Page 1

Page 2

PCI-DAS4020/12

Analog & Digital I/O Board

User’s Guide

© Copyright 2005, Measurement Computing Corporation

Document Revision 7, May, 2005

Page 3

Your new Measurement Computing product comes with a fantastic extra —

Management committed to your satisfaction!

Refer to www.mccdaq.com/execteam.html for the names, titles, and contact information of each key executive at

Measurement Computing.

Thank you for choosing a Measurement Computing product—and congratulations! You own the finest, and you can now

enjoy the protection of the most comprehensive warranties and unmatched phone tech support. It’s the embodiment of our

two missions:

To offer the highest-quality, computer-based data acquisition, control, and GPIB hardware and software

available—at the best possible price.

To offer our customers superior post-sale support—FREE. Whether providing unrivaled telephone technical and

sales support on our latest product offerings, or continuing that same first-rate support on older products and

operating systems, we’re committed to you!

Lifetime warranty: Every hardware product manufactured by Measurement Computing Corporation is warranted against

defects in materials or workmanship for the life of the product. Products found defective are repaired or replaced promptly.

Lifetime Harsh Environment Warranty®: We will replace any product manufactured by Measurement Computing

Corporation that is damaged (even due to misuse) for only 50% of the current list price. I/O boards face some tough

operating conditionssome more severe than the boards are designed to withstand. When a board becomes damaged, just

return the unit with an order for its replacement at only 50% of the current list price. We don’t need to profit from your

misfortune. By the way, we honor this warranty for any manufacturer’s board that we have a replacement for.

30 Day Money Back Guarantee: You may return any Measurement Computing Corporation product within 30 days of

purchase for a full refund of the price paid for the product being returned. If you are not satisfied, or chose the wrong

product by mistake, you do not have to keep it. Please call for an RMA number first. No credits or returns accepted without

a copy of the original invoice. Some software products are subject to a repackaging fee.

These warranties are in lieu of all other warranties, expressed or implied, including any implied warranty of

merchantability or fitness for a particular application. The remedies provided herein are the buyer’s sole and exclusive

remedies. Neither Measurement Computing Corp., nor its employees shall be liable for any direct or indirect, special,

incidental or consequential damage arising from the use of its products, even if Measurement Computing Corp. has been

notified in advance of the possibility of such damages.

HM PCI-DAS4020-12.doc

ii

Page 4

Trademark and Copyright Information

TracerDAQ, InstaCal, Universal Library, Universal Library for LabVIEW, Harsh Environment Warranty, Measurement

Computing Corporation, and the Measurement Computing logo are either trademarks or registered trademarks of

Measurement Computing Corporation.

SoftWIRE is a registered trademark of SoftWIRE Technology, Inc.

Windows, Microsoft, and Visual Studio are either trademarks or registered trademarks of Microsoft Corporation. National

Instruments, NI, and LabVIEW are trademarks of National Instruments. All other trademarks are the property of their

respective owners.

Information furnished by Measurement Computing Corporation is believed to be accurate and reliable. However, no

responsibility is assumed by Measurement Computing Corporation neither for its use; nor for any infringements of patents

or other rights of third parties, which may result from its use. No license is granted by implication or otherwise under any

patent or copyrights of Measurement Computing Corporation.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form

by any means, electronic, mechanical, by photocopying, recording, or otherwise without the prior written permission of

Measurement Computing Corporation.

Notice

Measurement Computing Corporation does not authorize any Measurement Computing Corporation product for

use in life support systems and/or devices without the written approval of the CEO of Measurement Computing

Corporation. Life support devices/systems are devices or systems which, a) are intended for surgical

implantation into the body, or b) support or sustain life and whose failure to perform can be reasonably

expected to result in injury. Measurement Computing Corporation products are not designed with the

components required, and are not subject to the testing required to ensure a level of reliability suitable for the

treatment and diagnosis of people.

iii

Page 5

Table of Contents

Preface

About this User's Guide ......................................................................................................................vi

What you will learn from this user's guide ........................................................................................................vi

Conventions in this user's guide ........................................................................................................................vi

Where to find more information ...................................................................................................................... vii

Chapter 1

Introducing the PCI-DAS4020/12 ..................................................................................................... 1-1

Overview: PCI-DAS4020/12 features ............................................................................................................ 1-1

Software features............................................................................................................................................ 1-1

Chapter 2

Installing the PCI-DAS4020/12 ......................................................................................................... 2-1

What comes with your PCI-DAS4020/12 shipment? ..................................................................................... 2-1

Hardware ....................................................................................................................................................................... 2-1

Software......................................................................................................................................................................... 2-1

Documentation............................................................................................................................................................... 2-1

Optional components ..................................................................................................................................................... 2-2

Unpacking the board....................................................................................................................................... 2-2

Installing the software .................................................................................................................................... 2-3

Installing the hardware ................................................................................................................................... 2-3

Configuring the hardware............................................................................................................................... 2-3

Connecting the board for I/O operations ........................................................................................................ 2-4

Connectors, cables – I/O connectors.............................................................................................................................. 2-4

BNC connectors............................................................................................................................................................. 2-4

Pinout – auxiliary connector .......................................................................................................................................... 2-5

Cabling........................................................................................................................................................................... 2-5

Field wiring and signal termination accessories............................................................................................................. 2-8

Chapter 3

Programming and Developing Applications .................................................................................. 3-1

Programming languages ................................................................................................................................. 3-1

Packaged applications programs..................................................................................................................... 3-1

Register level programming ........................................................................................................................... 3-1

Chapter 4

Functional Details ............................................................................................................................. 4-1

Analog input signal path................................................................................................................................. 4-1

Analog output ................................................................................................................................................. 4-2

Digital I/O....................................................................................................................................................... 4-2

Power distribution........................................................................................................................................... 4-2

Input impedance configuration....................................................................................................................... 4-2

Chapter 5

Calibrating the Board........................................................................................................................ 5-1

Calibration theory........................................................................................................................................... 5-1

Chapter 6

Specifications.................................................................................................................................... 6-1

Analog input ................................................................................................................................................... 6-1

Timing and throughput .................................................................................................................................................. 6-1

Accuracy........................................................................................................................................................................ 6-2

Temperature................................................................................................................................................................... 6-2

Dynamics and noise....................................................................................................................................................... 6-3

iv

Page 6

PCI-DAS4020/12 User's Guide

Trig/Ext Clk BNC........................................................................................................................................... 6-3

Analog output ................................................................................................................................................. 6-3

Accuracy........................................................................................................................................................................ 6-3

Digital input / output....................................................................................................................................... 6-4

Interrupts......................................................................................................................................................... 6-4

Environmental ................................................................................................................................................ 6-5

Power consumption ........................................................................................................................................ 6-5

Connector and pin out..................................................................................................................................... 6-5

Auxiliary connector P3 pinout ....................................................................................................................................... 6-5

v

Page 7

Preface

About this User's Guide

What you will learn from this user's guide

This user's guide explains how to install, configure, and use the PCI-DAS4020/12 so that you get the

most out of its analog and digital I/O features.

This user's guide also refers you to related documents available on our web site, and to technical support

resources that can also help you get the most out of these boards.

Conventions in this user's guide

For more information on …

Text presented in a box signifies additional information and helpful hints related to the subject matter you

are reading.

