REPROCESSING SYSTEMS

LT

User Manual

Automated Endoscope

Leak Tester

Veriscan® is a registered trademark of Minntech Corporation.

Fujinon® is a registered trademark of Fujinon Corporation.

OLYMPUS® is a registered trademark of Olympus Corporation.

PENTAX® is a registered trademark of Pentax Precision Instrument Corporation.

Storz® is a registered trademark of Karl Stroz.

50096-988 Rev A

© 2009, MINNTECH CORPORATION

All rights reserved. This publication is protected by copyright. Copying, disclosure to

others, or the use of this publication is prohibited without the expresswritten consent

of Minntech Corporation.

Minntech reserves the right to make changes in the specications shown herein

without notice or obligation. Contact your Medivators representative or Medivators

customer service for more information.

Table of Contents

Introduction ................................................................... 5

Using this Manual ....................................................... 5

Product Description .................................................... 5

Product Specications ............................................... 6

Safety ..............................................................................7

Intended Use .............................................................. 7

Electrical Compliance ................................................. 7

Operator Safety ......................................................... 7

General Cautions ....................................................... 7

Guidelines .................................................................. 8

Cleaning and Disinfection ..................................... 8

System Components ..................................................... 9

System Features .......................................................... 10

System Setup ............................................................... 11

Performing a Leak Test ................................................14

Performing a Screening test ...................................... 17

Testing a Failed Endoscope ....................................... 19

Daily Quality Assurance Test ..................................... 21

Data Access and Management ....................................22

Main Menu ............................................................... 22

Printing and Quick Reports ...................................... 26

ProV-LT Data Management Software ...................... 28

Maintenance, Handling and Care ............................... 30

Troubleshooting .......................................................... 33

Warranty ....................................................................... 34

USERS MANUAL | 3

Introduction

Using this manual

This manual describes the features of the Medivators Veriscan LT Automated Endoscope Leak Tester, including

system, setup, operation, safety, maintenance and troubleshooting procedures. It is important to follow the provided

instructions to keep the device in proper operating condition, to ensure accurate endoscope leak testing, and to

ensure long product life.

This is not a service manual and does not provide detailed instructions for service beyond general maintenance,

handling and care. Contact the manufacturer’s service representative if you have any questions regarding this

product, its use or operation.

Product Description

Flexible endoscopes are highly vulnerable to damage-causing moisture that enters the endoscope’s sensitive

interior through holes, tears, broken seals, cleaning cap leaks and loose contact pins. Prior to Veriscan LT, leak

detection has always been hampered by testing equipment that lacked precision, and required extraordinary skills

of observation beyond the capabilities of even the most experienced cleaning technician. As a result, undetected

leaks allow moisture to enter the endoscope’s interior through no fault of the technician. These leaks invariably

result in extensive endoscope damage, expensive endoscope repairs, and raise the risk of cross-patient infection

due to pathogens passing into subsequent patients through undetected leaks and moisture invasion.

The Veriscan’s automated endoscope leak testing technology transforms leak testing from a frustrating guessing

game into a simple, highly accurate, repeatable process that can be quickly mastered by cleaning technicians

and nurses. Veriscan’s innovative dry leak testing method accurately detects damage-causing endoscope leaks

without the need of immersing an endoscope in water. The endoscope is dry-leak tested through a process of

pressurizing the endoscope, monitoring the internal pressure level, and identifying if an endoscope leak exists

through a loss of pressure. An endoscope does not have to be placed in a uid-bath and visually observed for air

bubble leaks; the Veriscan’s visual display and printout automatically identify if an endoscope leak is detected.

Carefully review the User Manual to familiarize yourself with Veriscan’s features, operation and testing procedures.

We are condent the Veriscan system will quickly become an invaluable tool for enhancing reprocessing room

efciency, reducing endoscope damage and repair expense due to undetected leaks, and reduce the potential risk

of cross-patient infection.

USERS MANUAL | 5

Product Specications

Power Requirement: Universal Power Supply 100-240VAC, 50/60 Hz, .25 Ampere

Fuse Rating: 250V, 1 Ampere, Type S, 3AG style.

Dimensions: 13.125 H x 8.25 W x 19.25 L inches

(33.3 H x 21 W x 48.9 L cm)

Weight: 15.8 lbs. (7.18 kg)

PSI range: 3.500 - 3.999 PSI (comparable to current manual leak testers)

Display: Liquid Crystal Display (LCD) with LED backlight

ProV-LT Data Management

Connectivity Ports: USB communications port

Operating Temperature Range: +10°C (50°F) to + 40°C (104°F)

Storage Temperature Range: +20°C (68°F) to +45°C (113°F)

Humidity: 20% to 80% non-condensing

Electrical Safety Certications: UL Standard 61010-1

CAN/CSA Standard 61010-1

Environmental Rating: Standard

Designed for Use: Indoor Use Only

Warranty Period: One (1) Year

6 | USERS MANUAL

Safety

Intended Use

The Medivators Veriscan system is intended for endoscope leak testing of exible, immersible endoscopes. The

Medivators Veriscan system has been validated by Medivators for use on Olympus, Pentax, Fujinon, and Storz

exible, immersible endoscopes.

Electrical Compliance

The Medivators Veriscan system was tested to stringent electrical certications and safety standards. This device

complies to UL Standard 61010-1 and CAN/CSA Standard 61010-1.

NOTE: This device must always be plugged into an electrical wall outlet that includes an approved Ground

Fault Interrupter (GFI) prior to operation.

Operator Safety

1) Veriscan is to be operated solely by properly trained and qualied personnel, and only used for its intended use.

2) WARNING: To avoid biological contamination and chemical burns, always wear appropriate personal protective

equipment (PPE) including clothing, gloves, and safety glasses when handling used endoscopes.

General Cautions

1) Veriscan users should be properly trained and instructed on the current procedures used to inspect, prepare,

clean, disinfect, rinse, dry, and store endoscopes. Follow recommended standards as referred by ASTM,

ASGE, SGNA and APIC.

2) The Veriscan system is intended to be used in conjunction with the instructions and labeling provided by the

endoscope manufacturer.

3) This is a dry leak test only - Do not place endoscope in water while testing.

4) Veriscan’s leak test parameter settings are pre-set at the factory for highly accurate endoscope leak test

measurements. Parameter settings should not be changed or adjusted, unless specically recommended by

Medivators. Parameter changes should only be performed by trained and qualied personnel.

5) The Veriscan system must be grounded in accordance with applicable electrical and safety regulations.

6) Read all precaution labels on the device before using.

7) Never use the device in a manner not specied or intended by the manufacturer.

8) The Veriscan system uses coin lithium batteries in the internal electronics for retaining memory settings. The

coin lithium batteries contain perchlorate material and if replaced, special handling may apply.

9) The Veriscan’s Quick Connect Tubings are not autoclavable and can only be decontaminated using low

temperature decontamination methods.

10) Inspect Quick Connect Tubings often and replace if damaged or worn.

11) Lubricate Quick Connect Tubing O-ring weekly with silicon oil to ensure a secure connection.

12) Monitor the condition of the desiccant drying crystals on a regular monthly basis. Replace as needed as

determined by comparing the crystals to the Drying Crystals Color Comparison Chart.

13) Monitor the condition of the coalescent lter for oil and particulates on a regular monthly basis. Replace once

yearly, or more if needed.

For service or service-related questions, contact Medivators Technical Support at 1.800.444.4729 or your

authorized Medivators distributor.

USERS MANUAL | 7

Guidelines

Endoscope Leak Testing and Pre-cleaning

An effective endoscope leak test and pre-cleaning process is an essential step in the reprocessing of an

endoscope. Always follow the endoscope manufacturer’s instructions and established professional guidelines to

properly leak test and clean an endoscope. If an endoscope leak is detected, the endoscope should be immediately

taken out of service and sent in for repair.

Endoscopes should always be dry leak tested before submersion in uid to prevent additional uid invasion and

internal endoscope contamination. Leak testing detects endoscope leaks within the interior and exterior of an

endoscope.

Cleaning and Disinfection

Professional Guidelines

The following organizations have published recommended guidelines for cleaning and disinfecting endoscopes.

Society of Gastroenterology

Nurses and Associates, Inc.

401 North Michigan Ave.

Chicago, Ill. 60611-4267 USA

Tel: 800.245.7462

Fax: 312.527.6658

www.sgna.org

American Society for Gastrointestinal Endoscopy

1520 Kensington Rd. Suite 202

Oak Brook, Ill. 60523-2141 USA

Tel: 630.573.0600

Fax: 630.573.0691

www.asge.org

Association of periOperative Registered Nurses, Inc.

2170 S. Parker Rd., Suite 300

Denver, CO 80231-5711 USA

Tel: 800.755.2676

Fax: 303.750.3462

www.aorn.org

British Society of Gastroenterology

3 St. Andrews Place

Regents Park, London, NW1 4LB England

Tel: +44.020.7387.3534

ww.bsg.org.uk

Association of Professionals in Infection

Control and Epidemiology, Inc.

