Page 1

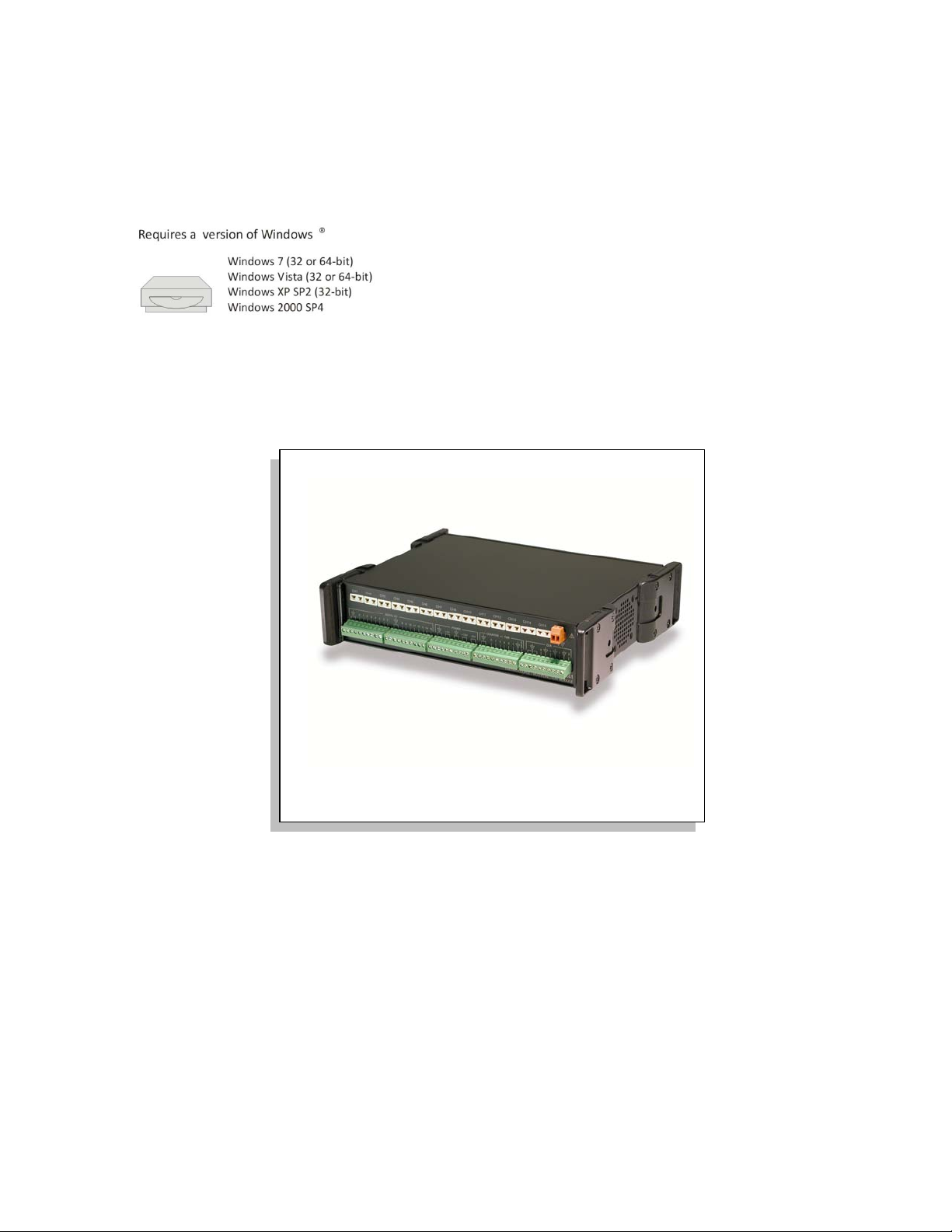

Option Cards and Modules for

WaveBook Systems

Measurement Computing Corporation

**

WBK Options

**

USER’S MANUAL

** Neither Windows Vista nor Windows 7 support WaveBook/512A, /516, or /516A.

Windows Vista and Windows 7 both support WaveBook/516E.

*372187C-01*

372187C-01 489-0902 rev 4.4

10 Commerce Way

Norton, MA 02766

USA

Phone: (508) 946-5100

Fax: (508) 946-9500

e-mail: info@measurementcomputing.com

Page 2

Your warranty is as stated on the product warranty card. You may contact MCC by phone,

fax machine, or e-mail in regard to warranty-related issues.

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

Warranty Information

Limitation of Liability

MCC cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without prior written

consent. IOtech product names are trad emarked; other product names, as applicable, ar e trademarks of their respective

holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs) may only be

used on one installation. You may make archival backup copies.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, include Declarations of Conformity on our website. The declarations state which

standards and operating conditions apply.

Warnings, Cautions, Notes, and Tips

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, MCC calibrates its hardware to published specifications. Periodic hardware calibration is not

covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

WaveBook/512A, /516, /516A, /516E 988789 WaveBook User’s Manual iii

Page 3

Note:

PDF

489-0902

CAUTION

CAUTION

CAUTIONCAUTION

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Before setting up and using your

equipment, you should read all documentation that covers your system.

Pay special attention to Warnings and Cautions.

During software installation, Adobe

install onto your hard drive as a part of product support. The default location is in the

Programs group, which can be accessed from the Windows Desktop. You can also

access the PDF documents directly from the CD vis the <View PDFs> button on the

CD’s opening screen. Refer to the PDF documentation for details regarding both

hardware and software.

A copy of the Adobe Acrobat Reader® is included on your CD. The Reader provides

a means of reading and printing the PDF documents. Note that hardcopy versions of the

manuals can be ordered from the factory.

®

PDF versions of user manuals will automatically

WBK Option Cards and Modules User’s Manual

The WBK Option Cards and Modules Manual discusses each of the WBK products

available at the time of print. The following documents are related.

PDF

489-0901

PDF

481-0901

PDF

PDF

PDF

1008-0901

WaveBook User’s Manual,

Explains how to make signal and power connections and how to install software and

product support for the WaveBook/512A, /516, /516A, & /516E.

WaveBook User’s Manual,

Explains how to make signal and power connections and how to install software and

product support for the WaveBook/512 and WaveBook/512H.

for WaveBook/512A, /516, /516A, & /516E

for WaveBook/512 and /512H

WaveView

Discusses how to install and use this “out-of-the-box” data acquisition program that

was designed for use with WaveBook systems.

Post Acquisition Data Analysis User’s Guide

Programmer’s Manual

The programmer’s manual pertains to developing custom programs using Applications

Program Interface (API) commands.

Note that the install CD-ROM includes WaveBook program examples.

iv

988296

WBK Option Cards and Modules

Page 4

Table of Contents

An Introduction to WBKs

WBK10A – Analog Expansion Module

WBK11A – Simultaneous Sample and Hold (SSH) Card

WBK12A and WBK13A – Programmable Filter Cards

WBK14 – Dynamic Signal Conditioning Module

WBK15 – 5B Isolated Signal Conditioning Module

WBK16 – Strain Gage Module

WBK17 – Counter-Input Module with Quadrature Encoder Support

WBK18 – Dynamic Signal Conditioning Module

WBK20A – PCMCIA/EPP Interface Card and Cable

WBK21 – ISA/EPP Interface Plug-In Board

WBK23 – PCI/EPP Interface Plug-In Board

WBK25 – Ethernet Interface Module User's Guide (p/n 1087-0901)

WBK30 – WaveBook Memory Options

WBK40 and WBK41 – Thermocouple and Multi-Function I/O Modules

PDF Note:

WBK61 and WBK62 – High Voltage Adapters

Glossary

CAUTION

CAUTION

CAUTIONCAUTION

Using the equipment in ways other than described in this manual can cause personal injury or

equipment damage. Pay special attention to all cautions and warnings.

Reference Notes:

➣

Information (not available at the time of publication), will be made available in ReadMe files,

or in supplemental documentation.

➣

For programming-related information refer to the separate Programmer’s Manual,

p/n 1008-0901. (See PDF Note, below).

➣

WaveBook/512A, WaveBook/516, and WaveBook/516A are covered in the WaveBook User’s

Manual, p/n 489-0901.

➣

WaveBook/512 and WaveBook/512H are covered in WaveBook User’s Manual, p/n 481-0901.

During software installation, Adobe

®

PDF versions of user manuals will automatically install onto

your hard drive as a part of product support. The default location is in the Programs group, which

can be accessed from the Windows Desktop. Refer to the PDF documentation for details regarding

both hardware and software. The PDF documents can also be read directly from the CD using the

<View PDFs> button on the CD’s opening screen.

A copy of the Adobe Acrobat Reader

®

is included on your CD. The Reader provides a means of

reading and printing the PDF documents. Note that hardcopy versions of the manuals can be ordered

from the factory.

WBK Option Cards and Modules

v

967896

Page 5

An Introduction to WBKs

What are WBKs?…… 1

How do WaveBooks and WBKs Interrelate? ……4

How are WaveBook Systems Powered? …… 5

How are WBK Modules Mounted to other Modules or to WaveBooks? …… 5

What are WBKs?

WBKs are WaveBook system options that exist in the form of cards or modules. The WBK options can be used to

enhance and/or expand your WaveBook system.

Internally, WaveBook has room for one signal-conditioning card. Externally, one or more expansion modules can be

used with a WaveBook.

Reference Note:

The WBK option cards and modules that follow are detailed immediately after this introduction.

The information is presented in alpha-numerical order and includes product specifications.

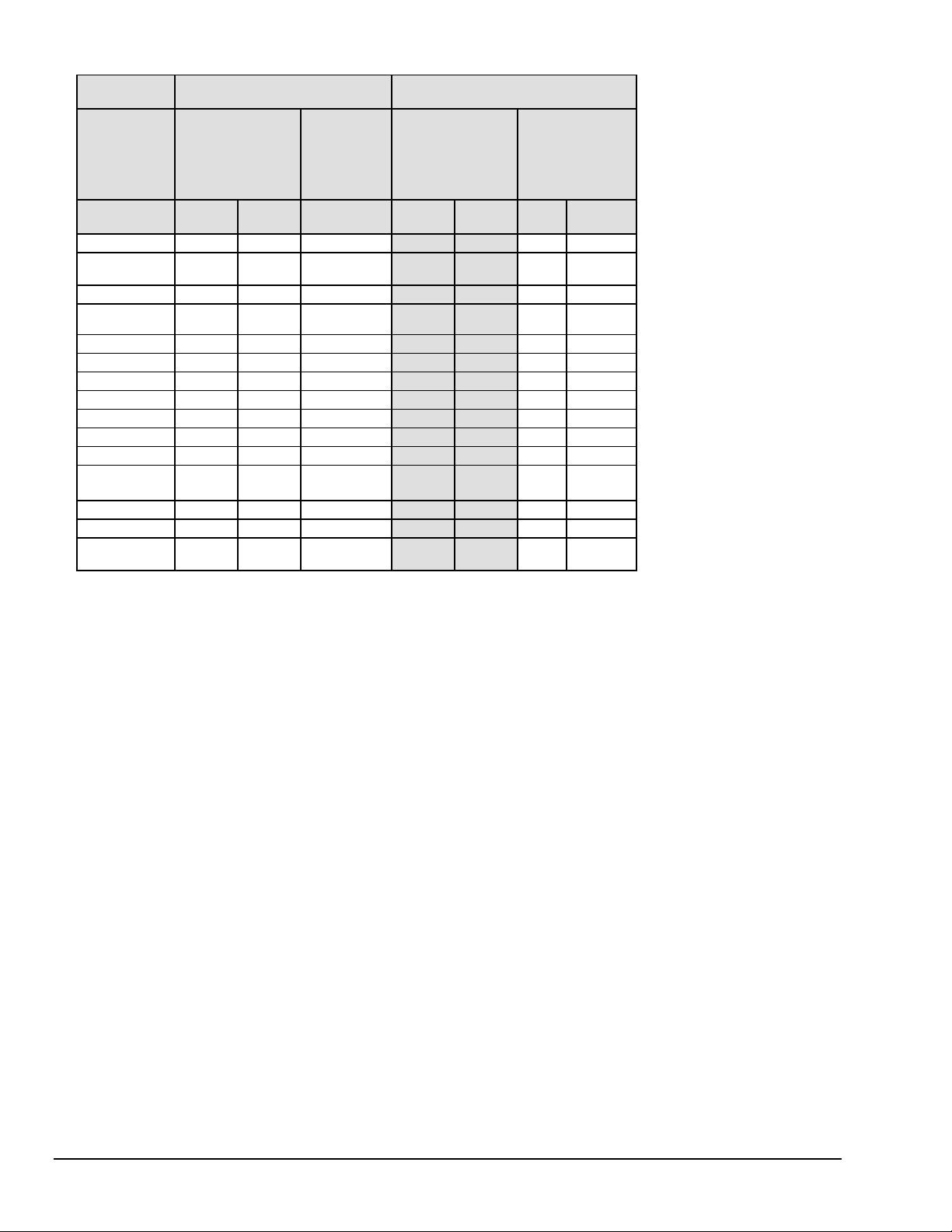

WBK Options

Note: The items represented in the table are not shown to the same scale.

Each WBK10A module can be used to provide W aveBook with 8

additional differential-analog-inputs. The modules are equipped with

WBK10A

Analog Expansion Module

8 Channels via BNC Connectors

a programmable gain instrumentation amplifier (PGA) and, like the

WaveBook, each has a built-in expansion bus.

Up to eight WBK10A modules can be cascaded together for a

system capacity of 72 differential channels. Each module is capable

of supporting a WBK11A, WBK12A, or WBK13A option card.

WBK11A

Simultaneous Sample & Hold Card (8 channels)

WBK12A

Programmable Low-Pass Filter Card

(8 channels)

WBK13A

Programmable Low-Pass Filter Card with SSH

(8 channels)

WBK14

Dynamic Signal Conditioning Module

8 Channels via BNC Connectors

The WBK11A card can simultaneously sample 8 channels and can

be installed inside a WaveBook or in a WBK10A module. The cards

allow for concurrent (<150 ns) capture of multiple input channels and

virtually eliminate channel-to-channel time skewing.

The WBK11A option is factory install only.

WBK12A and WBK13A are 8-channel programmable low-pass filter

cards for use with WaveBook data acquisition systems. These cards

install directly into a WaveBook or WBK10A module and provide

programmable low-pass filtering over all channels. Multiple WBK12A

and WBK13A cards can be installed in one system for up to 72

channels. All of the cards’ low-pass filters and cutoff frequencies are

configured via software.

WBK13A cards have the additional capability of sampling all

channels at the same time.

The WBK12A and WBK13A options are factory install only.

The WBK14 is a dynamic analog signal input module. It enables

WaveBooks to interface with piezoelectric transducers that include

accelerometers, microphones, and force/pressure transducers.

