Page 1

DBK52 14-Channel Thermocouple Input Module

Overview …… 1

Hardware Setup …… 2

Module Connection …… 2

Module Configuration …… 3

DaqBook/100 Series & /200 Series and DaqBoard [ISA type] Configuration …… 3

DaqBook/2000 Series and DaqBoard/2000 Series Configuration …… 3

Software Setup …… 4

DBK52 – Specifications …… 4

Reference Notes:

o Chapter 2 includes pinouts for P1, P2, P3, and P4. Refer to pinouts applicable to

Overview

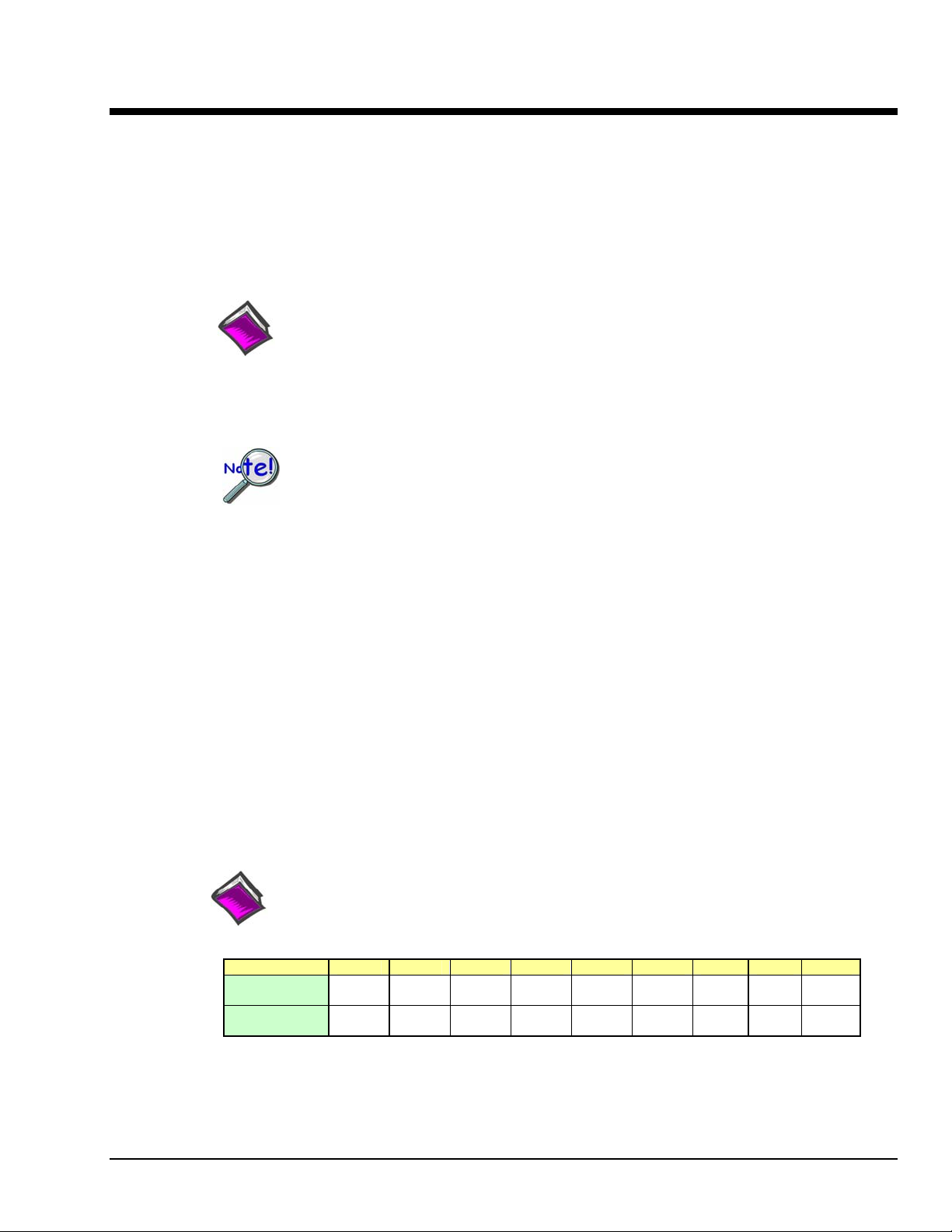

The DBK52 provides the ability to scan and input thermocouple data for various computer-based

temperature-monitoring systems. Features include:

• Each DBK52 can connect up to 14 thermocouples. Up to 16 DBK52s may attach to a single

your system, as needed.

o In regard to calculating system power requirements, refer to DBK Basics located

near the front of this manual.

