Page 1

WBK15

Description

5B Isolated Signal-Conditioning Module

Description …… 1

Hardware Setup …… 2

Configuration …… 2

Connection …… 3

Power …… 4

Safety Concerns …… 4

Using Fastener Panels to Stack Modules …… 4

Software Setup …… 5

WBK15 – Specifications …… 7

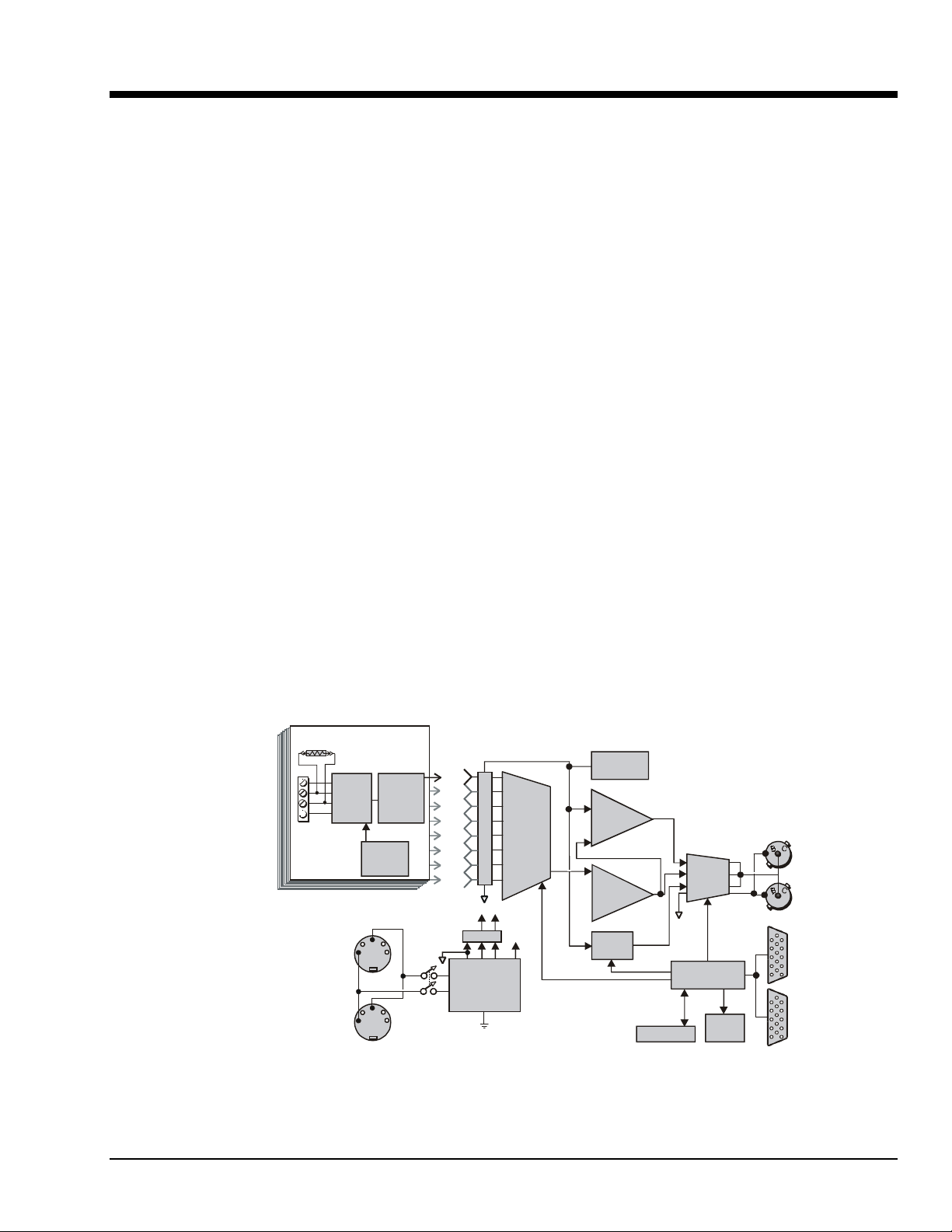

The WBK15 module can accommodate eight 5B isolated-input signal-conditioning modules for use with the

WaveBook. The WaveBook can accommodate 8 WBK15s for a maximum of 64 expansion channels. The

WaveBook scans WBK15’s channels at the same 1 µs/channel rate that it scans all WBK analog inputs,

allowing it to measure all channels of a fully configured 72-channel system in 72 µs.