1275 K. Street NW, Suite 1000

Washington, DC 20005-4006 USA

Tel: 202.789.1890

Fax: 202.789.1899

www.apic.org

American Society for Testing and Materials

100 Barr Harbor Drive

West Conshohocken, PA 19428-2959 USA

Tel: 610.832.9585

Fax: 610.832.9555

www.astm.org

Canadian Society of Gastroenterology

Nurses and Associates

27 Nicholson Dr.

Lakeside, NS B3T 1B3 Canada

Fax: 902.473.4406

www.csgna.com

Societe Francaise d’Hygiene Hospialiere S.F.H.H.

Hopital de la Croix-Rousse

Unite h’Hygiene Hospitaliere-Epidemiologie

93 Grande Rue de la Croix-Rousse

69317 Lyon Cdx04 France

Tel: 04.72.07.19.83

Fax: 0.4.72.07.19.85

www.sfhh.net

8 | USERS MANUAL

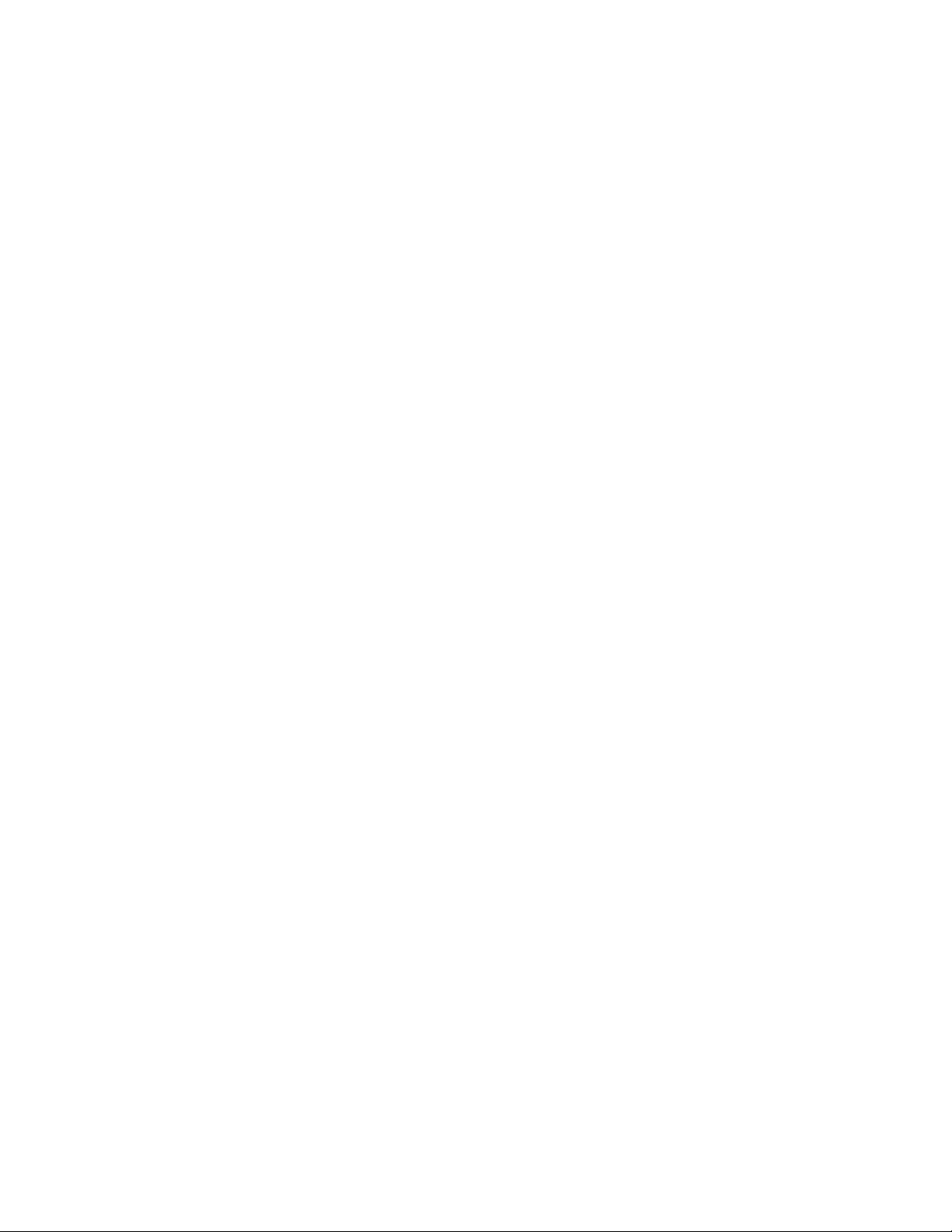

System Components

Veriscan Box

This box contains the following components:

• One (1) Veriscan-LT System

• One (1) Power cord

• One (1) Crystal desiccant bag

• One (1) Silicon Oil

• One (1) ProV-LT Link Database Software

• One (1) Quick Start Guide

• One (1) Veriscan Users Manual

If any of the components are missing, contact Medivators

Customer Support at 1-800-444-4729

or your authorized distributor.

Installation Kit (endoscope specic)

This box contains the following components:

• One (1) Quick connect tubing

• Five (5) printer paper rolls

• One (1) Crystal desiccant bag

• One (1) USB cable

USERS MANUAL | 9

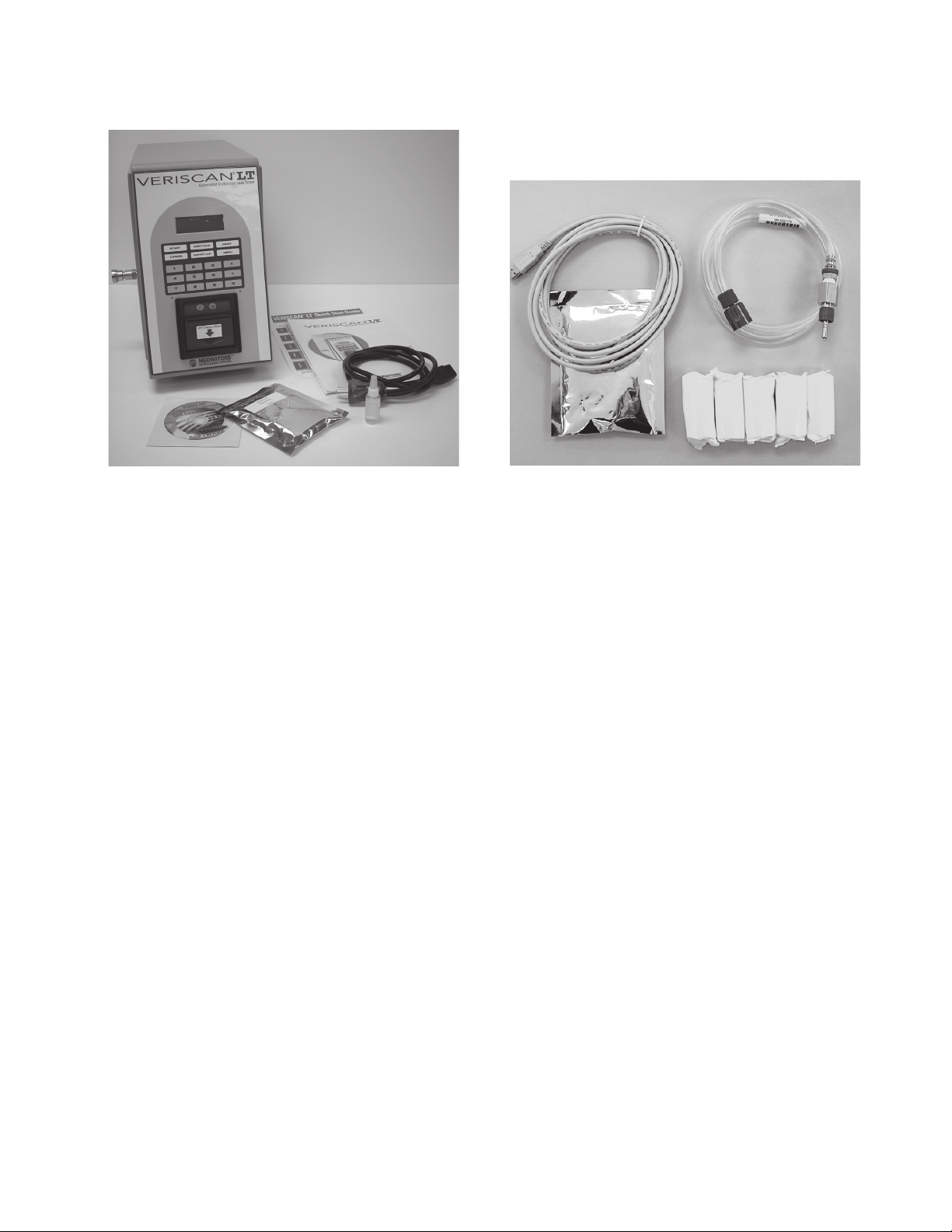

System Features

LT

1. Display Screen

Displays information and test results

2. Control Keypad

Touchpad used to operate Veriscan System

3. Printer

Provides printout of test results

4. Quick Connect Port

Veriscan connector for Quick Connect Tubing

to endoscope

5. Power Switch

Used to turn Veriscan system ON/OFF

6. Power Cord Outlet

Receptacle for AC power cord

7. Power Cord

Provides electrical connection for Veriscan to

AC wall outlet

8. RS232 Port

Not currently used

9. USB Port

Port to connect Veriscan to separate computer

via USB cable

10. Drying Crystals Bulb

Receptacle for desiccant crystals

11. Metal Bulb Receptacle

Removable metal receptacle for securing

drying crystals bulb

12. Receptacle Release Button

Button to release metal bulb receptacle to

provide access to drying crystals bulb

13. Bulb Housing Structure

Housing for securing and linking drying

crystals bulb and metal bulb receptacle to

the device

14. Coalescent Filter Housing

Housing for securing and linking the oil and

particle lter to the device

15. Coalescent Filter

Oil and particle lter removes foreign

substances from air that enters and exits the

endoscope during testing

1

4

9

6

5

7

8

2

3

10 | USERS MANUAL

System Setup

Installation

• Position Veriscan system on a at, level surface and within six (6) feet/

two (2) meters of the electrical AC wall outlet.

