Page 1

WavePort

User's Manual

High-Speed Portable Data Acquisition Systems

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail (Product Information): sales@iotech.com

E-mail (Technical Support): productsupport@iotech.com

Internet: www.iotech.com

WavePort

High-Speed Portable Data Acquisition Systems

p/n

User's Manual

1036-0901

Rev.

3.0

© 2000 by IOtech, Inc.

September 2000

Printed in the United States of America

Page 2

Page 3

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior

written consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their

respective holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs)

may only be used on one installation. You may make archival backup copies.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission rules (Part 15)

for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve Radio-TV Interference Problems

(stock # 004-000-00345-4) which is available from the U.S. Government Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is

not covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and

review our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech

welcomes your suggestions.

03-10-00

Page 4

Page 5

Manual Layout

This manual pertains to setup and operation of a WavePort data acquisition system.

The material is organized as follows:

Chapter 1: Unpacking and Inspecting your WavePort Package

Chapter 2: An Introduction to WavePort

Chapter 3: System Setup

Chapter 4: Hardware and Operation Reference

Chapter 5: Software, An Introduction

Chapter 6: WaveView

Chapter 7: DIAdem - the PC Workshop, Quick Start and User’s Guide

Chapter 8: Troubleshooting

Chapter 9: Maintenance, Service, and Part Replacement

Chapter 10: Specifications

Appendix A: Using Accelerometers

Appendix B: WBK20A PCMCIA Option, Setup Notes

Glossary

WARNING

WARNING

WARNINGWARNING

The Notebook Power receptacle is “LIVE” whenever WavePort is plugged into a live AC power source.

The Module Power Switch can not be used to turn this receptacle “Off.”

WavePort contains no user serviceable components. Do not remove WavePort’s cover plate.

Lethal voltages are present which could cause serious injury or death.

CAUTION

CAUTION

CAUTIONCAUTION

Using this equipment in ways other than described in this manual can cause personal injury or

equipment damage. Pay special attention to all cautions and warnings.

Reference Note:

Additional information (not available at the time of publication), can be found in ReadMe files,

or in supplemental documentation.

WavePort User’s Manual

09-29-00

i

Page 6

Table of Contents

1 – Unpacking and Inspecting your WavePort Package ….. 1-1

2 – An Introduction to WavePort

What is WavePort?......2-1

What Types of I/O Signals Apply to WavePort?….. 2-2

3 – System Setup

Choosing a Notebook PC …… 3-1

Attaching the Notebook to WavePort …… 3-1

Connecting the Communication Cable and Notebook Power Cable …… 3-4

Connecting the WavePort to Power…… 3-5

Installing Software …… 3-5

Using the Daq Configuration Applet to Check Connections…… 3-6

A Guide to Using the Daq Configuration Applet …… 3-7

4 – Hardware and Operation Reference

WavePort/PE Devices …… 4-1

Overview ……4-2

Basic Operation ……4-3

Signal Aspects ……4-5

WavePort/PE16 ……4-5

WavePort/PE8 …… 4-6

WavePort/V Devices …… 4-8

Overview……4-8

Basic Operation ……4-9

Signal Aspects ……4-10

Ground Connections ……4-11

DB25F “Digital I/O, External Clock, TTL Trigger” Connection ……4-12

Programmable Features ……4-12

Triggers ……4-13

Pulse Trigger ……4-13

Digital-Pattern Trigger ……4-14

Multi-channel Triggering ……4-14

External Clock and Counter-Timer ……4-15

Power Aspects ……4-16

Power Module Operation ……4-18

Charging ……4-19

Fuse Replacement …… 4-19

Factory-Installed Option Cards (for WaveBook and WBK10A-based modules) …… 4-20

WBK11A – Simultaneous Sample and Hold Card……4-20

WBK12A and WBK13A Programmable Low-Pass Filter Cards ……4-21

WavePort’s Fan ……4-22

5 – Software, An Introduction ….. 5-1

6 – WaveView…… 6-1

Software Setup Notice for WavePort… 6-1

Introduction…… 6-2

Software Startup & Sample Acquisition…… 6-2

Startup WaveView…… 6-2

Configure Channels…… 6-4

Configure Acquisition…… 6-5

Collect Data…… 6-6

Store Data [and View File Data], Option…… 6-7

WaveView Configuration Main Window…… 6-7

Data Conversion…… 6-12

ii WavePort User’s Manual

Page 7

Acquisition Configuration…… 6-13

General Information ….. 6-13

Trigger Types ….. 6-14

External Clock and Counter-Timer …… 6-15

Digital Pattern Trigger…… 6-16

Pulse Trigger …… 6-17

WaveView Scope Window…… 6-18

WaveView Direct-To-Disk Window… 6-21

7 – DIAdem

Preface …… 7-2

DIAdem Quick Start…… 7-3

Installing DIAdem …… 7-3

Launching DIAdem from an Acquisition Program …… 7-3

Using DIAdem with ChartView …… 7-5

Where to go from here …… 7-9

DIAdem-VIEW Help Files ……7-9

“Examples” Help Files …… 7-10

DIAdem - the PC Workshop …… 7-13

The Overall Design …… 7-13

DIAdem Help …… 7-18

Options …… 7-19

DIAdem DATA: Loading and Saving Data …… 7-23

The Data Area …… 7-23

Copying, Pasting, and Deleting Data Channels …… 7-25

Saving and Opening Data Sets …… 7-26

DIAdem VIEW: Viewing, Measuring & Editing Data …… 7-27

Viewing Data as Graphs …… 7-28

Using the Cursor Position to Measure a Graph …… 7-29

How to Copy or Delete a Graph …… 7-32

Using Zoom, Scrolling, & Screen Partition …… 7-33

8 – Troubleshooting …… 8-1

Electrostatic Discharge (ESD), Handling Notice…… 8-1

ReadMe Files and the Install CD-ROM …… 8-1

Driver Support…… 8-2

Connection Problems…… 8-2

32-Bit WaveView Issues…… 8-2

Windows NT V3.51…… 8-3

Windows 95/98/2000 Problems…… 8-3

Resource Settings…… 8-3

Parallel Port Setup…… 8-3

Customer Assistance …… 8-5

9 – Maintenance, Service, and Part Replacement …… 9-1

General Maintenance......9-1

Fan Filter: Cleaning and Replacement ….. 9-2

What Type of Environment is WavePort Intended for? …..9-3

How Should WavePort be Transported? …… 9-3

Should I Calibrate the WavePort? ……9-4

How do I get Replacement Parts or Service? …..9-4

10 - Specifications

Appendix A – Using Accelerometers …… A-1

Appendix B – WBK20A PCMCIA Option, Setup Notes …… B-1

Glossary

WavePort User’s Manual

09-29-00

iii

Page 8

iv WavePort User’s Manual

Page 9

Unpacking and Inspecting your WavePort Package 1

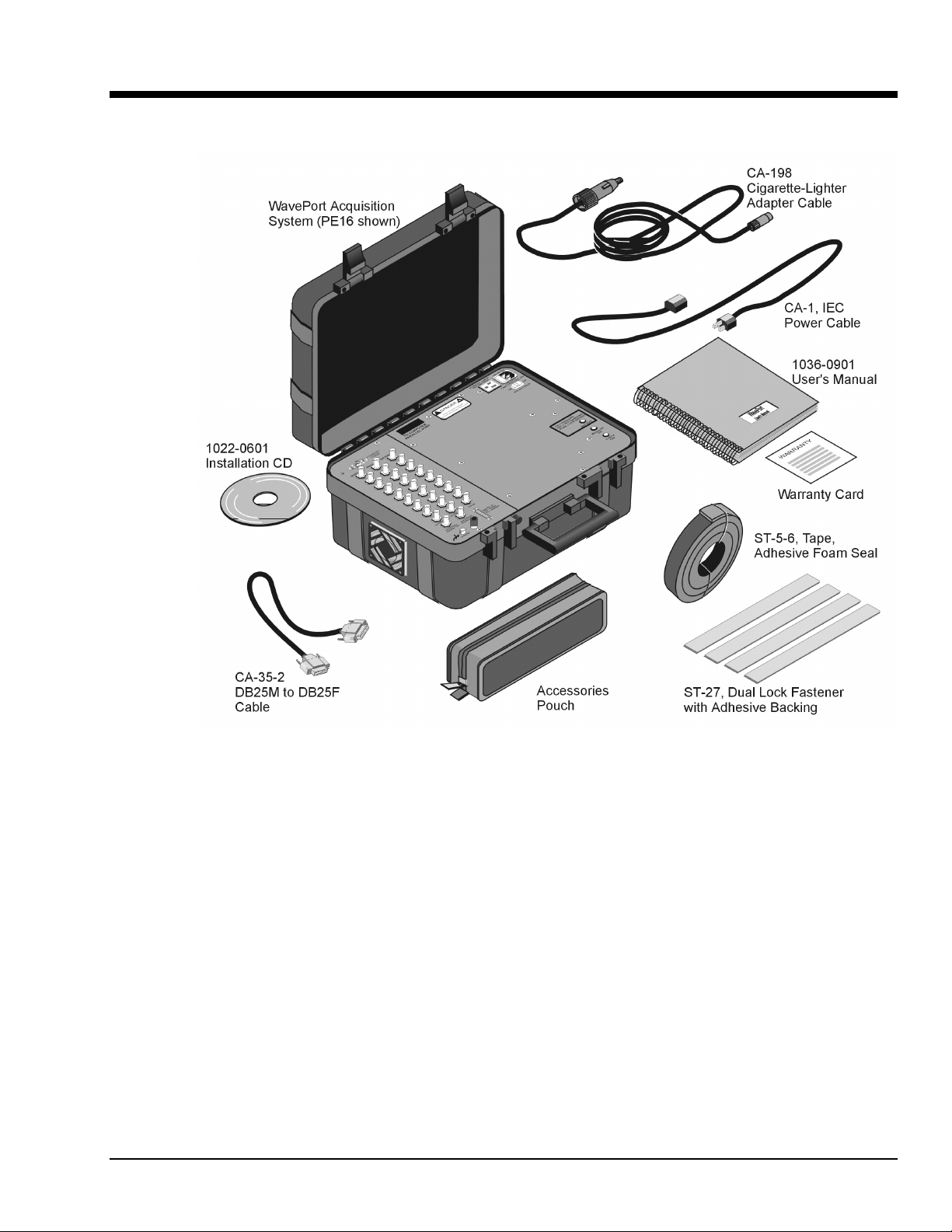

A typical WavePort package consists of the items depicted in the above figure. For reason of clarity,

packaging materials are not shown. Note that the WavePort/PE8 (not illustrated) has two rows of BNC

connectors instead of three, as depicted for the PE16 represented in the above figure. The WavePort/V

series (/V8, /V16, /V24) BNC connectors and signal channels are discussed in chapters 2 and 4.

Your order was carefully inspected prior to shipment. When you receive your order, carefully unpack all

items from the shipping carton and check for physical signs of damage that may have occurred during

shipment. Promptly report any damage to the shipping agent and the factory. Retain all shipping materials

in case the unit needs returned.

If you ordered any accessories, e.g., the WBK20A option, check the package to ensure the additional items

are included.

Report any problems to your sales agent.

At this point in time, do not be concerned with the purpose of each item that was included with your

shipment. Chapter 3, System Setup identifies the role of each item, when the purpose is not obvious.

WavePort User’s Manual

WavePort/PE, Standard Package

09-29-00

Unpacking 1-1

Page 10

1-2 Unpacking

09-29-00

WavePort User’s Manual

Page 11

An Introduction to WavePorts 2

What are WavePorts?......2-1

What Types of I/O Signals Apply ?….. 2-2

What are WavePorts ?

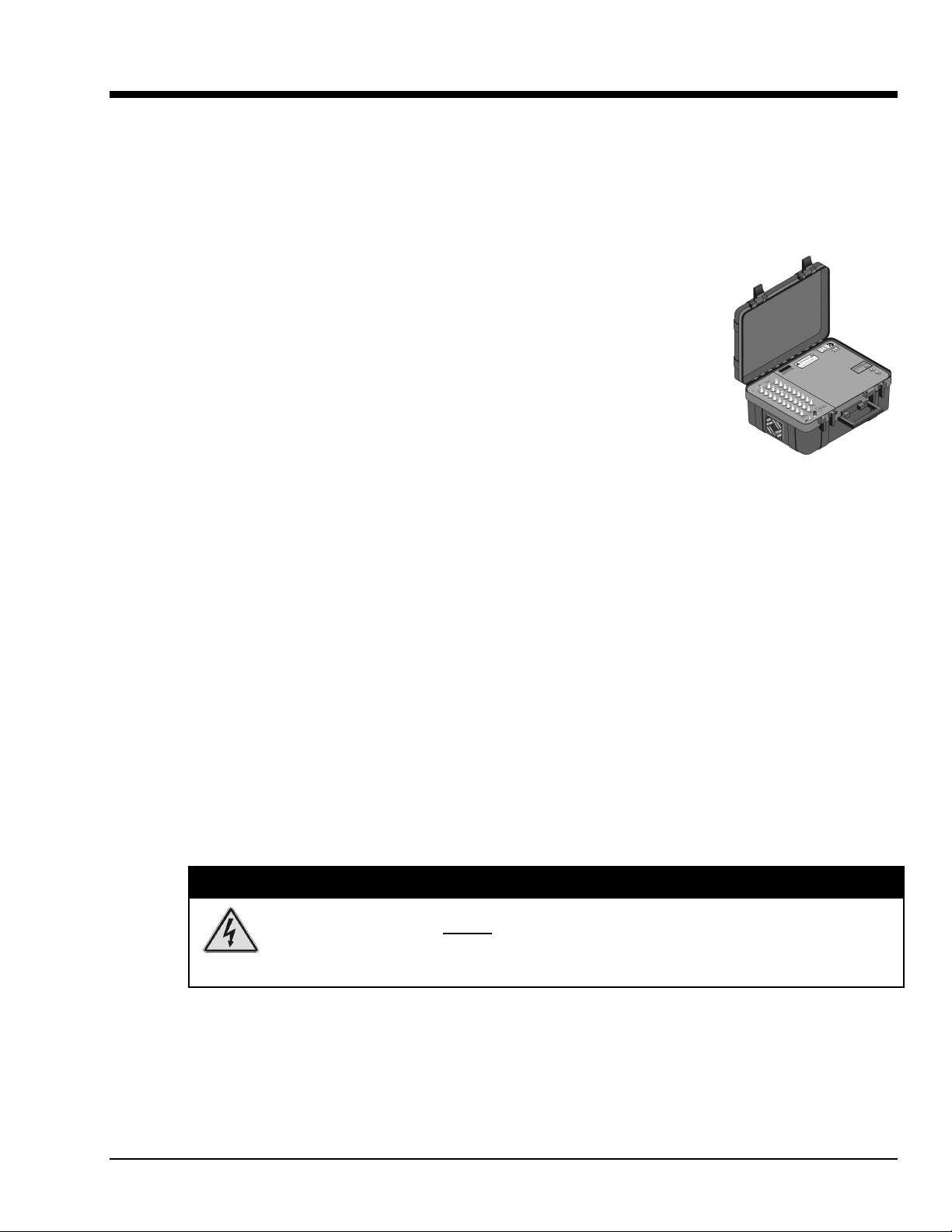

WavePorts are high-speed, portable data acquisition systems housed in a rugged

case. At present there are two distinct WavePort product lines; these are the

WavePort/PE (piezoelectric) and WavePort/V (voltage) models.