Other features of WBK15 include:

• Built-in power supply that operates from 10 to 30 VDC and can power a full complement of 5B

modules (even with bridge excitation).

• Removable, plug-in screw-terminal blocks for convenient connection of 5B modules.

•

On-board cold-junction sensing for thermocouple 5B modules.

•

For each 5B module, 1500 V isolation from the system and from other channels.

Current-Sense

Resistor

5.000 V

Buffered

5B

Low-

Module

Pass

Socket

Filter

#1

Input

Terminal

Block

Channel 1

Channels 2-8 identical

DC Power

Input &

Expansion

+V

Cold

Junction

Sensor

GND

DIN-5

Power

Switch

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

+15 V

Filters

Isolated

+5, ±15 VDC

Power

Supply

Channel

Selection

MUX

Internal Jumpers

-15 V

+5 V

WBK15 Block Diagram

Reference

Bipolar

Offset

Amp

Buffer

Amp

Control

DAC

µP &

Control Logic

EEPROM

Output

MUX

Status

LEDs

BNC

N

N

Analog

Output to

Wave Book

Expansion

Control

From

WaveBo ok

WBK15, 5B Isolated Signal Conditioning Module

988396

WBK15, pg. 1

Page 2

Hardware Setup

Configuration

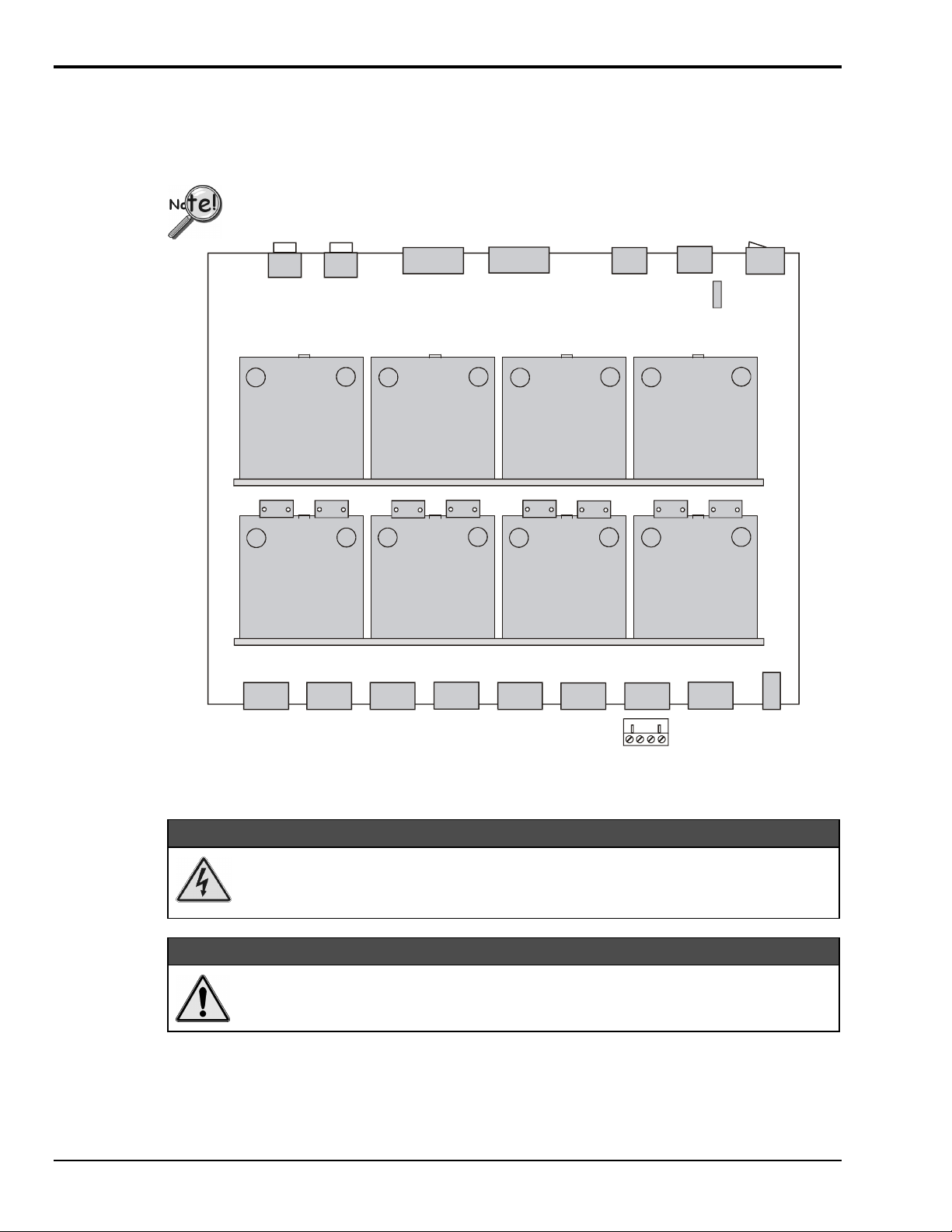

