Page 1

Personal488

User's Manual

PC/IEEE 488 Controller For DOS & Windows 3.Xi

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail: sales@iotech.com

Internet: www.iotech.com

Personal488

PC/IEEE 488 Controller

For DOS & Windows 3.X

Personal488-902

p/n

User's Manual

3.0

Rev.

© 1998 by IOtech, Inc. February 1998 Printed in the United States of America.

Page 2

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior

written consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their

respective holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs)

may only be used on one installation. You may make archival backup copies.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission rules (Part 15)

for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve Radio-TV Interference Problems

(stock # 004-000-00345-4) which is available from the U.S. Government Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is

not covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and

review our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech

welcomes your suggestions.

Page 3

Personal488 PC/IEEE 488 Controller

General Table of Contents

General Table of Contents .....................................................................................iii

Detailed Table of Contents ......................................................................................v

Introduction to this Manual................................................................................. xv

SECTION I: HARDWARE GUIDES......................................................................I-1

1. Overview.............................................................................................................I-3

2. Personal488 (with GP488B): 8-bit DMA Interface Board .....................................I-8

3. Personal488/AT: 16-bit DMA Interface Board .......................................................I-13

4. Personal488/NB: 170 kByte Interface Module for Notebook, Laptop, & Desktop PCs...I-17

5. Personal488/MM: 330 kByte Interface Board........................................................I-18

6. Personal488/CARD: Type II PCMCIA Interface Card for Notebook & Desktop PCs ...I-22

SECTION II: SOFTWARE GUIDES.................................................................. II-31

7. Overview......................................................................................................... II-33

8. Driver488/DRV: All Languages Compatible ........................................................ II-34

9. Driver488/SUB: C Language, Pascal & QuickBasic Compatible............................ II-133

10. Driver488/W31: C Language & Visual Basic Compatible ..................................... II-191

11. Driver488/W95: (Software Revisions Pending)................................................... II-257

12. Driver488/WNT: (Software Revisions Pendin g).................................................. II-258

SECTION III: COMMAND REFERENCES..................................................III-259

13. Overview......................................................................................................III-261

14. Command Summaries...............................................................................III-262

15. Command References...............................................................................III-282

SECTION IV: TROUBLESHOOTING..............................................................IV-353

16. Overview...................................................................................................... IV-355

17. Radio Interference Problems..................................................................IV-356

18. Troubleshooting Checklists ....................................................................IV-357

19. Error Messages...........................................................................................IV-361

SECTION V: APPENDIX.....................................................................................V-367

SECTION VI: INDEX.......................................................................................... VI-375

Personal488 User’s Manual, Rev. 3.0 iii

Page 4

iv Personal488 User’s Manual, Rev. 3.0

Page 5

Personal488 PC/IEEE 488 Controller

Detailed Table of Contents

FCC Radio Frequency Interference Statement................................................................Error!

Warranty.....................................................................................................................................iii

Limitation of Liability ..............................................................................................................iii

Copyright Notice........................................................................................................................iii

Trademark Notice......................................................................................................................iii

Quality Notice ............................................................................................................................iii

General Table of Contents .......................................................................................v

Detailed Table of Contents ...................................................................................vii

Introduction to this Manual...............................................................................xvii

About this Manual.................................................................................................................. xvii

How to Use this Manual......................................................................................................... xvii

Header Files & Command References..................................................................................xvii

SECTION I: HARDWARE GUIDES.........................................................................I-1

1. Overview...........................................................................................................I-3

Introduction ..............................................................................................................................I-3

IEEE 488.2 Interface Boards...................................................................................................I-4

Driver488 Software Interface..................................................................................................I-4

Interface & Interface Board Specifications .........................................................................I-6

IEEE 488.1-1987 Interface ........................................................................................................... I-6

IEEE 488.2-1987 Interface ........................................................................................................... I-6

GP488B Interface Board............................................................................................................... I-6

AT488 Interface Board.................................................................................................................. I-6

MP488 Interface Board................................................................................................................. I-6

MP488CT Interface Board............................................................................................................ I-7

GP488/2 Interface Board............................................................................................................... I-7

GP488/MM Interface Board.......................................................................................................... I-7

NB488 Interface Module............................................................................................................... I-7

PCMCIA Interface Card................................................................................................................ I-7

2. Personal488 (with GP488B) ..........................................................................I-8

The Package ..............................................................................................................................I-8

Hardware Installation (for PC/XT/AT) .................................................................................I-8

Installation & Configuration of the Interface Card ....................................................................I-8