WavePort/PE

excitation through BNC connectors; and are ideal for applications pertaining to

vibration, rotating machinery, and acoustic measurements.

WavePort/PEs measurement capabilities are as follows:

• WavePort/PE8 - up to eight channels of voltages within ±10V and

up to 8 channels of ICP® transducer excitation (PE8)

• WavePort/PE16 - up to eight channels of voltages within ±10V and

up to 16 channels of ICP® transducer excitation

Illustrations of the BNC sections [for both PE16 and PE8 units] are featured on the

following pages.

The unit’s portability makes it an excellent choice for engineers and technicians on

the go. WavePort can be powered from a standard AC outlet, an external DC

source, or its own internal batteries.

WavePort/V

The “V” series offers 8, 16, or 24 channels through BNC connectors.

WavePort/V measurement capabilities are as follows:

• WavePort/V8 - up to eight channels of voltages within ±10V

• WavePort/V16 - up to sixteen channels of voltages within ±10V

• WavePort/V24 - up to twenty-four channels of voltages within ±10V

Illustrations of the BNC sections [for both PE and V units] are featured on the following pages.

devices are pre-configured to measure voltages and transducer

Dimensions:

470 mm wide, 369 mm

deep, 191 mm high

(18.5” x 14.5” x 7.5”)

Weight (excluding cables):

13 kg (28 lbs.)

devices provide a convenient acquisition package for general-purpose voltage measurements.

WavePorts can be powered from a standard AC outlet, an external DC source, or from internal batteries.

Their portability makes each an excellent choice for engineers and technicians on the go.

WavePort User’s Manual

WARNING

WARNING

WARNINGWARNING

The Notebook Power receptacle is “LIVE” whenever WavePort is plugged into a live AC power source.

The Module Power Switch

WavePort contains no user serviceable components. Do not remove WavePort’s cover plate.

Lethal voltages are present which could cause serious injury or death.

09-29-00

cannot

be used to turn this receptacle “Off.”

An Introduction to W avePort 2-1

Page 12

What Types of I/O Signals Apply ?

The following pages contain descriptions of signal panels for WavePort/PE and WavePort/V devices. Brief

descriptions of signal types are included with each panel

More detailed information regarding signals and connections is provided in chapter 4.

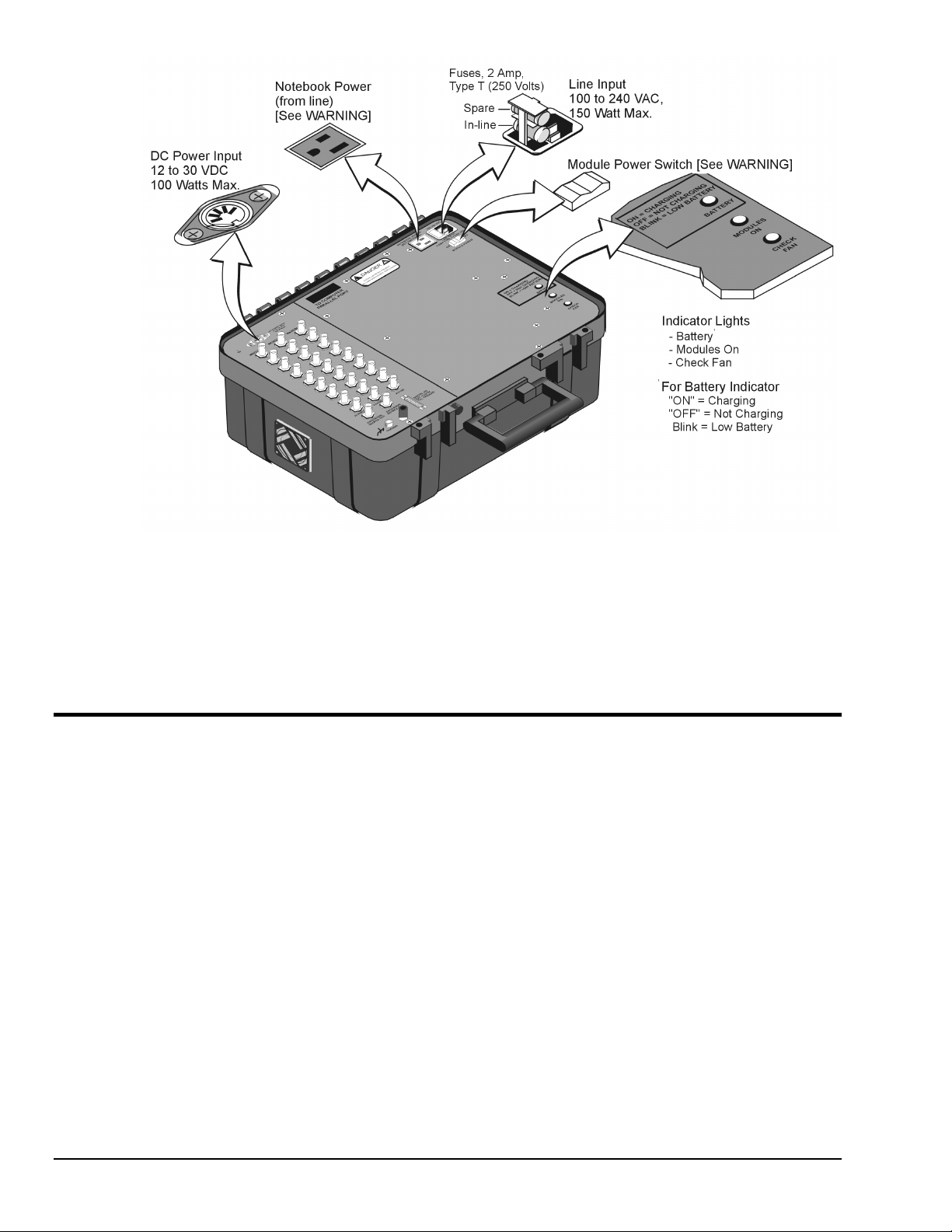

Power-Related Items

2-2 An Introduction to W avePort

09-29-00

WavePort User’s Manual

Page 13

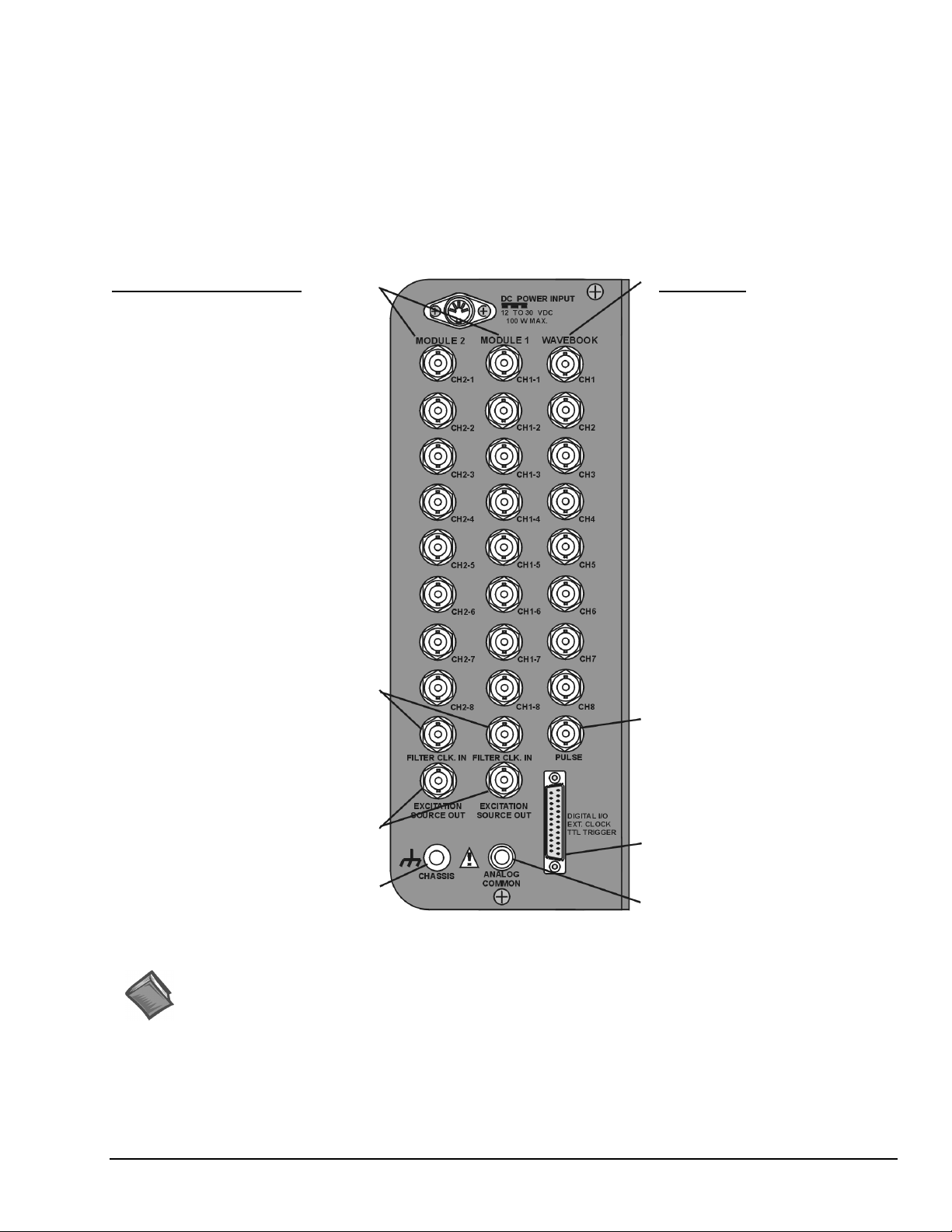

WavePort/PE16

WavePort/PE16 can measure up to eight channels of voltages within ±10V; and up to 16 channels of ICP® transducer

excitation.

The unit receives its channel-input signals through three columns of eight BNC connectors (24 channel inputs total). The

columns are labeled MODULE 2, MODULE 1, and WAVEBOOK. In addition to the channel-input BNCs, WAVEBOOK

contains a BNC for PULSE Trigger Input, and the two MODULEs include BNCs for filter clock input (FILTER CLK. IN),

and EXCITATION SOURCE OUT (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided. An illustration follows.

Module 1 and Module 2

Dynamic Signal Conditioning

CH1-1 through CH1-8 and

CH2-1 through CH2-8, respectively

• Gain Ranges:

x1, 2, 5, 10, 20, 50, 100, and 200

• Input Ranges:

5V, 2.5V, 1V,

500 mV, 250 mV,

100 mV, 50 mV,

and 25 mV peak

AC-Coupled Only

BNC shells are analog common.

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Filter Clock In

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

• 16 bit resolution

•

Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

• Maximum Overvoltage: +/-30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for additional

information.

Pulse Trigger Input

•

Input Signal Range: ±5V

• Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

•

Maximum Pulse Width: 0.8 sec

•

Latency: 300 ns

Excitation Source Out

Reference Notes:

Additional information regarding WavePort signal connections appears elsewhere in this manual.

•

• Chapter 6, WaveView, includes information regarding channel configuration.

•

• Chapter 10 provides device specifications.

WavePort User’s Manual

Digital I/O

External Clock

Chassis Ground

WavePort/PE16 Signal Panel

Chapter 4, Hardware and Operation Reference, includes details regarding signal connections.

Chapter 9 contains maintenance, intended environment, and transportation information.

09-29-00

TTL Trigger

Analog Common

An Introduction to W avePort 2-3

Page 14

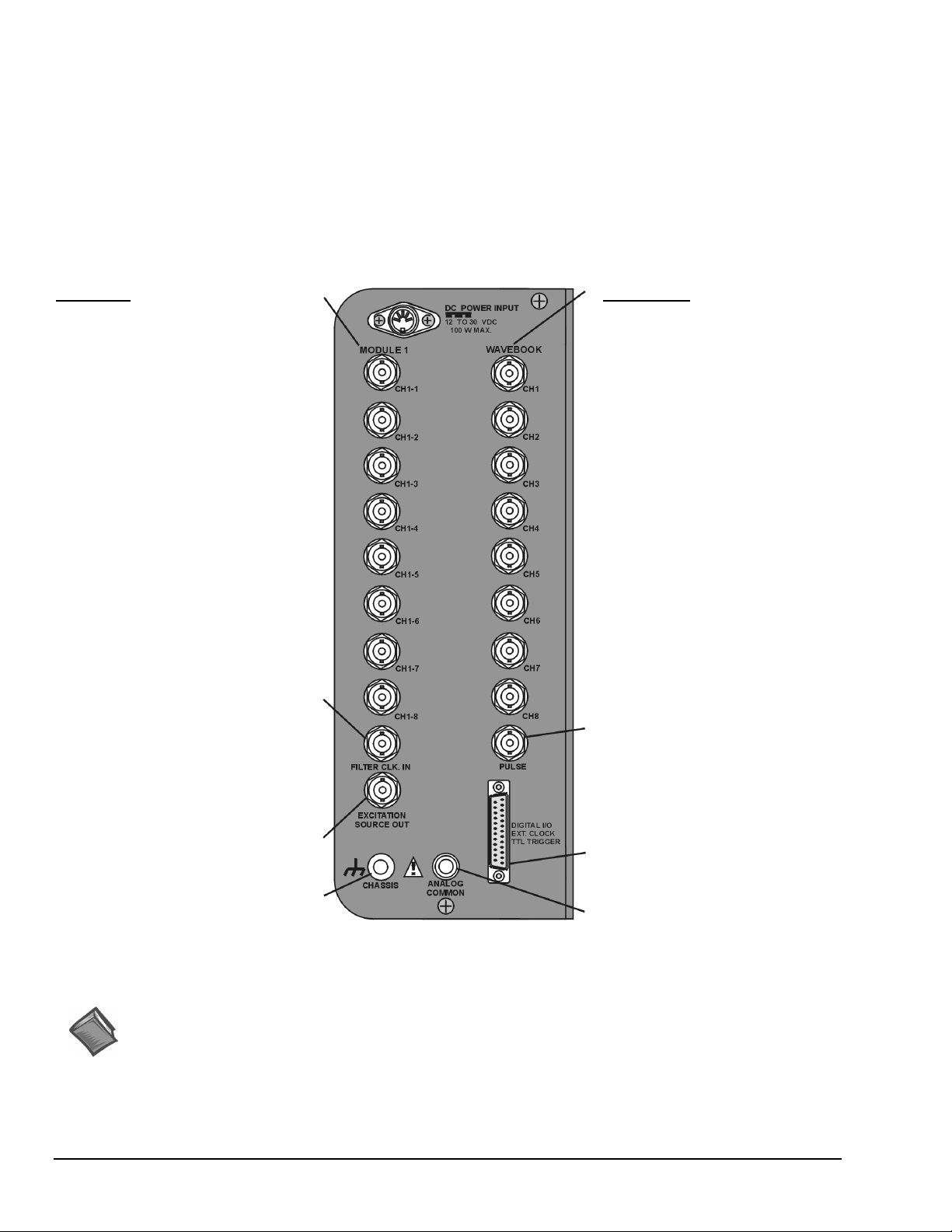

WavePort/PE8

WavePort/PE8 can measure up to eight channels of voltages within ±10V; and up to 8 channels of ICP® transducer excitation.

