Page 1

Model 9116

Intelligent Pressure Scanner

User’s Manual

August 2007

NetScanner™ System

www.PressureSystems.com

Page 2

Pressure Systems, Inc. Model 9116 User’s Manual

REVISION REVISION HISTORY PRINT DATE

1

Updated manual terminology and deleted all

April 2004

references to UDP Query and to O-ring part

numbers.

2 Update terminology November 2004

3 Update commands August 2007

©This User’s Manual is a copyright product of Pressure Systems, Inc. , 2007.

Permission is hereby granted to make copies and distribute verbatim copies of this manual,

provided the copyright notice and this permission notice are preserved on all copies.

Page i www.PressureSystems.com

Page 3

Pressure Systems, Inc. Model 9116 User’s Manual

Table of Contents

Chapter 1: General Information ...........................................................................................1

1.1 Introduction ..............................................................................................................1

1.2 Description of the Instrument ....................................................................................... 2

1.2.1 Differences Between Models 9016 and 9116................................................... 3

1.3 Options.........................................................................................................................5

1.3.1 Pressure Ranges.............................................................................................. 5

1.3.2 Manifolds and Pressure Connections............................................................... 5

1.3.3 Communication Interfaces................................................................................ 6

Chapter 2: Installation and Set Up ......................................................................................7

2.1 Unpacking and Inspection............................................................................................ 7

2.2 Safety Considerations ..................................................................................................7

2.3 Preparation for Use ......................................................................................................7

2.3.1 Environment .....................................................................................................7

2.3.2 Power ............................................................................................................... 8

2.3.3 Mounting and Module Dimensions ................................................................... 9

2.3.4 Network Communications Hookup ................................................................... 9

2.3.4.1 Ethernet Host Port Hookup................................................................ 9

2.3.5 Diagnostic Port Hookup.................................................................................... 13

2.3.6 Pressure Connections ......................................................................................13

2.3.6.1 RUN Mode Inputs .............................................................................. 14

2.3.6.2 CAL Mode Inputs............................................................................... 15

2.3.6.3 PURGE Mode Inputs ......................................................................... 15

2.3.6.4 LEAK Mode Inputs.............................................................................16

2.3.6.5 Supply Air .......................................................................................... 16

2.3.7 Case Grounding ............................................................................................... 17

2.3.8 Trigger Input Signal ..........................................................................................17

2.3.9 Power Up Checks and Self-Diagnostics........................................................... 17

Chapter 3: Programming and Operation ............................................................................18

3.1 Commands & Responses ............................................................................................18

3.1.1 Introduction....................................................................................................... 18

3.1.1.1 TCP/UDP/IP Protocols....................................................................... 18

3.1.2 Commands ....................................................................................................... 19

3.1.2.1 General Command Format ................................................................19

3.1.2.2 Command Field ................................................................................. 20

3.1.2.3 Position Field ..................................................................................... 20

3.1.2.4 Datum Fields......................................................................................21

3.1.2.5 Format Field.......................................................................................21

Page ii www.PressureSystems.com

Page 4

Pressure Systems, Inc. Model 9116 User’s Manual

Table of Contents (continued)

3.1.3 Responses ....................................................................................................... 22

3.1.3.1 Interpreting Offset Values (Re-zero Calibration Adjustment)............. 23

3.1.3.2 Interpreting Gain Values (Span Calibration Adjustment) ................... 23

3.1.3.3 Interpreting Engineering Units Output ............................................... 23

3.1.4 Functional Command Overview ....................................................................... 23

3.1.4.1 Startup Initialization ...........................................................................24

3.1.4.2 Module Data Acquisition.................................................................... 24

3.1.4.3 Calibration Adjustment of Offset/Gain Correction Coefficients .......... 25

3.1.4.4 Delivery of Acquired Data to Host...................................................... 26

3.1.4.5 Network Query and Control Functions............................................... 27

3.1.4.6 Other Functions ................................................................................. 27

3.2 Detailed Command Description Reference.................................................................. 28

TCP/IP Commands

Power Up Clear (Command ‘A’) ....................................................................... 29

Reset (Command ‘B’) ....................................................................................... 30

Configure/Control Multi-point Calibration (Command ‘C’) ................................31

Sub-command Index 00: Configure & Start Multi-Point Calibration.............. 32

Sub-command Index 01: Collect Data for a Calibration Point ...................... 34

Sub-command Index 02: Calculate & Apply Correction Coefficients............ 36

Sub-command Index 03: Abort Multi-Point Calibration................................. 38

Read Tranducer Voltages (Command ‘V’)........................................................39

Calculate and Set Gains (Command ‘Z’).......................................................... 41

Read Transducer A/D Counts (Command ‘a’).................................................. 43

Read High-Speed Data (Command ‘b’)............................................................ 45

Define/Control Autonomous Host Streams (Command ‘c’) .............................. 46

Sub-command Index 00: Configure a Host Delivery Stream........................ 48

Sub-command Index 01: Start Streams(s) ................................................... 52

Sub-command Index 02: Stop Stream(s) ..................................................... 54

Sub-command Index 03: Clear Stream(s) .................................................... 55

Sub-command Index 04: Return Stream Information ...................................56

Sub-command Index 05: Select Data in a Stream .......................................58

Sub-command Index 06: Select Protocol for Stream Delivery .....................61

Calculate and Set Offsets (Command ‘h’) ........................................................ 63

Read Temperature Counts (Command ‘m’) .....................................................65

Read Temperature Voltages (Command ‘n’).................................................... 67

Read Module Status (Command ‘q’) ................................................................69

Read High-Precision Data (Command ‘r’) ........................................................ 72

Read Transducer Temperature (Command ‘t’)................................................. 74

Read Internal Coefficients (Command ‘u’)........................................................76

Download Internal Coefficients (Command ‘v’) ................................................80

Set/Do Operating Options/Functions (Command ‘w’).......................................83

UDP/IP Commands

Network Query (UDP/IP Command ‘psi9000’) .................................................87

Re-Boot Module (UDP/IP Command ‘psireboot’) ............................................. 89

Change Module’s IP Address Resolution Method & Re-Boot

(UDP/IP Command ‘psirarp’) ............................................................. 90

Page iii www.PressureSystems.com

Page 5

Pressure Systems, Inc. Model 9116 User’s Manual

Table of Contents (continued)

Chapter 4: Calibration ...........................................................................................................91

4.1 Introduction .................................................................................................................. 91

4.2 Re-Zero Calibration...................................................................................................... 93

4.2.1 Re-Zero Calibration Valve Control....................................................................93

4.2.2 Re-Zero Calibration Summary.......................................................................... 94

4.3 Span Calibration........................................................................................................... 94

4.3.1 Span Calibration Valve Control ........................................................................95

4.3.2 Span Calibration Summary ..............................................................................96

4.4 Integrated Multi-Point Calibration Adjustment.............................................................. 98

4.4.1 Multi-Point Calibration Valve Control................................................................ 98

4.4.2 Multi-Point Calibration Summary...................................................................... 99

4.5 Coefficient Storage....................................................................................................... 100

4.6 Line Pressure Precautions ...........................................................................................101

Chapter 5: Service .................................................................................................................102

5.1 Maintenance................................................................................................................. 102

5.1.1 Common Maintenance ..................................................................................... 104

5.1.2 Module Disassembly ........................................................................................105

5.1.3 Electronic Circuit Board Replacement.............................................................. 105

5.1.3.1 PC-327 Analog Board .........................................................................106

5.1.3.2 PC-322/323 Main Board/Power PC Daughter Board Assembly.......... 106

5.1.3.3 Remove and Replace PC-323 on PC-322........................................... 108

5.1.4 Replacement of Transducers ...........................................................................109

5.1.5 Calibration Valve Solenoid Replacement ......................................................... 110

5.1.6 Replacement of O-Rings .................................................................................. 111

5.1.6.1 DH200 Pressure Transducer O-Ring Replacement ............................ 112

5.1.6.2 Tubing Plate O-Ring Replacement...................................................... 113

5.1.6.3 Adapter Plate O-Ring Replacement .................................................... 114

5.1.6.4 Calibration Manifold Piston O-Ring Replacement ............................... 115

5.1.6.5 Solenoid Valve O-Ring Replacement .................................................. 116

5.2 Upgrading Module Firmware........................................................................................ 117

5.2.1 Upgrading Firmware Via Host TCP/IP Port ...................................................... 117

Page iv www.PressureSystems.com

Page 6

Pressure Systems, Inc. Model 9116 User’s Manual

Table of Contents (continued)

Chapter 6: Troubleshooting Guide...................................................................................... 118

6.1 Ethernet Module Troubleshooting ................................................................................118

6.1.1 Checking Module Power-Up Sequence............................................................118

6.1.2 Checking Module TCP/IP Communications .....................................................119

6.1.2.1 Module IP Address Assignment ..........................................................119

6.1.2.2 Host IP Address Assignment for Windows® 95/98/2000/XP/NT......... 120

6.1.2.3 Verifying Host TCP/IP Communications..............................................121

6.2 Zero and Gain Calibration Troubleshooting ................................................................. 122

6.3 User Software .............................................................................................................. 123

Chapter 7: Start-up Software ................................................................................................124

7.1 Introduction .................................................................................................................. 124

Appendices:

Appendix A: All Commands – Quick Reference .....................................................................125

Appendix B: Model 9116 Response Error Codes ................................................................... 126

Appendix C: Cable Diagrams.................................................................................................. 127

Appendix D: 9116 Mounting Dimensions................................................................................ 129

Appendix E: Model 9116 Range Codes.................................................................................. 130

Appendix F: NetScannerAppendix D: 9116 Mounting Dimensions........................................ 132

Appendix G: Binary Bit Map.................................................................................................... 133

Page v www.PressureSystems.com

Page 7

Pressure Systems, Inc. Model 9116 User’s Manual

Preface

This manual describes the NetScanner

9116). It does not cover the pressure scanner Models 9016, 9021, 9022, the 98RK Scanner

Interface Rack, Model 9816 Intelligent Pressure Scanner, nor Models 903x (Pressure

Standards/Controllers. These products are covered in their individual User’s Manuals.

