Page 1

Annual

For

use

with

78399-880

XXXXX-XXX

Prior

to

performing

e

If

e

If

disassembling

e

Carefully

e

Precautions

Personnel

disinfectants.

DSD-201

PM

kit

possible,

the

disinfectant

Disconnect

Ra

Attach

Begin

If

software

Press

8,

Press

Repeat

Press

Start

the

purge

read

0,

CANCEL

anton

Con

PM

P/N:

the

preventative

schedule

the

on

side

ENTER,

ENTER

steps 3 — 6 for

flush

of

the

should

should

this

is

not

the

machine:

the

disinfectant

restrictor

A.

Enter

version

18

to

deactivate

twice

cycle

flush

cycle.

through

be

wear

Instructions

maintenance:

service

dumped

adapter

5.07

ENTER

to

for

the

taken

the

so

that

prior

filters.

in

both

the

diagnostics

or

above,

and

then

all

components.

side

B.

Press

exit

Diagnostics.

both

stations,

procedure

to

prevent

appropriate

it

coincides

to

the

basins.

mode,

press

O,

7,

ENTER

14,

ENTER

then

prior

to

spillage

personal

DRAFT

with

PM,

purge

SETUP

ENTER.

press

performing

If

to

purge

when

CANCEL

of

disinfectant

protective

COPY

the

replacement

the

disinfectant

88,

ENTER,

lower

level,

the

disinfectant

complete

and

the

PM.

when

equipment

135 and

proceed

with

the

ENTER

performing

when

of

the

lines

ENTER

to

out

steps

key

during

disinfectant.

prior

to

step

5.

of

the

pumps.

for

side

the

the

PM.

handling

B.

air

Tools

NOTE:

to

the

e

e

e

e

e

e

Required:

This

is a comprehensive

specific

7/16

instructions

in

nut

9/64-inch

5/16

nut

driver

Small

Flat-bladed

Asetof

3/8

“Philips”

open

end

driver,

and

3/32-inch

wrench

for

open

screw

screw

or

list

of

the

PM

end

wrench

hex

keys

driver

drivers

socket

all

tools.

kit

purchased.

wrench

Not

all

or

socket

Page 1 of

PM

kits

wrench

32

require

all

the tools

listed.

Please

refer

Page 2

Annual

e

Valve

e

John

ο

Lint

Description

Check

machine

Inspect

Inspect

Clean

out

Drain

Air

Inspect

Inspect

Clean

the

Verify

proper

Review

Rebuild

Replace

Replace

Replace

Replace

Inspect

Endoscope

hydraulic

the

tank

the

electrical

Active

filters

the

the

the

the

the

Leak

DSD-201

stem

wrench

Guest

47049-157

free

cloth/rags.

of

Action

level

hook

and

air

LCG

Reservoir

of

sediment/liquid

gas

springs

temperature

change

%” drain

disinfectant

air-operated

peristaltic

eight

tester

for

connections

Vapor

Management

logs.

valves

pump

check

traps

PM

for

ups

for

fitting

proper

for

in

basins

Change

pump

valve

tubing

valves

for

liquid

Instructions

air

actuated

integrity

for

integrity

(Should

operations.

integrity

and

filters

head

assembly

and

solenoid

in

be

system

LCG

as

alcohol

valves

performed

(If

reservoir

required

seals

(Medivators

equipped)

and

detergent

DRAFT

daily)

pumps

COPY

P/N

MW03-0002

Service

6

Month

X|x|xX|x|x|x|x|x|x|x

Interval

12

month

X|x|x|x|x|x|x|x|x|x|x|x|x|x|x|x

PM

kit

parts

%"

Valve

Rebuild

Hydraulic

Solenoid

Peristaltic

Disinfectant

Check

PM

%"

Valve

%"

Valve

Hydraulic

Solenoid

Peristaltic

Disinfectant

Check

valves

kit

valves

Valve

Valve

Pump

pump

parts

Rebuild

Rebuild

Valve

Valve

Pump

pump

content

kit

Seals

Seal

Head

head

content

kit—

kit — BACK

Seals

Seal

Head

head

of

P/N

Kit

kit

of

P/N

FRONT

Kit

kit

78399-880

MK01-0029

78398-538

MV01-0035

MT01-0500

47049-193

MK01-0068

78400-323

78400-324

78398-538

MV01-0035

MT01-0500

47049-193

MK01-0068

(Kit

of 4 seals)

A

(Kit

of 4 seals)

RUN

BP

EN

Page 2 of

32

Page 3

Annual

DSD-201

Preparation

Unplug

Close

the

If

equipped

Bleed

the

the

bleeder

1.

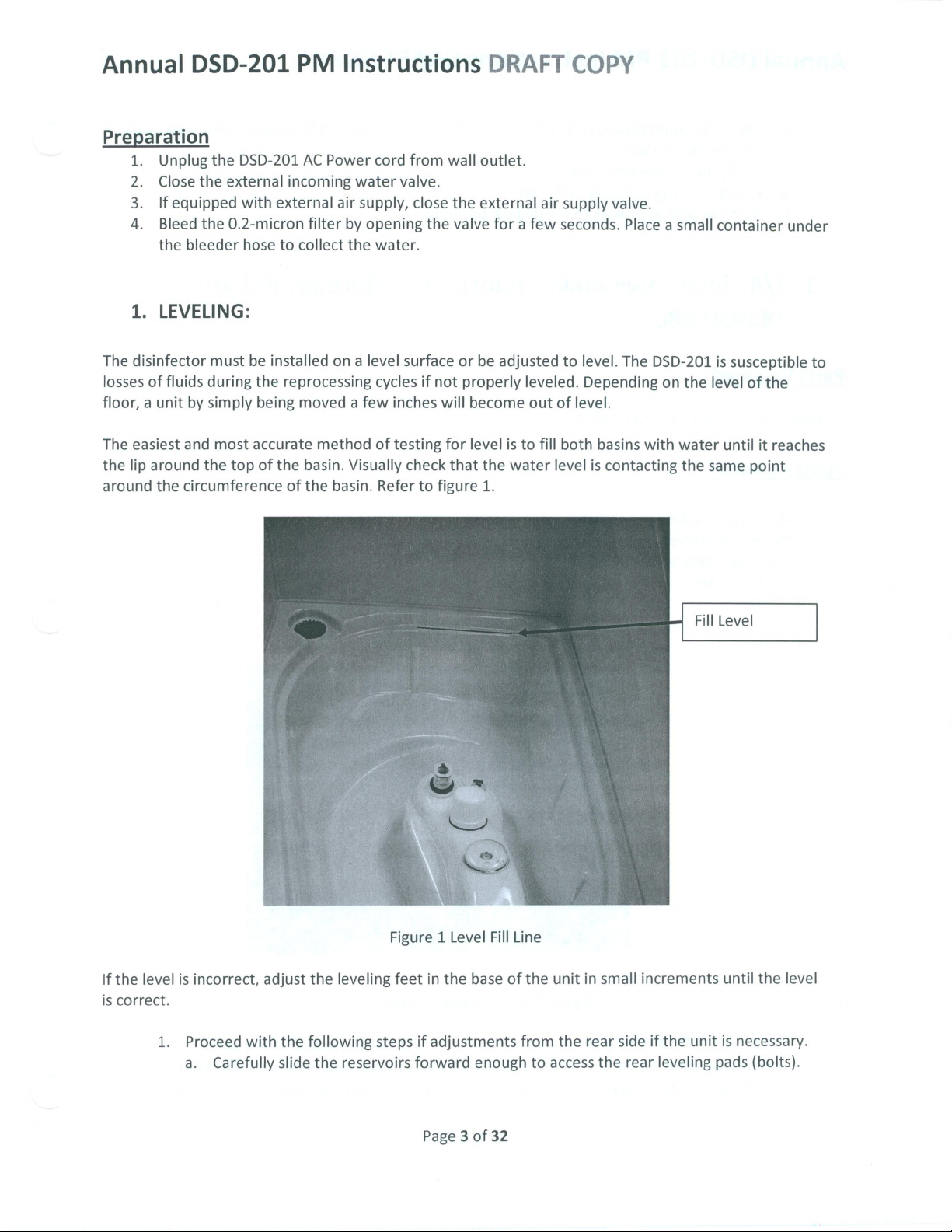

LEVELING:

The

disinfector

losses

of

fluids

floor, a unit

The

easiest

the

lip

around

by

and

around

the

circumference

the

DSD-201

external

with

0.2-micron

hose

must

be

during

simply

most

the

top

PM

AC

incoming

external

filter

to

collect

installed

the

reprocessing

being

moved a few

accurate

of

the

basin.

of

the

Instructions

Power

method

cord

water

valve.

air

supply,

by

opening

the

water.

on a level

cycles

inches

of

testing

Visually

basin.

