Page 1

WaveBook

User's Manual

High-Speed Portable Data Acquisition Systems

• WaveBook/512

• WaveBook/512H

• WaveBook/516

• Related WBKs, DBKs, and Software

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail: sales@iotech.com

Internet: www.iotech.com

WaveBook

High-Speed Portable Data Acquisition Systems

Various Models, Software, and System Expansion

p/n

User's Manual

481-0901

Rev.

3.0

© 1999 by IOtech, Inc. July 1999 Printed in the United States of America

Page 2

Page 3

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior

written consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their

respective holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs)

may only be used on one installation. You may make archival backup copies.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission rules (Part 15)

for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve Radio-TV Interference Problems

(stock # 004-000-00345-4) which is available from the U.S. Government Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is

not covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and

review our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech

welcomes your suggestions.

Page 4

Your WaveBook order was carefully inspected prior to shipment. When you receive your

system, carefully unpack all items from the shipping carton and check for physical signs of

damage that may have occurred during shipment. Promptly report any damage to the

shipping agent and your sales representative. Retain all shipping materials in case the unit

needs returned to the factory.

Page 5

How To Use This Manual

This manual pertains to setup and operation of WaveBook data acquisition systems as indicated in the following

chapter descriptions.

Quick Start: Provides instructions for getting a basic WaveBook system connected, powered-up, and collecting

data with use of WaveView software.

Chapter 1: WaveBook Overview describes basic system features and operation. Includes a system block

diagram, introduction to out-of-the-box software, and recommendations regarding software drivers.

Chapter 2: Setup Notes and System Testing provides information regarding hardware connections and system

testing.

Chapter 3: WBK Expansion Options describes the various WBK devices that interface with the WaveBook for

expansion and signal conditioning. The discussion includes block diagrams, setup procedures, operation,

and software concerns.

Chapter 4: System Power & Assembly discusses power supplies and ways of mounting system modules.

Chapter 5: WaveView pertains to WaveBook’s primary software program. This chapter explains how to

configure the software to meet your system requirements.

Chapter 6: PostView explains how to use this program for post-acquisition data viewing.

Chapter 7: Calibration discusses WaveBook’s calibration software. Both automatic and manual calibrations

are discussed.

Chapter 8: Theory of Operation explains a variety of concepts, including: initial acquisition steps, scans, signal

processing, trigger types, and data transfer.

Chapter 9: Troubleshooting suggests solutions to certain technical problems. Please refer to this chapter before

calling for technical assistance.

Appendix A: Accessories, Specifications, & Abbreviations includes a list of the available accessories and

options for the WaveBook system and a list of the physical and performance specifications for related

products. The Abbreviations includes acronyms and ASCII control codes.

Appendix B: this appendix presently lists data acquisition terms and definitions.

Appendix C: contains daqX API programming models. This appendix is intended for users wishing to create

their own applications programs.

Appendix D: contains daqX API command references. This appendix is intended for users wishing to create

their own applications programs.

CAUTION

CAUTION

CAUTIONCAUTION

Using this equipment in ways other than described in this manual can cause personal injury or

equipment damage. Pay special attention to all cautions and warnings.

If you plan to create your own applications programs refer to Appendices C and D. These

two appendices contain API information, including program examples.

WaveBook User’s Manual,

Reference Note:

Additional information (not available at the time of publication), can be found in a

file, or in supplemental documentation.

6-23-99

README.TXT

i

Page 6

Table of Contents

Quick Start …… QS-1

Connect WaveBook to the Host PC …… QS-1

Connect Signals …… QS-2

Connect Power …… QS-3

Install Software …… QS-3

Test Your System ……QS-4

Start WaveView and Collect Data …… QS-4

1 – WaveBook ar Overview

Hardware Overview…… 1-1

Product Comparison......1-1

WaveBook Features …… 1-2

Block Diagrams and Board Layouts……1-3

Software Overview...... 1-6

WaveView Features......1-6

Programming Environments…… 1-8

2 – Setup Notes and System Testing

Hardware Setup Notes …… 2-1

WBK20A – PCMCIA/EPP Interface Card …… 2-1

WBK21 – ISA/EPP Interface Card …… 2-2

Optional Printer Connection ……2-4

Analog-Signal Connections & Grounds ……2-4

Digital I/O Connection

(WaveBook/512 and /512H Only) ……2-5

Digital I/O Connection

(WaveBook/516 Series Only) ……2-5

Pulse Trigger Connection

(WaveBook/516 Series Only) ……2-6

System Testing …… 2-6

3 - WBK Expansion Options

Using Shielded BNC Connectors

for CE Compliance ……3-1

WBK10/10H – Expansion Modules…… 3-2

WBK11 – SSH Card…… 3-6

WBK12/13 – Programmable LPF Cards…… 3-8

WBK14 - Dynamic Signal Input Module… 3-10

WBK15 - 5B Isolated Signal-Conditioning

Module…… 3-17

WBK16 - Strain-Gage Module…… 3-22

WBK30 - WaveBook Memory Option… 3-45

WBK61/62 - High-Voltage Adapters…… 3-43

4 - System Power & Assembly

Power Management…… 4-1

Calculating the System Power Requirement…… 4-1

CA-115 & CA-116 Power Cable Connections…. 4-3

DBK30A – Rechargeable Battery Module…… 4-4

Hardware Setup…… 4-5

DBK30A - Specifications…… 4-6

DBK34 - Vehicle UPS Module…… 4-7

Hardware Setup…… 4-8

DBK34 - Specifications…… 4-9

Stacking Modules…… 4-10

5 – WaveView

Introduction…… 5-1

Software Startup & Sample Acquisition… 5-2

Startup WaveView…… 5-2

Configure Channels…… 5-3

Configure Acquisition…… 5-4

Collect Data…… 5-5

Store Data…… 5-6

WaveView Configuration Main Window… 5-6

Menu Items & Buttons…… 5-6

File…… 5-7

Edit…… 5-7

View…… 5-7

System…… 5-7

Input Channel Configuration…… 5-9

Acquisition Configuration…… 5-11

General Information ……5-11

Trigger Types ……5-11

Expanded Acquisition Features, WaveBook/516

Only…… 5-13

Counter-Timer ……5-13

Digital Pattern Trigger ……5-13

Pulse Trigger …… 5-14

WaveView Scope Window…… 5-15

Menu Items & Buttons…… 5-16

File…… 5-16

Acquire…… 5-16

Charts…… 5-16

Options…… 5-16

Window…… 5-16

Scope Display…… 5-17

WaveView Direct-To-Disk Window…… 5-18

File…… 5-18

Acquire…… 5-18

Window…… 5-19

Data Destination Area…… 5-19

ii WaveBook User’s Manual

Page 7

6 - PostView

Data File Accessibility…… 6-1

Starting PostView…… 6-3

Toolbar…… 6-4

Channel Information Region…… 6-5

Menu Items…… 6-6

Understanding Groups, Charts & Channels……

6-7

Chart Setup Wizard…… 6-7

Introduction…… 6-7

Automatic Display Creation…… 6-8

Display Configuration…… 6-9

Editing a Display…… 6-10

Manually Creating a Display…… 6-12

PostView Timebase…… 6-15

7 - Calibration

Two Methods of Calibration…… 7-1

WaveCal…… 7-1

Configuring System Calibration…… 7-2

Performing System Calibration…… 7-3

Manual Calibration…… 7-4

Trigger Operation…… 8-10

Digital Trigger & Single-Channel Trigger… 8-10

Hysteresis……8-11

Multi-Channel Trigger…… 8-12

Multi-Channel Trigger Types…… 8-12

Above-Level Trigger…… 8-13

Below-Level Trigger…… 8-13

Above-Level-With-Latch Trigger…… 8-13

Below-Level-With-Latch Trigger…… 8-13

Rising-Edge Trigger…… 8-14

Falling-Edge Trigger…… 8-14

Rising-Edge-With-Latch Trigger…… 8-14

Falling-Edge-With-Latch Trigger…… 8-14

Trigger Latency & Jitter…… 8-14

Data Processing…… 8-15

Data Packing (WaveBook/512 Only)…… 8-16

Data Transfer…… 8-17

Time-Outs…… 8-17

Buffer Size and Type…… 8-17

Overlapped Execution…… 8-19

Foreground-Linear Transfers…… 8-19

Foreground-Circular Transfers…… 8-20

Background-Linear Transfers…… 8-20

Background-Circular Transfers…… 8-21

Direct-to-Disk Transfers…… 8-21

9 – Troubleshooting

8 - Theory of Operation

Introduction…… 8-1

Acquisition Steps…… 8-2

Initialize the WaveBook…… 8-2

One-Step Acquisitions…… 8-2

Configure an Acquisition…… 8-2

Channel Numbering…… 8-2

Specifying the Scan…… 8-2

Specifying the Trigger Source…… 8-3

Specifying the Number of Scans…… 8-3

Specifying the Scan Rate…… 8-3

Start the Acquisition…… 8-4

Transferring Results…… 8-4

Stop the Acquisition…… 8-4

Shut Down the WaveBook…… 8-4

Signal Processing…… 8-5

WaveBook/512…… 8-5

Analog Signal Processing…… 8-5

Digital I/O Signal Processing…… 8-5

WaveBook/516 …..8-7

Analog Signal Processing…… 8-7

Digital I/O Signal Processing…… 8-7

Acquisition Operation…… 8-8

Acquisition Modes…… 8-8

N-Shot Acquisition Mode…… 8-8

Infinite Post-Trigger Acquisition Mode…… 8-8

N-Shot with Re-Arm Acquisition Mode…… 8-8

Pre/Post-Trigger Acquisition Mode…… 8-9

Scan Composition…… 8-9

Scan Period…… 8-9

External Clock Input (WaveBook/516 Only) …..8-10

Radio Interference Problems…… 9-1

Electrostatic Discharge (ESD) Damage… 9-1

WaveBook W95/WNT Driver Readme File

(Readmew.txt)…… 9-1

Overview…… 9-2

Driver Support…… 9-2

Connection Problems…… 9-2

32-Bit WaveView Issues…… 9-3

Windows NT V3.51…… 9-3

Windows 95/98 Problems…… 9-3

Resource Settings…… 9-3

Parallel Port Setup…… 9-4

Appendices

A - Accessories, Specifications, &

Abbreviations

B - Acquisition Terms

C - daqX API – Programming Models

D - daqXAPI – Command Reference

WaveBook User’s Manual,

6-23-99

iii

Page 8

iv WaveBook User’s Manual

Page 9

Quick Start

Connect WaveBook to the Host PC …… QS-1

Connect Signals …… QS-2

Connect Power …… QS-3

Reference Note: These Quick Start instructions are for use with basic setups. For complex systems, you may

need to refer to additional text in this manual, or to separate documentation. You may want to refer to the

following:

• Chapter 1 – contains software and hardware overviews.

•

Chapter 2 – pertains to connections and system testing.

• Chapter 3 – discusses WBK units.

• Chapter 4 – pertains to system power use and mechanical assembly options.

• If using the WBK20A or WBK21, refer to separate instructions, supplied with the WBK device.

1. Connect WaveBook to the Host PC

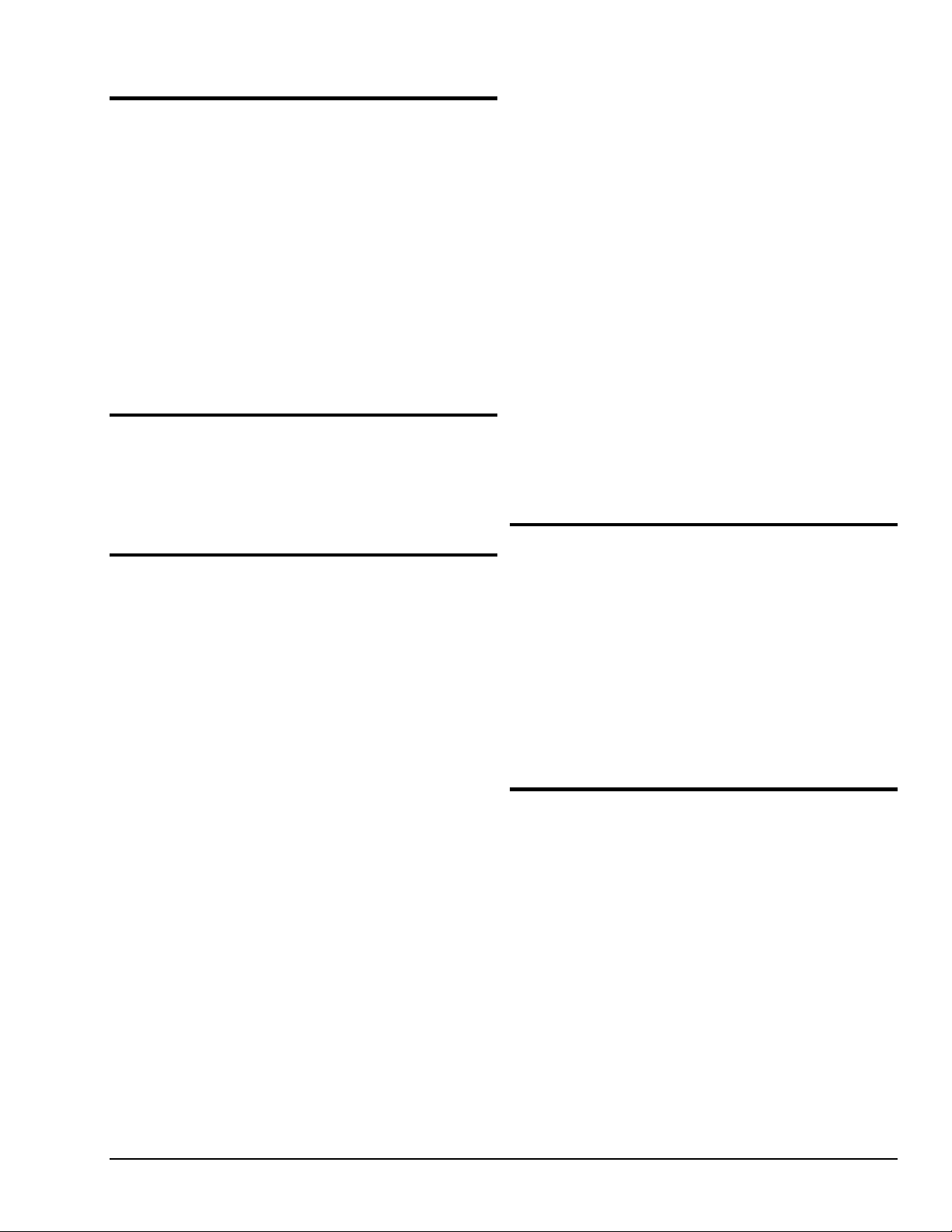

WARNING

WARNING

WARNINGWARNING

Electrical Shock Hazard! Perform all hardware setups with all power off to the device serviced

and to all connected equipment; otherwise, personal injury may result.

WaveBook connects to a host NoteBook or desktop PC through a 25 pin (male connector) located on the

rear panel. The connector is labeled “To Computer.” A simple illustration of the rear panel follows.

WaveBook rear panels have the following components:

Install Software …… QS-3

Test your System …… QS-4

Start WaveView and Collect Data …… QS-4

Note: Height dimension for WaveBook/516 is 1.75"; WaveBook/512 is 1.38".

• 1 POWER switch (0-off; 1-on)

•

2 circular 5-pin DIN connectors for POWER IN and POWER OUT (pass-through)

•

1 DB25F for TO PARALLEL PRINTER (pass-through) connection

• 1 DB25M for TO COMPUTER (LPT/EPP host) connection

• 1 HD-15F EXPANSION CONTROL output

•

1 BNC connector for analog input EXPANSION SIGNAL IN

WaveBook can be set up to work with Notebook or desktop PCs as follows:

Notebook PCs – Wavebook communicates with a Notebook PC through the PC’s parallel port, or its PC-Card port

using a WBK20A PCMCIA/EPP interface-card.

Desktop PCs - WaveBook communicates with a desktop PC through the PC’s parallel port, or its ISA bus using a

WBK21 ISA/EPP interface-board.

a. Connect the matching end of the supplied communications cable to the computer’s parallel or interface port.

b. Connect the other end of the communications cable to the WaveBook port labeled “TO COMPUTER.”

Desktop PC with WBK21 ISA/EPP

WaveBook/516

POWER

MADE IN USA

POWER IN POWER OUT

TO PARALLEL PRINTER

(+10VDC TO +30VDC)

DB25M Connector “

(links to LPT/EPP on host PC)

TO COMPUTER

Desktop PC (with WBK21) Connected to WaveBook/516

EXPANSION

EXPANS ION

CONTROL

SIGNAL IN

TO COMPUTER

”

WaveBook User’s Manual,

6-24-99

Quick Start QS-1

Page 10

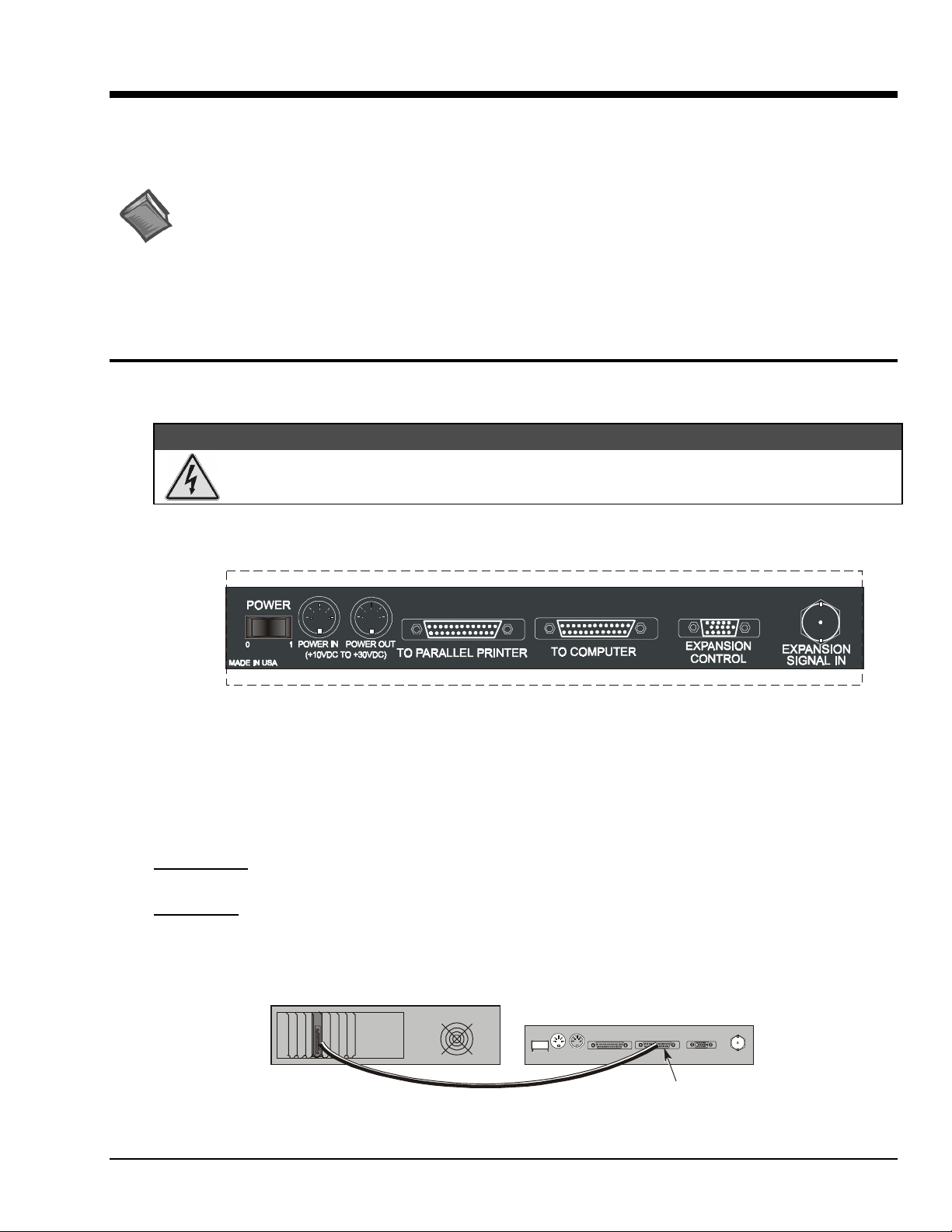

2. Connect Signals

Voltages applied to WaveBook's BNC connectors must not exceed ±35 VDC.

Exceeding these specifications could result in equipment damage.

Signal connections are made on the WaveBook’s front panel. The front panels of the WaveBook/512 and

WaveBook/516 are similar. The /516 is taller and has one extra BNC connector (used for pulse trigger).