Each WBK14 channel has a:

• current source for transducer biasing

• high-pass filter

• programmable gain amplifier

• anti-aliasing low-pass filter

• simultaneous sample-and-hold (SSH) amplifiers

WBK Option Cards and Modules

988397

Introduction 1

Page 6

WBK15

8-Slot 5B Signal Conditioning Module

8 channels via 5B Modules

WBK16

Strain-Gage Module

8 channels via Standard Female DB9

WBK17

Counter-Input Module with Quadrature Encoder

Support

8 channels via Removable Screw Terminal Blocks

WBK18

Dynamic Signal Conditioning Module with

Transducer Electronic Data Sheet support

(T.E.D.S).

8 channels via BNC Connectors

WBK20A, WBK21, and WBK23

– Three Interface options that can be used to obtain an Enhanced Parallel Port.

The WBK15 module provides for a diverse range of signals available

through optional 5B modules. Measurement types include: LVDT,

potentiometer, isolated current loop, ±10mV to ±40V inputs,

linearized RTD, thermocouple, frequency-to-voltage, and strain

gage.

See latest catalog or contact your sales representative in regard to

the types of 5B Modules available for your application.

WBK16 is an 8-channel strain-gage signal-conditioning module. Up

to eight WBK16 modules (64 channels) can be accommodated by

the WaveBook and scanned at 1 µs/channel. Almost all bridge

configurations are supported via a bridge-completion network and

software. High-gain differential-amplifier applications are also

supported. Software controls bridge configuration, gain, offset,

excitation voltage, polarity, filtering, and the calibration process.

The WBK17 is an 8-channel multi-function counter/encoder module

for use with Wavebook/512A, /516, /516A, and /516E. Each of the

high-speed, 32-bit counter channels can be configured for counter,

period, pulse width, time between edges, or encoder modes. All

channels are capable of measuring analog inputs that are digitized by

the WaveBook.

WBK18 provides 8 channels of dynamic signal input for WaveBook

systems. Each channel on the WBK18 has independent, software

control for AC or DC coupling, ICP biasing (0 or 4 mA), and low-pass

filter cut-off frequency. The 8-pole Butterworth filter on each channel

is programmable from 5 Hz to 50 kHz, in a 1-2-5 progression. The

filter can also be bypassed, resulting in a bandwidth of greater than

200 kHz.

WBK20A

PC-Card /EPP

Interface & Cable

WBK21

ISA/EPP Interface

Plug-in Board

WBK23

PCI/EPP Interface Plug-In Board

WBK25

10/100BaseT Ethernet Interface Module

WBK20A – PCMCIA/EPP Interface Card and Cable

For linking WaveBook to a Notebook PC. This interface

provides an Enhanced Parallel Port via a PC-Card Slot.

WBK21 – ISA/EPP Interface Plug-in Board

For linking WaveBook to a desktop PC. This interface

provides an Enhanced Parallel Port via an ISA Bus-slot.

WBK23 – PCI/EPP Interface Plug-In Board

(For linking WaveBook to a desktop PC)

Provides an Enhanced Parallel Port from a PCI Bus-slot.

These three interfaces are shipped with separate documentation and

are not detailed in this manual.

The WBK25 provides high-speed Ethernet connectivity for

WaveBook, DaqBook and WBK40 series products. The WBK25

contains one 10/100BaseT Ethernet port for connection to a PC,

and three expansion ports that can attach to any model of

WaveBook, DaqBook, WBK40 Series option, or any combination

of these devices.

2 Introduction

988397

WBK Option Cards and Modules

Page 7

WBK30

WaveBook Memory Options

WBK40

Thermocouple Input Module

14 channels via Mini-T/C Connectors

WBK41

Multi-Function I/O Module

14 Thermocouple channels via Mini-T/C Connectors

40 Digital I/O Lines

4 Counter Inputs

2 Timer Outputs

(Optional) 4 Analog Channel Outputs

WBK30 is a DRAM-based memory board that installs inside a

WaveBook. There are three models of WBK30 available; each

significantly increases the capacity of a WaveBook's standard data

buffer of 64 K samples. Capacities are as follows:

WBK30/16 — 16 MB

WBK30/64 — 64 MB

WBK30/128 — 128 MB

Note: For WaveBook/516E the WBK30 option, if selected, must be

factory installed.

The WBK40 attaches to any one of the three expansion ports on the

WaveBook/516E or the WBK25, and provides 14 thermocouple input

channels. The 14 built-in TC channels accept any type of

thermocouple, including types J, K, S, T, E, B, R, and N. Mini-TC

connections make it quick and easy to attach thermocouples. The

WBK40 can be expanded in 14 channel increments using the

DBK84 TC expansion module. A total of 15 DBK84s can be attached

to one WBK40, for a total TC channel capacity of 224 channels.

The WBK41 attaches to any one of the three expansion ports on the

WaveBook/516E or WBK25 and provides 14 thermocouple inputs,

40 digital I/O lines, 4 counter inputs, and 2 timer outputs. The

WBK41 can also be supplied with an internal, 4-channel, 16-bit,

100-kHz analog output option.

The built-in TC channels on the WBK41 are accessed via mini-TC

connectors on the front panel. The counter/timer functions and 16

bits of digital I/O are accessed via removable front panel screwterminal connectors. Additional digital I/O and expansion connectors

are located at the rear of the WBK41.

The WBK41 can be easily expanded beyond its built-in channel

capacity. A maximum WBK41 system can include up to 224 TC

input channels, 272 digital I/O channels, 4 analog output channels,

4 counter input channels and 2 timer output channels.

WBK61 and WBK62

WBK61: High-Voltage Adapter with 200:1 Voltage

Divider (1 channel)

WBK62: High-Voltage Adapter with 20:1 Voltage

Divider (1 channel)

WBK61 and WBK62 are single-channel high-voltage adapters that

can be used with the WaveBook or with a WBK10A expansion

module. In addition, W BK61 and WBK62 can be used in conjunction

with WBK11A, W BK12A, and W BK13A cards.

WBK61 and WBK62 include safety-style banana-jacks for the high

and low inputs, and 60-inch (152 cm) cables with probe tips and

alligator clips for easy input connection.

WBK Option Cards and Modules

988397

Introduction 3

Page 8

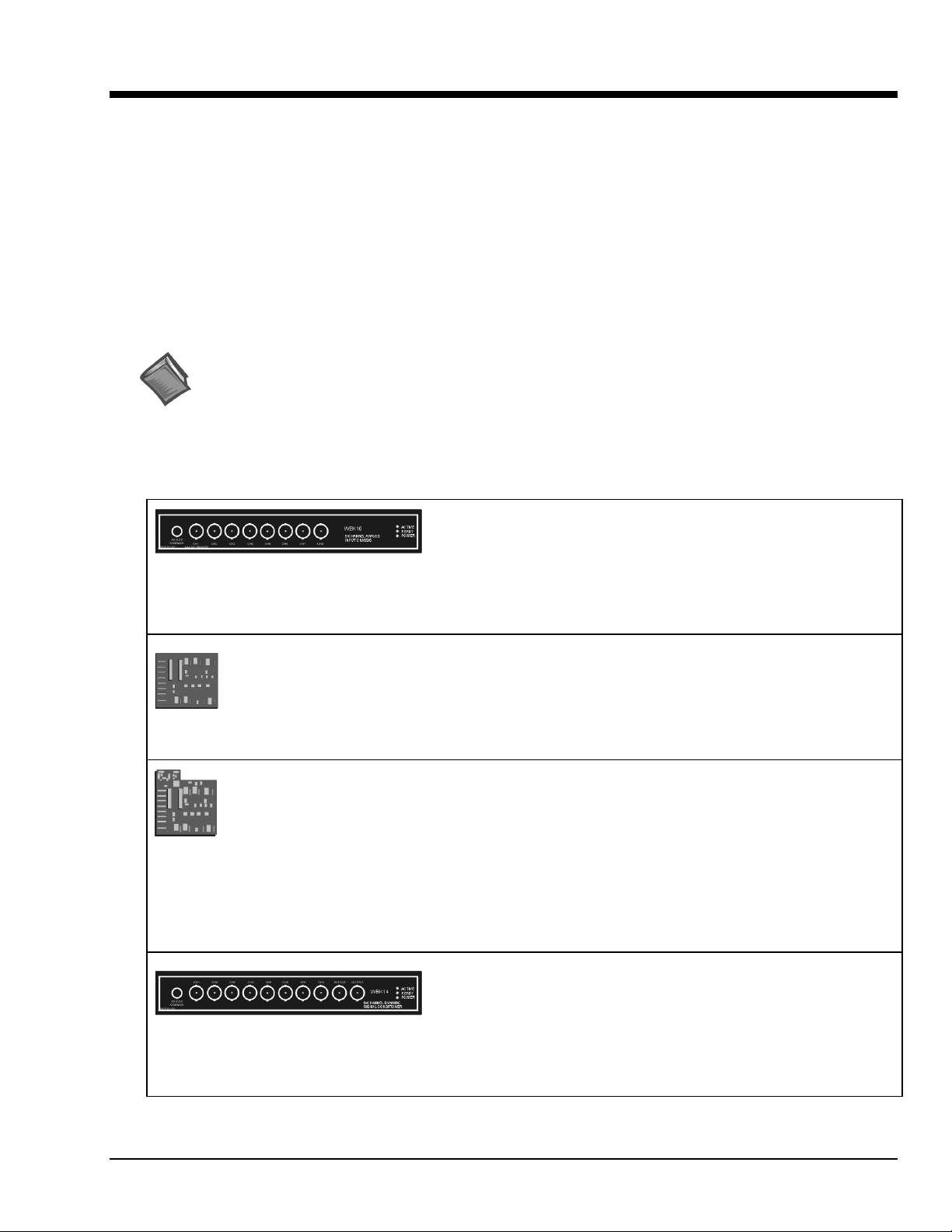

How do WaveBooks and WBKs Interrelate?

WaveBooks and WBKs interrelate when they become part of the same data-acquisition system. The

relationship can be broken down into enhancement, expansion, or both. The following illustrates the

relationship of various system components.

WaveBook System Components

4 Introduction 988397 WBK Option Cards and Modules

Page 9

How are WaveBook Systems Powered?

Power supply input voltage to the WaveBook and to the system modules, e.g., WBK10A, WBK14,

WBK15, WBK16, WBK17, WBK18, WBK40, and WBK41 must be in the range of 10 VDC to 30 VDC

and can come from an appropriate AC-to-DC adapter or a battery option. The latter includes DBK power

modules and batteries in the range of 10 VDC to 30 VDC.

Note: Power supply input to the WBK25 Ethernet Module must be in the range of 10 VDC to 20 VDC.

Available AC-to-DC adapters include the TR-40U (supplied), which has an input of 90-264 VAC and a

output rating of 2.2 amps @ 15 VDC.

Battery options include the DBK30A, DBK34A, and other 10 to 30 VDC sources, such as car batteries.

The DBK30A provides 14 VDC and when fully charged has a storage capacity of 3.4 A⋅hr; car batteries

have much higher capacities. The basic formula for battery life is:

Runtime (hr) = Battery capacity (A⋅⋅⋅⋅hr) / Current load (A)

System cards, e.g., WBK11A, WBK12A, and WBK13A, get power from their host WaveBook or their host

WBK10A expansion module.

Before connecting your system to power, you need to know the power requirements of your specific system.

A calculation method that incorporates the use of worktables is presented in Chapter 2 of the WaveBook

User’s Manual (p/n 489-0901).

Reference Notes:

•

In the WaveBook User’s Manual (p/n 489-0901), the System Setup and Power Options

chapter includes examples of power connections for different WaveBook system

scenarios. In these examples the included TR-40U power adapters are used.

• In the WaveBook User’s Manual (p/n 489-0901), the WaveBook Operation Reference

chapter includes discussions of power supplies other than the TR-40U.

How are WBK Modules Mounted to other Modules or to WaveBooks?

The fastener panels and associated

screws are from fastener-panel kit,

p/n 262-0801.

Fastener Panels

Using Fastener Panels to Stack a WaveBook and two WBK Modules (use of the handle is optional)

WBK Option Cards and Modules

988397

(p/n HA-111)

Introduction 5

Page 10

WBK modules can be stacked using fastener panels, sometimes referred to as splice plates. The panels

provide a means of stacking modules to create one rigid assembly. The Fastener Panel Kit, p/n 262-0801,

is available from the factory and consists of two metal plates and the necessary mounting screws.

A Fastener-Panel Handle (p/n HA-111) is also available from the factory. HA-111 consists of 1 handle and

two mounting screws.

The previous figure illustrates the simplicity of the mounting process.

Note:

When used with a WBK16, WaveBook/516, WaveBook/516A, or WaveBook/512A, fastener

panels will partially block the vents on the side of the module. This partial blocking of vents

does not jeopardize the cooling process.

6 Introduction

988397

WBK Option Cards and Modules

Page 11

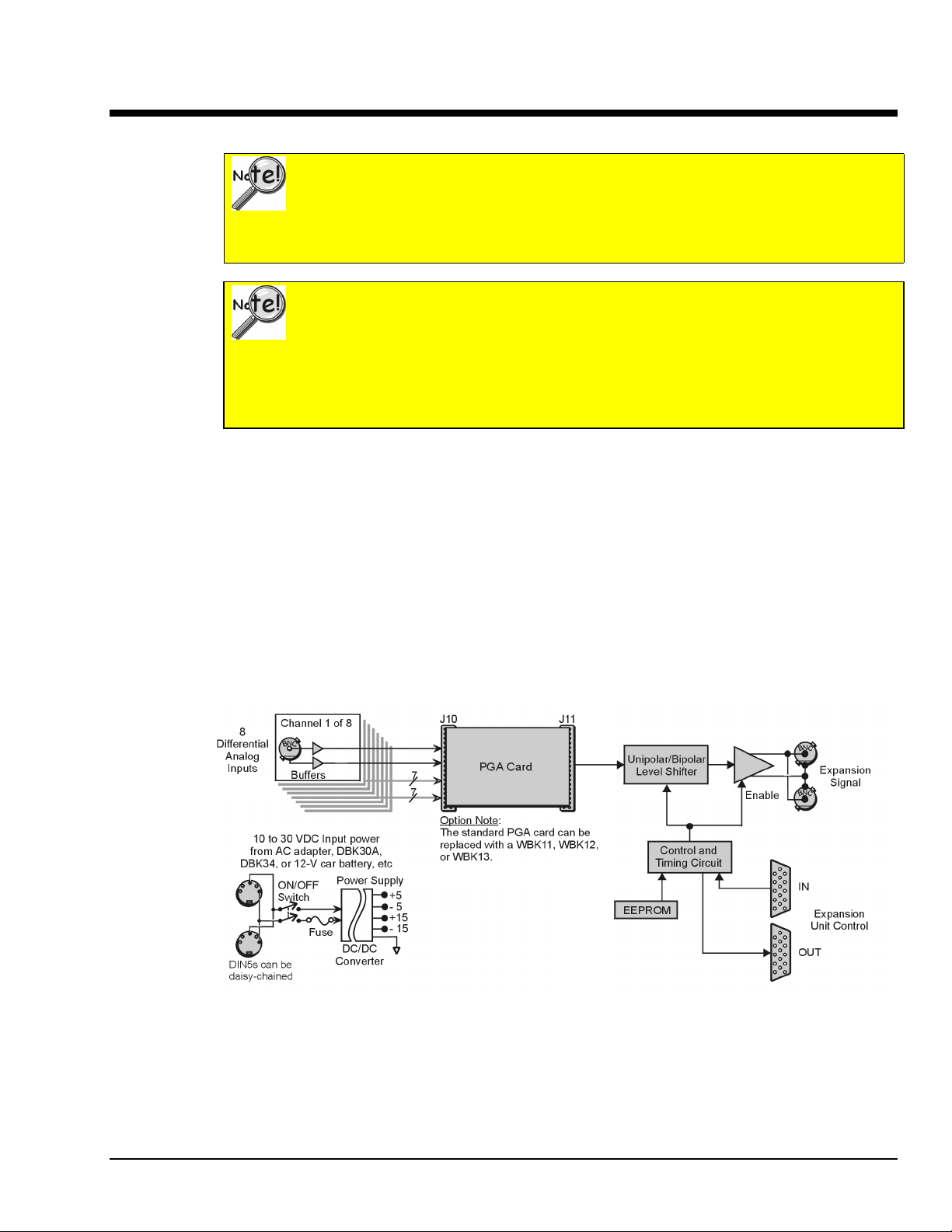

WBK10A

The WBK10A Analog Expansion Module can be used to provide WaveBook with 8 additional differentialanalog-inputs. The WBK10A is equipped with a programmable gain instrumentation amplifier (PGA) and,

like the WaveBook, has a built-in expansion bus.