Refer

from

close

surface

check

to

wall

the

if

not

will

for

figure

DRAFT

outlet.

the

external

valve

or

be

properly

become

level

that

the

1.

air

for a few

adjusted

leveled.

out

is

to

fill

water

COPY

supply

seconds.

to

level.

Depending

of

level.

both

basins

level

is

contacting

valve.

Place a small

The

DSD-201

on

with

water

the

the

level

same

container

is

susceptible

of

the

until

it

reaches

point

under

to

If

the

is

correct.

level

1.

is

incorrect,

Proceedwith

a.

Carefully

adjust

the

the

following

slide

leveling

the

reservoirs

Figure 1 Level

feet

in

the

steps

if

adjustments

forward

Fill

base

of

enough

Line

the

from

to

unit

in

the

rear

access

small

side

the

rear

Fill

increments

if

the

unit

leveling

Level

until

the

is

necessary.

pads

(bolts).

level

Page 3 of

32

Page 4

Annual

2.

δω

5.

1.

3/4

783990-880

DSD-201

Adjust

“A”

Verify

Ensure

Slide

and

the

the

the

“B”

that

disinfector

reservoirs

-inch

PM

appropriate

are

level.

is

the

reservoirs

back

valve

Instructions

leveling

level.

are

to

pads

clean.

the

original

until

the

positions.

maintenance

DRAFT

(Figure

COPY

1)

level

procedure

fill

lines

for

shows

PM

that

both

Kit

basin

Parts

%"

Drain

Tools

Required

valve

rebuild

Required

7/16-inch

Adjustable

Small

flat

Silicon

Grease

kit

nut

driver

wrench

blade

MKO1-0029

or

socket

or 1 1/8”

screw

driver

Qty

or

deep

6.

open

well

ended

socket

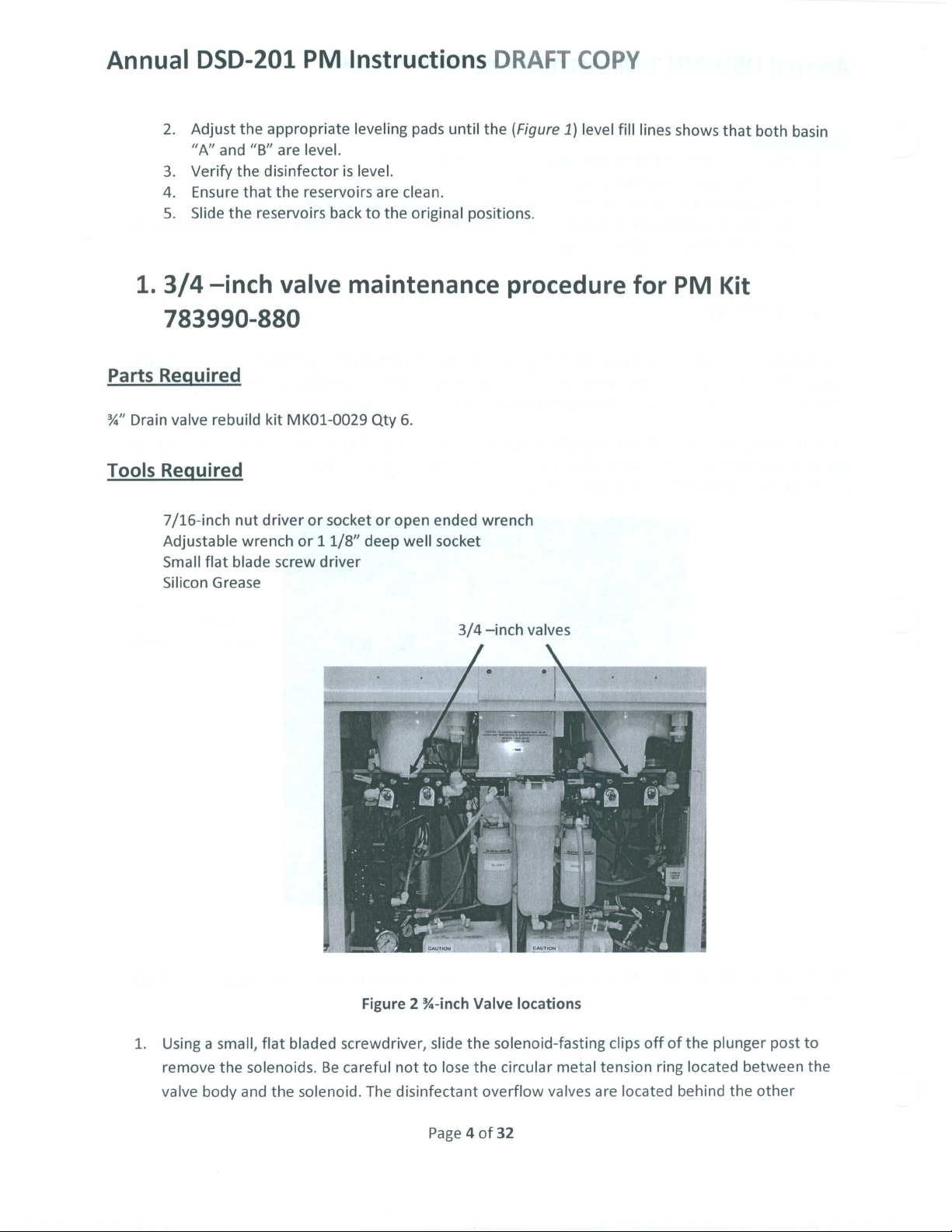

3/4

wrench

-inch

valves

1.

Using a small,

remove

valve

the

body

flat

bladed

solenoids.

and

the

solenoid.

Figure 2 %-inch

screwdriver,

Be

careful

not

The

disinfectant

Valve

slide

the

to

lose

the

Page 4 of

locations

solenoid-fasting

circular

overflow

32

metal

valves

clips

tension

are

located

off

ring

of

the

located

behind

plunger

between

the

other

post

to

the

Page 5

Annual

DSD-201

PM

Instructions

DRAFT

COPY

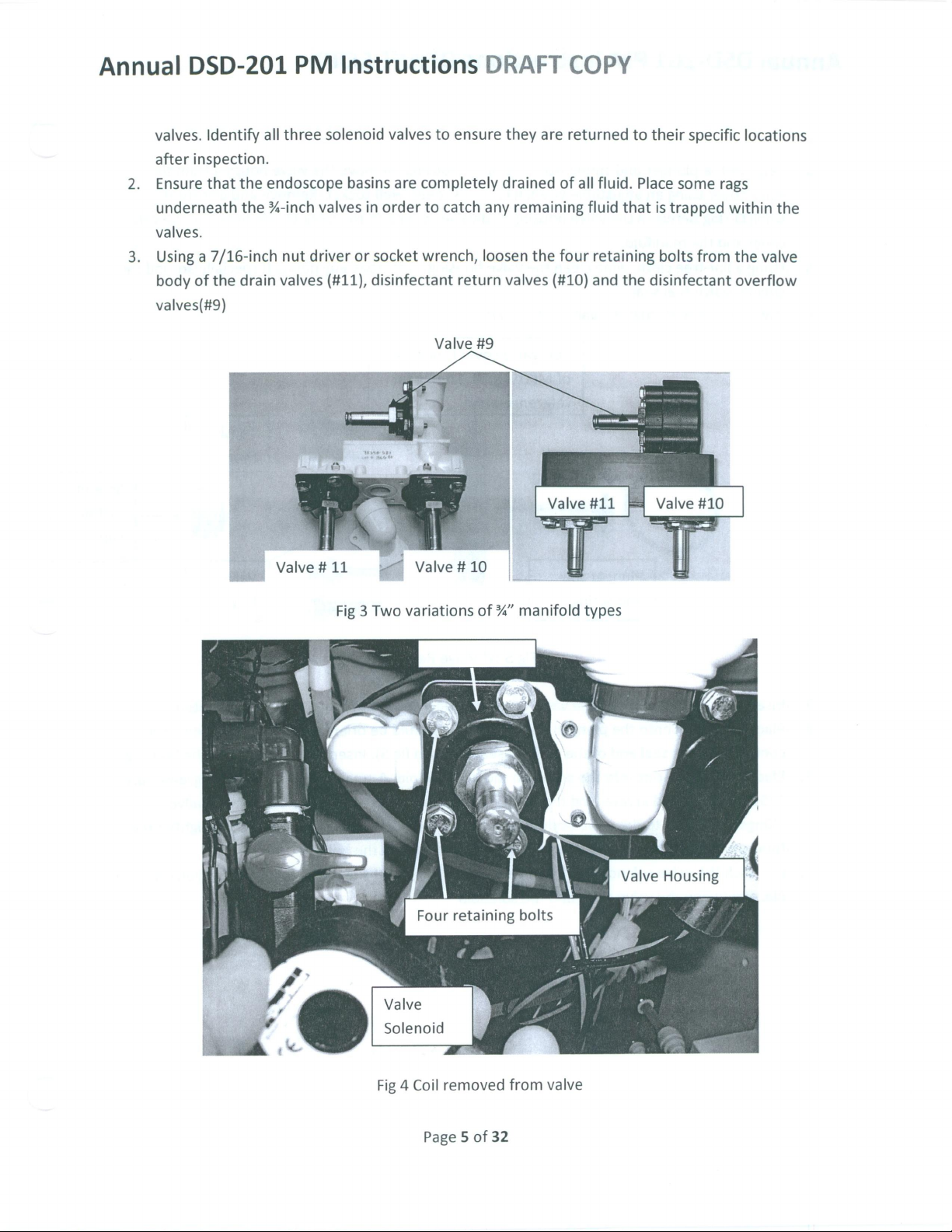

valves.

after

2.

