Page 1

USER’S MANUAL

DaqScan/2000 Series

1126-0901 rev 2.2

*327556B-01*

372556B-01

DaqScan/2001

DaqScan/2002

DaqScan/2004

DaqScan/2005

Measurement Computing

10 Commerce Way

Norton, MA 02766

(508) 946-5100

Fax: (508) 946-9500

info@mccdaq.com

www.mccdaq.com

DaqScan/2000 Series

Ethernet-Based Data Acquisition System Components

Page 2

ii

Page 3

Warranty Information

Contact Measurement Computing by phone, fax, or e-mail in regard to warranty-related issues:

Phone: (508) 946-5100, fax: (508) 946-9500, e-mail: info@mccdaq.com

Many Measurement Computing products carry the CE marker indicating they comply with the safety and emissions

standards of the European Community. When applicable these products have a Declaration of Conformity stating which

specifications and operating conditions apply. You can view the Declarations of Conformity at

www.mccdaq.com/legal.aspx (CE Information page).

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective bags

and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of great

benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Limitation of Liability

Measurement Computing cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All Measurement Computing documentation, software, and hardware are copyright with all rights reserved. No part of

this product may be copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method

without Measurement Computing’s prior written consent. IOtech product names are trademarked; other product names, as

applicable, are trademarks of their respective holders. All supplied IOtech software (including miscellaneous support

files, drivers, and sample programs) may only be used on one installation. You may make archival backup copies.

CE Notice

Warnings, Cautions, Notes, and Tips

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, the hardware is calibrated to published specifications. Periodic hardware calibration is not

covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Page 4

CAUTION

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Before setting up and using your

equipment, you should read all documentation that covers your system.

Pay special attention to Warnings and Cautions.

Note:

During software installation, Adobe® PDF versions of user manuals will automatically

install onto your hard drive as a part of product support. The default location is in the

Programs group, which can be accessed from the Windows Desktop. Initial navigation

is as follows:

Start [Desktop “Start” pull-down menu]

Programs

IOtech DaqX Software

You can also access the PDF documents directly from the data acquisition CD by using

the <View PDFs> button located on the opening screen.

Refer to the PDF documentation for details regarding both hardware and software.

PDF

1126-0901

DaqScan2000.pdf

Contains hardware-related material for DaqScan/2000 Series devices. This pdf file

plus the following constitute a complete set of documentation for these devices.

PDF

457-0909

DaqView_DaqViewXL.pdf

Discusses how to install and use these “out-of-the-box” data acquisition programs.

PDF

1086-0926

1086-0922

PostAcquisition Analysis.pdf

This pdf consists of two documents. The first discusses eZ-PostView, a post data

acquisition analysis program. The application is included free as a part of product

support. The second includes information regarding eZ-FrequencyView and

eZ-TimeView. These two applications have more features than does eZ-PostView

and are available for purchase. They can; however, be used freely during a 30-day

trial period.

iv 947091 DaqScan/2000 Series

Page 5

PDF

457-0905

DBK Options.pdf

The DBK Option Cards and Modules User’s Manual discusses each DBK product.

In addition, the document includes chapters on signal management, system

connections, pinouts, DBK set up in software, and troubleshooting.

PDF

1008-0901

ProgrammersManual.pdf

The Programmer’s Manual pertains to developing custom programs using Applications

Program Interface (API) commands.

Programmers should check the readme.file on the install CD-ROM for the location of

program examples included on the CD.

Reference Note:

A reference to additional documents of importance begins on page iv.

Manual Layout

Chapter 1 – Daq Systems

Chapter 2 – DaqScan/2000 Series, Device Overviews

Chapter 3 – Block Diagrams

Chapter 4 – Connectors, Indicators, Cables, & Pinouts

Chapter 5 – Software

Chapter 6 – Configuring the System for Operation

Chapter 7 – CE Compliance and Noise Considerations

Chapter 8 – Taking Measurements

Chapter 9 – Calibration

Chapter 10 – Troubleshooting and Customer Support

Chapter 11 – Specifications

Glossary

DaqScan/2000 Series 947091 v

Page 6

This page is intentionally blank.

vi 947091 DaqScan/2000 Series

Page 7

Table of Contents

Quick Start

1 – Daq Systems

2 – DaqScan/2000 Series, Device Overviews

Overview …… 2-1

Product Features …… 2-2

System Applications …… 2-3

3 – Block Diagrams

4 – Connectors, Indicators, Cables, & Pinouts

DaqScan/2000 Series Hardware …… 4-1

Cables ……4-3

Pinouts ……4-5

5 – Software

6 – Configuring the System for Operation

7 – CE Compliance and Noise Considerations

8 – Taking Measurements

Introduction …… 8-1

Scanning …… 8-1

Triggering …… 8-2

Synchronous I/O Operations …… 8-3

Asynchronous I/O Operations …… 8-5

Synchronizing Multiple Units …… 8-6

Using DBK Cards and Modules for Signal Conditioning …… 8-8

9 – Calibration

10 – Troubleshooting and Customer Support

Electrostatic Discharge (ESD), Handling Notice…… 10-1

Product Care …… 10-1

ReadMe Files and the Install CD-ROM …… 10-2

Driver Support…… 10-2

DaqCOM Issues …… 10-2

Ethernet Problems …… 10-3

Frequently Asked Questions …… 10-4

Customer Support …… 10-5

11 - Specifications

Glossary

DaqScan/2000 Series 898095 vii

Page 8

This page is intentionally blank.

viii 898095 DaqScan/2000 Series

Page 9

DaqScan/2000 Series Quick Start

Daq

S

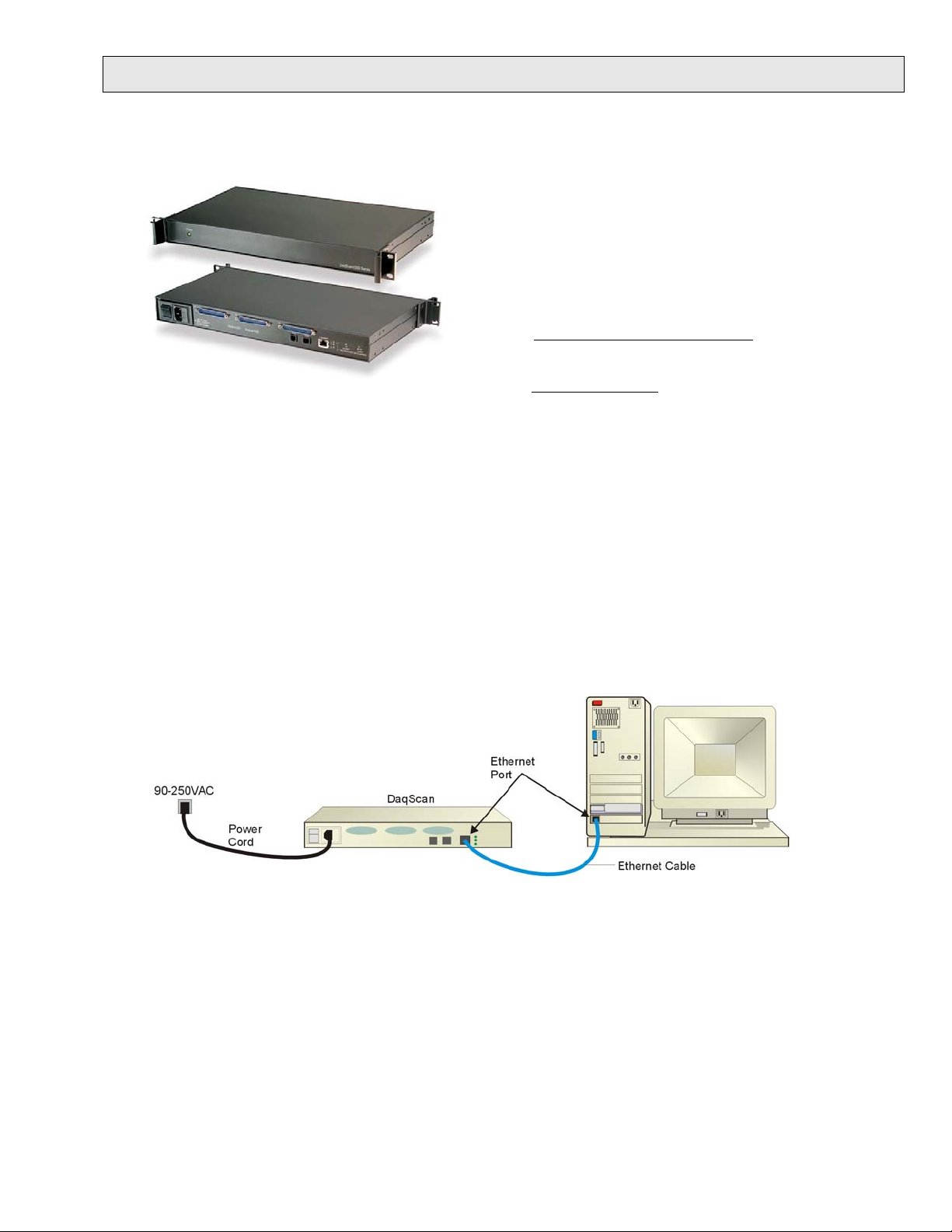

Ethernet-Based Data Acquisition Components

can/2001

Step 1 - Install Software

1. Close all running applications on the host PC.

2. Insert the Data Acquisition CD into your CD-ROM drive and wait for the CD to auto-run. An Opening

Screen will appear. As an alternative, you can download software from www.PFFGDT.com/VRIWZDUH

Before you get started

Verify that you have the following items.

•

DaqScan/2000 Series Device

•

AC Power Cord

•

Ethernet Patch Cable

•

Ethernet jack

Data Acquisition CD

•

Monitor: SVGA, 1024 x 768 screen resolution

•

Windows 2000 and Windows XP users

•

PC with Intel™ Pentium, 1 GHz or equivalent;

512 MB memory; 10 GB disk space

• Windows Vista users:

PC must be Windows Vista Premium Ready

[on PC or on a hub connected to the Ethernet]

:

3. Click the <

Note: If you are downloading software from our website, follow instructions provided there.

4. From the hardware selection screen [which follows a licensing agreement], select the

device from the drop-down list and follow the on-screen instructions.

ENTER SETUP> button.

Step 2 - Connect the DaqScan to the Ethernet

In the figure, the DaqScan is connected directly to an Ethernet port on a host computer. Please consult your user’s

manual (located in PDF format on the CD) should you need information regarding network types other than this simple

direct connection.

1. Connect the Ethernet cable to the Ethernet jack on the DaqScan rear panel.

2. Connect the other end of the Ethernet cable to the Ethernet jack on the host computer or

network hub.

Step 3 - Connect the DaqScan to Power

1. With the DaqScan’s power switch “OFF,” connect the power cord to the unit.

2. Connect the cord’s plug to a standard AC outlet; then turn the DaqScan Po wer switch to “ON.”

1126-0940, rev 1.0 324633A-01 Printed in Hungary

Page 10

Step 4 - Configure Computer Network Settings

Measurement Computing

10 Commerce Way

Norton, MA 02766

(508) 946-5100

Fax: (508) 946-9500

info@mccdaq.com

www.mccdaq.com

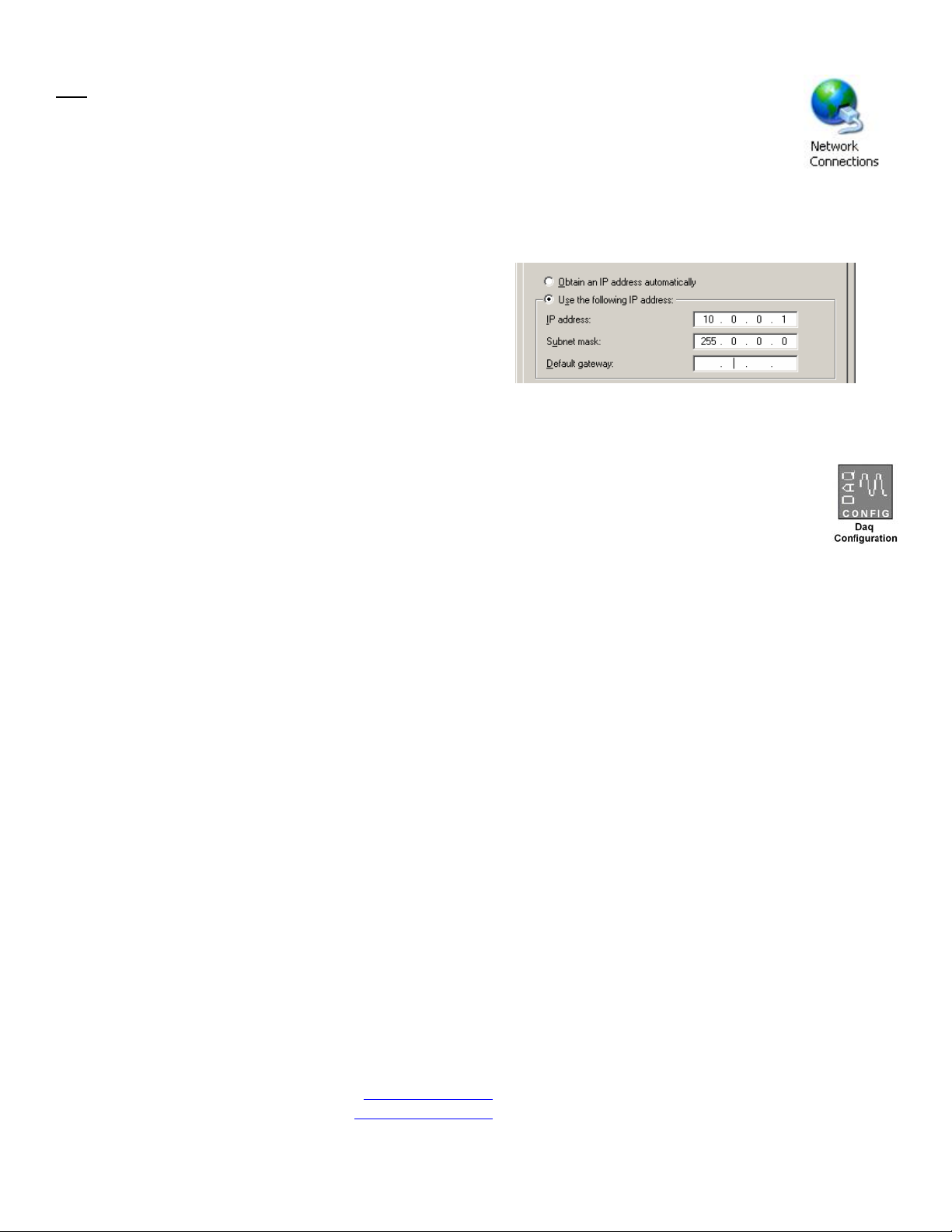

Note: We recommend that you discuss this procedure with your Network Administrator before proceeding.