WaveBook/512 front panel has the following components:

• 1 Binding post for ANALOG COMMON reference

• 8 BNC connectors for analog inputs (analog channel 1 is also the low-latency analog trigger)

•

1 DB25F for DIGITAL I/O TRIGGER input

• 3 Status LEDs (ACTIVE, READY, POWER)

The WaveBook/516 front panel has the following components:

CAUTION

CAUTION

CAUTIONCAUTION

• 1 Binding post for ANALOG COMMON reference

•

8 BNC connectors for analog inputs (analog channel 1 is also the low-latency analog trigger)

• 1 BNC connector for PULSE TRIGGER input

• 1 DB25F for DIGITAL I/O including trigger input and EXTERNAL CLOCK input

• 3 Status LEDs (ACTIVE, READY, POWER)

WaveBook’s front panel has eight BNC connectors for analog inputs, a binding post for analog common,

and a DB25F connector for Digital I/O. Channel 1 is also used for low-latency analog triggering.

WaveBook/516 has an additional BNC connector for pulse trigger.

The center pin of each BNC connector is the high input and the outer shell is the low input. The inputs are

differential, the measured voltage being the difference between the high and low signal levels.

For proper operation, each analog input signal (high or low) must be within ±11 V of the WaveBook's

analog common level.

A few notes regarding ground, follow. Refer to Chapter 2 for more detailed information.

•

When connected, WaveBook’s ANALOG COMMON is at the same potential as the host PC’s digital

ground.

•

WaveBook’s analog channels are not isolated from the host PC.

• WaveBook’s power supply input is isolated from the rest of the WaveBook, including the

ANALOG COMMON and the PC’s digital ground.

For WaveBook [or WBK10/10H] to correctly measure analog signals, each signal must be within

±11 volts of ANALOG COMMON. Refer to Chapter 2 for detailed information.

QS-2 Quick Start,

6-24-99

WaveBook User’s Manual

Page 11

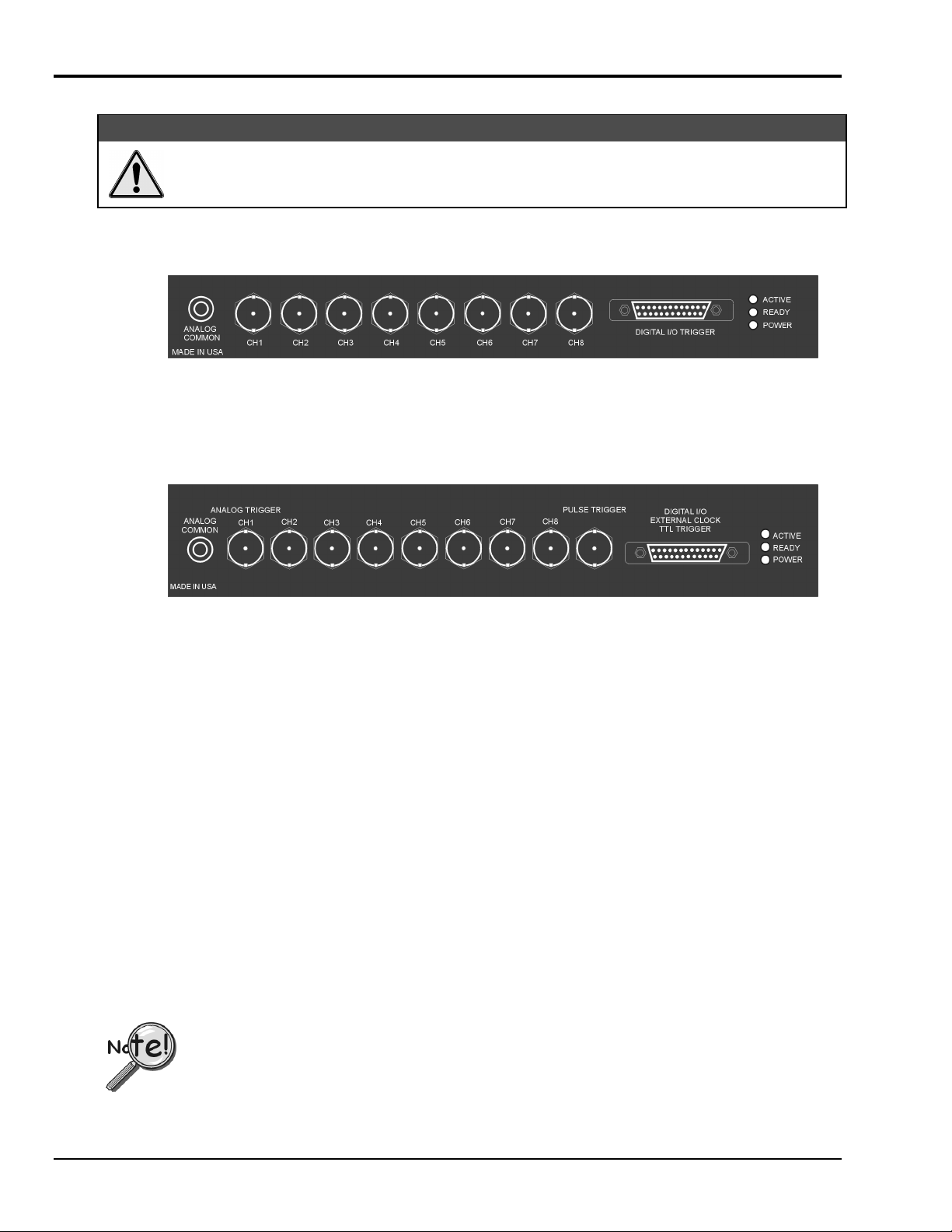

3. Connect Power

WaveBook can be powered from the included wall-mount AC adapter (TR-40U) or from a 10 to 30 VDC source, such

as a car battery. The AC adapter plugs into a standard wall outlet, and its DIN5 end plugs into the DIN5 “Power In”

receptacle on WaveBook’s rear panel.

AC Adapter Connection

Power options include the DBK30A (a rechargeable battery module) and the DBK34 (uninterruptible power supply

module).

Reference Note: If using DBK30A or DBK34, refer to the following sections of your user’s manual for

additional information.

• Chapter 3, WaveBook Expansion Options

• Chapter 4, System Power & Assembly

4. Install Software

WaveBook software includes WaveView, a Windows-based data acquisition program. For successful operation, your

computer should have the following, as a minimum:

• Microsoft Windows 95/98/NT

• 5x86 or Pentium

•

16 Mbytes of RAM (32 Mbytes recommended)

Remove any previous-installed version of the WaveBook drivers before installing a new version.

Install software according to the following procedure.

1. Close all other programs. Use the Microsoft Windows Run dialog box and direct Windows to the

found on Disk 1 (or CD-ROM, if applicable). Follow the on-screen dialog boxes to complete the installation.

2. When the installation is complete, check the WaveBook program group and verify all programs are present.

®

processor

SETUP.EXE file

WaveBook User’s Manual,

6-24-99

Quick Start QS-3

Page 12

5. Test your System

After software installation, the hardware must be tested to verify communication between the PC and the WaveBook.

To test hardware performance, the software installs the Daq Configuration applet into the Windows Control Panel.

This tests the PC parallel port (or WBK20/21 interface) capabilities, and then estimates the maximum performance,

using both standard and enhanced protocols. Testing also verifies that the WaveBook is properly attached and ready to

operate.

To run the WaveBook test program:

1. Ensure the WaveBook is connected to the host computer, and both devices are powered-on.

2. Double-click on the Daq Configuration applet (in the Windows Control Panel).

3. Select the WaveBook device.

4. Click on Properties.

5. Click on the Resource Test button (within the Test Hardware tab).

The program performs several tests on the PC and WaveBook and displays the results. Once communication (between

PC and WaveBook) has been established, you can start WaveView and begin to collect data.

6. Start WaveView and Collect Data

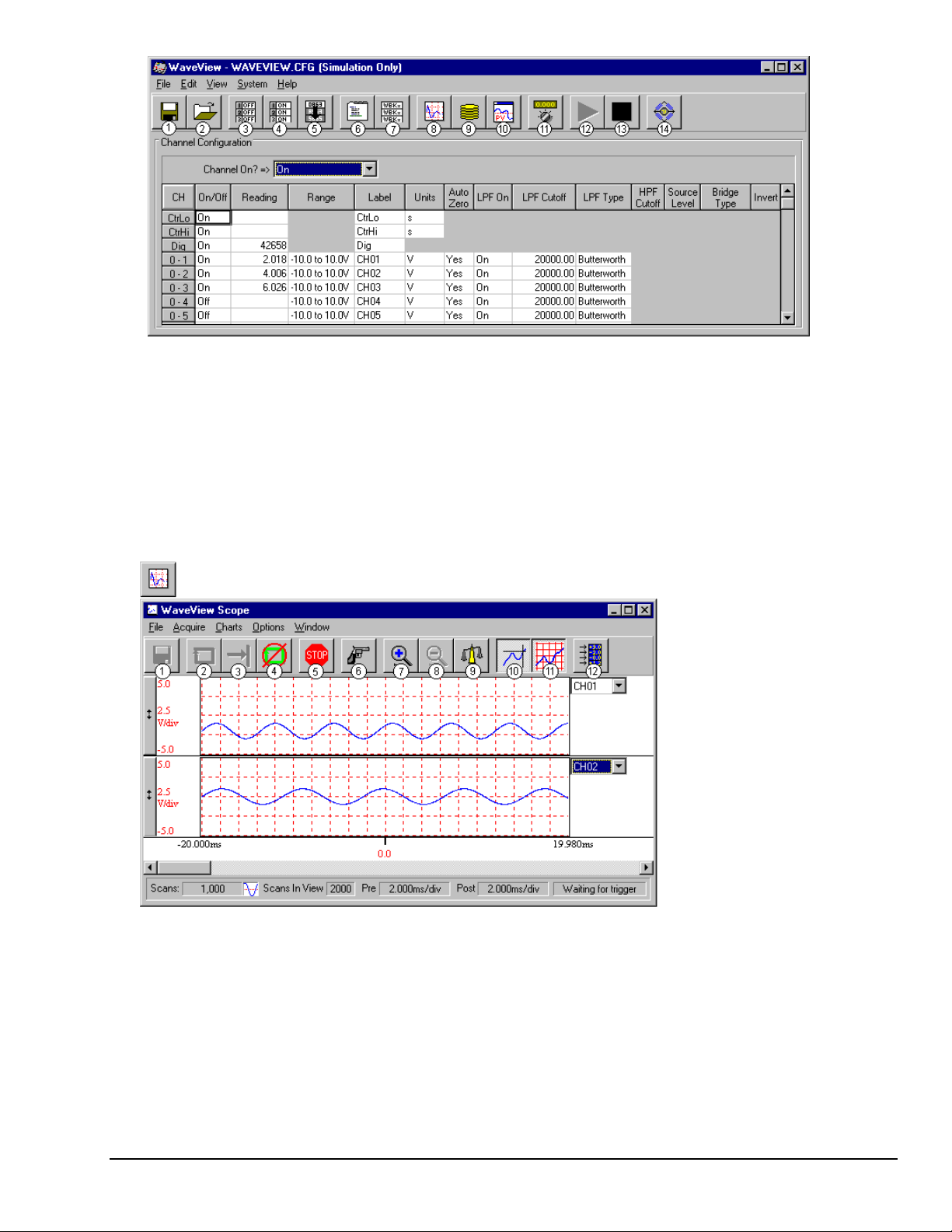

WaveView is a Windows-based application that enables you to acquire data for immediate viewing or for storage to PC

hard disk. No programming knowledge is required.

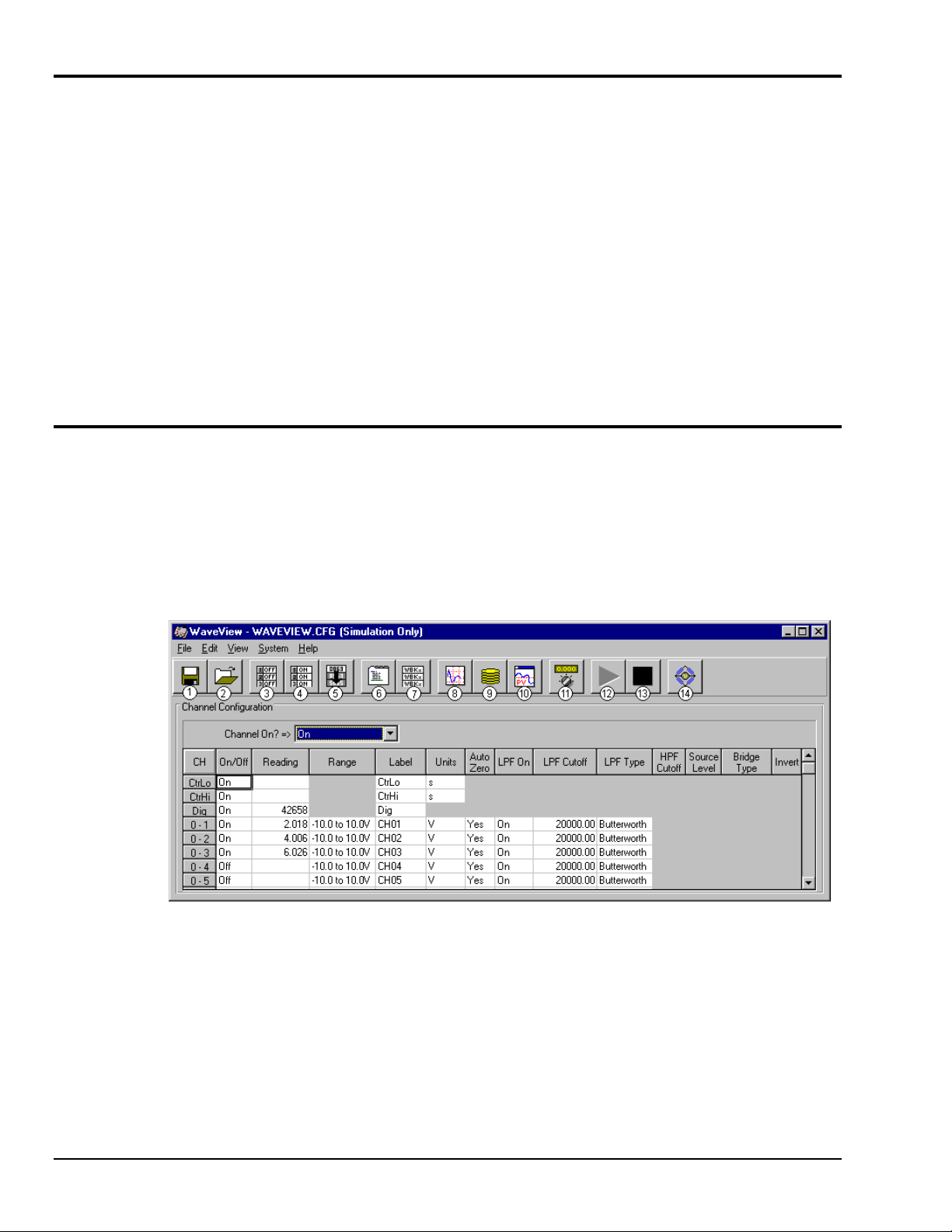

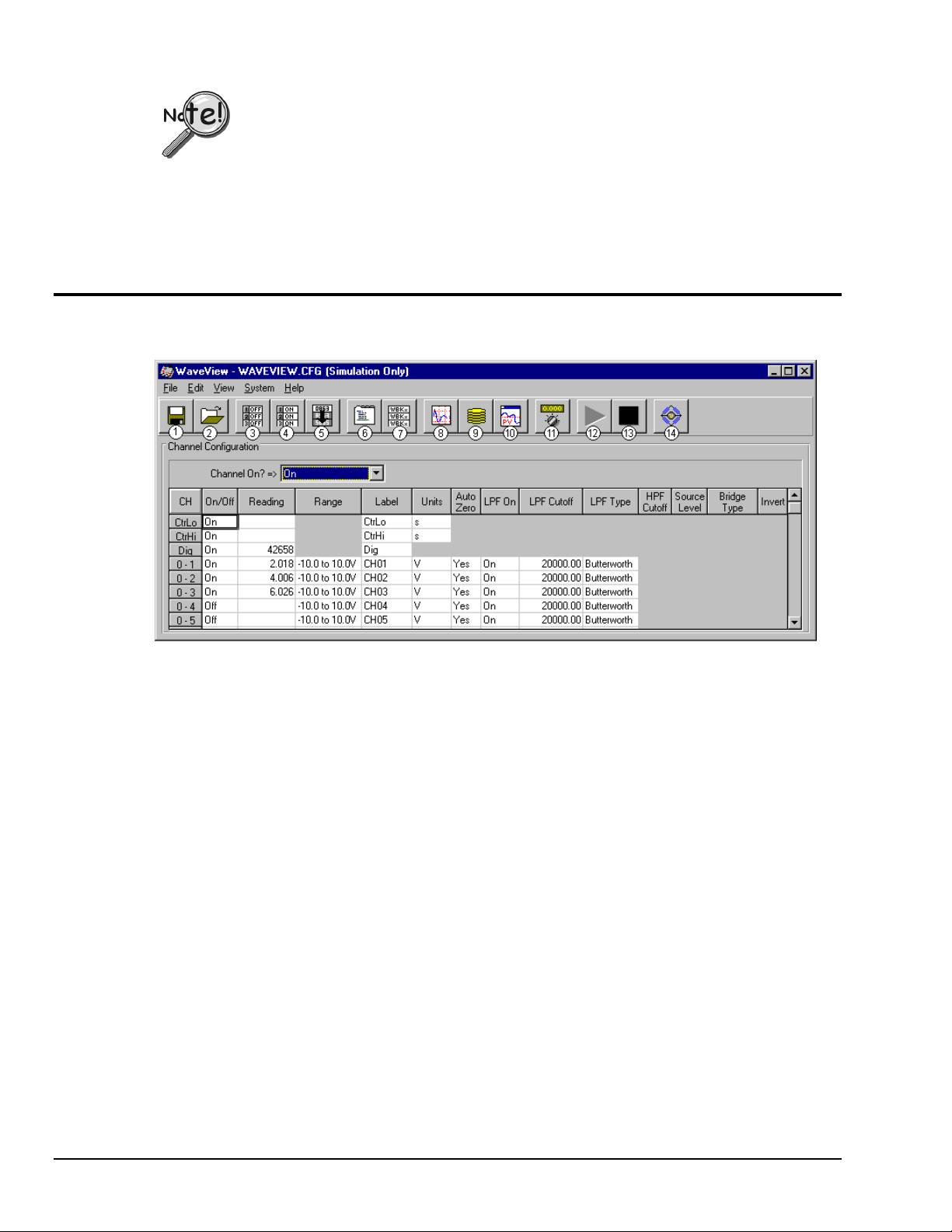

1. Start WaveView by double-clicking on its icon. The WaveView Configuration window appears

(see following figure).

Note: WaveView interrogates the hardware to see what options and expansion modules are connected to the

WaveBook. The total number of channels displayed on the configuration menu corresponds to the number

of channels connected.

