Page 1

Service

Instructions

|

BASIC

036

Order

Nr.

190.0101b

MEDIAN

DOMINANT

046

056

medela

Page 2

Table

1.

2.

3.

4.

5.

6.

7.

of

Contents

Technical

Construction

Pneumatic

Electric

Trub

leshoot

Maintenance

Servicing

Dismat ing

Reassemb

Replacement

Service

Correcting

Spare

Drawings

Spare Parts

Parts

Data

Diagram

Circuit

ing

Procedures

and

ly

Piston/Cy

Flat-

Call

Indicator

an

List / Order

Diagrams

Cleaning

Linder

and

Toothed

Electronic

Piston/Cy

Unit

Be

Fault

Numbers

linder

lts

Unit

Page

3

4

5

6-

8-

9

10 - 13

10

11

11

11

12

13

14 - 19

14

17

Median

Dominant

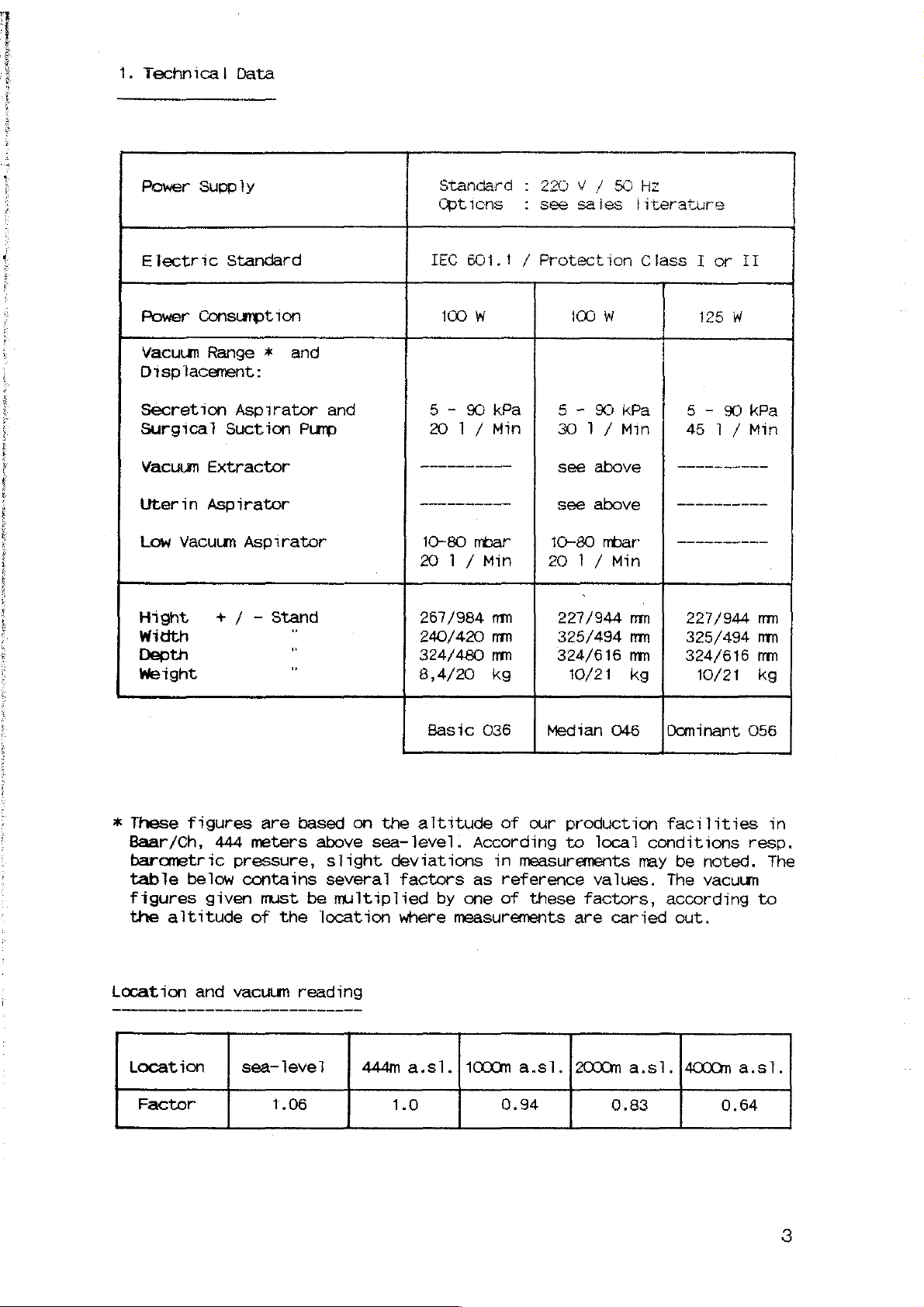

Page 3

.

