Page 1

USER’S MANUAL

TempScan/1100

MultiScan/1200

High-Speed Temperature & Voltage Systems

TempScan/1100

MultiScan/1200

IOtech

25971 Cannon Road

Cleveland, OH 44146-1833

p/n 446-0901 rev 3.3

(440) 439-4091

Fax: (440) 439-4093

sales@iotech.com

productsupport@iotech.com

www.iotech.com

Page 2

TempScan / MultiScan User’s Manual

Page 3

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this

product may be copied, reproduced or transmitted by any mechanical, photographic, electronic, or other

method without IOtech’s prior written consent. IOtech product names are trademarked; other product names,

as applicable, are trademarks of their respective holders. All supplied IOtech software (including

miscellaneous support files, drivers, and sample programs) may only be used on one installation. You may

make archival backup copies.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards

of the European Community. As applicable, we ship these products with a Declaration of Conformity

stating which specifications and operating conditions apply.

Warnings and Cautions

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or

equipment damage under noted conditions. Follow all safety standards of professional practice and the

recommendations in this manual. Using this equipment in ways other than described in this manual can

present serious safety hazards or cause equipment damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from

electrical shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from

electrostatic discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist

straps, ESD-protective bags and cartons, and related procedures.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or

revision to the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic

hardware calibration is not covered under the warranty and must be performed by qualified personnel as

specified in this manual. Improper calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our

products and review our documentation to assure the highest quality in all aspects. In a spirit of continuous

improvement, IOtech welcomes your suggestions.

TempScan / MultiScan User’s Manual

Page 4

TempScan / MultiScan User’s Manual

Page 5

Manual Layout

Note: For benefit of those who have not yet installed their TempScan/1100 or MultiScan/1200, this

TempScan / MultiScan Quick Start Guide (p/n 446-0940)

Chapter 1 - System Overview provides a detailed discussion of TempScan/1100 and MultiScan/1200,

Chapter 2 – Expansion Units provides a detailed discussion of the two-slot expansion unit, Exp/10A

Chapter 3 – Scanning Cards discusses the three scanning card options available to the TempScan/1100

Chapter 4 - System Configuration discusses TempScan/1100 or MultiScan/1200 memory allocation, the

Chapter 5 - System Operation discusses how the TempScan/1100 or MultiScan/1200 system operates.

manual begins with a copy of the installation guide that is shipped with those products. Use the

guide to install the associated software, product support, and hardware.

their features, front and rear panel descriptions, and necessary hardware configurations. Both IEEE

488 and RS-232 interfaces are covered. Also provides detailed instructions on line-voltage selection

and fuse replacement, rack-mount and bench-top installation, as well as power-up activation.

Expansion Unit and the ten-slot expansion unit, Exp/11A Expansion Unit. This chapter covers, their

features, front and rear panel descriptions, and necessary hardware configurations.

unit: The TempTC/32B thermocouple scanning card, the TempV/32B volts scanning card, and the

TempRTD/16B RTD scanning card. It also discusses the two scanning card options available to the

MultiScan/1200 unit: The MTC/24 thermocouple/volt scanning card and the MHV/24 high-voltage

scanning card.

required configuration of channels, scans, acquisitions, and triggers, as well as the additional

configuration of alarms, data format, and power-up.

This includes the operation of the acquisition buffer, the digital input/output, the High/Low/Last

(HLL) Registers, the Status and Event Reporting Registers, as well as the channels.

Chapter 6 - System Calibration states how to access ChartView’s built-in automated calibration feature

and also discusses the manual calibration for the TempScan/1100 and MultiScan/1200 units, and for

their respective scanning cards.

Software

Appendices

ChartView discusses the ready-to-use Windows-based data-logging software that features a strip-chart

style graphical interface. The various windows, toolbar buttons and menu items are described and

explained.

ViewXL discusses the ViewXL Microsoft Excel Add-In. The application provides setup and data

acquisition for personal computers running 32-bit versions of Windows. The features of Excel and

ChartView combine seamlessly to form a powerful data acquisition tool.

Appendix A - API Command Reference discusses the entire command set covering both the

TempScan/1100 and MultiScan/1200 units. The command syntax, interpretation, and reference are

provided. The description format of the individual API commands includes the command type,

execution, syntax, description, and an example program excerpt.

Appendix B – IEEE 488, Serial, and ASCII - This appendix provides background information

concerning the IEEE 488 bus, the serial bus, and ASCII controls.

Appendix C - Program Examples in Quick Basic. This appendix is included as a reference for those

individuals who are interested in writing their own programs for use with MultiScan/1200 and/or

TempScan/1100.

Information which may have changed since the time of printing will be found in a

disk, or in an addendum to the manual.

TempScan / MultiScan User’s Manual 879596 v

README.TXT file on

Page 6

vi TempScan / MultiScan User’s Manual

Page 7

Table of Contents

TempScan/MultiScan Quick Start Guide

(p/n 446-0940)

1 - System Overview

Introduction ...... 1-1

TempScan/1100 ...... 1-1

MultiScan/1200 ...... 1-1

Front Panel Indicators ...... 1-2

Rear Panel Switches & Connectors ...... 1-3

TempScan/1100 & MultiScan/1200

Specifications ...... 1-4

Hardware Configuration ...... 1-7

IEEE 488 Configuration ...... 1-8

RS-232/422 Serial Configuration ...... 1-9

Calibration Protection Configuration ...... 1-13

Digital I/O Configuration ...... 1-13

TTL Output & Trigger Input

Configuration ...... 1-14

Expanded Memory Configuration ...... 1-15

Scanning Card & Channel Expansion ...... 1-16

Power Line & Fuse Configuration ...... 1-17

Introduction ...... 1-17

Line Voltage Selection ...... 1-18

Fuse Replacement ...... 1-20

Rack-Mount & Bench-Top Assembly ...... 1-21

Rack Mount ...... 1-21

Bench Top ...... 1-21

Power-Up Activation ...... 1-22

2 – Expansion Units

Exp/10A Expansion Unit ...... 2-1

Introduction ...... 2-1

Front Panel Indicators ...... 2-1

Rear Panel Switches & Connectors ...... 2-2

Exp/10A Specifications ...... 2-3

Exp/10A Hardware Configuration ...... 2-4

Master/Slave Connection ...... 2-4

Slave Configuration ...... 2-5

Channel Assignment ...... 2-5

Exp/11A Expansion Unit ...... 2-7

Introduction ...... 2-7

Front Panel Indicators ...... 2-7

Rear Panel Switches & Connectors ...... 2-7

Exp/11A Specifications ...... 2-8

Exp/11A Hardware Configuration ...... 2-9

Master/Slave Connection ...... 2-9

Slave Configuration ...... 2-10

3 – Scanning Cards

TempScan Scanning Cards ...... 3-1

TempTC/32B Thermocouple Scanning

Card ...... 3-2

TempV/32B Voltage Scanning Card ...... 3-4

TempRTD/16B RTD Scanning Card ...... 3-6

MultiScan Scanning Cards ...... 3-7

MTC/24 Thermocouple/Volt Scanning

Card ...... 3-8

MHV/24 High-Voltage Scanning Card ...... 3-10

4 – System Configuration

Introduction …… 4-1

Memory Allocation …… 4-2

Measuring Modes

(MultiScan/1200 Only) …… 4-2

Line-Cycle Integration / High-Speed Multi-

Channel Mode …… 4-3

Single-Channel High-Speed Burst Mode …… 4-5

Required Configuration …… 4-6

Channel Configuration …… 4-7

Scan Configuration …… 4-9

Acquisition Configuration …… 4-13

Trigger Configuration …… 4-16

Additional Configuration …… 4-18

Alarm Configuration …… 4-19

Stamp Configuration …… 4-22

Data Format Configuration …… 4-26

Power-Up Configuration …… 4-32

TempScan / MultiScan User's Manual vii

Page 8

5 – System Operation

Acquisition Buffer …… 5-1

Buffer Organization …… 5-2

Buffer Query Operation …… 5-4

Buffer Read Operations …… 5-5

Buffer Overrun …… 5-11

High/Low/Last (HLL) Registers …… 5-13

Contents of the HLL Registers …… 5-13

Access to the HLL Registers …… 5-14

Comparing Buffered Data to HLL Data …… 5-18

Status-Reporting & Mask Registers …… 5-18

Theory of Operation …… 5-21

Status-Reporting Registers …… 5-21

Mask Registers …… 5-28

Using Status-Reporting Registers …… 5-28

Additional Operation …… 5-28

Trigger Latency …… 5-28

Real-Time Clock …… 5-28

Open Thermocouple & Range Error

Checking …… 5-28

Software Digital Filtering

(TempScan/1100 Only) …… 5-28

6 – System Calibration

Manual Calibration and

Software-Automated Calibration …… 6-1

Calibration Setup …… 6-2

Calibration Properties …… 6-2

Calibration Protection …… 6-2

Calibration Status …… 6-3

Calibration Password …… 6-3

Calibration of Master Chassis …… 6-4

Calibration of Scanning Cards …… 6-6

Calibration of Thermocouple Scanning

Cards …… 6-8

Calibration of Voltage Scanning Cards …… 6-12

Calibration of RTD Scanning Cards …… 6-13

Software

ChartView Software Reference

ViewXL

viii TempScan / MultiScan User's Manual

Page 9

Appendix A - API Command Reference

Appendix C – Program Examples

in Quick Basic

Introduction …… A-2

Command Syntax …… A-2

Command Interpretation …… A-3

Command Summary …… A-6

Command Reference …… A-11

Command Description Format …… A-11

The Commands …… A-11

@ - Trigger On Command …… A-12

*B - Flush Acquisition Buffer …… A-13

*C - Clear Channel Configuration …… A-14

*F - Restore Factory Settings …… A-15

*G - Set RTD Gain Calibration Reference … A-16

*K - Change Calibration Keyword …… A-17

*P - Adjust Calibration Card Pots …… A-18

*R - Reset Power-On …… A-19

*S - Set Power-Up Configuration …… A-20

*T - Set Scan Time Stamping …… A-21

*W - Set Software Digital Filtering …… A-22

A - Assign Alarm Output …… A-23

A# - Set Scan Alarm Stamping …… A-24

C - Configure Channels …… A-25

C# - Select Cards …… A-28

D# - Set Relay Make Time …… A-29

E - End Calibration Mode …… A-30

E? - Query Error Status …… A-31

F - Set Data Format …… A-32

F# - Set Burst Mode Frequency …… A-34

G - Calibrate Channel Gain …… A-35

H - Calibrate Channel Offset …… A-36

I - Set Scan Interval …… A-37

I# - Set Digital Input Stamping …… A-38

J - Calibrate Cold Junction Offset …… A-39

K - Enter Calibration Mode …… A-40

L - Set Trigger Level …… A-41

L# - Set Scan Rate …… A-42

M - Set SRQ Mask …… A-43

M# - Set Measuring Mode …… A-44

N - Set Event Mask …… A-45

O - Set Digital Output …… A-46

P - Program Trigger Times …… A-47

Q - Set Query Terminator …… A-48

QC? - Query Card Data …… A-49

R - Read Buffered Data …… A-50

R# - Read Last Readings …… A-51

S - Set Real-Time Clocks …… A-52

T - Set Trigger Configuration …… A-53

U - User Status …… A-55

V - Set User Terminator …… A-58

W# - Set Averaging Weight …… A-59

X - Execute …… A-60

Y - Set Counts …… A-61

? - Query …… A-62

Introduction …… C-1

Reading HLL Status …… C-3

TempScan/1100 …… C-3

MultiScan/1200 …… C-4

Reading HLL Data from Thermocouple &

Volts Cards …… C-5

TempScan/1100 …… C-5

MultiScan/1200 …… C-6

Acquiring Pre- & Post-Trigger Data at

Different Rates …… C-7

TempScan/1100 …… C-7

MultiScan/1200 …… C-9

Acquiring Pre- & Post-Trigger Data at the

Same Rate …… C-11

TempScan/1100 …… C-11

MultiScan/1200 …… C-13

Operating Alarms …… C-15

TempScan/1100 …… C-15

MultiScan/1200 …… C-17

Using the IEEE 488 SRQ with

Alarms …… C-19

TempScan/1100 …… C-19

MultiScan/1200 …… C-21

Acquiring Buffer Data in Binary

Format …… C-23

TempScan/1100 …… C-23

MultiScan/1200 …… C-25

Acquiring HLL Data in Binary

Format …… C-27

TempScan/1100 …… C-27

MultiScan/1200 …… C-29

Using Auto Re-arm to Capture Multiple

Trigger Blocks …… C-31

TempScan/1100 …… C-31

MultiScan/1200 …… C-33

Acquiring Burst Mode Data (MultiScan/1200

Only) …… C-35

Appendix B – IEEE488, Serial, and ASCII

IEEE 488 Bus & Serial Bus Lines …… B-1

IEEE 488 Bus Commands …… B-2

ASCII Codes …… B-3

ASCII Code Summary …… B-3

ASCII Code Details …… B-5

Abbreviations …… B-10

TempScan / MultiScan User's Manual ix

Page 10

x TempScan / MultiScan User's Manual

Page 11

TempScan / MultiScan Quick Start Guide

High-Speed Temperature & Voltage Systems

Reference Note: Adobe PDF versions of user manuals will automatically install onto your hard drive as a part of

product support. The default location is in the Programs group, which can be accessed from the Windows Desktop

Start menu. Refer to the PDF documentation for details regarding both hardware and software. Note that PDF

versions of the documents can also be accessed directly from the data acquisition CD via the <View PDFs> button

located on the CD’s opening screen.