The next figure shows the board layout within a WBK15. Note the channel-number layout for the 5B

modules and the location for plug-in current-sense resistors.

Only current-input type modules require the plug-in resistors.

The plug-in resistors must be removed for all other module types.

Rear Panel

Front Panel - signal inputs from 8 channels

BNC

Expansion

Signal Out

CHANNEL 1

R10

ch 2

CHANNEL 2 CHANNEL 4

ch 1

BNC

Expansion

Signal In

R5

ch 1

ch 2

ch 4

Expansion

Control Out

CHANNEL 3

R16 R13

ch 3

DB15

ch 4 ch 5 ch 6

DB15

Expansion

Control In

ch 6

ch 3

WBK15 Board Layout

CHANNEL 5

R20

CHANNEL 6

R18

DIN5

Power

Out

ch 8

ch 5

CHANNEL 7

R22

CHANNEL 8

ch 7

DIN5

Power

In

Fuse

R23

ch 8

Screw-terminal

Signal Plug

ON/OFF

Switch

ch 7

Status

LEDs

WBK15, pg. 2

Installation of 5B Modules

WARNING

WARNING

WARNINGWARNING

Electric shock hazard! Turn off power to WBK15 and all connected modules and

devices before inserting or removing modules. Failure to do so could lead to injury or

death due to electric shock.

CAUTION

CAUTION

CAUTIONCAUTION

Handle the 5B module carefully while inserting pins into the daughterboard. Do not

over-tighten mounting screw.

