Page 1

DBK213 Screw-Terminal & Expansion Card Module

3-Card Slot, Includes P1/P2/P3/P4 compatibility for Analog I/O, Digital I/O, & Pulse/Frequency

Overview …… 1

Connection Tips…… 2

Installing DBK Cards …… 3

System Examples …… 4

Using the Screw-Terminal Blocks …… 6

Adding RC Filter Networks …… 10

Specifications …… 12

Reference Notes …… 13

Overview

The DBK213 module is compatible with the following products:

• DaqBook/2000 Series • DaqBoard/2000 Series • DaqLab • DaqScan

The DBK213 module includes:

o P1, male DB37 connector for Analog I/O.

o P2, male DB37 connector for Digital I/O.

o P3, male DB37 connector for Pulse/Frequency (Digital and Counter/Timer) I/O.

o P4, 100-pin connector. Provides same signal connection as P1, P2, and P3 combined.

o Three slots for housing optional DBK cards. The DB37 connector of each card will extend out

through the rear panel where it can be secured with hex nuts.

o 12 on-board screw-terminal blocks (accessible after removal of cover)

o The terminal blocks [TB1 through TB12] tie in to P1, P2, P3, and P4 and provide for easy signal

connection.

o Three front panel slots for wiring pass-through.

o On-board socket locations for custom RC Filter networks (accessible after removal of cover).

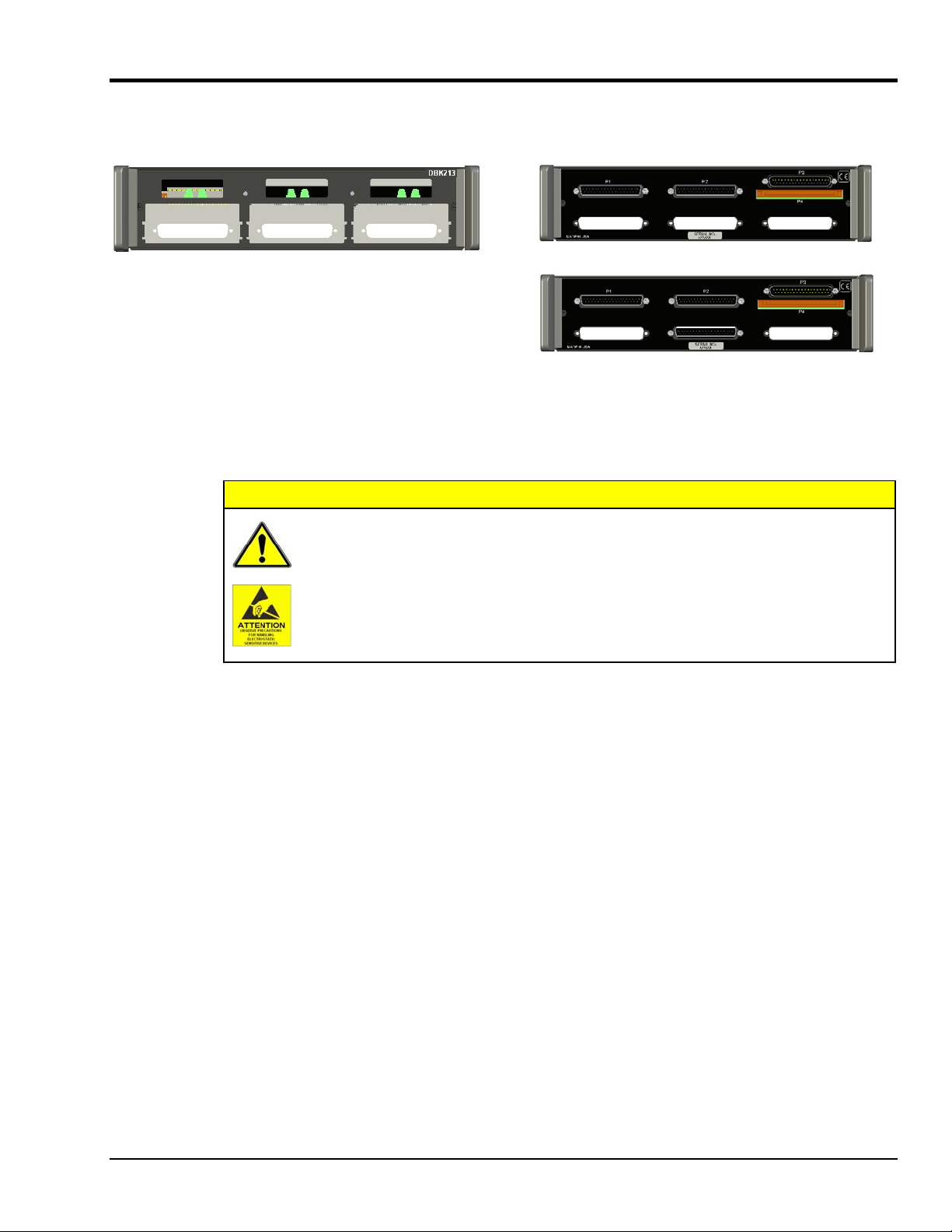

DBK213 Front Panel

Upper Slots for Terminal Board Wiring Pass-Through

Lower Slots for Housing up to 3 DBK options, 1 per slot

DBK213 Rear Panel

The upper section includes P1, P2, P3 and P4 connectors. The lower section

has 3 openings for pass-through of DB37 connectors from optional DBK cards.