Minimum System Requirements

PC system with Pentium® Processor

Windows 2000 or /XP

64 Mbytes RAM

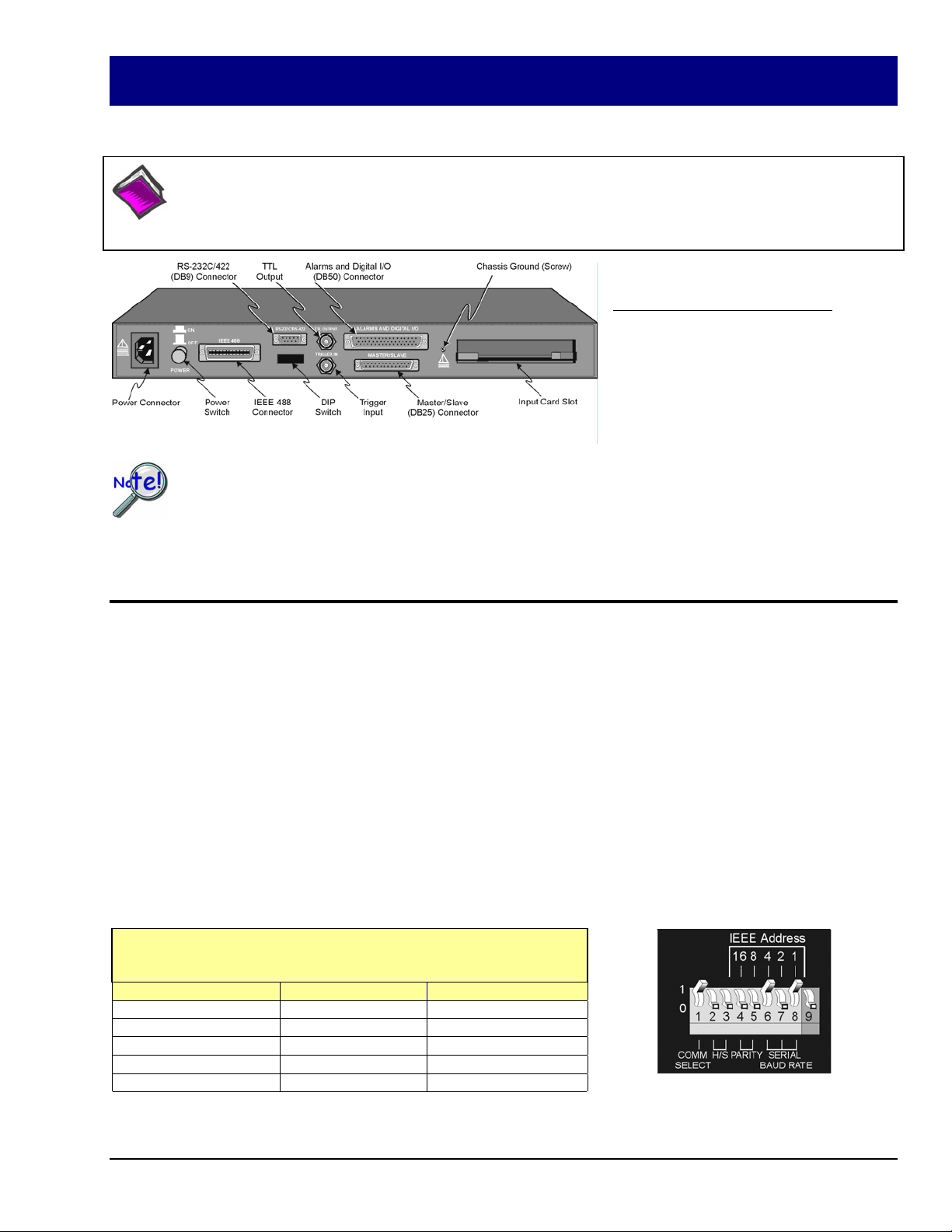

Rear Panel, Applies to both TempScan and MultiScan

o This quick start covers connecting a TempScan/1100 or a MultiScan/1200 to the host computer’s

RS-232 serial port and configuring the device for RS-232 serial operation.

o Because you will be using ChartView, an “out-of-the-box” Windows-based data acquisition program,

no programming is required.

Note: Throughout the remainder of this document the term “scan device” refers to both the TempScan/1100 and to the

MultiScan/1200 data acquisition device.

Hardware Setup

Step 1: Check the Voltage Setting

Based on your order, your scan device was set at the voltage indicated on the sticker located on the rear panel of the unit

(near the power switch): 105-125 or 210-250 volts AC. Verify that the voltage value indicated on the sticker matches the

voltage of your intended AC power supply. If you need to change the AC power line selection for any reason, refer to the

chapter Power & Assembly in your user's manual.

Step 2: Set the Operation Mode via DIP Switch

The scan device is default configured for IEEE 488 port connection to a PC. To configure the unit for RS-232 serial

operation, change the DIP switch setting as indicated in the following table and figure. Otherwise, to configure the unit for

RS-422 serial operation or IEEE 488 operation refer to chapter 1 in your TempScan/1100 & MultiScan/1200 user’s manual.

A PDF version of the manual is included on the data acquisition CD.

The DIP switch is located on the rear panel of your unit. One possible RS-232 serial setting is indicated in the following

figure and table. We make use of this serial setting in this Quick Start Guide. For alternative serial settings, refer to chapter

1 in your TempScan/1100 & MultiScan/1200 user's manual.

DIP Switch Configuration

One of many possible settings for RS-232 Serial Communication*

Selection Micro-switch Setting

COMM SELECT 1 1- RS-232

HANDSHAKE (H/S) 2,3 00 - No Handshake

PARITY 4,5 00 - No Parity

BAUD RATE 6,7,8 101 - 9600 Baud

CALIBRATION 9 0 - Disabled

*Refer to the user’s manual in regard to other configurations.

446-0940, rev 2.2 988892 TempScan / MultiScan Quick Start Guide QS-1

DIP Switch (on Rear Panel)

Set for RS-232 Serial, see table at left.

Page 12

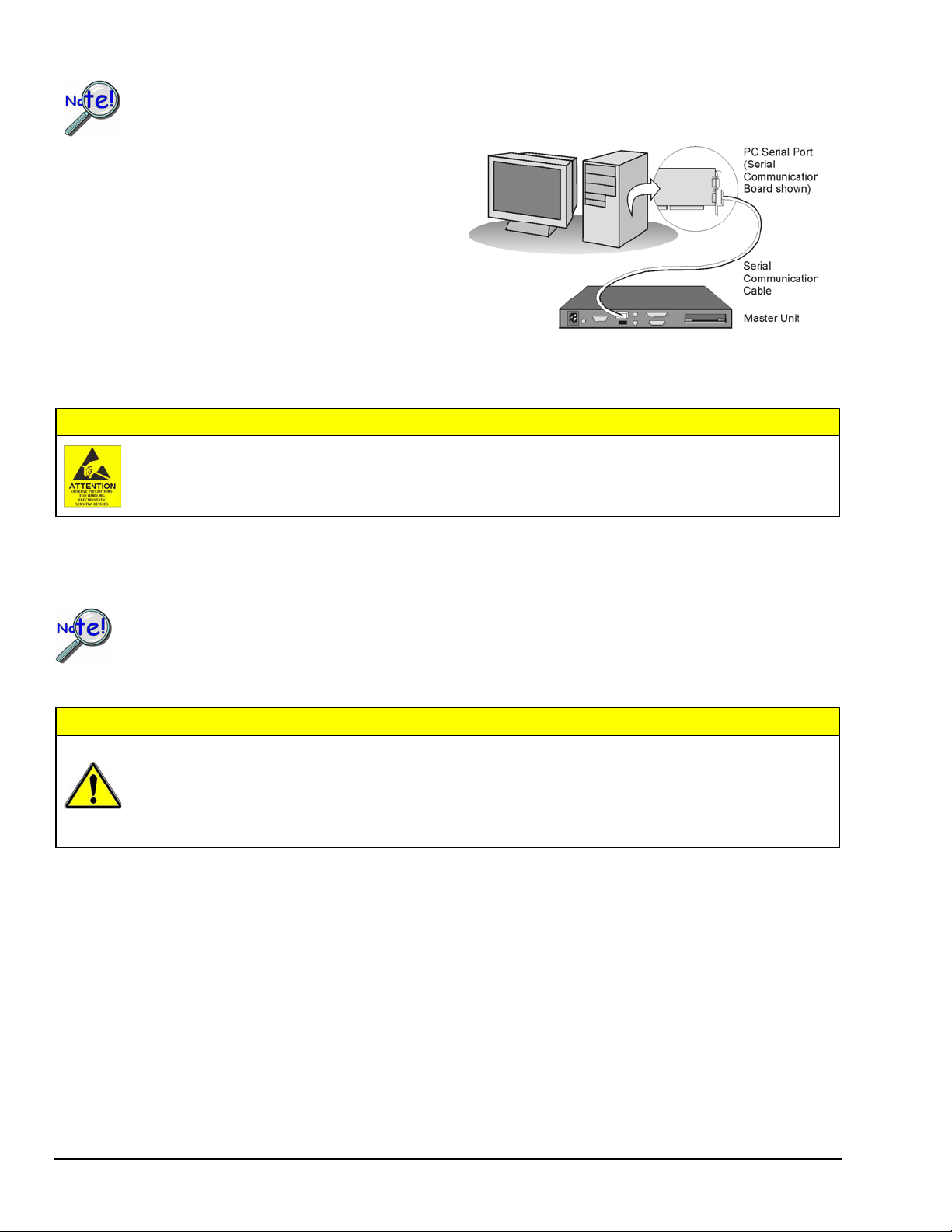

Step 3: Connect the Unit to Your PC

Prior to making a serial connection, make sure that the host PC’s serial (COM) port is available and

properly configured to match the DIP switch setting in Step 2. Do this by navigating from the Windows

Desktop, i. e., Control Panel ⇒ System ⇒ Device Manager tab, then clicking on Ports (COM & LPT).

Use a CA-47 serial communication cable (or equivalent) to

connect the scan device’s RS-232/RS-422 serial port to an

available serial port on your PC.

Note that the single DB9-end of the CA-47 cable connects

to the scan device (referred to as “Master Unit” in the righthand figure).

Note: The PC-end of the CA-47 cable has two connectors,

i.e., one DB9 and one DB25 connector.

Step 4: Connect the Channel Inputs to the Scanning Card

RS-232/RS-422 Serial Communication

Use approved ESD precautions, including static-free work area and grounded wrist strap, when handling

circuit boards and electronic components. Failure to do so could cause equipment damage due to

electrostatic discharge.

Insert the appropriate wires into the selected screw-terminal sockets of your scanning card to make the channel input

connections. Each scanning card contains screw-terminal blocks for making quick input connections. Labeling is provided

on the card for channel identification. Note that tie-wraps can be used in conjunction with the card’s tie-down holes to

provide strain relief and to keep the channel wires organized.

When making differential voltage measurements, you should ensure that one of the common terminal

blocks is connected to the common of the unit being measured.

Step 5: Install the Scanning Card into the Unit

CAUTION

TempScan/1100 scanning cards are designed for and supported only by the TempScan/1100 master unit.

MultiScan/1200 scanning cards are designed for and supported only by the MultiScan/1200 master unit.

Use of a wrong card can cause operating errors and possibly damage equipment.

Do not connect the power to any devices that are connected to the scanning card inputs until after the

scanning cards have been properly installed in the scan device.

1. When the channel input connections on the scanning card are ready, make sure that the POWER pushbutton on the

scan device (TempScan or MultiScan) is in the "OFF" position (extended out).

CAUTION

2. Plug the CA-1 power cable into the unit and then into the proper AC power outlet. Do not connect the power to any

devices that are connected to the scanning card inputs at this time.

3. Install the scanning card into the INPUT CARD slot of the unit.

4. After the scanning card is installed, connect the power lines to the devices that are connected to the scanning card inputs.

Then make other connections as applicable to your system.

Step 6: Apply Power to the System

1. Turn on the host PC.

2. Turn on the scan device (TempScan/1100 or MultiScan/1200) by pushing in the POWER pushbutton.

3. Turn on any applicable devices that are connected to the scanning card inputs.

QS-2 TempScan / MultiScan Quick Start Guide 988892 446-0940, rev 2.2

Page 13

Reference Note:

If the ERROR LED indicator starts flashing, refer to the chapter entitled, Power & Assembly, in your user's

manual. The section includes details regarding possible power-up activation errors. The default location of the

manual and other support documentation is the Program group, accessible from the Windows Desktop Start

menu. Documents can also be accessed directly from the data acquisition CD via the <View PDFs> button

located on the CD’s opening screen.

Software Setup & Startup

Step 1: Install Software and Manuals

1. Remove previous version Scan drivers, if present. You can do this through Microsoft’s Add/Remove Programs feature.

2. Place the Data Acquisition CD into the CD-ROM drive. Wait for PC to auto-run the CD. This may take a few moments,

depending on your PC. If the CD does not auto-run, use the Desktop’s Start/Run/Browse feature to locate and launch the

CD’s setup.exe file.

3. After the intro-screen appears, follow the screen prompts. Upon completing the software installation, continue with

step 2, Start ChartView & Collect Data.

NOTE: Prior to CD 501395D-01, ChartView enhancements were available for purchase. We now provide them at no

additional cost. To enable all ChartView features: (1) From ChartView’s main window, open the File pull-down

menu, (2) select Authorization, (3) enter code C3523DFA6C0A in the dialog box and apply the code.

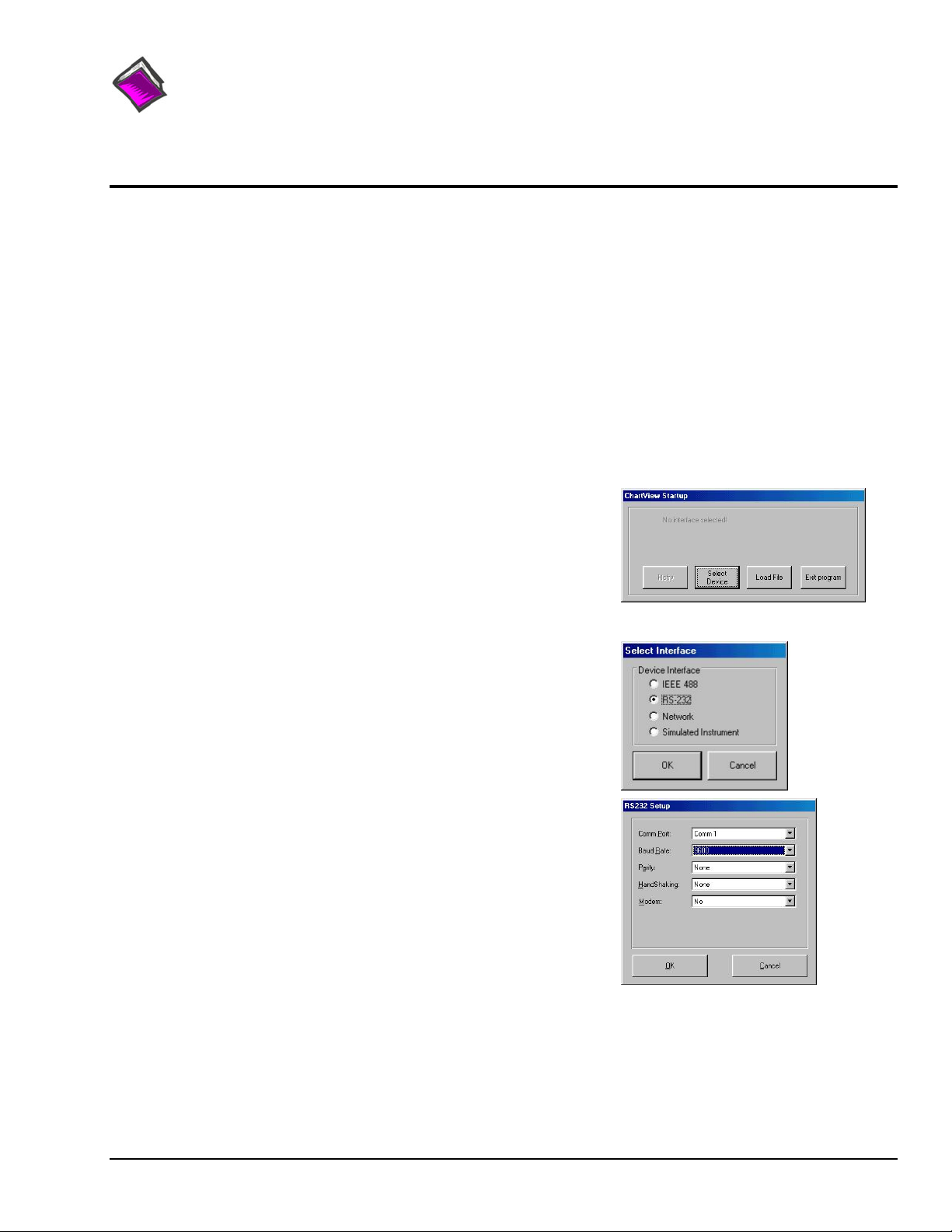

Step 2: Start ChartView & Collect Data

1. Double-click on the ChartView icon, or select the ChartView option from

the ChartView program group. The ChartView Startup dialog box will

appear with three selectable options: Select Device, Load File, and Exit

program. See figure at right.