1. Open the Control Panel by navigating from the Windows Desktop as follows:

Start Menu ⇒ Settings ⇒ Control Panel.

2. Double-click the “Network Connections” icon.

3. Double-click the icon for the network that the 2000 Series device is connected to.

4. In the “Local Area Connection Status” box, click on the <Properties> button. The “Local Area Connection

Properties” box will appear.

5. Double-click the “Internet Protocol (TCP/IP)” component. The “Internet Protocol (TCP/IP) Properties” box

will appear.

6. Select the “Use the following IP Address” radio

button. (See figure at left).

7. Set the IP address field to 10.0.0.x

where x is some number from 1 to 254.

Make sure that each computer and each device on

the dedicated network has a unique IP address.

8. Set the Subnet mask to 255.0.0.0. Note that the

remaining fields can be left as is. Click <OK>.

9. Click <OK> o n follow-up screens to exit.

Internet Protocol (TCP/IP) Properties

(Partial View)

Step 5 - Configure & Test the System

1. Open the Daq Configuration Applet.

a. Navigate from the Windows’ Desktop: Start Menu ⇒ Settings ⇒ Control Panel

b. From the Control Panel, double-click the Daq Configuration icon.

2. Add the 2000 Series Device to the list of installed devices.

a. Select the Computer image in the Device Inventory configuration tree.

b. Click the <Add Device> button. The “Select Device Type” box will appear.

c. Select the DaqScan/2000 Series device from the list of devices.

d. Click the <OK> button. The “Properties” box will appear for the selected device.

e. En ter the Serial Number of the device. The number is on the MAC label (rear panel, upper left). The

serial number is located just below a barcode.

f. Select the “Auto IP Setting” radio button. The IP Address of the device will automatically be

calculated and displayed in the IP Address field

g. Click the <OK> button.

3. Test the system connections.

a. Make sure the device has been properly installed and is powered-on.

b. Make sure all cables are properly and securely connected.

c. Click the “Test Hardware” tab.

d. Click the <TCP/IP Test> button. This tests the Transmission Control Protocol / Internet Protocol.

e. Upon completion of the TCP/IP test, click the <Resource Test> button.

When testing, if the unit does not respond within 30 seconds perform the following steps:

1) reboot the system, 2) upon power-up, re-open the Daq Configuration applet, 3)select another

configuration setting, 4) reinitiate the test.

Step 6 - Connect Data Acquisition Signal Lines

Prior to making signal connections review the Specifications chapter of your user’s manual to ensure that your

intended signal inputs do not exceed the specified limits. The manual is included in PDF format on your CD.

*324633A-01*

324633A-01

Printed in Hungary

Page 11

Daq Systems 1

Daq Systems, the Modular Concept …… 1-1

DaqBooks, DaqBoards, and Daq PC-Cards ….. 1-2

Using DBK Cards and Modules for Signal Conditioning …… 1-4

Daq Software …… 1-5

This chapter provides a brief overview of Daq devices.

Users interested in jumping straight to DaqScan information

should skip directly to chapter 2.

Daq Systems, the Modular Concept

Daq equipment and software form a modular, interrelated family of products that provide

great flexibility in data acquisition system design. This flexibility allows for the development

of custom systems that are unique to the user, and which can be optimized for his or her

specific application needs. With the Daq product line, system expansion or redesign can

typically be accomplished with relative ease.

• Primary Acquisition Device. This is the main data acquisition device, e.g., a

DaqBook, DaqBoard, DaqLab, DaqScan, or Daq PC-Card. These devices provide a vital

data conversion and communications link between the data source of transducers and

signal conditioners and the data processor of the host computer.

• DBK Option Cards and Modules. Over 35 DBK cards and modules (the number is

constantly growing) provide various types of signal conditioning and system expansion.

Note that certain DBK modules exist for the purpose of supplying power to other

members of the acquisition system. The DBK options are discussed in the DBK Option

Cards and User’s Manual (p/n 457-0905).

Note: Only passive DBKs, such as the DBK1 BNC module, the DBK11A screw terminal

card, and the DBK40 BNC analog interface, can be used with a Daq PC-Cards.

Reference Note:

DBK options are discussed in the DBK Option Cards and Modules User’s

Manual (p/n 457-0905). As a part of product support, this manual is

automatically loaded onto your hard drive during software installation. The

default location is the Programs directory, which can be accessed through the

Windows Desktop.

Software. DaqView out-of-the-box software provides a graphical user interface with

•

easy to read spreadsheet formats for viewing channel data, as well as a choice of analog,

digital, and bar-graph meters. Waveform analysis can be performed, when applicable.

A product support option, included on the data acquisition CD, provides a means of

performing post data analysis. More information is included in the software-specific PDF

documents that are installed on your hard-drive as a part of product support.

In addition to the included out-of-the-box software, Daq products can be controlled via

user-written custom programs through Applications Program Interface (API). Several

languages are supported, e.g., C/C++, and VisualBASIC.

Note that third party icon-driven software, such as DASYLab and LabView, can be used

with the Daq devices.

DaqScan/2000 Series 949595 Daq Systems 1-1

Page 12

DaqView and DASYLab can only be used with one DaqScan/2000

Series device at a time.

LabView can be used with multiple Daq/2000 Series devices.

For multiple device applications (via custom programming) refer to

the Using Multiple Devices section of the Programmer’s Manual.

During software installation from the data acquisition CD

(p/n 1022-0601), a PDF version of the Programmer’s Manual is

automatically loaded onto your hard drive as a part of product

support. The default location is the Programs directory.

Reference Note:

Programming topics are covered in the Programmer’s User Manual

(p/n 1008-0901). As a part of product support, this manual is automatically

loaded onto your hard drive during software installation. The default location

is the Programs directory, which can be accessed through the Windows

Desktop.

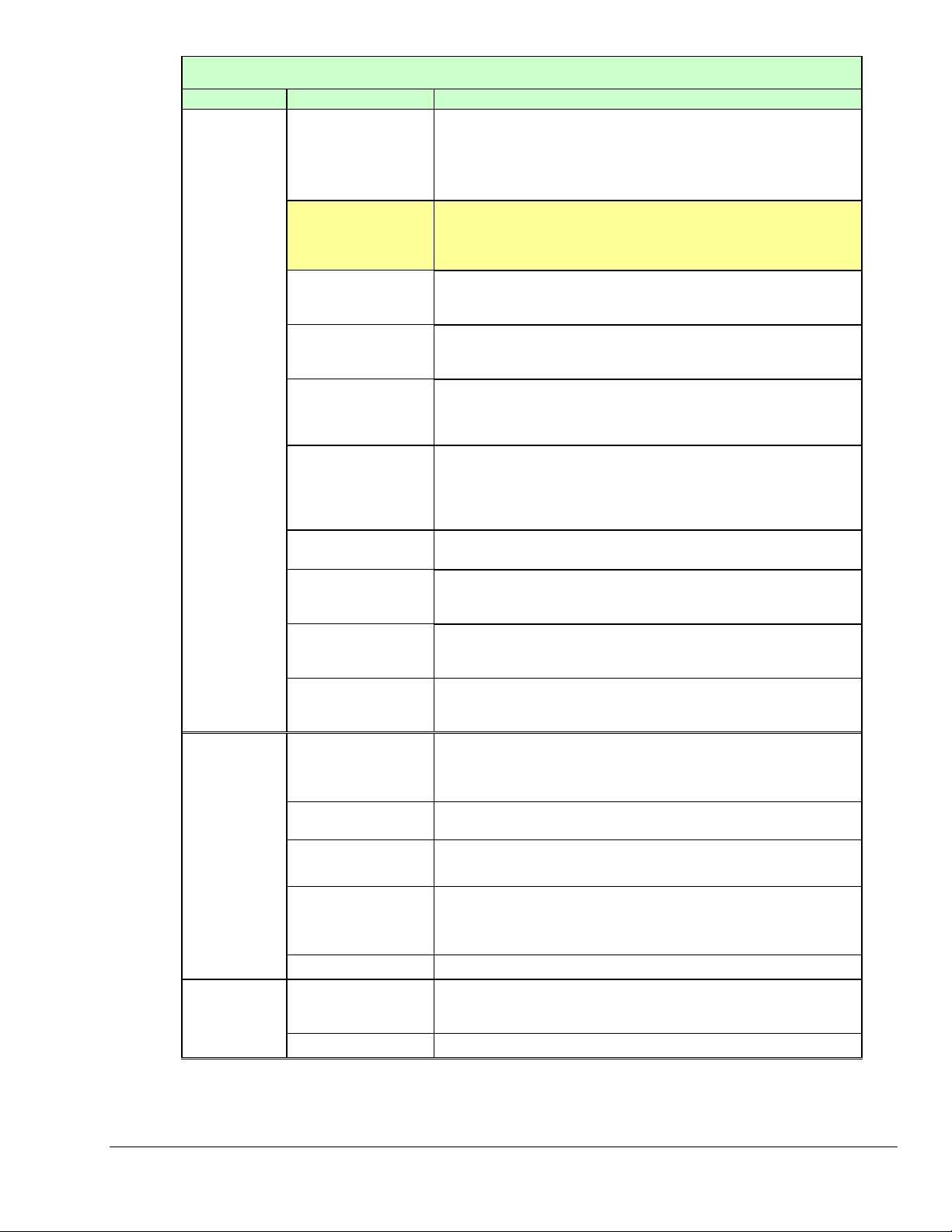

DaqBooks, DaqBoards and Daq PC-Cards

Daq products typically connect to one or more DBKs on their signal input side and to a host

computer on their output side. The following table categorizes the various Daq devices and

provides very basic information.

1-2 Daq Systems 949595 DaqScan/2000 Series

Page 13

Daq Data Acquisition Devices

Category Device Description

Primary

Data

Acquisition

Device

DBK Option

Cards and

Modules*

Software

DaqLab/2001

DaqLab/2005

DaqScan/2001

DaqScan/2002

DaqScan/2004

DaqScan/2005

DaqBook/2001

DaqBook/2005

DaqBook/2020

DaqOEM/2001

DaqOEM/2005

DaqBook/100

Series

DaqBook/200

Series

DaqBook/2000A

DaqBook/2000E

DaqBook/2000X

DaqBoard/2000

Series

DaqBoard/2000c

Series

DaqBoard

(ISA types)*

Daq PC-Card*

Analog Signal

Conditioning

Analog Output

Digital I/O and

Control

Expansion

Connections

Power Supply

Included Software

Optional Software

Ethernet-Based Laboratory Data Acquisition

16-bit, 200 kHz devices with Ethernet connectivity.

Each can serve as host to an internal analog and/or digital DBK

card. Each has a built-in AC-to-DC power circuit and can be

plugged directly into a standard AC outlet.

Ethernet-Based Data Acquisition System Components

16-bit, 200 kHz devices with Ethernet connectivity.

Each has a built-in AC-to-DC power circuit and can be plugged

directly into a standard AC outlet.

Portable Data Acquisition

16-bi

t, 200 kHz

Make use of an external power supply.

Portable Data Acquisition

16-bit, 200 kHz

These boards reside external to the host PC.