The unit receives its channel-input signals through two columns of eight BNC connectors (16 channel inputs total). The

columns are labeled MODULE 1 and WAVEBOOK. In addition to the channel-input BNCs, WAVEBOOK contains a BNC

for PULSE Trigger Input, and MODULE 1 include one BNCs for filter clock input (FILTER CLK. IN), and another BNC for

EXCITATION SOURCE OUT (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

Module 1

Dynamic Signal Conditioning

CH1-1 through CH1-8

• Gain Ranges:

x1, 2, 5, 10, 20, 50, 100, and 200

• Input Ranges:

5V, 2.5V, 1V,

500 mV, 250 mV,

100 mV, 50 mV,

and 25 mV peak

AC-Coupled Only,

BNC shells are analog common.

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Filter Clock In

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

• 16 bit resolution

•

Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

• Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Pulse Trigger Input

•

Input Signal Range: ±5V

• Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

•

Maximum Pulse Width: 0.8 sec

•

Latency: 300 ns

Excitation Source Out

Chassis Ground

Reference Notes:

Additional information regarding WavePort signal connections appears elsewhere in this manual.

•

Chapter 4, Hardware and Operation Reference, includes details regarding signal connections.

•

Chapter 6, WaveView, includes information regarding channel configuration.

•

Chapter 9 contains maintenance, intended environment, and transportation information.

•

Chapter 10 provides device specifications.

2-4 An Introduction to W avePort

WavePort/PE8 Signal Panel

09-29-00

Digital I/O

External Clock

TTL Trigger

Analog Common

WavePort User’s Manual

Page 15

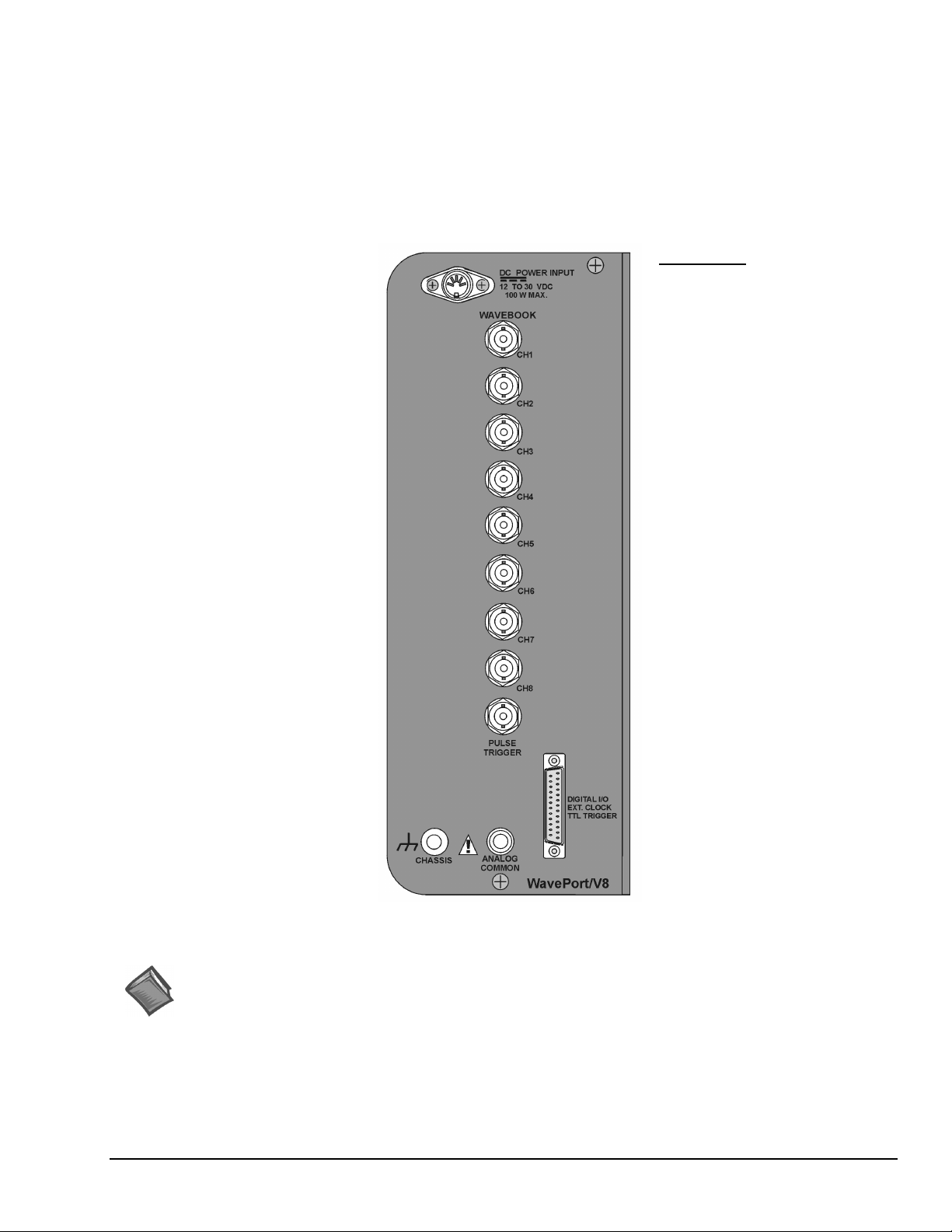

WavePort/V8

WavePort/V8 can measure up to eight channels of voltages within ±10V.

The unit receives its channel-input signals through eight BNC connectors. In addition to the channel-input BNCs, there is one

BNC for PULSE Trigger Input (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

•

Maximum Overvoltage: ±30 VDC

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information that includes

ranges available with WBK11A,

WBK12A, and WBK13A factoryinstalled options.

DC-Coupled Only,

Fully Differential

Pulse Trigger Input

• Input Signal Range: ±5V

• Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

• Maximum Pulse Width: 0.8 sec

• Latency: 300 ns

Reference Notes:

Additional information regarding WavePort signal connections appears elsewhere in this manual.

•

• Chapter 6, WaveView, includes information regarding channel configuration.

•

• Chapter 10 provides device specifications.

WavePort User’s Manual

Digital I/O

External Clock

TTL Trigger

Analog Common

WavePort/V8 Signal Panel

Chapter 4, Hardware and Operation Reference, includes details regarding signal connections.

Chapter 9 contains maintenance, intended environment, and transportation information.

09-29-00

An Introduction to W avePort 2-5

Page 16

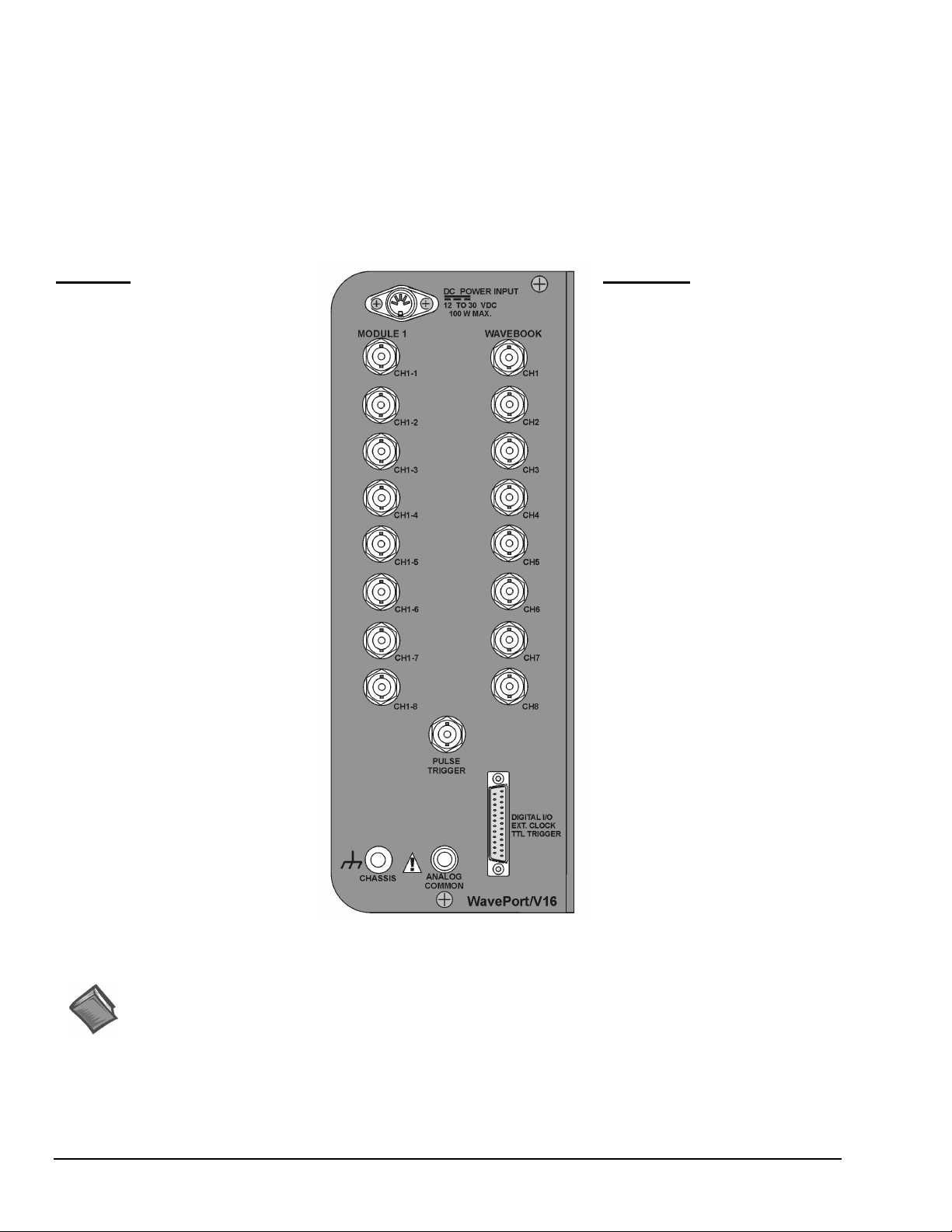

WavePort/V16

WavePort/V16 can measure up to sixteen channels of voltages within ±10V.

The unit receives its channel-input signals through two columns of eight BNC connectors (16 channel inputs total). The

columns are labeled MODULE 1 and WAVEBOOK. In addition to the channel-input BNCs, WAVEBOOK contains a BNC

for PULSE Trigger Input (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

Module 1

Analog Inputs

CH1-1 through CH1-8, Analog Inputs

via BNC Connectors.

•

16 bit resolution

•

Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 5V

0 t0 + 2V

0 to +1V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V, ±0.5V

• Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information that includes

ranges available with WBK11A,

WBK12A, and WBK13A factoryinstalled options.

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

•

16 bit resolution

•

Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

•

Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Pulse Trigger Input

• Input Signal Range: ±5V

•

Input Characteristics: 75 Ω

• Input Protection: ±10V max.

•

Minimum Pulse Width: 100 ns

•

Maximum Pulse Width: 0.8 sec

•

Latency: 300 ns

Reference Notes:

Additional information regarding WavePort signal connections appears elsewhere in this manual.

• Chapter 4, Hardware and Operation Reference, includes details regarding signal connections.

•

Chapter 6, WaveView, includes information regarding channel configuration.

• Chapter 9 contains maintenance, intended environment, and transportation information.

•

Chapter 10 provides device specifications.

2-6 An Introduction to W avePort

WavePort/V16 Signal Panel

09-29-00

Digital I/O

External Clock

TTL Trigger

Analog Common

WavePort User’s Manual

Page 17

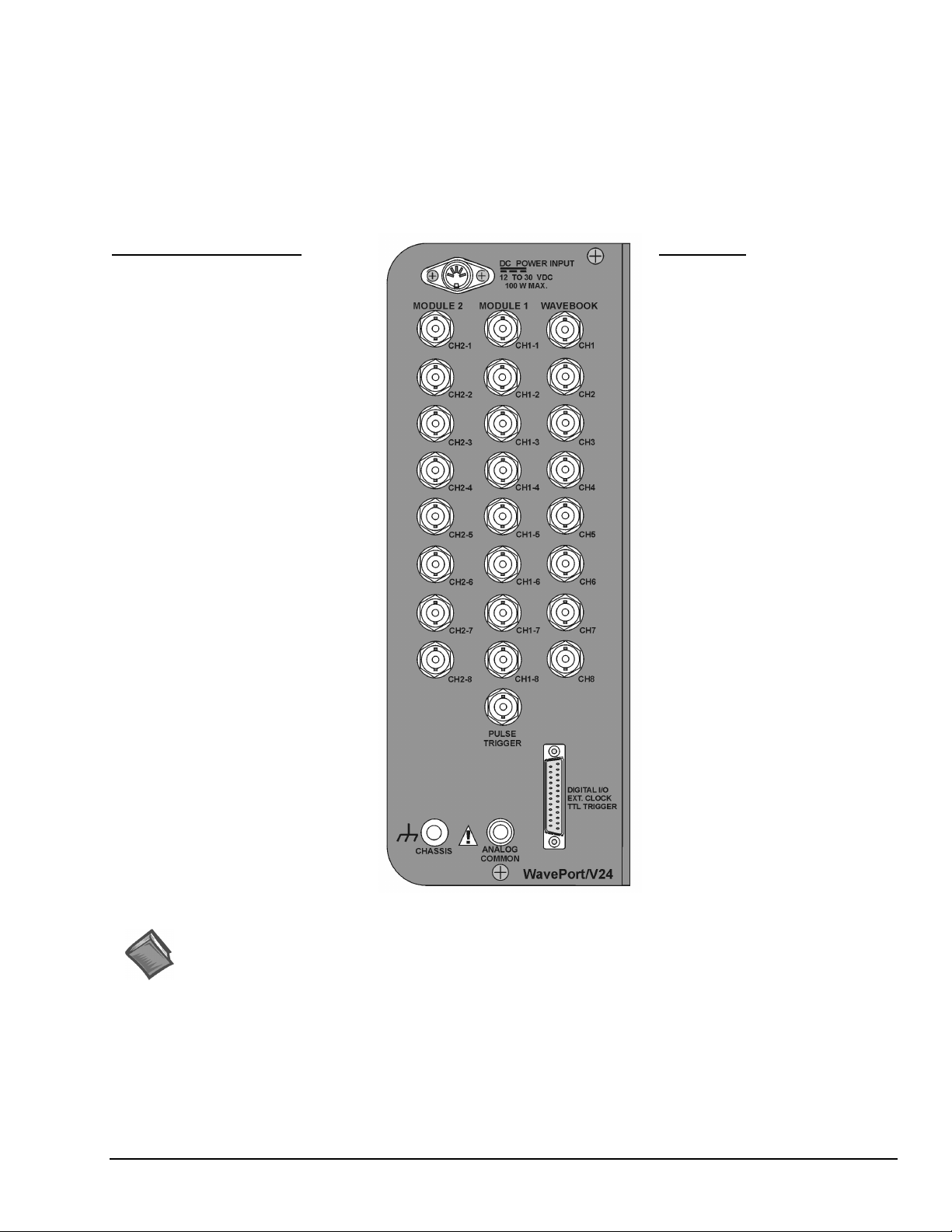

WavePort/V24

WavePort/V24 can measure up to 24 channels of voltages within ±10V.

