Page 1

DBK44 2-Channel 5B Signal-Conditioning Card

Overview ….. 1

Hardware Setup ….. 2

Power Considerations ….. 2

Card Configuration ….. 3

5B Module Connection ….. 3

Terminal Block Connection ….. 4

P1 Connection ….. 4

CE Compliance ….. 5

DaqBook/100 Series & /200 Series and DaqBoard [ISA type] Configuration …… 5

DaqBook/2000 Series and DaqBoard/2000 Series Configuration …… 6

Software Setup ….. 6

mx+b Values for 5B Modules ….. 7

DBK44 – Specifications ….. 7

Reference Notes:

o Chapter 2 includes pinouts for P1, P2, P3, and P4. Refer to pinouts applicable to your

system, as needed.

o In regard to calculating system power requirements, refer to DBK Basics located near

the front of this manual.

Reference Note:

Users of the DBK44 signal-conditioning card may be interested in the DBK207 and DBK207/CJC,

Carrier Boards for 5B Compatible Analog I/O Modules. Each DBK207 and DBK207/CJC board

includes a 100-pin P4 connector for DaqBoard/2000 Series and /2000c Series compatibility, two P1

connectors for analog expansion, a power connection terminal, and 16 signal terminal blocks. In

addition, the DBK207/CJC board includes CJC (Cold Junction Compensation) for thermocouple

applications. DBK207 and DBK207/CJC can be mounted in Nema-type panels.