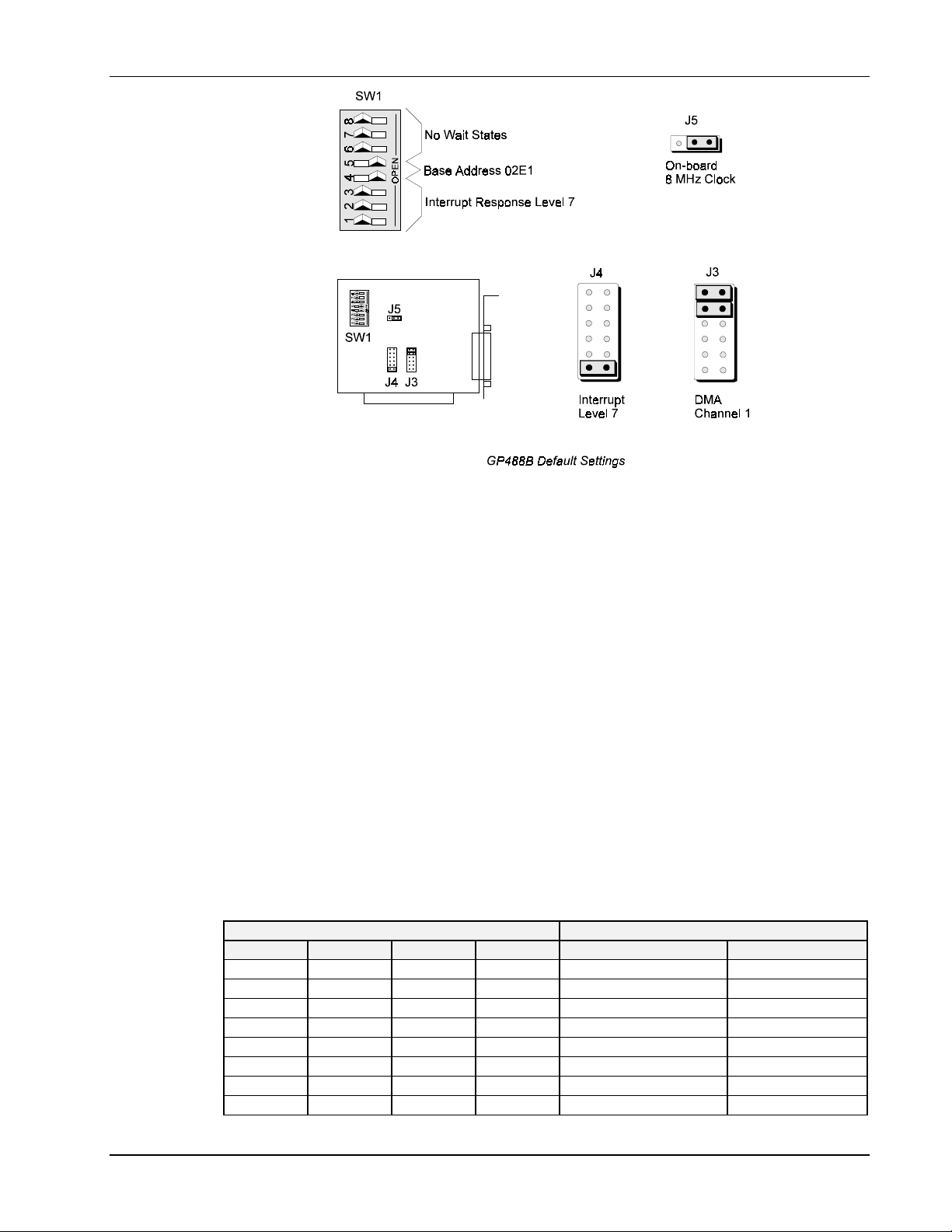

Default Settings............................................................................................................................. I-9

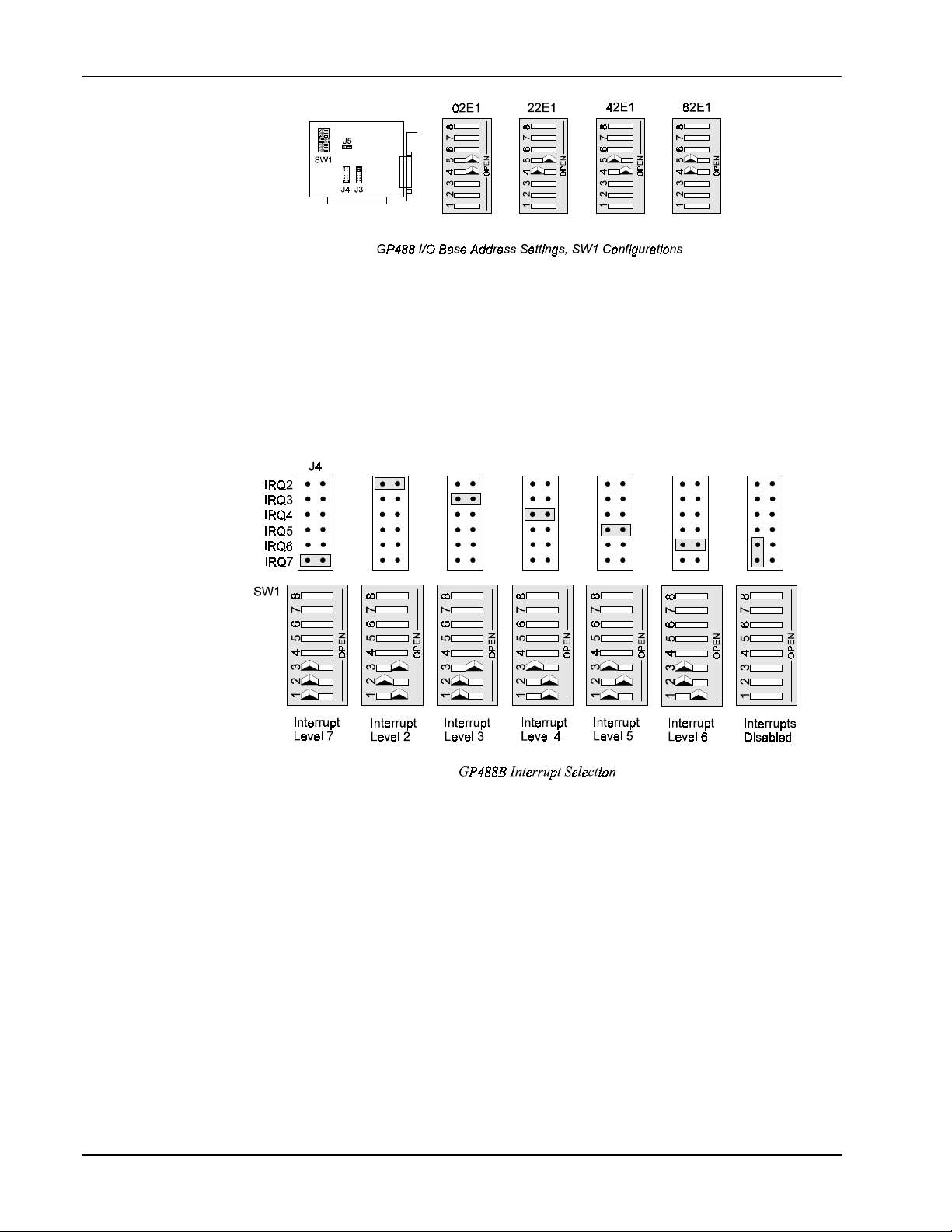

I/O Base Address Selection........................................................................................................... I-9

Interrupt Selection...................................................................................................................... I-10