Technica!

Data

Power

Electric

Power

Vacuum

Displacement:

Secretion

Surgical

Vacuum

Uterin

Low

Hight

Width

Depth

weight

Supply

Standard

Consumption

Range

Aspirator

Suction

Extractor

Aspirator

Vacuum

+ / -

Aspirator

*

Stand

and

Pump

.

and

Standard

Options

IEC

601.1 / Protection

100

W

5 - SO

20 1 /

| 一 一 一 一

一

一 一

10-80

20

267/984

240/420

324/480

8,4/20

mbar

1 / Min

kPa

Min

一

mm

mm

mm

kg

:

220 V /

:

see

5 -

30 1 /

see

see

10-80

20 1 /

227/944

325/494

324/616

sales

100

W

90

above

above

mbar

Min

10/21

50

Hz

literature

Class I or

kPa

Min

|

|

“|

m

mm

mm

kg

II

125

W

5 -

90

kPa

45 1 /

一

----------

-一 一 -一

227/944

325/494

324/616

10/21

Min

一 一 一

一

一

пт

mm

mm

kg

*

These

Baar/Ch,

barometric

table

figures

the

altitude

Location

Location

Factor

figures

444

pressure,

below

given

and

vacuum

are

based

meters

contains

must

of

the

reading

sea-

level

1.06

on

above

slight

several

be

multiplied

location

Basic

the

altitude

sea-level.

deviations

factors

where

According

as

by

one

measurements

1000m

036

of

our

in

measurements

reference

of

these

a.s1.1200Om

0.94

Median

046

|Dominant

production facilities

to

local

values.

factors,

are

conditions

may

The

according

caried

a.s1.|4000m

0.83

be

out.

noted.

vacuum

a.sl.

0.64

056

in

resp.