The three DB37 connectors can be used as direct connections points for I/O signals, or signals can be

connected to each 37-pin connector via a DBK card or module. The lower section of the DBK213 includes

three built-in expansion slots for housing card options.

The unit includes screw-terminal access to all analog and digital I/O from the host data acquisition device.

Related to the screw-terminals are 3 front panel upper slots for routing all I/O wiring.

DBK Option Cards and Modules 969294 DBK213, pg. 1

Page 2

Connection Tips

CAUTION

Turn off power to the host PC and externally connected equipment prior to connecting

cables or signal lines to DBKs. Electric shock or damage to equipment can result even

under low-voltage conditions.

Take ESD precautions (packaging, proper handling, grounded wrist strap, etc.)

Use care to avoid touching board surfaces and onboard components. Only handle

boards by their edges (or ORBs, if applicable). Ensure boards do not come into

contact with foreign elements such as oils, water, and industrial particulate.

Do not confuse connectors. Ensure that you only connect P1 I/Os to P1, P2 I/Os to P2,

and P3 I/Os to P3. Improper connection may result in equipment damage.

When using P4, e.g., for a DaqBoard/2000, be sure to align the P4 orientation

indicators [white arrows] prior to mating the P4 connectors.

1. Ensure power is removed from the device(s) to be connected.

2. Observe ESD precautions when handling the board and making connections.

3. Do not make redundant connections. For example, for ANALOG IN you could use

the P1 (DB37) connector or Terminal Blocks TB9 through TB12. You would not use both

sets of ANALOG IN connectors.

4. You do not need to remove the cover unless you need to access a terminal block or customize

an RC filter network. Information regarding both tasks follows shortly. Note that RC filter

networks are not to be made or used in association with additional DBK expansion options.

5. DBK213’s 100-pin P4 connects to a DaqBoard/2000 Series board’s P4 via a CA-195

one-hundred conductor ribbon cable.

The DaqBoard/2000 Series boards communicate [external from the host

PC] through a 100-pin P4 connector. The P1, P2, and P3 connectors

discussed in association with these boards are subset connectors of the 100pin P4 connector. The System Connections and Pinouts chapters of the

product hardware manuals include pinouts.

6. Connections to the DB37 connectors are made via CA-37 cables or CA-255 cables:

(a) P1 connects to an analog DBK card or module’s P1 connector.

(b) P2 connects to a Digital DBK card or module’s P2 connector.

(c) P3 connects to a Pulse/Frequency DBK card module’s P3 connector.

7. Refer to the separate CE Cable Kit instructions that are included with the associated

CE cable kit.

DBK213, pg. 2

969294 DBK Option Cards and Modules

Page 3

Installing DBK Cards

Front Panel with 3 Vacant Card Slots

Beneath

P3

The DBK213 has three card slots which allow for the easy installation of DBK cards. To install a card

observe the following CAUTION and then complete the few simple steps.

Beneath

P2

Turn off power to the host PC and externally connected equipment prior to connecting

cables or signal lines to DBKs. Electric shock or damage to equipment can result even

under low-voltage conditions.

Take ESD precautions (packaging, proper handling, grounded wrist strap, etc.)

Use care to avoid touching board surfaces and onboard components. Only handle

boards by their edges (or ORBs, if applicable). Ensure boards do not come into

contact with foreign elements such as oils, water, and industrial particulate.

Beneath

P1 P2 P3

Rear Panel View with No Card Installed

P1

Rear Panel View with

Card Installed in Slot 2 Beneath P2

CAUTION

1. Refer to your specific DBK card instructions prior to installing the card. You may need to make

physical hardware configurations, for example, regarding channel assignments.

2. Complete all DBK card configuration per your application and channel assignment needs.

3. Make signal line connections on your DBK card as applicable. Screw-terminal connections and BNC

connections are typical.

4. If hex nuts are present on your DBK card’s DB37 connector, remove them and put them aside for

reuse in step 7.