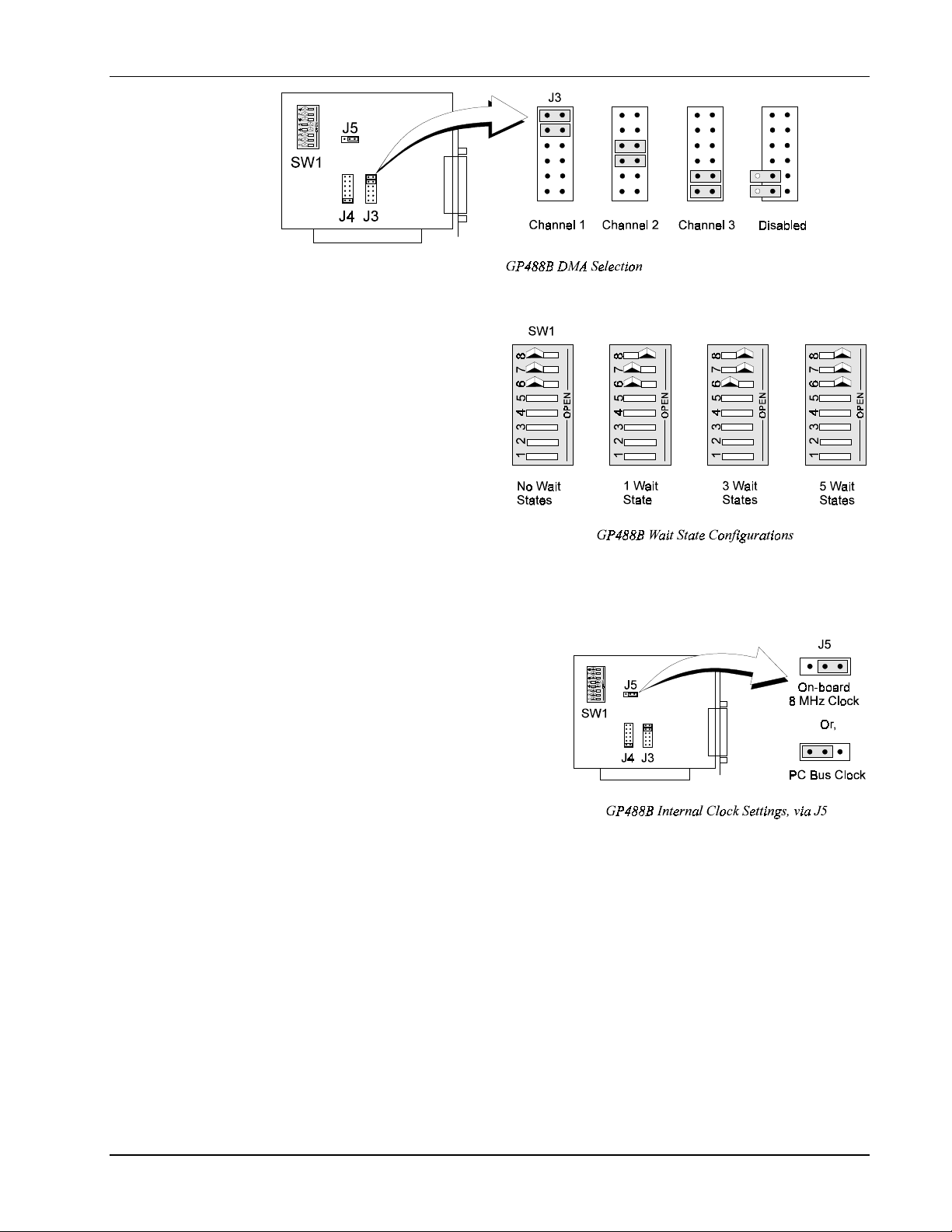

DMA Channel Selection.............................................................................................................. I-10

Wait State Configuration............................................................................................................ I-11

Internal Clock Selection.............................................................................................................. I-11

Board Installation ....................................................................................................................... I-11

3. Personal488/AT..............................................................................................I-13

The Package ............................................................................................................................I-13

Hardware Installation (for PC/XT/AT) ...............................................................................I-13

Personal488 User’s Manual, Rev. 3.0 v

Page 6

Installation & Configuration of the Interface Card...................................................................I-13

Default Settings ...........................................................................................................................I-13

