Page 1

the smart approach to instrumentation

™

IOtech, Inc.

25971 Cannon Road Cleveland, OH 44146

Phone: (440) 439-4091 Fax: (440) 439-4093

E-mail: sales@iotech.com Internet: http://www.iotech.com

Digital232 User’s Manual

p/n DIGITAL232-901 Rev 2.0

©1998 by IOtech, Inc.

Printed in the United States of America

Page 2

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights

reserved. No part of this product may be copied, reproduced or transmitted by

any mechanical, photographic, electronic, or other method without IOtech’s prior

written consent. IOtech product names are trademarked; other product names, as

applicable, are trademarks of their respective holders. All suppli ed IOtech

software (including miscellaneous support files, drivers, and sample programs)

may only be used on one installation. You may make archival backup copies.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission rules (Part 15)

for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve Radio-TV Interference Problems

(stock # 004-000-00345-4) which is available from the U.S. Government Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment i n ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed

in an addendum or revision to the manual. As applicable, IOtech calibrates its hardware to

published specifications. Periodic hardware calibration is not covered under the warranty

and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and

review our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech

welcomes your suggestions.

Page 3

Table of Contents

Section1 INTRODUCTION Page

1.1 General Description 1.1

1.2 Available Accessories 1.2

1.3 Specifications 1.3

Section 2 GETTING STARTED Page

2.1 Inspection 2.1

2.2 Configuration 2.2

2.2.1 Serial Baud Rate Selection 2.3

2.2.2 Xon/Xoff Serial Control 2.5

2.2.3 Serial Word Length Selection 2.5

2.2.4 Serial Stop Bit Selection 2.6

2.2.5 Serial Terminator Selection 2.6

2.2.6 Serial Echo Selection 2.7

2.2.7 Serial Parity Selection 2.7

2.3 Digital I/O Ports 2.8

2.3.1 Logic Levels 2.8

2.3.2 Digital I/O Port Pinout 2.8

2.3.3 Control Lines 2.10

2.3.3.1 Clear 2.10

2.3.3.2 Data Strobe 2.10

2.3.3.3 External Data Ready 2.11

2.3.3.4 Inhibit 2.11

2.3.3.5 Trigger 2.12

2.3.3.6 Service Input 2.13

2.4 Installation 2.13

2.5 Errors 2.14

Page 4

Table of Contents

Section 3 COMMAND DESCRIPTIONS Page

@ Reset 3.2

An Bit Set 3.3

Bn Bit Clear 3.4

Cn Configure 3.5

Dn…Z Data 3.6

Fn Format 3.7

Gn Output Select 3.12

Hn Handshake 3.13

In Invert 3.14

Mn Service Request (SRQ) 3.15

Pn Port 3.16

Qn Inhibit 3.17

Rn Data ready 3.18

Tn Test 3.19

Un Status 3.20

X Execute 3.24

Yn Terminator 3.25

Section 4 SERVICE INFORMATION Page

4.1 Factory Service 4.1

4.2 Digital232 Component Layout 4.2

4.3 Digital232 Parts List 4.3

Appendix A Digital232 Command Summary

Appendix B ASCII Character Codes

Appendix C IBM PC Interfacing

A.1

B.1

C.1

Page 5

Section 1 Introduction

Introduction

1.1 General Description

The

Digital232

unit has 40 TTL level digital I/O lines, divided into five 8-bit ports. Each port is

software programmable as input or output.

The

Digital232

trigger output signal can be asserted on a Trigger command. Edge-triggered inputs

can generate a Service Request to the RS-232 host. Five data formats are software

programmable, including hexadecimal, ASCII, binary, high speed binary and decimal.

There are also individual bit set and bit clear commands.

A status mode enables the host to interrogate the programmed status of the

Digital232

RAM and ROM operation.

When data is requested, the

ports, all output ports, or from a specific 8 bit port. When being programmed, the unit

will input data and programming information from the host, and output the data to the

selected I/O port.

at any time. A self-test is initiated at power-on which checks for proper

is a digital input and output interface to the RS-232 standard. The

has several features which give it versatile interface capability. A

Digital232

will output from all forty bits, all input

1.1

Page 6

Section 1 Introduction

1.2 Available Accessories

Additonal accessories that can be ordered for the

CN-6-50

109-0920

CA-11

50 Pin solder tab edge connector.

Instruction Manual

12 ft. RS-232 cable, compatible with IBM PCs or

Digital232

include...

similar computers.

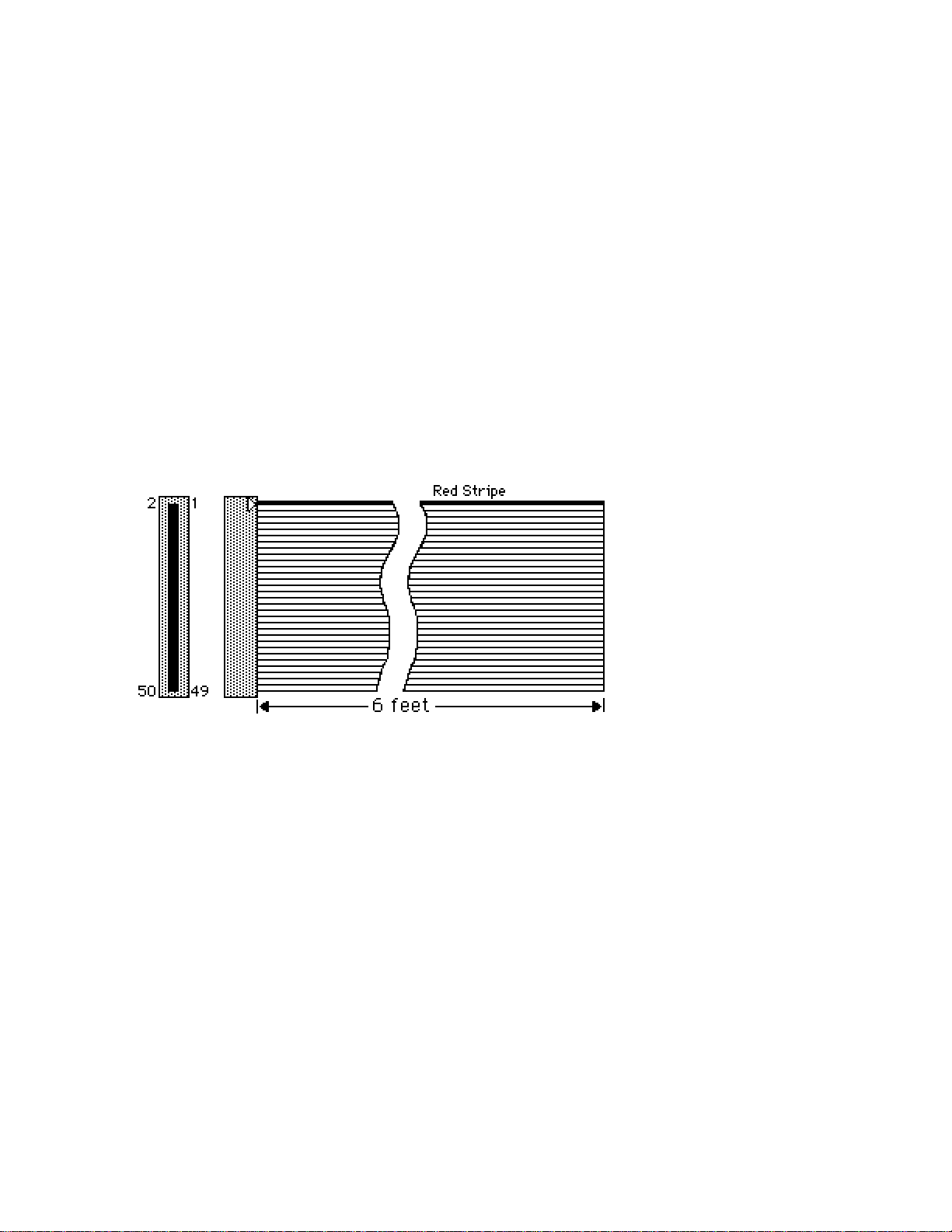

CA-8-50

6 foot, 50 conductor ribbon cable with a card edge

connector on one end, the other end unterminated.

CA-8-50

1.2

Page 7

Section 1 Introduction

1.3 Specifications DIGITAL I/O:

Configuration: Five 8 bit ports, programmable as inputs or outputs.

Also included are programmable handshake lines, data

latching capability, and trigger output.

Logic Levels: Outputs will drive 2 TTL loads.

Connector: I/O Port: One 50 pin card-edge. Mating connector

supplied.

SERIAL INTERFACE:

EIA RS-232C: AB, BA, BB, CA, CB

Duplex: Full with switch selectable echo/no-echo

Data Bits: 7 or 8 (switch selectable)

Stop bits: 1 or 2 (switch selectable)

Parity: Switch selectable on transmit for odd, even,

mark, space or disabled. No parity test on receive

Baud Rates: 110, 135, 150, 300, 600, 1200, 1800, 2400, 3600,

4800, 7200, 9600, and 19200 (switch selectable)

Terminator: Switch selectable CR, LF, CR-LF, or LF-CR

Control: Supports Clear To Send (CTS), Request To Send

(RTS) and switch selectable XON/XOFF

Serial I/O Buffers: 3500 Characters each

Serial Connectors: Mates with a 25-Pin Sub-D male: DCE configured.

GENERAL:

Indicators: LEDs for Send, Receive, Test, Error, and Power

Power: 105-125V or 210-250V,50, 60 Hz; 15 VA MA X.

Environment: 0 to 50 deg C; 0 to 70% RH

Dimensions: 188mm deep x 140mm wide x 68mm high. (7.39" x

5.5" x 2.68")

Weight: 1.55 kg (3.6 lbs)

Controls: Power switch, internal dip switch for RS-232

parameters

Supplied Accessories: I/O port connector, power supply and manual.