Up to eight WBK10A modules can be cascaded together for a system capacity of 72 differential channels.

Each module is capable of supporting a WBK11A, WBK12A, or WBK13A option card.

Analog Expansion Module

Important Notice! WaveBook/516E Users

WBK option cards for WaveBook/516E are installed at the factory per customer order.

Users are not to remove or install cards for these products as the cards are not “plug-andplay” for these devices and erroneous signal values could result. If you desire to remove

or add a card to WaveBook/516E contact the factory or your service representative.

Important Notice! WaveBook/516, /516A, /512A, and WBK10A Users

With exception of the WBK30 option, WBK option cards for WaveBook/516, /516A,

/512A, and WBK10A are installed at the factory per customer order. Users are not to

remove or install cards for these products [other than WBK30 series cards] as the cards

are not “plug-and-play” for these devices and erroneous signal values could result. If you

desire to remove or add a card to these products, contact the factory or your service

representative.

Note: WBK10A can be ordered with a PGA, WBK11A, WBK12A, or a WBK13A card installed.

WBK10A Block Diagram

WBK10A, Analog Expansion Module

988397

WBK10A, pg. 1

Page 12

The front panel has the following connectors and indicators:

WBK10A Front Panel

• 1 Analog Common binding post for reference.

• 8 BNC connectors for analog inputs. Channels are labeled 1 through 8.

• 3 Status LEDs (Active, Ready, Power).

The rear panel has a power switch and the following connectors:

WBK10A Rear Panel

•

2 DIN5 connectors [one for Power In, one for Power Out]

• 1 HD-15M Expansion Control In

• 1 HD-15F Expansion Control Out

•

2 BNC connectors [one for analog Expansion Signal In,

one for analog Expansion Signal Out]

Reference Notes:

➣

Setup information pertaining to power, expansion control, and expansion signal connections

is contained in the System Setup and Power Options chapter of the WaveBook User’s

Manual (p/n 489-0901).

➣

For detailed WaveView information, refer to the WaveView Document PDF that is

included on the data acquisition CD. The document can be accessed using the

<View PDFs> button on the CD’s opening screen.

pg. 2, WBK10A

988397

WBK10A, Analog Expansion Module

Page 13

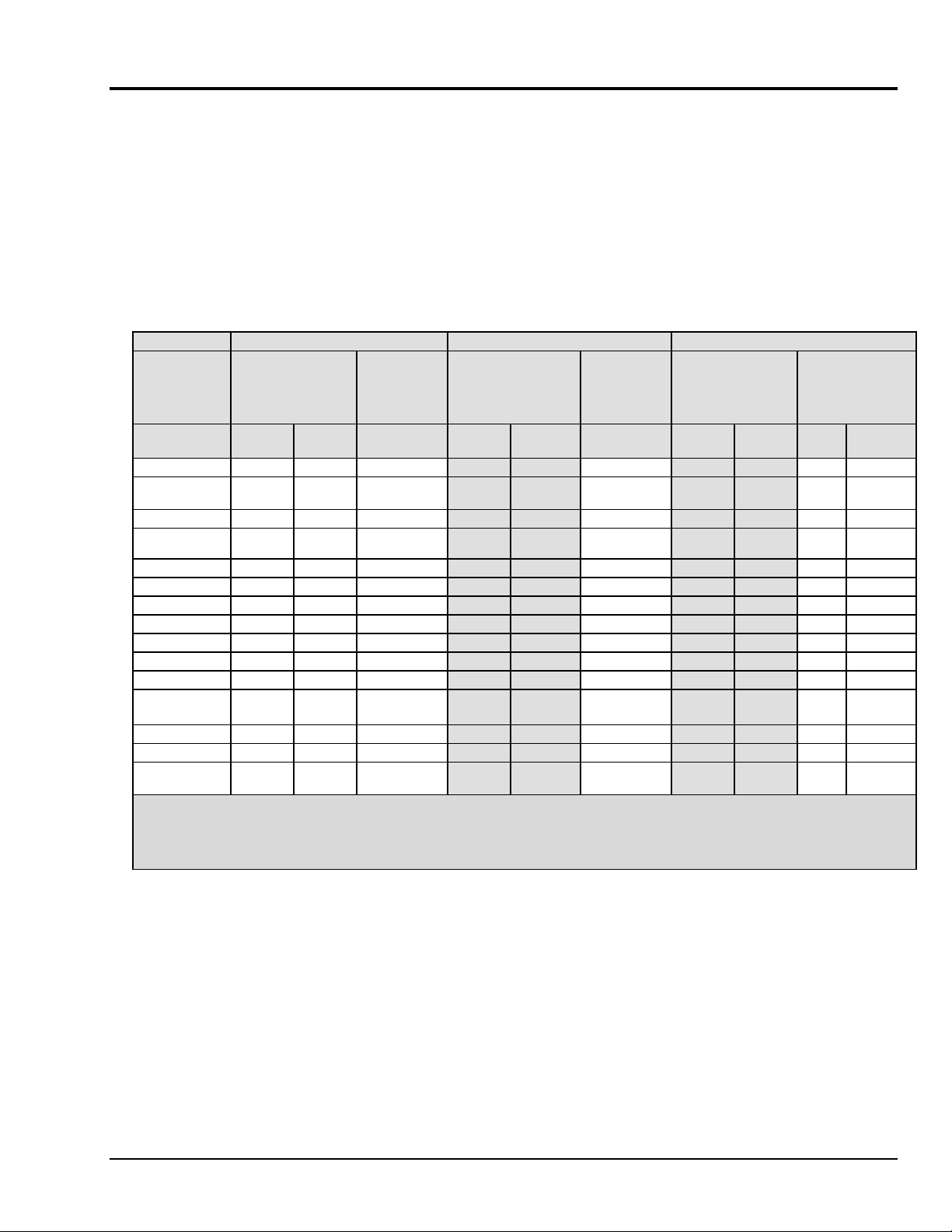

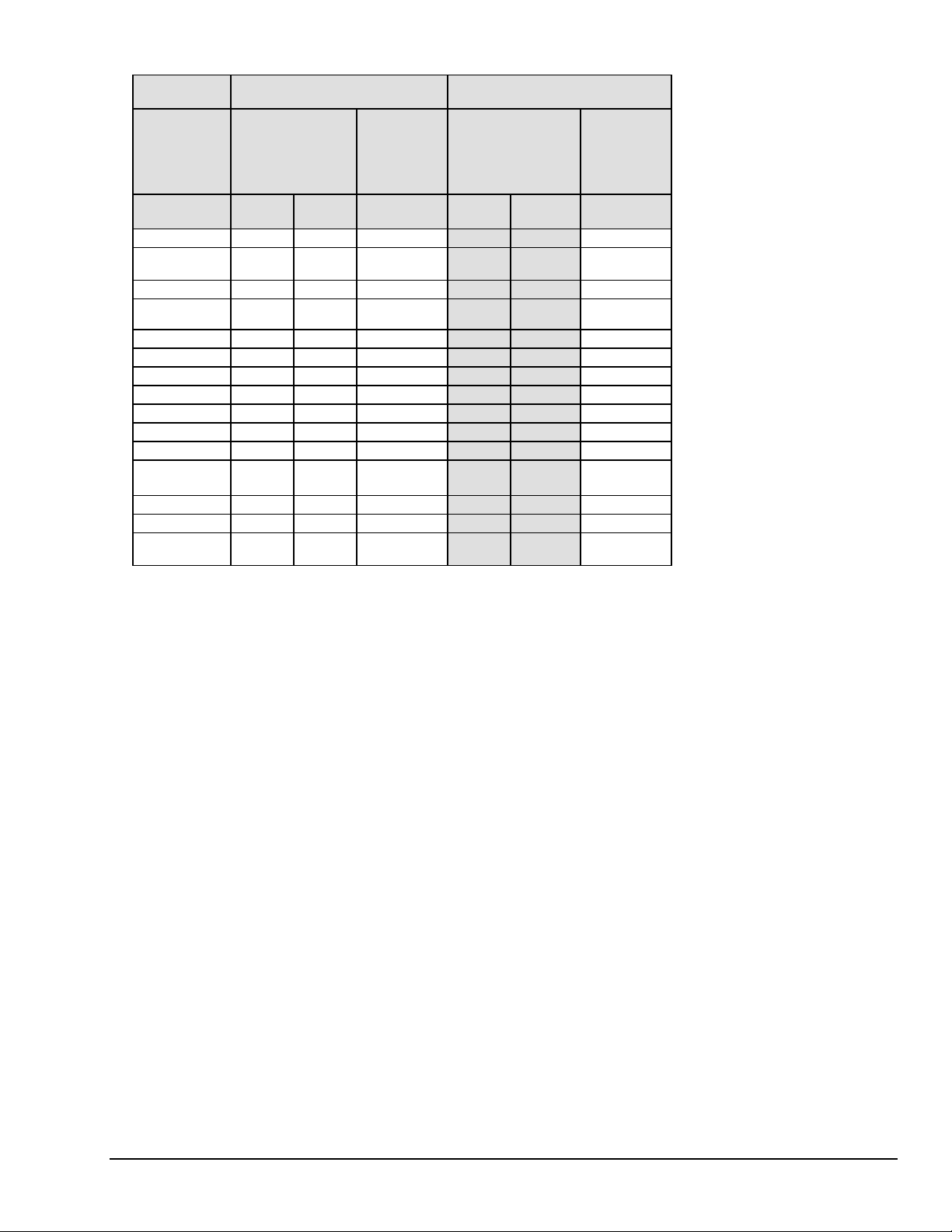

Specifications - WaveBook/516, /516A, /516E, and WBK10A

(

)

(

y)

(

y)

Analog Specifications

For either a stand alone WaveBook, or for a WBK10A with a WaveBook

Channel Capacity

WaveBook/516E

WaveBook/516 and /516A

BNC Input Connectors

Input Voltage Ranges (DC Specifications)

Voltage

Range

0 to +10V .012% .008% 2 .012% .008% 2 .012% .008% 2.2 2.2

0 to +5V (10A)

0 to +4V

0 to +2V .012% .012% 3 .012% .012% 3 .012% .012% 2.2 3

0 to +1V

10A onl

0 to +.5V .018% .033% 6 .018% .033% 2.2 6

0 to +.2V .018% .08% 8 .018% .08% 2.2 12

0 to +.1V .018% .16% 15 .018% .16% 2.2 20

-10 to +10V .012% .008% 2 .012% .008% 2 .012% .008% 2.2 2.2

-5 to +5V .012% .008% 2 .012% .008% 2 .012% .008% 2.2 2.2

-2 to +2V .012% .009% 2 .012% .009% 2 .012% .009% 2.2 3

-1 to +1V .018% .012% 3 .018% .012% 3 .018% .012% 2.2 3.3

-.5 to +.5V

(10A only)

-.2 to +.2V .018% .033% 8 .018% .033% 2.2 12

-.1 to +.1V .018% .08% 15 .018% .08% 2.2 20

-.05 to +.05V

10A onl

Notes: 1. Specifications assume differential input scan, unfiltered.

2. Accuracy specification is exclusive of noise.

516

3. Unipolar ranges are not available for WaveBook/516, /516A, or /516E when a WBK11A, WBK12A,

:

: 8 built-in voltage channels, expandable up to 72 channels via WBK options. In addition, WaveBook/516E can

accommodate up to 3 WaveBook/516A, /512A, or WBK40 options, in any combination. Each added on WaveBook can

be expanded up to 72 channels. The maximum W BK41 capacity is 224 T/C channels, 4 analog output channels, 272

digital I/O channels, and 6 counter/timer channels.

: 8 differential, expandable up to 72 differential

: Center conductor is Channel Hi, outer conductor is Channel Low

Standard Unit With WBK11A

Input Noise

Accuracy

One Year, 18-28

±

reading

.012% .009% 2 .012% .009% 2 .012% .009% 2.2 2.2

.012% .018% 3 .012% .018% 3 .012% .018% 2.2 3

.018% .018% 5 .018% .018% 6 .018% .018% 2.2 6

or WBK13A option is installed. Unipolar ranges are available with WBK10A and any option.

(Note 2)

%

%

±

range

°C

LSB rms

DC-500KHz

(typical)

Accuracy

One Year, 18-28

±

reading

.018% .16% 26 .018% .16% 440

(Note 2)

%

±

range

°C

%

(Note 3)

Input Noise

LSB rms

DC-500KHz

(typical)

With WBK12A/13A

Accuracy

One Year, 18-28

±

reading

(Note 2)

%

±

range

°C

1KHz

%

Filter

(Note 3)

Input Noise

LSB rms

(typical)

Filter

Bypass

System Performance:

Differential Nonlinearity:

Total Harmonic Distortion (10Hz-20KHz)

Signal to Noise and Distortion (SINAD, 10Hz-20KHz):

Temperature Coefficient of Accuracy (0-18 and 28-50°C)

Input Resistance

Bias Current

Common Mode Rejection

Input Bandwidth:

Hostile Channel-to-channel Crosstalk (5Vrms input signal, DC-100KHz):

Over-Voltage Protection

WBK10A, Analog Expansion Module

one year, 18-28°C unless otherwise noted

±2 LSB max

: -84dB typical

-74dB typical

:

With PGA and WBK11A:

With WBK12A/13A:

: 5MΩ (single ended); 10MΩ (differential), in parallel with 30pF

: <400 nA (0 to 35°C)

: >70dB minimum; >80dB typical; DC-20KHz

DC to 500KHz

: ±35 V relative to analog common

988397

± (.002% + 0.6 LSB)/°C typical, -10 to +10V range

± (.002% + 1 LSB)/°C typical, -10 to +10V range

Note

: Specifications are subject to change without notice.

