Page 1

Medallion Rotate User’s Manual

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail (sales): sales@iotech.com

E-mail (post-sales): productsupport@iotech.com

Internet: www.iotech.com

Medallion Rotate User’s Manual

p/n 1086-0926, rev 2.3

© 2001 by IOtech, Inc August 2001 Printed in the United States of America

Page 2

Page 3

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior written

consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their respective

holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs) may only be used

on one installation. You may make archival backup copies.

VSI Rotate®, VSI Rotate Plus®, and VSI DSPLibs®, are owned and registered by Vold Solutions Incorporated. Vold Solutions

Incorporated maintains the copyright to the material presented in this user’s guide, unless otherwise noted or implied.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission rules (Part 15)

for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve Radio-TV Interference Problems

(stock # 004-000-00345-4) which is available from the U.S. Government Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This warns of possible personal injury or equipment damage under noted

conditions. Follow all safety standards of professional practice and the recommendations in this manual. Using this

equipment in ways other than described in this manual can present serious safety hazards or cause equipment damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

Use proper ESD handling guidelines when handling equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective bags

and cartons, and related procedures.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to the

manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is not covered

under the warranty and must be performed by qualified personnel as specified in this manual. Improper calibration procedures

may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and review

our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech welcomes

your suggestions.

Page 4

Page 5

October 2000 Medallion Rotate Manual

TABLE OF CONTENTS

CHAPTER ONE

INTRODUCTION TO MEDALLION ROTATE ..................................7

OVERVIEW OF MEDALLION ROTATE ............................................................8

OVERVIEW OF THIS USER’S GUIDE ............................................................9

O

RGANIZATION ...................................................................................9

DOCUMENT CONVENTIONS ....................................................................9

TERMS USED IN THIS GUIDE .................................................................9

CUSTOMER SUPPORT ...........................................................................9

FEATURES AVAILABLE ONLY IN MEDALLION ROTATE PLUS ............................10

BEARING, GEARBOX, AND SIDEBAND CURSORS ......................................10

ORDER NORMALIZING ........................................................................10

MILLSTRUM ANALYSIS ........................................................................10

RPM FROM WATERFALL ANALYSIS ......................................................11

CHAPTER TWO

MEDALLION ROTATE GUIDED TOUR ....................................12

USING MEDALLION ROTATE.....................................................................13

STARTING THE SOFTWARE ..................................................................13

THE MEDALLION ROTATE USER INTERFACE .............................................13

SETTING YOUR PREFERENCES ............................................................14

STARTING MEDALLION ROTATE AND DISPLAYING CHANNELS ..........................15

DISPLAYING DATA AND PROCESSING A SIGNAL...........................................17

EXPORTING A CHANNEL AND FILE MANAGEMENT ........................................19

CHAPTER THREE

MEDALLION ROTATE APPLICATIONS ....................................21

NOTES ON COLLECTING DATA ..................................................................21

SAMPLE RATE ...................................................................................21

ALIASING .........................................................................................22

PROCESSING A TACHOMETER SIGNAL .......................................................22

APPLICATIONS ..................................................................................23

INPUT SIGNAL REQUIREMENTS .............................................................23

EXAMPLE .........................................................................................24

THEORY ..........................................................................................24

WATERFALL ANALYSIS ...........................................................................25

APPLICATIONS ..................................................................................26

INPUT SIGNAL REQUIREMENTS .............................................................26

EXAMPLE .........................................................................................27

THEORY ..........................................................................................28

RPM FROM WATERFALL .......................................................................29

APPLICATIONS ..................................................................................29

INPUT .............................................................................................29

Page 6

Medallion Rotate Manual October 2000

EXAMPLE .........................................................................................29

THEORY ..........................................................................................30

COMPUTED ORDER TRACKING ................................................................31

APPLICATIONS ..................................................................................31

INPUT SIGNAL REQUIREMENTS .............................................................31

EXAMPLE .........................................................................................32

THEORY ..........................................................................................32

TORSIONAL ANALYSIS ...........................................................................33

APPLICATIONS ..................................................................................33

INPUT SIGNAL REQUIREMENTS .............................................................33

EXAMPLE .........................................................................................34

THEORY ..........................................................................................36

ORDER NORMALIZATION .........................................................................37

APPLICATIONS ..................................................................................37

INPUT SIGNAL REQUIREMENTS .............................................................37

EXAMPLE .........................................................................................38

THEORY ..........................................................................................38

MILLSTRUM ANALYSIS ...........................................................................39

APPLICATIONS ..................................................................................39

INPUT SIGNAL REQUIREMENTS .............................................................39

EXAMPLE .........................................................................................40

THEORY ..........................................................................................40

EXPORTING CALCULATED ORDERS DATA TO ME’SCOPE ...............................41

APPLICATIONS ..................................................................................41

INPUT SIGNAL REQUIREMENTS .............................................................42

EXAMPLE .........................................................................................42

CHAPTER FOUR

MEDALLION ROTATE PLOTTING FEATURES ...........................43

GENERAL PLOT FEATURES .....................................................................44

RIGHT-CLICK MENU ..........................................................................44

SELECTING THE ACTIVE TRACE ............................................................44

SELECTING THE ACTIVE CURSOR .........................................................44

MOVING A CURSOR ...........................................................................44

SAVING THE PLOT APPEARANCE AS THE DEFAULT ....................................45

TIME WAVEFORM PLOT ..........................................................................45

RPM (MACHINE SPEED) PLOTS .............................................................46

WATERFALL PLOT .................................................................................46

CONTOUR PLOT ...................................................................................47

ORDER TRACKING PLOT ........................................................................47

Index ..............................................................................................49

Page 7

October 2000 Medallion Rotate Manual

CHAPTER ONE

INTRODUCTION TO MEDALLION ROTATE

This chapter introduces you to Medallion Rotate™. It describes Medallion

Rotate in broad terms, including how it can assist you in diagnosing machine

problems. It also describes the differences between Medallion Rotate and

Medallion Rotate Plus™. Medallion Rotate Plus is an enhanced version of the

product, including powerful features that increase your capability to diagnose

problems.

7

Page 8

Medallion Rotate Manual October 2000

OVERVIEW OF MEDALLION ROTATE

Medallion Rotate is a powerful software package for analyzing noise and

vibration in mechanical equipment. It includes a set of analytical functions that

process machine speed (tachometer) and time waveform (data) signals from

almost any type of sensor.

Medallion Rotate is designed for Engineers and advanced machinery

analysts who diagnose vibration, acoustic, and other problems. Medallion

Rotate takes raw time waveform data as the input, and lets you analyze the data

in many different ways to support the clearest diagnosis. However, you must

understand the machinery and be able to identify the frequencies originating

from the different components.

One of the many advantages is that you can collect hours of time

waveform data, then pick out only the few minutes of interest. Medallion Rotate

is fast, and provides the following analysis functions.

• Tachometer analysis processes a machine speed signal (pulsed or DC

voltage) to create the instantaneous machine speed curve in RPM.

• Waterfall analysis computes and displays multiple spectra over time in a

traditional 3-dimensional Waterfall plot or Color Contour plot.

• RPM from Waterfall analysis allows you to compute an instantaneous

speed curve from a time waveform (data) when you do not have or

cannot use a tachometer on a machine.This allows you to accurately

determine the machine speed in many cases without a tachometer.

• Computed Order Tracking shows you the magnitude and phase change

for multiple orders over time in a Bode plot.

• Order normalization order normalizes the data when performing a

Waterfall analysis.

• Torsional vibration analysis creates an accurate kinematic description

of torsional vibrations from a single tachometer or other machine speed

signal.

• Millstrum analysis in Medallion Rotate Plus simplifies the process of

identifying families of harmonics and sidebands.

• Advanced plotting features such as sophisticated cursors simplify

identifying the spectral peaks in Waterfall and Contour plots.

• Medallion Rotate can import time waveform data from many sources,

including Teac, Sony, HP-SDF, Zonic Medallion, Vibe-Tech, ASCII,

WAV, MATLAB, Dactron, SDRC-UFF, MEGADAC, Nicolet Prism,

Nicolet NRF, STAC Rex, and SoMat Ease.

• If you have the ME’Scope™ program from Vibrant Technology, you can

export computed order tracking data to ME’scope for operating

deflection shape analysis.