Specifications are subject to change without notice.

1.3

Page 8

Page 9

Section 2 Getting Started

GETTING STARTED

2.1 INSPECTION

The

Digital232

to shipment. When you receive the interface, carefully unpack all items from the

shipping carton and check for any obvious signs of physical damage which may have

occurred during shipment. Immediately report any such damage found to the shipping

agent. Remember to retain all shipping materials in the event that shipment back to the

factory becomes necessary.

Every

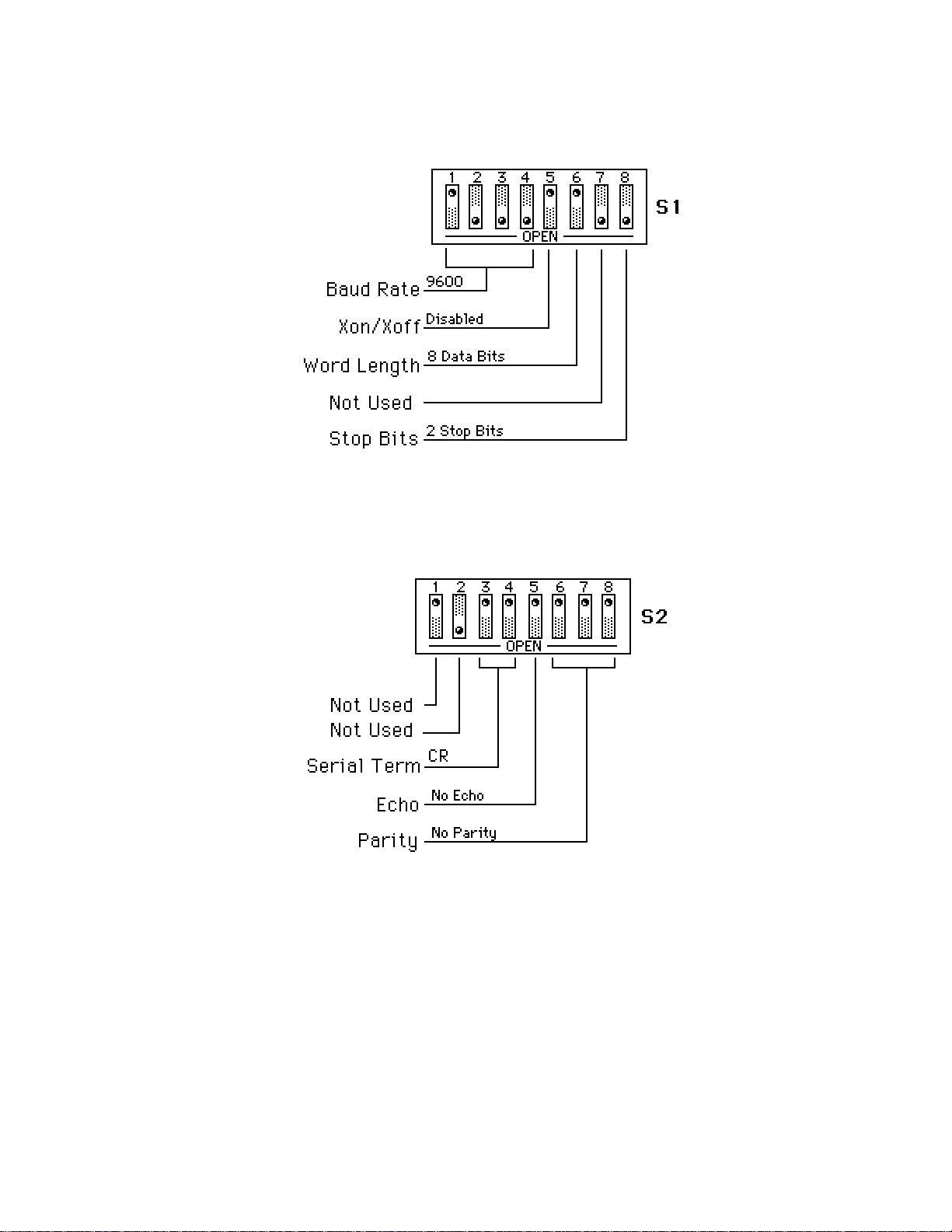

2.2 CONFIGURATION

interface. NOTE: Most selectable functions are read ONLY at power-on and should

only be set prior to applying power to the interface. The following figures illustrate

the factory default conditions which are:

Digital232

•

•

•

•

Two DIP switches internal to the

was carefully inspected, both mechanically and electrically, prior

is shipped with the following....

Digital232

109-0920

CN-6-50

TR-2

TR-2E

Digital I/O Interface

Instruction Manual

50 pin card edge connector

115 volt Power Supply or

220 volt Power Supply

Digital232

set the configuration of the

9600 Baud

8 Data Bits

2 Stop Bits

No Parity

Xon/Xoff Disabled

Echo Disabled

Serial Terminator = CR Only

2.1

Page 10

Section 2 Getting Started

S1 Factory Default Settings

S2 Factory Default Settings

2.2

Page 11

Section 2 Getting Started

Switch S1 is the 8-position dip switch close to the front of the unit. Switch S2 is

near the rear power switch. To modify any of these defaults, follow this simple

procedure:

Disconnect the power supply from the AC line and from the interface.

Disconnect any digital I/O or serial cables prior to disassembly.

WARNING

Never open the

Digital232

case while it is connected to

the AC line. Failure to observe this warning may result

in equipment failure, personal injury or death.

Remove the four screws located in each corner of the rear panel. Hold the

case firmly and pull the rear panel outward, noting the slot location of the main

circuit board. Modify those parameters which are appropriate for your

installation and reassemble the unit. Slide the main circuit board into the

previously noted slot and finish reassembly by tightening the four screws into

the rear panel.

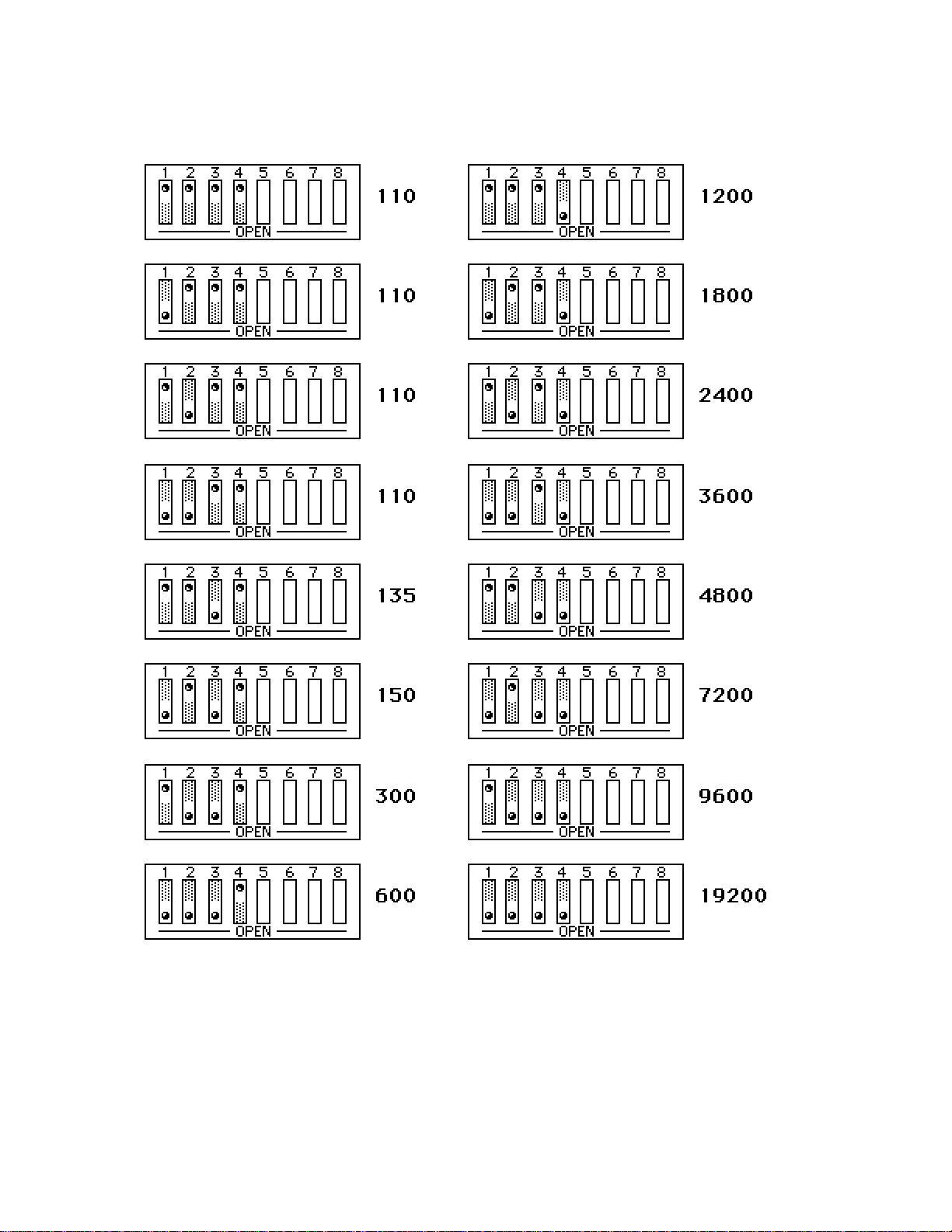

2.2.1 Serial Baud Rate Selection

S1-1 through S1-4 determine the serial baud rate. The factory default is 9600

baud. The baud rate may be selected from 110 to 19200. (Switch S1 is located near

the front of the interface)