Portable Data Acquisition

12-

DaqBook/100, /112, /120

bit:

16-bit: DaqBook/200, /216, /260

Portable Data Acquisition

16-bi

t, 200 kHz

the DaqBook/2000E provides for a direct Ethernet connection.

These devices include a 100-pin P4 connector.

Each makes use of an external power supply.

Plug-In Boards for PCI Bus-Slots

16-bit ,

200 kHz. Six boards identified as /2000 through /2005

Plug-In Boards for Compact-PCI Bus-Slots

16-bit ,

200 kHz. Six boards identified as /2000c through

/2005c

Plug-In Boards for ISA Bus-Slots

12-bit:

DaqBoard/100A, /112A

16-bit: DaqBoard/200A, /216A, /2000

Plug-In PCMCI Card

12-

bit:

Daq/112B

16-bit: Daq/216B

Cards and DBK modules used to condition Analog Signals

DBK/ 4,

52, 53, 54, 55, 65, 80, 81, 82, 83, 84, 85, 90, 100, 207,

207/CJC

Cards used to modify Analog Output Signals

DBK/ 2,

Cards and DBK modules used to condition Digital I/O

DBK/ 20, 21, 23, 24, 25, 208, 210

Cards and DBK modules used to expand the acquisition

system.

D

206, 209

DBKs: 30A, 32A, 33, 34

DaqView, Post Data Acquisition Analysis Program (actual

application not specified), Visual Basic ex

Programming Interface (API)

DaqViewXL, DASYLab

7, 8, 9, 12, 13, 15, 17, 18, 19, 42, 43A, 44, 45, 50, 51,

5

BK/ 1,

10, 11A, 35, 40, 41, 60, 200, 201, 202, 203, 204, 205,

devices with Ethernet connectivity.

boards with Ethernet connectivity.

devices with Ethernet connectivity, though only

tensions, Application

* The list of DBK cards and modules continues to grow. For information regarding new and upcoming

products consult out website, your sales representative, or contact the factory directly.

DaqScan/2000 Series 949595 Daq Systems 1-3

Page 14

Using DBK Cards and Modules for Signal Conditioning

The DBK signal-conditioning cards and modules are designed for use with DaqLab, DaqScan,

DaqBook, LogBook, and various data acquisition boards, i.e., ISA, PCI, and compact-PCI

types. The DBKs perform best when used with an acquisition device that can dynamically

select channel, gain, and range. DBK cards and modules with dynamic channel and

gain/range selection allow for high channel-to-channel scan rates with a variety of

transducers.

Note: Only passive DBKs, such as the DBK1 BNC module, the DBK11A screw terminal card,

and the DBK40 BNC analog interface, can be used with Daq PC-Cards.

DBK output signals can be bipolar, e.g., -5 to +5 V, or unipolar, e.g., 0 to 10 V. The user can

select a range of relevant values to correspond to the lowest signal (e.g., -5 or 0 V) and the

highest signal (e.g., 5 or 10 V) signal. This type of range selection guarantees the highest

resolution in 12-bit or 16-bit conversion.

DBK modules share the same footprint as the DaqBook and a typical notebook PCs; allowing

for convenient stacking. The majority of these modules have their own power supply;

however, several options exist for packaging and powering the DBKs.

Reference Note:

DBK options are detailed in the DBK Option Cards and Modules User’s Manual

(p/n 457-0905). As a part of product support, this manual is automatically loaded

onto your hard drive during software installation. The default location is the

Programs directory, which can be accessed through the Windows Desktop

.

1-4 Daq Systems 949595 DaqScan/2000 Series

Page 15

Daq Software

The Daq devices have software options capable of handling most applications. Three types of

software are available:

• ready-to-use graphical programs, e.g., DaqView, DaqViewXL, and post acquisition

• drivers for third-party, icon-driven software such as DASYLab and LabView

• various language drivers to aid custom programming using API

Ready-to-use programs are convenient for fill-in-the-blank applications that do not require

programming for basic data acquisition and display:

• DaqView is a Windows-based program for basic set-up and data acquisition. DaqView

• DaqViewXL allows you to interface directly with Microsoft Excel to enhance data

• A post acquisition data analysis programs, e.g., eZ-PostView, typically allows you to

data analysis programs such as eZ-PostView

lets you select desired channels, gains, transducer types (including thermocouples),

and a host of other parameters with a click of a PC’s mouse. DaqView lets you

stream data to disk and display data in numerical or graphical formats. PostView is a

post-acquisition waveform-display program within DaqView.

handling and display. Within Excel you have a full-featured Daq control panel and all

the data display capabilities of Excel.

view and edit post-acquisition data.

• The Daq Configuration control panel allows for interface configuration, testing, and

troubleshooting.

Each Daq system comes with an Application Programming Interface (API) via a subroutine

library (DAQ) or an ActiveX/COM based library (DaqCOM). API-language drivers include:

C/C++, and Visual Basic. The latest software is a 32-bit version API.

Reference Notes:

¾ The software document modules, DaqView, DaqViewXL, and Post Acquisition

Data Analysis User’s Guide, are not included as part of the hardcopy manual,

but are available in PDF version. See the PDF Note, below.

¾ Programming topics are covered in the Programmer’s User Manual (1008-

0901). As a part of product support, this manual is automatically loaded onto

your hard drive during software installation. The default location is the

Programs directory, which can be accessed through the Windows Desktop.

PDF

Note:

During software installation, Adobe® PDF versions of user manuals will

automatically install onto your hard drive as a part of product support. The

default location is in the Programs group, which can be accessed from the

Windows Desktop. Refer to the PDF documentation for details regarding both

hardware and software.

®

A copy of the Adobe Acrobat Reader

provides

a means of reading and printing the PDF documents. Note that hardcopy

versions of the manuals can be ordered from the factory.

is included on your CD. The Reader

DaqScan/2000 Series 949595 Daq Systems 1-5

Page 16

1-6 Daq Systems 949595 DaqScan/2000 Series

Page 17

DaqScan/2000 Series 2

Device Overviews

Overview …… 2-1

Product Features …… 2-2

System Applications …… 2-3

Overview

DaqScan/2000 Series devices are high-speed, multi-function, data acquisition devices for use

with Ethernet PCs and Ethernet networks. Each unit connects directly to a PC’s Ethernet port

or network hub. All I/O is accessed via female DB37 connectors located on the rear of the

unit, making cabling easy from the DaqScan to the test device.

The DaqScan/2000 Series includes four models, ranging from the DaqScan/2002, which offers

gital/frequency I/O,

di

analog outputs, 40 digital I/O, 4 counter inputs and 2 timer outputs. Each features a 16-bit,

200 kHz A/D converter and digital calibration. In addition, all four units include an internal

AC-to-DC power converter.

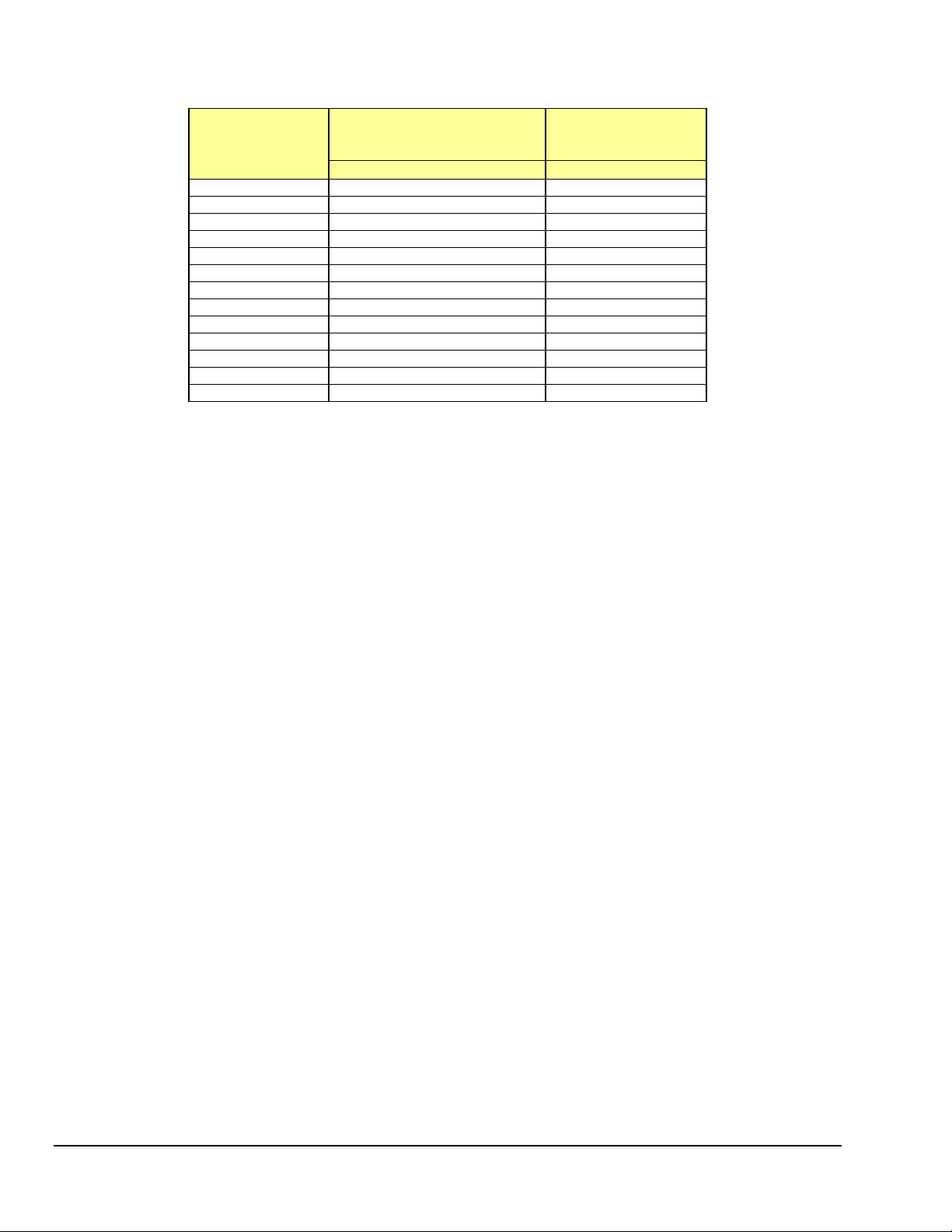

I/O Comparison Matrix

to the full-featured DaqScan/2001 which includes 16 analog inputs, 4

Model Analog Inputs

SE / DIFF

DaqScan/2001 16/8 40 4 2 4

DaqScan/2002 0 40 4 2 0

DaqScan/2004 0 40 4 2 4

DaqScan/2005 16/8 40 4 2 0

Digital

I/O

Counter

Inputs

Timer

Outputs

Analog

Outputs

Synchronous Operation Matrix

Operation

Synchronous Input

DaqScan/

2001

Analog Main Unit Inputs Yes No No Yes

Analog Expansion Input Yes No No Yes

Counter Inputs Yes Yes Yes Yes

Digital Main Unit Inputs Yes Yes Yes Yes

Digital Expansion Inputs Yes Yes Yes Yes

Synchronous Output

Analog D/A Waveform Output Yes No Yes No

Asynchronous IO

Main Unit Digital I/O Yes Yes Yes Yes

Expansion Digital I/O Yes Yes Yes Yes

Timer Output

Yes Yes Yes Yes

(Pulse Generation)

Analog Output Yes No Yes No

DaqScan/

2002

DaqScan/

2004

DaqScan/

2005

DaqLab/2000 Series 898095 Device Overviews 2-1

Page 18

Each DaqScan/2000 Series model is packaged in 1U high (1.75”), 19” wide full-rack package,

and includes a rackmount kit that can attach to either the front or the rear of the enclosure.

Multiple DaqScan models can be combined in the same system. Up to 4 units can be

synchronized [scan synchronous post-trigger] via rear panel SYNC connectors.

DaqScan/2000 Series devices include comprehensive drivers for popular Windows-based

environments, including Visual Basic, C/C++, ActiveX/COM, LabVIEW, MATLAB, and DASYLab.

The devices include DaqView, an interactive spreadsheet-style application that is ideal for

verifying signal connections during system design.

¾ Block diagrams are presented in chapter 3.

¾

Product Features

• Can be used to add analog I/O, digital I/O and frequency I/O to Ethernet-based test

systems. Each DaqScan/2000 Series device has a different combination of features

(see comparison matrix on page 2-1).

• All I/O can be synchronous, enabling precise timing between various I/O functions

Up to 4 units can be synchronized [scan synchronous post-trigger] via rear panel

SYNC connectors.

• 8 differential, or 16 single-ended inputs, expandable up to 256 voltage or 896 TC

channels using signal conditioning and expansion options

• Up to 40 built-in TTL-level digital I/O, expandable up to 256 channels of isolated I/O

using low-cost isolation modules

• Configuration through software only. Device settings are made via software. There

are no hardware settings to be made, for example, there are no device DIP switches

to be set or jumpers to be positioned. However, note that DBK expansion options

may require s small degree of manual set up. Refer to the DBK Option Cards and

Modules User’s Manual (457-0905) for details. A PDF version of the document is

included on the installation CD.