Caution! Shaded caution statements present information to help you avoid injuring yourself and

others, damaging your hardware, or losing your data.

<#:#>

bold text Bold text is used for the names of objects on the screen, such as buttons, text boxes, and check

italic text

Angle brackets that enclose numbers separated by a colon signify a range of numbers, such as those

assigned to registers, bit settings, etc.

boxes. For example:

1. Insert the disk or CD and click the OK button.

Italic text is used for the names of manuals and help topic titles, and to emphasize a word or phrase.

For example:

The InstaCal installation procedure is explained in the DAQ Software Quick Start.

Never touch the exposed pins or circuit connections on the board.

vi

Page 8

PCI-DAS4020/12 User's Guide About this User's Guide

Where to find more information

The following electronic documents provide information that can help you get the most out of your PCIDAS4020/12.

MCC's Specifications: PCI-DAS4020/12 (the PDF version of Chapter 6 in this guide) is available on

our web site at www.mccdaq.com/pdfs/PCI-DAS4020-12.pdf

MCC's Register Map for the PCI-DAS4020/12 Series is available on our web site at

www.mccdaq.com/registermaps/RegMapPCI-DAS4020-12.pdf

MCC's DAQ Software Quick Start is available on our web site at

MCC's Guide to Signal Connections is available on our web site at

www.mccdaq.com/signals/signals.pdf

.

MCC's Universal Library User's Guide is available on our web site at

.

MCC's Universal Library Function Reference is available on our web site at

MCC's Universal Library for LabVIEW

™

User’s Guide is available on our web site at

12.pdf.

.

.

.

.

vii

Page 9

Chapter 1

Introducing the PCI-DAS4020/12

Overview: PCI-DAS4020/12 features

This manual explains how to install and use the PCI-DAS4020/12 board.

The PCI-DAS4020/12 is a multi-function high-speed data acquisition I/O board that is designed for the PCI

bus. It provides the following features:

Four high-speed 12-bit analog input channels

The input range for each channel is software-configurable for ±1 V or ±5 V. The sample rate is from

10 to 20 MHz, depending on the number of channels accessed. Triggering sources and A/D gating are

via hardware or software, and can be internal or external. Four different modes are software selectable.

Analog input connectors are standard BNC types.

Two 12-bit analog output channels

Each analog output channel can be configured by software for an output range of ±10 V or ±5 V.

Throughput is system-dependent. Triggering mode is software gate. D/A pacing is software paced. The

analog output channels terminate at a 40-pin auxiliary connector.

24 digital I/O channels

An on-board industry standard 82C55A I/O chip provides 24 digital I/O channels configured as two

banks of eight and two banks of four. You can configure each bank independently as input or output.

Signal levels are TTL. The digital I/O channels terminate at a 40-pin auxiliary connector.

Software features

The following software ships with the PCI-DAS4020/12 free of charge.

InstaCal installation, calibration, and test utility

TracerDAQ™ suite of virtual instruments

SoftWIRE® for Visual Studio® .NET graphical programming

MCC DAQ Components for VS .NET (installed with SoftWIRE® for VS .NET)

For information on the features of

booklet that shipped with the PCI-DAS4020/12.

Start

InstaCal, TracerDAQ, and SoftWIRE, refer to the DAQ Software Quick

1-1

Page 10

Installing the PCI-DAS4020/12

What comes with your PCI-DAS4020/12 shipment?

As you unpack your board, make sure that each of the items shown below is included.

Hardware

The following items should be included with your shipment.

PCI-DAS4020/12 board

Chapter 2

Software

The Measurement Computing Data Acquisition Software CD contains the following software:

InstaCal installation, calibration, and test utility

TracerDAQ suite of virtual instruments

SoftWIRE for VS .NET

SoftWIRE MCC DAQ Components for .NET

(installed with SoftWIRE for VS .NET)

Documentation

2-1

Page 11

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

Optional components

If you ordered any of the following products with your board, they should be included with your

shipment.

Universal Library

Universal Library™ Data Acquisition and Control Programming Tools (also includes the InstaCal

utility, the

Cables

Universal Library User's Guide, and the Universal Library Function Reference)

C40FF-x

C40-37F-x

BP40-37F-x

Signal termination and conditioning accessories

MCC provides signal termination products for use with the PCI-DAS4020/12. Refer to the "Field wiring,

signal termination and conditioning" section on page 2-8 for a complete list of compatible accessory

products.

Unpacking the board

The PCI-DAS4020/12 board is shipped in an antistatic container to prevent damage by an electrostatic

discharge. To avoid such damage, perform the following procedure when unpacking and handling your

board:

1.

Before opening the antistatic container, ground yourself with a wrist-grounding strap or by holding

onto a grounded object (such as the computer chassis).

2.

Touch the antistatic container to the computer chassis before removing the board from the container.

3.

Remove the board from the container. Never touch the exposed pins or circuit connections on the

board.

If your PCI-DAS4020/12 is damaged, notify Measurement Computing Corporation immediately by

phone, fax, or e-mail. For international customers, contact your local distributor where you purchased the

PCI-DAS4020/12.

2-2

Page 12

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

Phone: 508-946-5100 and follow the instructions for reaching Tech Support.

Fax: 508-946-9500 to the attention of Tech Support

Email: techsupport@measurementcomputing.com

Installing the software

Refer to the DAQ Software Quick Start for instructions on installing the software on the Measurement

Computing Data Acquisition Software CD. This booklet is shipped with the hardware, and is also

Install the software before you install the hardware

Installing the software first ensures that the information required for proper board detection is installed

and available at boot up.

.

Installing the hardware

PCI-DAS4020/12 is completely plug-and-play. There are no switches or jumpers to set on these boards.

Configuration is controlled by your system's BIOS. To install your board, follow the steps below:

1.

Turn your computer off, open it up, and insert your board into an available PCI slot.

2.

Close your computer and turn it on.

If you are using an operating system with support for plug-and-play (such as Windows 95 or

Windows 2000), a dialog box opens as the system loads, indicating that new hardware has been

detected. If the information file for this board is not already loaded onto your PC, you are prompted

for the disk containing this file. The

supplied with your board contains this file. If required, insert the disk or CD and click

3.

4. If your board has been powered-off for more than 10 minutes, allow your computer to warm up for at

least 15 minutes before acquiring data. This warm-up period is required in order for the board to

achieve its rated accuracy. The high speed components used on the board generate heat, and it takes

this amount of time for a board to reach steady state if it has been powered off for a significant

amount of time.

InstaCal.

Measurement Computing Data Acquisition Software CD

OK.

DAQ Software Quick Start that came with your board

) for information on how to initially

Configuring the hardware

All of the hardware configuration options on the PCI-DAS4020/12 are software controlled. Use InstaCal

to select the number of channels to sample (one, two or four channels), and the analog output range

(±10 V or ±5 V.) Once selected, any program that uses the Universal Library will initialize the hardware

according to your selections.