8

Page 9

October 2000 Medallion Rotate Manual

OVERVIEW OF THIS USER’S GUIDE

ORGANIZATION

This User’s Guide contains the following chapters.

Chapter 1 “Introduction to Medallion Rotate”, introduces the Medallion

Rotate program. It provides an overview of this User’s Guide, and also

describes the additional analysis features available in Medallion Rotate Plus.

Chapter 2 “Medallion Rotate Guided Tour”, describes the Medallion Rotate

program. It guides you through the user interface. It then explains how to

operate the software by leading you through a tour of the basic features.

Chapter 3 “Medallion Rotate Applications”, describes the powerful

analysis tools available in Medallion Rotate and Medallion Rotate Plus. It

begins with some general notes on collecting data. Then each section includes

a description of the analysis tool, some possible applications, conditions for

the input data, and a brief explanation of the theory behind the analysis tool.

Chapter 4 “Medallion Rotate Plotting Features”, describes the various

plotting tools available in Medallion Rotate and Medallion Rotate Plus. It

covers both the plotting features and the different types of plots.

DOCUMENT CONVENTIONS

This User’s Guide uses the following conventions.

Menu names, commands, and controls in dialog boxes are in boldface type.

Keys on the computer keyboard are in boldface type.

Caution: Cautions warn you about actions that could delete data.

Hint: Hints point out additional useful information, such as alternative

ways to do certain tasks.

TERMS USED IN THIS GUIDE

Medallion Rotate and Rotate are used interchangeably throughout this

User’s Guide and in the online help. In general, they refer to both Medallion

Rotate and Medallion Rotate Plus. Some features are available only in

Medallion Rotate Plus—see “Features Available Only in Medallion Rotate

Plus.”

Time waveform is used for any time domain data that you can process in

Medallion Rotate. This includes, but is not limited to, signals from tachometers,

accelerometers, non-contact eddy current probes, encoders, and microphones.

Order normalization is used in describing the process of resampling a time

waveform using a constant angular rotational interval, as opposed to

conventional sampling using a constant time interval. Medallion Rotate Plus

uses resampling to order normalize the data.

9

Page 10

Medallion Rotate Manual October 2000

FEATURES AVAILABLE ONLY IN MEDALLION ROTATE PLUS

The following features are available only in Medallion Rotate Plus, and not

in the standard Medallion Rotate. You can upgrade your copy of Medallion

Rotate to Medallion Rotate Plus to get these additional features. Contact Zonic

Corporation for more information.

BEARING, GEARBOX, AND SIDEBAND CURSORS

Medallion Rotate Plus includes three new cursors. For more information on

plotting features, refer to Chapter 4, “Medallion Rotate Plotting Features”.

• The Rolling Element Bearing cursor displays up to 6 cursors to help

you identify peaks caused by individual components of a bearing.

• The Gearbox cursor displays up to 8 cursors based on the number of

input and output gear teeth to help you identify peaks caused by gears.

• The Planetary Gearbox cursor displays up to 11 cursors based on the

number of gear teeth to help you identify peaks caused by planetary

gears.

• The Sideband cursor displays a user-defined number of sideband

cursors to help you identify sideband frequencies around a primary

frequency.

ORDER NORMALIZING

Medallion Rotate Plus can resample a time waveform to order normalize the

data when performing a Waterfall analysis. Order normalization cancels the

effect of frequency smearing across spectral bins when the shaft speed is

changing rapidly (high slew rate). It ensures that order-related peaks are aligned

with the orders when plotted against the orders.

MILLSTRUM ANALYSIS

Millstrum analysis in Medallion Rotate Plus simplifies the process of

identifying families of harmonics and sidebands. Millstrum analysis does this

by removing non-repetitive events and presenting the results in an easilyunderstood format. It is similar to using the cepstrum, but goes further in

simplifying the results so that you do not have to perform any additional

calculations.

10

Page 11

October 2000 Medallion Rotate Manual

RPM FROM WATERFALL ANALYSIS

The RPM from Waterfall analysis in Medallion Rotate Plus allows you to

determine the machine speed from a Waterfall analysis. Even though you do

not have a tachometer signal, you can create the smoothed machine speed

curve that describes the instantaneous speed of the machine over time.

11

Page 12

Medallion Rotate Manual October 2000

CHAPTER TWO

MEDALLION ROTATE GUIDED TOUR

This chapter provides a brief overview of the Medallion Rotate program. It

then leads you through a short tutorial to introduce you to the basic functions

of Medallion Rotate. After you have completed this chapter, you will be able to

perform the steps to import and begin to analyze data in Medallion Rotate.

This tutorial uses the demonstration data that is automatically installed

with Medallion Rotate.

12

Page 13

October 2000 Medallion Rotate Manual

USING MEDALLION ROTATE

STARTING THE SOFTWARE

To start Medallion Rotate, click Start, point to Programs, then to

Medallion Rotate, then click Medallion Rotate.

The Medallion Rotate program window appears.

To stop Medallion Rotate, simply choose Exit from the File menu.

THE MEDALLION ROTATE USER INTERFACE

Medallion Rotate follows the standard Windows¨ user interface standards,

and consists of the usual windows, menus, and toolbars. A picture of the

Medallion Rotate window appears below.

Title bar

Menu bar

Toolbar

Status bar

• The title bar displays the program name.

• The menu bar appears directly below the title bar. It contains the menus

of commands for the program.

• The toolbar appears directly below the menu bar. It contains the tool

buttons that are shortcuts to the most often used functions of the

program. A short ToolTip describing the button function appears when

you move the mouse pointer over a button. You can click and drag a

toolbar to any position within the program window, and “dock” it to

any side of the window. You can also show or hide any toolbar with the

commands on the View menu.

• The status bar shows a brief description of the current command or

button under the mouse pointer.

• Many parts of the program have right-click menus. For example, you

can right-click on a plot window to display a menu of functions for that

plot.

13

Page 14

Medallion Rotate Manual October 2000

• The Channel List window shows the channels (tachometer and data)

that you have imported into, or created in, Medallion Rotate. To display

the Channel List window, right-click anywhere in the Medallion Rotate

program window (except on the menu bar).

• The online help describes each command, dialog box, and plot. To

display the online help, do one of the following:

• Highlight a command on a menu and press F1. This displays an

explanation of the command.

• Open a dialog box and press F1. This displays an explanation of the

controls in the dialog box.

• Make a plot window active by clicking on the plot and press F1.

This displays a description of the functions available for that plot.