• Veriscan’s electrical requirements can be found under the “Introduction,

Product Specications” section.

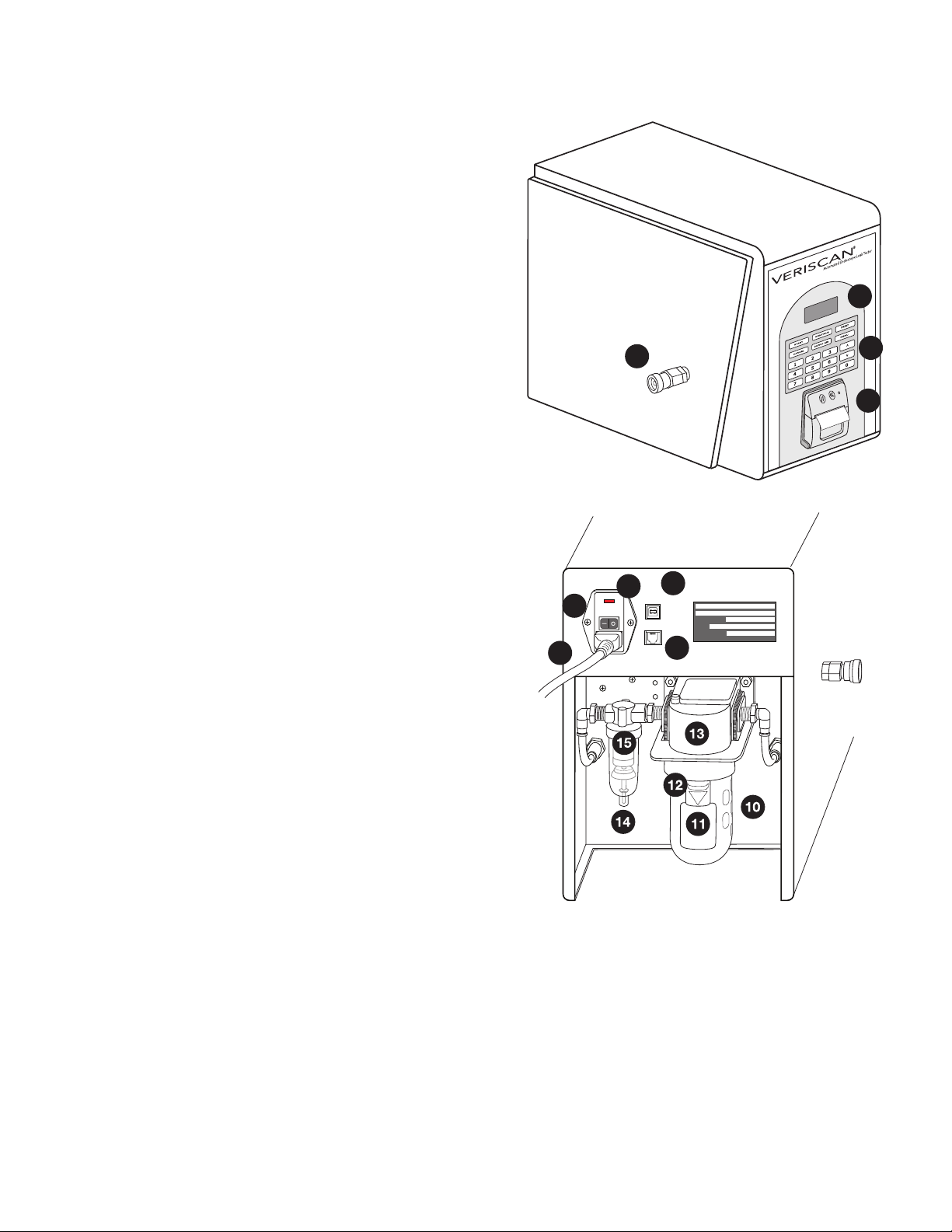

Attaching the Power Cord

• WARNING: Exercise caution when plugging in this electrical

device. Risk of electric shock.

• Connect power cord to power cord outlet located on rear of unit. Gently

push cord in until fully inserted. (see gure 1)

• Plug the other end of the power cord into a standard AC wall outlet.

• NOTE: This device must always be plugged into an electrical wall

outlet that includes an approved Ground Fault Interrupter (GFI)

prior to operation.

Powering the Veriscan System “ON”

• Press the power switch located on the back of the unit to turn system

power ‘on’. (see gure 2)

Figure 1

• When Veriscan is turned on, it will automatically perform an initialization

process which includes a series of diagnostic self-tests. When this

process is complete, the display will indicate that the unit is ready for

testing as displayed below:

mm/dd/yy hh:mm

Connect Scope

Press “Start”

Setting the Time and Date

The Veriscan’s internal clock will record the time of all leak test

procedures. To set the clock:

• Press the MENU button on the display keyboard

• Press the arrow down key until Set Date/Time selection is reached

• Press the CONTINUE key to select the Set Date/Time option

• To enter the month, press CONTINUE and then enter the correct month

in the “month = “ area: 1 = January, 2 = February, etc.. If an incorrect

entry is made, press CANCEL to start the process over. Press

CONTINUE when nished.

• To enter the date, press the down arrow key from the “month” row until

the “date” row is reached. Press CONTINUE to reach the date set

area. Enter the date. For single digit numbers, it is not necessary to

enter a “0” before the number (e.g. enter 3 for the 3

CONTINUE when nished.

rd

). Press

Figure 2

Figure 3

• To enter the year, press the down arrow key from the “date” row until

the “year” row is reached. Press CONTINUE to reach the year set

area. Enter the year as a single digit where 6 = 2006, 70 = 2007, etc.

Press CONTINUE when nished.

USERS MANUAL | 11

System Setup

• To enter the hour, press the down arrow key from the “year” row until

the “hour” row is reached. Press CONTINUE to reach the hour set

area. Using the 24 hour system, enter the hour (e.g. 5 A.M. = 5,

noon = 12, 2 P.M. = 14, midnight = 24, etc.). Press CONTINUE

when nished.

• To enter the minute, press the down arrow key from the “hour” row until

the “minute” row is reached. Press CONTINUE to reach the minute set

area and enter the minute. For single digit numbers it is not necessary

to enter a “0” before the number (e.g. enter 3 for :03). Press

CONTINUE when nished.

• When the date and time are all set, press CANCEL to return to the

MENU area. Press CANCEL again to return to the main display screen.

Attaching the Quick Connect Tubing

• The Veriscan uses Quick Connect Tubing to attach to Olympus®,

Pentax®, Storz® and Fujinon® exible, immersible endoscopes. Verify

the endoscope name labeled on the Quick Connect Tubing to ensure it

matches the specic endoscope brand being leak tested. If

replacement or additional tubings are needed for connecting other

brands of endoscopes, contact Medivators Customer Support at

1-800-444-4729 or your authorized distributor.

NOTE: Inspect Quick Connect Tubings often and replace if damaged

or worn.

NOTE: Lightly Lubricate Quick Connect Tubing O-ring with silicon oil

weekly to ensure a secure connection.

• Insert the Quick Connect Tubing prong into the quick connect port located

on the side of the Veriscan unit and apply inward pressure until the prong

clicks into place (see gure 3). To remove the tubing, gently push inward on

the quick

prong is released.

connect port’s outer metal housing, until the Quick Connect Tubing

Figure 4

Figure 5

Installing or Replacing the Desiccant Drying Crystals

The drying crystals must be installed before leak testing an endoscope. The

drying crystals ensure that only dry air is introduced into the endoscope during

leak testing.

NOTE: Monitor the condition of the drying crystals on a regular basis.

Replace as needed as determined by comparing the crystals to the

Desiccant Drying Crystals Color Comparison Chart.

CAUTION: Disconnect system power before installing or replacing the

drying crystals.

Step 1: Turn off and unplug the Veriscan system before installing

the drying crystals.