WaveView Configuration Window

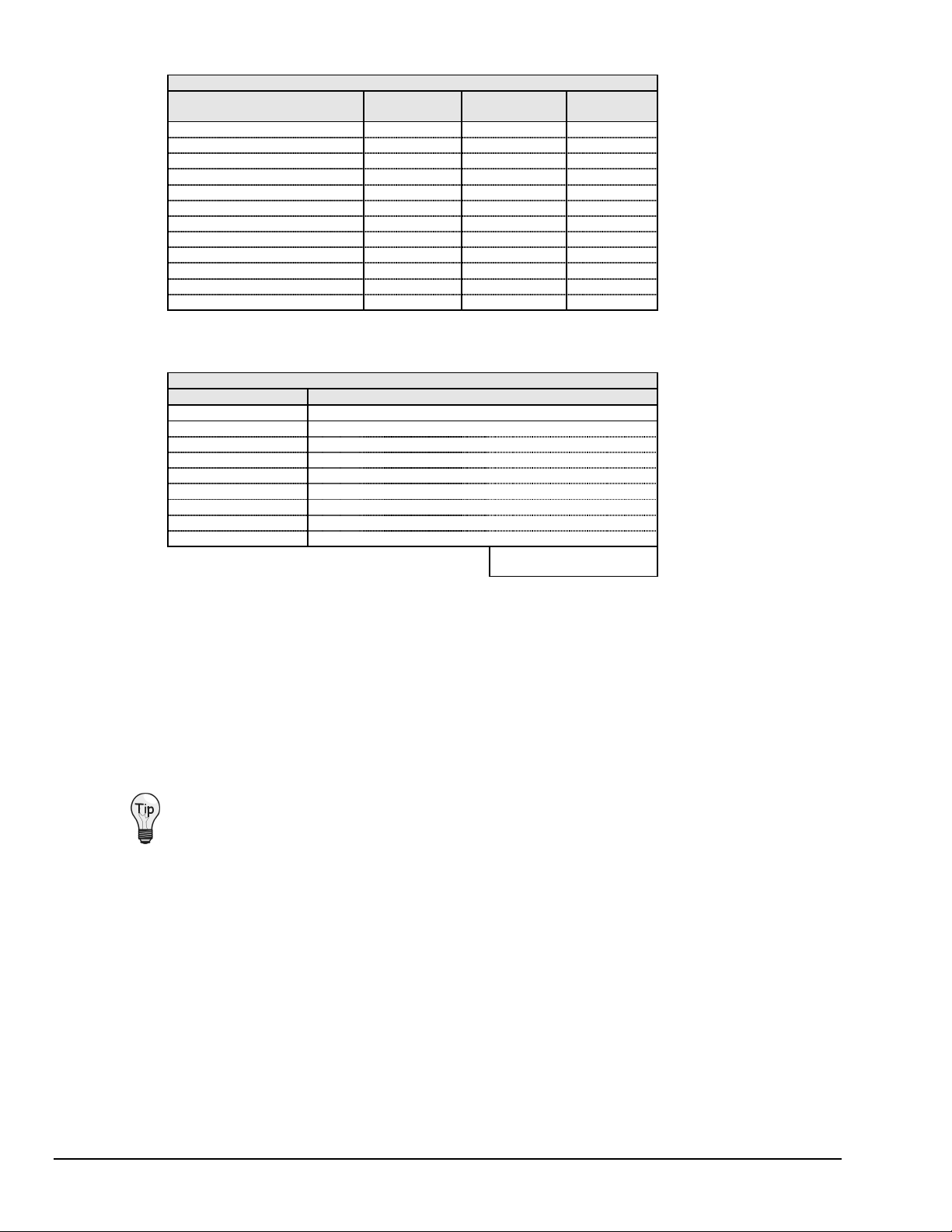

Item Description Item Description

1 Save Configuration 8 Open Scope Window

2 Load Configuration 9 Open Direct to Disk

3 Turn All Channels Off 10 Launch PostView with Latest Acquisition File

4 Turn All Channels On 11 Auto Zero Enabled Channels

5 Fill Down 12 Enable Spreadsheet Reading Column

6 Open Acquisition Configuration Dialog 13 Disable Spreadsheet Reading Column

7 Open Module Configuration Dialog 14 Open WBK16 Sensor Calibration Window

QS-4 Quick Start,

6-24-99

WaveBook User’s Manual

Page 13

2. Turning on a channel allows it to be sampled during an acquisition. To begin acquiring data with WaveView, turn on only

those channels that have signal connections. You can do this by either of the following methods:

(a) Double-click on the channel’s “On/Off” cell to select the proper status. This action toggles the On/Off status.

or

(b) Click once on the channel’s “On/Off” cell, then select “On” or “Off” from the listbox above the spreadsheet.

3. Select the appropriate parameters for each channel. The spreadsheet entries can be changed for all channels by clicking

once on the column label at the top of the spreadsheet to highlight the column, and then making the appropriate entry

within the selection box that appears above the spreadsheet:

• Gain and offset are selected by choosing an entry from the Range entry box.

• A name may be assigned to each channel by editing the Label box for that channel.

•

Volts, millivolts, or mX+b for each channel may be selected within the Units column.

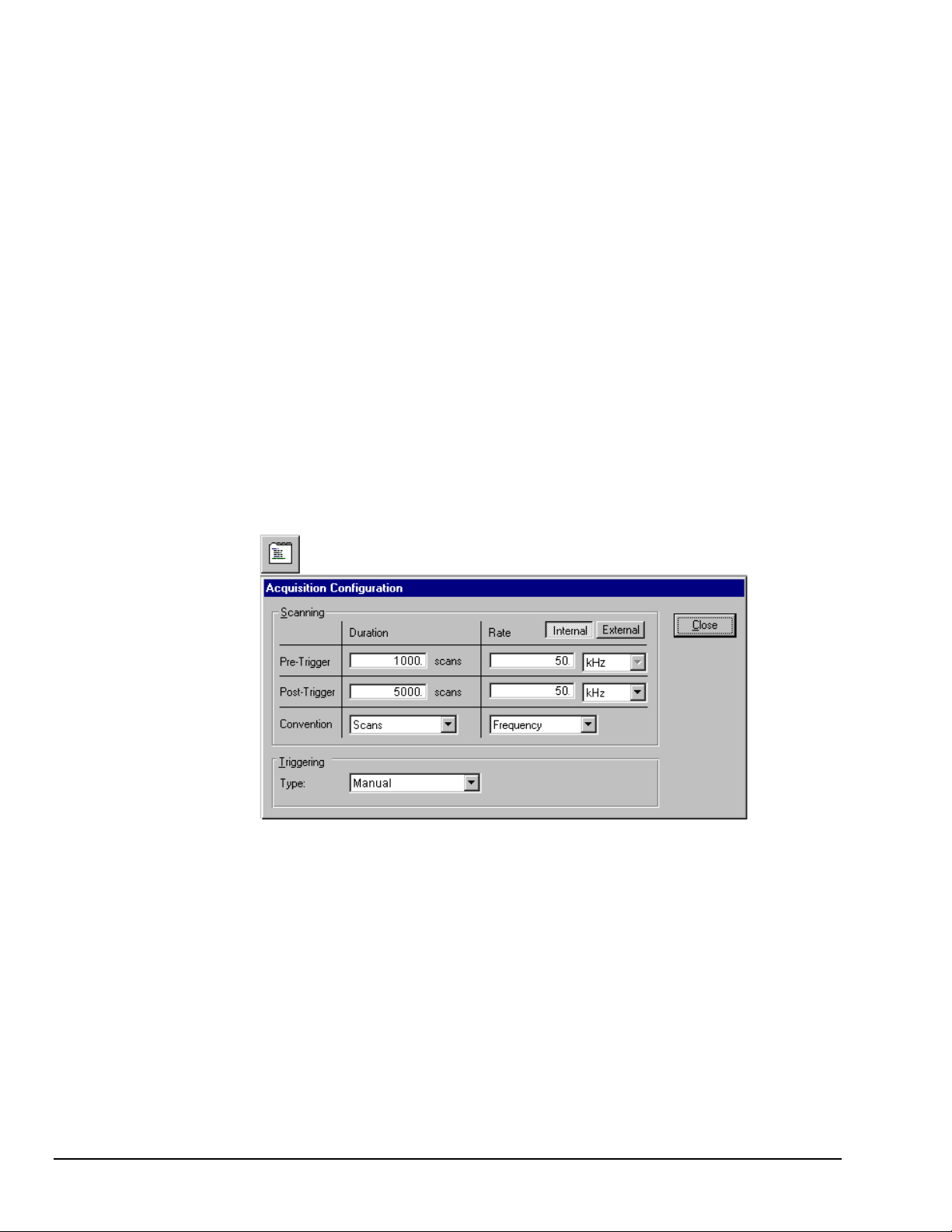

4. Select Acquisition Configuration from the View pull-down menu. When the Acquisition Configuration window is

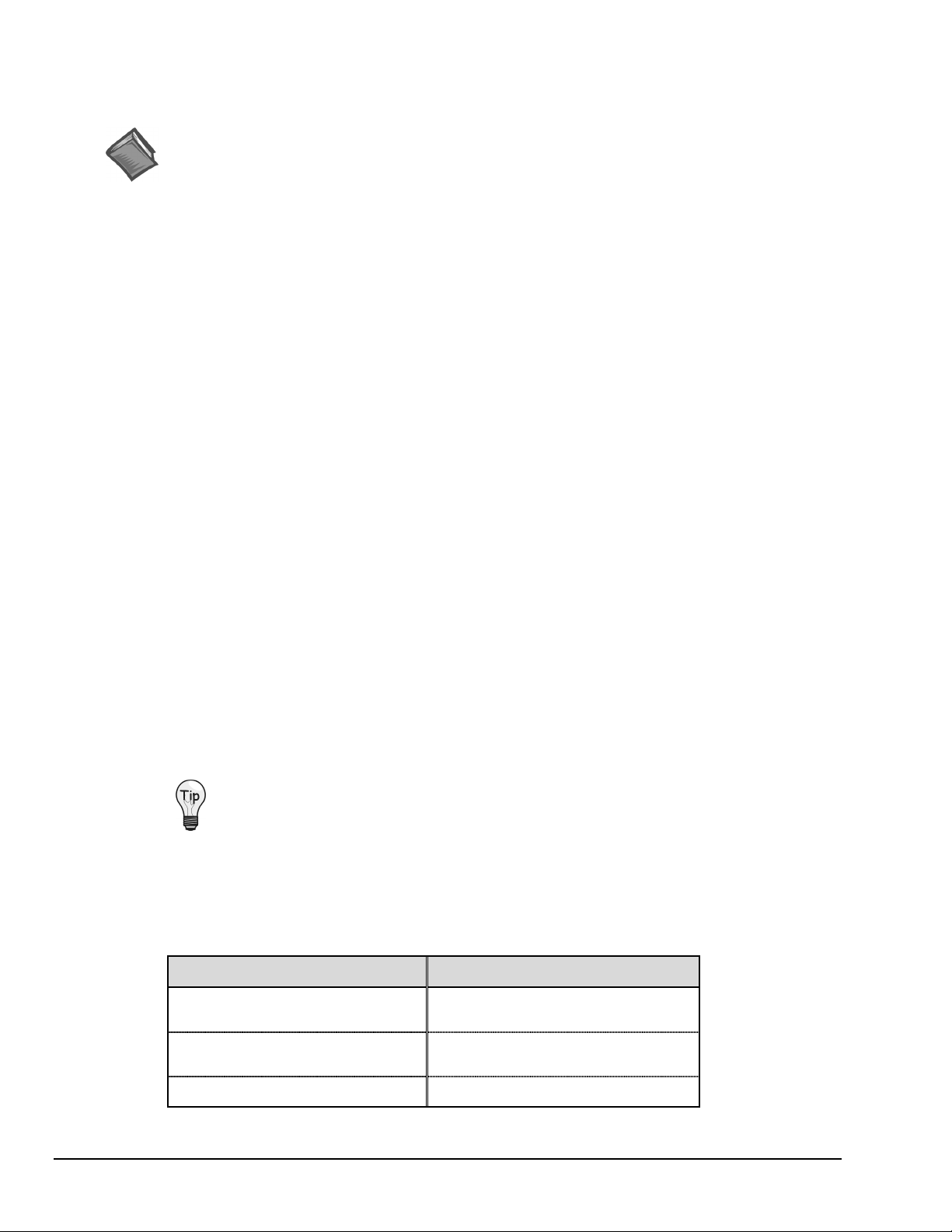

displayed, enter values for Pre-trigger, and/or Post-trigger [scans or time periods] as desired. The timebase for the

acquisition can be set to Frequency or Period. The desired trigger source and parameters are selected in the Trigger

selection box.

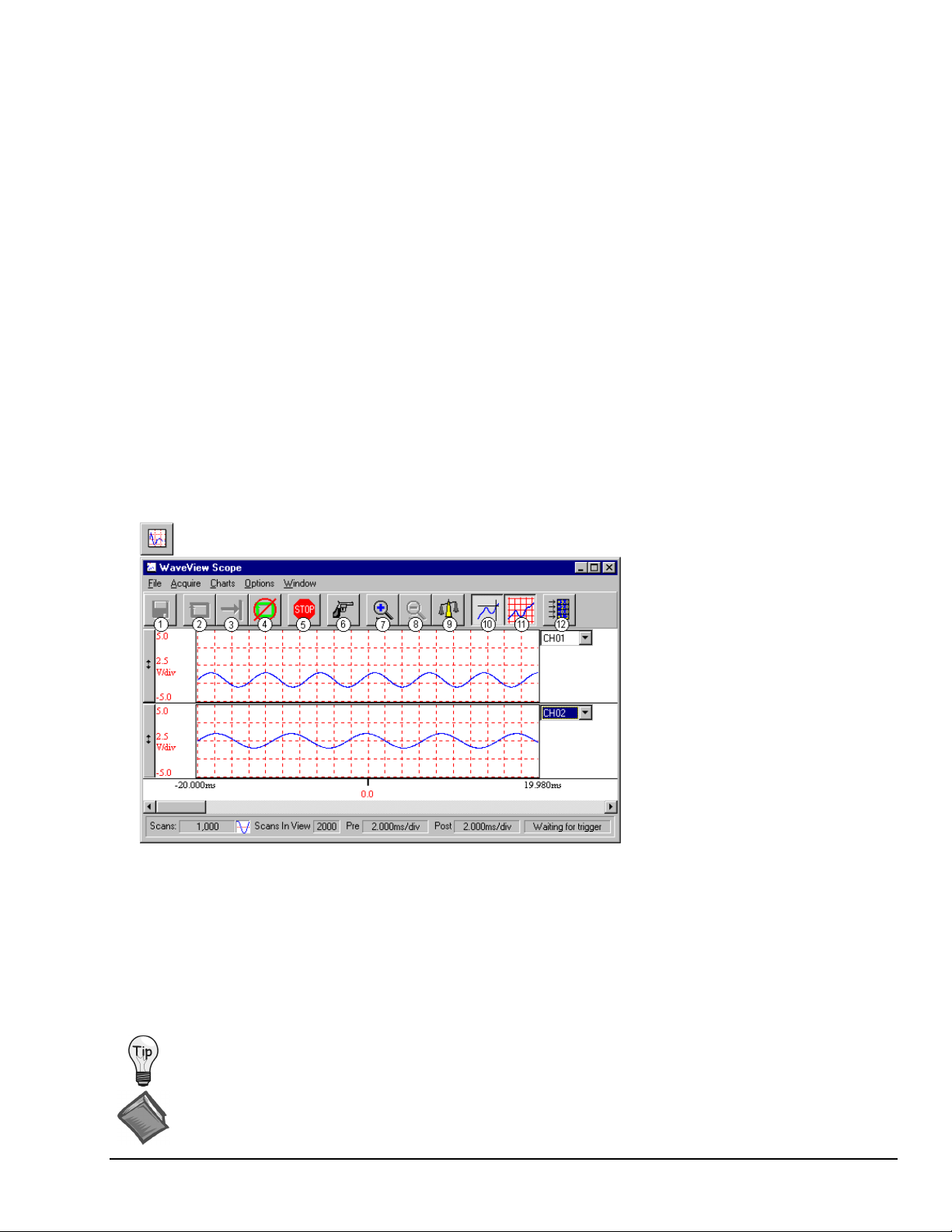

5. To read data from WaveBook:

(a) Select Scope from the View pull-down menu. (The next figure shows a sample Scope screen).

(b) Click the Acquire One Shot button, or the Acquire Continuously button.

(c) Click the Manual Trigger button.

6. If desired, save collected data to disk by clicking on the Save button (“floppy disk” icon (1)),

or use the save option in the File pull-down menu.

WaveView Scope Button and Window

Item Description Item Description

1 Save Data 7 Zoom In

2 Acquire Auto-Rearm 8 Zoom Out

3 Acquire One Shot 9 Scale All Charts

4 Stop After Acquisition Complete 10 Toggle Cross Hairs

5 Stop Immediately 11 Toggle Grids

6 Manual Trigger 12 Open Configuration Window

To view additional channels in Scope Display, simply change the entry in the Number of Charts selection

of the Charts pull-down menu. In Scope Display, you can simultaneously view up to eight channels.

Reference Note:

For detailed WaveView information, refer to Chapter 5.

Chapter 5 includes material on WaveView Scope.

WaveBook User’s Manual,

6-24-99

Quick Start QS-5

Page 14

QS-6 Quick Start,

6-24-99

WaveBook User’s Manual

Page 15

WaveBook Overview 1

Hardware Overview…… 1-1

Product Comparison......1-1

WaveBook Features......1-2

Block Diagrams and board Layouts…… 1-3

WaveBook/512 and 512H......1-4

WaveBook/516……1-5

Hardware Overview

Product Comparison

High resolution and high-speed signal capture make WaveBooks an ideal choice for a variety of

applications, such as testing engine strain, multi-channel acoustics, mechanical integrity, and

vibration/shock/strain.

As listed in the following table, the WaveBook series presently includes three models. Each provides

1 MHz sampling and supports the WBK expansion options described in chapter 3.

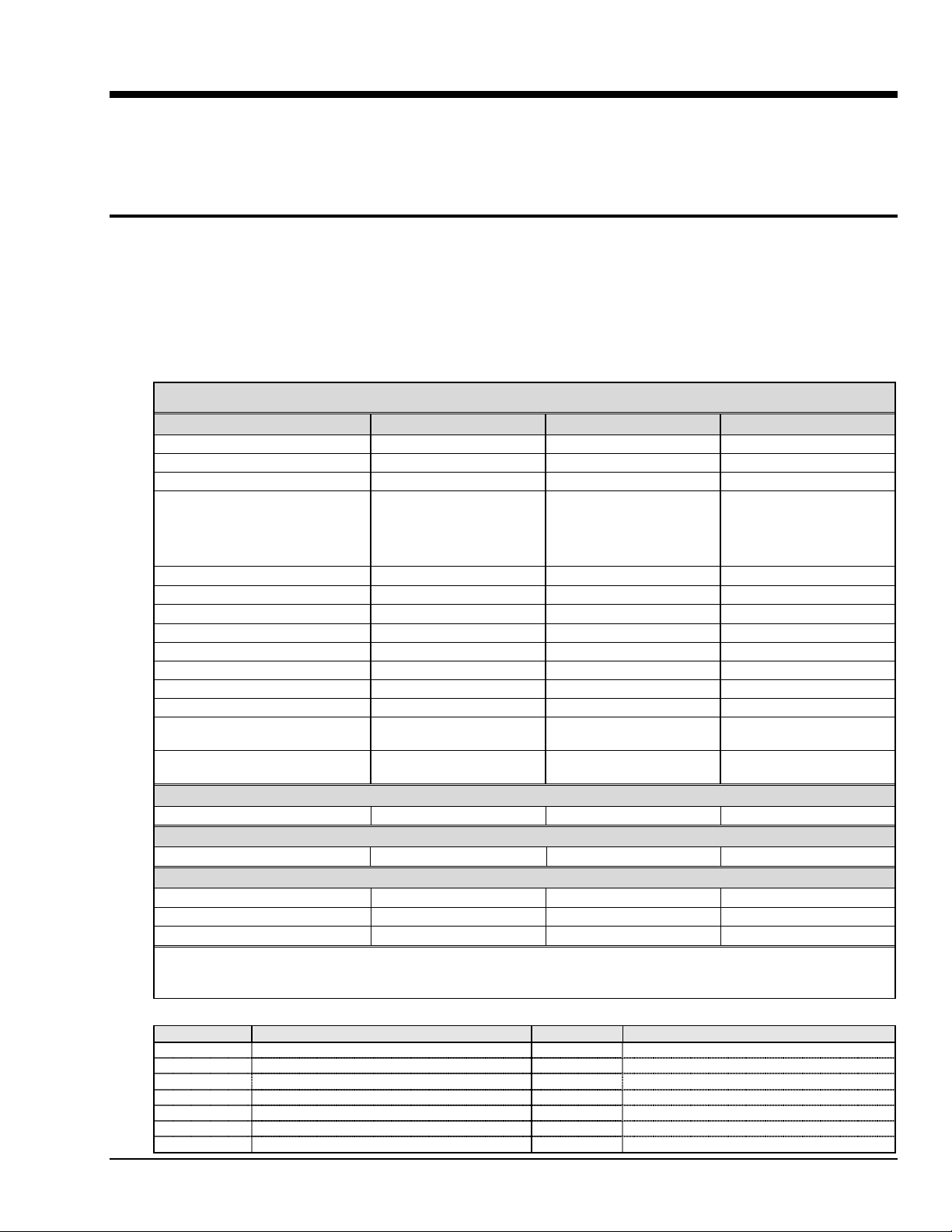

WaveBook Product Comparison*

Analog Input WaveBook/512 WaveBook/512H WaveBook/516

A/D resolution

A/D speed

Sample rate

Ranges

Unipolar (

Bipolar

A/D accuracy

Data packing

20-kHz low-pass filter

Analog input channels

Differential amplifiers

PGAs

Maximum capacity

FIFO depth

Total Harmonic Distortion

10Hz to 20Khz, Typical

Signal to Noise and Distortion

(SINAD)

High-Speed Digital Inputs

Digital I/O

Timer Input

32-Bit Timer

Trigger

Single and multi-channel

Digital Pattern

Pulse

1

For WaveBook512, the Total Harmonic Distortion (THD) and SINAD values shown apply to the –5 to +5 V range.

For WaveBook512H and /516, the THD and SINAD values apply to the –10 to +10 V range.

2

Unipolar ranges do not apply to WaveBook/512H or WaveBook/516 when a WBK11, WBK12, or W BK13 is installed.

Specifications subject to change without notice.

