Page 1

E-1608-OEM

Document Revision 1

December 2014

© Copyright 2014

User's Guide

Ethernet-based High-speed Multifunction DAQ

Page 2

HM E-1608-OEM.docx

Your new Measurement Computing product comes with a fantastic extra —

Management committed to your satisfaction!

Thank you for choosing a Measurement Computing product—and congratulations! You own the finest, and you can now enjoy

the protection of the most comprehensive warranties and unmatched phone tech support. It’s the embodiment of our mission:

To provide data acquisition hardware and software that will save time and save money.

Simple installations minimize the time between setting up your system and actually making measurements. We offer quick and

simple access to outstanding live FREE technical support to help integrate MCC products into a DAQ system.

Limited Lifetime Warranty: Most MCC products are covered by a limited lifetime warranty against defects in materials or

workmanship for the life of the product, to the original purchaser, unless otherwise noted. Any products found to be defective in

material or workmanship will be repaired, replaced with same or similar device, or refunded at MCC’s discretion. For specific

information, please refer to the terms and conditions of sale.

Harsh Environment Program: Any Measurement Computing product that is damaged due to misuse, or any reason, may be

eligible for replacement with the same or similar device for 50% of the current list price. I/O boards face some harsh

environments, some harsher than the boards are designed to withstand. Contact MCC to determine your product’s eligibility for

this program.

30 Day Money-Back Guarantee: Any Measurement Computing Corporation product may be returned within 30 days of

purchase for a full refund of the price paid for the product being returned. If you are not satisfied, or chose the wrong product by

mistake, you do not have to keep it.

These warranties are in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or

fitness for a particular application. The remedies provided herein are the buyer’s sole and exclusive remedies. Neither

Measurement Computing Corporation, nor its employees shall be liable for any direct or indirect, special, incidental or

consequential damage arising from the use of its products, even if Measurement Computing Corporation has been notified in

advance of the possibility of such damages.

Trademark and Copyright Information

Measurement Computing Corporation, InstaCal, Universal Library, and the Measurement Computing logo are either trademarks

or registered trademarks of Measurement Computing Corporation. Refer to the Copyrights & Trademarks section on

mccdaq.com/legal for more information about Measurement Computing trademarks. Other product and company names

mentioned herein are trademarks or trade names of their respective companies.

© 2014 Measurement Computing Corporation. All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form by any means, electronic, mechanical, by photocopying, recording, or otherwise

without the prior written permission of Measurement Computing Corporation.

Notice

Measurement Computing Corporation does not authorize any Measurement Computing Corporation product for use

in life support systems and/or devices without prior written consent from Measurement Computing Corporation.

Life support devices/systems are devices or systems that, a) are intended for surgical implantation into the body, or

b) support or sustain life and whose failure to perform can be reasonably expected to result in injury. Measurement

Computing Corporation products are not designed with the components required, and are not subject to the testing

required to ensure a level of reliability suitable for the treatment and diagnosis of people.

Page 3

Table of Contents

Preface

About this User's Guide ....................................................................................................................... 5

What you will learn from this user's guide ......................................................................................................... 5

Conventions in this user's guide ......................................................................................................................... 5

Where to find more information ......................................................................................................................... 5

Chapter 1

Introducing the E-1608-OEM ................................................................................................................ 6

Ethernet interface ................................................................................................................................................ 6

Functional block diagram ................................................................................................................................... 7

Chapter 2

Installing the E-1608-OEM .................................................................................................................... 8

Unpacking........................................................................................................................................................... 8

Downloading the software .................................................................................................................................. 8

Connecting the external power adapter .............................................................................................................. 8

Connecting the E-1608-OEM ............................................................................................................................. 8

Configuring network settings ............................................................................................................................. 9

Address mode settings ...................................................................................................................................................... 9

IP address settings ............................................................................................................................................................. 9

Setting up the E-1608-OEM for communication across networks ................................................................... 10

Configuring network alarms ............................................................................................................................. 10

Restoring factory default network settings ....................................................................................................... 10

Calibrating the hardware................................................................................................................................... 10

Updating firmware ................................................................................................................................ ............ 11

Chapter 3

Functional Details ............................................................................................................................... 12

Analog input modes .......................................................................................................................................... 12

Software paced .................................................................................................................................................................12

Hardware paced ...............................................................................................................................................................12

Device components........................................................................................................................................... 12

Ethernet connector ...........................................................................................................................................................13

External power connectors ...............................................................................................................................................13

LEDs ................................................................................................................................................................................13

Factory reset button .........................................................................................................................................................13

Header connectors ............................................................................................................................................................13

Screw terminal connectors ...............................................................................................................................................14

Signal connections ............................................................................................................................................ 14

Analog input ....................................................................................................................................................................14

Analog output ..................................................................................................................................................................15

External clock I/O ............................................................................................................................................................16

Digital I/O ........................................................................................................................................................................16

Trigger input ....................................................................................................................................................................17

Counter input ...................................................................................................................................................................17

Power output ....................................................................................................................................................................17

Ground ................................................................................................................................................................ .............17

Mechanical drawings ................................................................................................................................ ........ 18

Chapter 4

Specifications ...................................................................................................................................... 19

Analog input ..................................................................................................................................................... 19

Accuracy ........................................................................................................................................................... 20

3

Page 4

E-1608-OEM User's Guide

Analog input DC voltage measurement accuracy ............................................................................................................20

Noise performance ...........................................................................................................................................................20

Settling time .....................................................................................................................................................................20

Analog output ................................................................................................................................................... 21

Analog input/output calibration ........................................................................................................................ 22

Digital input/output........................................................................................................................................... 22

External trigger ................................................................................................................................ ................. 23

External clock input/output............................................................................................................................... 23

Counter ............................................................................................................................................................. 24

Memory ............................................................................................................................................................ 24

Power ................................................................................................................................................................ 24

Network ............................................................................................................................................................ 25

Ethernet connection .........................................................................................................................................................25

Network interface ............................................................................................................................................................25

Network factory default settings ......................................................................................................................................25

Network security ..............................................................................................................................................................25

LED displays and the factory reset button ........................................................................................................ 26

Environmental .................................................................................................................................................. 26

Mechanical ....................................................................................................................................................... 26

Header connectors ............................................................................................................................................ 26

Screw terminal connector (not populated) ........................................................................................................ 27

4

Page 5

Preface

About this User's Guide

What you will learn from this user's guide

This user's guide describes the Measurement Computing E-1608-OEM data acquisition device and lists device

specifications.