2.3

Page 12

Section 2 Getting Started

S1 View for Serial Baud Rate Selection

2.4

Page 13

Section 2 Getting Started

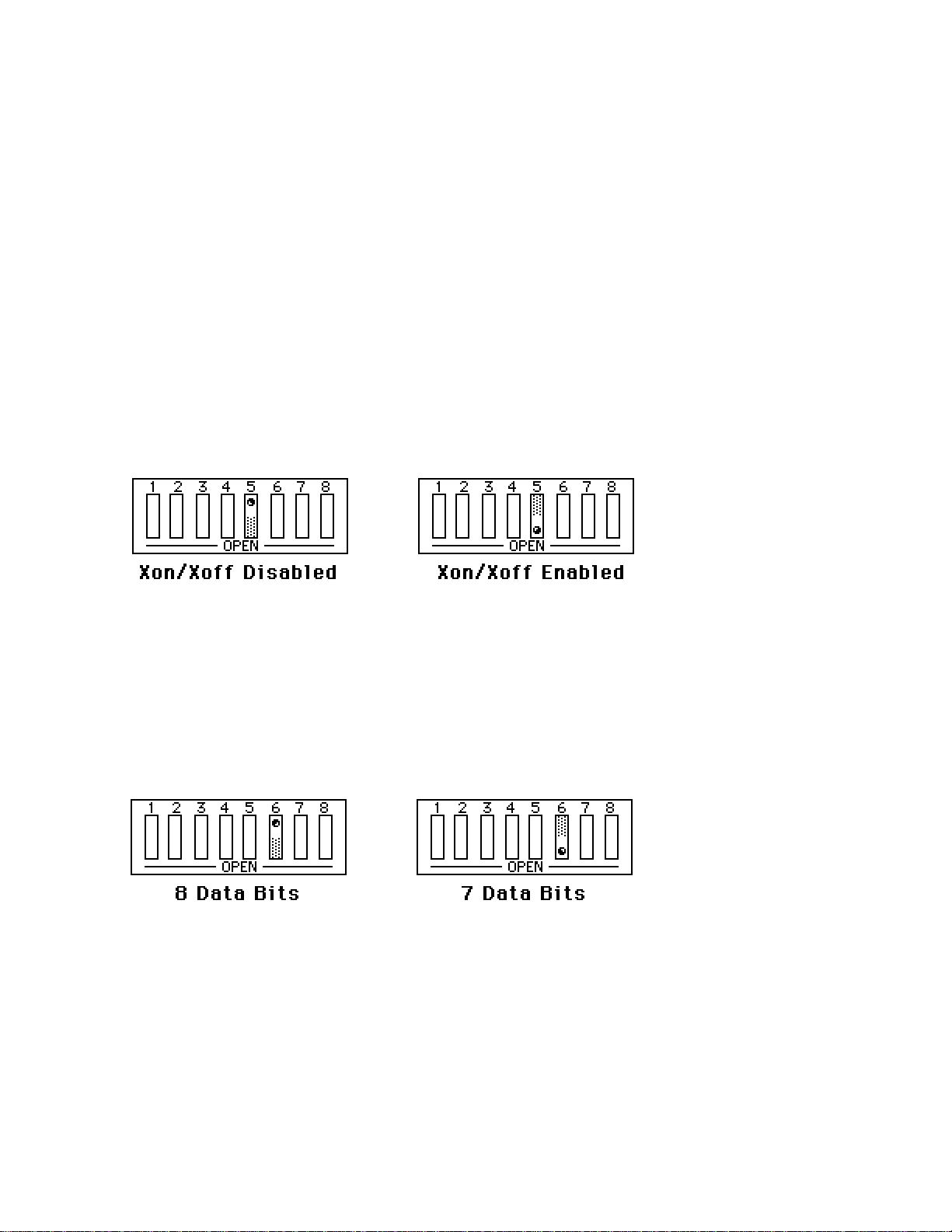

2.2.2 Xon/Xoff Serial Control Selection

Switch S1-5 is used to enable

Digital232

issues

when its serial input buffer is near full. When it is able to

Xoff

accept more information, it issues

Xon/Xoff

. The

Xon

serial control. When enabled, the

Digital232

transmit from the serial device it is communicating with.

When the

Xon/Xoff

set to +5 volts, and the

Digital232

default is

should be wired to the

Xon/Xoff

disabled.

S1 View for Xon/Xoff Serial Control

mode is enabled, the

input is ignored. However, the

CTS

+Vtest

to avoid any problems. The factory

output from the

RTS

also accepts

CTS

Xon/Xoff

on

Digital232

input to the

is

2.2.3 Serial Word Length Selection

S1-6 determines the number of bits per each serial character transmitted or

received. The factory default is 8 data bits.

S1 View of Serial Word Length (Data Bits)

2.5

Page 14

Section 2 Getting Started

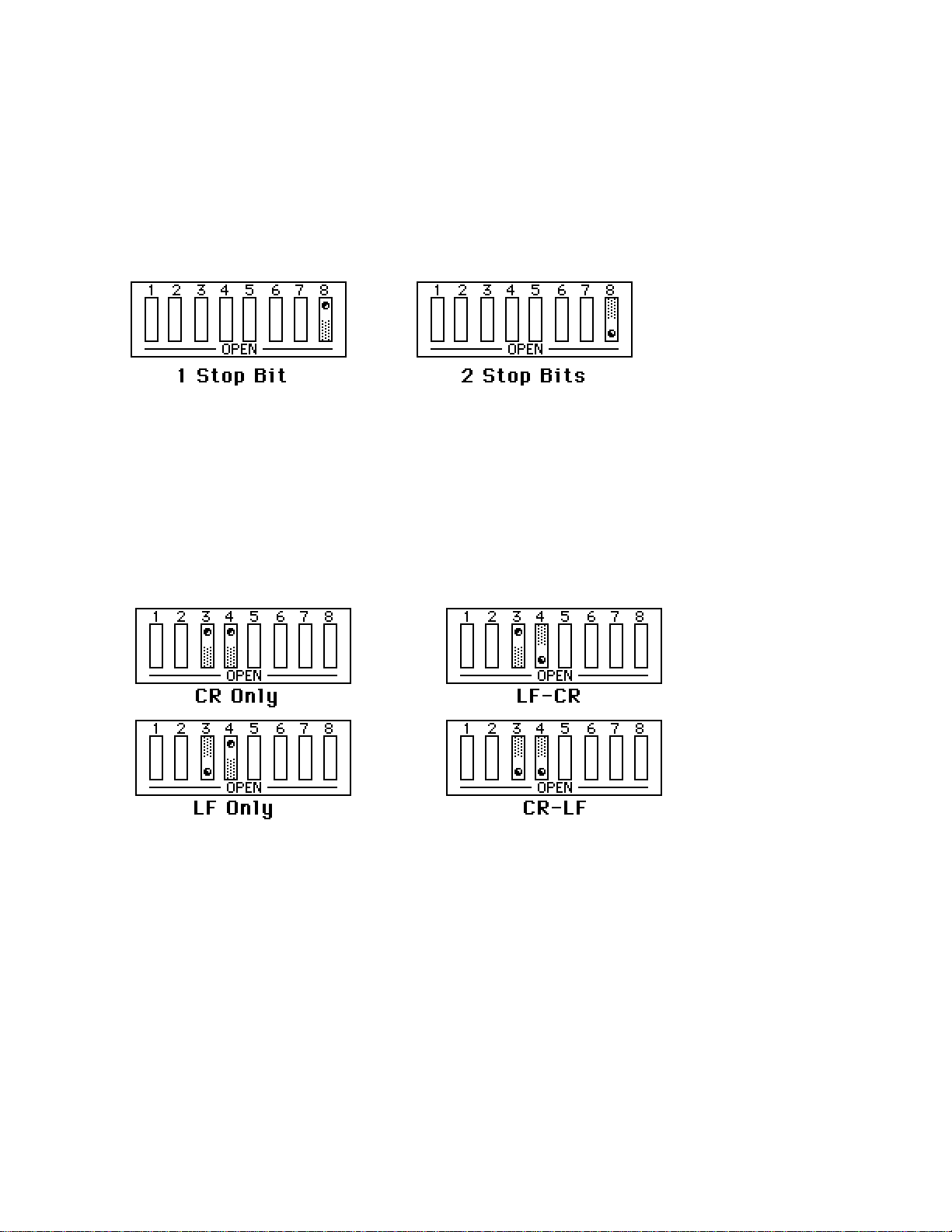

2.2.4 Serial Stop Bit Selection

Switch SW1-8 determines the number of stop bits contained in each serial

character transmitted and received. The factory default is 2 stop bits.

SW1 View for Serial Stop Bit Selection

2.2.5 Serial Terminator Selection

S2-3 and S2-4 select the serial terminators for the serial input and output. The

factory default is

. (switch S2 is located near the rear power switch).