*

Module Description Module Description

DBK30A

DBK34

WBK10/10H

WBK11

WBK12

WBK13

WBK14

WaveBook User’s Manual

Note 2)

1

Rechargeable battery module

Vehicle Uninterruptible Power Supply module

8-channel Expansion Chassis

Simultaneous Sample & Hold (SSH) Card

Programmable Low-Pass Filter Card

Programmable Low-Pass Filter Card with SSH

Dynamic Signal Conditioning Module

6-25-99

Software Overview......1-6

WaveView Features......1-6

Programming Environments…… 1-8

Standard API (wbk…)…… 1-8

Enhanced API (daq…)…… 1-8

Language Support…… 1-8

12-bit 12-bit 16-bit

1 MHz 1 MHz 1 MHz

1 µs/channel 1 µs/channel 1 µs/channel

0 to +10V, 0 to +5V,

0 to +2V, 0 to +1V

±5V, ±2.5V, ±1V, ±0.5V

±0.025% FS ±0.025% FS ±0.012% FS

44

optional optional

8 DE 8 DE 8 DE

1 (shared by all 8 inputs) 1 (shared by all 8 inputs) 8 (1 per analog input)

1 (shared by all 8 inputs) 1 (shared by all 8 inputs) 1 (shared by all 8 inputs)

72 Channels 72 Channels 72 Channels

64K samples 64K samples 64K samples

1

-78dB -78dB -84dB

-66dB -66dB -74dB

8816

None None

444

None None

None None

0 to +10V, 0 to +4V,

0 to +2V

±10V, ±5V, ±2V, ±1V

WBK15

WBK16

WBK20A

WBK21

WBK30

WBK61/62

(Note 2)

8-Slot 5B Signal Conditioning Module

Strain-Gage Module

PC-card / parallel port interface and cable

ISA/EPP Interface Plug-in Board

WaveBook Memory Option

High-Voltage Adapter and Probes

0 to +10V, 0 to +4V,

0 to +2V

±10V, ±5V, ±2V, ±1V

For 12-bit resolution only

WaveBook Overview 1-1

(Note 2)

4

4

4

4

Page 16

WaveBook Features

WaveBook features include:

• Power Options: Power can be supplied from an AC-to-DC adapter, battery, DBK30A rechargeable

battery module, or DBK34 uninterruptible power supply module.

• Easy Connection to Notebook or Desktop PCs.

• Analog Input Channels: BNC connectors keep input signals isolated from the chassis and commons.

• High-Speed Digital Inputs: 8 high-speed digital inputs (16 for WaveBook/516).

• Digital Signal Processing (DSP): Allows you to define a channel scan-sequence and associated gains

across all channels. Also provides for real-time digital calibration on a per-sample basis.

• Programmable Scan Sequencing: A 128-location scan sequencer allows you to program the analog

channel scan sequence, the associated unipolar/bipolar A/D range, and the input amplifier gain.

WaveBook performs 1 MHz scanning and gain switching over both its built-in and expansion channels.

• Single, or Multi-Channel Triggering

• Pre- and Post-Trigger Readings

• Digital-Pattern Trigger (WaveBook/516 Series Only): Trigger occurs when a Digital I/O pattern is

equal too, not-equal too, greater than, or less than a user-defined 16-bit digital pattern. This is useful

when trying to capture noise, vibrations or some other physical disturbance that occurs at a particular

point in a digitally-sequenced process, such as a relay-logic-control system. Trigger latency of the

digital pattern trigger is less than 200 ns for post-trigger acquisitions.

• Pulse Trigger (WaveBook/516 Series Only): Enables triggering and the correlation of lower-speed

waveforms with the occurrence of a user-defined, high-speed pulse.

• 20 kHz Low Pass Filter (WaveBook/516 Series Only): Each of the eight channels has its own low

pass, anti-alias filter.

• External Clock Input (WaveBook/516 Series Only): The external clock is useful when data collection

depends on rotational speed or axial position. Note that the external clock’s input can be reset to a

slower rate.

Reference Note:

In regard to WaveBook expansion options, refer to chapter 3.

1-2 WaveBook Overview,

6-25-99

WaveBook User’s Manual

Page 17

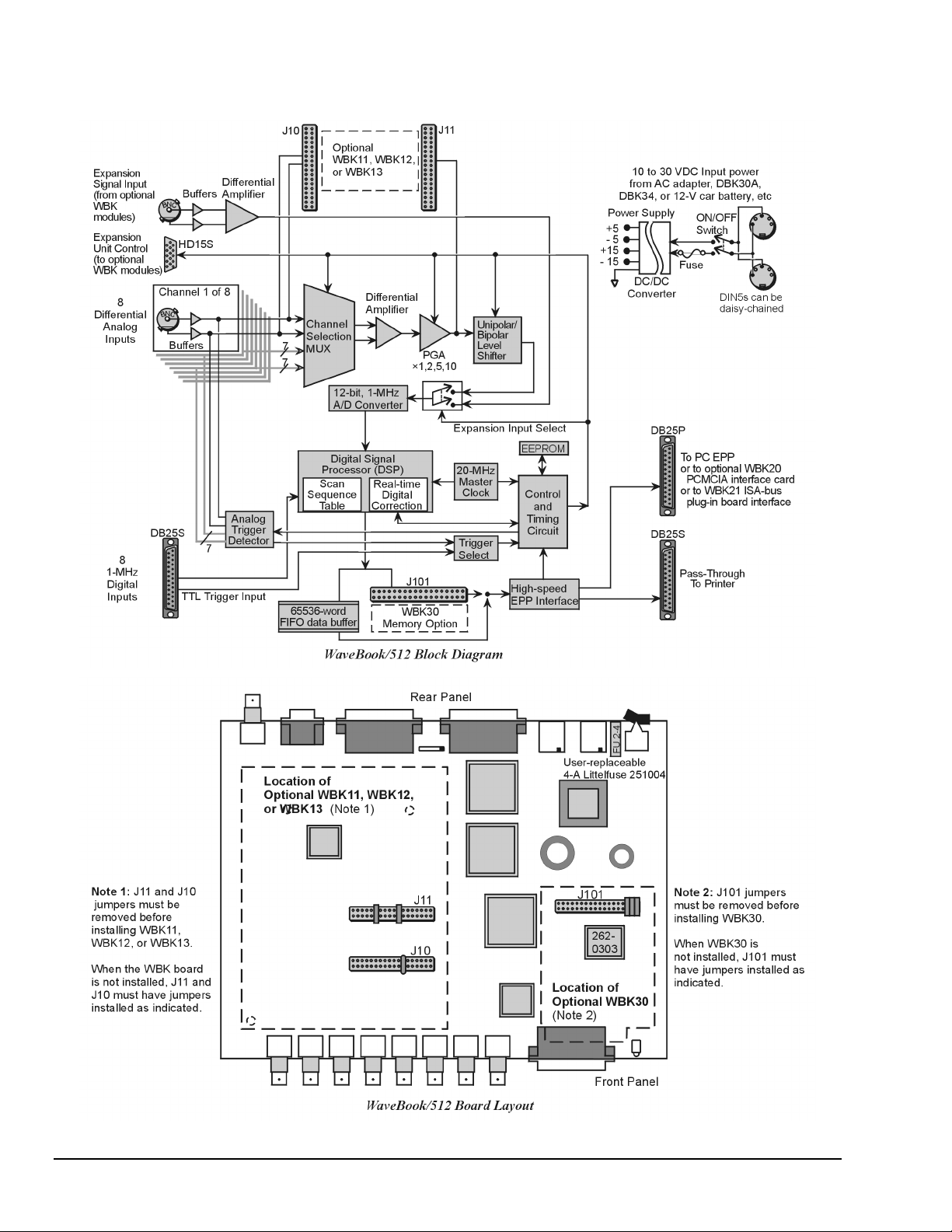

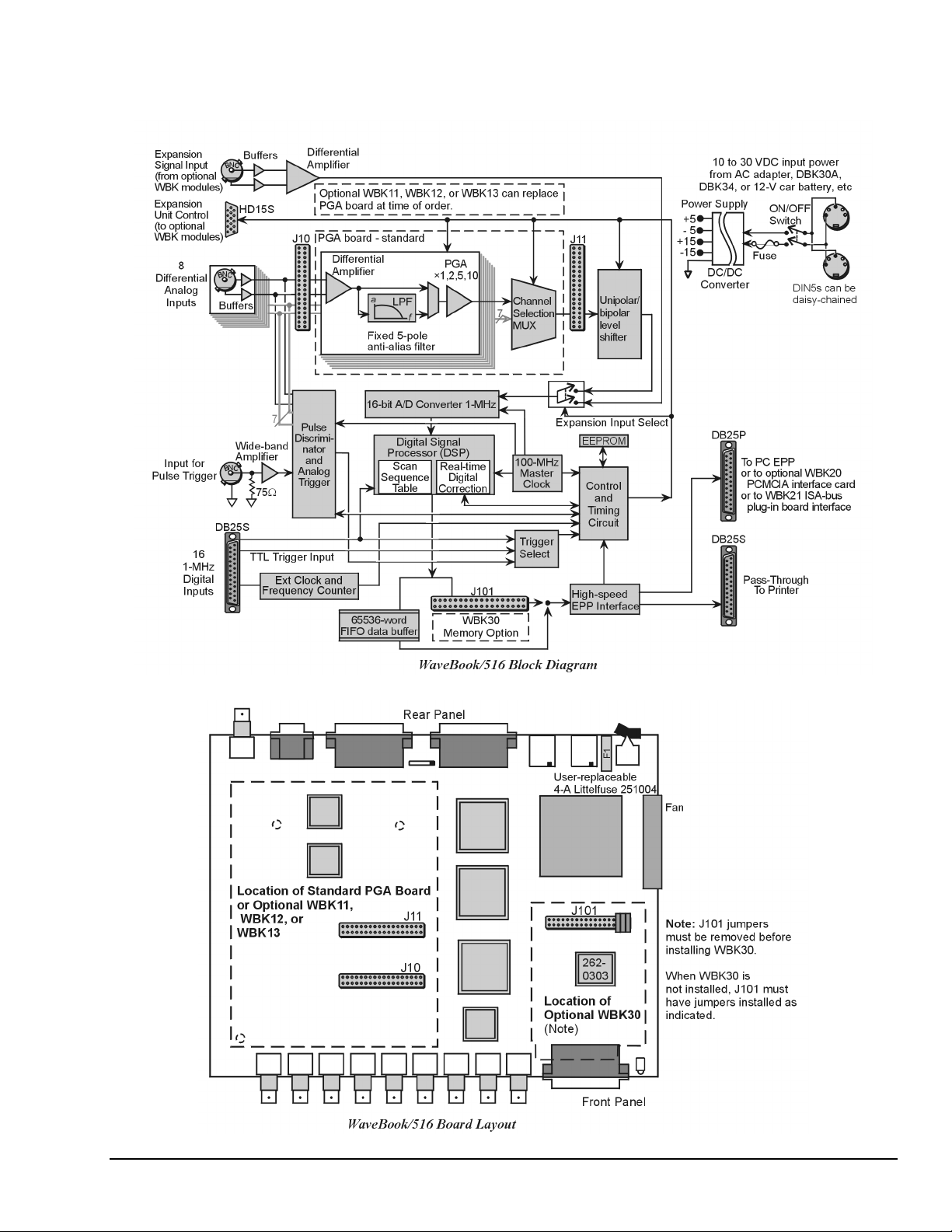

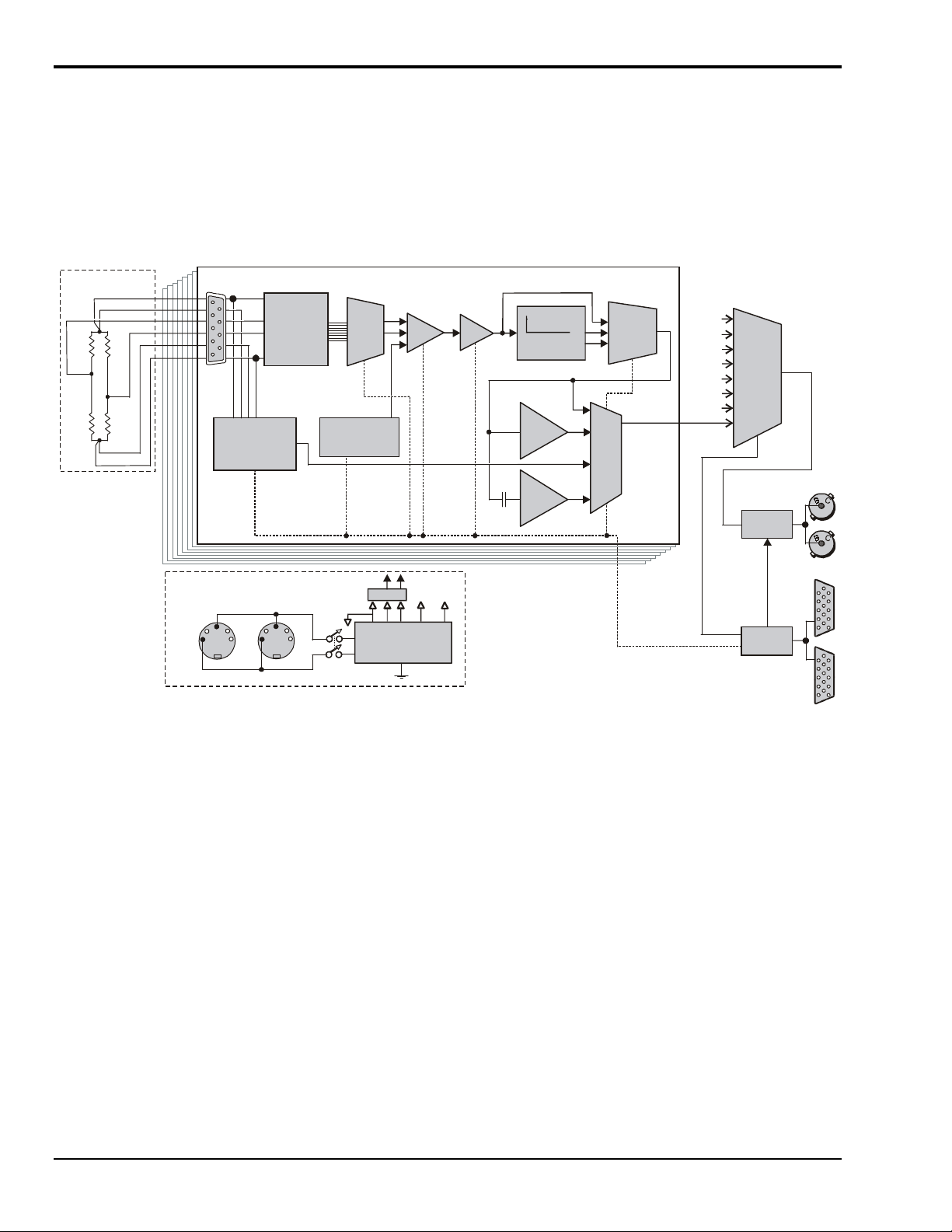

WaveBook Block Diagrams and Board Layouts

Reference Notes: Pages 1-4 and 1-5 contain the functional block diagrams and board layouts for

WaveBook/512, WaveBook/512H, and WaveBook/516. Chapters 3 and 4 include block diagrams for

WBKs and DBKs, respectively. Simple board layouts have been included when considered useful.

The following block diagrams should help you to better understand the information below.

For all three models (/512, /512H, and /516), the analog input signal path proceeds as follows:

• WaveBook/512 and WaveBook/512H: Each of the 8 pairs of differential signals (one per BNC

connector) is buffered and then switched by the channel-selection multiplexer.

•

The selected differential pair is then converted to a single-ended signal by the programmable gain

amplifier (PGA). The WaveBook/512 has gain factors of ×1, ×2, ×5, or ×10 (corresponding to input

ranges of 10, 5, 2, or 1 volts). The /512H gain factors are similar.

•

WaveBook/516: Each of the 8 pairs of differential signals (one per BNC connector) is buffered and

applied to a differential amplifier. The output of each differential amplifier is applied to a 5 pole, low

pass filter. The 8 channels and their low pass signals are then switched by the channel-selection

multiplexer into a the programmable gain amplifier (PGA). The WaveBook/516 has gain factors of

×1, ×2, ×5, or ×10 (corresponding to input ranges of 10, 5, 2, or 1 volts).

• The amplified signal is then level-shifted to locate the desired range within the A/D converter's fixed

input range. Two offset settings are available, unipolar and bipolar. Unipolar offset is used for

sampling signals that are always positive. Bipolar offset is used for signals that may be positive or

negative. For example, when a /512, or /516 is set for unipolar at a gain of ×5, the input span is 2 volts

and the amplified signal is offset so that input voltages from 0 to +2 volts can be digitized. When set

for bipolar operation, the offset is adjusted so that input voltages from -1.0 to +1.0 volts can be

digitized.

• The signal is then switched over to the A/D converter. For /512 and /512H units, the A/D converter

digitizes the signal to12 bits in 1 µs. For WaveBook/516, the A/D converter digitizes the signal to

16 bits in 1 µs. Note that the A/D converter's input can be switched to the expansion signal input,

allowing the device to read one of 64 possible expansion channels (supplied by up to eight WBK10

expansion chassis).

The digital signal processor (DSP) processes the digitized value and corrects the value for gain and offset

errors. The DSP places the corrected result into the FIFO data buffer that holds the samples until the PC

reads the data. If the sample is used for triggering, the DSP determines if a valid trigger event has occurred.

The WaveBook also includes low-latency analog or TTL-level triggering. The low-latency analog trigger

detector examines the WaveBook input channel 1 to determine if a trigger has occurred. The selected lowlatency trigger is presented to the control and timing circuit that starts the acquisition after the trigger. The

TTL trigger is taken directly from the digital I/O port.

The control and timing circuit and the DSP together coordinate WaveBook activities. Every sample time,

the DSP reads from the scan sequence table and accordingly programs the control and timing circuit for the

next sample. The control and timing circuit waits precisely until the start of the next sample and then selects

the input channel, the PGA gain, the level-shifter offset, and the A/D input source. It also conveys this

information to any attached expansion units and precisely controls the A/D conversion timing.

WaveBook User’s Manual

6-25-99

WaveBook Overview 1-3

Page 18

WaveBook/512 and /512H, Block Diagram and Board Layout

The illustrations on this page can be used for both WaveBook/512 and WaveBook/512H.

1-4 WaveBook Overview,

6-25-99

WaveBook User’s Manual

Page 19

WaveBook/516 Block Diagram and Board Layout

The illustrations on this page only apply to WaveBook/516.

WaveBook User’s Manual

6-25-99

WaveBook Overview 1-5

Page 20

The EEPROM holds the calibration information needed for the DSP-based real-time sample correction.

The digital I/O port is read and written by the DSP to transfer bytes of digital data. It may be used as a

simple 8-bit input port or as a 32-address byte-wide I/O port.

The high-speed EPP interface circuit connects the WaveBook and any attached printer to the PC via

standard DB-25 connectors. When the WaveBook is active, the interface holds the printer in a stable state;

and when the WaveBook is inactive, the interface connects the PC to the printer.

Pin-header J101 allows the addition of the WBK30 memory option. The WBK30 is discussed in chapter 3.

Pin-headers J10 and J11 allow the addition of the optional WBK11, WBK12, or WBK13. These cards can

also be added toWBK10/10H expansion modules.

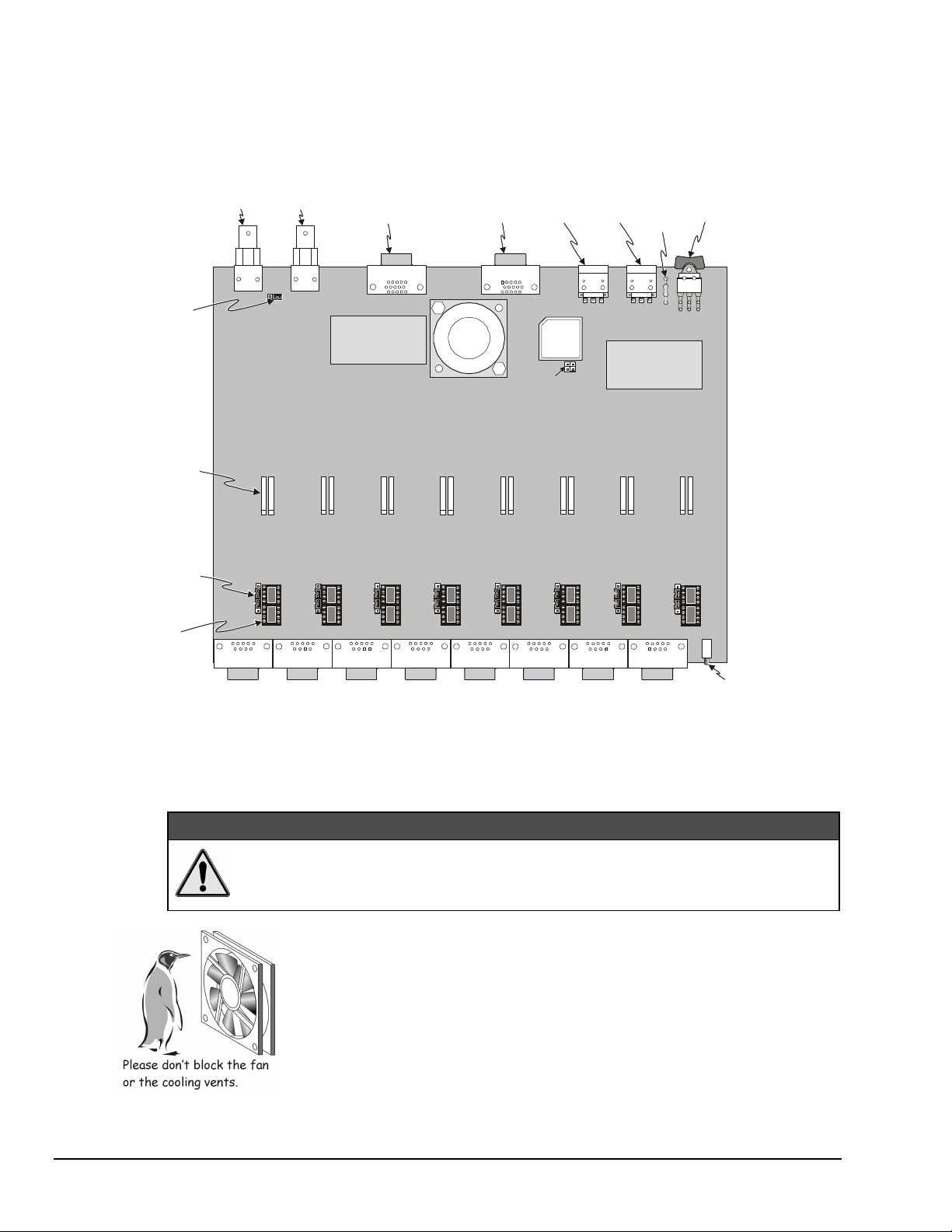

WaveBook/516’s Fan

To maintain sufficient cooling, it is important to keep the fan and vents free of obstruction.