Ensure

underneath

valves.

3.

Using a 7/16-inch

body

valves(#9)

Identify

inspection.

that

of

all

three

the

endoscope

the

%-inch

nut

the

drain

valves

Valve#11

solenoid

basins

valves

driver

(#11),

只

valves

are

in

order

or

socket

disinfectant

т

제

j=

Valve

to

ensure

completely

to

catch

any

wrench,

Valve

loosen

return

#9

#10

they

are

drained

remaining

the

valves

(#10)

Valve

ET

returned

of

all

fluid.

fluid

four

retaining

and

#11

to

their

Place

that

is

trapped

bolts

the

disinfectant

Valve

specific

some

rags

from

#10

locations

within

the

the

valve

overflow

Fig 3 Two

Valve

Solenoid

variations

of

%”

manifold

types

Fig 4 Coil

Page 5 of

removed

32

from

valve

Page 6

Annual

4.

Remove

valve

small

cover

5.

Using a lint-free

circular

6.

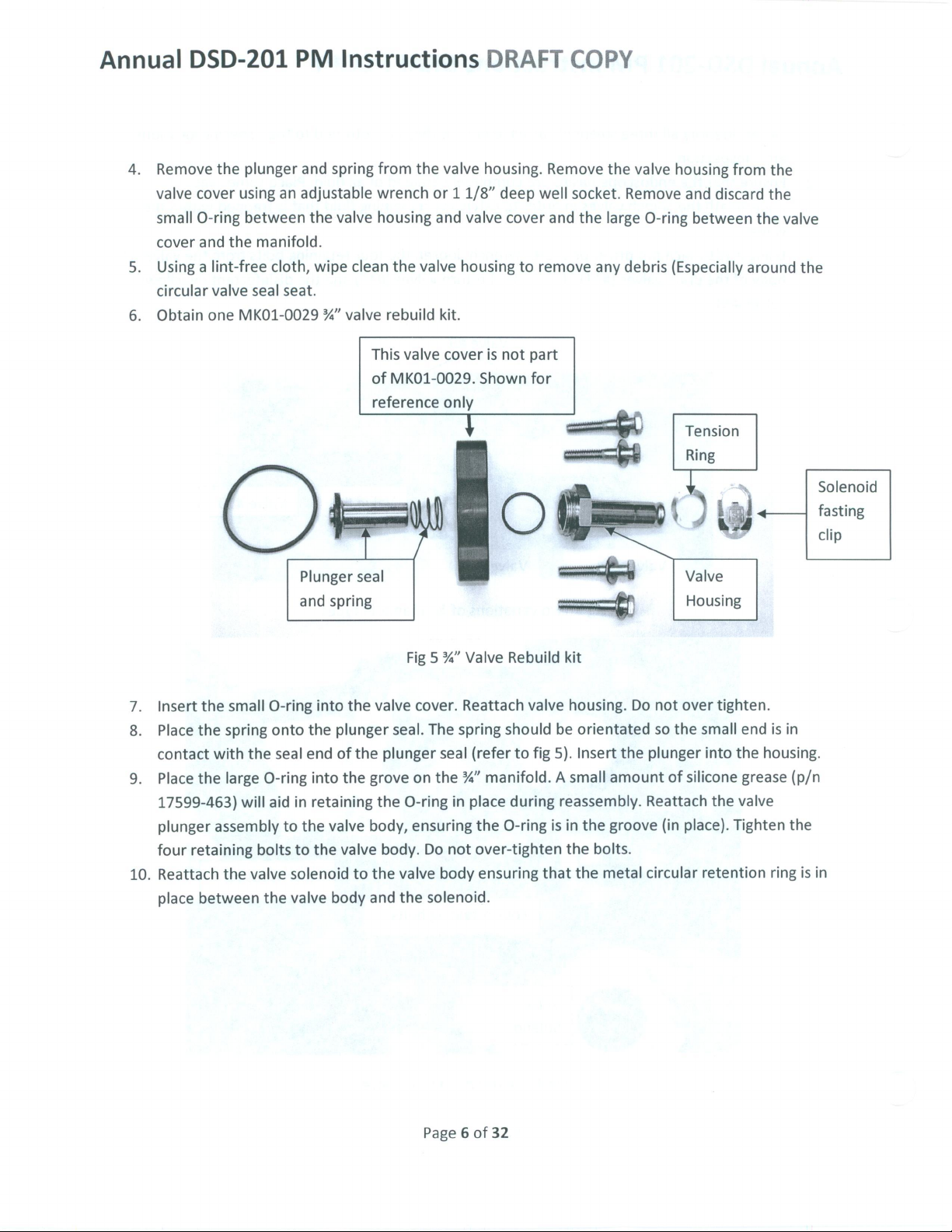

Obtain

DSD-201

the

plunger

cover

using

O-ring

and

valve

one

between

the

manifold.

seal

MK01-0029

PM

and

an

adjustable

the

cloth,

wipe

seat.

Plunger

and

Instructions

spring

from

the

wrench

valve

housing

clean

%”

valve

This

of

reference

seal

spring

or 1 1/8”

and

the

valve

rebuild

MK01-0029.

kit.

valve

valve

valve

housing

cover

only

DRAFT

housing.

deep

cover

is

not

Shown

well

to

remove

part

for

COPY

Remove

socket.

and

the

the

large

any

valve

Remove

O-ring

debris

housing

(Especially

Tension

(

Valve

and

discard

between

Ring

|

)

而

に

Housing

from

the

around

A

を

the

the

valve

一

the

Solenoid

fasting

clip

7.

Insert

8.

Place

contact

9.

Place

17599-463)

plunger

four

10.

Reattach

place

the

small

the

spring

with

the

the

large

will

assembly

retaining

the

valve

between

O-ring

onto

seal

O-ring

aid

to

bolts

solenoid

the

valve

into

the

plunger

end

of

into

in

retaining

the

valve

to

the

valve

body

the

the

the

to

Fig 5 %”

valve

seal.

plunger

grove

the

O-ring

body,

body.

the

valve

and

the

Valve

cover.

on

ensuring

Reattach

The

spring

seal

the

%”

in

Do

not

body

solenoid.

Rebuild

should

(refer

to

manifold. A small

place

during

the

O-ring

over-tighten

ensuring

kit

valve

housing.

be

fig

5).

reassembly.

is

in

the

that

Do

orientated

Insert

the

amount

the

groove

bolts.

the

metal

not

over

so

the

small

plunger

of

silicone

Reattach

(in

place).

circular

retention

tighten.

end

into

the

grease

the

valve

Tighten

is

in

housing.

(p/n

the

ring

is

in

Page 6 of

32

Page 7

Annual

2.

3/4

783990-XXX

DSD-201

—inch

PM

valve

Instructions

maintenance

DRAFT

COPY

procedure

for

PM

Kit

Parts

Tools

Required

Required

Medium

#2

Phillips

___

Allen

____

Allen

flat

screw

blade

driver

screw

drive

|

Barbed

Elbows

1.