Conventions in this user's guide

For more information about …

Text presented in a box signifies additional information and helpful hints related to the subject matter you are

reading.

Caution! Shaded caution statements present information to help you avoid injuring yourself and others,

damaging your hardware, or losing your data.

bold text Bold text is used for the names of objects on a screen, such as buttons, text boxes, and check boxes.

italic text Italic text is used for the names of manuals and help topic titles, and to emphasize a word or phrase.

Where to find more information

Additional information about E-1608-OEM hardware is available on our website at www.mccdaq.com. You can

also contact Measurement Computing Corporation by phone, fax, or email with specific questions.

Knowledgebase: kb.mccdaq.com

Tech support form: www.mccdaq.com/support/support_form.aspx

Email: techsupport@mccdaq.com

Phone: 508-946-5100 and follow the instructions for reaching Tech Support

5

Page 6

Chapter 1

Introducing the E-1608-OEM

The E-1608-OEM is compatible with both TCP/IP (IPv4 only) and user datagram protocol (UDP) network

protocols.

The E-1608-OEM provides the following features:

Four differential (DIFF) or eight single-ended (SE) analog input channels (16-bit)

Sample rates up to 250 kS/s aggregate

Two analog output channels (16-bit)

Eight individually configurable digital I/O channels

One counter channel (32-bit) that counts TTL pulses

Header connectors for field wiring connections and power supply

Ethernet interface

The E-1608-OEM has one built-in 10/100 BASE-T auto-negotiation, high-speed communication port.

With the Ethernet interface, you can remotely access and configure your E-1608-OEM from anywhere on the

network. Only one computer can control the E-1608-OEM at one time. The networking protocols are TCP/IP

and UDP.

A unique media access control (MAC) address is assigned to each device at the factory.

You configure the Ethernet connection settings through software. A network name in the format E-1608-

xxxxxx, is assigned to the E-1608-OEM, where xxxxxx represents the lower six characters of the device MAC

address.

6

Page 7

E-1608-OEM User's Guide Introducing the E-1608-OEM

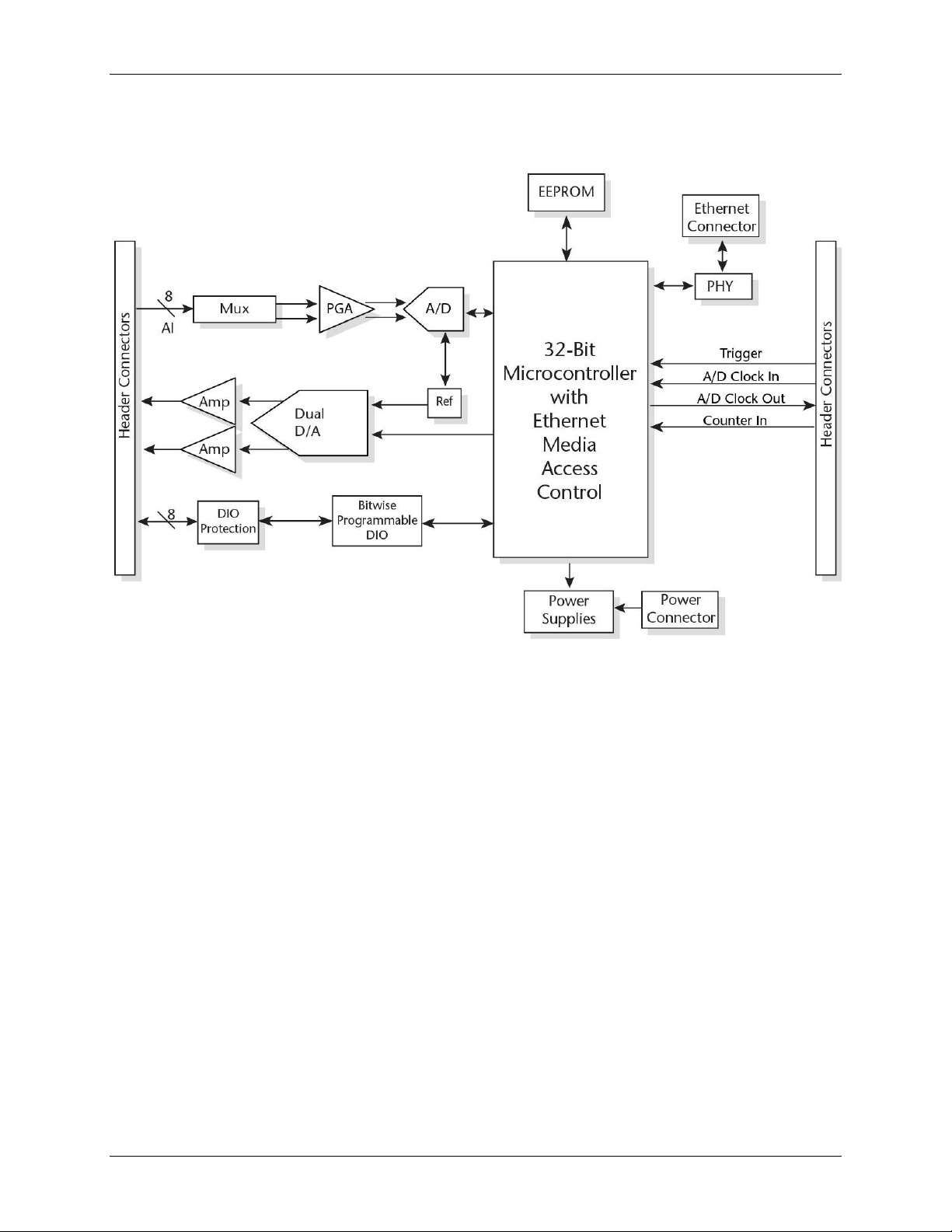

Functional block diagram

E-1608-OEM functions are illustrated in the block diagram shown here.

Figure 1. Functional block diagram

7

Page 8

Chapter 2

Installing the E-1608-OEM

Unpacking

As with any electronic device, you should take care while handling to avoid damage from static

electricity. Before removing the device from its packaging, ground yourself using a wrist strap or by simply

touching the computer chassis or other grounded object to eliminate any stored static charge.

Contact us immediately if any components are missing or damaged.

Downloading the software

Refer to the E-1608-OEM product page on the Measurement Computing website for information about the

supported software you can download.