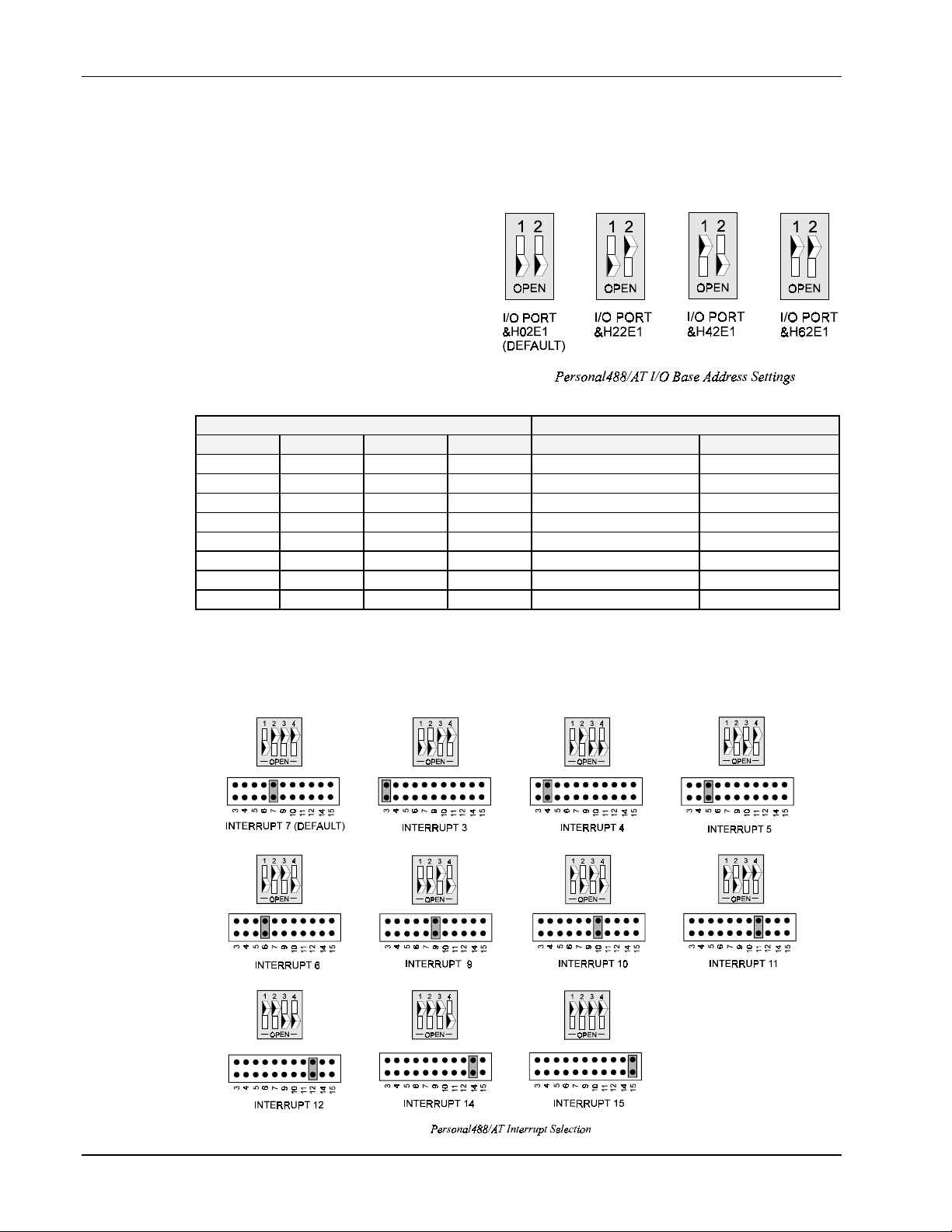

I/O Base Address Selection..........................................................................................................I-13

Interrupt Selection.......................................................................................................................I-14

DMA Channel Selection ..............................................................................................................I-15

Board Installation........................................................................................................................I-15

4. Personal488/NB..............................................................................................I-17

The Package.............................................................................................................................I-17

Hardware Installation (for Notebook, Laptop, & Desktop PCs)......................................I-17

5. Personal488/MM.............................................................................................I-18

The Package.............................................................................................................................I-18

Hardware Installation (for PC/XT/AT)................................................................................ I-18

Installation & Configuration of the Interface Card...................................................................I-18

Default Settings ...........................................................................................................................I-18

I/O Base Address Selection..........................................................................................................I-19

Interrupt Selection.......................................................................................................................I-20

DMA Channel Selection ..............................................................................................................I-20

Internal Clock Selection ..............................................................................................................I-21

Board Installation........................................................................................................................I-21

6. Personal488/CARD........................................................................................I-22

The Package.............................................................................................................................I-22

Introduction.............................................................................................................................I-22

Hardware Installation (for Notebook & Desktop PCs).....................................................I-23

Interfaces & Connectors..............................................................................................................I-23

Interface Cable Connection.........................................................................................................I-23

Installation into a PC...................................................................................................................I-24

Interface Cable & IEEE 488 Accessories....................................................................................I-24

Software Installation.............................................................................................................I-24

Initialization Software.................................................................................................................I-24

Configuration Software ...............................................................................................................I-27

Functionality...........................................................................................................................I-29

SECTION II: SOFTWARE GUIDES....................................................................II-31

7. Overview .......................................................................................................II-33

8. Driver488/DRV .............................................................................................II-34

8A. Introduction ...........................................................................................II-34

8B. Installation & Configuration..............................................................II-35

Before You Get Started......................................................................................................... II-35

Making Backup Disk Copies............................................................................................... II-36

Driver Installation................................................................................................................II-36

Selective Installation of Support files....................................................................................... II-36

Driver Installation to Disk ........................................................................................................II-37

Configuration Utility............................................................................................................ II-38

Interfaces.................................................................................................................................... II-38

External Devices........................................................................................................................ II-38

Opening the Configuration Utility............................................................................................ II-38

Configuration of IEEE 488 Interfaces................................................................................II-39

Configuration of Serial Interfaces..................................................................................... II-41

Configuration of IEEE 488 External Devices....................................................................II-42

Multiple Interface Management......................................................................................... II-43

8C. External Device Interfacing................................................................II-45

Introduction........................................................................................................................... II-45

Character Command Language (CCL).............................................................................. II-45

DOS Devices...........................................................................................................................II-46

vi Personal488 User’s Manual, Rev. 3.0

Page 7

Configuration of Named Devices.........................................................................................II-46

Use of External Devices.........................................................................................................II-47

Direct I/O with DOS Devices ................................................................................................II-47

Extensions For Multiple Interfaces.....................................................................................II-48

Duplicate Device Names............................................................................................................II-48

Access of Multiple Interfaces.....................................................................................................II-48

Example ......................................................................................................................................II-49

8D. Getting Started...................................................................................... II-49

Introduction ...........................................................................................................................II-49

Keyboard Controller Program.............................................................................................II-50

Direct Control from DOS Using CCL..................................................................................II-51

8E. Microsoft C.............................................................................................. II-53

Use of the Character Command Language........................................................................II-53

Initialization of the System..................................................................................................II-53

Configuration of the 195 DMM ............................................................................................II-56

Taking Readings....................................................................................................................II-56

Buffer Transfers.....................................................................................................................II-56

Interrupt Handling ...............................................................................................................II-57

IEEEIO.C.................................................................................................................................II-59

CRITERR.ASM (Microsoft C & Turbo C)............................................................................II-61

Sample Program....................................................................................................................II-62

8F. Microsoft Fortran.................................................................................. II-63

Sample Program....................................................................................................................II-63

8G. QuickBASIC ........................................................................................... II-64

Use of the Character Command Language........................................................................II-64

Initialization of the System..................................................................................................II-64

Configuration of the 195 DMM ............................................................................................II-66

Taking Readings....................................................................................................................II-66

Buffer Transfers.....................................................................................................................II-67

BASIC VARPTR & SADDR...................................................................................................II-68

Interrupt Handling ...............................................................................................................II-68

Sample Program....................................................................................................................II-70

8H. Turbo C ................................................................................................... II-71

Use of the Character Command Language........................................................................II-71

Initialization of the System..................................................................................................II-72