CR

S2 View for Serial Terminator

2.6

Page 15

Section 2 Getting Started

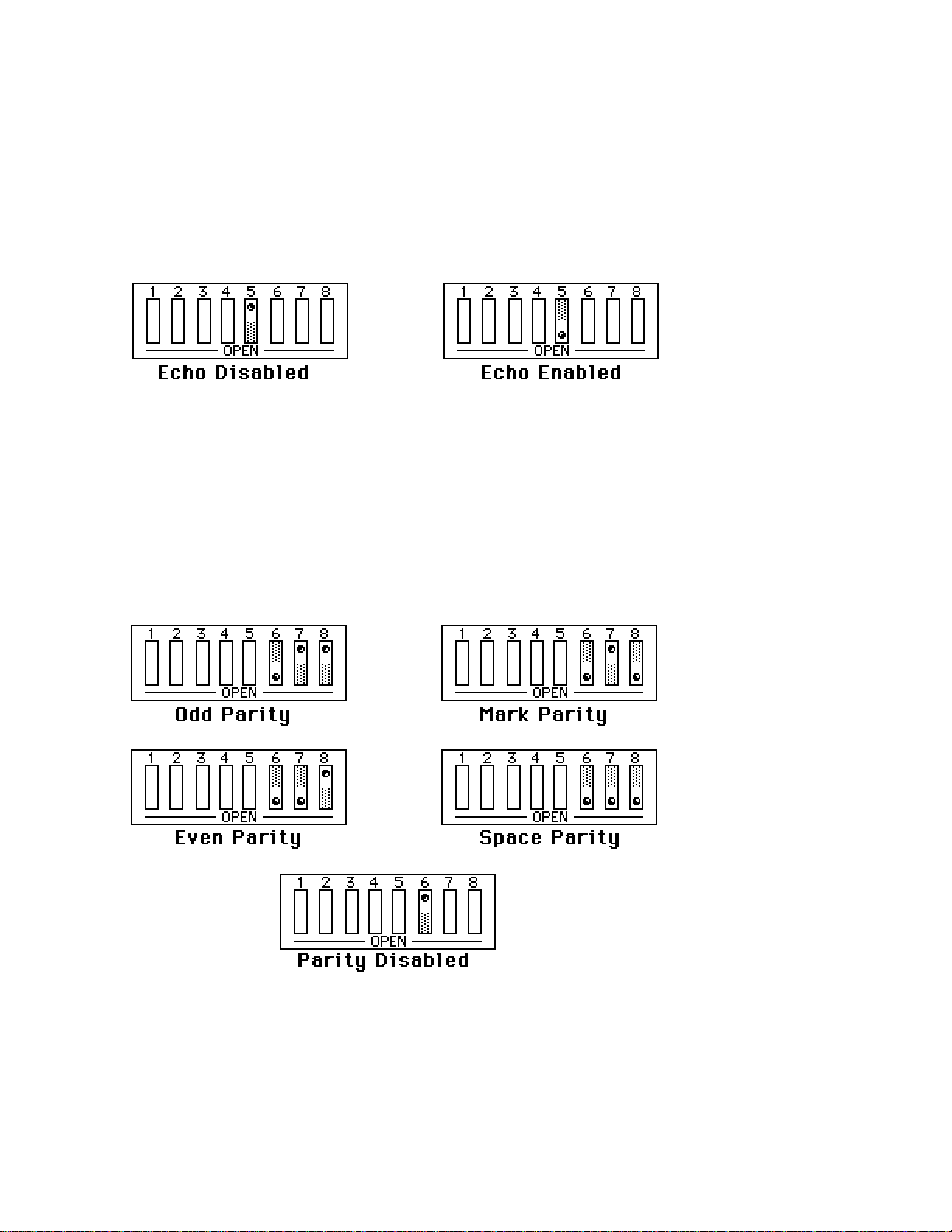

2.2.6 Serial Echo Selection

Serial data sent to the

Digital232

will be echoed back to the serial host if S2-5

is set to the open position. Factory default is Echo Disabled.

S2 View for Echo

2.2.7 Serial Parity Selection

Serial Parity is selected with S2-6 through S2-8. The

Digital232

generates the

selected parity during serial transmissions but it does not check parity on data

received. The factory default is parity disabled.

S2 View for Serial Parity Selection

2.3 Digital Input/Output Ports

The

Digital232

has 40 data lines which can be programmed in groups of 8 as

2.7

Page 16

Section 2 Getting Started

either input or output. At power on, all 40 bits are in the input mode. Each 8 bit

group is one port, beginning with

Port 1

as the least significant 8 bits, and

Port 5

as

the most significant 8 bits.

2.3.1 Logic Levels

The data and handshake output lines will drive two TTL loads. In addition,

ports 3, 4, and 5 outputs are 5 Volt CMOS compatible. All input lines are less than

1.5 TTL loads. All inputs are protected against damage due to high static voltages.

Normal precautions should be taken to limit the input voltages to -0.3 to +7.0 volts.

All I/O lines are referenced to

COMMON

(Pin 50).

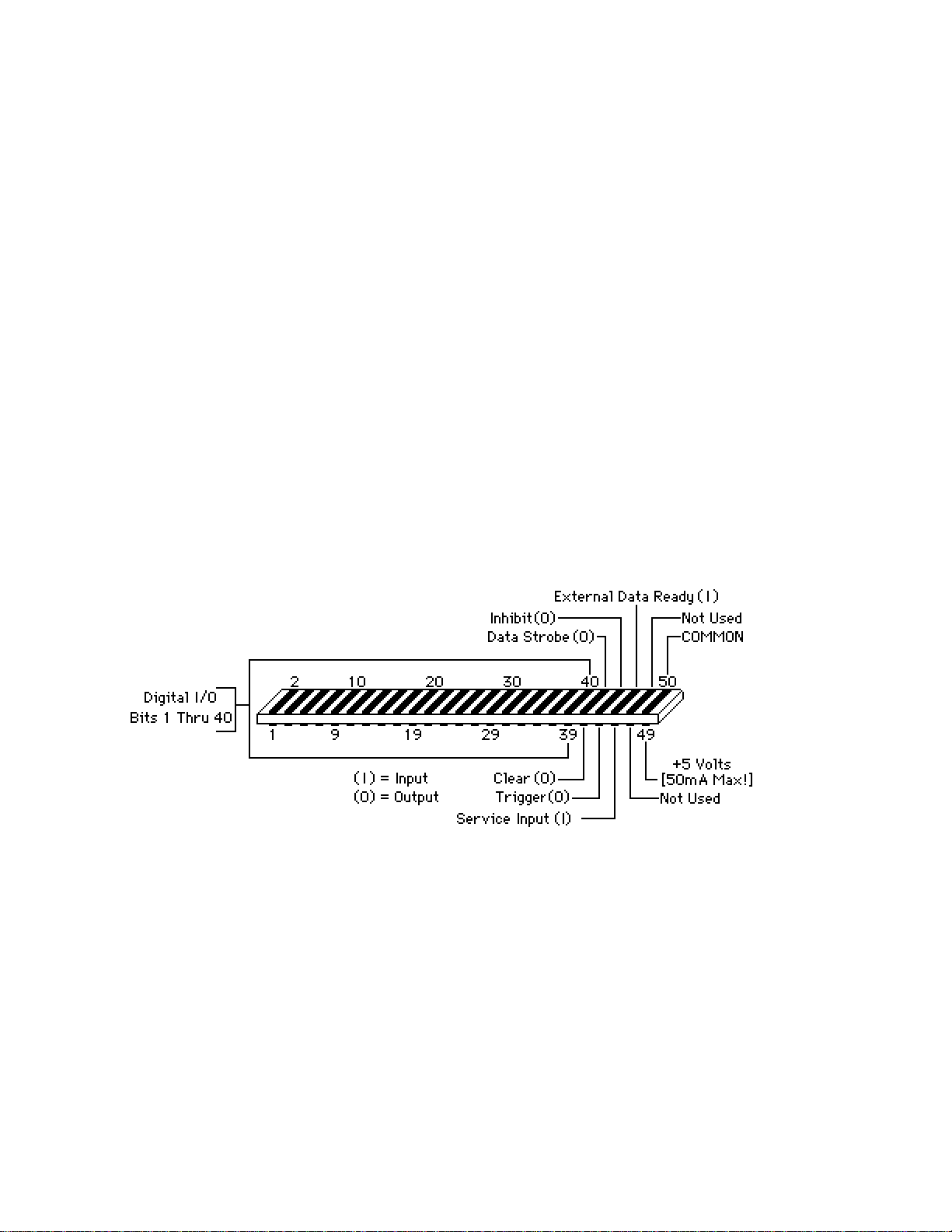

2.3.2 Digital I/O Port Pinout (rear view)

The following diagram illustrates the digital I/O edge connector as view from

the rear of the

Digital232

2.8

Page 17

Section 2 Getting Started

Pin Description

1 thru 8

9 thru 16

17 thru 24

25 thru 32

33 thru 40

41

DATA PORT1

(Input or Output).

Pin 1 is bit 1 (LSB), Pin 8 is bit 8 (MSB).

Least Significant Port

DATA PORT2

(Input or Output).

Pin 9 is bit 1 (LSB), Pin 16 is bit 8 (MSB).

DATA PORT3

(Input or Output).

Pin 17 is bit 1 (LSB), Pin 24 is bit 8 (MSB).

DATA PORT4

(Input or Output).

Pin 25 is bit 1 (LSB), Pin 32 is bit 8 (MSB).

DATA PORT5

(Input or Output).

Pin 33 is bit 1 (LSB), Pin 40 is bit 8 (MSB).

Most Significant Port

CLEAR

(Output).

42

43

44

45

46

DATA STROBE

TRIGGER

INHIBIT

SERVICE INPUT

EXTERNAL DATA READY [EDR]

47,48 Not used.

49

50

+5 Volts

I/O COMMON.

(Output).

(Output).

(Output).

(Input).

(

Do not exceed 50 mA load

(Input).

).

2.9

Page 18

Section 2 Getting Started

2.3.3 Control Lines

Five control lines enable handshaking of digital I/O data transfer to the

Digital232

and can also be independently activated with the

. They are automatically activated with the corresponding I/O activity

Handshake (Hn)

command.

