Page 1

LogBook/300 & 360

p/n 461-0901 rev 7.0

*372180C-01*

372180C-01

Measurement Computing

10 Commerce Way

Norton, MA 02766

(508) 946-5100

Fax: (508) 946-9500

info@mccdaq.com

www.mccdaq.com

LogBook/300 & /360

Stand-alone, Intelligent PC-Based

Data Acquisition Systems

USER’S MANUAL

Page 2

This page is intentionally blank.

Page 3

Warranty Information

Contact Measurement Computing by phone, fax, or e-mail in regard to warranty-related issues:

Phone: (508) 946-5100, fax: (508) 946-9500, e-mail: info@mccdaq.com

Many Measurement Computing products carry the CE marker indicating they comply with the safety and emissions

standards of the European Community. When applicable these products have a Declaration of Conformity stating which

specifications and operating conditions apply. You can view the Declarations of Conformity at

www.mccdaq.com/legal.aspx (CE Information page).

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective bags

and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of great

benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Limitation of Liability

Measurement Computing cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All Measurement Computing documentation, software, and hardware are copyright with all rights reserved. No part of

this product may be copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method

without Measurement Computing’s prior written consent. IOtech product names are trademarked; other product names, as

applicable, are trademarks of their respective holders. All supplied IOtech software (including miscellaneous support

files, drivers, and sample programs) may only be used on one installation. You may make archival backup copies.

CE Notice

Warnings, Cautions, Notes, and Tips

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, the hardware is calibrated to published specifications. Periodic hardware calibration is not

covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Page 4

CAUTION

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Before setting up and using your

equipment, you should read all documentation that covers your system.

Pay special attention to Warnings and Cautions.

Note:

During software installation, Adobe

®

PDF versions of user manuals will automatically

install onto your hard drive as a part of product support. The default location is in the

Programs group, which can be accessed from the Windows Desktop. Initial

navigation is as follows:

Start [Desktop “Start” pull-down menu]

⇒ Programs

⇒ IOtech LogBook Software

You can also access the PDF documents directly from the data acquisition CD by using

the <View PDFs> button located on the opening screen.

Refer to the PDF documentation for details regarding both hardware and software.

®

A copy of the Adobe Acrobat Reader

is included on your CD. The Reader provides

a means of reading and printing the PDF documents. Note that hardcopy versions of

the manuals can be ordered from the factory.

Your order was carefully inspected prior to shipment. When you receive your system, carefully

unpack all items from the shipping carton and check for physical signs of damage that may have

occurred during shipment. Promptly report any damage to the shipping agent and your sales

representative. Retain all shipping materials in case the unit needs returned to the factory.

iv

929196 LogBook User’s Manual

Page 5

Manual Layout

Chapter 1 – An Introduction to LogBook discusses LogBook basics and highlights operational features.

The last part of the chapter contains product specifications.

QS300 – LogBook/300 Quick Start Guide

QS360 – LogBook/360 Quick Start Guide

(Includes Installation Procedure)

(Includes Installation Procedure)

Chapter 4 – System Expansion discusses the expansion of LogBook systems in regard to LBK and

DBK options. Power considerations and pinouts for P1, P2, and P3 DB37 connectors are also

included.

DBK Basics – discusses option cards and modules (DBKs) that can be used to enhance and expand data

acquisition systems. Note that DBK Basics is not a chapter, but an independent document that is

applicable to this user’s manual, as well as others.

Chapter 5 – LBK and other non-DBK Options discusses the RS-422/485 Communications Card,

memory expansion, remote LogBook Terminal, four-channel Digital-to-Analog Output card, and

three options regarding a remote on/off switch and LED indicator.

Chapter 6 – GPS and Serial Device Data Collection discusses the LogBook/360 support for the Global

Positioning System (GPS).

Chapter 7 – Using Modems and the Upload Scheduler provides instruction for communicating with

remote LogBooks via modem. The chapter also discusses the independent Upload Scheduler

application which can be used to configure events to initiate data uploads for one or more LogBooks.

Chapter 8 - CE Compliance pertains to CE standards and conditions relevant to LogBook systems.

LogView

- is a reference document for the “out-of-the-box” data acquisition software.

Appendix A – A Supplement to the HopNet 10 Series Wireless Modems User’s Manual. This appendix

only applies to users of Cirronet’s HopNet 10 Series Wireless Modems. In regard to using other

modems with LogBook refer to chapter 7.

Error Codes – two lists of error codes, one for LogView software and another for LogBook hardware.

Dimensional Drawings – Contains basic dimensional drawings that apply to several data acquisition

products, including LogBook/300, LogBook/360, and DBK options.

Glossary

Reference Notes:

During software installation, Adobe

installed onto your hard drive as a part of product support. The default location is in the

Programs directory, which can be accessed from the Windows Desktop.

®

PDF versions of user manuals are automatically

For detailed information regarding specific DBKs, refer to the DBK Option Cards and

Modules User’s Manual PDF. Each DBK section includes device-specific hardware and

software information. The document includes a chapter on power management.

Check the README.TXT file for information that may not have been available at the

time this manual went to press.

LogBook User’s Manual 989492 v

Page 6

This page is intentionally blank.

vi 989492 LogBook User’s Manual

Page 7

Table of Contents

Chapter 1 – An Introduction to LogBook

LogBook Basics……1-1

What are LogBooks? ….. 1-1

Front and Rear Panels……1-2

Highlight of Features …… 1-3

LogBook/300 Block Diagram …… 1-4

LogBook/360 Block Diagram …… 1-5

The Use of PC-Cards with LogBook…..1-6

System Software……1-7

Operational Features……1-9

Data Acquisition, An Overview……1-9

LogBook System File [Must be on the PC-Card!] ……1-10

Communications……1-10

Triggering and Scan Timing……1-11

Scan Rate Limitations……1-11

Use of Outputs to Alarm and Control……1-13

Acquisition……1-13

Data Storage and Retrieval……1-13

Specifications …. 1-15

QS300 – LogBook/300 Quick Start Guide (Includes Installation Procedure)

QS360 – LogBook/360 Quick Start Guide (Includes Installation Procedure)

Chapter 4 – System Expansion

Expansion and Enhancement Options…..4-1

What are LBK Options?……4-1

What are DBK Options?……4-2

Power Options …… 4-3

Other Options …… 4-3

Considerations …… 4-4

DBK Configuration ….. 4-4

Dimensional and Environmental Factors……4-4

Mechanical Setup Options……4-5

P1, P2, P3 Port Connectors……4-6

LogBook User’s Manual 989492 vii

Page 8

DBK Basics

Chapter 5 – LBK and other non-DBK Options

LBK Options, Location Reference …… 5-1

LBK/COM/422/485 …… 5-2

LBK/MEM1-U, Expanded Memory (16 MB Upgrade) ……5-3

LBK1, Remote LogBook Terminal …… 5-4

LBK2, Four Channel, Digital-to-Analog Output …… 5-9

Remote On/Off Switch and LED Indicator Options …… 5-11

Chapter 6 – GPS and Serial Device Data Collection

Chapter 7 – Using Modems and the Upload Scheduler

Chapter 8 - CE-Compliance

Overview …… 8-1

CE Standards and Directives …… 8-1

Safety Conditions …… 8-2

Emissions/Immunity Conditions …… 8-3

CE Enhancements …… 8-3

Edge Guards for DBK5, DBK8, & DBK44 …… 8-3

DBK41/CE …… 8-4

BNC Connectors for CE Compliance …… 8-4

LogView

Understanding LogView…… LV-1

Modes of LogView Operation…… LV-2

LogView Features and Capabilities… LV-5

Software User-Interface…… LV-5

File Management...... LV-8

Procedures…… LV-12

Flowchart of a Simple Acquisition..…. LV-13

Using an Attached LogBook…… LV-13

Using LogBook “Unattached”…… LV-15

Simple Data Logging…… LV-15

Setting Up DBK Cards…… LV-17

Using Multiple Timebases…… LV-18

Using Digital 2-Point Calibration…… LV-21

Using Digital Outputs As Alarms…… LV-22

Using Exception Capturing…… LV-24

Menu Descriptions…… LV-25

File Menu…… LV-25

View Menu…… LV-30

Hardware Configuration…… LV-30

Analog Input Channel Configuration…… LV-31

Digital and Counter Input Channel Configuration…… LV-35

Output Channels Configuration…… LV-36

Serial / GPS Channels (LogBook/360 Only)…… LV-37

Calculated-Channel Configuration…… LV-37

Acquisition Configuration…… LV-43

Preferences…… LV-46

Note: Use of the following

Authorization Code will enable

complete LogView functionality:

ED7B55484273

viii 989492 LogBook User’s Manual

Page 9

Device Menu…… LV-48

Select PC-Card...... LV-48

Select LogBook…… LV-48

Attach…… LV-48

Break…… LV-48

Arm Acquisition…… LV-48

Stop Acquisition…… LV-48

LogBook Monitor …… LV-49

Explorer…… LV-50

Tools Menu…… LV-51

Convert Binary Data…… LV-51

Merging Binary Data…… LV-53

View Data …… LV-54

Indicators Menu…… LV-55

Bar Graph Meters…… LV-55

Analog Meters…… LV-55

Digital Meters…… LV-56

Meters Configuration…… LV-56

Enable Input Reading Column…… LV-58

Start (or Stop) All Indicators…… LV-58

Appendix A – Supplement to the HopNet 10 Series

Wireless Modems User’s Manual

Error Codes

Dimensional Drawings

Glossary

LogBook User’s Manual 989492 ix

Page 10

This page is intentionally blank.

x 989492 LogBook User’s Manual

Page 11

An Introduction to LogBook 1

LogBook Basics……1-1

What are LogBooks? ….. 1-1

Front and Rear Panels……1-2

Highlight of Features …… 1-3

LogBook/300 Block Diagram …… 1-4

LogBook/360 Block Diagram …… 1-5

The Use of PC-Cards with LogBook …. 1-6

System Software……1-8

Operational Features……1-8

Data Acquisition Overview……1-8

LogBook System File [Must be on the PC-Card!] ……1-9

Communications……1-10

Triggering and Scan Timing……1-11

Scan Rate Limitations……1-11

Use of Outputs to Alarm and Control……1-13

Acquisition……1-13

Data Storage and Retrieval……1-13

Specifications …… 1-15

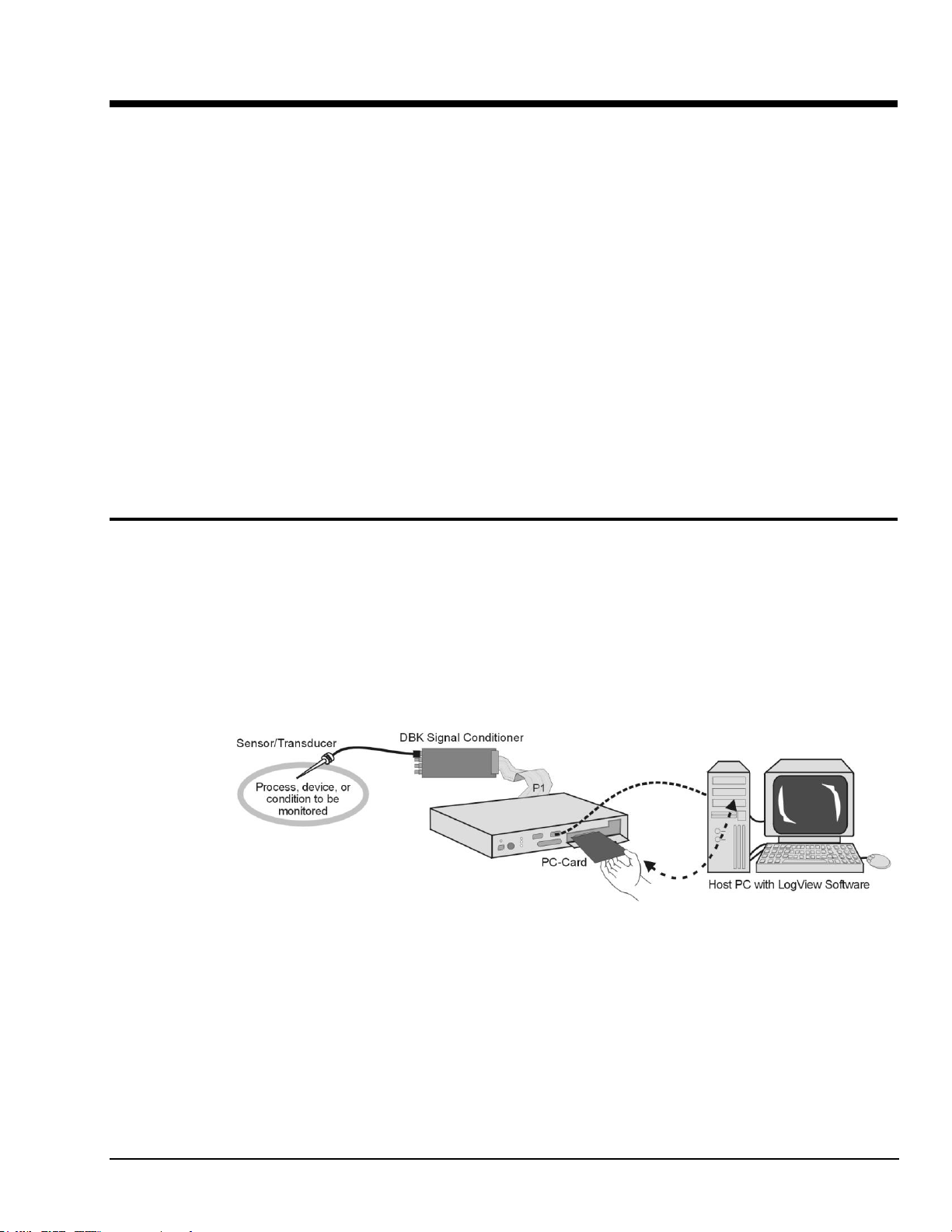

LogBook/300, Simple System Setup

LogBook Basics

What are LogBooks?

