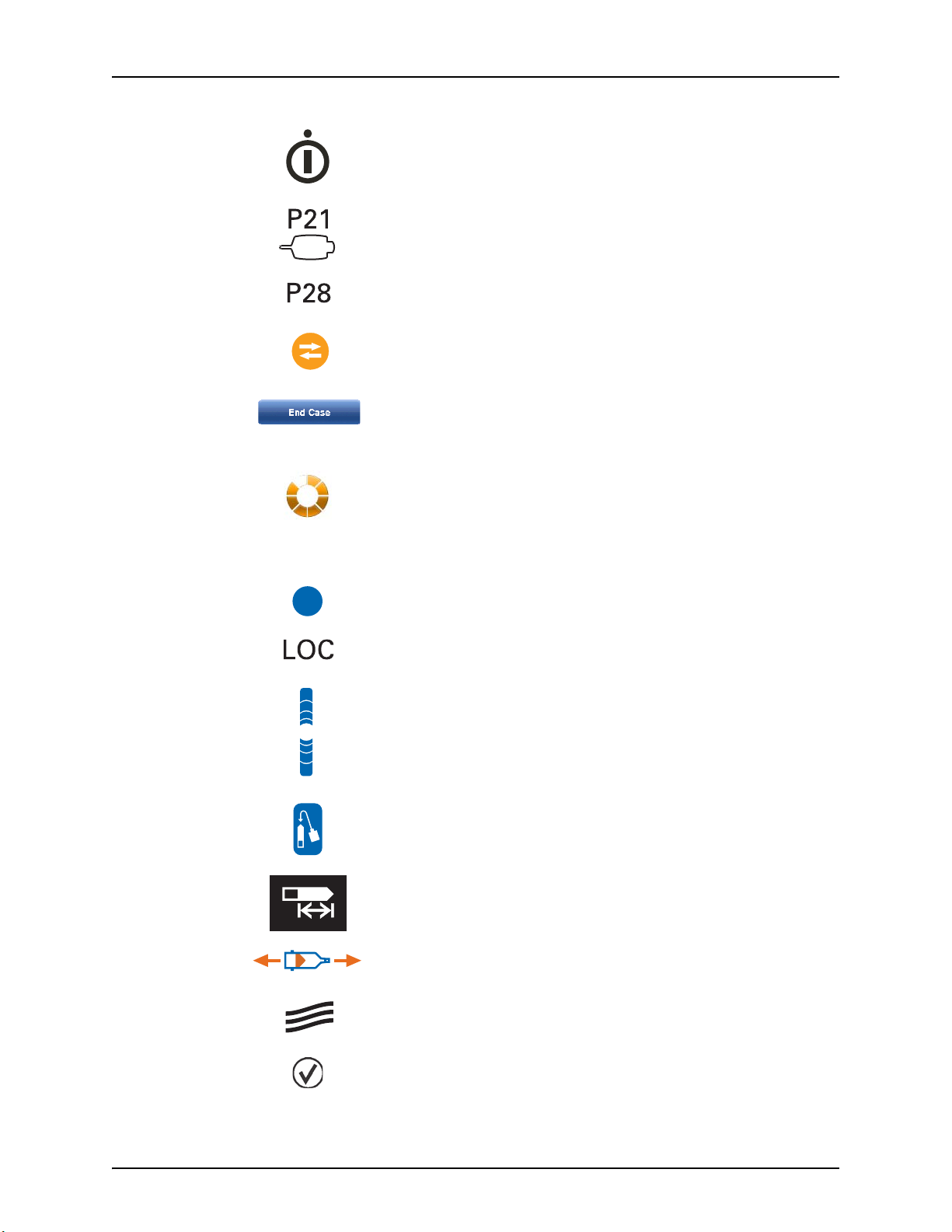

3 Symbols and Icons ..........................................................................................................3 - 9

3.1 Notified Body..................................................................................................................................................... 3 - 9

3.2 Regulatory Classifications ................................................................................................................................. 3 - 9

3.3 Warnings........................................................................................................................................................... 3 - 9

3.4 Buttons and Icons ........................................................................................................................................... 3 - 10

3.4.1 Display Control Unit Buttons and Icons.................................................................................................. 3 - 10

3.4.2 Injector Head Buttons and Icons............................................................................................................ 3 - 11

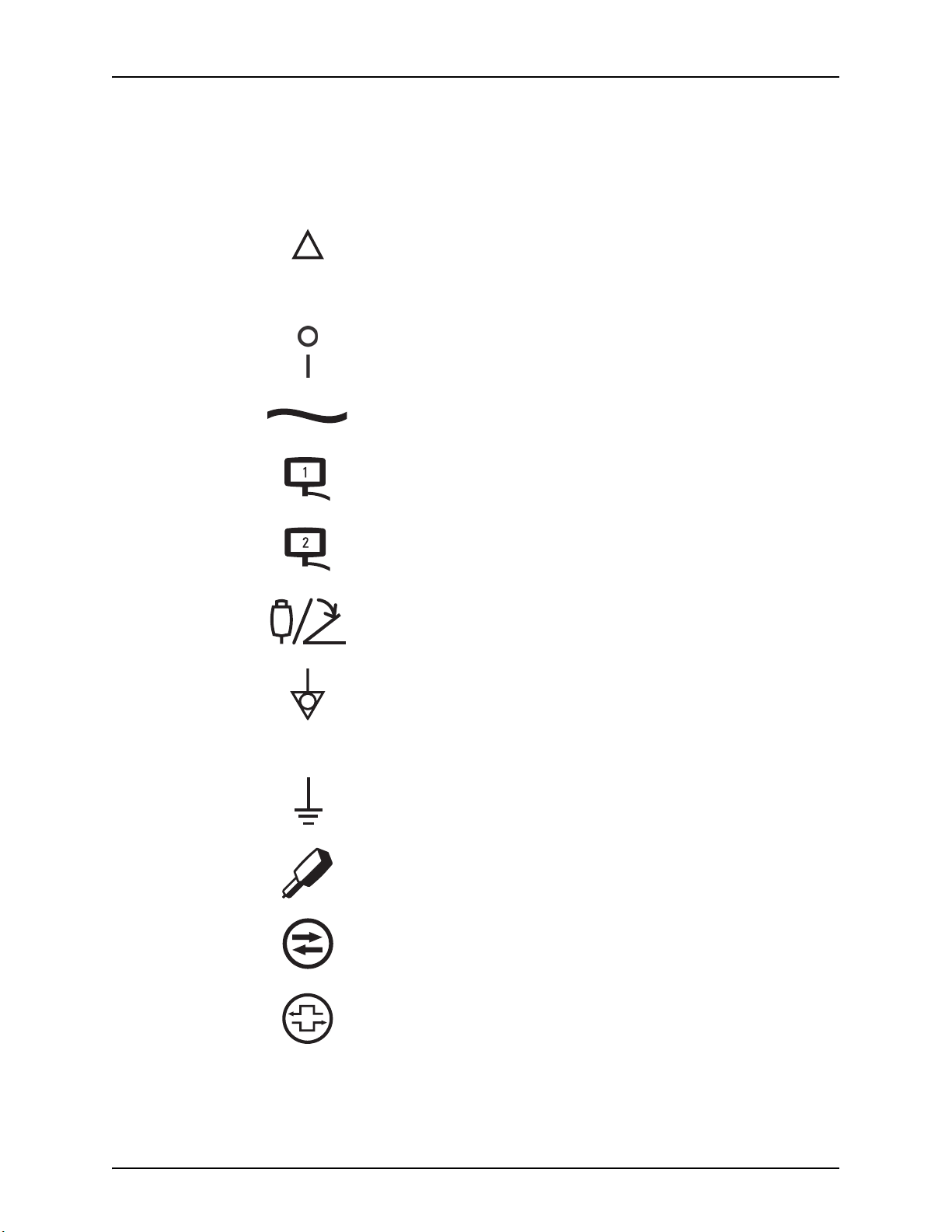

3.4.3 Power Unit Icons................................................................................................................................... 3 - 12