Note: Partial blocking that results from the use of splice plates does not jeopardize cooling.

Software Overview

WaveBook provides for several software options.

• WaveView, PostView, and WaveCal are the "out-of-the-box" programs included with the hardware.

WaveView provides visual representation of the collected data in real-time or an extended-time view

via PostView. WaveCal uses a 2-pt linear approximation method to calculate gain and offset errors for

each channel..

Reference Note:

WaveView, PostView, and WaveCal are discussed in chapters 5, 6, and 7, respectively.

• DASYLab is a customizable graphical application that allows you more options in designing your

operator interface or performing real-time analysis or control. DASYLab is documented separately.

• Programming environments include standard and enhanced Application Programming Interfaces

(API) with drivers for popular languages. Refer to Appendices C and D for detailed API information.

WaveView Features

WaveView is a Windows-based setup and acquisition program that allows you to configure, display, and

save data to disk within minutes of unpacking the WaveBook. The point-and-click interface simplifies

hardware setup including WBKs without programming or connecting icons. The intuitive control

automatically queries the WaveBook upon connection to your PC. As WBK options are added for signal

conditioning or increased channel count, WaveView's configuration spreadsheet automatically expands to

accommodate them. Specific channel characteristics, such as gain, unipolar/bipolar, and channel labels are

automatically updated. Additional functions (such as low-pass filtering, filter cut-off, or excitation output)

appear in the configuration spreadsheet.

The following two figures show the configuration window and a scope/display window:

1-6 WaveBook Overview,

6-25-99

WaveBook User’s Manual

Page 21

WaveView Configuration Window

Item Description Item Description

1 Save Configuration 8 Open Scope Window

2 Load Configuration 9 Open Direct to Disk

3 Turn All Channels Off 10 Launch PostView with Latest Acquisition File

4 Turn All Channels On 11 Auto Zero Enabled Channels

5 Fill Down 12 Enable Spreadsheet Reading Column

6 Open Acquisition Configuration Dialog 13 Disable Spreadsheet Reading Column

7 Open Module Configuration Dialog 14 Open WBK16 Sensor Calibration Window

WaveView Scope Button and Window

Item Description Item Description

1 Save Data 7 Zoom In

2 Acquire Auto-Rearm 8 Zoom Out

3 Acquire One Shot 9 Scale All Charts

4 Stop After Acquisition Complete 10 Toggle Cross Hairs

5 Stop Immediately 11 Toggle Grids

6 Manual Trigger 12 Open Configuration Window

WaveBook User’s Manual

6-25-99

WaveBook Overview 1-7

Page 22

Programming Environments

Reference Note:

Individuals who want to write their own applications programs should refer to Appendices C and D for

detailed API information.

The install disks (or CD-ROM) include “drivers” to accommodate various programming environments. This

section will help you decide which Application Program Interface (API) and programming language to use

in developing your application. WaveBook applications can be written to either the Standard WaveBook

API or to the Enhanced Daq* API:

• The Standard API has the same format (only written to 32-bit mode) as the 16-bit Windows 3.X version of the

driver. Standard API functions have the specific wbk… prefix.

• The Enhanced API is a newer format that can be used with the WaveBook, DaqBook, DaqBoard, Daq PC-Card

and TempBook product lines. Enhanced API functions share the daq… prefix.

In general:

• You cannot mix standard and enhanced API commands; you must choose one or the other.

• If starting with an existing WaveBook application written to Windows 3.X, the quickest port is to use or rewrite

code to the Standard API.

•

If writing a new application, it is best to write code to the Enhanced API due to its improved performance and

enhanced feature set (see following).

Standard API (wbk…)

The Standard API was originally written for the WaveBook’s Windows 3.X driver. However, it can be

used under Windows 95/98 in 16-bit or 32-bit mode; and under Windows NT in 32-bit mode. The Standard

API is the only API option available for DOS or Windows 3.X applications. The standard API does not

support the WBK30 memory option. You can use the Standard API when:

• developing a new or existing DOS application

• developing a new or existing Windows 3.X application

• a quick port of an existing 16-bit Windows 3.X application to 32-bit mode Windows 95/98/NT is required

Enhanced API (daq…)

The Enhanced API for 32-bit systems has several features that are not present in the Standard API:

•

Multi-device: Can concurrently handle up to 4 devices (including WaveBooks, Daq* products, and/or

TempBooks)

• Larger buffer: Can handle up to 2 billion samples at a time

•

Enhanced acquisition and trigger modes

• Direct-to-disk capabilities

• Wait-on-event features

•

Uses multi-tasking advantages of Windows 95/98/NT

Use the Enhanced API when:

• developing new or existing Windows 95/98 applications

•

developing new or existing Windows NT applications

• using a WBK30 memory option

• porting an existing Standard API application to 32-bit mode to take advantage of the Enhanced API features

Language Support

Enhanced API (or 32-bit Standard)

Supported Languages

C/C++

Microsoft Visual C++

Borland C++ (v4.0 and greater)

BASIC

Microsoft Visual Basic (v4.0 and greater)

Delphi

Borland Delphi (v2.0)

1-8 WaveBook Overview,

When creating your own programs, use the Enhanced API (daq…), if feasible.

Standard API (16-bit)

Supported Languages

C/C++

Microsoft Visual C++

Borland C++ (v4.0 and greater)

BASIC

Microsoft Visual Basic (v4.0 and greater)

QuickBASIC

Pascal

Turbo Pascal

6-25-99

WaveBook User’s Manual

Page 23

Setup Notes and System Testing 2

Hardware Setup Notes …… 2-1

WBK20A – PCMCIA/EPP Interface Card (for linking WaveBook to a Notebook PC) …… 2-1

WBK21 – ISA/EPP Interface Card (for linking W aveBook to a Desktop PC) …… 2-2

Optional Printer Connection ……2-4

Analog-Signal Connections & Grounds ……2-4

Digital I/O Connection (WaveBook/512 and /512H) ……2-5

Digital I/O Connection (WaveBook/516 Series Only) ……2-5

Pulse Trigger Connection (WaveBook/516 Series Only) ……2-6

System Testing …… 2-6

This chapter is intended primarily for users having systems that are beyond the scope of the Quick Start (presented at

the beginning of this manual).

Reference Note: For more advanced system setups, you should refer to the following, as needed.

• Chapter 3 – discusses WBK expansion options.

• Chapter 4 – pertains to system power use and mechanical assembly options.

• If using the WBK20A or WBK21, refer to separate instructions, supplied with that device.

Hardware Setup Notes

If you are connecting your WaveBook to a Notebook PC, you will be using a WBK20A, PCMCIA Interface

Card. If connecting WaveBook to a desktop PC, you will use a WBK21 ISA/EPP Interface Card. Both

interface types are detailed in the following text.

Electrical Shock Hazard! Perform all hardware setups with all power off to the device serviced

and to all connected equipment; otherwise, personal injury may result.

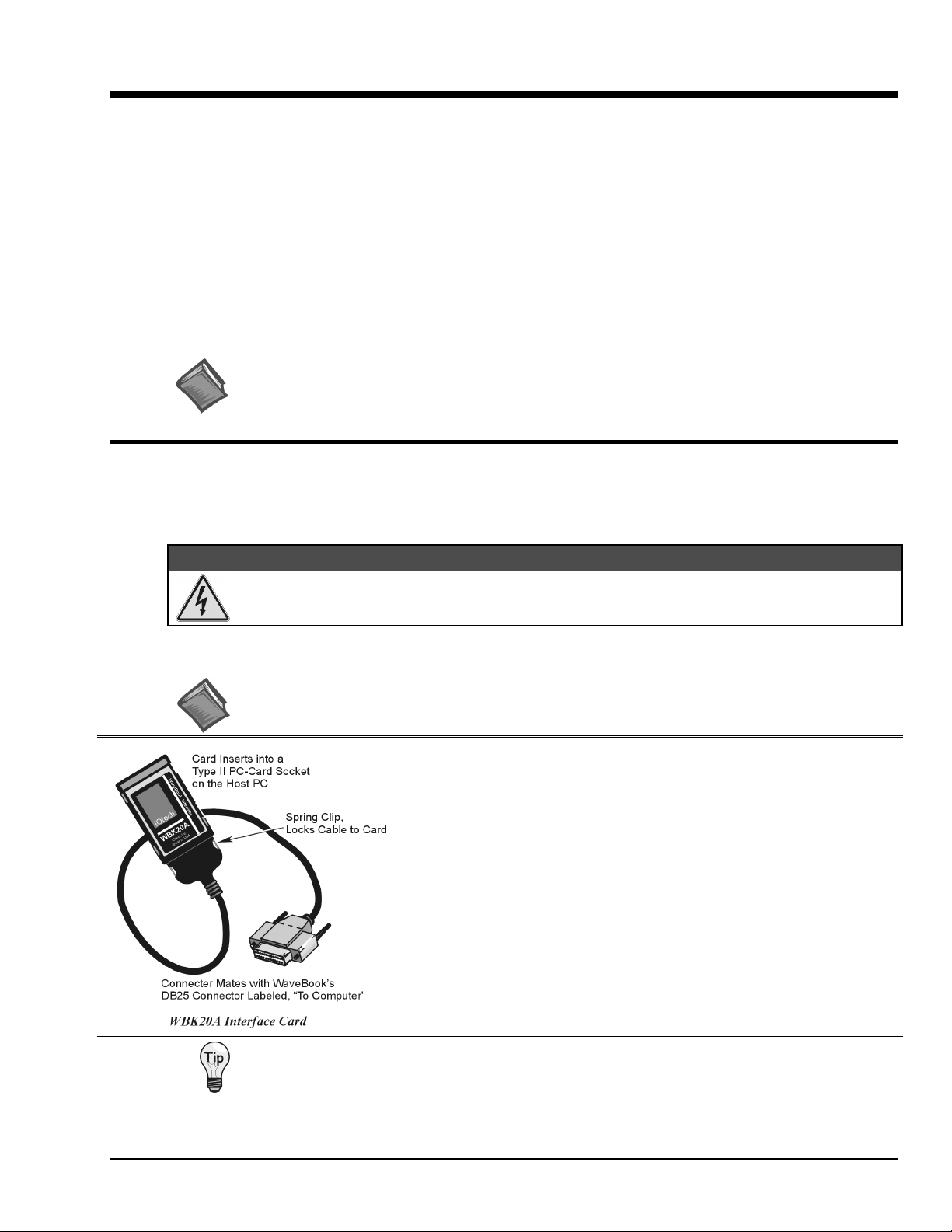

WBK20A - PCMCIA/EPP Interface Card

Reference Note:

WBK20A is shipped with a PC-Card-to-Parallel-Port Adapters User’s Manual.

Refer to that document for installation details.

To link a WaveBook to a Notebook PC using a WBK20A:

1. Insert the WBK20A card into a Type II PCMCIA socket on the Notebook.

2. Connect cable (CA-191-1) to the PCMCIA card.

3. Connect the cable’s DB-25 socket-connector to WaveBook's DB25 plug

connector labeled “TO COMPUTER.”

4. Load the required software drivers by following the instructions provided

with the WBK20A.

Note that no hardware configuration is required. Software configuration is

performed from within the provided software.

WARNING

WARNING

WARNINGWARNING

(for linking WaveBook to a Notebook PC)

Record the WBK20A DMA address and IRQ interrupt settings for future reference.

WaveBook User’s Manual

6-23-99

WaveBook Setup 2-1

Page 24

To ensure proper operation of WBK20A card, you will need to boot up the computer with

the WBK20A inserted in the PC’s card slot. Failure to do so may prevent the application

software from recognizing the card as a parallel port device.

You can use the earlier version WBK20 card/cable to connect your WaveBook to a

Notebook PC. WBK20 is identical to WBK20A in performance, but requires a different

cable (CA-157-1). WBK20A uses cable CA-191-1, which locks to the card.

It is important to note that these two cables are not interchangeable.

WBK20A - Specifications

Specifications are provided in Appendix A.

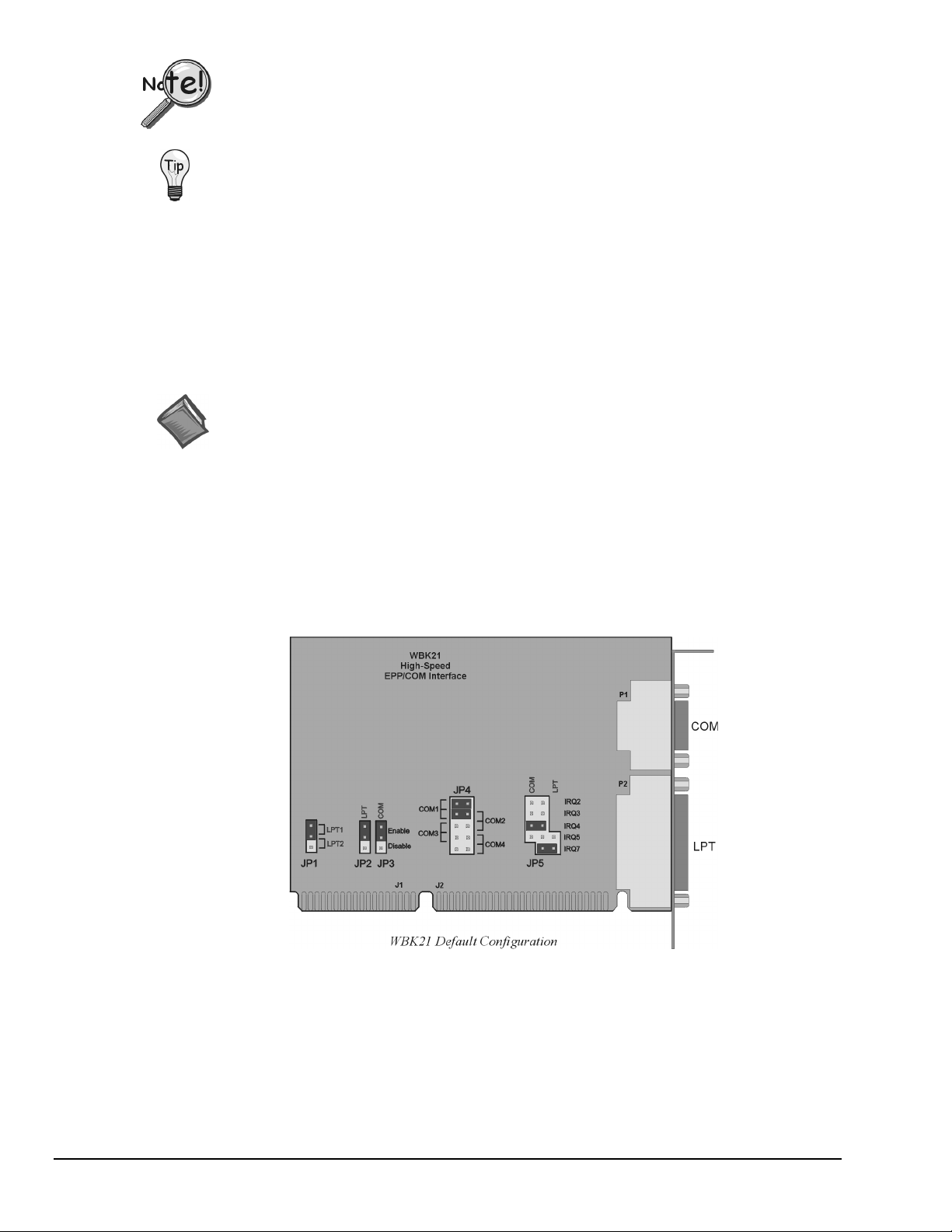

WBK21 - ISA/EPP Interface Card

Reference Note:

WBK21 is shipped with an installation guide. Refer to that document for additional details.

WBK21 is used to link WaveBook to a desktop PC. WBK21 contains the following two ports:

• 2.5 Mbyte/second (enhanced parallel port), often referred to as an LPT printer port.

•

16550 type buffered, high-speed, serial port. Often referred to as serial communication, or COM port.

WBK21 installs into an IBM compatible computer using any available 16-bit ISA bus backplane slot. Prior

to installing the card, make sure it is configured for your preferences. A discussion of card configuration

now follows.

(for linking WaveBook to a Desktop PC)

2-2 WaveBook Setup,

6-23-99

WaveBook User’s Manual

Page 25

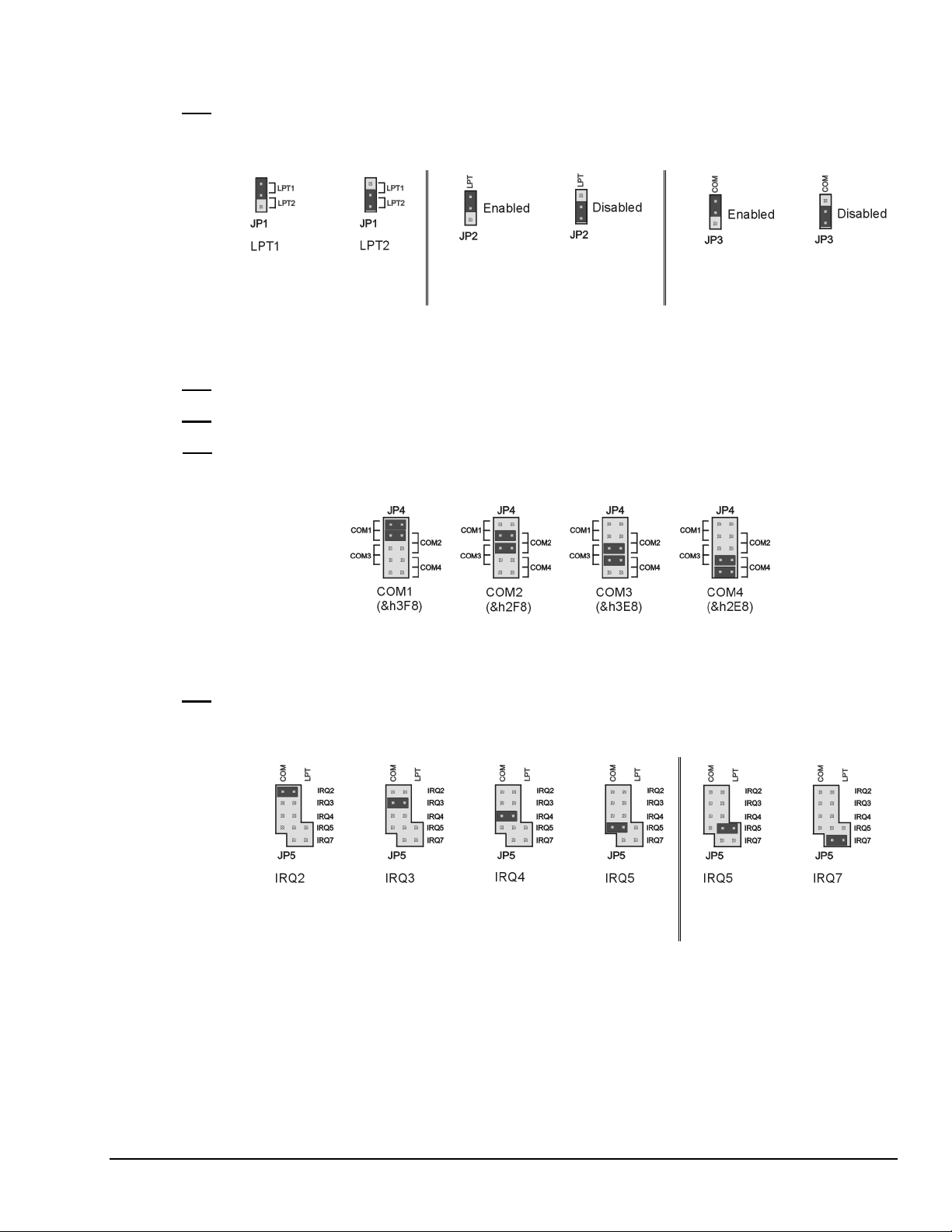

WBK21 Jumper Settings

JP1

WBK21 occupies the I/O address space of one parallel printer port (LPT1, LPT2, or LPT3). The factory

default setting (via JP1) is LPT1 (&h378).