Step 2: Locate a new, unopened crystal desiccant bag. (see gure 4)

Step 3: Carefully position the Veriscan system so that the back of the unit can

be easily accessed with a six (6) inch clearance off of the counter surface. The

recommended method for installing or changing the drying crystals is to extend

the last six inches (6”) out over the end of the counter surface.

12 | USERS MANUAL

Figure 6

System Setup

Step 4: Push the metal housing release button down and hold. (see gure 5)

Step 5: While continuing to hold the button, gently pull down on the metal

bulb housing and rotate it to the left, until it releases down and away from the

machine’s bulb housing structure. Gently lower the bulb housing unit away from

the machine. (see gure 6)

Step 6: Remove the drying crystal bulb from the bulb housing structure by placing

one hand on top of the Veriscan, grasping the dry crystal bulb with the other hand

and pulling downward in a twisting motion (either direction) until the bulb can be

removed from the housing structure. (see gures 7 and 8).

Step 7: Empty and discard any used drying crystals from the bulb, and carefully

pour the entire bag of new crystals into the bulb. (see gure 9). Do not allow

crystals to enter the metal tube located in the center of the bulb.

Step 8: Return the bulb to its original housing by placing one hand on the top

of the unit and grasping the glass bulb with other hand, while inserting the glass

bulb vertically up and into the bulb housing structure until the top of the structure

is reached. This is a reverse of the process described in Step 6. Apply careful

upward pressure while turning the bulb (either direction) to help the bulb pass

through the tight gasket seal and seat to the top of the bulb housing structure.

(see gure 7)

Figure 7

Step 9: Return the metal bulb housing unit to the Veriscan by holding down the

bulb receptacle release button and lifting up on the bulb receptacle over the

drying crystal bulb. This is a reverse of the process described in step 5. Align the

release button with the center of the bulb housing structure and lift until resistance

is felt. While holding the button down, turn the receptacle to the left until it

reaches a slot and can be lifted in an upward direction. (see gure 6)

Step 10: Let go of the release button and turn the metal bulb housing unit until

the receptacle button clicks into place. (see gure 5)

WARNING: THE METAL BULB HOUSING STRUCTURE MUST BE IN PLACE

BEFORE OPERATING THE VERISCAN DEVICE. THE GLASS DRYING

CRYSTAL BULB CAN BECOME DISLODGED DURING LEAK TESTING, AND

LEAK TEST RESULTS WILL BE AFFECTED IF THE METAL BULB HOUSING

IS NOT PROPERLY IN PLACE.

Figure 8

Figure 9

USERS MANUAL | 13

Performing a Leak Test

Attaching a exible, immersible endoscope to the Veriscan System

• Ensure the Quick Connect Tube is connected to the Veriscan

system. If not, refer to the System Setup section.

• Check the endoscope cleaning cap to ensure it is securely in place over the

endoscope’s ETO connector. A faulty cleaning cap connection or O-ring seal

onto the endoscope will be detected as an endoscope leak by Veriscan.

• Align Veriscan’s Quick Connect Tubing connector to the pin on the

endoscope’s cleaning cap leak test tting, and then push the connector over

the tting. Rotate the connector until the pin reaches the end of the channel on

the connector. Verify the Quick Connect Tubing connecting the endoscope

to the Veriscan system is not twisted. (see gures 10, 11 and 12)

NOTE: If the connector rotates with difcultly, then verify the o-ring is

properly lubriated.

NOTE: This is a dry leak test only – Do not place or immerse the

endoscope in any type of uid or water while testing.

Performing the Leak Test

The heat of an endoscope can affect leak test measurement accuracy though the

expansion of the soft components of the endoscope. Leak test accuracy is

maximized by identifying if the endoscope was used in a patient procedure

within the last 30 minutes.

If the endoscope was used within the last 30 minutes, then the factory default

“Standard Test” setting should be used.

If the endoscope was not used within the last 30 minutes, then the “Screening

Test” setting should be used. Go to the section labeled “Performing a Screening

Test” for further instructions.

• To begin the leak test, press the START button located on the

Veriscan keypad.

• If optional “OPERATOR ID” screen activated, the following information

will display:

Leak Test Start

Enter Operator ID

Press “Continue”

Enter Operator ID number (maximum 4 digits) and then press CONTINUE.

• If optional “PATIENT ID” screen activated, the following information

will display:

Leak Test Start

Enter Patient ID

Press “Continue”

Enter Patient ID number (maximum 10 digits) and then press CONTINUE.

• The “ENTER SCOPE S/N” screen will now display as:

Leak Test Start

Enter Scope SN

Press “Continue”

Enter last three digits of endoscope’s serial number and then press CONTINUE

(A maximum of 10 digits can be entered).

Figure 10

Figure 11

Figure 12

14 | USERS MANUAL

Performing a Leak Test

• The leak test will now automatically begin when Veriscan is operating in the

factory default “STANDARD TEST” mode, and the following information will

be displayed:

Leak Test Start

Please standby...

• If Veriscan is operating in the “MANUAL” mode, the following information will

display: (The manual mode is used for selecting alternative parameter settings,

other than the factory default “STANDARD TEST” settings.)

Select Test Setting

Standard Test 1

Standard Test 2

Standard Test 3

Use the up/down arrow keys to select the desired test, and then press

“CONTINUE” to begin the leak test.

• After a pre-set period of time, an audible tone will sound. The Veriscan will

display the below listed information which prompts the operator to turn all of

the endoscope’s angulation knobs and to press all of the camera buttons. (see

gures 13, 14 and 15). These endoscope areas are common uid invasion

problem spots which can only be accurately leak tested when all knobs and

buttons are activated.

Leak Test

Oper Knobs & Buttons

“Continue” to Ack

Results in 112 Seconds

NOTE: Turn all endoscope angulation knobs and press all camera buttons

when audible tone is heard.

Figure 13

Figure 14

When all knobs and buttons have been manipulated, press the CONTINUE

button on the display keypad and the test will automatically continue.

• The endoscope leak test continues.

• When the endoscope leak test completes, a humidity test is initiated which

veries the condition of the dry air used during the leak test.

• At the completion of the humidity test, an audible tone is heard and the

Veriscan screen displays the PASS or FAIL, test results.

If a PASS result is displayed, then go to “Printing Results”.

If a FAIL result is displayed, then go to “Testing a Failed Endoscope” section.

Printing Results

• Press the PRINT button to print results, or CONTINUE to start a new

endoscope leak test. Tear the printout off by pulling upwards on the printout

towards the tear bar, and tear from one side to the other across the serrated

edge (see gure 16). For directions on how to load printer paper, see the

“Changing Printer Paper” heading located in the Maintenance, Handling &

Care section.

• For other printing options, (e.g., printing quick reports on daily, weekly

and monthly summary activity,) see the Quick Report Printing heading located

in the Data Access and Management section.

Figure 15

Figure 16

USERS MANUAL | 15

Performing a Leak Test

Disconnecting the Endoscope

• Disconnect the Quick Connect Tubing from the endoscope (see gure 17).

The endoscope is now ready for the next step in the manual cleaning process.

Shut Down and Start Up of the Veriscan system

• Shut Down: The Veriscan system should be turned off

at the end of each day. To turn off the machine, toggle the on/off

switch to the right (see gure 18) and the Veriscan display will go blank.

• Start Up: To start the Veriscan system, toggle the on/off switch to the

left. The system will automatically begin a series of diagnostic self tests during the initializing process. When initialization is complete,

the display will appear as below indicating that the system is ready

to begin testing endoscopes.

mm/dd/yy hh:mm

Connect Scope

Press “Start”

Figure 17

Figure 18

16 | USERS MANUAL

Performing a Screening Test

Veriscan’s “Screening Test” is an extremely accurate, dry endoscope leak test which is

ideal for evaluating “cold” or stable temperature endoscopes.

Use the “Screening Test” to:

1) Evaluate an endoscope that was not used on a patient within the last 30 minutes.

2) Evaluate a facility’s inventory of endoscopes.

Due to Veriscan’s extreme

endoscopes be tested within

time. A facility can also routinely test endoscopes using the “Screening Test” to

ensure ongoing early endoscope leak detection.

NOTE: The screening test is only to be used on stable temperature endoscopes

which have not been used within the last 30 minutes.

Performing the “Screening Test”

• Press the “Menu” button located on the keypad and the following

information will display:

Main Menu

Stored Runs

Quick Reports

Screening Test

Set Test Parameters

• Use the up/down arrow keys to align the curser with the “Screening Test” and then

press “CONTINUE” followed by “START” to begin the leak test.

• If optional “OPERATOR ID” screen activated, the following information

will display:

Screening Test Start

Enter Operator ID

Press “Continue”

Enter Operator ID number (maximum 4 digits) and then press CONTINUE.

• If optional “PATIENT ID” screen activated, the following information

will display:

Screening Test Start

Enter Patient ID

Press “Continue”

Enter Patient ID number (maximum 10 digits) and then press CONTINUE.

• The “ENTER SCOPE S/N” screen will now display as:

Screening Test Start

Enter Scope SN

Press “Continue”

Enter last three digits of endoscope’s serial number and then press CONTINUE (a

maximum of 10 digits can be entered).