This manual is divided into six (6) chapters and several appendices, each covering a specific

topic. They are summarized below:

Chapter 1: General Information describes Model 9116 Intelligent Pressure

Chapter 2: Installation and Set Up describes the unpacking and inspection of a

Chapter 3: Programming & Operation provides the information needed to program a

Chapter 4: Calibration describes methods of calibrating a module.

Chapter 5: Service describes general safety precautions and

Chapter 6: Troubleshooting describes module troubleshooting techniques.

Chapter 7: Start-up Software briefly describes NUSS software.

Appendix A: All Commands — Quick Reference

Appendix B: Response Error Codes

Appendix C: Cable Diagrams

Appendix D: Module Mounting Dimensions

Appendix E: NetScanner System Range Codes

Appendix F: NetScanner

™

System Products

Appendix G: Binary Bit Map

™

System Intelligent Pressure Scanner module (Model

Scanner and its various options.

module, and its connection to power, pressure,

and a communications network.

module from a host computer and to get

meaningful data from it.

maintenance procedures.

Page vi www.PressureSystems.com

Page 8

Pressure Systems, Inc. Model 9116 User’s Manual

Our Company

Pressure Systems Incorporated, (PSI) develops, manufactures, and services level and pressure

measuring instruments where the highest level of traceable accuracy is required for aerospace,

industrial, municipal, and environmental applications. Our products have become the world

standard for electronic level and pressure measurement and scanning. We are committed to

the highest quality design, manufacture, and support of level and pressure instrumentation that

is in the best interest of our customers. PSI is an ISO-9001:2000 certified company.

Our Warranty

Pressure Systems, Inc., warrants NetScanner

material and workmanship under normal use and service for one (1) year.

™

System products to be free of defects in

Technical Support

Monday through Friday, during normal working hours, (7:30 am through 5:30 pm, Eastern time)

knowledgeable personnel are available for assistance and troubleshooting. Contact the

Applications Support Group or the Customer Services Department at Pressure Systems

(757-865-1243 or toll free 1-800-328-3665) if your scanner is not operating properly or if you

have questions concerning any of our products. E-mail assistance is available by contacting

Applications@PressureSystems.com.

Merchandise Return Procedures

If your scanner needs to be returned to Pressure Systems, obtain a Returned Merchandise

Authorization (RMA) from the Customer Service Department.

Be prepared to supply the following information when requesting the RMA:

• Part number

• Serial number

• Complete description of problems/symptoms

• Bill To and Ship To address

• Purchase order number (not required by PSI warranty repairs)

• Customer contact and telephone number

The above information, including the RMA number must be on the customer’s shipping

documents that accompany the equipment to be repaired. PSI also requests that the outside of

the shipping container be labeled with the RMA number to assist in tracking the repairs. All

equipment should be sent to the following address:

ATTN: PSI REPAIR DEPARTMENT (7-digit RMA number)

Pressure Systems, Inc.

34 Research Drive

Hampton, Virginia 23666

Page vii www.PressureSystems.com

Page 9

Pressure Systems, Inc. Model 9116 User’s Manual

PSI will return warranty items prepaid via UPS GROUND. If the customer desires another

method of return shipment, PSI will prepay and add the shipping charges to the repair bill.

Incoming freight charges are the customer’s responsibility. The customer is also responsible for

paying shipping charges to and from PSI for any equipment not under warranty.

All products covered under the PSI warranty policy will be repaired at no charge. An analysis

fee will be charged to quote the cost of repairing any item not under warranty. If, for any

reason, the customer decides not to have the item repaired, the analysis fee will still be

charged. If the quote is approved by the customer, the analysis fee will be waived. The quote

for repair will be based on the PSI flat rate for repair, calibration, and board replacement. When

these prices do not apply, the quote will be based on an hourly labor rate plus parts. All

replaced parts are warranted for 90 days from the date of shipment. The 90-day warranty is

strictly limited to parts replaced during the repair.

Website and E-Mail

Visit our website at www.PressureSystems.com to look at our new product releases, application

notes, product certifications, and specifications. E-mail your questions and comments to us:

Sales@PressureSystems.com

.

Our Firmware

This manual was prepared for various versions of module firmware as were released at

the time of this manual publication. Addenda will be distributed as deemed necessary

by PSI. Any questions regarding firmware upgrades may be addressed to the

Applications Support Group. Firmware revisions, manual addenda, and utility

software may also be obtained from the PSI web page at www.PressureSystems.com.

Our Publication Disclaimer

This document is thoroughly edited and is believed to be thoroughly reliable. Pressure

Systems, Inc., assumes no liability for inaccuracies. All computer programs supplied

with your products are written and tested on available systems at the factory. PSI

assumes no responsibility for other computers, languages, or operating systems. PSI

reserves the right to change the specifications without notice.

Page viii www.PressureSystems.com

Page 10

Pressure Systems, Inc. Model 9116 User’s Manual

Chapter 1

General Information

1.1 Introduction

This User’s Manual will:

! Explain the electrical and pneumatic pressure connections for the Model 9116 Intelligent

Pressure Scanner.

! Provide computer set-up instructions to make a proper Ethernet connection on most

Windows

! Instruct you on using the PSI start-up software to manipulate and acquire data from each

module.

! Instruct you on how to program each module with computer software.

Model 9116 is a pneumatic Intelligent Pressure Scanner, with integral pressure transducers and

a pneumatic calibration manifold.

The Model 9116 provides engineering unit pressure data with guaranteed system accuracy.

This is achieved by reading factory-determined pressure and temperature engineering-unit data

conversion coefficients from its transducers’ nonvolatile memories at power-up. It also allows

additional adjustment coefficients to be “fine-tuned” with a multi-point calibration under host

control (e.g., possibly utilizing optional Pressure Systems 903x Pressure Calibrator modules).

Model 9116 provides an auto-configuring 10BaseT/100BaseT Ethernet communications port.

Half duplex/full duplex operation is also automatically configured. The Model 9116

communicates using the TCP/UDP/IP protocols.

The Model 9116 Intelligent Pressure Scanner is a component of a networked data acquisition

concept called the NetScanner™ System. Multiple NetScanner modules measuring a wide

variety of parameters can be networked to form a distributed intelligent data acquisition system.

®

95/98/XP/NT-based personal computers.