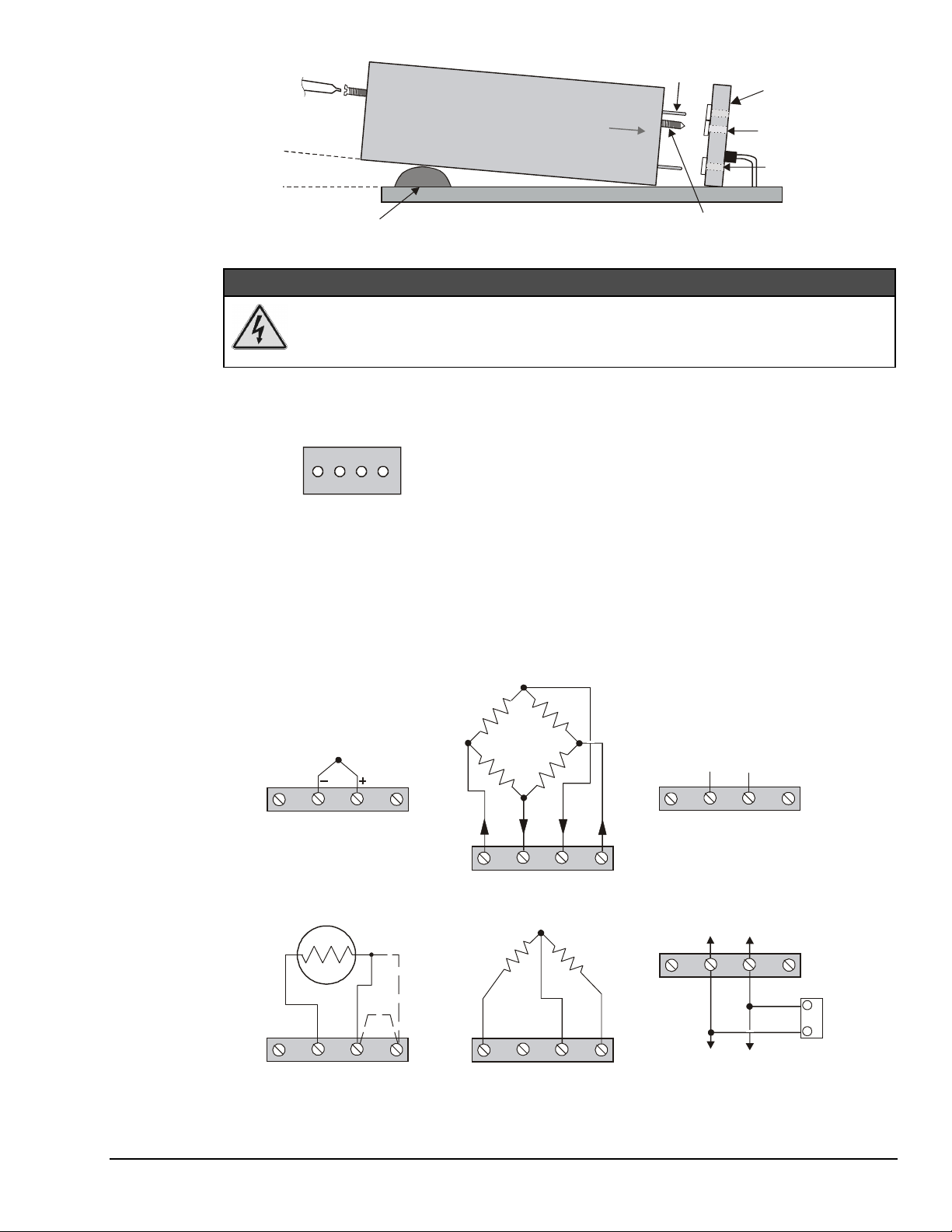

The 5B modules plug into a daughterboard (×2) on WBK15’s motherboard. Rubber bumpers on one side

and a tilted daughterboard allow the module to rest at a 5° angle to facilitate insertion and removal. The

adjacent daughterboard has a cut-a-way to allow room for a screwdriver (see figure).

988396

WBK15, 5B Isolated Signal Conditioning Module

Page 3

Connection

Screwdriver

5°angle to

facilitate installation

Rubber Rest

5B Module

5B Module

WBK15 Main Board

5B Module Insertion/Removal

WARNING

WARNING

WARNINGWARNING

5B Pins

(×14)

Mounting Screw

Daughterboard

Screw

Receptacle

Pin (×14)

Receptacles

Electric shock hazard! De-energize circuits connected to WBK15 before changing the

wiring or configuration. Failure to do so could lead to injury or death due to electric

shock.

Signals are connected by screw-terminal signal plugs that plug into the 4-pin jacks on WBK15’s front panel

(see figure).

+EXC

-

-EXC

+

-EXC Negative excitation output - only used on strain-gage type modules

- Negative signal input

+ Positive signal input

+EXC Positive excitation output - only used on strain-gage type modules

Signal Connection Jacks (per channel)

Input signals (and excitation leads) must be wired to the plug-in terminal blocks. Eight 4-terminal blocks

accept up to 8 inputs.

Terminal blocks are connected internally to their corresponding signal conditioning module. The terminal

blocks accept up to 14-gage wire into quick-connect screw terminals. Each type of input signal or

transducer (such as a thermocouple or strain gage) should be wired to its terminal block as shown in the

figure below. Wiring is shown for RTDs, thermocouples, 20mA circuits, mV/V connections, and for fulland half-bridge strain gages.