• The leak test will now automatically begin when Veriscan is operating in the

factory default “SCREENING TEST” mode, and the following information will

be displayed:

Leak Test Start

Please standby...

leak detection accuracy, it is recommended that all

a facility when a Veriscan unit is received for the rst

USERS MANUAL | 17

• If Veriscan is operating in the “MANUAL” mode, the following information will display:

(The manual mode is used for selecting alternative parameter settings, other than the

factory default “SCREENING TEST” settings.)

Select Test Setting

Screen Test 1

Screen Test 2

Screen Test 3

Use the up/down arrow keys to select the desired test, and then press “CONTINUE” to

begin the leak test.

• After a pre-set period of time, an audible tone will sound. The Veriscan will display

the below listed information which prompts the operator to turn all of the endoscope’s

angulation knobs and to press all of the camera buttons. (see gures 13, 14 and 15).

These endoscope areas are common uid invasion problem spots which can only be

accurately leak tested when all knobs and buttons are activated.

Leak Test

Oper Knobs & Buttons

“Continue” to Ack

Results in 112 Seconds

NOTE: Turn all endoscope angulation knobs and press all camera buttons when

audible tone is heard.

When all knobs and buttons have been manipulated, press the CONTINUE button on the

display keypad and the test will automatically continue.

• The endoscope leak test continues.

• When the endoscope leak test completes, a humidity test is initiated which veries the

condition of the dry air used during the leak test.

• At the completion of the humidity test, an audible tone is heard and the Veriscan screen

displays the PASS or FAIL, test results.

If a PASS result is displayed, then go to “PRINTING RESULTS”.

If a FAIL result is displayed, then go to “Testing a Failed Endoscope” section.

Printing Results

• Press the PRINT button to print results, or CONTINUE to start a new

endoscope leak test. Tear the printout off by pulling upwards on the printout

towards the tear bar, and tear from one side to the other across the serrated

edge (see gure 16).

• For other printing options, (e.g., printing quick reports on daily, weekly

and monthly summary activity,) see the Quick Report Printing header located in

the Data Access and Management section.

18 | USERS MANUAL

Testing a Failed Endoscope

Majority of FAIL leak test results are due to true endoscope leaks. On occasion, a FAIL test

result can be traced to other preventable and correctable issues such as:

• Nicks in the endoscope cleaning cap gasket: If the rubber seal or gasket on the inside

of the endoscope cleaning cap is damaged, a false FAIL leak test result can occur. If the

rubber sealing area is not in perfect condition, replace the cleaning cap with a new one.

• ETO valve loose on endoscope cleaning cap: If the ETO valve on the endoscope

cleaning cap is loose, air can escape and cause a false FAIL leak test results. If the

ETO valve is loose, replace the cleaning cap with a new one.

• Quick Connect Tubing: If the Veriscan’s Quick Connect Tubing is damaged due to a small

hole, or worn due to an O-ring leak, a false FAIL leak test result can occur. Always have a

spare Quick Connect Tubing available to test for a tubing leak.

• Screening Test used to test a warm, unstable temperature endoscope: A false FAIL

leak test result can occur if the “Screening Test” was used to leak test an endoscope used on

a patient within the previous 30 minutes. The screening test should only be used on stable

temperature endoscopes which have not been used within the last 30 minutes. Allow the

endoscopes the recommeneded time to cool, and then re-perform the leak test.

Retesting a Failed Endoscope

In the event of a FAIL test result, the endoscope leak test should be rerun as follows:

Retest Endoscope

Remove the Quick Connect Tubing from the endoscope.

Inspect the tubing for wear, damage or holes.

Inspect the O-ring for rips or tears.

Inspect the O-ring for sufcient silicon oil lubrication. The O-ring can tear if dry or not properly

lubricated.

Replace if worn or damaged.

• Remove the cleaning cap from the endoscope. Inspect the cleaning cap, cleaning cap

O-ring, and ETO valve, and replace if worn or damaged.

• Reattached cleaning cap and Quick Connect Tubing, and initiate a new endoscope leak

test by pressing CONTINUE and the START.

Endoscope Fails Again

If the endoscope fails a second time, then:

• Press the CONST AIR button on the keypad and visually observe the endoscope’s distal

end for ination.

1) Endoscope Distal End Inates:

If the distal end of an endoscope inates, then it can be safely submerged for cleaning before

being sent in for repair. The endoscope must be cleaned with a continuous air ow during

the entire cleaning process. The continuous air ow creates a constant internal endoscope

pressure that prevents uid from invading through the leak. Clean the endoscope as follows:

• Verify the CONS AIR button remains on and the endoscope’s distal tip is inated.

• Submerge the endoscope in uid and look for an air bubble leak.

• Hand clean according to your cleaning room protocol for handling endoscopes

with leaks.

• Remove endoscope from uid and dry. Press CANCEL to stop constant air ow.

• Remove endoscope from service.

• Contact endoscope repair company to arrange for endoscope servicing.

USERS MANUAL | 19

2) Endoscope Distal End Does Not Inate:

Do not submerge the endoscope in uid. This is an indication of a large endoscope leak. Press CANCEL to stop

the constant air ow. The endoscope must be hand cleaned before being sent in for repair by following these

steps:

• Do not submerge the endoscope in any uids or in an automated endoscope reprocessor.

• Hand clean the endoscope according to your cleaning room protocol for handling endoscopes with leaks.

• Remove endoscope from service.

• Contact endoscope repair company to arrange for endoscope servicing.

NOTE: DO NOT SUBMERGE ENDOSCOPE IN FLUID

20 | USERS MANUAL

Daily Quality Assurance Test

To verify the Veriscan device is operating properly, the Daily Quality Assurance Test must be performed prior to the

rst use of the day. This test ensures the internal integrity of the Veriscan unit and its ability to properly sense an

endoscope leak.

Contact Medivators Technical Support or your authorized Medivators distributor if the Daily Quality Assurance

Test fails.

WARNING: Failure to perform the Daily Quality Assurance Test can result in the device not accurately detecting an

endoscope leak.

Performing the Daily Quality Assurance Test

• Plug Veriscan into the appropriate AC wall outlet.

• Press the power switch located on the back of the unit to turn system power “on”.

• Veriscan will automatically perform an initialization process which includes a series of diagnostic self-test.

When this process is complete, the display will indicate that the unit is ready for testing as displayed below:

mm/dd/yy hh:mm

Connect Scope

Press “Start”

• Verify the Veriscan display information is correct.

• Do not connect an endoscope or the Quick Connect Tubing to Veriscan, and then press START.

• Enter endscope serial number “1, 2, 3” and a leak test will now automatically begin.

• After a pre-set period of time, an audible tone will sound and the following screen information will display:

Leak Test

Oper Knobs & Buttons

“Continue” to Ack

• Press the CONTINUE button on the keyboard and the test will automatically resume.

• When the endoscope leak test completes, a humidity test is initiated which veries the condition of the dry air

used during the leak test.

• At the completion of the humidity test, an audible tone is heard and the Veriscan screen displays the PASS or

FAIL, test result.

• If a PASS result is displayed, then press the PRINT button and verify the correct leak test information is

printed. If the printed information is correct, then Veriscan has passed the Daily Quality Assurance Test and

is ready for endoscope use.

• If a FAIL result is displayed or the printed information is incorrect, then the Daily Quality Assurance Test

has failed.

Contact Medivators Technical Support or your authorized Medivators distributor for further assistance.

USERS MANUAL | 21

Data Access and Management

Main Menu

Veriscan can be used as a productive tool for data management, asset tracking,

equipment utilization and infection control. Additional system capabilites are

available through the “MENU” key pad and the ProV-LT data management

software. See “ProV-LT Data Management Software” located in the “Data

Access and Management” section for further details.

Pressing the MENU key displays the following additional system capabilities:

Main Menu

Stored Runs

Quick Reports

Screening Test

Set Test Parameters

Using the up/down arrow keys, allows access to additional system capabilities

including:

Set Date/Time

System Status

Self Test

Pump/Valve Control

Fluid Sensor Cal

Line Frequency

Set Pressure UM

Effective data management begins with the operator entering key identifying

data including endoscope serial number, operator ID and patient ID. The initial

entry of the endoscope serial number allows the Veriscan to link all leak test

results to the specic endoscope tested. This information is used and displayed

in Quick Reports and in the ProV-LT Data Management Software.

1) Enter Scope S/N

• The prompt to enter this information is automatically displayed during the

endoscope leak test, and is displayed as: “Enter Scope SN”.

Figure 19

Figure 20

Enter the last three digits of the endoscope’s serial number and then press

CONTINUE to begin the leak test (a maximum of 10 digits can be entered).

Using MENU button for Operator and Patient ID: The data collected during

an endoscope’s leak test can also include identication of the operator and

patient ID number by following these steps:

2) “Operator ID” prompt activation

• Press the “Menu” key on the keypad

• Use down arrow to toggle to “Set Test Parameters” and press

CONTINUE

• To enable the operator ID function use the down arrow to toggle to

“use oper ID” and press CONTINUE

• Use down arrow to toggle to “Yes” and press CONTINUE

• Press the CANCEL button until the “Connect Scope” language is

displayed is on the screen.