Click the < Select Device> button. The Select Interface dialog box will

2.

appear. The Select Interface dialog box presents four options:

IEEE 488, RS-232, Network, and Simulated Instrument.

3. Select the RS-232 radio button, then click <OK>.

Note: If using an IEEE 488 or Network interface, refer to the

TempScan/MultiScan User’s Manual (p/n 446-0901). You can access

the manual directly from the data acquisition CD by using the

<View PDFs> button located on the CD’s opening screen.

To practice using ChartView with no instrument connected

select Simulated Instrument as the device interface.

4. When you choose RS-232, the RS-232 Setup dialog box appears.

Information regarding Comm Port, Baud Rate, Parity, Handshaking, and

Modem can be viewed and changed from this box. Make sure that the

information matches the current hardware configuration of the DIP switch

setting. Note that a baud setting of 9600 is recommended.

Note: Make sure that the information in the RS232 Setup box matches

the hardware configuration of the DIP switch.

When the dialog box information is complete, click OK.

At this point, the Chart Setup Wizard dialog box opens.

446-0940, rev 2.2 988892 TempScan / MultiScan Quick Start Guide QS-3

Page 14

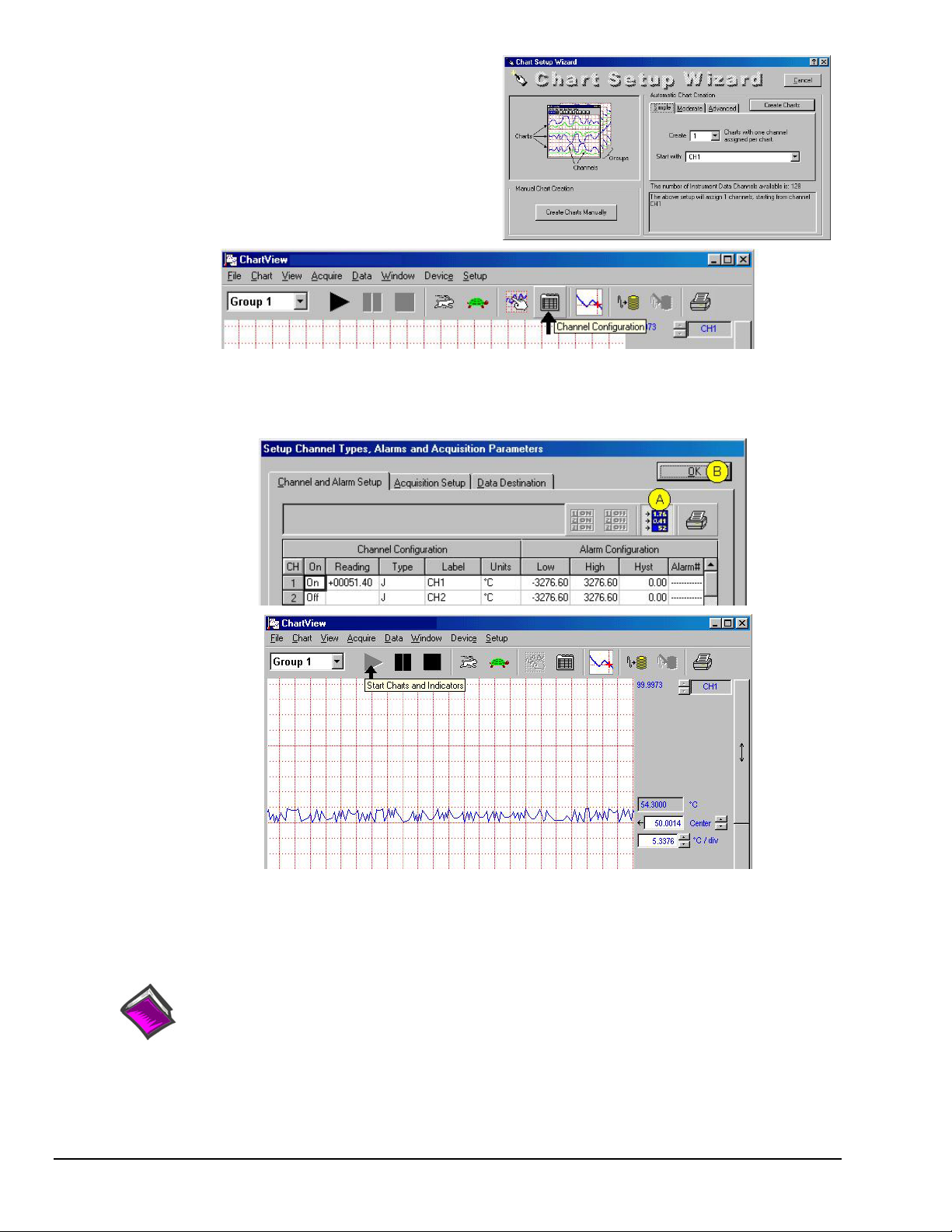

5. In the Automatic Chart Creation portion of the Chart Setup

Wizard box, click the <Create Charts> button. ChartView’s

main window opens. Here we are using the program default

settings. Note that you can go back later and edit the chart setup.

6. In ChartView’s toolbar, click the <Channel Configuration>

button (first figure, following page).

The “Setup Channel Types, Alarms and Acquisition Parameters”

window will open.

7. In the “Setup Channel Types, Alarms and Acquisition Parameters” window (following figure), perform the following

actions: Click the <Turn On/Off Channel Readings> button (item “A”). This activates the Reading column.

Click the <OK> button (item “B”). This accepts the settings. After clicking <OK> the ChartView Main Window will

open.

ChartView Main Window (Partial View)

8. To start the chart scrolling click on the <Start Charts and Indicators> (

click on the <Stop Charts> (

Black Square) button. Feel free to continue exploring ChartView to become more familiar

with the application.

Reference Note:

For detailed information regarding ChartView and the post-acquisition data viewer program,

e.g., PostView, refer to the Adobe PDF version documentation. The default location of the electronic

documents is the Programs group, accessible from the Windows Desktop Start menu.

Documents can also be accessed directly from the data acquisition CD via the <View PDFs>

button on the CD’s opening screen.

Black Triangle) button. To stop the chart scrolling

QS-4 TempScan / MultiScan Quick Start Guide 988892 446-0940, rev 2.2

Page 15

System Overview 1

Introduction ...... 1-1

TempScan/1100 ...... 1-1

MultiScan/1200 ...... 1-1

Front Panel Indicators ...... 1-2

Rear Panel Switches & Connectors ...... 1-3

TempScan/1100 & MultiScan/1200 Specifications ...... 1-4

Hardware Configuration ...... 1-7

IEEE 488 Configuration ...... 1-8

RS-232/422 Serial Configuration ...... 1-9

Calibration Protection Configuration ...... 1-13

Digital I/O Configuration ...... 1-13

TTL Output & Trigger Input Configuration ...... 1-14

Expanded Memory Configuration ...... 1-15

Scanning Card & Channel Expansion ...... 1-16

Power Line & Fuse Configuration ...... 1-17

Introduction ...... 1-17

Line Voltage Selection ...... 1-18

Fuse Replacement ...... 1-20

Rack-Mount & Bench-Top Assembly ...... 1-21

Rack Mount ...... 1-21

Bench Top ...... 1-21

Power-Up Activation ...... 1-22

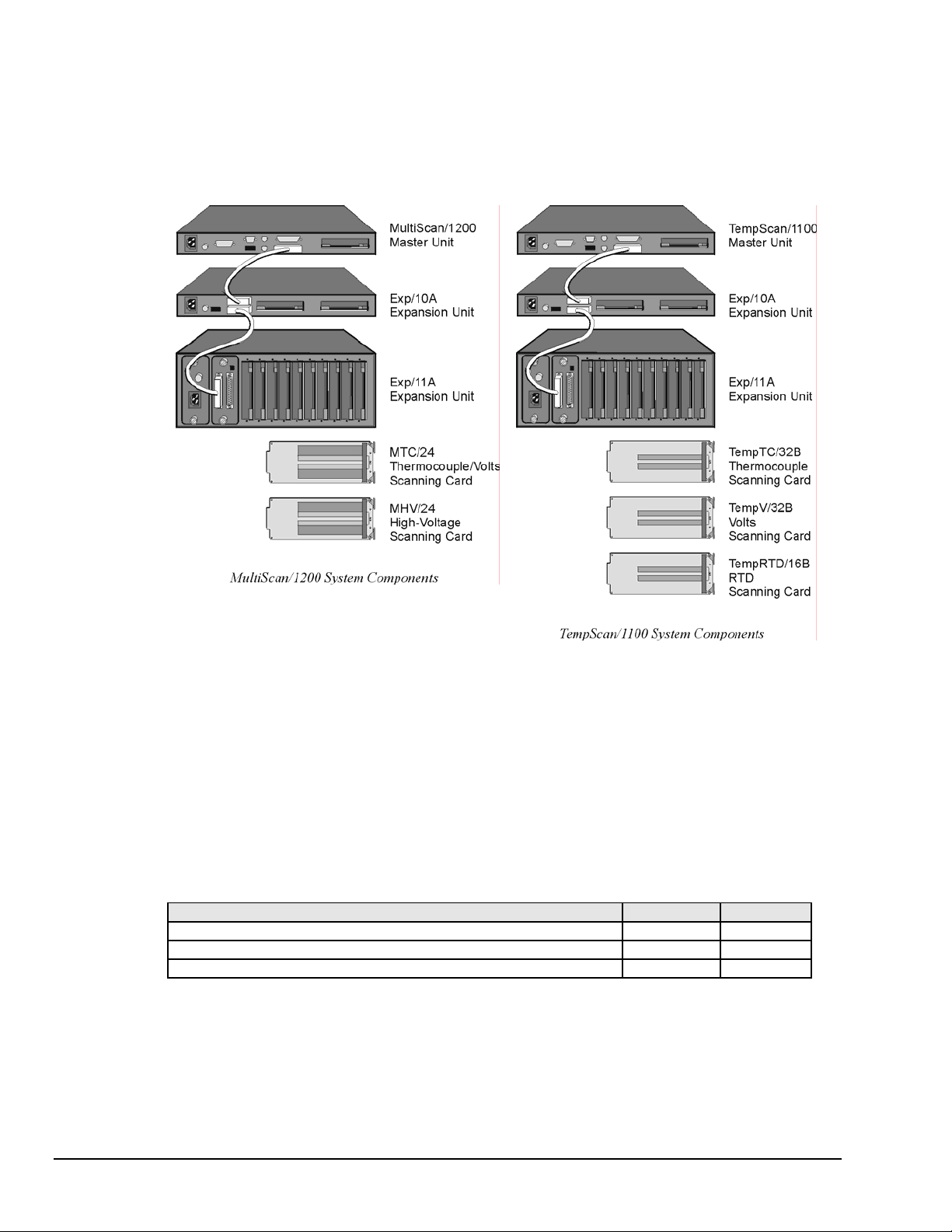

Introduction

All TempScan/1100 and MultiScan/1200 components are carefully inspected prior to shipment.

When you receive your temperature-and-voltage measurement system, carefully unpack all items from the

shipping carton and check for any damage which may have occurred during shipment. Promptly report the

damage to the shipping agent and your sales representative. Retain all shipping materials in case you must

return the unit to the factory. Refer to the QuickStart Guide at the front of this manual for installation

instructions.

The TempScan/1100 and MultiScan/1200 are high-speed, compact, rack-mountable instruments that

measure up to 992 or 744 channels of temperature or voltage, respectively. Because of their unique

architecture, both instruments offer unrivaled low cost per channel. They connect to a computer via

IEEE 488 or RS-232 interfaces, or via modem, and can be disconnected from the computer for

stand-alone operation.

TempScan/1100

The TempScan/1100 is well-suited for temperature and lower-voltage measurement because its solid-state

scanning provides temperature readings at speeds up to 960 channels per second, an important feature in

applications that require monitoring of tens or hundreds of channels.

MultiScan/1200

The MultiScan/1200 is ideal for temperature and voltage measurements that require channel-to-channel

isolation. The unit provides 500 V of channel-to-channel isolation for voltage, and 200 V of channel-tochannel isolation for thermocouples. The MultiScan/1200 uses relays to provide isolation and to scan

thermocouples and volts at up to 147 channels per second. The unit can also digitize waveforms on

a single channel at up to 20 kHz.

TempScan / MultiScan User’s Manual 899493 System Overview 1-1

Page 16

Front Panel Indicators

Ten (10) LED indicators on the front panel of either the TempScan/1100 or MultiScan/1200 display the

status of the temperature-and-voltage measurement system:

ALARM ON when an alarm has occurred. The indicator remains ON until the alarm condition

TRIGGER Flashes when

SCAN ON when the unit is storing a channel scan in its internal buffer.

SEND (For RS-232 operation only) ON when transmitting data to the serial interface.

RECEIVE (For RS-232 operation only) ON when receiving data from the controlling computer.

TALK (For IEEE 488 operation only) ON when the unit is in the Talker state, OFF when the unit

LISTEN (For IEEE 488 operation only) ON when the unit is in the Listener state, OFF when the

SRQ (For IEEE 488 operation only) ON when the unit has generated a Service Request (SRQ),

ERROR ON when an error has occurred, OFF when no error condition exists. For more

POWER ON when power is applied to the unit and the power switch on the back panel is in the ON

clears. OFF when no alarm condition exists.

Armed and waiting for a Trigger; is ON continuously when triggered; is OFF

when data collection is finished. The Trigger is also turned OFF by IEEE

DCL or SDC.

is in the Idle or Listener state.

unit is in the Idle or Talker state.

OFF when no SRQ is pending. For more information, see command Set SRQ Mask (

information, see command Query Error Status (

E?).

position (depressed). OFF if power is not present.

M).

1-2 System Overview 899493 TempScan / MultiScan User's Manual

Page 17

Rear Panel Switches & Connectors

Two (2) switches, seven (7) connectors, one (1) grounding nut, and one (1) input card slot on the rear panel

of either the TempScan/1100 or MultiScan/1200 provide power, IEEE 488 addressing, triggering, a single

point grounding node, and I/O connections.