LogBook/300 and LogBook/360 are PC-based data acquisition systems that can work in a stand-alone

mode (no PC present), or linked to a PC. They combine onboard intelligence with a removable PC-Card

that stores the configuration file and the collected data. LogBooks have many options, most of which are

detailed in the LBK chapter, and in the DBK Option Cards and Modules document. Note that the PC link

can be by serial or parallel port.

LogBook User’s Manual 969591 An Introduction to LogBook 1-1

The PC-Card holds the configuration file [created by LogView]. The file tells LogBook how to perform a

particular acquisition. The PC-Card also holds the acquired data files. The PC can upload to or download

from the PC-Card by cable if the PC is attached to LogBook, or by physical transport of the PC-Card from

one unit to the other. Multiple configuration files and multiple PC-Cards allow the system to handle

complex data acquisition environments with a large number of data-files.

Page 12

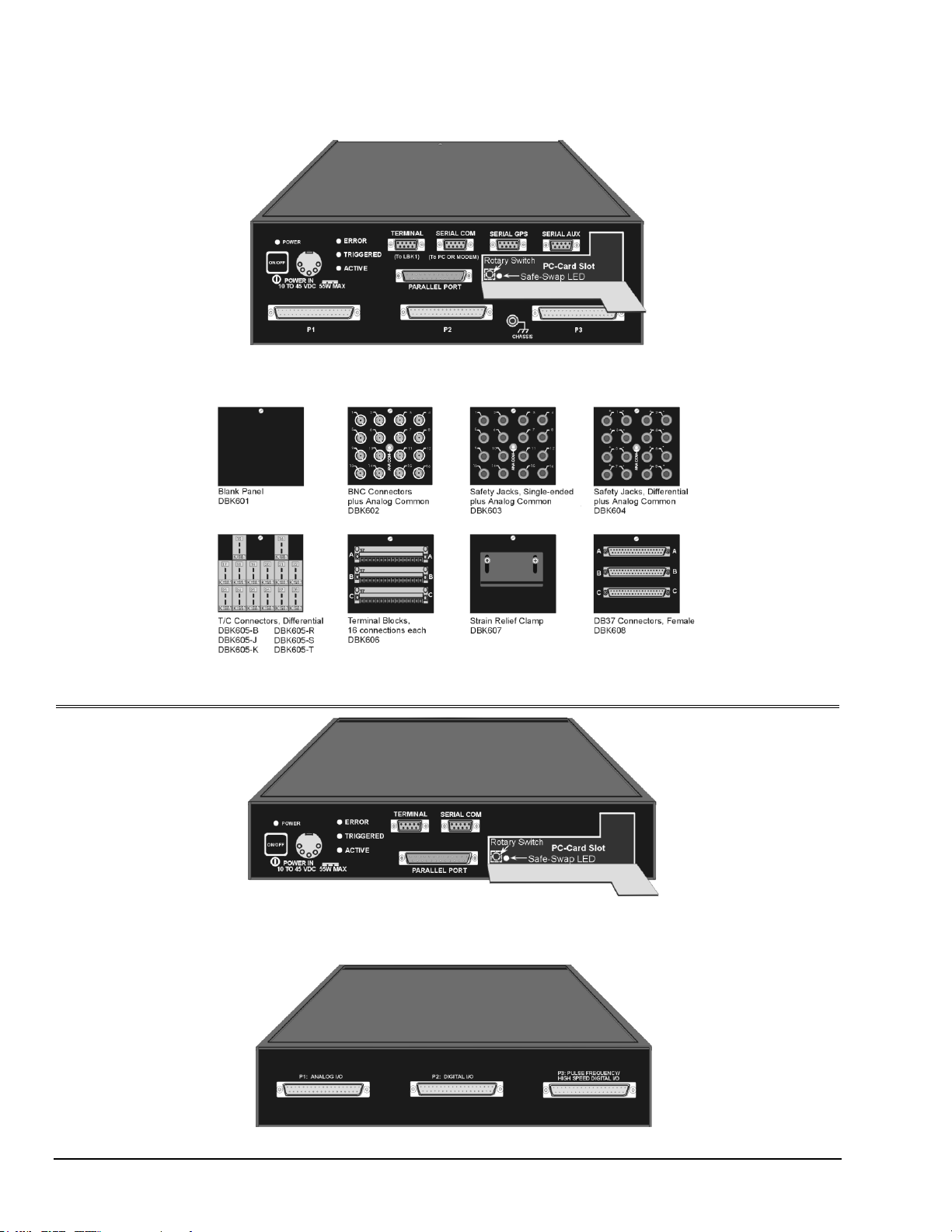

Front and Rear Panels

LogBook/360, Front Panel

LogBook/360, Terminal Panels (A combination of 3 make up the rear panel)

LogBook/300, Front Panel

Note: In earlier models, the PC-Card Door has a right-edge hinge (not shown).

LogBook/300, Rear Panel

Note: Descriptions of panel items appear on the following page.

1-2 An Introduction to LogBook 969591 LogBook User’s Manual

Page 13

LogBook/360 panel items are listed in the following table. Note that LogBook/300 panel items are the same as those on

the 360, except as called out in the following bulleted list:

Slight differences in the overlay.

P1, P2, and P3 appear on LogBook/300’s rear panel.

LogBook/300 has no SERIAL GPS connection.

LogBook/300 has no SERIAL AUX connection.

LogBook/300 has no CHASSIS grounding post.

LogBook/300 does not make use of Terminal Panels.

Switches

ON/OFF

Depressing the push-button switch turns the power on.

(interior rotary switch)

PC-Card door provides access to a rotary switch to set device address when used in an RS-485 network.

Connectors

POWER IN

This locking DIN5 input connector accepts +10 to +45 VDC.

PARALLEL PORT

This DB-25 plug is a parallel port connector to a host PC (set to ECP mode)

TERMINAL PORT (TO LBK1)

This DB-9 socket is a serial port connector for the LBK1 remote control panel (user-interface terminal).

SERIAL COMM

(TO PC OR MODEM)

This DB-9 male serial COM port connects to a host PC or modem.

SERIAL GPS

(LogBook/360 Only)

LogBook/360 only. This DB-9 male serial port option connects to a Global Positioning System.

SERIAL AUX

(LogBook/360 Only)

LogBook/360 only. This DB-9 male serial port option connects to optional auxiliary devices.

P1 - ANALOG I/O

Provides 16 analog input channels, 3 TTL inputs, and various signals for driving expansion cards.

P2 - DIGITAL I/O

Provides 3 8-bit TTL programmable I/O ports and external interrupt input.

P3 - PULSE FREQUENCY /

HIGH-SPEED DIGITAL I/O

Provides 4 16-bit counters, 4 analog outputs, and 16 high-speed digital I/O.

(PC-Card door, no label)

Door provides access to PCMCIA connector—for removable PC-Card memory devices.

Indicator LEDs

POWER

LED lights when power is applied to LogBook and the power switch is depressed into the ON position.

ERROR

LED lights steady ON when a routine error occurs (e.g. disk full).

LED flashes for fatal errors; refer to Hardware Errors near the end of the manual.

No data can be acquired until the error is cleared.

TRIGGERED

LED lights after trigger event and during an A/D scan sequence.

ACTIVE

LED lights to show that LogBook is ready to begin a scan at the next trigger event.

Safe-Swap Light

(interior green LED)

LED lights when it is safe to swap PC-Cards.

Highlight of Features

LogBooks can be left unattended for long testing periods and used in environments not suitable for PCs.

With the use of PC-Cards, one PC can support several LogBooks. Other LogBook features include:

Onboard processor capable of real-time data reduction and system control in stand-alone mode

Non-volatile storage of configuration files and samples via removable, transportable PC-Cards

4 MB RAM onboard, expandable to 16 MB

100 kHz 16-bit Analog-to-Digital Conversion

8 differential, 16 single-ended inputs; expandable to 256 input channels via DBK cards

7 gain/input ranges, unipolar and bipolar

40 digital I/O lines, expandable to 208

4 pulse-counting inputs

Gain and unipolar/bipolar settings are programmed in real time (10 µs max)

Scan-sequence memory (1024 analog channels plus 128 digital channels)

for any combination of channels/gains

Input power: 10 to 45 VDC (AC adapter included)