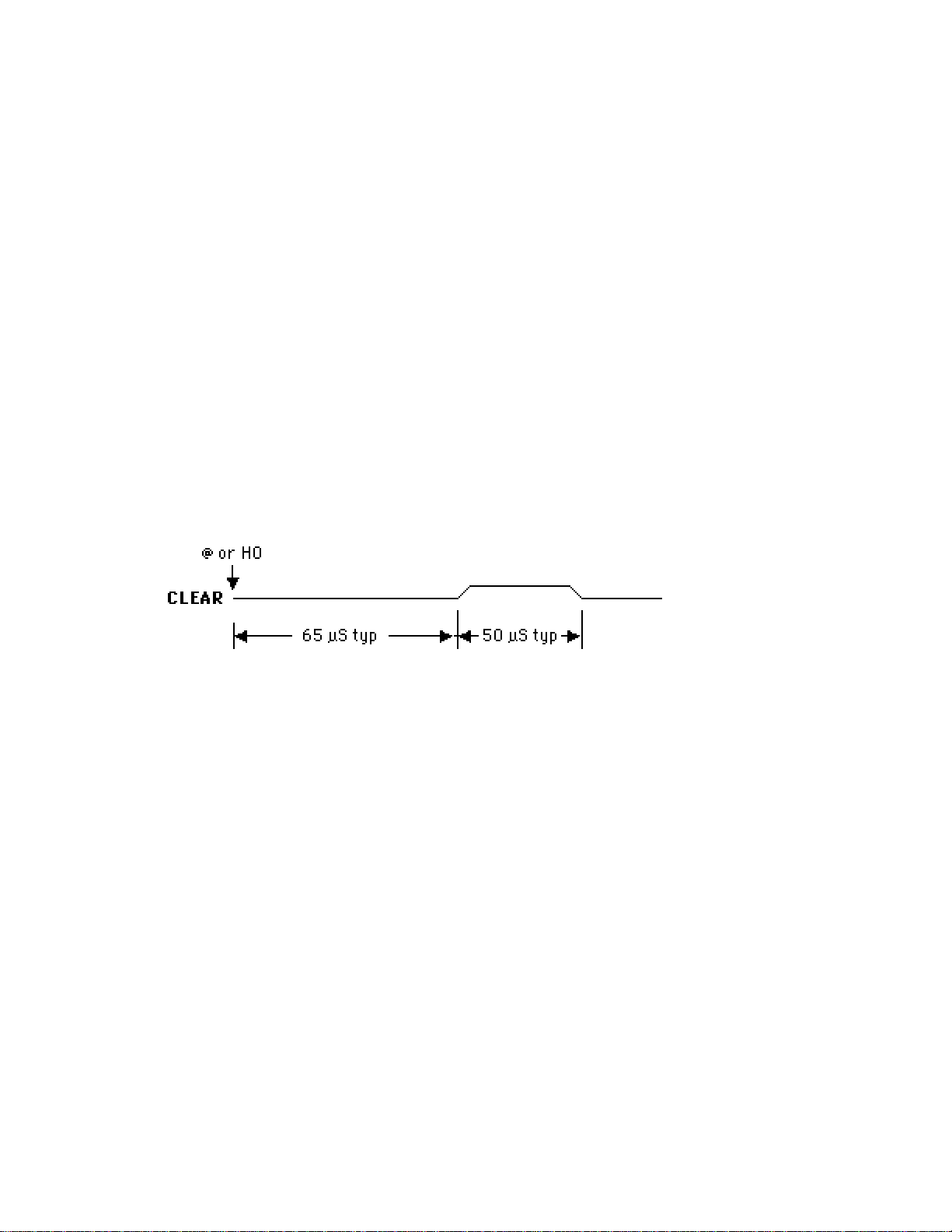

2.3.3.1 Clear

The

Clear

(Pin 41)

output is pulse for approximately 50 microseconds at power-on,

or upon receipt of the

active high. The

Handshake

command

Invert

operations.

2.3.3.2 Data Strobe

TIMING DIAGRAM FOR CLEAR OUTPUT

(Pin 42)

RESET (@

) command. The

Clear

line is normally

command (I8) will program it active low. The

(H0)

can pulse the

Clear

line, independent of any I/O

The

Data Strobe

new data is output on the I/O port. The

output is pulse for approximately 50 microseconds after

Data Strobe

high but may be programmed active low by the

Handshake

command

can pulse the

(H1)

Data Strobe

I/O operations.

2.10

line is normally active

Invert

command (I4). The

line, independent of an

Page 19

Section 2 Getting Started

TIMING DIAGRAM FOR STROBE OUTPUT

2.3.3.3 External Data Ready [EDR]

The

External Data Ready [EDR

used to latch input data. It is used in conjunction with the

command (R1). The

signal must be at least 1 microsecond wide and must

EDR

have a rise and fall time of less than one microsecond. The

normally rising-edge sensitive but can be programmed with the

command (

) to be falling-edge sensitive. Refer to the following diagram for

I32

(Pin 46)

] line is an edge sensitive input which is

Data Ready

EDR

line is

Invert

timing relationships.

When using the

line transitions.

EDR

2.3.3.4 Inhibit

The

Inhibit

(Pin 44)

output is asserted while data on the selected I/O port is being

EDR

line the

Digital232

will only output data when the

read into the I/O port buffer. This line is normally active high but may be

programmed active low by the

Invert

programmed independent of any I/O operations with the

command (I1). The

Inhibit

Inhibit

line can be

command

(Qn). Refer to the following diagram for timing relationships.

The

Inhibit

[Fn] modes.

line is asserted once for each data read operation for all format

2.11

Page 20

Section 2 Getting Started

2.3.3.5 Trigger

The

Trigger

Handshake

TIMING DIAGRAM FOR EDR AND INHIBIT

(Pin 43)

output is pulse for approximately 50 microseconds after the

command (H2) is received. The trigger pulse is normally active

high, but can be made active low with the

Invert

command (I2).

TIMING DIAGRAM FOR TRIGGER OUTPUT

2.12

Page 21

Section 2 Getting Started

2.3.3.6 Service

The

Service

Service Request (SRQ).

(Pin 45)

input is an edge sensitive input capable of generating a

It is enabled with the

defaults to rising-edge sensitive. The

program it to be falling-edge sensitive.

2.4 INSTALLATION

To begin operating the

Digital232,

jack on the interface.

Never install the power supply into the interface while it

is connected to AC line power. Failure to observe this

caution may result in damage to the

The power supply provided with the interface is

intended for

INDOOR USE ONLY.

this warning could result in equipment failure, personal

injury or death.

command (

Invert

SRQ

command (

) can be used to

I64

M1

plug the external power supply into the rear

CAUTION

Digital232.

WARNING

Failure to observe

) and

After installing the power supply connector into the interface, turn on the

Digital232

should light for approximately one second while the

by depressing the rear panel power switch. All the front panel LEDs

Digital232

performs an internal

ROM and RAM self check. At the end of this self check all indicators should turn off

except

POWER

If you obtain the above response then your

.

Digital232

is alive and well. If all

LEDs remain on, then a ROM error has occurred. If all LEDs continue to flash

(except the power LED), then a RAM error has occurred. Try cycling the power to the

Digital232

If the LEDs do not flash and the

to determine that the error is repeatable.

POWER

indicator does not remain lit, there

may not be any power supplied to the interface. In this event, check to make sure the

AC power is supplied to the power supply, and that the supply is properly installed

2.13

Page 22

Section 2 Getting Started

into the unit. If the problem is unresolved, refer to the

Service Information

section

of this manual.

Connect a serial cable to the DB-25 connector on the rear of the

Digital232

Connect the other end of the cable to the serial host. Running a dumb terminal

program similar to that shown in Appendix C, type the following....

@

R0

Reset the

Digital232

Request data from the

The

Digital232

should respond with '

Digital232

FFFFFFFFFF'

2.5 Errors

The

Digital232

has built-in error checking, to ensure that it has received valid

commands and data, and to alert the user if an inappropriate situation has occurred.

The front panel

Error

remain lit until the status command

LED will illuminate when an error condition occurs, and will

is received. The

U0

Digital232

will continue to

operate after an error has occurred, but in the instance of an invalid command, the

command will not be executed and must be re-sent.

.

The

Service Request

command

can be used to automatically send an SRQ

M4

message to the host whenever an error occurs. This is particularly helpful when first

configuring the system using a 'dumb terminal' program, as described for the IBM PC

in Appendix C. Refer to the

Status

command (U0) for more information on error

codes.

2.14

Page 23

Section 3 Command Descriptions

COMMAND DESCRIPTIONS

Control of the

detail. Examples are given for many of the commands using an IBM PC and the

"dumb terminal" program described in Appendix C. The underlined portion of the

example refers to text which is typed into the PC when the program is running. It is

implied that each command is terminated by the ''RETURN' key on the PC in order to

execute the command.

When the

or

Execute

order:

Command Code

Reset @ (executed immediately)

Invert I

Configure C

Format F

Data D

Bit Set A

Bit Clear B

Inhibit Q

Handshake H

Service Request M

Status U

Terminator Y

Test T

Data Ready R (executed last)

command, the accumulated commands are executed in the following

Digital232

Digital232

is implemented with 17 commands, described here in

receives multiple commands before receiving a terminator

3.1

Page 24

Section 3 Command Descriptions

RESET @

The

Reset

not require an

Reset

practice to precede it with an

Example:

X@ reset the

command is not confused with the argument of a previous command it is a good

@

command returns the

Execute

Reset the

command or terminator to be executed. To be sure that the

Digital232

Digital232

Digital232

Execute (X)

to its power-on conditions

to its power-on conditions. It does

command.

3.2

Page 25

Section 3 Command Descriptions

BIT SET An

The

Bit Set

argument 'n'. Setting a bit may represent either a +5 volt or 0 volt output, depending

on whether an

condition),

command string, an

command.

The bit which is being set must have been configured as an output bit by the

Configure

Error.

The

sent.