5. Using the lower card-edge-guide on the DBK213 front panel [and possibly the upper guide for high

cards such as the DBK82], carefully slide the card into the desired slot such that the card’s DB37

connector goes to the rear panel of the DBK213. The following should be considered when choosing

a card slot.

o Analog I/O cards will connect to the DBK213’s P1 male DB37 connector.

o Digital I/O cards will connect to the DBK213’s P2 male DB37 connector.

o Pulse/Frequency (Digital and Counter/Timer) I/O will connect to the DBK213’s P3

male DB37 connector.

6. Push the DBK card until its DB37 connector extends through the rear panel of the DBK213.

7. Using the hex nuts removed in step 4 (or replacement hex nuts if needed), secure the card at the rear

panel. Tighten the hex nuts snug, but do not over tighten.

8. Repeat these steps for each remaining card.

DBK Option Cards and Modules 969294 DBK213, pg. 3

Page 4

System Examples

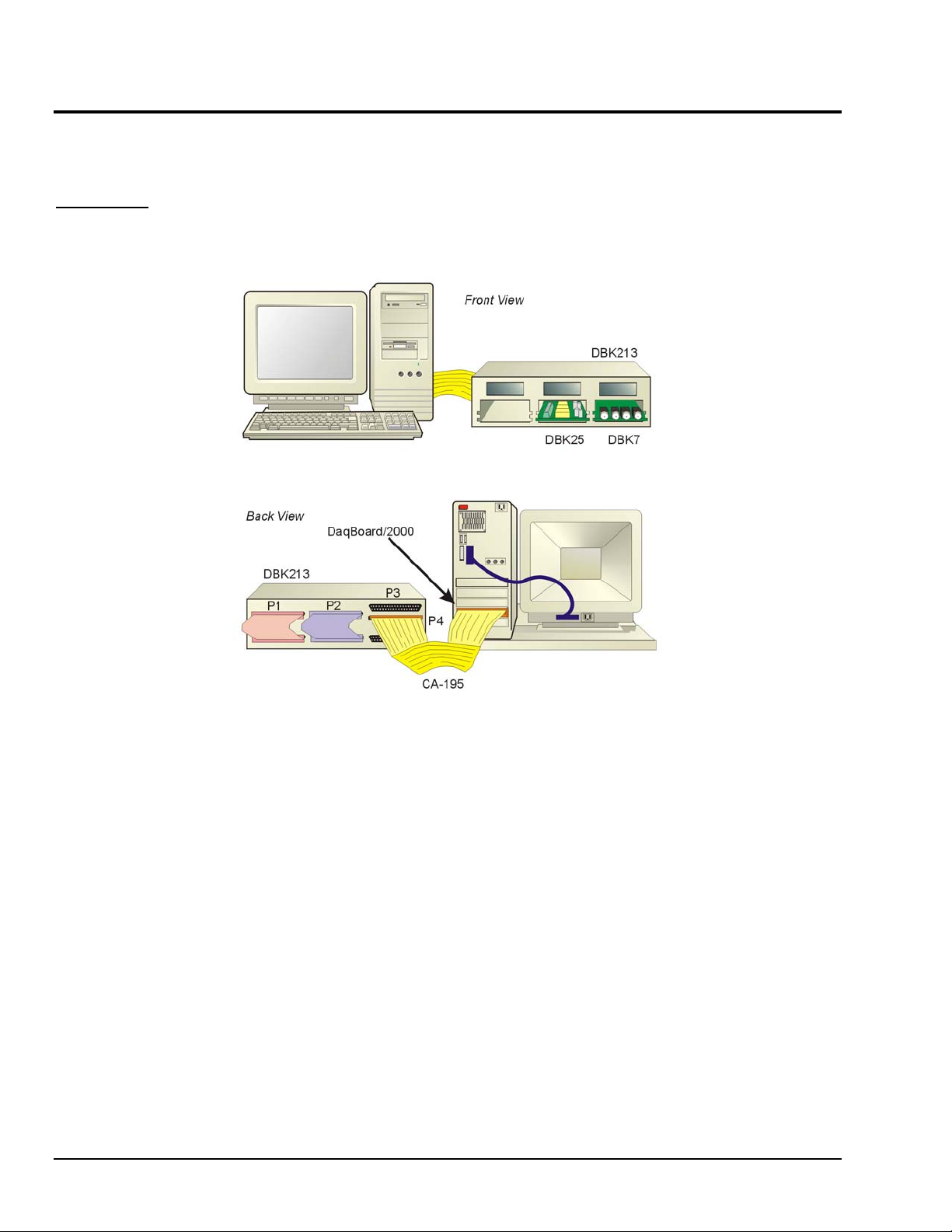

Example 1:

DaqBoard/2000 • DBK7 Analog I/O Card • DBK25 Digital I/O Card

Notes regarding the above system example:

1) A CA-195 100-conductor ribbon cable connects the P4 connector of the DBK213 to the P4 connector of the

DaqBoard/2000 (which is installed in the host PC).