LBK options

DBK options

LogBook User’s Manual 969591 An Introduction to LogBook 1-3

Page 14

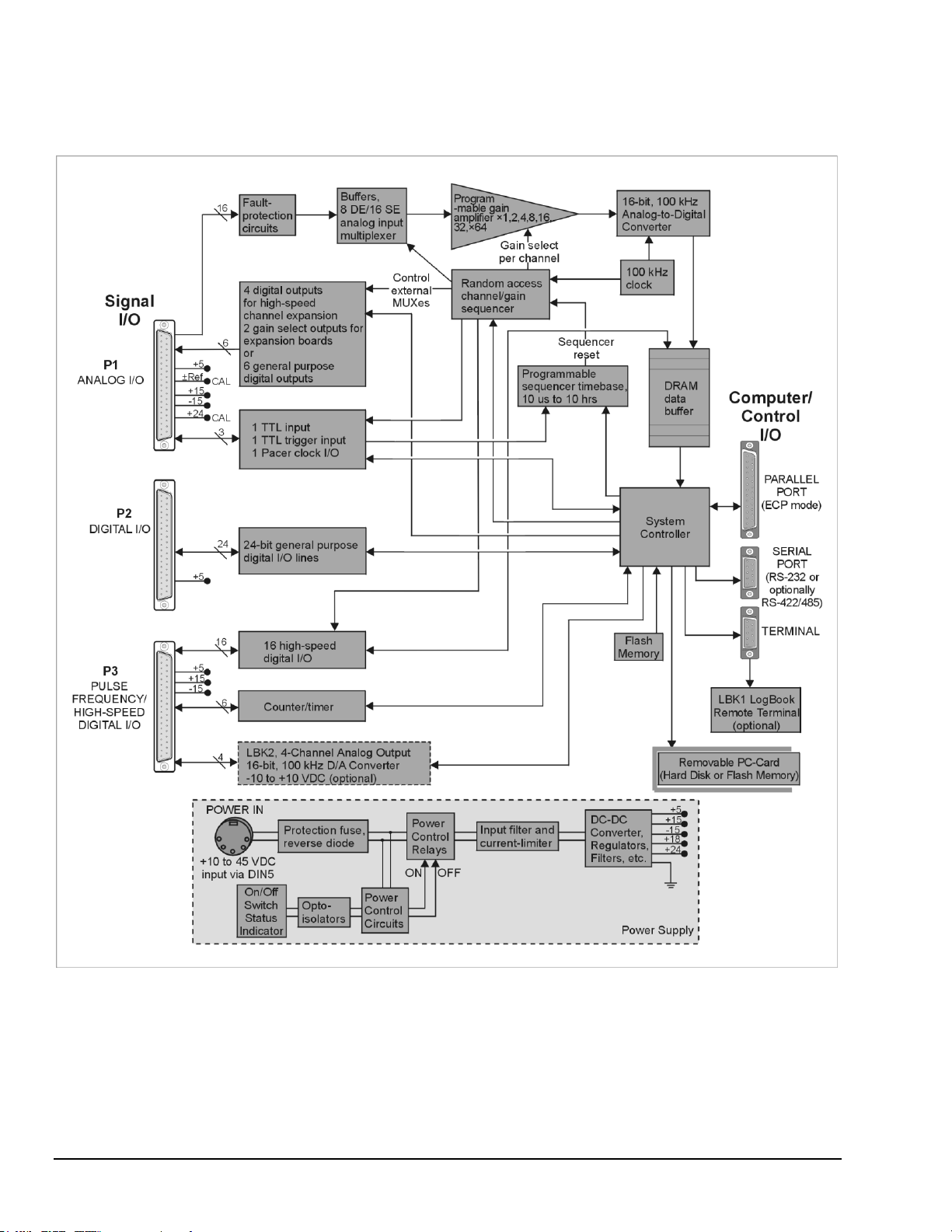

LogBook/300 Block Diagram

1-4 An Introduction to LogBook 969591 LogBook User’s Manual

Page 15

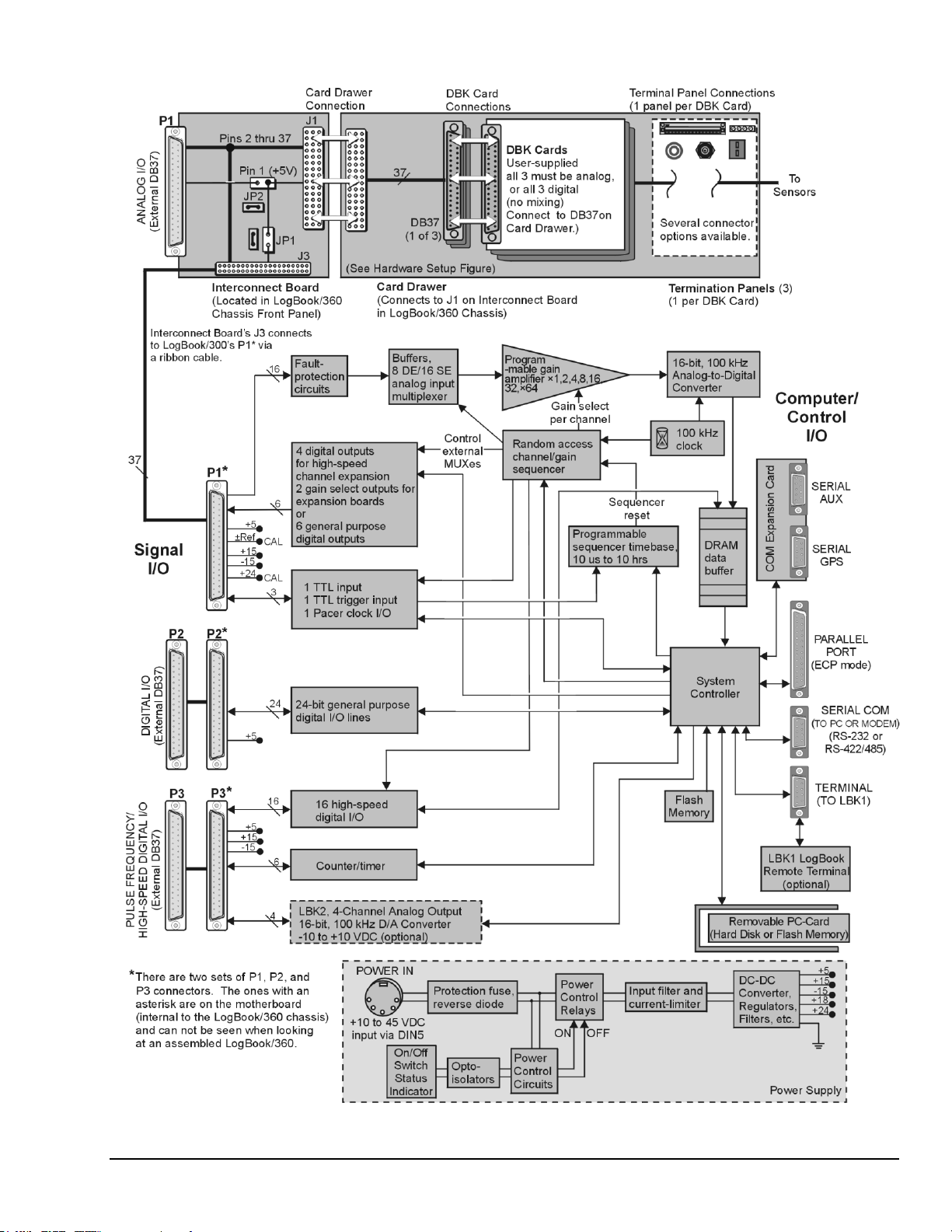

LogBook/360 Block Diagram

LogBook User’s Manual 969591 An Introduction to LogBook 1-5

Page 16

The following components are represented in the previous block diagrams. Certain items apply only to

LogBook/360, as noted.

Removable PC-Card. A 12-520 MB capacity holds the software, operating system, user

configurations and the acquired data. The PC-Card is at the center of LogBook operations.

A PC-Card [pre-programmed by LogView] ensures an unattached LogBook comes up properly.

Power Supply. The internal power supply accepts an input of 10 to 45 VDC and supplies filtered

regulated voltages to its internal circuits and to accessories connected via P1/2/3. An external

AC to-DC adapter for all standard voltages is included with the system.

System Controller. A microprocessor chip is used within LogBook with either 4 MB (standard) of

RAM or 16 MB (optional). A field-upgradeable 512 KB Flash memory is used to store the system

startup code, self-diagnostics, and Field Programmable Gate Array (FPGA) configuration. The

FPGA controls every LogBook operation, including real-time control. By using Internal flash

memory instead of EPROMs, field upgrades of virtually all functions [including FPGA circuitry] are

possible. Most software will be read from the disk drive.

Analog Input via P1. 16 main channels that can each accommodate 16 sub-channels via

multiplexing for a total of 256 analog input channels. Fault protection and buffer circuits prevent

overloads and cross-channel noise due to impedance mismatch.

A/D Converter. The A/D converter uses 16-bit resolution @ 100 kHz sample rate.

Digital I/O. 16 high-speed digital inputs via P3, three 8-bit TTL programmable I/O ports via P2,

three TTL inputs via P1. Note that LogBook/360 has P1, P2, and P3 connectors on the motherboard

that are connected [by ribbon cable] to secondary P1, P2, and P3 connectors [located on the chassis

front panel]. LogBook/300’s P1, P2, and P3 are located on the rear panel.

LBK2 Analog Output (optional): This option provides four channels of analog output,

16-bit @ 100 kHz @ ±10 VDC.

LogBook/360 only, Interconnect Board, Card Drawer (for three DBK cards), and

three Terminal Panels.

Computer/Control/I/O – Includes: PARALLEL PORT (ECP Mode), SERIAL PORT (for RS-232

or RS-422/485), TERMINAL PORT (for LBK1 LogBook Remote Terminal option). In addition, for

LogBook/360 only, there is a COM Expansion Card with two serial ports (SERIAL AUX and

SERIAL GPS). These two ports are for connecting auxiliary serial devices, such as a Global

Positioning System.

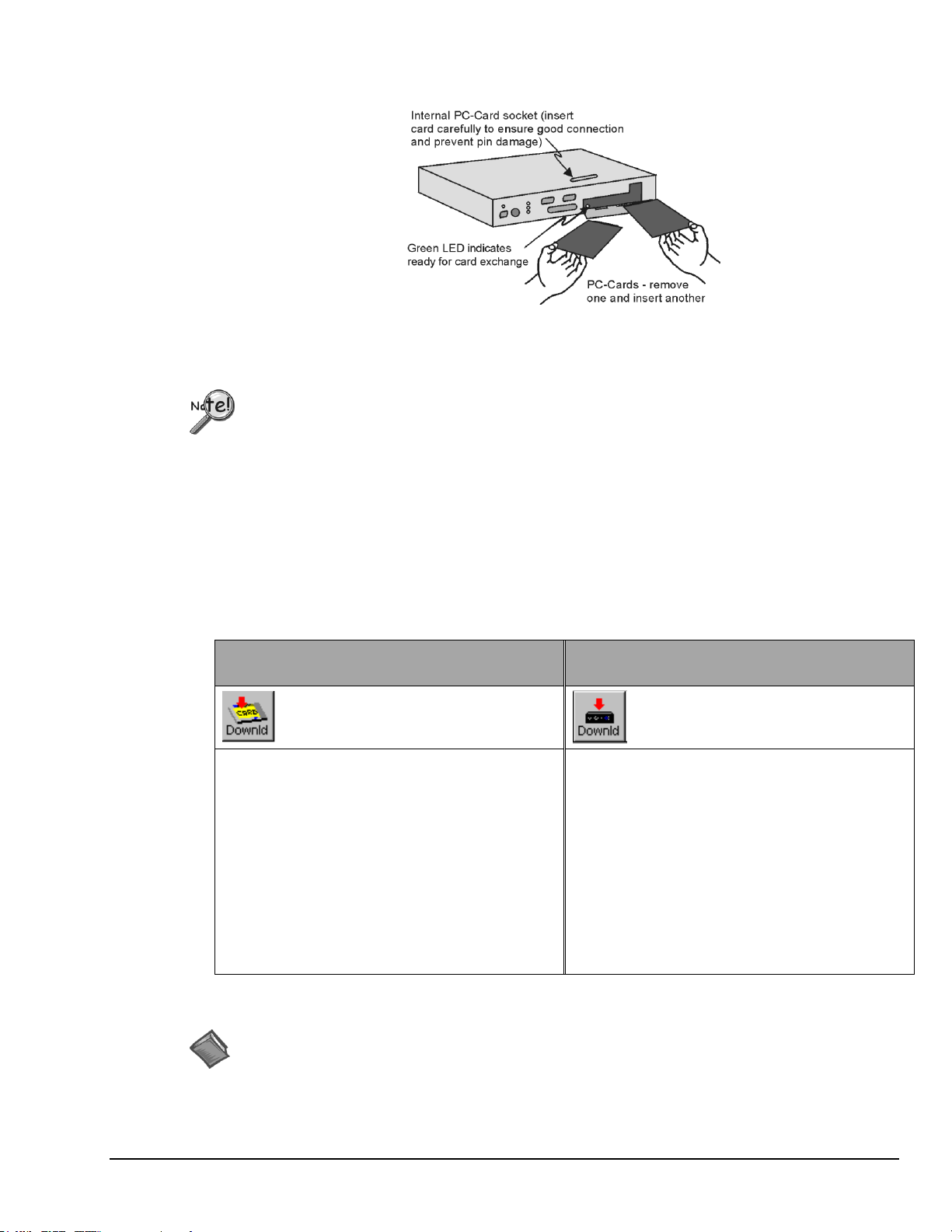

The Use of PC-Cards with LogBook

After the initial setup, you can interact with LogBook via PC-Cards. A safe-swap LED (inside the PC-Card

access door) lights when it is safe to change PC-Cards. You can also interact with LogBook using the

LBK1 Remote Terminal Panel option (discussed in the LBK chapter). The LBK1 option provides limited

LogBook control without use of the LogView program. As can be seen from the following PC-Card

Compatibility information, some PC-Cards should be avoided in regard to use with LogBook.

Note: during operation, LogView is the primary system interface for control and configuration.

PC-Card Compatibility with LogBook Operation

To work properly, the LogBook requires compatible PC-Card memory. You can purchase 100%

compatible cards through your LogBook sales representative. If you prefer to buy your card from another

source, make sure it is an ATA-style memory card. Also, make sure the card's memory capacity is sufficient

for your purpose.

You can change PC-Cards to load setup files, replace full cards, or transport data to an unattached PC.

