Page 1

eZ-Record User’s Manual

Data Acquisition and Record

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail (sales): sales@iotech.com

E-mail (post-sales): productsupport@iotech.com

Internet: www.iotech.com

eZ-Record Manual

Data Acquisition and Record

p/n 1086-0922 Rev. 2.1

© 2001 by IOtech, Inc August 2001 Printed in the United States of America

Page 2

Page 3

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior written

consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their respective

holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs) may only be used

on one installation. You may make archival backup copies.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission rules (Part 15)

for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve Radio-TV Interference Problems

(stock # 004-000-00345-4) which is available from the U.S. Government Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This warns of possible personal injury or equipment damage under noted

conditions. Follow all safety standards of professional practice and the recommendations in this manual. Using this

equipment in ways other than described in this manual can present serious safety hazards or cause equipment damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

Use proper ESD handling guidelines when handling equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective bags

and cartons, and related procedures.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to the

manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is not covered

under the warranty and must be performed by qualified personnel as specified in this manual. Improper calibration procedures

may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and review

our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech welcomes

your suggestions.

Page 4

Page 5

January 2001 eZ-Record Manual

TABLE OF CONTENTS

INTRODUCTION ............................................................................................. 7

THIS MANUAL .......................................................................................... 7

ACTION BUTTONS ..................................................................................... 7

HOT KEYS (KEY COMMANDS)...................................................................... 8

GETTING STARTED ........................................................................................ 9

VERIFY SWITCH SETTINGS ......................................................................... 9

CONNECT SIGNALS TO THE INPUT BNCS ........................................................ 9

VERIFYING MEDALLION’S OPERATING CONDITION .......................................... 10

ORDER OF OPERATION ............................................................................ 10

CHAPTER ONE - MENUS ............................................................................. 11

FILE MENU ............................................................................................ 11

EDIT MENU ........................................................................................... 12

PLAYBACK SETUP ................................................................................... 22

WINDOW COLORS................................................................................... 23

PREFERENCES ....................................................................................... 24

TASK BAR ............................................................................................. 25

TASK MENU .............................................................................................. 27

MEASUREMENT ....................................................................................... 27

PLAYBACK / REVIEW ................................................................................ 27

CALIBRATION .......................................................................................... 27

AUTORANGE ........................................................................................... 30

EXPORT MENU .......................................................................................... 31

EXPORT TIME HISTORY DATA ..................................................................... 31

SETUP EXPORT FUNCTION DATA ................................................................ 32

WINDOW MENU ........................................................................................ 33

ADD FUNCTION VIEW .............................................................................. 33

ADD STRIP CHART ................................................................................. 33

DELETE WINDOW .................................................................................... 33

MODAL LOCATIONS WINDOW .................................................................... 33

CHANNEL MONITOR ................................................................................. 34

CASCADE .............................................................................................. 34

TILE VERTICALLY .................................................................................... 34

TILE HORIZONTALLY ................................................................................. 35

PLOT DISPLAY WINDOW .............................................................................. 35

USING BANKS AND FUNCTION FILES .............................................................. 47

Index .................................................................................................... 48

Page 6

eZ-Record Manual January 2001

6

Page 7

January 2001 eZ-Record Manual

INTRODUCTION

eZ-Recorder is a graphical software interface that is used to measure and record

high frequency (vibration) data to the Medallion FFT Analyzer.

The Medallion Analyzer comes with 2-, 4-, 6-, 8-, or 16-input channels and one

output channel. It is used to acquire high frequency simultaneous data across all

active channels.

Data can be captured for instantaneous observation and analysis; and also

recorded at the same time. Recorded data can be analyzed at a later time. The

recorded data is raw Time data that is unaffected by display functions or any

averaging used to display the data during acquisition. You can therefore play

back this data many times using a different set of analysis features each time. As

you review the data, you have the option of saving individual functions. These

functions can also be saved and recalled.

Saved functions and saved recorded data can also be reviewed without the

Medallion hardware. Some limitations exist; for example, you can not trigger

recorded data. General post processing and the review and analysis of recorded

data does not require the presence of the Medallion hardware.

There are a series of built-in hot keys that facilitate operations. These are

especially useful, for example, when you are trying to operate the Medallion while

also driving a piece of equipment that you are testing.

Because this is a both a data acquisition system and a recorder for playback

operations, not all menu options and buttons are always operational. We

deliberately disable any operations that we think will allow you to corrupt your

data.

THIS MANUAL

In the Getting Started Section configuring and verifying the hardware setup is

explained. Correct switch settings are imperative for accurate results. Y ou are

also presented with an Order of Operation. Y ou will find that you will not always

need to follow this order . However when you don’t get the results you expected,

you may want to review this section and the section prior to it: “Verifying

Medallion’ s Operating Condition.” The rest of the manual explains the Menu

system and how to present the data in a meaningful format.

ACTION BUTTONS

Apply: Applies changes made in a window without closing the window.

OK: Applies changes made in a window and closes the window.

Cancel: Closes a window without applying changes. This is only valid if you

have not clicked the APPLY Button. If you have clicked the APPLY button,

only the changes you made since clicking the APPLY button are canceled.

7

Page 8

eZ-Record Manual January 2001

HOT KEYS (KEY COMMANDS)

Hot Keys or Key Commands are often used by technicians and engineers when

they are in the field or anywhere it is not convenient to use a mouse. The best

way to learn key commands and exactly what you can and cannot do with them is

to practice using them when it is not critical and when you have a functioning

mouse to use if necessary.

Menu Control

File Menu: “Alt” + “F”. Presents the File Menu.

File Open: “Alt” + “F” + “O” or “Ctrl” + “O”. Presents the Open File Dialog

window. Then use the “Tab” and arrow keys to select a file, provided it

appears in the window. You will have to use your mouse if the desired file is

located in another folder.

File Print: “Alt” + “F” + “P” or “Ctrl” + “P”. Presents the Print Dialog

window. If necessary, use the down arrow key to select a printer; then press

“Enter.”

Edit Menu: “Alt” + “E”. Presents the Edit Menu.

Edit Medallion: “Alt” + “E” + “M” or “Ctrl” + “M”. Presents the Medallion

Configuration window. You will need a mouse to access all the panels.

Edit Playback Setup: “Alt” + “E” + “P”. Presents the Playback Setup window.

Use the “Tab” and arrow keys to use this window; then press “Enter.”

Edit Window Colors: “Alt” + “E” + “C”. Presents the Plot Window Colors

window. Use the “Tab” to select a plot window characteristic, then press

“Enter”. The colors palette will open. Use the “Tab” to select a color. Press

“Enter”. Select another characteristic button, open the color palette, select a

color and press Enter. Repeat for each characteristic.

Window Menu: “Alt” + “W”. Presents the Window Menu. You will need the

mouse to make selections on this menu.

Plot Display Control

Display Function Menu: “D”

You can continue to use Key Commands and the Arrow keys to maneuver

through this menu and its submenus. i.e. Press D, C, then use the down arrow

and stop at Cursor, then press the right arrow to open the submenu, then use the

Up or Down arrow to select either Cursor On or Cursor Off. Finally press “Enter.”

Plot Grid On/Off: “G”

Cursor On/Off: “C”

Linear/Log Scale Toggle: “L”

Y-Axis Menu: “Y”

X-Axis Menu: “X”

Record/Playback Control

Play Forward: “P”

Play Backward: “Shift + P”

Step Forward and Record: “O”

Step Backward and Record: “Shift + O”

Halt Playback: “H”