DaqView Users: When DBK52 is used with /2000 Series Devices, the Internal Clock Speed

should be set to 100 kHz as described in Chapter 3, DBK Setup in DaqView.

LogBook or Daq Device to measure a maximum of 224 (16 × 14) temperatures.

• Standard, miniature jacks can connect to all T/C types.

• Onboard cold junction sensor (CJS) circuitry is accessible via a built-in channel to the system.

• A built-in short-to-ground channel back to the system eliminates offset errors via software.

• RC low-pass input filters reject high frequency noise for thermocouple shields.

• An external analog-common access jack provides a bias-current return path for differential

signal inputs.

• An onboard programmable gain amplifier supports most thermocouple types and temperature

ranges.

• Software-based linearization (in LogView and DaqView) converts analog signals into

temperature values.

Reference Note:

In regard to Daq devices, related material for programmers is included in the separate

Programmer’s Manual (p/n 1008-0901).

The following table shows the temperature range for each thermocouple type.

T/C Type J K T E N28 N14 S R B

Temperature

Range °C

Temperature

Range °F

-200 to

760

-328 to

1400

-200 to

1260

-328 to

2300

-200 to

400

-328 to

752

-270 to

1000

-454 to

1832

-270 to

400

-454 to

752

0 to

1300

32 to

2372

0 to

1780

32 to

3236

0 to

1780

32 to

3236

0 to

1820

32 to

3308

Thermocouple accuracy depends on the thermocouple itself, the cold-junction sensor, A/D conversion, and

linearization. The DBK52, LogBook, and Daq device systems use quality components and software

compensation to minimize error from these sources. Systems achieve a ±1°C CJS accuracy that contributes

to the overall accuracy. When the software is calibrated, gain and offset errors are virtually eliminated.

The DBK52’s built-in auto-zero channel dynamically eliminates any other system offset-errors.

DBK Option Cards and Modules 989594 DBK52, pg. 1

Page 2

True differential measurements of T/Cs require bias-current referenced to the analog common. Resistors

from each input T/C are connected to the analog common. Filter capacitors across each input operate with

input protection resistors to form a single-pole RC low-pass filter.

Hardware Setup

Module Connection

The DBK52 has miniature T/C jacks to connect different types of thermocouples and an analog-ground

access point. Connections are provided for 14 thermocouples. Thermocouple polarities must be

observed. Thermocouple types J, K, T, E, N28, N14, S, R and B are supported by the LogView or

DaqView software and may be connected to DBK52 board channels CH2 through CH15.

Note: CH0 is reserved for the cold-junction compensation sensor (factory installed).