• Includes support for Visual Basic®, C/C++, ActiveX/COM, LabVIEW®, MATLAB®, and

DASYLab®

• Includes Out-of-the-Box™ DaqView™ software to facilitate signal and wiring

verification with no programming required

• Convenient 1U high (1.75”), 19” wide rack mount package minimizes rack space in

test systems

Reference Notes:

Connectors and pinouts are discussed chapter 4.

• Four 16-bit counters. Each can accept frequency inputs up to 10 MHz. The counters

can be cascaded into two 32-bit counters. Counter connection is via a removable

screw terminal block on the front panel.

• Two 16-bit timer outputs. Each can generate square waves from 16 Hz to 1 MHz.

Connection to the timer outputs is via a removable screw terminal block on the front

panel

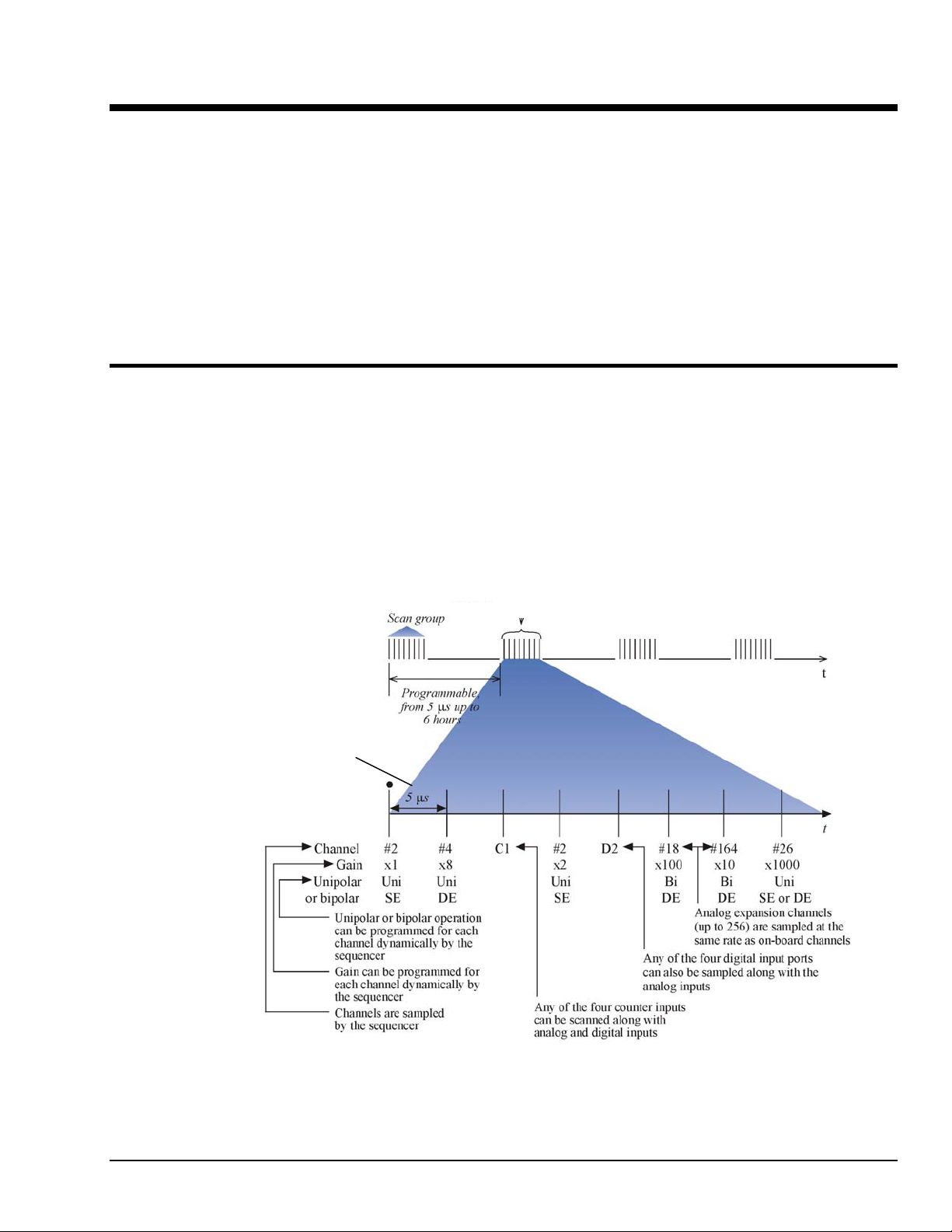

• Scan Sequencing. Each DaqLab/2000 Series device has a scan sequencer that can

select up to 16384 channel/range combinations. Scan rates are programmable on a

per channel basis to 5 µs/channel, 10 µs/channel, or 1000 µs/channel.

Note: Inputs can be measured at the 5 µs/channel rate. However, some DBK

expansion options require more settling time and can be measured at the

slower rate of 10 µs/channel or 1000 µs/channel. All types of measurements

can be mixed within the scan group.

2-2 Device Overviews 898095 DaqLab/2000 Series

Page 19

System Applications

In addition to basic applications that make use of a DaqScan model’s built-in I/O, a wi de

variety of signal conditioning and expansion options make additional applications possible.

Each of the following sample systems are obtained by using a DaqScan along with one or

more DBK options. The applications, which are only briefly discussed, include:

• High Channel Count Thermocouple Measurements

• High-Isolation Voltage & Thermocouple Measurements

• Isolated Digital I/O

• High Speed Voltage Measurement

• Multifunction I/O

High Channel Count Thermocouple Measurements

When combined with 56-channel DBK90 thermocouple input modules, DaqScan can measure

up to 896 channels of thermocouple (TC) input. Any TC type can be installed into any channel

using standard mini-TC connectors. DBK90’s built-in cold junction compensation (CJC)

coupled with the software’s TC conversion algorithms make temperature measurements easy.

Note that thermocouples are measured at a rate of 1 ms/channel in DBK90 based systems.

High-Isolation Voltage & Thermocouple Measurements

DaqScan units can be combined with DBK207/CJC™ options to create an isolated system

capable of measuring up to 256 channels of voltage, thermocouple, RTD and strain gage

inputs. All input channels can be scanned up to 200 kHz, and are isolated by 500V from other

channels and from system common. Any combination of input signals is possible by selecting

the appropriate 5B signal conditioning module for the DBK207/CJC.

Isolated Digital I/O System

When the DaqScan/2002 is combined with a DBK208 or DBK210, up to 256 channels of

isolated digital I/O are possible, capable of controlling AC or DC voltages up to 250V, or

sensing the presence of AC or DC voltages. All channels are isolated from one another and

from the system by up to 500V. Inputs can be scanned in 16-bit increments at speeds up to

200 Kreadings/s.

High-speed Voltage Measurement System

The DaqScan/2005 can be combined with DBK85 16-channel voltage input modules. This

creates a 5 µs/channel voltage measurement system with up to 256 channels. Each input can

have a range from 156 mV FS to 10V FS, which is programmable on a per-channel basis.

Multifunction I/O System

All of the aforementioned capabilities can be combined into one system, using one

DaqScan/2001 as the heart of the system. Such a DaqScan/2001 system could provide

56 non-isolated TC inputs, 16 isolated voltage inputs, 16 low-voltage inputs, 4 analog outputs,

4 frequency inputs, and 32 isolated discrete high-voltage outputs.

Reference Note:

For information regarding DBK options refer to the DBK Options User’s Manual

(p/n 457-0905). A PDf version of the manual is included on your installation CD.