If an IBM Monochrome board is not installed, then WBK21 would be designated as LPT1 or LPT2.

JP1 Configurations for

Parallel Port Selection

JP2 Configurations for

Parallel Port Enabled or Disabled

JP3 Configurations for

Serial Port Enabled or Disabled

If an IBM Monochrome display board (with an on-board parallel printer port) is installed in your PC, the

Monochrome printer port will always be designated LPT1 and have an address designation of &h03BC.

Other parallel printer ports (or WBK21s) are then designated as LPT2, or LPT3.

JP2

The JP2 configuration enables (or disables) the parallel port. Enabled is the default.

JP3

The JP3 configuration enables (or disables) the serial port. Enabled is the default.

JP4

JP4’s configuration determines the serial port (COM port) used. COM1 is the default. The COM port that

designates WBK21 depends on two factors: (1) WBK21 configuration, and (2) other installed devices

making use of COM ports.

JP4 Configurations for Serial Port Selection

JP5

In reference to the following figure, the top four jumper positions on JP5 select the serial port IRQ level.

IRQ4 is the default setting. The bottom two jumper rows select the parallel port IRQ level. IRQ7 is the

default parallel port setting. Note that COM and LPT ports cannot both be configured for IRQ5 at the same

time.

After WBK21 is properly configured, power-off your computer and install WBK21 into an available 16-bit

ISA bus. Consult your PC user’s manual as needed.

After WBK21 has been physically installed, power up your PC.

WBK21 - Specifications

Specifications are provided in Appendix A.

WaveBook User’s Manual

6-23-99

JP5 Configurations for Serial Port IRQ Level JP5 Configurations for

Parallel Port IRQ Level

WaveBook Setup 2-3

Page 26

Optional Printer Connection

WaveBook allows for LPT pass-through for printer operation while the WaveBook is connected, but not

operating. When using a printer in the system configuration, attach the original printer cable (plug DB25)

into WaveBook’s connector labeled "TO PRINTER." Note that some software programs, including

WaveView, must be closed to release the driver for printer pass-through operation.

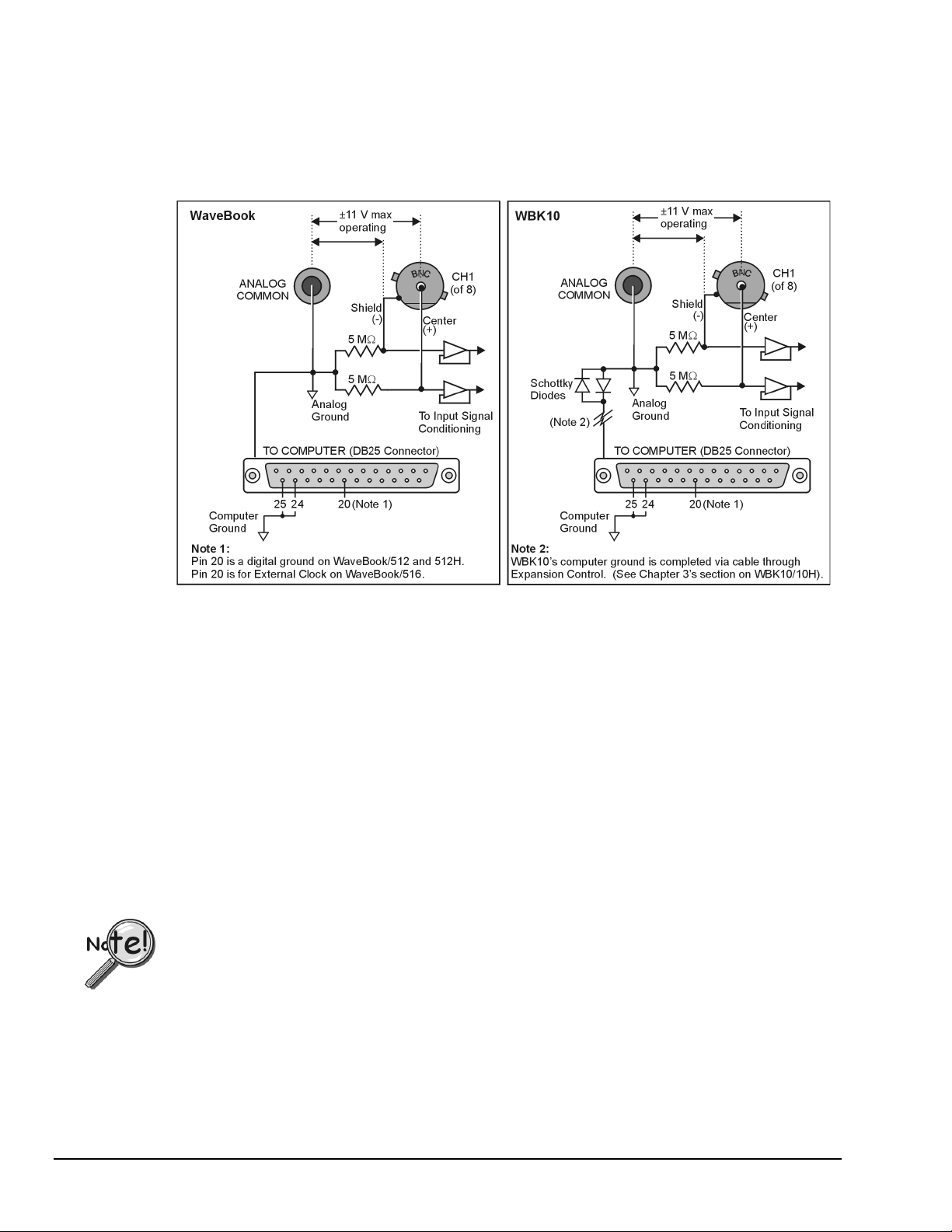

Analog Signal Connections & Grounds

Channel Analog Input, BNC Signal Connections

For each of the eight channel analog inputs, the BNC center (+) and shield (-) are internally connected to

WaveBook’s binding post labeled, ANALOG COMMON. The center (+) and shield (-) each connect to

ANALOG COMMON through a 5 M

Ω

resistor, resulting in a 10 MΩ differential input resistance

(see figures). WaveBook’s ANALOG COMMON connects to the computer power supply ground through

the TO COMPUTER DB25 connector and cable.

•

If the host computer is a desktop PC, then the computer ground will likely connect to the

AC power line ground.

•

If the host computer is a notebook PC, then the computer ground could be:

(a) floating, for example, when operating on batteries, or

(b) connected to a vehicle ground, for example, when using an automotive cigarette lighter adapter in conjunction

with the vehicle’s battery.

Note that a pair of Schottky diodes is used in the WBK10 to clamp the ANALOG COMMON to within

0.3V of computer ground (see figure).

WaveBook and WBK10/10H both have isolated power supplies. Power input common is isolated from

ANALOG COMMON by >10

9

Ω in parallel with 0.1µF.

For WaveBook [or WBK10/10H] to correctly measure analog signals, each signal must be within

±11 volts of ANALOG COMMON. The following notes provide guidelines on how to achieve this.

Like WaveBooks, notebook computers are rarely connected to AC power line ground.

This is true even when these devices are plugged into AC adapters.

Floating Grounds: If the computer is battery operated and the signal source is floating (such as an

Ω

ungrounded sensor), then the internal 5 M

resistors may provide enough of a return path to ANALOG

COMMON. If either the computer or the analog signal source is committed to AC power line ground, then

you will require a direct connection between the signal source and ANALOG COMMON.

When in doubt, connect the signal source common to ANALOG COMMON.

2-4 WaveBook Setup,

6-23-99

WaveBook User’s Manual

Page 27

A single-ended signal source needs to have its common connected to ANALOG COMMON.

When connecting several signal source commons to ANALOG COMMON, it is important that there is no voltage

potential [between these signal source commons]. Otherwise, ground currents will circulate, leading to measurement

errors.

If there is a fixed voltage potential between multiple signal source commons, then only one of these signal source

commons needs connected to ANALOG COMMON. This is true as long as the common mode voltage of any input

does not exceed ±11 volts.

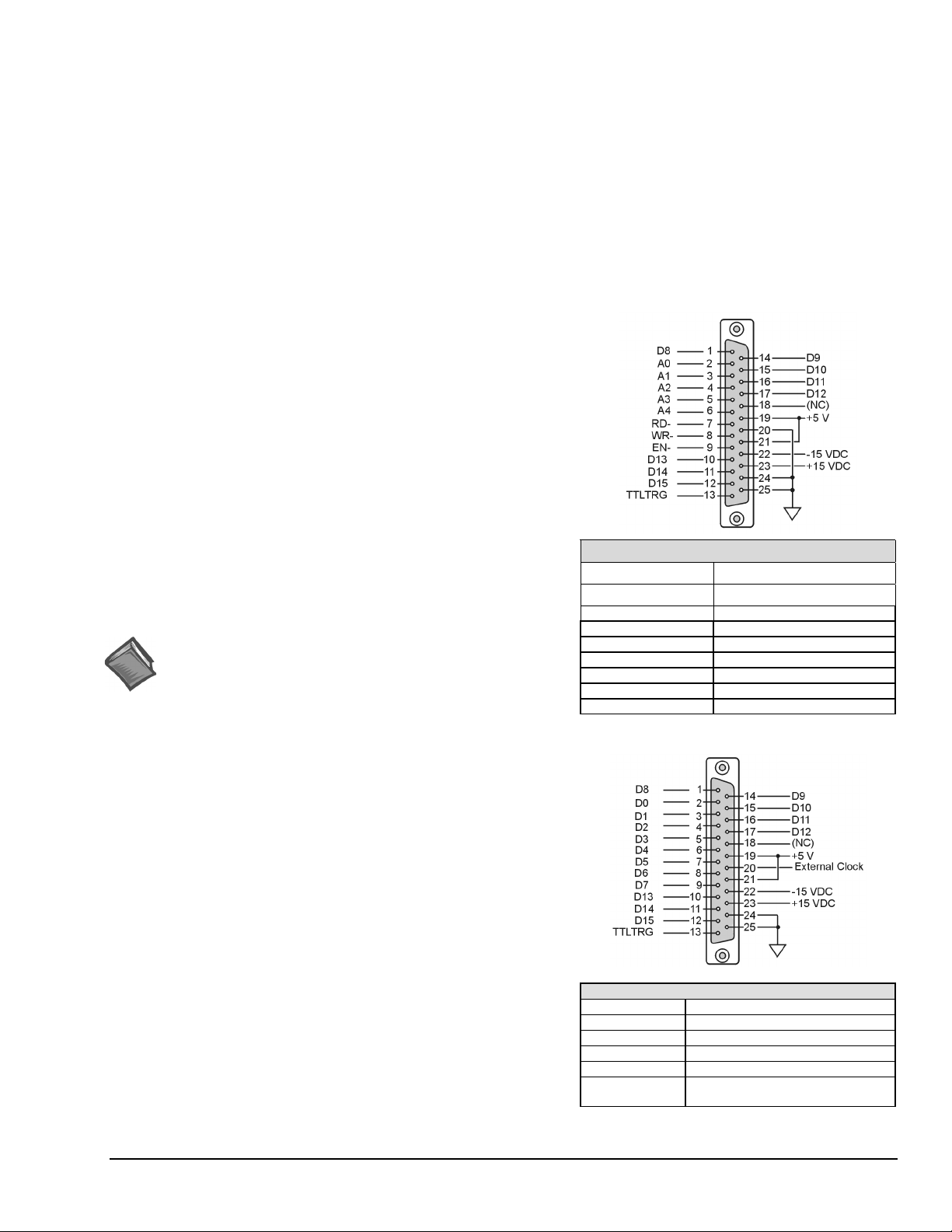

Digital I/O Connection (WaveBook/512 and /512H)*

*Note: The following pinout can be used for WaveBook/516, providing the unit is in the 8-bit mode (instead of 16-bit).

If using this pinout for WaveBook/516 (in 8-bit mode), pin 20 will be assigned to external clock input.

With the WaveBook/512 series, the following signals are present on

the DB25F high-speed digital I/O connector.

•

8 Digital I/O Lines (D8 – D15)

• 5 Address Lines (A0 –A4)

• Active-low Digital I/O Enable output (EN-)

• Active-low Digital I/O Write Strobe (WR-)

• Active-low Digital I/O Read Strobe (RD-)

• TTL Trigger Input (TTLTRG)

• +15 V (pin 23), -15 V (pin 22), 50 mA max. (each)

•

two +5 V power (pins 19 and 21), 250 mA max. (total)

•

three Digital Grounds (pins 20, 24, and 25)

To sample just 8 digital input signals, connect them directly to the

digital I/O data lines. D15 is the most significant bit, and D8 is the

least. The address lines, the read and write strobes, and enable signal

may all be left disconnected.

Reference Note: To use digital I/O address lines

(A0 –A4) to select from up to 32 input bytes, or to use the

digital I/O port for output, refer to chapter 8,

Theory of Operation.

Digital I/O Connections, WaveBook/512

D8-D15 Digital I/O data lines

A0-A4 Digital I/O address lines

EN- Active-low digital I/O enable

RD- Active-low read strobe

WR- Active-low write strobe

TTLTRG TTL trigger input

+5 VDC 250 mA maximum

+15,-15 VDC 50 mA maximum (each)

Digital Grounds Pins 20, 24, and 25

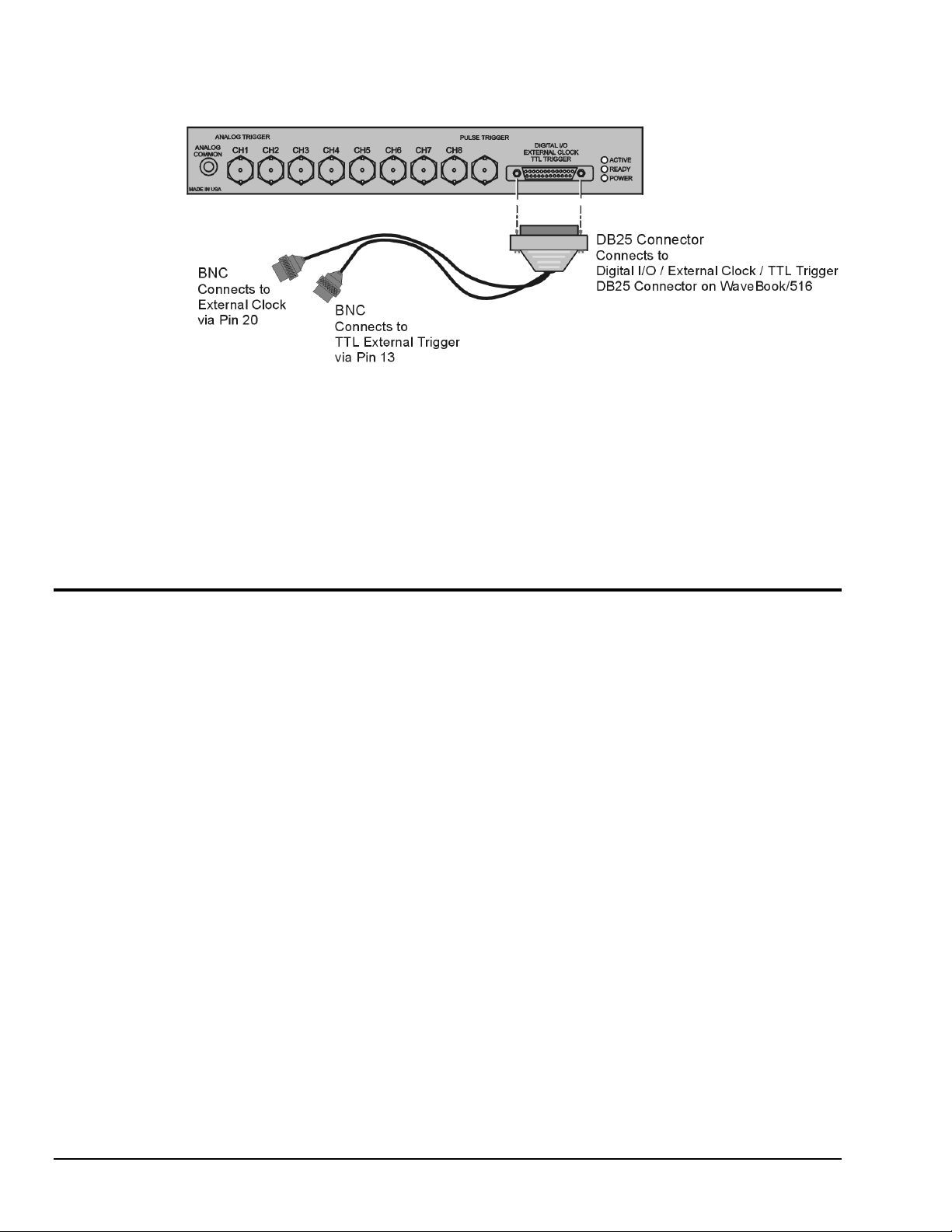

Digital I/O Connection (WaveBook/516 Only) 16-bit mode*

With the WaveBook/516 series, the following signals are present on

the DB25F high-speed digital I/O connector.

•

16 High-Speed Digital I/O Lines (D0 through D15)

• TTL Trigger Input (TTLTRG)

• +15 V (pin 23), -15 V (pin 22), 50 mA max. (each)

• two +5 V (pin 19 and pin 21), 250 mA max. (total)

• External Clock (pin 20)

• two Digital Grounds (pins 24 and 25)

To sample just 16 digital input signals, connect them directly to

the digital I/O data lines. D15 is the most significant bit, and D0

is the least.

*Note: For 8-bit mode, refer to the WaveBook/512 pinout, with noted

exception that pin 20 is for an external clock (with

WaveBook/516).

Note: The following figure depicts WaveBook/516’s Front Panel,

showing the DB25 connector and cable for External Clock and

TTL External Trigger.

WaveBook User’s Manual

6-23-99

D0 – D15 High Speed Digital I/O data lines

TTLTRG TTL trigger input

External Clock 16 bit mode, read/write strobe

+5 VDC 250 mA maximum

+15,-15 VDC 50 mA maximum (each)

Digital Grounds Pins 24 and25

Digital I/O Connections, WaveBook/516

WaveBook Setup 2-5

Page 28

WaveBook/516 with Optional Clock and External Trigger Cable (CA-178)

Pulse Trigger Connection (WaveBook/516 Series Only)

To the right of the 8 BNC connectors for analog inputs, the WaveBook/516 series provides one additional

BNC connector for pulse trigger (see previous figure). This high-bandwidth input enables the triggering

and hence the correlation of lower-speed waveforms with the occurrence of a high-speed anomaly. With

pulse trigger, the user defines a pulse amplitude between +5 and -5 volts, and a pulse width between

100 ns and 800 ms.