8

Page 9

January 2001 eZ-Record Manual

GETTING STARTED

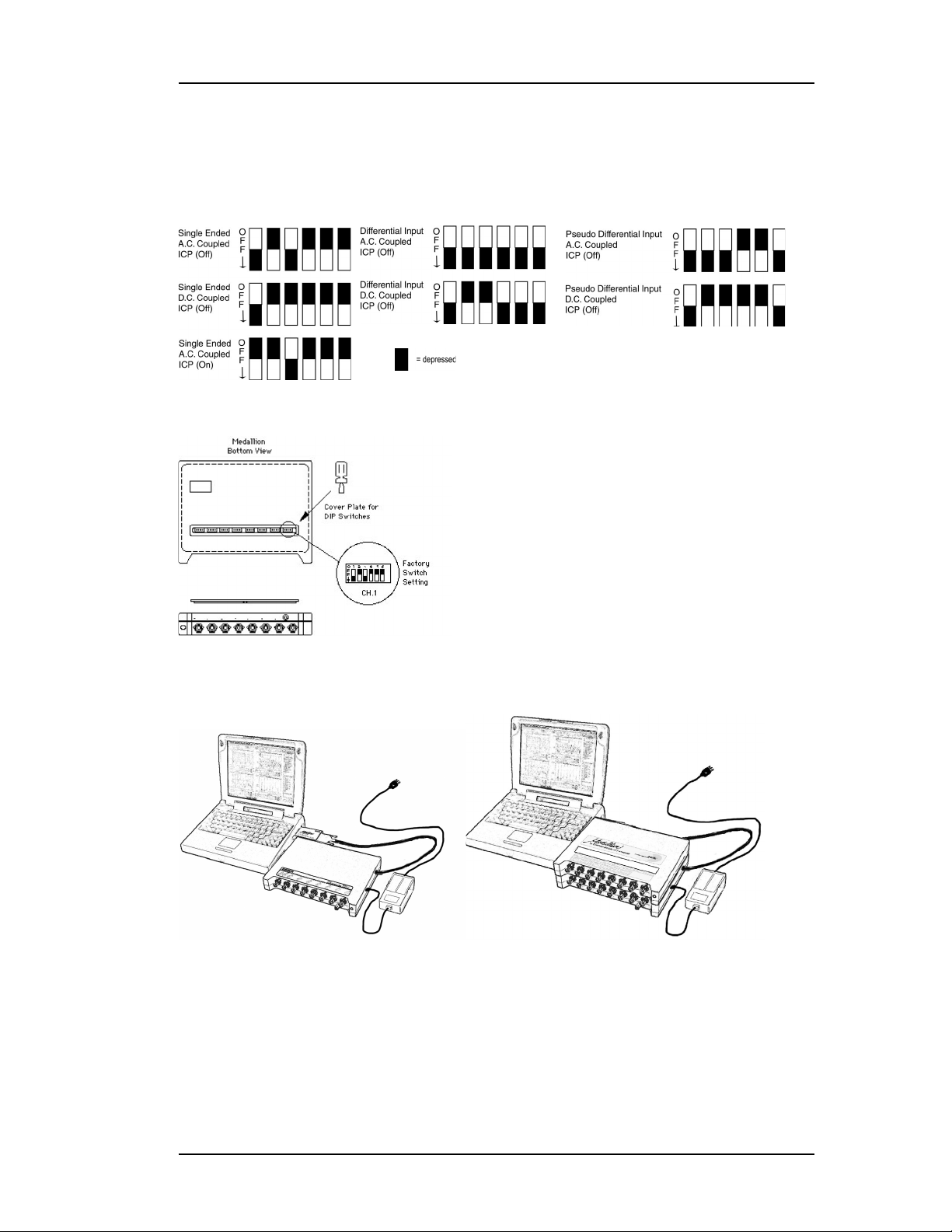

VERIFY SWITCH SETTINGS

The Medallion contains no relays. Switches control the input configuration.

These switches are set with rocker switches located under the access panel on

the bottom of the Medallion.

Improper settings CAN DAMAGE your equipment, and WILL PRODUCE

erroneous measurements.

CONNECT SIGNALS TO THE INPUT BNCS

Tip: Cap unused BNCs to reduce extraneous noise.

9

Page 10

eZ-Record Manual January 2001

VERIFYING MEDALLION’S OPERATING CONDITION

After the hardware is assembled, and the software is installed (See Getting

Started manual), you are ready to run your Medallion. Use this checklist to verify

that the Medallion hardware and software are operating properly .

Software Installed? See Software Installation in the Getting Started manual.

Hardware Switches Set? See Configuring the Medallion Front-End .

Hardware Connected? See Hardware Assembly .

eZ-Record Software running? On the Start menu select Programs, then

Zonic Medallion, and then eZ-Record. Your software opens to a Main

window where you can acquire/record new data, post-process existing data

either by playing back previously recorded data or recalling previously saved

functions.

If you are not using your Medallion analyzer, a message will appear that

hardware is not present. This is a reminder to you that new data can not be

acquired and that recorded data can not be processed with a trigger.

Signal Connected to Channel 1? Use Internal or External Signal Generator.

Signal Generator Turn ON? If using the Internal Signal Generator, press

Signal Generator button on the Task Bar in the Main window.

Medallion Acquiring Data? Click the Scope button. You should see a signal

with a 500 Hz Peak in the Plot Display window.

ORDER OF OPERA TION

1. Verify switch settings.

2. Connect signals to the input BNCs on the front of the Medallion.

3. Start the eZ-Record Software.

4. Configure the Medallion. On the Edit Menu select Medallion to open the

Medallion Configuration window. Review and edit the Medallion

configuration using the six tabs in the window.

5. If you need an output signal, click the Signal Generator button at the top of

the Main window.

6a. Recall previously captured data.

6b. Capture or record data. Click the SCOPE or Record button in the Task bar.

If you are setup for triggered acquisition, the analyzer status bar will change

from “Idle” to “A waiting T rigger .” When a trigger is recognized, the analyzer

status will change to “Triggered.” When a frame of data is captured, the

analyzer status will change to “Completed” and increment the Averages

status by one.

If the Averages status does not equal the number of averages requested in

the Analyzer Setup, the status will briefly change from “Idle” to “A waiting

Trigger.” If the Averages status does equal the number of averages

requested, the status will change to IDLE and the HALT button will change

to ACQUIRE. This indicates that one measurement has been captured.

7. Save your data. To save the function files, select Export on the File menu.

10

Page 11

January 2001 eZ-Record Manual

CHAPTER ONE - MENUS

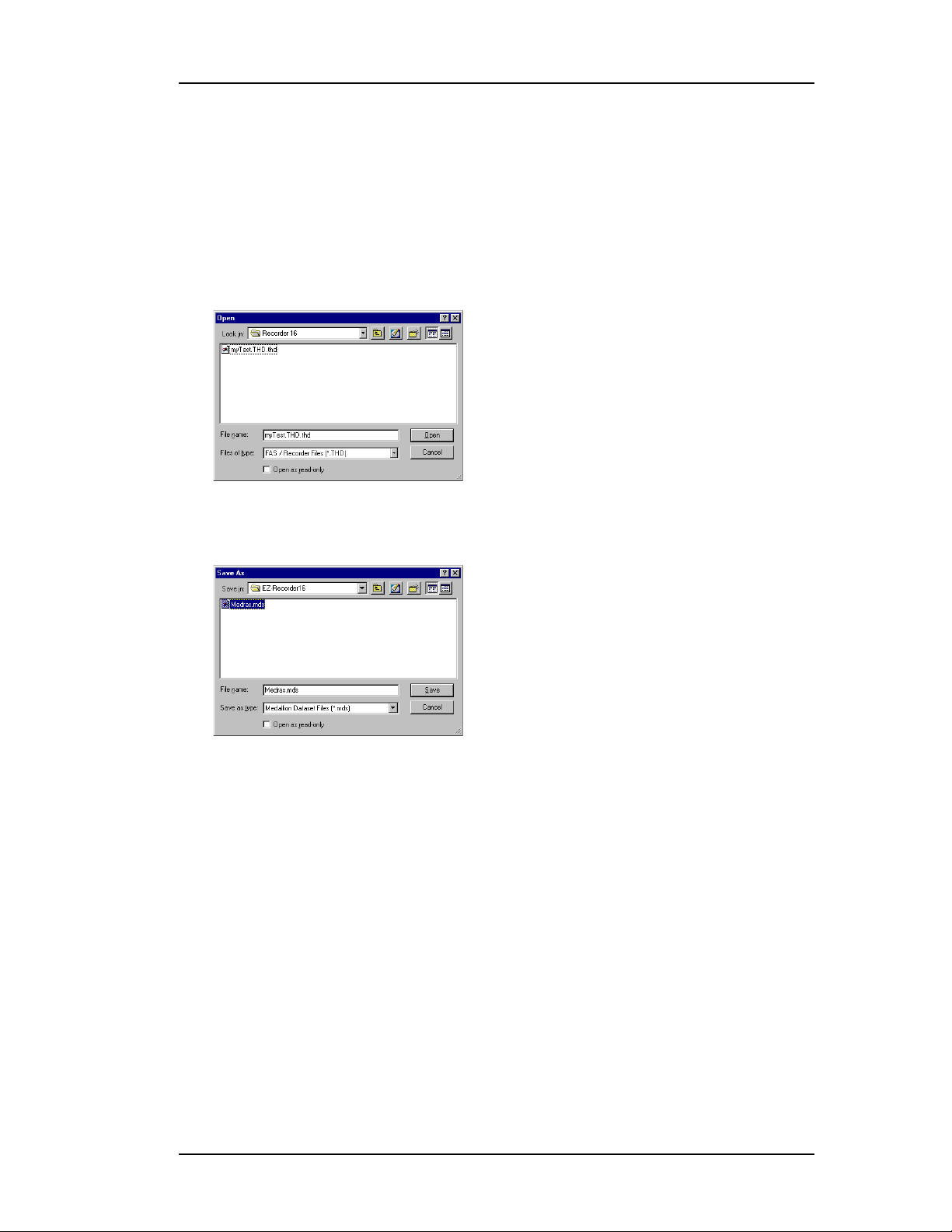

FILE MENU

File Menu selections provide the means for opening, saving, and exporting files;

in addition to printing plotted data. File formats are .thd (time history data) and

.mds (medallion data set).

PEN FILE

O

This menu item opens saved files. Use standard Windows conventions to find the

file of interest. Highlight the file name of interest and click the Open button.

SAVE DATA SET

This menu item saves the current function files and their display setup. The file

extension is .mds. T o export these files see the Export Menu.

The standard print window associated with your specific computer will open.

Select a printer and the number of copies needed before clicking OK.

Note: For printing purposes, if the background of the plot is black, it will be

changed to white.

EXIT

This menu item closes the eZ-Record application.

11

Page 12

eZ-Record Manual January 2001

EDIT MENU

Edit Menu selections provide the means make changes to the software

configuration.