The unit receives its channel-input signals through three columns of eight BNC connectors (24 channel inputs total). The

columns are labeled [from left to right] MODULE 2, MODULE 1, and WAVEBOOK. In addition to the channel-input

BNCs, WAVEBOOK contains a BNC for PULSE Trigger Input (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

Module 1 and Module 2

Analog Inputs

CH1-1 through CH1-8, and

CH2-1 through CH2-8, respectively.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 5V

0 t0 + 2V

0 to +1V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V, ±0.5V

• Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information that includes

ranges available with WBK11A,

WBK12A, and WBK13A factoryinstalled options.

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

•

Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

Pulse Trigger Input

• Input Signal Range: ±5V

• Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

• Maximum Pulse Width: 0.8 sec

•

Latency: 300 ns

Reference Notes:

Additional information regarding WavePort signal connections appears elsewhere in this manual.

• Chapter 4, Hardware and Operation Reference, includes details regarding signal connections.

•

• Chapter 9 contains maintenance, intended environment, and transportation information.

•

WavePort User’s Manual

Digital I/O

External Clock

TTL Trigger

Analog Common

WavePort/V24 Signal Panel

Chapter 6, WaveView, includes information regarding channel configuration.

Chapter 10 provides device specifications.

09-29-00

An Introduction to W avePort 2-7

Page 18

2-8 An Introduction to W avePort

09-29-00

WavePort User’s Manual

Page 19

System Setup

1. Choosing a Notebook PC …… 3-1

2. Attaching the Notebook to WavePort …… 3-1

3. Connecting the Communication Cable and Notebook Power Cable …… 3-4

4. Connecting the WavePort to Power…… 3-5

5. Installing Software …… 3-5

6. Using the Daq Configuration Applet to Check Connections…… 3-6

A Guide to Using the Daq Configuration Applet …… 3-7

1. Choosing a Notebook PC

A Notebook PC provides a means of communicating

with WavePort’s acquisition hardware.

The Notebook you choose must meet the following

requirements:

• Maximum Height (when closed): 1.5” (38 mm)

• Maximum Length: 12.75” (323 mm)

• Maximum Width: 10.19” (259 mm)

• 16MB Ram (32MB Ram recommended)

• Pentium

• 10 MB of Available Disk Space

• Windows Operating System

•

EPP (Enhanced Parallel Port) –

•

Power Consumption: Not to exceed 50 Watts

®

90 Processor (or equivalent)

(Windows95/98/NT or 2000)

Optional, but recommended

3

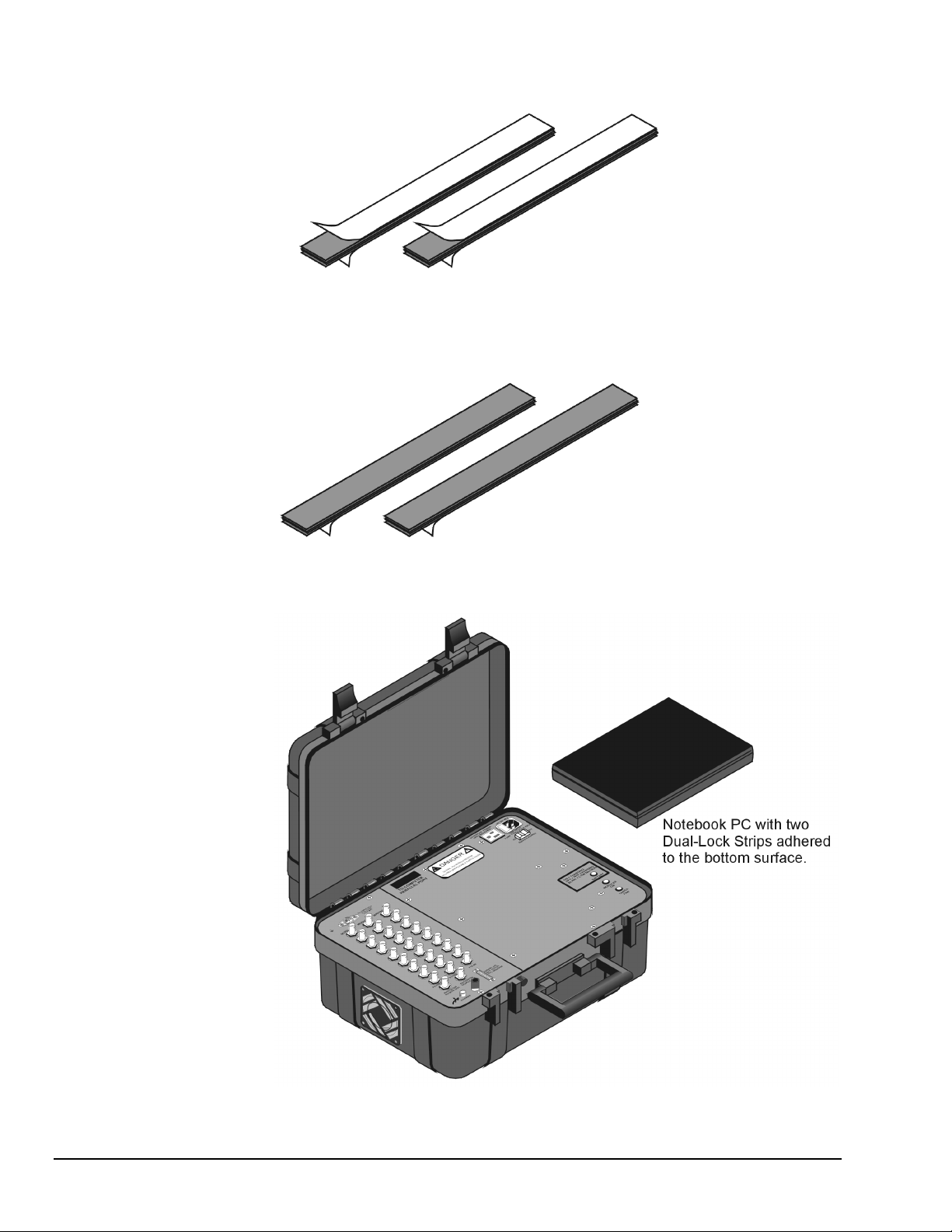

2. Attaching the Notebook to WavePort

You can use the included Dual-Lock Fasteners (ST-27) to hold your Notebook PC firmly to WavePort’s

cover plate.

Prior to attaching the strips, verify that WavePort’s cover plate and the bottom of the Notebook are clean.

Isopropyl Alcohol swabs, or commonly available “rubbing alcohol” with clean, lint-free rags can be used to

achieve a clean mounting surface.

WavePort User’s Manual

06-14-00

System Setup 3-1

Page 20

Use the following technique to ensure proper alignment of the strips.

(1) Make two mounting strips that consist of mated Dual-Lock surfaces, such that the

outer surfaces of the strips are the “adhesive” sides of the strips. Note that these

adhesive edges are initially covered with protective “peel-off” paper.

(2) Trim the strips to fit the bottom surface of your Notebook PC, as needed.

(3) Remove the protective “peel-off” paper and attach the two strips to the bottom surface

of the Notebook PC.

3-2 System Setup

(4) Remove the lower protective “peel-off” and position the Notebook PC onto

WavePort’s cover plate.

06-14-00

WavePort User’s Manual

Page 21

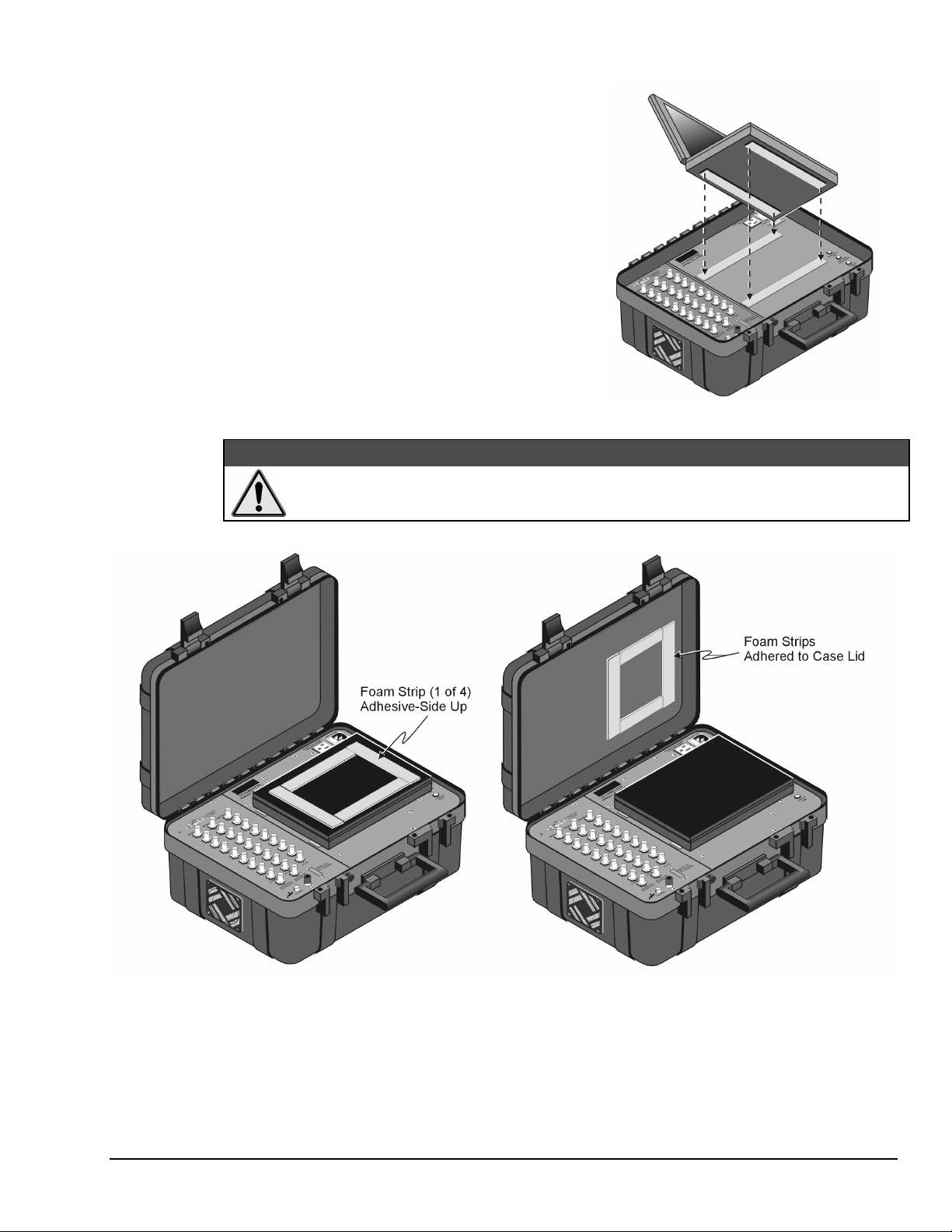

(5) Push firmly down on the Notebook to ensure the

adhesive makes good contact. The Notebook should

now be adequately secured to WavePort’s cover plate.

The Notebook PC can now be easily removed from

WavePort, and easily re-attached.

After securing the Notebook PC to the cover plate

you should add four foam strips to the inside of

WavePort’s hinged lid. Cut the strips as needed to

form a rectangle on the Notebook’s cover (see the

figure following the Caution).

CAUTION

CAUTION

CAUTIONCAUTION

Forcing WavePort’s cover to close on a Notebook PC that exceeds the height restriction

of 1.5” (38 mm) is likely to result in damage to the Notebook PC.

How to use foam strips (part no. ST-5-6) to pad your Notebook PC.

1. Verify that the Notebook PC does not exceed a height (when the PC is closed) of 1.5 inches (38 mm). Notebook’s

exceeding this dimension can be damaged when closing WavePort’s cover.