2-3

Page 13

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

k

Connecting the board for I/O operations

Connectors, cables – I/O connectors

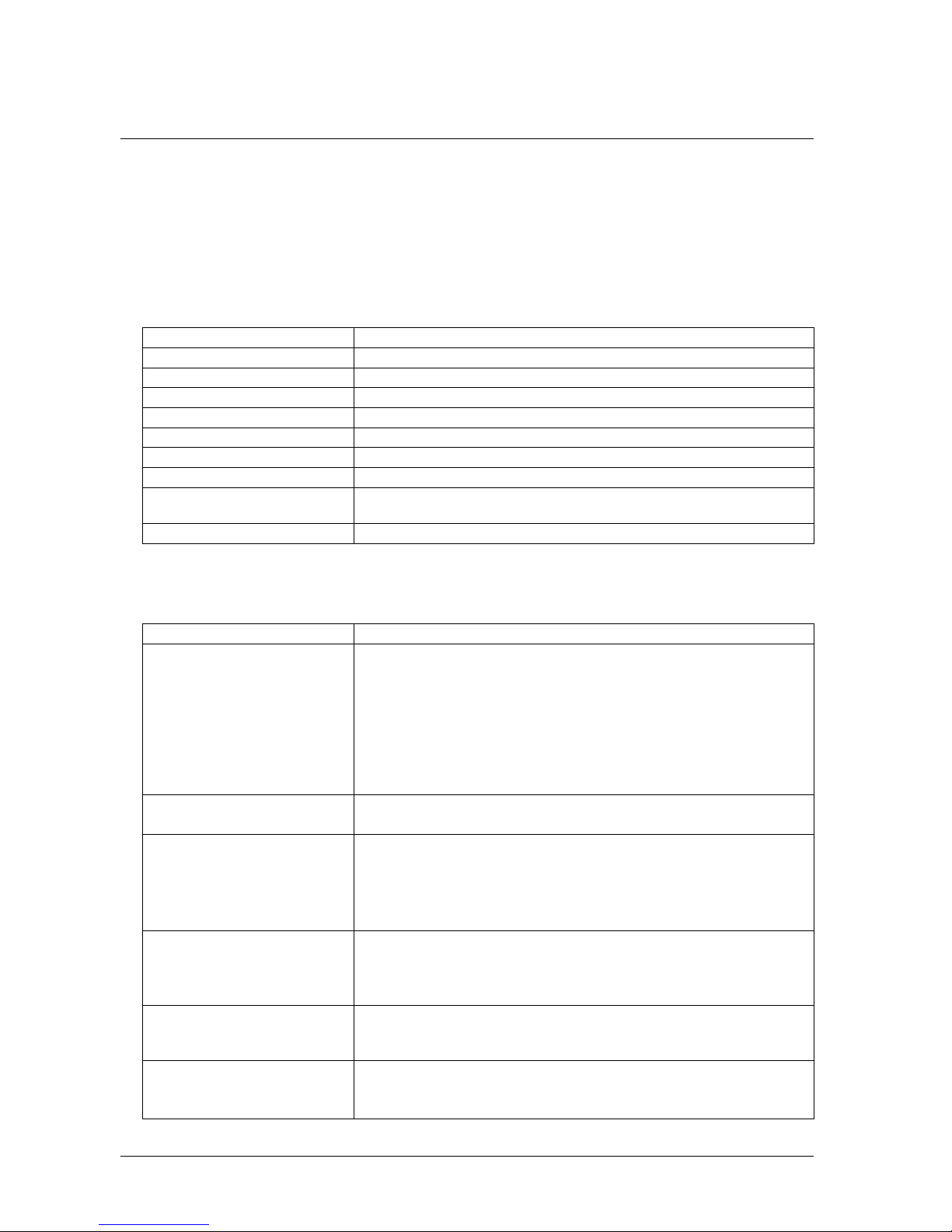

Table 2-1

lists the board connectors, applicable cables, and compatible accessory products for the PCI-

DAS4020/12.

Table 2-1. Board connectors, cables, compatible hardware

Connector type BNC connector: five standard female

Auxiliary connector: 40-pin header connector

Compatible cables

C40FF-x

C40-37F-x

BP40-37-x

Compatible accessory products With the C40FF-x cable:

CIO-MINI40

With the C40-37F-x cable:

CIO-MINI37

SCB-37

With the BP40-37-x and the C37FF-x or C37FFS-x cable:

SCB-37

CIO-ERB24

CIO-ERB08

SSR-RACK24

SSR-RACK08

Information on signal connections

General information regarding signal connection and configuration is available in the Guide to Signal

Connections. This document is available on our web site at

http://www.measurementcomputing.com/signals/signals.pdf.

BNC connectors

The board’s analog input and trigger input connectors are standard female BNC connectors that are

visible from the rear of the computer when you install the board.

Channel 0

Channel 1

Channel 2

Channel 3

TRIG /Ext Cl

Figure 2-1. Analog inputs and trigger Input BNC connectors

2-4

Page 14

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Pinout – auxiliary connector

Table 2-2

defines the pinout for the board’s 40-pin on-board auxiliary connector (labeled P3 on the

board). Pin 1 is identified by a beveled edge on the board silkscreen.

Table 2-2. 40-pin auxiliary connector P3

Signal Name Pin Pin Signal Name

D/A OUT 1 40

D/A GND 38

Port A 0 36

Port A 1 34

Port A 2 32

Port A 3 30

Port A 4 28

Port A 5 26

Port A 6 24

Port A 7 22

Port C 0 20

Port C 1 18

Port C 2 16

Port C 3 14

Port C 4 12

Port C 5 (Start Trigger In/Ext

Port C 6 (A/D Stop Trigger In) 8

Port C 7 (A/D Pacer Gate) 6

GND 4

+5V 2

PCI slot ↓

10

39 D/A OUT 0

37 GND

35 +5V

33 GND

31 n/c

29 GND

27 n/c

25 GND

23 n/c

21 GND

19 Port B 0

17 Port B 1

15 Port B 2

13 Port B 3

11 Port B 4

9 Port B 5

7 Port B 6

5 Port B 7

3 INTERRUPT ENABLE *

1 INTERRUPT IN *

* Pin 1 and pin 3 have 10 K pull-up resistors installed.

Use pin 38 for analog output return

When using the analog output pins D/A OUT 0 (pin 39) and D/A OUT 1 (pin 40), use D/A GND only

(pin 38) for the return.

Cabling

For signal connections and termination, you can use the CIO-MINI40 screw terminal board and C40FF-x

cable. For connections to 37-pin screw terminal boards, you can use the C40-37F-

The red stripe

2

40

40-pin Female

IDC Connector

1

39

Figure 2-2. C40FF-x cable

identifies pin # 1

x cable.

2

40

40-pin Female

IDC Connector

1

39

2-5

Page 15

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

2

40

40-pin Female

IDC Connector

1

39

The red stripe

identifies pin # 1

1

19

37-pin Female

Dsub Connector

20

37

Figure 2-3. C40-37F-x cable

If you don’t need to connect to the PCI-DAS4020/12 analog outputs (pins 38 to 40), you can connect to a

BP40-37-x cable. The BP40-37-x cable brings pins 1 through 37 of the 40-pin connector out to 37-pin

male "D" connector mounted on a backplane bracket.