Power Switch

Used to turn power to the unit ON and OFF. When the switch is in

the depressed position the power is ON. When in the extended

position, the power is OFF.

DIP Switch

For IEEE 488: Used for selecting IEEE 488 communication and bus

address.

For RS-232: Used for selecting RS-232 serial

communication, handshaking, parity and baud rate.

Microswitch 9 is used to enable/disable the hardware

protected portion of NV-RAM.

Power Connector

Provides power for the unit. Internally configurable for either 105125 or 210-250 VAC, 50/60Hz, plus fuse circuit breaker.

IEEE 488 Connector

RS-232C Connector

Port for the IEEE 488 interface.

DB9 serial port for operation at remote distances from controlling

computer supports 300 to 9,600 baud using RTS/CTS or

XON/XOFF handshaking (XON/XOFF for ASCII transmissions

only).

TTL Output Connector

BNC TTL scan output signal occurs for each channel scan; used for

synchronizing other equipment with TempScan/1100 or

MultiScan/1200 acquisition.

Trigger Input Connector

BNC trigger input for starting and/or stopping acquisition of the

TTL output signal.

Alarms & Digital I/O Connector

DB50 port offers easy access to Alarms and Digital I/O

(32 digital outputs and 8 digital inputs)

Master/Slave Connector

DB25 master/slave port connects to Exp/10A and/or Exp/11A

expansion slave units to support applications of up to 992 channels

with the TempScan/1100 master unit, or up to 744 channels with the

MultiScan/1200 master unit.

Grounding Screw

An external single-point grounding node has been supplied for (but

not limited to) thermocouple shield termination.

TempScan / MultiScan User’s Manual 899493 System Overview 1-3

Page 18

TempScan/1100 & MultiScan/1200 Specifications

CAUTION

Note:

Channels

Number of Slots: One (1) slot

Number of Channels (TempScan/1100): Up to 32 differential thermocouple or voltage inputs, or up to

16 RTD inputs; accepts TempTC/32B, TempV/32B, or TempRTD/16B scanning modules

Number of Channels (MultiScan/1200): Up to 24 differential thermocouple or voltage inputs; accepts

MTC/24 or MHV/24 scanning modules.

Channel Attributes: High and low set points; hysteresis values for high and low set points.

Scan Sequence: Any combination of temperature and voltage channels may be scanned, but channels are

scanned in ascending numerical order.

Scan Interval: Absolute time between scans (

Note that specifying a value of 00:00:00.0 results in no delay between channel scans.

Scanning Modes (TempScan/1100): For thermocouples up to 500 feet: 960 channels/sec @ 60 Hz;

800 channels/sec @ 50 Hz; For thermocouples over 500 feet: 240 channels/sec @ 60 Hz,

200 channels/sec @ 50 Hz.

Scanning Modes (MultiScan/1200): For multi-channel scanning: 147 channels/sec @ 50 or 60 Hz;

For 32-point line-cycle averaging enabled: 44 channels/sec @ 60 Hz, 38.5 channels/sec @ 50 Hz;

For single-channel burst mode: 1 channel @ 20K samples/sec.

Please read this manual carefully! If equipment is used in any manner not

specified in this manual, the protection provided by the equipment may be

impaired.

These specifications are subject to change without notice.

hh:mm:ss.s); min = 00:00:00.0, max = 99:59:59.9.

Triggers

Installation Category: For CE: Category 1.

Programmable Triggering: Temperature or Voltage level (above or below), absolute time of day, alarm

condition (on or off), IEEE GET, IEEE TALK, external TTL trigger (rising or falling), specified

number of readings.

Temperature-Level Trigger: Programmable value for any one channel. For MultiScan/1200: This

trigger not available when in single-channel burst mode.

TTL Trigger: Programmable for rising or falling edges.

Pre-Trigger Count: Programmable integer (< memory size -1).

Post-Trigger Count: Programmable integer.

Trigger Input Connector: External BNC connector

Trigger Output Connector: External BNC connector

1-4 System Overview 899493 TempScan / MultiScan User's Manual

Page 19

Data Storage & Format

Storage: 128 K reading (256 Kbyte) standard; optional 500 K reading (1 Mbyte), 2 M reading (4 Mbyte),

4 M reading (8 Mbyte).

Data Formats: ASCII and binary; binary format returns a 16-bit compensated and linearized temperature

value (0.1°C/bit); user-programmable for hi/low byte or low/hi byte. Note that high speed DMA

transfers are binary format only.

Statistical Parameters: High, Low, and Last available per channel. For MultiScan/1200: Not available

when in single-channel burst mode.

Time Stamping: Available for each scan group and for each channel’s high, low, and last parameters.

For MultiScan/1200: Not available when in single-channel burst mode.

Time Format: Absolute Time/Date stamping (

+hh:mm:ss.mil,DDDDDDD) and scan interval timebase (hh:mm:ss.t). For MultiScan/1200: Not

(

hh:mm:ss.mil,MM/DD/YY), relative Time/Date stamping

available when in single-channel burst mode.

Alarm Stamp: Available for each scan group. For MultiScan/1200: Not available when in single-channel

burst mode.

Digital Input Stamp: Available for each scan group. For MultiScan/1200: Not available when in single-

channel burst mode.

IEEE 488 Interface

CAUTION

The IEEE 488 terminal must only be used to control a non-isolated IEEE 488

system. The common mode voltage (cable shell to earth) must be zero.

Interface Use: Digital communication (as opposed to analog) for IEEE 488 compliant computer platforms,

as well as IEEE 488 compliant platform-independent configurations. Messages sent 1 byte (8 bits) at

a time. Supports data rates up to 1 Mbyte/sec. Up to 15 devices can be connected to one bus.

Total bus length up to 20 meters. Allowable cable distance between devices is up to 2 meters.

Message transactions are hardware handshaked.

Installation Category: For CE: Category 1.

Implementation: SH1, AH1, T6, TE4, L4, LE4, SR1, PP0, RL0, DC1, DT1, C0, E1.

Programmable Parameters: Alarm set points, thermocouple type, temperature units, Trigger level,

Pre-Trigger and Post-Trigger scan interval, Trigger mode, SRQ mask, scan count, Pre-Trigger count,

digital input, digital output, real time settings, data output format, and terminators.

Data Transfer Speed: Up to >300 Kbytes/s.

Connector: Standard IEEE 488 connector with metric studs.

RS-232 Serial Interface

CAUTION

The RS-232 terminal is only for connecting devices having signals at serial

communications levels.

Installation Category: For CE: Category 1.

Baud Rates: 300, 600, 1200, 2400, 4800 and 9600.

Data Bits: 8.

Stop Bits: 1.

Parity: Even, Odd, None.

Handshaking: RTS/CTS, XON/XOFF (for ASCII transmissions only).

Connector: Male DB-9.

TempScan / MultiScan User’s Manual 899493 System Overview 1-5

Page 20

Digital I/O Interface & Alarms

Installation Category: For CE: Category 1.

Number of Digital Inputs: 8 bits, TTL level compatible.

Number of Digital Outputs: 32 bits, TTL level compatible. Can be programmed as alarms. Note that the

32 TTL outputs can be set or cleared via program control.

Alarm Conditions: May be detected by SRQ or by software query (SPoll or U command).

Alarm Update Rate: Alarms are updated whenever a channel assigned to an alarm is measured.

Connector: Female DB50 50-pin (32 Alarms, 8 digital inputs, 10 ground pins), mating connector supplied.

General

Installation Category: For CE: Category 2 for Line Voltage Input terminal. All other terminals are

Category 1.

Warm Up: 1 hour to rated accuracy.

Master/Slave Port: Female DB-25.

Chassis Ground Connection: Screw terminal.

Dimensions: 425 mm wide × 305 mm deep × 45 mm high (16.75” × 12” × 1.75”).

Weight: 3.62 kg. (8 lbs.).

Operating Environment: For standard: Indoor use, 0 to 50°C; 0 to 95% RH (non-condensing) to 35°C;

linearly derate 3% RH/°C from 35 to 50°C; For CE: Indoor use at altitudes below 2000 m,

0 to 40°C; 0 to 80% RH up to 31°C decreasing linearly 4% RH/°C to 40°C.

Control Switches: Power Switch, IEEE 488 or RS-232, IEEE address, handshake, parity,

baud rate, calibration memory write enable/disable.

Front Panel Indicators: LED indicators for ALARM, TRIGGER and SCAN; for SEND and RECEIVE

(serial interface); for TALK, LISTEN and SRQ (for IEEE 488 interface); and for ERROR and

POWER.

Power: 105-125 or 210-250 VAC, 50/60 Hz; 20 VA maximum (internal slide switch).

CAUTION

Line Voltage: The protective conductor terminal on the AC line connector must

be connected to an external protective earthing system. Failure to make such a

connection will impair protection from shock.

WARNING

Fuse: 1/2A, 250 V, Slo Blo, 3AG (for 105-125V power line) or 1/4A, 250V, Slo Blo, 3AG (for 210-250V

power line).

Service: This product contains no operator serviceable parts. Service must be

performed by qualified personnel. All terminals, including the AC line and

scanning cards, must be disconnected prior to opening the TempScan/1100 or

MultiScan/1200 case. Internal voltage potentials exist which could cause bodily

injury or death!

CAUTION

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry.

If a fuse blows, contact a qualified service representative. Replacement fuses are

to be installed by qualified service personnel with the unit disconnected from the

power source and with all other terminals disconnected. If the line voltage

selector is changed, then the fuse designated for that line voltage must be used.

1-6 System Overview 899493 TempScan / MultiScan User's Manual

Page 21

Calibration

Calibration of cold junction sensor: Software control of calibrated thermocouple using ChartView’s

built-in calibration feature. The automated calibration function is accessed from ChartView’ Device

pull-down menu using “Select Status” and then selecting “Calibration.” Note that calibration is

performed for each card and chassis in the system.

Voltage Calibration: Software control of gain and offset.

Calibration Constants: Chassis constants stored in NV-RAM. Card constants stored in card’s on-board

EEPROM.

Hardware Configuration

The TempScan/1100 or MultiScan/1200 unit is equipped with a high-speed IEEE 488 interface and an

RS-232 interface. Its IEEE 488 interface is useful in laboratory applications and enables real-time transfers

of acquired data to the host computer’s hard drive for inexpensive mass storage.

Its RS-232 interface is ideal in applications that require the placement of instrumentation at remote

distances from the controlling computer, such as process and environmental control.

This unit can be set up with an IEEE 488 or a RS-232 interface configuration, as determined by the DIP

switch accessible from the rear panel. This DIP switch via its nine microswitches select which command

set is to be used – IEEE 488 or RS-232 – and the operating parameters for each.

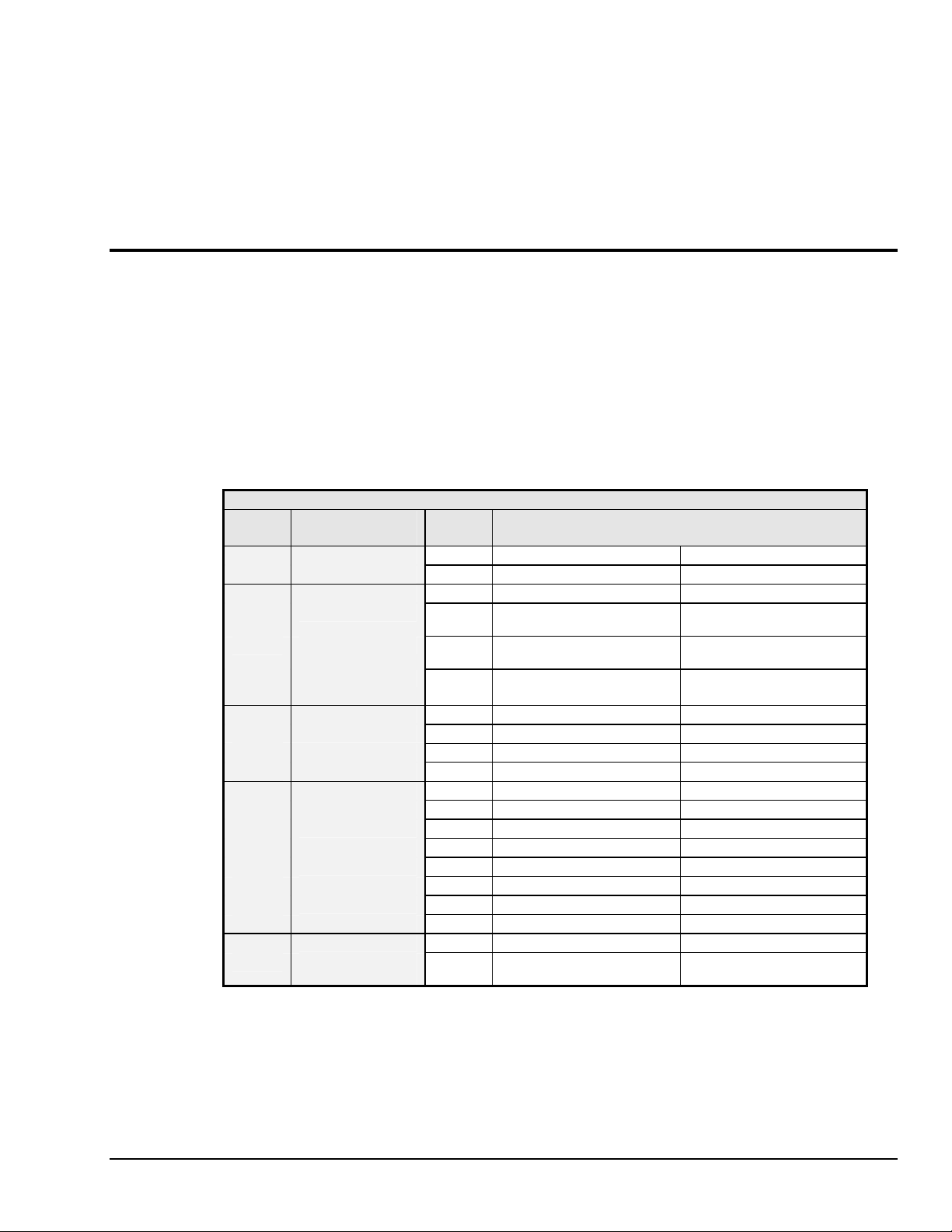

The table shows the options for its nine microswitches. Additional DIP switch settings are shown in the

following sections.