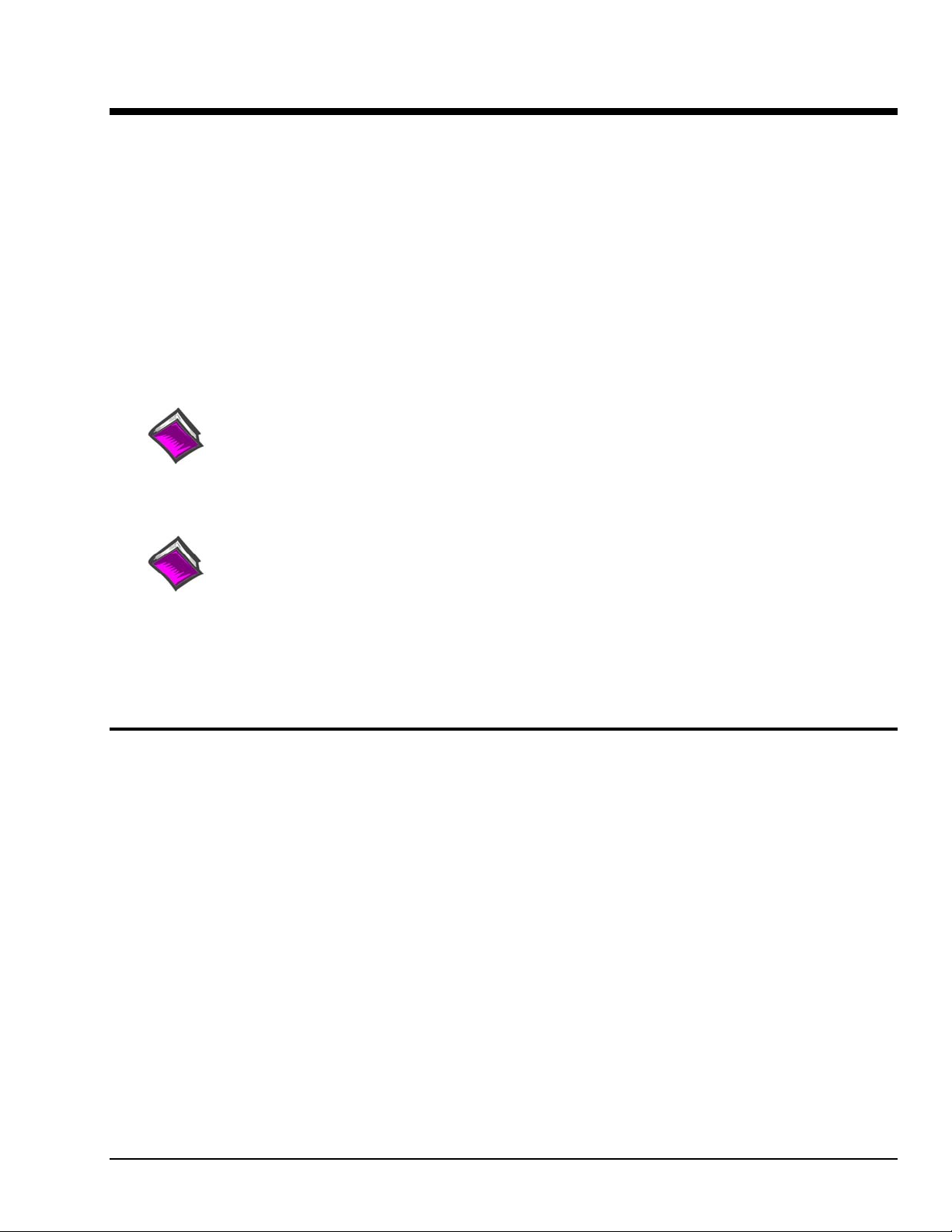

Overview

The 2-channel DBK44 allows LogBook or Daq device systems to use any combination of 5B signalconditioning modules. 5B modules can accommodate a variety of signals (low-level thermocouple signals

to strain-gage signals, etc). Configuration options are flexible. You can select the type of signal attached

to each channel. One LogBook or Daq device can support up to 128 DBK44 cards, providing up to 256

isolated, analog input channels.

DBK Option Cards and Modules 877095 DBK44, pg. 1

Page 2

The LogBook or Daq device scans the DBK44’s channels at the same 10 µs/channel rate as other DBKs

(256 scans in 2.56 ms in a full system). Each user-installed 5B module offers 500 V isolation from the

system and between channels. The DBK44 has convenient screw-terminal blocks for signal inputs and

excitation outputs (for use with a strain gage or RTD). Cold junction compensators (CJC) are installed and

ready to use with thermocouple 5B modules. Sockets are provided for AC1362 current-sense resistor

modules.

Hardware Setup

Power Considerations

The DBK44 requires +5 and ±15 VDC from a LogBook, Daq device P1

connector, or auxiliary power supply. In some applications, the DBK44 can draw

enough power from the LogBook’s internal power supply via the P1 connector.

However, the 5B power requirements (+5 VDC only) may be greater than the

LogBook or DaqBook/DaqBoard can provide (see table).

For applications with more than 4 channels, it may be better to use

the DBK42 instead of the DBK44. The DBK42 is a 16-channel

module with a built-in power supply.

External power can be obtained from any regulated 5 V source or from a

TR-4 power supply. External power attaches to the DBK44 via onboard

screw-terminal connections (the Auxiliary Power Input J9 Combicon

terminal at the rear of the board).

5B

Model

5B30 30 mA

5B31 30 mA

5B32 30 mA

5B34 30 mA

5B37 30 mA

5B38 200 mA

5B39 *170 mA

5B40 30 mA

5B41 30 mA

5B47 30 mA

* Maximum output load

resistance is 750 Ω

Current

Required

The 5B38 series strain-gage modules with excitation output require an external power

source. Auxiliary power is also necessary in systems equipped with more than one DBK44.

Prior to using auxiliary power, you must select AUXL on the Power Source Select Jumper

(J10).

CAUTION

DBK44, pg. 2 877095 DBK Option Cards and Modules

Auxiliary power input must not exceed +5 VDC. DBK44 does not regulate auxiliary

power input.