2) In the illustration, DBK213 is housing a DBK7 (Analog I/O card) and a DBK25 (Digital I/O card).

3) A CA-255 [or CA-37] cable is used to connect the DBK7’s DB37 P1 connector to the DBK213’s P1 connector.

4) A CA-255 [or CA-37] cable is used to connect the DBK25’s DB37 P2 connector to the DBK213’s P2 connector.

DBK213, pg. 4

969294 DBK Option Cards and Modules

Page 5

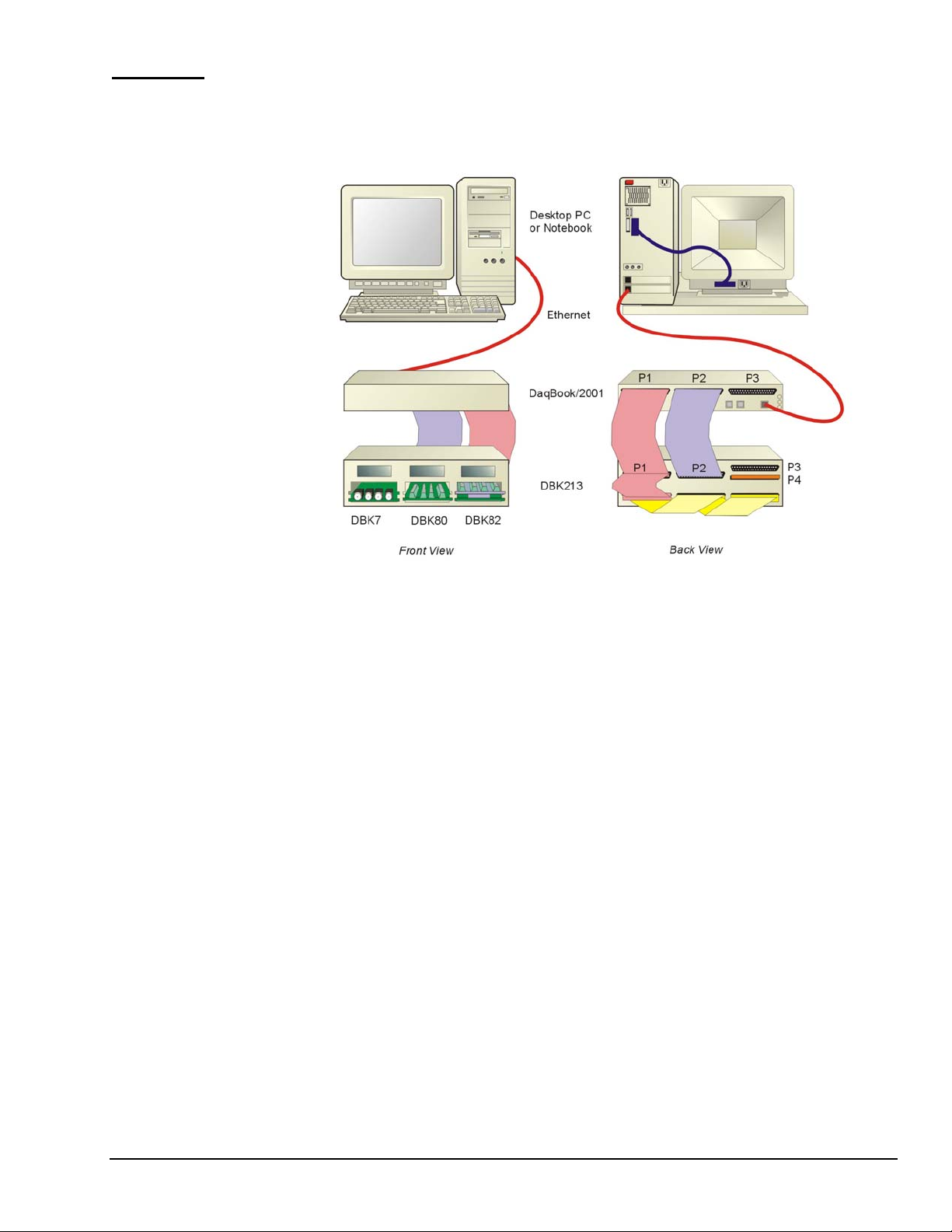

Example 2:

DaqBoook/2001 • DBK7 • DBK80 • DBK82

-------- (3 Analog I/O Cards)---------

Notes regarding the above system example:

1) Either of two Ethernet cables can be used: CA-242 is a 1.5 ft cable; CA-242-7 is a 7 ft. cable.

2) In the illustration, DBK213 is housing a DBK7, DBK80, and DBK82. Each is an analog card that will make use of P1

in regard to analog signal I/O.

st

P1 Cable (back view, bottom cable): A CA-37-3 cable is being used to link together to DB37 connectors of all

3) 1

three analog DBK cards.

nd

P1 Cable (back view, left cable): A CA-255-2T is being used to connect the other P1 cable and the DBK213’s P1

4) 2

to the P1 connector of the DaqBook/2001.