The

to

Page 4

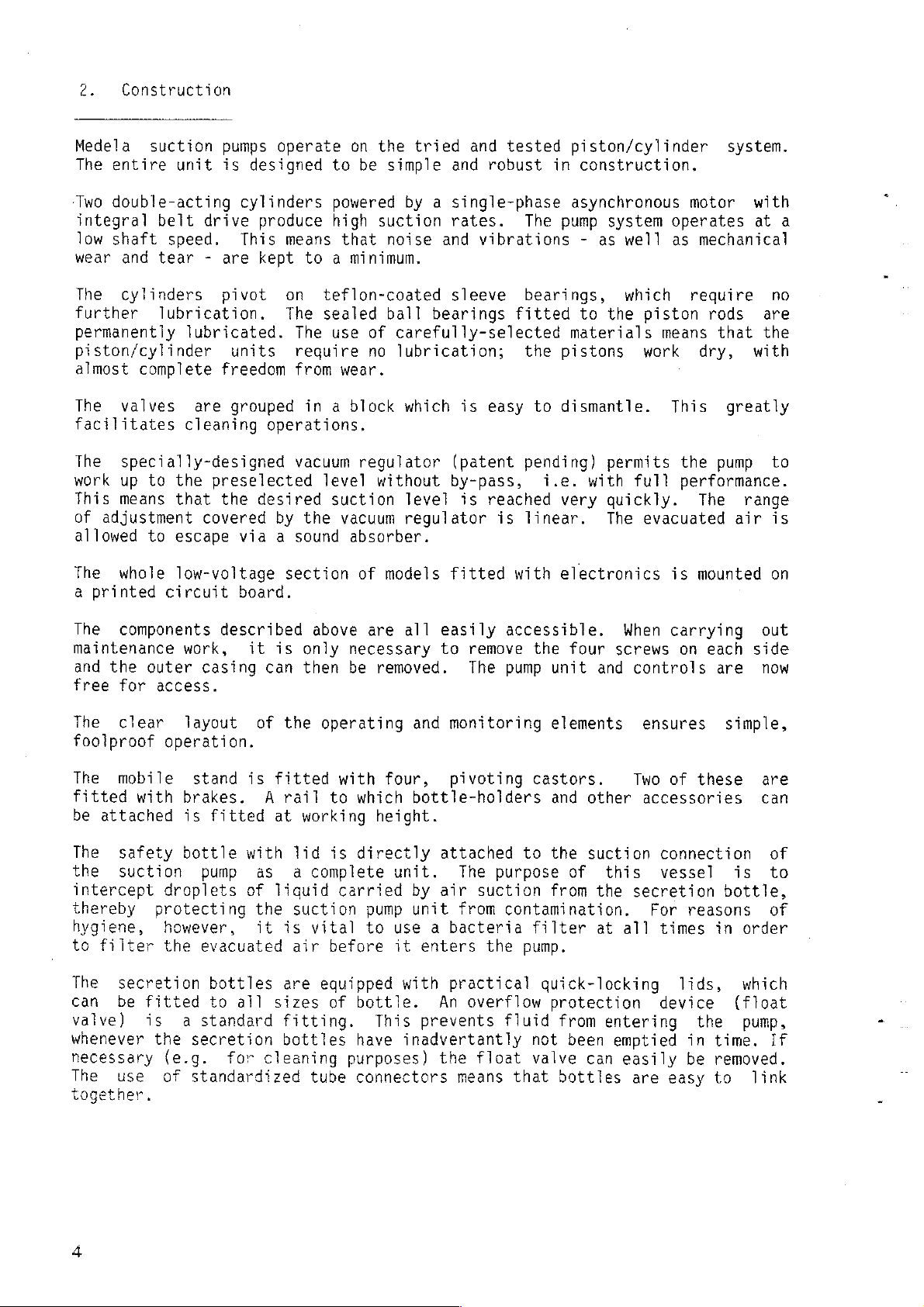

2.

Construction

Medela

The

‘Two

integral

low

wear

The

further

permanently

piston/cylinder

almost

The

suction

entire

double-acting

shaft

and

cylinders

unit

belt

speed.

tear - are

lubrication.

complete

valves

facilitates

The

specially-designed

work

This

of

The

a

up

means

adjustment

allowed

whole

printed

to

the

that

to

escape

low-voltage

circuit

pumps

is

designed

cylinders

drive

produce

This

kept

pivot

lubricated.

units

freedom

are

grouped

cleaning

preselected

the

desired

covered

via a sound

board.

operate

means

on

The

The use

require

from

on

to

powered

high

that

to a minimum.

teflon-coated

sealed

wear.

in a block

operations.

vacuum

level

suction

by

the

vacuum

absorber.

section

the

tried

be

simple

suction

noise

ball

of

carefully-selected

no

lubrication;

and

by a single-phase

rates.

and

sleeve

bearings

which

regulator

without

(patent

by-pass,

level

regulator

of

models

fitted

and

tested

robust

piston/cylinder

in

asynchronous

The

pump

vibrations - as

bearings,

fitted

materials

the

pistons

is

easy

to

dismantle.

pending)

i.e.

is

reached

is

with

very

linear.

electronics

construction.

to

system

well

which

the

operates

as

piston

means

work

This

permits

with

full

quickly.

The

evacuated

is

system.

motor

with

at

mechanical

require

rods

dry,

that

are

the

with

greatly

the

pump

performance.

The

range

air

mounted

a

no

to

is

on

The

components

maintenance

and

the

outer

free

for

The

clear

foolproof

The

mobile

fitted

be

The

the

with

attached

safety bottle

suction

intercept

thereby

hygiene,

to

filter

The

secretion

can

be

fitted

valve)

whenever

is a standard

necessary

The

together.

use

described

work,

casing

access.

layout

operation.

stand

brakes.

is

fitted

pump

droplets

protecting

however,

the

evacuated

bottles

to

the

secretion

(e.g.

of

for

standardized

above

it

is

only

can

then

of

the

operating

is

fitted

A

rail

to

at

working

with

lid

is

as a complete

of

liquid

the

suction

it is

all

air

are

sizes

vital

before

equipped

of

fitting.

bottles

cleaning

tube

are

all

necessary

be

removed.

with

four,

which

height.

directly

unit.

carried

pump

to

use a bacteria

it

with

bottle.