3) “Patient ID” prompt activation

• Press the MENU key on the keypad

• Use down arrow to toggle to “Set Test Parameters” and press

CONTINUE

• To enable the patient ID function use the down arrow to toggle to

“use patient ID” and press CONTINUE

22 | USERS MANUAL

• Use down arrow to toggle to “Yes” and press CONTINUE

• Press the CANCEL button until the “Connect Scope” language is

displayed is on the screen.

Using MENU button for setting Automatic or Manual Test Mode

The Veriscan system is normally used in the Automatic Test Mode which uses factory

default parameter settings for endoscope leak testing. Veriscan always uses “Standard

Test 1” and “Screen Test 1” as the “Automatic” factory default parameter settings. If

special endoscope parameter settings are to be used for a leak test, then the Manual

Test Mode is to be used. The manual mode is only to be used for selecting alternative

endoscope parameter settings, other than the factory default “Standard Test” settings.

Alternative test parameter settings can affect Veriscan accuracy at detecting endoscope

leaks, and should only be performed by qualied and trained personnel. Alternative

parameter settings can be helpful when different settings are required for testing a

unique or specialized endoscope.

Activate the Automatic or Manual Test Mode by:

• Press the “MENU” button located on the keypad and the following information

will display:

Main Menu

Stored Runs

Quick Reports

Screening Test

Set Test Parameters

Use the up/down arrow keys to align the cursor with the “Set Test Parameters” and

then press “CONTINUE”.

• The “Set Test Parameters” screen will now display as:

Settings Mode: Auto or Manual (whichever active)

Use Oper ID: No (whichever active)

Use Pat ID: Yes (whichever active)

Use the up/down arrow keys to align the cursor with the “Setting Mode” and then

press “CONTINUE”.

• The “Select Settings Mode” screen will now display with “automatic” or “manual”

centered in the screen depending on which is active, plus:

Automatic (whichever active)

Automatic

Manual

Use the up/down arrow keys to align the cursor with “automatic” or “manual” mode

and then press “CONTINUE”. The selected mode is now saved.

USERS MANUAL | 23

Manual Test Mode

• If Veriscan is operating in the “manual” mode, the following information will display when performing

either the Standard or Screen leak test:

Standard Test

Select Test Setting

Standard Test 1

Standard Test 2

Standard Test 3

Screening Test

Select Test Setting

Screen Test 1

Screen Test 2

Screen Test 3

Up to three different endoscope parameter settings can be programmed and stored under the “Standard Test”

and also three under the “Screen Test”. Each parameter setting is stored as either 1, 2 or 3. Veriscan always

uses “Standard Test 1” and “Screen Test 1” as the factory default “Automatic” settings and it is not recommended

to change these settings. Any alternative endoscope parameter setting should be programmed and saved under

settings 2 or 3 for the Standard or Screen test. All settings are initially set to factory defaults, unless manually

programmed differently.

Contact Medivators Technical Support for further information.

NOTE: Veriscan’s leak detection accuracy is affected by parameter changes.

NOTE: Parameter changes should only be performed by Medivators trained and qualied personnel.

If the Veriscan is operating in the “Manual” test mode and needs to be changed back to the “Automatic” test

mode, then follow the steps listed under “Activate the Automatic or Manual Test Mode by” to select the

Automatic mode.

Contact Medivators Technical Support or your authorized Medivators distributor if further assistance is required.

24 | USERS MANUAL

Data Access and Management

Managing Leak Test Results Data:

Data can be managed, viewed, downloaded and printed

by using the following features:

Display Screen Data Review - The display screen

features a procedure results review capability that

allows an operator or nurse the ability to scroll through

the past 2500 procedure results to conrm leak testing

protocol compliance, determine reprocessing activity

and review past results. Once 2500 tests have been

accumulated, each successive test replaces the oldest

of the prior 2500 tests. (see gure 20)

Accessing Past Leak Test Results

To access and review past procedure data follow

these steps:

• Press the MENU key on the keypad.

• Press the up/down arrows on the keypad until the

display arrow points to the “Stored Runs” selection.

• Press CONTINUE to select this option

• Press the “select run” option to access past test

data. Press CONTINUE to access stored runs.

• The last leak test run will appear at the top of the

screen (e.g. run 14). Use the up/down arrow keys

to select the desired leak test run. Press

CONTINUE to view leak test result.

• When nished, press CANCEL to return to the list

of stored runs. Press CANCEL again to return to

the MENU.

• Press CANCEL to return to the original

START menu.

Deleting Past Leak Test Results

To delete past procedure results follow these steps:

• Press the MENU key on the keypad.

• Press the up/down arrows on the keypad until the

display arrow points to the “Stored Runs” selection.

• Press CONTINUE to select this option

• Arrow down to select the “delete all” option and to

purge all past test data. To delete all stored runs,

press the CONTINUE button and the program will

begin the deletion process.

• When complete, the display screen will return to

the rst MENU screen.

• Press CANCEL to return to the original

START menu.

Other Menu Options

The MENU key on the keypad provides several types

of program tools:

Programming tools for the operator:

• Set Date/Time: A date/time feature allows the

Veriscan

system to time stamp every leak test.

See the System Setup section for directions on

setting the date/time.

• Stored Runs: The Veriscan system data storage

capability features the ability to store prior test

results. The Veriscan stores the last 2,500

leak tests.

• Quick Reports: The Veriscan system data

storage allows the user to print custom reports that

summarize daily, weekly and month leak testing

results. It also prints a list of all endoscopes that

failed a leak test within the previous 30 days. See the

Quick Report Printing area of the Data Access and

Management section for directions on printing Quick

Report data.

Programming tools for certied Veriscan system

technicians only: These menu items should not be

accessed by any non-Veriscan system technician.

These technician-only settings include:

• System Status

• Self Test

• Sensor Cal

• Line Frequency

• Set Pressure UOM

• Pump/valve Control

NOTE: Accessing these areas of the MENU program

will void the Medivators Reprocessing Systems

Veriscan Warranty. Contact Medivators Technical

Support at 1-800-444-4729 or your authorized

Medivators distributor if you have questions about this

area.

USERS MANUAL | 25

Data Access and Management

Printing and Quick Reports

The Veriscan system features a compact thermal printer that allows the

operator to:

1) Print the leak test results of any test upon completion.

2) Print quick reports summarizing daily, weekly, and monthly results.

3) Print quick reports summarizing all endoscopes that failed a leak test

within the last 30 days.

Post Procedure Printing: After the leak test completes, a printout

summarizing the results is created by pressing the PRINT key. To tear the

printout off, pull the printout upwards toward the tear bar, and tear from

one side to the other across the serrated edge (see gures 21 and 22).

The information on the printout is identical to that contained on the display

screen. When nished printing, the display will revert to the original screen

that begins the leak testing process for a new endoscope.

Quick Report Printing: Quick reports can be generated that summarize

the daily, weekly and monthly leak testing activity. Additionally, a report can

be generated that lists all of the endoscopes that failed a leak test within the

past 30 days. This report is useful for tracking down a specic endoscope

that might be part of an infection outbreak due to cross-patient infection.

Generate quick reports by following these steps:

Figure 21

• Press the MENU key on the keypad.

• Press the up/down arrows on the keypad until the cursor points to

the “Quick Reports” selection.

• Press CONTINUE select this option

• To print a printout of the current day’s procedures, use the up/down arrow

keys to select “Curr Day Results”. When the option is selected, the printer

will automatically print the previous day’s report which includes:

• # of endoscopes tested

• # of scopes that passed

• # of endoscopes that failed the leak test

Press CANCEL to return to the prior screen. Press CANCEL again to reach

the start menu.

• To print a a summary of the previous day’s procedures, use the up/down

arrow keys to select “Prev Day Summary”. When the option is selected, the

printer will automatically print the previous day’s report which includes:

• # of endoscopes tested

• # of scopes that passed

• # of endoscopes that failed the leak test

Figure 22

Press CANCEL to return to the prior screen. Press CANCEL again to reach

the start menu.

26 | USERS MANUAL

Data Access and Management

• To print a summary of the week’s procedures, use the up/down arrow

keys to select “Previous 7 day summary”. When the option is selected,

the printer will automatically print the previous 7 day’s report

which includes:

• # of endoscopes tested

• # of endoscopes that passed

• # of endoscopes that failed the leak test

Press CANCEL to return to the prior screen. Press CANCEL again to reach

the start menu.

• To print a summary of the month’s procedures, use the up/down arrow

keys to select “Previous 30 day summary”. When the option is selected

the printer will automatically print the previous 30 day’s report

which includes:

• # of endoscopes tested

• # of endoscopes that passed

• # of endoscopes that failed the leak test

Press CANCEL to return to the prior screen. Press CANCEL again to reach

the start menu.