5) The DBK213’s P1 connector [rear panel, upper-left] connects to the internal screw-terminal board to which analog I/O

signals could be connected via wire. The wires would be routed out through the upper slots of the front panel.

6) A CA-255 [or CA-37] cable is used to connect the DBK213’s P2 connector to the DaqBook/2001 P2 connector.

7) The DBK213’s P2 connector connects to the internal screw-terminal board, to which digital I/O signals could be

connected via wire. The wires would be routed out through the upper slots of the front panel.

8) In a different scenario, the DBK213’s P2 connector could be connected to digital DBK options instead of connecting

the P1 connector to analog DBK options as illustrated.

DBK Option Cards and Modules 969294 DBK213, pg. 5

Page 6

Using the Screw-Terminal Blocks

You must remove the DBK213 module’s cover plate to access the screw terminal blocks. This is described in steps

1 and 2 below.

1. Remove the top inward screws from each of the 4 mounting brackets. See following figure.

To remove the cover plate you

must first remove the top

inward screw from each of the

4 mounting brackets.

The Cover Plate is Secured by 4 Srews

2. After the 4 screws have been removed, carefully remove the cover plate.

3. Make the wiring connections to the terminals. Refer to the board’s silkscreen and to

the pin correlations on the next few pages.

[2 Screws per-side]

In general, the following terminal block-to-signal relationships apply:

DBK213

Terminal

Blocks

TB9

TB10

TB11

TB12

TB5

TB6

TB7

TB8

TB1

TB2

TB3

TB4

Used for . . . Alternative

ANALOG I/O P1 or P4*

DIGITAL I/O P2 or P4*

PULSE/

FREQUENCY/

DIGITAL I/O

P3 or P4*

DBK213 Board

Note that the P3 DB37 Connector and its associated board cable

has been removed for clarity.

* P4 is used for connecting to DaqBoard/2000 Series devices.

DBK213, pg. 6

4. Tighten the terminal block screws snug; but do not over-tighten.

5. After all terminal connections are made and verified correct, return the cover to the unit and

secure in place with the 4 screws removed earlier. Tighten snug, but do not over-tighten.

The following pages correlate the DBK213 terminal block connectors with the associated pins of

the P1, P2, and P3 DB37 connectors. Note that the System Connections and Pinouts chapter

contains additional pin-outs, and includes references to the 100-pin P4 connector.

969294 DBK Option Cards and Modules

Page 7

Correlation to P1 – Pertains to Terminal Blocks TB9, TB10, TB11, and TB12 for Analog I/O.

TB9 P1 Pin Number and Description (see Note 1)

DIFF SE

0H 0 37 CH 0 IN (Single-Ended Mode) / CH 0 HI IN (Differential Mode)

0L 8 18 CH 8 IN (Single-Ended Mode) / CH 0 LO IN (Differential Mode)

1H 1 36 CH 1 IN (Single-Ended Mode) / CH 1 HI IN (Differential Mode)

1L 9 17 CH 9 IN (Single-Ended Mode) / CH 1 LO IN (Differential Mode)

2H 2 35 CH 2 IN (Single-Ended Mode) / CH 2 HI IN (Differential Mode)

2L 10 16 CH 10 IN (Single-Ended Mode) / CH 2 LO IN (Differential Mode)

3H 3 34 CH 3 IN (Single-Ended Mode) / CH 3 HI IN (Differential Mode)

3L 11 15 CH 11 IN (Single-Ended Mode) / CH 3 LO IN (Differential Mode)

FILT CAP LO N/A For RC filter networks install a wire jumper between the relevant FILT CAP LO and

SGND 19 Signal Ground, Sense Common; reference ground, not for general use.

TB10 P1 Pin Number and Description (see Note 1)

DIFF SE

4H 4 33 CH 4 IN (Single-Ended Mode) / CH 4 HI IN (Differential Mode)

4L 12 14 CH 12 IN (Single-Ended Mode) / CH 4 LO IN (Differential Mode)

5H 5 32 CH 5 IN (Single-Ended Mode) / CH 5 HI IN (Differential Mode)

5L 13 13 CH 13 IN (Single-Ended Mode) / CH 5 LO IN (Differential Mode)

6H 6 31 CH 6 IN (Single-Ended Mode) / CH 6 HI IN (Differential Mode)

6L 14 12 CH 14 IN (Single-Ended Mode) / CH 6 LO IN (Differential Mode)

7H 7 30 CH 7 IN (Single-Ended Mode) / CH 7 HI IN (Differential Mode)

7L 15 11 CH 15 IN (Single-Ended Mode) / CH 7 LO IN (Differential Mode)

FILT CAP LO N/A For RC filter networks install a wire jumper between the relevant FILT CAP LO and

SGND 19 Signal Ground, Sense Common; reference ground, not for general use.