When the PC-Card door is opened, a detector starts a preparatory routine to clean up files on the installed

disk. Within a few seconds, a green LED indicates it is safe to swap PC-Cards. Swapping should be done

quickly to prevent gaps in the recorded data. 4 MB RAM provides about

10 seconds at 100 kHz and 1.75 minutes at 10 kHz. 16 MB RAM provides over a minute at 100 kHz and

about 12 minutes at 10 kHz for one-channel scans.

1-6 An Introduction to LogBook 969591 LogBook User’s Manual

Page 17

Swapping PC-Cards in a LogBook/300

Note: Some models have PC-Card doors with right-edge hinges (not shown).

Swapping time is measured from when the door opens. Keep door closed unless you are

in the process of swapping cards.

PC-Cards must be pre-configured by LogView—if anticipating the need for multiple cards,

download the exact SAME ACQUISITION SETUP FILE to each PC-Card.

The PCMCIA slot accepts a Type I, II, or III hard-disk card or ATA flash-memory

solid-state card.

Download Method I:

PC-Card in Computer’s PC-Card Slot

Download Method II:

PC-Card in LogBook’s PC-Card Slot

LogView’s <Download> button as it appears

when a PC-Card in the PC can accept a

download.

LogView’s <Download> button as it appears

when a PC-Card in the LogBook can accept a

download.

1. Insert a formatted PC-Card into the computer’s

PC-card slot.

2. Run LogView.

3. From LogView’s Device pull-down menu choose

―Select PC Card.‖

4. Select the applicable PC-Card drive from the

resulting pull-down list.

5. Click LogView’s <DownLoad> button.

For this method the LogBook must be connected to

the PC’s serial* or parallel port.

1. Insert a formatted PC-Card into LogBook’s

PC-Card slot.

2. Run LogView.

3. From LogView’s Device pull-down menu.

choose ―Select LogBook.‖

4. Click on the desired LogBook.

5. Click the <Attach> button.

6. Click LogView’s <DownLoad> button.

Reference Notes:

Additional information regarding PC-Cards can be found in the chapter sections entitled,

Data Acquisition Overview (page 1-8) and LogBook System File (page 1-9).

For information regarding LogView, refer to the independent LogView section of this manual.

How to Download a Configuration to a PC-Card

The download of a configuration to a PC-Card can be done in either of two ways, both of which make use

of LogView’s <Download> button. One method is to download the file to the PC-Card while it is installed

in a card slot on the PC. The second method is to download the file while the PC-Card is in a LogBook. In

that scenario the LogBook must be connected to the serial or parallel port of a PC. A brief description of

both methods follows. In both cases the filename will be the same as the LogView setup name.

*Note: For method II only, if downloading a modem configuration, LogBook’s communication cable must

connect to a parallel port on the PC. Otherwise parallel or serial communications will do.

LogBook User’s Manual 969591 An Introduction to LogBook 1-7

Page 18

System Software

Although LogBook can read volts directly, many sensor types still require signal

conditioning before they can be correctly interpreted.

LogBook software includes LogView, Upload Scheduler (optional) and a post acquisition data analysis

application such as eZ-PostView. A synopsis of each application follows.

LogView is a ready-to-use Windows-based program for data acquisition and logging. The program

Upload Scheduler is an application that exists as part of the LogBook/Modem option. Upload

Post Acquisition Data Analysis programs provide a means of viewing and analyzing data via

provides a means of selecting channels, gains, transducer types, and various parameters. After setting

up the configuration on the PC, you must download the configuration file to LogBook’s PC-Card.

LogBook then uses the PC-Card to start the pre-configured acquisition. During an acquisition,

LogView can display channel values on its Graphical User Interface in the form of a spreadsheet,

bargraph, analog meter, or digital indicator. LogBook data can be uploaded to your PC in various

data formats (Excel™, SnapMaster™, MATLAB™, DASYLab™, Lotus®, Quattro, and ASCII) for

compatibility with virtually all post-acquisition analysis software.

Scheduler allows you to configure upload events for one or more LogBooks. A scheduled event can

be configured to execute one time, or periodically, with no post-configuration intervention by the

user. The Upload Scheduler is detailed in chapter 7, Using Modems and the Upload Scheduler.

interactive graphics. Refer to the document module for detailed information. The post data analysis

programs are discussed in an independent document. PDF versions of the documents are loaded on

to your computer’s hard drive during software installation. The default location for the files is the

Programs group, which is accessible from the Windows Desktop.

Operational Features

Data Acquisition Overview

Note: Acquired data is signal-conditioned before it is logged (recorded by LogBook). The data can be

post-processed via analytical programs.

A Sensor/Transducer reacts to a physical quantity (such as stress, strain, frequency, temperature,

acceleration, light intensity, etc) and encodes that quantity into an analogous electrical signal. A wide

variety of transducers produce signals that vary in type and strength—some generate a voltage; others alter

an electrical property. As the measured condition changes, the analog sensor signal can vary directly or

inversely and in a linear or non-linear way.

The Signal Conditioner changes the raw transducer signal into a voltage for use by

LogBook’s Analog-to-Digital Converter (ADC). Depending on signal quality, several steps may be

involved (e.g., linearization, isolation of high voltages, amplification of weak signals, attenuation of strong

signals, filtering of noise and irrelevant frequencies, differential voltage measurement, simultaneous sampleand-hold, and pulse/current-to-voltage conversions). DBK option modules are designed for conditioning a

particular type of transducer signal. The signal conditioner’s output voltage range is ―normalized‖ to a

user-selected range for the measured values.

Note: Multi-channel DBKs can multiplex several input signals into one of LogBook’s 16 main inputs.

Multiplexing up to 16 analog channels for each LogBook main channel allows system expansion

up to 256 analog input channels.

1-8 An Introduction to LogBook 969591 LogBook User’s Manual

Page 19

LogBook’s onboard microprocessor and PC-Card allow it to operate independent of a host PC.

The file logbook.sys is LogBook’s operating system. Without it, LogBook will not work.

In fact, if the logbook.sys file is not on LogBook’s internal PC-Card, the LogBook will not

power-on.

Failure to upgrade to the current release version of logbook.sys can result in software

glitches. This problem can be resolved by reformatting the PC-Card using Windows

Explorer’s File/Format feature, and then reinitializing the PC-Card.

Functionally, LogBook can perform:

Analog-to-Digital Conversion. The ADC changes a conditioned analog signal to a corresponding

digital value. LogBook’s 16-bit ADC uses 65,536 numbers (216) to quantify values within the

specified range and gain. Each input channel’s buffer amplifier ensures constant input impedance.

The buffers also eliminate any noise effects from multiplexing of the input signals.

Acquisition Control. The microprocessor controls the data acquisition by managing trigger

conditions, gains, offsets, scan sequencing, and data formatting. LogBook can continuously collect

information, or be used for exception-capturing (with triggers). Pre-trigger and post-triggers allow

for capture of specific data, thus making more efficient use of memory.

Analog and Digital I/O. With the standard digital I/O, standard analog input, and the optional

analog output board, LogBook can perform virtually any data acquisition task as well as more

complex tasks for alarm and control systems.

Data Logging. Data can be saved in one of several formats and later downloaded to a PC.

Communication with PC. LogBook provides for serial and parallel port communication. In the

stand-alone mode, the PC-Card must be manually transported between the PC and LogBook.

The PC-Card is a memory device (rotating or flash, PCMCIA types I, II, or III)) that holds the system

software and the acquired data in multiple formats. System software includes the configuration file that

directs a specific acquisition and LogBook’s operating system. The PC-Card as programmed in LogView

allows LogBook to operate without PC intervention if so desired. LogView can configure a PC-Card in

LogBook if the PC and LogBook are electronically connected via serial or parallel port. In a stand-alone

mode, the PC-Card must be physically transported between a PC with LogView and one or more LogBooks

for uploading and downloading. Using a 500-Mbyte PC-Card, for example, you can store up to 250 million

samples in non-volatile memory; that equates to more than forty minutes of recording time on one channel

at the full 100 kHz acquisition rate. For continuous data collection, PC-Cards can be swapped while the

acquisition is taking place. As one card becomes nearly full, it can be removed and another card inserted

without causing a gap in the acquired data.

The user’s PC (typically a laptop or desktop) runs the supplied LogView software. LogView’s userinterface includes a virtual instrument panel with meters and controls to fit various applications. Through

LogView you can configure the system, apply further data processing, or manage multiple LogBooks.

LogView stores data in a conventional format so that other software can use the acquired data for analysis,

control, alarms, reporting, etc.

Note: The PC can be attached to LogBook via a serial or parallel connection; alternatively in the stand-

alone mode, the PC can be unattached and communicate with LogBook via a PC-Card that is

manually transferred between the PC and LogBook.

LogBook System File [ Must be on the PC-Card! ]

After software is installed [as discussed in the Quick Start sections] the 500-KB logbook.sys file will

reside in the LogView folder (on the hard drive of the host PC). To be used by a LogBook, logbook.sys

must have already been downloaded to the PC-Card, which resides inside LogBook.

Downloading. When LogView downloads the *.lvc acquisition setup file to a PC-Card, it checks to see if

the current release version of logbook.sys is already on the PC-Card. If so, fine; if not, logbook.sys

must also be downloaded to the PC-Card. Thus, downloading to a PC-Card that is being used for the first

time will take longer than subsequent downloads.

LogBook User’s Manual 969591 An Introduction to LogBook 1-9

Page 20

Due to the file size and relative transfer time, insert first-time PC-Cards into the PC’s card

socket rather than LogBook’s. Downloading via the PC’s socket takes only a few seconds;

however, using LogBook’s socket and a communications channel will take much longer

(about 7 minutes at 9600 bps).

Because LogBook needs the logbook.sys file to become operational after loosing power

(due to an outage or being turned off), keep the logbook.sys file on all PC-Cards that will

be used for data storage.

Regarding the logbook.sys file and Power Loss. After LogBook is started, it can store data to a

PC-Card that does not have the logbook.sys file. However, in this case if LogBook loses power it will

not be able to restart! LogBook will restart when powered-on with a PC-Card that does have the

logbook.sys file.

Communications

Protocols

LogBook uses only standard, supported, widely available communication channels to minimize devicedriver development. The messages transmitted over these channels are also standard: human-readable

ASCII for commands and status, and standard file-transfer protocols (such as X-modem) for block data

transfers. The messages and protocols are independent of the choice of communication channel, except

when a channel explicitly requires a different protocol (such as FTP over TCP/IP). The use of such

standards makes LogBook easier to use and extend.

To implement these standards, LogBook includes a command parser and conversion software to convert

measured voltages into physical measurements such as temperature, force, or acceleration. This software is

used for monitoring transducer measurements, both at the PC and the LBK1. LogBook can return all data

as physical quantities and/or raw voltage measurements.

Large blocks of raw or converted data (such as entire acquisitions or a set of consecutive scans) are

transferred as binary files, using file-transfer protocols. Smaller blocks (such as individual readings or

scans) are transferred in readable ASCII.

Parallel Port – ECP Mode

LogBook includes an ECP parallel port for high-speed local communication with a PC in the ECP mode

(the only supported protocol is ECP). Your PC mode may need to be changed in its BIOS or in the

Window Settings—consult your PC’s documentation or the PC’s manufacturer as needed.

Serial Port

LogBook includes an RS-232 (RS-422/485 optional, call factory for availability) serial port supporting both

point-to-point and multi-drop remote communication.

Other Communication Channels

The serial communication protocols are standard so non-PC hosts can communicate with LogBook. The

use of printable ASCII for commands and status and the use of standard file-transfer protocols make it

practical to add additional ports such as USB, IEEE 488, TCP/IP. Consult factory for availability of these

communication options.

1-10 An Introduction to LogBook 969591 LogBook User’s Manual

Page 21

Triggering and Scan Timing

Reference Note: For information on defining triggering conditions through LogView, refer

to the Acquisition Configuration text and screen shots, which are provided in the LogView

document module.

If data collection is desired only under specific conditions, you can specify appropriate trigger conditions.

By defining a trigger, pre-trigger, and post-trigger, you can collect data surrounding a specific event. This

event can be an absolute time or a defined condition such as a particular analog channel measuring a certain

quantity. If a calculated channel is chosen as the trigger source, you have greater flexibility in defining the

trigger based on multiple inputs and conditional logic. An auto re-arm feature allows many successive

acquisitions to take place automatically, with each acquisition using the same settings.