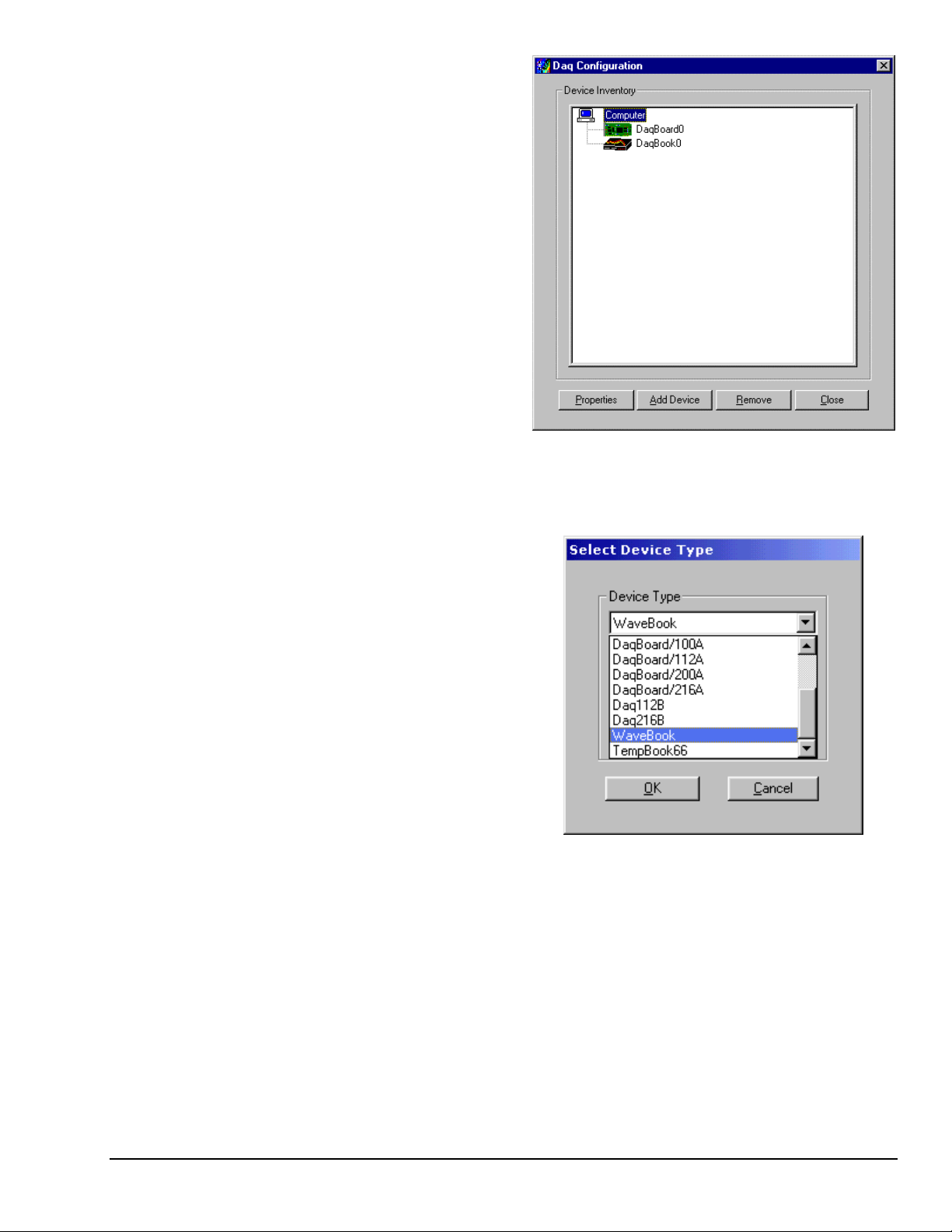

System Testing

Windows 95/98/NT WaveBook Configuration

The Daq Configuration applet, designed for 32-bit Windows 95/98/NT systems, is located in the Windows

Control Panel. It allows you to add or remove a device and change configuration settings. The included

test utility provides feedback on the validity of current configuration settings, as well as performance

summaries.

Device Inventory Dialog Box

Run the applet by double-clicking on the Daq Configuration icon in the Windows Control Panel.

The Device Inventory dialog box will open, displaying all currently configured devices. Displayed devices

show their name and an icon to identify the device type. If no devices are currently configured, no devices

will appear in this field.

The four buttons across the bottom of the dialog box are used as follows:

• Properties: Current configuration settings for a device can be changed by first bringing up the

2-6 WaveBook Setup,

corresponding Properties dialog box. Open the Properties dialog box by double-clicking on the device

icon or selecting the device and then clicking on the Properties button.

6-23-99

WaveBook User’s Manual

Page 29

• Add Device: The Add Device button is

used to add a device configuration

whenever a new device is added to the

system. Failure to perform this step will

prevent applications from properly

accessing the device. Clicking on the Add

Device button will open the Select Device

Type dialog box.

• Remove: The Remove button is used to

remove a device from the configuration.

A device may be removed if it is no

longer installed, or if the device

configuration no longer applies.

Note: If a device is removed, applications

may no longer access the device.

However, the device can be

re-configured at any time using the

Add Device function described above.

• Close: The Close button may be used at

any time to exit the Daq Configuration

applet.

Daq Configuration - Device Inventory Dialog Box

Select Device Type Dialog Box

This dialog box opens when the Add Device

button of the Device Inventory dialog box is

selected.

The device type you select for configuring will

appear in the main edit box. Clicking on the

OK button will then open the Properties dialog

box (following figure).

Daq Configuration - Select Device Type Dialog Box

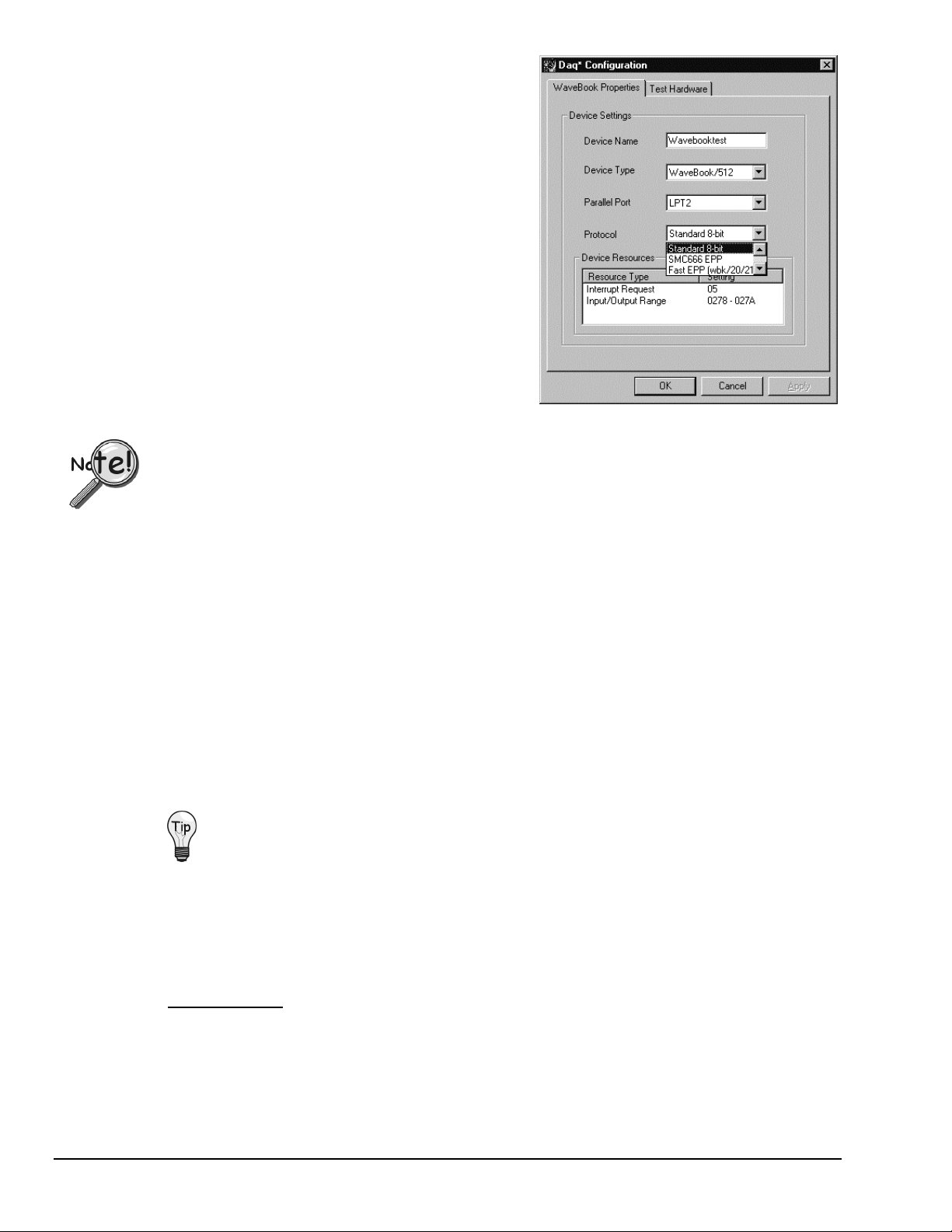

Properties Dialog Box

This dialog box opens when the Properties button of the Device Inventory dialog box is selected, or when

the OK button of the Select Device Type dialog box is selected. It displays the properties for the WaveBook

device with the default configuration settings. The fields include:

WaveBook User’s Manual

6-23-99

WaveBook Setup 2-7

Page 30

• Device Name: The Device Name field is displayed

with the default device name. As shown, this field

can be changed to any descriptive name as desired.

This device name is the name to be used with the

daqOpen

function to open the device. This name

will also be displayed in the device lists for opening

the device in the WaveView and WaveCal

applications.

• Device Type: The Device Type field indicates the

device type that was initially selected. However, it

can be changed here if necessary.

• Parallel Port: The Parallel Port field is used to set

the parallel port for communicating with the

WaveBook.

• Protocol: The Protocol field is used to set the

parallel port protocol for communicating with the

WaveBook. Depending on your system, not all

protocols may be available. (See following Note).

Daq Configuration - Properties Dialog Box

In regard to Protocol – If you are using a WBK20A or WBK21, you must select

“Fast EPP (wbk/20/21)” to achieve the best performance.

• Device Resources: The Device Resources field lists settings for various resources, among them

Interrupt Request, Input/Output Range, and Direct Memory Access.

• OK: Click on the OK button to store the configuration and exit the current dialog box.

• Cancel: Click on the Cancel button to exit the current dialog box without storing any changes.

• Apply: Click on the Apply button to store the configuration.

Or you can click the following tab:

• Test Hardware: Click on the Test Hardware tab to test the current stored configuration for the device.

This selection will open the Test Hardware dialog box.

Test Hardware Dialog Box

Before testing WaveBook, make sure the device has been properly installed and powered-on. Make sure

the parallel port cable is firmly in place on both the WaveBook and the proper LPT port in the computer.

When testing WaveBook, if the unit does not respond within 30 seconds perform the

following steps:

1) reboot the system

2) upon power-up, re-open the Daq Configuration applet

3) select another configuration setting

4) reinitiate the test

To test the currently stored configuration for the WaveBook device, click the Test button. Results should be

displayed in a few seconds. The test results have two components: Resource Tests and Performance Tests.

Resource Tests. The resource tests are intended to test system capability for the current device

configuration. Resource tests are pass/fail. Test failure may indicate a lack of availability of the resource,

or a possible resource conflict.

2-8 WaveBook Setup,

Base Address Test. This resource test checks the base address for the selected parallel port. Failure of

this test may indicate that the parallel port is not properly configured within the system. See relevant

operating system and computer manufacturer’s documentation to correct the problem.

6-23-99

WaveBook User’s Manual

Page 31

Performance Tests. These types of tests are intended

to check various WaveBook functions, using the current

device configuration. Performance tests provide

quantitative results for each supported functional group.

Test results represent maximum rates the various

operations can be performed. The rates depend on the

selected parallel port protocol, and vary according to

port hardware capabilities.

WBK30 FIFO Test. This performance test checks

the data-storing capabilities of the optional, WBK30

memory card.

Note that the figure to the right represents results

from a previous test. Initially, the screen shows no

test results.

Daq Configuration - Test Hardware Dialog Box

When the test is completed successfully, the Daq Configuration Test Dialog Box indicates a passed

condition. For example, in the above figure: WBK30 FIFO Test ÆÆÆÆ Passed.

These “Passed” messages indicate you can exit the test program and run your application.

WaveBook User’s Manual

6-23-99

WaveBook Setup 2-9

Page 32

2-10 WaveBook Setup,

6-23-99

WaveBook User’s Manual

Page 33

WBK Expansion Options 3

WBK10/10H

Expansion Module (8 channels)

WBK11

Simultaneous Sample & Hold Card (8 channels)

WBK12/13

WBK12: Programmable Low-Pass Filter Card (8 channels)

WBK13: Programmable Low-Pass Filter Card with SSH (8 channels)

WBK14

Dynamic Signal Conditioning Module (8 channels)

WBK15

8-Slot 5B Signal Conditioning Module (8 channels)

WBK16

Strain-Gage Module (8 channels)

WBK30

WaveBook Memory Option, 16 MB, 64 MB, or 128 MB

WBK61/62

WBK61: High-Voltage Adapter with 200:1 Voltage Divider (1 channel)

WBK62: High-Voltage Adapter with 20:1 Voltage Divider (1 channel)

3-2

3-6

3-8

3-10

3-17

3-22

3-45

3-49

You can use various modules and option cards to expand your WaveBook system. Internally, WaveBook has room for

one signal-conditioning card. Externally, you can use one or more WBK10/10H expansion modules. Note that unless

you placed a special order, WaveBook/516 will have a pre-installed PGA card.

Reference Notes:

The following items are not directly related to channel expansion and appear elsewhere in this manual.

• WBK20A – PCMCIA/EPP Interface Card (for linking a WaveBook to a Notebook PC) ……. Page 2-1

• WBK21 – ISA/EPP Interface Card (for linking WaveBook to a Desktop PC) …… page 2-2

• DBK30A – Rechargeable Battery Module …… page 4-4

• DBK34 – Vehicle UPS Module …… page 4-7

•

Power-supply options and setups are discussed in chapter 4, System Power & Assembly.

Using Shielded BNC Connectors (for CE Compliance)

Certain Declarations of Conformity identify specific cables and connectors that must be used to meet

CE requirements. CE compliant BNC-equipped cards and modules have BNC connectors that are insulated

from high voltage sources, including electrostatic discharges (ESD). Such voltages could enter the circuitry

through the exposed conductive surface of a connector, possibly resulting in damage to components.

O-Ring

Shielded

BNC Connector

WaveBook User’s Manual,

ch03A 6-18-99

Dust Cap

Shielded BNC Connector (with O-Ring) and PVC Dust Cap

WBK Expansion Options 3-1

Page 34

To meet CE requirements, PVC dust caps (p/n CN-96) must cover all unused BNC connectors. When dust

caps are not in place, special coaxial cables (with insulated end-connectors and rubber O-rings) must be

used. Note that part number 418-0800 includes two cables (with shielded BNC connectors at each end),

and four insulating O-rings.

Properly installed connectors and dust caps ensure the metallic surfaces of the connectors are not exposed to

undesirable electrical charges.

WBK10/10H - Expansion Modules

Description

The WBK10/10H expansion modules provide the WaveBook with 8 additional differential analog inputs,

each equipped with a programmable gain instrumentation amplifier (PGA). (The two models are the same

except for analog input ranges.) The WaveBook and WBK10/10H have a built-in expansion bus. Up to

eight WBK10/10Hs can be cascaded together for a system capacity of 72 differential channels. Each

WBK10/10H is also capable of supporting a WBK11, WBK12, or WBK13 option card.

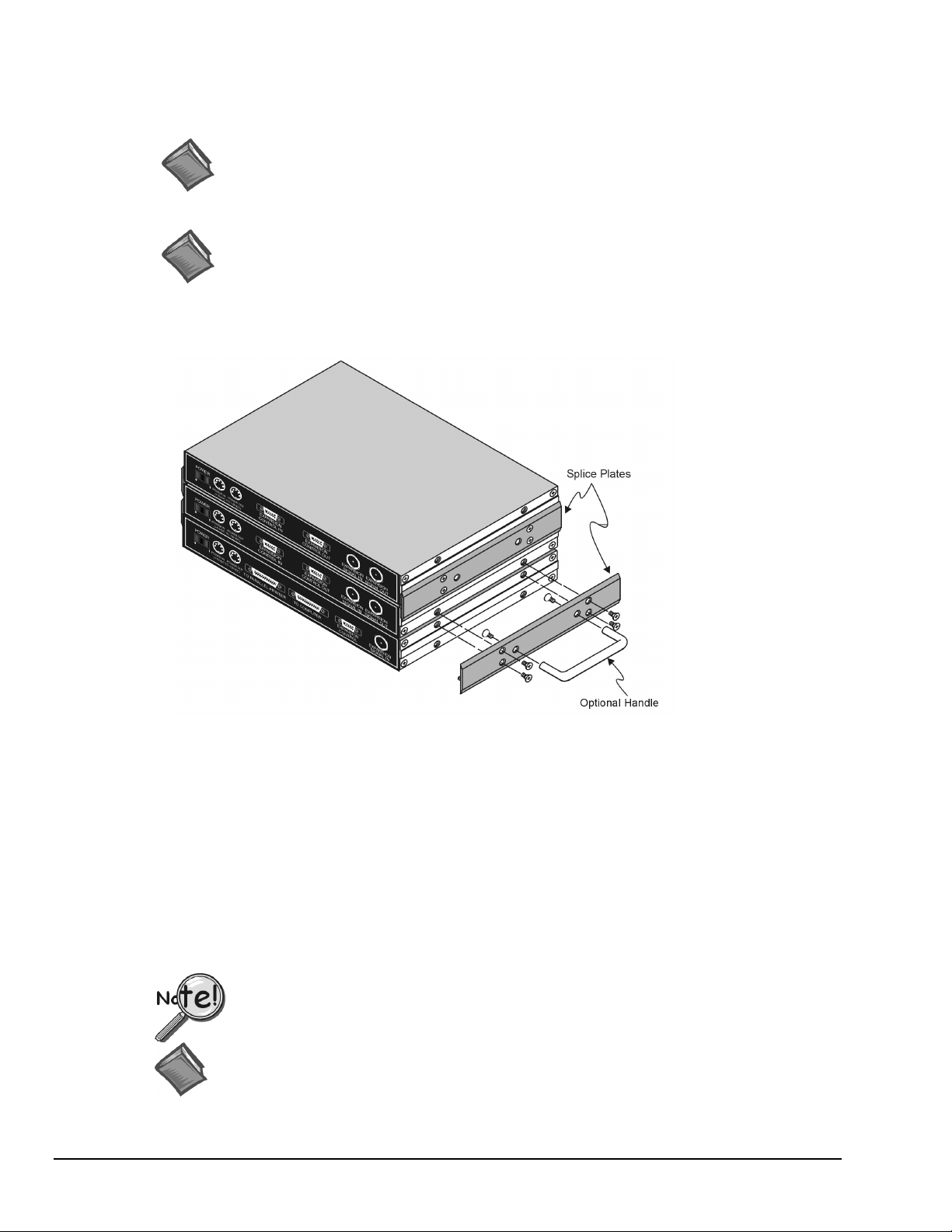

Physically, the WBK10/10H is the same size (8½×11 in) as the WaveBook for convenient mounting. A

splice plate kit allows multiple units to be stacked vertically. Screw-on handles are available for portable

applications.

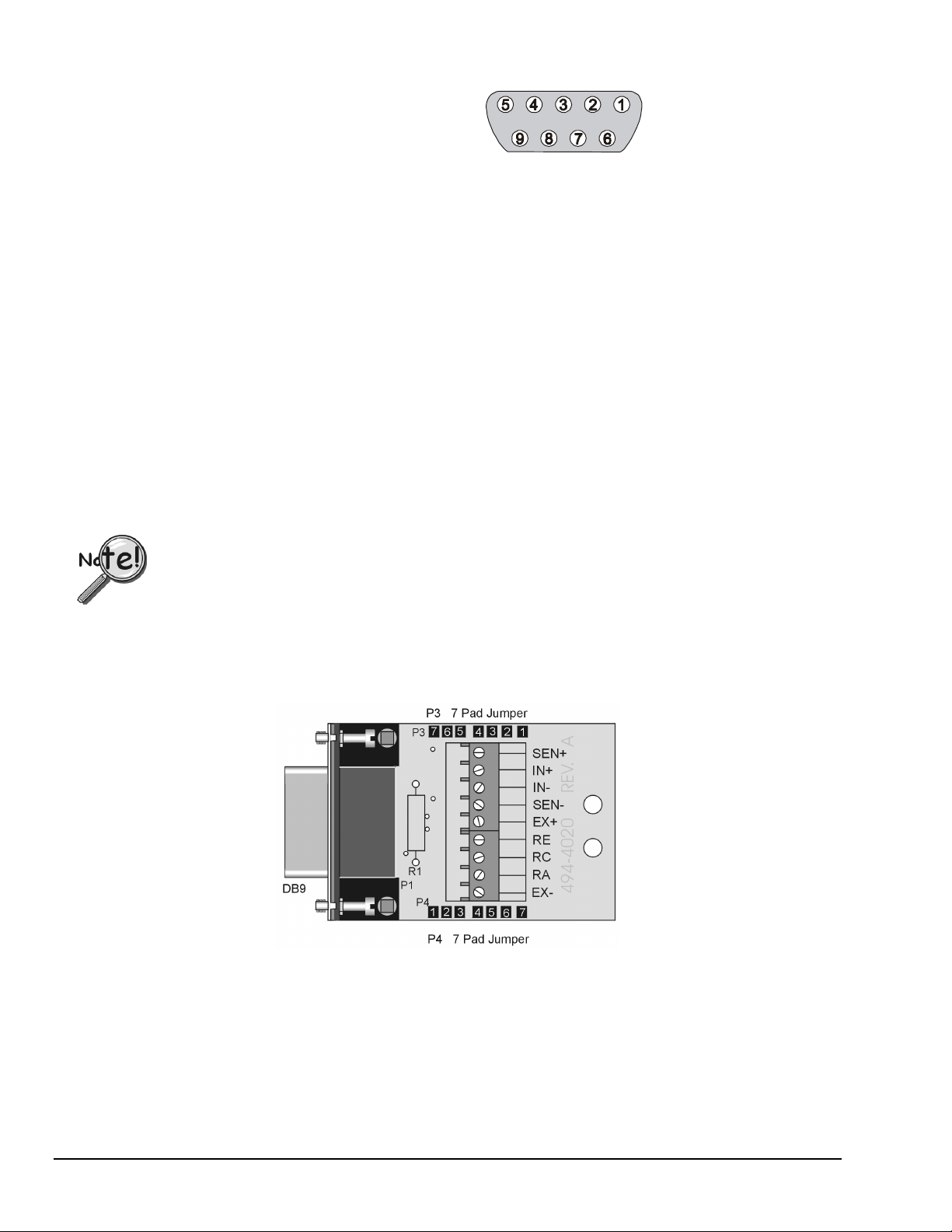

J10

Optional

WBK11

J11

Channel 1 of 8

8

Differential

Analo g

Inputs

DIN5s can be

dais y-ch ained

N

Buffers

10 to 30 VDC Input power

from AC adapter, DBK30A,

DBK34, or 12-V car battery, etc

Fuse

Converter

Power Supply

DC/DC

ON/OFF

Switch

+5

- 5

+15

- 15

7

7

8-channel

Differential

MUX

Offset Adjust

Differential

Amplifier

WBK10 Block Diagram

+

-

PGA

Unipolar/Bipolar

Level Shifter

EEPROM

Front & Rear Panels

The front panel of the WBK10/10H has the following connectors and indicators:

• 1 Analog Common binding post for reference.