TB11 P1 Pin Number and Description

TTL TRIG 25 TTL Trigger, Digital IN, External TTL Trigger Input

A/I CLK 20 A/I Clock, External ADC Pacer Clock Input/ Internal ADC Pacer Clock Output

EXP 5 5 Expansion 5. Digital OUT, external GAIN select bit 1

EXP 6 6 Expansion 6. Digital OUT, external GAIN select bit 0

EXP 7 3 Expansion 7. Digital OUT, external ADDRESS, select bit 3

EXP 8 22 Expansion 8. Digital OUT, external ADDRESS, select bit 2

EXP 9 4 Expansion 9. Digital OUT, external ADDRESS, select bit 1

EXP 10 23 Expansion 10. Digital OUT, external ADDRESS, select bit 0

EXP 11 26 Expansion 11. Simultaneous Sample and Hold (SSH)

AGND * Analog Ground, Common

TB12 P1 Pin Number and Description

AGND * Analog Ground, Common

AGND * Analog Ground, Common

AGND * Analog Ground, Common

AGND * Analog Ground, Common

AGND * Analog Ground, Common

AGND * Analog Ground, Common

+ 15 V 21 Expansion, +15 V Power

- 15 V 2 Expansion, -15 V Power

AGND * Common Ground

+ 5 V 1 Expansion, +5 V Power

*Refer to Ground Correlation Tables in the DBK Options Manual (457-0905), chapter 2, System Connections and Pinouts.

AGND. Note that there is no association between FILT CAP LO and P4.

AGND. Note that there is no association between FILT CAP LO and P4.

P1 – TB9

P1 – TB10

P1 – TB11

P1 – TB12

Note 1: For TB9 and TB10, the filter network portion of the silk screen is not shown. Instead, the DIFF and SE channel

identifiers have been moved next to the screws for ease in identification.

DBK Option Cards and Modules 969294 DBK213, pg. 7

Page 8

Correlation to P2 – Pertains to Terminal Blocks TB5, TB6, TB7, and TB8 for Digital I/O.