Figure 23

• To print a summary of all of the endoscopes that have failed the leak test

in the previous 30 days, use the up/down arrow keys to select “30

Day Failure List”. When the option is selected, the printer will

automatically print the 30 day failure report which includes:

• The list of failed endoscopes from the most current to the least current

• The dates endoscopes failed the test

• The serial number of the failed endoscopes

• The leak test measurements reported on the display screen at the time of the test

Press CANCEL to return to the prior screen. Press CANCEL again to reach

the start menu.

Tearing the Printout Off: To tear the print out off, pull the printout upwards toward the

tear bar, and tear from one side to the other across the serrated edge (see gures 23 and

24). If it is necessary to advance the paper forward, press the Paper Feed Button (vv) on

the printer display. For directions on how to load printer paper, see the “Changing Printer

Paper” heading in the Maintenance, Handle and Care section.

Figure 24

USERS MANUAL | 27

Data Access and Management

ProV-LT Data Management Software

Downloading Past Leak Test Results

The Veriscan system includes a simple-to-use feature for downloading past

leak test results into a spreadsheet format on a PC computer. Downloading

is accomplished by using the ProV-LT software CD which is loaded onto a

separate PC. Veriscan test data is downloaded through the USB port which

is located on the Veriscan’s back panel. The supplied USB cable connects

the Veriscan unit to the PC.

NOTE: For detailed software installation and use instructions, please

refer to the Veriscan ProV-LT Data Management Software Installation

and User Manual.

To download data follow these steps to :

• Load ProV-LT CD software into the CD-rom drive located on a

computer (PC only). The software will automatically load.

• Connect the USB cable to the USB port located on the back of the

Veriscan unit. (see gure 25) Connect the remaining USB cable end to the

corresponding port located on the computer PC.

• Verify the Veriscan system is turned on and displays the

“Connect Scope” screen.

Figure 25

• Open the ProV-LT software and access the ProV-Link le. Select the

spreadsheet where the dowloaded Veriscan data is to be saved. The

Veriscan data can be saved in a new spreadsheet, or it can be added to

an existing spreadsheet.

1) If saving the Veriscan data to a new spreadsheet, then open the ProV

template and save it under a new name, then open the spreadsheet under

the new name.

2) If saving the Veriscan data to an existing spreadsheet, then use the

computer’s browse function to locate the spreadsheet, and then open it.

• Using the dialog box displayed on the computer, select “Download”

to transfer the Veriscan data.

• Veriscan will automatically output all stored runs (oldest to newest) to the

specied Microsoft® Excel™ le. All downloaded data is not automatically

erased from Veriscan. Data les must be erased from Veriscan if

no longer needed. Contact Medivators Technical Support for further

information. The screen will display “downloading data” with an active

progress bar.

• When download is complete, the Veriscan display will return to the original

start screen display.

28 | USERS MANUAL

Data Access and Management

• The transferred data will be housed in a Microsoft Excel spreadsheet

on the computer. The Microsoft Excel spreadsheet format allows data

analysis based upon a variety of user-sort functions depending on the

precise data required. The following data is stored in columns:

Unit Information (this data refers to the type of Veriscan unit in operation)

• data ver

• sfw ver

• model type

• serial number

• cycle

Test Result Data (this data refers to the individual leak test results)

• The Veriscan system’s microprocessor stores a broad range of

individual leak test result data including: operator ID, patient ID, test

date and time, endoscope serial number, pressure test results, and

angulation knobs turned (yes or no).

Test Parameter Settings

This data refers to the technical setting information that a Medivators

Service Technician would access in the event of a service call.

USERS MANUAL | 29

Maintenance, Handling and Care

Veriscan requires a minimal amount of regular maintenance and care to keep

the unit in excellent operating condition.

NOTE: There are no user serviceable parts in Veriscan, and only a

Veriscan certified technician is authorized to replace any internal

components. Removing Veriscan’s outer case will void the product

warranty.

For service or service related questions, contact Medivators Technical

Support at 1-800-444-4729 or your authorized Medivators distributor.

Drying Crystals Color Chart

Fully Activated

Color: Blue

20% Order New Desiccant

Color: Bubblegum Pink

Maintenance Frequency

• Desiccant drying crystals: Monitor Check self-indicating

the condition of the drying crystals on a crystals monthly.

regular monthly basis. Replace as needed

as determined by comparing the crystals to

the Drying Crystals Color Comparison Chart.

• Changing the coalescent lter (oil and Replace once yearly,

particle removal lter). Monitor the condition or more if needed.

of the coalescent lter for oil and particulates

on a regular monthly basis.

• Cleaning the unit As needed

• O-ring lubrication in Quick Connect Tubing: Monitor daily, lubricate

Monitor on a regular basis as used daily. weekly

Ensure a small amount of silicon oil is present

on the O-ring.

1) The Veriscan system uses coin lithium batteries in the internal electronics

for retaining memory settings. The coin lithium batteries contain perchlorate

materials and if replaced, special handling may apply.

NOTE: System uses primary lithium coin cell batteries containing

perchlorate material - special handling may apply.

40% Have New Desiccant

on Hand

Color: Pale Peach

60% Replace Desiccant

Color: Pale Pink

Figure 26

Changing the Desiccant Drying Crystals

The Veriscan system uses self-indicating silica desiccant drying crystals to

remove moisture from the outside air that enters the endoscope during the

pressurization process of the leak test.

Determining When to Change Drying Crystals

The crystals in the drying crystal bulb are blue and white when in an active

state. As the blue crystals become saturated with moisture, they lose their

ability to completely remove moisture from the air and begin to change color.

When the crystals turn a vivid bubble gum pink color, it is recommended to

ensure you have a replacement bag of drying crystals available or on order

from Medivators. As the crystals continue to absorb moisture, their color

continues to change until they reach a pale pink which indicates it is time to

change the crystals. A color-coded comparison chart is located on the metal

housing of the crystal bulb which identies the three color stages (see gure

26). The drying crystals should be checked monthly and compared to the

color-coded chart to determine if the drying crystals require replacement.

30 | USERS MANUAL

Maintenance, Handling and Care

Changing the Drying Crystals

The crystals in the drying crystal bulb are blue and white in their active

state. Once the crystals have turned pale pink, then they must be

replaced. Follow the steps detailed under “Installing or Replacing the

Desiccant Drying Crystals” located in the “System Setup” section for

further instructions.

Changing the Coalescent (Oil & Particulate) Removal Filter

Before pressurizing the endoscope, the incoming air must rst be ltered.

Veriscan lters the air through the coalescent lter which is an oil and

particulate removal lter. This ltration system ensures that only ltered

air enters the endoscope. This lter should be monitored regularly, and

changed once a year. To replace the lter follow these simple steps:

CAUTION: Disconnect all power before performing the lter

installation

Step 1: Turn off and then unplug the Veriscan system before performing

this operation.

Step 2: Unscrew the clear plastic bowl from the lter housing in a

counterclockwise direction until free. Set bowl aside.

(see gures 27 and 28)

Figure 27

Step 3: Remove the lter element from the lter housing by unscrewing

it in a counterclockwise direction until free. Discard the used lter. (see

gure 29)

Step 4: Take new lter element and screw it into the lter housing unit in a

clockwise direction.

Step 5: Replace the clear plastic bowl by screwing it back into the lter

housing unit in a clockwise direction.

Changing the Fuse

In the rare event that the device will not power up, the fuse may need to

be replaced. The Veriscan system uses a Littlefuse PN 31300, which is

a 3AG style fuse. The fuse rating is: 250V, 1 Ampere, Type S. Contact

Medivators Technical Support at 1-800-444-4729 or your authorized

distributor to order a new fuse or for technical assistance.

Performing a System Self Test

The Veriscan system automatically performs a system self test each

time the unit is powered on. In the event that the self-test fails or leak

test performance results yield an unusually high rate of failures, contact

Medivators Technical Support.

Cleaning Care

Gently clean the Veriscan system with a soft cloth soaked in a mild soapy

detergent and water mix solution. Do not allow cleaning solution to enter

the on-off switch on the back of the unit. Do not remove the metal case

for cleaning or any other reason. Do not use alcohol or alcohol-based

products to clean Veriscan.

Figure 28

Figure 29

USERS MANUAL | 31

Maintenance, Handling and Care

Changing Printer Paper

The printer will automatically detect when the thermal paper roll has run

out and report this condition with a ashing light on the LED display.

To replace the printer paper follow these steps:

Step 1: Pull the lever on the front of the printer paper access door upwards

until the lid is released from its locked position (see gure 30). To avoid

damage do not use excessive force.

Step 2: Replacing the paper roll

• With the printer access door open remove the empty paper roll spool.

(see gure 31).

• Locate a new paper roll and reel off approximately one-half inch (1/2”)

of paper. Place the new paper roll in the printer paper compartment

with the leading edge of the paper coming off the top of the paper roll

(see gure 32).

• Close the printer paper access door by applying a small amount of

pressure onto the front of the door, ensuring that the lid clicks into the

locked position (see gure 33). Teat the excess paper off by pulling it in

an upward direction so it tears against the serrated plastic edge.

Figure 30

Figure 31

Storage

To store the Veriscan system: unplug the unit, remove the power cord (see

“Attaching the power cord” directions) and disconnect the quick connect

tubing (see “Attaching the quick connect tubing” ). Store all components

together in a dry, cool environment (see “Product Specications” for proper

storage temperature range).