Install the software before you install the hardware

The driver needed to run the device is installed when you install the software. Therefore, you need to install the

software package you plan to use before you install the hardware.

Connecting the external power adapter

Power to the E-1608-OEM is provided with the 5 V external power adapter (PS-5V1AEPS). Connect the

adapter cord to the power connector on the E-1608-OEM device, and plug the AC adapter into an electrical

outlet.

The Power LED turns on when 5 V power is supplied to the E-1608-OEM. If the voltage supply is less than

3.3 V or more than 5.9 V, the POWER LED does not turn on.

Refer to Figure 2 on page 12 for the location of the Power LED.

Connecting the E-1608-OEM

The E-1608-OEM requires a TCP/IP and UDP connection to a network or computer. Use the standard Ethernet

cable provided to connect the E-1608-OEM to a 10Base-T- or 100Base-TX compatible Ethernet port, hub, or

switch.

When connecting the E-1608-OEM for the first time, make sure that you connect to a local network with DHCP

enabled.

If you are unsure whether you have access to a local network or that DHCP is enabled on that network, you

should use a direct connection to a Windows PC.

It may take a minute or two to detect the device and assign the address. The green Link/activity LED on the

lower left of the Ethernet connector turns on when there is a valid Ethernet link, and blinks when network

activity is detected.

Once the E-1608-OEM is physically connected to the local network or PC, you can run the software (InstaCal

for example) to establish a connection. If a connection cannot be established, make sure the device is using the

default configuration by following the instructions in the Restoring factory default network settings on page 10.

Once a connection is established and you can communicate to the device, you can change the configuration for

other network scenarios.

8

Page 9

E-1608-OEM User's Guide Installing the E-1608-OEM

Configuring network settings

The following E-1608-OEM network settings are software-selectable. Only one user at a time can connect to

the E-1608-OEM to configure network options on the device. For typical local networks, the default settings are

recommended.

Address mode settings

The address mode setting determines whether the default IP parameters (IPv4 address, subnet mask, and

gateway) are assigned to the E-1608-OEM or an auto-addressing method is used to assign these parameters.

DHCP or link-local enabled (default)

If connected to a network with a DHCP server, the service automatically assigns IP addresses to the E-1608OEM.

If the connected network does not have a DHCP server, the address stored in the default IP address is assigned

to the E-1608-OEM.

If the E-1608-OEM is directly connected to a Windows PC, a link-local address is assigned to the device. A

link-local address is valid only for communications between the E-1608-OEM and the PC to which it is

connected

DHCP Only

Enables configuration by a DHCP server if one is available. The E-1608-OEM is assigned an IP address shortly

after it is powered up and attached to the network.

Link Local Only

The E-1608-OEM is assigned a link-local IP address by the Windows PC to which it is connected. A link-local

address is valid only for communications between the E-1608-OEM and the PC to which it is connected.

Static

The default IPv4 Address is manually configured on the E-1608 -OEM.

IP address settings

The default settings of the following IP address are assigned to the E-1608-OEM when automatic addressing is

disabled or not available (DHCP or Link Local for example)

IPv4 address – The IP address that is stored on the device. The default IPv4 address is 192.168.0.101.

Subnet mask – The Subnet mask that is stored on the E-1608-OEM . The subnet mask determines the

number of bits of the IP address that is used for the host portion of the address vs. the number of bits used

for the network portion. The default subnet mask is 255.255.255.000

Gateway – The gateway IP address that is stored on the E-1608-OEM. The gateway address of the device

that bridges subnets within a network. The default gateway is 192.168.0.1

Connection code

The connection code is a number between 0 (default) and 999999999. Change this number from its default of 0

to prevent other users from connecting to and configuring the device. The device remains visible to other users

on the network, but connection by another user is not allowed.

9

Page 10

E-1608-OEM User's Guide Installing the E-1608-OEM

Setting up the E-1608-OEM for communication across networks

In order to communicate with the E-1608-OEM from a computer connected to a different network – such as

over the Internet – you must change the network configuration of the network router.

In the following procedure, the E-1608-OEM is installed on the host LAN, and the computer is installed on the

client LAN.

Caution! This procedure should only be performed by a network administrator or computer professional.

Incorrect settings can significantly disrupt a network.

1. Assuming you have successfully connected to a local network, determine the IP address of the device. If

the address was assigned by DHCP, it is recommended you change it to a static address by setting the

default address to the address assigned and setting the device network configuration to static.

2. Configure the firewall/router to forward incoming traffic to the following ports to the IP address assigned

to the device:

o UDP:54211 (discovery)

o TCP:54211 (commands)

o TCP:54212 (scan data)

3. On the computer connected to the client LAN, manually enter the WAN address of the host router, and

specify the ports that were forwarded to connect to the remote E-1608-OEM.

If the ports listed above are not available on your router, you can use the following guidelines to select different

ports: The first port must be configured for both UDP and TCP. The second port must be adjacent to the first

and configured for TCP. For example, you could use 54221 (TCP and UDP) and 54222 (TCP).

Configuring network alarms

You can use software to configure any digital output bit and/or each analog output channel to generate specific

values to indicate when the device is connected and/or disconnected.

The settings can also be used to initialize an output to a specific value when the device connects or disconnects

from the network.

Restoring factory default network settings

To reset the network configuration settings to the factory default values, complete the following steps (refer to

Device components on page 12 for the location of this button):

1. Remove power from the device.

2. Press and hold the Factory reset button while re-applying power.

3. Hold the button for at least four seconds until both the Power and Activity LEDs blink, indicating that the

settings have been restored to the factory defaults.

4. Release the button so the device continues startup with the default settings. If the button is released before

the two LEDs blink, the settings are not affected and the device starts up normally.

If InstaCal is open when default settings are restored, click the Refresh Boards button on the InstaCal toolbar

to reflect the changes

Calibrating the hardware

The Measurement Computing Manufacturing Test department performs the initial factory calibration. Contact

Measurement Computing for details about how to return your device and have it calibrated to the factory

specifications. The recommended calibration interval is one year.

Field calibration is not supported.

10

Page 11

E-1608-OEM User's Guide Installing the E-1608-OEM

Updating firmware

Your DAQ device contains firmware that can be updated in the field if required. Firmware is available for

download at www.mccdaq.com/firmware.aspx. MCC recommends that you check this page periodically to see

if an update to your device firmware is available.