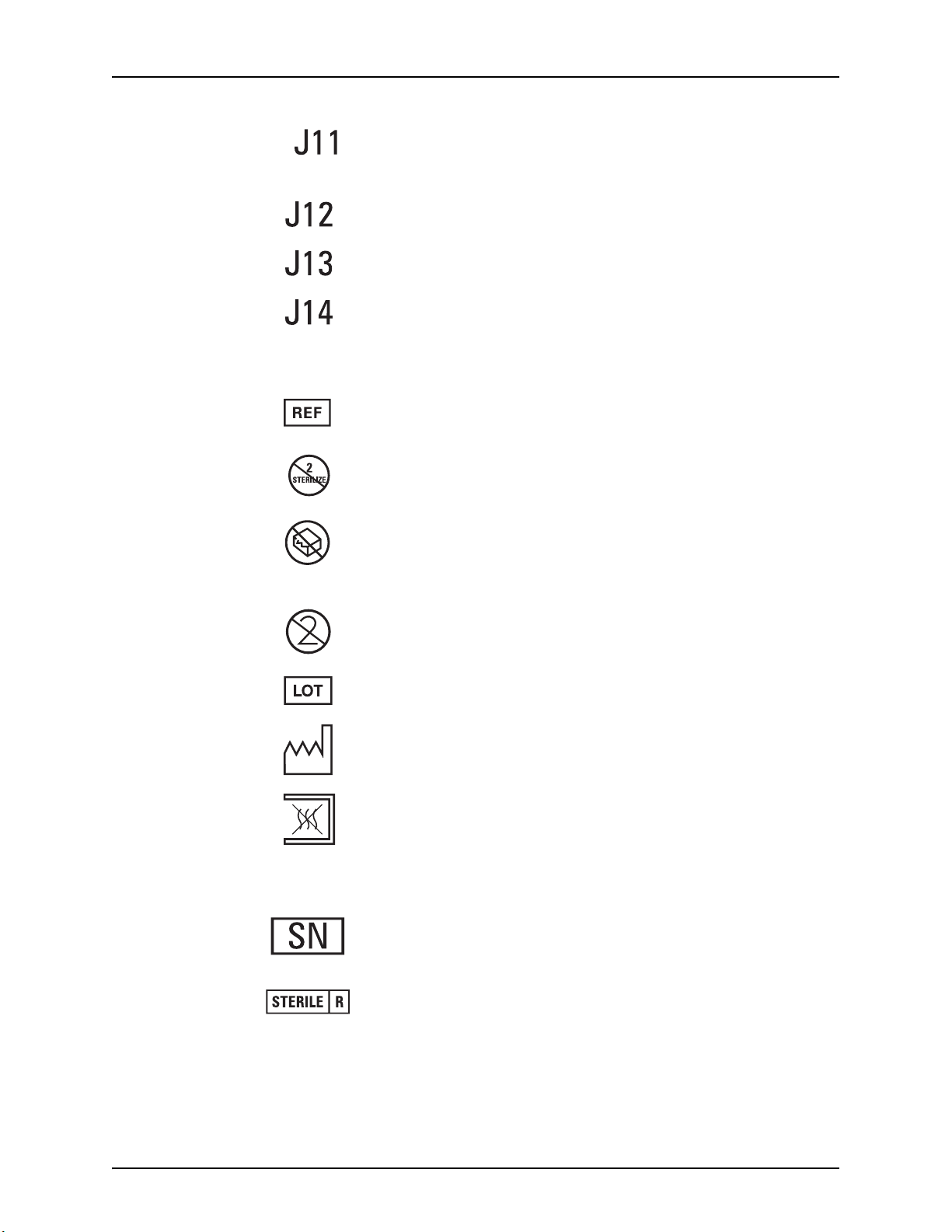

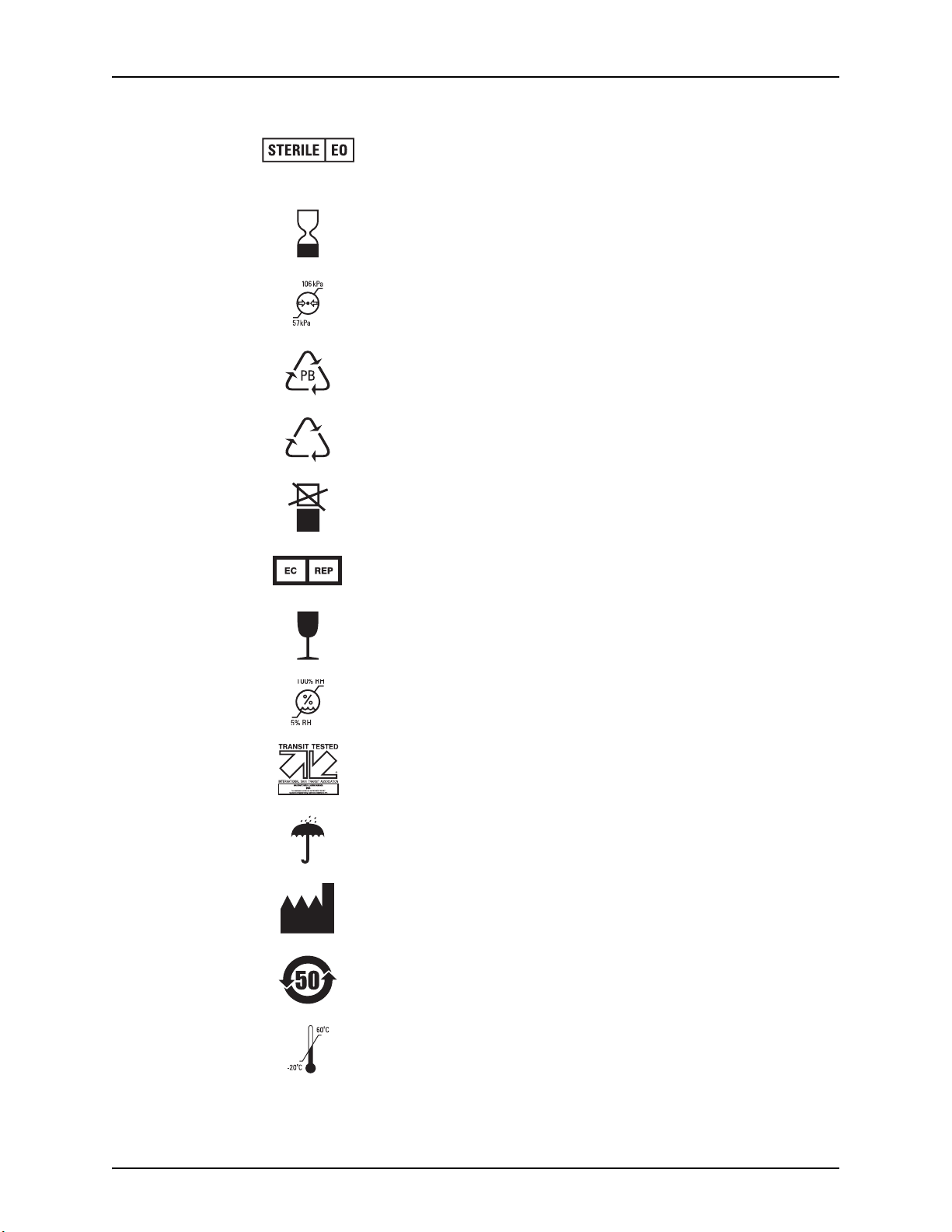

3.5 Packaging ....................................................................................................................................................... 3 - 13

4 System Warnings, Precautions, and Notices .............................................................. 4 - 17

4.1 Warnings......................................................................................................................................................... 4 - 17

4.2 Cautions.......................................................................................................................................................... 4 - 18

4.3 Notices............................................................................................................................................................ 4 - 18

5 System Overview ...........................................................................................................5 - 19

5.1 Injection Protection.......................................................................................................................................... 5 - 19

5.2 Pressure Limiting ............................................................................................................................................ 5 - 20

5.3 System Technical Specifications ..................................................................................................................... 5 - 20

5.3.1 Input Power Requirements.................................................................................................................... 5 - 20

5.3.2 Technical Specifications ....................................................................................................................... 5 - 21

5.4 High Pressure Connector Tubing Specifications (Non-Twist & Go).................................................................... 5 - 21

5.5 Display Control Unit......................................................................................................................................... 5 - 22

5.5.1 Display Control Unit Sterile Sheath........................................................................................................ 5 - 22

5.6 Injector Head................................................................................................................................................... 5 - 22

5.7 Power Unit ...................................................................................................................................................... 5 - 23

5.8 Imaging System Interface................................................................................................................................ 5 - 23

5.9 MEDRAD® VFlow........................................................................................................................................... 5 - 23

5.10 Start Switches............................................................................................................................................... 5 - 23

5.10.1 Hand Switch and Foot Switch ............................................................................................................. 5 - 23

5.10.2 MEDRAD VFlow Hand Controller ......................................................................................................... 5 - 24

5.11 Pedestal and Stand Movement ...................................................................................................................... 5 - 25

5.11.1 Pedestal System ................................................................................................................................. 5 - 25

5.11.2 Head Stand (KMA 320 RT) and Adjustable Height Stand (KMA 330)..................................................... 5 - 26

5.11.3 Mark 7 Arterion Stand Mounting Kit Configuration............................................................................... 5 - 27

6 Using and Understanding the Display Control Unit Screen ......................................6 - 29

6.1 Home Tab ....................................................................................................................................................... 6 - 29

6.1.1 Programmed Window ........................................................................................................................... 6 - 29

i

Page 4

MEDRAD® Mark 7 Arterion Injection System

6.1.2 Actuals Window.................................................................................................................................... 6 - 30

6.1.3 Sentinel Window................................................................................................................................... 6 - 30

6.2 Protocols Tab .................................................................................................................................................. 6 - 30

6.3 History Tab...................................................................................................................................................... 6 - 30

6.4 Options Tab..................................................................................................................................................... 6 - 30

6.4.1 Modify Options ..................................................................................................................................... 6 - 31

6.5 Help Tab ......................................................................................................................................................... 6 - 31

6.6 Display Control Unit Lock-outs ........................................................................................................................ 6 - 32

6.7 Performing Touch Screen Calibration .............................................................................................................. 6 - 32

7 Using and Understanding the Injector Head............................................................... 7 - 33

7.1 Injector Head Components .............................................................................................................................. 7 - 33

7.2 Injector Head Position...................................................................................................................................... 7 - 34

7.3 Syringe Interface............................................................................................................................................. 7 - 34

7.3.1 Piston Auto Retract ............................................................................................................................... 7 - 35

7.4 Pressure Jacket .............................................................................................................................................. 7 - 35

7.4.1 Pressure Jacket Storage....................................................................................................................... 7 - 35

7.5 Injector Head Displays..................................................................................................................................... 7 - 36

7.5.1 Flow Rate (A) ........................................................................................................................................ 7 - 36

7.5.2 Volume (B)............................................................................................................................................ 7 - 36

7.5.3 Pressure Limit (C) ................................................................................................................................. 7 - 36

7.5.4 Volume Remaining (D) .......................................................................................................................... 7 - 36

7.6 Injector Head Controls ..................................................................................................................................... 7 - 37

7.6.1 Enable Button (F) .................................................................................................................................. 7 - 37

7.6.2 Fill Strip (H)........................................................................................................................................... 7 - 37

7.6.3 Auto-Fill Button (I)................................................................................................................................. 7 - 37

7.7 Armed Light .................................................................................................................................................... 7 - 37

7.8 Manual Knob................................................................................................................................................... 7 - 38

7.9 Syringe Heat Maintainer .................................................................................................................................. 7 - 38

7.10 Injector Head Lock-outs ................................................................................................................................ 7 - 38

8 Power Up and Shutdown the Injector.......................................................................... 8 - 39

8.1 Powering up the System.................................................................................................................................. 8 - 39

8.2 Shutdown........................................................................................................................................................ 8 - 39

8.3 Emergency Shutdown ..................................................................................................................................... 8 - 39

9 Setting and Managing Protocols..................................................................................9 - 41

9.1 Set Injection Parameters from the Home Tab................................................................................................... 9 - 41

9.1.1 Set Injection Parameters on Home Tab - Single .................................................................................... 9 - 41

9.1.2 Set Injection Parameters on Home Tab - Phased................................................................................... 9 - 42

9.1.3 Set Injection Parameters on Home Tab - Variable Flow Rate .................................................................9 - 43

9.2 Manage Protocols from the Protocols Tab........................................................................................................ 9 - 44

9.2.1 Create Protocols ................................................................................................................................... 9 - 44

9.2.2 Recall a Stored Protocol........................................................................................................................ 9 - 47

9.2.3 Edit an Existing Protocol ....................................................................................................................... 9 - 48

9.2.4 Delete a Protocol .................................................................................................................................. 9 - 49

10 Preparing for Injection ..............................................................................................10 - 51

10.1 Installing the Mark 7 Arterion or Twist & Go Syringe .................................................................................... 10 - 51