2. Place four foam strips on the cover of the Notebook PC. The adhesive-side faces the WavePort’s hinged cover.

3. Fully close, then reopen WavePort’s cover.

4. Verify that the foam strips are attached firmly to WavePort’s cover.

WavePort User’s Manual

06-14-00

System Setup 3-3

Page 22

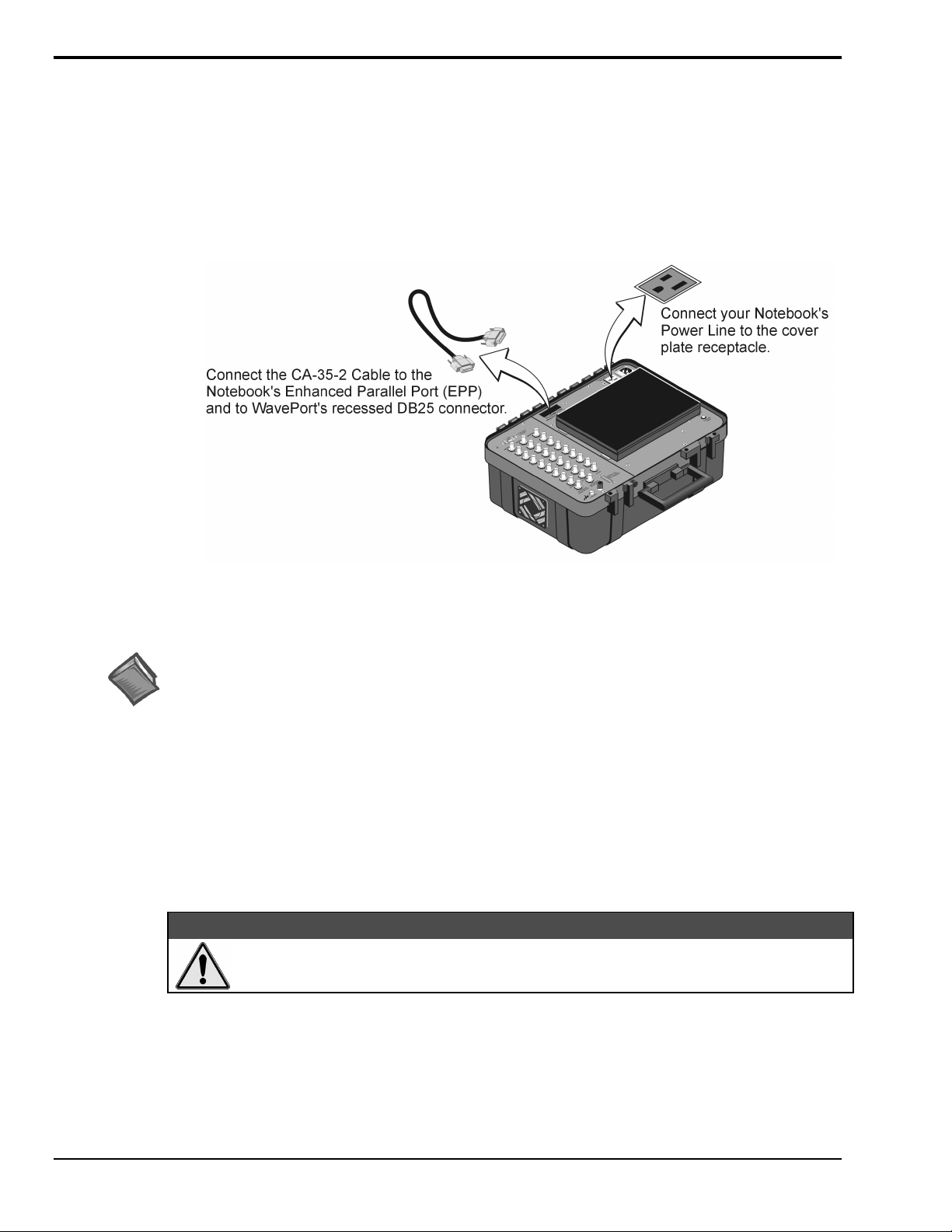

3. Connecting the Communication Cable and Notebook Power Cable

WavePort’s communication line connects to a host PC through a 25 pin (male connector) located in a

recess on WavePort’s cover plate. The connector is labeled “TO COMPUTER PARALLEL PORT.”

WavePort communicates with a Notebook through the PC’s enhanced parallel port (EPP). An

alternative is to use a WBK20A PCMCIA/EPP interface-card in conjunction with the Notebook’s

PC-Card port. This option is discussed in Appendix B.

Connecting the Notebook PC to WavePort

Reference Note:

An optional WBK20A PCMCIA/EPP interface-card can be used instead of the CA-35-2 cable.

WBK20A connects to the Notebook’s PC-Card port. This PC-Card option is discussed in Appendix B.

Connect the Notebook’s power line to the Notebook Power receptacle located on WavePort’s cover plate.

This receptacle is “live” whenever WavePort has AC line power connected to a live source. The position of

WavePort’s Module Power switch has no bearing on the Notebook Power receptacle.

The Notebook can be powered from the Notebook Power Receptacle [non-switched] as long as

LINE INPUT power is supplied to the WavePort (as discussed in the following section). Do not plug

anything into the Notebook Power Receptacle that exceeds a power rating of 50 Watts, as this could

overload the WavePort.

CAUTION

CAUTION

CAUTIONCAUTION

Do not plug anything into the Notebook Power Receptacle that exceeds a power rating of

50 Watts. Such action could result in overloading the WavePort and blowing a fuse.

3-4 System Setup

06-14-00

WavePort User’s Manual

Page 23

4. Connecting the WavePort to Power

The Notebook Power receptacle is “LIVE” whenever WavePort is plugged into a live AC power source.

The Module Power Switch can not

WavePort contains no user serviceable components. Do not remove WavePort’s cover plate.

Lethal voltages are present which could cause serious injury or death.

Although WavePort can be powered from external DC or internal batteries, we are only concerned at this point

with powering the system via 100 to 240 VAC through its Line Input receptacle.

Simply connect the female-end of power cable CA-1, IEC to WavePort’s Line Input receptacle, and connect the

male-end of the cable to an appropriate 100 to 240 VAC power supply.

After cable CA-1 is connected to both WavePort and the AC power supply, turn the Module Power Switch to

“ON.”

Note that DC power supplies are discussed in the following chapter entitled, Hardware and Operation Reference.

be used to turn this receptacle “Off.”

WARNING

WARNING

WARNINGWARNING

Line Input (VAC) Receptacle and Module Power Switch

5. Installing Software

Software that can be used with WavePort includes WaveView, DIAdem, DASYlab, and LabVIEW. Programmers can

create customized programs using DaqX Applications Program Interface (API) commands. Chapter 5 provides a brief

synopsis of the software options.

For your initial setup of WavePort we recommend that you only install the following, per the steps provided below.

Ρ WaveBook Support 32-bit (Includes WaveView)

Ρ Acrobat Reader

Ρ DIAdem Post Acquisition Data Analysis Program

Remove any previous-installed versions of WaveBook software before installing a newer version.

WavePort User’s Manual

06-14-00

System Setup 3-5

Page 24

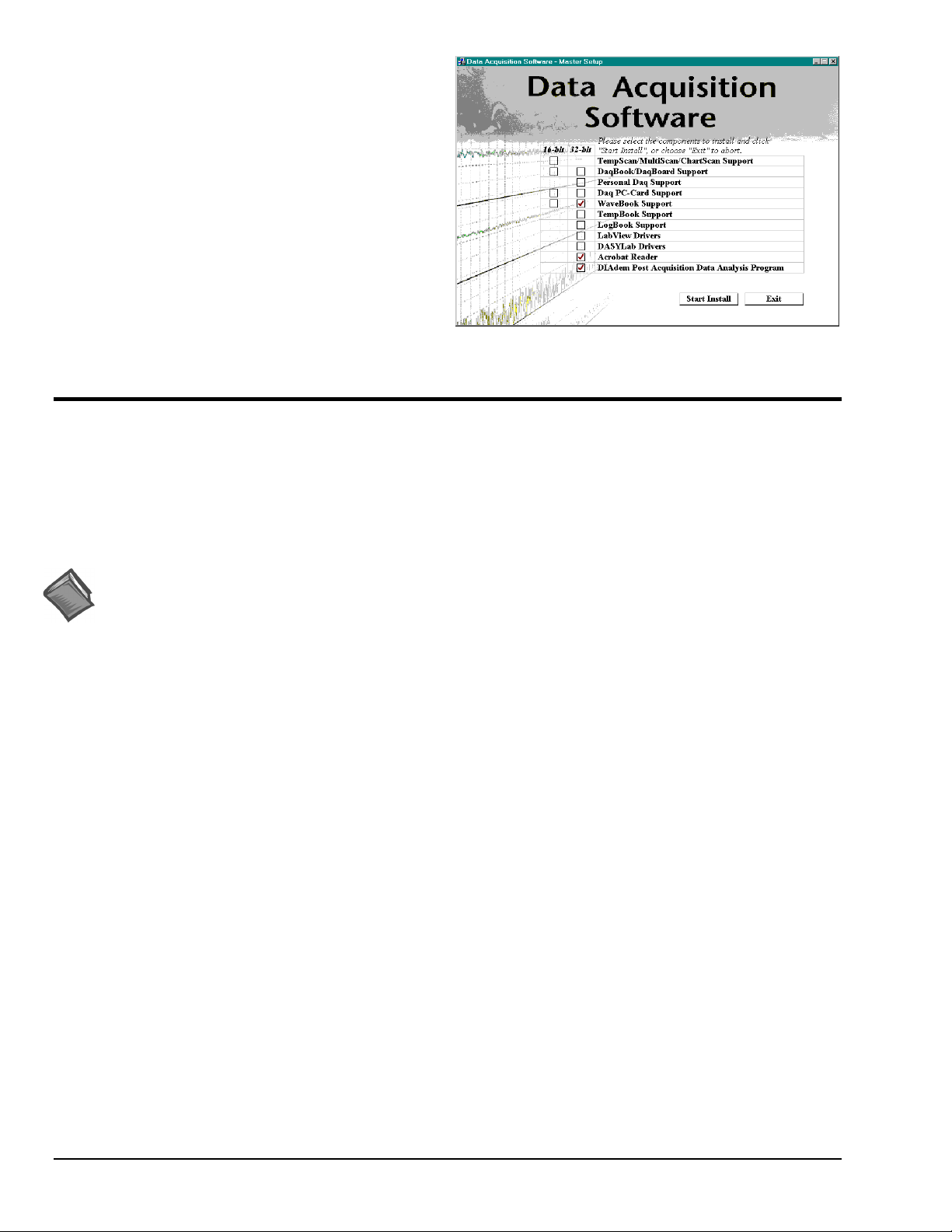

Install software according to the following

procedure.

1. Close all other programs. Insert CD-ROM and

wait for Notebook PC to auto-access the CD.

2. On the Master Setup Screen check:

Ρ WaveBook Support 32-bit

Ρ Acrobat Reader

Ρ DIAdem Post Acquisition Data Analysis

Program. Note that DIAdem is detailed in

Chapter 7.

3. Follow the on-screen dialog boxes to complete

the installation.

Master Setup Screen

6. Using the Configuration Applet to Check Connections

After software installation you should verify that proper communication exists between the WavePort and your

Notebook. You can use the Daq Configuration applet to test this aspect of hardware performance. Note that the applet

is automatically installed in the Windows Control Panel during installation of the WaveBook program group.

The Daq Configuration applet tests the capabilities of the PC parallel port (or WBK20/21 interface), then estimates the

maximum performance, using both standard and enhanced protocols. In addition, the test verifies WavePort is

connected and ready for operation.

Reference Note:

A section entitled, A Guide to Using the Daq Configuration Applet, begins on the following page. The section

includes detailed information regarding the Daq Configuration applet and includes screen shots.

To run the WavePort test program:

1. Ensure WavePort is connected to the Notebook PC.

2. Verify both the Notebook and WavePort are powered.

3. Double-click on the Daq Configuration applet (in the Windows Control Panel).

4. Select the WaveBook device.

5. Click on Properties.

6. Click on the Resource Test button (within the Test Hardware tab).

The program performs several tests on the Notebook and WavePort and displays the results. Once communication

between the Notebook and WavePort has been established you can start WaveView and collect data.

3-6 System Setup

06-14-00

WavePort User’s Manual

Page 25

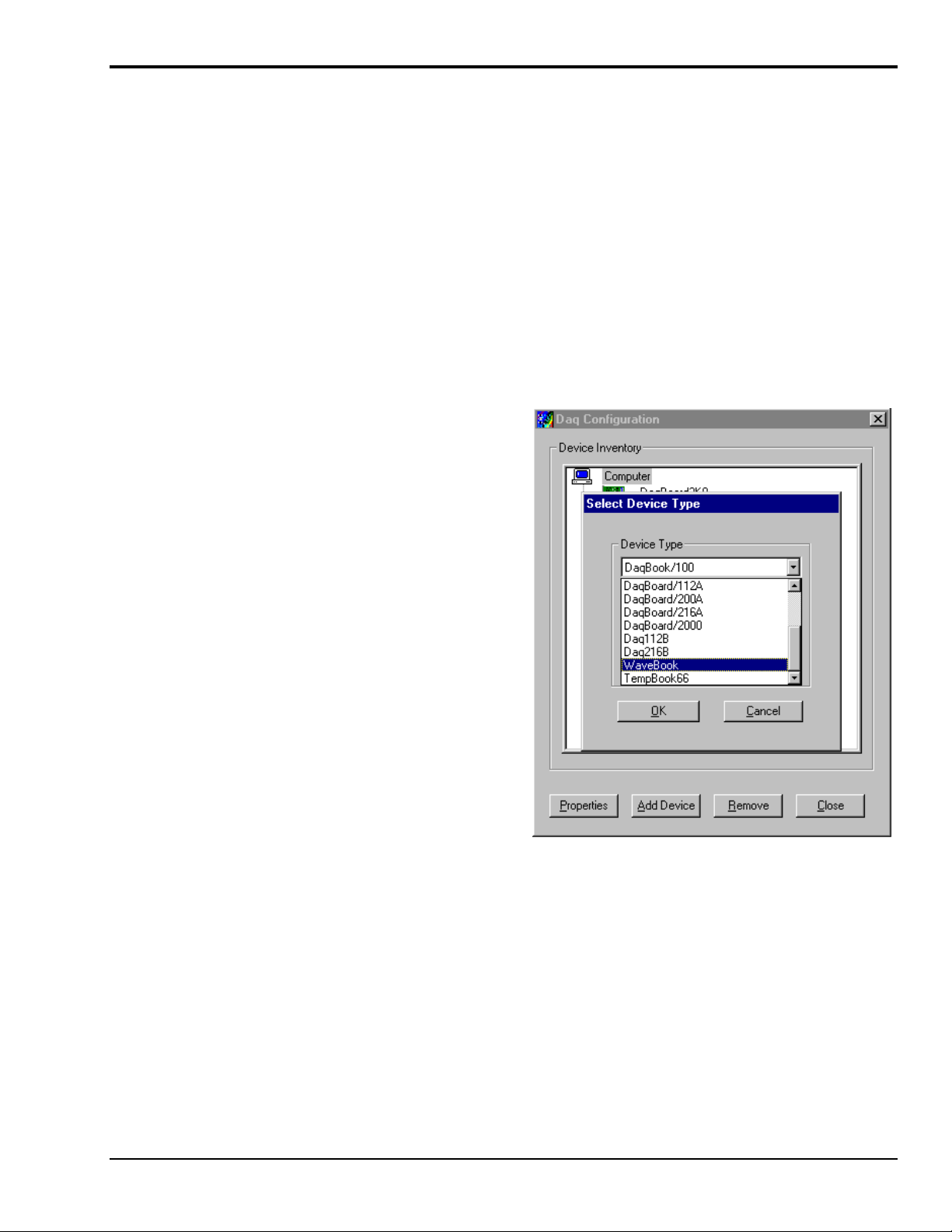

A Guide to Using the Daq Configuration Applet

The Daq Configuration applet, designed for 32-bit Windows 9x/2000/NT systems, is located in the

Windows Control Panel. It allows you to add or remove a device and change configuration settings.

The included test utility provides feedback on the validity of current configuration settings, as well as

performance summaries.

Device Inventory Dialog Box

Run the applet by double-clicking on the Daq Configuration icon in the Windows Control Panel.

The Device Inventory dialog box will open, displaying all currently configured devices. Displayed devices

show their name and an icon to identify the device type. If no devices are currently configured, no devices

will appear in this field.