11

Page 12

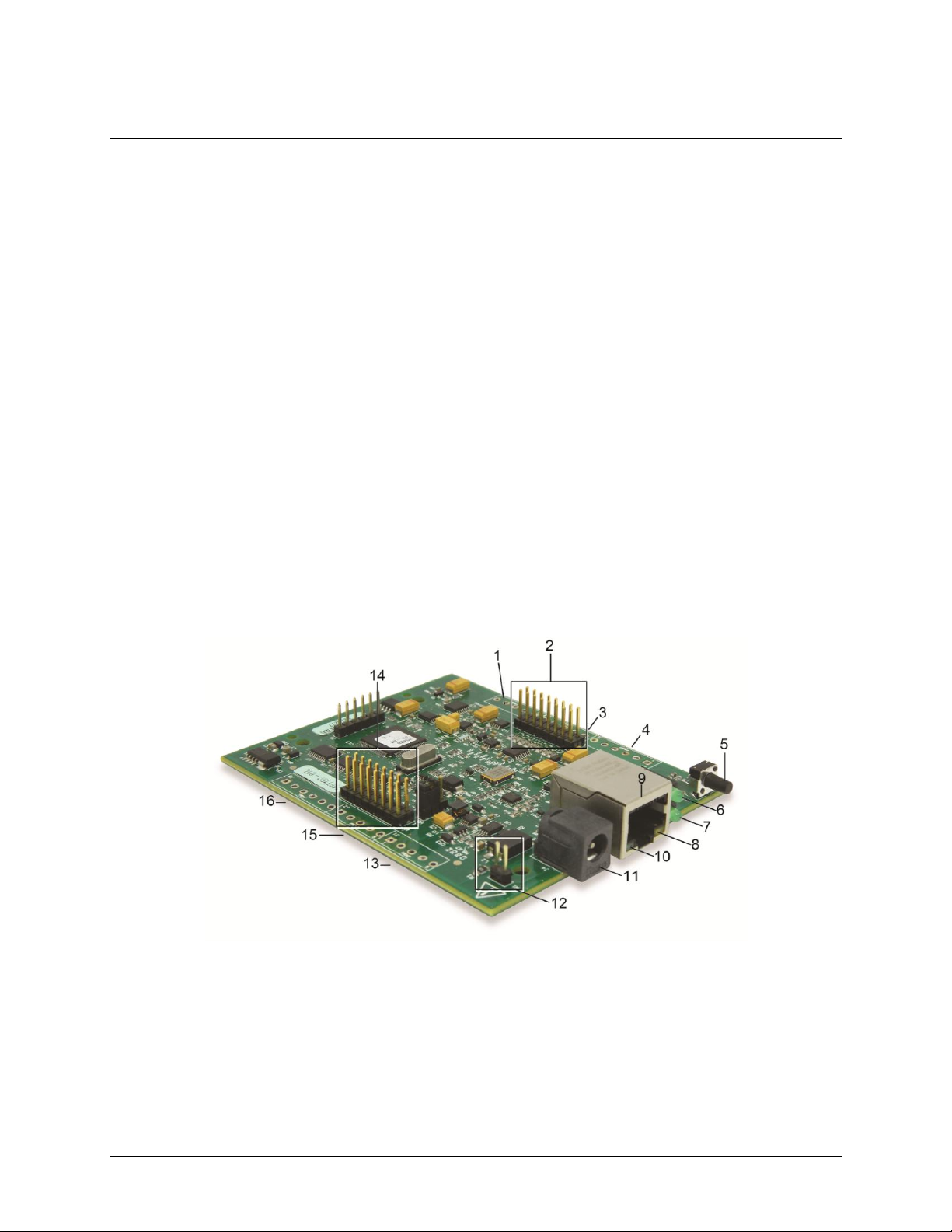

1

Screw terminal J9

9

Ethernet connector

2

Header connector w4

10

Link/activity LED

3

Screw terminal J8

11

External power connector (power adapter sold separately)

4

Screw terminal J7

12

Power header connector W1

5

Factory reset button

13

Screw terminal J1

6

Power LED

14

Header connector W2

7

Activity LED

15

Screw terminal J2

8

Speed LED

16

Screw terminal J3

Chapter 3

Functional Details

Analog input modes

The E-1608-OEM can acquire analog input data in two basic modes – software paced and hardware paced.

Software paced

You can acquire one analog sample at a time in software-paced mode. You initiate the A/D conversion with a

software command. The analog value is converted to digital data and returned to the computer. Repeat this

procedure until you have the total number of samples that you want.

The sample rate in software paced mode is system-dependent and can range from 1000 S/s to 5000 S/s on local

networks (lower over the Internet or wireless networks).

Hardware paced

You can acquire data from up to eight channels in hardware-paced mode. The analog data is continuously

acquired, converted to digital values, and written into the FIFO buffer on the device until you stop the scan. The

FIFO buffer is serviced in blocks as the data is transferred from the FIFO buffer to the computer memory

buffer. You start a continuous scan with either a software command or with an external hardware trigger event.

The maximum sample rate in hardware paced-mode from one to eight channels is 250 kS/s aggregate on local

hardwired networks (may be lower over the Internet or local wireless networks).

Device components

Device components are shown in Figure 2. Note that each screw terminal location is unpopulated.

Figure 2. E-1608-OEM components

12

Page 13

E-1608-OEM User's Guide Functional Details

Ethernet connector

The E-1608-OEM has one 10/100 BASE-T, auto-negotiation, high-speed communication port. The port

connector is an RJ-45, eight-position connector. The Ethernet port accepts CAT-5 shielded or unshielded

twisted pair cable. The maximum communication distance without using a repeater is 100 meters. You can send

your data 100 meters at data speeds of up to 100 Mbps using only one Ethernet cable connected to your

computer.

External power connectors

The E-1608-OEM requires external power, and has a 1 × 2 pin, 0.1 in. pitch header labeled W1 for an external

power connection.

The device also has a DC barrel input jack labeled J4. A compatible 5 V external power adapter (PS-5V1AEPS)

can be purchased separately.

LEDs

The Power LED is steady green when external power between 3.3V to 5.9 V is supplied to the E-1608-OEM.

The Power LED turns off when:

power is not supplied by the external supply (make sure that the supply is fully connected to the power

connector)

the input power is outside of the specified voltage range of the external supply (3.3V to 5.9 V ), causing a

power fault

The E-1608-OEM has an onboard voltage supervisory circuit that monitors the 5 V external power supply.