TB5 P2 Pin Number and Description

DGND * Digital Ground, Common

DGND * Digital Ground, Common

A7 30 Digital I/O: P2, Digital Port A, Bit 7; or P2 Expansion Data Bit 15

A6 31 Digital I/O: P2, Digital Port A, Bit 6; or P2 Expansion Data Bit 14

A5 32 Digital I/O: P2, Digital Port A, Bit 5; or P2 Expansion Data Bit 13

A4 33 Digital I/O: P2, Digital Port A, Bit 4; or P2 Expansion Data Bit 12

A3 34 Digital I/O: P2, Digital Port A, Bit 3; or P2 Expansion Data Bit 11

A2 35 Digital I/O: P2, Digital Port A, Bit 2; or P2 Expansion Data Bit 10

A1 36 Digital I/O: P2, Digital Port A, Bit 1; or P2 Expansion Data Bit 9

A0 37 Digital I/O: P2, Digital Port A, Bit 0; or P2 Expansion Data Bit 8

TB6 P2 Pin Number and Description

+5 V 18 Expansion +5 V Power

+5 V 20 Expansion +5 V Power

DGND * Digital Ground, Common

DGND * Digital Ground, Common

DGND * Digital Ground, Common

DGND * Digital Ground, Common

DGND * Digital Ground, Common

DGND * Digital Ground, Common

DGND * Digital Ground, Common

DGND * Digital Ground, Common

TB7 P2 Pin Number and Description

DGND * Digital Ground, Common

DGND * Digital Ground, Common

C7 22 Digital I/O: P2, Digital Port C, Bit 7; or P2 Expansion Data Bit 7

C6 23 Digital I/O: P2, Digital Port C, Bit 6; or P2 Expansion Data Bit 6

C5 24 Digital I/O: P2, Digital Port C, Bit 5; or P2 Expansion Data Bit 5

C4 25 Digital I/O: P2, Digital Port C, Bit 4; or P2 Expansion Data Bit 4

C3 26 Digital I/O: P2, Digital Port C, Bit 3; or P2 Expansion Data Bit 3

C2 27 Digital I/O: P2, Digital Port C, Bit 2; or P2 Expansion Data Bit 2

C1 28 Digital I/O: P2, Digital Port C, Bit 1; or P2 Expansion Data Bit 1

C0 29 Digital I/O: P2, Digital Port C, Bit 0; or P2 Expansion Data Bit 0

TB8 P2 Pin Number and Description

DGND * Digital Ground, Common

DGND * Digital Ground, Common

B0 10 Digital I/O: P2, Digital Port B, Bit 0; or P2 Expansion READ Output

B1 9 Digital I/O: P2, Digital Port B, Bit 1; or P2 Expansion WRITE Output

B2 8 Digital I/O: P2, Digital Port B, Bit 2; or P2 Expansion RESET Output

B3 7 Digital I/O: P2, Digital Port B, Bit 3; or P2 Expansion Address Bit 4 Out

B4 6 Digital I/O: P2, Digital Port B, Bit 4; or P2 Expansion Address Bit 3 Out

B5 5 Digital I/O: P2, Digital Port B, Bit 5; or P2 Expansion Address Bit 2 Out

B6 4 Digital I/O: P2, Digital Port B, Bit 6; or P2 Expansion Address Bit 1 Out

B7 3 Digital I/O: P2, Digital Port B, Bit 7; or P2 Expansion Address Bit 0 Out

*Refer to Ground Correlation Tables in the DBK Options Manual (457-0905), chapter 2, System Connections and Pinouts.

P2 – TB5

P2 – TB6

P2 – TB7

P2 – TB8

DBK213, pg. 8

969294 DBK Option Cards and Modules

Page 9

Correlation to P3 – Pertains to Terminal Blocks TB1, TB2, TB3, and TB4 for Pulse/Frequency/Digital I/O.

TB1 P3 Pin Number and Description

D0 10 P3 Digital Port Bit 0

D1 9 P3 Digital Port Bit 1

D2 8 P3 Digital Port Bit 2

D3 7 P3 Digital Port Bit 3

D4 6 P3 Digital Port Bit 4

D5 5 P3 Digital Port Bit 5

D6 4 P3 Digital Port Bit 6

D7 3 P3 Digital Port Bit 7

DGND * Digital Ground, Common

+5V 20 Expansion, +5 Volt Power

TB2 P3 Pin Number and Description

D8 29 P3 Digital Port Bit 8

D9 28 P3 Digital Port Bit 9

D10 27 P3 Digital Port Bit 10

D11 26 P3 Digital Port Bit 11

D12 25 P3 Digital Port Bit 12

D13 24 P3 Digital Port Bit 13

D14 23 P3 Digital Port Bit 14

D15 22 P3 Digital Port Bit 15

DGND * Digital Ground, Common

DGND * Digital Ground, Common

TB3 P3 Pin Number and Description

CH0 (DAC0) 34 Analog Out; Analog DAC 0 Output

AGND * Analog Ground, Common; intended for use with DACs

EXP 0 (DAC2) 32 Analog Out; Analog DAC 2 Output

AGND * Analog Ground, Common; intended for use with DACs

CH1 (DAC1) 33 Analog Out; Analog DAC 1 Output

A/O CLK 21 Analog Out Clock; External DAC Pacer Clock Input/

Internal DAC Pacer Clock Output

EXP 1 (DAC3) 31 Analog Out; Analog DAC 3 Output

DGND * Digital Ground, Common

+15 V 19 Expansion, + 15 VDC

-15 V 37 Expansion, -15 VDC

TB4 P3 Pin Number and Description

EXP 2 12 Reserved

EXP 3 13 Reserved

EXP 4 14 Reserved

TMR 0 15 P3 Timer 0 Output

TMR 1 16 P3, Timer 1 Output

CNT 3 35 P3 Counter 3 Input

CNT 2 17 P3 Counter 2 Input

CNT 1 36 P3 Counter 1 Input

CNT0 18 P3 Counter 0 Input

DGND * Digital Ground, Common

*Refer to Ground Correlation Tables in the DBK Options Manual (457-0905), chapter 2, System Connections and Pinouts.

P3 – TB1

P3 – TB2

P3 – TB3

P3 – TB4

DBK Option Cards and Modules 969294 DBK213, pg. 9

Page 10

Adding Resistor/Capacitor Filter Networks

WARNING

Disconnect the DBK213 from power and signal sources prior to installing capacitors or

resistors.

Ensure wire strands do not short power supply connections (+15 V, -15 V, +5 V, etc.) to

any terminal potential. Failure to do so could result in damage to DaqBook/2000 Series

devices or DaqBoard/2000 Series boards.

Do not exceed maximum allowable inputs (as listed in product specifications). There

should never be more than 30 V with reference to analog ground (AGND) or earth

ground.

You must provide strain-relief (lead slack) to all leads leaving the module. Use tie-wraps

[not included] to secure strain-relief.

Always connect the CHASSIS terminal to earth ground. This will maximize static

protection.

If a channel is not associated with a DBK expansion option you can install a customized RC filter network

to improve the signal-to noise ratio, assuming that an unacceptable level of noise exists. DBK213’s

internal board includes silk-screened sockets for installing RC filter networ ks. The following table

contains values that are typical for RC filter network components.