-88dB typical

WBK10A, pg. 3

Page 14

PGA Filter

WBK11A Functions

WBK12A, WBK13A Functions

Triggering

Filter Type

Input Voltage Ranges:

Aperture Uncertainty (SSH)

Voltage Droop (SSH)

Input Voltage Ranges:

Low Pass Filter Type

Anti-Aliasing Filters

Low-Pass Filter Frequency Cutoff Range

Filter Grouping:

Aperture Uncertainty (SSH)

Voltage Droop (SSH)

Channel 1 Analog Trigger

Input Signal Range:

Input Characteristics and Protection:

Latency

: 20KHz low pass, Butterworth, 5-pole filter

N=3 to 750

: 300ns

Software programmable prior to a scan sequence

: 75ps max

: 0.01mV/ms typ

Software programmable prior to a scan sequence

: Software selectable, 8-Pole elliptic or linear phase

: Single-pole pre and post filters, automatically set depending on filter frequency selected

: 100KHz, 75KHz, 60KHz…400Hz, bypass (fc=300KHz/N where

4 Channels each in two programmable banks

: 75ps max

: 0.01mV/ms typ

-10 to +10V

Same as channel inputs

Multi-Channel Analog Trigger (up to 72 channels)

Range

Latency

TTL Trigger

Input Signal Range

Input Characteristics

Input Protection:

Latency

Software Trigger

Latency:

Pulse Trigger

Input Signal Range:

Input Characteristics

Input Protection:

Minimum Pulse Width:

Latency

External Clock

Connector:

Input Signal Range:

Input Characteristics:

Input Protection:

Delay: 200ns

Signal Slew Rate Requirement:

Rate:

Divisor ratio:

Clock Counter Accuracy:

Clock Counter Range:

:

: Selectable per channel to input range

: 2us/channel, plus 4us maximum

:

: 0-5V

: TTL-compatible with 10K ohm pull-up resistor

Zener clamped –0.7 to +5V

: 300ns

100us typical

0-5V

: 75 ohms

±10V maximum

100ns

: 300ns

Available on DB25 digital input

5V TTL compatible

50K ohms pull up (to +5V) in parallel with 50pF

Zener clamped –0.7 to +5V

20V/us minimum

Up to 1MHz

Divide by 1 through 255, selectable

<0.02% error

0.01Hz to 100KHz

pg. 4, WBK10A

988397

WBK10A, Analog Expansion Module

Page 15

Sequencer

Operation

Depth

Channel-to-Channel Rate

Maximum Repeat Rate

Minimum Repeat Rate

Expansion Channel Sample Rate

:

Programmable for channel, gain, and for unipolar/bipolar range in random order

: 128 location

: 1.0-1.1us/channel, all channels equal

: 1MHz

: 100 seconds per scan

: Same as on-board channels

High-Speed Digital Inputs/General-Purpose Outputs

Connector:

Configuration

Input Characteristics:

Output Characteristics:

Output Updates

Input/Output Protection:

DB25 Female

: 16 TTL-compatible pins, selectable for input or output

TTL-compatible

ALS TTL output in series with 33 ohms

: Outputs may be changed via program control

Diode clamped to ground and +5V

Period Counter

Operation

Clock Counter Accuracy

Clock Counter Range

: Internal counter calculates and reports the external clock’s period;

counter can be read with each scan

General Specifications

Warm-up:

Environment

Power Consumption

Input Power Range

Input Power Fuse F201

Vibration:

PC Communication

Channel Capacity

Dimensions

Weight

30 minutes to rated specifications

:

Operating:

Storage:

/516E

/516, /516A & /512A:

MIL STD 810E, Category 1 and 10

/516E

/516, /516A & /512A:

/516E

/516, /516A & /512A:

:

/516E

/516, /516A & /512A:

:

/516E

/516, /516A & /512A

: <0.02% error

: 0.01 Hz to 100 kHz

0-50°C, 0-95% RH (non-condensing)

-20 to 70°C

:

: 1.8A max @ 15 VDC

1.4A max @ 15VDC

: 10 VDC to 30 VDC

: 4A MINI ATO; See chapter 9 for fuse replacement instructions.

:

: 10/100BaseT Ethernet

Enhanced Parallel Port (EPP)

:

: 8 built-in voltage channels, expandable up to 72 channels via WBK options. In

addition, WaveBook/516E can accommodate up to 3 WaveBook/516A, /512A, or

WBK40 options, in any combination. Each added on WaveBook can be expanded

up to 72 channels. The maximum WBK41 capacity is 224 T/C channels, 4 analog

output channels, 272 digital I/O channels, and 6 counter/timer channels.

8 built-in voltage channels, expandable up to 72 channels via WBK

options

: 285 mm wide x 220 mm deep x 70 mm high (11 x 8.5 x 2.70 inches)

285 mm wide x 220 deep x 45 mm high (11 x 8.5 x 1.75 inches)

: 1.9 kg (4.2 lbs)

: 1.5 kg (3.3 lbs)

WBK10A, Analog Expansion Module

988397

WBK10A, pg. 5

Page 16

WBK11A

Description

The WBK11A is a simultaneous sample-and-hold card (SSH) that provide a means of obtaining concurrent

(<150 ns) capture from up to 8 input channels. The card virtually eliminates channel-to-channel time

skewing. The card is controlled by the acquisition system’s base WaveBook.

Simultaneous Sample & Hold Card

Important Notice! WaveBook/516E Users

WBK option cards for WaveBook/516E are installed at the factory per customer order.

Users are not to remove or install cards for these products as the cards are not “plug-andplay” for these devices and erroneous signal values could result. If you desire to remove

or add a card to WaveBook/516E contact the factory or your service representative.

Important Notice! WaveBook/516, /516A, /512A, and WBK10A Users

With exception of the WBK30 option, WBK option cards for WaveBook/516, /516A,

/512A, and WBK10A are installed at the factory per customer order. Users are not to

remove or install cards for these products [other than WBK30 series cards] as the cards

are not “plug-and-play” for these devices and erroneous signal values could result. If you

desire to remove or add a card to these products, contact the factory or your service

representative.

The WBK11A can be installed inside a WaveBook or in a WBK10A series module; however, it must be

installed by a qualified service representative (see the important notice above).

When using a WaveBook with an SSH channel enabled, the per-channel sample rates are

reduced. The rate reduction is the same as that which would occur if another channel were

added. The per-channel rate (with SSH enabled) is:

1 MHz / (n+1), where n is the number of active channels.

The WBK11A SSH card can accommodate higher gains than the main unit because its gains are fixed for

each channel prior to the acquisition. You can use WaveView to set each channel to the ranges listed in the

specifications on page 2. All channels equipped with SSH circuitry are sampled simultaneously as a

system.

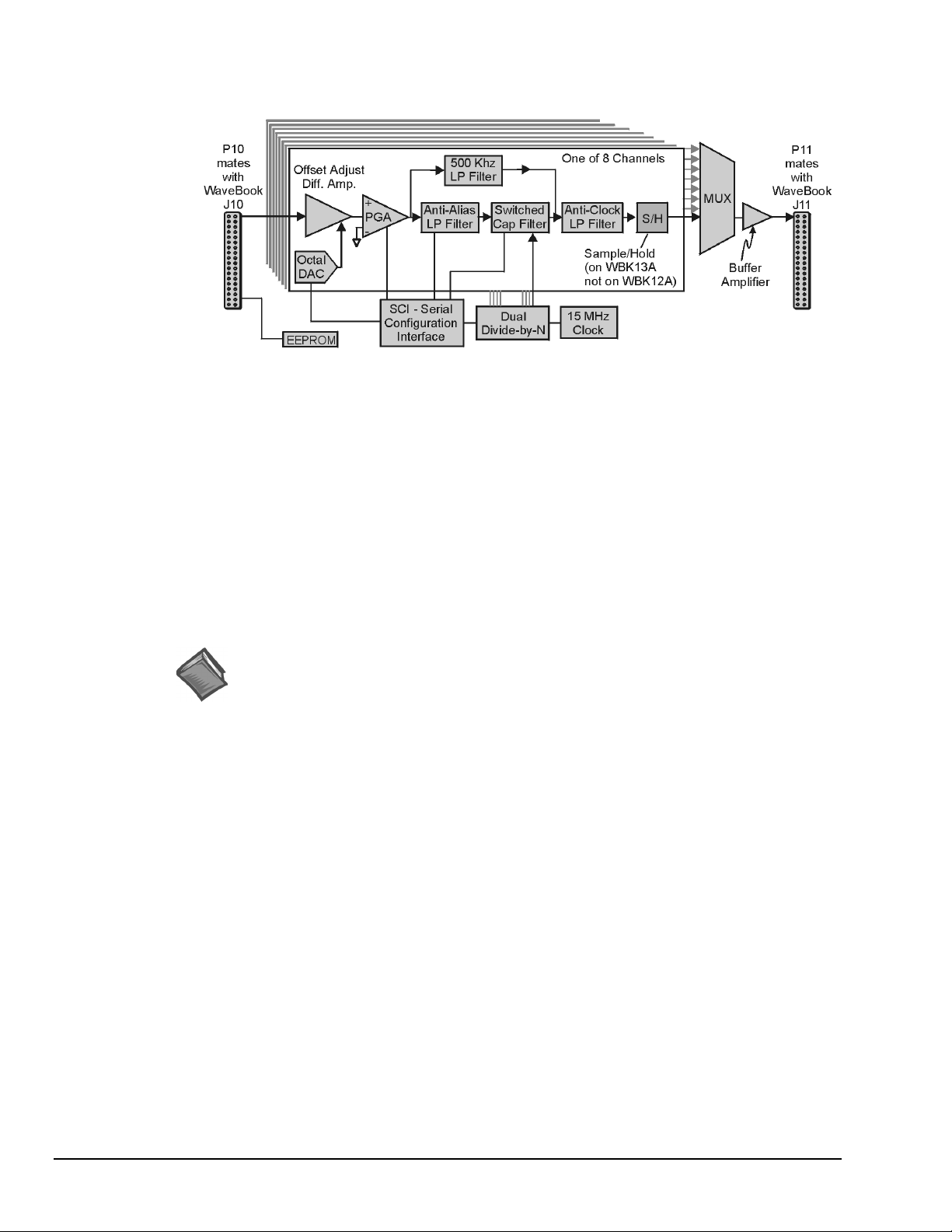

P10

mates

with

WaveBook

J10

One of 8 Channels (Typical)

Offset Adjust

Diff. Amp.

+

PGA

-

Octal

DAC

SCI - Serial

Configuration Interface

Sample/

MUX

Hold

Buffer

Amplif ier

P11

mates

with

WaveBook

J11

WBK11A – SSH Card

WBK11A Block Diagram

988396

WBK11A, pg. 1

Page 17

Hardware Setup

Configuration

All WBK11A configurations are controlled by software. There are no hardware settings.

Reference Note:

For detailed WaveView information refer to the WaveView Document. A PDF version of

the document can be accessed from the data acquisition CD via the <View PDFs> button

on the CD’s opening screen.

Installation

There is no user installation permitted. See notes on page 1.

WBK11A – Specifications

Name/Function:

Number of Channels

Connectors

a 36 pin-socket connector mates with a 36-pin connector

Accuracy

Offset

Aperture Uncertainty

Voltage Droop

Maximum Signal Voltage

: ±0.025% FS for WaveBook/512A applications.

: ±1 LSB max

Input Voltage Ranges

Before a scan sequence begins, the input voltage ranges can be programmed via software.

The ranges can be expanded as follows:

Unipolar

0 to +10 V

0 to +5 V

0 to +2 V

0 to +1 V

0 to +0.5 V

0 to +0.2 V

0 to +0.1 V

Bipolar

: Bipolar applies to

-10 to +10 V

-5 to +5 V

-2 to +2 V

-1 to +1 V

-0.5 to +0.5 V

-0.2 to +0.2 V

-0.1 to +0.1 V

-.05 to + .05 V This range applies to WBK 10A only.

WBK11A; 8-Channel Simultaneous Sample-and-Hold Card

: 8

: Internal to the WaveBook/512 series, or WaveBook/516 series device;

For WaveBook/516 Series applications, see the table on page 3 of this WBK11A document module.

: 75 ps max

: 0.1 mV/ms max

: ±5.00 VDC (×1)

:

: Unipolar applies to WBK 10A only.

WaveBook/516, /516A, /516E, /512A, and WBK10A

Programmable Gain Amplifier Gain Ranges

Weight

: 0.14 kg (0.3 lb)

pg. 2, WBK11A

: ×1, 2, 5, 10, 20, 50, 100

988396

WBK11A – SSH Card

Page 18

Accuracy and Noise Specifications

(

)

(

y)

(

y)

WaveBook/516 Series

(Alone)

Voltage

Range

Accuracy

(Note 2)

One Year, 18-28

°C

Input Noise

LSB rms

DC-500KHz

(typical)

(Note 4)

%

±

reading

%

±

range

0 to +10V .012% .008% 2 .012% .008% 2

0 to +5V (10A)

0 to +4V

516

.012% .009% 2 .012% .009% 2

0 to +2V .012% .012% 3 .012% .012% 3

0 to +1V

.012% .018% 3 .012% .018% 3

10A onl

0 to +.5V .018% .033% 6

0 to +.2V .018% .08% 8

0 to +.1V .018% .16% 15

-10 to +10V .012% .008% 2 .012% .008% 2

-5 to +5V .012% .008% 2 .012% .008% 2

-2 to +2V .012% .009% 2 .012% .009% 2

-1 to +1V .018% .012% 3 .018% .012% 3

-.5 to +.5V

.018% .018% 5 .018% .018% 6

(10A only)

-.2 to +.2V .018% .033% 8

-.1 to +.1V .018% .08% 15

-.05 to +.05V

10A onl

WaveBook/516 Series

with a WBK11A

(Note 3)

Input Noise

Accuracy

(Note 2)

One Year, 18-28

°C

LSB rms

DC-500KHz

(typical)

%

±

reading

%

±

range

.018% .16% 26

Notes

: 1. Specifications assume differential input scan, unfiltered.

2. Accuracy specification is exclusive of noise.

3. Unipolar ranges unavailable for a WaveBook/516, /516A, or /516E

that has a WBK11A, WBK12A, or WBK13A option installed.

Unipolar mode is available with WBK10A and any option.

4. Maximum limit is 1.3X typical.

WBK11A – SSH Card

988396

WBK11A, pg. 3

Page 19

WBK12A and WBK13A

Important Notice! WaveBook/516E Users

WBK option cards for WaveBook/516E are installed at the factory per customer order.