Configuration of the 195 DMM ............................................................................................II-74

Taking Readings....................................................................................................................II-74

Buffer Transfers.....................................................................................................................II-75

Interrupt Handling ...............................................................................................................II-76

IEEEIO.C.................................................................................................................................II-78

CRITERR.ASM (Microsoft C & Turbo C)............................................................................II-80

Sample Program....................................................................................................................II-80

8I. Turbo Pascal............................................................................................ II-82

Use of Character Command Language..............................................................................II-82

Initialization of the System..................................................................................................II-83

Configuration of the 195 DMM ............................................................................................II-84

Taking Readings....................................................................................................................II-85

Buffer Transfers.....................................................................................................................II-85

Interrupt Handling ...............................................................................................................II-86

Sample Program....................................................................................................................II-88

8J. Spreadsheets........................................................................................... II-90

Use of Direct DOS I/O Devices..............................................................................................II-90

Initialization of the System..................................................................................................II-90

Configuration of the 195 DMM ............................................................................................II-91

Personal488 User’s Manual, Rev. 3.0 vii

Page 8

Taking Readings................................................................................................................... II-92

Interrupt Handling............................................................................................................... II-92

8K. Other Languages ...................................................................................II-96

Introduction........................................................................................................................... II-96

Finding Addresses................................................................................................................. II-97

Garbage Collection..................................................................................................................... II-97

Memory Models..........................................................................................................................II-97

Calling Protocols ........................................................................................................................ II-99

Opening & Closing the Driver........................................................................................... II-100

I/O Control (IOCTL) Communication.............................................................................. II-100

IOCTL Get & Set Device Data ................................................................................................ II-100

IOCTL Read & Write............................................................................................................... II-101

Data & Command Communication.................................................................................. II-102

ARM Condition Detection.................................................................................................. II-102

Sample Program................................................................................................................. II-102

8L. Language-Specific Information........................................................II-104

Aztec C .................................................................................................................................. II-104

Use of Character Command Language................................................................................... II-104

CRITERR.C (for Aztec C) ........................................................................................................II-105

GW-BASIC (for GW-BASIC or Interpreted BASIC)........................................................ II-105

Use of Direct DOS I/O Devices................................................................................................ II-105

BASIC VARPTR & SADDR..................................................................................................... II-105

GET & PUT (for GW-BASIC only)..........................................................................................II-106

JPI TopSpeed Modula-2..................................................................................................... II-106

Use of Direct DOS I/O Devices................................................................................................ II-106

Logitech Modula-2 .............................................................................................................. II-106

Use of Direct DOS I/O Devices................................................................................................ II-106

True Basic............................................................................................................................ II-107

Use of Character Command Language................................................................................... II-107

IEEEIO.TRU............................................................................................................................ II-107

TOOLKIT.LIB.......................................................................................................................... II-107

Turbo Basic.......................................................................................................................... II-108

Use of Character Command Language................................................................................... II-108

8M. Data Transfers.....................................................................................II-108

Terminators......................................................................................................................... II-108

End-Of-Line (EOL) Terminators............................................................................................. II-108

TERM Terminators.................................................................................................................. II-112

Direct I/O & Buffered I/O................................................................................................... II-113

Direct Bus OUTPUT................................................................................................................ II-113

Direct Bus ENTER................................................................................................................... II-113

Buffered I/O.............................................................................................................................. II-114

Asynchronous Transfers .................................................................................................... II-115

8N. Operating Modes .................................................................................II-115

Introduction......................................................................................................................... II-116

Operating Mode Transitions............................................................................................. II-116

System Controller Mode..................................................................................................... II-117

System Controller, Not Active Controller Mode..............................................................II-117

Not System Controller Mode.............................................................................................. II-119

Active Controller, Not System Controller Mode..............................................................II-119

8O. Utility Programs..................................................................................II-120

Printer & Serial Redirection.............................................................................................II-120

Removal & Reinstallation................................................................................................. II-122

MARKDRVR & REMDRVR ....................................................................................................II-122

Moving Files from an IEEE 488 (HP-IB) Controller to a PC ........................................II-123

PRNTEMUL Files.................................................................................................................... II-123

viii Personal488 User’s Manual, Rev. 3.0

Page 9

Configuration of the IEEE Interface for PRNTEMUL ..........................................................II-123

Running PRNTEMUL..............................................................................................................II-124

Data Transfer ...........................................................................................................................II-124

8P. Command Descriptions...................................................................... II-124

Introduction .........................................................................................................................II-124

Format...................................................................................................................................II-125

Syntax .......................................................................................................................................II-125

Response ...................................................................................................................................II-127

Mode..........................................................................................................................................II-127

Bus States.................................................................................................................................II-127

Examples...................................................................................................................................II-131

Data Types ............................................................................................................................II-131

CCL Reserved Words............................................................................................................II-132

List of Reserved Words ...........................................................................................................II-132

8Q. Command Reference.......................................................................... II-132

9. Driver488/SUB ........................................................................................... II-133

9A. Introduction......................................................................................... II-133

9B. Installation & Configuration............................................................ II-134

Before You Get Started........................................................................................................II-134

Making Backup Disk Copies..............................................................................................II-135

Driver Installation..............................................................................................................II-135

Configuration Utility ..........................................................................................................II-135

Interfaces ..................................................................................................................................II-136

External Devices.......................................................................................................................II-136

Opening the Configuration Utility..........................................................................................II-136

Configuration of IEEE 488 Interfaces..............................................................................II-136

Configuration of Serial Interfaces....................................................................................II-139

Configuration of IEEE 488 External Devices..................................................................II-140

9C. External Device Interfacing............................................................. II-141

Introduction .........................................................................................................................II-141

Subroutine Calls.......................................................................................................................II-142

Configuration of Named Devices.......................................................................................II-142

Use of External Devices.......................................................................................................II-143

Extensions for Multiple Interfaces....................................................................................II-144

Duplicate Device Names..........................................................................................................II-144

Access of Multiple Interfaces...................................................................................................II-144

Example ....................................................................................................................................II-145

9D. Getting Started.................................................................................... II-145

Introduction .........................................................................................................................II-145

C Language...........................................................................................................................II-145

Required Headers.....................................................................................................................II-146