Page 1 www.PressureSystems.com

Page 11

Pressure Systems, Inc. Model 9116 User’s Manual

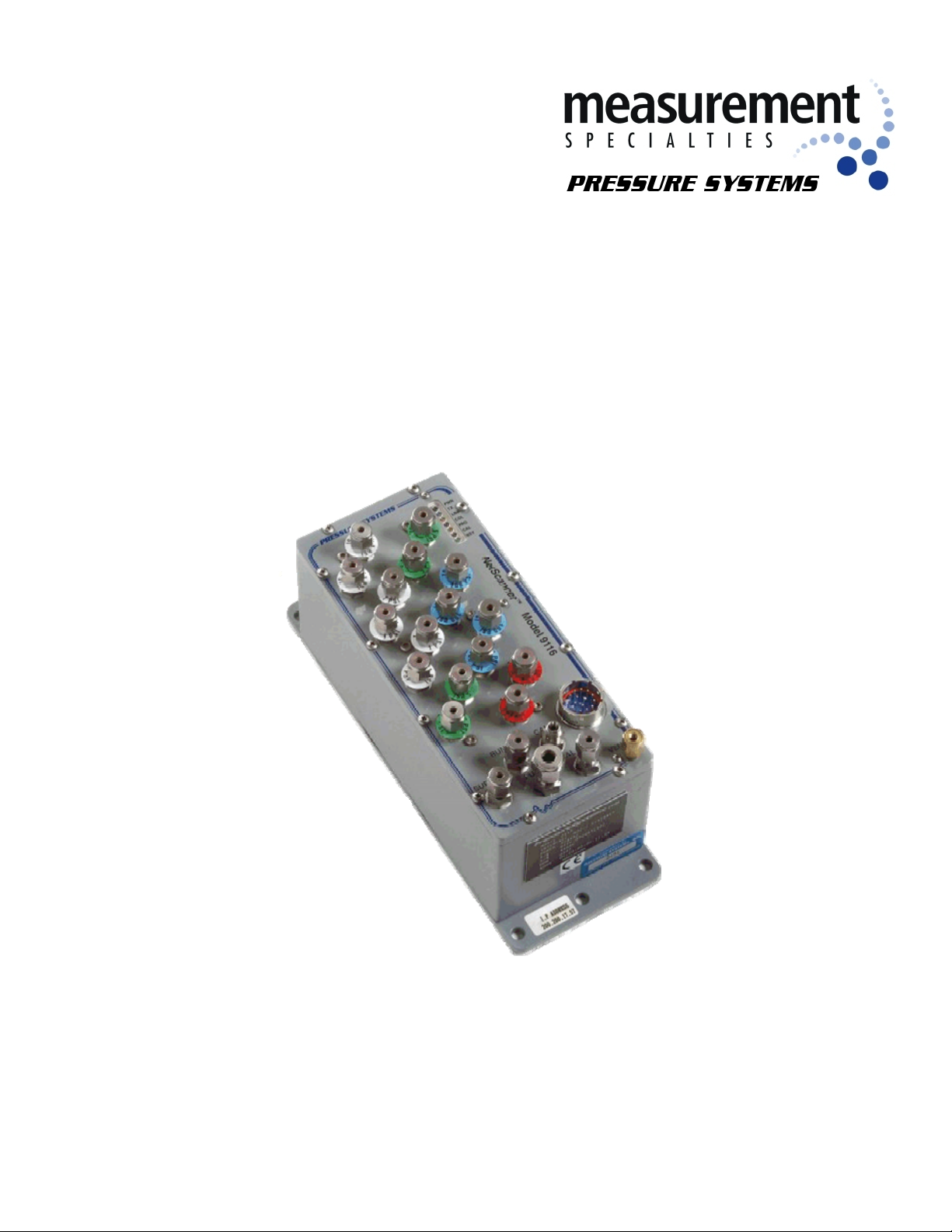

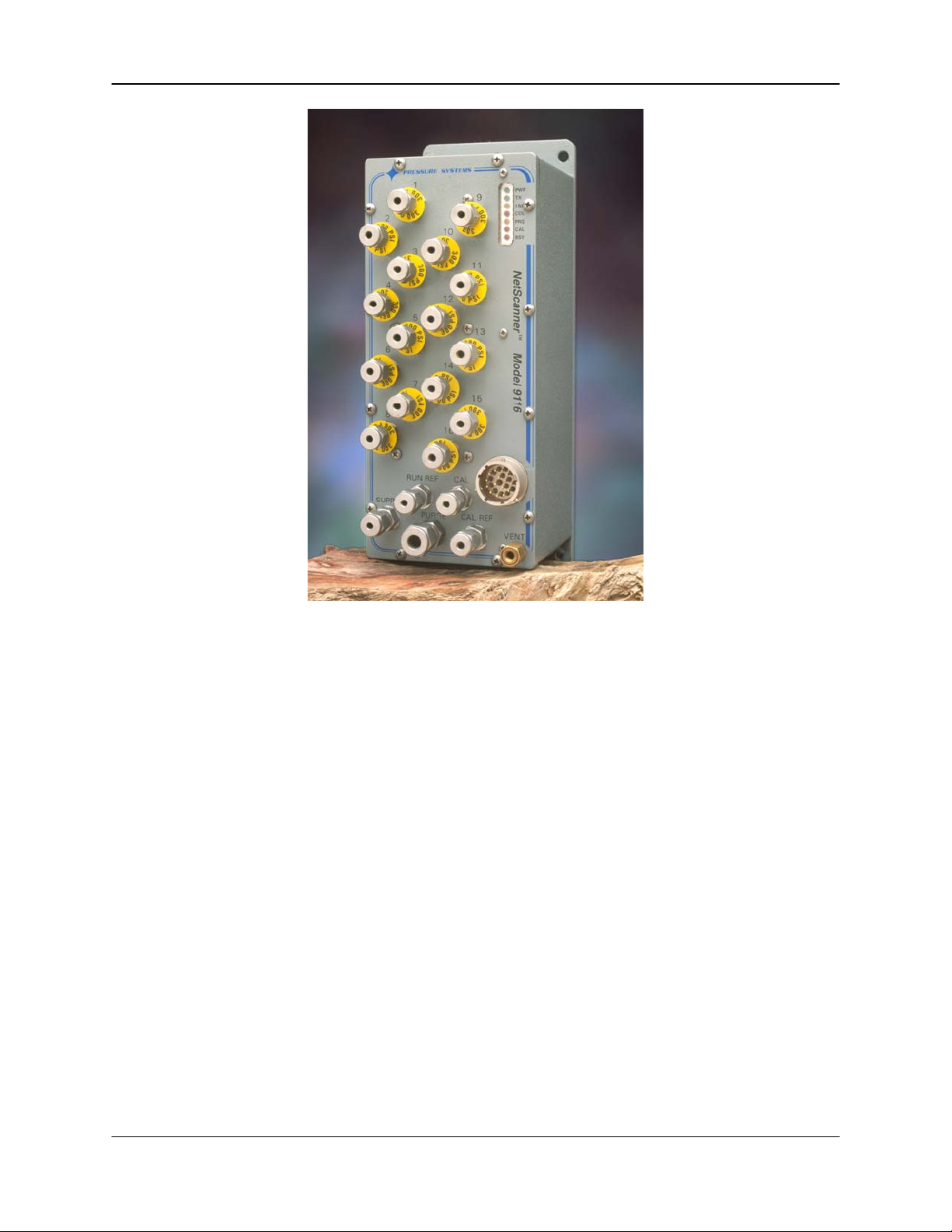

Figure 1.1

Model 9116 Intelligent Pressure Scanner

1.2 Description of the Instrument

The Model 9116 is available with16 channels, each with individual pneumatic transducers per

channel. The most distinctive features are highlighted below:

● Pre-calibrated Transducer - a memory chip containing full calibration data is embedded

within each internal transducer.

● Individual transducer per measurement input channel - mixed transducer ranges may

be installed in a single Model 9116 module.

● Low cost per point - per-channel cost is less than a typical industrial pressure

transducer/transmitter.

Page 2 www.PressureSystems.com

Page 12

Pressure Systems, Inc. Model 9116 User’s Manual

● High accuracy - Model 9116 pressure scanners are capable of accuracies up to

±0.05%. Accuracy is maintained through use of built-in re-zero, span, or multi-point

calibration capabilities. Accuracies are maintained for six (6) months after calibration.

● Low thermal errors - each internal transducer contains an individual

temperature sensor and thermal calibration data for internal use by software

correction algorithms. Thermal errors are reduced as low as ±0.001%FS/ºC over

the calibrated temperature span.

● Re-zero upon demand - an integrated calibration valve allows for automatic re zero adjustment calibration of dry gas transducers to null offset drift errors.

● Ease of transducer replacement - factory calibrated transducer assemblies may

be stocked and rapidly replaced in the field. Storage of thermal coefficients

within the transducer allows for ‘plug and play’ transducer replacement.

● Ease of calibration - each Model 9116 module contains a pneumatic

calibration manifold and software commands to automatically perform re-zero,

span, and multi-point adjustment calibrations. New offset and gain coefficients

that result from the most recent calibration may be stored in non-volatile

transducer memory.

● Ease of use - modules have simple command sets and provide engineering units

output. They may interface directly to a desktop or laptop computer or they may

be interconnected into a large network controlled by many types of host

computers.

● Connectivity - use of industry-standard communications network protocols to

control and read data from NetScanner

™

System modules allows distribution to

the point of measurement and ensures compatibility with third party hardware

and software.

1.2.1 Differences Between Models 9016 and 9116

The all new electronics of the Model 9116 reduces data acquisition noise and capture latency,

while actually improving channel settling time and boosting data throughput. Additionally, the

Ethernet interface has been upgraded to 10BaseT/100BaseT with half and full duplex

capabilities to provide significant flexibility in network configuration. The Ethernet interface is

completely auto-configuring, ensuring the best utilization of network capabilities, while ensuring

the maximum backward compatibility. The trigger circuitry has been upgraded to allow triggering

on positive, negative, or both transitions of the trigger signal. By configuring the Model 9116 to

trigger on both transitions, the Model 9116 can be integrated into existing systems, providing

twice the data throughput for most users, without modification to the system trigger circuit.

The firmware in the Model 9116 implements the Model 9016 command set further simplifying

use with existing systems. In fact, the Model 9116 can be configured to report its identity as a

Model 9016 to ensure compatibility with system software that is sensitive to the reported model

type.

Page 3 www.PressureSystems.com

Page 13

Pressure Systems, Inc. Model 9116 User’s Manual

Consolidated below are the new commands added to the Model 9016 command set, as well as

differences in existing commands, command parameters, or command responses:

Set Module type alias: w3200 xxxx

See the ‘SET/DO OPTION/FUNCTIONS’ (command ‘w’)’ in Section 3.2.

Configures the Model 9116 to report its model type as Model 9116 or as a

Model 9016 for compatibility with model type sensitive system software.

Set Hardware Trigger Mode: w320x

See the ‘SET/DO OPTION/FUNCTIONS’ (command ‘w’)’ in Section 3.2.

Configures the trigger to response to positive going, negative going, or to

any transition on the trigger input.

Query the Hardware Trigger Mode: q32

See the ‘READ MODULE STATUS’ (command ‘q’)’ in Section 3.2.

The Model 9116 will respond with a 1, 2, or 3 indicating, respectively, that its

trigger is set to respond to a positive going, negative going or to any

transition on the trigger input. The Model 9016 will respond to this command

with an ‘N08’.

Query the Module Hardware Version: w31

See the ‘READ MODULE STATUS’ (command ‘q’)’ in Section 3.2.

The Model 9116 will report the version of hardware present as a floating

point number of the format x.xxxxxx The Model 9016 will respond to this

command with a ‘N08’.

Modifications to existing commands, (See Section 3.2):

In the ‘CONFIGURE A HOST DELIVERY STREAM’ (command ‘c’), the sync delay

can now be set as small as 2 milliseconds and the granularity is 2 milliseconds with

all other values rounded down to the nearest 2 milliseconds. This value was 10

milliseconds in the Model 9016.

In the Set Number of A/D Samples to Average, (command ‘w’). the minimum

value and the default value is 4. The interleaved instrumentation amplifiers utilized

in the Model 9116 allows it to provide the same throughput with one to four

averages. With the quieter electronics of the Model 9116 and no speed advantage

for lower numbers of averaged samples, the minimum and default is set to four.

Valid values are 4, 8, 16, 32, and 64. Other values below 64 are rounded up to the

next valid value listed above.”

Page 4 www.PressureSystems.com

Page 14

Pressure Systems, Inc. Model 9116 User’s Manual

Additional enhancements to the Model 9116

Software Scan List Speeds:

Software Scan lists can be run as fast as hardware trigger scan lists on the

Model 9116 (~500 Hz. See specification sheet). The Model 9016 was

limited to 100 Hz maximum software trigger scan lists.

Firmware Updates/Boot Loader:

The firmware in the Model 9116 may be updated in situ, over its Ethernet

connection. This is the preferred method for updating the firmware and may

be invoked at any time. (See Section 5.2.1).

The user must connect to the updated module. Establishing a TCP/IP

connection is the last step in validating a successful firmware update. If the

unit is power-cycled four times without establishing a TCP/IP connection, the

firmware update will be tagged as invalid. The Model 9116 contains a

protected resident boot loader that will then take over operation of the

module. The resident boot loader resides in protected memory. It monitors

the state of the firmware and the operation of any downloads. Even in the

event of a power failure during a firmware update, upon return of power, the

resident boot loader will be available, and will establish communications for

downloading new firmware. The user can determine that the Model 9116 is

in boot loader mode by observing that the firmware version reported by the

module is less than 1.0 In boot loader mode, the Model 9116 will return an

‘N08’ in response to the ‘a’, ‘c’, ‘m’, ‘n’, ‘r’, and ‘t’ commands.

1.3 Options

1.3.1 Pressure Ranges

Model 9116 contains sixteen (16) DH200 transducers. These transducers are available with full

scale pressure ranges from 10" H

kPa). Transducers with different pressure ranges may be combined in a single module.

Please consult the Sales Department at Pressure Systems for availability of other pressure

ranges (1-800-678-SCAN (7226)).