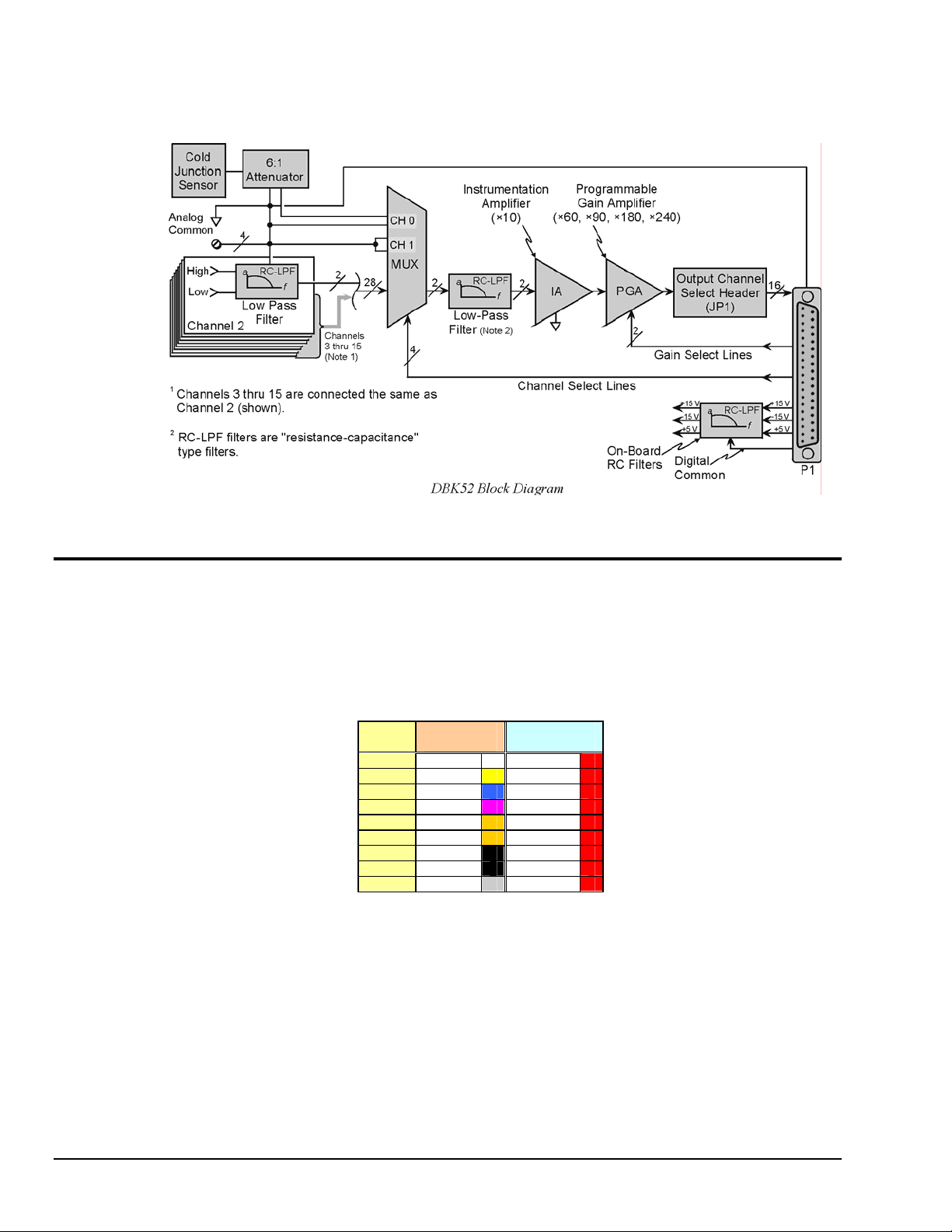

Thermocouple wire is standardized and color-coded as shown in the table. T/Cs have a very small output.

Long T/C leads can pickup lots of noise. Use shielding as needed, and average several readings in

software to minimize noise effects.

T/C

Type

J White Red

K Yellow Red

T Blue Red

E Violet Red

N28 Orange Red

N14 Orange Red

S Black Red

R Black Red

B Gray Red

(+) Lead to

Channel-Hi

(-) Lead to

Channel-Lo

CH1 is permanently shorted to allow software-driven auto-zero to compensate for

temperature drift.

After all connections are in place, secure wires to captive areas (pre-drilled holes) at the rear edge of the

board. Nylon tie wraps (not included) work well for this purpose.

DBK52, pg. 2 989594 DBK Option Cards and Modules

Page 3

Module Configuration

Up to 16 DBK52s may be connected to a LogBook or a Daq Device. As a daisy-chain

interface, each module must appear unique. Each module uses a different analog input

channel. To configure the module:

1. Assign a channel number to the module. The assigned number must

not be used by any other DBK card or module.

2. Locate the 16×2-pin header near the front of the board labeled JP1, and

place the jumper on the LogBook or Daq Device channel you wish to

use. There are 16 jumper locations on this header labeled CH0 through

CH15. Only one jumper setting is used on a single module; no other

module in a common daisy-chain can use the same jumper setting.

DaqBook/100 Series & /200 Series and DaqBoard [ISA type] Configuration

Three setup steps and needed to configure DaqBooks/100 Series & /200 Series devices and

DaqBoards [ISA type] for a DBK52.

1. If not using auxiliary power, place the JP1 jumper in the Analog Option Card Use (expanded

analog) mode.