Users are not to remove or install cards for these products as the cards are not “plug-andplay” for these devices and erroneous signal values could result. If you desire to remove

or add a card to WaveBook/516E contact the factory or your service representative.

Important Notice! WaveBook/516, /516A, /512A, and WBK10A Users

With exception of the WBK30 option, WBK option cards for WaveBook/516, /516A,

/512A, and WBK10A are installed at the factory per customer order. Users are not to

remove or install cards for these products [other than WBK30 series cards] as the cards

are not “plug-and-play” for these devices and erroneous signal values could result. If you

desire to remove or add a card to these products, contact the factory or your service

representative.

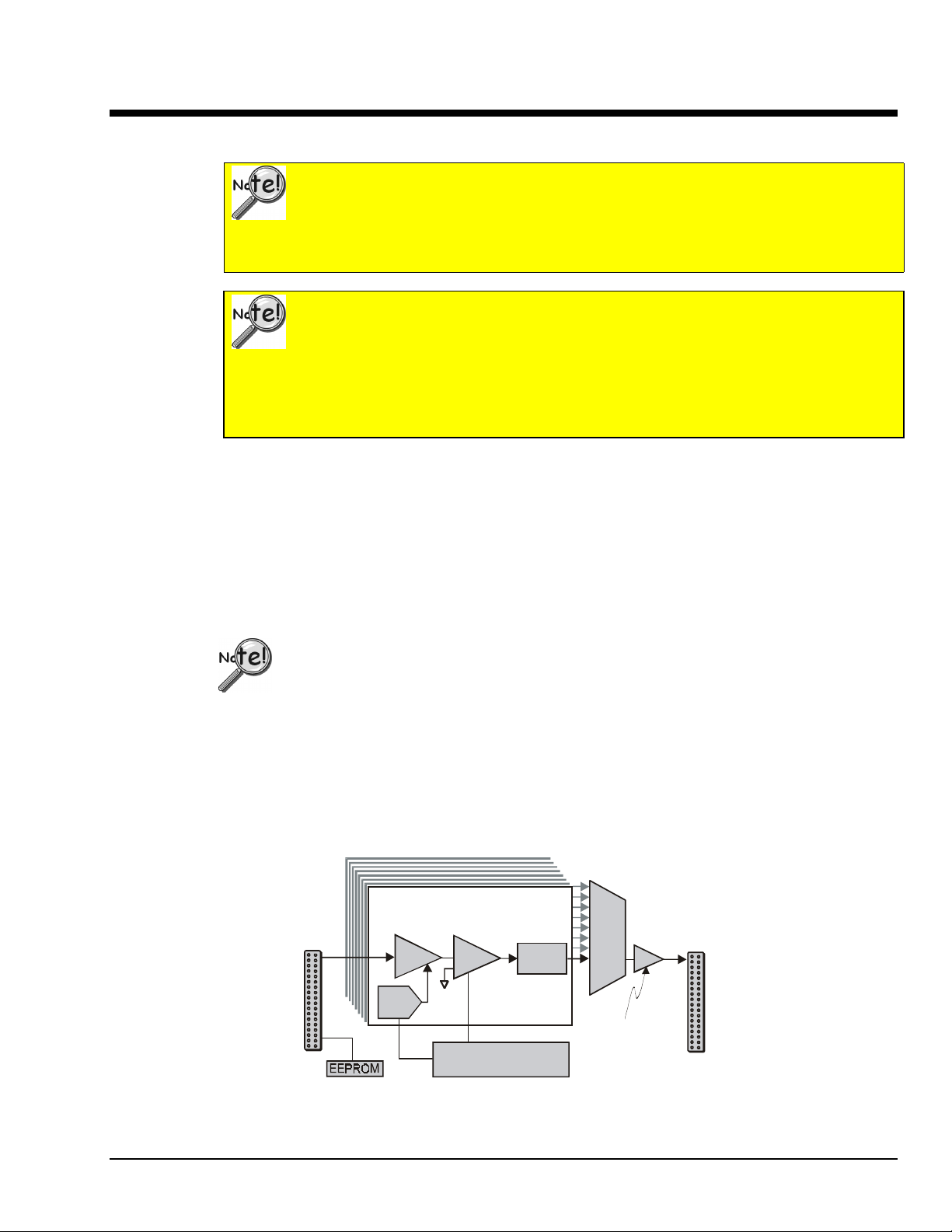

Description

The WBK12A and WBK13A are 8-channel programmable low-pass filter cards for use with 1-MHz

WaveBook data acquisition systems. These cards install directly into a WaveBook or WBK10A module and

provide programmable low-pass filtering over all channels. Multiple WBK12A and WBK13A cards can be

installed in one system for up to 72 channels. All of the cards’ low-pass filters and cutoff frequencies are

configured via software.

Programmable Low-Pass Filter Cards

The WBK13A card has the additional capability of sampling all channels at the same time. If more than one

WBK13A card is installed [within one system] all channels will be sampled within 100 ns of each other.

Features of the WBK12A and WBK13A include:

• Anti-Alias Low-Pass Filters. Each card provides 8 input channels, arranged in two 4-channel banks;

the filter and cutoff frequency configurations are applied per bank. The cards’ filters can be configured

as either an 8-pole elliptic filter with cutoff frequencies of 400 Hz to 100 kHz, or an 8-pole linearphase filter with 400 Hz to 50 kHz cutoff frequencies.

• 500 Khz Low Pass Filter. You can individually configure channels to bypass the programmable filter.

The bypass option results in a 1-pole low-pass filter at approximately 500 kHz.

• Cutoff Frequencies. The WBK12A and WBK13A provide 748 discrete cutoff frequencies that can be

determined exactly by the formula Fc = 300 kHz/N; where the integer N = 3 to 750. Alternatively, you

can configure any channel to bypass the programmable filter entirely, resulting in a 1-pole low-pass

filter at about 500 kHz.

• Programmable-Gain Amplifiers. The cards’ programmable-gain instrumentation amplifiers can be

software selected to various gains on a per channel basis. The gains are set prior to the beginning of an

acquisition sequence and cannot be changed during an acquisition.

• Simultaneous Sample-and-Hold (SSH) (WBK13 only). In addition to the filtering capability of the

WBK12A, the WBK13A provides per channel SSH. Simultaneous sampling of all channels occurs at

the start of a scan sequence.

When using a WaveBook with an SSH channel enabled, the per-channel sample rates

are reduced. The rate reduction is the same as that which would occur if another

channel were added. The per-channel rate (with SSH enabled) is:

1 MHz / (n+1), where n is the number of active channels.

Programmable Low-Pass Filter Cards

988396

WBK12A and WBK13A, pg. 1

Page 20

Hardware Setup

Configuration

All WBK12A and WBK13A series configurations are controlled by software. There are no hardware

settings.

Installation

There is no user installation permitted. See notes on page 1.

Software Setup

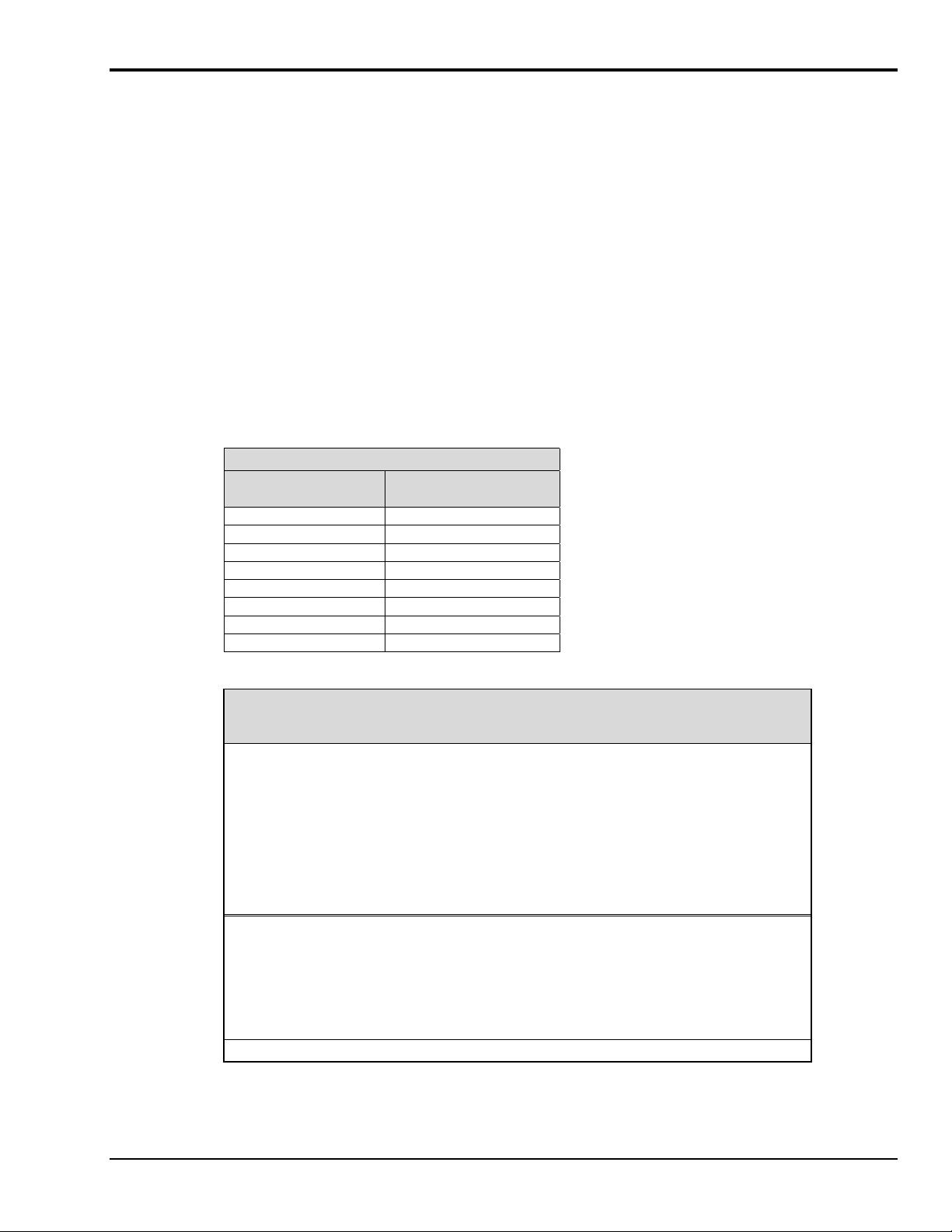

WBK12A and WBK13A Block Diagram

Reference Notes:

➣

Setup information pertaining to power, expansion control, and expansion signal

connections is contained in the System Setup and Power Options chapter of the

WaveBook User’s Manual (p/n 489-0901).

➣

For detailed WaveView information, refer to the WaveView Document PDF that is

included on the data acquisition CD. The document can be accessed using the

<View PDFs> button on the CD’s opening screen.

pg. 2, WBK12A and WBK13A

988396

Programmable Low-Pass Filter Cards

Page 21

WBK12A and WBK13A – Specifications

Name/Function:

WBK12A, Programmable Low-Pass Filter Card

WBK13A, Programmable Low-Pass Filter Card With

SSH

Number of Channels

Connector

/516E, and WBK10A

(two 36-pin sockets mate with 36-pin connectors)

Programmable Gain Amplifier Ranges

×1, 2, 5, 10, 20, 50, and 100

Switched Capacitor Filter Cutoff Frequencies Range

400 Hz to 100 kHz

Number of Cutoff Frequencies

Filter Grouping

banks

: Internal to WaveBook/512A, /516, /516A,

Low-Pass Filter

elliptic filter

Low-Pass Filter Type

elliptic or linear phase

Software Selectable Cutoff Frequencies

Octave (kHz) Number of Cutoff

0.400 to 0.780 512

0.780 to 1.570 256

1.57 to 3.15 128

3.15 to 6.3 64

6.3 to 12.5 32

12.5 to 25 16

25 to 50 8

50 to 100 5

: 8

:

: 1024

: 4 channels each in 2 programmable

: Software selectable, 8-pole

: Software selectable,

Frequencies

Low-Pass Filter Frequency Cutoff Range

100 kHz, 75 kHz, 60 kHz...400 Hz,

bypass defined as Fc = 300 kHz/N where N = 3 to 750

Anti-Alias Frequencies

Accuracy

Offset

Aperture Uncertainty

Voltage Droop

Maximum Signal Voltage

:

THD

Number of Cutoff Frequencies Simultaneously Set

Weight

: ±0.03% FS DC, for WaveBook/512A

For WaveBook/516 Series see the table on

page 4 of this document module.

: ±1 LSB max (for WaveBook/512A)

: 1 mV/ms max (0.01 mV/ms typ)

: -65 dB (-70 dB typ) (for WaveBook/512A)

two, one for each 4-channel bank of inputs

: 0.14 kg (0.3 lb)

: determined by software control

: 75 ps max

: ±5.00 VDC (×1)

:

:

Input Voltage Ranges

Before a scan sequence begins, the input voltage ranges can be programmed via software.

The ranges can be expanded as follows:

Unipolar

0 to +10 V

0 to +5 V

0 to +2 V

0 to +1 V

0 to +0.5 V

0 to +0.2 V

0 to +0.1 V

Bipolar

-10 to +10 V

-5 to +5 V

-2 to +2 V

-1 to +1 V

-0.5 to +0.5 V

-0.2 to +0.2 V

-0.1 to +0.1 V

-.05 to + .05 V This range applies to WBK 10A only.

Programmable Gain Amplifier Gain Ranges

: Unipolar applies to WBK 10A only.

: Bipolar applies to

:

WaveBook/516, /516A, /516E, /512A, and WBK10A

: ×1, 2, 5, 10, 20, 50, 100

Programmable Low-Pass Filter Cards

988396

WBK12A and WBK13A, pg. 3

Page 22

Accuracy and Noise Specifications

(

)

(

y)

(

y)

WaveBook/516 Series

(Alone)

Input Noise

Voltage

Range

Accuracy

(Note 2)

One Year, 18-28

°C

LSB rms

DC-500KHz

One Year, 18-28

(typical)

(Note 4)

%

±

reading

%

±

range

reading

0 to +10V .012% .008% 2 .012% .008% 2.2 2.2

0 to +5V (10A)

0 to +4V

516

.012% .009% 2 .012% .009% 2.2 2.2

0 to +2V .012% .012% 3 .012% .012% 2.2 3

0 to +1V

.012% .018% 3 .012% .018% 2.2 3

10A onl

0 to +.5V .018% .033% 2.2 6

0 to +.2V .018% .08% 2.2 12

0 to +.1V .018% .16% 2.2 20

-10 to +10V .012% .008% 2 .012% .008% 2.2 2.2

-5 to +5V .012% .008% 2 .012% .008% 2.2 2.2

-2 to +2V .012% .009% 2 .012% .009% 2.2 3

-1 to +1V .018% .012% 3 .018% .012% 2.2 3.3

-.5 to +.5V

.018% .018% 5 .018% .018% 2.2 6

(10A only)

-.2 to +.2V .018% .033% 2.2 12

-.1 to +.1V .018% .08% 2.2 20

-.05 to +.05V

10A onl

WaveBook/516 Series

with a WBK12A or a WBK13A

Accuracy

(Note 2)

°C

Input Noise

LSB rms

(typical)

±

%

±

range

1KHz

%

Filter

Bypass

.018% .16% 440

(Note 3)

Filter

Notes

: 1. Specifications assume differential input scan, unfiltered

2. Accuracy specification is exclusive of noise.

3. Unipolar ranges are unavailable for a WaveBook/516 Series with a

WBK11A, W BK12A, or W BK13A option installed.