Required Libraries ...................................................................................................................II-146

QuickBASIC..........................................................................................................................II-148

Required Definition File ..........................................................................................................II-149

Required Libraries ...................................................................................................................II-149

Pascal....................................................................................................................................II-149

Required Libraries ...................................................................................................................II-149

9E. C Languages........................................................................................ II-150

Accessing from a C Program..............................................................................................II-150

Establishing Communications..........................................................................................II-151

Confirming Communication..............................................................................................II-152

Setting Up Event Handling................................................................................................II-152

Reading Driver Status........................................................................................................II-152

External Device Initialization...........................................................................................II-153

Personal488 User’s Manual, Rev. 3.0 ix

Page 10

Interrupt Handling............................................................................................................. II-153

Basic Data Acquisition...................................................................................................... II-154

Block Data Acquisition...................................................................................................... II-154

Sample Program................................................................................................................. II-155

Command Summary........................................................................................................... II-158

9F. QuickBASIC..........................................................................................II-159

Accessing from a QuickBASIC Program.........................................................................II-159

Establishing Communications..........................................................................................II-159

Confirming Communications............................................................................................ II-160

Setting Up Event Handling............................................................................................... II-160

Reading Driver Status ....................................................................................................... II-161

External Device Initialization.......................................................................................... II-161

Interrupt Handling............................................................................................................. II-162

Basic Data Acquisition...................................................................................................... II-162

Block Data Acquisition...................................................................................................... II-162

Sample Program................................................................................................................. II-163

Command Summary........................................................................................................... II-166

9G. Pascal.....................................................................................................II-166

Accessing from a Pascal Program....................................................................................II-166

Establishing Communications..........................................................................................II-167

Confirming Communication............................................................................................. II-168

Setting Up Event Handling............................................................................................... II-168

Reading Driver Status ....................................................................................................... II-168

External Device Initialization.......................................................................................... II-169

Interrupt Handling............................................................................................................. II-169

Basic Data Acquisition...................................................................................................... II-170

Block Data Acquisition...................................................................................................... II-170

Sample Program................................................................................................................. II-171

Command Summary........................................................................................................... II-174

9H. Data Transfers.....................................................................................II-175

Terminators......................................................................................................................... II-175

TERM Terminators.................................................................................................................. II-175

Data Input and Output...................................................................................................... II-176

Asynchronous Transfers .................................................................................................... II-177

9I. Operating Modes...................................................................................II-177

Introduction......................................................................................................................... II-177

Operating Mode Transitions............................................................................................. II-178

System Controller Mode..................................................................................................... II-179

System Controller, Not Active Controller Mode..............................................................II-179

Not System Controller Mode.............................................................................................. II-181

Active Controller, Not System Controller Mode..............................................................II-181

9J. Utility Programs...................................................................................II-182

Printer & Serial Redirection.............................................................................................II-182

Removal & Reinstallation................................................................................................. II-184

MARKDRVR & REMDRVR ....................................................................................................II-184

Moving Files from an IEEE 488 (HP-IB) Controller to a PC ........................................II-185

PRNTEMUL Files.................................................................................................................... II-185

Configuration of the IEEE Interface for PRNTEMUL.......................................................... II-185

Running PRNTEMUL .............................................................................................................II-185

Data Transfer........................................................................................................................... II-186

9K. Command Descriptions......................................................................II-186

Introduction......................................................................................................................... II-186

Format.................................................................................................................................. II-187

Syntax....................................................................................................................................... II-187

Returns..................................................................................................................................... II-187

x Personal488 User’s Manual, Rev. 3.0

Page 11

Mode..........................................................................................................................................II-187

Bus States.................................................................................................................................II-187

Examples...................................................................................................................................II-189

Data Types ............................................................................................................................II-189

Arm Condition Bit Masks ........................................................................................................II-189

Control Line Bit Masks............................................................................................................II-189

Terminator Structures.............................................................................................................II-189

Status Structure.......................................................................................................................II-190

Completion Code Bit Masks.....................................................................................................II-190

Miscellaneous Constants..........................................................................................................II-190

9L. Command Reference........................................................................... II-190

10. Driver488/W31.......................................................................................... II-191

10A. Introduction....................................................................................... II-191

10B. Installation & Configuration.......................................................... II-192

Before You Get Started........................................................................................................II-192

Making Backup Disk Copies..............................................................................................II-193

Driver Installation..............................................................................................................II-193

Enhanced Mode DMA Transfers .............................................................................................II-194

Configuration Utility ..........................................................................................................II-195

Interfaces ..................................................................................................................................II-195

External Devices.......................................................................................................................II-195

Opening the Configuration Utility..........................................................................................II-195

Configuration of IEEE 488 Interfaces..............................................................................II-196

Configuration of IEEE 488 External Devices..................................................................II-198

Modification of the Initialization File .............................................................................II-199

Driver Core Sections ................................................................................................................II-200

10C. External Device Interfacing........................................................... II-202

Introduction .........................................................................................................................II-202

Subroutine Calls.......................................................................................................................II-202

Configuration of Named Devices.......................................................................................II-202

Use of External Devices.......................................................................................................II-204

Extensions For Multiple Interfaces...................................................................................II-204

Duplicate Device Names..........................................................................................................II-205

Access of Multiple Interfaces...................................................................................................II-205

Example ....................................................................................................................................II-205

10D. Getting Started.................................................................................. II-205

Introduction .........................................................................................................................II-206

C Languages .............................................................................................................................II-206

Visual Basic ..............................................................................................................................II-206

C Languages.........................................................................................................................II-206

Required Headers.....................................................................................................................II-206

Required Libraries ...................................................................................................................II-207

Visual Basic..........................................................................................................................II-207

Required Files...........................................................................................................................II-207

10E. C Languages...................................................................................... II-208

Accessing from a Windows Program.................................................................................II-208

Opening & Closing the Driver.................................................................................................II-208

Establishing Communications..........................................................................................II-209

Confirming Communications ............................................................................................II-211

IEEE 488 Event Message.....................................................................................................II-211

Reading Driver Status........................................................................................................II-213

External Device Initialization...........................................................................................II-214

Basic Data Acquisition.......................................................................................................II-214