This

have

inadvertantly

purposes)

connectors

easily

to

and

monitoring

pivoting

bottle-holders

attached

The

by

air

unit

from

enters

accessible,

remove

The

pump

purpose

suction

contamination.

the

practical

An

overflow

prevents

the

means

fluid

float

that

the

four

unit

and

elements

castors.

and

other

to

the

suction

of

this

from

the

filter

pump.

at

quick-locking

protection

from

entering

not

been

valve

can

bottles

When

screws

controls

ensures

Two

accessories

connection

vessel

secretion

For

all

times

device

emptied

easily

are

carrying

on

each

are

of

these

reasons

in

lids,

the

in

time.

be

removed.

easy

to

out

side

now

simple,

are

can

of

is

to

bottle,

of

order

which

(float

pump,

If

link

Page 5

3.

Pneumatic

Diagram

Jdequosqy

punog

MOOLE

9ALBA

JEPULLÁD

BALUG

/

UOJSLd

O

UOLYDAUUOJ

UOLIONS

X

JOIN

UNNIEA

JOJE|NBBY

WNNOBA

Page 6

4.

Electric

A.

Without

circuit

electronics

diagrams

B.

Without

Protection

|

Ki

I/V

K

M

Schutzleiter

Getriebegehóuse

4

T

electronics

Class

|

Kit

|

/

|

|

K2

K2

E

\

II

„EP

Fw

FI

ES

TT

Schutzleiter

Geháuse

Fi

=

_FH1

ES»

F2

DI

「

|

|

|

|

IT

1

oe

Ld

「

|

si

|

|

|

|

È

|

K4 KS

7

|

(

M

)

“Aa

T

| |

| |

| |

+

|

|

|

+

(M

)

e

+

Los

K3

к

K5

С.

Without

connector

electronics,

for

foot

ion

Getriebegehduse

with

switch

FA

\Schutzleiter

Gehause

K15

pm

K

(a)

1

TT

/

KK 位 一

Fuss-Schalter

E

o

Li

2

Rel 2 Za

Е

o

K19

ОЗ

o

5

si

で

i

Page 7

D.

Without

(anaesthet

electronics,

ic-proof

)

АР

M

120

$

chutzleite:

Getriebegehduse

E.

Without

with

foot

7

|

V

X

г

electronics,

switch

e

LIE...

FH

F2

chutzteiter

Gehduse

AP

/

[2

1

ヒーーーー

blau

+

À

UA

|

|

71

7

/

κ

|

κό

|

|

4

y

K20

M

Schutzleiter

GetriebegehGuse

\"

E

4

the

\

—

F2

chutzieiter

GehGuse

LL

|

의

K12

=

|

K5

Page 8

F.

With

Bg

electronics

su

+

Ki

|

ュー

+

+

<a

1

т

KU

р

a

キーーー

ET

ee

ー

F2

FHI

Faz

|

er

La

1

BURSİN

|

|

|

|

|

|

ot

any

K7

si

|

n

1

lAs

K

1

|

K3a,

OI

À

G.

==>

With

st1

HA

e

Schutzleiter

Getriebegehůuse

electronics,

ки

|

A

N

D

IA

7

Schutzleiter

Getriebegehóuse

[|

AP

TES

一

レー

FI

ビー

Schutzleiter

Gehäuse

Ft

ュ

Fe

K

Schutzleiter

GehGuse

C1

κ.α.

La

A

|

51

SİNİ

^

7

«

~

(

Μ

Entlüftungs-

ventit

PT

|

|

|

|

L

o

Entiüf{ungs-

venti!

]

VET

VET

/

к

1

~

/

Ka

Ω

K6

|

|

|

|

1

K6

803

Bu?

st3

T

ué

|

iste

A

의

52

ul

Sté

16007

o]

|

Sté

3.

|

zg

|

pa

wh

|

|

bu

|

|

|

|

|

JU

E

|

245

1

status

.

1

S65jBus

3

MPG

|

|

|

|

D

|

|

|

|

SteBuê

(Bué

Externer

Schyester

Fülistand

Kİ

Service

8ut5|St45

к

-

>

|

|

|

|Finter

|

|

Exterer

Schalter

K7

gyz

Fülisland

[ция

고

還

KS

Service - |

|

80999

|

nota

|

оне

Lruf

24

エーー

ュ

Ban

|5

3

1

sumStT

H.

Foot

with

Switch

electronics

for

pumps

sus

5

4

m

i ㅣ

3

SH

59!

1

|

en

PT

|

Li

1

|

2

1

Page 9

5.