Transportation

The Veriscan system should always be handled with extreme care when

being moved. To transport the Veriscan: rst unplug the unit, remove the

power cord (see “Attaching the power cord” directions) and disconnect the

quick connect tubing (see “Attaching the quick connect tubing”). Secure

these items. Carefully lift the Veriscan system from the bottom and

securely carry it, or secure it to a transportation device (e.g. a cart). If

shipping the system, remove the accessories as described above and then

separately wrap them and the Veriscan system in thick, padded packaging

materials. Secure in a sturdy, well-sealed container and mark the package

as “FRAGILE HANDLE WITH CARE” .

Figure 32

Figure 33

32 | USERS MANUAL

Troubleshooting

The Veriscan system was designed to deliver consistent and reliable

leak testing performance. Troubleshooting power and display failures is

described below.

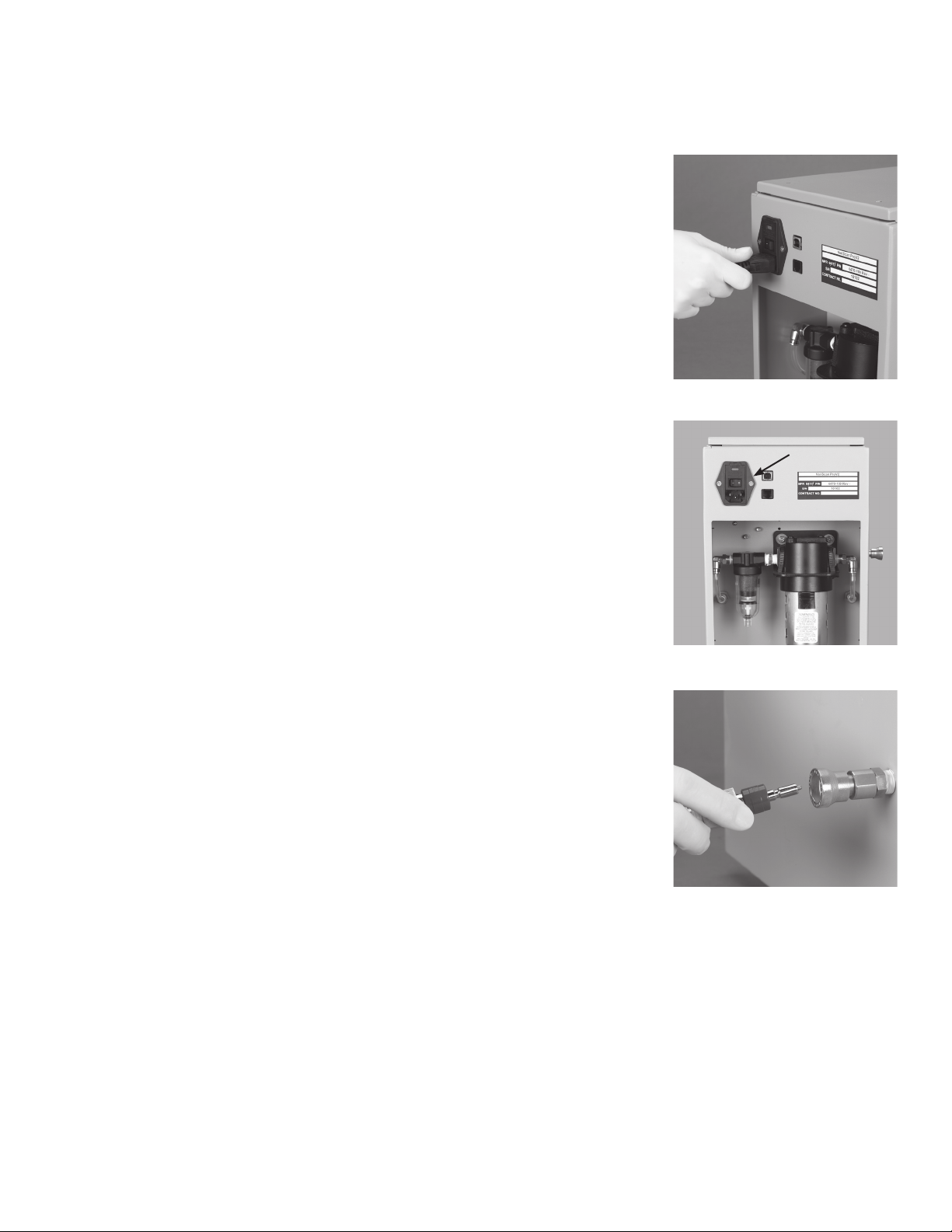

Veriscan Does Not Power On (Display screen does not appear)

• Check the power cord to ensure it is securely plugged into the rear of

the Veriscan system and into the properly rated wall outlet.

(see gure 40).

• Turn the Veriscan system off. Wait 15 seconds and then turn it back on.

(see gure 41).

• If the sytem still does not power on, contact your Medivators

service representative.

For all other Veriscan performance inquiries, contact your local

representative or Medivators Technical Support at 1-800-444-4729.

Figure 34

Figure 35

USERS MANUAL | 33

Limited Warranty Information

Limited Warranty

Medivators Reprocessing Systems, a division of Minntech Corporation (the “Company”), warrants that the endoscope

reprocessor and associated equipment it manufactures (collectively, the “Products”) will conform to the Company’s

written specications and will be free from defects in material and workmanship under normal use and service for a

period (the “Warranty Period”) of fteen (15) months from date of shipment from the Company or one (1) year from

the date of installation, whichever occurs rst.

Notwithstanding anything herein to the contrary, the Warranty Period for consumables and accessories supplied

by the Company, including, but not limited to, endoscope hook-ups, lters, printers, printer supplies, test strips, and

accessory bags, is ninety (90) days from the date of installation.

The warranty does not cover, and the Company will have no warranty obligation whatsoever with respect to, any

damage to a Product caused by or associated with: (i) external causes, including without limitation, accident,

vandalism, acts-of-god, power failure or electric power surges, (ii) abuse, misuse or neglect of the Product by the

customer or use of unauthorized third party lters or other consumables and accessories, (iii) usage not in accordance

with product instructions, (iv) the customer’s failure to perform required preventive maintenance, or (v) servicing or

repair not authorized by the Company.

Limitation of Remedy

The warranty obligation of the Company hereunder is limited to the repair or replacement (at its option) of the

defective Products or any parts it deems defective. This will be customer’s exclusive remedy for a covered defect.

In order to recover under the warranty, the customer must notify the Company in the state (if in the USA) or the

country of installation of the defect (describing the problem in reasonable detail) prior to the expiration of the warranty

period and within thirty (30) days of discovery of the defect. Upon receiving the Company’s ofcial “return goods

authorization” (RGA), the customer must promptly return the defective part or Product to the Company (or the service

center indicated on the RGA), freight and insurance prepaid. The Company will not be responsible for any damage

during shipment.

Warranty Disclaimer

THE WARRANTY ABOVE IS THE COMPANY’S ENTIRE WARRANTY OBLIGATION TO THE PURCHASER

OF PRODUCTS. IT IS IN LIEU OF ALL OTHER WARRANTIES OF THE COMPANY, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, AND THE COMPANY DOES NOT REPRESENT OR WARRANT THAT ANY PRODUCT WILL MEET

CUSTOMER’S REQUIREMENTS. THE COMPANY’S RESPONSIBILITY FOR DEFECTS IN A PRODUCT IS

LIMITED SOLELY TO REPAIR AND REPLACEMENT AS SET FORTH IN THIS WARRANTY STATEMENT.

TO THE EXTENT PERMITTED BY LAW, THE COMPANY SHALL NOT, UNDER ANY CIRCUMSTANCES, BE

LIABLE TO CUSTOMER FOR CONSEQUENTIAL, INCIDENTAL, INDIRECT OR SPECIAL DAMAGES OR

LOSSES, INCLUDING WITHOUT LIMITATION, DAMAGES ARISING OUT OF OR IN CONNECTION WITH ANY

MALFUNCTIONS, DELAYS, LOSS OF PROFIT, INTERRUPTION OF SERVICE, OR LOSS OF BUSINESS OR

ANTICIPATORY PROFITS, EVEN IF THE COMPANY HAS BEEN APPRISED OF THE LIKELIHOOD OF SUCH

DAMAGES OCCURRING.

This Warranty gives the customer of Products specic legal rights, and customers may also have other rights which

vary from jurisdiction to jurisdiction.

In no event shall the Company’s liability exceed the original purchase price of the covered Product.

No representative or agent of the Company has any authority to bind the Company to any other representation or

warranty with respect to the Products, and the customer accepts the Products subject to all of the terms above.

34 | USERS MANUAL

© 2009, Minntech Corporation

36 | USERS MANUAL

50096-988 Rev A

Distributed in Canada by:

CARSEN MEDICAL INC.

151 Amber Street

Unit 17 & 18

Markham, ON L3R 3B3

1-866-677-4122

Loading...

Loading...