10.2 Filling and Purging the Mark 7 Arterion or Twist & Go Syringe ..................................................................... 10 - 53

10.3 Installing and Purging Standard High Pressure Connector Tubing ............................................................... 10 - 54

10.4 Installing and Purging Twist & Go HPCT....................................................................................................... 10 - 55

10.5 Installing the MEDRAD® VFlow Hand Controller .......................................................................................... 10 - 56

ii

Page 5

10.6 Connecting to and Purging the Catheter ...................................................................................................... 10 - 57

10.7 Enabling 15 mL Purge Feature and Choosing Configuration Options ............................................................ 10 - 58

10.7.1 15 mL Purge ON ............................................................................................................................... 10 - 58

10.7.2 15 mL Purge OFF.............................................................................................................................. 10 - 58

10.8 Defining a Protocol...................................................................................................................................... 10 - 59

10.9 Turning ISI On or Off.................................................................................................................................... 10 - 59

11 Arming and Injecting .................................................................................................11 - 61

11.1 Purged Air Confirmation .............................................................................................................................. 11 - 61

11.2 Arming the Injector...................................................................................................................................... 11 - 61

11.2.1 Arm Single Mode .............................................................................................................................. 11 - 62

11.2.2 Arm Multi Mode ................................................................................................................................ 11 - 64

11.3 Performing an Injection ............................................................................................................................... 11 - 65

11.3.1 Performing a Single mL/s Injection in Arm Single Mode .................................................................... 11 - 65

11.3.2 Performing a Single mL/m Injection in Arm Single Mode .................................................................. 11 - 65

11.3.3 Performing a Single mL/s or Variable Flow Rate Injection in Arm Multi Mode..................................... 11 - 65

11.3.4 Performing a Phased Injection ......................................................................................................... 11 - 66

11.3.5 Performing an Injection with Imaging System Interface (ISI) .............................................................. 11 - 66

11.4 Completing an Injection .............................................................................................................................. 11 - 69

11.5 Refilling Syringe During a Procedure ........................................................................................................... 11 - 70

11.5.1 Refilling Syringe with 15 mL Purge Feature Enabled ......................................................................... 11 - 71

12 Tear Down ..................................................................................................................12 - 73

12.1 Remove Disposables ................................................................................................................................... 12 - 73

12.2 Clean up ..................................................................................................................................................... 12 - 73

12.3 Storing the Injector...................................................................................................................................... 12 - 74

13 System Messages......................................................................................................13 - 75

13.1 Error Messages ........................................................................................................................................... 13 - 75

13.2 Sentinel Messages ...................................................................................................................................... 13 - 75

13.3 Popup Messages......................................................................................................................................... 13 - 77

14 VirtualCare Option .....................................................................................................14 - 81

15 Cleaning and Maintenance .......................................................................................15 - 83

15.1 Daily ........................................................................................................................................................... 15 - 83

15.1.1 Cleaning the Injector Head, Syringe Heat Maintainer, Drop Front Cover, Pressure Jacket, Piston, Syringe

Interface, and Table Bracket ....................................................................................................................................... 15 - 83

15.1.2 Inspecting the Injector Head.............................................................................................................. 15 - 85

15.1.3 Inspecting the Pressure Jacket ......................................................................................................... 15 - 85

15.1.4 Inspecting the Heat Maintainer ......................................................................................................... 15 - 86

15.1.5 Inspecting the Display Control Unit.................................................................................................... 15 - 86

15.1.6 Inspecting the Table Mount Bracket.................................................................................................. 15 - 86

15.1.7 Inspecting the Pedestal..................................................................................................................... 15 - 87

15.1.8 Inspecting the Power Unit ................................................................................................................. 15 - 87

15.2 Monthly....................................................................................................................................................... 15 - 87

15.2.1 Cleaning the Display Control Unit, Pedestal, Power Unit, and Table Bracket ...................................... 15 - 87

15.2.2 Inspecting and Cleaning the Internal Air Filter ................................................................................... 15 - 87

15.2.3 Performing an Operational Checkout................................................................................................. 15 - 88

15.3 Annually...................................................................................................................................................... 15 - 90

15.3.1 Injection System Calibration.............................................................................................................. 15 - 90

15.3.2 Checking Leakage ............................................................................................................................ 15 - 90

16 Installation - System and Accessory .......................................................................16 - 91

16.1 Unpacking the Injection System................................................................................................................... 16 - 91

iii

Page 6

MEDRAD® Mark 7 Arterion Injection System

16.2 Pedestal Mount Installation ......................................................................................................................... 16 - 92

16.3 Power Unit Installation................................................................................................................................. 16 - 95

16.3.1 Power Unit Connections.................................................................................................................... 16 - 96

16.3.2 Power Unit Floor Mount Bracket Assembly........................................................................................ 16 - 97

16.3.3 Relocate Power Unit Connectors ....................................................................................................... 16 - 98

16.4 Injector Head Mounting Options................................................................................................................... 16 - 99

16.4.1 Head Stand Installation (KMA 320RT)................................................................................................ 16 - 99

16.4.2 Adjustable Height Stand Installation (KMA 330)................................................................................. 16 - 99

16.4.3 Adjustable Table Bracket Installation (KMA 350) ............................................................................... 16 - 99

16.4.4 Overhead Counterpoised System Installation..................................................................................... 16 - 99

16.5 Display Control Unit Mounting Options......................................................................................................... 16 - 99

16.5.1 Fulcrum Mount Kit Installation........................................................................................................... 16 - 99

16.5.2 Desk Stand Kit Installation .............................................................................................................. 16 - 100

16.5.3 Fixed Table Mount Installation......................................................................................................... 16 - 101

16.5.4 Wall Mount Bracket Installation....................................................................................................... 16 - 103

16.6 Accessory Installation................................................................................................................................ 16 - 105

16.6.1 Syringe Heat Maintainer Installation................................................................................................ 16 - 105

16.6.2 Syringe Pressure Jacket Installation................................................................................................ 16 - 106

16.6.3 Hand Switch and Foot Switch Installation........................................................................................ 16 - 106

16.6.4 Hand Switch Mount Kit .................................................................................................................. 16 - 107

16.6.5 Display Control Unit Sterile Sheath Installation ................................................................................ 16 - 108

16.6.6 Cable Bracket Installation ............................................................................................................... 16 - 109

16.7 Stand Mounting Kit Installation .................................................................................................................. 16 - 116

16.8 Power Unit Bracket Installation.................................................................................................................. 16 - 116

16.9 Display Control Unit (DCU) Support Assembly Installation........................................................................... 16 - 118

17 Specifications...........................................................................................................17 - 121

17.1 System Component Weights and Dimensions ............................................................................................ 17 - 121

17.1.1 Pedestal System Weight and Dimensions........................................................................................ 17 - 121

17.1.2 Display Control Unit Weight and Dimensions ................................................................................... 17 - 122

17.1.3 Injector Head Weight and Dimensions............................................................................................. 17 - 122

17.1.4 Power Unit Weight and Dimensions ................................................................................................ 17 - 123

17.2 Mounting Components Weights and Dimensions ....................................................................................... 17 - 123

17.2.1 Pedestal Mount Weight and Dimensions ......................................................................................... 17 - 123

17.2.2 Head Stand Weight and Dimensions ............................................................................................... 17 - 124

17.2.3 Adjustable Height Stand Weight and Dimensions ............................................................................ 17 - 124

17.2.4 Stand Mounting Kit Components Weights and Dimension................................................................ 17 - 125

17.2.5 Adjustable Table Mount (KMA 350) Weight and Dimensions............................................................ 17 - 126

17.2.6 OCS Mount Weight and Dimensions................................................................................................ 17 - 126

17.2.7 Fixed Table Mount Weight and Dimensions..................................................................................... 17 - 129

17.2.8 Display Control Unit Desk Stand Mount Weight and Dimensions...................................................... 17 - 129

17.2.9 Display Control Unit Wall Mount Weight and Dimensions................................................................. 17 - 130

17.2.10 Power Unit Floor Mount Weight and Dimensions ........................................................................... 17 - 130

17.3 ISI Technical Specifications ....................................................................................................................... 17 - 131

17.3.1 ISI Output Specifications ................................................................................................................. 17 - 131

17.3.2 ISI Input Specifications.................................................................................................................... 17 - 132

17.3.3 ISI Connector Specifications............................................................................................................ 17 - 132

17.4 Environmental Specifications..................................................................................................................... 17 - 136

17.4.1 Operating........................................................................................................................................ 17 - 136

17.4.2 Non-Operating: (Transportation and Storage) .................................................................................. 17 - 136

17.4.3 EMI/RFI........................................................................................................................................... 17 - 136

17.4.4 Equipment Classification................................................................................................................. 17 - 136

17.4.5 Class I Product................................................................................................................................ 17 - 136

iv

Page 7

17.4.6 Type CF Defibrillation-proof Applied Part......................................................................................... 17 - 136

17.4.7 IPX1................................................................................................................................................ 17 - 136

17.4.8 Continuous Mode of Operation........................................................................................................ 17 - 137

17.4.9 EU Directive.................................................................................................................................... 17 - 137

18 Options and Accessories ........................................................................................18 - 139

18.1 Mark 7 Arterion Disposables/Syringe Kits .................................................................................................. 18 - 139

18.2 Mark 7 Arterion System Mount Options ..................................................................................................... 18 - 139

18.2.1 Injector Head Mount Options........................................................................................................... 18 - 139

18.2.2 Power Unit Mount Options .............................................................................................................. 18 - 139

18.2.3 Display Control Unit Mount Options ................................................................................................. 18 - 140

18.2.4 Cable Brackets ............................................................................................................................... 18 - 140

18.3 Mark 7 Arterion Accessory Devices and Kits.............................................................................................. 18 - 140

18.3.1 Switches......................................................................................................................................... 18 - 140

18.3.2 Accessory Devices and Kits ............................................................................................................ 18 - 140

18.4 Mark 7 Arterion Cords and Cables ............................................................................................................. 18 - 141

18.4.1 Power Cords................................................................................................................................... 18 - 141

18.4.2 Head Power and Communication Extension Cables ......................................................................... 18 - 141

18.4.3 Display Cables................................................................................................................................ 18 - 141

18.5 OCS Mounting Systems............................................................................................................................. 18 - 142

18.5.1 Stationary Ceiling Mount................................................................................................................. 18 - 142

18.5.2 Mobile Ceiling Mount ..................................................................................................................... 18 - 142

18.5.3 Wall Mount .................................................................................................................................... 18 - 142

18.5.4 Ceiling Mount Plate......................................................................................................................... 18 - 142

18.6 OEM Imaging System Interface Cables ...................................................................................................... 18 - 142

18.6.1 General Electric .............................................................................................................................. 18 - 142

18.6.2 Philips ............................................................................................................................................ 18 - 143

18.6.3 Siemens ......................................................................................................................................... 18 - 143

18.6.4 Ziehm............................................................................................................................................. 18 - 143

18.6.5 Universal Imaging System Interface Cables..................................................................................... 18 - 143

18.6.6 Equipotential Cables ....................................................................................................................... 18 - 143

v

Page 8

MEDRAD® Mark 7 Arterion Injection System

vi

Page 9

1Information

1.1 Important Safety Notice

This manual and the equipment it describes are for use by qualified medical professionals with

proper training and experience in angiographic procedures and the use of the MEDRAD

Arterion (Mark 7 Arterion) Injection System. The manual is intended as instructions on the proper

use of the Mark 7 Arterion Injector and Syringe.