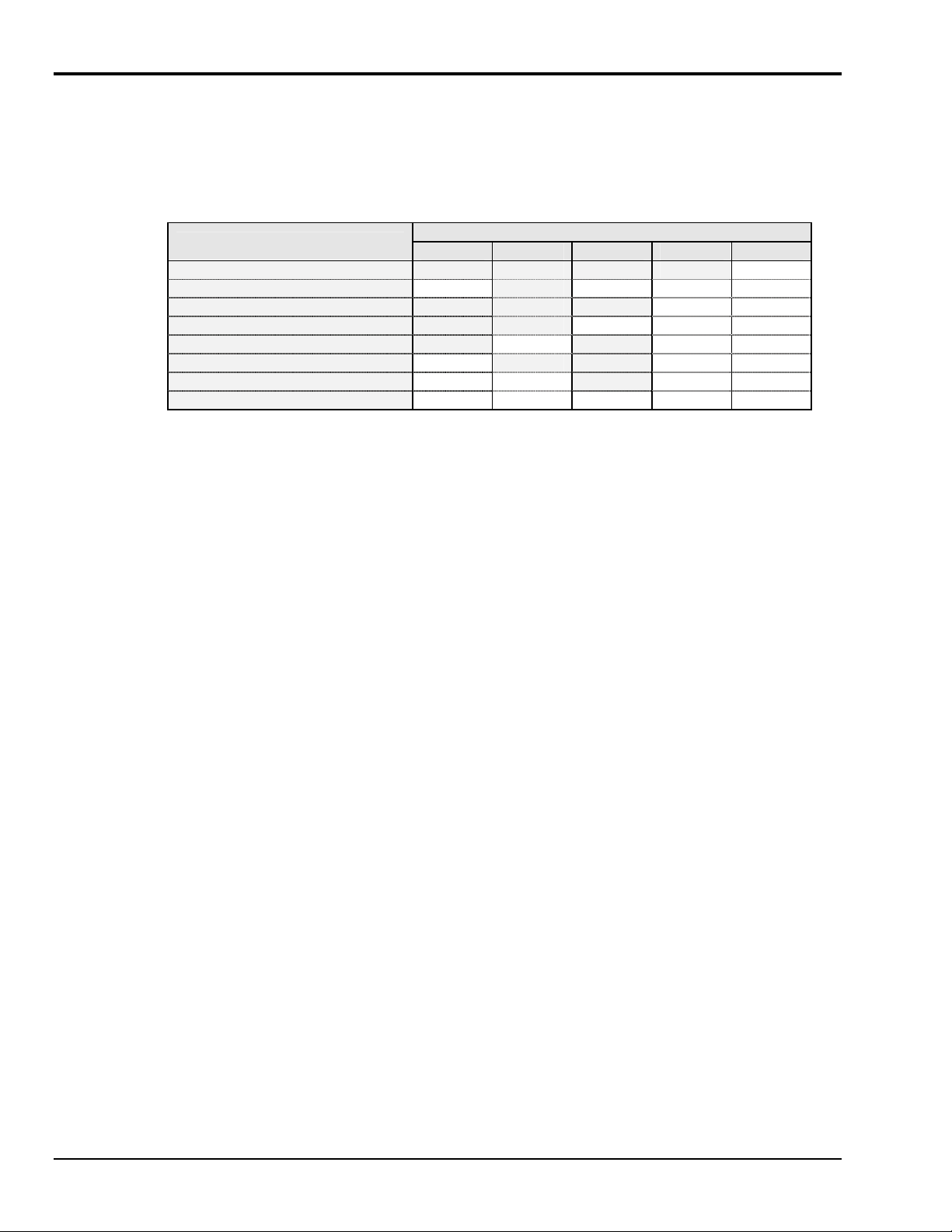

Micro- Label Setting Description

switch #

2,3

4,5

6,7,8

Note:

COMM SELECT 0 IEEE 488 (N/A)

1

1 (N/A) RS-232

HANDSHAKE (H/S) 00 No Handshake No Handshake

01 Software Handshake only

10 Hardware Handshake only

11

IEEE ADDRESS or 00 Decimal value 0 No Parity

PARITY 01 Decimal value 8 Odd Parity

10 Decimal value 16 Even Parity

11 Decimal value 24 (N/A)

IEEE ADDRESS or 000 Decimal value 0 300 baud

BAUD RATE 001 Decimal value 1 600 baud

010 Decimal value 2 1200 baud

011 Decimal value 3 2400 baud

100 Decimal value 4 4800 baud

101 Decimal value 5 9600 baud (See Note)

110 Decimal value 6 (N/A)

111 Decimal value 7 (N/A)

CHASSIS 0 Disabled Disabled

9

CALIBRATION

ENABLE

(1) XON/XOFF handshaking is valid for ASCII transmissions only. (2) At 9600 baud,

hardware (RTS/CTS) handshaking and possibly software (XON/XOFF) handshaking may be

required to maintain serial performance.

Rear Panel DIP Switch

IEEE 488 RS-232

(XON/XOFF) (See Note)

(RTS/CTS)

Both Hardware and Software

1 Enabled Enabled

Handshake

Software Handshake only

(XON/XOFF) (See Note)

Hardware Handshake only

(RTS/CTS)

Both Hardware and Software

Handshake

TempScan / MultiScan User’s Manual 899493 System Overview 1-7

Page 22

The rear panel DIP switch is read only during power-on or reset and should be set before applying power.

To modify any of these defaults, change the microswitch settings using a small screwdriver. The enclosure

does not need to be opened to change these settings.

IEEE 488 Configuration

One way in which the TempScan/1100 or MultiScan/1200 unit can be controlled, is through its IEEE 488

port connector. Consequently, when configured as an IEEE 488 bus device, the unit must have an IEEE

488 bus address.

DIP Switch

For IEEE 488 operation, the single microswitch labeled COMM SELECT should be down (0) on the rear

panel DIP switch . This down (0) position is the factory default. The up (1) position is reserved for

RS-232 serial communication. When IEEE 488 operation is enabled, the five microswitches labeled

IEEE ADDRESS are used to configure the required IEEE 488 bus address.

The bus address can be set from 0 through 30 and is read only at power-on or reset. The address is selected

by simple binary weighting. The switch labeled 1 is the least significant bit (LSB); 16 is the most

significant bit (MSB). The factory default is bus address 7. Note that if address 31 is selected, it defaults

to address 30 because the IEEE 488 standard has reserved address 31.

The rear panel DIP switch is read only during power-on or reset and should be set before applying power.

To modify any of these defaults, change the microswitch settings using a small screwdriver. The enclosure

does not need to be opened to change these settings.

1-8 System Overview 899493 TempScan / MultiScan User's Manual

Page 23

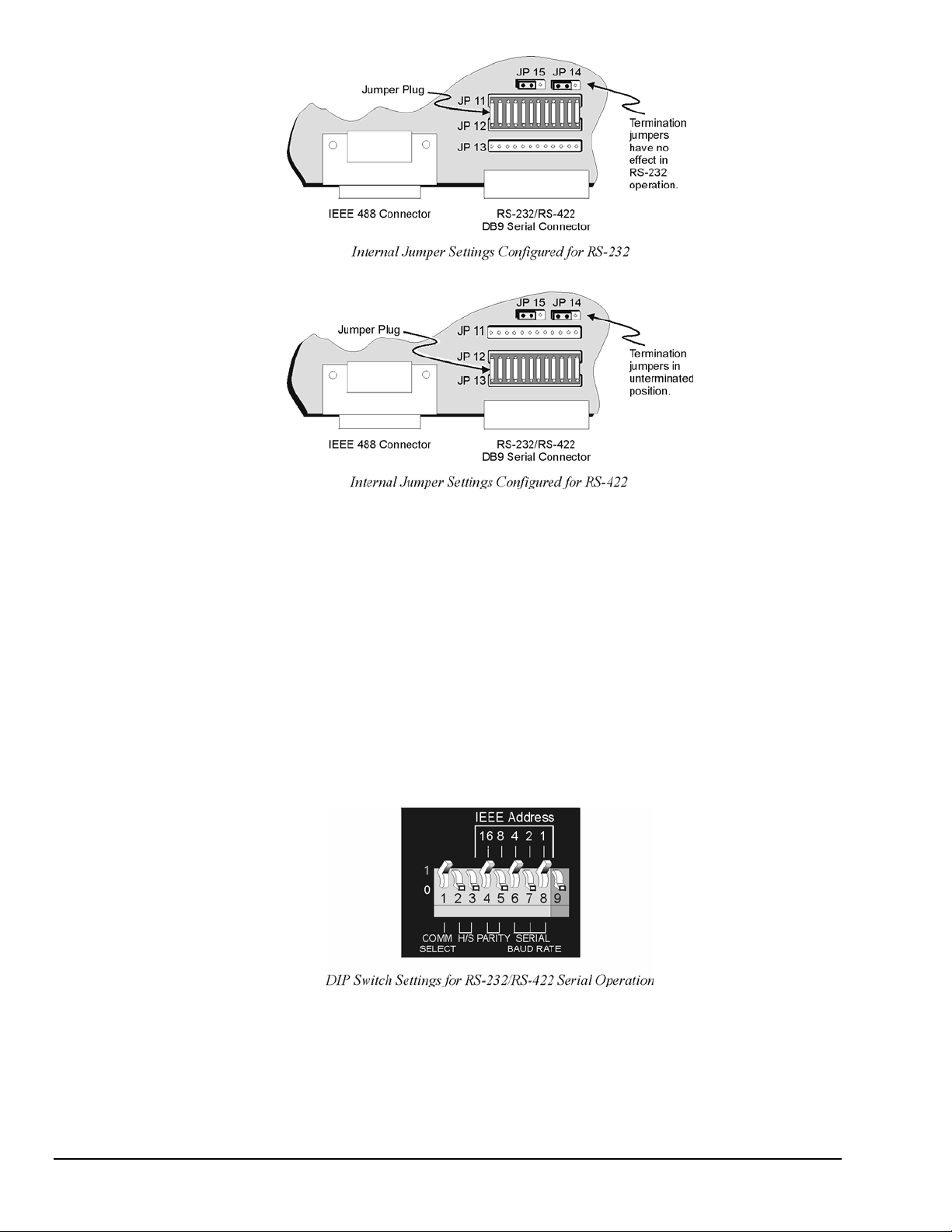

RS-232/RS-422 Serial Configuration

Alternatively, the TempScan/1100 or MultiScan/1200 unit can be controlled through its serial port

connector. Complete serial port configuration is accomplished by using both internal jumpers and DIP

switch settings. The internal jumpers, located on the main board behind each serial connector, are used to

configure the port with either RS-232 or RS-422 electrical characteristics. The DIP switch, located on the

rear panel, is used to determine handshaking, parity, and baud rate. Furthermore, the selection of an

RS-232 or RS-422 electrical configuration determines the serial port pattern of pin connector signals, as

discussed later.

Internal Jumpers

The jumpers within the unit configure the serial port electrically as either RS-232 or RS-422. To change

the serial port configuration, it is necessary to perform the following steps:

Never disassemble the case while it is connected to the AC power line!

Internal voltage potentials exist which could cause bodily injury or death!

Never disconnect the AC power line from the TempScan/1100 or MultiScan/1200

while its scanning cards are connected to an external device! Common mode

voltage potentials exceeding 60 VDC or 30 Vrms at the terminals, may exist which

could cause bodily injury or death!

WARNING

WARNING

Note:

If disassembly or disconnections are necessary, first turn off the power, then disconnect the

scanning cards, next disconnect the AC power line, and then any other cables, prior to unit

disassembly.

To Change the Serial Configuration

1. Turn off the power, disconnect the scanning cards, the power line cord, then all other cables from the

unit. For more information, see section Disconnecting & Reconnecting the System During Setup on

page 1-6.

2. Place the unit on a flat surface. Remove the six screws on top of the case. Remove the top cover.

3. The serial port is capable of operating in RS-232 or RS-422 mode. This selection is done via a set of

hardware jumpers located on the main board behind the serial connector. A 12-position jumper plug

must be inserted in one of the two available positions for proper operation (across JP11 and JP12 for

RS-232, across JP12 and JP13 for RS-422). These jumpers are factory set for RS-232 as shown in the

figure. To reconfigure the serial port for RS-422 operation, remove the jumper plug and reinsert it

into the lower 2 rows of jumpers.

TempScan / MultiScan User’s Manual 899493 System Overview 1-9

Page 24

4. If configured for RS-422, the port’s Receive Data (RxD+) and Clear to Send (CTS+) input lines may

optionally be terminated with a 100-Ohm resistor. Termination resistors are selected by positioning

the two flea clips (labelled JP14 and JP15). These jumpers are factory set to the unterminated

position,

as indicated in the previous figures. Note that when using RS-422 in a single-ended configuration,

ports must be unterminated. Termination jumpers have no effect when the port is configured for

RS-232 operation.

5. Once the jumper(s) have been repositioned for your application, make note of the new jumper settings

for later reference.

6. Carefully reassemble the unit.

Note:

For re-assembly, first reconnect the AC power line (with the power OFF), next reconnect the

scanning cards, and then any other cables, prior to reapplying power to the entire system.

DIP Switch

To configure the TempScan/1100 or MultiScan/1200 for RS-232/RS-422 serial operation, the single

microswitch labeled COMM SELECT must be up (1) on the rear panel DIP switch. The down (0) position

is reserved for IEEE 488 communication. When serial operation is enabled, additional DIP microswitches

configure the following required parameters: Handshaking, parity, and baud rate.

1-10 System Overview 899493 TempScan / MultiScan User's Manual

Page 25

Handshaking. When the RS-232 port is used, the type of handshaking must be selected by the two

microswitches labeled H/S. The options available are: No handshaking, XON/XOFF, RTS/CTS or both

XON/XOFF and RTS/CTS handshaking. Note that XON/XOFF handshaking is valid for ASCII

transmissions only, and for RS-422 operation with a Macintosh, RTS/CTS handshaking is not

recommended.

Parity. The parity must be selected using the two microswitches labeled PARITY. The options provided

are: No parity, odd parity or even parity.

Baud rate. The baud rate is selected using the three microswitches labeled SERIAL BAUD RATE.

The available baud rates are 300, 600, 1200, 2400, 4800, and 9600.

Note:

(1) XON/XOFF handshaking is valid for ASCII transmissions only. (2) At 9600 baud,

hardware (RTS/CTS) handshaking and possibly software (XON/XOFF) handshaking may be

required to maintain serial performance. However, for RS-422 operation with a Macintosh,

RTS/CTS handshaking is not recommended.

The rear panel DIP switch is read only during power-on or reset and should be set before applying power.

To modify any of these defaults, change the microswitch settings using a small screwdriver. The enclosure

does not need to be opened to change these settings.

Serial Connector Pins

The TempScan/1100 or MultiScan/1200 unit is equipped with one DB-9S serial connector on its rear panel

and requires a DB-9P mating connector. This connector is configured as an IBM PC when RS-232 levels

are selected, and as a Macintosh when RS-422 levels are selected.