The Activity LED is on when there is a valid host connection, and blinks when a command is received or an

analog input scan is running.

Ethernet connector LEDS

The green Link/activity LED on the lower left of the Ethernet connector is on when there is a valid Ethernet

link, and blinks when network activity is detected.

The yellow Speed LED on the lower right of the Ethernet connector is on when the transmission speed is

100 Mbps, and off when the transmission speed is 10 Mbps or there is no link.

Factory reset button

Use the factory reset button to reset network configuration settings to the factory default values.

Refer to Restoring factory default network settings on page 10 to learn about resetting these values.

Header connectors

The E-1608-OEM header connectors provide the following connections:

Eight SE or four DIFF (CH0H/CH0L to CH3H/CH3L) analog input connections

Eight digital I/O connections (DIO0 to DIO7)

Two analog output connections (AOUT0, AOUT1)

One external clock input (AICKI) and one external clock output (AICKO) for analog inputs

One digital trigger input (TRIG)

One counter input (CTR)

One power output (+VO)

Six analog ground (AGND) and three digital ground (GND) connections

The E-1608-OEM pinout locations are shown in the Connector W2 and Connector W4 pinout tables on page 14.

13

Page 14

E-1608-OEM User's Guide Functional Details

Pin

Signal name

Pin description

Pin

Signal name

Pin description

1

DIO0

DIO channel 0

2

DIO1

DIO channel 1

3

DIO2

DIO channel 2

4

DIO3

DIO channel 3

5

DIO4

DIO channel 4

6

DIO5

DIO channel 5

7

DIO6

DIO channel 6

8

DIO7

DIO channel 7

9

GND

Digital ground

10

+VO

User voltage output

11

GND

Digital ground

12

AICKO

External clock pacer output

13

AICKI

External clock pacer input

14

CTR

Counter input

15

TRIG

Digital trigger input

16

GND

Digital ground

Pin

Signal name

Pin description

Pin

Signal name

Pin description

1

CH0H

Channel 0 high (SE channel 0)

2

CH0L

Channel 0 low (SE channel 1)

3

AGND

Analog ground

4

CH1H

Channel 1 high (SE channel 2)

5

CH1L

Channel 1 low (SE channel 3)

6

AGND

Analog ground

7

CH2H

Channel 2 high (SE channel 4)

8

CH2L

Channel 2 low (SE channel 5)

9

AGND

Analog ground

10

CH3H

Channel 3 high (SE channel 6)

11

CH3L

Channel 3 low (SE channel 7)

12

AGND

Analog ground

13

AOUT0

Analog output 0

14

AGND

Analog ground

15

AOUT1

Analog output 1

16

AGND

Analog ground

Connector W2

Header connector W2 provides connections for the DIO, external clock I/O, trigger, counter, power output, and

digital ground reference.

W2 pinout

Connector W4

Header connector W4 provides connections for the analog inputs, analog outputs, and the analog ground

reference.

W4 pinout

Screw terminal connectors

Screw terminals J1 through J3 and J7 through J9 are unpopulated. When populated, the screw terminals provide

alternative connections to the header connectors. Refer to the Specifications chapter for screw terminal pinouts.

Signal connections

Analog input

You can configure the analog inputs for SE or DIFF mode. The input voltage range is software selectable for

±10 V, ±5 V, ±2 V, or ±1 V.

With SE mode, connect up to eight inputs to CH0x to CH3x. SE mode requires two wires:

Connect one wire to the signal you want to measure (CH#x).

Connect one wire to the analog ground reference (AGND).

With DIFF mode, connect up to four differential inputs to CH0H/CH0L to CH3H/CH3L. DIFF mode requires

two wires plus a ground reference:

Connect one wire to the high/positive signal (CHxH).

Connect one wire to the low/negative signal (CHxL).

Connect one wire to the analog ground reference (AGND).

Floating voltage source

When connecting DIFF voltage inputs to a floating voltage source, make sure the DIFF input channel has a DC

return path to ground. To create this path, connect a resistor from each low channel input to an AGND pin. A

value of approximately 100 kΩ can be used for most applications.

14

Page 15

E-1608-OEM User's Guide Functional Details

Element

Channel

Range

0

CH5

BIP5V

1

CH1

BIP10V

2

CH3

BIP1V

3

CH5

BIP5V

Leave unused input channels either floating or tied to an AGND connector. Source impedances should be kept

as small as possible to avoid settling time and accuracy errors.

Figure 3 shows DIFF channels 0-3 connected to a ground path resistor.

Figure 3. DIFF connections with ground path resistor

Channel-Gain queue

The channel-gain queue feature allows you to configure a list of channels, modes, and gains for each scan. The

settings are stored in a channel-gain queue list that is written to local memory on the device.

The channel-gain queue list contains one or more channel numbers, modes, and range settings. You can

configure up to 8 elements. The channels can be listed in any order, and can include duplicate channels for

sampling at different ranges.

An example of a 4-element list is shown in the table below.

Sample channel gain queue list (SE mode)

Carefully match the gain to the expected voltage range on the associated channel or an over range condition

may occur. Although this condition does not damage the device, it does produce a useless full-scale reading,

and can introduce a long recovery time due to saturation of the input channel.

For more information about analog signal connections

For more information about analog input connections, refer to the Guide to Signal Connections (this document

is available on our website at www.mccdaq.com/signals/signals.pdf).

Analog output

Two 16-bit analog outputs are available at AOUT0 and AOUT1.

Each analog output channel has an output range of ±10 V. Throughput is system-dependent.

The D/A is software-paced. Each 16-bit analog output (AOUT0 and AOUT1) can be updated simultaneously at

rates from 1000 S/s to 5000 S/s. This is the typical throughput when the device and host are both connected by

15

Page 16

E-1608-OEM User's Guide Functional Details

1

W3 pull-up/pull-down jumper

Ethernet to the same local network. Typical throughput is not guaranteed if a wireless connection is involved or

data is sent over the Internet.

External clock I/O

The E-1608-OEM provides one external clock input (AICKI) and one clock output (AICKO) for analog inputs.

You can connect an external clock signal to AICKI.

When using the internal clock, AICKO outputs the ADC scan clock.