The Mark 7 Arterion injector system is designed to operate with syringes from Bayer and that use of

other, unauthorized syringes, may result in syringe rupture or leaking. Accordingly, only authentic

syringes from Bayer should be used in the operation of Arterion Injector system.

The safe and effective use of the Mark 7 Arterion Injection System to a large degree depends upon

factors solely under the control of the medical professionals using the system. There is no

substitute for a properly trained and vigilant angiographic team. It is important that the operating

instructions and the user warnings and cautions supplied with this injection system be read,

understood and followed.

Before starting any angiographic injection procedure, the angiographic team should be trained in

the particular angiographic procedures to be performed. In addition, the angiographic team should

be familiar with the medical literature related to angiographic procedures and the benefits of

performing angiographic procedures with automated injection systems versus the potential

complications and risks, including but not limited to air embolism.

Read and understand all the information contained in this manual. Understanding this information

will assist you in operating the Mark 7 Arterion Injection System in a safe and effective manner.

®

Mark 7

1.2 Disclaimers

Operating specifications and feature availability may vary by country. Check with your local product

representative and county-specific operating instructions.

External wiring and modifications disclaimers: Bayer disclaims liability for any modifications or

interfaces with other equipment that are not in conformity with the specifications and information

contained in this manual.

Accessory equipment connected to the MEDRAD Mark 7 Arterion Injection System must be certified

according to EN 60601-1 / IEC 60601-1 standard. Furthermore, all configurations shall comply with

system standard EN 60601-1-1/IEC 60601-1-1 Second Edition and EN 60601-1/IEC 60601-1 Third

Edition. Anyone who connects additional equipment to the signal input or output part configures a

medical system and is therefore responsible that the system complies with the requirements of the

standard EN 60601-1-1/IEC 60601-1-1 Second Edition and EN 60601-1/IEC 60601-1 Third Edition. To

obtain on-site consulting or consulting references, contact Bayer HealthCare Services.

1.3 Training Information

This manual is intended as an extension of the user interface of the Mark 7 Arterion Injection System to

provide procedural and technical information. Additional Mark 7 Arterion training information will be

available in the following formats:

• On-site initial installation and additional training, as requested

• In-service video/DVD

• Syringe instruction for use (IFU)

• Service Manual

Please contact Bayer HealthCare Services or local Bayer representative if any of these resources are

needed.

1 - 1

Page 10

MEDRAD® Mark 7 Arterion Injection System

1 - 2

Page 11

2 About This Manual

This manual applies to the MEDRAD Mark 7 Arterion Injection System.

Read all of the information contained in this manual. Understanding this information will assist you in

operation of the MEDRAD Mark 7 Arterion Injection System in a safe manner.

2.1 Intended Use

The MEDRAD Mark 7 Arterion Injection System is intended to be used specifically for the purposes of

injecting contrast medium and common flushing solutions into humans for angiographic studies.

2.2 Contraindications

This device is not intended to be used for chemotherapy and is not intended to administer fluids other

than intravascular contrast agents and common flushing solutions.

2.3 Certifications

This device is equipped to operate at 100-240 VAC, 50/60 Hz, and is designed to comply with EN

60601-1 / IEC 60601-1 Second/Third Edition and EN 60601-1-2/IEC 60601-1-2 Third Edition.

2.3.1 Safety Certifications

The MEDRAD Mark 7 Arterion Injection System complies with the requirements of CAN/CSA-C22.2 No.

0-M91 - General Requirements - Canadian Electrical Code, Part II CAN/CSA-C22.2 No. 601.1-M90 Medical Electrical Equipment Part I: General Requirements for Safety UL 60601-1 - Medical Electrical

Equipment IEC 60601-1:2005 - Medical Electrical Equipment Part 1: General Requirements for Safety,

CAN/CSA-C22.2 No. 60601-1-08 Medical Electrical Equipment - Part 1: General Requirements for

basic safety and essential performance, ANSI/AAMI ES60601-1:2005 Medical electrical equipment,

Part 1: General requirements for basic safety and essential performance.

2.3.2 EMC Certifications

The MEDRAD Mark 7 Arterion Injection System complies with the requirements of:

EN 60601-1-2:2007, (3rd Ed.). Medical Electrical Equipment-Part 1: General Requirements for Safety,

Amendment No. 2. Collateral Standard: Electromagnetic Compatibility Requirements and Tests.

2 - 3

Page 12

MEDRAD® Mark 7 Arterion Injection System

NOTICE

d

3.5

V

1

-------

p=

d

3.5

E

1

-------

p=

d

7

E

1

----- -

p=

2.4 Additional Information Regarding Compliance to IEC 60601-1-2/2007

This section is intended to reflect conformance to IEC-60601-1-2 / 2007 3rd edition.

The following statements are notices. Notices advise of circumstances that could result in damage to

the device. Read and understand these cautions before operating the injector system.

Electro-Mechanical Hazard - Equipment Damage may result.

• For proper operation, use only accessories and options provided by Bayer that are

designed specifically for the injector system. Other non-Bayer approved accessories or

options may cause equipment damage or may result in increased emissions or decreased

immunity of the injector system. Injector system accessories listed in it’s operation

manual comply with the requirements of electromagnetic emissions and immunity

standards IEC 60601-1-2/2007 3rd edition.

• Injector may disarm or fail to operate when exposed to high magnetic fields. Portable and

mobile RF communications equipment can affect the injector.

• Do not use injector adjacent to or stacked with other equipment. If adjacent or stacked

use is necessary, the injector should be observed to verify normal operation in the

configuration in which it will be used.