TempScan / MultiScan User’s Manual 899493 System Overview 1-11

Page 26

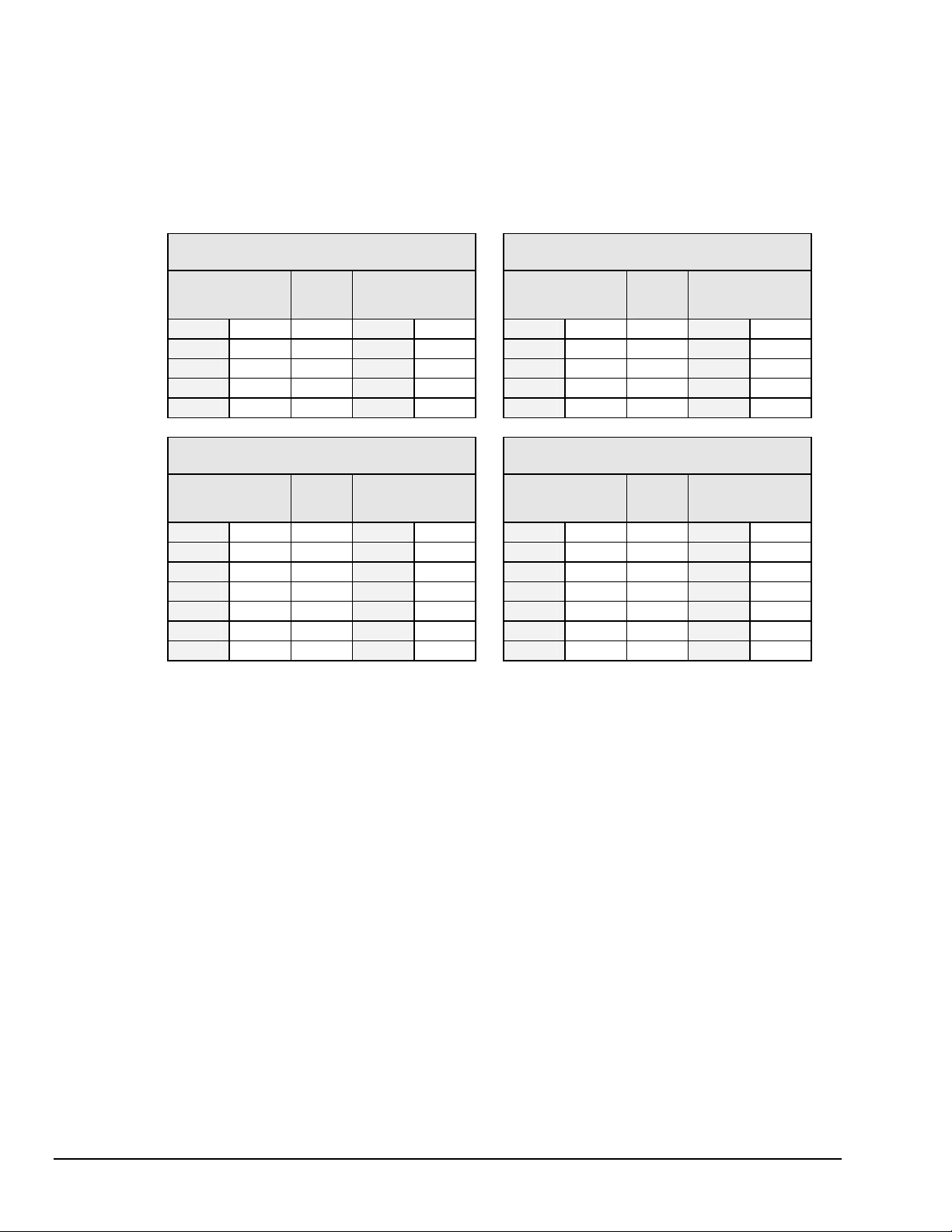

A CA-47 cable connects the unit with the computer. The TempScan/1100 or MultiScan/1200 end has one

DB9 connector, and the computer end has two connectors – one for a DB9 and one for a DB25. O

ther crossover-type cables can be used if they are wired as shown in the tables. The tables list the

following four connections from the TempScan/1100 or MultiScan/1200 unit:

• To a DB9 connector configured for RS-232

• To a DB25 connector configured for RS-232

• To a DB9 connector configured for RS-422

• To a Mini DIN8 connector configured for RS-422.

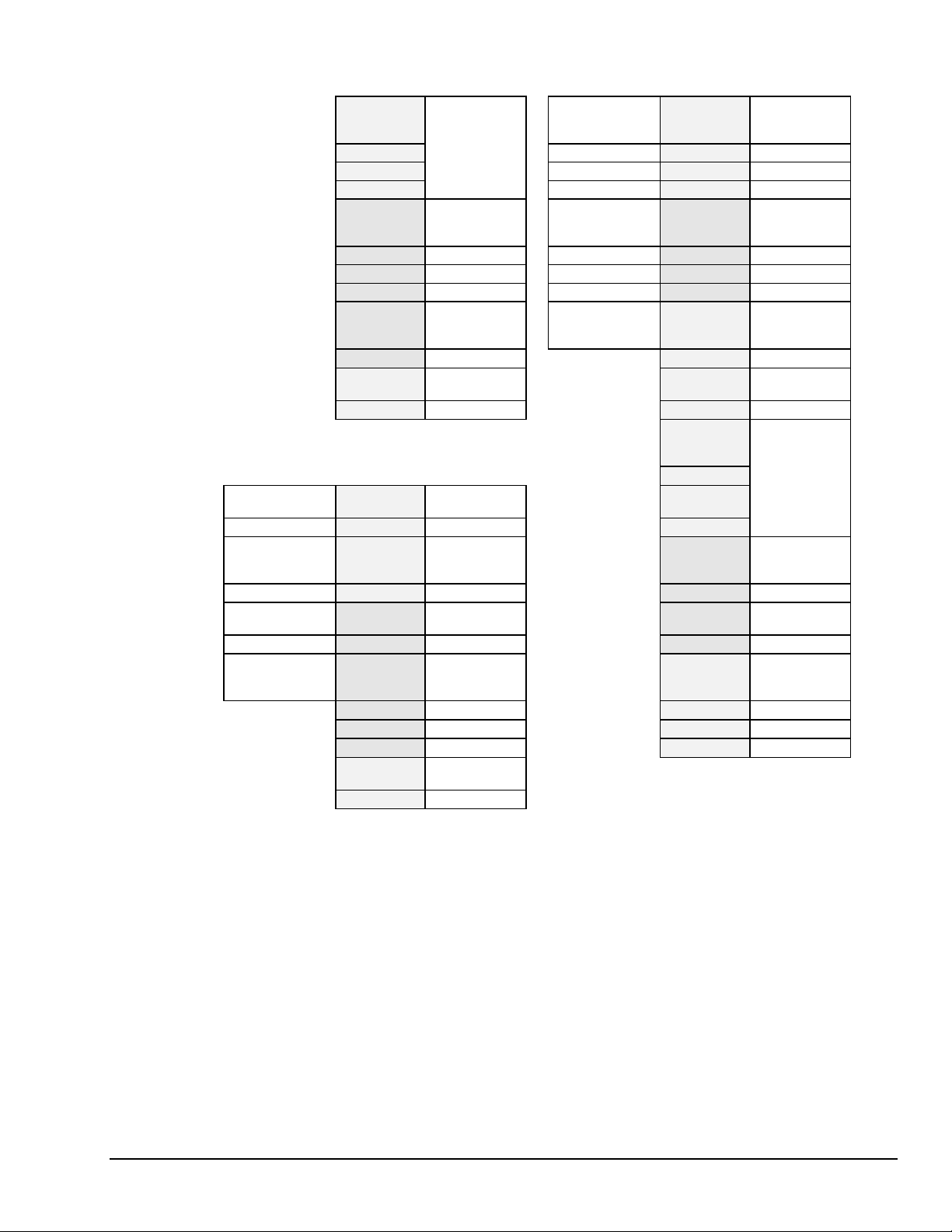

TempScan/1100 or MultiScan/1200

To PC Connection (RS-232)

DB9 Male

Pin & Signal

2 RxD-

3 TxD-

5 GND

7 RTS+

8 CTS+

Cable

Wirin

g

←--

--→

←→

--→

←--

DB9 Female

Pin & Signal

3 TxD- 2 RxD-

2 RxD- 3 TxD-

5 GND 5 GND

8 CTS+ 7 RTS+

7 RTS+ 8 CTS+

TempScan/1100 or MultiScan/1200

To PC Connection (RS-232)

DB9 Male

Pin & Signal

Cable

Wirin

g

←--

--→

←→

--→

←--

DB25 Female

Pin & Signal

2 TxD-

3 RxD-

7 GND

5 CTS+

4 RTS+

TempScan/1100 or MultiScan/1200

To Macintosh Connection (RS-422)

DB9 Male

Pin & Signal

1 GND

2 RTS+

4 TxD+

5 TxD-

6 CTS+

8 RxD+

9 RxD-

Cable

Wirin

g

←→

--→

--→

--→

←--

←--

←--

DB9 Male

Pin & Signal

3 GND 1 GND

7 CTS+ 2 RTS+

8 RxD+ 4 TxD+

9 RxD- 5 TxD-

6 RTS+ 6 CTS+

4 TxD+ 8 RxD+

5 TxD- 9 RxD-

TempScan/1100 or MultiScan/1200

To Macintosh Connection (RS-422)

DB9 Male

Pin & Signal

Cable

Wirin

g

←→

--→

--→

--→

←--

←--

←--

Mini DIN8 Male

Pin & Signal

4 GND

2 CTS+

8 RxD+

5 RxD-

1 RTS+

6 TxD+

3 TxD-

The following text describes the various pin connector signals:

• Transmit Data Negative (TxD-): This output pin transmits serial data to an RS-232 or RS-422 device.

The serial data received is sent with the word length, baud rate, stop bits, and parity configured for the

particular port. This signal is low true.

• Transmit Data Positive (TxD+): This output pin transmits serial data to an RS-422 device only.

The pin functions identically to TxD- except that its polarity is inverted. This signal is high true.

• Receive Data Negative (RxD-): This input pin accepts serial data sent by an RS-232 or RS-422 device.

The serial data received is expected to match the word length, baud rate, stop bits, and parity

configuration of the particular port. This signal is low true.

• Receive Data Positive (RxD+): This input pin accepts serial data sent by an RS-422 device only.

It functions identically to RxD- except that its polarity is inverted. This signal is high true.

• Request To Send Positive (RTS+): This output pin is used as a hardware handshake line to prevent an

RS-232 or RS-422 device from transmitting serial data to the TempScan/1100 or MultiScan/1200 unit

when it is not able to accept it. When automatic RTS/CTS handshaking is selected, the unit will assert

(high) the RTS+ signal when greater than 4096 memory locations are available in its internal buffers. If

available memory drops below 4096 bytes, the unit unasserts (low) the RTS+ signal.

• Request To Send Negative (RTS-): This output pin is used as a hardware handshake line with an

RS-422 device only. The pin functions identically to RTS+ except that its polarity is inverted. This

signal is low true.

1-12 System Overview 899493 TempScan / MultiScan User's Manual

Page 27

• Clear To Send Positive (CTS+): This input pin is used as a hardware handshake line to prevent the

TempScan/1100 or MultiScan/1200 unit from transmitting serial data to an RS-232 or RS-422 device

when it is not able to accept it. When RTS/CTS handshaking is selected, the unit will not Transmit

Data (TxD+) out while the CTS+ signal is un-asserted (low). When XON/XOFF or no handshaking is

selected, the CTS+ line is ignored.

• Clear To Send Negative (CTS-): This input pin is used as a hardware handshake line with an RS-422

device only. It functions identically to CTS+ except that its polarity is inverted. This signal is low true.

• Ground (GND): This signal sets the ground reference point for the other RS-232/RS-422 input and

output signals.

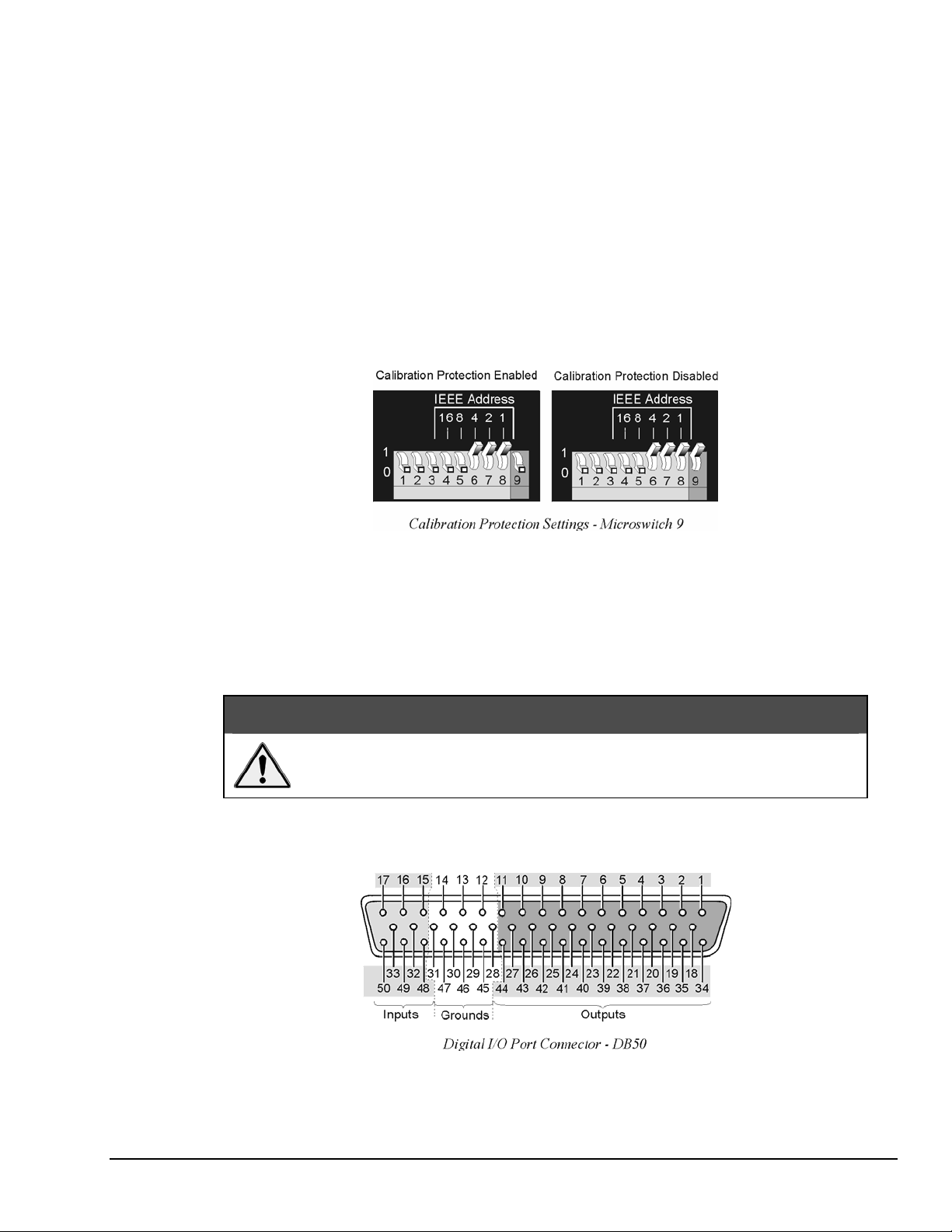

Calibration Protection Configuration

The chassis calibration constants and the calibration password are stored by the TempScan/1100 or

MultiScan/1200 in Non-Volatile RAM (NV-RAM). The password is a safety feature used to prevent

unauthorized personnel from entering calibration mode and altering the calibration constants.