Digital I/O

You can connect up to eight digital I/O lines to DIO0 through DIO7. Each digital channel is individually

configurable for input or output. The digital I/O connectors can detect the state of any TTL-level input and offer

. advanced BiCMOS output.

Refer to the schematic shown in Figure 4.

Figure 4. Schematic showing switch detection by digital channel DIO0

If you set the switch to the +5 V input, DIO0 reads TRUE (1). If you move the switch to GND, DIO0 reads

FALSE (0).

Pull-up/down configuration

Unconnected inputs are pulled high by default to 5 V through 47 kΩ resistors via jumper W3 on the circuit

board (see Figure 5).

Figure 5. W3 jumper location

The pull-up/pull-down voltage is common to all 47 kΩ resistors. Jumper W3 is configured by default for pullup. Figure 6 shows the jumper configured for pull-up and pull-down.

Caution! The discharge of static electricity can damage some electronic components. Before touching the

board, ground yourself using a wrist strap or touch the computer chassis or other grounded object

to eliminate any stored static charge.

16

Page 17

E-1608-OEM User's Guide Functional Details

Figure 6. W3 jumper configurations

For more information about digital signal connections

For general information about digital signal connections and digital I/O techniques, refer to the Guide to Signal

Connections (available on our web site at www.mccdaq.com/signals/signals.pdf).

Trigger input

The TRIG connector is an external digital trigger input. The trigger mode is software selectable for edge or level

sensitive.

Edge sensitive mode is configurable for rising or falling edge.

Level sensitive mode is configurable for high or low level.

The default setting at power up is edge sensitive, rising edge.

Counter input

The CTR connector is a 32-bit event counter that can accept frequency inputs up to 10 MHz. The internal

counter increments when the TTL levels transition from low to high.

Power output

The +VO connector can output up to 10 mA maximum. You can use this connector to supply power to external

devices or circuitry.

Ground

The analog ground (AGND) connectors provide a common ground for all analog channels.

The digital ground (GND) connectors provide a common ground for the digital, counter, timer, and clock

channels and the power connector.

17

Page 18

E-1608-OEM User's Guide Functional Details

Mechanical drawings

Figure 7. E-1608-OEM dimensions

18

Page 19

Parameter

Condition

Specification

A/D converter type

Successive approximation

ADC resolution

16 bits

Number of channels

4 differential, 8 single-ended

Software-selectable

Input voltage range

±10 V, ±5 V, ±2 V, ±1 V; software-selectable per channel

Absolute max input voltage

CHx relative to AGND

±20 V max (power on)

±12 V max (power off)

Input impedance

1 GΩ (power on)

1200 Ω (power off)

Input bias current

±10 nA

Input bandwidth

All input ranges,

small signal (–3 dB)

700 kHz

Input capacitance

60 pf

Max working voltage (signal

+ common mode)

±10 V range

±10.2 V max relative to AGND

±5 V range

±10.2 V max relative to AGND

±2 V range

±9.5 V max relative to AGND

±1 V range

±9.0 V max relative to AGND

Common mode rejection ratio

(fIN = 60 Hz, all input

ranges)

86 dB

Crosstalk

Adjacent differential mode

channels, DC to 10 kHz

–75 dB

Input coupling

DC

Sample rate

0.019 Hz to 250 kHz

Software-selectable

Trigger source

TRIG (see External trigger on page 23)

Sample clock source

Internal A/D clock or external A/D clock (AICKI pin)

Internal sample clock stability

±50 ppm

Internal sample clock

timebase

80 MHz timer with 32-bit period

(available frequencies are 80 MHz / integer period)

Throughput

Software paced

1000 to 5000 S/s typ, on local network (Note 1)

Hardware paced

250 kS/s max

Channel gain queue

Up to 8 elements

Software-selectable channel and range for each queue

element

Warm-up time

15 minutes min

Specifications

All specifications are subject to change without notice.

Typical for 25 °C unless otherwise specified.

Specifications in italic text are guaranteed by design.

Analog input

Table 1. General analog input specifications

Chapter 4

Note 1: This is the typical throughput when the device and host are both connected by Ethernet to the same

local network. The throughput can vary significantly if a wireless connection is involved or data is sent

over the internet and is not guaranteed.

Page 20

Range

Gain error

(% of reading)

Offset error

(µV)

INL error

(% of range)

Absolute

accuracy at

Full Scale

(µV)

Gain

temperature

coefficient

(% reading/°C)

Offset

temperature

coefficient

(µV/°C)

±10 V

0.024

915

0.0076

4075

0.0014

47

±5 V

0.024

686

0.0076

2266

0.0014

24

±2 V

0.024

336

0.0076

968

0.0014

10

±1 V

0.024

245

0.0076

561

0.0014

5

Range

Counts

LSBrms

±10 V

6

0.91

±5 V

6

0.91

±2 V

7

1.06

±1 V

9

1.36

Range

4 µS settling accuracy (% FSR)

6 µS settling accuracy (% FSR)

10 µS settling accuracy (% FSR)

±10 V

0.0061

0.0031

0.0015

±5 V

0.0061

0.0031

0.0015

±2 V

0.0061

0.0031

0.0015

±1 V

0.0061

0.0031

0.0015

Accuracy

Analog input DC voltage measurement accuracy

Table 2. DC Accuracy components and specifications. All values are (±)

Noise performance

For the peak-to-peak noise distribution test, a differential input channel is connected to AGND at the input

terminal block, and 16384 samples are acquired at the maximum rate available at each setting.

Table 3. Noise performance specifications

Settling time

Settling time is defined as the accuracy that can be expected after one conversion when switching from a

channel with a DC input at one extreme of full scale to another channel with a DC input at the other extreme of

full scale. Both input channels are configured for the same input range.

Table 4. Input settling time specifications in µS, typical

20

Page 21

Parameter

Condition

Specification

Number of channels

2 Resolution

16 bits

Output ranges

Calibrated

±10 V

Output transient

Powered on

Duration: 5 ms

Amplitude: 2 V p-p

Powered off

Duration: 400 ms

Amplitude: 10 V p-p

Differential

non-linearity

16-bit monotonic

±0.35 LSB typ

±1 LSB max

Output current

AOUTx pins

±3.5 mA max (Note 2)

Output coupling

DC

Power on and

reset state

DACs cleared to uncalibrated zero-scale: 0 V, ±50 mV unless the alarm

function is enabled for the output (Note 3)

Alarm functionality

Either or both outputs may be configured to go to defined values when

an Ethernet connection with a host is established or lost.