DaqLab/2000 Series 898095 Device Overviews 2-3

Page 20

2-4 Device Overviews 898095 DaqLab/2000 Series

Page 21

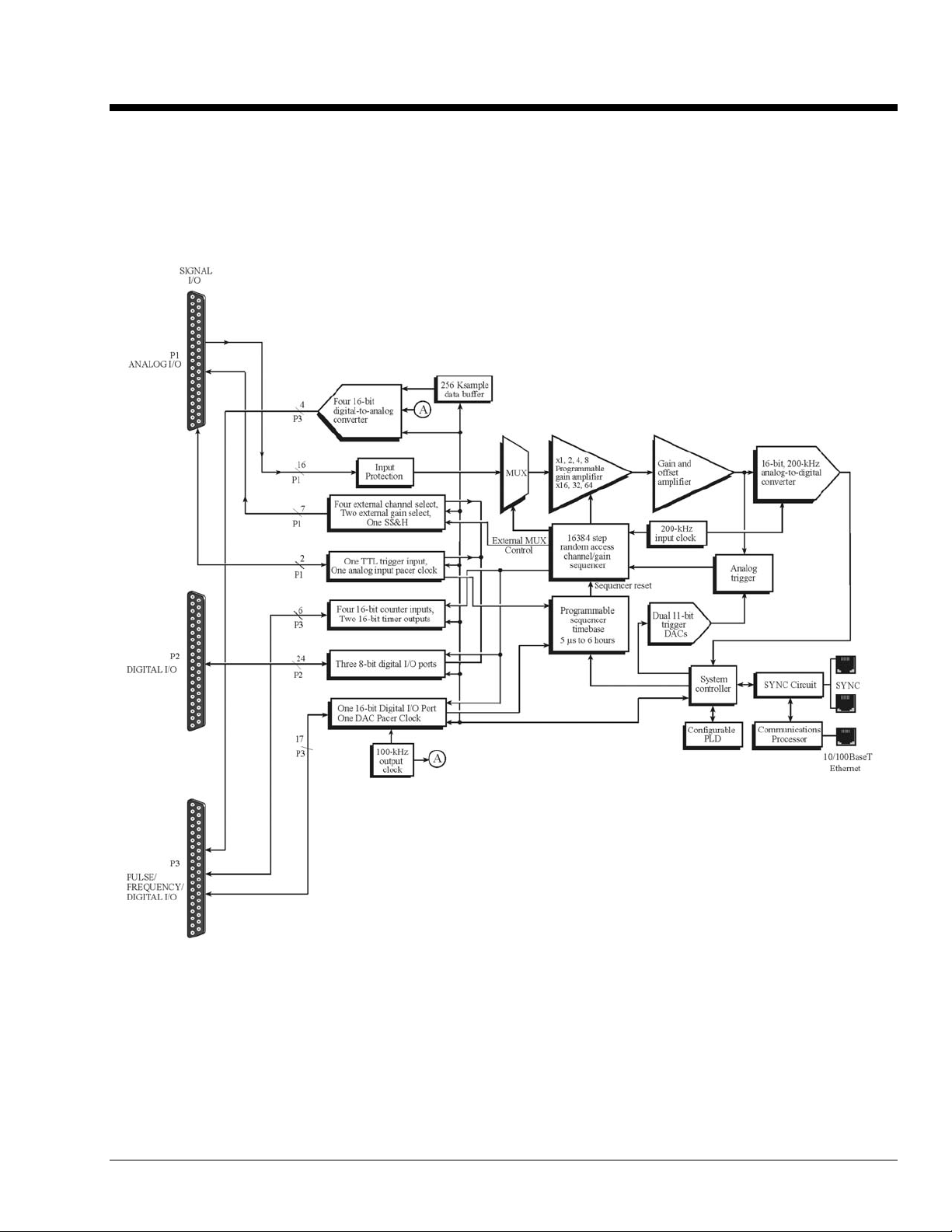

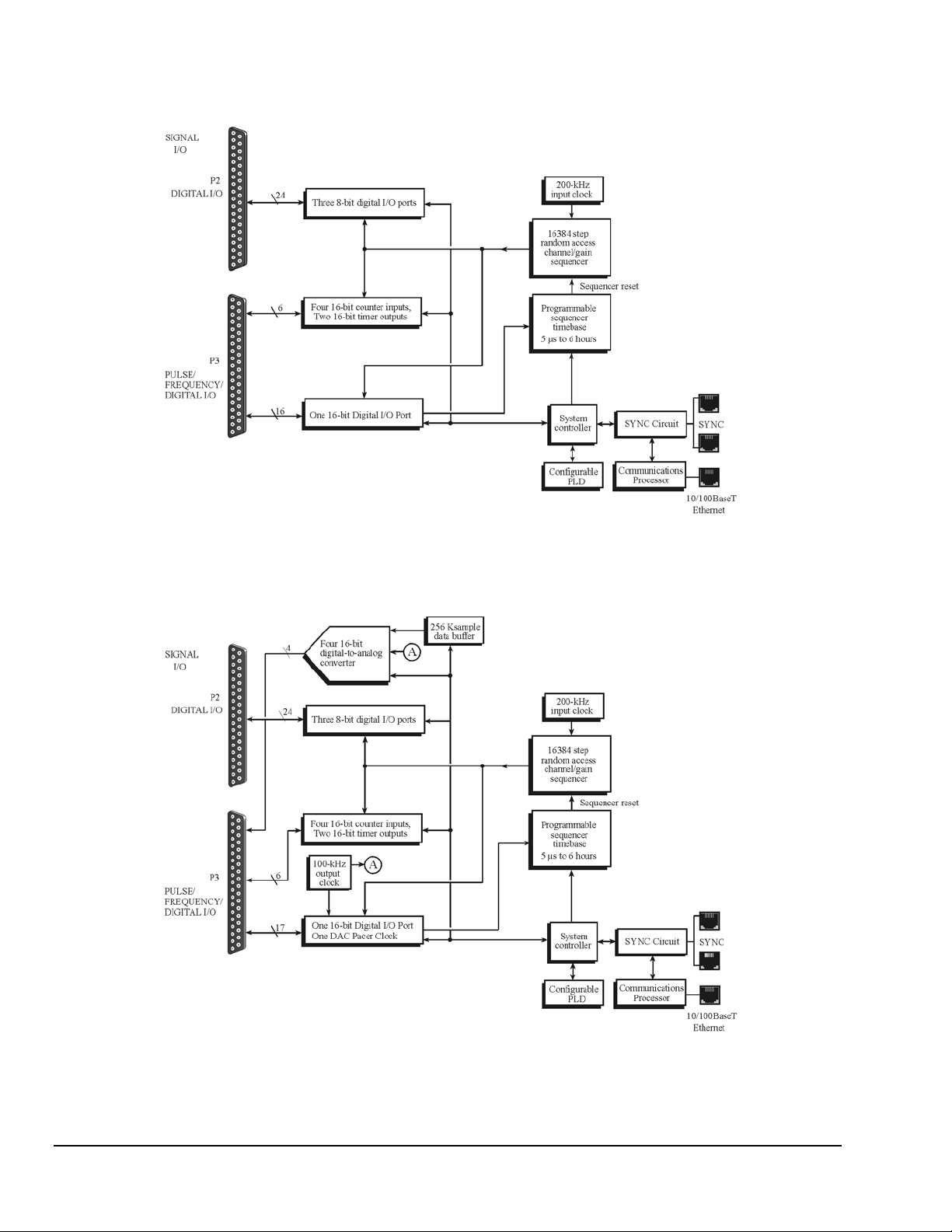

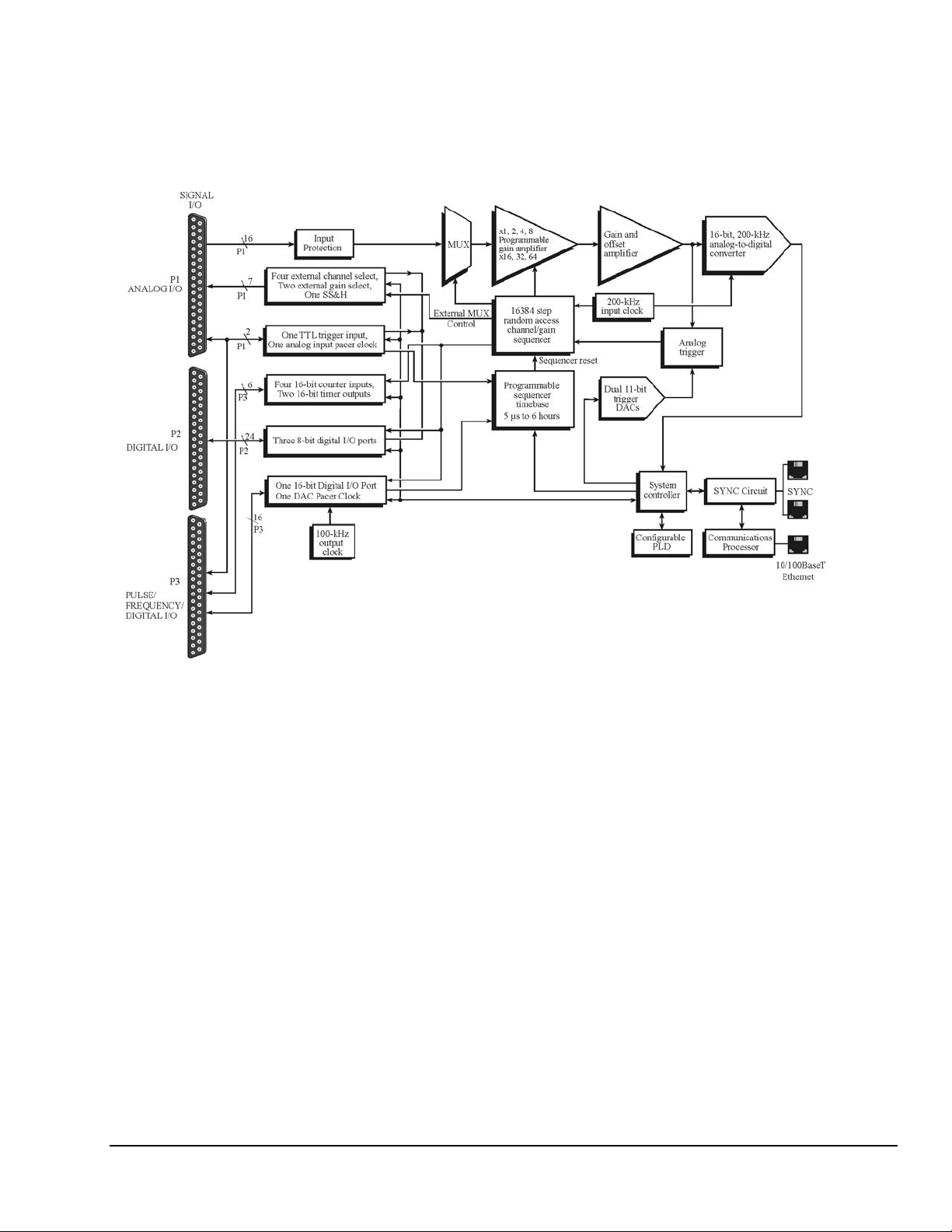

Block Diagrams 3

DaqScan/2001 Block Diagram

DaqScan/2000 Series 947495 Block Diagrams 3-1

Page 22

DaqScan/2002 Block Diagram

DaqScan/2004 Block Diagram

3-2 Block Diagram 947495 DaqScan/2000 Series

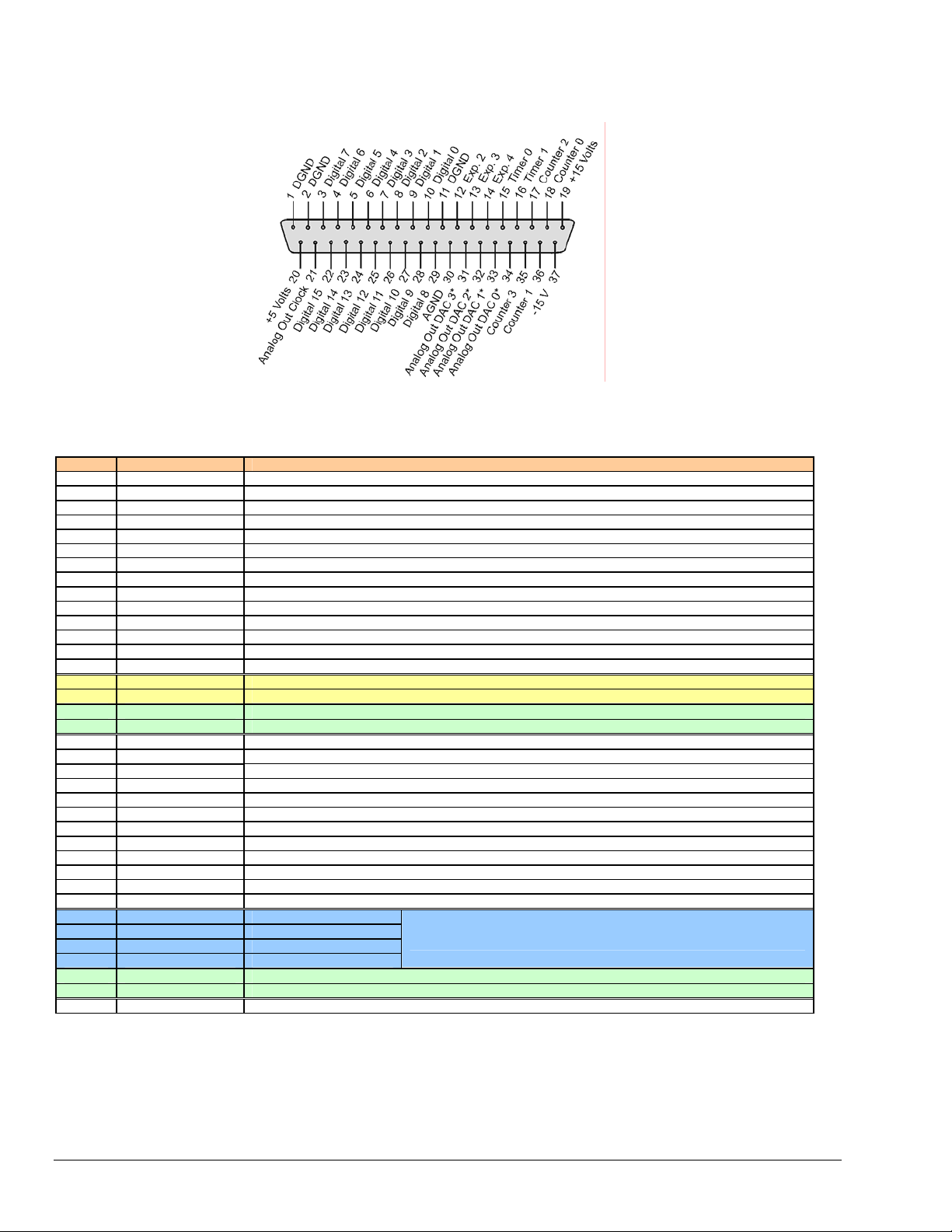

Page 23

DaqScan/2005 Block Diagram

DaqScan/2000 Series 947495 Block Diagrams 3-3

Page 24

3-4 Block Diagram 947495 DaqScan/2000 Series

Page 25

Connectors, Indicators, Cables, & Pinouts 4

DaqScan/2000 Series Hardware …… 4-1

Cables …… 4-3

Pinouts …… 4-5

DaqScan/2000 Series Hardware

DaqScan Front Panel

Front Panel

The DaqScan/2000 Series front panels contain a power indicator LED. The power switch and

connectors are on the rear panel.

DaqScan/2001, Rear Panel

Rear Panel

The DaqScan/2000 Series rear panels each contain a Power Switch, AC power cord connector,

2 Synchronization jacks, a MAC Address Label, Ethernet connector, 5 LEDs [ 2 of which are on

the Ethernet connector], and a set of DB37 connectors. All four DaqScan models have P2 and

P3 connectors; but in addition, DaqScan/2001 and DaqScan/2005 have P1 connectors for

analog I/O.

P1 - DB37 Connector: P1 applies to DaqScan/2001 and DaqScan/2005 only. P1 is the

analog input port for 16 single-ended analog inputs or 8 differential, programmable on a perchannel basis as single-ended or differential and as uni-polar or bipolar. The 3 programmable

ranges are from ±10 V to ±156 mV full scale. P1 can be used to connect the DaqScan to an

optional analog DBK card.