Block Data Acquisition.......................................................................................................II-215

Personal488 User’s Manual, Rev. 3.0 xi

Page 12

Sample Programs................................................................................................................ II-216

Data Acquisition Sample Programs........................................................................................ II-216

IEEE 488 Event Message Sample Programs .........................................................................II-224

Command Summary........................................................................................................... II-231

10F. Visual Basic.........................................................................................II-232

Accessing from a Windows Program................................................................................ II-232

Opening & Closing the Driver................................................................................................. II-233

Establishing Communications..........................................................................................II-234

Confirming Communications............................................................................................ II-235

IEEE 488 Event Custom Control....................................................................................... II-235

Reading Driver Status ....................................................................................................... II-238

External Device Initialization.......................................................................................... II-238

Basic Data Acquisition...................................................................................................... II-239

Block Data Acquisition...................................................................................................... II-239

Dynamic Data Exchange (DDE)....................................................................................... II-241

Application ............................................................................................................................... II-241

Server Links............................................................................................................................. II-241

Acquisition Engine................................................................................................................... II-243

Sample Programs................................................................................................................ II-246

Data Acquisition Sample Program ......................................................................................... II-246

IEEE 488 Event Custom Control Sample Program............................................................... II-249

Acquisition Engine Sample Program...................................................................................... II-250

Command Summary........................................................................................................... II-251

10G. Utility Programs................................................................................II-251

Introduction......................................................................................................................... II-251

WINTEST.............................................................................................................................. II-251

Opening a Device Handle for Communication....................................................................... II-252

Handle Lists............................................................................................................................. II-252

WINTEST Session ................................................................................................................... II-253

QUIKTEST ........................................................................................................................... II-254

Application Files ......................................................................................................................II-254

Installation............................................................................................................................... II-254

Operation of the Application ................................................................................................... II-255

Cutting & Pasting to Other Applications............................................................................... II-255

Dynamic Data Exchange (DDE) ............................................................................................. II-255

Loading the Project into Visual Basic..................................................................................... II-256

Licensing.............................................................................................................................. II-256

10H. Command Reference........................................................................II-256

11. Driver488/W95..........................................................................................II-257

12. Driver488/WNT .........................................................................................II-258

SECTION III: COMMAND REFERENCES.................................................... III-259

13. Overview ................................................................................................. III-261

14. Command Summaries .......................................................................... III-262

14A. Driver488/SUB, C Languages....................................................... III-262

Function Descriptions.......................................................................................................III-262

The Commands...................................................................................................................III-264

Syntax Parameters ............................................................................................................III-264

Defined Constants..............................................................................................................III-265

Structure Definitions ........................................................................................................III-265

14B. Driver488/SUB, QuickBASIC ........................................................ III-266

Function Descriptions.......................................................................................................III-266

The Commands...................................................................................................................III-268

Syntax Parameters ............................................................................................................III-268

xii Personal488 User’s Manual, Rev. 3.0

Page 13

Defined Constants..............................................................................................................III-269

Structure Definitions........................................................................................................III-269

14C. Driver488/SUB, Pascal ....................................................................III-270

Function Descriptions.......................................................................................................III-270

The Commands...................................................................................................................III-272

Syntax Parameters............................................................................................................III-272

Defined Constants..............................................................................................................III-272

Structure Definitions........................................................................................................III-273

14D. Driver488/W31, C Languages.........................................................III-274

Function Descriptions.......................................................................................................III-274

The Commands...................................................................................................................III-276

Syntax Parameters............................................................................................................III-276

Defined Constants..............................................................................................................III-276

Structure Definitions........................................................................................................III-277

14E. Driver488/W31, Visual Basic ..........................................................III-278

Function Descriptions.......................................................................................................III-278

The Commands...................................................................................................................III-280

Syntax Parameters............................................................................................................III-280

Defined Constants..............................................................................................................III-281

Structure Definitions........................................................................................................III-281

15. Command References ...........................................................................III-282

15A. Driver488/DRV Commands ............................................................III-282

15B. Driver488/SUB, W31, W95, & WNT Commands ..........................III-312

SECTION IV: TROUBLESHOOTING................................................................IV-353

16. Overview.................................................................................................. IV-355

17. Radio Interference Problems.............................................................. IV-356

18. Troubleshooting Checklists.................................................................IV-357

18A. Introduction......................................................................................IV-357

18B. Driver488/DRV.................................................................................. IV-357

18C. Driver488/SUB...................................................................................IV-358

18D. Driver488/W31................................................................................... IV-359

18E. Driver488/W95 & Driver488/WNT.................................................. IV-360

19. Error Messages....................................................................................... IV-361

SECTION V: APPENDIX.......................................................................................V-367

SECTION VI: INDEX............................................................................................ VI-375

Personal488 User’s Manual, Rev. 3.0 xiii

Page 14

xiv Personal488 User’s Manual, Rev. 3.0

Page 15

Personal488 PC/IEEE 488 Controller

Introduction to this Manual

About this Manual

This edition of the Personal488 User’s Manual supersedes all previous editions.

The material in this manual reflects the particular combinations of IEEE 488 I/O adapter and driver

software, and is comprised of four primary Sections: Hardware Guides, Software Guides, Command

References, and Troubleshooting, followed by two more Sections: Appendix and Index. The last two

pages contain a List of IEEE 488 Acronyms & Abbreviations and a List of ASCII Acronyms &

Abbreviations as additional references for this manual and for other related literature.

Before calling for technical assistance, check the Troubleshooting section for a possible solution to the

problem.

Since much of the hardware and software material in this manual is similar to material elsewhere in the

manual, make sure you view the material which corresponds to your specific hardware and software.

For example, do not read about Driver488/DRV when your application pertains to Driver488/W31

Information which may have changed since the time of printing will be found in a

disk, or in an addendum to the manual.

How to Use this Manual

Because this manual contains a large volume of information, a four-level table of contents system is

used in addition to a complete Detailed Table of Contents. In this four-level system, the General Table

of Contents at the front of this manual should be used primarily to locate the main Sections of the

manual, i.e., specific hardware guides and software guides. The first page of each Section contains a

second-level table, listing the Chapters with their page locations. Next, many of these Chapters

contain a third-level table, listing the Sub-Chapters or specific Topics with their page locations.