40

19

37

39

20

1

37-pin Male D Connector

with Backplate Assembly

The red stripe and arrow

identify pin # 1

Figure 2-4. BP40-37 cable

Key

40-pin Female

IDC Connector

2

1

2-6

Page 16

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

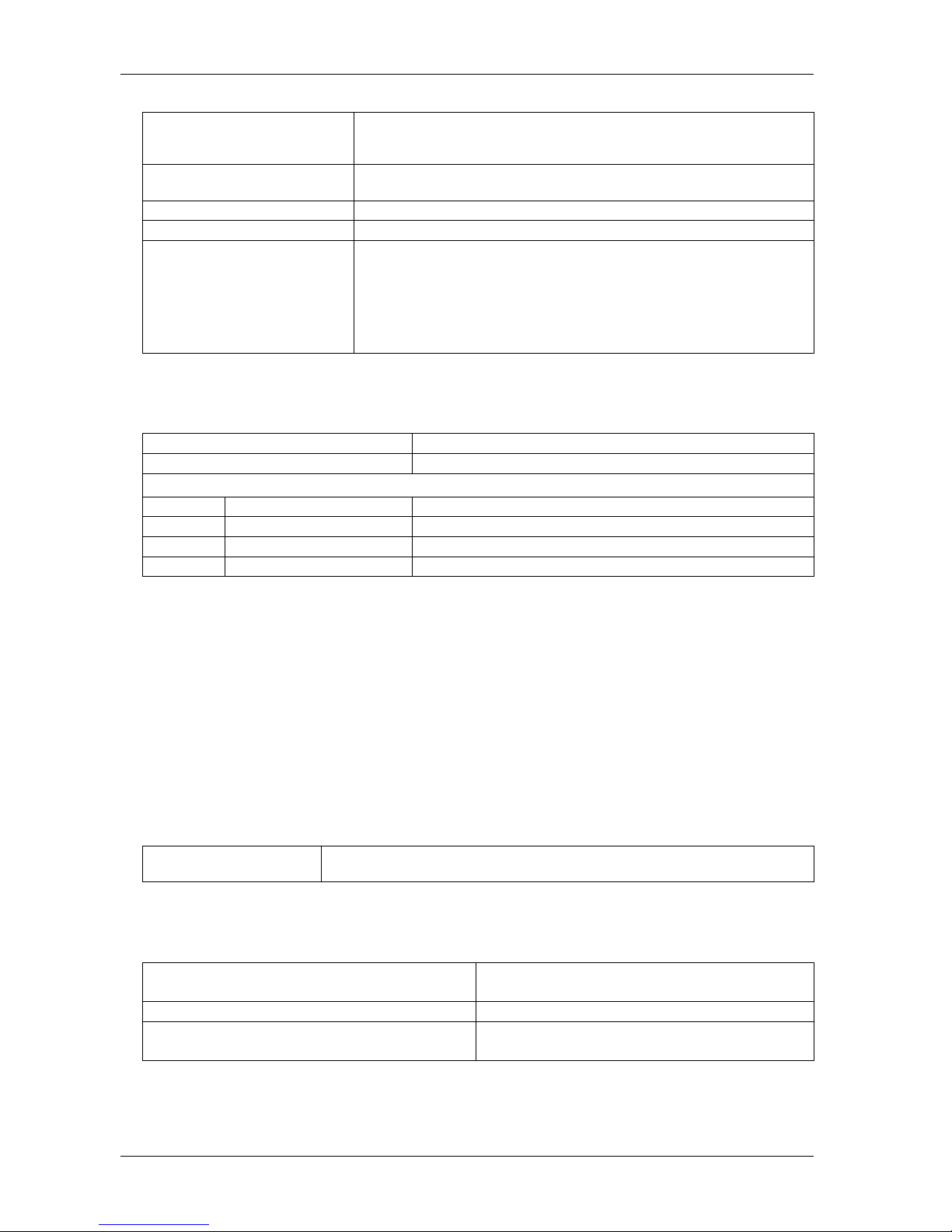

40-pin to 37-pin signal mapping

Signal mapping on the C40-37F-x and the BP40-37-x cables is not 1:1. lists the pin numbers of

Table 2-3

the signals on the 40-pin end and the pin numbers of the associated signals on the 37-pin end.

Table 2-3. Signal mapping on the C40-37F-x and BP40-37F-x cables

40-pin cable end 37-pin cable end

Pin Signal Name Pin Signal Name

1 INTERRUPT IN 1 INTERRUPT IN

2 +5V 20 +5V

3 INTERRUPT ENABLE 2 INTERRUPT ENABLE

4 GND 21 GND

5 Port B 7 3 Port B 7

6 Port C 7 22 Port C 7

7 Port B 6 4 Port B 6

8 Port C 6 23 Port C 6

9 Port B 5 5 Port B 5

10 Port C 5 24 Port C 5

11 Port B 4 6 Port B 4

12 Port C 4 25 Port C 4

13 Port B 3 7 Port B 3

14 Port C 3 26 Port C 3

15 Port B 2 8 Port B 2

16 Port C 2 27 Port C 2

17 Port B 1 9 Port B 1

18 Port C 1 28 Port C 1

19 Port B 0 10 Port B 0

20 Port C 0 29 Port C 0

21 GND 11 GND

22 Port A 7 30 Port A 7

23 N/C 12 N/C

24 Port A 6 31 Port A 6

25 GND 13 GND

26 Port A 5 32 Port A 5

27 N/C 14 N/C

28 Port A 4 33 Port A 4

29 GND 15 GND

30 Port A 3 34 Port A 3

31 N/C 16 N/C

32 Port A 2 35 Port A 2

33 GND 17 GND

34 Port A 1 36 Port A 1

35 +5V 18 +5V

36 Port A 0 37 Port A 0

37 GND 19 GND

38 N/C 39 N/C 40 N/C -

For digital signal conditioning, you can connect the BP40-37 cable to a C37FF-x or C37FFS- x cable, and

then connect one of these cables to the 37-pin connector on MCC’s digital signal conditioning boards.

Refer to page 2-8 for a list of compatible boards.

1

19

The red stripe

identifies pin # 1

20

37

1

19

20

37

Figure 2-5. C37FF-x cable

2-7

Page 17

PCI-DAS4020/12 User's Guide Installing the PCI-DAS4020/12

1

20

37

19

Figure 2-6. C37FFS-x cable

1

20

37

19

Field wiring and signal termination accessories

You can use the following MCC screw terminal board to terminate field signals and route them into the

PCI-DAS4020/12 board using the C40FF-x cable:

CIO-MINI40 – 40-pin universal screw terminal board. Details are available on our web site at

www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=102&pf_id=257

You can use the following MCC screw terminal boards to terminate field signals and route them into the

PCI-DAS4020/12 board using the C40-37F-x cable:

CIO-MINI37 – 37-pin universal screw terminal board. Details are available on our web site at

www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=102&pf_id=255

SCB-37 – 37 conductor, shielded signal connection/screw terminal box. Details on are available on

our web site at www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=196&pf_id=1166

Digital Signal Conditioning

.

.

.

For digital signal conditioning, you can connect the PCI-DAS4020/12 to the following boards using the

BP40-37-x cable in conjunction with the C37FF-x or C37FFS-x cable.

CIO-ERB24 – 24 Form C, 6A relays. Details on this product are available on our web site at

www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=123&pf_id=241

.

CIO-ERB08 – Eight Form C, 6A relays. Details are available on our web site at

www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=123&pf_id=240

.