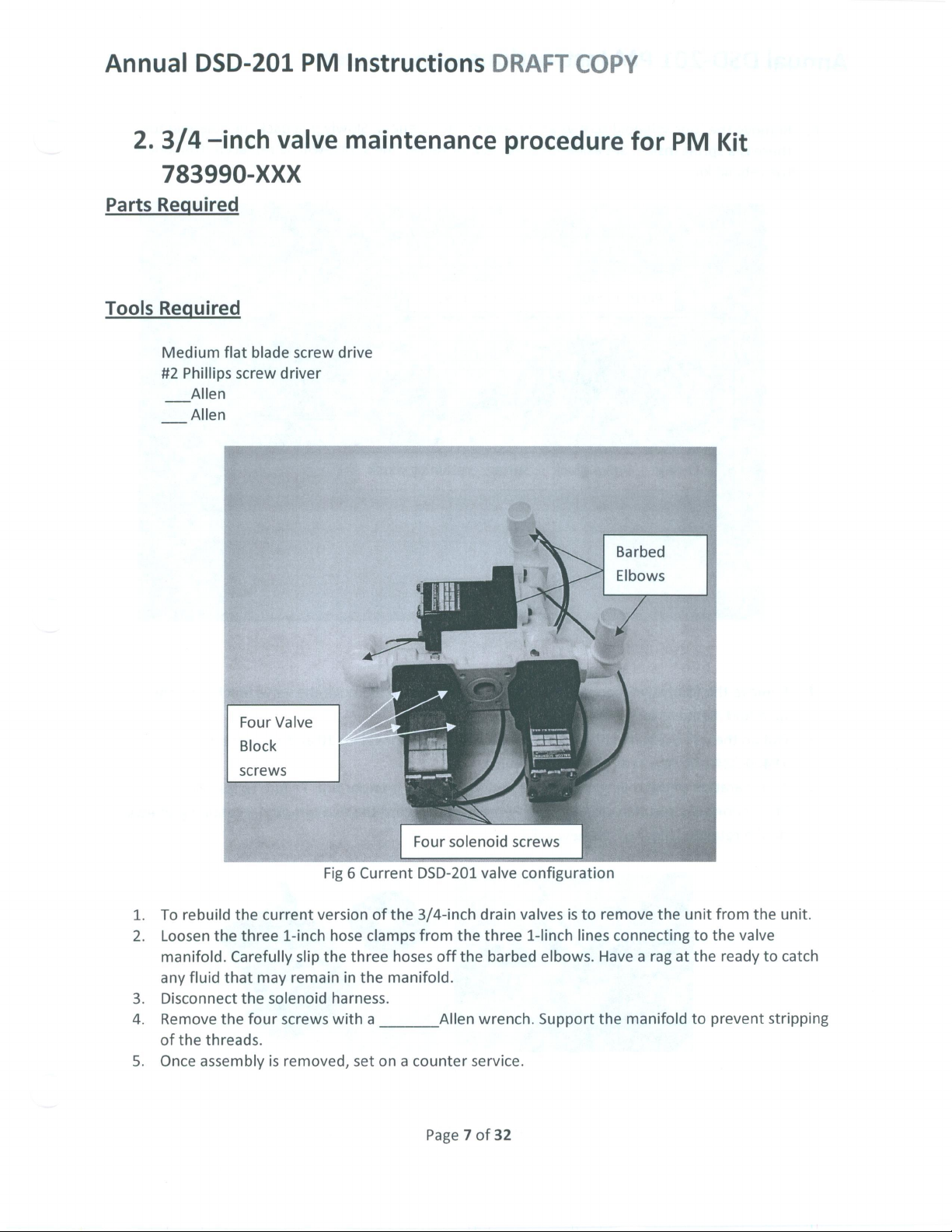

To

2.

Loosen

manifold.

any

3.

Disconnect

4.

Remove

of

5.

Once

|

Four

Valve

|

Block

|

screws

rebuild

the

the

fluid

that

the

threads.

assembly

the

current

three

Carefully

may

the

solenoid

four

is

Fig 6 Current

version

1-inch

slip

the

remain

screws

removed,

hose

harness.

with

of

clamps

three

in

the

a

set

on a counter

Four

solenoid

DSD-201

the

3/4-inch

from

hoses

off

manifold.

Allen

Page 7 of

screws

valve

configuration

drain

valves

the

three

1-linch

the

barbed

wrench. Support

service.

32

elbows.

is

to

remove

lines

Have a rag

the

the

unit

connecting

at

manifold

from

to

the

the

to

prevent

the

valve

ready

unit.

to

catch

stripping

Page 8

Annual

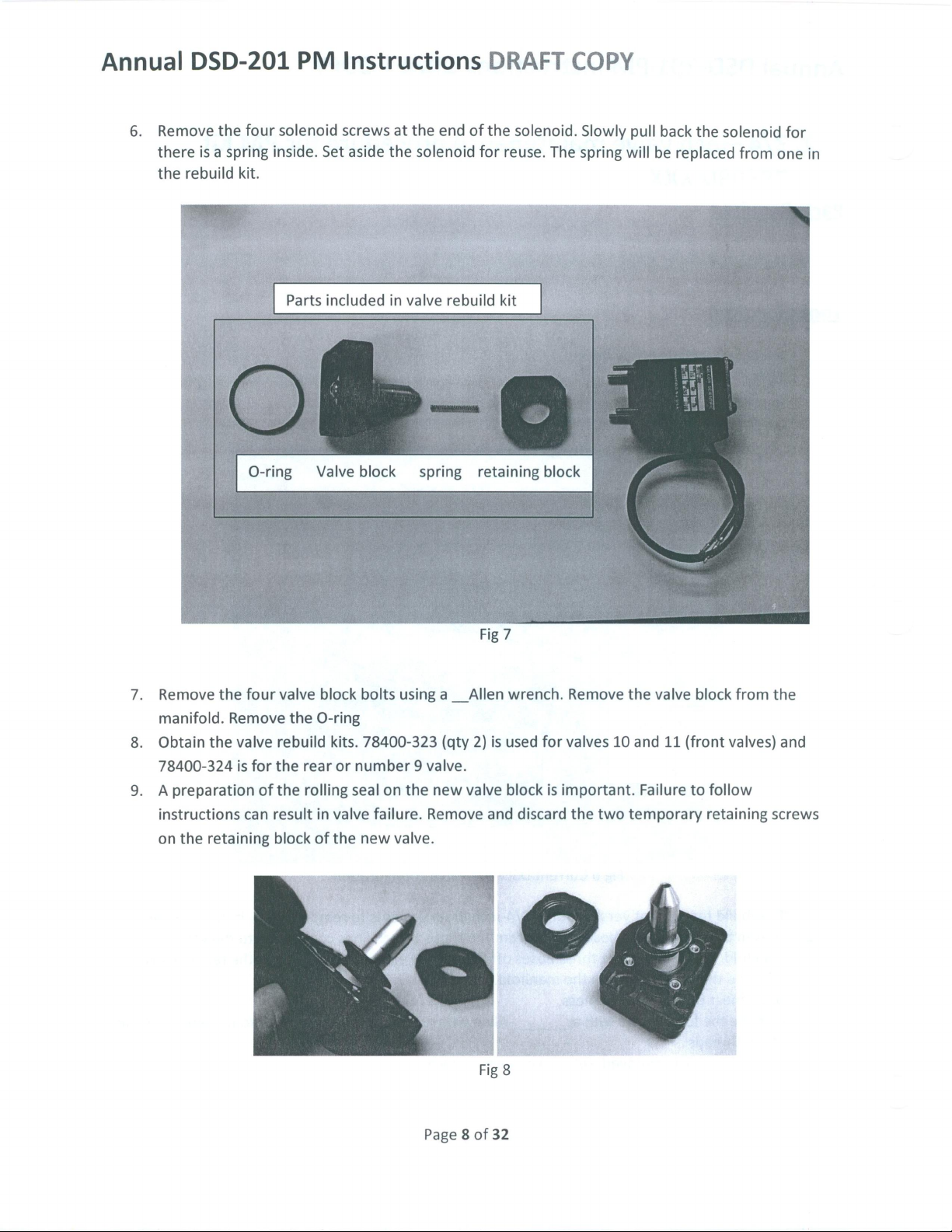

6.

Remove

there

the

DSD-201

the

four

is a spring

rebuild

kit.

PM

solenoid

inside.