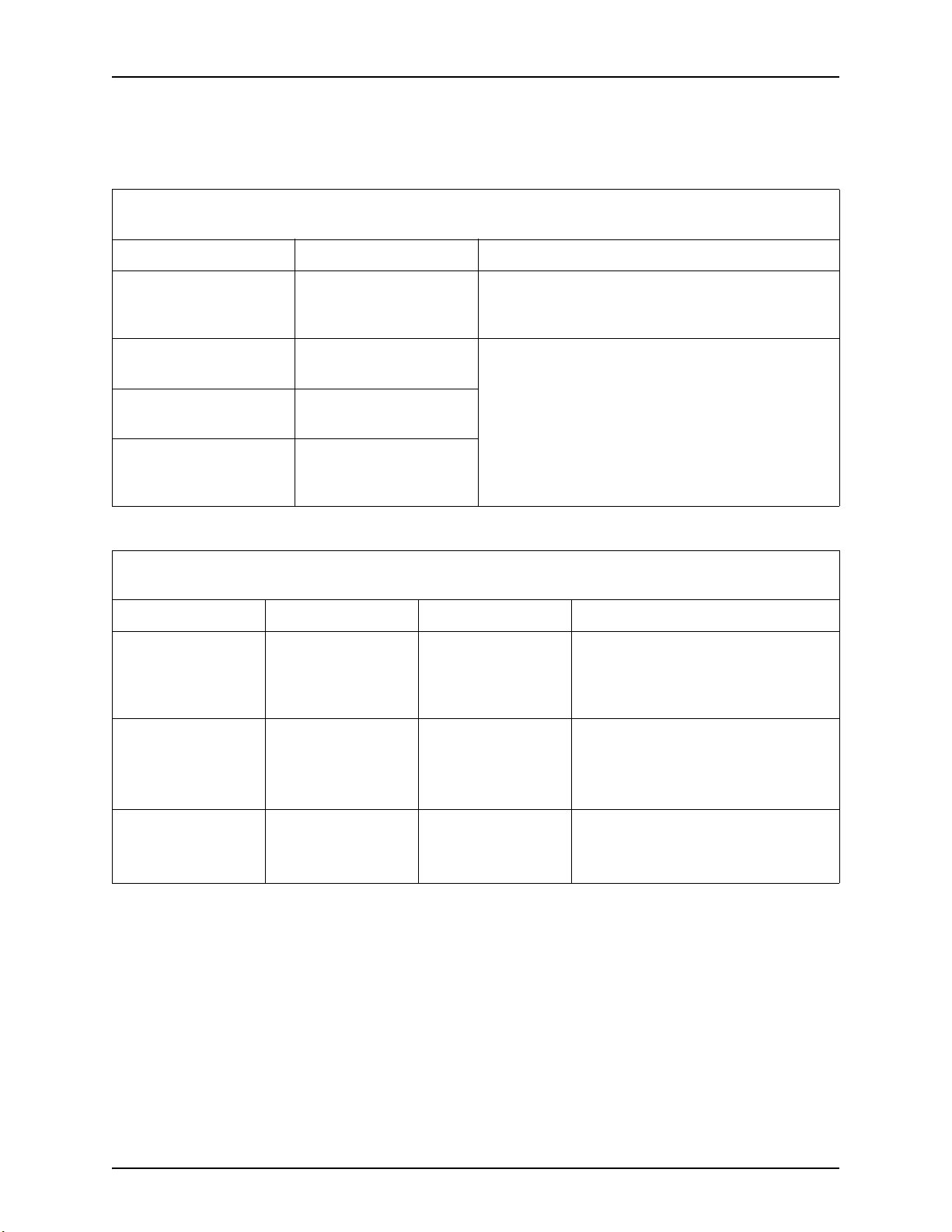

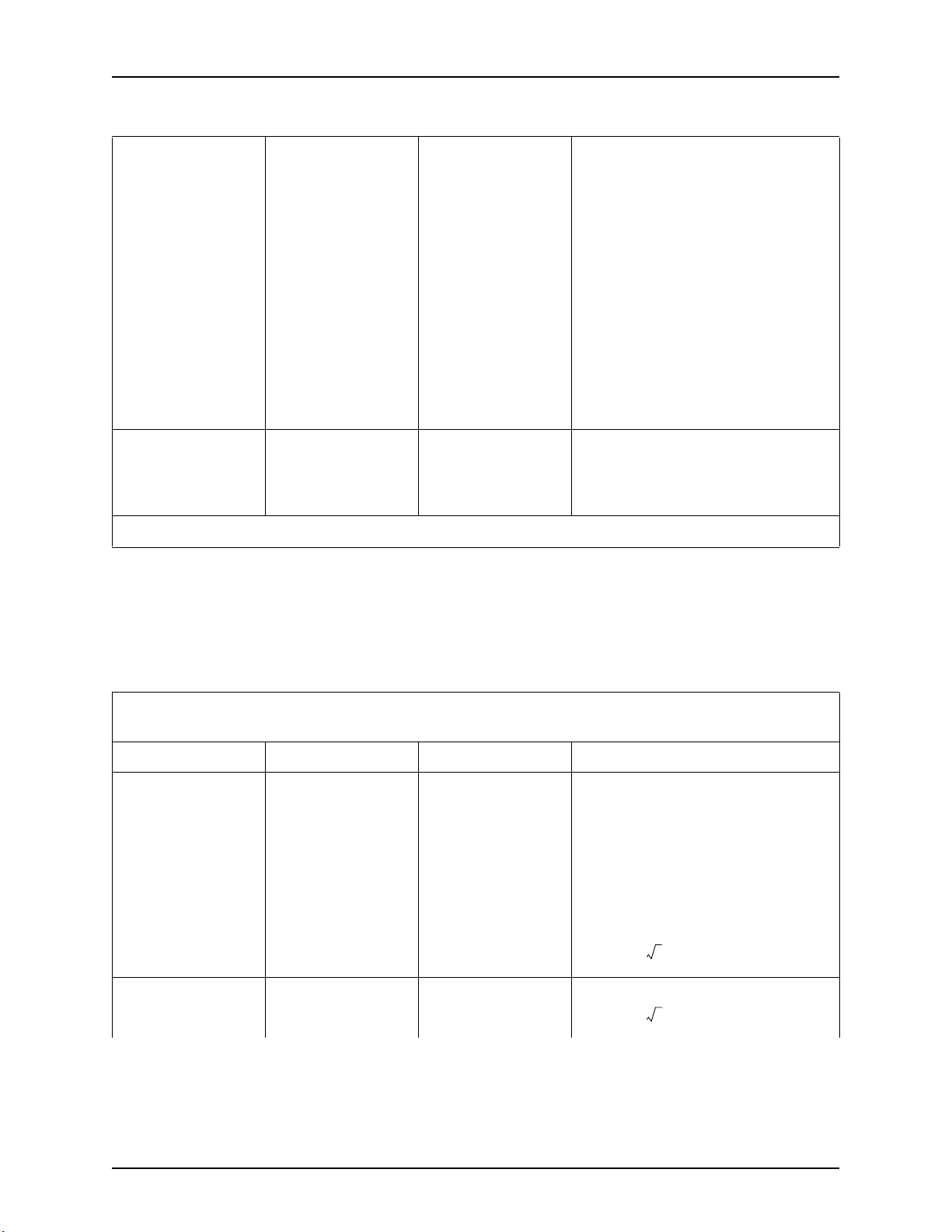

Table 2 - 1: Recommended separation distances between portable and mobile RF communications equipment and the

injector

The injector is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The

customer or the user of the injector can help prevent electromagnetic interference by maintaining a minimum distance

between portable and mobile RF communications equipment (transmitters) and the injector as recommended below,

according to the maximum output power of the communications equipment

Separation distance according to frequency of transmitter

Rated maximum output

power of transmitter W

150 KHz to 80 MHz

80 MHz to 800 MHz

800 MHz to 2.5 GHz

0.01 0.12 0.12 0.23

0.1 0.37 0.37 0.74

1 1.17 1.17 2.33

10 3.69 3.69 7.38

100 11.67 11.67 23.33

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m)

can be estimated using the equation applicable to the frequency of the transmitter, where p is the maximum output power

rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

2 - 4

Page 13

About This Manual

INJECTOR REQUIRES SPECIAL PRECAUTIONS REGARDING EMC. Install and put into service according

to the EMC information provided below:

Table 2 - 2: Guidance and manufacturer's declaration - electromagnetic emissions

The injector is intended for use in the electromagnetic environment specified below. The customer or user of the injector

should assure that it is used in such an environment.

Emission Test Compliance Electromagnetic Environment - Guidance

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic current emissions

IEC 61000-3-2

Voltage fluctuations/flicker

emissions

IEC 61000-3-3

Table 2 - 3: Guidance and manufacturer's declaration - electromagnetic immunity

The injector is intended for use in the electromagnetic environment specified below. The customer or user of the injector

should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Electrostatic discharge

(ESD)

IEC 61000-4-2

Electrical/fast

transient/burst

IEC 61000-4-4

Group 1

Class A

Class A

Complies

6 kV contact

8 kV air

2 kV for power supply

lines

1 kV for input/output

lines

6 kV contact

8 kV air

2 kV for power supply

lines

1 kV for input/output

lines

The injector uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely

to cause any interference in nearby electronic equipment.

Notice: This injector is intended for use by healthcare

professionals only. This injector may cause radio

interference or may disrupt the operation of nearby

equipment. It may be necessary to take mitigation

measures, such as re-orienting or relocating the injector or

shielding the location.

Floors should be wood, concrete or

ceramic tile. If floors are covered with a

synthetic material, the relative humidity

should be at least 30%

Mains power quality should be that of a

typical commercial or hospital

environment.

Surge

IEC 61000-4-5

1 kV differential

mode

2 kV common mode

1 kV differential

mode

2 kV common mode

Mains power quality should be that of a

typical commercial or hospital environment

2 - 5

Page 14

MEDRAD® Mark 7 Arterion Injection System

d 1.17 p=

d 1.17 p=

Table 2 - 3: Guidance and manufacturer's declaration - electromagnetic immunity

<5% UT

(>95% dip in UT)

for 0.5 cycle

40% UT

(60% dip in UT)

for 5 cycles

70% UT

(30% dip in UT)

for 25 cycles

<5% UT

(>95% dip in UT)

for 5 sec

Voltage dips, short

interruptions and

voltage variations on

power supply input

lines

IEC 61000-4-11

<5% UT

(>95% dip in UT)

for 0.5 cycle

40% UT

(60% dip in UT)

for 5 cycles

70% UT

(30% dip in UT)

for 25 cycles

<5% UT

(>95% dip in UT)

for 5 sec

Power frequency

(50/60 Hz)

magnetic field

3 A/m 3 A/m

IEC 61000-4-8

NOTE: UT is the a.c. mains voltage prior to application of the test level.

Mains power quality should be that of a

typical commercial or hospital

environment. If the user of the injector

requires continuous operation during

power mains interruptions, it is

recommended the injector be powered

from an uninterruptible power supply or

battery

Power frequency magnetic fields should be

at levels characteristic of a typical location

in a typical commercial or hospital

environment.

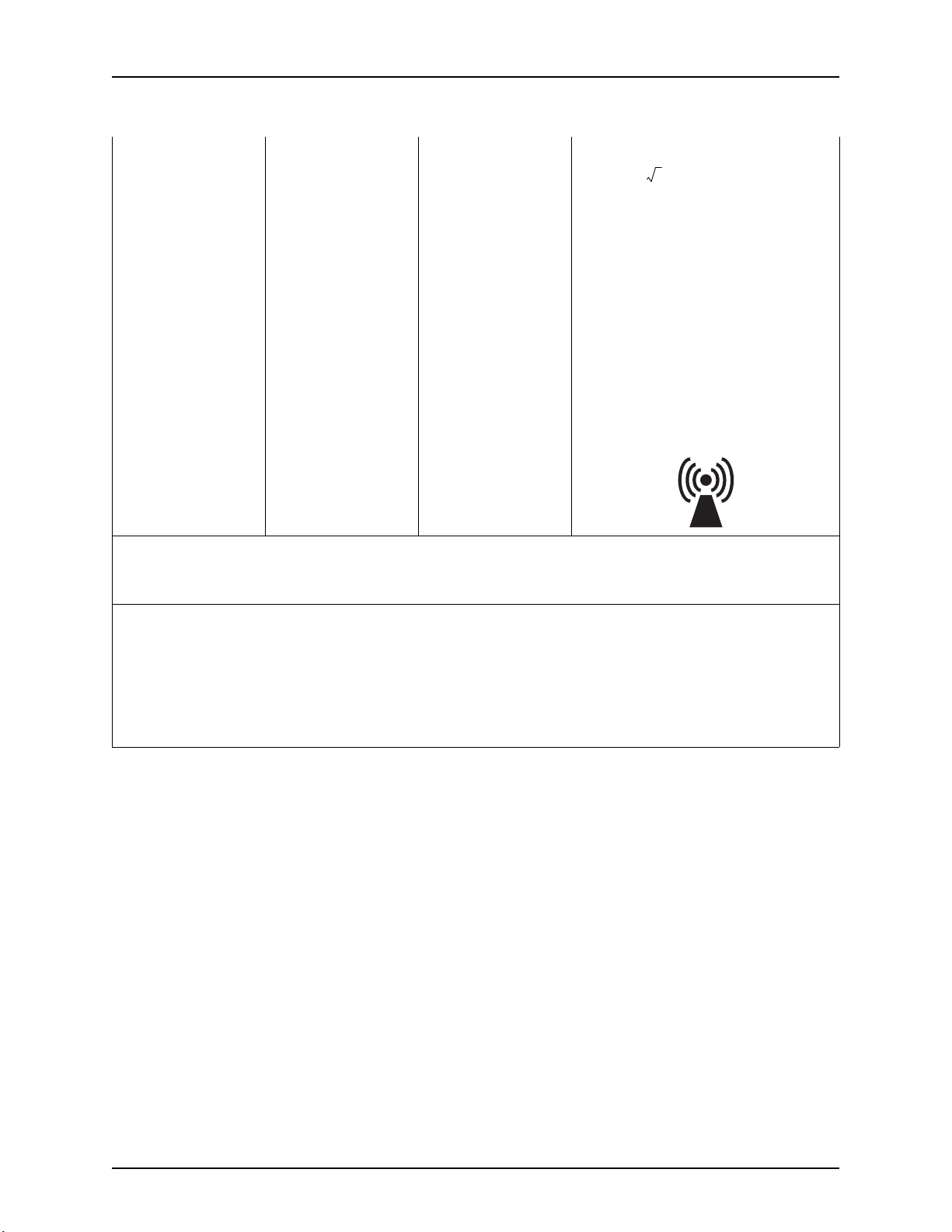

Table 2 - 4: Guidance and manufacturer's declaration - electromagnetic immunity

The injector is intended for use in the electromagnetic environment specified below. The customer or user of the injector

should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to any

part of the injector, including cables, than

the recommended separation distance

calculated from the equation applicable to

the frequency of the transmitter.