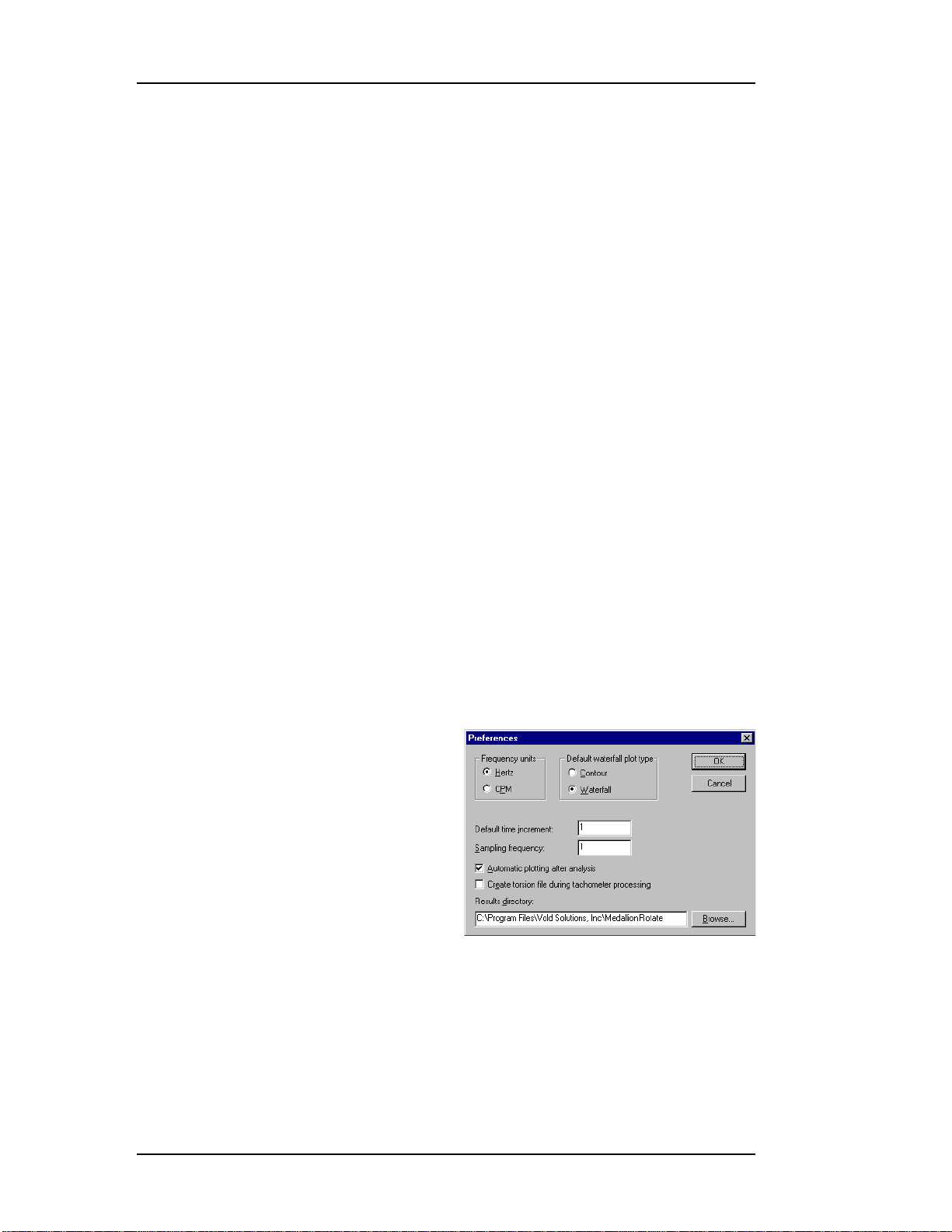

SETTING YOUR PREFERENCES

The preferences settings control the default Medallion Rotate appearance

and functions. These include the following defaults.

• Frequency units in plots

• Waterfall plot type (waterfall or contour)

• Default time increment and sampling frequency

• Automatic plot display after analysis

• Creation of a Torsional analysis file when processing a tachometer

signal

• The directory for the files created by the Medallion Rotate analysis

functions

To set your preferences, follow these steps.

1. Start Medallion Rotate. See “Starting the Software.”

2. From the Edit menu choose

Preferences.

3. In the Preferences dialog box,

select or enter the desired

defaults. Press F1 for a

description of the options.

4. Choose OK when finished.

14

Page 15

October 2000 Medallion Rotate Manual

STARTING MEDALLION ROTATE AND DISPLAYING CHANNELS

The first section of the Tutorial leads you through starting Medallion

Rotate, as well as opening a data file and displaying data channels in the file.

START MEDALLION ROTATE

1. To start Medallion Rotate, click Start, point to Programs, then to

Medallion Rotate, then click Medallion Rotate. The Medallion Rotate

program window appears.

VIEW THE CHANNEL LIST

Medallion Rotate displays the

Channel List window when it starts.

Initially the Channel List shows the 2

channels of data from the demonstration

data file.

Hint: Don’t worry if the Channels

List window is empty, or contains different files than the ones shown in

the picture. Adding files to the Channel List window is described below.

2. You can hide the Channel List window by clicking anywhere on the

Medallion Rotate window or by pressing Esc.

3. You can restore the Channel List window by doing one of the following:

• Right-click on the Medallion Rotate window.

• Press Ctrl+L.

• Click the Channel List

button .

• From the Channels menu

choose Channel List

Window.

REMOVE CHANNELS FROM THE CHANNEL LIST

Removing “channels from the Channel List window does not delete any

data, and you can add the channels back in at any time.

4. Select the 2 channels in the Channel List by holding down the Ctrl key

and clicking the two channels. You can also hold down the Shift key

and select a range of channels.

5. Press Del.

Hint: You can also right-click a

channel and choose Remove.

Note that this removes all

selected channels, not just the

one you right-clicked.

15

Page 16

Medallion Rotate Manual October 2000

ADD A DAT A FILE

Adding a data “file displays all the channels

of data from that file. Medallion Rotate can display

the channels from a number of different file

formats.

6. Right-click on the Channel List and choose

Add File.

7. Select the correct Files of type. If you don’t know the file type, select

All Files (*.*). For this example, select Medallion File (*.mrd).

8. Select the Demo_Data.MRD file and choose Open. The data channels

from the data file appear in the Channel List (Channel 1, Channel 2).

Hint: You can also do one of the following to add a file:

• Click the Add File button

• From the Channels menu choose Add File.

.

16

Page 17

October 2000 Medallion Rotate Manual

DISPLAYING DATA AND PROCESSING A SIGNAL

The second section of the Tutorial leads you through displaying a time

waveform plot. It then describes the steps to process a tachometer signal to get

the instantaneous machine speed in RPM (revolutions per minute).

The Demo_Data.MRD file contains two channels.

• Channel 1 is a time waveform of a pulse tachometer signal varying

between 0 and 4 Volts.

• Channel 2 is a time waveform from a vibration sensor.

PLOT A TIME WAVEFORM

1. Make sure that Channel 1 is the

only selected channel in the

Channel List window. Then

right-click Channel 1 and

choose Plot. You can also do

one of the following:

• Select the channel and click the Plot button .

• Double-click the channel.

• Select the channel and choose Plot from the Channels menu.

Medallion Rotate displays a plot of the time waveform.

ZOOM IN ON THE TIME WAVEFORM

2. Right-click the plot and choose

Zoom.

3. Click and drag the mouse over a

part of the plot to enlarge that

part of the plot.

The plot redraws the zoomed part

when you release the mouse button.

Note the signal amplitude is from -0.5 to

4 Volts.

4. Right-click the plot and choose

Auto-scale to show the whole signal again.

17

Page 18

Medallion Rotate Manual October 2000

PROCESS A TACHOMETER SIGNAL

Channel 1 should still be selected in the Channel List window. Channel 1 is

a tachometer signal; you can process it to get the instantaneous RPM. You do

not have to display the Channel List window again.

5. Click the Tachometer Processing button

Tachometer Processing command from the Analysis menu.

6. Make sure the Trigger Level is

between 1 and 4 Volts. In general,

the trigger level should be in the

middle of the amplitude of the

tachometer signal for a pulse

tachometer. Choose OK to process

the tachometer signal.

Medallion Rotate displays a plot

of the machine RPM. There are actually

two curves on the plot. One is the

smoothed (spline-fit) RPM curve. The

other is the Raw RPM curve before

Medallion Rotate applied the spline-fit

to smooth the RPM curve.

7. Zoom in on the peak of the

RPM curve to see the two

curves. Right-click the plot,

choose Zoom, then click and

drag over the region you want

to zoom.

. You can also choose the

The smooth curve is the spline-fit

RPM curve, while the jagged curve is

the raw RPM curve before smoothing.

8. Click the Channel List

button or press Ctrl+L to

display the Channel List

window. Note that there are two

new generated files in the

Channel List, each with one

channel. Medallion Rotate

created and saved these files in

the Results directory (see

“Manage Files” to set the

Results directory).

• The smoothrpm0.spl file is the smooth (spline-fit) RPM data.

• The rpm0.raw file is the Raw RPM data.

18

Page 19

October 2000 Medallion Rotate Manual

OTHER TYPES OF ANALYSES

You can perform many other types of analyses in Medallion Rotate to

assist in diagnosing a variety of difficult problems.

• Refer to Chapter 3 “Medallion Rotate Applications” for more

information on the different types of analyses and their uses.

• Refer to Chapter 4 “Medallion Rotate Plotting Features” for more

information on using the plotting functions to manipulate plots.

EXPORTING A CHANNEL AND FILE MANAGEMENT

The third section of the Tutorial describes the process of exporting a

channel to a Universal File Format (UFF) file. It also describes channel and file

management. Medallion Rotate can generate a large number of files during an

analysis, and it is important to manage them so that you do not fill up the

Medallion Rotate directory with unnecessary files.

EXPORT A CHANNEL TO A UFF FILE

Exporting a channel to a UFF file provides 2 useful functions:

• It creates a new ASCII or binary data file in a widely-accepted format.