Troubleshooting

Problem

will

Motor

performance

suction

Inadequate

vacuum

a

run

not

however

Possible

Mains

Power

Electrical

Fuses

Drive

Electronic

Leak

external

External

Push-in

Safety

Air

Push-in

Tubing

Lids

Bottles

Bacteria

Filter

Internal

Tubing

Blockage

within

external

External

switch

supoly

unit

within

bottle

filter

paper

or

the

source

cord

jammed

fault

the

suction

cause:

connector

O-rings

O-rings

connectors

filter

cause:

mechanical

or

kink

pump

or

suction

cause:

of

trouble

pump

or

circuit

O-rings

housing

components

in

tubing

in

the

circuit

in

the

Check/action

Set

at

"ON"

Voltage,

Plug

connections,

cord

Type,

Summon

repair

See

Isolate

trouble

the

Section

Condition

Condition

Condition

No

Push

Cracks,

Airtight

Condition,

cracked

cracks

Condition,

leaks

Condition,

housing

Summon

repair

Isolate

trouble

Remove

from

suction

If

indicates

the

condition

page

checks

leaks

in

the

the

cause

technician,

service

by

6.

as

brittle

edges,

technician

service

as

the

pump;

connection

vacuum

to

power

type,

12/13

the

carrying

outlined

at

tube

far

fit

to

absence

position

source

follows:

safety

zero

is

external

be

socket

damaged

source

ends

as

stop

areas

bottle

passible

hairline

bottle

leave

gauge

vacuum

taken

plug

or

of

out

in

of

of

or

of

the

open,

now

=

suck,

indicates

not

gauge

does

Pump

Vacuum

Bacteria

Safety

Overflow

lid,

push-in

tubing,

Internal

Tubing

filter

bottle

valve

(float

connectors,

etc.

cause:

or

mechanical

in

valve)

the

components

Investigate

external

for

blockage(s),

valve

tubing

If

still

=

the

Summon

repair

sticking,

and

the

indicates

cause

service

the

suction

rectify.

vacuum

technician

is

internal

circuit

a

whole

float

kinked

gauge

vacuum

or

Page 10

6.

Maintenance

procedures

The

operating

To

by

as

pump

ensure

an

agent

belt

Servicing

The

following

end

of

this

General:

Disconnect

Release

Check

the

tear

the

flat

on

replaced

Check

Ensure

check

All

them

All

far

check

the

for

pieces

from

tubing

as

that

must

troublefree

hours

be

or

authorized

changing.

figures

manual.

the

electrical

the

eight

toothed

belt

the

according

sound

that

discoloration,

jamming

the

all

belt.

all

of

tubing

ends

stop,

pieces

(17).

absorber

tubing

must

given a routine service

at

screws

belt

If

the

to

the

or

kinking

extend

and

of

least

operation,

should

once

by

Medela.

refer

to

cord

(14)

(26)

after

Wipe

all

belt

special

(80)

connections

cracks

be

anywhere.

over

must

be

tubing

every

the

(7)

and

year.

repairs

This

also

drawings

from

remove

removing

surfaces

indicates

instructions.

and

remove

are

or

defective

of

adequate

the

full

free

are

from

routed

at

intervals

to

the

includes

and

the

mains

the

pump

the

free

of

excessive

any

dirt

clean,

connectors.

length

length

cracks.

freely

pump

the

supply.

housing

cover

dust

signs

if

both

and

of

By

without

of

approximately

may

only

cylinder

spare

parts'

(2).

plate

resulting

of

(43).

wear,

necessary.

inside

and

Replace

routed

the

connector

pulling

any

be

carried

cleaning

list

Also

from

it

outside,

if

necessary.

so

as

to

ferrule

on

them

kinks.

as

at

wear

must

prevent

gently,

1,000

out

well

the

check

and

be

and

as

ee

Enea

It

is

vital

that

only

ends

ensure

(3,10)

Valve

Undo

the

are

pushed

that

are

block:

the

tubing

genuine

knurled

replacements

compressed

prior

reassembly,

Please

If

that

Please

(53,

the

to

note:

sound

the

take

57,

valves

dismantled

Electrical

Ensure

Make

In

switch

Check

that

certain

the

case

housing

fuses

when

replacing a piece

Medela tubing

the

free

well

to

onto

pieces

move

nuts

if

the

or

cleaning

air.