SSR-RACK24 – 24-channel solid state module rack. Details are available on our web site at

www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=122&pf_id=1193

.

SSR-RACK08 – 24-channel solid state module rack. Details are available on our web site at

www.mccdaq.com/cbicatalog/cbiproduct.asp?dept_id=122&pf_id=620

.

2-8

Page 18

Chapter 3

Programming and Developing Applications

After following the installation instructions, your PCI-DAS4020/12 is ready for use. Although the board is

part of the larger DAS family, there is no correspondence between registers. Software written at the register

level for other DAS models will not work with the PCI-DAS4020/12.

Programming languages

Packaged applications programs

Many packaged application programs, such as SoftWIRE, Labtech Notebook™, and HP-VEE™, now

have drivers for your board. If the package you own does not have drivers for the board, please fax or email the package name and the revision number from the install disks. We will research the package for

you and advise how to obtain drivers.

or any other language, please refer to the Universal Library User's Guide

).

Some application drivers are included with the Universal Library package, but not with the application

package. If you have purchased an application package directly from the software vendor, you may need to

purchase our Universal Library and drivers. Please contact us by phone, fax or e-mail:

Phone: 508-946-5100 and follow the instructions for reaching Tech Support.

Fax: 508-946-9500 to the attention of Tech Support

Email: techsupport@measurementcomputing.com

Register level programming

You should use the Universal Library or one of the packaged application programs mentioned above to

control your board. Only experienced programmers should try register-level programming. To program at

the register level in your application, refer to the

www.mccdaq.com/registermaps/RegMapPCI-DAS4020-12.pdf

Register Map for the PCI-DAS4020/12 Series (available at

.

3-1

Page 19

s

Chapter 4

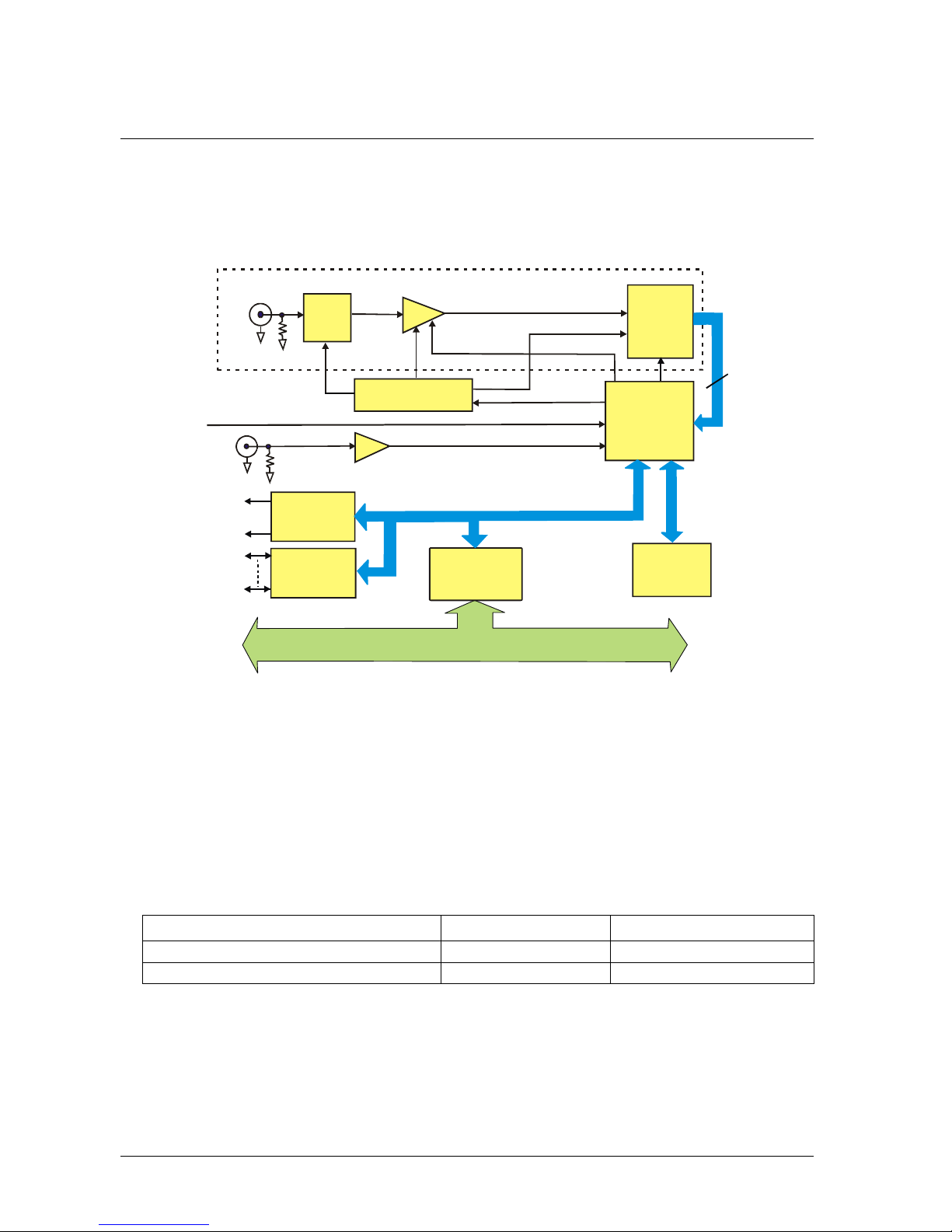

Functional Details

The PCI-DAS4020/12 provides four high-speed 12-bit analog input channels, dual 12-bit analog outputs

and 24 digital I/O channels. This functionality is illustrated in the block diagram shown here.

Four analog input channels per board

BNC

50 Ohm

Attenuator/

Amplifier

Input

MUX

S

IN

VREF

ADC

CONV

Four

Channel

External Pacer

TRIG1, TRIG2,

or GATE

BNC

Analog

Outputs

24 I/O

Analog

Clock/

Trigger

Dual12-bit

DAC

Digital I/0

(82C55)

Gain & Offset

AUTOCAL

PCI Bus Connector

(5V, 32 BIT, 33 MHZ)

Local Bus

PC Bus

Controller

System

Timing

Controller

32K x 24

SRAM

Dual

12

Figure 4-1. PCI-DAS4020/12 Block Diagram

Analog input signal path

Four single-ended analog input channels, connect from BNC connectors to individual amplifiers and then

connect to dedicated ADC’s. Each path allows for:

50 ohm or high-Z termination, selected by solder gap

±1 V or ±5 V bipolar ranges, software-selectable (see Ta ) ble 4-1

Auto-calibration for offset and gain adjustments for each channel and each range

Full Scale Input Range Attenuation Divider Output

+5 V to -5 V 5 ±1 V

+1 V to -1 V 1 ±1 V

Table 4-1. Input range

4-1

Page 20

PCI-DAS4020/12 User's Guide Functional Details

Analog output

Two 12-bit voltage outputs are software programmable for ±10 V or ±5 V. The D/A is the Analog

Devices AD7237 Dual DAC. Since the DAC is dual buffered, the DAC output voltage is updated after

the MS nibble is written to the DAC.