Note:

These jumpers do not

apply to /2000 Series

devices.

To power the interface circuitry of the DBK52 via the internal ±15 VDC power supply,

JP1 must be set to “Analog Option Card Use.” However, if using auxiliary power, e.g.,

the DBK32A or the DBK33, you must remove both JP1 jumpers. Refer to

Power Requirements in the DBK Basics section and to the DBK32A and DBK33

sections for additional information, as applicable.

2. For DaqBook/100, DaqBook/112 and DaqBook/120 only, place the JP3 jumper in

bipolar mode.

3. For DaqBook/100, DaqBook/112 and DaqBook/120 only, place the JP4 jumper in

single-ended mode.

Note: The DaqBook/200 Series devices and DaqBoards do not have a JP4. The single-ended or differential

choice is made via software configuration commands.

DaqBook/2000 Series and DaqBoard/2000 Series Configuration

No jumper configurations are required for the /2000 series devices.

DBK Option Cards and Modules 989594 DBK52, pg. 3

Page 4

Software Setup

Reference Notes:

o DaqView users - Refer to Chapter 3, DBK Setup in DaqView.

o LogView users - Refer to Chapter 4, DBK Setup in LogView.

o DBK52 Calibration Disk – Each DBK52 card is shipped with a calibration disk with constants

used to correct gain and offset errors inherent in the hardware. This calibration is done

automatically by DaqView and LogView. Refer to the readme.txt file on the disk.

DaqView Users: When DBK52 is used with /2000 Series Devices, the Internal Clock Speed should be

set to 100 kHz as described in Chapter 4, DBK Setup in DaqView.

The DBK52 selection allows the user to define the thermocouple types by using the Type column of the

analog input spreadsheet.

Each DBK52 card is shipped with a calibration disk with constants used to correct gain and offset errors

inherent in the hardware. This gain and offset calibration is done automatically by DaqView and

LogView. See the DBK52 readme.txt file on the disk shipped with the board for details on creating this

file.

DBK52 - Specifications

Name/Function: Thermocouple Input Module

Connectors:

DB37 male, mates with P1.

Thermocouples attach directly to on-board jacks.

Thermocouple Types: J, K, S, T, E, B, R, N

Gain Ranges: ×60, ×90, ×180, ×240

Inputs:

14 differential thermocouples

1 cold-junction compensation

1 auto zero

Cold Junction Sensor Output: 100 mV/°C

Voltage Ranges/Gains:

Input Impedance: 20 kΩ

Input RC Filter -3 dB Frequency: 15.9 kHz

Gain Accuracy:

Uncalibrated: 0.15%

Calibrated: 0.02%

Maximum Input Voltage: 35 VDC

CMRR (Input Stage): 110 dB type DC to 60 Hz

Offset: Software compensated

Type/Range/Accuracy/Resolution: refer to the

following table

0 to 80 mV ×60

0 to 50 mV ×90

0 to 25 mV ×180

0 to 20 mV ×240

0 to ±10 mVDC

Thermocouple Reference

Range Accuracy Resolution

Type Min Max (<0°C) (>0°C)

J

K

T

E

N28

N14

S

R

B

-200°C 760°C 0.6°C 0.6°C 1.2°C 0.5°C 0.1°C 0.1°C

-200°C 1260°C 1.6°C 1.0°C 1.1°C 0.8°C 0.1°C 0.1°C

-200°C 400°C 1.4°C 0.8°C 0.8°C 0.3°C 0.1°C 0.1°C

-270°C 1000°C 1.4°C 0.9°C 1.6°C 0.7°C 0.1°C 0.1°C

-270°C 400°C 0.8°C 0.8°C 1.0°C 1.0°C 0.1°C 0.1°C

0°C 1300°C

0°C 1780°C

0°C 1780°C

0°C 1820°C

— 1.0°C — 5.0°C — 5.0°C

— 1.6°C — 1.3°C — 0.1°C

— 1.6°C — 1.7°C — 0.1°C

— 1.8°C — 1.5°C — 0.1°C

12-bit

<0°C

12-bit

>0°C

16-bit

<0°C

16-bit

>0°C

DBK52, pg. 4 989594 DBK Option Cards and Modules

Loading...

Loading...