1.3.2 Manifolds and Pressure Connections

Model 9116 sixteen-channel Intelligent Pressure Scanners are available with a true differential

or common reference pneumatic manifold, and have a standard purge and leak check manifold.

They are available with standard 1/8" or optional 1/16" and 1/4" compression fittings. All fittings

utilize an SAE 5/16 - 24 O-ring boss which supports a variety of other adapter compression

fittings. They are also available with a quick disconnect plate which contains 0.063" bulge

tubulation. The common differential version is available with all choices of fittings. The true

differential version is available with 0.063" bulged tubulation fittings only.

Consult the Sales Department at Pressure Systems at 1-800-678-SCAN (7226) for availability of

other input fittings.

Page 5 www.PressureSystems.com

O (inches of water column) to 750 psid (2.5 kPa to 5200

2

Page 15

Pressure Systems, Inc. Model 9116 User’s Manual

1.3.3 Communication Interfaces

All standard NetScanner

compensated and linearized pressure data in engineering units via digital methods. They have a

10BaseT Ethernet host communications interface using industry standard TCP/IP or UDP/IP

protocol. This interface provides high data transfer rates and system connectivity. The Model

9116 adds auto-configuring 10BaseT/100BaseT, half duplex/full duplex capabilities for improved

network flexibility.

™

System Intelligent Pressure Scanners provide temperature

Page 6 www.PressureSystems.com

Page 16

Pressure Systems, Inc. Model 9116 User’s Manual

Chapter 2

Installation and Set Up

2.1 Unpacking and Inspection

The NetScanner

either as an entire system, or as individual pieces of equipment. Before assembling the system,

use the shipping bill as a reference to ensure that all parts have arrived. Pressure Systems

takes no responsibility for equipment that is damaged during shipment. If containers are

broken, ripped, or damaged, contact the transportation carrier. If the equipment itself appears

to be damaged, contact the Repair Department at Pressure Systems.

Each Model 9116 Intelligent Pressure Scanner shipment will contain the following minimum

components:

• Model 9116 Intelligent Pressure Scanner module

• Start-up software CD-ROM

• Model 9116 User’s Manual for Intelligent Pressure Scanners CD-ROM

™

System product family has many components which may be purchased

2.2 Safety Considerations

It is always a good idea to wear safety glasses when operating this equipment or when working

with pressurized lines. Always ensure that high pressure lines are properly secured and that all

pneumatic lines are rated for the proper pressure and temperature environments.

All system power should be OFF during installation (or removal) of any components in a

NetScanner

permanent damage to the module. Use caution and check line voltages before applying power

to the module.

™

System module. Failure to turn power OFF prior to installation may cause

2.3 Preparation for Use

2.3.1 Environment

All standard Intelligent Pressure Scanners are factory calibrated to be accurate over a specified

temperature range, but may be operated or stored over a wider temperature range (see

Environmental/Physical Specifications in the Model 9116 Data Sheet. Operating or storing

an instrument outside its specified range(s) will result in a loss of measurement accuracy and

may cause permanent damage to the instrument electronics.

Page 7 www.PressureSystems.com

Page 17

Pressure Systems, Inc. Model 9116 User’s Manual

WARNING: Exceeding the specified storage or operating temperatures may result

in permanent damage to the Model 9116 electronics.

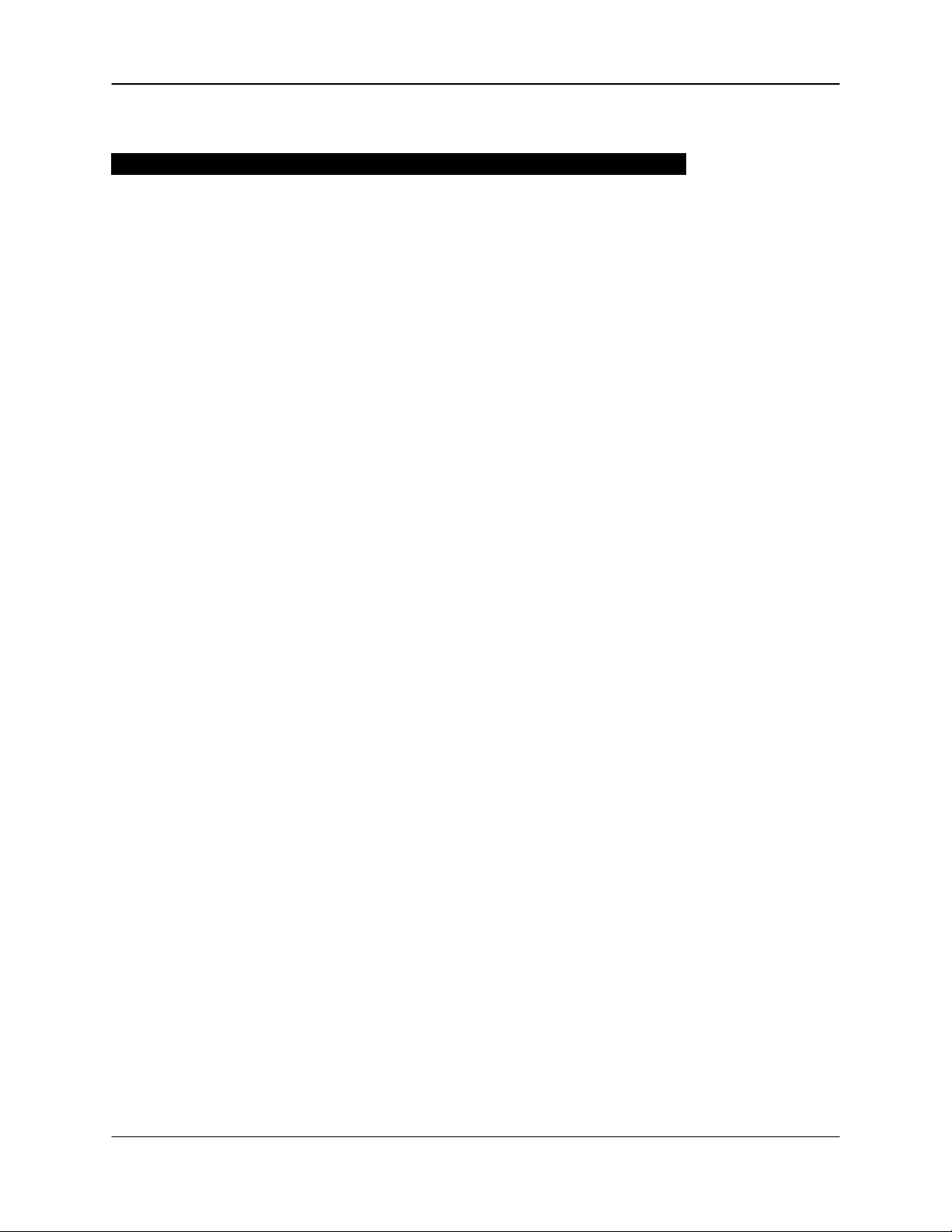

2.3.2 Power

The Model 9116 Intelligent Pressure Scanner needs only a single unregulated power supply.

See the Model 9116 Data Sheet for actual power requirements.

Model 9116 has a single round, ruggedized connector through which all power and input/output

signals pass as shown in Figure 2.1.

WARNING: Improper connection of power to the Intelligent Pressure Scanner can

result in permanent damage to module electronics.

Figure 2.1

9116 Power Pin Assignments

Page 8 www.PressureSystems.com

Page 18

Pressure Systems, Inc. Model 9116 User’s Manual

2.3.3 Mounting and Module Dimensions

See the Model 9116 Data Sheet for exact dimensions of the module. A detailed mechanical

drawing is also included in Appendix E.

2.3.4 Network Communications Hookup

Every NetScanner

interconnected in a network with other modules and a host computer. Model 9116 has an

Ethernet Host Port using TCP/IP and UDP/IP transmission protocols.

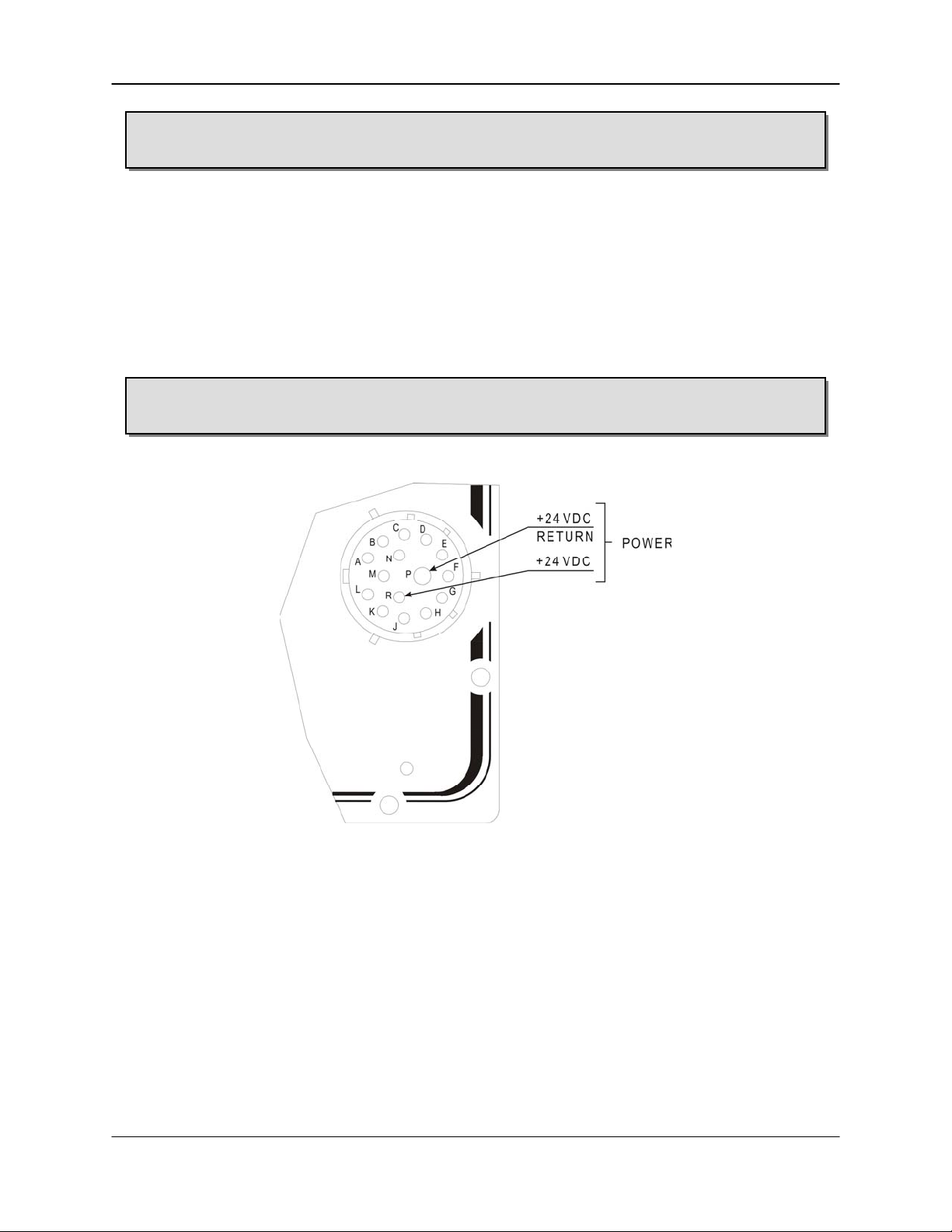

2.3.4.1 Ethernet Host Port Hookup

The Ethernet Host port of every Model 9116 Intelligent Pressure Scanner module, and its host