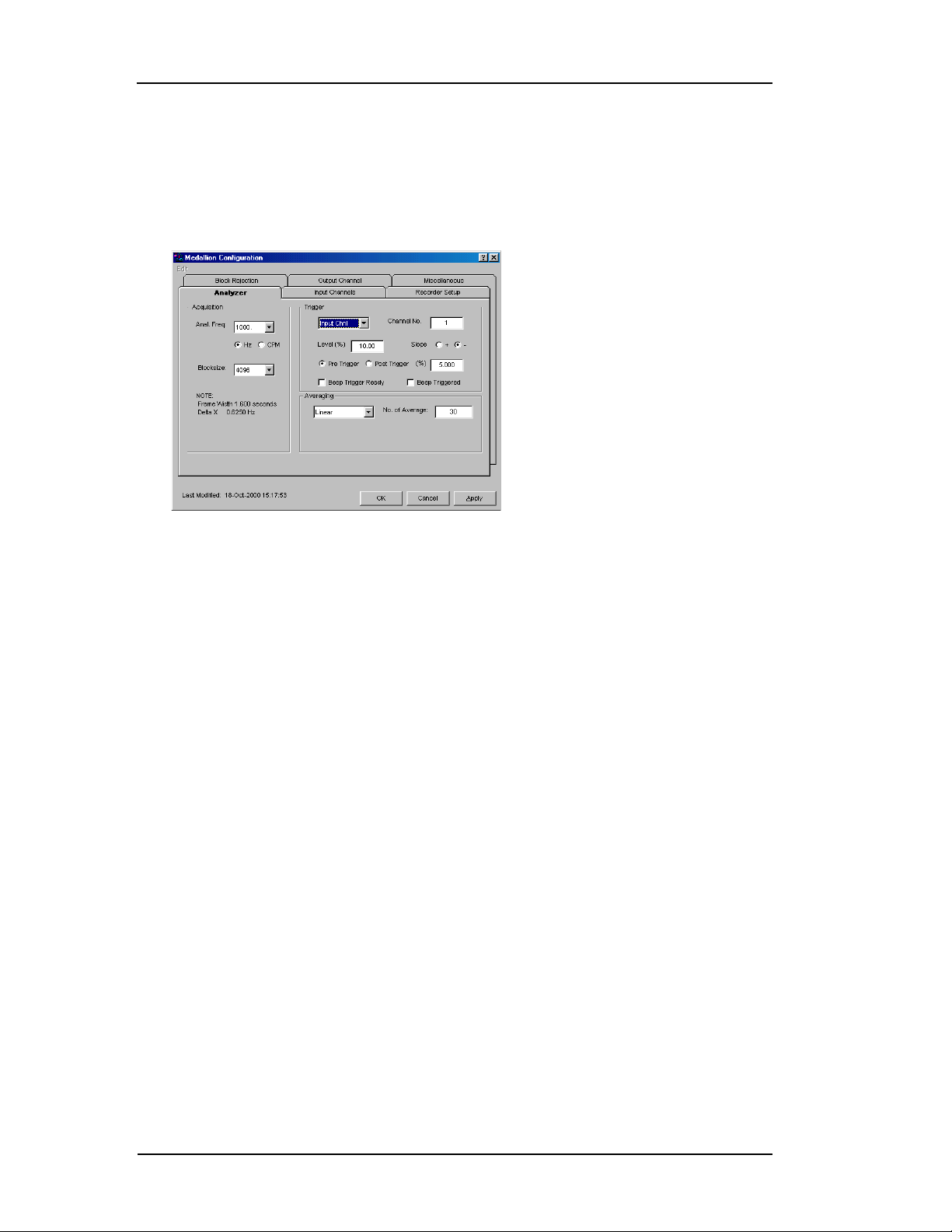

EDALLION

M

In the Main Menu select Edit and then select Medallion. The Medallion

Configuration window will open. This window has six (6) panels.

Analyzer Tab - Acquisition Panel

Analysis Frequency: Selections range from 10 to 20,000 for 8 channel analyzers

and 10 to 10,000 for 16 channel analyzers. The bandwidth measurement unit

for the X-axis is specified in Hertz (Hz) or Cycles Per Minute (CPM). Click to

place a bullet next to your preference.

Blocksize is the number of data points in a frame or block of data. Sizes range

from 128 to 16384. Make your selection in the popup menu.

As frame size increases, the resolution of the data increases, the time required

to acquire a block of data increases and the amount of space required to save

the data increases.

The rest of the information in this section is calculated using your

specifications.

Frame Width = Frame Size / (Bandwidth x 2.56)

Delta X = (Bandwidth x 2.56) / Frame Size

12

Page 13

January 2001 eZ-Record Manual

Analyzer Tab - Trigger Panel

Triggering is the method used by the analyzer to start capturing and

processing data. To capture continuous data, select Free Run. To capture

transient data, select Input Channel and specify the channel where the

analyzer should expect to “see” the signal.

For example, if you are using an impact hammer for modal analysis, the

hammer is attached to the specified input channel. For this type of test, you

may also want to average a set number of acquisitions before saving the data

(See Number of Averages). Y ou may also want the option to automatically or

manually reject measurements caused by double hammers and overloads.

(See Block Rejection.) (Also see: Hints for Trigger Setup and Double

Hammer Rejection.)

Trigger conditions are used by the analyzer to determine the trigger signal’s

attributes required to start data acquisition. Triggered acquisition is typically

used to capture a specific recurring event. Because the analyzer is always

capturing data, and storing it in the memory buffer , you can specify a pretrigger that tells the analyzer how much data you want captured before that

event occurs. This also insures that you get the full event and not just the

data that follows it. On the other hand, you may know that something is

occurring x amount of time after an event. In that case, you may want to set

up a post-trigger. A post-trigger tells the analyzer to look for an event, then

wait a specific amount of time and then start capturing data.

A trigger is specified by the signal level (as a percent of the Full Scale), the

signal’s location on a slope (ascending/positive; or descending/negative).

Other factors that determine what data is captured when a trigger condition

occurs are the amount of time (as a percentage of the frame/block of data)

associated with a pre- or post-trigger .

To understand the concept of Pre and Post Triggering you must remember

that when the green light on the front of the Medallion is glowing, it is

“seeing” data and sending that data to the DSP. If you have not clicked the

acquire button, this data is not processed. However, the DSP has 4 MB of

memory (memory buffer). It therefore has the capability to “remember” this

unprocessed data.

That said, lets look at trigger modes and what they mean.

13

Page 14

eZ-Record Manual January 2001

The pre-trigger mode includes data before the trigger event. When you specify a

pre-trigger, data in the memory buffer that precedes the trigger event is included

in the frame of captured data. The amount of data included is based on a percent

of the frame size.

A post trigger skips data immediately after the trigger event before it starts

capturing data. The amount of skipped data is based on a percent of the frame

size. This is specified in the Delay text field.

Free Run: Data acquisition and processing begin as soon as the Acquire

button is clicked.

Input Channel: Data acquisition and processing begin after the signal on the

specified channel reaches the defined trigger conditions.

Channel: This is the channel number where the analyzer will “look for” the

trigger signal.

Pre/Post Trigger: This is the amount of data, as a percent of the frame size,

that is captured before a trigger event (pre-trigger mode) or that is skipped

after a trigger event (post-trigger).

Neg/Pos: This is the (negative/decreasing or positive/increasing) slope of the

signal that defines a trigger condition. The signal must be on the defined

slope before it is considered a candidate for a trigger.

Trigger Level: This is as a percent of the Full Scale Voltage of the trigger

channel. The signal must pass through this level before it is considered a

candidate for a trigger. The slope of the signal must also meet defined trigger

slope condition before it is recognized as a trigger or trigger event.

Analyzer Tab - Averaging Panel

This is the type of averaging that will be calculated during data acquisition.

Averaging is one technique used to decrease the noise in a measurement.

Linear: All blocks of data are treated equally in terms of their effect on the

averaged result.

Exponential: Similar to linear averaging, Exponential requires a weighting factor

that either increases or decreases the effect of each new data block on the

resultant average.

Average Weight Factor: The Weighting Factor either increases or decreases

the effect of each new data block on the resultant average when

Exponential Averaging is used.

New Average = ((New Data) * A.W.F.) + (Old Average * (1-A.W.F))

Peak Hold: The resultant block of data is a collection of points that represent

the peak amplitude for each point in the block. With each new block of data,

the current data is compared with the new data on a point by point basis.

The highest amplitude for each point in the block is retained.