CAUTION

Typical One-Pole Low Pass Filter

Values

for DBK213

Do not use RC filters in conjunction with additional DBK expansion

accessories.

R C f f

Ohms µF Hertz

(-3dB)

kHz

(-3dB)

510 1 312 0.31

510 0.47 664 0.66

510 0.22 1419 1.42

510 0.1 3122 3.12

510 0.047 6643 6.64

510 0.022 14192 14.19

510 0.01 31223 31.22

510 0.0047 66431 66.43

470 0.0033 102666 102.67

In this example Channels 0 and 8 are shown as Single-Ended.

Channel 1 is Differential, i.e., using 1H and 1L (channel High and Low).

The following three notes pertain to the above figure.

Note 1: The 3 horizontal capacitors [as oriented in the illustration] are optional filter capacitors.

Note 2: The vertical capacitor [as oriented in the illustration] is an optional isolation capacitor used for the

reduction of Differential noise. Such capacitor placement is

Note 3: If installing filter resistors, carefully drill out the indicated centers with a 1/16 inch drill-bit. Otherwise

the resistor will be short-circuited.

An Example of Customer-Installed

Capacitors and Filters for RC Networks

not used in Single-Ended applications.

DBK213, pg. 10

Prior to installing RC components, review the previous Warning and Caution

statements, then read over the following information regarding resistors and

capacitors.

969294 DBK Option Cards and Modules

Page 11

• Do not use RC filters in conjunction with additional DBK expansion accessories.

• Prior to installing a resistor to the filter network you must drill a 1/16” hole through

the center pinhole [beneath the board’s silkscreen resistor symbol] as indicated in the

preceding figure. Failure to do so will short-circuit the resistor.

• Do not drill holes on the board for channels, unless those channels are to receive a

filter network (see preceding statement).

• Resistors should be ¼ watt, film-type with up to 5% tolerance. Do not use wire-

wound resistor types.

• A resistor value of 510 Ω is recommended. Do not exceed 510 Ω.

• Capacitors used are to be of the film dielectric type (e.g., polycarbonate or

NPO ceramic), above 0.001 µF.

• RECOMMENDED: For reduction of both Common Mode Noise and Differential

Mode Noise, use one capacitor between Channel High and AGND; and use a second

capacitor between Channel Low and AGND.

• For reduction of Differential Noise [when no reduction of Common Mode Noise is

needed] position a capacitor across the respective Channel High and Channel Low.

• When in Differential Mode, using capacitors between Channel High, Channel Low,

and AGND may cause a slight degradation of wideband Common Mode rejection.

• When making a RC filter network, always install a wire jumper between the relevant

FILT CAP LO and AGND. FILT CAP LO terminals are located on TB9 and TB10.

DBK Option Cards and Modules 969294 DBK213, pg. 11

Page 12

Specifications for DBK213

Operating Environment:

Temperature: -30°C to 70°C

Relative Humidity: 95% RH, non-condensing

Connectors:

P1: male DB37 connector for analog expansion or connection to primary acquisition device*

P2: male DB37 connector for digital expansion or connection to primary acquisition device*

P3: male DB37 connector for pulse/frequency/digital I/O, or connection to primary acquisition device*

P4: 100-pin connector for connection to a /2000 Series device that includes a P4 connector;

e.g., DaqBoard/2000.

Screw Terminals: 12 banks of 10-connector blocks

Dimensions:

285 mm W x 220 mm D x 45 mm H (11” x 8.5” x 2.7”)

Weight:

1.45 kg (3.2 lbs)

Cables and Accessories:

Item Description Part Number

Rack Mount Kit, p/n RackDBK4

100-conductor expansion cables; mate with P4 connectors:

3 ft., non-CE Compliant CA-195

3 ft., CE Compliant CA-209

6 ft., non-CE Compliant CA-195-6

37-conductor cables; mate with DB37 connectors:

2 in., shielded T-cable CA-255-2T

4 in., shielded T cable CA-255-4T

8 in., shielded T cable CA-255-8T

37-conductor ribbon cable CA-37-X

*DaqBook/2000 Series, DaqLab/2000 Series, DaqScan/2000 Series

Specifications subject to change without notice.

DBK213, pg. 12

969294 DBK Option Cards and Modules

Page 13

Reference Notes:

In regard to calculating system power requirements refer to the DBK Basics section.

Chapter 2 includes pinouts for P1, P2, P3, and P4. Refer to pinouts applicable to your

system, as needed.

For a quick comparison of all DBK200 Series boards, refer to the DBK200 Series

Matrix. The matrix is located just before the DBK200 section of this manual.

Refer to the documentation for your primary data acquisition device as needed.

DBK Option Cards and Modules 969294 DBK213, pg. 13

Page 14

DBK213, pg. 14

969294 DBK Option Cards and Modules

Loading...

Loading...