LogBook can be triggered by several types of sources, including analog and digital triggering, multi-step

triggering, multi-channel triggering, time-of-day triggering, and manual trigger. The manual trigger can be

implemented in the following ways:

With a computer attached, you can trigger LogBook from LogView’s LogBook Monitor window.

Without a computer, you can use a manual trigger switch by attaching it to the TTL trigger input

(pin 25, on P1).

With a logic device you can engage the TTL trigger on P1’s pin 25, as programmed.

Without a computer, you can use the LBK1’s manual trigger button.

LogBook time-of-day clock has 1/256-second resolution for data-logging applications where acquisitions

must be performed at specific times during the day. The time of occurrence of each acquisition and its

trigger are also recorded with the data. The scan-to-scan timing may be set by a fixed-frequency pacer

clock. Or, an external clock can start each scan individually to allow the scan rate to track a variable-speed

event (such as engine revolutions).

Note: Time-stamping is done in 1/256-second units; but the absolute trigger is in 1-second units.

For data acquisition applications that include both fast and slow signals, multiple sample rates can be

configured. In the acquisition setup dialog box, a primary acquisition rate and divisors for up to 3 more

rates can be configured. Using multiple sample rates, fast signals like vibration can be sampled at a high

rate while slow signals like thermocouples are sampled at lower rates, optimizing the system’s storage

capacity.

Scan Rate Limitations

LogBook’s internal clock runs at 100 kHz, and this is the fastest scan rate possible with just one input

channel in the scan list and no outputs. As input, calculated, and output channels are added to the scan list,

the usable scan rate is correspondingly reduced. The system does not automatically compute an optimum

scan rate for you. However, LogView will generate an error message in the LogBook Monitor window if

timing problems occur, and the following sections explain such problems and how to solve them.

External TTL Trigger and Stop Events

An external TTL trigger can repeat before the trigger block completes; extra trigger signals will be ignored.

Likewise, multiple stop signals received before restarting the next scan will be ignored. Such ignored

signals are noted in the LogBook Monitor window as ―Losing Trigger Events‖ and ―Losing Stop Events‖.

Problems Arising From Too Fast a Scan Rate

If the user-specified scan rate does not provide enough time to complete the necessary tasks of the entire

scan list, various problems can occur. Bear in mind that LogBook places the highest priority on reading

input channels—it is primarily a data logger. Also realize that calculated and output channels are based on

input channels and come typically at the end of the scan list. Thus, if the scan rate is too fast and the next

sequence begins before the first is completed, the outputs may suffer. When outputs can’t keep up with the

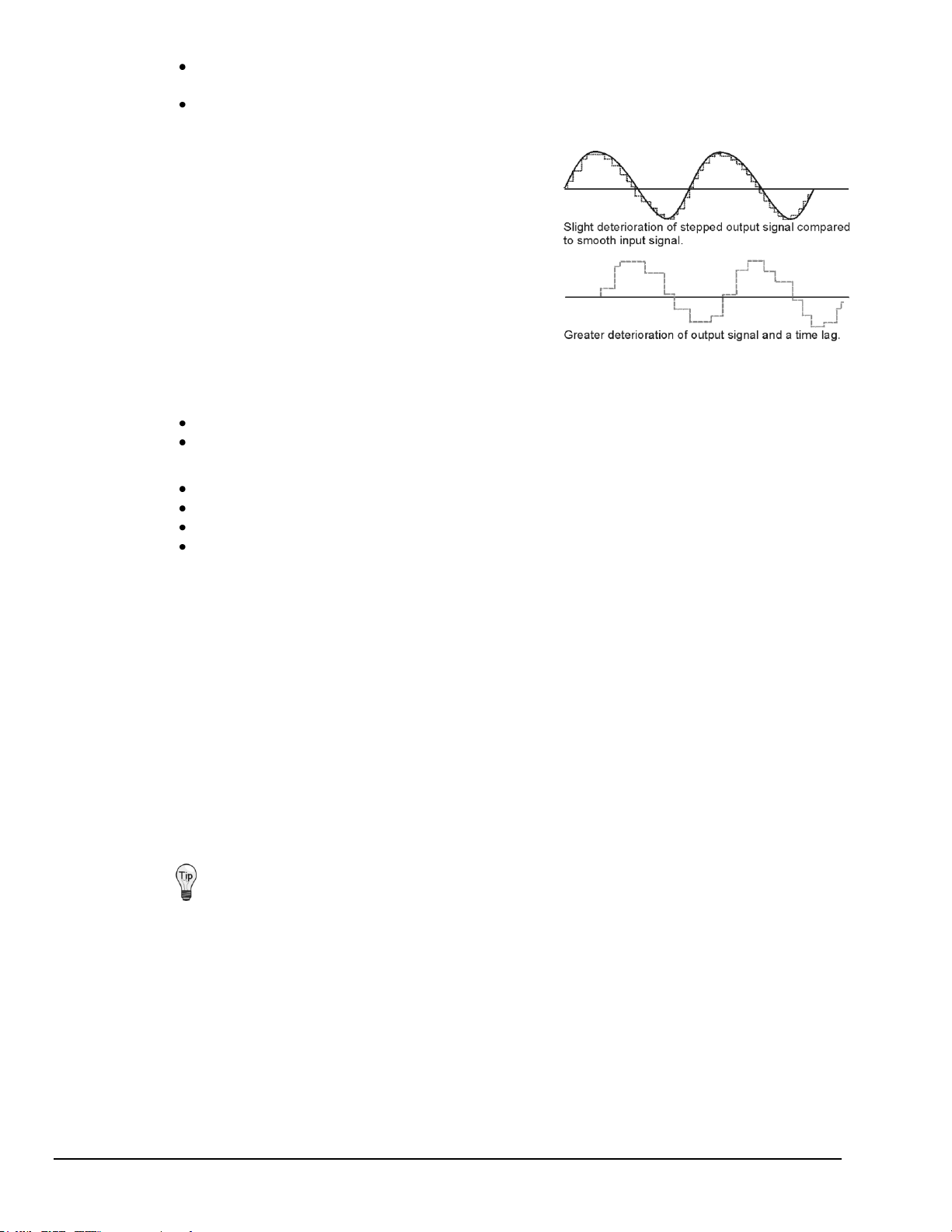

inputs, possible consequences include:

Missing/late Outputs. The outputs are not updated in a timely fashion and may not represent their

sources in real time (LogBook Monitor error message is ―Outputs Deteriorating‖).

Missed Alarms. Digital alarm outputs may not be initiated soon enough—important alarms might

never go off.

LogBook User’s Manual 969591 An Introduction to LogBook 1-11

Page 22

Faulty Control. Control systems based on digital outputs or a DBK25 could fail if dependent on a

After running the acquisition, check the LogBook Monitor screen for error messages.

A list of Software and Hardware-related error codes is included near the end of the manual.

Output Signal Deterioration

fast critical response time.

Distorted Outputs. Analog outputs may appear to be "jaggy" or other distortions such as aliasing-

type errors.

Ideally, each output signal is based on one input, resulting in

an accurate output waveform. Factors such as scan rate,

number of output channels and calculated channels can

overload the system, resulting in one output signal for

multiple input scans. The resulting signal deterioration can

increase over time and shows up as a distorted and/or lagging

output signal. Such output errors can resemble aliasing

errors where output signals are distorted from their input

signals because the effective sampling frequency was not

high enough (see figure).

Solutions To Scan Rate Problems

To confirm a suspected timing problem with your acquisition, run the acquisition and then check:

The LogBook Monitor window in LogView for a corresponding error message.

Actual deterioration of outputs as described in the previous section.

To solve timing problems you may need to perform one or more of the following, in order of effectiveness:

Choose a slower scan rate, or change the trigger parameters.

Reduce the number of output channels.

Reduce the number or complexity of calculated channels.

Reduce the number of input channels.

Estimating an Optimum Scan Rate

Note: The scan rate can be measured as a frequency in Hz or kHz or as a period in ms or µs. These

two measures are reciprocals of each other; e.g., 1/100 kHz = 10 µs.

Processing input channels is LogBook’s highest priority; each input channel is collected at 10 µs. After all

the inputs are collected, LogBook performs the necessary calculations and then updates the enabled outputs.

The time to perform calculations and outputs varies with the type of calculation, and this makes it difficult

to predict the exact length of time required. Simple calculations are done much faster than functions for

non-linear thermocouples and RTDs or the use of logical and bitwise calculated channels. Output channels

can take from 100 µs to 300 µs; so for very approximate results, we’ll use 200 µs.

To estimate the maximum scan rate, use the following formula:

approximate scan period = (number of inputs × 10 µs) + (number of outputs × 200 µs)

If only 5 input channels are enabled, the scan period equals 50 µs with a frequency of 20 kHz. If one output

channel is added, the period becomes 250 µs with a frequency of 4 kHz.

1-12 An Introduction to LogBook 969591 LogBook User’s Manual

Page 23

Use of Outputs to Alarm and Control

Reference Note: For information on how LogView allows you to set outputs

based on user-defined conditions, refer to the LogView document module’s section entitled,

Calculated-Channel Configuration.

Replacement PC-Cards for use with LogBook must be pre-configured in order to store

acquisition data.

By careful setup of LogBook’s analog and digital outputs, you can control external devices and/or stimulate

the unit-under-test. Using LogView’s calculated channels, equations can be derived that can be used to

stimulate digital outputs for use as alarms or for on/off control. For example, the equation:

DIG1 = (CH1 - CH2) < 2

turns on digital output ―1‖ if the difference between channels 1 and 2 is less than 2.

The system’s four 16-bit analog outputs can also be used for controlling or stimulating external devices.

Using channel data derived from input channels and equations or canned waveforms, the analog outputs can

be updated at rates as high as 100 kHz.

Acquisition

A selected acquisition can be armed:

on command from the keypad or PC

at power-on, or

After an acquisition, LogBook may continue the same or begin a new acquisition. The new acquisition can

begin immediately, after a specified time interval, or at a specified time.

Data Storage and Retrieval

The quantity of acquired data can be reduced by block averaging or by decimation (skipping samples

without averaging). Then, data is placed onto the DOS-compatible disk drive using a proprietary format in

a DOS-compatible file. The acquisition setup name and a time stamp are also written to disk.

Post-processing programs can thereby correctly interpret the related data.

The PC can retrieve the acquired data through the serial or parallel port, during or after the acquisition.

Upon command from the PC, LogBook can switch to storing data into a new file. After the PC retrieves

data [from the first file], it can erase that file and reuse the space.

Note: Data is never erased without a specific command from the PC.

Data can also be retrieved from a PC-Card. LogBook copies enough information from the old card to the

new (replacement) card to make sure the current acquisition can continue on the replacement PC-Card.

LogBook User’s Manual 969591 An Introduction to LogBook 1-13

Page 24

1-14 An Introduction to LogBook 969591 LogBook User’s Manual

Page 25

General

Supply Voltage Range: 10 to 45.0 VDC

Power Consumption: 0.9 A @ 15 VDC

Operating Temperature: -40° to 140°F (-40°C to 60°C)

Storage Temperature: -40° to 176°F (-40°C to 80°C)

Humidity: 0 to 95% RH, non-condensing

PC-Card Memory: Standard ATA Type

LogBook/300:

Size: 8½ × 11 × 1¾ in. (216 × 279 × 44 mm)

Weight: 3.3 lb (1.5 kg)

LogBook/360:

Size: 14 × 11 × 3.5 in. (356 x 279 × 89 mm)

Weight: 7.3 lb (3.3 kg)

A/D Specifications

Type: Successive approximation

Resolution: 16 bit

Conversion Time: 10 µs

Monotinicity: No missing codes

Linearity: ±1 bit

Analog Inputs

Channels: 16 single-ended, 8 differential,

expandable up to 256 differential; singleended or differential operation is software

programmable.

Connector: DB37 male, P1

Maximum Overvoltage: -35 V, +45 V

Input Current:

Differential: 0.4 µA typical, 0.7 µA max

Single-ended: 0.2 µA typical, 0.35 µA max

Input Impedance:

10 M differential in parallel with 20 pF

5 M single-ended in parallel with 30 pF

Calibration: Digital software calibration

Channel-to-channel Crosstalk: 100 dB

Ranges: Unipolar/Bipolar operation is software-programmable

on a per-channel basis.