14

Page 15

January 2001 eZ-Record Manual

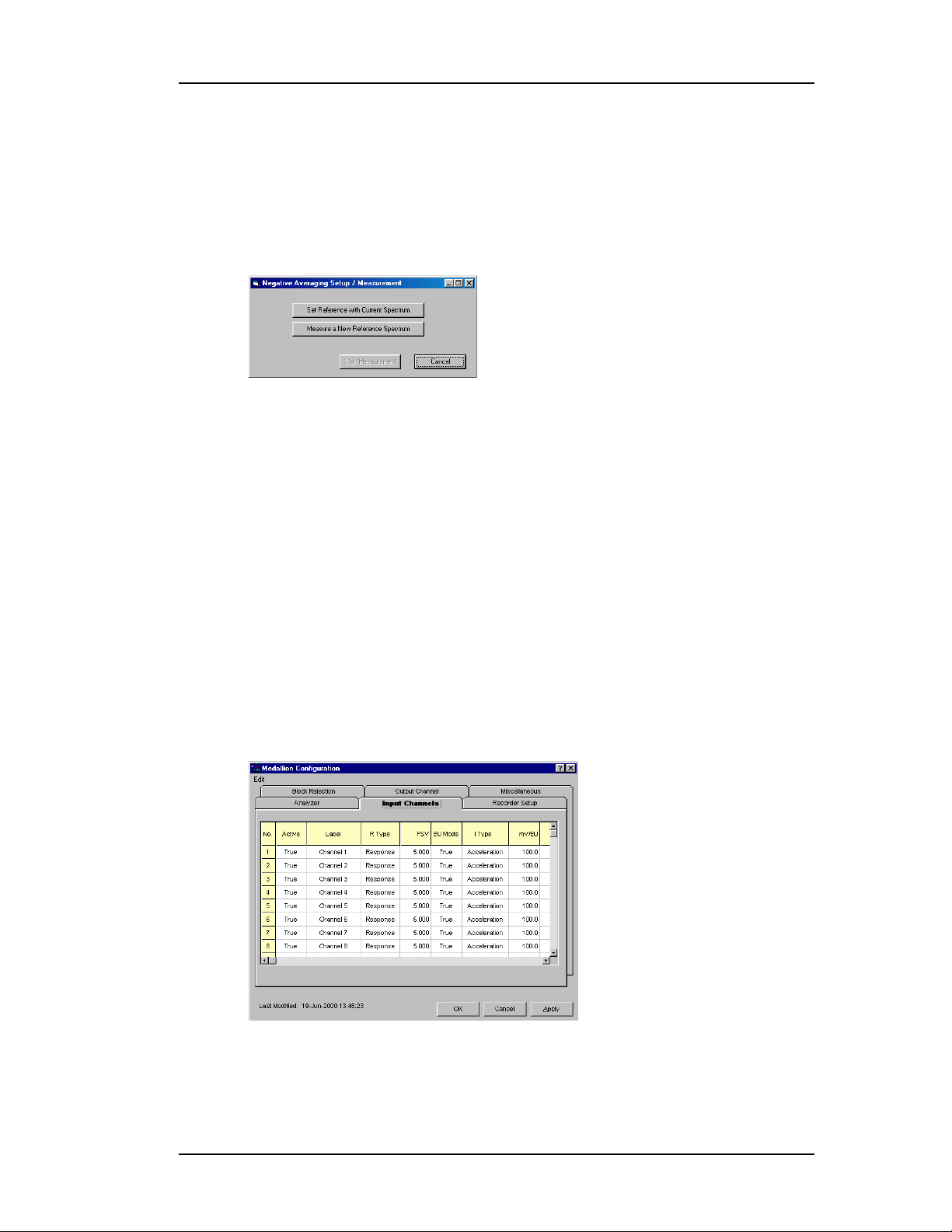

Linear (-): Also known as Negative Averaging; Linear (-) Averaging is a

technique used to identify the natural frequencies of in-service machines that

cannot be shut down for analysis. Linear (-) Averaging is a two step process.

First, a reference average is acquired. Second, a normal linear average is

acquired for each frame. The running average is subtracted from the

reference average and the result is displayed. The first time you attempt to

start data acquisition after you select Linear (-) averaging, the Negative

Averaging Setup/ Measurement window opens.

Time Sync: Time synchronous averaging uses a keyway, or a similar point of

reference, as a trigger. The blocksize is set to allow enough time for at least

one full revolution. This must be performed in Scope Mode.

Number of Averages: This specifies the condition for terminating a data

acquisition sample. After the number of averages (blocks/frames of data)

have been captured and averaged, the analyzer will automatically stop taking

new data. This sample can then be saved. If the number of averages is set to

zero, acquisition is continuous and must be halted by you.

Input Channels Tab

The Input Channel panel displays the current setup conditions of the input

channels on a channel-by-channel basis. Displays change as soon as they are

applied or okayed. Click on the Input Channels tab.

Note: When using the grid in this window, select a cell by clicking in it. You

many also highlight a range of cells by clicking on a second cell while

holding down the Shift key. A cell is selected (highlighted) when there is

a blue border around it.

No.: This column lists all the analyzer’s channels.

Active: When you start the analyzer, all input channels are active. For

channels you are not using, change the active status to FALSE. (Note: This

is optional.)

15

Page 16

eZ-Record Manual January 2001

To change the Active Status of a Channel, click in the cell for the channel of

interest and select True or False on the popup menu.

Label: This should be a meaningful name that you assign to the signal received

on a channel. The channel number is automatically assigned. Highlight a cell

before typing a label. When you press the Enter key, the value is accepted.

R T ype: There are two types of Channels: Response or Reference. All

channels are initialized as response channels. If you are using a force

channel highlight that channels R Type cell, select reference on the

popup menu and press Enter.

FSV: F(ull) S(cale) V(oltage): The value in this field sets the Full Scale value in

Volts. The acceptable range of values is 0.0019 V to 25 V.

EU Mode: E(ngineering) U(nits): Select True or False.

I Type: This is the type of instrument attached to the channel. Menu selections

include: Acceleration, Velocity, Displacement, Force, Pressure, Stress, Strain,

and General.

mV/EU: This is the scaling factor of millivolts to your Engineering Units.

dB EU Ref: dB EU Reference is applied to displayed data when the Y-axis scale

is set to dB. This is valid only for frequency domain data.

The formula for dB display for Unaveraged Spectrum, Averaged Spectrum,

and FRF is:

dB = 20 log (x/dBEUref)

The formula for dB display for Autospectrum, Cross Spectrum, and PSD is:

dB =10log[x/((dBEUref)^2)]

See also dB Reference (Volt) in the Miscellaneous T ab.

Units: Enter the measurement units you will be using.

Location: This is a simple numbering system. The channel number is the

default value for location. However, you can highlight a cell and type a

different location number. When you press the Enter key, the value is

accepted.

Coord: This is the axial direction of the transducer connected to the channel.

Make your selection on the popup menu. Note: The coordinate system is

selected in the Miscellaneous panel.

16

Page 17

January 2001 eZ-Record Manual

Recorder Setup Tab

Active Channels: This is the number of contiguous channels (starting with

channel 1) being used.

Recording Duration/Trigger: The amount of time (in seconds) or data blocks

(number) to be included in the recorded file.

Trigger Delay: This value is used with Pre Trigger and Post Trigger. With Pre

Trigger, Trigger Delay is the amount of time or the percentage of the data

block prior to the Trigger when data acquisition is captured. With Post

Trigger, Trigger Delay is the amount of time or the percentage of the data

block that is skipped from the time of the trigger to the start of data

acquisition. With Post Trigger

Comments: Your comments about this file. For example, they may include the

environmental condition at the time of the recording, the phase of a project,

or a problem that you are investigating.

Block Rejection Tab

This panel is only active when Measure on the Task menu is selected.

Because each strike of an impact hammer may not have the desired results, Block

Rejection allows you to reject a block of data that is the result of a double strike,

an over or under load, or simply because it “doesn’t look right.” Auto block

rejection looks at the acceptable parameters for a block and automatically rejects

blocks that do not meet those parameters. Manual rejection allows you to look at

each block of data and allows you to determine if it should be rejected.

17

Page 18

eZ-Record Manual January 2001

Block Rejection Tab - Reject Panel

There are three block rejection modes: Double Hammer protects measurements

against double hammering: Overload protects the measurement by automatically

rejecting overloaded data, and Manual allows you to inspect a measurement and

optionally reject it for any reason. You can select any or all of the rejection

modes. (See also: Hints for T rigger Setup and Double Hammer Rejection)

Double Hammer: A double hammer occurs when a signal goes outside of the

acceptable range that is set up in the Hammer Rejection section. Click in the

Double Hammer box to turn the Double Hammer option ON and OFF. When

the box is checked, the option is ON.

Overload: An overload is any input signal that reaches or exceeds the specified

input Full Scale Voltage range. Click in the Overload box to turn the Overload

Rejection option ON and OFF. When the box is checked, the option is ON.

Manual: This option allows you to review each block of data before acquiring

the next block. When manual rejection is selected, a “Reject?” button is

activated in the main window. At the end of each average, if you want to

reject that measurement, click on the “Reject?” button. The analyzer will then

reject the current frame of data. The data and average counter will go back to

the previous measurement. Click in the Manual box to turn the Manual

option ON and OFF. When the box is checked, the option is ON.

Block Rejection Tab - Hammer Rejection Panel

In this panel you define the acceptable range for a hammer signal. Any signal

outside of this range is detected as a double hammer . The acceptable range looks

like the intersection of two roads. The signal must occur at the intersection.

X-axis Limits (% of blocksize): The x-axis Limits set the intersection at which

the impact must occur on the “road.”

Y-axis Limits (% of F(ull) S(cale): The y-axis Limits set the “road or lane

width” that extents across the x-axis.

Hints for Trigger Setup and Double Hammer Rejection

There are three major interrelated components to consider when setting up the

analyzer for double-hammer rejection.

1. Trigger Mode and Delay

2. Force Window

3. Double Hammer Region.

A trigger is used to ensure time synchronous measurements across all the active

channels. Pre-trigger states that the amount of data (specified by the delay) is

captured before a trigger event and prefixed to the data following the trigger

event. Post-trigger states that the amount of data (specified by the delay) is

discarded after the trigger event before capturing a block of data.