Page 3

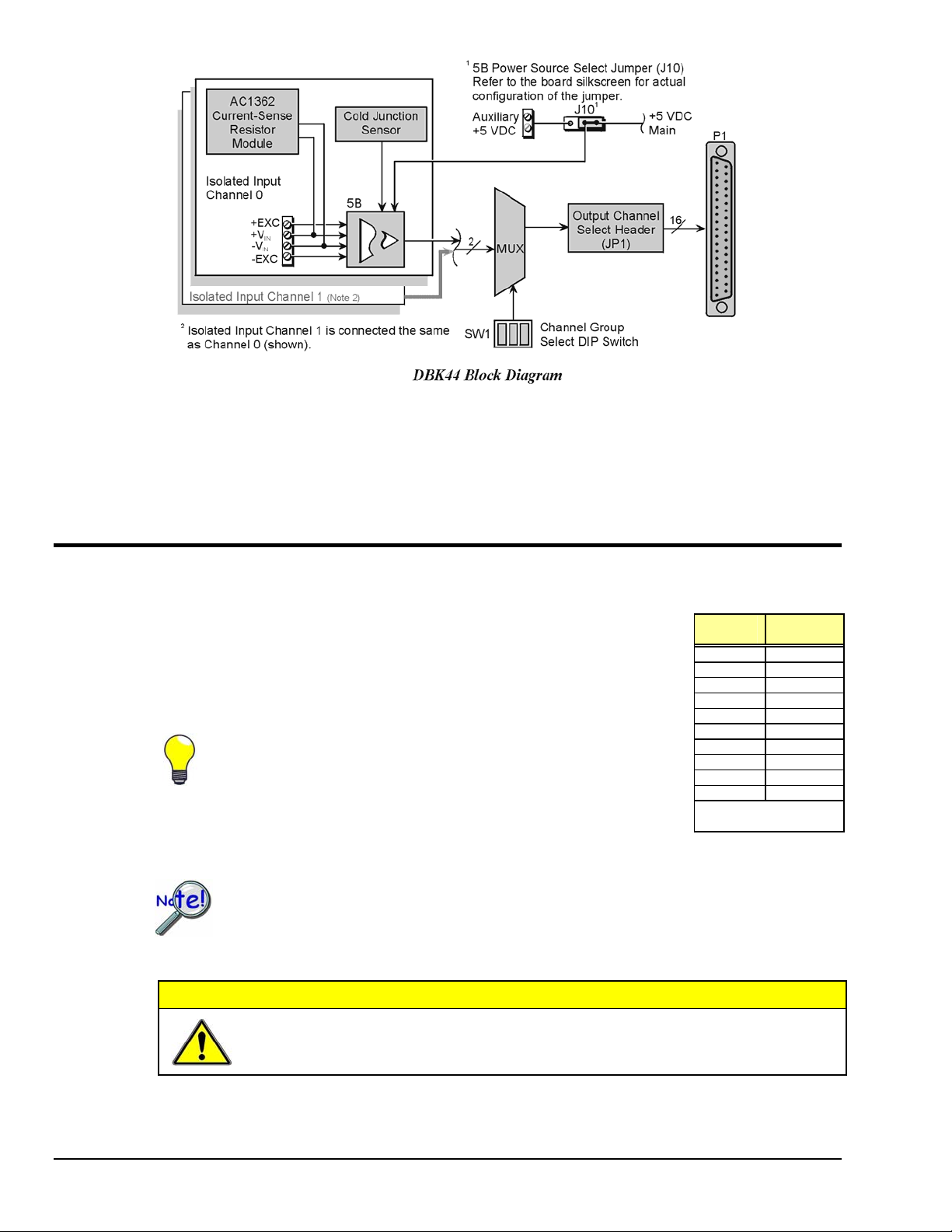

Card Configuration

Up to 128 DBK44s may connect to a LogBook or a Daq device system. Since this is a

daisy-chain interface, each module must appear unique and use a different analog input

channel. To configure the card’s channel, you must set the JP1 jumper and the

SW1 DIP switch to your chosen channel as follows.

1. Locate the 16×2-pin header (labeled JP1) near the front of the card. Note the

16 jumper locations labeled CH0 through CH15 to match the main channel.

2. Place the JP1 jumper on the channel you wish to use. Only one jumper is

used per card, but up to 8 DBK44s can occupy one main channel and use the

same JP1 setting (but with different SW1 settings).

3. Locate the SW1 DIP switch that serves as a channel group select switch and

can distinguish up to 8 cards on a channel.

4. Place the 3 mini switches (CBA) in the position that corresponds to your

chosen channel as shown in the table below. For each JP1 setting, there

are 8 possible SW1 settings to allow two input channels per card).