BIPOLAR

±10V

±5V

±2.5V

±1.25V

±0.625V

±0.3125V

±0.15625V

±(% Reading + µV)

0.015 + 500

0.015 + 500

0.015 + 300

0.015 + 250

0.015 + 150

0.020 + 150

0.050 + 100

UNIPOLAR

0 to +20V

0 to +10V

0 to +5V

0 to +2.5V

0 to +1.25V

0 to +0.625V

0 to +0.3125V

±(% Reading + µV)

0.015 + 500

0.015 + 500

0.015 + 300

0.015 + 250

0.015 + 150

0.020 + 150

0.050 + 100

Triggering

Analog Trigger:

Programmable Level Range: full range of

specified channel

Trigger to A/D Latency: 10 µs max

Digital Trigger:

Logic Level Range: 0.8 V low/2.2 V high

Trigger to A/D Latency: 10 µs max

Software Trigger:

Trigger to A/D Latency: Dependent on PC

Pre-Trigger: Up to 4 gig scans, depends on

PC-card memory

LogBook Specifications Specifications are subject to change without notice.

LogBook User’s Manual 969591 An Introduction to LogBook 1-15

Page 26

Sequencer

Randomly programmable for channel and gain and for

unipolar/bipolar (where applicable)

Depth: 1024 analog channels plus 128 digital

channels

Channel to Channel Rate: 10 µs/channel, fixed

Maximum Rep Rate: 100 kHz

Minimum Rep Rate: 10 hours

Expansion Channel Sample Rate: Same as on-board

channels, 10 µs/channel

General Purpose Digital I/O

24 I/O channels, expandable up to 192

Connector: DB37 male, P2

Device: 82C55

Maximum Input and Update Rate: 100 kHz

Output Voltage Levels:

Minimum “1" Voltage: 3.0 @ 2.5 mA sourcing

Maximum ”0" Voltage: 0.4 @ 2.5 mA sinking

Output Current:

Maximum Source Current: 2.5 mA

Maximum Sink Current: -2.5 mA

Input Voltage Levels:

Minimum Required “1" Voltage Level: 2.0 V

Maximum Allowed ”0" Voltage Level: 0.8 V

Output Float Leakage Current: 10 µA

High-Speed Digital I/O

Channels: 16 input lines

Connector: DB37 male, P3

Maximum Sampling Rate: 100K words/s

Input Low Voltage: 0.8 V max

Input High Voltage: 2.0 V min

Input Low Current: 10 µA

Input High Current: -10 µA

Frequency/Pulse Counter

Channels: 4, 16 bits per channel, cascadeable

Connector: DBK37 male, P3

Maximum Pulse Count: 32-bit binary (2 channels

cascaded)

Maximum Input Rate: 1 MHz

Input Voltage: -15 to +15 V

Threshold Voltage (Low): 0.8 V typical, 0.5 V min

Threshold Voltage (High): 1.6 V typical, 2.1 V max

Hysteresis: 400 mV min

Pulse Width (High or Low): 520 ns min

Input Impedance: 27 K pull-up to +5 V in

parallel with 50 pF

Frequency/Pulse Generator

Channels: 2, 16 bits per channel

Connector: DB37 male, P3

Frequency/Pulse Generating Mode: Input frequency

divided by

1 to 65,535

Input Low Voltage: 0.8 V max

Input High Voltage: 2.0 V min

Input Low Current: -10.0 µA max

Input High Current: 10.0 µA max

Output High Voltage: 2.4 V min @ -8 mA

Output Low Voltage: 0.5V max @ 8 mA

1-16 An Introduction to LogBook 969591 LogBook User’s Manual

Page 27

LogBook/300 Quick Start

Software Installation …… QS300-2

Hardware Connection …… QS300-2

Hardware Configuration …… QS300-4

LogBook/300 Device Configuration …… QS300-5

Testing the Hardware …… QS300-7

Acquisition Configuration …… QS300-8

A Note about Calibration …… QS300-8

Before you get started

Verify that you have the following items.

LogBook/300

TR-40U Power Supply

Serial/Parallel Patch Cable, or PC Card Reader

PC with ECP (Enhanced Capabilities Port)

Data Acquisition CD

Monitor: SVGA, 1024 x 768 screen resolution

Windows 2000 SP4 and Windows XP users:

PC with Intel™ Pentium [or equivalent], 1 GHz;

Windows Vista users:

PC must be Windows Vista Premium Ready

WARNING

Electric shock hazard. Turn off power to all system-connected devices prior to connecting

or disconnecting cables, or setting hardware configurations. Failure to do so could result

in electric shock or death, and equipment damage, even under low-voltage conditions.

When using LogBook/300 in attached mode, the PC-Card [in LogBook/300] must already

have the file logbook.sys. Otherwise, LogView cannot communicate with LogBook/300,

and LogBook/300 will appear dead.

IMPORTANT! Software must be installed first!

512 MB memory; 10 GB disk space

Software Installation

1. Close all running applications on the host PC.

2. Remove previous version drivers, if present. You can do this through Microsoft’s Add/Remove Programs

feature.

3. Insert the Data Acquisition CD (8.1.2 or higher) into your CD-ROM drive and wait for the PC to auto-run. An

Opening Screen will appear. If AutoRun is disabled: (a) right click Windows Start menu, (b) select Explore; and

(c) double-click MasterSetup.exe. As an alternative to using the CD, you can download software from:

www.mccdaq.com/products/software.aspx

4. Click the <ENTER SETUP> button.

Note: If you are downloading software from our website, follow instructions provided there.

5. From the hardware selection screen, select your data acquisition device then follow the on-screen instructions.

Note: To enable all LogView features:

(a) From LogView’s main window, open the File pull-down menu,

(b) select Authorization,

(c) enter ED7B55484273 in the dialog box and apply the code.

Hardware Connection

QS300-2 LogBook/300 Quick Start Guide

Page 28

Reference Notes:

Depending on the nature of your LogBook system, you may find one or more of the following

references to the LogBook User’s Manual PDF helpful. The PDF manual is included on the Data

Acquisition CD and is also available on our web-site.

o For system block diagrams and operational overviews, refer to Chapter 1 of the PDF.

o For information on system expansion and calculating system power, refer to Chapter 4 and to

the DBK Basics section.

o For information regarding LBK options, refer to Chapter 5.

o For specific DBK card information, refer to the DBK Options Manual PDF.

Note: Other power options are discussed in

the DBK Basics section of this

manual.

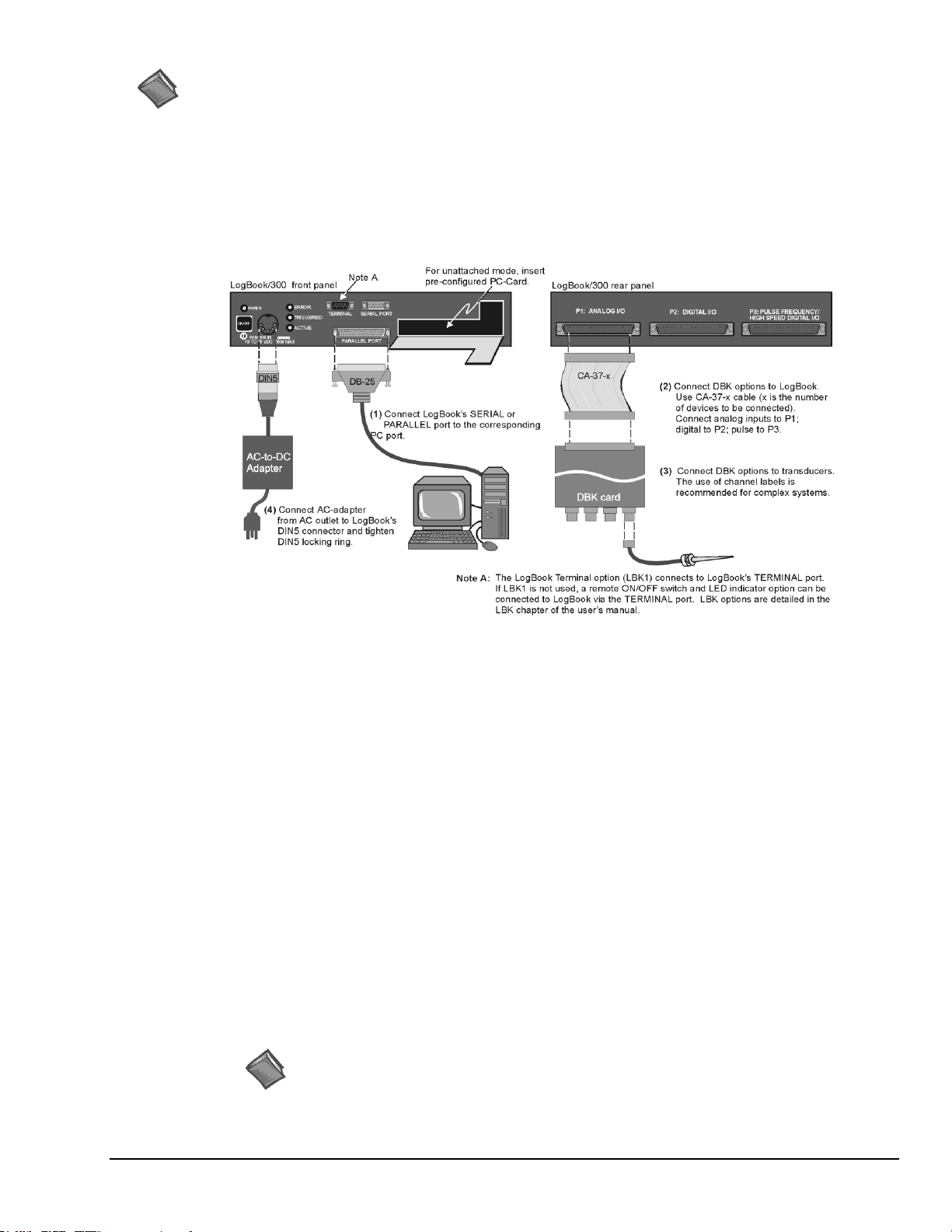

The following hardware-connection figure and procedure are generic; details vary with system complexity.

After verifying that all equipment power is off, hardware connection typically proceeds as follows.

Refer to the previous figure as needed.

1. Connect LogBook/300 to PC. There are four ways for LogBook/300 to communicate with the host

PC. These are: parallel port, serial port to serial port, serial port to USB, and manual transportation

of the PC-Card. Note that the parallel port method is represented in the previous figure.

a) Parallel port to parallel port – If using the parallel port, connect a DB25male to DB25female parallel cable

[e.g., CA-35-2 or CA-35-6 (2ft. or 6ft. respectively)] to PARALLEL PORT on LogBook/300, and to the

corresponding parallel port on the host PC. When this method is used, the PC must be set to the ECP

mode. See ECP Parallel Port, page QS300-6 for additional information.

b) Serial port to serial port – If using the serial port, use a null modem serial cable (CA-47) to connect the

DB9 SERIAL PORT on LogBook/300 to the corresponding DB9 serial port on the host PC.

c) Serial port to USB port - Requires an adapter kit. To connect the LogBook to a USB port you will need a

RS-232 to USB Interface Adapter Kit p/n CA-232-USB-KIT (available from Measurement Computing).

Refer to the associated Quick Start document (QS RS-232_to_USB_Interface.pdf) for a list of the kit’s

contents and for RS-232 to USB conversion instructions. The pdf is included on Data Acquisition CD

(rev 8.1.2 and hig

.

d) PC-

LogBook/300 Quick Start Guide QS300-3

Reference Note:

LogBook User’s Manual PDF.

Card

communication is accomplished via the PC-Card. To provide the PC-Card with the correct configuration

file, it must be configured from the PC, through LogView. After the PC-Card is configured, it is inserted

into LogBook’s PC-Card slot, located behind the front panel door.

Information pertaining to PC-Cards can be found in chapter 1 and in the LogView section of the

her)

–

With PC-Card communication, LogBook/300 does not require a connection to the computer, as

Page 29

Reference Note:

For DBK card related information, refer to the DBK Options Manual PDF. The document is

included on the Data Acquisition CD and is also available on our web-site.

CAUTION

For analog signal inputs via P1, do not exceed -35 VDC or +45 VDC.

Exceeding these limits could result in equipment damage.