•

8 BNC connectors for analog inputs. Channels are labeled 1 through 8. Note that additional WBK10/10H unit

channels are identified by higher channel numbers as discussed in upcoming text.

•

3 Status LEDs (Active, Ready, Power).

Control and

Timing Circuit

Enable

N

Expansion

Signal

N

IN

Expansion

Unit Control

OUT

The rear panel of the WBK10/10H has a power switch and the following connectors:

• 2 circular 5-pin DIN5 connectors for Power-in and Power Pass-Through.

• 1 HD-15M expansion control input.

• 1 HD-15F expansion control output.

•

2 BNC connectors for analog expansion, in and out.

3-2 WBK10/10H, W BK Expansion Options WaveBook User’s Manual

Page 35

Hardware SetupConfiguration

The analog input channel numbers are determined by the order of connection

among the WaveBook and attached WBK10/10H units.

• Channel 0 is the WaveBook’s 8-bit digital I/O port.

•

Channels 1 through 8 are the WaveBook’s main channels.

•

Channels 9 through 16 are located on the first expansion unit connected

directly to the WaveBook.

• Additional channel numbers (in groups of 8) are added consecutively with

added WBK10/10Hs (see table).

Power, Expansion Control, and Expansion Signal Connections

WBK expansion modules can be configured in various ways, such as:

• A WBK10/10H connects to a WaveBook or to another WBK10/10H.

• A lone WBK10/10H in the system connects directly to the WaveBook.

•

An add-on WBK10/10H connects to the previous WBK10/10H in a daisy-chain fashion.

• Other WBK expansion modules are connected in a similar way.

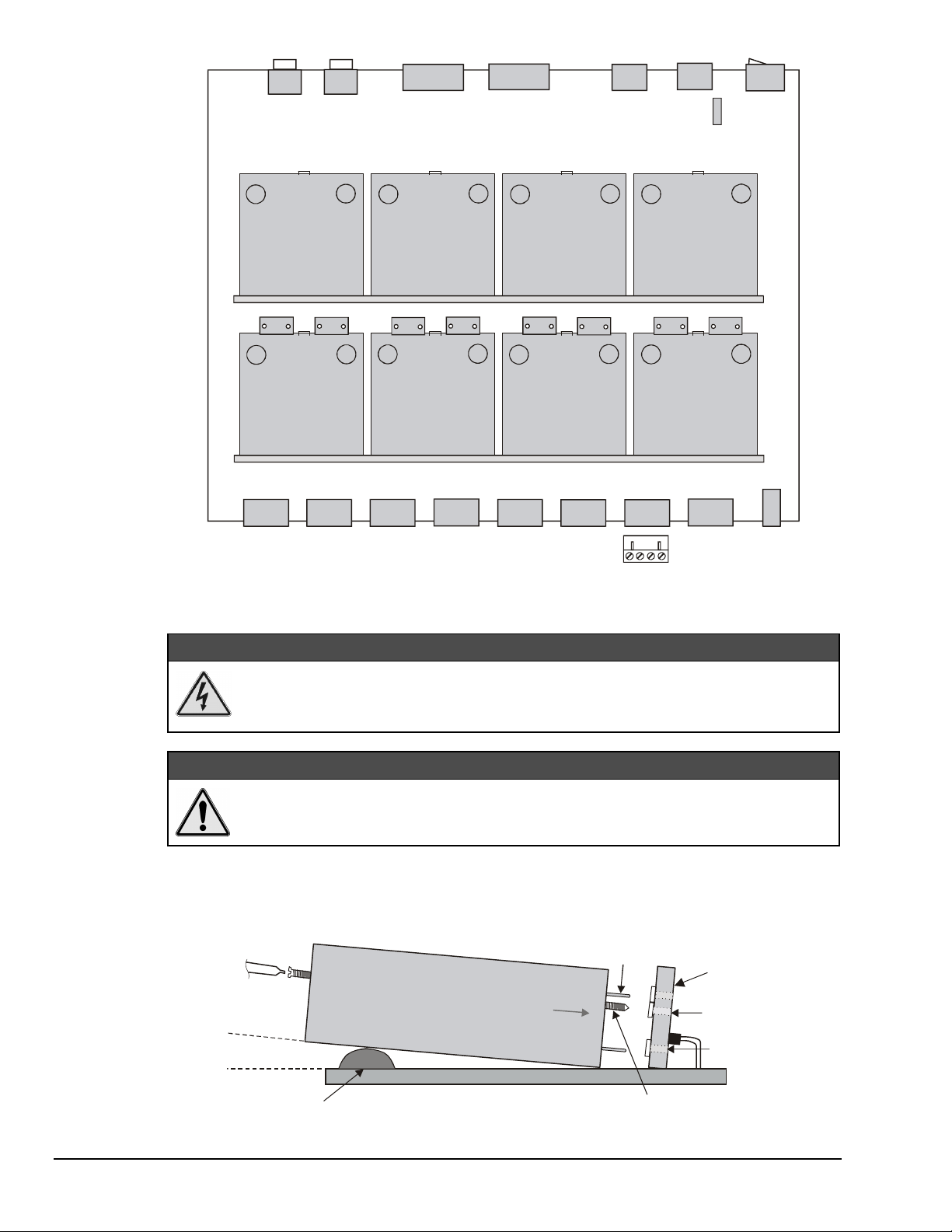

You must make connections for power, expansion control, and expansion signals. A system using three

WBK10 modules (daisy-chained to a WaveBook) is depicted in the following figure.

Unit Channel #

WaveBook 0 (dig I/O)

WaveBook 1-8

1st WBK10 9-16

2nd WBK10 17-24

3rd WBK10 25-32

4th WBK10 33-40

5th WBK10 41-48

6th WBK10 49-56

7th WBK10 57-64

8th WBK10 65-72

WaveBook User’s Manual,

Example of WaveBook and WBK10 Daisy-Chain

s

CAUTION

CAUTION

CAUTIONCAUTION

Do not daisy-chain the power connections of more than three WBK10/10H units.

Daisy-chaining a power connection to a fourth module will exceed the power connector

5 amp current limit.

CA-115 Power Cables. CA-115 cables are 6 inches long and have two 5-pin male DIN connectors.

CA-115s are frequently used to link WaveBook’s power out to a WBK10/10H module’s power in

connector. CA-115 cables are also commonly used to link WBK10/10H power out connectors to

the next daisy-chained module’s power in. See previous figure.

ch03A 6-18-99

WBK Expansion Options 3-3

Page 36

Reference Note: More power-related information can be obtained from the Power Connection

text, below, and from chapter 4, System Power & Assembly.

CA-129 Expansion Control Cables. Control messages are carried by CA-129 expansion-control

cables (HD-15, plug and socket connectors). The first expansion unit’s control input is driven from

the main unit’s control output. Control inputs of additional WBK10/10Hs are driven from the

preceding unit’s control output.

CA-150 Expansion Signal Cables. Expansion signals are carried by a CA-150-1 male BNC to

male BNC coaxial cable. Each WBK10/10H drives a common parallel analog bus that carries the

signals to the ADC in the WaveBook. Each WBK10/10H has input and output connectors for

daisy-chaining multiple units.

Power Connections

Reference Note: More power-related information can be obtained from chapter 4,

System Power & Assembly. CA-115 cables are discussed in preceding text.

10 to 30 VDC power can be supplied to a WBK10/10H unit through its POWER IN DIN5 connector in any

of the following ways.

• Separate power supplies. Each WBK10/10H can have its own, separate power supply. In other words,

the power set-up does not need to be dasiy-chained. Note that each WBK10/10H is shipped with a

power adapter.

• Single power supply. A single power supply can be used to power several WBK10/10H units.

An optional TR-40U power adapter can power several WBK10/10Hs when the units are daisy-chained

with CA-115 power cables (preceding figure). The number of WBK10/10Hs is limited to the amount

of power available and the amount of power used by option cards. As stated in the earlier caution, do

not daisy-chain the power for more than three WBK10/10H units.

• DBK30A Rechargeable Battery Module. The DBK30A can provide battery power for portable

applications via a CA-115 power cable. DBK30A is detailed in chapter 4,beginning on page 4-3.

DBK30A Rechargeable Battery Module

• DBK34 Vehicle UPS Module. The DBK34 can provide back-up battery power as an uninterruptible

power supply (UPS) for portable applications via the CA-115 power cable. DBK34 is detailed in

chapter 4, beginning on page 4-6.

DBK34 Vehicle UPS Module

• CA-116 cable. A car battery can be used for power when connection is made via the optional CA-116

cable. The CA-116 is a 5-pin DIN to automotive cigarette lighter power cable.

3-4 WBK10/10H, W BK Expansion Options WaveBook User’s Manual

Page 37

Assembly

The WBK10/10H base dimension is the same as WaveBook’s. This allows for convenient stacking, since

horizontal and depth requirements remain unchanged. A fastener panel is used to stack the units. Screw-on

handles are available for portable applications. For detailed assembly information, see chapter 4: System

Power & Assembly.

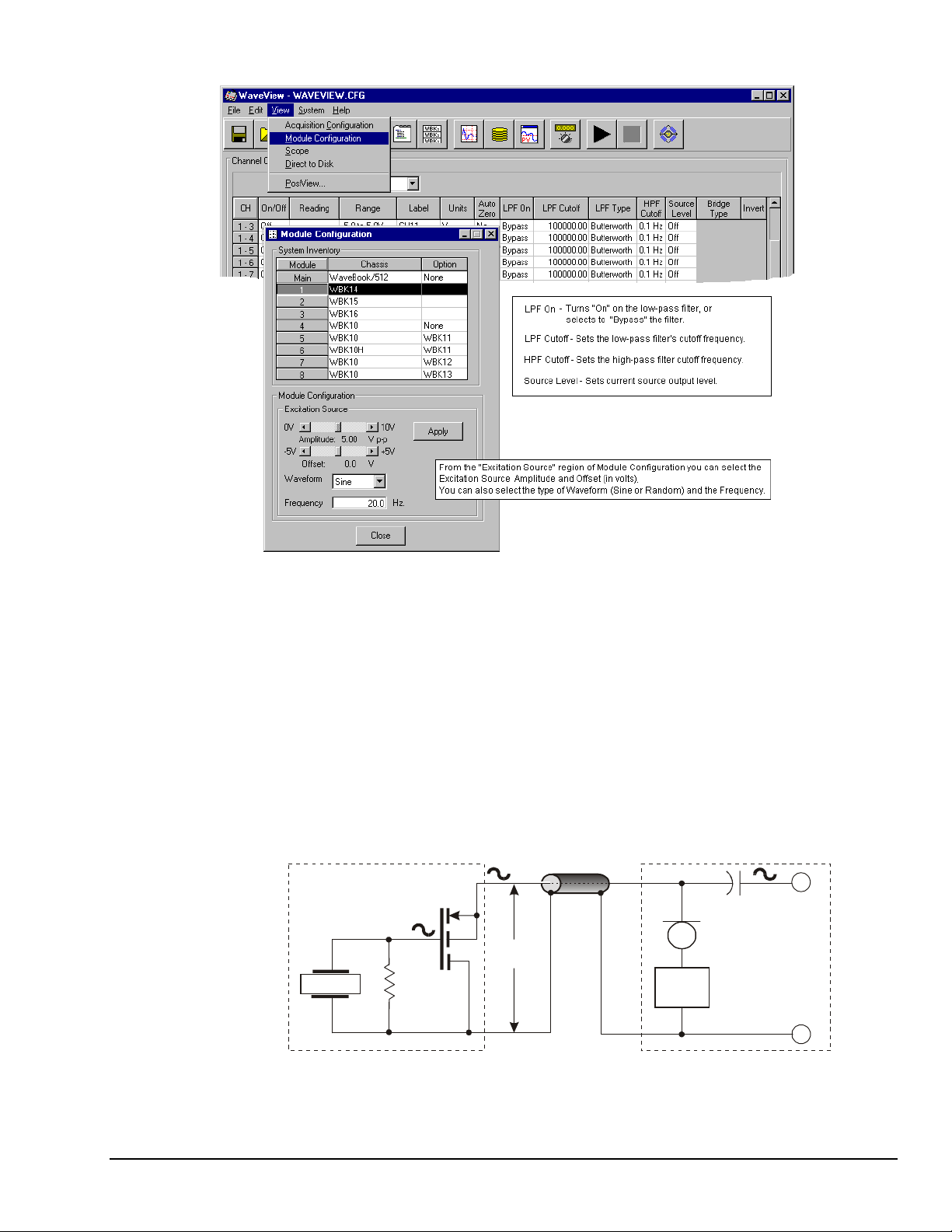

Software Setup

You will need to set several parameters so WaveView can best meet your application requirements. For

software setup information, refer to the "Software Setup" section in Chapter 2: WaveBook Setup. For

detailed WaveView information, refer to Chapter 5: WaveView.

WBK10/10H - Specifications

Specifications are provided in Appendix A.

WaveBook User’s Manual,

ch03A 6-18-99

WBK Expansion Options 3-5

Page 38

WBK11 - Simultaneous Sample & Hold Card

Description

WBK11 is a simultaneous sample-and-hold card (SSH) that can be installed in the field. The card can

simultaneously sample 8 channels. WBK11 can be installed inside a WaveBook or a WBK10/10H and is

controlled by the WaveBook. WBK11 allows concurrent (<150 ns) capture of multiple input channels and

virtually eliminates channel-to-channel time skewing.

When using WaveBook with an SSH channel enabled, the per-channel sample rates are

reduced. The rate reduction is the same as that which would occur if another channel

were added. The per-channel rate (with SSH enabled) is:

1 MHz / (n+1), where n is the number of active channels.

The WBK11 SSH card can accommodate higher gains than the main unit because its gains are fixed for

each channel prior to the acquisition. Each channel may be set, in software for ranges shown in the table.

All channels equipped with SSH circuitry are sampled simultaneously as a system.

The figure shows a block diagram of the WBK11. All connections are through P10 and P11.

Hardware Setup

Configuration

All WBK11 configurations are controlled by software. There are no hardware settings.

Installation

The WBK11 connects to headers J10 and J11 in the base unit. The base unit can be a WaveBook/512,

/512H, WaveBook/516, or WBK10/10H. The jumpers located on J10 and J11 provide signal pass-through

when the WBK11 is not installed. Use the following steps to install the WBK11 into a WaveBook, or

WBK10/10H module.

P10

mates

with

WaveBook

J10

One of 8 Channel s (Typical)

Offset Adjust

Diff. Amp.

Octal

DAC

+

PGA

-

SCI - Serial

Configuration Interface

Sample/

Hold

MUX

Buffer

Amplifier

P11

mates

with

WaveBook

J11

WBK11 Block Diagram

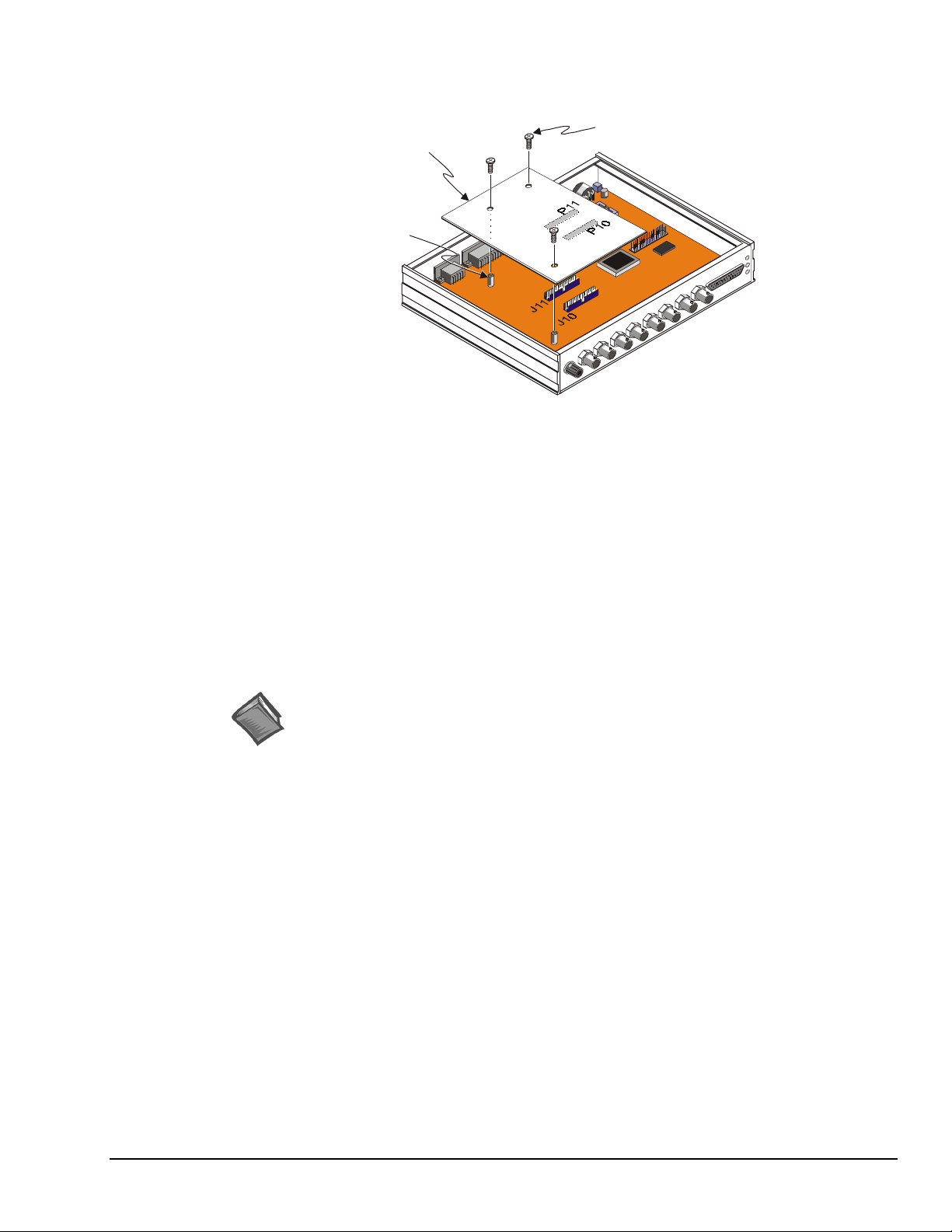

Although the next figure represents installation of a WBK11 into a WaveBook/512,

installation into other WaveBooks (and WBK10/10H) are similar. Note that the

following steps should be used when installing WBK11, WBK12, or WBK13.

1. Remove all power from the unit and any connected devices.

For WaveBook/512 series only, remove the screw holding down the top panel (cover), and slide the

2.

panel out towards the back.

For WaveBook/516 only, remove four side screws and lift the cover free of the chassis.

Remove present board from J10 and J11. If no board is installed in J10 and J11, skip to step 4.

3.

If a board is already installed:

(a) remove that board’s stand-off screws

(b) remove the board

Note: Unless a special order has been placed, WaveBook/516 series is shipped with a PGA card

installed.

3-6 WBK14, WBK Expansion Options WaveBook User’s Manual

Page 39

4. Locate the headers J10 & J11 on the main board, and remove the jumpers (if present).

Save the jumpers in the event the SSH board needs to be removed.

WBK11 Board.

P11 connects to J11,

and P10 connect s to J10.

Standoff (×3)

WBK11 Connection to WaveBook

Use 3 screws to secure

the WBK11 to the standoffs.

5. Align WBK11 headers (P11 & P10) with the host board headers (J11 & J10), respectively.

6. Verify alignment of the board. An easy way is to check that the board’s screw holes are in line with the

standoffs.

7. Carefully push the WBK11 down until the connectors fully mate.

8. Using three screws, secure the WBK11 to the standoffs. Do not over-tighten.

9. Slide the top panel onto the unit, and secure it using the top panel screw.

10. Power up the unit.