Double hammer reject is only meaningful with the pre-trigger specified. Double

hammer rejection protects the measurement from a bad hammering.

It is desirable to set the pre-trigger to fall within the hammer region, since it is a

common practice to set the trigger channel to an impact channel.

18

Page 19

January 2001 eZ-Record Manual

Example

Set a Pre - Trigger with a 10% Delay.

Set a Rectangular Force Window with a Start Edge of 9% and an End Edge of

15%.

So far we have said we want to start looking for a trigger event in the data

somewhere after 10% of the block and before 15% of the block. When impact

testing we also want to make sure that a double hammer does not occur . Through

trial and error we may start by setting the Double Hammer range at 12% and 14%,

or 11% and 13% of the block. Typically this range is fine tuned using sample

acquisitions prior to starting a real test.

Output Channel Tab

The Internal Signal Generator is set up in the Output Channel panel. Select an

output waveform (Sine, Random, or Sine+Random) on the popup menu.

Sine Amplitude: The maximum amplitude range is 1.4 volts zero-to-peak. Type

a value, in Volts, and press the “Enter” key.

Sine Frequency: This is the frequency, in Hz, for a Sine waveform. Type a

value (2,000 maximum) in Hz and press the “Enter” key.

Random Amplitude: This is the amplitude variance for the Random output

signal. The maximum value is 1.4 volts zero-to-peak. Type a value, in Volts,

and press the “Enter” key.

19

Page 20

eZ-Record Manual January 2001

Miscellaneous Tab - FFT Window (Response) Panel

The FFT (Response) window is a time-domain weighting window . A response

window is usually applied to data to reduce FFT leakage errors. FFT theory

assumes that the signal being analyzed is periodic in the data acquisition block.

When this is not the case, energy from a signal at a specified frequency can leak

into nearby spectral bins causing spectral amplitude inaccuracies. Applying a

windowing function controls, but doesn’t completely eliminate, the error by

multiplying each data frame by a suitable time-domain weighting window . This

calculation reduces the amplitude/magnitude of the data near the ends of each

data frame prior to performing the FFT and forces the data to be nearly periodic in

the window , thus reducing leakage errors. Response window options are:

None: No weighting window is applied.

Hanning: The Hanning window is typically used to analyze continuous

signals. It offers a reasonable trade-off of frequency accuracy versus

amplitude accuracy .

FlatTop: Compared to the very similar 4-term “Max Flat Top,” this window also

has a very low peak amplitude error, and its frequency resolution is

somewhat better . Its side lobes are considerably higher. Its effective noise

bandwidth is still almost twice that of the Hanning window , therefore this

window is used mainly to measure accurate peak amplitudes of discrete

spectral components that are known to be separated by at least several

spectral lines.

Blackman-Harris: This window function was designed to provide the

minimum side lobe level of any three-term window . Compared with the very

similar Hanning window , it has a slightly wider main lobe but much better

dynamic range. This window has the smallest 60 dB bandwidth of any

window listed. The Blackman-Harris window may be preferred over the

Hanning for measurements requiring better dynamic range.

Exponential: An exponential weighting window is equal to 1.0 at the beginning

of the block and decays exponentially to a smaller value at the end of the

block. Exponential is used only with transient data that is captured with

pre-trigger to assure that the initial values in all data channels are very

20

Page 21

January 2001 eZ-Record Manual

close to zero. Exponential can be used with all transient excitation methods

in order to force the signals to decay close to zero, (See Response Decay

Percent,) even if the block length is not sufficient to capture all of the

naturally occurring response. If the data decays naturally to a low

amplitude within the block, so that leakage is not significant, exponential

windowing can improve the signal-to-noise ratio by giving reduced weight

to the very low-amplitude data at the end of the block.

Response Decay Percent: The Response Decay Percent is used when an

Exponential Window is applied to the Response Channel. It is the rate of

decay from the first to the last block value.

Miscellaneous Tab - FFT Window (Reference) Panel

The FFT Reference Window is applied to the output (force) of a transducer to

avoid collecting extraneous signals caused by an excitation device, such as an

impulse hammer .

When Rectangular is selected, specify the Start and End of the rectangle as a

percentage of the Frame Period.

When Cosine Taper is selected, specify the Start, End, and Taper of the Cosine

Taper as a percentage of the Frame Period.

Start: This is the percent of the Frame Period at which the Rectangular and

Cosine Taper Windowing functions start.

Stop: This is the percent of the Frame Period at which the Rectangular and

Cosine Tape Windowing functions stop.

Edge: This is the percent of the Frame Period during which the Cosine Taper

Windowing function tapers up and down.

Miscellaneous Tab - Octave Panel

Weighting: No weighting, A B or C Weighting

Filter: Analog or Digital

Miscellaneous Tab -

Differentiation/Integration: g’s-ips-mils, g’s-ips-in, g’s-fps-ft, ips^2-ips-in,

ips^2-ips-ft, fps^2-fps-ft, g’s-mmps-micr, g’s-mmps-mm, g’s-cmps-cm,

mmps^2-mmps-mm, cmps^2-cmps-cm, mps^2-mps-m

Miscellaneous Tab - Low Frequency Cutoff Panel

Low frequency cutoff is used to remove the low frequency effects of integration.

All data point below the value specified are set to zero.

Single: Enter a value for the cutoff amount for single integration.

Double (Hz): Enter a value for the cutoff amount for double integration .

Integration Panel

21

Page 22

eZ-Record Manual January 2001

Miscellaneous Tab - Modal Coordinate System Panel

There are three coordinate systems - Rectangular, Spherical, and Cylindrical.

Make your selection on the menu.

Auto Bank Switch: If the Auto Bank Switch checkbox is checked, the bank is

automatically incremented or decremented each time the Export button is

pressed at the end of an acquisition.

A Bank is a set of response channels. You can have the analyzer increment

your banks automatically after each measurement, or you can manually

increment the banks. The number of active channels is used as the skip

factor for bank switching

Skip Ref Channels: If the checkbox is checked, then the number of locations

skipped is the same as the number of Response Channels. Click to place an

X in the check box.

Skip Res Channels: If the checkbox is checked, the only channel skipped is

the Reference Channel. The Response channels DO NOT SKIP.

dB Reference (Volt): dB EU Reference (Volt) is applied to displayed data (all

channels) when the Y-axis scale is set to dB. This is valid only for frequency

domain data.

See also: dB EU Ref in the Input Channels Tab.

PLAYBACK SETUP

After you open a recorded file to be played back, you have the option to change

the blocksize and frequency range, for viewing purposes only.

Frequency Range selections are from 31.25 to 1000 Hz.

Blocksize selections are 4096, 8192, and 16,384.

22

Page 23

January 2001 eZ-Record Manual

WINDOW COLORS

Plot window defaults:

Frame Border = Grey

Plot Background = Black

Grid Lines = Grey

Cursor = White

There are four cursors.

1: Single cursor

2: Second cursor of band cursors

3: Peak Search cursor

4: Data List

1. To change a display characteristic’s color, click on the appropriate button,

to open the Color Palette.

2 . Click on a color square, and click OK.

3. Repeat for each color you want to change.

4 . When finished, click OK in the Plot W indow Colors window .

23

Page 24

eZ-Record Manual January 2001

PREFERENCES

The Preferences window provides a means for you to set some defaults for your

acquisitions.

T race Colors - Click on a channel’ s color chip to open a color palette. Pick a

new color and click ok.

Labels Colors - These are the on-plot text labels you can add to notate your

data plots. Click on a color chip to open a color palette. Pick a new color

and click ok.

Monitor Window - Sets how the monitor window displays information.

Cursor Movement Control - Sets the cursor’s action. Pick means any mouse

click on the plot will move the cursor to the location of the click. Drag

means you must click on and then drag the cursor to a new location.

Peak Search - Sets the minimum data searched. You can set this value

somewhere above the extraneous noise level. Peak averages are evaluated

by first finding a peak and then averaging the specified number of spectral

lines on either side of the peak. The default is 3.

Band Bin: This number specifies the number of data bins used for peak

searching. For example, “3” means that the left three and the right three

adjacent data are compared for around a peak.

Sort By - Specifies the order of the data in the peak search table.

Octave band type: When this box is checked solid color bars are used in Octave

plots. When this box is unchecked, the bars are “hollow,” only the outline

of each bar is displayed.

24

Page 25

January 2001 eZ-Record Manual

TASK BAR

Playback Controls

The Playback option appears on your main screen as a series of icons that

resemble and work like a VCR. The left arrows “backward playing” and the

right arrows “play .” The arrows with vertical lines “backward playing” and

“play” one frame at a time. The square stops play . Select Playback/Review

on the Task Menu to activate the Playback Controls

Record Button

This button is used to start recording. Select Measurement on the Task

Menu to activate the Record Button.

Scope Button

This button is used to start data acquisition. If averaging is being performed,

it changes to ACQUIRE after all measurements and averaging is complete.

Select Measurement on the Task Menu to activate the Scope button.

Signal Generator On/Off Button

T oggles the Signal Generator between on and off. The Signal Generator

button is only active when hardware is present.

Cursor Lock

The Cursor Padlock button toggles the cursor between a lock position and

free movement. If the Padlock is closed, cursors are synchronized in multiple

windows when they are of the same time domain, same frequency domain, or

same octave band data.

Export Button

Click this button to export data. Prior to using this button you must first set

up the condition for Exporting data in the Save Export Function Data window

access via the Export Menu.