Output update rate

1000 to 5000 S/s typ, on local network (Note 4)

Slew rate

5 V/µs

Throughput

Software paced

1000 to 5000 S/s typ, on local network (Note 4)

Range

Absolute accuracy (±LSB)

±10 V

18.7

Range

% of reading

Offset

(±mV)

Offset tempco

(µV/°C)

Gain tempco

(ppm of range/°C)

±10 V

± 0.024

2.2

30.1

13.2

Range

Relative accuracy (INL)

±10 V

4.0 typ

Analog output

Table 5. Analog output specifications

Note 2: Leave unused AOUTx output channels disconnected.

Note 3: AOUTx defaults to 0 V whenever the device is powered on or a reset command is issued to the device,

unless the alarm functionality is enabled for the output.

Note 4: This is the typical throughput when the device and host are both connected by Ethernet to the same

local network. The throughput can vary significantly, and typical throughput is not guaranteed if a

wireless connection is involved or data is sent over the internet.

Table 6. Calibrated absolute accuracy specifications

Table 7. Calibrated absolute accuracy components specifications

Table 8. Relative accuracy specifications (±LSB)

21

Page 22

Parameter

Specification

Recommended warm-up time

15 minutes min

Calibration method

Factory

Calibration interval

1 year (factory calibration)

Parameter

Specification

Digital type

5 V TTL input / advanced BiCMOS output

Number of I/O

8

Configuration

Independently configured for input or output

Pull-up configuration

All pins pulled up to 5 V using 47 K resistors (default).

Can be changed to pull-down using an internal jumper.

Digital I/O transfer rate

(system-paced)

100 to 5000 port reads/writes or single bit reads/writes per second typ, on local

network (Note 5)

Alarm functionality

Any combination of DIO bits may be configured to become outputs and go to defined

values when an Ethernet connection with a host is established or lost.

Power on and reset state

All bits are input unless the alarm functionality is enabled for them.

Input high voltage threshold

2.0 V min

Input high voltage limit

5.5 V absolute max

Input low voltage threshold

0.8 V max

Input low voltage limit

–0.5 V absolute min

0 V recommended min

Output high voltage

3.8 V typ at no load

3.0 V min (IOH = –3 mA)

2.0 V min (IOH = –32 mA)

Output low voltage

0.15 V typ at no load

0.55 V max (IOL = 64 mA)

Power on and reset state

Input

Analog input/output calibration

Table 9. Analog input/output calibration specifications

Digital input/output

Table 10. Digital input/output specifications

Note 5: This is the typical throughput when the device and host are both connected by Ethernet to the same

local network. The throughput can vary significantly, and typical throughput is not guaranteed if a

wireless connection is involved or data is sent over the internet.

22

Page 23

Parameter

Condition

Specification

Trigger source

External digital

TRIG

Trigger mode

Software-selectable

Edge or level sensitive: user configurable for CMOS

compatible rising or falling edge, high or low level.

Trigger latency

2 µs + 1 pacer clock cycle max

Trigger pulse width

1 µs min

Input type

Schmitt trigger, 47 kΩ pull-down to ground

Schmitt trigger hysteresis

1.01 V typ

0.6 V min

1.5 V max

Input high voltage threshold

2.43 V typ

1.9 V min

3.1 V max

Input high voltage limit

5.5 V absolute max

Input low voltage threshold

1.42 V typ

1.0 V min

2.0 V max

Input low voltage limit

–0.5 V absolute min

0 V recommended min

Parameter

Specification

Terminal names

AICKI, AICKO

Terminal types

AICKI: Input (receives A/D pacer clock from external source)

AICKO: Output (outputs internal A/D pacer clock)

Input clock rate

250 kHz max

Clock pulse width

AICKI: 1 µs min

AICKO: 1.8 µs min

Clock mode

Edge-sensitive, rising

Input type

Schmitt trigger, 47 kΩ pull-down to ground

Schmitt trigger hysteresis

1.01 V typ

0.6 V min

1.5 V max

Input high voltage threshold

2.43 V typ

1.9 V min

3.1 V max

Input high voltage limit

5.5 V absolute max

Input low voltage threshold

1.42 V typ

1.0 V min

2.0 V max

Input low voltage limit

–0.5 V absolute min

0 V recommended min

Output high voltage

4.4 V min (IOH = –50 µA)

3.80 V min (IOH = –8 mA)

Output low voltage

0.1 V max (IOL = 50 µA)

0.44 V max (IOL = 8 mA)

External trigger

Table 11. External trigger specifications

External clock input/output

Table 12. External clock I/O specifications

23

Page 24

Parameter

Specification

Pin name

CTR

Counter type

Event counter

Number of channels

1

Input type

Schmitt trigger, 47 kΩ pull-down to ground

Input source

CTR screw terminal

Resolution

32 bits

Schmitt trigger hysteresis

1.01 V typ

0.6 V min

1.5 V max

Input high voltage threshold

2.43 V typ

1.9 V min

3.1 V max

Input high voltage limit

5.5 V absolute max

Input low voltage threshold

1.42 V typ

1.0 V min

2.0 V max

Input low voltage limit

–0.5 V absolute min

0 V recommended min

Input frequency

10 MHz max

High pulse width

50 ns min

Low pulse width

50 ns min

Parameter

Specification

Data FIFO (analog input)

49,152 samples

Non-volatile memory

2,048 bytes (768 bytes for calibration, 256 bytes for user, 1,024 bytes for network

settings)

Parameter

Condition

Specification

External power supply

5V, 1A

Supply current

Quiescent current

330 mA typical (Note 6)

710 mA max including all external loading

User output voltage range

Available at +VO pin

4.40 V min to 5.25 V max, assumes supplied

AC adapter is used

User output current

Available at +VO pin

10 mA max

Counter

Table 13. Counter specifications

Memory

Table 14. Memory specifications

Power

Table 15. Power specifications

Note 6: This is the total quiescent current requirement for the device that includes the LEDs. This does not

include any potential loading of the digital I/O bits, +VO pin, or the AOUTx outputs.