As a safeguard, the calibration password and chassis calibration constants are hardware protected.

This protection is enabled by setting the microswitch 9 to the down (0) position on the rear panel DIP

switch. This is the default factory setting and should remain in this position unless purposely attempting to

change the password or chassis constants.

If it is necessary to change the calibration password (via the

hardware write protection can be disabled by setting microswitch 9 to the up (1) position. For details on

calibration, see chapter System Calibration.

Do not forget to set back the DIP microswitch 9 to the down (0) position when

calibration is complete. Otherwise, the calibration password and calibration

constants may be corrupted and normal operation may be disrupted.

Digital I/O Configuration

*K command) or to recalibrate the chassis, this

CAUTION

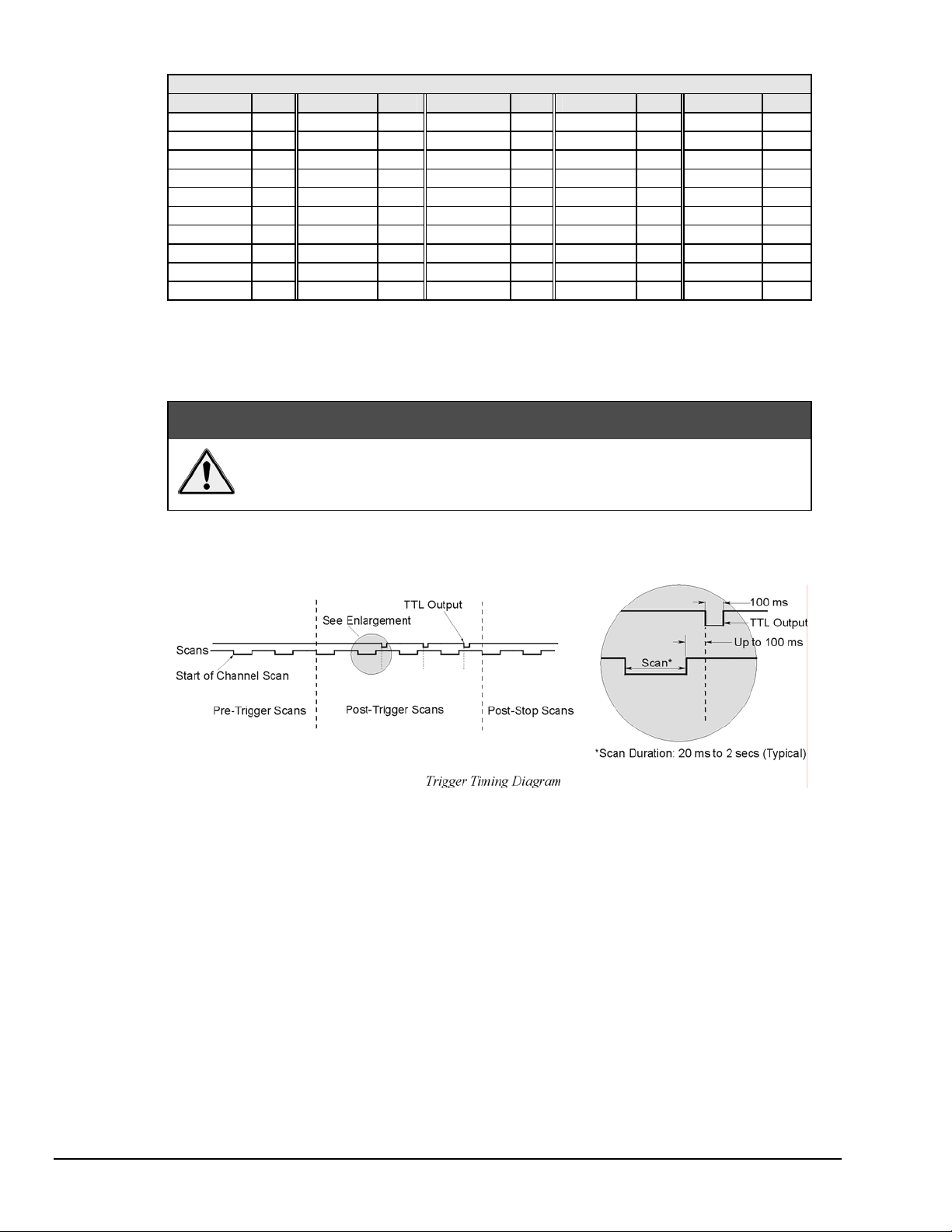

Located on the TempScan/1100 or MultiScan/1200 rear panel, the DB50 digital I/O connector provides

eight (8) digital input lines and thirty-two (32) digital output lines. The figure and table locate and describe

the input, output, and ground lines of this connector.

TempScan / MultiScan User’s Manual 899493 System Overview 1-13

Page 28

DB50 Digital I/O Pin Descriptions

Line Pin Line Pin Line Pin Line Pin Line Pin

Output 1 1 Output 11 37 Output 21 24 Output 31 11 Ground 12

Output 2 34 Output 12 21 Output 22 8 Output 32 44 Ground 13

Output 3 18 Output 13 5 Output 23 41 Input 1 15 Ground 14

Output 4 2 Output 14 38 Output 24 25 Input 2 48 Ground 28

Output 5 35 Output 15 22 Output 25 9 Input 3 32 Ground 29

Output 6 19 Output 16 6 Output 26 42 Input 4 16 Ground 30

Output 7 3 Output 17 39 Output 27 26 Input 5 49 Ground 31

Output 8 36 Output 18 23 Output 28 10 Input 6 33 Ground 45

Output 9 20 Output 19 7 Output 29 43 Input 7 17 Ground 46

Output 10 4 Output 20 40 Output 30 27 Input 8 50 Ground 47

Each digital output line will drive five (5) standard TTL (transistor-transistor logic) loads. All digital input

lines are one-eighth (0.125) TTL loads. All inputs are protected against damage from high static voltage.

Normal precautions should be taken to limit the input voltages to the range of 0.0 to 5.3 volts. All digital

I/O lines are referenced to digital ground.

CAUTION

Do not exceed the levels described. Otherwise, the TempScan/1100 or

MultiScan/1200 unit may be damaged in a way that is not covered by the

warranty.

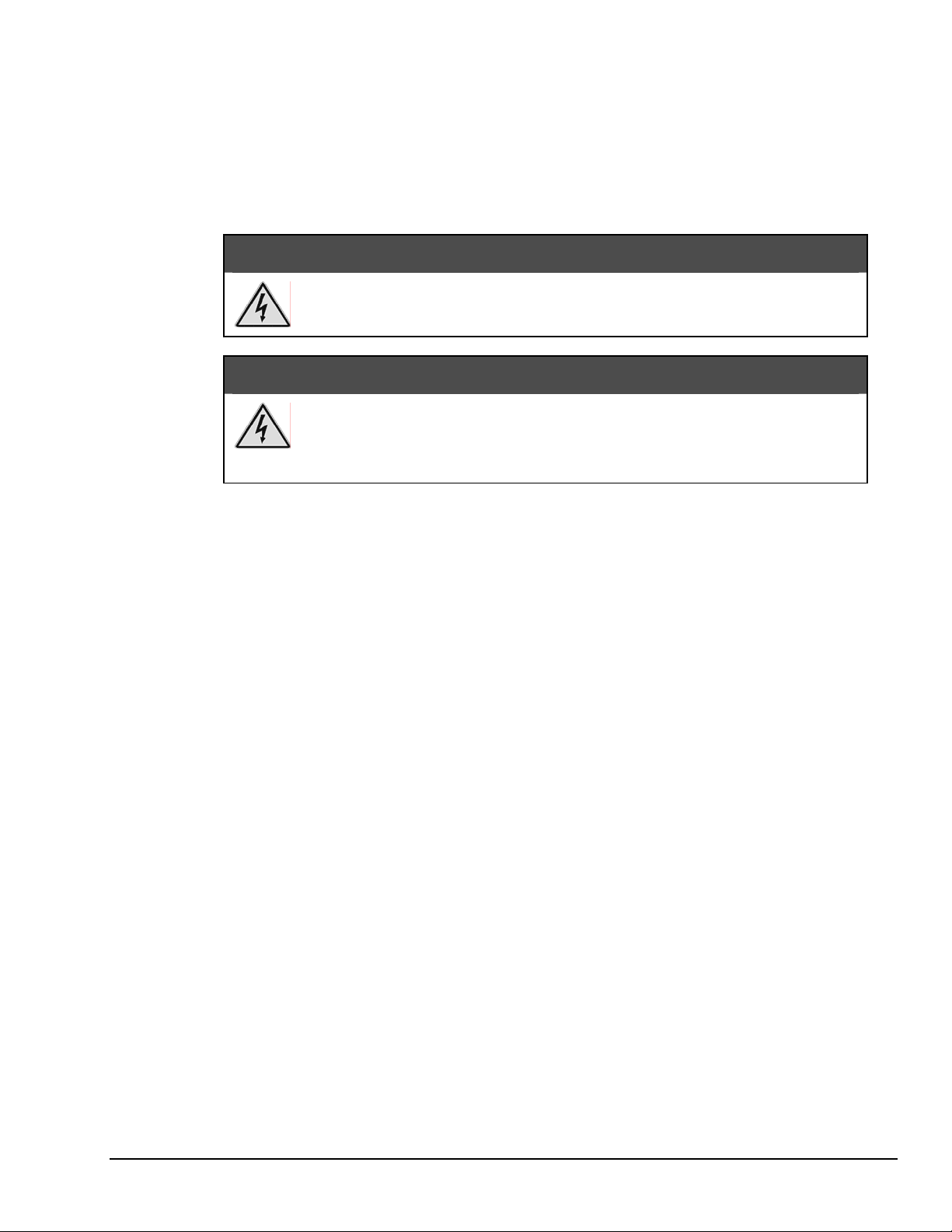

TTL Output & Trigger Input Configuration

The rear panel of the TempScan/1100 or MultiScan/1200 unit also provides two external BNC connectors:

The TTL output and the trigger input. The BNC TTL scan output is used for synchronizing equipment

with TempScan/1100 or MultiScan/1200 acquisition, while the BNC trigger input is used for starting

and/or stopping acquisition of the TTL output. This trigger input can be programmed to activate on a

rising (positive-going) or falling (negative-going) TTL level edge. Any TTL level signal

(> 2.2V = Hi, < 0.8V = Lo) may be used as a trigger pulse. A trigger pulse may also be used to generate a

Service Request. Note that the TTL Out is a LS-TTL compatible output, 0.4 mA sourcing, 8 mA sinking.

When a scan is logged into the acquisition buffer (after the actual scan), the TTL output signal is pulsed for

100 ms. Refer to the timing diagram.

1-14 System Overview 899493 TempScan / MultiScan User's Manual

Page 29

Expanded Memory Configuration

The TempScan/1100 or MultiScan/1200 can accommodate 8 MBytes of memory, which is ideal for both

high-speed and long-term data logging. Measurements can be stored in memory and read out by

a controlling computer as time permits. Readings may be transferred at up to 300 KBytes per second over

the IEEE 488 bus, or up to 9600 baud using the unit’s standard RS-232 port.

To install expanded memory into the unit, it is necessary to perform the following steps:

Never disassemble the case while it is connected to the AC power line!

Internal voltage potentials exist which could cause bodily injury or death!

Never disconnect the AC power line from the TempScan/1100 or MultiScan/1200

while its scanning cards are connected to an external device! Common mode

Note:

voltage potentials exceeding 60 VDC or 30 Vrms at the terminals, may exist which

could cause bodily injury or death!

If disassembly or disconnections are necessary, first turn off the power, then disconnect the

scanning cards, next disconnect the AC power line, and then any other cables, prior to

disassembly.

WARNING

WARNING

To Install Expanded Memory

1. Turn off the power, disconnect the scanning cards, the power line cord, and then all other cables

from the unit.

2. Place the unit on a flat surface. Remove the six screws on top of the case and remove the top cover.

3. Located on the main circuit-board assembly, alongside the scanning card enclosure, are SIMM

memory module slots JP8 and JP7. Remove the 256 KB module from JP7, insert one

4 MB module in its place, and insert the second 4 MB module in JP8.

4. Carefully reassemble the unit, replacing the top cover and screws.

Note:

For re-assembly, first reconnect the AC power line (with the power OFF), next reconnect the

scanning cards, and then any other cables, prior to reapplying power to the entire system.

TempScan / MultiScan User’s Manual 899493 System Overview 1-15

Page 30

Scanning Card & Channel Expansion

Scanning Card Expansion

Each TempScan/1100 or MultiScan/1200 unit can accept one scanning card to provide signal conditioning.

However, if your application demands more channels then you can expand the master unit’s capabilities

with either or both types of expansion units: Exp/10A and/or Exp/11A. Each Exp/10A expansion unit

allows for the addition of two scanning cards, while each Exp/11A expansion unit allows for the addition

of ten scanning cards. Up to fifteen Exp/10A units can be attached to the master unit, giving a maximum

of

30 additional scanning-card slots. Similarly, up to three Exp/11A units can be linked to the master unit,

also giving a maximum of 30 additional scanning-card slots, as shown in the following table.

Expansion Capabilities Exp/10A Exp/11A

Number of expansion scanning-card slots per expansion unit 2 10

Number of identical expansion units that can be linked to the master unit 15 3

Maximum number of expansion scanning-card slots 30 30

Note:

If a combination of Exp/10A and Exp/11A expansion units are linked together, then the

maximum number of expansion scanning-card slots is still 30.

1-16 System Overview 899493 TempScan / MultiScan User's Manual

Page 31

Channel Expansion

The TempScan/1100 system can be expanded up to 992 channels, while the MultiScan/1200 system can be

expanded up to 744 channels. This is easily accomplished via a master/slave architecture wherein a main

or master unit can be connected to as many expansion slave units as allowable within the maximum of

30 scanning cards.

Each Exp/10A or Exp/11A expansion unit has a form factor identical to that of either the TempScan/1100

or MultiScan/1200 master unit, allowing the expansion unit to accept the same scanning cards as its master

unit. When connected to the TempScan/1100, the Exp/10A or Exp/11A is configurable for 32 or 64 input

channels, providing a total expansion capacity of up to 992 channels. When connected to the

MultiScan/1200, the Exp/10A or Exp/11A is configurable for 24 or 48 input channels, providing a total

expansion capacity of up to 744 channels.

An expansion unit can only be controlled by the TempScan/1100 or MultiScan/1200 master unit, and no

digital I/O or alarms are included. However, expansion channels can be programmed to stimulate the

alarms located on the master unit. From the programmer’s perspective, channels are accessed in the same

way as channels in the master unit. When the master unit detects the presence of expansion units during its

power-on sequence, it makes the additional channels available to the programmer. The

U8 command is

available to query the master unit for the total number of channels in the system.