Unipolar mode is available with WBK10A and any option.

4. Maximum limit is 1.3X typical.

pg. 4, WBK12A and WBK13A

988396

Programmable Low-Pass Filter Cards

Page 23

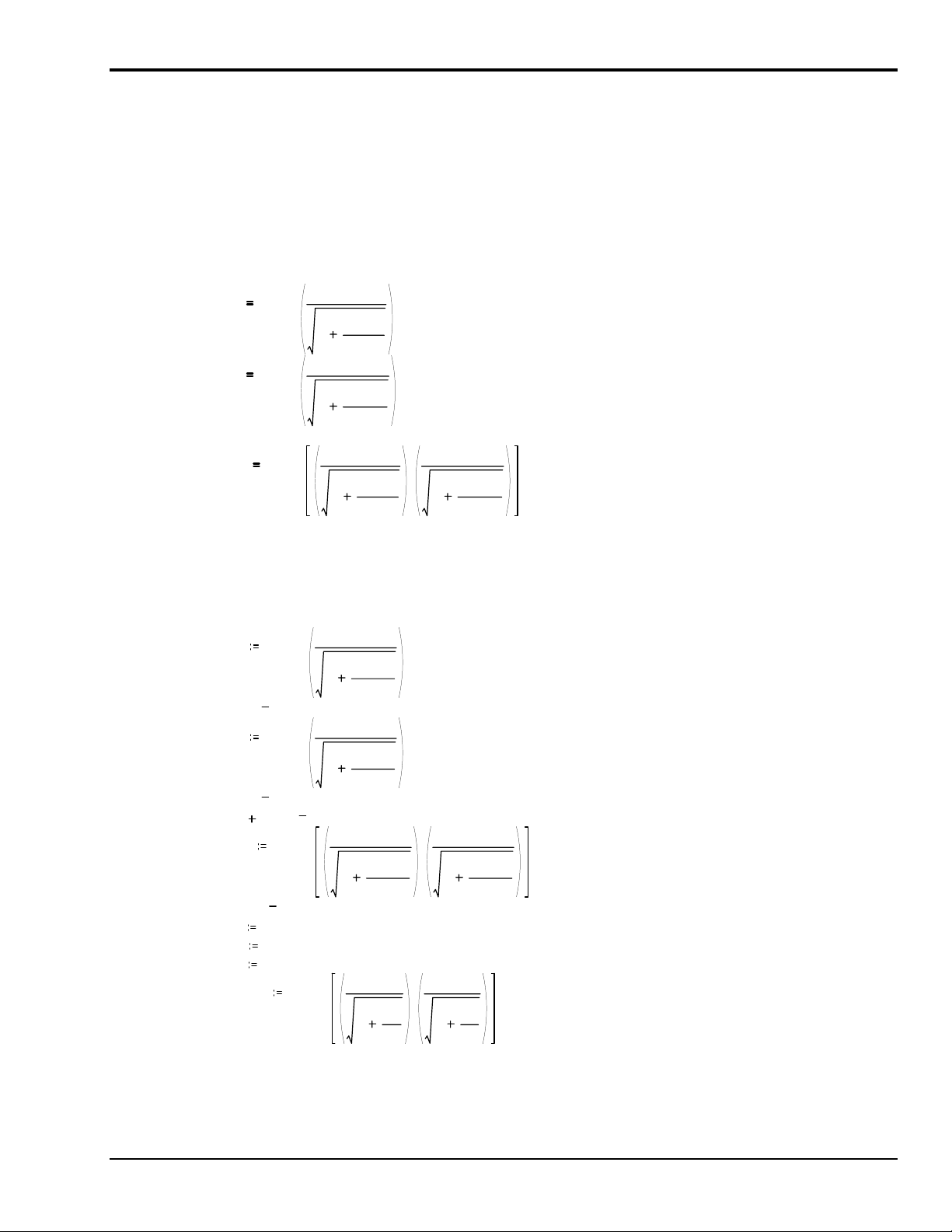

Predicting Amplitude Loss

The following equations can be used to predict the amplitude loss when passing a signal through either the

anti-alias or clock suppression filter.

Definition of equation terms:

Fin is the signal to be measured.

Falias is the cutoff frequency of the anti-alias filter.

Fclock is the cutoff frequency of the clock suppression filter.

1

1

1

Fin

Falias

1

Fin

Fclock

Err 20 log

Err 20 log

.

.

Total error, in dB, due to both filters is :

Etot 20 log

1

1

Falias

..

Fin

1

1

Fin

Fclock

As an example, with the switched capacitor filter set to 10,000 Hz. and the input frequency set to 6000 Hz.

Fin = 6000

Falias = 33554

Fclock = 14848

Total amplitude loss = sum of both errors = -2.188 dB.

1

1

1

33554

1

14848

1

1

6000

6000

1

6000

33554

1

Fx

Fp

..

..

1

6000

1

14848

1

Fx

1

Fc

E1 20 log

E1 0.71446

E2 20 log

E2 1.47396

E1 E2 2.18843

Etot 20 log

Etot 2.18843

Fx 1 2,8000

Fp 33554

Fc 14848

EFx( ) 20 log

.

=

.

=

=

=

..

Programmable Low-Pass Filter Cards

988396

WBK12A and WBK13A, pg. 5

Page 24

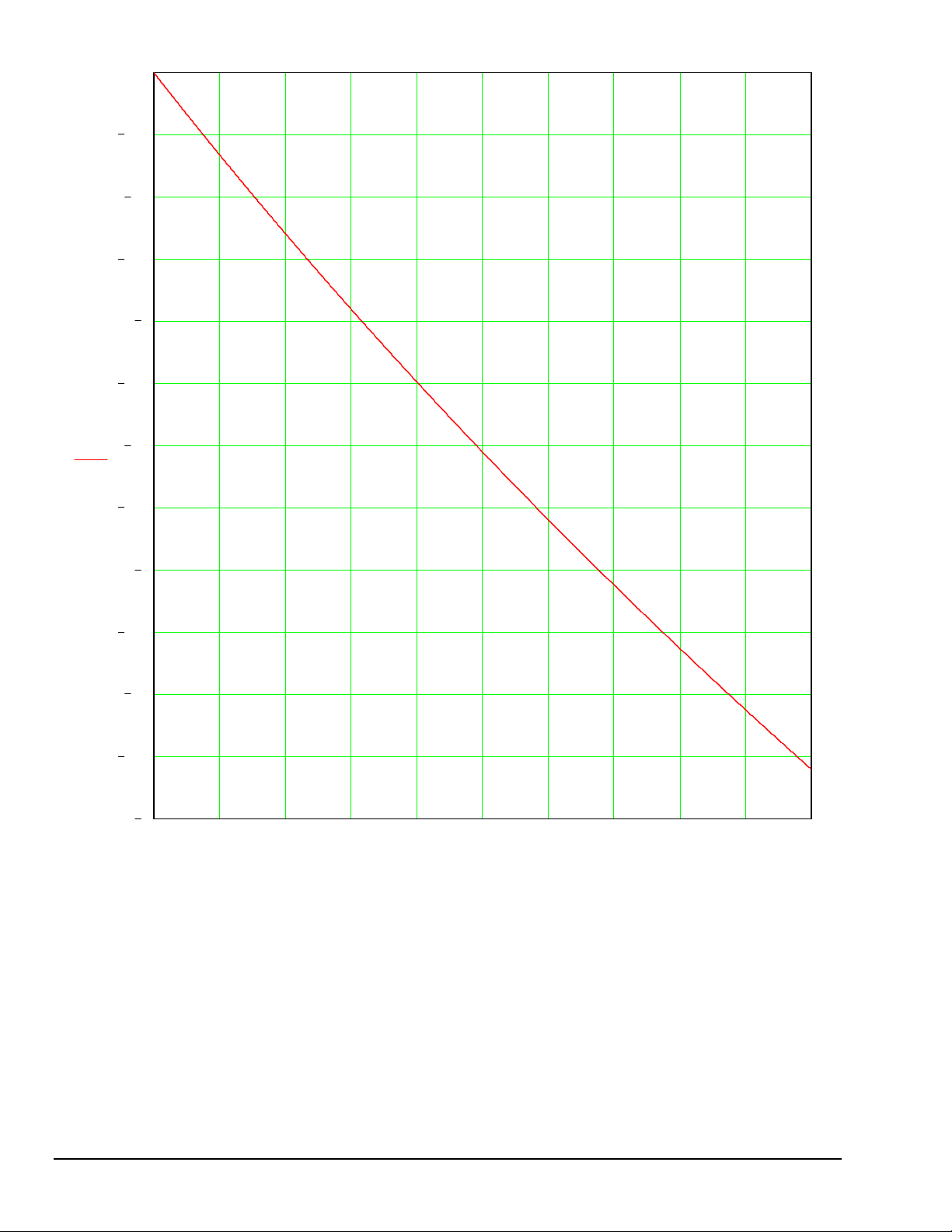

0.25

0.5

0.75

1.25

0

1

EFx()

1.5

1.75

2

2.25

2.5

2.75

3

0 800 1600 2400 3200 4000 4800 5600 6400 7200 8000

Fx

WBK12A & WBK13A, Amplitude Loss in dB due to Anti-alias and Clock Filters

Input signal is swept from 1 to 8000 Hz

switched capacitor filter frequency = 8,000 Hz

anti-alias filter cutoff = 33.554 Hz

clock filter = 14,848 Hz

pg. 6, WBK12A and WBK13A

988396

Programmable Low-Pass Filter Cards

Page 25

WBK14

Dynamic Signal Input Module

Description…… 1

Current Source …… 2

High-Pass Filter (HPF) …… 2

Programmable Gain Amplifier (PGA) …… 2

Programmable Low-Pass Filter Phase Equalizer …… 3

Programmable Low-Pass Anti-Aliasing Filter…… 2

Simultaneous Sample and Hold…… 3

Excitation Source …… 3

Calibration …… 3

Hardware Setup …… 4

Configuration…… 4

Power…… 4

Assembly…… 4

Software Setup …… 5

Using Accelerometers with WBK14 …… 6

Overview …… 6

Accelerometer Specification Parameters …… 6

Electrical Grounding…… 8

Cable Driving…… 8

WBK14 – Specifications …… 9

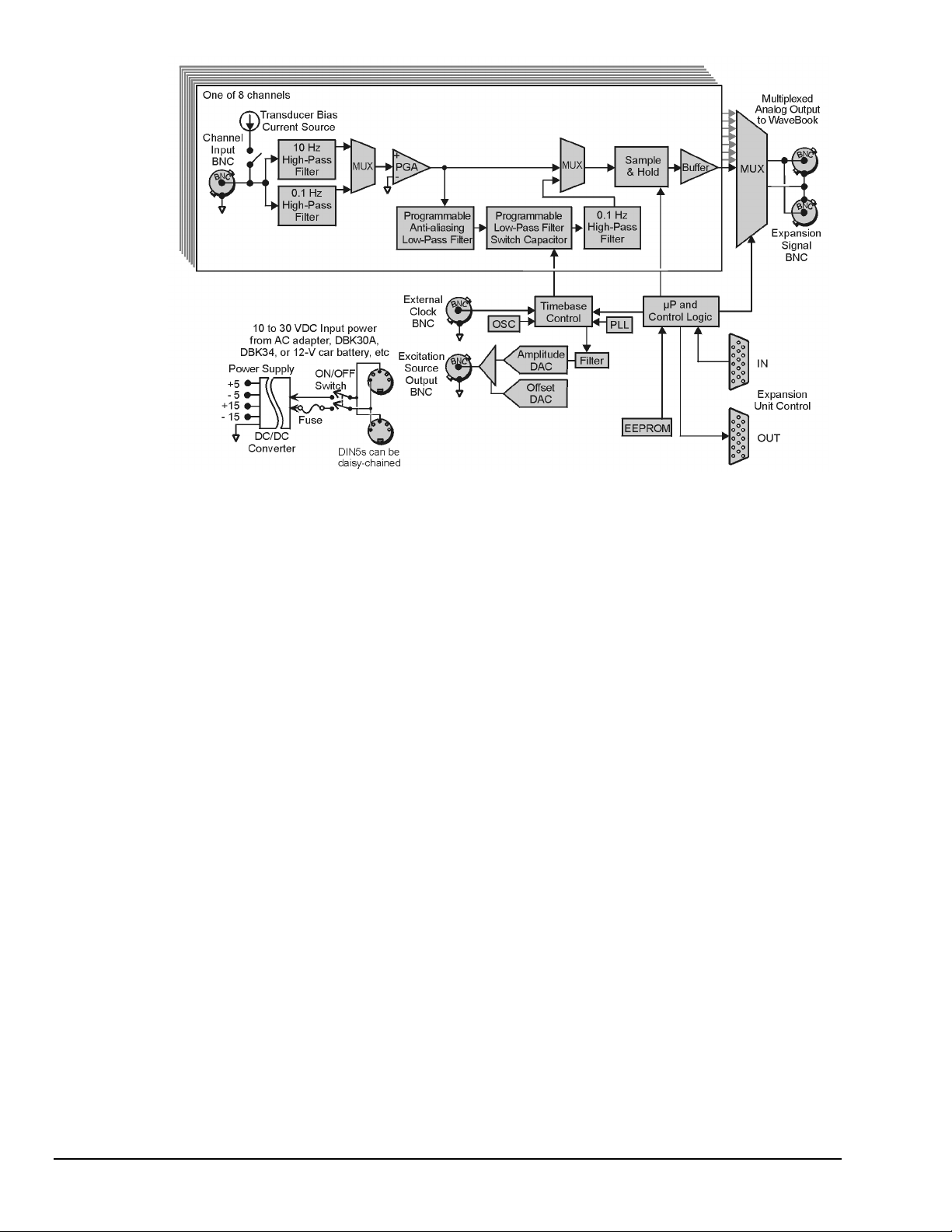

Description

The WBK14 is a dynamic analog signal input module for the WaveBook data acquisition system. The

WBK14 provides a complete system to interface to piezoelectric transducers that include accelerometers,

microphones, force/pressure transducers, and others.

Reference Note:

Information regarding accelerometers begins on page 6 of this document module.

Each WBK14 channel has a:

•

current source for transducer biasing

•

high-pass filter

• programmable gain amplifier

•

anti-aliasing low-pass filter

•

simultaneous sample-and-hold (SSH) amplifiers

The gain, filter cut-off frequencies and current biasing levels are software programmable.