Wash

reassembly.

dust

all

used

absorber

(62 - 65)

note

of

the

75)

to

the

and

cleaned

connections:

all

screw-

that

all

of AP

models

are not

(86).

the

ferrules

of

tubing

without

(4)

and

remove

inspection

are

required.

off

any

stubborn

Replace

and

new

(80)

and

the

and

the

section

vacuum

regulator

according

and

push-on

wiring

damaged,

insulation

(non-electronic),

of

tubing:

is

used

for

internal

as

far

(61,66)

any

kinks

measures

the

which

when

valve

Clean

dirt

any

damaged

rubber

tubing

pump

on

"Piston/cylinders"!

to

connections

i.e.

components

are

cylinder(s)

(73/74)

the

detail

is

intact

in

perfect

connections,

as

the

stop.

come from

the

motor

assembly

described

off

all

parts

with cold

rubber

Tightly

contaminated,

(3/10)

are

dirty,

drawing.

are

not

and

free

check

that

condition.

It is

the

(28)

(62-65).

above

of

water

seals

with

it

require

If

the

the

loose.

from

the

seals

pump

is

running.

indicate

the

and

dry

(63).

talc.

must

pieces

latter

damage.

and

that

important

cylinders

Only

remove

valves

all

Prior

be

assumed

cleaning.

of

tubing

must

on

the

the

to

that

with

items

to

et

be

power

10

Page 11

Piston/cylinder

unit:

dismantling

and

cleaning

Remove

Tne

to

cover

not

Dirt

agents!).

sealed

the

cylinders

the

cylinder

(104)

usually

and

deposits

The

for

screw

can

necessary

agents.

Black

a

black

surfaces.

polished

Warning:

surface-treated

discolorations

sign

of

powder

in

satisfactory

Using emery

the

The

Piston/cylinder

Warning:

No

lubricants

(49)

(3,10)

end

now

ball

life

and

is

the

direction

cylinder

and

unit:

together

can

covers

be

removed

to

can

be

bearing

must

on

the

lubrication

result

cloth,

wall

must

be

reassembly

may

be

removed

(91,92)

carry

removed

in

on

no

cylinder

of

extremely

the

of

piston

handled

be

used

with

spacers

by

and the

after

out any

and the

the

with

the

integral

account

wall

and

corresponding

travel.

accordingly.

in

the

(46 - 48).

gentle

pressure

cranks

screws

further

lukewarm

piston

come

should

small,

piston

into

(96)

not

course

Slacken

applied

(105).

(93)

have

dismantling

water

or

but

areas

rod

of

(do

rod/big

contact

on

the

be

removed.

sharp

should

have been

the

The

been

operations.

not

use

end

with

piston

The

ridges

be

very

following

screw

lower

released.

unit

on

very

(106).

simultaneously

cylinder

It is

any

cleaning

(105)

any

cleaning

rod

(105)

presence

the

rubbing

carefully

carefully

operations!

is

are

of

Reassemble

When

cold,

a

force

to

ensure

that

the

Replacement

If,

during

discovered

question

Flat

belt:

Rotate

the

Fit a new

motor

.

it,

the

Toothed

To

is

does

belt

belt:

change

instructions

flange

tension

cannot

The

attention

ring

is

be

drive

the

cylinders

it

must

of

between 6 -

that

two

must

the

cranks

of

flat-

servicing,

and/or

be

flat belt

belt

running,

not

centres

the

using

do

so,

toothed

above.)

(38)

determined

altered.

mechanism

to

the

be

possible

10

fine

coating

are

offset

and

the

inner

replaced.

pulley

the

i.e.

adjust

itself

during

belt

Then

via

the

by

the

is

reassembled

above

instructions

(3,10)

to

kg.

by

toothed

excessive

belt

(16)

same

method.

it

must

the

position

running,

(26),

unscrew

screws

distance

in

the

slide

The

on

the

90°.

belts

wear

face

by

not

first

(39)

reverse

the

piston

cylinders

sleeve

and

tear

shows

hand

and

The

belt

run

over

of

the

belt

remove

(40)

the

and

change

and

position

in

the

reverse

on

cylinder/piston

order

rods

must

be

bearings

(fine

clear

signs

withdraw

should

the

edge

motor

tension

the

cylinder

bearing

the

of

order.

to

that

described

(105)

refitted

is

not

rubber

of

wear,

the

belt

centre

of

the

via

the

is

automatically

(3).

cover

toothed

the

reassembly.