A general description of both types of expansion units, their connections and their configurations,

is discussed in the following chapters.

Power Line & Fuse Configuration

Introduction

The power configuration of any master or expansion unit consists of selecting the line voltage and

replacing the fuses. All of these units – TempScan/1100, MultiScan/1200, Exp/10A, and Exp/11A – each

has a factory default to operate at 105-125 volts AC. However, each unit may be operated at either 105125 or 210-250 VAC.

Do not use this unit outdoors! The unit is intended for indoor use only! Outdoor

conditions could result in equipment failure, bodily injury or death!

Never disassemble the case while it is connected to the AC power line! Internal

voltage potentials exist which could cause bodily injury or death!

Never disconnect the AC power line from the unit while its scanning cards are

connected to an external device! Common mode voltage potentials exceeding 60

VDC or 30 Vrms at the terminals, may exist which could cause bodily injury or

death!

WARNING

WARNING

WARNING

TempScan / MultiScan User’s Manual 899493 System Overview 1-17

Page 32

To change the operating voltage of the TempScan/1100, MultiScan/1200, Exp/10A, and/or Exp/11A unit,

it is necessary to open the enclosure. However, before modifying the voltage, disconnect any input or

output connections from the rear panel of the affected unit and then disconnect the power cord from the

power line terminal.

Line voltage must be set for 105-125 or 210-250 VAC to match the power being supplied to the

TempScan/1100, MultiScan/1200, Exp/10A, and/or Exp/11A unit. If the line voltage is changed, the fuse

must also be changed. Refer to the following text for the line voltage switch and fuse locations.

Line Voltage Selection

As already mentioned, the TempScan/1100, MultiScan/1200, Exp/10A and Exp/11A unit can each operate

with 105-125 or 210-250 VAC, 50-60 Hz power, as set by its internal line-voltage switch (labelled S2 or

SW2). Each unit is shipped from the factory with this operating voltage setting marked on its rear panel.

If this is not the appropriate power setting to be supplied to the unit, then the line voltage and power fuse

must be changed to avoid damage to the unit. The locations of switch S2 or SW2 and the fuse are shown

in the figures. The line-voltage selection procedure is outlined in the following steps.

WARNING

Do not perform the procedures for line voltage selection and fuse replacement,

unless qualified to do so! These procedures are intended to be used by qualified

service personnel only!

WARNING

Never disassemble the unit casing while it is connected to the AC power line!

Internal voltage potentials exist which could cause bodily injury or death!

WARNING

Never disconnect the AC power line from the unit while its scanning cards are

connected to an external device! Common mode voltage potentials exceeding 60

VDC or 30 Vrms at the terminals, may exist which could cause bodily injury or

death!

Note:

If disassembly or disconnections are necessary, first turn off the power, then disconnect the

scanning cards, next disconnect the AC power line, and then any other cables, prior to

disassembly.

To Change the Line-Voltage Selection

1. Turn off the power, disconnect the scanning cards, the power line cord, and then all other cables from

the unit.

2. Place the unit on a flat surface. For the TempScan/1100, MultiScan/1200, and/or Exp/10A: Remove

the six screws on top of the case and remove the top cover. For the Exp/11A: Loosen the two thumb

screws – one at each end – of the power module (left-most panel) and slide out the power module.

3. Located next to the main power supply transformer is the line voltage selection switch (labeled S2 or

SW2). Using a small screwdriver, insert the tip of the screwdriver into the slot of the switch and slide

the switch to the left or right until it "clicks" into place with the desired line voltage selection visible.

1-18 System Overview 899493 TempScan / MultiScan User's Manual

Page 33

CAUTION

It is possible to place the line voltage switch (S2 or SW2) in a partial position

which could cause equipment damage or malfunction. When changing the

position of the line voltage selection switch (S2 or SW2), make sure the switch is

completely positioned to the 115 V or 220 V selection. The switch will “click” into

place when properly positioned.

4. Install a power line fuse appropriate for the line voltage. See section Fuse Replacement – Step 3,

following this section.

CAUTION

Do not use a fuse with a rating higher than specified. Otherwise the unit may be

damaged. If the instrument repeatedly blows fuses, locate and correct the cause of

5. Make note of the new voltage setting for later reference.

6. Carefully reassemble the unit.

Note:

the trouble before replacing the fuse.

For re-assembly, first reconnect the AC power line (with the power OFF), next reconnect the

scanning cards, and then any other cables, prior to reapplying power to the entire system.

TempScan / MultiScan User’s Manual 899493 System Overview 1-19

Page 34

Fuse Replacement

The TempScan/1100, MultiScan/1200, Exp/10A and Exp/11A each contains an internal AC line fuse. This

fuse is located next to the internal line-voltage switch (labelled S2 or SW2). You may replace the fuse by

using the procedures found in the following text.

Note:

WARNING

Never disassemble the unit casing while it is connected to the AC power line!

Internal voltage potentials exist which could cause bodily injury or death!

WARNING

Never disconnect the AC power line from the unit while its scanning cards are

connected to an external device! Common mode voltage potentials exceeding 60

VDC or 30 Vrms at the terminals, may exist which could cause bodily injury or

death!

If disassembly or disconnections are necessary, first turn off the power, then disconnect the

scanning cards, next disconnect the AC power line, and then any other cables, prior to

disassembly.

To Replace the Fuse

1. Turn off the power, disconnect the scanning cards, the power line cord, and then all other cables

from the unit. For more information, see section Disconnecting & Reconnecting the System During

Setup on page 1-6.

2. Place the unit on a flat surface. For the TempScan/1100, MultiScan/1200, and/or Exp/10A: Remove

the six screws on top of the case and remove the top cover. For the Exp/11A: Loosen the two thumb

screws – one at each end – of the power module (leftmost panel) and slide out the power module.

3. Located next to the line-voltage selection switch (labeled S2 or SW2) is the power fuse. Gently pull

upward on the plastic fuse housing. The entire housing with the fuse inside should be removed.

4. Open the fuse housing by pushing up on the tab on the bottom of the housing. Remove the fuse, and

replace it with the proper type using the following list as a guide:

• For line voltage 105-125 V, use fuse type 1/2 A 250 V, Slo Blo, 3AG

• For line voltage 210-250 V, use fuse type 1/4 A 250 V, Slo Blo, 3AG

CAUTION

1. Close the housing. Insert the fuse into the fuse holder.

2. Make note of the new fuse rating for later reference. If you have also changed the operating line-

voltage selection, return to the previous section Line Voltage Selection – Step 5.

3. Carefully reassemble the unit.

Note:

Do not use a fuse with a rating higher than specified. Otherwise the unit may be

damaged. If the instrument repeatedly blows fuses, locate and correct the cause of

the trouble before replacing the fuse.

For re-assembly, first reconnect the AC power line (with the power OFF), next reconnect the

scanning cards, and then any other cables, prior to reapplying power to the entire system.

1-20 System Overview 899493 TempScan / MultiScan User's Manual

Page 35

Rack-Mount & Bench-Top Assembly

The TempScan/1100, MultiScan/1200, Exp/10A and Exp/11A package each includes accessories for rack-mount or benchtop assembly.

Rack Mount

Bench Top

If rack-mount assembly is required, remove the two plastic screws from the pre-drilled holes on each side

of the unit. Since the unit can be mounted with the front or rear panel facing the front of the rack fixture,

remove only those screws from the set of holes that will be toward the front of the rack. Attach the two

rack ears using the enclosed screws.

If bench-top assembly is required, install the self-adhesive rubber feet on the bottom of the unit

approximately one inch from each corner.

TempScan / MultiScan User’s Manual 899493 System Overview 1-21

Page 36

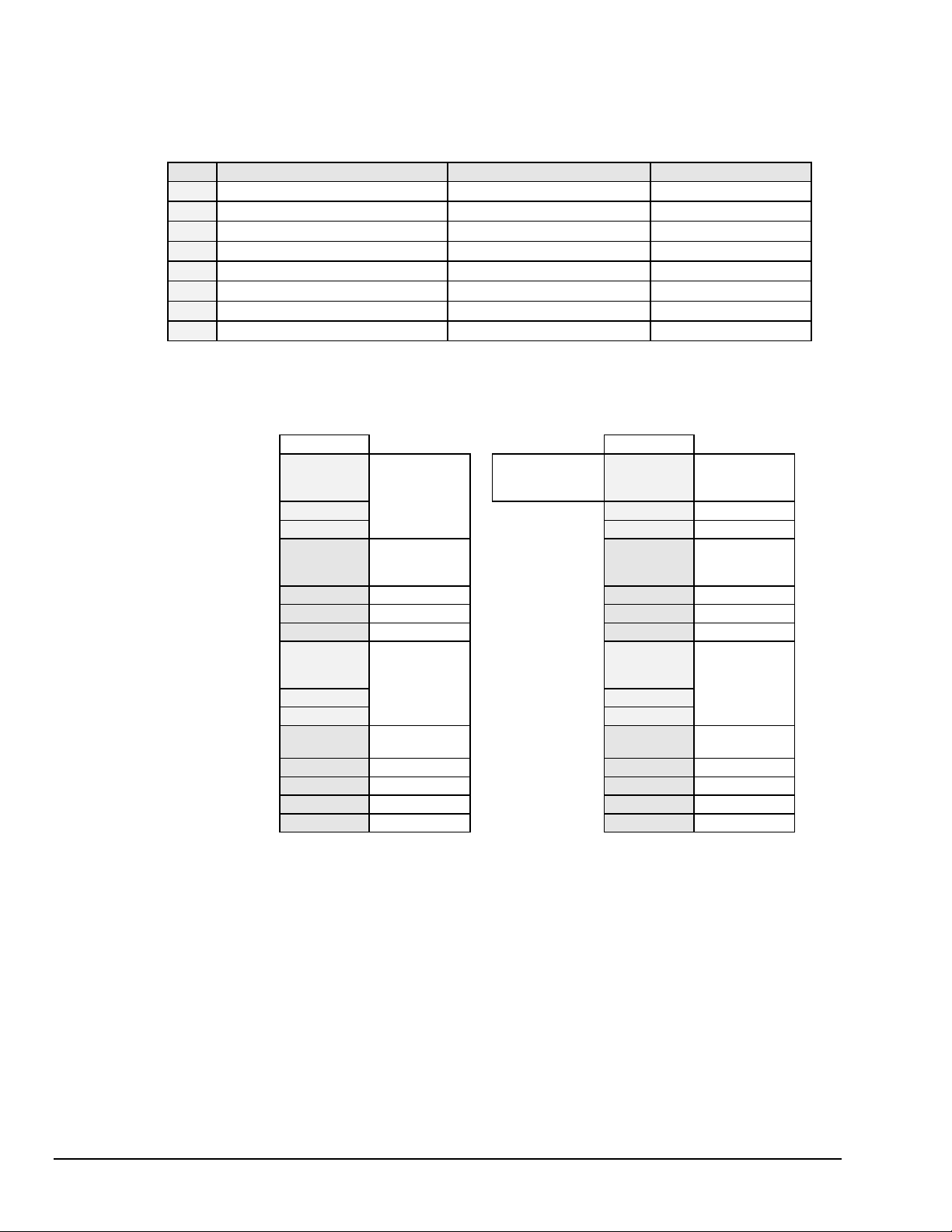

Power-Up Activation

At initial power-up or on the Reset Power-On (*R) command, the TempScan/1100 or MultiScan/1200

performs automatic self-tests to ensure that it is fully functional. The front panel LED indicators show any

errors if they occur. Possible error conditions and their corresponding LED indicator patterns are shown in

the following table. Any LED pattern not shown is an internal error that is not field-serviceable; in this

case, contact the factory. If ERROR is on by itself, there is a configuration error due to setup information

in NV-RAM. Check the error using the Query Error Status (

Error Condition

No Errors

General Hardware Failure

Position-U22 ROM Invalid

Position-U21 ROM Checksum Error

Position-U22 ROM Checksum Error

Non-Volatile RAM Error

Dynamic RAM Error

Interprocessor COM Error

If no problems are found, the POWER LED indicator will remain on while the rest of the indicators will go

out, and the TempScan/1100 or MultiScan/1200 will begin its power-up initialization. This self test is

performed each time the unit is powered up regardless of whether power-on was caused by the power

switch or the Reset Power-On (

steps:

1. Checks for errors at power-up.

2. Checks the flag in the NV-RAM to determine if it should power-up with factory default settings or a

user-defined configuration.

3. Loads appropriate registers with corresponding values in NV-RAM.

4. Checks a flag to see if alarms should be enabled at power-up, and if so, enables them.

5. Loads channel configuration registers.

6. Loads program sequencer with appropriate channel configurations.

7. Resets computations processor to begin acquiring scans.

The self test takes approximately five seconds to complete, after which the TempScan/1100 or

MultiScan/1200 unit is ready for normal operation.

For more information, see section Power-Up Configuration.

E?) command.

LED Indicators

TALK LISTEN SRQ ERROR POWER

(Off) (Off) (Off) (Off) ON

ON

(Off) (Off) (Off) FLASHING ON

(Off) (Off) ON FLASHING ON

(Off) ON (Off) FLASHING ON

ON

ON ON

ON ON ON FLASHING ON

*R) command. During initialization, the self test performs the following

(Off) ON FLASHING ON

(Off) (Off) FLASHING ON

(Off) FLASHING ON

1-22 System Overview 899493 TempScan / MultiScan User's Manual

Page 37

Expansion Units 2

Exp/10A Expansion Unit ...... 2-1

Introduction ...... 2-1

Front Panel Indicators ...... 2-1

Rear Panel Switches & Connectors ...... 2-2

Exp/10A Specifications ...... 2-3

Exp/10A Hardware Configuration ...... 2-4

Master/Slave Connection ...... 2-4

Slave Configuration ...... 2-5

Channel Assignment ...... 2-5

Exp/11A Expansion Unit ...... 2-7

Introduction ...... 2-7

Front Panel Indicators ...... 2-7

Rear Panel Switches & Connectors ...... 2-7

Exp/11A Specifications ...... 2-8

Exp/11A Hardware Configuration ...... 2-9

Master/Slave Connection ...... 2-9

Slave Configuration ...... 2-10

Channel Assignment ...... 2-11

Exp/10A Expansion Unit

Introduction

All Exp/10A components are carefully inspected prior to shipment. When you receive your two-slot

expansion chassis, carefully unpack all items from the shipping carton and check for any damage which may

have occurred during shipment. Promptly report the damage to the shipping agent and your sales

representative. Retain all shipping materials in case you must return the unit to the factory.

Front Panel Indicators

Three (3) LED indicators on the front panel of the Exp/10A display the status of the expansion unit:

• SCAN: ON when the master unit is storing a expansion channel scan in its internal buffer.

• ERROR: ON when an error has occurred, OFF when no error condition exists. For more information,

see command Query Error Status (

• POWER: ON when power is applied to the unit and the power switch on the back panel is in the ON