SIG H

SIG L

+Vin

-Vin-EXC

Thermocouple

Connection

+EXC

4-Wire

+

_

Full-Bridge Strain-Gage Connection

+EXC+Vin-Vin-EXC

mV and V Connection

-Vin

+EXC+Vin-Vin-EXC

+Vin

3-Wire2-Wire

+Vin

-Vin-EXC

RTD Connection

+EXC

Half-Bridge

Strain-Gage Connection

Typical Signal Connections

WBK15, 5B Isolated Signal Conditioning Module

-Vin-EXC

988396

+Vin

+EXC

-EXC

4-20 mA

Connection

+EXC

AC1362

20 Ohm

Plug-In Resistor

(SC-AC-1362)

On-Board Socket

WBK15, pg. 3

Page 4

Power

Like the WaveBook, WBK15 contains an internal power supply. The unit can be powered by the included

AC power adapter or any 10 to 30 VDC source, such as a 12 V car battery. For portable or field

applications, WBK15 and the WaveBook can be powered by the DBK30A rechargeable battery module or

DBK34 vehicle UPS module. The supply input is fully isolated from the measurement system. If the fuse

requires replacement, it is a 2 A fuse (Littelfuse #251002).

Safety Concerns

WBK15 is specified for 1500 VDC isolation in a normal environment free from conductive pollutants and

condensation. The 1500 VDC rating requires a proper earth ground connection to the chassis and treatment

of adjacent inputs as potentially hazardous. CE-marked units used in the European community are rated at

600 VDC isolation. The 600 VDC CE isolation specification is based on a double insulation requirement,

and no earth ground is required.

Prior to daisy-chaining from one module’s power connector to another, be sure to

compute the power consumption for the entire system. Some modules may need

independent power adapters. The WaveBook manual’s chapter entitled, System Setup

and Power Options contains detailed information regarding power supply issues.

WARNING

WARNING

WARNINGWARNING

Shock Hazard! Voltages above 50 Vrms AC and voltages above 100 VDC are

considered hazardous. Safety precautions are required when 5B modules are used in

situations that require high-voltage isolation from the rest of the system. Failure to

practice electrical safety precautions could lead to injury or death.

Input cables must be rated for the isolation potential in use. Line voltage ratings are much lower than the

DC isolation values specified due to transients that occur on power lines. Never open the lid unless all

inputs with potentially hazardous voltages are removed. The lid must be securely screwed on during use.

Some things to remember:

• Before closing up an open WBK15, ensure no foreign objects are inside.

• Properly tighten all chassis screws before system use.

• Properly tighten the screw that retains the 5B module.

•

Never plug in or unplug potentially hazardous connections with power applied to any

connected equipment.

• Never attempt to change 5B modules or open the lid with power applied to the WBK15. You

could short out internally exposed circuits and cause personal injury or equipment damage.

Reference Note:

Refer to the System Setup and Power Options chapter of the WaveBook User’s Manual for

detailed information regarding the power aspects of WaveBook systems.

Using Fastener Panels to Stack Modules

For convenient mounting, the WBK15 has the same footprint as other WBK modules and WaveBooks.

Fastener panels (splice plates) provide a means for stacking WaveBooks and modules. Screw-on handles

are available for portable applications.

WBK15, pg. 4

Reference Note:

For an illustration pertaining to mounting modules with fastener panels refer to the introduction

of this manual.

When using WBK17 modules in conjunction with other WBK modules, the WBK17

modules must be located closest to the WaveBook/516 (or /516A), due to the CA-217

cable length. The order of the other WBK modules does not matter.

988396

WBK15, 5B Isolated Signal Conditioning Module

Page 5

Software Setup

You will need to set several parameters so WaveView can best meet your application requirements.

For detailed WaveView information, refer to the WaveView Document Module.

After the 5B module type is identified, WaveView figures out the m and b (of the mx+b equation) for

proper engineering units scaling. An example of the mx + b equation follows shortly.

PDF Note:

Fastener panels will partially block the vents on WBK16, WaveBook/516, and

WaveBook/516A when stacked. This partial blocking of vents does not jeopardize the

cooling process.

Reference Note:

➣

For detailed WaveView information, refer to the

➣

The API does not contain functions specific to WBK15. Refer to related material in the

WaveView Document Module

.

Programmer’s Manual (p/n 1008-0901) as needed.

During software installation, Adobe

®

PDF versions of user manuals automatically install onto

your hard drive as a part of product support. The default location is in the Programs group,

which can be accessed from the Windows Desktop. Refer to the PDF documentation for details

regarding both hardware and software. Note that you can also access PDF documents directly

from the data acquisition CD via the <View PDFs> button on the CD’s opening screen.