(41).

belt

toothed

Please

up

and

with

great

damaged!

particles)

the

(17)

itself

drive

screws

when

shaft.

(Refer

Remove

(26).

pulleys

pay

above.

down with

care

Ensure

are

belt

in

sideways.

the

If

(12).

If

correct.

to

the

the

Belt

and

careful

T

Page 12

Service

A.

Models

The

alarm

(bottles

—

Return

agent

described

-

The

also

triggered

-

The

also

B.

Models

call

indicator

without a liquid

indicates

not

emptied/mechanical

the

pump

for

dismantling

on

pages

internal

be

fuse

cancel

with a liquid

liquid

cleaned

off

again.

on

the

the

that

to

the

10/11.

sensor

and

dried,

back

of

visual

crystal

moisture

technical

and

cleaning.

(see

otherwise

the

service

crystal

display:

has

overflow

department

item

circuit

alarm.

display:

gained

The

access

valve

work

disassembled)

or a Medela

to be

121 / pages

the

same

board

must

(see

illustration

to

done

14/19)

service

be

replaced.

the

service

is

must

alarm

suction

.

will

This

p.

13)

unit

be

will

Several

with

-

Press

the

the

appear

alarm)

meaning:

reasons

aid

of

the

keys

vacuum

0 = No

1 = The

4 = Moisture

extractor

on

the

will

service

changed

(7)

display.

appear,

battery

(bottles

disassembled).

-

Return

service

done

~

The

internal

14/19)

same

-

For

resetting

and

briefly

circuit

means

now

ready

for

this

integral

and

has

not

the

agent

is

described

must

service

board.

of an

alarm

(2)

on

simultaneously.

When

together

required

on

the

gained

are

possible.

diagnostic

the

low

released, a symbolic

with

(as

there

PCB

(for

access

emptied/mechanical

pump

to

the

technical

for

desmantling

on

pages

liquid

also

alarm

the

sensor

be

cleaned

will

electronics,

short-circuit

This

resetting

acoustic

for

operation

signal

program

vacuum

a

to

pump

An

"S"

number

is

no

memory

the

overflow

and

10/11.

(see

and

be

triggered

switch

connections

operation

and

again.

The

cause

(*).

resp.

for

"Service"

"G"

with

alarm

and

suction

department

cleaning.

item

dried,

the

the

timer)

valve

121 / pages

otherwise

off

on

39

electronic

can

be

(1)

and

(reason

following

condition)

must

unit,

e.g.

or a Medela

The

again.

the

pump

and

54

is

acknowledged

system

traced

(3)

will

be

work

the

(K)

on

now

for

to

the

on

the

be

by

is

*

Note:

During

Return

pump)

12

the

to

resp.

diagnostic

normal

key 1 (vacuum

operation

phase,

extractor)

the

is

"Start/Stop"

effected

by

three

key

pressing

times.

cannot

key 7 (low

be

used.

vacuum

Page 13

correcting

A.

The

"Start/stop"

-

Check

~

Probably,

on

the

programs

eliminates

an

fuses

vacuum

the

electrical

(L).

keys

(7)

extractor

electronics

normal

key

does

The

main

and

control

fault

not

switch

(2)

on

were

to a help

functions.

funtion:

(K)

the

low

pressed

must

be

vacuum

simultaneously

setting

for

set

to

pump

resp.

servicing

"ON",

by

mistake.

(1)

and

purposes

(3)

This

and

Press

controlled

the

key

(7)

resp.

again

using

FRS

(a

|

INTERVAL

MEA

indicate

that

mains

unit

supply.

to

AO

B.

Electronics

-

It

is

peak

-

Connect

la)

possible

in

the

the

key

(1)

three

the

"Start/stop"

(a),

Lola

malfunctions:

supply.

other

the

programming

the

mains

times.

has

Set

key.

been

switch

The

pump

E

affected

(K)

can

now

he

by a voltage

set

to

"ON"

-

Briefly

operation

-

If

after

to

carried

short-circuit

is

the

electronic

this

has

restarting,

out

first

PCB-connections

acknowledged

system

been

done,

the

resetting

(shorting

by

means

does

the

operation

PCB-

of

not

return

circuit

connections

39

and

an

acoustic

to

normal

board

must

described

54.

This

signal.

be

above

39/54).

resetting

operation

replaced.

must

even

Prior

also

be

Loading...

Loading...