Finally, many of these Sub-Chapters contain a fourth-level table, listing the specific Topics with their

page locations. While this multi-level method is easy to use, experienced users may prefer the

traditional table of contents.

As mentioned above, this manual also includes an Index, so you can quickl y find the page(s) pertaining

to a specific topic.

Header Files & Command References

Since changes are taking place in Driver488/W95 and Driver488/WNT software as this publication

goes to press, please refer to your operating system header file for the latest available information

specific to your application.

README.TXT

file on

Personal488 User’s Manual, Rev. 3.0 xv

Page 16

xvi Personal488 User’s Manual, Rev. 3.0

Page 17

Section I:

HARDWARE GUIDES

Personal488 User’s Manual, Rev. 3.0 I-1

Page 18

I-2 Personal488 User’s Manual, Rev. 3.0

Page 19

I. HARDWARE GUIDES 1. Overview

I. HARDWARE GUIDES

Chapters

1. Overview............................................................................................I-3

2. Personal488 (with GP488B)...........................................................I-8

3. Personal488/AT ..............................................................................I-13

4. Personal488/NB..............................................................................I-17

5. Personal488/MM.............................................................................I-18

6. Personal488/CARD ........................................................................I-22

1. Overview

• Introduction........................................................................................I-4

• IEEE 488.2 Interface Boards............................................................I-4

• Driver488 Software Interface..........................................................I-4

• Interface & Interface Board Specifications.................................I-6

Introduction

The Hardware Guides section contains chapters pertaining to different Personal488 Drivers, as

indicated in the previous Section I Table of Contents. Each Driver488 section contains information

regarding specific PC/IEEE 488 controllers. The hardware guide describes the I/O adapter and

includes instructions for inspecting, configuring, and installing the adapter.

Topics

IEEE 488.1-1987 Interface................................................................................I-6

IEEE 488.2-1987 Interface................................................................................I-6

GP488B Interface Board..................................................................................I-6

AT488 Interface Board.....................................................................................I-6

MP488 Interface Board ....................................................................................I-6

MP488CT Interface Board ............................................................................... I-7

GP488/2 Interface Board..................................................................................I-7

GP488/MM Interface Board .............................................................................I-7

NB488 Interface Module...................................................................................I-7

PCMCIA Interface Card...................................................................................I-7

In addition to this manual, Power488 and Power488CT users receive a manual supplement describing

the Standard Commands for Programmable Instruments (SCPI) command set and the

a Microsoft Windows Dynamic Link Library of functions. This overview introduces the hardware and

software sections of this manual.

The Personal488 converts your PC or PC/AT into an IEEE 488.2-compliant controller. Each controller

package includes an interface board or module, driver software and complete documentation. The

following information provides a brief overview of a specific PC/IEEE 488 interfaces and software

drivers, and of the Driver488 components.

Personal488 User’s Manual, Rev. 3.0 I-3

IOTTIMER.DLL

,

Page 20

1. Overview I. HARDWARE GUIDES

IEEE 488.2 Interface Boards

The family of PC/IEEE 488 controllers includes the GP488B, the GP488/2, the AT488, the MP488,

the MP488CT, the GP488/MM and the NB488. All are IEEE 488.2 compatible and supported by

Driver488 software. The MP488 and MP488CT also provide digital I/O, and the MP488CT provides a

set of programmable counter/timers, all of which are fully supported by Driver488. Some features of

the interfaces are listed below:

•

GP488B interface board (for PC/XT/AT): Features five jumper-selectable interrupt lines. Three

8-bit jumper-selectable DMA channels are also available. The 8-bit DMA mode provides full

compatibility with programs written for GP488 series boards.

•

AT488 interface board (for PC/XT/AT and PS/2 with the ISA bus): Features eleven jumper-

selectable interrupt lines. Three 16-bit and four 8-bit jumper-selectable DMA channels are also

available. The 8-bit DMA mode provides full compatibility with programs written for the GP488

series boards.

•

MP488 interface board (for PC/XT/AT and PS/2 with the ISA bus): Features eleven jumper-

selectable interrupt lines. Three 16-bit and four 8-bit jumper-selectable DMA channels are also

available. The 8-bit DMA mode provides full compatibility with programs written for the GP488

series boards. The digital I/O section of this board provides 4 0 digital I/O lines which can be

programmed for a mix of input and output.

•

MP488CT interface board (for PC/XT/AT and PS/2 with the ISA bus): Features eleven jumper-

selectable interrupt lines. Three 16-bit and four 8-bit jumper-selectable DMA channels are also

available. The 8-bit DMA mode provides full compatibility with programs written for the GP488

series boards. The digital I/O section of this board provides 4 0 input or output lines which can be

programmed for a mix of input and output. The counter/timer section features a programmable

clock generator plus 5 fully independent versatile counter/timer channels.

•

GP488/2 interface board (for Personal Systems/2 with MicroChannel architecture): Features seven

software selectable interrupt lines and fourteen 8-bit software selectable DMA arbitration levels.

•

GP488B/MM interface board: Converts your Ampro PC/104 Single Board PC into an IEEE 488.2

compliant controller or peripheral.

•

NB488 external interface module (for notebook, laptop and desktop PCs): Connects to a PC’s

parallel port eliminating the need for an internal expansion slot.

Driver488 Software Interface

Driver488 is the software interface between DOS or Windows and the IEEE 488 controller board.

Driver488 software includes the driver itself, an installation program, other utility programs, and

programming examples. Driver488 provides a full implementation of the IEEE 488.2 standard, plus

advanced capabilities such as high-speed DMA data transfers, interrupt vectoring on specified events,

automatic error detection, callable subroutines, and serial (COM) port support.

Driver488 monitors all IEEE 488 bus monitoring and control lines and generates an interrupt based on

SRQ

status and various other bus conditions. Driver488 software supports automatic program vectoring

to service routines for C, Pascal, and BASIC. On a specified event (

Controller, Trigger, Clear, Talk, Listen, Idle, ByteIn, ByteOut, Change

Driver488 can either call a specified application routine or simulate a light pen interrupt to signal that

the event has occurred.