WBK14 includes a built-in programmable excitation source. This source stimulates dynamic systems for

transfer function measurements, and serves as a reference signal for calibration.

WBK14, Dynamic Signal Input Module

988396

WBK14, pg. 1

Page 26

Current Source

WBK14 provides constant current to bias ICP transducers. Two current levels (2 mA or 4 mA) with

voltage compliance of 27 V can be selected via software. The bias current is sourced through the center

conductor of a coaxial lead and returns to the WBK14 by the outer conductor. The output impedance is

larger than 1 MΩ and presents virtually no loading effect on the transducer’s output. For applications that

do not require bias, the current source can be removed from the BNC input by opening a relay contact.

The current sources are applied to (or removed from) the input in channel groups of two; i.e.,

channels 1-2, 3-4, 5-6, 7-8.

High-Pass Filters (HPF)

Each WBK14 channel has three High-Pass Filters (HPFs) with a 3-dB cut-off frequency (Fc). Two filters

are at 0.1 Hz and the other is 10 Hz. The 0.1-Hz HPF filters are single-pole RC filters. They are primarily

used to couple vibration signals. The 10-Hz HPF is a 2-pole Butterworth type that can be used to couple

acoustic signals or attenuate setup-induced low-frequency signals; since these can reduce the dynamic range

of the measurement (for example when using tape recorders as signal sources).

Programmable Gain Amplifier (PGA)

The HPF removes the DC voltage from the input signal. A PGA amplifies the AC voltage with flat response

up to 500 kHz. Each channel has a PGA with programmable gains (1, 2, 5, 10, 20, 50, and 100) and a

software-controlled DAC for offset nulling. The WBK14 measures only bipolar signals up to 5 V peak.

WBK14 Block Diagram

Programmable Low-Pass Anti-Aliasing Filter

The first filter stage is a programmable 2-pole continuous-time low-pass filter. The filter provides more than

65 dB alias protection to the next filter stage. In addition, it fine-tunes the phase shift of the channel to

optimize the phase-matching between channels. At calibration, the phase shift of each channel is measured

and stored in an EEPROM that is read at configuration.

WBK14, pg. 2

988396

WBK14, Dynamic Signal Input Module

Page 27

Programmable Low-Pass Filter, Switch-Capacitor

Most of the signal alias rejection is performed by an 8-pole Butterworth filter. This filter is implemented

with a switch-capacitor network driven by a programmable clock (timebase control). Each channel has an

independent clock whose frequency determines the 3-dB cut-off frequency of the filter. The switchcapacitor filter provides no attenuation at the clock frequency—hence, the need for the continuous-time

low-pass filter.

Note: The Low-Pass Anti-Aliasing Filter can be bypassed to process signals with a bandwidth higher

than 100 kHz.

The External Clock input provides a path to externally control the cut-off frequency of the Low-Pass

Anti-Aliasing Filter. The input waveform can be TTL or sinusoidal, with an amplitude peak of at least

500 mV. In this mode, the cut-off frequency is set to the input frequency divided by 50.

Simultaneous Sample and Hold

All WBK14 channels are sampled simultaneously, after which the WaveBook measures each output at

1 µs/channel until all channels are digitized. The time-skew between sampling on all channels (up to 72)

is 150 ns, regardless of the number of WBK14s attached to the WaveBook.

When using WaveBook with an SSH channel enabled, the per-channel sample rates are

reduced. The rate reduction is the same as that which would occur if another channel

were added. The per-channel rate (with SSH enabled) is:

1 MHz / (n+1), where n is the number of active channels.

Excitation Source

The excitation source includes a sine/random waveform generator, a programmable gain amplifier (PGA), a

DC-level DAC, and a phase-lock loop (PLL). The PLL is used to synthesize the frequency of a fixedamplitude sine wave and control the bandwidth of the random signals. The PGA conditions the signal

amplitude to a value between 0 V to 5 V peak. The DC level of the signal is varied independently of signal

amplitude by a software-controlled DAC from -5 V to +5 V. The DC level of the excitation signal can be

used to balance static loads, while the AC signal provides the dynamic excitation.

Calibration

WBK14 is calibrated digitally, eliminating the need for all potentiometers and manual adjustments.

WaveCal, a provided Windows-based program, simplifies the calibration process.

Reference Note:

The calibration program is detailed in the WaveCal Document Module.

WBK14, Dynamic Signal Input Module

988396

WBK14, pg. 3

Page 28

Hardware Setup

Configuration

All WBK14 configurations are controlled by software. The WBK14 requires no hardware settings.

Power

Like the WaveBook, the WBK14 contains an internal power supply. The unit can be powered by an

included AC power adapter or from any 10 to 30 VDC source, such as a 12 V car battery. For portable or

field applications, the WBK14 and the WaveBook can be powered by the DBK30A rechargeable battery

module or the DBK34 uninterruptible power supply (UPS) / battery module.

CAUTION

CAUTION

CAUTIONCAUTION

If the following two conditions exist simultaneously:

• operating WBK14s in a configuration of 4 or more modules

• ambient temperature >40°C;

then you must mount the modules on their side (vertically) to facilitate air flow through the

side plates. Failure to due so could result in thermal-related problems.

Reference Notes:

➣

Setup information pertaining to power, expansion control, and expansion signal connections

is contained in the chapter System Setup and Power Options, in the WaveBook User’s

Manual (p/n 489-0901).

➣

For detailed WaveView information, refer to the WaveView document PDF. The document

can be accessed from the data acquisition CD via the <View PDFs> button on the opening

screen.

Assembly

You must compute power consumption for your entire system and (if necessary) use

auxiliary or high-current power supplies.

Reference Note:

For details regarding power, refer to the chapter, System Setup and Power Options, in the

WaveBook User’s Manual (p/n 489-0901).

The WBK14 shares the same footprint as other WBK modules and WaveBooks, allowing for convenient

mounting. A fastener panel allows multiple units to be stacked vertically. Screw-on handles are available for

portable applications. For more assembly information refer to this manual’s introduction.

WBK14, pg. 4

988396

WBK14, Dynamic Signal Input Module

Page 29

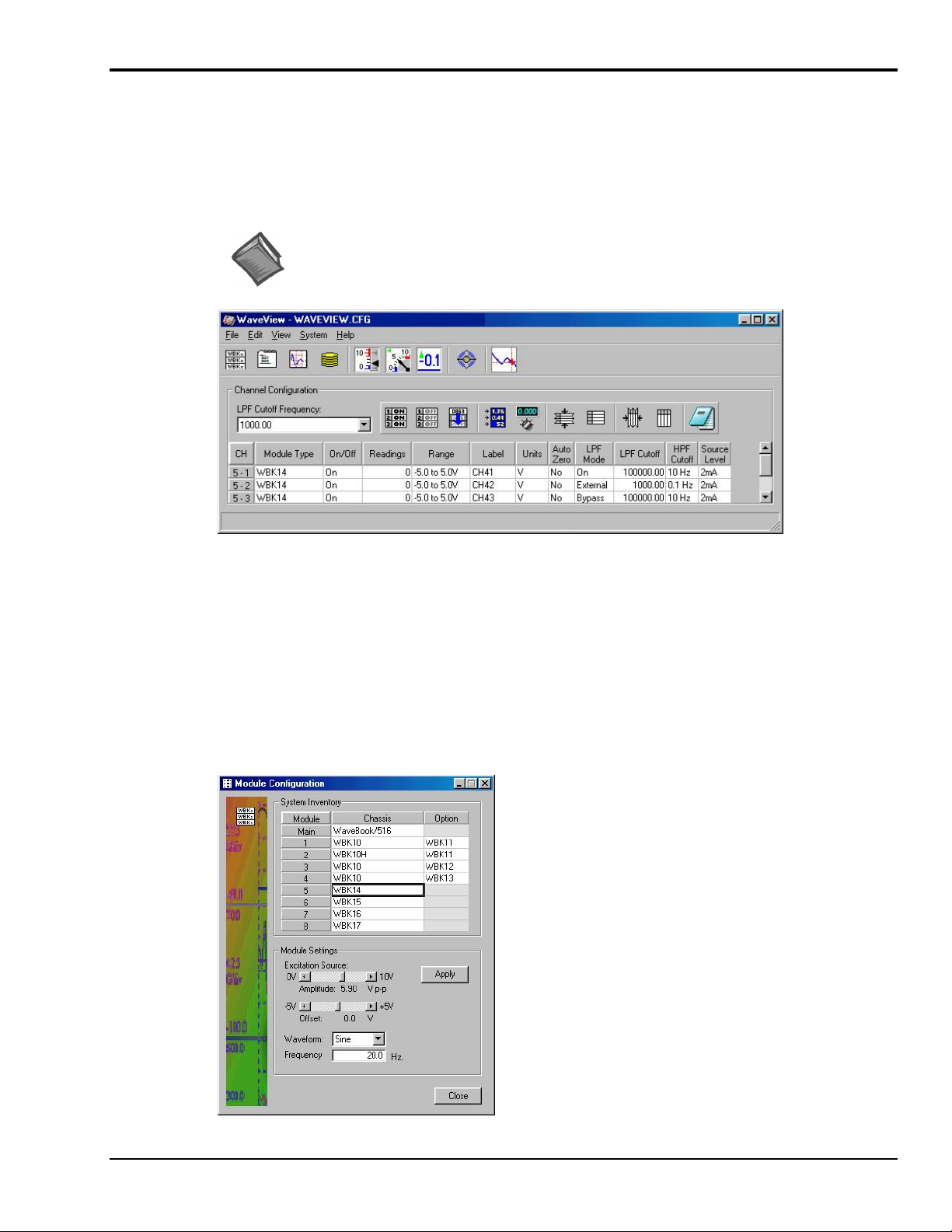

Software Setup

Depending on your application, you will need to set several software parameters. Proper settings will allow

WaveView to organize data to meet your requirements. Some items of importance to the WBK14 are the

low-pass and high-pass filter options that can be selected from the WaveView Configuration main window

and the excitation source parameters that can be chosen from the Module Configuration window. The

Module Configuration window can be accessed from the View pull-down menu or by use of the first toolbar

button (located just below the File pull-down menu).

Reference Note:

For detailed WaveView information, refer to the WaveView Document PDF. The

document can be accessed directly from the data acquisition CD via the <View PDFs>

button on the opening screen.

WaveView Configuration Window

In the WaveView Configuration main window (see figure) the following columns are

important in regard to filters.

LPF Mode – You can click on a cell in the LPF Mode column to make the cell “active,” and

then change its setting. Options for WBK14’s LPF Mode are:

(a) On – turns the Low-Pass Filter on

(b) External – selects an external filter

(c) Bypass – bypasses the low-pass filter

LPF Cutoff – the cells in this column are used to set the Low-Pass Filter cutoff frequency.

HPF Cutoff – the cells in this column are used to set the High-Pass Filter cutoff frequency.

For WBK14 applications, the Module

Configuration window allows you to set

the excitation source in regard to:

amplitude

offset

waveform (Sine, or Random)

frequency

The Module Configuration window can

be accessed from the View pull-down

menu or by use of the first toolbar button

(located just below the File pull-down

menu).

Module Configuration Window

WBK14, Dynamic Signal Input Module

988396

WBK14, pg. 5

Page 30

Using Accelerometers with WBK14

(

)

Overview

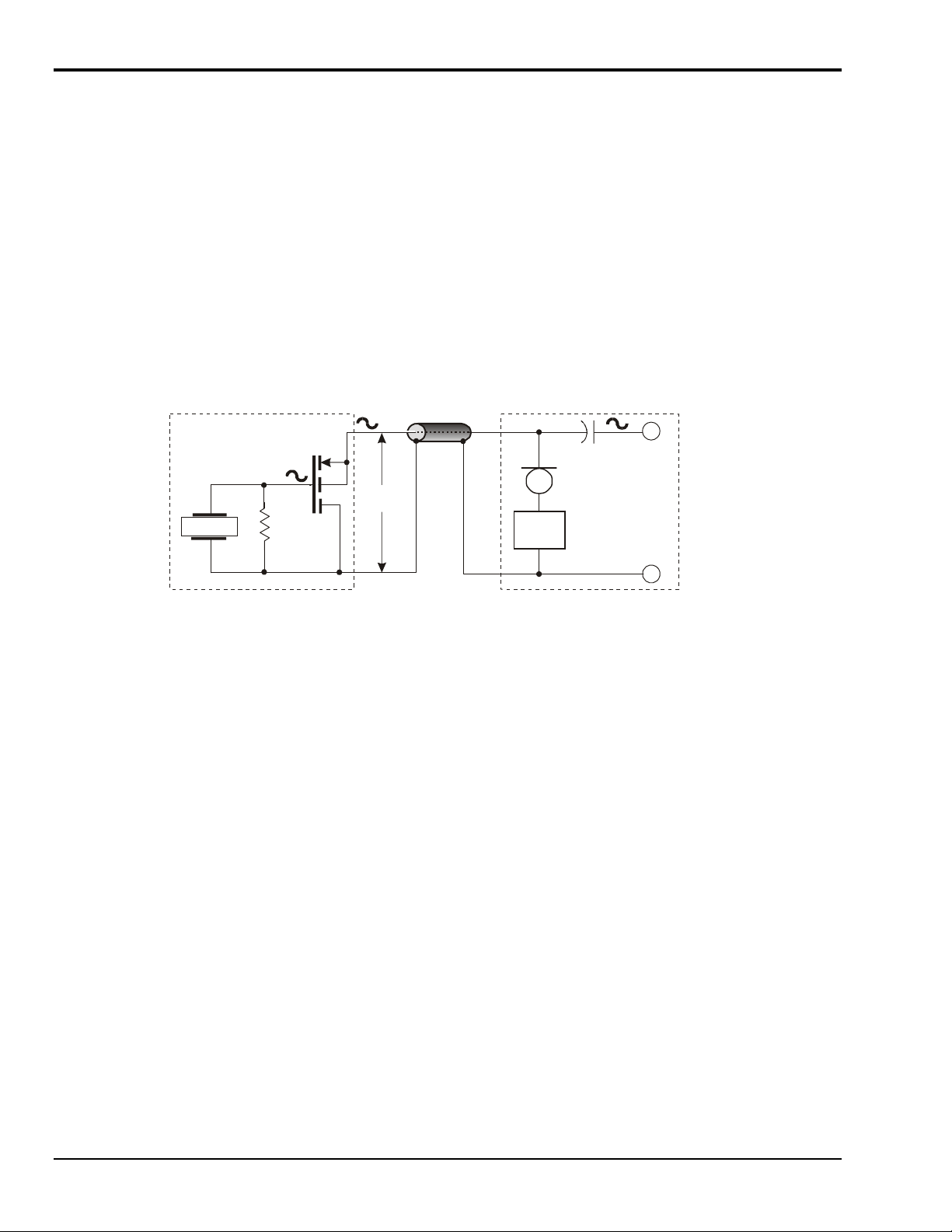

A low-impedance piezoelectric accelerometer consists of a piezoelectric crystal and an electronic amplifier.