computer, may be interconnected in a “star” network via a standard 10BaseT or 100BaseT, half

or full duplex hub or switch. These standard devices will have their own power requirements.

Hubs will treat the host computer connection and all NetScanner

alike. Switches may provide, or negotiate different speeds and/or different handshaking on its

various ports. The Model 9116 will auto-negotiate through the hub or with the switch, for a half

or full duplex connection at 10BaseT or 100BaseT speeds, establishing the best connection

available. Ethernet communications pin assignments for the Model 9116 electrical connector

are shown in Figure 2.2. See Figure 2.3 for typical network topology.

™

System Intelligent Pressure Scanner contains a Host Port, allowing it to be

™

System module connections

Figure 2.2

Ethernet Host Port Connector Pins

Page 9 www.PressureSystems.com

Page 19

Pressure Systems, Inc. Model 9116 User’s Manual

The host and each module must have a unique Ethernet Hardware Address (a.k.a. MAC

Address) and a unique IP Address. The Ethernet Hardware address is generally fixed (at

manufacturing time of the Ethernet microprocessor board inside the module). The Ethernet

Hardware address is shown on each module’s label. The Ethernet Intelligent Pressure

Scanners are capable of supporting various methods for IP address assignment, using either

the factory default (static IP addressing) or user-configured Static IP addressing or Dynamic IP

address assignment. Dynamic IP address assignment is through the use of RARP or BOOTP

protocols. Unless your application requires the use of Dynamic IP address assignments, it is

strongly suggested that the module be left configured for the Static IP address protocol. This

default method is typically the simplest method for using the Intelligent Pressure

Scanner.

In the Static IP addressing mode, the module will use a factory default IP address on power-up.

This default address is set to 200.20x.yyy.zzz where x is derived from the module type (0 for

Model 9116 and 1 for 9021/9022) and yyy.zzz is derived from the module serial number. A

similar method is used to calculate each module’s Ethernet hardware address shown on the

module tag. Note that each of these fields (separated by a period, ‘.’) is a decimal

representation of a byte value. This means that each field may have a maximum value of 255.

For Model 9116 modules, the default IP address will be 200.200.y.zzz where y and zzz are

calculated as follows:

y is the integer result of dividing the module serial number by 256.

zzz is the remainder of dividing the serial number by 256 (serial number modulus 256).

These calculations may be verified by checking that y * 256 + zzz equals the original module

serial number. Once a module has powered-up and has assigned itself a default IP address, it

is capable of communications.

An alternate method for assigning an IP address to an Ethernet module is referred to as a

Dynamic IP assignment. This method allows a module to have its IP address dynamically

assigned at power-up by an application running on a node of the TCP/IP or UDP/IP network.

When configured for Dynamic IP address assignment protocols, the reset module will broadcast

its Ethernet hardware (MAC) address on the network in a Dynamic IP request packet. This

broadcast packet identifies the module by its hardware address and requests that a dynamic IP

server application return to it an IP address for use. Once this broadcast message is received,

the dynamic server application will then return an IP address to the module in a dynamic IP

reply packet. Most dynamic IP server applications determine this IP address from a user

maintained file that lists Ethernet hardware addresses with their desired IP address. If modules

are added to the network or module IP addresses are to be changed, the user can simply edit

this configuration file. This capability is common on most UNIX based machines and is also

available (although less common) in some TCP/IP packages available for PC platforms.

Support of the Dynamic IP server protocol is not currently included in the Windows

Windows

Dynamic IP capabilities of the Model 9116, a simple Windows

®

NT operating systems. In order to allow users of PC platforms to make use of the

®

95/98/XP/NT application was

®

95/98/XP or

developed by Pressure Systems which is capable of acting as a Dynamic IP server. This

application is referred to as BOOTP Lite since it actually makes use of the BOOTP protocol that

closely resembles the Dynamic IP request. Like traditional dynamic IP servers, this application

allows the user to configure a file that contains Ethernet hardware addresses and the

corresponding IP address to assign to those devices. This application is free of charge and

capable of running as a background program on Windows

®

95/98 and NT machines. It may be

downloaded from the PSI home page, www.PressureSystems.com.

Page 10 www.PressureSystems.com

Page 20

Pressure Systems, Inc. Model 9116 User’s Manual

Use of Static or Dynamic IP settings may be selected through the Set Operating Options ('w')

command. If you are unsure how your module is configured, check the Tx LED during module

power-up. If it begins to blink periodically after the module power-up, your instrument is

configured for the Dynamic IP assignment protocol. (Tx LED remains OFF in static IP

configuration.) If configured for Dynamic IP assignment, a dynamic server must be configured

on the network to return an IP address to the module. Without an IP address, the host will be

unable to open a TCP/IP or UDP/IP connection to the module.

Note

Obtaining the maximum performance of an Ethernet network is a

complex process, involving many tradeoffs and is best performed by

IT professionals or other personnel familiar with Ethernet

parameters, topologies, and equipment capabilities. See Pressure

Systems Web site (www.PressureSystems.com)

for application

notes and characteristics of the Model 9116 together with some

hints for its use in high-speed, high-volume Ethernet networks.

Note

After closing the TCP/IP connection to the Model 9116, the host must

wait 10 seconds before re-connecting.