The four buttons across the bottom of the dialog box are used as follows:

• Properties: Current configuration settings for a device can be changed by first bringing up the

corresponding Properties dialog box. Open the Properties dialog box by double-clicking on the device

icon or selecting the device and then clicking on the Properties button.

• Add Device: The Add Device button is

used to add a device configuration

whenever a new device is added to the

system. Failure to perform this step will

prevent applications from properly

accessing the device. Clicking on the Add

Device button will open the Select Device

Type dialog box.

• Remove: The Remove button is used to

remove a device from the configuration.

A device may be removed if it is no

longer installed, or if the device

configuration no longer applies.

Note: If a device is removed, applications

may no longer access the device.

However, the device can be

re-configured at any time using the

Add Device function described above.

• Close: The Close button may be used at

any time to exit the Daq Configuration

applet.

Daq Configuration - Device Inventory Dialog Box

WavePort User’s Manual

06-14-00

System Setup 3-7

Page 26

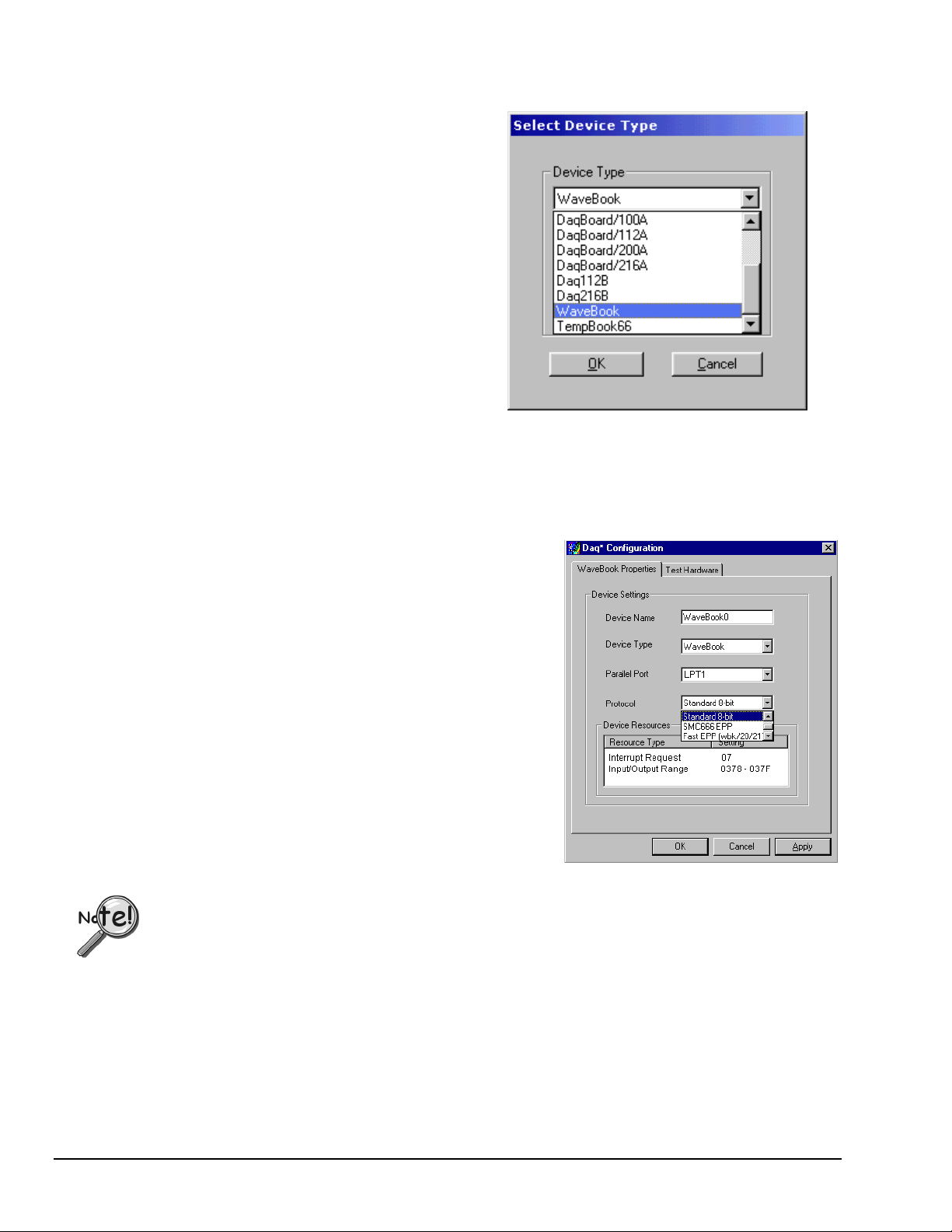

Select Device Type Dialog Box

This dialog box opens when the Add Device

button of the Device Inventory dialog box is

selected.

The device type you select for configuring will

appear in the main edit box. Clicking on the

OK button will then open the Properties dialog

box (following figure).

Note: As there is no specific “WavePort”

device to select, choose “WaveBook”

(see figure at right).

Daq Configuration - Select Device Type Dialog Box

Properties Dialog Box

This dialog box opens when the Properties button of the Device Inventory dialog box is selected, or when

the OK button of the Select Device Type dialog box is selected. It displays the properties for the WaveBook

device with the default configuration settings. The fields include:

• Device Name: The Device Name field is displayed with

the default device name. As shown, this field can be

changed to any descriptive name as desired. This

device name is the name to be used with the

daqOpen

function to open the device. This name will also be

displayed in the device lists for opening the device in

the WaveView and WaveCal applications.

• Device Type: The Device Type field indicates the

device type that was initially selected. However, it can

be changed here if necessary.

• Parallel Port: The Parallel Port field is used to set the

parallel port for communicating with the WaveBook.

• Protocol: The Protocol field is used to set the parallel

port protocol for communicating with the WaveBook.

Depending on your system, not all protocols may be

available. (See following Note).

Daq Configuration - Properties Dialog Box

In regard to Protocol – If you are using a WBK20A you must select “Fast EPP (wbk/20/21)” to achieve

the best performance. WBK20A is discussed in Appendix B.

• Device Resources: The Device Resources field lists settings for various resources, among them

Interrupt Request, Input/Output Range, and Direct Memory Access.

3-8 System Setup

• OK: Click on the OK button to store the configuration and exit the current dialog box.

• Cancel: Click on the Cancel button to exit the current dialog box without storing any changes.

• Apply: Click on the Apply button to store the configuration; or click the Test Hardware tab.

• Test Hardware: Click on the Test Hardware tab to test the current stored configuration for the device.

This selection will open the Test Hardware dialog box.

06-14-00

WavePort User’s Manual

Page 27

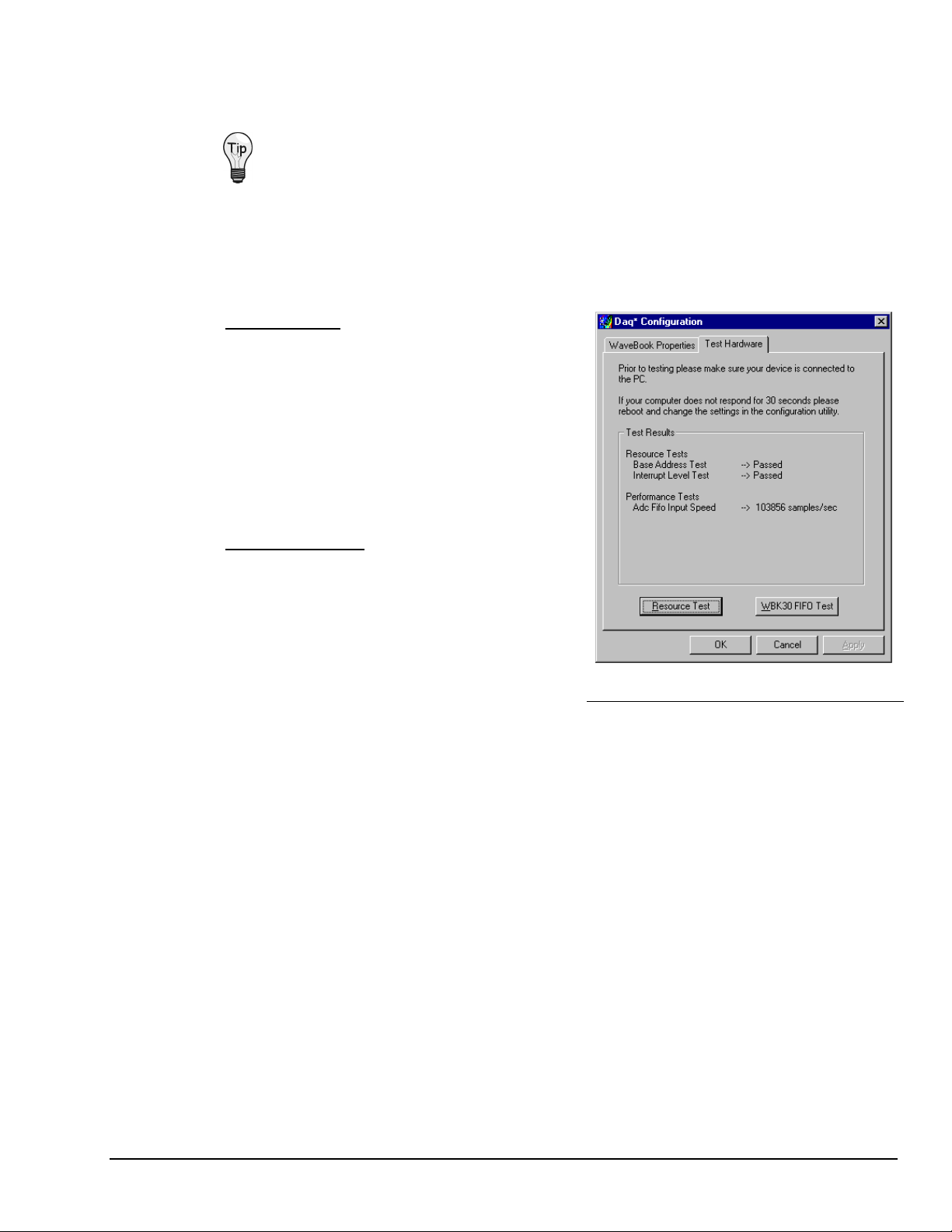

Test Hardware Dialog Box

Before testing WaveBook, make sure the device has been properly installed and powered-on. Make sure

the parallel port cable is firmly in place on both the WaveBook and the proper LPT port in the computer.

When testing WaveBook, if the unit does not respond within 30 seconds perform the

following steps:

1) reboot the system

2) upon power-up, re-open the Daq Configuration applet

3) select another configuration setting

4) reinitiate the test

To test the currently stored configuration for the WaveBook device, click the Test button. Results should be

displayed in a few seconds. The test results have two components: Resource Tests and Performance Tests.

Resource Tests. The resource tests are intended to

test system capability for the current device

configuration. Resource tests are pass/fail. Test failure

may indicate a lack of availability of the resource, or a

possible resource conflict.

Base Address Test. This resource test checks the base

address for the selected parallel port. Failure of this test

may indicate that the parallel port is not properly

configured within the system. See relevant operating

system and computer manufacturer’s documentation to

correct the problem.

Performance Tests. These types of tests are intended

to check various WaveBook functions, using the current

device configuration. Performance tests provide

quantitative results for each supported functional group.

Test results represent maximum rates the various

operations can be performed. The rates depend on the

selected parallel port protocol, and vary according to

port hardware capabilities.

Daq Configuration - Test Hardware Dialog Box

WBK30 FIFO Test. This performance test checks the data-storing capabilities of the optional,

WBK30 memory card.

When the test is completed successfully, the Daq Configuration Test Dialog Box indicates a passed

condition.

“Passed” messages indicate you can exit the test program and run your application.

WavePort User’s Manual

06-14-00

System Setup 3-9

Page 28

3-10 System Setup

06-14-00

WavePort User’s Manual

Page 29

Hardware and Operation Reference 4

WavePort/PE Devices …… 4-1

Overview ……4-2

Basic Operation ……4-3

Signal Aspects ……4-5

WavePort/PE16 ……4-5

WavePort/PE8 …… 4-6

WavePort/V Devices …… 4-7

Overview……4-7

Basic Operation ……4-8

Signal Aspects ……4-9

Ground Connections ……4-10

DB25F “Digital I/O, External Clock, TTL Trigger” Connection ……4-11

Programmable Features ……4-12

Triggers ……4-13

Pulse Trigger ……4-13

Digital-Pattern Trigger ……4-14

Multi-channel Triggering ……4-14

External Clock and Counter-Timer ……4-15

Power Aspects ……4-16

Power Module Operation ……4-18

Charging ……4-19

Fuse Replacement …… 4-19

Factory-Installed Option Cards (for WaveBook and WBK10A-based modules) …… 4-20

WBK11A – Simultaneous Sample and Hold Card……4-20

WBK12A and WBK13A Programmable Low-Pass Filter Cards ……4-21

WavePort’s Fan ……4-22

WavePort User’s Manual

09-29-00

Hardware and Operation Reference 4-1

Page 30

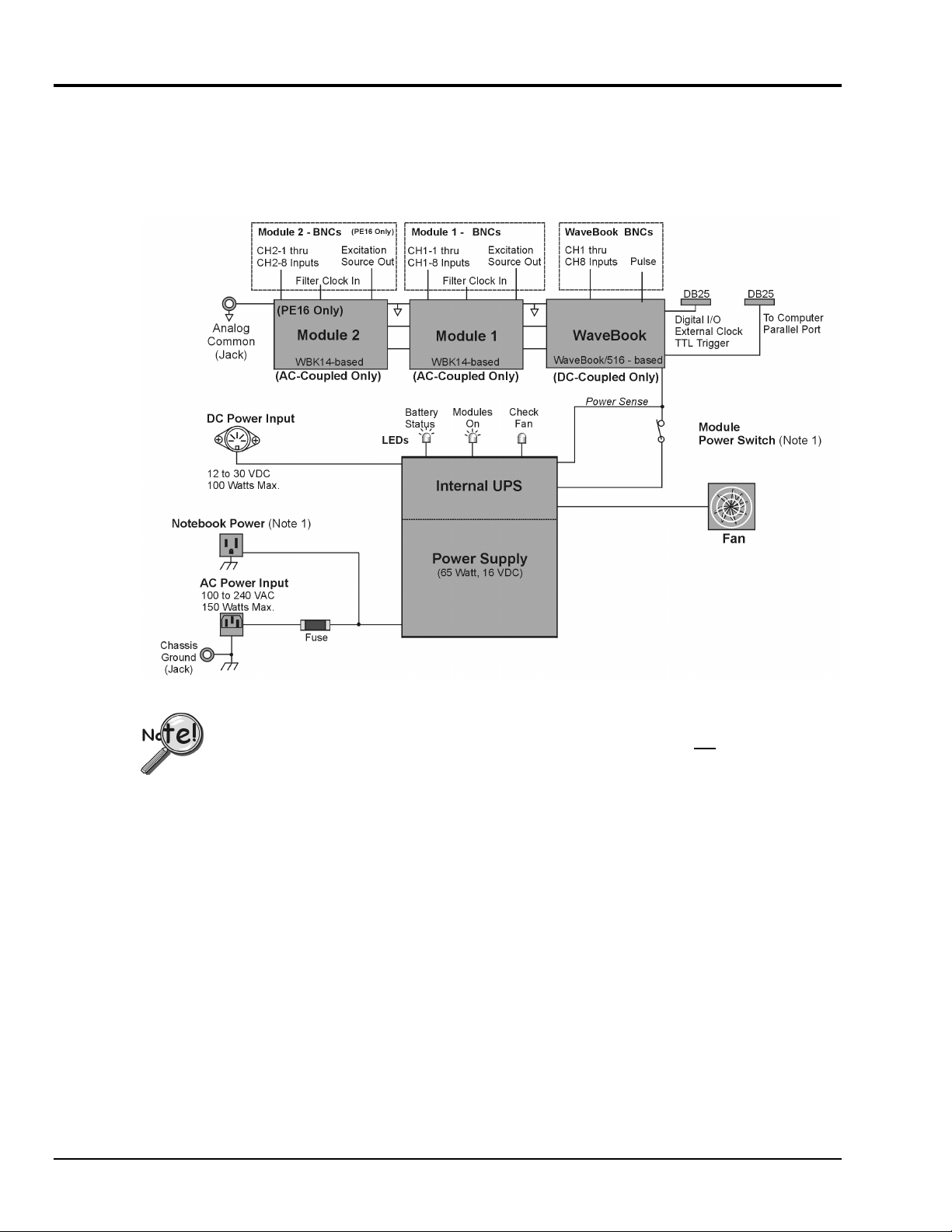

WavePort/PE Devices

Overview

The following block diagram serves to provide a general understanding of WavePort/PE devices. Detailed

information regarding such items as the signal and power modules, indicator lights, and the unit fan are

included later in this chapter.