The DACs initially power-up and are reset to 0 V. There is no calibration on these DACs. The offset and

gain errors are minimized by using precision components. shows the DAC input coding. Table 4-2

Table 4-2. DAC input coding

DAC Range Input Code Binary 12 bit Input Code Hex 12 bit Output Voltage

± 10 V 0000 0000 0000 000h

± 10 V 1000 0000 0000 800h 0 V

± 10 V 1111 1111 1111 FFFh +9.99513 V

± 5 V 0000 0000 0000 000h

± 5 V 1000 0000 0000 800h 0 V

± 5 V 1111 1111 1111 FFFh +4.99756 V

−10.000 V

−5.000 V

Figure 4-2. Analog output block diagram

Digital I/O

The digital I/O is an 82C55 digital logic device. An external interrupt source pin (pin 1) and external

interrupt enable pin (pin 3) on the auxiliary 40-pin connector (

P3) are used for external interrupts. These

lines are pulled up and an OR operation is performed on them to generate the external interrupt signal.

Both are active low.

Power distribution

The PCI-DAS4020/12 board is powered by the PCI bus. The only power used is +5 V.

Input impedance configuration

Each analog input and the trigger/clock input channel on the PCI-DAS4020/12 has a dedicated solder

gap. A solder gap consists of two copper pads that you can solder together to change the input impedance

of the channel. When the solder gaps are open (default), the input impedance is 1.5 Mohm. When the

solder gaps are closed, the input impedance is 50 ohm.

To close the solder gaps and change the impedance to 50 ohm, solder the two copper pads together. To

close the solder gap, touch a soldering iron to the two contacts until some rosin core solder flows across

the copper pads and forms a small blob of solder. Be careful not to overheat the pads, or they may

delaminate from the circuit board. Do not add too much solder, as it could flow onto other components

and cause an electrical short or other defect.

4-2

Page 21

PCI-DAS4020/12 User's Guide Functional Details

e

Solder Gap Configuration Input Impedance

Open

Close

1.5 MΩ typical

50 Ω

The board designation for the analog input channels and the trigger/clock BNC input are listed below.

Solder Gap board label Channel

SG1 Channel 0

SG2 Channel 1

SG3 Channel 2

SG4 Channel 3

SG5

TRIG/Ext Clock input

Solder gaps for the analog input channels are located on the rear of the board (circuit-side) and are

labeled

SG1 to SG4. See . Figure 4-3

Analog input chann

solder gap locations

SG1 - SG4

Figure 4-3. Analog input channel solder gap locations (circuit-side)

The solder gap for the trigger/clock input is located on the front of the board (component-side) and is

labeled

SG5. See . Figure 4-4

TRIG/Ext Clk input

solder gap location SG5

Figure 4-4. Trigger/clock input solder gap location (component-side)

An example of each input impedance configuration option is shown in . Figure 4-5

4-3

Page 22

PCI-DAS4020/12 User's Guide Functional Details

Solder gap SG3

is open (1.5 Mohms)

Solder gap SG4

is closed (50 ohms)

Figure 4-5. Open and closed solder gaps

4-4

Page 23

A

A

Chapter 5

Calibrating the Board

Use the InstaCal utility program to calibrate the PCI-DAS4020/12. InstaCal calibrates the PCIDAS4020/12 using on-board digital potentiometers and trim D/A converters. No external equipment or

user adjustments are required.

The PCI-DAS4020/12 is factory calibrated. The calibration coefficients are stored in nvRAM. Analog input

adjustments are made via 10-bit calibration DACs that are referenced to the on-board factory calibrated

standard. Each channel has a pair of dedicated 10-bit DACs that trim out offset and gain errors.

calibrates the offset by adjusting the offset voltage at the input of each ADC, and adjusts the gain via the

ADC reference pin.

At run time, the calibration factors are loaded into system memory and are automatically retrieved each

time a different ADC range is specified. You can recalibrate any time using factory voltage standards with

InstaCal. A full calibration typically takes less than two minutes.

Before you calibrate the board, turn your computer on and allow at least 30 minutes for the internal case

temperature to stabilize. For best results, calibrate the board immediately before making critical

measurements. The high resolution analog components on the board are sensitive to temperature. Premeasurement calibration insures that your board is operating with optimum calibration values.

InstaCal

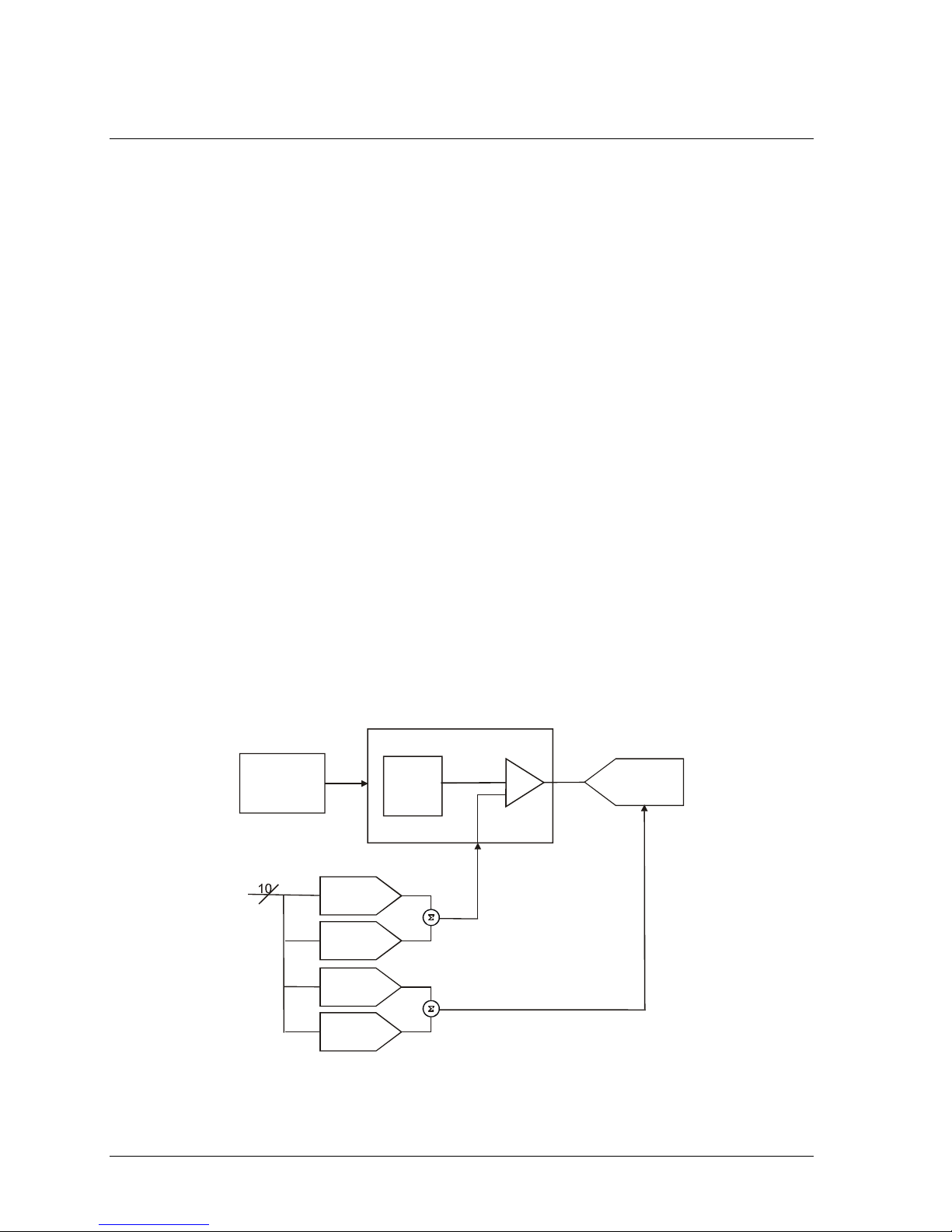

Calibration theory

Analog inputs are calibrated for offset and gain. Offset calibration is performed directly on the input

amplifier, with coarse and fine trim DACs acting on the amplifier.