• It allows you to export only a part of the file instead of the entire file.

For example, the original file might contain 6 hours of data, but you can

export just the 5 minutes of data that contain the desired event.

1. Right-click a channel and choose Export.

2. Enter the file name and choose Browse to

select the directory. Choose Export.

Hint: You can also select a channel and choose

the Export command from the Channels

menu.

RENAME A GENERATED CHANNEL

Medallion Rotate generates one or more channels each time you perform

any type of analysis. Medallion Rotate automatically names a generated

channel by combining the channel name and the data file name. Renaming a

generated channel can help you remember the purpose or parameters of that

analysis.

Note that you can only rename generated channels. You cannot rename

channels from an original data file.

1. Right-click a channel and

choose Rename Channel.

2. Enter the new name for the

channel and press Enter.

Hint: You can also select a channel

and choose the Rename

command from the Channels menu.

19

Page 20

Medallion Rotate Manual October 2000

RENAME A GENERATED DATA FILE

When you perform an analysis, Medallion Rotate generates a data file for

each generated channel. Medallion Rotate automatically names generated files,

but you can determine the type of the file from the file name (Raw RPM, smooth

RPM, waterfall, É). Renaming the generated file can help you remember the

purpose of the analysis or the original data file.

Note that you can only rename generated

files. You cannot rename an original data file.

1. Right-click the generated channel for the desired file and choose

Rename File.

2. Enter the new name for the file and choose OK.

Hint: You can also select a channel and choose the Rename File command

from the Channels menu.

MANAGE FILES

As mentioned above, Medallion Rotate can generate a large number of files

during an analysis. Managing your files in a logical manner can make it much

easier to keep the generated files with the original data files, and to delete files

that you no longer need.

The easiest way to manage files in Medallion Rotate is to use a separate

directory for each set of original data files. Then you can create a new directory

for each set of analyses. Alternatively. you could use the same directory for all

your analysis if you delete all the files after you are done with the analysis.

1. Create a directory for the project. The directory can be anywhere on

your computer or network, but you must have read/write permissions

for the project directory (if on a network).

2. Copy your original data files for the analysis into the project directory.

3. In Medallion Rotate, from the Edit menu choose Preferences.

4. Edit the Result(s) directory so that it is the project directory or a subdirectory of the project directory. Click Browse to select the Result(s)

directory.

5. Perform the analysis. Medallion Rotate stores the generated files in the

Result(s) directory. This makes it easy to keep all the files for a project

together.

6. When you are done with your analysis, you can delete the generated

files if you do not want to keep them.

CAUTION!

Make sure you do not delete your original data files by accident!

20

Page 21

October 2000 Medallion Rotate Manual

CHAPTER THREE

MEDALLION ROTATE APPLICATIONS

This chapter describes the analysis methods available in Medallion Rotate.

The chapter begins with some notes on collecting data. It then lists some uses

for each method, then goes on to present a sample application of the method.

You can use this chapter as a guide to selecting the best method to analyze

data for a particular type of problem. However, this chapter is not meant to be

the last word on analysis using Medallion Rotate. You are likely to discover

other applications for Medallion Rotate after you have been using it for a while.

NOTES ON COLLECTING DATA

SAMPLE RATE

Guidelines for the sample rate for each type of application are described

under the application. One thing to note is that the sample rate of the

tachometer signal does not have to be the same as the sample rate for a data

channel. For example, the sampling rate on the tachometer channel can be much

higher than the sampling rate on a vibration transducer channel.

In general, the sampling rate must be at least 2.5 times the maximum

frequency of interest to avoid aliasing effects (described below). Note that most

analyzers require that you use the sample rate, not the maximum frequency, in

setting up to collect time waveform data. So for a maximum frequency of 400 Hz,

set the sampling rate at 1000 samples/second.

400 Hz <

400 Hz x 2.5 < 1000 = Sampling rate

1000

2.5

Sampling rate

=

2.5

21

Page 22

Medallion Rotate Manual October 2000

ALIASING

Aliasing is an artifact of collecting data caused by using a sampling rate

that is less than twice as high as the highest frequency sampled. Aliasing

results in extra spectral peaks from higher frequencies that get “folded back” by

the signal processing. Most data collection instruments use a low pass filter,

called an anti-aliasing filter, to exclude frequencies that would cause aliasing.

Some instruments that can capture a time waveform (time history) signal do

not include anti-aliasing filters. With this type of equipment, you must be

careful when analyzing spectra, since there may be extra spectral peaks due to

aliasing.

The following example shows a Waterfall plot with aliasing. This torque

data was collected without anti-aliasing filtering. In this plot, speed is

increasing, as you can see by the rising frequency in the cursored spectral

peaks. However, there are several sets of peaks that appear to be decreasing as

speed increases. These are due to alias frequencies “folding back”.

If you were looking at a single spectrum from this data, it would not be

possible to determine which peaks were due to aliasing.

PROCESSING A TACHOMETER SIGNAL

Medallion Rotate can process a tachometer or other machine speed signal

to create an RPM curve that describes the instantaneous speed of the machine

over time. The machine speed signal can be either a pulse or a DC-voltage level

signal from a tachometer, counter, encoder, or other speed sensor.

You can use the speed curve to diagnose some problems directly. You can

also use the speed curve along with other data, such as vibration, as an input

for additional sophisticated Medallion Rotate analysis techniques. Finally, you

can create a torsion file when processing a tachometer signal. See “Torsional

Analysis.”

22

Page 23

October 2000 Medallion Rotate Manual

APPLICATIONS

Processing the tachometer signal results in an RPM curve describing the

instantaneous machine speed. Medallion Rotate uses a spline-fit process to

create a smoothed speed curve from the tachometer signal. The speed curve is

a high-resolution view of the machine speed.

You can use this smooth speed curve to diagnose problems related to the

speed or speed change of a machine. This provides an independent verification

of the machine speed, since some process control indicators suffer from “flat

spots” in their response to speed changes.

Other applications include the following:

• Examining the effects

of changing load or

other process dynamic

on the speed.

• Determining the effect

of power fluctuations

(brownouts) on the

speed.

• Speed profiling on a

multi-drive machine to

determine if there slip at any of the drive units (over- or under- speed).

• Threading analysis on a sheet mill.

• Evaluating the actual machine speed against the ideal constant speed.

• Verification of the speed change between two points to determine the

elongation of the material, such as in a rolling mill.

• Examination of the speed curve to diagnose speed oscillation due to a

loose coupling, hunting motor, or other cause.

INPUT SIGNAL REQUIREMENTS

The input signal to the tachometer analysis is a tachometer or other

machine speed signal. As with all analysis techniques, the better the input

signal, the clearer the results—so a good, clean tachometer signal is essential.

For a pulsed tachometer signal (non-contact probe, encoder, …) the

sampling rate must be at least 2.5 times the maximum frequency of interest to

avoid aliasing effects. A good rule of thumb is to use 5–10 time oversampling of

the tachometer pulse frequency (not the machine speed) to get good, clean

tachometer pulses. For example, if a tachometer produces one pulse per

revolution on a 600 RPM machine, sample the tachometer data at a rate of 50–

100 samples/second (Hz).

600 RPM x

For a DC voltage tachometer signal, you must know the machine speed

when the signal is at 0 volts. For some sensors, the DC speed signal falls to 0

volts before the machine is at a standstill.

1 minute

60 seconds

23

Page 24

Medallion Rotate Manual October 2000

EXAMPLE

The following example is taken from a rolling mill. As the sheet of metal is

rolled out, the speed of the sheet increases. This produces a distinctive speed

profile, as shown in the data collected from several stands along the mill.

This plot is the raw DC tachometer signal.

1. The first step is to process the tachometer signal to create a smoothed

speed curve. For the steps to process a tachometer signal, see “Process

a Tachometer Signal.”

2. Repeat the first step to get smoothed speed curves for each stand.

3. Overlay the speed curves from different stands to see the speed profile

for the machine. You can overlay multiple speed curves by selecting

them in the Channel List window then clicking the Plot button.