An

Example:

@

C5

A22

A23XA24

command to be valid, otherwise the

Strobe

command programs a logic one output to a bit described by the

Invert

Bit Set

and

command (

outputs +5 volts. If multiple bits are to be set within the same

Execute

Inhibit

Bit n (1 thru 40) is set to logic one

reset the

configure all ports as output

set bit 22 to a logic one

set bits 23 and 24 to a logic one

command (X) must be included after every

output lines are not pulsed when the

Digital232

has been sent. If data is active high (default

I16)

Digital232

will generate a Conflict

Bit Set

command is

Bit Set

3.3

Page 26

Section 3 Command Descriptions

BIT CLEAR Bn

The

Bit Clear

argument 'n'. Clearing a bit may represent either a 0 volt or +5 volt output, depending

on whether an

condition), then

used in the same command string, an

command.

The bit which is being cleared must have been defined as an output by the

Configure

Conflict Error.

The

is sent.

Bn

Example:

command in order to be valid, otherwise the

Strobe

command will clear to a logic zero an output bit described by the

Invert

Bit Clear

and

command (

Inhibit

Bit n (1 thru 40) is cleared to a logic 0

outputs 0 volts. When multiple

output lines are not pulsed when the

) has been sent. If data is active high (default

I16

commands are

will generate a

Bit Clear

command

Execute

Bit Clear

command (X) must follow each

Digital232

@

C5

A7XA8XA9

B7

B8XB9

reset the

configure all ports as output

set bits 7, 8, and 9 to +5 volts

clear bit 7 to zero volts

clear bits 8 and 9 to zero volts

Digital232

3.4

Page 27

Section 3 Command Descriptions

CONFIGURE Cn

Ports 1 thru 5 are configured as inputs or outputs with the

Each port is eight bits wide. At power-on, all ports are initialized as inputs. The

Configure

programmed as outputs will be set to a logic zero after receiving the

command. The actual output level is dependent on the

Cn

command is usually the first command to be sent after power on. All ports

Invert

Mode n (0 thru 5) defines which ports are input and output

Port 5

in in in in in

C0

in in in in out

C1

in in in out out

C2

in in out out out

C3

C4

C5

in = programmed as an input port

out = programmed as an output port

4 3 2 1

in out out out out

out out out out out

Configure

command (

command.

Configure

I16).

Example:

@

C1

reset the

select port 1 as output, ports 2 thru 5 as inputs

Digital232

3.5

Page 28

Section 3 Command Descriptions

DATA Dn....Z

The

Data

of bits which can be sent with the

programmed as outputs. For formats F0 through F3, if the amount of data sent is less

than the the number of bits programmed as outputs, the least-significant bits will

contain the data sent and the most-significant bits will be cleared to logic zero. If a

single port is selected with the

command. The

new data is output on the selected ports.

For formats F0 through F3, data sent by the controller is contained within a prefix

(D) and a suffix (Z). In format F4, the five bytes immediately following the prefix (D)

is interpreted as data and the suffix (Z) is not used. Refer to the Fn command for

additional details.

Dn...Z

(note: in the F4 mode, the Z terminator is not allowed)

Example:

command outputs up to 40 bits of data to the output ports. The number

command is limited by the number of bits

Data

command, only eight bits may sent with the

Port

Data Strobe

represents the data to be output, terminated by Z.

n...

output is pulse for approximately 50 microseconds after

Data

@

C5P1

D55Z

R0

P0

D1234567890Z

R0

reset the

configure all ports as output, select port 1

send "55" to port 1

read data from port 1,

display shows 55

select all ports

send data to all 40 bits

read data from the

display shows 1234567890

Digital232

Digital232

,

3.6

Page 29

Section 3 Command Descriptions

FORMAT Fn

The

Format

will be described. Five data formats are available and are described in detail in the

following paragraphs.

When data is requested from the

from all ports, unasserts

the Gn and

are appended to the output. After output the

subsequent reads.

each character having a value from 0 thru 9 or A thru F. Each ASCII character

describes 4 bits of data.

Pn

F0 Format- ASCII Hexadecimal

In the default

command determines the method by which input and output data

ASCII Hexadecimal (4 bits per character)

F0

ASCII Character (4 bits per character )

F1

ASCII Binary (1 bit per character)

F2

ASCII Decimal (8 bits per number)

F3

F4

commands. Leading zeros are not suppressed and the serial terminators

EDR (R1

F0

Binary (each byte represents 8 bits)

Digital232 (R0

Inhibit

format, the data is described in ASCII hexadecimal, with

and outputs the number of characters determined by

Digital232

) may also be used to capture data in these formats.

) it asserts

must be requested to perform

Inhibit

, reads the data

F0 Character Decimal

00 8 8

11 9 9

22 A 10

33 B 11

44 C 12

55 D 13

66 E 14

77 F 15

Equiv F0 Character Decimal Equiv

3.7

Page 30

Section 3 Command Descriptions

Data received for output to the digital ports must be contained within a

prefix (D) and a suffix (Z). If the amount of data sent is less than the number of

bits programmed as outputs, the least-significant bits will contain the data sent

and the most-significant bits will be cleared to logic zero. If the data sent is

greater than the number of bits programmed for output or selected by the

command, the

Digital232

command string. The

will generate a conflict error and ignore the entire

Data Strobe

output is pulse for approximately 50

Pn

microseconds after new data is output on the selected port(s).

Example:

@

C2G2

D4E6BZ

R0

reset the

Digital232

configure ports 1 & 2 as output

output hexadecimal '4E6B' to ports 1 & 2

read data from the

Digital232

display shows 4E6B

F1 Format - ASCII Character

In the F1 format, the data is coded and transmitted in ASCII Characters

with the four least significant bits of each ASCII character representing four

bits of data.

F1 Character Decimal

Equiv F1 Character Decimal Equiv

00 8 8

11 9 9

22 : 10

33 ; 11

44 < 12

55 = 13

66 > 14

77 ? 15

3.8

Page 31

Section 3 Command Descriptions

Data received for output to the digital ports must be contained within a

prefix (D) and a suffix (Z). If the amount of data sent is less than the number of

bits programmed as outputs, the least-significant bits will contain the data sent

and the most-significant bits will be cleared to logic zero. If the data sent is

greater than the number of bits programmed for output or selected by the

command, the

Digital232

command string. The

will generate a conflict error and ignore the entire

Data Strobe

output is pulse for approximately 50

Pn

microseconds after new data is output on the selected port(s).

Example:

F1

R0

D1??2Z

R0

select ASCII mode

read data from the

send 1??2 to the

Digital232

read data from the

Digital232,

Digital232,

display shows 4>6;

display shows 1??2

F2 Format - ASCII Binary

In the F2 format, the each data bit is described with an ASCII 0 or 1. Each

byte is formatted in two 4-bit multiples separated by semicolons.

F2 String Decimal

Equiv F2 String Decimal Equiv

0000;0000 0 0000;1001 9

0000;0001 1 0000;1010 10

0000;0010 2 0000;1011 11

0000;0011 3 0000;1100 12

0000;0100 4 0000;1101 13

0000;0101 5 0000;1110 14

0000;0110 6 0000;1111 15

0000;0111 7 1000;0001 129

0000;1000 8 1111;1111 255

3.9

Page 32

Section 3 Command Descriptions

Data received for output to the digital ports must be contained within a

prefix (D) and a suffix (Z) and each 4-bit quantity must be separated by

semicolons. Leading zeros are not required. If the amount of data sent is less

than the number of bits programmed as outputs, the least-significant bits will

contain the data sent and the most-significant bits will be cleared to logic zero.

If the data sent is greater than the number of bits programmed for output or

selected by the Pn command, the

Digital232

ignore the entire command string. The

will generate a conflict error and

Data Strobe

output is pulse for

approximately 50 microseconds after new data is output on the selected port(s).

Example:

F2

R0

select ASCII/binary mode

read data from the

Digital232,

display shows

0001;1111;1111;0001

D1111;0;1010;0101Z

R0

read data from the

Digital232

,

display shows 1111;0000;1010;0101

F3 Format - ASCII Decimal

In the

format, the data is described in decimal 8 bit multiples and

F3

transmitted in ASCII. Each decimal number (0 to 255) to be output must be

separated by semicolons.

F3 Number Decimal

Equiv F3 Number Decimal Equiv

000 0 008 8

001 1 009 9

002 2 010 10

003 3 020 20

004 4 100 100

005 5 200 200

006 6 210 210

007 7 255 255

Data received for output to the digital ports must be contained within a

3.10

Page 33

Section 3 Command Descriptions

prefix (D) and a suffix (Z). If the amount of data sent is less than the number

of bits programmed as outputs, the least-significant bits will contain the data

sent and the most-significant bits will be cleared to logic zero. If the data sent

is greater than the number of bits programmed for output or selected by the

command, the

Digital232

command string. The

will generate a conflict error and ignore the entire

Data Strobe

output is pulse for approximately 50

Pn

microseconds after new data is output on the selected port(s).

Example:

F3

R0

D100;200Z

R0

output 100 & 200

select decimal mode

read data from the

Digital232,

to the

read data from the

Digital232,

display shows 240;165

Digital232

display shows 100;200

F4 Format - Binary

In the F4 binary format the

Digital232

five bytes of data beginning with PORT5 without

expects the "D" prefix followed by

the "Z" suffix. If any digital

I/O port is configured as an input, the data to that input port will be ignored and

no error will be generated.

When data is requested from the

the data from all ports, unasserts

Digital232 (R0

Inhibit

and outputs 5 bytes beginning with

) it asserts

Inhibit

, reads

PORT5. Serial terminators are appended to the output. After output the

Digital232

must be requested to perform subsequent reads.

EDR (R1

) may

also be used to capture data in this format.