Acquisition Status Panel

This icon indicates the acquisition status of the analyzer.

Waiting Trigger: A trigger has not been recognized, since the Acquire button

was clicked.

Triggered: Analyzer is capturing and processing data based on the setup

conditions.

Completed: Analyzer has finished processing the frame of data. The “Averages

Count” increments by 1 at this time.

Analyzer Status Message Area

The analyzer status is displayed in this area. Messages you may see are

Armed, W aiting Trigger , T riggered, Completed, Stopped, Double Hammer

Rejected, Overload Rejected, Exporting Function Data.

25

Page 26

eZ-Record Manual January 2001

Playback Display Bar

The sliding bar indicates the relative location of the displayed data. The

record number and the number of records in the file are listed to the right.

The slider can be used to quickly locate a specific record.

Channels

Each of these boxes represents an analyzer channel.Drag a channel to the

plot area to have its data displayed. That channel’s data is plotted in a

distinct color and a color-coded channel button is displayed to the right of

the plot. Reference channels ar bold and italic. The underlined channel is the

current reference channel. Use the right mouse button to select current

reference channel. Reference channels are specified in the Medallion

Configuration accessed via the Edit Menu.

Averaging Status 5/10

The Averaging Status displays the current number of the averages for the

current record and the total number of averages to be collected.

i.e. 5/10 means that so far 5 averages have been been performed and there are

a total of 10 averages to be performed.

26

Page 27

January 2001 eZ-Record Manual

TASK MENU

MEASUREMENT

Select Measurement to activate the Record and Scope buttons on the Task bar.

PLAYBACK / REVIEW

Select Playback/Review to activate the Playback Controls on the Task bar.

CALIBRATION

Transducer calibration may be performed when a calibration signal of a

known level or RMS content is available. The known signal can be applied to

the transducer connected to an input channel. Two types of calibrators are

commonly used; 1) desktop calibrators for transducers such as

accelerometers, strain gauge, etc. and 2) piston phones for microphone

calibration. Linear engineering units are commonly used for the former type

and dB engineering units for the latter type.

After calibration is finished, the measured voltage(s) for the selected

channel(s) is(are) displayed in the Volts field and used in the calculation of

EU/Volt.

Note: When using one calibrator, you can only calibrate one channel at a time.

No.: This column lists the channels of the Medallion Data Acquisition Module.

Active: True, False. Select True for each channel to be calibrated. Select False

for each channel not to be calibrated. Note: This is independent of

selections in the Input Channel Setup window.

Type: Peak, RMS. Highlight a cell, or range of cells, in the grid before selecting a

Calibration Type on the popup menu.

Peak uses the peak amplitude of the spectrum around the specified

frequency of the calibration signal. The measured peak voltage is entered

into the “Volt” field and further used to determine “EU/Volt”. Please see

the section, “Performing Calibration”, for examples. It searches total seven

spectral lines for the peak; three lines on either side of the specified

calibration frequency.

RMS uses a compensated overall level calculation to determine the RMS

level of the calibration signal, as specified in the Units field. The overall

calculation compensates for the effect of low frequency noise in the

calibration signal by ignoring the first four spectral lines.

27

Page 28

eZ-Record Manual January 2001

Unit: dB, EU.

dB is applied to displayed data when the Y-axis scale is set to dB. This is

valid only for frequency domain data.

The formula for dB display for A veraged Spectrum is:

dB = 20 log (x/dBEUref)

EU/Volt is determined as follows:

EU/Volt = Units / Volts / Trans. Gain, where Units is linear.

Highlight a cell, or cells, in the grid before typing a value in the data entry

box. Then press the Enter key to accept the value. All other fields linked to

this value are updated when the value is accepted.

Amplitude: The amplitude of the calibrator.

Gain: This is an auxiliary scaling factor. It is typically used to compensate for

the signal gain of external signal conditioning such as a charge amplifier with

gain.

mV/EU: Units and Volts: These fields can be either entered by you or

measured by calibration. The separate Units and Volts fields are provided for

easy EU/Volt specification and calibration. Volts is used in conjunction with

the Units to determine the EU/Volt.

Trans. Gain is used as auxiliary scaling to compensate for the transducer gain.

Date: The date and time of the last calibration is recorded in this column. If

any channel value changes (even if the original number is restored), the

calibration date and time are removed for that channel.

Calibration Signal Frequency: Enter the frequency of the calibrator. The

frequency range is set to 2.56 times the frequency of the calibrator.

When you press the Calibration button, the Signal Range is calculated and

displayed to the left of the Calibration Status bar.

Start button: Clicking this button will perform calibration for all the selected

channels. The measured voltage will be displayed in the “Volts” field that is

used for the determination of “EU/Volt”.

28

Page 29

January 2001 eZ-Record Manual

CALIBRATION PROCEDURE

Example

Accelerometer type - Piezotronics 303A03

Calibrator - Piezotronics 394B05 - 1.02 G (RMS) at 80Hz

Unit of acceleration - in/sec^2

Note:

1.02 G RMS is equivalent to 1.4423 G PEAK (=1.414*1.02) and 1G=386.089 in/

sec^2. Thus 1.02 G RMS is equal to 556.8484 in/sec^2. This is a linear type. Thus

select “Linear” calibration unit.

1. Attach the accelerometer to the calibrator (signal source). Connect the other

end of the accelerometer cable to the channel you want to calibrate (i.e.

channel 1).

2. Set an appropriate bandwidth in the Analyzer Setup window (i.e. 200 Hz).

Select a response window other than exponential and no force window. If you

are not providing a trigger signal choose free run Start Mode.

3. Set the FSV into a proper range (i.e. 32.4 mV) in the Input Setup window and

click the Apply button.

4. Open the Calibration Window.

5. Select True for the channel(s) to be calibrated.

6. Enter the scale (i.e. 556.843) in the Units field.

7. Enter the calibrator frequency. (i.e. 80 Hz).

8. Click the Start Button to begin calibration.

29

Page 30

eZ-Record Manual January 2001

AUTORANGE

Autoranging is a procedure that automatically sets the input full scale voltage

(FSV) range for input channels. FSV is set by measuring a representative sample

of real-time data. It is performed only on active channels.

Autoranging works best if you supply the same type live data you will be

capturing during data acquisition. If you are performing an averaged count, the

count will automatically reset to one. If your capture mode is triggered, you will

have to supply a trigger . If your capture mode is Free Run, the autoranging

process starts automatically.

When the Auto Range window opens, the number at the bottom of each column

is the Current FSV are the same values that were entered in the Vpeak column in

the Channel Setup window . These values are immediately replaced when the

Auto ranging process begins.

For example, if in the Autorange Setup window you specify Maximum FSV as 80,

Minimum FSV as 45, Increasing factor as 1.333 and Decreasing factor as 1.333 the

following will occur.

For the first iteration, if the peak value of the data block is greater than 0.8 times

the FSV set in the Channel Setup window , or less than 0.45 times the FSV, then the

Current FSV fields are changed to 1.333 times the peak found in the acquisition.

For the rest of the iterations, if the instantaneous peak value is greater than 80

percent of the Current FSV, the Current FSV is recalculated to 1.333 times the peak

found in the acquisition. This process will continue for 100 iterations, or you may

click the OK button when you are satisfied with the input range.

If the Capture Mode is Input Channel (Trigger Mode), the Auto Range process

waits for a trigger .

Monitoring the Instantaneous Signal Level

The instantaneous peak value is graphically displayed in the vertical bars.

Yellow= signal range is from 0 to the minimum Full Scale voltage set in the

Autorange Setup window.

Gre en = signal range is from the minimum to the maximum of the Full Scale

voltage set in the Autorange Setup window.

Red = signal range is over the maximum of the Full Scale voltage set in the

Autorange Setup window.

30

Page 31

January 2001 eZ-Record Manual

Setup Autoranging Parameters

1. On the Task Menu select Autorange to open the Auto Range window.

2. Select the Setup Menu to open the Autorange Setup window. Use this

window when you want to change the default values described above.

3. Type values for the Minimum and Maximum FSV; and for the Increasing

and Decreasing Factors.

EXPORT MENU

EXPORT TIME HISTORY DATA

This menu item is for exporting Recorded Files.

1. Select the type of file you want. Binary (THD) Time History or ASCII (TXT).

2. Type the directory path and file name for the recorded file. The correct file

extension will be appended to the file name when the OK button is clicked.

3. Optionally, add comments about the file in the data entry area provided.

4. Specify the channels of interest. Click to place a checkmark in the channel

box for each of the channels you want to export.

5. Specify the First (Starting) and Last (Ending) records (blocks) that you want

saved; and click the OK button.

31

Page 32

eZ-Record Manual January 2001

SETUP EXPORT FUNCTION DATA

This menu item is for exporting function files.

1 . T ype the directory path and file name for the function file. The correct file

extension will be appended to the file name when the OK button is clicked.

2 . Select the type of file you want. Universal ASCII T ype 58 or Universal

Binary T ype 58.

3 . Select Automatic Save after Averaging to have records automatically

appended to the specified file.

4 . Specify either All Ch Pairs or Displayed Ch and Functions.

All Ch Pairs exports all the data for all the channels pairs so that all

functions can be retrieved if desired

Displayed Ch and Functions exports only the data for the displayed

functions.