Reference Note:

Refer to the device-specific sections of the LBK Options chapter of the user’s manual and to

the DBK Options Manual PDFs for information regarding these devices. Note that certain

DBK options require manual configuration.

2. Connect the LogBook/300 to the DBK cards and modules. Most of the analog DBKs connect to P1

on the rear panel; the digital DBKs generally connect to P2.

Note: The CA-37-x cable can daisy-chain several DBKs including the DBK41, which has a built-in

P1 bus connection for 10 DBK cards. The x in the cable part number refers to the number of

devices that can be connected to a device, for example: a CA-37-1 cable has two DB-37

connectors, one for connecting to the LogBook and another for connecting the card or

module. Pinouts for P1, P2, and P3 are included in the System Expansion chapter.

3. Connect DBK(s) to transducer(s). Follow instructions for the specific DBK(s) as described in the

DBK Option Cards & Modules User’s Manual, as well as instructions for the applicable transducers.

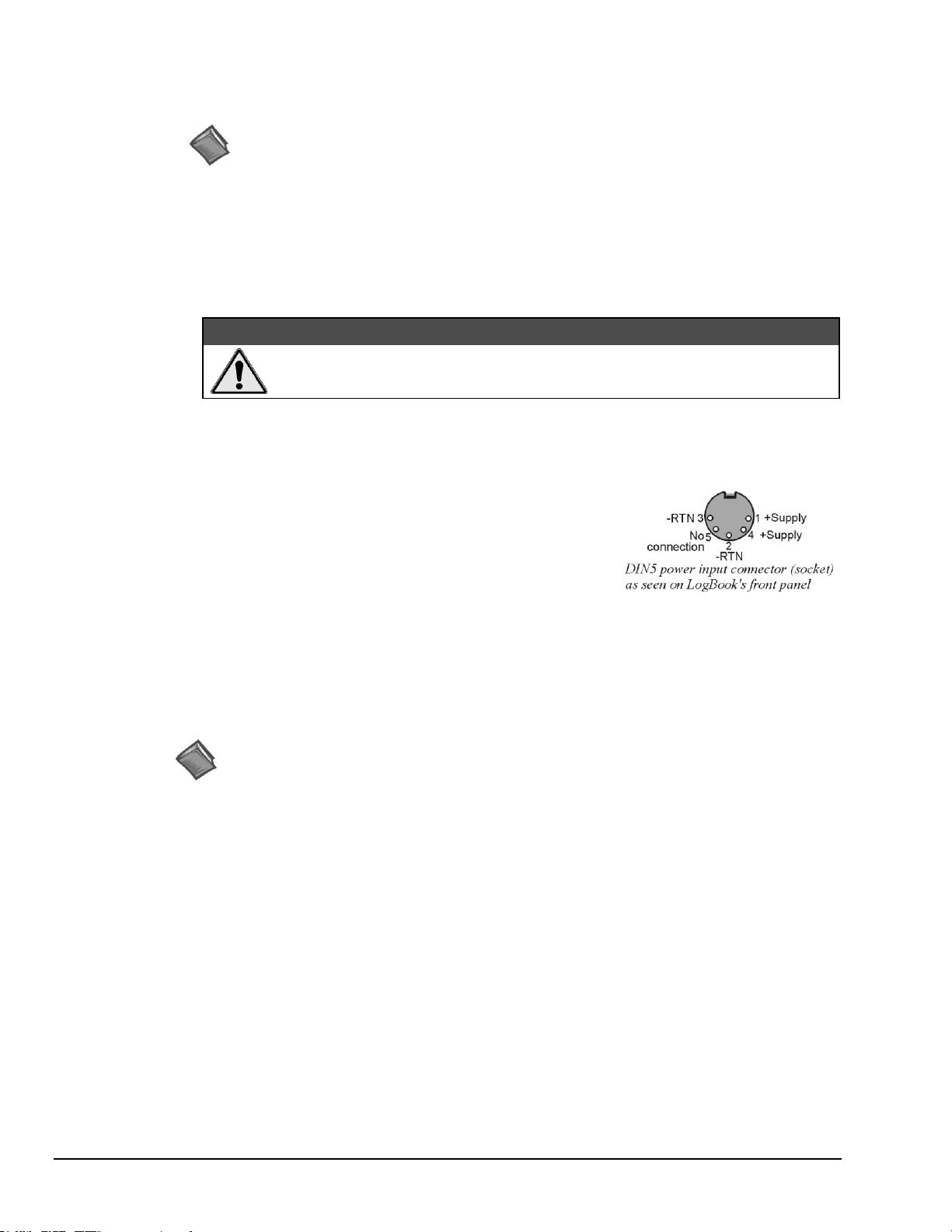

4. Connect the LogBook/300 to a suitable power source such as the

included AC-to-DC adapter or the optional DBK34A. DC

power sources such as a car batteries must supply 10 to 45 VDC

and use the correct DIN5 pinout (see figure). A locking DIN5

connector assures a secure power connection for applications

subject to vibration or thermal stress.

5. Optional - Just one cable connects between the LBK1

(via RJ-11 connector) and the LogBook/300 (via a DB9 connector). The standard cable is 6 feet

long. An optional 25 foot cable is available. See chapter 5 of the LogBook User’s Manual PDF for

details regarding the installation of LBK1.

Hardware Configuration

LogBook/300's top cover does not need to be removed, except to add or remove an LBK option, or to

replace the fuse.

Most LogBook/300 configuration is done via software as described in the LogBook/300 Device

Configuration section of this document (page QS300-5). LogBook/300 configuration does not require the

setting of jumpers or switches, unless the RS-485 communication option is being used.

QS300-4 LogBook/300 Quick Start Guide

Page 30

Upon completing the software installation, continue with LogBook/300 Device Configuration.

LogBook/300 Device Configuration

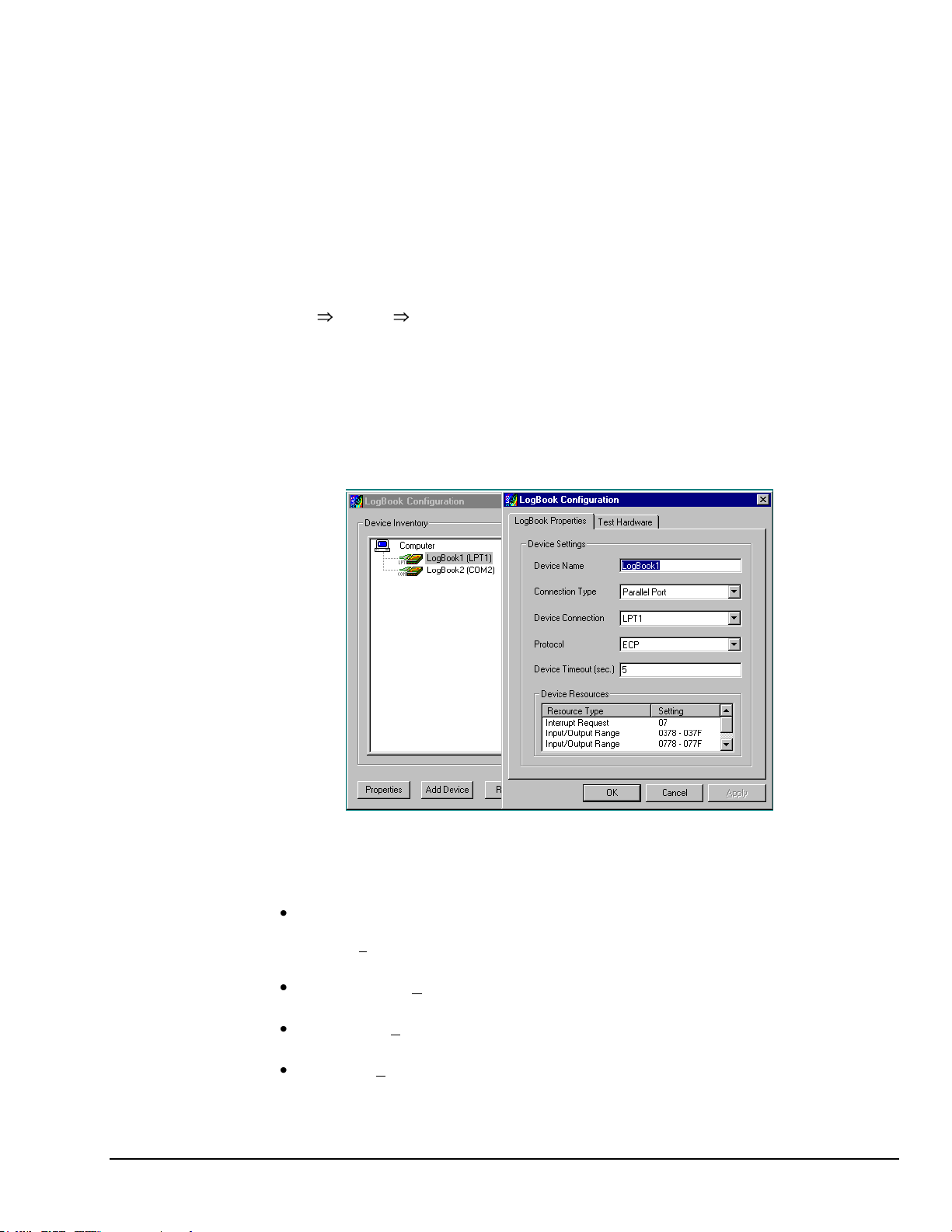

A configuration utility is supplied via a control panel applet. The LogBook Configuration applet allows

you to add a device, remove a device, or change existing configuration settings. From this same window,

you can also access a built-in utility to test the connected device for current setup and performance.

LogBook Configuration can be found in the Microsoft Windows Control Panel. The Control Panel can be

navigated to from Windows desktop Start button as follows:

Start Settings Control Panel

You can enter LogBook Configuration during driver installation or whenever you wish to add, remove or

change device configuration settings.

The first configuration window will display configured devices in the Device Inventory field based on the

port they’re connected to. Devices are represented by an icon and text, e.g., LogBook (LPT1), as can be

seen in the following figure. If no devices are configured, the device inventory field will remain blank.

The figure shows the first and second configuration windows overlapped.

LogBook Configuration Windows

The four buttons across the bottom of the first configuration window (previous figure) are used as follows:

Properties. Configuration settings for a device can be changed or modified from the corresponding

properties window. To do so, double-click the device icon or single-click the device and then singleclick the Properties button. The second configuration window will appear for the selected device as

shown in the previous figure.

Add Device. The Add Device button is used to add a device configuration whenever a new device is

added to the system. LogView cannot recognize a device unless listed in the configuration window.

Remove. The Remove button is used to remove a device from the configuration. A device may be

removed if it is no longer installed or if the device’s configuration no longer applies.

Close. The Close button may be used at any time to exit the LogBook Configuration applet.

The second configuration window displays the properties for the selected LogBook/300. Fields include:

LogBook/300 Quick Start Guide QS300-5

Page 31

Device Name is displayed with the default name, numbered successively as configured. This field can

To use parallel port communication with an attached LogBook/300, your PC must

support the ECP protocol AND be set in the ECP mode.

To ensure ECP compatibility after proper setup, use the Test Hardware utility

(described on page QS300-7). Before testing, make sure LogBook/300 is properly

connected, powered on, and that the Parallel Port Mode is set to ECP (in BIOS Setup).

CAUTION

Making errors in BIOS Setup can disrupt your system’s operation. If test hardware

indicates a problem and you have inadequate experience with the BIOS Setup utility,

consult your System Administrator or other qualified individual.

be changed to any descriptive name as desired.

Connection Type can be serial or parallel port.

Device Connection specifies the port name.

Protocol is used to set the parallel port protocol (ECP only) or serial protocol (RS-232 or RS-485).

Device Timeout specifies the number of seconds LogView will be wait for a LogBook response before

displaying an error condition.

ECP Parallel Port

The majority of today’s PCs support the Enhanced Computer Port protocol (ECP). If your computer does

not support ECP, you can communicate with the LogBook/300 via the RS-232 serial port, or you can add an

ECP-compatible ISA board or PC-Card parallel port. Setting the PC to ECP mode varies with different

computers. On some computers, you can enter the BIOS Setup utility from Windows Settings or during

startup by pressing the F1 function key. The Parallel Port Mode property can be found under the Peripheral

Configuration group menu item. If necessary, consult your PC’s documentation or your PC’s manufacturer.