Recommended Separation Distance

Conducted RF

IEC-61000-4-6

Radiated RF

IEC 61000-4-3

3 V rms

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

3 V rms

3 V/m

80 MHz to 800 MHz

2 - 6

Page 15

About This Manual

d 2.33 p=

Table 2 - 4: Guidance and manufacturer's declaration - electromagnetic immunity

800 MHz to 2.5 GHz

Where p is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters,

as determined by an electromagnetic site

a

survey,

should be less than the

compliance level in each frequency range.

Interference may occur in the vicinity of

equipment marked with the following

symbol:

b

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

a Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile

radios, amateur radio, AM and FM radio broadcast cannot be predicted theoretically with accuracy. To assess the

electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the

measured field strength in the location in which the injector is used exceeds the applicable RF compliance level above, the

injector should be observed to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as reorienting or relocating the injector.

b Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

2.5 Restricted Sales

Rx Only - U.S. Federal law restricts this device to sale by or on the order of a licensed health care

practitioner.

2 - 7

Page 16

MEDRAD® Mark 7 Arterion Injection System

2 - 8

Page 17

3 Symbols and Icons

IPX1

The symbols and icons discussed in the sections below describe the requirements to which the Mark 7

Arterion Injection System conforms, how warnings are displayed in manual, and the icons used on the

equipment and equipment packaging.

3.1 Notified Body

Indicates that this device conforms to requirements of the European Medical

Device Directive 93/42/EEC

3.2 Regulatory Classifications

.

3.3 Warnings

Type Cardial Floating (CF) Defibrillation-Proof applied part as defined by IEC

60417-2.

IPX1 Code that specifies the degree of protection against vertically falling water

drops (IEC 60529).

Indicates separate collection for Electrical and Electronic Equipment per

Directive 2002/96/EC . Refer to the following website for additional information:

http://www.medrad.com/en-us/resources/Pages/WEEE.aspx

Indicates risk of electric shock.

Warning: Refer to warnings and cautions on Instructions for Use packaged in

each carton.

Indicates a pinch or crush hazard.

Attention: Refer to warnings and cautions on Instructions for Use packaged in

each carton.

Indicates hot surface. Item can be hot and should not be touched without taking

care.

3 - 9

Page 18

MEDRAD® Mark 7 Arterion Injection System

Pushing Prohibited. Do not push at or above this point on the Injector.

Air Warning Label

• Air Embolism Hazard: injury or death can result.

• Read operation manual.

• Expel air from syringe/disposable before connecting or injecting to patient.

• Observe change in FluiDots Indicators, for syringes from Bayer.

Table Mount Warning

Patient or operator injury could occur if all knobs are not properly tightened.

Ensure that all knobs are securely tightened before use. Do not overtighten.

Indicates that the information is a warning. Warnings advise you of

WARNING

circumstances that could result in serious injury or death to the patient or

operator. Read and understand the warnings before operating the injection

system.

Indicates that the information is a caution. Cautions advise you of

CAUTION

NOTICE

NOTE

circumstances that could result in minor or moderate injury to the patient or

operator. Read and understand the cautions before operating the injection

system.

Indicates that the information is a notice. Notices advise you of circumstances

that could result in damage to the device. Read and understand the notices

before operating the injection system.

Indicates that the information that follows is additional important information or

a tip that will help you recover from an error or point you to related information

within the manual.

3.4 Buttons and Icons

The buttons on the Display Control Unit (DCU), Injector Head, and Power Unit allow operators to access

functions on the injector system. The icons used on the DCU, Injector Head, and Power Unit notify

operators about system processes and identify connection ports.

3.4.1 Display Control Unit Buttons and Icons

The Display Control Unit brightness controls.

Purged Air Confirmation icon - indicates that the operator has confirmed that all

air has been purged.

3 - 10

Indicates that Display Control Unit is locked because someone is accessing

another Display Control Unit or the Injector Head controls.

Page 19

Symbols and Icons

The On/Off Switch.

The hand switch connection location found on the back of the Display Control

Unit.

The Power Unit cable connection location found on the back of the Display

Control Unit.

Indicates that an Imaging System Interface (ISI) is enabled and functioning

properly.

This symbol is also used throughout the manual to indicate ISI specific steps.

Operators use the End Case button to end the injection for a patient case, to

retract the syringe plunger, to clear the Total Contrast number, and to create a

record of the case.

Injection Indicator displays during an injection.

3.4.2 Injector Head Buttons and Icons

The Enable button activates the Fill Strip and Auto-Fill button.

Displays in Volume Remaining LED on the Injector Head when an operator is

accessing the Display Control Unit.

The Fill Strip allows operators to retract and advance the piston from the

Injector Head.

The Auto-Fill button fills the syringe with a user defined contrast volume and at

a user defined speed.

Identifies the Volume Remaining LED.

Identifies rotation direction on the manual knob for manually moving

the piston. Clockwise is forward movement.

The Syringe Heat Maintainer connection location.

Future expansion port.

3 - 11

Page 20

MEDRAD® Mark 7 Arterion Injection System

J31

J32

Hand Controller.

Identifies the Service Port.

Pressure Jacket Syringe Alignment.

3.4.3 Power Unit Icons

Power Unit On/Off switch.

Indicates Alternating Current and identifies the Power Unit power cord

connection.

Identifies a connection for Display Control Unit1. The Power Unit has two

connection points.

Identifies a connection for Display Control Unit2. The Power Unit has two

connection points.

Identifies the hand switch or foot switch connection.

Identifies the Equipotential connection. The Equipotential Connector (EPC) is an

electrically bonded terminal on the injector, used as a connection point between

other medical electrical equipment. The EPCs function is to minimize any

voltage potentials differences between all connected equipment. The EPC is not

designed to be an electrical safety ground.

Identifies the Earth Ground point (this terminal is meant for supplementary

grounding please contact Bayer prior to using this terminal).

Identifies an Injector Head connection. The Power Unit has two connection

points.

Identifies the Imaging System Interface connection.

Identifies the CAN connection.

3 - 12

Page 21

3.5 Packaging

Rx Only

Symbols and Icons

Identifies the service port.

NOTE: Used by Bayer HealthCare Services or Bayer trained

personnel.

Future expansion port.

Future expansion port.

Future expansion port.

Catalog Number

Do not Re-sterilize.

Do not use if package is damaged.

Do Not Reuse

Batch Code

Date of Manufacture/Sterilization

Non-Pyrogenic Fluid Path

Prescription Device - U.S. Federal law restricts this device to sale by or on the

order of a (licensed health care practitioner).

Serial number

Sterilized using Irradiation.

3 - 13

Page 22

MEDRAD® Mark 7 Arterion Injection System

CB

Sterilized with Ethylene Oxide.

Use By

Atmospheric Pressure Limitation

Chinese Recycling symbol for paperboard.

Chinese Recycling symbol for corrugated cardboard.

Do Not Stack

Authorized Representative in the European Community.

Fragile, Handle with care

Humidity limitation

ISTA tested

Keep Dry

Manufacturer

China ROHS - Environmental Protection use Period Mark.

Temperature Limitation

3 - 14

Page 23

This Way Up

Not made with natural rubber latex.

Symbols and Icons

3 - 15

Page 24

MEDRAD® Mark 7 Arterion Injection System

3 - 16

Page 25

4 System Warnings, Precautions, and Notices

4.1 Warnings

Air Embolism Hazard - Serious patient injury or death may result.

• Do not inject air.

• Purge all air from syringe and disposables before connecting or injecting to patient.

• Use only accessories and options provided by Bayer which are designed specifically for

the injection system.

• Inspect system and do not use when signs of damage are evident.

• Verify that the FluiDots indicators are rounded to ensure that fluid is present in the

syringe.

• No modification of equipment is allowed.

Serious patient and/or worker injury or death may result.

• Use of non-Bayer supplied disposables, including administration sets and additions to

administration sets, such as but not limited to bleed back control devices and pressure

transducers may cause patient injury if not properly connected or flushed. These devices

must be compatible with your system. Refer to manufacturer's instructions for proper use

of these devices.

Do not use if sterile package is opened or damaged.

• Patient or operator injury may result if package is opened or damaged, or if damaged

components are used. Visually inspect contents and package before each use.

Cross contamination hazard - Serious patient and/or worker injury or death may result.

• Ensure only syringes from Bayer are used on the system.

• Do not store filled syringes for later use.

• Discard previously filled unused syringes.

• Do not reuse disposables.

• For devices labeled for single use, please note: This product is intended for single

use only. Do not resterilize, reprocess or reuse. The disposable devices have been

designed and validated for single use only. Re-use of the single use disposable

devices pose risks of device failure and risks to the patient. Potential device failure

includes significant component deterioration with extended use, component malfunction,

and system failure. Potential risks to the patient include injury due to device malfunction

or infection as the device has not been validated to be cleaned or re-sterilized.

Procedure Delay Hazard - Serious patient and/or worker injury or death may result.

• Turn off any equipment that could generate an electrostatic discharge during procedure.

Electric Shock Hazard - Serious patient and/ or worker injury or death may result.

• The system should be opened and serviced by Bayer HealthCare Services or Bayer trained

service personnel.

• Use only power cord approved for use on Mark 7 Arterion.

• For U.S. installations, equipment shall only be connected to Hospital Grade or Hospital

Only outlets.

• Disconnect the system from line power before cleaning or attempting to perform any

maintenance or repairs.

• Avoid contact with pins.

• Ensure that connector covers are in place or cables are connected.

• Do not allow injector head to contact patient.

• Equipment must only be connected to supply mains with protective earth.

• Unplug system prior to servicing.

4 - 17

Page 26

MEDRAD® Mark 7 Arterion Injection System

CAUTION

NOTICE

4.2 Cautions

Environmental Contamination Hazard - Minor or moderate patient and/ or worker injury may

result.

• Follow sterile technique specifically, maintain sterility of the syringe tip and plunger,

syringe barrel internal surface, Quick Fill Tube, high pressure connector tubing, catheter,

and Display Control Unit Sheath.