When stretched or compressed, the two crystal surfaces develop a charge variation that is related to the

amount of stress, shock, or vibration on the crystal. The amplifier outputs a corresponding signal and

transforms the sensor’s high impedance to a lower output impedance of a few hundred ohms. Note that, in

addition to acceleration, these sensors can also measure pressure and force.

The circuit requires only two wires (coax or twisted pair) to transmit both power and signal. At low

impedance, the system is insensitive to external or “triboelectric” cable noise. Cable length does not affect

sensitivity.

The following figure shows a simple sensor-WBK14 connection. The voltage developed across R is

applied to the gate of the MOSFET. The MOSFET is powered from a constant current source of 2 or 4 mA

and 27 volts.

Sensor to WBK14

Coaxial Cable

MOSFET

Bias

Vol tage

Sensor

R

Accelerometer Circuit

Crystal

The MOSFET circuit will bias off at approximately 12 V in the quiet state. As the system is excited,

voltage is developed across the crystal and applied to the gate of the MOSFET. This voltage will cause

linear variation in the impedance of the MOSFET and a proportional change in bias voltage. This voltage

change will be coupled to the WBK14 input amplifier through the capacitor C. The value of R and the

internal capacitance of the piezoelectric crystal control the low frequency corner. Units weighing only a

few grams can provide high level outputs up to 1 V/g with response to frequencies below 1 Hz.

Accelerometer Specification Parameters

Noise in Accelerometers

The noise floor or resolution specifies lowest discernible amplitude (minimum “g”) that can be measured.

There are two main sources of noise as follows:

• Noise from the crystal and microcircuit inside the accelerometer. Some types of crystals, such as

quartz, are inherently more noisy than others. A good noise floor is 10 to 20 µV.

-

+

30 VDC

Power

C

Constant

Current

2 or 4 mA

WBK14

Amplifier

Input

GND

• Noise from electrical activity on the mounting surface. Since the signal from the accelerometer is a

voltage, 60 Hz or other voltages (ground loop, etc) can interfere with the signal. The best protection is

to electrically isolate the accelerometer.

Sensitivity

The sensitivity of an accelerometer is defined as its output voltage per unit input of motion. The unit of

motion used is “g.” One “g” is equal to the gravitational acceleration at the Earth’s surface, which is

32.2 ft/(sec)(sec) or 981 cm/(sec)(sec). The output is usually specified in millivolts per “g” (mV/g).

Sensitivity is usually specified under defined conditions such as frequency, testing levels, and temperature.

An example: 100 mV/g at a frequency of 100 Hz, level +1 g, at 72°F. Note that, although a sensor may

have a “typical” sensitivity of 100 mV/g, its actual sensitivity could range from 95 to 105 mV/g (when

checked under stated conditions). Manufacturers usually provide sensor calibration values.

WBK14, pg. 6

988396

WBK14, Dynamic Signal Input Module

Page 31

Transverse Sensitivity - An accelerometer is designed to have one major axis of sensitivity, usually

perpendicular to the base and co-linear with its major cylindrical axis. The output caused by the motion

perpendicular to the sensing axis is called transverse sensitivity. This value varies with angle and frequency

and typically is less than 5% of the basic sensitivity.

Base-Strain Sensitivity - An accelerometer’s base-strain sensitivity is the output caused by a deformation

of the base, due to bending in the mounting structure. In measurements on large structures with low natural

frequencies, significant bending may occur. Units with low base-strain sensitivity should be selected.

Inserting a washer (smaller in diameter than the accelerometer base) under the base reduces contact surface

area; and can substantially reduce the effects of base-strain. Note that this technique lowers the usable

upper frequency range.

Acoustic Sensitivity - High-level acoustic noise can induce outputs unrelated to vibration input. In general,

the effect diminishes as the accelerometer mass increases. Use of a light, foam-rubber boot may reduce this

effect.

Frequency Response

An accelerometer’s frequency response is the ratio of the sensitivity measured at frequency (f) to the basic

sensitivity measured at 100 Hz. This response is usually obtained at a constant acceleration level, typically

1 g or 10 g. Convention defines the usable range of an accelerometer as the frequency band in which the

sensitivity remains within 5% of the basic sensitivity. Measurements can be made outside these limits if

corrections are applied. Care should be taken at higher frequencies because mounting conditions greatly

affect the frequency range (see Mounting Effects, in upcoming text).

Dynamic Range

The dynamic measurement range is the ratio of the maximum signal (for a given distortion level) to the

minimum detectable signal (for a given signal-to-noise ratio). The dynamic range is determined by several

factors such as sensitivity, bias voltage level, power supply voltage, and noise floor.

Bias Level

Under normal operation, a bias voltage appears from the output signal lead to ground. There are two basic

MOSFET configurations commonly used. One exhibits a 7-8 V bias and the second a 9-12 V bias.

Operation of the two circuits is identical except for the available signal swing. The low-voltage version

typically exhibits 5-10 µVrms versus 10-20 µVrms for the high voltage.

Thermal Shock - Temperature Transients

Piezoelectric accelerometers exhibit a transient output that is a function of a temperature’s “rate-of-change.”

This “thermal shock” is usually expressed in g/°C and is related to:

•

Non-uniform mechanical stresses set up in the accelerometer structure.

•

A pyroelectric effect in piezoelectric materials—an electrical charge is produced by the

temperature gradient across the crystal.

This quasi-static effect produces a low-frequency voltage input to the MOSFET amplifier. This voltage is

usually well below the low-frequency corner, but the effect can reduce the peak clipping level and cause

loss of data. This effect does not affect the accelerometer’s basic sensitivity or the data unless the thermal

shift in the operation bias level results in clipping. Where drastic thermal shifts are expected, use 12 V bias

models. The effect’s severity is related to the mass of the accelerometer. In 100 mV/g industrial units, the

effect is usually negligible. Using rubber thermal boots can reduce the effect significantly.

Overload Recovery

Recovery time from clipping due to over-ranging is typically less than 1 ms. Recoveries from quasi-static

overloads that generate high DC bias shifts are controlled by the accelerometer input RC time constant that

is fixed during manufacture.

Power Supply Effects

The nominal power supply voltage recommended by most manufacturers is 15 to 24 V. Units may be used

with voltages up to 28 volts. Sensitivity variations caused by voltage change is typically 0.05%/volt.

Power supply ripple should be less than 1 mVrms.

WBK14, Dynamic Signal Input Module

988396

WBK14, pg. 7

Page 32

Connector

This parameter specifies the connector type and size (4-48, 6-40, 10-32 coaxial etc) and the location on the

sensor, that is, top or side (usually on the hex base). Where there is no connector on the sensor, an integral

cable is specified with the length and the connector, that is, integral 6-ft to 10-32.

Electrical Grounding

Case-Grounded Design

In case-grounded designs, the common lead on the internal impedance matching electronics is tied to the

accelerometer case. The accelerometer base/stud assembly forms the signal common and electrically

connects to the shell of the output connector. Case-grounded accelerometers are connected electrically to

any conductive surface on which they are mounted. When these units are used, take care to avoid errors

due to ground noise.

Isolated-Base Design

To prevent ground noise error many accelerometers have base-isolated design. The outer case/base of the

accelerometer is isolated electrically off ground by means of an isolation stud insert. The proprietary

material used to form the isolation provides strength and stiffness to preserve high-frequency performance.

Cable Driving

Operation over long cables is a concern with all types of sensors. Concerns involve cost, frequency

response, noise, ground loops, and distortion caused by insufficient current available to drive the cable

capacitance.

The cost of long cables can be reduced by coupling a short (1 m) adapter cable from the accelerometer to a

long low-cost cable like RG-58U or RG-62U with BNC connectors. Since cable failure tends to occur at

the accelerometer connection where the vibration is the greatest, only the short adapter cable would need

replacement.

Capacitive loading in long cables acts like a low-pass, second-order filter and can attenuate or amplify highfrequency signals depending on the output impedance of the accelerometer electronics. Generally this is not

a problem with low-frequency vibration (10 Hz to 2000 Hz). For measurements above 2000 Hz and cables

longer than 100 ft, the possibility of high-frequency amplification or attenuation should be considered.

The WBK14 constant-current source provides 2 or 4 mA to integral electronics. Use the higher current

setting for long cables, high peak voltages, and high signal frequencies.

The maximum frequency that can be transmitted over a given length of cable is a function of both the cable

capacitance and the ratio of the maximum peak signal voltage to the current available from the constant

current source:

Drive Current

(mA)

2 10 185 kHz 37 kHz

2 100 18.5 kHz 3.7 kHz

2 1000 1.85 kHz 370 Hz

4 10 550 kHz 110 kHz

4 100 55 kHz 11 kHz

4 1000 5.5 kHz 1.1 kHz

Cable Length

@30 pF/ft (Ft)

Frequency Response to 5% of

Maximum Output Signal Amplitude

± 1 V ± 5 V

Where:

f

K

V

2

C

π

Icc Ib=−

WBK14, pg. 8

f = Maximum frequency in Hz

K = 3.45 ×10

and a factor to allow cable capacitance to charge to 95% of the final charge.

C = Cable capacitance in picoFarads

V = Maximum peak measured voltage from sensor in volts

Icc = Constant current from current source in mA

Ib = Current required to bias the internal electronics, typically 1 mA

9

. K is the scale factor to convert Farads to picoFarads and Amperes to milliAmperes

988396

WBK14, Dynamic Signal Input Module

Page 33

WBK14 – Specifications

Name/Function: WBK14, 8-Channel Dynamic Signal Conditioning Module

Connectors

Channels

Gain Ranges

Power Consumption:

Input Power Range:

Operating Temperature:

Storage Temperature:

Dimensions:

Weight:

ICP Current Source:

Output Impedance:

Compliance:

Current Levels:

Coupling :

10 Hz High-Pass Filter - Input Impedance:

0.1 Hz High-Pass Filter - Input Impedance:

Input Ranges:

Anti-Aliasing Low-Pass Filter:

Excitation Source:

Sine:

Frequency:

Distortion:

Amplitude:

Steps:

Random:

Spectral Distribution:

Amplitude Distribution:

Bandwidth:

RMS level:

External Clock:

Digital:

Sine:

: BNC connector, mates with expansion signal input on the WaveBook/512, /512A, /516, /516A, or /516E.

Two 15-pin connectors, mate with expansion signal control on the WaveBook; signals via 1 BNC per channel

: 8

: ×1, 2, 5, 10, 20, 50, 100

15 Watts typical

10 to 30 VDC

0°C to 70°C

216 mm wide × 279 mm long × 35 mm high (8.5” × 11” × 1.375”)

1.32 kg (2.9 lb)

> 1.0 MΩ @ 20 kHz

27 V

2 & 4 mA

AC

±5.0 V, ±2.5 V, ±1.0 V, ±500 mV, ±250 mV, ±100 mV, ±50 mV

Accuracy

Frequency Span:

Frequency Settings:

Dynamic Range @ 1 kHz:

THD @ 1 kHz

Amplitude Matching:

Phase Matching:

Max. Output Voltage:

Max. Output Current:

DC Output:

> 500 mV peak

: ±0.5 dB at the pass-band center

: 70 dB

± 5 V

20 Hz to 100 kHz

< 0.1%

± 5 V

256

20 Hz to 100 kHz

Adjustable in binary steps

TTL levels

0°C to 50°C

590K

10 MΩ

30 Hz to 100 kHz

300 kHz / N; N = 3,4,...10000

69 dB

± 0.1 dB

± 2°

± 10 V

10 mA

White, Band-limited

Gaussian

WBK14, Dynamic Signal Input Module

988396

WBK14, pg. 9

Page 34

WBK15

Description

5B Isolated Signal-Conditioning Module

Description …… 1

Hardware Setup …… 2

Configuration …… 2

Connection …… 3

Power …… 4

Safety Concerns …… 4

Using Fastener Panels to Stack Modules …… 4

Software Setup …… 5

WBK15 – Specifications …… 7

The WBK15 module can accommodate eight 5B isolated-input signal-conditioning modules for use with the

WaveBook. The WaveBook can accommodate 8 WBK15s for a maximum of 64 expansion channels. The

WaveBook scans WBK15’s channels at the same 1 µs/channel rate that it scans all WBK analog inputs,

allowing it to measure all channels of a fully configured 72-channel system in 72 µs.

Other features of WBK15 include:

• Built-in power supply that operates from 10 to 30 VDC and can power a full complement of 5B

modules (even with bridge excitation).

• Removable, plug-in screw-terminal blocks for convenient connection of 5B modules.

•

On-board cold-junction sensing for thermocouple 5B modules.

•

For each 5B module, 1500 V isolation from the system and from other channels.

Current-Sense

Resistor

5.000 V

Buffered

5B

Low-

Module

Pass

Socket

Filter

#1

Input

Terminal

Block

Channel 1

Channels 2-8 identical

DC Power

Input &

Expansion

+V

Cold

Junction

Sensor

GND

DIN-5

Power

Switch

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

+15 V

Filters

Isolated

+5, ±15 VDC

Power

Supply

Channel

Selection

MUX

Internal Jumpers

-15 V

+5 V

WBK15 Block Diagram

Reference

Bipolar

Offset

Amp

Buffer

Amp

Control

DAC

µP &

Control Logic

EEPROM

Output

MUX

Status

LEDs

BNC

N

N

Analog

Output to

Wave Book

Expansion

Control

From

WaveBo ok

WBK15, 5B Isolated Signal Conditioning Module

988396

WBK15, pg. 1

Page 35

Hardware Setup

Configuration

The next figure shows the board layout within a WBK15. Note the channel-number layout for the 5B

modules and the location for plug-in current-sense resistors.

Only current-input type modules require the plug-in resistors.

The plug-in resistors must be removed for all other module types.

Rear Panel

Front Panel - signal inputs from 8 channels

BNC

Expansion

Signal Out

CHANNEL 1

R10

ch 2

CHANNEL 2 CHANNEL 4

ch 1

BNC

Expansion

Signal In

R5

ch 1

ch 2

ch 4

DB15

Expansion

Control Out

CHANNEL 3

R16 R13

ch 3

DB15

Expansion

Control In

CHANNEL 5

R20

ch 6

ch 3

CHANNEL 6

ch 4 ch 5 ch 6

WBK15 Board Layout

R18

DIN5

Power

Out

ch 8

ch 5

CHANNEL 7

R22

CHANNEL 8

ch 7

DIN5

Power

In

Fuse

R23

ch 8

Screw-terminal

Signal Plug

ON/OFF

Switch

ch 7

Status

LEDs

WBK15, pg. 2

Installation of 5B Modules

WARNING

WARNING

WARNINGWARNING

Electric shock hazard! Turn off power to WBK15 and all connected modules and

devices before inserting or removing modules. Failure to do so could lead to injury or

death due to electric shock.

CAUTION

CAUTION

CAUTIONCAUTION

Handle the 5B module carefully while inserting pins into the daughterboard. Do not

over-tighten mounting screw.