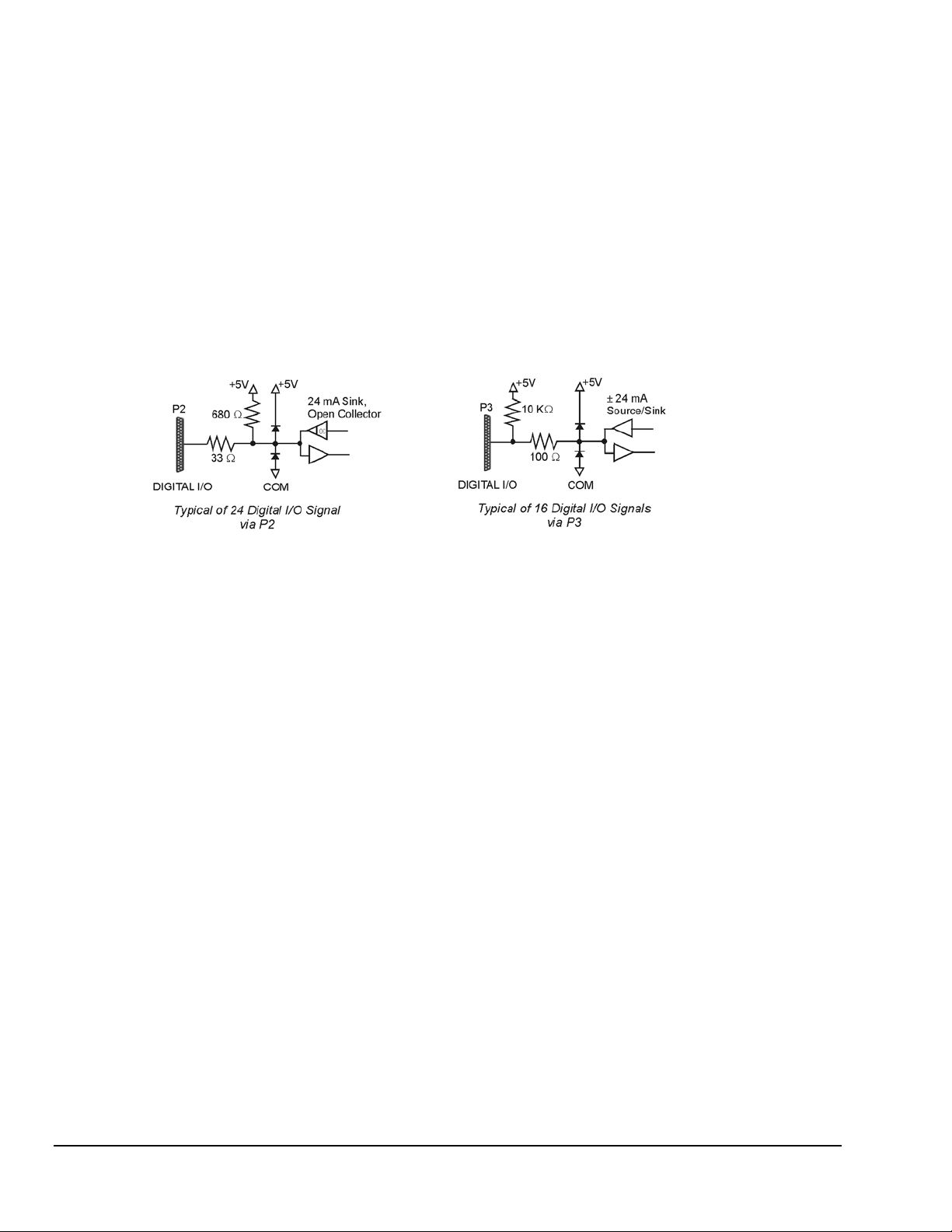

P2 - DB37 Connector: P2 is a general purpose digital I/O port with 24 (3 x 8-bit) lines on P2,

or digital I/O expansion port controlling up to 272 external lines. Programmable as input or

output. P2 can be used to connect to an optional digital DBK card.

P3 - DB37 Connector: 16-bit digital I/O port with 4 counter inputs and 2 timer outputs. In

addition, DaqScan/2001 and DaqScan/2004 each have a P3 connection to 4 analog outputs

(DAC0, DA1, DAC2, and DAC3).

DaqScan/2000 Series 898095 Connectors, Indicators, Cables, & Pinouts 4-1

Page 26

POWER Switch and Power LED: A rocker-type switch with a “0” label for Power Off, and a

“1” for Power On. When the unit is on and has power, the POWER LED will light. An AC to DC

power converter resides within each DaqScan/2000 series device.

MAC Address Label: The Media Access Control (MAC) label shows the device serial number in

three formats: (1) Barcode, (2) base 10, and (3) hexadecimal. If prompted to enter a serial

number in software, use the base 10 number. Conversion to a hexadecimal number for use in

addressing will be automatic.

ETHERNET: The 10/100BaseT Ethernet jack can be used to connect to the Ethernet port of

the host PC, or to an Ethernet network. Either of two Ethernet patch cables may be used to

make the connection. CA-242 is a 1.5 foot cable. CA-242-7 is a 7-foot cable.

The Ethernet connector has two built in LEDs (Tx and Rx) that indicate traffic flow. These are

defined in the following LED section. Note that the Ethernet cable length must be <10m in

order for the system to be CE Compliant.

LEDs: There are 5 ETHERNET Status LEDS. Two rectangular LEDs, Tx

and Rx are built right into the frame of the Ethernet jack. The other

three, located just to the right of the jack, are round and are labeled L, T,

and D.

Tx – “ON” indicates traffic is being transmitted (see figure at

right).

Rx – “ON” indicates that the port is receiving traffic.

L (Link) “ON” indicates a link exists. “OFF” indicates no link.

T (Transmit) “ON” indicates 100 M-Bits, “OFF” indicates

10 M-Bits.

D (Duplex) “ON” indicates full duplex, which allows

simultaneous two-way data traffic. “OFF” indicates halfduplex, which only allows one-way data traffic at any

given time.

Tx and Rx LEDs

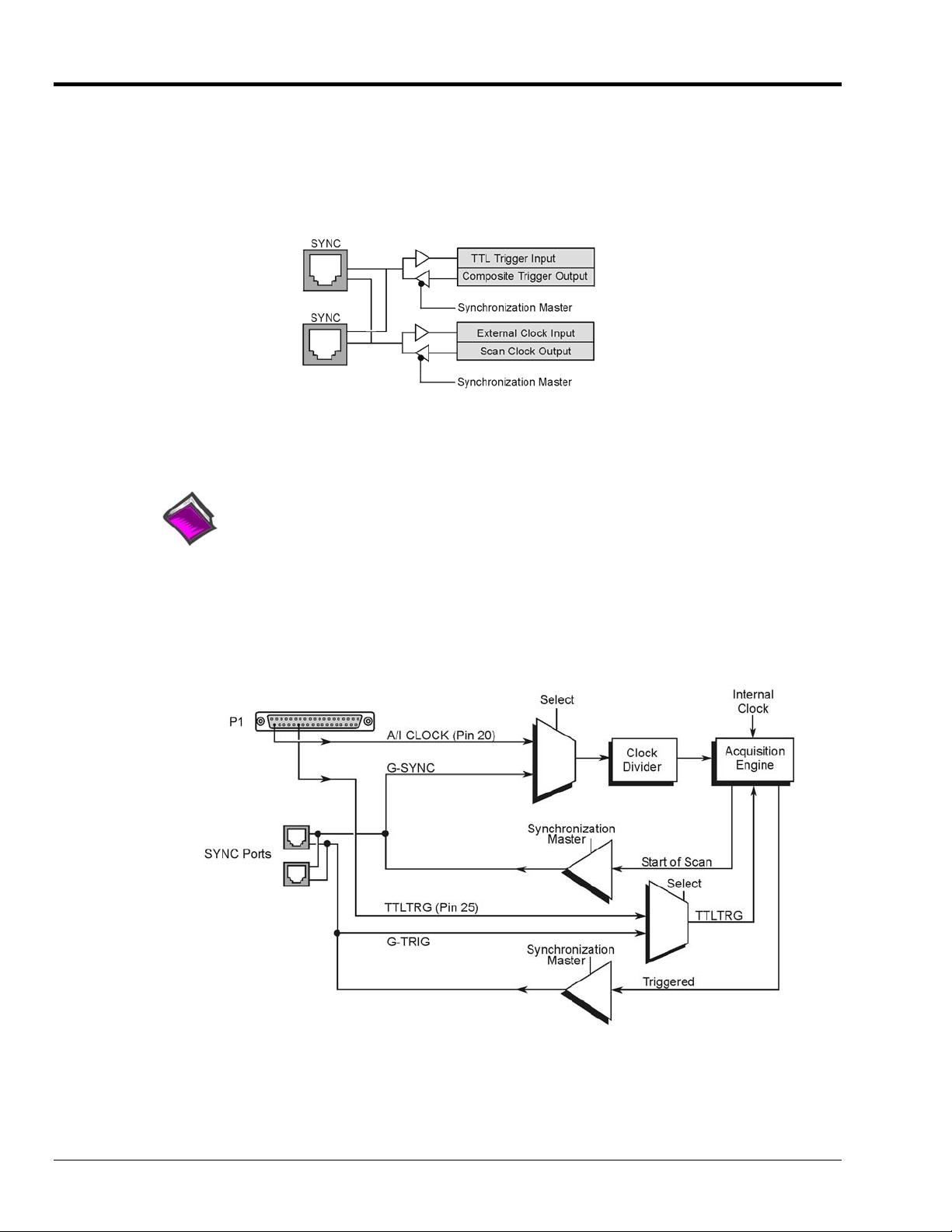

SYNC (Qty of 2) – Two “synchronization ports” provide a means of synchronizing up to four

DaqScan/2000 Series units in regard to post post-trigger scanning. The ports accept CA-74-1

and CA-74-5 RJ-11, 6 conductor type cables. The total combined length of the SYNC cables is

not to exceed 15 feet (4.57 m).

POWER IN: 90 to 250 VAC, 3-prong socket for power cord.

4-2 Connectors, Indicators, Cables, & Pinouts 898095 DaqScan/2000 Series

Page 27

Cables

Should you need help in regard to cables or have any other product inquiries

please contact the factory.

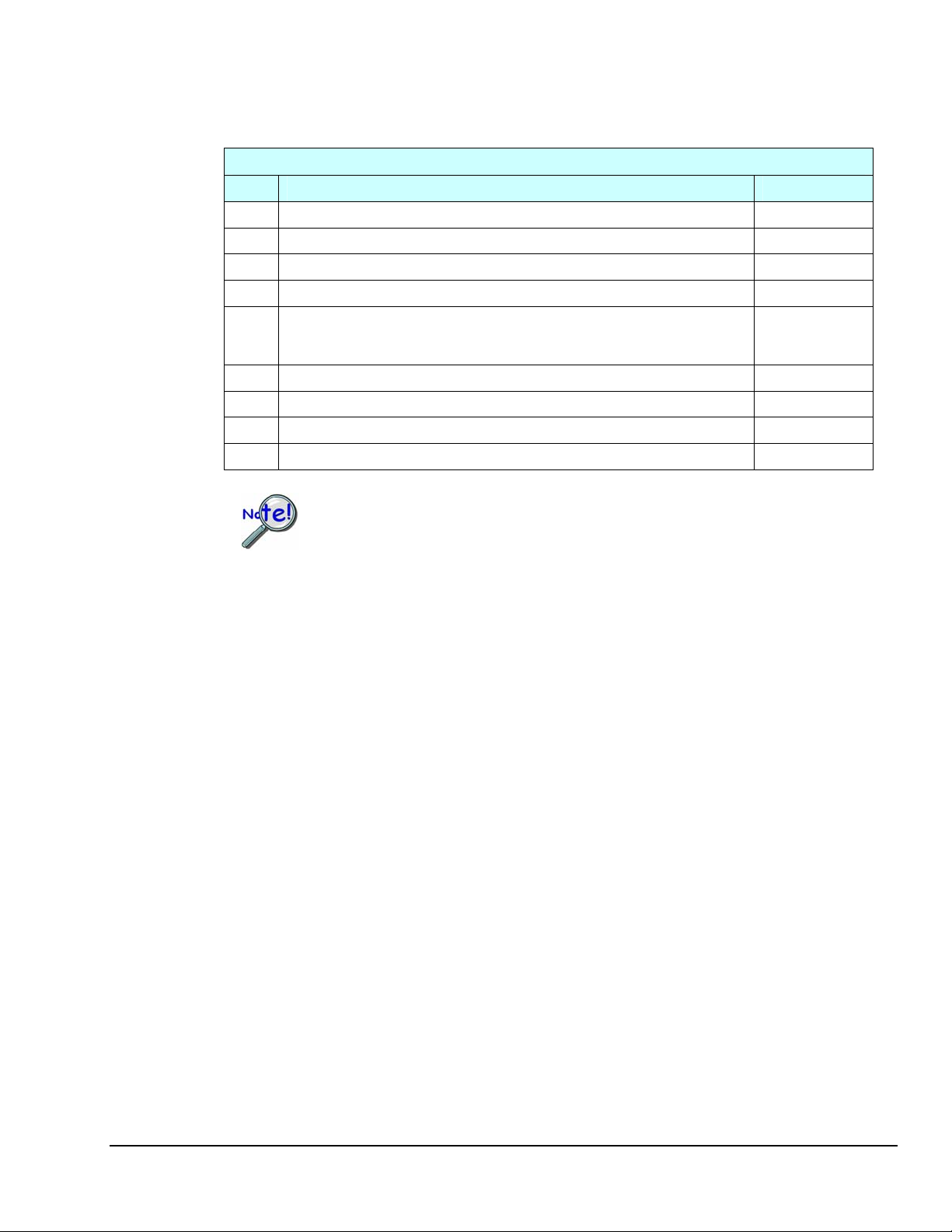

Cables for use with DaqScan/2000 Series Devices

Description Part No.

1. Molded expansion cable. Connects a

DBK module to a DaqScan, 2 in.

2. Molded expansion cable. Connects a

DBK module to a DaqScan, 4 in.

3. DBK expansion cable. Connects a

DBK module to a DaqScan, 2.5 in.

4. DBK expansion cable. Connects a

DBK module to a DaqScan, 4.5 in.

5. Expansion-card cable. Connects DBK

series expansion card options. The

“x” in the part no. indicates the

number of cards that can be

connected via the cable.

6. Ethernet patch cable, shielded, 18 in. CA-242

7. Ethernet patch cable, shielded, 7 ft. CA-242-7

8. Sync cable, RJ-11, 6 conductor, 1 ft. CA-74-1

9. Sync cable, RJ-11, 6 conductor, 5 ft. CA-74-5

CA-255-2T

CA-255-4T

CA-37-1T

CA-37-3T

CA-37-x

The total combined length of the SYNC cables is not to

exceed 15 feet (4.57 m).