• Properly discard disposables after use, in accordance with hospital hazard waste disposal

procedures.

Mechanical Hazard - Minor or moderate patient and/ or worker injury may result.

• Do not use injector head handle to move injector system.

• Do not use the cabling or syringe to position injector system.

• Do not use system in the presence of flammable or combustible gases or other agents.

• Turn off system power and disconnect patient when system malfunction occurs.

4.3 Notices

Mechanical Hazard - Equipment Damage may result.

• Do not hang items on the Display Control Unit or Wall Mounting Bracket.

• Do not oil the friction plate on the Wall Mount Bracket.

Electro-Mechanical Hazard - Equipment Damage may result.

• Do not use tools to over tighten connections or to assist in the removal of disposables.

• Do not roll pedestal over cables.

• Regular preventive maintenance is recommended to ensure that the system stays

calibrated and functions properly. Refer to maintenance section of this manual or contact

Bayer for additional information.

• Allow two hours for the injector to reach room temperature before use.

• Follow Electrostatic Discharge (ESD) protection practices.

• Disconnect the power cord before removing or replacing PC boards.

• Do not apply voltage to ISI connector.

• Provide only a switch closure if the injector is being started by an external start

connection.

• Do not block Power Unit vents.

• Installation clearance should be a minimum of 3 to 5 inches (8 to 13 cm).

• Before installing the Table Mount, ensure the table rail can withstand a minimum vertical

static load of 18 kg (40 lbs.) Refer to the table manufacturer documentation for weight

load information.

• Do not over tighten Table Mount knob.

• Do not force the Table Mount onto the table rail.

• Loosen Table Mount knob prior to removal of components.

4 - 18

Page 27

5 System Overview

This chapter describes:

• "Injection Protection"

• "Pressure Limiting"

• "System Technical Specifications"

• "High Pressure Connector Tubing Specifications (Non-Twist & Go)"

• "Display Control Unit"

• "Injector Head"

•"Power Unit"

• "Imaging System Interface"

• "Start Switches"

• "Pedestal and Stand Movement"

A Display Control Unit B Injector Head C Power Unit

5.1 Injection Protection

The following means are provided to protect against over and under injections:

An on-screen indication of insufficient volume is provided whenever the total volume programmed to

be delivered is greater than the amount of fluid in the syringe.

The system monitors injections to detect over rate or over volume conditions due to system faults. The

delivered volume is also monitored against the total programmed volume for the injection.

Once the system has disarmed a tone will sound and a disarm message displays on the Display Control

Unit screen.

When any fault condition is detected, the injection will stop.

Figure 5 - 1: Mark 7 Arterion Injection System

5 - 19

Page 28

MEDRAD® Mark 7 Arterion Injection System

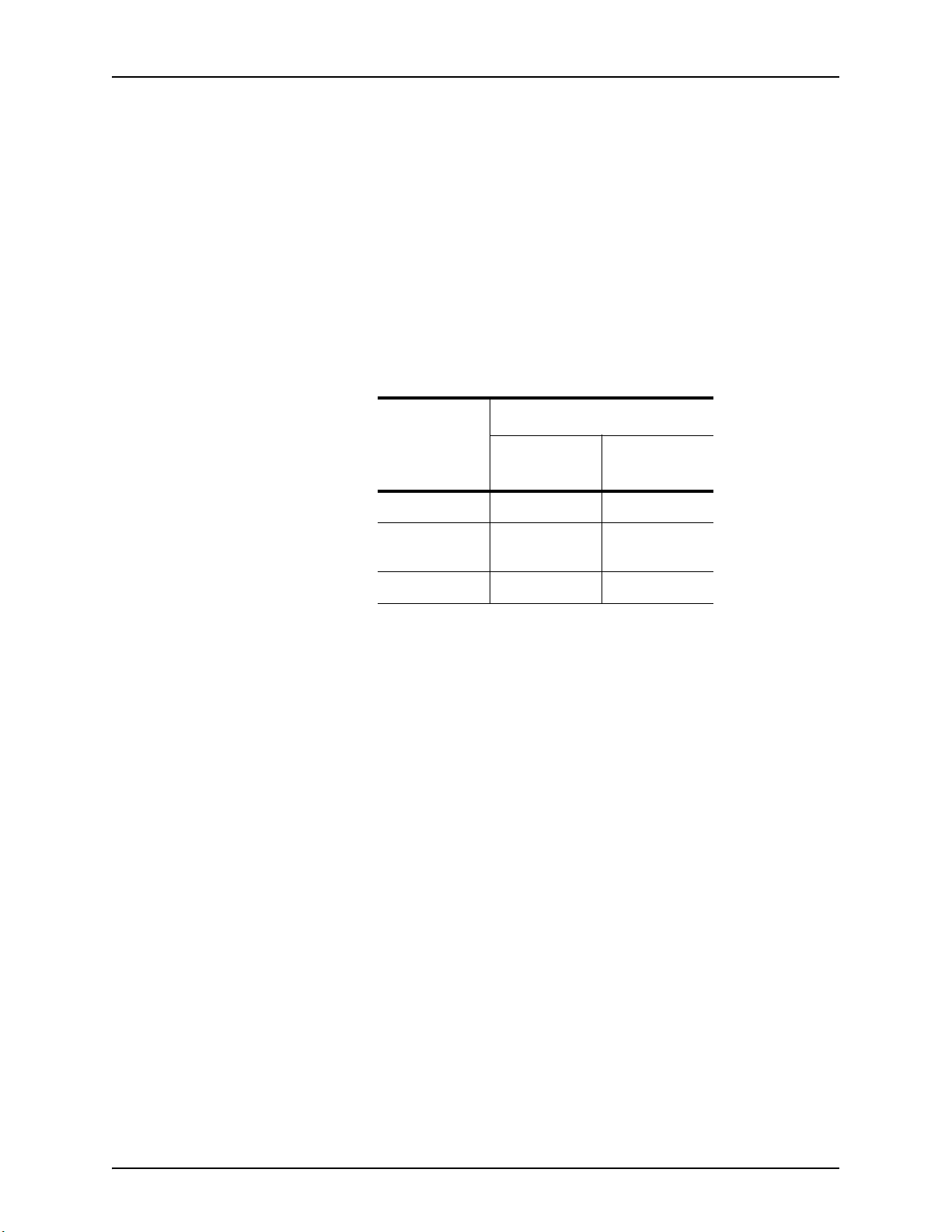

5.2 Pressure Limiting

The purpose of the programmed pressure limit is to protect the patient, the catheter, and any

disposable device attached to the injector.

As a general rule, set pressure limit no higher than the max pressure rating of the weakest component

in the fluid path (tubing, stopcocks, connectors, catheters, administration sets, etc.).

Max pressure rating examples for an example scenario:

• Tubing - 1200 psi

• Stopcock - 1050 psi

• Catheter - 1200 psi

In this case, set the pressure limit no higher than 1050 psi because anything higher could potentially

cause the component to fail.

Typical factors to consider and how they affect Pressure:

Effects on Pressure

Factors

Fluid Viscosity Low High

Catheter and

Tubing Length

Catheter ID Large Small

Consider the above factors when setting pressure limit to achieve the desired injection flow rate.

Proper pressure limit setting optimizes the angiographic images.

The injector applies the minimum pressure needed to achieve the programmed flow rate. If the

pressure from the injector exceeds the programmed pressure limit, the system cannot achieve the flow

rate and a Sentinel message displays.

Pressure information can be found in the History tab.

5.3 System Technical Specifications

5.3.1 Input Power Requirements

100-240 VAC

50/60 Hz

1000 VA

Decrease

Pressure

Short Long

Increase

Pressure

5 - 20

Page 29

5.3.2 Technical Specifications

Flow Rate:

Volume: 1-150 mL in 1 mL increments

System Overview

Table 5 - 1: System Technical Specs

0.1-45.0 mL/s in 0.1 mL/s

increments (single and phased)

0.1-59.9 mL/m in 0.1 mL/m

increments (single mL/m)

1.0-10.0 mL/s in 0.1mL/s

increments (variable)

Pressure Limit (150 mL

syringe):

Rise Time: 0.0-9.9 seconds in 0.1s increments

Delay Time:

Manual Fill Speed: 1-20 mL/s in 1 mL/s increments

Auto Fill Speed: 1-10 mL/s in 1 mL/s increments

Fill Volume: 1-150 mL in 1 mL increments

Syringe Size: 150 mL

Protocol Memory: 39 Protocols (4 default, 35 storable)

Injection History Memory Approximately 50 injections

100-1200 psi in 1 psi increments

689-8273 kPa in 1 kPa increments

0.0-99.9 seconds in 0.1s

increments

5.4 High Pressure Connector Tubing Specifications (Non-Twist & Go)

The injection system was designed to use the MEDRAD Mark 7 Arterion Syringe and Twist and Go

Syringe. When using the Mark 7 Arterion Syringe, tubing should meet the following specifications to

operate in a safe and effective manner.

• Disposable tubing shall be rated to a minimum of 1200 psi

• Disposable tubing shall have a minimum internal diameter of .070" with a maximum length

of 72".

• Syringe interface luer shall be a standard female luer as defined in:

• ISO 594-1:1986

• EN 20594-1:1993/AC:1996/A1:1997.

• Catheter interface luer shall be a standard male luer as defined in:

• ISO 594-1:1986

• ISO 594-2: 1998

• EN 20594-1:1993/AC:1996/A1:1997.

• Disposable tubing shall be made from a clear polymeric material that allows for proper

visualization of fluid path to ensure all air has been adequately purged with fluid before

connection to a patient.