Channel Pair Determined by JP1 and SW1

JP1

Jumper

CH0 16-17 18-19 20-21 22-23 24-25 26-27 28-29 30-31

CH1 32-33 34-35 36-37 38-39 40-41 42-43 44-45 46-47

CH2 48-49 50-51 52-53 54-55 56-57 58-59 60-61 62-63

CH3 64-65 66-67 68-69 70-71 72-73 74-75 76-77 78-79

CH4 80-81 82-83 84-85 86-87 88-89 90-91 92-93 94-95

CH5 96-97 98-99 100-101 102-103 104-105 106-107 108-109 110-111

CH6 112-113 114-115 116-117 118-119 120-121 122-123 124-125 126-127

CH7 128-129 130-131 132-133 134-135 136-137 138-139 140-141 142-143

CH8 144-145 146-147 148-149 150-151 152-153 154-155 156-157 158-159

CH9 160-161 162-163 164-165 166-167 168-169 170-171 172-173 174-175

CH10 176-177 178-179 180-181 182-183 184-185 186-187 188-189 190-191

CH11 192-193 194-195 196-197 198-199 200-201 202-203 204-205 206-207

CH12 208-209 210-211 212-213 214-215 216-217 218-219 220-221 222-223

CH13 224-225 226-227 228-229 230-231 232-233 234-235 236-237 238-239

CH14 240-241 242-243 244-245 246-247 248-249 250-251 252-253 254-255

CH15 256-257 258-259 260-261 262-263 264-265 266-267 268-269 270-271

CBA CBA CBA CBA CBA CBA CBA CBA

0 0 0 0 0 1 0 1 0 0 1 1 1 0 0 1 0 1 11 0 1 1 1

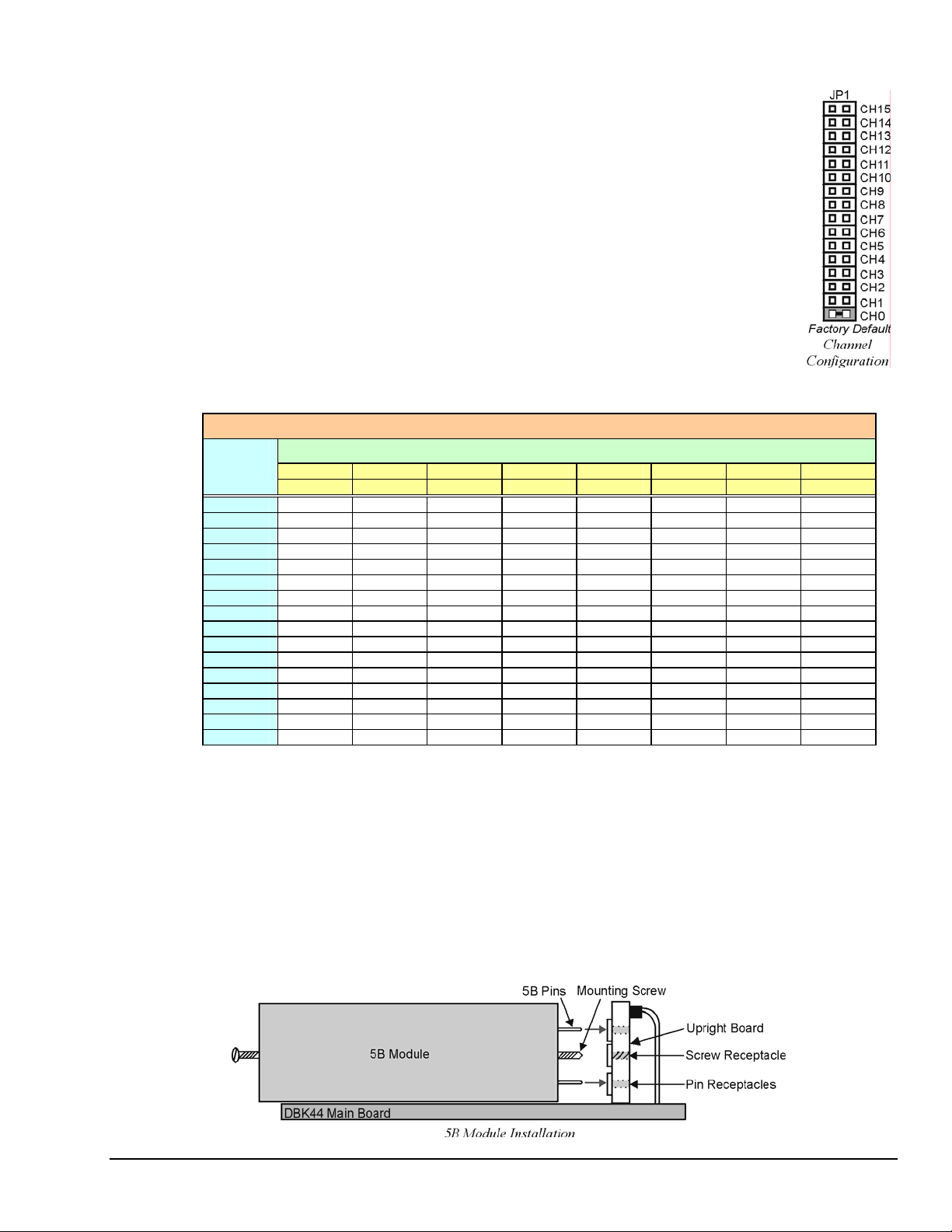

5B Module Connection

Each input of the DBK44 is processed through a user-installed 5B signal-conditioning module. Different