Page 11 www.PressureSystems.com

Page 21

Pressure Systems, Inc. Model 9116 User’s Manual

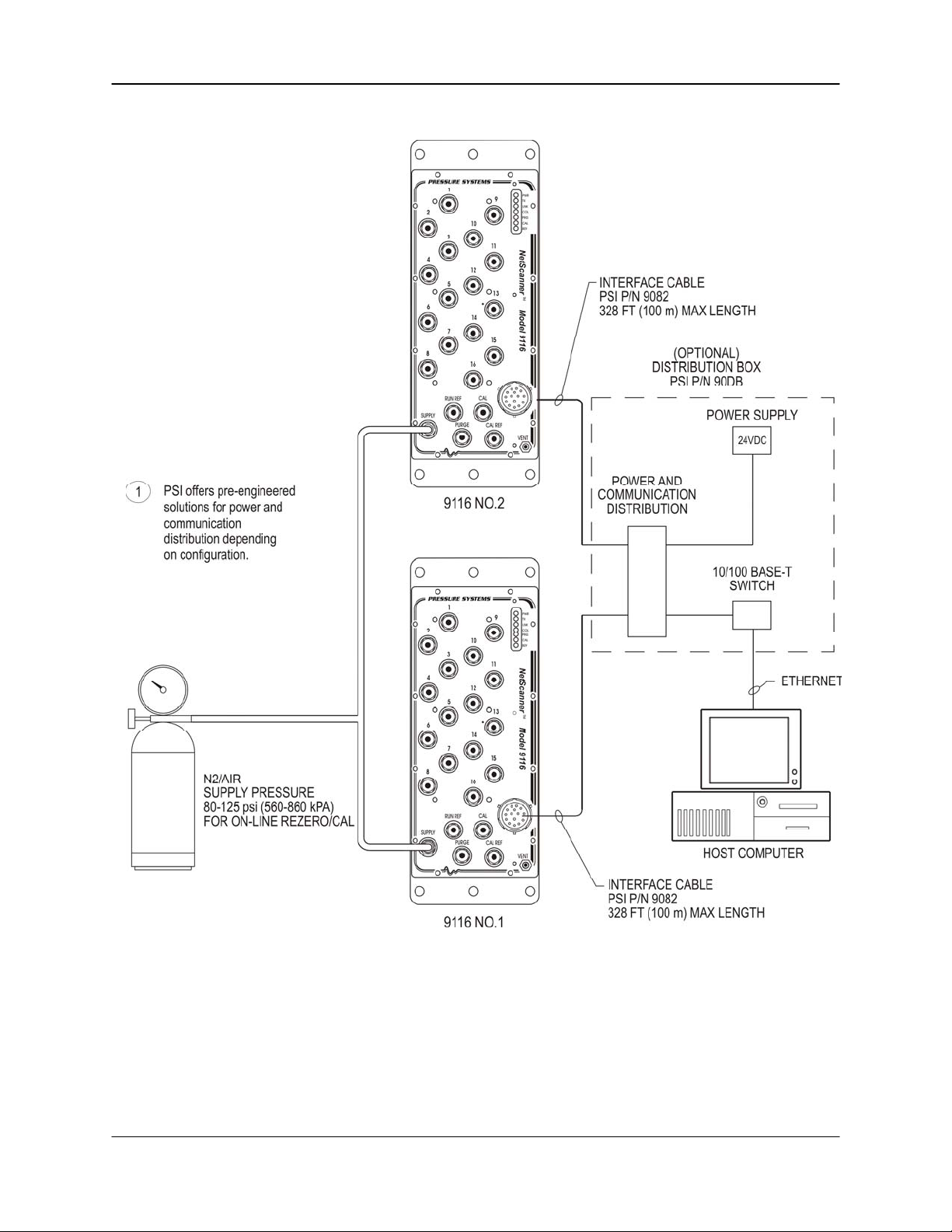

Figure 2.3

Ethernet Network Topology

Page 12 www.PressureSystems.com

Page 22

Pressure Systems, Inc. Model 9116 User’s Manual

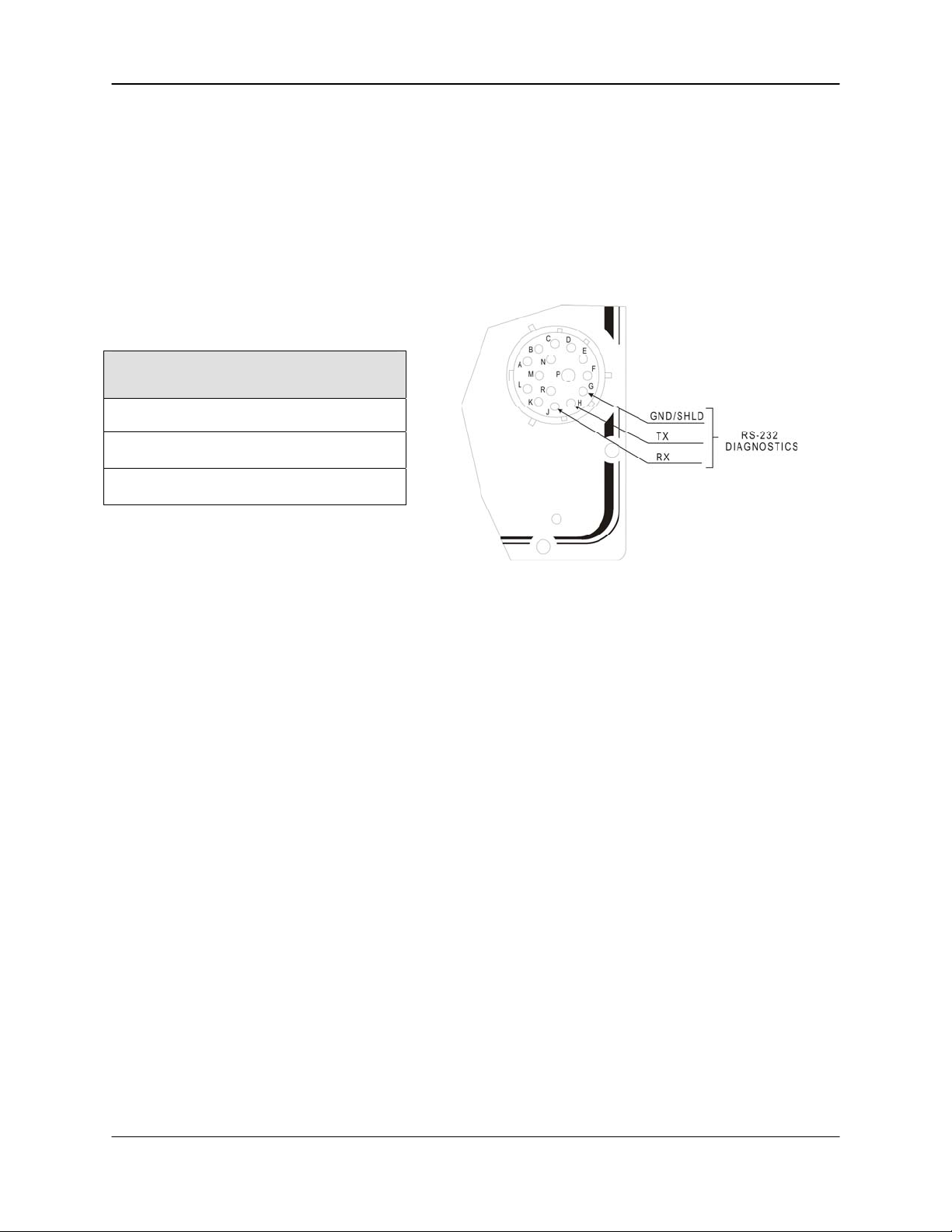

2.3.5 Diagnostic Port Hookup

Each NetScanner

operational functions. The Diagnostic Port has only a simple RS-232 asynchronous serial

interface. The connections are made via certain pins of its common circular connector. Cable

connection should be made according to Table 2.1.

NetScanner™ System

Diagnostic Port Connector

The RS-232 interface is capable of supporting simple asynchronous communications with fixed

parameters of 9600 baud, no parity, 8 data bits, and 1 stop bit. Only communication cable

lengths less than 30 feet (10 m) are recommended.

The Model 9116 uses the diagnostic interface for optional configuration and diagnostic

purposes only. The diagnostic port functions on the Model 9116 is generally not required by the

end user. Standard cables for this module do not include diagnostic port connections.

™

System module contains a Diagnostic Port that supports diagnostic and

Table 2.1

Diagnostic Port Wiring

GND

Tx

Rx

2.3.6 Pressure Connections

All pneumatic connections to Model 9116 are found on the instrument top panel. The function

of each input port is clearly engraved or printed next to each input. Connections are through

bulge tubing, compression fittings, or special user-supplied fittings on the tubing plate. All

pneumatic inputs to the Model 9116 should contain only dry, non-corrosive gas.

All Model 9116 standard Intelligent Pressure Scanners are supplied with the purge/leak check

calibration manifold. Through software commands, this valve may be placed in one of four

positions; RUN, CAL, PURGE, or LEAK-CHARGE. Pneumatic input requirements for these

four operating positions are described in the following sections.

Page 13 www.PressureSystems.com

Page 23

Pressure Systems, Inc. Model 9116 User’s Manual

The following guidelines should be used when installing pressure connections to the Model

9116 Intelligent Pressure Scanner modules.

● Always wear safety glasses when working with pressurized lines.

● Ensure that user input pressure will not exceed the proof pressure ratings of

the corresponding instrument transducer. Applying excessive pressure to

measurement inputs can permanently damage the pressure transducers.

● Ensure that all tubing material is rated for the expected pressure and

environmental conditions. Failure to use the proper tubing material may

result in ruptured lines and possible personal injury.

● Ensure all high pressure lines are properly secured.

● Place retaining springs over all bulge tube fittings to ensure pneumatic lines

remain attached and leak free. Springs should be pushed down on

connections so that half of the spring length extends past the tube bulge.

Warning: Introduction of contaminants or corrosive materials to the module

pneumatic inputs may damage module transducers, manifolds, and O-ring seals.

2.3.6.1 RUN Mode Inputs

The standard pneumatic tubing plate for the Model 9116 contains sixteen numbered pneumatic

input channels. These numbered inputs are attached to corresponding pressure transducers

inside the instrument and should be pneumatically attached to the pressure measurement

points under test.

The standard tubing plate also contains an input labeled RUN REF. The RUN REF input is

pneumatically connected to the reference side of all internal DH200 pressure transducers. The

RUN REF connection is used for situations where all channels have one reference pressure.

The reference pressure may be as high as 250 PSI (1720 kPa). See the Model 9116 Data

Sheet for detailed specifications. This input may also be left unattached to provide atmospheric

reference pressure.

When using instruments with the reference per channel option (true differential), two pneumatic

inputs will be provided for every numbered channel. These inputs are labeled ‘P’ and ‘R’. The

‘P’ connection is the test pressure input. The ‘R’ connection is the transducer reference input

pressure. Since each channel has its own reference pressure input, the RUN REF input is not

provided on the true differential tubing plate.

Page 14 www.PressureSystems.com

Page 24

Pressure Systems, Inc. Model 9116 User’s Manual

p

2.3.6.2 CAL Mode Inputs

The Model 9116 tubing plates contain inputs labeled CAL and CAL REF. When the module’s

internal calibration valve is placed in the CAL/RE-ZERO position, all DH200 transducer

pressure inputs are pneumatically connected to the CAL input port. All DH200 reference inputs

are pneumatically connected to the CAL REF input port. The CAL input may be used to

perform on-line zero adjustment of the transducers. The CAL input may also be used for DH200

span adjustment calibrations and accuracy tests if appropriate pressure calibrators (such as the

903x series) are available. Span calibration of multi-range scanners may also utilize the CAL

port if the highest applied pressure does not exceed the proof pressure rating of any other

installed transducer, otherwise the individual transducers must be calibrated with the valve in

the RUN position.

When the internal calibration valve is in the CAL/RE-ZERO position, the RUN inputs (RUN REF

and numbered input ports) are pneumatically dead-ended to prevent migration of contaminants

into the instrument.

2.3.6.3 PURGE Mode Inputs

All standard Model 9116s contain a purge/leak check option. The purge option allows users to

apply positive pressure to the PURGE input which will then be vented out of the user input

ports, forcing contaminants (such as moisture) out of the pneumatic input lines. Note that on

common reference Model 9116 scanners, only the numbered input ports will be purged

(RUN REF is not purged). True differential Model 9116 scanners will purge both the run and

reference input ports for all channels. The purge supply provided to the Model 9116 must

always be a higher pressure than the highest pressure present on the input ports of the

module. The purge supply must also be capable of maintaining proper purge pressure at

the high flow rates encountered while the module is in the purge mode.

Warning: Failure to provide proper purge supply pressure will result in

migration of moisture and contaminants into the Model 9116 module which can

result in

ermanent damage to module components.

When commanded into the PURGE position, the purge input pressure will be connected to the

numbered measurement input ports allowing for a flow of air away from the instrument. The

purge cycle should be terminated by commanding the Model 9116 into a non-purge mode such

as CAL. Purge cycles should never be terminated by turning off the purge supply air

while in the purge position.

Page 15 www.PressureSystems.com

Page 25

Pressure Systems, Inc. Model 9116 User’s Manual

2.3.6.4 LEAK Mode Inputs

The purge/leak charge valve design includes a leak check feature capable of testing the

integrity of user pneumatic connections as well as those within the Model 9116 module. For the

leak mode to be used, all RUN mode pressure inputs must be dead ended (closed) by the user.

When the Model 9116 is commanded into the LEAK-CHARGE position, the CAL input port will

be pneumatically connected to module run side inputs. Common reference modules will

connect only the numbered run side inputs to CAL (RUN REF is not charged). True differential

(reference per port) modules will connect both the measurement input and reference port to

CAL. While in the LEAK-CHARGE position, a test pressure may be applied through the CAL

port which will charge the dead ended run side tubulation.