Example:

F4

D!&Jg(Z

select the binary mode

the binary representation of the characters

!&Jg(

will be output to the digital I/O port

3.11

Page 34

Section 3 Command Descriptions

OUTPUT SELECT Gn

The

Output Select

transmitted when the

sent is dependent on the Pn command. In any port mode other than

selected by the

The default mode,

mode causes only data from the ports programmed as inputs to be sent when data is

requested. The G2 mode causes only data from ports programmed as outputs to be

returned when data is requested.

If all ports are programmed as outputs with G1 selected and data is requested,

nothing will be transmitted. Conversely, nothing will be transmitted with all ports

programmed as inputs and G2 selected.

G0

G1

G2

Port

command determines the I/O port from which data will be

Digital232

command will be output from the

causes all 40 bits to be sent when data is requested. The

G0

Input and output

Only input port data is output

Only output port data is output

outputs data to its serial port. The amount of data

only the 8 bits

P0,

Digital232

port data is output

serial port.

G1

Example:

@

P0C1

G1

R0

G2

R0

reset the

configure port 1 as input, ports 2-5 as output

select only input ports when data is requested

read data from the

display shows 000000FF (data is dependent

on what is connected to the input)

select output ports when data is requested

read data from the

display shows 00 (outputs default to 0)

Digital232

Digital232

Digital232

input ports

input ports

3.12

Page 35

Section 3 Command Descriptions

HANDSHAKE Hn

The

Handshake

lines, independent of any other I/O operations. When the

command, the respective handshake line is pulsed for approximately 50 microseconds.

It returns to its steady-state condition after pulsing. The

used to change the active state of any of the handshake lines.

H0

H1

H2

Example:

The

H1

The

The

The

control command enables software control of the handshake

receives an

command may be

Clear

Strobe

Trigger

Strobe

line is pulsed

line is pulsed

line is pulsed

Digital232

Invert

line is pulsed

Hn

3.13

Page 36

Section 3 Command Descriptions

Invert In

The

Invert

lines. At power up all handshake and control lines are active high (logic one = + 5

volts). The

handshake lines, and of the data lines. If multiple

within the same string, then an

each

desired, and send one command with the sum of the desired commands. The

commands are Ored together as received. To delete any one command, it is necessary

to program the default mode I0, then re-program the desired commands.

Invert

I0

I1

I2

I4

I8

I16

I32

I64

command is used to change the polarity of the handshake and data

Invert

command. An alternative is to add the values of each

All control lines are active high, all data lines are high true.

Inhibit

Trigger

Data Strobe

Clear

Data

EDR

Service

command can selectively change the polarity of each of the

commands are contained

Invert

output

output

output

is low

input

input

Execute

is active low

is active low

output

is active low

true

is falling-edge sensitive

is falling-edge sensitive

is active low

command (X) should be included between

Invert

command

Invert

Example:

@

I32XI64

note:

I96 performs the same function as above

reset the Digital 232

select EDR and Service

falling-edge sensitive

input

as

3.14

Page 37

Section 3 Command Descriptions

Service Request (SRQ) Mn

The

Service Request (SRQ

computer to one of several conditions described below. When a service request

condition occurs, the string “

where “n” is a number from 1 through 7. The number “n” is determined by the

conditions which have caused the service request, and is the sum of M1, M2, and M4.

Multiple

commands are contained within the same command string, each

should be followed by an

of each

commands. The

modes will remain enabled until the

SRQ

command is received.

M0

M1

M2

M4

command desired, and send one command with the sum of the desired

SRQ

default mode disables the SRQ function, preventing the Digital232 from

generating a Service Request

will generate a Service Request when the Service Input line makes a

transition. Refer to the Invert command (I64) description for

programming the polarity of the Service input line.

will generate a Service Request when the EDR input makes a transition.

Refer to the Invert command (I32) description for programming the

polarity of the EDR input line.

will generate a Service Request when a programming error occurs. For

example, attempting to select an ‘F6’ format when no ‘F6’ format exists

will generate a Service Request when the M4 mode is selected.

conditions can be enabled simultaneously. If multiple

SRQ

Execute

commands are ORed together as received. The programmed

SRQ

) mode is used by the

SRQ n

” will automatically be sent to the host computer,

command (X). An alternative is to add the values

command is sent, or a

M0

Digital232

SRQ

to alert the host

SRQ

command

Reset (@)

Example:

@

M4 select

F7 send an invalid command.

reset the

ERROR LED

Digital232

on error

SRQ

should illuminate and “SRQ” is sent to the host

3.15

Page 38

Section 3 Command Descriptions

Port Pn

The

In the default mode (P0), all ports are selected. The P1 thru P5 commands select a

specific eight bit port.

The Output Select (Gn) command is used to determine whether input or output

port data is sent out the serial port when requested. Data in modes P1 through P5 is

input or output in groups of eight bits.

P0

P1

P2

P3

P4

P5

Example:

@

P4 select port 4

command determines which port is selected for output and input data.

Port

All five ports are selected

Port 1 is selected

Port 2 is selected

Port 3 is selected

Port 4 is selected

Port 5 is selected

reset the Digital 232

3.16

Page 39

Section 3 Command Descriptions

INHIBIT Qn

The

independent of any other I/O activities. The 'set' and 'clear' levels of the

are determined by the

Q0

Q1

Example:

@

Q1

Inhibit

control command allows software control of the

Invert

Clear the

Set the

reset the

set the

Inhibit

Inhibit

Digital232

command.

Inhibit

line (place in the asserted state)

line

line (return to unasserted state)

Inhibit

Inhibit

line,

line

3.17

Page 40

Section 3 Command Descriptions

Data Ready Rn

The

transmitted out the serial port. When used in conjunction with the

function, the

host computer that new data is available.

In the default mode (R0) data is read and transmitted out the serial port when the

Digital232 receives an R0 command. In R1 mode, data on an input port is latched on

the transition of a signal applied to the

same time, the latched data is transmitted out the Digital232’s serial port to the host

computer. If EDR transitions again before the previous

formatted for output and sent to an internal serial output queue, the Digital232 will

generate an

The

fall time of less than 1.0 microsecond. The

but can be changed to falling-edge sensitive with the

In the R2 mode, serial data is sent to the host every time the last serial terminator

is received. If, for example, the serial terminators selected are CR and LF then data is

read and transmitted on receipt of the LF.

Data Ready

External Data Ready

EDR Overrun

signal must be at least 1 microsecond wide and should have a rise and

EDR

command enables digital input data to be latched and

Service Request

line can both latch the input data and signal the

External Data Ready (EDR

error and ignore the

EDR

buffered data has been

EDR

read request.

EDR

line defaults to rising-edge sensitive,

Invert

command (

) line. At that

).

I32

R0

R1

R2

Example:

@

R1

Data is read and transmitted to the serial host computer.

Data is latched on an EDR transition and transmitted to the host.

Data is sent to the host computer after every receipt of the last serial

terminator from the host

reset the

request digital I/O data to be sent to the serial host

Digital232

3.18

Page 41

Section 3 Command Descriptions

Test Tn

The

command will turn-off the front panel

Test LED

If the test is successful, all LEDs will flash for one-half second. If a test fails, the

Error

of the self test error.

Example:

@

T0

T1 turn-on the Test LED

LED will remain illuminated. Use the

command is used to verify hardware and LED operation. The

Test

Test LED

. The T2 command will cause the Digital232 to initiate a ROM/RAM test.

reset the

turn-off the front panel Test LED

Digital232

. The T1 command will turn-on the

Status

command to determine the cause

T0

3.19

Page 42

Section 3 Command Descriptions

Status Un

The

Status

the host computer. The status of the Digital232 may be read at any time without

interfering with normal operation. Any error conditions are cleared after the status

string is read by the host. The

read any single bit from the I/O ports (U1 through U40).

U0 Send the Digital232 status and clear any error conditions

Un Send the status of bit n (1 thru 40)

The format of the status byte returned by the Digital232 after receiving a U0

command is as follows….

1.0C#E#F#G#I###M#P#R#Y#

where each “#” equals the number corresponding to that command. The leading

information “1.0” is the revision level of the Digital232 software.

Example:

command (U0) will cause the Digital232 to send its status message to

Status

command (Un) also enables the controller to

@@ reset the

U0 send U0 to the Digital232

read the status byte

display = *.*C0E0F0G0I000M0P0R0Y*

The status returned after receiving a U1 through U40 is an ASCII character ‘1’ or

‘0’, depending on the level of the line, and the state of the Invert command (I16).

Example:

U22 request the status of bit 22, display shows, a 0 (dependent on

the signal applied to the input)

Below is a summary of the Status (U0) information.

Digital232

3.20

Page 43

Section 3 Command Descriptions

C# Configuration

C0 All ports are inputs

C1 Port 1 is an output, ports 2 thru 5 are inputs

C2 Ports 1 and 2 are outputs, ports 3 thru 5 are inputs

C3 Ports 1 thru 3 are outputs, ports 4 and 5 are inputs

C4 Ports 1 thru 4 are outputs, port 5 is an input

C5 All ports are outputs

E# Error Message

E0 No error

E1 Unrecognized command (ex. W3)

E2 Illegal command option (ex. F8)

E3 Conflict (attempt to output data to an input port)

E4 EDR overrun (EDR pulses occurred faster than data should

be transmitted to the host)

E5 ROM error (a bit or bits in the ROM have changed state,

consult the factory for further action)

E6 RAM error (a bit or bits in the RAM are not working

properly, consult the factory for further action)

F# Data Format

F0 ASCII Hexadecimal

F1 ASCII Character

F2 ASCII Binary

F3 ASCII Decimal

F4 Binary

G# Output Select

G0 Input and Output port data is output

G1 Only Input port data is output

G2 Only Output port data is output

3.21

Page 44

Section 3 Command Descriptions

I### Invert Control Lines

I0 All control and data lines are active high

I1 Inhibit output is active low

I2 Trigger output is active low

I4 Data Strobe Output is active low

I8 Clear output is active low

I16 Data is active low

I32 EDR input is falling edge sensitive

I64 Service input is falling edge sensitive

Note: the status indication reflects the sum of all received Invert commands.