Set

Parts

Instructions

screws

included

aside

at

the

the

solenoid

in

valve

end

of

rebuild

DRAFT

the

solenoid.

for

reuse.

kit

The

COPY

Slowly

spring

pull

will

back

be

replaced

the

solenoid

from

for

one

in

O-ring

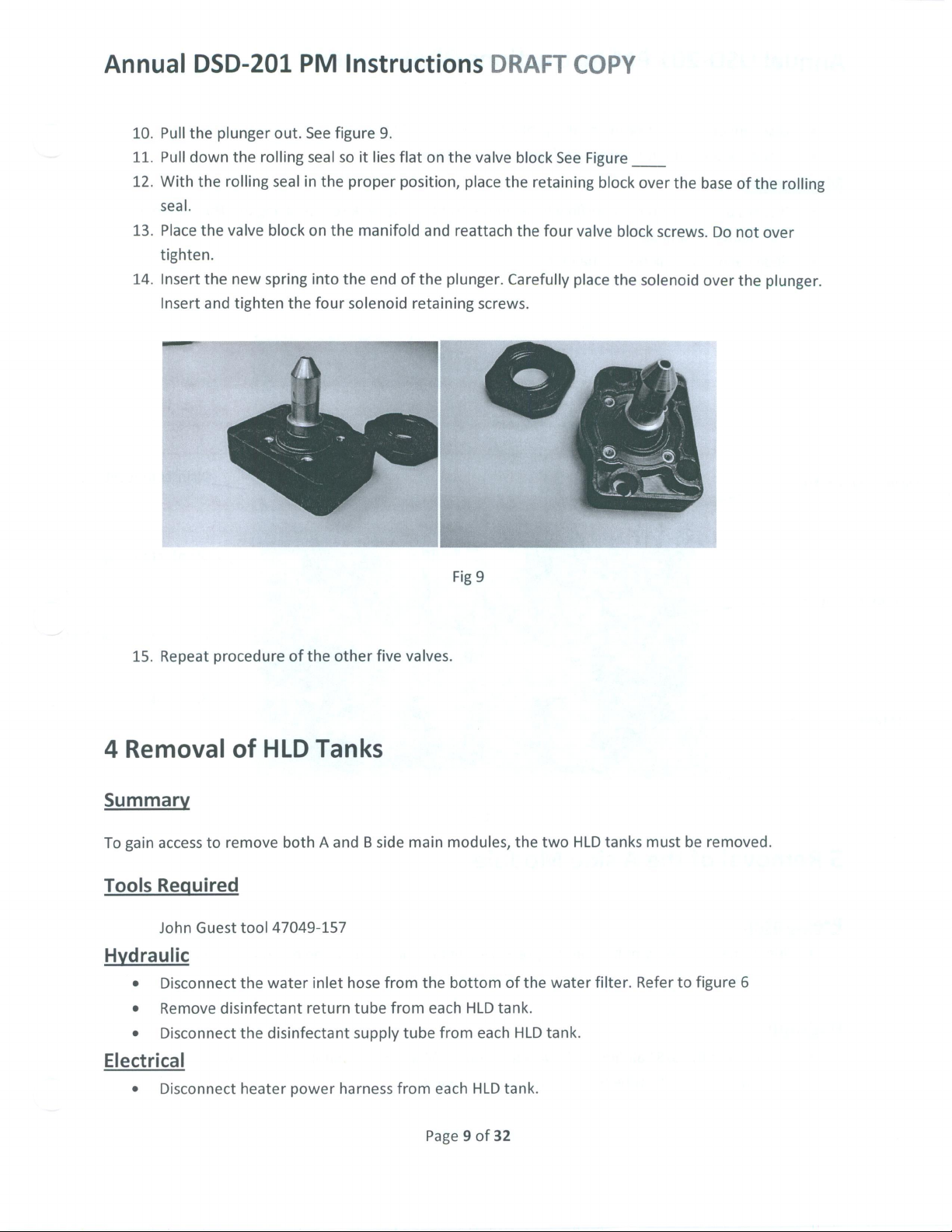

7.

Remove

manifold.

8.

Obtain

78400-324

9. A preparation

instructions

on

the

the

retaining

the

four

Remove

valve

is

can

for

valve

the

rebuild

the

of

the

result

block

Valve

block

O-ring

kits.

rear

or

rolling

in

valve

of

the

block

bolts

78400-323

number 9 valve.

seal

new

spring

using

on

the

failure.

Remove

valve.

a__

(qty

new

retaining

Fig

7

Allen

wrench.

2)

is

used

valve block

and

discard

block

Remove

for

valves

is

important.

the

the

10

two

temporary

valve block

and

11

(front

Failure

from

valves)

to

follow

retaining

the

and

screws

Fig

8

Page 8 of

32

Page 9

Annual

10.

Pull

11.

Pull

12.

With

seal.

13.

Place

tighten.

14.

Insert

Insert

DSD-201

the

plunger

down

the

rolling

the

rolling

the

valve

the

new

and tighten

PM

out.

See

seal

in

block

spring

the

Instructions

figure

9.

seal

so

it

lies

flat

the

on

the

into

four

proper

the

solenoid

position,

manifold

end

of

on the

and

the

retaining

valve

place

reattach

plunger.

DRAFT

block

the

the

Carefully

screws.

COPY

See

Figure

retaining

four

valve

place

|

block

block

the

over

the

screws.

solenoid

base

Do

over

of

the

not

over

the

plunger.

rolling

15.

Repeat

4

Removal

Summary

To

gain

access

Tools

Hydraulic

Required

John

e

Disconnect

e

Remove

e

Disconnect

procedure

of

to

remove

Guest

tool

the

disinfectant

the

of

the

other

HLD

water

disinfectant

Tanks

both A and B side

47049-157

inlet

hose

return

tube

supply

five

from

from

valves.

main

modules,

the

each

tube

from

Fig

9

bottom

HLD

each

the

of

the

tank.

HLD

two

water

tank.

HLD

filter.

tanks

must

Refer

be

to

figure

removed.

6

Electrical

e

Disconnect

heater

power

harness

from

each

HLD

Page 9 of

tank.

32

Page 10

Annual

e

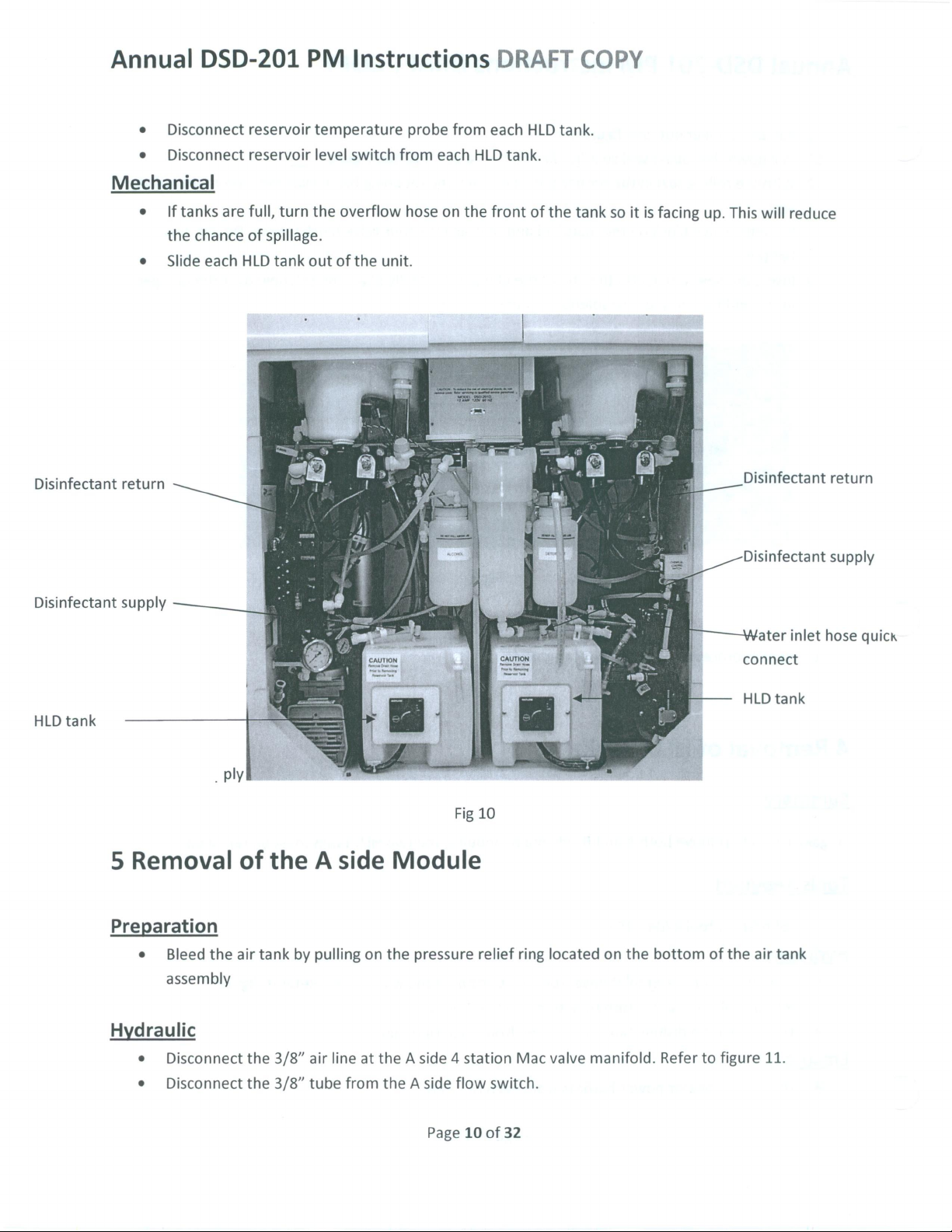

Disconnect

e

Disconnect

Mechanical

ο

If

tanks

the

e

Slide

DSD-201

reservoir

reservoir

are

full,

chance

each

of

HLD

PM

temperature

level

turn

the

spillage.

tank

out

Instructions

probe

switch

overflow

of

the

from

hose

unit.

each

on

from

HLD

the

DRAFT

each

tank.

front

ο

νο

HLD

of

tank.

the

ο.