THEORY

Medallion Rotate uses a spline-curve fit algorithm that computes raw or

initial estimates of a machine’s instantaneous rotating speed by utilizing

sampled analog data from the sensor. With pulse tachometer data, Medallion

Rotate computes an initial estimate by measuring the time between pulses. Next,

it uses a series of cubic splines that enforce continuity at their boundaries to

create a smooth estimate of the machine’s rotating speed.

x 5 = 50 samples/second

Medallion Rotate then uses a unique technology to remove the “outliers”

from the raw estimate before re-evaluating the spline fit. This allows you to use

noisy tachometer signals or tachometer signals with dropouts. In some cases,

this can delay the need to repair or replace the tachometer.

24

Page 25

October 2000 Medallion Rotate Manual

WATERFALL ANALYSIS

You can perform a Waterfall analysis

on time waveform data from any

transducer. The data transducer can be a

vibration sensor (accelerometer, velocity

sensor, non-contact probe) or any other

meaningful sensor (temperature,

thickness, pressure, …).

You can use Waterfall analysis on a

data channel without a machine speed signal; however, you will not be able to

use the machine speed or order tracking

capabilities of the Waterfall plot. If you

have a tachometer signal you can create

the smooth speed curve as described in

“Processing a Tachometer Signal.” Then

you can combine the speed curve with

data from a correlated transducer in the

Waterfall analysis.

The result of the Waterfall analysis is

a series of spectra displayed on a three-dimensional (X-Y-Z) plot. The Waterfall

plot provides several useful ways of

looking at the data:

• The plot cursors can track the X

axis or the Z axis.

• You can choose frequency or

orders for the X axis and X axis

cursors.

• You can choose spectrum number,

RPM, or seconds for the Z axis and Z axis cursors. If you use order

normalization, you can also choose the number of revolutions for the Z

axis.

• You can display the data in a traditional spectral Waterfall plot, or as a

Color Contour plot. See “Contour Plot.”

Medallion Rotate can also order normalize the data so that the order-related

peaks line up exactly on the orders (when the X axis is in orders). See “Order

Normalization.”

25

Page 26

Medallion Rotate Manual October 2000

APPLICATIONS

The Medallion Rotate Waterfall plot is ideal for non-steady state processes

such as variable speed machinery. The plot shows you the change in the

appearance of the spectra over time. This is particularly useful in the following

applications:

• Analyzing the machine’s behavior during run-up or coast-down.

• Diagnosing amplitude modulation (“beat”).

• Determining the frequency and severity of resonances, such as shaft

critical speeds.

• Analyzing a machine’s response to speed or load variations.

• Isolating non-varying spectral peaks (such as those caused by electric

power or resonance) from speed-dependent peaks (such as vibration).

• Isolating spectral peaks from other processes that are linked to the

machine.

• Ruling out spurious spectral peaks caused by aliasing when using timecapture equipment that does not have anti-aliasing filtering. See

“Aliasing.”

• Performing Waterfall analysis directly on a DC speed signal to diagnose

torsional problems. For more on torsional analysis, see “Torsional

Analysis.”

INPUT SIGNAL REQUIREMENTS

Medallion Rotate Waterfall analysis

requires a smoothed speed curve from

performing a Tachometer analysis if you

want to use the order tracking features of

the Waterfall plot. When collecting the

non-tachometer data (vibration,

temperature, …), note the following:

• If you want to see low frequency

data in the Waterfall analysis, make sure that the high pass filter setting

in your analyzer is not excluding the desired low frequencies.

• The sample rate in the analyzer must be at least 2.5 times the maximum

frequency of interest to avoid aliasing.

• The choice of window function for

analysis depends on the type of

resolution you need (amplitude or

frequency resolution).

26

Page 27

October 2000 Medallion Rotate Manual

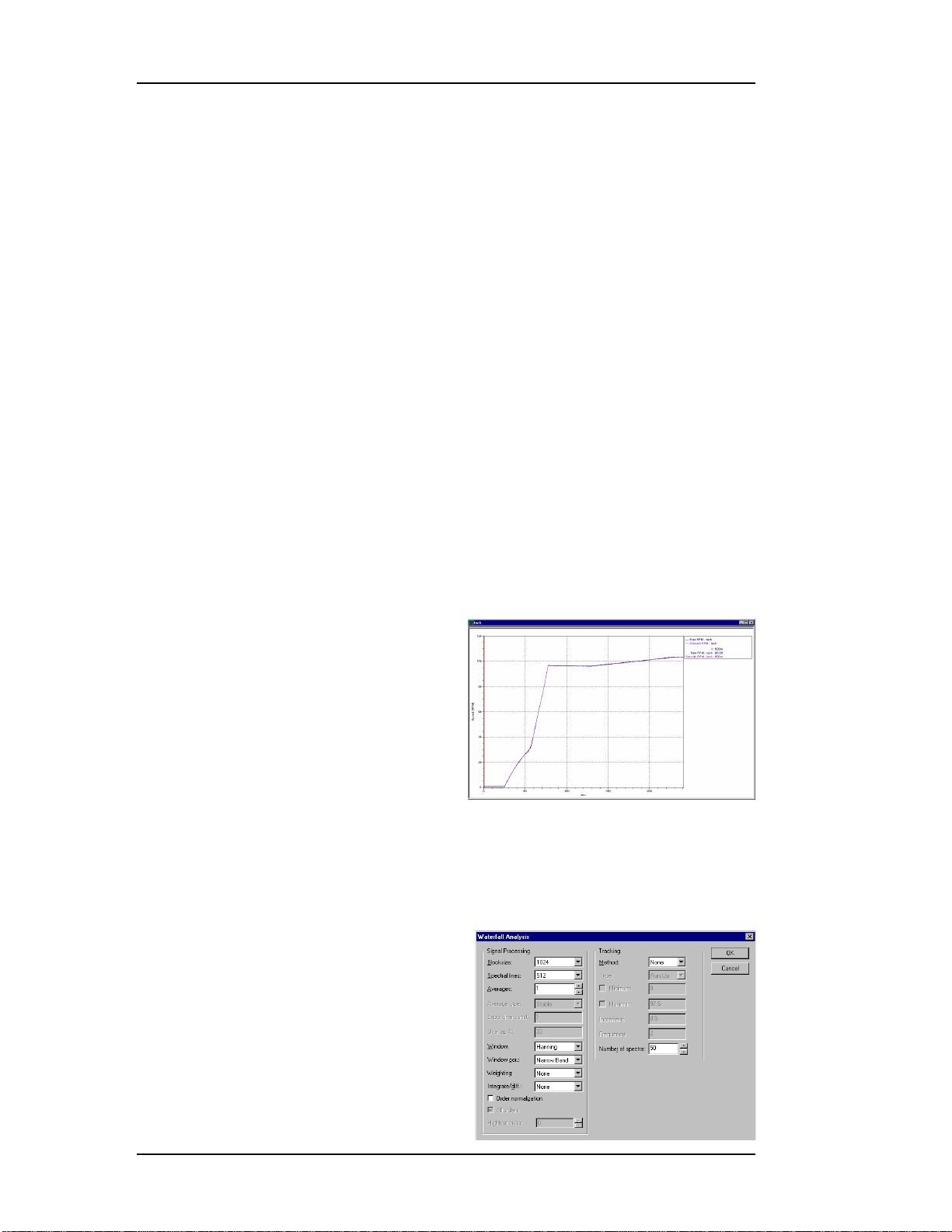

EXAMPLE

The following example is from a turbine.

1. Process the tachometer signal to get the smoothed speed curve. See

“Process a Tachometer Signal.” If you do not have a tachometer signal,

skip this step.

2. Use Waterfall analysis to create the Waterfall plot. In order to use the

order tracking features, select both the smoothed machine speed curve

and the data channel in the Channel List window. If you do not have a

tachometer signal, select the data channel. Then do one of the

following:

• Click the Waterfall analysis button

• Choose Waterfall Analysis from the Analysis menu.

3. Press F1 for an explanation of the dialog box. After selecting the desired

parameters, choose OK to display the Waterfall plot.

.

27

Page 28

Medallion Rotate Manual October 2000

In this Waterfall plot, there are

cursors at 0.5 1, 1.5, and 2 orders. The 0.5

order cursor highlights a turbine rub that

“locks” onto one of the shaft critical

frequencies and then deviates from the 0.5

order cursor.