WavePort/PE, Simple Block Diagram

The Notebook Power receptacle on WavePort’s cover plate is “LIVE” whenever WavePort is

connected to a “live” AC power source. The Module Power Switch can not be used to turn

off the Notebook Power Receptacle.

From the diagram we can see that WavePort/PE16* consists of:

•

Two Dynamic Signal Input Modules (Module 2 and Module 1).* Both modules provide for 8 input

channels (through BNC connectors), an Excitation Source Out BNC, and a Filter Clock In BNC. The

dynamic signal input modules are based on WBK14 architecture.

•

One WaveBook Module. This module provides for 8 analog channel inputs through BNC connectors

and a Pulse input.

•

A 65 watt, 16 VDC Power Supply and Internal UPS (Uninterruptible Power Supply) System

• Two 25-pin connectors (DB25). One for connecting to the Notebook’s parallel port and another for

connecting to Digital I/O, External Clock, and TTL Trigger signals

• Three electrical connectors: DC Power Input, AC Power Input, and AC Auxiliary Output

•

Three Indicator Lights: for “Battery” Status, indication of “Modules On,” and “Fan” On

• Fan, variable speed to provide system cooling

*WavePort/PE 8 has one Dynamic Signal Input Module (Module 1).

4-2 Hardware and Operation Reference

09-29-00

WavePort User’s Manual

Page 31

Basic Operation

WavePort/PE units integrate WaveBook/516 architecture with that of one or two Dynamic Signal Modules.

The PE8 version has one dynamic module, and the PE16 has two. The architecture includes buffered input

for all channels, individual instrumentation amp/channel, per-channel programmable gain, and an

anti-aliasing filter. The operational description is presented separately for both the WAVEBOOK Module

and the Dynamic Signal Module(s).

WAVEBOOK Module Operation

WavePort’s WAVEBOOK Module includes 8 signal-input channel BNCs (CH1 through CH8). Each of

these BNCs allows for two differential signals.

• Both signals are buffered and applied to a differential amplifier.

• The output of each differential amplifier is applied to a low pass filter.

•

• The amplified signals are level-shifted to the specified range. Note that unipolar offset (for sampling

•

• The digitized value is conditioned to compensate for gain and offset errors.

• The conditioned signal is held in a FIFO data buffer until the PC reads the data. An internal processor

The signals are switched (via multiplexer) to a programmable gain amplifier.

signals that are always positive) and bipolar offset (for signals that may be positive or negative) are

available.

The signal is switched over to the A/D converter. The converter digitizes the signal to16 bits in 1 µs.

checks WAVEBOOK channel 1 to determine if a valid trigger event has occurred.

• The low-latency trigger is presented to a control and timing circuit for to start the acquisition after the

trigger. The TTL trigger is taken directly from the digital I/O port.

• At every sample time, WavePort’s Digital Signal Processor reads from the scan sequence table and

accordingly programs the Control and Timing Circuit for the next sample. In regard to the next sample,

the Control and Timing Circuit selects the input channel, PGA gain, level-shifter offset, and the A/D

input source. It also conveys this information to dynamic signal modules (MODULE 1 and

MODULE 2) and precisely controls the A/D conversion timing.

• The Digital Signal Processor makes real-time sample corrections using calibration information that is

stored in an EEPROM.

• The digital I/O port is read and written by the processor to transfer bytes of digital data. The I/O port

may be used as a simple 8-bit input port or as a 32-address byte-wide I/O port.

•

Acquisition data is sent from WAVEBOOK to the Notebook PC through a high-speed EPP

(Enhanced Parallel Port). The port makes use of a DB25 connector labeled “TO COMPUTER

PARALLEL PORT.”

MODULE 1 and MODULE 2, Dynamic Signal Module Operation

WavePort’s WAVEBOOK module is connected to two dynamic analog signal input modules, for PE16; and

one such module for PE8. The dynamic modules are referred to, simply, as MODULE 1 and MODULE 2.

Each module provides a means of interfacing with piezoelectric transducers. These transducers include, but

are not limited to, accelerometers, microphones, and force/pressure transducers.

Reference Note:

Appendix A contains information regarding the use of accelerometers.

MODULE 1 and MODULE 2 each include:

The gain, filter cut-off frequencies and current biasing levels are software programmable.

WavePort User’s Manual

• excitation source for transducer biasing

•

high-pass filter

• programmable gain amplifier (PGA)

•

anti-aliasing low-pass filter

• simultaneous sample-and-hold (SSH) amplifiers

09-29-00

Hardware and Operation Reference 4-3

Page 32

Excitation Source

A built-in, programmable excitation source stimulates dynamic systems for transfer function measurements,

and serves as a reference signal for calibration. The excitation source includes a sine/random waveform

generator, a programmable gain amplifier (PGA), a DC-level DAC, and a phase-lock loop. The phase-lock

loop synthesizes the frequency of a fixed-amplitude sine wave and controls the bandwidth of the random

signals. The PGA conditions the signal amplitude to a value between 0 V to 5 V peak. The DC level of the

signal is varied independently of signal amplitude by a software-controlled DAC from -5 V to +5 V. The

DC level of the excitation signal can be used to balance static loads, while the AC signal provides the

dynamic excitation.

MODULE 1 and MODULE 2 provide constant current to bias ICP® transducers. Two current levels

(2 mA or 4 mA) with voltage compliance of 27 V can be selected via software. The bias current is sourced

through the center conductor of a coaxial lead and returns to the dynamic signal MODULE by way of the

outer conductor. The output impedance is larger than 1 MΩ and presents virtually no loading effect on the

transducer’s output. For applications that do not require bias, the current source can be removed from the

BNC input by opening a relay contact.

The Dynamic Signal MODULE’s current sources are applied to (or removed from) the input in

channel-groups of two.

For MODULE 1 these are: [CH1-1 / CH1-2], [CH1-3 / CH1-4], [CH1-5 / CH1-6] and [CH1-7 / CH1-8].

For MODULE 2 these are: [CH2-1 / CH2-2], [CH2-3 / CH2-4], [CH2-5 / CH2-6] and [CH2-7 / CH2-8].

High-Pass Filter

– for MODULES 1 & 2

Every Dynamic Signal MODULE’s signal input channel has two independent High-Pass Filters (HPFs) with

a 3-dB cut-off frequency (Fc) at 0.1 Hz and 10 Hz. The 0.1-Hz HPF is a single-pole RC filter, and is

primarily used to couple vibration signals. The 10-Hz HPF is a 2-pole Butterworth type and can be used to

couple acoustic signals or attenuate setup-induced low-frequency signals that can reduce the dynamic range

of the measurement (for example when using tape recorders as signal sources).

Programmable Gain Amplifier (PGA)

– for MODULES 1 & 2

The High-Pass Filter removes the DC voltage from the input signal. A PGA amplifies the AC voltage with

flat response up to 500 kHz. Each channel has a PGA with 8 programmable gains (1, 2, 5, 10, 20, 50, 100,

and 200) and a software-controlled DAC for offset nulling. The Dynamic Signal MODULES measure only

bipolar signals up to 5 V peak.

Programmable Low-Pass Filter Phase Equalizer

– for MODULES 1 & 2

The first filter stage is a programmable 2-pole continuous-time low-pass filter. The phase equalizer provides

more than 65 dB alias protection to the next filter stage. In addition, it fine-tunes the phase shift of the

channel to optimize the phase-matching between channels. At calibration, the phase shift of each channel is

measured and stored in an EEPROM that is read at configuration.

Programmable Low-Pass Anti-Aliasing Filter [

and

FILTER CLK. IN]

for MODULES 1 & 2

Most signal alias rejection is performed by an 8-pole Butterworth filter. This filter is implemented with a

switch-capacitor network driven by a programmable clock. Each channel has an independent clock that

determines the filter’s 3dB cut-off frequency. The switch-capacitor filter provides no attenuation at the

clock frequency—hence, the need for the continuous-time low-pass filter.

Note: The Low-Pass Anti-Aliasing Filter can be bypassed to process signals with a bandwidth higher

than 100 kHz.

FILTER CLK. IN - MODULE 1 and MODULE 2 each have a BNC labeled FILTER CLK. IN (Filter

Clock In). These BNC connectors provide a path to externally control the cut-off frequency of the LowPass Anti-Aliasing Filter. The input waveform can be TTL or sinusoidal, with an amplitude peak of at least

500 mV. In this “External Clock” mode, cut-off frequency is set to the input frequency divided by 50.

Simultaneous Sample and Hold

– for MODULES 1 & 2

All MODULE 1 and MODULE 2 channels are sampled simultaneously, after which the WAVEBOOK

Module measures each output at 1 µs/channel until all channels are digitized. The time-skew between

sampling on all channels is 150 ns.

When a Dynamic Signal MODULE’s SSH channel is enabled, the per-channel sample rates are reduced.

The rate reduction is the same as that which would occur if another channel were added.

The per-channel rate (with SSH enabled) is:

1 MHz / (n+1), where n is the number of active channels.

4-4 Hardware and Operation Reference

09-29-00

WavePort User’s Manual

Page 33

Signal Aspects, WavePort/PE16

WavePort/PE16 can measure up to eight channels of voltages within ±10V and up to 16 channels of ICP® transducer

excitation. WavePort/PE16 receives its channel-input signals through three columns of eight BNC connectors (24 channel

inputs total). The columns are labeled MODULE 2, MODULE 1, and WAVEBOOK. In addition to the channel-input BNCs,

WAVEBOOK contains a BNC for PULSE Trigger Input, and the two MODULEs include BNCs for filter clock input

(FILTER CLK. IN), and EXCITATION SOURCE OUT (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

Module 1 and Module 2

Dynamic Signal Conditioning

CH1-1 through CH1-8 and

CH2-1 through CH2-8, respectively

• Gain Ranges:

x1, 2, 5, 10, 20, 50, 100, and 200

• Input Ranges:

5V, 2.5V, 1V,

500 mV, 250 mV,

100 mV, 50 mV,

and 25 mV peak

AC-Coupled Only,

BNC shells are analog common.

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Filter Clock In

(See page 4-4)

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

•

Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Pulse Trigger Input (see page 4-13)

• Input Signal Range: ±5V

•

Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

• Maximum Pulse Width: 0.8 sec

• Latency: 300 ns

Excitation Source Out

Reference Notes:

Additional information regarding WavePort/PE signal connections appears elsewhere in this manual.

WavePort/PE8 information appears on the following page. Chapter 6, WaveView, includes information

regarding channel configuration. Maintenance, intended environment, and transportation issues are discussed

in chapter 9. Specifications are provided in chapter 10.

WavePort User’s Manual

(See page 4-4)

Chassis Ground

(See page 4-10)

WavePort/PE16 Signal Panel

09-29-00

Digital I/O (see page 4-11)

External Clock (see page 4-11, 15)

TTL Trigger (see page 4-11)

Analog Common (see page 4-10)

Hardware and Operation Reference 4-5

Page 34

WavePort/PE8

WavePort/PE8 can measure up to eight channels of voltages within ±10V; and up to 8 channels of ICP® transducer excitation.

The unit receives its channel-input signals through two columns of eight BNC connectors (16 channel inputs total). The

columns are labeled MODULE 1 and WAVEBOOK. In addition to the channel-input BNCs, WAVEBOOK contains a BNC

for PULSE Trigger Input, and MODULE 1 include one BNCs for filter clock input (FILTER CLK. IN), and another BNC for

EXCITATION SOURCE OUT (see following figure).

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

Module 1

Dynamic Signal Conditioning

CH1-1 through CH1-8

• Gain Ranges:

x1, 2, 5, 10, 20, 50, 100, and 200

• Input Ranges:

5V, 2.5V, 1V,

500 mV, 250 mV,

100 mV, 50 mV,

and 25 mV peak

AC-Coupled Only,

BNC shells are analog common.

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Filter Clock In

(See page 4-4)

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

• Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information.

Pulse Trigger Input (see page 4-13)

• Input Signal Range: ±5V

•

Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

• Maximum Pulse Width: 0.8 sec

• Latency: 300 ns

Excitation Source Out

(See page 4-4)

Chassis Ground

(See page 4-10)

WavePort/PE8 Signal Panel

Reference Notes:

Additional information regarding WavePort/PE signal connections appears elsewhere in this manual.

WavePort/PE16 information appears on the previous page. Chapter 6, WaveView, includes information

regarding channel configuration. Maintenance, intended environment, and transportation issues are discussed

in chapter 9. Specifications are provided in chapter 10.

4-6 Hardware and Operation Reference

09-29-00

Digital I/O (see page 4-11)

External Clock (see page 4-11, 15)

TTL Trigger (see page 4-11)

Analog Common (see page 4-10)

WavePort User’s Manual

Page 35

WavePort/V Devices

Overview

The following block diagram serves to provide a general understanding of WavePort/V devices. Detailed

information regarding such items as the signal and power modules, indicator lights, and the unit fan are

included later in this chapter.