For input gain calibration, a precision calibration reference is used in conjunction with coarse and fine trim

DACs acting on the ADC. See . Figure 5-1

nalog In

Gain

Calibration

Reference

Trim DAC

Coarse

Trim DAC

Fine

Trim DAC

Coarse

MUX

Offset

Adjust

DC

Gain Adjust

Trim DAC

Fine

Figure 5-1. Analog input calibration

5-1

Page 24

Specifications

Typical for 25 °C unless otherwise specified.

Specifications in italic text are guaranteed by design.

Analog input

Table 6-1. Analog input specifications

A/D converter type AD9225, 25 MSPS pipelined A/D

Resolution 12-bits

Programmable ranges ±5 V, ±1 V

Number of channels 4 single-ended, independent ADC’s per channel

Connection 4 independent BNC

Bandwidth 17 MHz typical

Coupling DC

Input leakage current 2 uA typ, 10 uA max

Input impedance

Absolute maximum input voltage ±15 V

1.5 Mohm typ, or 50 ohm, selectable

(coaxial cable termination)

Chapter 6

Timing and throughput

Table 6-2. Timing and throughput specifications

Simultaneous sampling Software selectable option - 1, 2, or 4 channels

A/D Convert clock source Internal: On-card crystal oscillator

Frequency: 40 MHz

Frequency accuracy: 50% duty cycle, 50 ppm

External: Trig/Ext Clk BNC, or A/D External Clock on the 40-pin

connector

24-bit internal pre-scale counter (min pre-scale = 2)

Clock Rate: 40 MHz max, 2 kHz min

Duty Cycle: 50% ± 5%

A/D Gate source Digital: Trig/Ext Clk BNC or A/D Pacer Gate on 40-pin connector

Analog: Any of the four input channels

A/D Gate modes Digital: Programmable active high/low, level/edge

Analog: Above/below reference, positive/negative

Hysteresis, inside/outside window

Resolution: 12-bit

Slew rate: 10V/sec. minimum

A/D Start Trigger (TRIG1) Software: Using a DAQ start command.

Digital: Trig/Ext Clk BNC, A/D Start Trigger In (on the 40-pin

connector)

Analog: Any of the four input channels

A/D Stop Trigger (TRIG2)

A/D Triggering modes Digital: Programmable rising or falling edge

Digital: Trig/Ext Clk BNC, A/D Stop Trigger In (on the 40-pin

connector)

Analog: Any of the four input channels

Analog: Trigger above/below reference

Resolution: 12-bit

6-1

Page 25

PCI-DAS4020/12 User's Guide Specifications

Pre-trigger mode

Data transfer

A/D Conversion time 40 ns

Sample rate 20 MHz max, 1 kHz min

Throughput Single channel: 20 MHz continuous

Unlimited number of pre-trigger samples, 16 Meg post-trigger samples.

Compatible with both digital and analog trigger/gate options. Data acquisition

initiated via TRIG1. Post-trigger phase initiated via TRIG2.

Via dual 32 K x 24 sample FIFO, SRAM based, with Bus-Master DMA and

scatter-gather, interrupt, or software polled.

Two channels (0 and 1 or 2 and 3): 20 MHz continuous

Four channels: 10 MHz continuous

In background mode, the maximum throughput may be impacted by bus or

interrupt activity.

Accuracy

Table 6-3. Analog input accuracy specifications

Absolute accuracy ±5.5 LSB worst case error (either range)

Typical accuracy ±3.0 LSB error (either range)

Accuracy components:

Gain error ±2.0 LSB max, ±1.0 LSB typ

Offset error ±1.5 LSB max, ±1.0 LSB typ

Integral linearity error ±2.5 LSB max, ±1.0 LSB typ

Differential linearity error ±1.0 LSB max , ±0.4 LSB typ (No missing codes guaranteed)

Board error is a combination of gain, offset, integral linearity, and differential linearity error. The overall

absolute worst-case error of the board may be calculated by summing these component errors. Worst case

error is realized only in the unlikely event that each of the component errors are both at their maximum

level, and causing error in the same direction. Though this is very uncommon, it is still possible, and the

calculated worst case error of the PCI-DAS4020/12 board is ±7.0 LSB.

Each PCI-DAS4020/12 board is tested at the factory to make sure that its actual worst case error is less

than ±5.0 LSB. Allowing for a 10% guard-band, the absolute worst-case error of a board is ±5.5 LSB.

Typical accuracy can be calculated from the various component typical errors in a similar fashion. This

typical maximum error calculation for the PCI-DAS4020/12 board yields ±3.4 LSB. However, this again

assumes that each of the errors is forcing an error in the same direction. Empirical evidence supports a

conservative typical error budget of ±3.0 LSB.

Table 6-4. Calibration specifications

Calibration

Auto-calibration. Calibration factors for each range stored on board in non-volatile

RAM

Temperature

Table 6-5. Temperature specifications

Gain drift ±5 V range: ±0.10 LSB/°C max

±1 V range: ±0.13 LSB/°C max

Offset drift ±0.11 LSB/°C max, all ranges

Overall board temperature drift ±5 V range: ±0.21 LSB/°C max

±1 V range: ±0.24 LSB/°C max

Overall, worst-case temperature drift is calculated by adding the drifts corresponding to the gain and

offset drifts. This worst case number is unlikely to occur, as it requires both gain and offset drifts to be at

their maximum levels, and to be affecting the measurement in the same direction. However, the overall

board D/A drift specifications have been calculated in this fashion.

6-2

Page 26

PCI-DAS4020/12 User's Guide Specifications

Dynamics and noise

Table 6-6. Dynamics and noise specifications

SNR (Signal-to-noise ratio) 66.6 dB

SINAD (signal-to-noise and distortion ratio) 66.5 dB

SFDR (spurious free dynamic range) 80 dB

THD (total harmonic distortion) 80 dB

Noise distribution:

(Rate = 10 KHz-20 MHz, Average % ± 2 bins, Average % ± 1 bin, Average #

bins)

Bipolar

(5V):

Bipolar

(1V):

100% / 98% / 5

bins

100% / 98% / 5

bins

Trig/Ext Clk BNC

Software selectable for A/D Start Trigger (TRIG1), A/D Stop Trigger (TRIG2) or A/D Pacer Gate

(AGATE); also used as an A/D clock input 2X clock source (DAQ_CLK).