QS300-6 LogBook/300 Quick Start Guide

Page 32

Serial Port

LogBook Properties Tab

Test Hardware Tab

Testing the LogBook/300 device might cause the system to hang. If test results are not

displayed within 30 seconds, or if the system does not respond properly do the following:

Reboot the system.

Upon power-up, re-enter the LogBook Configuration.

Ensure the configuration settings are correct. Change the settings as applicable.

If the selected device is connected to a serial port the properties window will include the fields shown in the

following figure. Baud rate can be set from 1200 to 115200 bits per second (default 9600). When all fields

have been changed to the desired settings, you can click on one of the following options:

Apply to store the device configuration. Parameters are not locked in until you click the Apply button.

If you make changes and don’t click Apply, clicking the Test button in Test Hardware will yield

unexpected errors.

OK to store the configuration and exit the current property screen.

Cancel to exit the current screen without storing any changes.

Test Hardware to test the current device.

Testing the Hardware

Before testing LogBook/300:

(a) Verify the device has been properly installed

(b) Make sure the communication cable (serial or parallel) is firmly in place to the proper ports.

(c) Verify the device is powered-on.

To begin the test, click the Test button. Test results should be displayed within a few seconds.

Test results indicate if the device is online (properly connected, powered on and ready to transfer the data)

or offline. If the device is online, Performance Test will display Download and Upload speed rates. These

rates represent the maximum speed at which downloading and uploading files can be performed. Actual

transfer time will depend on channel configuration and the size of the transfer.

LogBook/300 Quick Start Guide QS300-7

Page 33

Acquisition Configuration

Reference Note:

Configuring the acquisition is described in the LogView section of the LogBook User’s

Manual PDF, which is included on the Data Acquisition CD and on our web-site.

Reference Notes:

An example of 2-point calibration is provided under the Procedures heading in the

LogView section of the manual.

For information on calibrating the DBK16 and the DBK43A, refer to the

DBK Option Cards and Modules User’s Manual (p/n 457-0905).

An acquisition is configured using LogView on a PC and then stored as an acquisition setup file on a

PC-Card. The PC-Card may be in an attached LogBook/300 or in the PC to be later manually transferred to

an unattached LogBook/300. The system’s DBK cards are listed; the scan sequence is defined; the trigger

conditions are specified, etc.

A Note about Calibration

Calibration is typically performed automatically through LogView software; however, some DBKs may

require manual calibration. LogView’s 2-point calibration fine-tunes the reading’s slope and offset error

(mx+b). DBKs working with non-linear sensors typically condition/convert the reading to a linear form.

Otherwise, a non-linear analog input signal is difficult to read accurately. Careful use of the calculated

channels may yield usable approximations in simple, limited-range conditions.

QS300-8 LogBook/300 Quick Start Guide

Page 34

LogBook/360 Quick Start Guide

Software Installation …… QS360-1

Setting Up the Card Drawer …… QS360-3

Connecting the LogBook/360 to the PC,

External DBKs, and Power …… QS360-6

Hardware Configuration …… QS360-7

LogBook/360 Device Configuration… QS360-8

Testing the Hardware …… QS360-10

Acquisition Configuration …… QS360-10

A Note About Calibration …… QS360-11

Before you get started

verify that you have the following items.

LogBook/300

TR-40U Power Supply

Serial/Parallel Patch Cable, or PC Card Reader

PC with ECP (Enhanced Capabilities Port)

Data Acquisition CD

Monitor: SVGA, 1024 x 768 screen resolution

Windows 2000 SP4 and Windows XP users:

PC with Intel™ Pentium [or equivalent], 1 GHz;

Windows Vista users:

PC must be Windows Vista Premium Ready

LogBook/360 combines the features and capabilities of LogBook/300 with a DBK60 expansion chassis. The lower

portion of the front panel has three male DB37 connectors (P1, P2, and P3) for system expansion, and a post for

connecting to CHASSIS ground. The upper section is nearly identical to LogBook/300.

IMPORTANT! Software must be installed first!

512 MB memory; 10 GB disk space

Software Installation

1. Close all running applications on the host PC.

2. Remove previous version drivers, if present. You can do this through Microsoft’s Add/Remove Programs

feature.

3. Insert the Data Acquisition CD (8.1.2 or higher) into your CD-ROM drive and wait for the PC to auto-run. An

Opening Screen will appear. If AutoRun is disabled: (a) right click Windows Start menu, (b) select Explore; and

(c) double-click MasterSetup.exe. As an alternative to using the CD, you can download software from:

www.mccdaq.com/products/software.aspx.

4. Click the <ENTER SETUP> button.

Note: If you are downloading software from our website, follow instructions provided there.

5. From the hardware selection screen, select your data acquisition device then follow the on-screen instructions.

Note: To enable all LogView features:

(a) From LogView’s main window, open the File pull-down menu,

(b) select Authorization,

(c) enter ED7B55484273 in the dialog box and apply the code.

LogBook/360, Front Panel

LogBook/360 Quick Start Guide QS360-1

Page 35

Reference Notes:

Depending on the nature of your LogBook system, you may find one or more of the following references to the

LogBook User’s Manual PDF helpful. The PDF manual is included on the Data Acquisition CD and is also

available on our web-site.

o For block diagrams and operational overviews, refer to Chapter 1 of the LogBook User’s Manual PDF.

o For system expansion and calculating system power, refer to Ch. 4 and to the DBK Basics section.

o For information regarding LBK options, refer to Chapter 5.

o For specific DBK card information, refer to the DBK Options Manual PDF.

Note: The LogBook/360 rear panel supports three termination panels. Many different combinations are

possible.

WARNING

Electric shock hazard. Turn off power to all system-connected devices prior to connecting or

disconnecting cables, or setting hardware configurations. Failure to do so could result in electric shock

or death, and equipment damage, even under low-voltage conditions.

CAUTION

Use ESD tools, containers, and procedures during setup of DBK cards. Electrostatic

discharge can damage some components. To prevent pin damage, align DBK cards with the

backplane DB37 connectors, then gently press them together.

When using LogBook in attached mode, the PC-Card [in LogBook] must already have the file

logbook.sys. Otherwise, LogView cannot communicate with LogBook, and LogBook will

appear dead.

QS360-2 LogBook/360 Quick Start Guide

Page 36

Setting Up the Card Drawer

Leave jumpers JP1 and JP2 in place unless a DBK33 is being used. If a DBK33 is being

used configure the P1 interconnect board according to the table presented in step 6.

LogBook/360 can house three DBK cards internally, and make use of various termination panels. For user convenience, a card

drawer can be slid free of the device. The following steps should be used when adding, removing, or changing cards. Refer to

the following figure as needed.

1 – Turn off system power and disconnect LogBook/360.

Turn power off to the LogBook/360 and all connected devices. Disconnect LogBook/360 from the system.

2 – Remove top cover.

If you need to make any change on the LogBook motherboard, you will need to remove the top cover. Otherwise, the cover

can remain in place. To remove the top cover, simply remove the two top cover screws and slide the cover free of the

device.

3 – Remove card drawer.

A. Remove the two screws that hold the card drawer to the chassis.

B. Loosen the three termination panel thumbscrews.

C. Carefully pull the card drawer free of the chassis.

4 – Remove termination panels.

For each termination panel, remove the two screws that mount it to the card drawer, then remove the termination panel.

5 – Determine power requirements.

Depending on the power needs of your system’s DBK cards, you may need to add a power card.

Refer to the DBK Basics section of the LogBook User’s Manual PDF in regard to calculating your

system’s power requirement.

If the required power is more than the available power your system will require auxiliary power. One of two power

supply cards can be used with LogBook/360:

DBK32A – This DBK supplies ±15 V for use with a LogBook, DaqBook, or DaqBoard.

DBK33 – This DBK supplies +5 V and ±15 Vfor use with Log Book, DaqBook, DaqBoard,

or Daq PC-Card.

LogBook/360 Quick Start Guide QS360-3

Page 37

6 - FOR DBK33 USERS ONLY! Configure the P1 interconnect board for power source.

This step only applies when a DBK33 is being used with the system.

If you are not using a DBK33 skip to step 7.

The schematic to the right shows the LogBook/360 jumpers, JP1 and

JP2, which are used to distribute the LogBook’s +5V power supply.

DBK cards that attach to the LogBook’s P1 bus need +5V, +15V, and

-15V power sources to operate. Typically, the LogBook’s power supply

meets this requirement, but if additional power is needed, a DBK32A or

DBK33 must be added.

The LogBook’s power supply employs diode protection on its +/-15V

supplies so that no conflict will take place when a DBK32A or DBK33 is

added to the P1 bus. However, adding a DBK33, with its +5V source,

necessitates the proper positioning of the JP1 and JP2 jumpers.

Adding a DBK33 to your system with the jumpers set incorrectly can

damage your LogBook, DBK33, and other system components. Refer to

the following table for important information regarding configuration.

CAUTION

Adding a DBK33, with its +5V source, necessitates the proper positioning of the JP1 and JP2

jumpers on the LogBook/360 P1 interconnect board. Adding a DBK33 to your system with the

jumpers set incorrectly can damage the LogBook, DBK33, and other system components.

WHEN JP1 AND JP2 JUMPERS ARE IN PLACE A DBK33 CANNOT BE USED IN THE

SYSTEM!

P1 Interconnect Board Configurations for DBK33 Applications

JP1

JP2

P1 Interconnect

Board*

LogBook +5V Power Source

Notes Pertaining to DBK33

Internal P1

Bus

External P1

Bus

In

Out Yes

No

When the JP1 jumper is in place and the JP2

jumper is out, if the system is using external

DBKs the DBK33 will need to be external.

Internal DBKs will be powered from

LogBook’s internal P1 bus.

Out

In No

No

When the JP1 jumper is out and the JP2

jumper is in place, if DBKs are used

internally or externally, the DBK33 can be

internal or external and will power both

internal and external DBK cards.

Out

Out No

No

When the JP1 and JP2 jumpers are both out,

the following apply:

o If using internal DBKs, you will need to

use an internal DBK33.

o If using external DBKs, you will need to

use an external DBK33.

Leave jumpers JP1 and JP2 in place, unless a DBK33 is being used. If a DBK33 is being

used configure the P1 interconnect board according to the above table.

* Refer to the LogBook/360 Hardware Setup figure on page QS360-3 for the P1 interconnect board’s location.

QS360-4 LogBook/360 Quick Start Guide

Page 38

7 – Install power card if necessary.

If you determined in step 5 that additional power was needed, add a DBK32A or DBK33 power card to the

chassis. The DBK Option Cards & Modules User’s Manual includes detailed information regarding these

power-related cards.

A. Carefully align the power card’s DB37 connector with a DB37 connector on the interconnect board and

gently press them together.

B. Mount the power card with two screws into the standoffs on the card drawer.

8 – Configure DBK cards.

Configure unique channel addresses with the jumpers on the DBK cards. Some cards have other jumpers and/or

DIP switches. Refer to the specific DBK sections of the DBK Options Manual (p/n 457-0905) as needed.

9 – Install DBK cards.

You must use all analog DBK cards in the LogBook/360; unless you have a factory modification that allows the

use of all digital cards. You can not use both analog and digital cards at the same time.

A. Carefully align the DBK card’s DB37 connector with a DB37 connector on the interconnect board and

gently press them together (see figure).

B. Mount the DBK card with two screws into the standoffs on the card drawer (see previous figure).

C. Continue installation of any remaining DBK cards.

10 – Connect internal signals.

Connect signal inputs from DBK cards to termination panels. DBK cards connect to the termination panels in

various ways (see figure and particular DBK sections in the DBK Option Cards and Modules User’s Manual):

Single-ended connections use analog common.

Differential connections require the proper polarity, typically red-to-red for high (+)

and black-to-black for low (-).

For thermocouples, red is generally the low side. Always make sure the T/C connector and wire type

match the T/C type used.

11 – Install termination panels.

Mount the termination panels to the card drawer with two screws for each panel.

12 – Install card drawer.

The card drawer slides into the bottom track of the chassis.

A. Hold the card drawer by its handle and tilt it up slightly. Place it on the bottom track of the chassis.

B. Carefully slide the card drawer into the chassis. When it engages the bottom track, level the card drawer and

continue inserting it until it engages with the P1 interconnect board.