COPY

tank

so

it

is

facing

up.

This

will

reduce

Disinfectant

Disinfectant

HLD

tank

return

supply

5

Preparation

Removal

of

the A side

Module

Fig

10

inlet

return

supply

hose

Disinfectant

Disinfectant

Water

connect

HLD

tank

quick

e

Bleed

assembly

Hydraulic

e

Disconnect

e

Disconnect

the

air

the

the

tank

3/8”

3/8”

by

pulling

air

tube

on

the

pressure

line

at

the A side 4 station

from

the A side

Page

relief

flow

10

ring

Mac

switch.

of

32

located

valve

manifold.

on

the

bottom

Refer

of

to

figure

the

air

11.

tank

Page 11

Annual

DSD-201

PM

Instructions

DRAFT

COPY

Disconnect

Disconnect

Disconnect

reservoir

Disconnect

valve

manifold

reassembly

Electrical

Disconnect

Disconnect

Disconnect

Disconnect

Disconnect

compressor

Disconnect

Disconnect

the

3/8”

tube

at

the

3/8”

tube

at

the

check

valve

side

of

the

break.

the

check

valve

side

of

the

break.

process.

the A side

the A side 4 station

the A side

the A side

the

and

the A side

the A side

flow

alcohol/detergent

compressor

spade

connector

the

air

tank.

disinfection

drain

switch

the

water

the

chamber

of

the A side

Refer

to

of

the A side

Separating

electrical

Mac

connector

located

pump

valve

connections.

valve

valve

alcohol

figure

detergent

valve

connector.

on

connector

inlet

if A side

inlet

line,

11.

the

two

connector.

manifold

the

black

valve

of A side

leaving

line,

check

connector.

wire

the

leaving

valves

Refer

to

that

manifold.

manifold.

check

valve

the

check

in

this

figure

7.

runs

between

with

valve

manner

the A side

the

with

will

alcohol

the A side

simplify

the

Main

4-station

Alcohol

Air

tank

Mechanical

Remove

Slide

valve

manifold

Mac

Valve

Flow

switch

and

detergent

check

valves

pressure

relief

pull

the

the A side

ring

three

module

bolts

that

out

secure

of

the

the A side

unit.

main

Fig

11

module

to

the

unit.

¡ue

Flow

switch

electrical

connection

Disinfection

(behind

compressor)

Compressor

pump

Page

11

of

32

Page 12

Annual

6.

Preparation

Hydraulic

DSD-201

Removal

Due

to

space

at

the

same

time,

proceeded

remove

PM

of

the B side

limitations

time.

to

the B side

Instructions

Module

at

many

facilities,

If

space

limitations

the

next

section

module

DRAFT

it

dictate

and

return

may

the

not

need

to

these

COPY

be

possible

to

work

instructions

on

to

one

remove

side

when

both

module

ready

sides

at

a

to

Disconnect

12.

Disconnect

Disconnect

Disconnect

Disconnect

alcohol

Disconnect

B

side

will

Electrical

Disconnect

Disconnect

Disconnect

Disconnect

Disconnect

Disconnect

the

the

the

the

the

reservoir

the

valve

simplify

the B side

the B side

the B side

the B side

the B side

the B side

3/8”

air

3/8”

tube

3/8”

tube

3/8”

tube

check

side

check

manifold

the

reassembly

line

at

the B side 6 station

from

the B side

at

the

water

at

the

chamber

valve

of

the B side

of

the

break.

valve

of

the B side

side

of

the

break.

process.

flow

switch

6-station

alcohol/detergent

compressor

chemical

disinfectant

Disconnect

electrical

Mac

valve

connector.

load

switch.

pump

flow

switch.

valve

inlet

valve

inlet

alcohol

detergent

Separating

connector.

manifold

connector.

connector.

Mac

valve

of

the B side

of

the B side

line,

leaving

line,

the

two

the

3/8”

Refer

connector.

manifold.

valve

the

leaving

check

tube

at

to

manifold.

manifold.

check

the

check

valves

the

main

figure

Refer

valve

in

12.

to

with

valve

this

water

Figure

the

with

the

manner

valve.

Mechanical

Remove

Slide

the

three

the B side

bolts

module

that

out

secure

of

the

Page

the B side

unit.

12

of

32

main

module

to

the

unit.

Page 13

Annual

DSD-201

PM

Instructions

DRAFT

COPY

Flow

switch

connection

electrical

7.

Valve

Parts

Seal

required

Replacement

Fig

12

6-station

(behind

manifold)

Main

Flow

Alcohol

check

Compressor

Disinfectant

Mac

main

Manifold

Switch

and

valves

Detergent

pump

valve

valve

Replacement

DSD-201

required 4 kits.

Tools

Allen

wrench

Allen

wrench

Valve

stem

John

Guest

Small

vise

Procedure

e

Lay

e

Note

valve

without

Required

9/64”

3/32”

wrench

Tool

grips

the

main

or

label

seal

kit

(4

re-circulation

MW03-0002

47049-157

or

small

channel

module

the

air

back

hose

seals,

option,

lock

on

the

that

connect

screws

and

requires 3 kits,

pliers

work

surface

the

loctite

Mac

valve

per

pack)

DSD-201

to

with

the

pneumatic

re-circulation

block

valves.

option

Page

13

of

32

Page 14

Annual

DSD-201

e

Usinga___

manifold.

e

Set

the

e

Pull

the

e

Use

the

loosen

release,

a

vice

screw

e

Ensure

mounting

e

Assemble

assemble

e

Tighten

16.

e

Reattach

with

your

deformation.

e

Repeat

station

PM

Instructions

Allen

Refer

valve

old

valve

the

retaining

do

grips

completely.

that the

area.

the

the

the

the

thumb,

the

above

water & disinfectant

to

on the

valve

seal

stem

not

attempted

pliers

and

valve

new

valve

valve

block

Do

not

wrench,

Figure

Refer

valve

seal

valve

tighten

procedure

work

surface

off

the

wrench

screw

unscrew.

to Fig

is

completely

seal

seal

to

retaining

to

the

over

13

tighten

remove

retaining

to

hold

in

the

center

to

remove

Once

15

apply

the

valve

screw

the

main

screws

for

each

valve.

DRAFT

the

four

so

the

valve

screw.

the

valve

of

with

released

clean;

one

drop

shaft.

until

manifold.

in a uniform

the

screws

valve

Refer

to

COPY

screws

the

the

remove

the

on

figure

holding

seal

is

facing

Refer

to

shaft

and

valve

seal.

wrench.

use the

any

of

Loctite

seal

deforms

While

diagonal

retaining

the A and B main

17.

the

up.

fig

14

using

the

If

the

Grip

the

3/32”

Allen

traces

of

to

the

screw

the

pressing

manner

screws.

top

valve

3/32”

screw

edges

wrench

Loctite

threads

shape.

down

to

manifold

to

the

Allen

does

not

of

the

to

from

Refer

on

the

minimize

and

main

wrench,

easily

screw

with

remove

the

and

to

block valve

the

the

screw

re-

Figure

the

side

B

Page

14

of

32

Page 15

Annual

DSD-201

PM

Instructions

DRAFT

Fig

14

COPY

Page

Fig

15

of

15

32

Page 16

Annual

DSD-201

PM

Instructions

DRAFT

COPY

Fig

17

“B"

Station

ASM1-0086

LOT#144581

Water & Disinfectant

Page

16

REV.D

of

32

manifold

Page 17

Annual

8.

DSD-201

Check

Each

DSD-201

the

B

station

a

check

valve

PM

valve

has

three

water

and

and

two

Instructions

replacement

check

valves

disinfectant

sealing

O-rings.

located

valves.

DRAFT

in

both

Each

check

COPY

the A and B main

valve

kit

MKO1-0068

manifold

is

comprised

and

two

in

of

Parts

Required

MK01-0068

DSD-201

Tools

Silicon

with

Allen

Grease

wrench

Procedure:

e

e

e

e

Qty

8

recirculation

With

the

main

retaining

Once

back

all

and

screws

four

forth

manifold.