24

Page 25

Parameter

Specification

Ethernet type

100 Base-TX

10 Base-T

Communication rates

10/100 Mbps, auto-negotiated

Connector

RJ-45, 8 position

Cable length

100 meters max

Additional parameters

HP Auto-MDIX support

Parameter

Specification

Protocols used

TCP/IP (IPv4 only), UDP

Network ports used

UDP:54211 (discovery)

UDP:6234 (bootloader only)

TCP:54211 (commands)

TCP:54212 (scan data)

Network IP configuration

DHCP + link-local, DHCP, static, link-local

Network name

E-1608-xxxxxx, where xxxxxx are the lower 6 digits of the device MAC address

Network name publication

By NBNS (responds to b-node broadcasts, therefore only available on the local

subnet)

Parameter

Specification

Factory default IP address

192.168.0.101

Factory default subnet mask

255.255.255.0

Factory default Gateway

192.168.0.1

Factory default DHCP setting

DHCP + link-local enabled

Parameter

Specification

Security implementation

TCP sockets are not opened unless application sends the correct PIN code (stored in

non-volatile memory, may be changed by user, default value 0000)

Number of concurrent sessions

1

Vulnerabilities

TCP Sequence Number Approximation Vulnerability

Network

Ethernet connection

Network interface

Table 16. Ethernet connection specifications

Table 17. Factory default specifications

Network factory default settings

Table 18. Factory default specifications

Network security

Table 19. Factory default specifications

25

Page 26

Parameter

Specification

Power LED (top)

3.3 V < V

ext

< 5.9 V: On

V

ext

< 3.3 V, V

ext

> 5.9 V: Off (power fault)

Activity LED (bottom)

On when there is a valid host connection and blinks when a command is received or

an AInScan is running.

Ethernet connector LEDS

Left (green): Link/activity indicator; on when there is a valid Ethernet link and

blinks when network activity is detected.

Right (yellow): Speed indicator; on for 100 Mbps, off for 10 Mbps or no link.

Factory reset button

Used to reset the network configuration settings to the factory default values.

Press the button when applying power to the device and continue to hold for

4 seconds; the device LEDs stay off, and then both the Power and Activity LEDs

blink once indicating that the settings have been restored to the defaults.

Release the button so the device continues startup with the default settings. If the

button is released before the two LEDs blink, the settings are not affected and the

device starts up normally.

Parameter

Specification

Operating temperature range

0 °C to 55 °C max

Storage temperature range

–40 °C to 85 °C max

Humidity

0% to 90% non-condensing max

Parameter

Specification

Dimensions (L × W × H)

96.27 × 76.71 × 14.61 mm (3.79 × 3.02 × 0.575 in.) max

Parameter

Specification

I/O connector type

Two 2 × 8 pin 0.1 in. pitch headers labeled W2 and W4

Power connector type

DC barrel input jack labeled J4 (mates with 5.5mm OD / 2.1 mm ID plug) and

1 x 2 pin 0.1 in. pitch header labeled W1

LED displays and the factory reset button

Table 20. LED and button configurations

Environmental

Table 21. Environmental specifications

Mechanical

Header connectors

Table 22. Mechanical specifications

Table 23. Header connector specifications

26

Page 27

Pin

Signal name

Pin description

Pin

Signal name

Pin description

1

DIO0

DIO channel 0

2

DIO1

DIO channel 1

3

DIO2

DIO channel 2

4

DIO3

DIO channel 3

5

DIO4

DIO channel 4

6

DIO5

DIO channel 5

7

DIO6

DIO channel 6

8

DIO7

DIO channel 7

9

GND

Digital ground

10

+VO

User voltage output

11

GND

Digital ground

12

AICKO

External clock pacer output

13

AICKI

External clock pacer input

14

CTR

Counter input

15

TRIG

Digital trigger input

16

GND

Digital ground

Pin

Signal name

Pin description

Pin

Signal name

Pin description

1

CH0H

Channel 0 high (SE channel 0)

2

CH0L

Channel 0 low (SE channel 1)

3

AGND

Analog ground

4

CH1H

Channel 1 high (SE channel 2)

5

CH1L

Channel 1 low (SE channel 3)

6

AGND

Analog ground

7

CH2H

Channel 2 high (SE channel 4)

8

CH2L

Channel 2 low (SE channel 5)

9

AGND

Analog ground

10

CH3H

Channel 3 high (SE channel 6)

11

CH3L

Channel 3 low (SE channel 7)

12

AGND

Analog ground

13

AOUT0

Analog output 0

14

AGND

Analog ground

15

AOUT1

Analog output 1

16

AGND

Analog ground

Parameter

Specification

Connector type

3.51mm screw terminal footprints (not populated), labeled J1, J2, J3, J7, J8, J9

J1

J7

Pin

Signal name

Pin description

Pin

Signal name

Pin description

5

DIO0

DIO bit 0

1

CH0H

Channel 0 high (SE channel 0)

4

DIO1

DIO bit 1

2

CH0L

Channel 0 low (SE channel 1)

3

DIO2

DIO bit 2

3

AGND

Analog ground

2

DIO3

DIO bit 3

4

CH1H

Channel 1 high (SE channel 2)

1

DIO4

DIO bit 4

5

CH1L

Channel 1 low (SE channel 3)

6 AGND

Analog ground

J2

J8

Pin

Signal name

Pin description

Pin

Signal name

Pin description

5

DIO5

DIO bit 5

1

CH2H

Channel 2 high (SE channel 4)

4

DIO6

DIO bit 6

2

CH2L

Channel 2 low (SE channel 5)

3

DIO7

DIO bit 7

3

AGND

Analog ground

2

GND

Digital ground

4

CH3H

Channel 3 high (SE channel 6)

1

+VO

User voltage output

5

CH3L

Channel 3 low (SE channel 7)

J3

J9

Pin

Signal name

Pin description

Pin

Signal name

Pin description

6

GND

Digital ground

1

AGND

Analog ground

5

AICKO

External clock pacer output

2

AOUT0

Analog output 0

4

AICKI

External clock pacer input

3

AGND

Analog ground

3

CTR

Counter input

4

AOUT1

Analog output 1

2

TRIG

Digital trigger input

5

AGND

Analog ground

1

GND

Digital ground

Table 24. W2 pinout

Table 25. W4 pinout

Screw terminal connector (not populated)

Table 26. Screw terminal connector specifications

Table 27. Screw terminal pinout

27

Page 28

28

Page 29

Measurement Computing Corporation

10 Commerce Way

Suite 1008

Norton, Massachusetts 02766

(508) 946-5100

Fax: (508) 946-9500

E-mail: info@mccdaq.com

www.mccdaq.com

Loading...

Loading...