Test pressures applied to the CAL port during the leak check

Note

operation must not exceed the full scale pressure of any internal

transducers.

Once the lines are charged, the Model 9116 may be commanded back to the RUN position.

This will reattach the charged run side lines to their corresponding internal transducer.

Consecutive pressure readings from the Model 9116 will now allow user calculation of the line

leak rates. Once returned to the RUN position, lack of a pressure indicates a gross leak. A

slowly declining pressure indicates a slight leak. A leak is more difficult to detect as tubing

volume increases. In the case of true differential units where both sides of the sensor are

pressurized with the leak test pressure, an initial differential pressure of 0.0 psi should be

measured when the unit is placed in the RUN position. If the measurement or RUN side of the

channel leaks at a rate greater than the reference side, a resulting negative differential pressure

will be measured. Likewise, if the reference port tubing leaks at a rate greater than the

measurement side, a resulting positive differential pressure will be measured.

2.3.6.5 Supply Air

The Model 9116 modules require an 80 psig minimum dry air (or inert gas) supply which is used

to shift the internal calibration valve between its different positions. Each module contains a

fitting marked “SUPPLY” for this input. Internal solenoid valves direct this supply pressure to

the proper control port on the calibration valve as required by instrument commands. The

absence of sufficient supply air to the module will prevent the calibration valve from shifting into

requested positions (i.e., RUN, CAL, PURGE, LEAK-CHARGE).

WARNING! Supply air should not exceed 125 psi (875 kPa). Excessive pressure

may damage the internal solenoids.

Page 16 www.PressureSystems.com

Page 26

Pressure Systems, Inc. Model 9116 User’s Manual

2.3.7 Case Grounding

The Model 9116 module contains a case bypass capacitor which allows the module case to be

mounted on hardware with a small common mode line voltage (less than 20 Volts).

2.3.8 Trigger Input Signal

Model 9116 supports the use of a data acquisition synchronization signal, sometimes called

“Hardware Trigger.” When configured through the Define/Control Host Stream (‘c’) command,

the trigger signal can be used to initiate and synchronize data acquisition and stream outputs to

the host.

The trigger signal is intended to be a 2-wire differential signal brought in through the Model

9116 main electrical connector. The signal may be driven by a standard TTL compatible device.

The switching threshold for this signal is set at 2.5 VDC.

2.3.9 Power Up Checks and Self-Diagnostics

Upon power-up of the module, the internal firmware will perform a number of self-diagnostic

checks. The results of these tests are reflected by the ‘OK’ LED on the top panel. The Model

9116 module completes the power up and self diagnostic.

See Chapter 6, Troubleshooting Guide for additional information and potential problem areas

during the power-up sequence.

Page 17 www.PressureSystems.com

Page 27

Pressure Systems, Inc. Model 9116 User’s Manual

Chapter 3

Programming and Operation

3.1 Commands & Responses

3.1.1 Introduction

This chapter describes all commands a host computer program may send to a Model 9116

Intelligent Pressure Scanner module, as well as the data or status responses returned by the

module. Most applications require a working knowledge of only a small number of these

commands.

Model 9116 has an Ethernet interface, and uses layered TCP/IP or UDP/IP transmission

protocols to communicate with a host computer. All commands/responses to/from Model 9116

modules are embedded in the data fields of either a TCP or UDP packet header. In turn, these

packets are themselves embedded in the data field of an IP packet header, which is embedded

in the data field of an Ethernet packet header. Thus, the term layered protocols.

3.1.1.1 TCP/UDP/IP Protocols

Both TCP/IP and UDP/IP protocols are a well-established set of rules for communicating over a

network (LAN, intranet, or internet), and are independent of the network’s physical medium. All

the modules use the TCP/IP protocols for most commands and responses since the TCP layer

provides a robust error detection and correction mechanism. TCP/IP requires a formal

connection be established between host and module. The simpler UDP layer, requiring no

formal connection, is utilized for a subset of commands and query responses.

Using the underlying basic IP protocol, the host computer and interconnected modules are all

“peers” that can communicate equally. Each “peer” must have its own unique “logical” IP

Address (as well as its own unique “physical” Ethernet Address) to be directly addressed. Any

“peer” may initiate transmissions without permission from the receiver. In the NetScanner

System implementation, the host computer is normally a client and generally initiates most

transmissions by sending commands to the modules, which are normally servers. However, a

module can initiate its own transmissions in some operating modes (e.g., the hardware-

triggered or free-run autonomous host streams generated by the Configure/Control

Autonomous Host Streams (‘c’) command).

A “peer” may be directly addressed by its IP address (in xxx.xxx.xxx.xxx format), or by use of a

predefined logical name that allows its IP Address to be looked-up in the sender’s database or

in a central network server’s database. The Windows

a simple text file database called “Hosts.” Review the file “Hosts.sam” in the “C:\windows”

directory. Modify and rename it “Hosts.” (no file extension) to activate it.

Before the host computer and any module can communicate with the higher level TCP/IP

protocols, the host (client) must request a connection be established with the module (server).

Each module expects all such requests for connection to be requested by its IP Address, and

®

95/98/XP/NT operating systems provide

™

Page 18 www.PressureSystems.com

Page 28

Pressure Systems, Inc. Model 9116 User’s Manual

directed to “well-known” port 9000 (default). After the connection is made, a socket is

established as a logical handle to this connection. The host and module may then

communicate, via this socket, until it is closed or is lost at either module or host end, due to

power failure or reboot). The host and module may also communicate in a limited fashion

without a connection, using the middle-level UDP/IP protocols. In that case, the host simply

broadcasts commands via port 7000, and each module (that chooses to respond) returns the

response on port 7001. Only a few commands use UDP/IP in Model 9116 modules.

3.1.2 Commands

The commands (and responses) used by Model 9116 modules consist of short strings of ASCII

characters. The TCP/IP and UDP/IP protocols allow for the transfer of either printable ASCII

characters or binary data. When using certain formats, internal binary data values are often

converted to ASCII-hex digit strings externally. Such values may include the ASCII number

characters ‘0’ through ‘9,’ the uppercase ASCII characters ‘A’ through ‘F,’ and the lowercase

letters ‘a’ through ‘f’.’ These hex values may represent bit maps of individual options, or actual

integer or floating point (IEEE) binary data values. In other cases (see optional format 7 below)

binary data may be transmitted directly as 4-byte (32-bit) binary values without any formatting

change. Such binary transmissions use big-endian (default) byte ordering but may be

commanded to use little-endian for some data.

3.1.2.1 General Command Format

A typical TCP/IP command (contained in the data field following a TCP packet header) is a

variable-length character string with the following general fields:

! a 1-character command letter (c).

! an optional position field (pppp), a variable length string of hexadecimal digits.

! a variable number of optional datum fields ( dddd): each a variable length string, normally

formatted as a decimal number (with a leading space character, and with or without sign

and/or decimal point, as needed).

Using brackets ( [ ] ) to show optional elements, and ellipsis ( ...) to show indefinite repetition, a

typical TCP/IP command may be viewed schematically as follows:

“c[[[[p]p]p]p][ dddd][ dddd]...]”

From this schematic, it should be clear that the command letter (c) is required, the position field

(pppp) immediately follows it, and may have 0, 1, 2, 3, or 4 characters, and there may be zero

or more datum fields ( dddd), as required. For simplicity, the variable length nature of each “

dddd” string is not shown [with brackets] above, but the required leading space character is

shown. The position field is similarly simplified (as “pppp”) below.

Page 19 www.PressureSystems.com

Page 29

Pressure Systems, Inc. Model 9116 User’s Manual

A typical UDP/IP command (contained in the data field following a UDP packet header) is also a

variable length character string, but has a simpler format. Generally, it has a variable length

command string (cccccc), followed by one optional datum ( dddd) field (preceded by one space

character):

“cccccc[ dddd]”

Since there are only a few simple UDP/IP commands, all references to commands below should

assume TCP/IP commands, unless otherwise indicated.

3.1.2.2 Command Field

All Model 9116 scanners recognize a set of predefined commands. Most are TCP/IP

commands, having only a single alphabetic letter for a command field. These are recognized

only when a formal socket connection is established with the host computer. A few are UDP/IP

commands with a longer command field. These are recognized any time the module has power

applied. All commands are functionally summarized in the following sections and detailed in

reference Section 3.2.

3.1.2.3 Position Field

The Model 9116 Intelligent Pressure Scanner may contain up to sixteen (16) separate

input/output channels. When commands affect certain channels scanned by the module, the

position field is used to identify those channels as bits in a bit map. If a channel’s corresponding

bit in the position field is set to a one (1), then that channel is affected by the command. The

least-significant (rightmost) bit 0 corresponds to Channel 1, and the most-significant (leftmost)

bit 15 corresponds to Channel 16. Since neither model has more than sixteen (16) channels,

the position field will usually be 16-bits, represented by four (4) ASCII-hex characters in the

command. For example, only Channels 16 and 1 are selected below in this 16-bit (4-character)

position field:

Bit# 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Chan#

Binary 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

Hex 8 0 0 1

15 14 13 12 11 10 9 8 7 6 5 4 3 2

16

1

The above position field, with all applicable bits set (i.e., FFFF for 16-channel module), specifies

all channels. However, a module-independent variation allows a missing position field to

designate all channels — but only when there are no other parameters following the position

field in the command. For such commands, the hex position field may be reduced to 3, 2, or 1

characters when no channel bits need be set (1) in the discarded high-order characters

(nibbles).

Note

The channel data requested will always be returned in order of

highest requested channel to lowest requested channel.

Page 20 www.PressureSystems.com

Page 30

Pressure Systems, Inc. Model 9116 User’s Manual

3.1.2.4 Datum Fields

Any datum fields in a command generally contain data to be sent to the module, usually

specified by a position field bit map. In some commands (when data are received from a module

instead) no datum fields are required in the command itself but the position field bit map is still

used to specify the order that data are returned in the command’s response. In either case, the

order bits are set (to 1) in the position field bit map (highest channel # to lowest channel#, left to

right) is the order these datum fields are received or sent.