Table 6-7. Trig/Ext Clk BNC specifications

Input impedance 50 ohm, 1 Mohm selectable (coaxial cable termination)

Input threshold Programmable 2.5 V threshold or 0 V threshold

Input slew rate 1 V/µsec min

Input range ±5 V

Bandwidth 40 MHz

Coupling DC

Analog output

Table 6-8. Analog output specifications

D/A converter

type

Resolution 12-bits

Number of

channels

Output range ±10 V, ±5 V software selectable

D/A pacing Software paced

Throughput

Data transfer Programmed I/O

Accuracy

Absolute accuracy ±13 LSB max

Offset error ±6 LSB max

Gain error ±5 LSB max

Differential non-linearity ±1 LSB max

Integral non-linearity ±1 LSB max

AD7237

2

System dependent. Using the Universal Library programmed output function (cbAout) in a loop

in Visual Basic, a typical update rate of 500 Hz (± 50 Hz) can be expected. The rate was measured

on a 330 MHz Pentium II based PC.

Table 6-9. Analog output accuracy specifications

6-3

Page 27

PCI-DAS4020/12 User's Guide Specifications

Total analog output error is a combination of gain, offset, integral linearity, and differential linearity

error. The overall absolute worst-case error of the board may be calculated by summing these component

errors. Worst case error is realized only in the unlikely event that each of the component errors are both at

their maximum level, and causing error in the same direction. Though this is very uncommon, it is still

possible.

Monotonicity Guaranteed monotonic over temperature

Analog output

drift

Settling time

(20 V step to ± ½

LSB)

Slew rate 5 V/µs

Current drive ±5 mA

Output shortcircuit duration

Output coupling DC

Output

impedance

Miscellaneous Single buffered output latch

±0.11 LSB/°C max, all ranges

5µs max

25 mA indefinite

0.5 Ohm max

Update DACs individually

On power-up and reset, the inputs to both D/A output buffers are grounded and the board’s D/A

outputs will be set to 0 volts ± 6 mV. Upon writing to the D/A converters, the output buffers

will reflect the D/A outputs and achieve rated accuracy. However, upon writing a 0 to the

D/A’s, a small output change may be noted (up to 10 LSB).

Digital input / output

Table 6-10. DIO specifications

Digital type (40-pin connector) 8255A

Configuration 2 banks of 8, 2 banks of 4, programmable by bank as input or output

Number of channels 24 I/O

Output high 3.0 volts min @ 2.5 mA

Output low 0.4 volts max @ 2.5 mA

Input high 2.0 volts min, Vcc + 0.5 volts absolute max

Input low

Power-up / reset state Input mode (high impedance)

0.8 volts max, GND − 0.5 volts absolute min

Interrupts

Table 6-11. Interrupt specifications

Interrupts INTA# - mapped to IRQn via PCI BIOS at boot-time

Interrupt enable Software programmable

ADC Interrupt sources DAQ_ACTIVE: Interrupt is generated when a DAQ sequence is active.

DAQ_STOP: Interrupt is generated when A/D Stop Trigger In is detected.

DAQ_DONE: Interrupt is generated when a DAQ sequence completes.

DAQ_FIFO_1/2_FULL:

Interrupt is generated when ADC FIFO is ½ full.

DAQ_SINGLE: Interrupt is generated after each conversion completes.

External

External Interrupt Enable

Interrupt is generated via edge-sensitive transition on the Interrupt In pin on the 40pin connector. Rising/falling edge polarity selection. The Interrupt In pin is pulled up

to 5 V through a 10 K resistor.

Active low Interrupt Enable signal on the 40-pin connector. The Interrupt Enable pin

is pulled up to 5 V through a 10 K resistor.

6-4

Page 28

PCI-DAS4020/12 User's Guide Specifications

Environmental

Table 6-12. Environmental specifications

Operating temperature range 0 to 70 °C

Storage temperature range

−40 to 100 °C

Humidity 0 to 90% non-condensing

Power consumption

Table 6-13. Power consumption specifications

+5 V Operating (A/D to FIFO) 1.5 A typical, 2.0 A max

Connector and pin out

Table 6-14. Connector specifications

Connector type BNC connector: five standard female connectors

Auxiliary connector (P3): 40-pin header connector

Compatible cables (for the 40-pin auxiliary connector)

Compatible accessory products

(with the C40FF-x cable)

Compatible accessory products

(with the C40-37F-x cable)

OR

(with the BP40-37-x and the C37FF-x or C37FFS-x cable)

C40FF-x

C40-37F-x

BP40-37-x

CIO-MINI40

CIO-MINI37

SCB-37

CIO-ERB24

CIO-ERB08

SSR-RACK24

SSR-RACK08

Auxiliary connector P3 pinout

Table 6-15. Auxiliary connector (P3) pin out

Pin Signal Name Pin Signal Name

1 INTERRUPT IN * 2 +5V

3 INTERRUPT ENABLE * 4 GND

5 Port B 7 6 Port C 7 (A/D Pacer Gate)

7 Port B 6 8 Port C 6 (A/D Stop Trigger In)

9 Port B 5 10 Port C 5 (Start Trigger In/Ext Clock)

11 Port B 4 12 Port C 4

13 Port B 3 14 Port C 3

15 Port B 2 16 Port C 2

17 Port B 1 18 Port C 1

19 Port B 0 20 Port C 0

21 GND 22 Port A 7

23 n/c 24 Port A 6

25 GND 26 Port A 5

27 n/c 28 Port A 4

29 GND 30 Port A 3

31 n/c 32 Port A 2

33 GND 34 Port A 1

35 +5V 36 Port A 0

37 GND 38 D/A GND

39 D/A OUT 0 40 D/A OUT 1

* Pins 1 and 3 have 10 K pull-up resistors installed.

6-5

Page 29

EC Declaration of Conformity

We, Measurement Computing Corporation, declare under sole responsibility that the product

PCI-DAS4020/12 High speed analog and digital I/O board for the PCI bus

Part Number Description

to which this declaration relates, meets the essential requirements, is in conformity with, and CE marking

has been applied according to the relevant EC Directives listed below using the relevant section of the

following EC standards and other informative documents:

EU EMC Directive 89/336/EEC: Essential requirements relating to electromagnetic compatibility.

EN 55022 Class B (1995): Radiated and conducted emission requirements for information technology

equipment.

ENV 50204 (1995): Radio-frequency electromagnetic field immunity

EN 55024 (1998): EC generic immunity requirements.

EN 50082-1 (1997): EC generic immunity requirements.

EN 61000-4-2 (1995): Electrostatic discharge immunity.

EN 61000-4-3 (1997) ENV 50204 (1996): RF immunity.

EN 61000-4-4 (1995): Electric fast transient burst immunity.

EN 61000-4-5 (1995): Surge immunity.

EN 61000-4-6 (1996): Radio frequency common mode immunity.

EN 61000-4-8 (1994): Power frequency magnetic field immunity.

EN 61000-4-11 (1994): Voltage dip and interrupt immunity

Carl Haapaoja, Vice-President of Design Verification

Page 30

Measurement Computing Corporation

16 Commerce Boulevard,

Middleboro, Massachusetts 02346

(508) 946-5100

Fax: (508) 946-9500

E-mail: info@mccdaq.com

www.mccdaq.com

Loading...

Loading...