WaveView Configuration Main Window

mX +b, an Example

Customize Engineering Units

The

dialog box can be

accessed via the WaveView Configuration main

window

by activating the Units cell [for the desired

channel], then clicking to select mX+b.

From the Customize Engineering Units dialog box

(see figure at right), you can enter values for m and b

components of the equation that will be applied to

the data. There is also an entry field that allows you

to enter a label for the new units that may result from

the mX+b calculation.

An example of mX + b equation use follows.

WBK15, 5B Isolated Signal Conditioning Module

988396

WBK15, pg. 5

Page 6

Engineering Units Conversion Using mx + b

Most of our data acquisition products allow the user to convert a raw signal input (for example, one that is

in volts) to a value that is in engineering units (for example, pressure in psi). The products accomplish this

by allowing the user to enter scale and offset numbers for each input channel, using the software associated

with the product. Then the software uses these numbers to convert the raw signals into engineering units

using the following “mx + b” equation:

Engineering Units = m(Raw Signal) + b (1)

The user must, however, determine the proper values of scale (m) and offset (b) for the application in

question. To do the calculation, the user needs to identify two known values: (1) the raw signal values, and

(2) the engineering units that correspond to the raw signal values. After this, the scale and offset parameters

can be calculated by solving two equations for the two unknowns. This method is made clear by the

following example.

Example

An engineer has a pressure transducer that produces a voltage output of 10.5 volts when the measured

pressure is 3200 psi. The same transducer produces an output of 0.5 volt when the pressure is 0 psi.

Knowing these facts, m and b are calculated as follows.

A - Write a pair of equations, representing the two known points:

3200 = m(10.5) + b (2)

0 = m(0.5) + b (3)

B - Solve for m by first subtracting each element in equation (3) from equation (2):

3200 - 0 = m(10.5 – 0.5) + (b - b)(4)

Simplifying gives you:

This means:

m = 320 (6)

C - Substitute the value for m into equation (3) to determine the value for b:

3200 = m(10) (5)

0 = 320 (0.5) + b (7)

: b = - 160 (8)

So

Now it is possible to rewrite the general equation (1) using the specific values for m and b that we just

determined:

Engineering Units = 320(Raw Signal) - 160 (9)

The user can then enter the values of m and b into the appropriate location using the facilities provided by

compatible data acquisition software, for example: WaveView, DaqView, Personal DaqView, LogView,

and TempView. The software uses equation (9) to calculate signal values in engineering units from that

point on.

WBK15, pg. 6

988396

WBK15, 5B Isolated Signal Conditioning Module

Page 7

WBK15 – Specifications

Name/Function: WBK15 Multi-Purpose Isolated Signal Conditioning Module

Connectors: 2 BNC connectors, mate with expansion signal input on the WaveBook/512, /512A, /516,

/516A, /516E; two 15-pin connectors, mate with the WaveBook’s Expansion Signal Control

Module Capacity: Eight 5B modules (optional) See latest catalog or contact your sales representative in

Input Connections

Power Requirements

With 8 thermocouple-type modules: 12 VDC @ 0.25 A, 15 VDC @ 0.20 A, 18 VDC @ 0.2 A

With 8 strain-gage-type modules: 12 VDC @ 0.95 A, 15 VDC @ 0.75 A, 18 VDC @ 0.65 A

Cold-Junction Sensor

Shunt-Resistor Socket: One per channel for current loop inputs

Isolation

Signal Inputs to System

Input Channel-to-Channel: 1500 VDC (600 VDC for CE compliance)

Power Supply to System

Dimensions: 221 mm × 285 mm × 36 mm (8.5” × 11” × 1.375”)

Weight

: 1.8 kg (4 lb) [with no modules installed]

: Removable 4-terminal plugs (Weidmuller type BL4, PN 12593.6,

regard to the types of 5B Modules available for your application.

or type BLTOP4, PN 13360.6)

: 10 to 30 VDC, or 120 VAC with included adapter

: Standard per channel

: 1500 VDC (600 VDC for CE compliance)

: 50 VDC

WBK15, 5B Isolated Signal Conditioning Module

988396

WBK15, pg. 7

Page 8

WBK15, pg. 8

988396

WBK15, 5B Isolated Signal Conditioning Module

Loading...

Loading...