5 - 21

Page 30

MEDRAD® Mark 7 Arterion Injection System

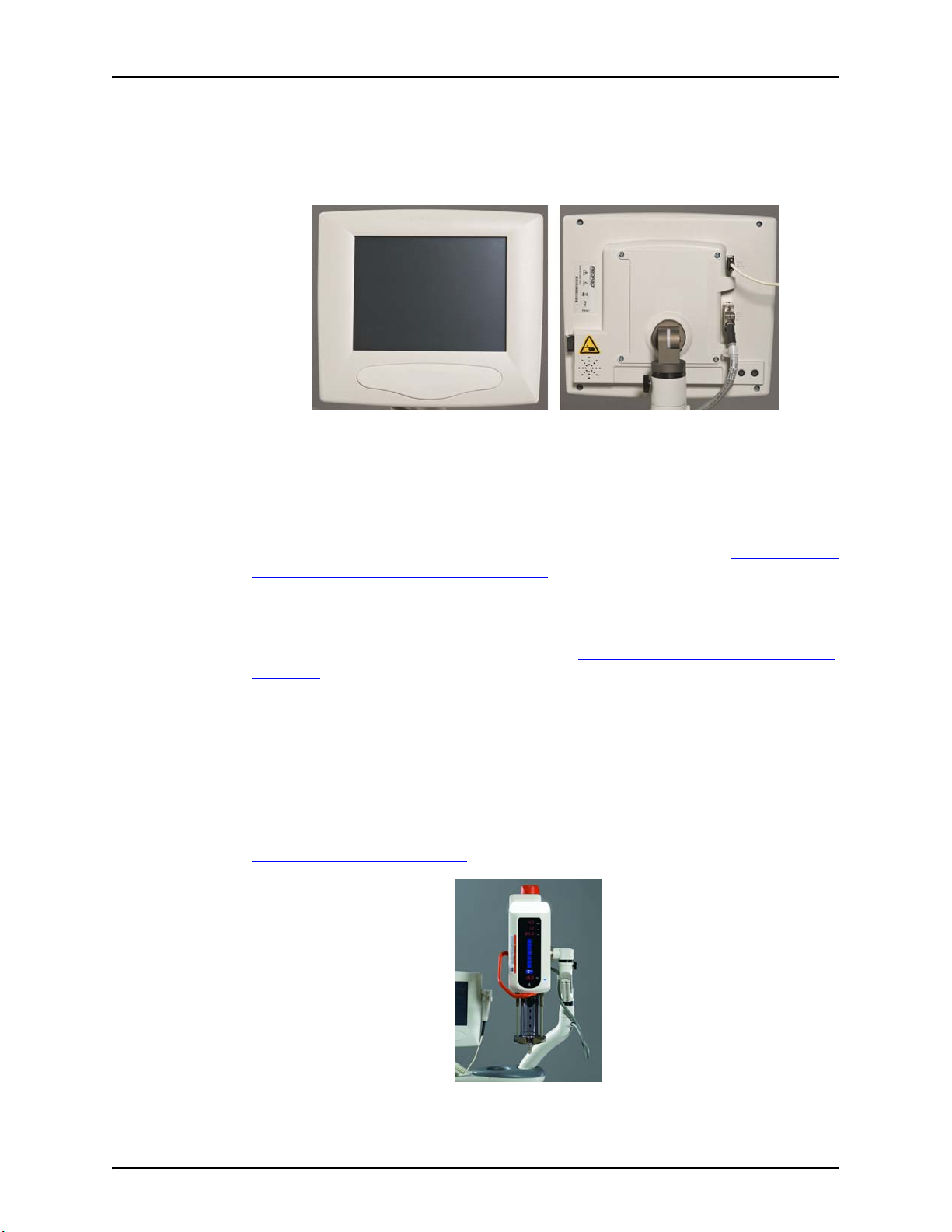

5.5 Display Control Unit

The injection system Display Control Unit consists of a touch screen display. From the Display Control

Unit, an operator can manage protocols, arm and disarm the injector, review injection history, set

options, and view help topics.

The injection system supports the connection of a second Display Control Unit. In a two Display Control

Unit system, both Display Control Units have the same controls and functionality. Depending on

operational situations, only one of the Display Control Units may be active at a time. For example, if an

operator is entering a protocol on a Display Control Unit in the Control room, the system locks-out the

Display Control Unit in the Scan room. See "6.6 - Display Control Unit Lock-outs"

Figure 5 - 2: Display Control Unit

for more information.

For more information about the navigating through Display Control Unit screens, see "Chapter 6 - Using

and Understanding the Display Control Unit Screen".

5.5.1 Display Control Unit Sterile Sheath

If the Display Control Unit will be used in the Sterile Field, a sheath such as the Display Control Unit

Sheath (AVA 500 DCOV) from Bayer should be used. See "16.6.5 - Display Control Unit Sterile Sheath

Installation".

5.6 Injector Head

The Injector Head has a handle that is used to rotate the head. The Injector Head position determines

what functions are active and what values display on the Injector Head. The Injector Head keypad and

Manual Knob can be used to fill and purge a syringe. A drop front allows operators to load syringes

from the front. The Syringe Heat Maintainer clamps onto the Pressure Jacket and connects to the

underside of the Injector Head and is designed to keep pre-warmed contrast in the syringe.

For more information about the Injector Head or the Syringe Heat Maintainer, see "Chapter 7 - Using

and Understanding the Injector Head".

5 - 22

Figure 5 - 3: Injector Head

Page 31

5.7 Power Unit

The injection system Power Unit supplies power to the Injector Head and the Display Control Unit. As

the main communications hub, the Power Unit provides system communications to all connected

components. A green light illuminates when the Power Unit is on.

The front plate on the Power Unit contains a serviceable air filter. For cleaning instructions, see

"Chapter 15 - Cleaning and Maintenance"

5.8 Imaging System Interface

The Imaging System Interface (ISI) allows the injection system to interface with an imaging system to

provide synchronization of an injection and an X-ray exposure. To use ISI on the injection system,

configure the system from the Display Control Unit Options tab. See "Chapter 6 - Using and

Understanding the Display Control Unit Screen". For more information on how ISI interacts with the

injection system, see "11.3.5 - Performing an Injection with Imaging System Interface (ISI)"

5.9 MEDRAD® VFlow

MEDRAD VFlow (VFlow) enables the use of Variable Flow Rate injections. In the Variable Flow Rate

injection mode, the injector automatically re-arms after each injection. A Variable Flow Rate injection

can be initiated by the Hand Controller and ranges from 1 - 10 mL/sec in increments of 0.1 mL/sec.

Variable Flow Rate is intended for use in those procedures where low volumes are injected and

Variable Flow Rate control is desired. The system has an option for receiving audible feedback when

using the Hand Controller. The feedback indicates the flow rate.

See "6.4 - Options Tab"

System Overview

.

.

for instructions on how to enable VFlow.

5.10 Start Switches

The injection system can be used with a hand switch, foot switch and/or hand controller. The switches

allow the operator to initiate an injection.

Single mL/s Phased Variable Flow Rate Single mL/m

Hand switch X X X

Foot switch X X X

Hand ControllerXXXX

5.10.1 Hand Switch and Foot Switch

For installation instructions, see "16.6.3 - Hand Switch and Foot Switch Installation"

Figure 5 - 4: Hand Switch and Foot Switch

.

5 - 23

Page 32

MEDRAD® Mark 7 Arterion Injection System

A

B

5.10.2 MEDRAD VFlow Hand Controller

The VFlow Hand Controller is a sterile device intended for single patient use.

The Hand Controller works in two different modes, Variable Flow Rate and Fixed Flow Rate. When in

the Variable Flow Rate injection mode, the flow rate increases incrementally as the Hand Controller

plunger (A) is depressed, and decreases as the Hand Controller is released. In the Fixed Flow Rate

injection mode, the Hand Controller acts as a start switch, and release of the device ceases all flow.

The Hand Controller button (B) is non-functional and will beep from the Injector head and DCU when

depressed.

Figure 5 - 5: Hand Controller

NOTE: The hand controller is required to perform Variable Flow Rate injections. For

installation instructions, see"10.5 - Installing the MEDRAD® VFlow Hand

Controller".

5 - 24

Page 33

5.11 Pedestal and Stand Movement

5.11.1 Pedestal System

Place pedestal system components into the approximate positions shown in Figure 5 - 6 prior to

moving the system. When necessary, lift pedestal by using the handle to move over obstacles.

System Overview

Figure 5 - 6: Approximate Component Positions for System Movement

5 - 25

Page 34

MEDRAD® Mark 7 Arterion Injection System

5.11.2 Head Stand (KMA 320 RT) and Adjustable Height Stand (KMA 330)

Place hands in the positions shown in Figure 5 - 7 to move an injector Head mounted on a Head Stand

and Adjustable Height Stand over obstacles.

5 - 26

Figure 5 - 7: Approximate Hand Positions to Move Head Stand and Adjustable Height Stand Over

Obstruction

Page 35

5.11.3 Mark 7 Arterion Stand Mounting Kit Configuration

Place the Mark 7 Arterion Stand Mounting Kit components into the approximate positions and place

hands in the positions shown in Figure 5 - 8 prior to moving the system.

System Overview

Figure 5 - 8: Approximate Hand Positions to Move Stand Mounting Kit Configuration over

Obstruction

5 - 27

Page 36

MEDRAD® Mark 7 Arterion Injection System

5 - 28

Page 37

6 Using and Understanding the Display Control Unit Screen

The Display Control Unit touch screen has five tabs from which an operator can manage protocols, arm

and disarm the injector, review injection history, set options, and view help topics.

6.1 Home Tab

NOTE: An operator will be locked-out from a Display Control Unit if another operator is

performing functions on the Injector Head or another Display Control Unit

connected to the same system.

The chapter discusses:

• "Home Tab"

• "Protocols Tab"

•"History Tab"

•"Options Tab"

•"Help Tab"

• "Display Control Unit Lock-outs"

• "Performing Touch Screen Calibration"

Operators can set protocols, select the Single or Phased protocol, or arm the injector on the Home tab.

This tab has a Programmed window (A), Actuals window (B), and Sentinel window (C). Each of these

windows is discussed below.

6.1.1 Programmed Window

The Programmed window displays the protocol parameters for an injection including Flow Rate,

Volume, Pressure, Rise time (Rise Time is not listed for Variable Flow Rate or mL/m protocols), and

Delay (Delay is not listed for phased and Variable Flow Rate or mL/m protocols).

Operators can set Single mL/s and mL/m, Phased, and Variable Flow Rate protocols from the

Programmed window. For more information, see "9.1 - Set Injection Parameters from the Home Tab"

Figure 6 - 1: Home Tab

.

6 - 29

Page 38

MEDRAD® Mark 7 Arterion Injection System

6.1.2 Actuals Window

The Actuals window displays Peak (maximum Flow Rate achieved), Delivered (actual total volume

delivered), Total Contrast (total volume delivered for the current case), and the End Case button. An

operator presses the End Case button after completing a patient procedure and before removing the

disposables to retract the syringe plunger. This button also zeroes the Total Contrast and creates a new

case entry on the History tab. For more information on cases, see "6.3 - History Tab"

6.1.3 Sentinel Window

The Sentinel window displays system messages, such as “Rotate head down to arm”. The Sentinel

window also displays the status of the last injection.

The Sentinel window message flashes momentarily when the system cannot arm.

A list of messages is available in Chapter 13 “System Messages.”

6.2 Protocols Tab