DaqScan/2000 Series 898095 Connectors, Indicators, Cables, & Pinouts 4-3

Page 28

4-4 Connectors, Indicators, Cables, & Pinouts 898095 DaqScan/2000 Series

Page 29

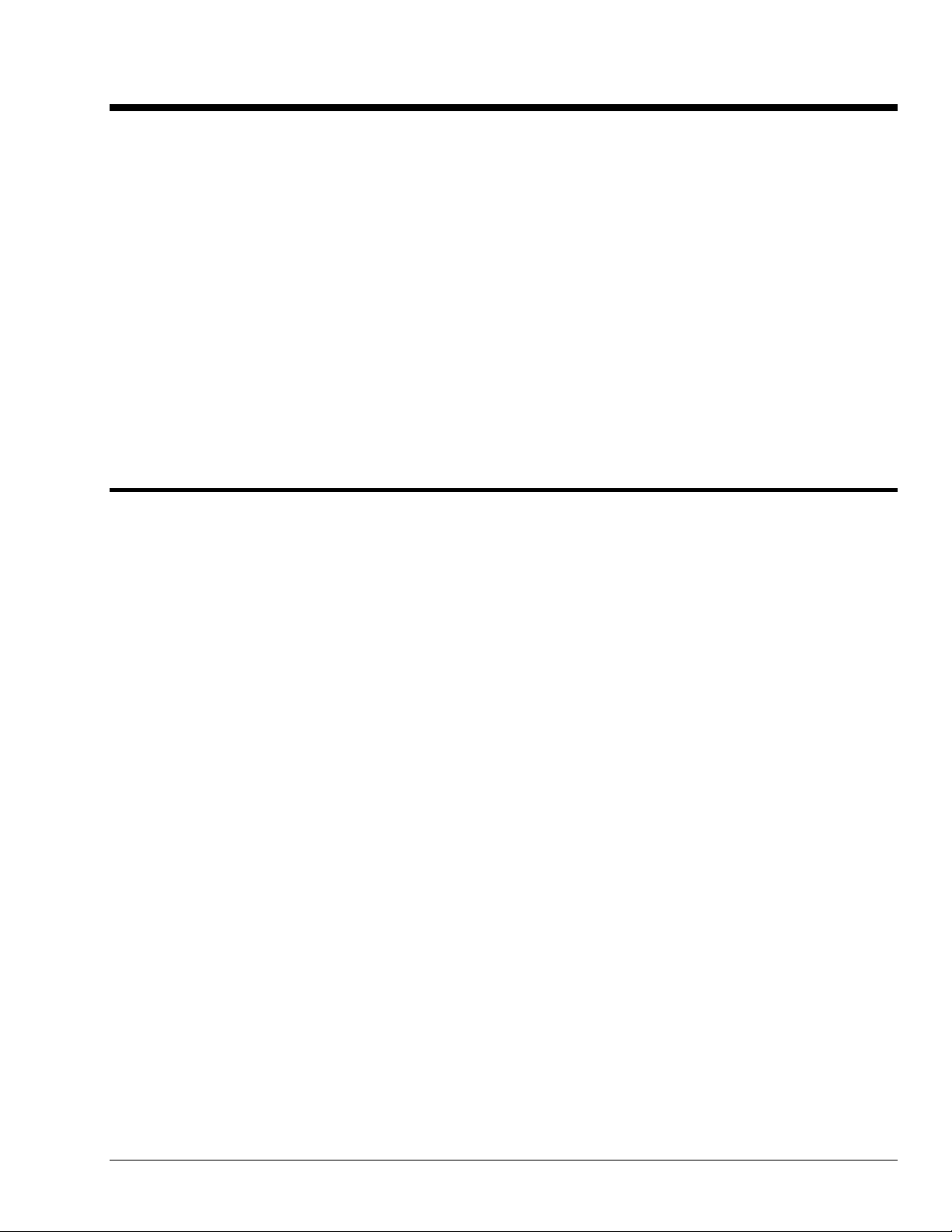

Pinouts

P1 – Analog I/O (Applies to DaqScan/2001 and DaqScan/2005 only) …… 4-6

P2 – Digital I/O …… 4-7

P3 – Pulse/Frequency/Digital I/O…… 4-8

CAUTION

Turn off power to all devices connected to the system before

connecting cables or setting configuration jumpers and switches.

Electrical shock or damage to equipment can result even under

low-voltage conditions.

CAUTION

The discharge of static electricity can damage some electronic

components. Semiconductor devices are especially susceptible to ESD

damage. You should always handle components carefully, and you

should never touch connector pins or circuit components unless you

are following ESD guidelines in an appropriate ESD controlled area.

Such guidelines include the use of properly grounded mats and wrist

straps, ESD bags and cartons, and related procedures.

Each of the four DaqScan/2000 Series devices has 37-pin connectors designated as P2 and P3.

In addition, DaqScan/2001 and DaqScan/2005 have a third DB37 connector, P1.

Signal assignment to connectors is as follows.

• P1 is used for Analog I/O (DaqScan/2001 and DaqScan/2005 only)

• P2 is used for Digital I/O

• P3 is used for Pulse/Frequency and Digital I/O; in addition, for DaqScan/2001 and

DaqScan/2004, P3 includes active pins for 4 analog output (DAC) channels.

To connect a DBK option to a DaqScan connect an appropriate cable (see table page 4-2) to

the appropriate DB37 connector [P1, P2, or P3] on the DaqScan and connect the free end of

the cable to the DBK card or module. If you are not familiar with DBK options, or need

refreshed, refer to the DBK Options Manual, p/n 457-0905.

DaqScan/2000 Series 898095 Connectors, Indicators, Cables, & Pinouts 4-5

Page 30

P1 (Applies only to DaqSCan/2001 and DaqScan/2004) Analog I/O

P1 Pin Signal Name Description

1 +5 Volts Expansion +5 V power

2 -15 Volts Expansion -15 VDC power

3 Expansion 7 Digital OUT, external ADDRESS select bit 3

4 Expansion 9 Digital OUT, external ADDRESS select bit 1

5 Expansion 5 Digital OUT, external GAIN select bit 1

6 Expansion 6 Digital OUT, external GAIN select bit 0

7 DGND Digital Ground

8 Negative Reference Analog, -5 V reference

9 Positive Reference Analog +5V reference

10 Not Connected N/A

11 CH 15 (SE), or CH 7 LO DIFF Ch 15 HI IN (single-ended mode) / Ch 7 LO IN (differential mode)

12 CH 14 (SE), or CH 6 LO DIFF Ch 14 HI IN (single-ended mode) / Ch 6 LO IN (differential mode)

13 CH 13 (SE), or CH 5 LO DIFF Ch 13 HI IN (single-ended mode) / Ch 5 LO IN (differential mode)

14 CH 12 (SE), or CH 4 LO DIFF Ch 12 HI IN (single-ended mode) / Ch 4 LO IN (differential mode)

15 CH 11 (SE), or CH 3 LO DIFF Ch 11 HI IN (single-ended mode) / Ch 3 LO IN (differential mode)

16 CH 10 (SE), or CH 2 LO DIFF Ch 10 HI IN (single-ended mode) / Ch 2 LO IN (differential mode)

17 CH 9 (SE), or CH 1 LO DIFF Ch 9 HI IN (single-ended mode) / Ch 1 LO IN (differential mode)

18 CH 8 (SE), or CH 0 LO DIFF Ch 8 HI IN (single-ended mode) / Ch 0 LO IN (differential mode)

19 Signal Ground (SGND) Sense Common (SGND)

20 A/I Clock External ADC Pacer Clock Input / Internal ADC Pacer Clock Output

21 +15 Volts Expansion +15 V power

22 Expansion 8 Digital OUT, external ADDRESS select bit 2

23 Expansion 10 Digital OUT, external ADDRESS select bit 0

24 Not Connected N/A

25 TTL Trigger Digital IN, External TTL Trigger Input

26 Expansion 11 Digital OUT, Simultaneou s sample and hold (SSH)

27 Not Connected N/A

28 AGND Analog Ground

29 AGND Analog Ground

30 CH 7 (SE), or CH 7 HI DIFF Ch 7 IN (single-ended mode) / Ch 7 HI IN (differential mode)

31 CH 6 (SE), or CH 6 HI DIFF Ch 6 IN (single-ended mode) / Ch 6 HI IN (differential mode)

32 CH 5 (SE), or CH 5 HI DIFF Ch 5 IN (single-ended mode) / Ch 5 HI IN (differential mode)

33 CH 4 (SE), or CH 4 HI DIFF Ch 4 IN (single-ended mode) / Ch 4 HI IN (differential mode)

34 CH 3 (SE), or CH 3 HI DIFF Ch 3 IN (single-ended mode) / Ch 3 HI IN (differential mode)

35 CH 2 (SE), or CH 2 HI DIFF Ch 2 IN (single-ended mode) / Ch 2 HI IN (differential mode)

36 CH 1 (SE), or CH 1 HI DIFF Ch 1 IN (single-ended mode) / Ch 1 HI IN (differential mode)

37 CH 0 (SE), or CH 0 HI DIFF Ch 0 IN (single-ended mode) / Ch 0 HI IN (differential mode)

4-6 Connectors, Indicators, Cables, & Pinouts

898095 DaqScan/2000 Series

Page 31

P2 Digital I/O

P2 Pin Signal Name Description

1 Not Connected N/A

2 Not Connected N/A

3 Port B - B7 Digital I/O: P2 Digital Port B, Bit 7; or, P2 Expansion Address Bit 0 Out

4 Port B - B6 Digital I/O: P2 Digital Port B, Bit 6; or, P2 Expansion Address Bit 1 Out

5 Port B - B5 Digital I/O: P2 Digital Port B, Bit 5; or, P2 Expansion Address Bit 2 Out

6 Port B - B4 Digital I/O: P2 Digital Port B, Bit 4; or, P2 Expansion Address Bit 3 Out

7 Port B - B3 Digital I/O: P2 Digital Port B, Bit 3; or, P2 Expansion Address Bit 4 Out

8 Port B - B2 Digital I/O: P2 Digital Port B, Bit 2; or, P2 Expansion RESET Output

9 Port B - B1 Digital I/O: P2 Digital Port B, Bit 1; or, P2 Expansion WRITE Output

10 Port B - B0 Digital I/O: P2 Digital Port B, Bit 0; or, P2 Expansion READ Output

11 DGND Digital Ground

12 Not Connected N/A

13 DGND Digital Ground

14 Not Connected N/A

15 DGND Digital Ground

16 Not Connected N/A

17 DGND Digital Ground

18 + 5 Volt Supply Expansion +5 Volt Power

19 DGND Digital Ground

20 + 5 Volt Supply Expansion +5 Volt Power

21 DGND Digital Ground

22 Port C - C7 Digital I/O: P2 Digital Port C, Bit 7; or, P2 Expansion Data Bit 7

23 Port C - C6 Digital I/O: P2 Digital Port C, Bit 6; or, P2 Expansion Data Bit 6

24 Port C - C5 Digital I/O: P2 Digital Port C, Bit 5; or, P2 Expansion Data Bit 5

25 Port C - C4 Digital I/O: P2 Digital Port C, Bit 4; or, P2 Expansion Data Bit 4

26 Port C - C3 Digital I/O: P2 Digital Port C, Bit 3; or, P2 Expansion Data Bit 3

27 Port C - C2 Digital I/O: P2 Digital Port C, Bit 2; or, P2 Expansion Data Bit 2

28 Port C - C1 Digital I/O: P2 Digital Port C, Bit 1; or, P2 Expansion Data Bit 1

29 Port C - C0 Digital I/O: P2 Digital Port C, Bit 0; or, P2 Expansion Data Bit 0

30 Port A - A7 Digital I/O: P2 Digital Port A, Bit 7

31 Port A - A6 Digital I/O: P2 Digital Port A, Bit 6

32 Port A - A5 Digital I/O: P2 Digital Port A, Bit 5

33 Port A - A4 Digital I/O: P2 Digital Port A, Bit 4

34 Port A - A3 Digital I/O: P2 Digital Port A, Bit 3

35 Port A - A2 Digital I/O: P2 Digital Port A, Bit 2

36 Port A - A1 Digital I/O: P2 Digital Port A, Bit 1

37 Port A - A0 Digital I/O: P2 Digital Port A, Bit 0

DaqScan/2000 Series

898095 Connectors, Indicators, Cables, & Pinouts 4-7

Page 32

P3 Pulse/Frequency/Digital I/O

P3 Pin Signal Name Description

1 DGND Digital Ground

2 DGND Digital Ground

3 Digital 7 P3 Digital Port Bit 7

4 Digital 6 P3 Digital Port Bit 6

5 Digital 5 P3 Digital Port Bit 5

6 Digital 4 P3 Digital Port Bit 4

7 Digital 3 P3 Digital Port Bit 3

8 Digital 2 P3 Digital Port Bit 2

9 Digital 1 P3 Digital Port Bit 1

10 Digital 0 P3 Digital Port Bit 0

11 DGND Digital Ground

12 Expansion 2 Reserved for XC/D13 Expansion 3 Reserved for XWR-

14 Expansion 4 Reserved for XRD-

15 Timer 0 P3 Timer 0 Output

16 Timer 1 P3 Timer 1 Output

17 Counter 2 P3 Counter 2 Input

18 Counter 0 P3 Counter 0 Input

19 + 15 Volts Expansion, +15 VDC

20 + 5 Volt Supply Expansion, +5 Volt Power

21 Analog Out Clock External DAC Pacer Clock Input/Internal DAC Pacer Clock Output

22 Digital 15 Digital I/O; P3 Digital Port Bit 15

23 Digital 14 Digital I/O; P3 Digital Port Bit 14

24 Digital 13 P3 Digital Port Bit 13

25 Digital 12 P3 Digital Port Bit 12

26 Digital 11 P3 Digital Port Bit 11

27 Digital 10 P3 Digital Port Bit 10

28 Digital 9 P3 Digital Port Bit 9

29 Digital 8 P3 Digital Port Bit 8

30 AGND Analog Ground

31 Analog Out DAC 3 Analog DAC 3 Output

32 Analog Out DAC 2 Analog DAC 2 Output

33 Analog Out DAC 1 Analog DAC 1 Output

34 Analog Out DAC 0 Analog DAC 0 Output

35 Counter 3 P3 Counter 3 Input

36 Counter 1 P3 Counter 1 Input

37 - 15 Volts Expansion, - 15 VDC Power

Note: DAC0, DAC1, DAC2, and DAC3 apply to DaqScan/2001 and

DaqScan/2004. They do not apply to DaqScan/2002 or DaqScan/2005.