With

the

block

imperative

Remove

both

holes

ends

on

the

both

requires

module

with a _Allen

retaining

gently

removed,

the

new

check

to

the

the

check

valve

check

check

12

on

lying

screws

to

release

note

valves

from

valve.

valve

check

on a table,

wrench.

are

the

the

be

the

The

block

valves.

remove

Refer

removed,

block

with

orientation

reinserted

check

valve

O-ring

and

may

the

to

figure

gently

the

of

the

in

the

block.

be

found

main

manifold.

the

four

18

rock

check

check

same

Remove

in

check

the

check

valves

valves.

direction.

the

both

the

valve

block

valve block

from

the

It

is

O-ring

from

check

main

valve

Page

17

of

32

Page 18

Annual

DSD-201

PM

Instructions

DRAFT

COPY

Fig

18

Fig

19

Page

18

of

32

Page 19

Annual

DSD-201

PM

Instructions

DRAFT

Fig

20

COPY

e

Insert

manifold.

valve

e

Insert

to

the

four

e

Repeat

manifold.

9.

Alcohol

Tools:

Small

Philips

Adjustable

Procedure:

e

wrench

Remove

coil,

21.

Retain

the

to

ease

the

main

screws

the

head

make

Older

this

new

O-rings

Coating

into

check

valves

manifold.

in a uniform

procedure

and

screw

the

large

note

of

DSD-201’s

spacer

into

check

the

the

O-ring

block

easier.

into

the

Insert

manner.

for

both

with a small

check

the

four

main

Detergent

driver

nut

on

top

of

the

the

position

will

for

reassembly.

of

have a spacer

valve

retaining

amount

valve

check

module

valve

alcohol and

the

coil.

washer

hole

of

block,

verifying

valve block

and

the

seal

detergent

Remove

the

located

and

the

hole

on

the

silicon

grease

the

retaining

“B”

station

will

allow

proper

direction.

screws

water & disinfectant

replacement

valves.

coil

by

between

Before

pulling

the

up.

coil

main

the

and

tighten

removing

Refer

to

and

valve

check

Attach

the

the

Figure

body.

Page

19

of

32

Page 20

Annual

DSD-201

e

Remove

Refer

to

e

Pull

the

press

back

e

Note:

lever;

e © Reattach

Each

this

PM

the

four

Figure

old

valve

onto

alcohol

will

the

valve

Instructions

Phillip

head

22.

seal

off

the

the

valve.

Refer

and

detergent

cause

the

valve

body

and

attach

screws

plunger

to

figure

valves

to

stay

the

DRAFT

from

the

valve

of

the valve.

23.

has a red

permanently

coil

and

COPY

and

lift

Obtain a mew

lever

on

open.

coil

retaining

the

valve

one

side.

screws.

off

valve

Do

the

manifold.

MV01-0035

not

rotate

and

the

Fig

Page

20

21

of

32

Page 21

Annual

DSD-201

PM

Instructions

Fig

DRAFT

22

COPY

10.

Disinfectant

Pump

Head

Page

21

replacement

of

32

Page 22

Annual

DSD-201

PM

Instructions

DRAFT

COPY

Tools

Large

John

Adjustable

required:

Phillips

Guest

Procedure

e

e

screw

driver

tool

wrench

for

Side

Disconnect

John

Guest

hoses

and

Refer

to

figure

the

motor assembly

head).

fittings

new

Remove

on

pump

A:

the

tool.

pump

the

input

head.

hose

from

Have a rag

head.

24

and

remove

(retain

the

pump

and

Discard

the

top

or

small

the

these

head.

output

the

pump

and

container

three

screws

Using

of

the

head.

bottom

screws

for

attaching

an

adjustable

pump

head.

of

the

ready

that

These

pump

to

capture

secure

the

replacement

wrench,

will

head

liquid

the

pump

remove

be

utilizing

reused

from

head

pump

the

on

the

two

the

to

the

Page

22

of

32

Page 23

Annual

DSD-201

PM

Instructions

DRAFT

COPY

Remove

three

these

screws

Remove

save

two

and

these

fittings

e

e

e

Unpack

three

screws.

shaft

from

Once

the

motor.

Apply

removed

Reattach

Refer

three

the

new

the

screws

to

from

the

pump

Please

motor

are

to

Figure

four

the

inlet

and

head

note

is

on

tighten,

25.

wraps

old

head.

outlet

Page

and

the

connection

an

eccentric,

the

of

Teflon

Reattach

hoses

23

of

32

fit

to

pump

tape

to

Fig

24

the

on

and

head

to

these

the

motor

the

will

will

the

threads

fittings

pump

assembly

pump

head

appears

line

properly

of

to

the

head.

using

to

be

the

new

the

that

not

with

two

pump

original

mates

with

centered.

the

pump

connectors

head.

the

Page 24

Annual

DSD-201

PM

Instructions

DRAFT

COPY

View

of

the

pump

head

side

that

mates

with

motor.

This

part

an

eccentric

and

will

not

center.

normal

type

head

of

This

for

pump

is

on

this

the

on

is

Procedure

for

side

e

Disconnect

John

hoses

e

Refer

the

head).

fittings

pump

ο

Rotate

e

Rotate

There

that

from

Discard

e

Apply

to

the

B:

Guest

and

to

motor

Remove

on

head.

the

the

is a

must

the

the

three

the

top

fitting

pump

figure

assembly

the

threaded

be

bottom

(output)

if

the

hose

tool.

Have a rag

head.

24

and

the

pump

input

silver

handle

three

way

coupling

retained

of

the

pump

head.

or

four

wraps

side

necessary.

from

the

remove

(retain

head.

and

output

on

valve

for

use

pump

Refer

of

of

the

top

and

or

small

the

three

these

screws

Using

of

the

the

three

counter

between

on

the

head

to

figure

Teflon

pump

bottom

container

screws

for

attaching

an

adjustable

pump

head.

way

valve

clockwise

the

pump

new

pump

for

reuse

27.

tape

to

the

head.

Apply

of

the

ready

that

These

90

degrees.

off

the

head

head.

on

the

threaded

Teflon

pump

head

to

capture

secure

wrench,

replacement

the

replacement

will

top

of

and

the

Remove

coupling

tape

the

pump

remove

be

Refer

the

three

the

to

utilizing

liquid

from

head

pump

the

reused

to

figure

pump

head.

way

coupling

pump

and

insert

both

ends

the

the

to

two

on

new

26

valve

head.

of

in

Page

24

of

32

Page 25

Annual

Three

rotated

position

the

valve

off

the

way

90

that

pump

valve

degrees

will

to

be

head.

DSD-201

e

e

e

handle

into

a

allow

rotated

PM

Screw

valve

Apply

removed

Reattach

Instructions

the

three

way

handle

three

to

from

the

90

degrees

four

the

inlet

wraps

old

and

valve

back

head.

outlet

DRAFT

back

on

to

of

Teflon

Reattach

hoses

top

the

original

tape

to

COPY

of

the

to

these

the

pump.

pump

position.

the

threads

fittings

to

head.

of

the

Return

the

two

new

pump

the

silver

connectors

head.

11.

Peristaltic

Pump

Retain

for

Tube

this

reuse.

Fig

threaded

27

coupling

Replacement

Page

25

of

32

Page 26

Annual

DSD-201

These

instructions

tubes.

PM

Instructions

should

be

followed

to

replace

DRAFT

the

COPY

detergent

and

alcohol

peristaltic

pump

Parts

Tools

Required

MT01-0500

Required

Phillips

John

Guest

Procedure

Place a small

disconnecting,

of

the

pump

The

two

housing

right

of

the

“A”

tubing

reassembly,

Peristaltic

Screw

Tool

alcohol

which

and

just

side

one

pump

Driver

container

small

amounts

tube.

pumps

is

in

the

behind

of

the

machine

at a time

label

each

Tube

or

rags

are

center

the

to

tube

Set

under

of

detergent

located

of

the

0.2

micron

and

the

avoid

before

each

of

the

and

alcohol

to

the

left

of,

machine.

filter

bottom

confusion

disconnection.

The

housing.

pump

with

tubing

connections

will

and

just

detergent

The

supply

the

plumbing.

be

lost

behind

pumps

top

pumps

the

“B”

when

during

the

0.2

are

on

side.

To

assist

replacement

micron

located

both

Replace

filter

to

side

the

with

the

supply

e

Identify

servicing.

e

Identify

e

Remove

pulling

gently

released.

e

Remove

e

Position

egual

e

Position

e

Lay

place

e

Replaced

e

Re-connect

and

and

the

pulling

length.

the

new

until

disconnect

remove

cover

to

tube

the

the

new

the

new

the

pinch

tube

the

tube

the

cover

the

expose

out

tube,

tube

tube

rollers

in

is

using

inlet

the

inlet

four

screws

pump

of

the

support

keep

set

from

over

the

as

in

the

recess

completely

the

and

outlet

Page

26

and

outlet

from

tube.

Remove

recess,

rotating

the

packaging.

pump

figure

29

and

rotate

installed.

screws

of

that

tubes

32

pump

and

head

were

that

tubing

covers.

the

rotate

pulling

so

that the

the

roller

Refer

removed

were

disconnected

from

Refer

tubing

the

pinch

until

the

inlet

as

you

to

figure

the

pump

to

Figure

from

the

roller

tube

and

feed

30.

earlier.

during

you

are

28.

pump

by

hand

is

completely

outlet

are

the

tube

removal.

hear

while

of

into

by

Page 27

Annual

DSD-201

e

PM

Priming

Instructions

of

the

pumps

will

DRAFT

be

performed

COPY

in

Section

14.