From the diagram we can see that WavePort/V24 consists of:

• Two Analog Input Modules (Module 2 and Module 1).* Both modules provide for 8 input channels

•

•

• Two 25-pin connectors (DB25). One for connecting to the Notebook’s parallel port and another for

•

• Three Indicator Lights: for “Battery” Status, indication of “Modules On,” and “Fan” On

• Fan, variable speed to provide system cooling

*In the WavePort/V product line, only WavePort/V24 includes a WaveBook module plus two additional

analog input modules (Module 1 and Module 2). WavePort/V8 includes the WaveBook module, but has

no WBK10-based modules. WavePort/V16 includes the WavePort module and the WBK10A-based

Module 1.

WavePort User’s Manual

WavePort/V, Simple Block Diagram

The Notebook Power receptacle on WavePort’s cover plate is “LIVE” whenever WavePort is

connected to a “live” AC power source. The Module Power Switch can not be used to turn

off the Notebook Power Receptacle.

(through BNC connectors). These modules are based on WBK10A architecture.

One WaveBook Module. This module provides for 8 analog channel inputs through BNC connectors

and a Pulse input.

A 65 watt, 16 VDC Power Supply and Internal UPS (Uninterruptible Power Supply) System

connecting to Digital I/O, External Clock, and TTL Trigger signals

Three electrical connectors: DC Power Input, AC Power Input, and AC Auxiliary Output

09-29-00

Hardware and Operation Reference 4-7

Page 36

Basic Operation

WavePort/V units integrate WaveBook/516 architecture. In addition, the V16 unit includes a WBK10Abased analog input module; and V24 units include two WBK10A-based analog input modules. The

architecture includes buffered input for all channels, individual instrumentation amp/channel, per-channel

programmable gain, and an anti-aliasing filter. The operational description is presented separately for both

the WAVEBOOK Module and the WBK10A-based module(s).

WAVEBOOK Module Operation

WavePort/V WAVEBOOK Modules include 8 signal-input channel BNCs (CH1 through CH8). Each of

these BNCs allows for two differential signals.

•

•

•

•

•

•

•

•

•

•

•

•

Both

signals are buffered and applied to a differential amplifier.

The output of each differential amplifier is applied to a low pass filter.

The signals are switched (via multiplexer) to a programmable gain amplifier.

The amplified signals are level-shifted to the specified range. Note that unipolar offset (for sampling signals that

are always positive) and bipolar offset (for signals that may be positive or negative) are available.

The signal is switched over to the A/D converter. The converter digitizes the signal to16 bits in 1 µs.

The digitized value is conditioned to compensate for gain and offset errors.

The conditioned signal is held in a FIFO data buffer until the PC reads the data. An internal processor checks

WAVEBOOK channel 1 to determine if a valid trigger event has occurred.

The low-latency trigger is presented to a control and timing circuit for to start the acquisition after the trigger. The

TTL trigger is taken directly from the digital I/O port.

At every sample time, WavePort’s Digital Signal Processor reads from the scan sequence table and accordingly

programs the Control and Timing Circuit for the next sample. In regard to the next sample, the Control and Timing

Circuit selects the input channel, PGA gain, level-shifter offset, and the A/D input source. It also conveys this

information to WBK10A-based modules (MODULE 1 and

MODULE 2) and precisely controls the A/D conversion timing.

The Digital Signal Processor makes real-time sample corrections using calibration information that is stored in an

EEPROM.

The digital I/O port is read and written by the processor to transfer bytes of digital data. The I/O port may be used

as a simple 8-bit input port or as a 32-address byte-wide I/O port.

Acquisition data is sent from WAVEBOOK to the Notebook PC through a high-speed EPP

(Enhanced Parallel Port). The port makes use of a DB25 connector labeled “TO COMPUTER PARALLEL

PORT.”

MODULE 1 and MODULE 2, Analog Expansion Modules

Each WBK10A-based expansion module provides 8 differential analog inputs. The modules are typically

equipped with a factory-installed programmable gain instrumentation amplifier (PGA). When WavePort/Vs

are ordered, the customer can specify that one of the following option cards be installed in place of the

standard PGA card: WBK11A, WBK12A, or WBK13A. Each of these options is discussed shortly.

Note 1: The standard WBK10A-based module comes with a pre-installed PGA card; however, WavePort

orders can specify that the module is to have a WBK11A, WBK12A, or WBK13A option card in

place of the PGA card.

Note 2: Refer to chapter 10 for specifications.

Hardware Setup Configuration

The analog input channel numbers are determined by the order

of connection among the WaveBook module and the

WBK10A-based modules (Module 1 and Module 2, as

applicable.)

• Channel 0 is the WaveBook module’s 8-bit digital I/O port.

• Channels 1 through 8 are the WaveBook’s main channels.

• Channels 9 through 16 (CH1-1 through CH1-8) are located on

the WBK10A-based Module 1 (not applicable to V8 units).

• Channels 17-24 (CH2-1 through CH2-8) are located on the

WBK10A-based Module 2 (not applicable to V8 or V16 units).

WavePort Module Channel #

/V8, /V16, /V24 WaveBook 0 (dig I/O)

/V8, /V16, /V24 WaveBook CH1-8

/V16 and /V24 Module 1 CH1-1 to

CH1-8

/V24 only Module 2 CH2-1 to

CH2-8

4-8 Hardware and Operation Reference

09-29-00

WavePort User’s Manual

Page 37

Signal Aspects, WavePort/V

WavePort/V24 can measure up to 24 channels of voltages within ±10V. The V8 and V16 version WavePorts measure up to 8

and 16 channels, respectively. WavePort/V24 receives its channel-input signals through three columns of eight BNC

connectors (24 channel inputs total). The columns are labeled [from left to right] MODULE 2, MODULE 1, and

WAVEBOOK. In addition to the channel-input BNCs, WAVEBOOK contains a BNC for PULSE Trigger Input (see

following figure). Note that WavePortV8 and V16 BNC panels are illustrated in chapter 2.

The signal panel includes a DB25 connector for DIGITAL I/O, EXT CLOCK (external clock), and TTL TRIGGER.

Connection nodes for CHASSIS (ground) and ANALOG COMMON are also provided.

Module 1 and Module 2*

Analog Inputs

CH1-1 through CH1-8, and

CH2-1 through CH2-8, respectively.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 5V

0 t0 + 2V

0 to +1V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V, ±0.5V

• Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

See Chapter 6, WaveView and

Chapter 10, Specifications for

additional information that includes

ranges available with WBK11A,

WBK12A, and WBK13A factoryinstalled options.

* WavePort/V16 does not include

Module 2. WavePort/V8 includes the

WaveBook and Pulse Trigger BNCs

(but no Module BNCs.

Chassis Ground

(See page 4-10)

WaveBook

Analog Inputs

CH1 through CH8, Analog Inputs via

BNC Connectors.

•

16 bit resolution

• Software selectable for unipolar or

bipolar operation

• Unipolar Ranges

0 to +10V

0 to + 4V

0 to +2V

• Bipolar Ranges

±10V, ±5V, ±2V, ±1V

• Maximum Overvoltage: ±30 VDC

DC-Coupled Only,

Fully Differential

Pulse Trigger Input (see page 4-13)

• Input Signal Range: ±5V

• Input Characteristics: 75 Ω

•

Input Protection: ±10V max.

• Minimum Pulse Width: 100 ns

• Maximum Pulse Width: 0.8 sec

• Latency: 300 ns

Digital I/O (see page 4-11)

External Clock (see page 4-11, 15)

TTL Trigger (see page 4-11)

Analog Common (see page 4-10)

WavePort/V24 Signal Panel

Reference Notes: Additional information regarding WavePort signal connections appears elsewhere in this

manual. Chapter 6, WaveView, includes information regarding channel configuration.

Information regarding maintenance, intended environment, and transportation is included in chapter 9.

Specifications are provided in chapter 10.

Software Setup

You will need to set several parameters so WaveView can best meet your application requirements. For

software setup information, refer to the "Software Setup" section in Chapter 2, WaveBook Setup. For

detailed WaveView information, refer to Chapter 5, WaveView.

WBK10A-Based Module Specifications

Specifications are provided in chapter 10.

WavePort User’s Manual

09-29-00

Hardware and Operation Reference 4-9

Page 38

Ground Connections

The center (+) and shield (-) each connect to ANALOG COMMON through a 5 MΩ resistor, resulting in a

Ω

10 M

differential input resistance (see above figure). WavePort’s ANALOG COMMON connects to the

computer power supply ground through the TO COMPUTER DB25 connector and cable.

When using a Notebook PC the computer ground could be:

(a) floating, for example, when the Notebook is operating on batteries, or

(b) connected to vehicle ground, for example, when using an automotive cigarette-lighter adapter in conjunction with

the vehicle’s battery.

Note that a pair of Schottky diodes is used in the WBK14 to clamp the ANALOG COMMON to within

0.3V of computer ground (see figure).

Channel Analog Input, WavePort/PE BNC Signal Connections

WavePort has an isolated power supply. Power input common is isolated from ANALOG COMMON by

9

>10

Ω in parallel with 0.1µF.

For the “WaveBook” module to correctly measure analog signals, each signal must be within

±11 volts of ANALOG COMMON. The following notes provide guidelines on how to achieve this.

Like WavePort, Notebook computers are rarely connected to AC power line ground.

This is true even when these devices are plugged into AC adapters.

Connecting to ANALOG COMMON

If the computer is battery operated and the signal source is floating (such as an ungrounded sensor), then the

internal 5 M

computer or the analog signal source is committed to AC power line ground, then you will require a

direct connection between the signal source and ANALOG COMMON.

When in doubt, connect the signal source common to ANALOG COMMON.

A single-ended signal source needs to have its common connected to ANALOG COMMON.

When connecting several signal source commons to ANALOG COMMON, it is important that there is

no voltage potential [between these signal source commons]. Otherwise, ground currents will circulate,

leading to measurement errors.

If there is a fixed voltage potential between multiple signal source commons, then only one of these signal

source commons needs connected to ANALOG COMMON. This is true as long as the common mode

voltage of any input does not exceed ±11 volts.

Ω

resistors may provide enough of a return path to ANALOG COMMON. If either the

4-10 Hardware and Operation Reference

09-29-00

WavePort User’s Manual

Page 39

Connecting to CHASSIS (Ground)

WavePort includes a CHASSIS ground node. Though it never hurts to connect the WavePort CHASSIS to

a reliable ground, it is recommended that you do make this connection to ground when WavePort is …

•

… being used in a vehicle.

• … being used in a static-prone environment.

• … experiencing Radio Frequency Interference (RFI) (see following note).

If WavePort experiences Radio Frequency Interference (RFI) you should:

(a) connect the WavePort CHASSIS to ground, and

(b) connect the cable-shields (of the channel inputs) to CHASSIS ground.

DB25F “Digital I/O, External Clock, TTL Trigger” Connection

The following signals are present on WavePort’s DB25F

(25-pin, female connector) labeled “Digital I/O, External Clock, and

TTL Trigger.”

•

16 High-Speed Digital I/O Lines (D0 through D15)

•

TTL Trigger Input (TTLTRG)

•

+15 V (pin 23), -15 V (pin 22), 50 mA max. (each)

• two +5 V (pin 19 and pin 21), 250 mA max. (total)

• External Clock (pin 20)

•

two Digital Grounds (pins 24 and 25)

To sample just 16 digital input signals, connect them directly to

the digital I/O data lines. D15 is the most significant bit, and D0

is the least.

The following figure depicts the DB25F connector (located on

WavePort’s cover plate) and the optional CA-178 cable. The

cable option is intended for External Clock and TTL External

Trigger applications. Both are discussed shortly.

Digital I/O Connections, WaveBook/516

D0 – D15 High Speed Digital I/O data lines

TTLTRG TTL trigger input

External Clock 16 bit mode, read/write strobe

+5 VDC 250 mA maximum

+15,-15 VDC 50 mA maximum (each)

Digital Grounds Pins 24 and25

WavePort User’s Manual

Optional Clock and External Trigger Cable (CA-178)

09-29-00

Hardware and Operation Reference 4-11

Page 40

Programmable Features

Channels can be configured through your own custom programs or through the included out-of-the-box

WaveView software. WaveView includes a Channel Configuration screen (following figure) that allows

you to turn channels ON or OFF, select channel ranges, change channel labels, and select engineering units.

Reference Note:

Chapter 6, WaveView contains more detailed information. Individuals who write their own

programs should refer to the readme.txt file on the install CD-ROM regarding the location of

API reference material, including program examples.

Selecting a Channel’s Range

You can use WaveView to select a channel’s range in one of two ways.

(1) Click in a channel’s Range cell, then select the desired range from the “Select Range” pull-down list.

(2) Continue to double-click in the applicable channel’s Range cell to cycle through the available ranges.

Stop double-clicking when the desired range is indicated.

Configuring Channels from WaveView’s Main Window

Selecting a Channel’s Units

You can use WaveView to select a channel’s units in one of two ways.

(1) Click in a channel’s Units cell, then select the desired units from the “Select Units” pull-down list.

(2) Double-click in a channel’s Units cell to cycle through the units. Note that after the mX+b dialog box

appears you must click “OK” to continue cycling.

Note: You can use the mX+b equation to adjust a channel’s scale and offset. You can enter

user-defined units from the mX+b dialog box.

After completing channel

configuration, you can select the

Acquisition Configuration option from

WaveView’s View menu or tool bar.

The figure to the right represents the

Acquisition Configuration dialog box.

The parameters shown are a result of

the values entered below the figure.

Clicking the Close button sets the

acquisition parameters as the active

parameters.

Acquisition Configuration Dialog Box

Triggering

Type: Manual

Scanning Duration

Convention: Scans

Pre-Trigger: 1000 scans

Post-Trigger: 5000 scans

Scanning Rate

Clock: Internal

Convention: Frequency

Pre-Trigger: 50 kHz

Post-Trigger: 50 kHz

4-12 Hardware and Operation Reference

09-29-00

WavePort User’s Manual

Page 41

Triggers

Pulse Trigger

This section discusses the following topics:

Pulse Trigger

•

• Digital-Pattern Trigger

• Multi-Channel Triggering

• External Clock and Timer

In addition to the standard “single-channel” trigger-on-level functions, the WavePort system supports

pulse trigger. With pulse trigger, you can define both the amplitude and the duration of the pulse that will

be used to trigger the acquisition. Pulse trigger can be used to detect spurious transients that can be missed

by simple level triggers.

WavePort includes a BNC connector labeled “PULSE.” This connector located on the cover plate (just

below the WaveBook Channel 8 BNC).

Pulse Trigger allows the use of a highbandwidth input for triggering, and the

correlation of lower-speed waveforms with

the occurrence of a high-speed pulse. You

can set a pulse amplitude between ±5 V and

a pulse width in the range of

100 ns and 800 ms.

This option allows you to trigger on analog level “pulses” on either the Channel 1 input or the Pulse Trigger

input. This trigger type is similar to the Channel 1 Analog trigger but places an additional time-based