THEORY

The Medallion Rotate Waterfall

analysis uses the standard Fast Fourier transform to calculate the array of FFT

spectra and then display them in a Waterfall or Color Contour plot

(spectrogram). The spectrum calculation allows for standard parameters such as

blocksize, averaging, windowing, weighting (A, B, and C), frequency domain

integration, and integration/differentiation functions as found on most

spectrum analyzers. Medallion Rotate can display spectra as a function of

either time or RPM.

28

Page 29

October 2000 Medallion Rotate Manual

RPM FROM WATERFALL

The RPM from Waterfall function in Medallion Rotate Plus allows you to

determine the machine speed from a waterfall file. If you do not have a

tachometer signal, or the signal is extremely noisy, you can use other data to

create an RPM curve that describes the speed of the machine over time.

Medallion Rotate can use this smoothed speed curve in the same ways as

a speed curve generated from a tachometer signal. You can use this speed

curve to diagnose some problems directly. You can also use the speed curve

along with other data, such as vibration, as an input for additional

sophisticated Medallion Rotate analysis techniques.

APPLICATIONS

The RPM from Waterfall function is applicable when you have a time

waveform from a data channel, but no tachometer signal or a noisy signal.

There may not be a tachometer available, or it may be impractical to use a

tachometer or other speed sensor on the machine. In some cases, the RPM from

Waterfall function may produce a better speed curve than a tachometer.

INPUT

When collecting the non-tachometer data (vibration, temperature, …), note

the following:

• If you want to see low frequency data in the Waterfall analysis, make

sure that the high pass filter setting in your analyzer is not excluding

the desired low frequencies.

• The sample rate in the analyzer must be at least 2.5 times the maximum

frequency of interest to avoid aliasing.

• The choice of window function for analysis depends on the type of

resolution you need (amplitude or frequency resolution). Since the

RPM from Waterfall function depends more on the position of the

spectral peaks than on the amplitude, the Hamming window is a good

default choice.

EXAMPLE

This example uses the RPMFromWaterfallDemo.wat file included with

Medallion Rotate Plus. You can also use any waterfall file generated by

Medallion Rotate using Waterfall analysis (see “Waterfall Analysis” ).

1. In the Channel List Window select

the RPMFromWaterfallDemo.wat

file, then select the waterfall

channel. You can display the

Waterfall by clicking on the Plot

button.

29

Page 30

Medallion Rotate Manual October 2000

2. From the Analysis menu,

choose RPM from Waterfall.

This displays a color contour

plot of the waterfall.

3. Enter the order you want to use

to find the machine speed. For

this example, leave the value at

1 for the first order.

4. Zoom in on the area around the first order.

5. Working from the bottom of the

plot to the top, click the peaks

for the order. Medallion Rotate

Plus draws a line for the order

by estimating the location of

the order. You can change the

location of the line by clicking

on the plot.

If you want to start over, simply choose Cancel.

6. When the line on the plot connects the peaks for the order, click OK.

Medallion Rotate Plus calculates a smoothed machine speed curve

based on the order number and

the line on the plot.

7. You can select the smoothed

speed curve and the waterfall

data in the Channel List

window, then click the Plot

button to display the Waterfall.

This allows you to use the

order tracking features of the

Waterfall plot.

THEORY

The RPM from Waterfall function

uses the assumption that an order of

running speed generates a distinct series of peaks in a Waterfall plot. After you

identify the peaks for the order, Medallion Rotate Plus determines the RPM

versus time function and generates a smooth RPM curve of the instantaneous

speed.

30

Page 31

October 2000 Medallion Rotate Manual

COMPUTED ORDER TRACKING

Computed Order Tracking uses the smooth speed curve from processing a

tachometer signal or from the RPM from Waterfall function. You can combine

the speed curve with data from a correlated transducer to perform a Computed

Order Tracking analysis. The correlated transducer can be an vibration sensor

(accelerometer, velocity sensor, non-contact probe) or any other meaningful

sensor (temperature, thickness, pressure, …).

APPLICATIONS

Computed Order Tracking shows you the amplitude and phase of the data

at selected orders, plotted against the machine’s speed. Computed Order

Tracking is ideal for variable speed machinery. This is particularly useful in the

following applications:

• Analyzing of the machine’s behavior during run-up or coast-down.

• Analyzing of a machine’s response to speed or load variations.

• Determining the frequency and severity of resonances, such as shaft

critical speeds, even when the resonances are heavily damped.

• Balancing rotors.

• Generating operating deflection shapes. For more on operating

deflection shapes, see “Exporting Calculated Orders Data to

ME’scope.”

INPUT SIGNAL REQUIREMENTS

Medallion Rotate Computed Order Tracking requires a smooth speed curve

from processing a tachometer signal or using the RPM from Waterfall function.

Medallion Rotate processes the machine speed with the transducer data to

create the plot of the orders. When collecting the non-tachometer data

(vibration, temperature, …), note the following:

• If you want to see low frequency data in the Order Track plot, make

sure that the high pass filter setting in your analyzer is not excluding

the desired low frequencies.

• The sample rate in the analyzer must be at least 2.5 times the maximum

frequency of interest to avoid aliasing. Be aware that the anti-aliasing

filter in many data collection instruments truncates the upper 20-30% of

the frequency range (the highest orders in the signal).

• The choice of window function for analysis depends on the type of

resolution you need (amplitude or frequency resolution).

31

Page 32

Medallion Rotate Manual October 2000

EXAMPLE

This example is from the demonstration data included with Medallion

Rotate.

1. Process the tachometer signal to

get the smoothed speed curve.

See “Process a Tachometer

Signal.”

2. Then use Computed Order

Tracking to get the order data.

Select both the smoothed

machine speed curve and the

data channel in the Channel List

window, then do one of the

following:

• Click the Computed Order Tracking button

• Choose Computed Order Tracking from the Analysis menu.

3. Press F1 for an

explanation of the dialog

box. After selecting the

desired parameters,

choose OK to display the

Bode plot of the orders.

THEORY

The order functions created by the Computed Order Tracking function are

leakage free because the instantaneous machine speed controls the resampling

in the Computed Order Tracking algorithm. Computed Order Track plots are

created from many more data points than the orders plotted in a Waterfall, and

are a more precise picture of each order.

.

32

Page 33

October 2000 Medallion Rotate Manual

TORSIONAL ANALYSIS

Medallion Rotate can process a tachometer or other machine speed signal

to create an accurate kinematic description of torsional vibrations from a single

measurement. The machine speed signal must be a pulsed signal from a

tachometer, counter, encoder, or other speed sensor that shows torsional

changes.

Note:Torsional analysis creates a time history of the machine speed, similar

to that from a high-resolution DC speed sensor. If you have a highresolution DC speed signal, you can simply perform a Waterfall analysis

on the speed signal to view the torsional vibration. See “Waterfall

Analysis.”

Torsional analysis results in a time history of instantaneous shaft speed

with even sample spacing in time (in revolutions per second). You can then use

Waterfall analysis of the torsion file to create a series of spectra displayed on a

three-dimensional (X-Y-Z) plot. The Waterfall plot provides several useful ways

of looking at the data:

• The plot cursors can track the X axis or the Z axis.

• You can choose frequency or orders for the X axis and X axis cursors.

• You can choose spectrum number, RPM, or seconds for the Z axis and

Z axis cursors.

• You can display the data in a traditional spectral Waterfall plot, or as a

Color Contour plot. See “Contour Plot.”

You can use the torsional Waterfall plot to diagnose a variety of problems

directly from the machine speed signal. In some cases, Medallion Rotate can

eliminate the need for slip rings, telemetry, and torsional transducers.

APPLICATIONS

Torsional analysis is useful in diagnosing any problems arising from

torsional vibration (variations in rotational speed of a component due to

twisting). This technique can identify problems that do not usually appear in

conventional vibration measurement and analysis. This is particularly useful in

the following applications:

• Finding shaft critical speeds in turbines.

• Identifying torsional resonances in internal combustion engines that

reduce the efficiency.

• Identifying torsional resonances in reciprocating machinery.

• Diagnosing the cause of gear “chatter” from torsional vibration.