5B modules are used with different transducer and signal sources. To install the modules:

1. Remove all power from the DBK44.

SW1 DIP Switch Setting

2. Match the footprint of the module with the footprint on the circuit board (see figure).

3. Gently place the module into the footprint, and screw it down.

4. Record the channel the module was placed in.

DBK Option Cards and Modules 877095 DBK44, pg. 3

Page 4

When installing current input modules (SC-5B32 series), be sure to install the current-sense resistor

(SC-AC-1362 shipped with the SC-5B32) in the resistor socket (J4 for ch 0, J3 for ch 1) near the input

screw-terminal block (see figure).

Terminal Block Connection

Input signals (and excitation leads) must be wired to the DBK44 via the 4-contact terminal blocks at the

end of the card. These terminal blocks connect internally to their corresponding signal conditioning

module. The terminal blocks accept up to 14-gage wire into quick-connect screw terminals that are labeled

as to their function. Each type of input signal or transducer (such as a thermocouple or strain gage) should

be wired to its terminal block as shown in the figure. Wiring is shown for RTDs, thermocouples, 20 mA

circuits, mV/V connections, and for full- and half-bridge strain gages.

Shock Hazard! De-energize circuits connected to the DBK44 before changing the

wiring or configuration. The DBK44 is designed to sense signals that may carry

dangerous voltages.

WARNING

P1 Connection

Reference Notes:

Chapter 2 includes pinouts for P1, P2, P3, and P4. Refer to pinouts applicable to your

system, as needed.

The DBK44 attaches to the LogBook’s or Daq Device’s P1 analog I/O connector. Connect the CA-37-x

accessory ribbon cable (with x indicating the number of cards to be connected) from P1 to the DB37

connector at the end of the DBK44 card.

DBK44, pg. 4 877095 DBK Option Cards and Modules

Page 5

Note: A series of interface cables are available to connect up to 128 DBK44s. You can also use a DBK41

DBK44 can be connected to the P1 connector of DBK200, DBK201, DBK202, or DBK203. Connect the

CA-37-x accessory ribbon cable (with x indicating the number of cards to be connected) from P1 to the

DB37 connector at the end of the DBK44 card.

Note: Interface cables are available to connect up to 128 DBK44s.

CE Compliance

10-slot expansion chassis.

Reference Notes:

Should your data acquisition system need to comply with CE standards, refer to

the CE Compliance section of the chapter Signal Management.

DaqBook/100 Series & /200 Series and DaqBoard [ISA type] Configuration

The DBK44 requires two setup steps in DaqBooks/100 Series & /200 Series devices and

DaqBoards [ISA type]—jumpers JP1 and JP4.

1. If not using auxiliary power, ensure the JP1 jumper is configured for Analog Option Card Use

(expanded analog mode).

Note: This default position is necessary to power the interface circuitry of the DBK44 via the

internal ±15 VDC power supply. If using auxiliary power from a DBK32A or DBK33 card,

you must remove both JP1 jumpers. Refer to Power Requirements in the DBK Basics section.

Also refer to the DBK32A and DBK33 sections as applicable.

2. For DaqBook/100, /112, and /120 only, place the JP4 jumper in the DaqBook or DaqBoard [ISA

type] in single-ended mode. Note that analog expansion cards convert all input signals to single-

ended voltages referenced to analog common.

Note: The configuration of the JP3 jumper depends on the output range of the 5B module. For

example, a 5B31 volt input module has an output range of -5 to +5 V in bipolar mode. A

5B47 T/C module (output 0 to +5 V) could use bipolar mode, but unipolar mode is more

appropriate.