5 . Click to place a checkmark by the functions to be saved; and click the OK

button.

32

Page 33

January 2001 eZ-Record Manual

WINDOW MENU

ADD FUNCTION VIEW

This menu selection opens an addition plot window.

ADD STRIP CHART

This menu selection opens a strip chart plot window.

DELETE WINDOW

Click on the window of interest to make it the “focus” window . Then select this

menu option to delete the window .

MODAL LOCA TIONS WINDOW

This window displays the current modal locations.

Clicking on the Up or Down buttons increments or decrements the locations

based on the bank setup criteria set in the Medallion Configuration –

Miscellaneous T ab. For example if you have Skip Response channels checked,

each time you click up or down, the only the location of the reference channel will

increment or decrement. However if you have Skip Reference channels checked,

each time you click up or down, the locations will change by the number of

response only channels you have defined. If you have neither of the above

checked, the locations will change by the number of active channels.

33

Page 34

eZ-Record Manual January 2001

CHANNEL MONITOR

Channels can be monitored in Volt or % of FSV mode.

Blue: The maximum time data value during the whole acquisition period.

Green: The current maximum time data value.

The Stop button on the Task bar resets the value of the blue bar.

CASCADE

When you have multiple plot windows open, this menu selection arranges them

on you screen as shown.

TILE VERTICALL Y

When you have multiple plot windows open, this menu selection arranges them

on you screen as shown.

34

Page 35

January 2001 eZ-Record Manual

TILE HORIZONTALLY

When you have multiple plot windows open; this menu selection arranges them

on your screen as shown.

PLOT DISPLAY WINDOW

The plot window is very interactive. Some activities are performed directly on the

plot, and clicking the right button on our mouse accesses many other options.

Change “focus window”

“Focus” window: When multiple plot windows are open one is always the

“focus window. ” In the below example, the top window is the “focus

window. ” It is the window with the dark blue border at the top. In the other

two windows, the top border is gray (dimmed).

To change the “focus window,” click on the top or right side border of the

window of interest.

35

Page 36

eZ-Record Manual January 2001

Change “focus plot”

“Focus” plot: When multiple plot windows are open, a plot other than the one

in the “focus” window can be the “focus plot.” You would typically do this

when you want to change a plot’s characteristics.

To change the “focus plot,” click in the plotted area of the window of

interest.

Change Plot Display Characteristics

To change a plot’s display characteristics; it must be the “focus plot.” Then,

you can either use the mouse or key commands to make changes.

Open Plot Display Characteristics Menu: Press “D” or right click with the

cursor hovering over the plotted data.

Use the down arrow key to highlight a menu option, then press “Enter”.

Note that in some cases you can press the first letter of an option to open its

sub menu. (i.e. “S” will open he Scale Type submenu.)

Add Channel to Plot

Using your mouse, click and drag a channel box (above the plot) to the plot

area.

Remove Channel from Plot

Using your mouse, click and drag a channel box (right of the plot) to the plot

area.

36

Page 37

January 2001 eZ-Record Manual

Display Functions

Open Function Menu: Right click on the plot.

Using Key Commands: Press “D” + “F”. Use the arrow keys to highlight your

selection and press “Enter”. Note that in some cases you can press the first

letter of an option to select it

The data type determines the functions available for display.

Time: A single-channel display function. Displays a time domain waveform of

filtered, sampled data scaled in either Volts or EUs.

Spectrum: A dual-channel display function. Displays averaged linear spectrum

computed as the square root of the averaged autospectrum. This function is

calibrated in peak engineering units (EU).

Auto Spec: A single-channel display function. Displays the square of the

magnitude of the complex (one-side) Fourier spectrum of x(t). Autospectra

are calibrated so that if A is the peak amplitude of a sinusoidal signal x(t),

then the autospectrum has the value A

2

at the sinusoidal frequency.

PSD: A single-channel display function. It is the Fourier Transform of the

Autocorrelation function. This normalization should be used with

continuous random signals.

Coherence: A dual-channel display function. At each frequency, the

coherence is a value between 0.0 and 1.0, which indicates the degree of

consistent linear relationship between two signals during the averaging

process. A value of less than one indicates that phase cancellation occurred

during cross-spectrum averaging, which may be due to uncorrelated noise on

one or both signals or to a nonlinear relationship between signals.

FRF: A dual-channel function for the single-input, single-output (SISO)

frequency response function between two specified input channels. FRF is

the averaged cross-spectrum divided by the averaged autospectrum of the

input (the second named channel).

Cross: A dual-channel display function in the frequency domain. It is equal to

the product of the complex Fourier spectrum of y(t) (the numerator or first

named channel) times the complex conjugate of the Fourier spectrum of x(t)

(the denominator or second named channel). The special case y=x yields the

autospectrum. Averaging of these functions (frequency-domain averaging)

forms the basic foundation on which virtually all other multichannel,

37

Page 38

eZ-Record Manual January 2001

frequency-domain analysis is built. The cross spectrum is calibrated in units

of (peak EUy) (peak EUx).

Octave: Many sounds, including audible noise for a transmission line, are

broad band, having components that are continuously distributed over a

range of frequencies. The spectrum of such a sound can be approximated in

terms of a series of octave band or one-third octave band pressure levels. A

band is designated by its center frequency, f

, which is the geometric mean of

0

the upper and lower frequencies of the band. (See ANSI/ASC S1.6-1984.

Activates the Octave Type menu. Select the desired Octave Type on the

Octave Type menu.

Transfer: Activates the Transfer Type menu option. Select the desired

Transfer Type on the Transfer Type menu.

Unaveraged Spectrum: A display function of the magnitude of instantaneous

unaveraged spectrum.

Averaged Time: A single-channel display function. Displays a time domain

waveform of filtered, averaged, sampled data scaled in either Volts or EUs.

Reference Spectrum minus Current Spectrum: Displays the difference

between the Reference Spectrum and the Current Spectrum when

Linear (-), Negative Averaging, is specified.

Windowed Time: Applies to the FFT Response window specified in the

Miscellaneous Tab of the Medallion Configuration window to time data.

38

Page 39

January 2001 eZ-Record Manual

COMPLEX DISPLAYS

Open Complex T ype Menu: Press “D” + “C” + “Enter”.

Use the down arrow key to highlight your selection and press “Enter”.

Options on the Complex Display menu are only available when a function

with complex data is displayed. The following options are available.

Magnitude: Plots only the magnitude of real or complex data.

Phase: Plots only the phase of complex data.

Real: Plots only the Real numbered data.

Imaginary: Plots only the imaginary numbered data.

Magnitude + Phase: Plots both Magnitude and Phase data.

Real + Imaginary: Plots both Real and Imaginarily data.

Nyquist: A Nyquist plot is another way to display real and imaginary data.

The real numbered data is plotted on the X-axis and the imaginary numbered

data is plotted on the Y-axis with consecutive points joined by line segments.

From basic vibration theory, a Nyquist plot of a mobility function should

trace out a circle (counter-clockwise) as the frequency is increased through

an isolated structural resonance.

TRANSFER TYPE

Open Transfer Type Menu: Press “D” + “T”.

Use the down arrow key to highlight your selection and press “Enter”.

These functions are calculated by dividing the cross spectrum of the channel

pair by the auto spectrum of the reference (force) channel.

· Inertance (acceleration/force)

· Mobility (velocity/force)

· Receptance or Compliance (displacement/force)

These reciprocal functions are derived from the first three by taking the

inverse of the magnitude reflecting the phase about the zero degree line (-1*

phase angle).

· Apparent Mass (force/acceleration)

· Impedance (force/velocity)

· Dynamic Stiffness (force/displacement)

39

Page 40

eZ-Record Manual January 2001

Note: Transfer function displays assume the reference channel is a force

channel. You MUST define the response channels to be the correct type of data

(acceleration, velocity, or displacement) that you are acquiring. Define these in

the data type column of the Calibration window. This allows the data to be

integrated or differentiated correctly to derive the desired transfer function.

OCTAVE TYPE

Many sounds, including audible noise for a transmission line, are broad band,

having components that are continuously distributed over a range of frequencies.

The spectrum of such a sound can be approximated in terms of a series of octave

band or one-third octave band pressure levels. A band is designated by its

center frequency , f

frequencies of the band. (See ANSI/ASC S1.6-1984.)

Open Octave Menu: Press “D” + “O”.

Use the down arrow key to highlight your selection and press “Enter”.

Full: An octave band extends from a lower frequency, f02 to twice the lower

frequency ( 2f0).

Third: A one-third octave band extends from a lower frequency ( f0/ 2) to

3 2 times the lower frequency (62 f0). The Octave (one-third octave)

band sound-pressure level is the integrated sound-pressure level of all

spectral components in the specified octave or one-third octave band.

, which is the geometric mean of the upper and lower

0

INTEGRA TION/DIFFERENTIATION

Open Int/Diff Menu: Press “D” + “I”.

Use the down arrow key to highlight your selection and press “Enter”.

This is for display purpose only and does not modify the data.

Differentiation/Integration is only active when frequency domain data is

displayed. Select single or double integration, single or double differentiation

or none. Make your selection on the popup menu.

Differentiation and Integration are calculated by dividing each element of the

function by (jw)^n, where j is the square root of -1; w is the product of 2 pi

times the frequency of the block element; and n is an integer from +2 to -2.

n = 2 is double integration

n = 1 is single integration

n = 0 has not effect

n = -1 is single differentiation

40

n = -2 is double differentiation.