P# Selected Port

P0 All five ports are selected

P1 Port 1 is selected

P2 Port 2 is selected

P3 Port 3 is selected

P4 Port 4 is selected

P5 Port 5 is selected

R# Data Ready

R0 Data is sent to the host immediately

R1 Data is latched on EDR transition, and sent to the host

R2 Data is sent to the host upon receipt of the serial terminator.

3.22

Page 45

Section 3 Command Descriptions

Y# Serial Terminator

Y0 CR

Y1 LF

Y2 LF-CR

Y3 CR-LF

3.23

Page 46

Section 3 Command Descriptions

EXECUTE X

Commands sent to the

instructed to execute these commands. This is done by sending an X command or a

serial terminator, which is usually the last character of a command string. Commands

sent without an X are stored in the internal buffer until an X or a serial terminator is

received. Any number of

string. Certain commands, such as

string if more than one of that command is within the same string.

Example:

@

A1XA2

Digital232

Execute

reset the

two

same string, requiring an X after each

command (unless separated by a terminator)

commands may be inserted into the same command

Bit Set

will result in no action until the unit is

Bit Set

Digital232

commands are within the

require an X after each command in a

3.24

Page 47

Section 3 Command Descriptions

Terminator Yn

The serial terminator(s) defaults at power-on to the settings on Switch S1. It also

may be programmed for any combination of Carriage Return (CR) and Line Feed

(LF). The Y0 mode is the most commonly accepted terminator, CR.

Y0 CR Only

Y1 LF Only

Y2 LF-CR

Y3 CR-LF

Example:

@

Y3 select line feed terminator

U0 send status to the host

reset the

status byte indicates Y3 selected

Digital232

3.25

Page 48

Page 49

Section 4 Service Information

Service Information

4.1 FACTORY SERVICE

IOtech

encountered in using the

problems can be resolved by discussing the problems with our applications

department. If the problem cannot be solved by this method, you will be instructed as

to the proper return procedure.

maintains a factory service center in Cleveland, Ohio. If problems are

Digital232

you should first telephone the factory. Many

4.1

Page 50

Section 4 Service Information

4.2 Digital232 Component Layout (Mother Board)

D102 D103 D104 D105 D106

C104

R102

C106

C105

C108

U105

R6551AP

U103

6264

U102

2764

P102/

P103

C123

R103

C103

C102

C119

C121

C122

C101

74HCT00

Y101

U117

C120

1044

R105

U111

U113

26LS33

U114

26LS30

-+

-+

-+

C107

U104

74LS373

R106

C118

C114

U112

74LS73

U115

MC14020

C116

U110

74HCT02

U109

74LS139

R104

C117

U116

7805

AB

J103

C113

C112

C115

RED

BLK

R107

Blk - Pin #7

Brn - Pin #2

Red - Pin #4

J102

Orn - Pin #5

Blu - Pin #3

Wht - Pin #6

R101

D101

4.2

Page 51

Section 4 Service Information

4.3 Digital232 Component Layout (I/O Board)

S201

C205C204

U205

74LS05

U204

MC68B21P

U203

MC68B21P

U202

MC68B21P

U201

MC68B09P

U206

74LS373

R205

C201

C202

C203

J202

J203

J201

R202

S202

R201

R204

250

4.3

Page 52

Page 53

Appendix A Digital232 Command Summary

Digital 232 Command Summary

Command Code Description

Bit Set An

Set bit n (1 thru 40)

Bit Clear Bn

Output G0

G1

G2

Configure C0

C1

C2

C3

C4

C5

Data Dn..Z

Data Ready R0

R1

R2

Clear bit n (1 thru 40)

Input and Output

Only Input port data is output

Only Output port data is output

All ports are inputs

Port 1 is an output, ports 2 thru 5 are inputs

Ports 1 and 2 are outputs, ports 3 thru 5 are inputs

Ports 1 thru 3 are outputs, ports 4 and 5 are inputs

Ports 1 thru 4 are outputs, port 5 is an input

All ports are outputs

Data to be outputted is entered after "D" and

terminated by "Z"

Data is transmitted to the host computer via the

serial port upon receipt of an

Data is latched on an EDR transition, and

transmitted to the host via the serial port

Data is transmitted to the host via the serial port

after receipt of a serial terminator

port data is output

command

R0

Execute X

Format F0

F1

F2

F3

F4

Execute preceding command string

ASCII Hexadecimal

ASCII Charater

ASCII Binary

ASCII Decimal

Binary

A.1

Page 54

Appendix A Digital232 Command Summaary

Handshake H0

H1

H2

Inhibit Q0

Q1

Invert I0

I1

I2

I4

I8

I16

I32

I64

Port P0

P1

P2

P3

P4

P5

Pulse the Clear line

Pulse the Strobe line

Pulse the Trigger line

Clear Inhibit line

Set Inhibit line

All control line outputs are active high

Inhibit output is active low

Trigger output is active low

Data Strobe output is active low

Clear output is active low

Data is low true

EDR input is falling-edge sensitive

Service input is falling-edge sensitive

All ports selected

Port 1 selected

Port 2 selected

Port 3 selected

Port 4 selected

Port 5 selected

Reset @

SRQ M0

M1

M2

M4

Status U0

Un

Terminator Y0

Y1

Y2

Y3

Reset the

Digital232

to power-on conditions

SRQ is disabled

SRQ on Service Input transition

SRQ on EDR input transition

SRQ on command error

Send Status information when next addressed to

talk (*.*C#E#F#G#I###M#P#R#Y#)

Read state of bit n (1 thru 40)

CR LF

LF CR

CR only

LF only

A.2

Page 55

Appendix A Digital232 Command Summary

Test T0

T1

T2

Turn off the TEST LED

Turn on the TEST LED

Perform a RAM and ROM test

A.3

Page 56

Page 57

Appendix B ASCII Character Codes

ASCII Character Codes

Dec Hex CHR Dec Hex CHR Dec Hex CHR Dec Hex CHR

00 00 NUL 32 20 SPACE 64 40 @ 96 60 '

01 01 SOX 33 21 ! 65 41 A 97 61 a

02 02 STX 34 22 " 66 42 B 98 62 b

03 03 ETX 35 23 # 67 43 C 99 63 c

04 04 EOT 36 24 $ 68 44 D 100 64 d

05 05 ENQ 37 25 % 69 45 E 101 65 e

06 06 ACK 38 26 & 70 46 F 102 66 f

07 07 BEL 39 27 ' 71 47 G 103 67 g

08 08 BS 40 28 ( 72 48 H 104 68 h

09 09 HT 41 29 ) 73 49 I 105 69 i

10 0A LF 42 2A * 74 4A J 106 6A j

11 0B VT 43 2B + 75 4B K 107 6B k

12 0C FF 44 2C , 76 4C L 108 6C l

13 0D CR 45 2D - 77 4D M 109 6D m

14 0E SO 46 2E . 78 4E N 110 6E n

15 0F SI 47 2F / 79 4F O 111 6F o

16 10 DLE 48 30 0 80 50 P 112 70 p

17 11 DC1 49 31 1 81 51 Q 113 71 q

18 12 DC2 50 32 2 82 52 R 114 72 r

19 13 DC3 51 33 3 83 53 S 115 73 s

20 14 DC4 52 34 4 84 54 T 116 74 t

21 15 NAK 53 35 5 85 55 U 117 75 u

22 16 SYN 54 36 6 86 56 V 118 76 v

23 17 ETB 55 37 7 87 57 W 119 77 w

24 18 CAN 56 38 8 88 58 X 120 78 x

25 19 EM 57 39 9 89 59 Y 121 79 y

26 1A SUB 58 3A : 90 5A Z 122 7A z

27 1B ESCAPE 59 3B ; 91 5B [ 123 7B {

28 1C FS 60 3C < 92 5C \ 124 7C |

29 1D GS 61 3D = 93 5D ] 125 7D }

30 1E RS 62 3E > 94 5E ^ 126 7E ~

31 1F US 63 3F ? 95 5F _ 127 7F DEL

Dec = decimal Hex = hexadecimal CHR = character

LF = Line Feed CR = Carrage Return FF = Form Feed

DEL = Rubout

B.1

Page 58

Page 59

Appendix C IBM PC Interfacing

IMB PC Interfacing

10 REM *** DUMB TERMINAL PROGRAM FOR THE

15 REM *** Running under IBM basica

20 REM *** This program allows direct interaction between the

25 REM *** IBM-PC and digital I/O devices through the Digital232.

30 REM *** Make sure the Digital232 is configured for its factory

35 REM *** default conditions, described in Section 2 of this manual.

40 REM ***

45 REM *** IOtech, Inc., P.O.Box 21204,

50 REM *** Cleveland, Ohio 44121 (440) 439-4091

60 CLS

70 REM *** Set communications parameters of COM1 port

80 OPEN "COM1:9600,N,8,2,cs,ds" AS 1

90 REM *** Display characters from COM1

100 IF LOC(1) THEN PRINT INPUT$(LOC(1),1);

110 REM *** Transmit any available characters from the keyboard

120 K$=INKEY$

130 PRINT #1,K$;: PRINT K $;

140 GOTO 100

Digital232

Wiring Diagram for interfacing the Digital232 to an IBM PC

note: if the

connected to +Vtest pin 9.

Xon/Xoff

mode is enabled, then CTS pin 4 of the

Digital232

must be

C.1

Loading...

Loading...