33

Page 34

Medallion Rotate Manual October 2000

INPUT SIGNAL REQUIREMENTS

The fixed sampling rate for the machine speed signal must be high enough

to give a good definition of pulses. Note that the number of tachometer pulses/

revolution determine the maximum torsional frequency of the analysis. In

addition, the sampling rate must be at least 2.5 times the maximum frequency of

interest to avoid aliasing effects. For example, for a maximum torsional

frequency of 10 orders, you must have a tachometer capable of providing at

least 2.5 x 10 pulses/revolution (25 pulses/revolution).

A good rule of thumb is to use 5–10 time oversampling of the tachometer

pulse frequency (not the machine speed) to get good, clean tachometer pulses.

For example, for a tachometer that produces 25 pulses per revolution on a 60

RPM machine, sample the tachometer data at a rate of 125–250 samples/second.

25 pulses/rev x 60 RPM x

Since the torsional analysis algorithm works in the time domain, do not use

aggressive anti-aliasing filters for the data acquisition.

EXAMPLE

This example is from a 3-cylinder

diesel engine. The data is from a noncontact sensor on a 72-teeth gear.

1. The first plot is the time waveform,

zoomed in to show more detail. To

display a time waveform, select the

tachometer channel in the

Channels List window and click

the Plot button.

2. Set the preferences to create the torsion file.

• From the Edit menu choose Preferences.

• Select Create torsion file during tachometer processing so Medallion

Rotate will create the torsion file.

• Medallion Rotate also uses the sampling rate from this dialog box when

processing the signal. This is not the same as the original sample rate

used when collecting the data. A

meaningful sample rate is 1/5 the

rate of the tachometer signal. For

example, for a 1 Hz tachometer

signal, use a sample rate of 0.2 Hz

when processing the tachometer

signal.

1 minute

60 seconds

x 5 = 125 samples/second

34

Page 35

October 2000 Medallion Rotate Manual

3. Choose OK to close the Preferences dialog box.

4. Process the tachometer signal. See “Process a Tachometer Signal.”

Medallion Rotate creates the torsion file at the same time, then displays

the machine speed curve. Note this is the instantaneous speed in

degrees/second. The machine speed curve shows the torsional speed

changes as oscillations around the mean speed.

Hint: After processing, choose Preferences from the Edit menu. Clear the

check box for Create torsion file during tachometer processing unless

you are going to create more torsion files immediately. Creating the

torsion file during Tachometer processing can slow down Medallion

Rotate.

5. Close or minimize the machine

speed plot.

6. In the Channel List window, select

the torsion file (*.tor) and the

smoothed speed curve, then click

the Waterfall analysis button to

create a Waterfall plot. The

amplitude axis for the plot is in degrees/second.

Note that the torsional file includes a large DC component, equal to the

mean machine rotational speed. The amplitude of the DC component is much

greater than that of the higher order torsional vibration components, and must

be excluded.

7. Right click on the plot and select

Zoom. Then click and draw a

rectangle on the plot that excludes

the DC component. See “Zoom in

on the Time Waveform.”

8. Right click on the plot and choose

Properties. Select Viewed data

only in the Amplitude Axis tab of

the dialog box to scale the

amplitude axis to the zoomed part

of the plot. Note that the torsion

Waterfall plot shows the firing

order at 1.5 orders, and that in

general, the torsional component

driven by the firing orders is lower

at higher speeds. The first order is

the crankshaft imbalance, which increases with increasing speed. The

other peaks are harmonics of the firing order.

There is also a resonance as shown in the second plot.

Hint: To change between frequency and order cursors, right click the plot

35

Page 36

Medallion Rotate Manual October 2000

and choose Properties. Then select the parameter for the cursor under

Track axis on the Cursor tab.

You can also use spline-fit machine speed curve produced by Tachometer

analysis to display the torsional orders.

1. Display the Channel List window.

2. Select the torsional file (*.tor) and the smoothed spline-fit file (*.spl).

and click the Computed Order Tracking button. For this example,

displaying the 1.0 and 1.5 orders

shows the firing order and the

imbalance. The upper curve on the

lower plot shows the firing order,

and the lower curve shows the

imbalance. Note the amplitude of

the firing order curve decreases

with increasing speed.

3. Running the Computed Order Tracking again using more orders, and

setting the X axis to frequency shows all the peaks lining up at the

resonant frequency.

THEORY

Torsional vibration causes small

variations in the speed of a rotating

component. These variations can be

detected in the speed signal from the

component, provided that the signal

provides sufficient resolution. Medallion

Rotate processes the speed signal, and converts the variations in speed to the

frequency domain. This generates a time history of the speed as a DC signal. If

the original tachometer signal contains N pulses/rev, Medallion Rotate can

extract torsional orders up to N/2 orders.

36

Page 37

October 2000 Medallion Rotate Manual

ORDER NORMALIZATION

Medallion Rotate Plus can resample a time waveform to order normalize the

data when performing a Waterfall analysis. Order normalization cancels the

effect of frequency smearing across spectral bins when the shaft speed is

changing rapidly (high slew rate). Order normalization ensures that orderrelated peaks are properly aligned when plotted against the orders.

Order normalization also allows you to use a smaller blocksize when

performing the Waterfall analysis. This can significantly shorten processing

time while maintaining good frequency and amplitude resolution.

APPLICATIONS

Order normalization is ideal for identifying order-related frequencies in the

Waterfall plot. Order-related frequencies are located at the running speed of the

component and multiples of the running speed. The running speed is the first

order. This is particularly useful when attempting to separate order-related and

non-order-related peaks in the Waterfall plot. Since the X axis is displayed in

orders, it is easy to pick out the order-related peaks.

INPUT SIGNAL REQUIREMENTS

Order normalization requires a smoothed speed curve from performing a

Tachometer analysis or using the RPM from Waterfall function. Medallion

Rotate Plus processes the machine speed with the transducer data to create the

order normalized Waterfall analysis. When collecting the non-tachometer data

(vibration, temperature, …), note the following:

• If you want to see low frequency data in the Waterfall analysis, make

sure that the high pass filter setting in your analyzer is not excluding

the desired low frequencies.

• The sample rate in the analyzer must be at least 2.5 times the maximum

frequency of interest to avoid aliasing.

• The choice of window function for analysis depends on the type of

resolution you need (amplitude or frequency resolution). The Hanning

window is a good default choice. The Uniform window is only a good

choice when the orders are integer multiples of the shaft speed (1x, 2x,

3x, …).

Order normalization requires a clean tachometer signal for best results.

Processing the tachometer signal must produce a good spline-fit to provide a

smooth speed curve. Note that the resampling algorithm does not require that

the tachometer pulses correlate with the resampling angle.

37

Page 38

Medallion Rotate Manual October 2000

EXAMPLE

This example shows the difference in

the appearance of a Waterfall plot

resulting from order normalization. The

first Waterfall plot does not use order

normalization.

The second Waterfall plot uses order

normalization. Notice that the non-orderrelated peaks have been minimized, while order-related peaks have been

enhanced.

1. To use order normalization when

performing a Waterfall analysis,

first select the smoothed machine

speed and the data channels in the

Channels List window. Then click

the Waterfall analysis button.

2. In the Waterfall analysis dialog

box, select Order normalize. Note

that this is not available if you do not select the smoothed machine

speed in the Channels List window.

3. Select the other desired parameters and choose OK to create the order

normalized Waterfall plot.

THEORY

Medallion Rotate Plus order normalizes the data by resampling it. Time

waveform data is usually collected using a fixed number of samples/second.

This means that more samples/revolution are collected at lower speeds, and

fewer

samples/revolution at higher speeds. Resampling allows Medallion Rotate Plus

to gather a constant number of samples per revolution, regardless of the speed

of the machine.

38

Page 39

October 2000 Medallion Rotate Manual

MILLSTRUM ANALYSIS

Millstrum analysis in Medallion Rotate Plus simplifies the process of

identifying families of harmonics and sidebands. Harmonics are multiples of a

primary frequency, and appear as a series of equally spaced spectral peaks of

increasing frequency. Sidebands are pairs of equally spaced spectral peaks that

appear to both sides of a primary frequency. Sidebands are often caused by

modulation of the primary (“carrier”) frequency by a second frequency.

In some cases, it can be difficult to identify harmonics and sidebands in a

conventional Spectrum plot—particularly in spectra that have many peaks

obscuring the harmonics or sidebands.