DBK Option Cards and Modules 877095 DBK44, pg. 5

Page 6

DaqBook/2000 Series and DaqBoard/2000 Series Configuration

No jumper configurations are required for these 2000 series devices.

Software Setup

Reference Notes:

o DaqView users - Refer to chapter 3, DBK Setup in DaqView.

o LogView users - Refer to chapter 4, DBK Setup in LogView.

DBK44, pg. 6 877095 DBK Option Cards and Modules

Page 7

mx+b Values for 5B Modules

The mx+b calculations for most 5B modules are included within LogView software. The table shows the

m and b values for various 5B modules.

5B Module m Value b Value Engineering

Isolated Voltage Input (5 V Current Requirement, 30 mA)

SC-5B31-01 1/5 0 mV, V

SC-5B31-02 1 0 mV, V

SC-5B31-03 2 0 mV, V

SC-5B31-04 2/5 -1 mV, V

SC-5B31-05 2 -5 mV, V

SC-5B31-06 4 -10 mV, V

Isolated Wideband Voltage (5 V Current Requirement, 30mA)

SC-5B41-01 1/5 0 V

SC-5B41-02 1 0 V

SC-5B41-03 2 0 V

SC-5B41-04 2/5 -1 V

SC-5B41-05 2 -5 V

SC-5B41-06 4 -10 V

Isolated Millivolt Input (5 V Current Requirement, 30 mA)

SC-5B30-01 2 0 mV

SC-5B30-02 10 0 mV

SC-5B30-03 20 0 mV

SC-5B30-04 4 -10 mV

SC-5B30-05 20 -50 mV

SC-5B30-06 40 -100 mV

Isolated Wideband Millivolt (5 V Current Requirement, 30 mA)

SC-5B40-01 2 0 mV

SC-5B40-02 10 0 mV

SC-5B40-03 20 0 mV

SC-5B40-04 4 -10 mV

SC-5B40-05 20 -50 mV

SC-5B40-06 40 -100 mV

Isolated Linearized T/C Input (5 V Current Requirement, 30 mA)

SC-5B47-J-01 152 0 °C

SC-5B47-J-02 80 -100 °C

SC-5B47-J-03 100 0 °C

SC-5B47-K-04 200 0 °C

SC-5B47-K-05 100 0 °C

SC-5B47-T-06 100 -100 °C

SC-5B47-T-07 40 0 °C

SC-5B47-E-08 200 0 °C

SC-5B47-R-09 250 +500 °C

SC-5B47-S-10 250 +500 °C

SC-5B47-S-11 260 +500 °C

Isolated RTD Input (5 V Current Requirement, 30 mA)

SC-5B34-01 40 -100 °C

SC-5B34-02 20 0 °C

SC-5B34-03 40 0 °C

SC-5B34-04 120 0 °C

SC-5B34-C-01 24 0 °C

SC-5B34-C-02 24 0 °C

SC-5B34-N-01 24 0 °C

Isolated Current Input (5 V Current Requirement, 30 mA)

SC-5B32-01 3.2 4 mA

SC-5B32-02 4 0 mA

Voltage Switch Input

SC-AC-1367 1 0 V

Unit(s)

DBK Option Cards and Modules 877095 DBK44, pg. 7

Page 8

DBK44 – Specifications

Name/Function: 2-Channel 5B Signal Conditioning Card

Module Capacity: 2 “input only” 5B modules

Weight: 0.25 kg (8 oz.) with no modules installed

Cable (optional): CA-37-x

DC Input Fuse: 4 A

Connections:

Male DB37 mates via CA-37-1 cable with P1 on the LogBook,

DaqBook, ISA-type DaqBoard*, or Daq PC-Card.

User connections include 8 screw-terminals (4 per channel).

Screw terminations, per channel, are: +EXC, +Vin, -Vin, -EXC

Isolation to Primary Acquisition Device (LogBook or Daq Device):

Input Power: 0 VDC

Signal Inputs: 1500 VDC

Input Channel-to-Channel: 500 VDC

Environmental:

Operating Temperature: 0 to 50°C

Humidity: 0 to 80% RH @ 30°C; de-rate 3%/°C

Altitude: 0 to 2000 m

*Note: For DaqBoard/2000 Series and /2000c Series boards, the use of a

DBK200 Series P4-to-P1 adapter is required.

DBK44, pg. 8 877095 DBK Option Cards and Modules

Loading...

Loading...