Each datum field may be variable in length, whether part of the command itself or the

command’s response. In its most common format, a datum begins with a space character (‘ ’),

and is followed by an optional sign, decimal digits, and a decimal point, as needed (e.g., ‘ vv.vvvvvv’). For other formats it may be a hex digit string or pure binary number.

3.1.2.5 Format Field

Some commands, that either send data to a module (as command parameters), or cause the

host to receive data (via command’s response), have an extra format parameter (f digit)

appended to (or specified in) the position field. This parameter, when specified (or implied by

default), governs how internal data are converted to/from external (user-visible) form.

• The most common format (f=0) causes each datum (in command or response) to be

represented as printable ASCII numbers externally (with optional sign and decimal point

as needed). Internally, the module sets/obtains each converted datum to/from a single

precision binary (32-bit) IEEE float

• Some formats (f=1, 2, 5) encode/decode the internal binary format to/from ASCII

hexadecimal external form. Some of these “hex dump” formats provide an external hex

bit map of the internal binary value (float or integer as appropriate). Format 5 may

encode/decode the internal float value to/from an intermediate scaled binary integer

(e.g., float value * 1000 into integer, then to/from a hex bit map).

• Two special “binary dump” formats (f=7 and f=8) may be used by some commands to

accept/return binary data directly from/to the user’s command/response. Such values

are not user-readable in their external form, but are directly machine readable and

provide highly compact storage without any accuracy loss due to formatting. Use of

these formats allows both the module and host program to operate in their most efficient,

low overhead mode. Format 7 returns the most significant byte first (i.e., big endian).

Format 8 returns the least significant byte first (i.e., little endian).

See the individual command descriptions for the formats a particular command recognizes.

Page 21 www.PressureSystems.com

Page 31

Pressure Systems, Inc. Model 9116 User’s Manual

3.1.3 Responses

Four (4) types of responses can be returned from a Model 9116 Intelligent Pressure

Scanner module:

• an Error response,

• an Acknowledge response,

• an Acknowledge with Data response, or

• a Network Query response.

The first three may be returned by TCP/IP commands, the latter from a UDP/IP command.

The error response consists of the letter ‘N’ (for NAK, or negative acknowledge), followed by a

2-digit hexadecimal error code. The following table lists the error codes that can be returned

from a Model 9116

module:

Table 3.1

Error Codes

CODE MEANING

00 (Unused)

01 Undefined Command Received

02 Unused by TCP/IP

03 Input Buffer Overrun

04 Invalid ASCII Character Received

05 Data Field Error

06 Unused by TCP/IP

07 Specified Limits Invalid

08 NetScanner error; invalid parameter

09 Insufficient source air to shift calibration valve

0A Calibration valve not in requested position

The Acknowledge response is returned from a module when a command is received that

requires no data to be returned, and no error is detected. It indicates successful parsing and

execution of the last received command. It consists of the letter ‘A’ (for ACK, or acknowledge).

The Acknowledge with Data response is returned when a module receives a command

requesting data. Model 9116 modules will typically return only the requested data values, each

preceded by a space character (except for format 7). No ‘A’ acknowledge letter begins this

data response. Data are returned for the highest requested channel number first.

Page 22 www.PressureSystems.com

Page 32

Pressure Systems, Inc. Model 9116 User’s Manual

3.1.3.1 Interpreting Offset Values (Re-zero Calibration Adjustment)

When a module is instructed to execute the command Calculate and Set Offsets (‘h’), a datum

corresponding to the calculated offset correction term (or coefficient) is returned for each

affected channel. Each such coefficient value is stored internally, and will be subtracted in all

subsequently calculated data conversions, to correct for zero drift effects. The command only

returns them in the response (in current engineering units (EU) of pressure) to allow the user to

make reasonableness checks on them. The Read Internal Coefficients (‘u’) command will

return them on demand.

3.1.3.2 Interpreting Gain Values (Span Calibration Adjustment)

When a module is instructed to execute the command Calculate and Set Gains (‘Z’), a datum

corresponding to the calculated gain correction term (or coefficient) is returned for each

affected channel. Like the offset coefficient, each gain coefficient is stored internally, and will

be used in all subsequently calculated data conversions, to correct for gain change effects. The

command returns them in the response (as a unitless scale factor near 1.0) to allow the user to

make reasonableness checks on them. The Read Internal Coefficients (‘u’) command will

return them on demand.

3.1.3.3 Interpreting Engineering Units Output

All modules perform all internal pressure calculations in engineering units of pounds per square

inch (psi). By default, all pressure data in responses and command parameters will also be in

psi. A different engineering unit (e.g., kPa) may be obtained by changing an internal EU

Pressure Conversion Scaler (normally 1.0). See the “Read/Download Internal Coefficients”

(‘u’/‘v’) commands (array 11, coefficient 01). Change this default multiplier value (1.0) to obtain

units other than psi.

3.1.4 Functional Command Overview

The various commands for Model 9116 modules are best introduced by classifying them into

functional groups and then describing how each function is carried out in a typical system. The

following functions are defined for this purpose:

• Start-up Initialization

• Scan List Definition for Acquisition

• Calibration Adjustment of Engineering Unit Correction Coefficients

• Acquisition/Delivery of Data to Host

• Network Query and Control

Please look ahead to Table 3.1, labeled Model 9116 Intelligent Pressure Scanner

Commands, in Section 3.2, for a quick-look summary of all commands available to the Model

9116 modules. Each command may be referenced by both its functional title and by its

command id in the functional discussion sub-sections below.

The Detailed Command Description Reference immediately follows the table in Section 3.2,

with each command description occupying a page (or more if necessary). Command

descriptions in this section (as in the table) are ordered first by type (TCP/IP then UDP/IP), then

by “command id” in ASCII order (UPPERCASE letters (A .. Z) first, then lowercase letters (a ..

z)) .

Page 23 www.PressureSystems.com

Page 33

Pressure Systems, Inc. Model 9116 User’s Manual

3.1.4.1 Startup Initialization

Since power supplies may be distributed widely across a network of modules and host

computer(s), it is not uncommon for modules (singly or together) and the host to lose power

independently. Thus, their power may be restored at different times. Startup initialization, for

every module, must normally be performed when its power is restored, as each module enters

default states after power-up, which may not be the state the host computer had previously

been operating in. Any previous TCP/IP socket connection is also lost after power failure and

must be re-established between host and module before any TCP/IP commands can be

recognized by the module. These commands are generally used to detect that startup

initialization has occurred (or to force reset at other times), after which other commands may be

used to restore the original operating condition.

With Model 9116 modules, the Power-Up Clear (‘A’) command is used as a simple command

to elicit a known response from a module. Although this causes no internal function within the

module, it will result in an acknowledgment being returned to the host computer to verify proper

communications. The best way to detect that a power reset has occurred in a module is to

notice that the TCP/IP socket connection is no longer valid. At any point during module

operation, the Reset (‘B’) command may be used to return any module to its default “reset”

state. If the module is then required to enter any other states (that were previously programmed

for it by the host), the host must then restore these states accordingly using the appropriate

commands. This reset command simply returns internal software parameters to a default state

(as after power up or reboot). It will not close the existing TCP/IP socket (as will power up or

reboot).

The Set/Do Operating Options/Functions (‘w’) command has many purposes, but may first

be utilized during the module initialization stage. It may also be executed at any time during

data acquisition. However, some non-factory-default options of ‘w’ may become the new reset

default, if a particular function is used to establish them in non-volatile memory.

If any form of the Configure/Control Autonomous Host Streams (‘c’) command or the

Configure/Control Multi-Point Calibration (‘C’) command was in use before reset, it must be

executed again after the reset to restore it. Any other command, that establishes the module in

a non-default reset state, must be re-executed after a reset, if processing is to continue in that

state.

The Network Query (“psi9000”) UDP/IP command may be used (at any time) to make each

module on the network identify itself to the host(s). A parameter, returned in each module’s

response, indicates whether or not a module still has a valid connection. This is a useful way to

detect if an overt reset occurs in a module. The module may be configured to emit this

response automatically after any reset (power on or reboot).

3.1.4.2 Module Data Acquisition

After power-up, all modules will begin to scan all attached transducer channels in channel

number order. Scanning will occur at the module’s maximum internal rate (using the previously

stored number of data averages per channel). The data are stored in an internal buffer,

available for retrieval by the host computer. Engineering units conversion of the scanned

channels is accomplished using thermal correction data extracted from each transducer at

power-up. While scanning, the module will automatically monitor the attached transducer’s

temperature, correcting engineering unit output for any temperature effects.

Page 24 www.PressureSystems.com

Page 34

Pressure Systems, Inc. Model 9116 User’s Manual

All modules effectively defer the host computer’s decision of “which channels of data do I want”

until that time when the host chooses to send read commands to actually retrieve the desired

data from the latest “buffered copy” of the continuously scanned, averaged, and engineeringunit-converted data.

See Section 3.1.4.4 (Delivery of Acquired Data to Host) for more information.

While scanning, all modules take multiple samples and average each channel. The number of

samples per scanned channel defaults to 8, but may be set to one (to disable averaging) or to

any power of 2 (1, 2, 4, 8, 16, 32) to change the degree of averaging (and its effect on

maximum scan rate). The Set Operating Options (‘w’) command may change this variable at

any time.

3.1.4.3 Calibration Adjustment of Offset/Gain Correction Coefficients

All Model 9116 Intelligent Pressure Scanners have built in software commands (and pneumatic

hardware) to perform a periodic zero and span calibration adjustment of attached pressure

transducers. Use of these periodic adjustments result in the highest possible data accuracy.

The result of these calibrations are a new set of internal offset and gain coefficients. These

correction coefficients are over and above those factory-determined and unchanging thermal

correction coefficients stored in each transducer's non-volatile memory. The factory coefficients

provide the basic engineering unit conversion capability, while also correcting for various nonlinear effects, including temperature effect compensation. The offset and gain correction

coefficients provide for fine linear fit adjustment of the factory calibration of each transducer. If

used properly, the periodic zero and span calibration adjustment should be the only

calibration required to maintain specified performance through the life of the Intelligent

Pressure Scanner.

It is generally necessary for the transducer to have real zero and span pressure (specified as 2

or more values) applied when calibration adjustment is required. These pressure values may