Millstrum analysis simplifies the process of identifying harmonics and

sidebands by removing everything that is not harmonic, and presenting the

results in an easily-understood format. Millstrum analysis is similar to using the

cepstrum, but goes further in simplifying the results so that you do not have to

perform any additional calculations. The fundamental frequency and

modulating frequencies appear clearly as peaks in the Waterfall plot from

Millstrum analysis.

APPLICATIONS

Millstrum analysis is ideal for identifying harmonics and sidebands in the

following applications:

• Heavily modulated signals.

• Low amplitude harmonics and sidebands, such as in early-stage

gearbox and bearing faults.

• Signals that produce complicated spectra with peaks obscuring the

harmonics or sidebands.

INPUT SIGNAL REQUIREMENTS

You can use Millstrum analysis on a data channel without a smoothed

machine speed curve; however, you will not be able to use the machine speed

or order tracking capabilities of the Millstrum plot.

Medallion Rotate processes the transducer data to create the Millstrum

analysis. When collecting the non-tachometer data (vibration, temperature, …),

note the following:

• If you want to see low frequency data in the Millstrum analysis, make

sure that the high pass filter setting in your analyzer is not excluding

the desired low frequencies.

• The sample rate in the analyzer must be at least 2.5 times the maximum

frequency of interest to avoid aliasing.

• When there is a tachometer signal, you can use the order domain for

easier identification of the periodic frequencies.

39

Page 40

Medallion Rotate Manual October 2000

• More spectral lines are required for the Millstrum analysis, since the

analysis reduces the number of lines in the result by half. Collect a large

number of sample points, and use the largest possible blocksize for the

signal. This is explained in the section on “Theory” below.

• The choice of window function for analysis depends on the type of

resolution you need (amplitude or frequency resolution). If you are

using order normalization, the Hanning window is a good choice. The

Uniform window is only a good choice when the orders are integer

multiples of the shaft speed (1x, 2x, 3x, …).

EXAMPLE

This example is from an automotive

dynamometer. The first Waterfall plot does

not use Millstrum analysis. Notice the

large number of peaks, and the difficulty in

sorting out the harmonics.

The second Waterfall plot is the result

of the Millstrum analysis. Note that the

peaks show the forcing and the harmonic

frequencies. Remember that the X axis, while in Hz, is not the same as the X axis

in the first Waterfall plot. Instead, you can read the forcing and harmonic

frequencies directly from the X axis.

To use Millstrum analysis, follow

these steps:

1. In the Channel List window, select

the data channel (and a

corresponding smoothed machine

speed curve if desired). Then click

the Waterfall analysis button.

2. In the Waterfall analysis dialog

box, select Millstrum for the Window cor.

3. Select the other desired parameters and choose OK to create the

Millstrum plot.

THEORY

A simple analogy is that Millstrum analysis looks at the spectrum as if it

were a time waveform, and attempts to identify periodic repeating events in the

spectrum. In other words, it takes the FFT of the FFT spectrum. Since both

harmonics and sidebands are periodic repeating peaks in a spectrum, they show

up in the Millstrum as single peaks. The “frequencies” of the peaks in the

Millstrum are the frequencies of the repeating events.

40

Page 41

October 2000 Medallion Rotate Manual

More formally, Millstrum analysis is essentially the Fourier transform of the

logarithm of the absolute value of the frequency spectrum. It identifies

periodicity in the frequency domain. The normal formulation, called the real

cepstrum, has as its abscissa the period of the harmonics, but by inverting

period, the Millstrum displays the results in the frequency domain.

Millstrum analysis uses the logarithm of the frequency spectrum to raise

the low amplitude peaks relative to higher amplitude components of the signal.

This amplifies the presence of low amplitude harmonics, such as those created

by early-stage bearing faults.

For harmonics, the peaks in the spectrum are located at multiples of the

primary frequency. The spacing (or “frequency”) between peaks is the same as

the primary frequency. So harmonics in a spectrum appear as a single peak at

the primary frequency in the Millstrum.

For sidebands, the peaks in the spectrum are located at the primary

frequency plus or minus multiples of the modulating frequency. The spacing

(“frequency”) between the peaks is the same as that of the modulating

frequency. So sidebands appear as a single peak at the modulating frequency.

EXPORTING CALCULATED ORDERS DATA TO ME’SCOPE

Medallion Rotate can export calculated order tracking data to the

ME’scope™ program (Vibrant Technology) for operating deflection shape

analysis. This allows you to see a animation of the machine as it moves in the

coherent pattern of a given order at a given speed.

There are two ways to export calculated order tracking data to ME’scope.

• You can calculate the order tracking data in Medallion Rotate, then

export that data to ME’scope. This is limited to data from only one file.

• You can create measurement sets from one or more data files that share

a common tachometer and reference channel. This automates the

process of calculating the order tracking data, and combines the

channels from the data files into the appropriate files for ME’scope.

APPLICATIONS

By showing you how the machine is moving, ME’scope allows you to

diagnose a variety of problems. For example, it

shows you how a drive train deflects in

response to an engine cylinder firing order. It is

also useful for diagnosing high-cycle fatigue

problems on the spring side of the engine. The

following graphic shows a wire-frame model for

data taken from a tractor engine. The data was

taken on the sub-frame and exhaust system of

the tractor during the tests.

41

Page 42

Medallion Rotate Manual October 2000

ME’scope animates the wire-frame model so that you can view the physical

deflection of the components at specific orders. For more detailed information,

refer to the ME’scope tutorial on the Medallion Rotate Installation CD ROM.

INPUT SIGNAL REQUIREMENTS

The input requirements are the same as for Computed Order Tracking. If

you are going to combine two or more data files for the same machine, all data

files must have a common tachometer channel and reference channel.

EXAMPLE

The first example shows how to export a order tracks for a single order of

data to ME’scope. If you want to export multiple orders, you must export each

one separately. Alternatively, you can use the process outlined in the second

example to export multiple orders at the same time.

TO EXPORT A SINGLE ORDER

1. Perform the steps for Computed Order

Tracking to create the order tracks.

2. Select the desired order track channels from

the Channel List window. Note that all the

selected order tracks must be the same order

(first order, for example). The order tracks are

identified by the channel name (Order 1, Order

2, …).

3. On the File menu point to Export, then choose Orders to ME’scope.

4. In the Export Orders dialog box, select or enter the desired values. Press

F1 for a description of the options.

5. Choose Export when finished. Medallion Rotate exports the selected

order tracks to a format that ME’scope can use.

TO EXPORT MULTIPLE ORDERS OR DATA FILES

The second example describes exporting multiple orders of data from two

or more files. This is useful when you have collected data during two or more

runs on the same machine. The data from each run becomes a measurement set

in Medallion Rotate (one data file = one measurement set). You then export one

or more measurement sets to ME’scope in a single set of steps.

To begin the process of creating and exporting measurement sets, from the

Edit menu choose Measurement Sets. Then choose Create to create the first

measurement set. After completing the information in a dialog box, choose Next

to go to the next step. You can also press F1 for a description of the current

dialog box options.

Medallion Rotate includes demonstration data for export to ME’scope. You

can find a complete tutorial on the process of exporting measurement sets on

the Medallion Rotate installation CD.

42

Page 43

October 2000 Medallion Rotate Manual

CHAPTER FOUR

MEDALLION ROTATE PLOTTING FEATURES

This chapter describes the plots in Medallion Rotate. It covers the general

features of plots that allow you to change the views of the data, as well as how

to save a particular plot setting as the default for that type of plot. It then

describes the individual plots that appear in Medallion Rotate. This chapter

does not describe the applications for each plot. Refer to Chapter 3 ÒMedallion

Rotate ApplicationsÓ for the analyses that produce each type of plot.

43

Page 44

Medallion Rotate Manual October 2000

GENERAL PLOT FEATURES

The plotting features described in this section are common to all of the

plots, unless otherwise noted.

RIGHT-CLICK MENU

To access the plot controls, right-click on the plot to display a menu of

commands.

• Auto-Scale - Set the plot axes to optimally display all the data on the

plot. This is useful after you have used Zoom to examine a part of the

plot in more detail.

• Zoom - Magnify a region defined by clicking and dragging a rectangular

region on the plot. The program enlarges the region to fill the plot

window.

• Orientation - Change the orientation of the plot axes by moving the

mouse pointer then clicking to display the new plot orientation

(Waterfall plot only).