Page 41

January 2001 eZ-Record Manual

If the signal is acceleration, then single integration (Int1) results in velocity,

and double integration (Int2) results in displacement. If the signal is

displacement, then single differentiation (Diff1) results in velocity, and

double differentiation (Diff2) results in acceleration.

Note:

Engineering Units change if instrument type is Acceleration and double

integration is selected.

SCALE TYPE

Open Scale Type Menu: Press “D” + “S”. Use the down-arrow key to highlight

your selection and press “Enter”.

RMS: (Root Mean Square): The square root of the average of the square of the

value of the function taken throughout one period.

Area (from Zero) under the peak.

Peak: Zero to Peak

Pk-Pk Peak to Peak

Absolute value from Zero

to Positive Peak

Absolute value from

Negative Peak to Positive Peak

41

Page 42

eZ-Record Manual January 2001

COPY

Open Copy Menu: Press “D” + “C” use the down arrow key to highlight Copy

and Press “Enter”. Use the down arrow key to highlight your selection and

press “Enter.”

You can copy the plotted data, the plot window, or the screen and then paste

them into other applications. For example, plotted data can be copied into

Notepad, Word, or Excel for use in reports or in the case of Excel further

calculations.

The plot window and full screen can be copied and then pasted into any

application that accepts graphics, such as MSPaint or Word.

CURSOR

Open Cursor Menu: Press “D” + “C.”

Use the down-arrow key to highlight Cursor and press “Enter”. Then use

the arrow key to highlight your selection and press “Enter .”

When Single Cursor is selected, a cursor appears at the far left of the plot

and cursor controls and cursor information are added below the plot. Click

on the plot where you want the cursor. To fine-tune the cursor location, use

the right and left arrows at the bottom. Use the X and Y information for

additional help. If you have multiple channels in the graph, use the up and

down arrows to move the cursor from plot to plot. Press “C” to toggle the

cursor on and off.

42

Page 43

January 2001 eZ-Record Manual

When Band Cursor is selected, two cursors appear at the far left of the plot

and cursor controls and cursor information are added below the plot. Click

on the plot where you want the first cursor, then click on the plot where you

want the second cursor. Press “C” to toggle the cursor through the following

cycle: on (add a cursor), add a second cursor, off.

LABEL/LIST

Open Label/List Menu: Pres “D” + “L.”

Use the down-arrow key to highlight Cursor and press “Enter”. Then use

the arrow key to highlight your selection and press “Enter.”

Data places up to 10 cursor values on your plot. After you select data, a

temporary cursor is placed on the plot and the x, y data values are shown

for that location. As you move your mouse, the temporary cursor will

move across the plot with data values continuously updated. When you

have the cursor where you want it, click on the mouse to place the label.

Another temporary cursor immediately appears. When you are finished

labeling values, right-click and select Pointer to return to a normal state.

43

Page 44

eZ-Record Manual January 2001

Text places a comments text box on the plot. After you select text, click on the

plot and start typing. You are limited to 26 character places. Click on the

right corner of the text box to move it anywhere on the plot window .

Peak Search (All) places a floating window of peak values on the plot.

Peak Search (Band) places of a floating window of peak values within the

limits of a cursor band.

DISPLAYING CHANNEL PAIRS

A channel pair is a reference channel and a response channel used to display a

dual channel function, such as an FRF.

In the Input channel configuration panel, set at least one channel as a reference

channel. After you click OK and look at the channel buttons in the main window,

you will notice that each reference channel now has a bold number. One of them

also is underlined. That channel will be used as the reference channel for any

dual function displays.

To change to another reference channel, right click on the channel of interest.

It will now be underlined.

Note: All channels are response channels, even those that have been

designated as reference channels.

44

Page 45

January 2001 eZ-Record Manual

CHANGE DISPLAY RANGE

Change the range of the display by clicking on the maximum or minimum

range value and entering a new value.

In the following examples the same area on the plot has been Expanded using

the techniques described.

Expand X-Axis: While holding down the Ctrl key, click and drag the mouse

horizontally on the plot.

Expand Y-Axis: While holding down the Alt key, click and drag the mouse

vertically on the plot.

Expand X & Y Axes: While holding down the Ctrl and Alt keys, click and drag

the mouse diagonally on the plot.

45

Page 46

eZ-Record Manual January 2001

CHANGE PLOT FORMAT/SCALE/GRID

Right-Click on the plot’ s border to open a popup menu. If you want to change the

y-axis click on the left border . If you want to change the x-axis click on the bottom

border.

Note: Changing the plot Format, Scale, or Grid affects the display only, not the

real data.

Format

The Format menu allows you to change the axis format of the plotted data.

Choices are Linear, Log, and dB (valid on for the y-axis).

Scale

The Scale menu allows you to change the plot scale to AutoScale, FixedScale,

or Manual. Autoscale insures that all the captured data is visible on the plot.

Grid

The Grid menu allows you to place and remove grid lines from the graph of

plotted data. You can also turn the grid on and off by pressing the “G” hot key.

46

Page 47

January 2001 eZ-Record Manual

USING BANKS AND FUNCTION FILES

A Bank is defined as a group of signals that are selected for simultaneous

measurement, together with all the associated transducer definitions and channel

assignment information. He concept of “banks” is helpful with a modal test where

the number of transducers on the test article exceeds the number of input

channels on your analyzer.

You can have the analyzer increment your banks automatically after each

measurement, or you can manually increment the banks. The Skip Factor is

typically the number of measurement points in a bank.

Use the Bank Up/Bank Dn button in the Main window to increment or

decrement your banks. Press the HOME key to switch this button between Bank

Up and Bank Down. The Bank control options are set up in the Channel Setup

window. Bank Up increments the Bank by the Skip Factor. Bank Dn decrements

the Bank by the Skip Factor. The number of channels associated with a bank are

based on the Response Channel and the Skip Factor.

HINTS FOR SETTING UP BANKS AND SKIP FACTORS

Visualize a test object with 27 transducer locations in 3 rows of 9. You have 1

reference, and 27 responses. Using all 8 channels you can build channel pairs

with channel 1 as the reference, and 2 through 8 as the responses. Your 7 channel

pair relationships would be 2,1 3,1 4,1 5,1 6,1 7,1 and 8,1

In the Channel Pairs window specify channel 1 as a reference channel; then

click the Build Pairs Button to create the channel pairs listed above.

In the Channel Setup window place an “X” in the Skip Factor Response

Channel check box. This tells the analyzer to count the number of active

response channels and use that number as the skip factor. Also place an “X” in

the Auto Bank Increment check box so that each time we click the Export button,

the bank will automatically increment for us.

Example: The skip factor is 7 in this example.

Bank Reference channel/location Response channel/location

1 1/1 2/2, 3/3, 4/4/, 5/5, 6/6, 7/7, 8/8

2 1/1 2/9, 3/10, 4/11, 5/12, 6/13, 7/14, 8/15

3 1/1 2/16, 3/17, 4/18, 5/19. 6/20, 7/21, 8/22

4 1/1 2/23, 3/24, 4/25, 5/26, 6/27

In the Export Setup window define the path to the directory where you want

files saved. Select only FRF as the function to save. Now each time an

acquisition is perform, an FRF is acquired into memory for each channel pair at the

defined location.

Before starting data acquisition, use the HOME key to toggle the Bank Up/

Bank Dn direction to Bank Up. This tells the analyzer to automatically increment

the bank each time the Export button is clicked.

After each acquisition, click the Export button to create an FRF file for each

channel pair. Each file name identifies the reference location and orientation, and

the response location and orientation, using the function abbreviation [in this

case FRF] as the file extension.

47

Page 48

eZ-Record Manual January 2001

Index

Symbols

3-term Blackman-Harris Windowing 20

A

Acquisition Status Panel 25

Action Buttons 7

Active Channel - Calibration 27

Active Channels 15

Active Channels - Recorder 17

Add Channel to Plot 36

Add Function V iew Window 33

Add Strip Chart Window 33

Amplitude - Calibrator 28

Analysis Frequency 12

Apparent Mass 39

Auto Scale Plot 46

Auto Spectrum Display Function 37

Autorange T ask 30

Averages

Number of 15

A veraging 14

B

Bank Switch 22

Banks 47

Skip Ref Channels 22

Skip Res Channels 22

Blocksize 12

C

Calibration Date 28

Calibration Procedure 29

Calibration Setup 27

Calibration Signal Frequency 28

Calibration T ask 27

Calibrator’s Amplitude 28

Cascade Windows 34

Change focus plot 36

Change Focus window 35

Change Plot Display Characteristics 36

Change Window Colors 23

Channel

Coordinate 16

Location 16

Measurement Units 16

Channel Pairs 44

Channel Trigger 14

Channels

Active 15

dB EU Ref 16, 22

EU Mode 16

Full Scale Voltage 16

Gain 28

Instrument T ype 16

Label 16

mV/EU 16

R T ype 16

Channels Icon 26

Characteristics - Plot Display 36

Coherence Display Function 37

Complex Displays 39

Compliance 39

Configuration 12

Analysis Frequency 12

Blocksize 12

Input Channels 15

Output Channel 19

Trigger 13

Configuraton

Miscellaneous 20

Coordinate - Channel 16

Cosine T aper Windowing 21