Remove

screws

these

Fig

28

Page

27

of

32

Page 28

Annual

DSD-201

PM

Instructions

DRAFT

COPY

12.

Preparation

Verify

all

work

Mechanical

Slide

Install

Hydraulic

Connect

Connect

Connect

Connect

Connect

Connect

valve

Reinstallation

is

complete

the A side

the

three

the

the

the

the

the

the

manifold

module

bolts

3/8”

3/8”

tube

3/8”

tube

3/8”

tube

check

check

side

on A side

out

that

air

line

to

to

to

valve

valve

of

the

of A side

module

of

secure

to

the A side 4 station

the A side

the

water

the

chamber

of

the A side

of

the A side

break.

the

unit.

the A side

flow switch.

valve

prior

valve

alcohol

detergent

Fig

30

Module

to

reinstallation.

main

module

Mac

valve

Refer

inlet

to A side

inlet

of A

line.

Refer

line,

leaving

to

manifold.

to

figure

valve

side

manifold.

to

figure

the

unit.

31.

manifold.

31.

the

check

Refer

valve

to

figure

with

31.

the A side

Electrical

Connect

the A side

flow

switch

electrical

connector.

Page

28

of

32

Refer

to

figure

31.

Page 29

Annual

Main

e

e

e

e

ο

e

valve

DSD-201

Connect

Connect

Reconnect

Connect

compressor

Connect

Connect

manifold

PM

Instructions

the A side 4 station

the A side

the A side

the

and

the A side

the A side

alcohol/detergent

compressor

spade

connector

the

air

disinfection

drain

tank.

valve

Mac

valve

manifold

connector.

connector

located

connections.

pump

on

connector

the

ve

DRAFT

connector.

black

wire

that

COPY

runs

between

the A side

Flow

switch

electrical

connection

4-station

Alcohol

tank

Air

Mac

Flow

and

detergent

check

pressure

pull

13.

Mechanical

Hydraulic

Valve

switch

valves

relief

ring

e | Slide

e

e

e

e

ο

e

Reinstallation

the B side

Insert

and

Reconnect

32.

Connect

Connect

Connect

Connect

Connect

the

the

the

the

the

module

tighten

the

3/8”

3/8”

3/8”

3/8”

check

check

of B side

into

the

three

air

line

tube

to

tube

to

tube

to

valve

of

valve

of

the B side

the

the

Fig

31

Module

the

unit.

bolts

that

secure

at

the B side 6 station

flow

switch.

water

valve

inlet

chamber

the B side

the B side

valve

alcohol

detergent

the B side

Mac

Refer

of

the B side

inlet

of

the B side

line.

Refer

line.

main

valve

to

Figure

to

module

manifold.

32.

valve

manifold.

manifold.

Figure

32.

to

the

Refer

Disinfection

(behind

compressor)

Compressor

unit

to

Figure

pump

Page

29

of

32

Page 30

Annual

Electrical

DSD-201

e

Connect

e

Disconnect

e

Disconnect

e

Disconnect

e

Disconnect

e

Disconnect

e

Disconnect

PM

the

3/8”

the B side

the B side

the B side

the B side

the B side

the B side

Instructions

tube

at

the

main

water

flow

switch

6-station

alcohol/detergent

compressor

chemical

disinfectant

electrical

Mac

connector.

load

pump

DRAFT

valve.

valve

manifold

connector.

switch.

connector.

COPY

connector.

connector.

Refer

to

Refer

figure

to

figure

32.

32.

14.

Final

Procedure:

Plug

the

up

correctly

Station A and

illuminated.

e

e

checks.

DSD-201

Open

Place a restrictor

power

and

is

Station B yellow

the

incoming

in

an

cord

idle

adaptor

back

state.

LED

water

into

the

Note:

the

indicators

supply

into

Page

valve.

each

30

of

Fig

12

power

unit

above

basin.

32

outlet.

is

in

the

and

Ensure

idle

below

that

state

the

the

when

LCD

machine

the

display

are

powers

not

Page 31

Annual

A.

B.

C.

D.

E.

F.

DSD-201

e

Fill

PM

the

reservoirs

instructions.

The

next

steps

will

appropriate

Using

pump

the

pump

Activating

e

e

Activating

e

valve

diagnostics

until fluid

and

run

appears

close

Side A Alcohol

Select

Station

Enter

diagnostics

valve

by

pressing

ENTER.

the

Once

pump

Side A Detergent

While

still

Activate

the

(detergent

restrictor,

Activating

Activating

Side B Alcohol

e | Select

e

Enter

diagnostics

valve

by

ENTER.

the

pump

Side B Detergent

e

While

Activate

restrictor,

e

Press

14,

CACNEL

Station

pressing

Once

still

the

ENTER

twice.

Commence a cycle

set

up

and

diagnostics

e

Cycle

parameters

e

e

e

e

e

Sensors

Proper

No

No

The

are

operation

leaks

occur

leaks

occur

external

requirements,

e

The

alcohol and

e

The

basins

Instructions

with

the

be

performed

or

alcohol)

the

appropriate

from

the

the

valves.

A.

fluid

and

valve.

in

diagnostics

pump

turn

off

B.

fluid

and

valve.

in

diagnostics

pump

turn

off

to

on

both

menus.

set

and

during

during

water

(35-40

detergent

fill

to

the

Repeat

pump:

by

pressing

12,

ENTER,

is

seen

pump:

by

pressing

the

pump

pump:

by

pressing

12,

ENTER,

is

seen

pump:

by

pressing

the

pump

open

sides,

are

adjusted

working

of

the

cycle.

the

the

pressure

PSI).

appropriate

DRAFT

disinfectant

once

the

unit

for

pump

scope

hook

the

above

88,

ENTER.

18,

ENTER.

coming

press

coming

press

the B side

performing

disinfectant

rinse

solutions

out

1,

ENTER,

19,

ENTER.

and

valves

88,

ENTER.

18,

ENTER.

out

1,

ENTER,

19,

ENTER.

and

valves

main

to

appropriate

properly.

cycle.

during

the

level

using

is

the

side

to

prime

up

of

of

the

cycle.

flush

are

during

by

by

Input

Then

the

which

Input

Then

the

which

water

injected

COPY

setup

1.

completely

of

the

machine

the

system.

or

restrictor.

process

Once

Once

following.

for

code

turn

the

restrictor,

opens

detergent

pressing

0,

code

turn

the

restrictor,

opens

detergent

pressing

0,

valve.

Refer

settings.

mode

meets

as

desired.

the

disinfectant

Refer

to

the

reassembled.

you

Continue

Once

fully

the

three

remaining

135,

ENTER.

pump

on

press

0,

Enter

the

valve,

then

is

seen

ENTER.

135,

ENTER.

pump

on

press

0,

Enter

the

valve,

then

is

seen

ENTER.

Exit

diagnostics

to

the

the

installation

REFER

and

use

manual

Open

are

working

running

primed,

Open

the

by

entering

to

18,

flowing

Open

the

by

entering

to

18,

flowing

by

service

TO

SECTION

rinse

phases.

for

the

on.

the

turn

off

pumps.

alcohol

3,

deactivate

Enter.

from

the

alcohol

3,

deactivate

Enter.

from

the

pressing

manual

for

Page

31

of

32

Page 32

Annual

DSD-201

e

No

e

When

located

plugged

order

step

b.

Ensure

During

the

housing

d.

Check

using

SETUP,

e.

Clean

PM

excessive

the

on

into

to

re-apply

where

that

the

the

cycle,

using

the

accuracy

2,

any

fluid

Instructions

noise,

fumes

disinfectant

the

inside

it.

Wait

it

had

DSD

ensure

the

of

ENTER

or

residue

cycle

back

five

AC

power.

stopped.

completes

that

bleeder

the

LCG

(for

the

from

or

orders

begins,

wall

of

seconds,

The

DSD

one

full

there

are

valve.

display

date)

and

the

cabinet

DRAFT

are

noted.

press

the

the

cabinet

and

then

depress

should

disinfection

no

for

date

SETUP,

resume

leaks inside the

and

3,

assembly.

COPY

TEST

and

cycle

time.

ENTER

button

has the

the

RESET

the

without

unit

If

incorrect,

(for

on

the

GFI

outlet

printer

transformer

button

Disinfectant

any

and

alarms.

bleed

cycle

any

reset

time).

on

the

which

the

GFI

from

air

from

valves

is

in

the

Page

32

of

32

Loading...

Loading...