4-8 Connectors, Indicators, Cables, & Pinouts 898095 DaqScan/2000 Series

Page 33

Software 5

Overview …… 5-1

Out-of-the-Box

Drivers for Third-party, Icon-driven Software …… 5-2

Language Drivers …… 5-2

Overview

The Daq devices have software options capable of handling most applications. Three types

of software are available:

• Out-of the-box graphical programs, e.

data analysis programs such as eZ-PostView, eZ-TimeView, and eZ-FrequencyView.

• drivers for third-party, icon-driven software such as DASYLab and LabVIEW.

• various language drivers to aid custom programming using API; includes

DaqCOM

Out-of-theBoxTM Software

Out-of-the-Box programs are convenient for fill-in-the-blank applications that do not require

programming for basic data acquisition and display:

• DaqView is a Windows-based program for basic set-up and data acquisition.

TM

Software …… 5-1

g., DaqView, DaqViewXL, and post acquisition

TM

ActiveX/COM support.

DaqView lets you select desired channels, gains, transducer types (including

thermocouples), and a host of other parameters with a click of a PC’s mouse.

DaqView lets you stream data to disk and display data in numerical or graphical

formats.

• DaqViewXL allows you to interface directly with Microsoft Excel to enhance data

handling and display. Within Excel you have a full-featured Daq control panel and all

the data display capabilities of Excel.

• eZ-PostView provides a simple method of graphically viewing acquired waveforms

from the acquisition device. Up to 8 windows can be displayed on one screen, with up

to 16 channels overlaid on each window. eZ-PostView makes it simple to visually

inspect acquired waveforms from multiple channels within seconds of acquiring the

data. Documentation, in Adobe PDF format, is provided on the CD. Refer to the

PostAcquisition Analysis.PDF.

• eZ-TimeView & eZ-FrequencyView

eZ-TimeView and eZ-FrequencyView are optional post-acquisition analysis packages,

which are related to eZ-PostView, but include more features. eZ-TimeView is

targeted at time-domain analysis, including min/max, peak-peak, mean, RMS, plus a

wide variety of plotting and waveform viewing capabilities. eZ-FrequencyView is

targeted at post-acquisition frequency-domain analysis, including FFT’s, octave analysis, plus dozens of other analysis features. Documentation, in Adobe PDF

format, is provided on the CD. Refer to the PostAcquisition Analysis.PDF.

• The Daq Configuration control panel allows for interface configuration, testing,

and troubleshooting.

DaqScan/2000 Series 948895 Software 5-1

Page 34

Reference Notes:

¾ The software documentation for DaqView, DaqViewXL, and Post

Acquisition Data Analysis are not included as part of the hardcopy

manual, but are available in PDF format. See the PDF Note, below.

¾ Programming topics are covered in the Programmer’s User Manual

(1008-0901). As a part of product support, that manual is automatically

loaded onto your hard drive during software installation. The default

location is the Programs directory, which can be accessed through the

Windows Desktop.

PDF

Note:

During software installation, Adobe® PDF versions of user manuals will

automatically install onto your hard drive as a part of product support. The

default location is in the Programs group, which can be accessed from the

Windows Desktop. Refer to the PDF documentation for details regarding both

hardware and software.

Note that the PDF documents can be read directly from the CD by using the

<View PDFs> button located on the opening install screen.

®

A copy of the Adobe Acrobat Reader

provides a means of reading and printing the PDF documents. Note that

hardcopy versions of the manuals can be ordered from the factory.

is included on your CD. The Reader

Drivers for Third-party, Icon-driven Software

LabVIEW® Support

We provide LabVIEW® support for expansion and signal conditioning modules. Our data

acquisition VIs for LabVIEW are more than just simple hardware access VIs, they are complete

with engineering data conversion, data display and logging capabilities.

DASYLab®

If your application requirements go beyond the scope of DaqView, you may want to consider

DASYLab software, as the latter offers a greater degree of flexibility and customizing.

Language Drivers

Each Daq system comes with an Application Programming Interface (API). API-language

drivers include: C/C++, and Visual Basic. The latest software is a 32-bit version API.

DaqScan/2000 Series devices are supplied with DaqX Subroutine API Libraries. These provide

complete support for all of the functionality available on each data acquisition device in Visual

Basic®, and C/C++. In addition, DaqX is supported under all versions of Windows®. Over

100 program examples are included with DaqX Subroutine API Libraries. API documentation

is provided in a Programmer’s Manual (p/n 1008-0901), which is included on the installation

CD.

The DaqCOM™ suite of programming allows applications developers to rapidly develop and

deploy custom systems by leveraging COM (Component Object Model) technology. DaqCOM

does this by providing a powerful easy-to-use interface to most programming languages

including, Visual Basic®, VBA, C++, and J++. In additi on, DaqCOM supports the new

Windows.NET architecture and includes examples for VisualBasic.NET and C++. Support for

VisualStudio.NET is accomplished via the COMInterop feature within VisualStudio.NET.

5-2 Software 948895 DaqScan/2000 Series

Page 35

Configuring the System for Operation 6

Connecting a DaqLab/2000 Series or DaqScan/2000 Series Device to the Ethernet

CAUTION

Turn off power to the system devices and externally connected equipment before

connecting cables. Electric shock or damage to equipment can result even under lowvoltage conditions.

Take ESD precautions (packaging, proper handling, grounded wrist strap, etc.)

Before you get started

Verify that you have the following items.

DaqLab/2000 or DaqScan/2000 Series Device

DBK option cards, as applicable

AC Power Cord

Ethernet Patch Cable

Ethernet jack [on PC or on a hub connected to the Ethernet]

Data Acquisition CD

Monitor: SVGA, 1024 x 768 screen resolution

Windows 2000 SP4 and Windows XP users:

PC with Intel™ Pentium, 1 GHz or equivalent;

512 MB memory; 10 GB disk space

Windows Vista users:

PC must be Windows Vista Premium Ready

Reference Note: Adobe PDF versions

of user manuals will automatically install

onto your hard drive as a part of

product support. The default location is

in the Programs group, which can be

accessed from the Windows Desktop.

You can also access documents directly

from the data acquisition CD via the

<View PDFs> button located on the

CD’s opening screen.

Step 1 - Install the Software ….. 6-2

Step 2 - Determine the type of Network Connection …… 6-2

Step 3 - Connect System Components …… 6-4

Step 4 - Power-up the System …… 6-5

Step 5 - Configure the Computer’s Network Settings …… 6-6

Step 6 - Configure Device Network Settings using DaqIPConfig …… 6-9

Step 7 - Configure and Test the System using the Daq Configuration …… 6-10

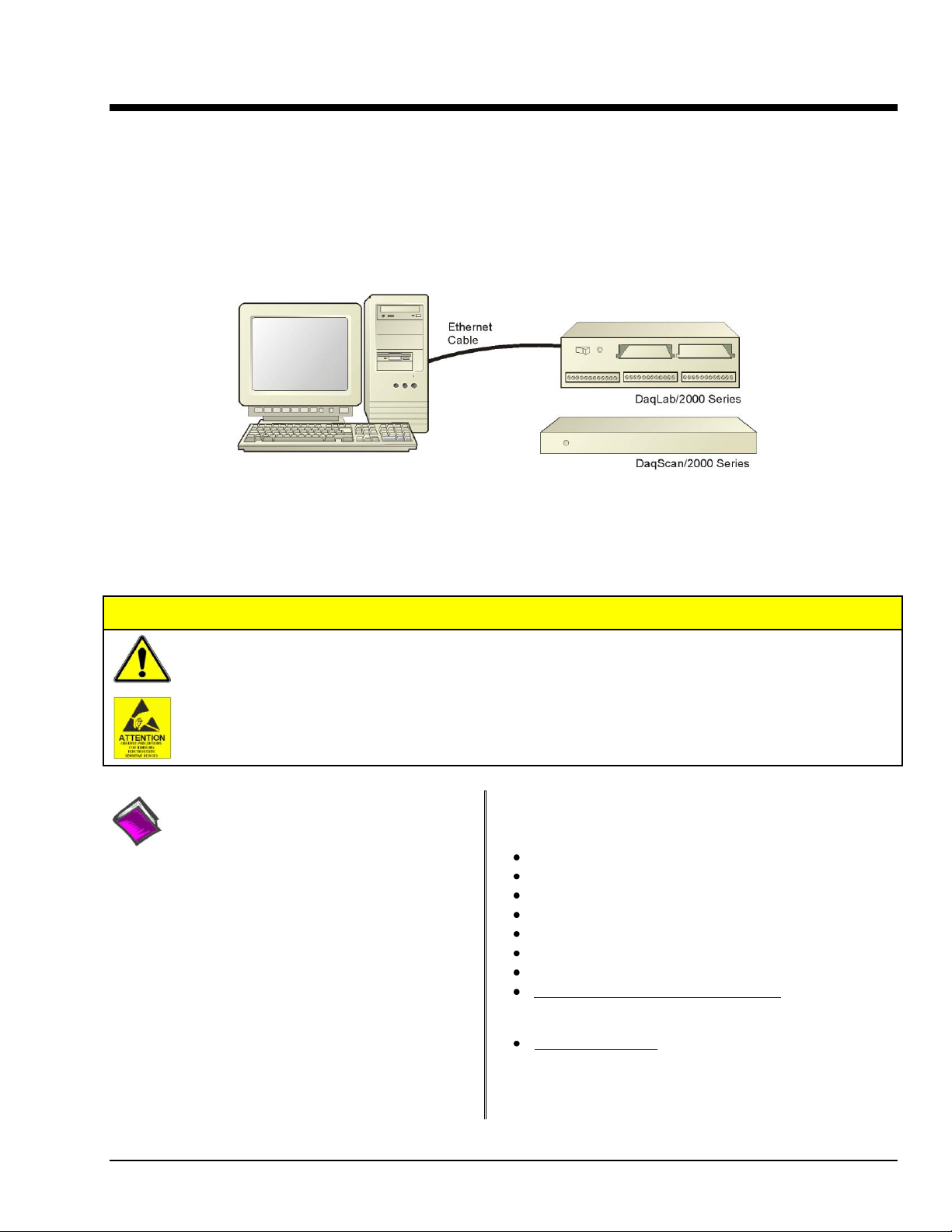

The DaqLab/2000 Series and DaqScan/2000 Series acquisition devices connect directly to an

Ethernet port on a PC or network hub via a built-in 10/100BaseT Ethernet interface. An Ethernet

patch cable CA-242 (1.5 foot) or CA-242-7 (7 foot) cable is used to make the connection.

DaqLab/2000 Series & DaqScan/2000 Series 947091 Configuring the System for Operation 6-1

Page 36

STEP 1 – Install the Software

1. Remove previous version Daq drivers, if present. You can do this through Microsoft’s

Add/Remove Programs feature.

2. Place the Data Acquisition CD into the CD-ROM drive. Wait for PC to auto-run the CD. This

may take a few moments, depending on your PC. If the CD does not auto-run, use the

Desktop’s Start/Run/Browse feature to locate and run Setup.exe [from the applicable

CD-ROM drive].

3. After the intro-screen appears, follow the screen prompts.

STEP 2 – Determine the type of Network Connection

To properly connect and configure the device you must determine the type of network it will

become part of. This is because the type of network used has a direct bearing on the IP

address of the device.

Briefly, the four network types are as follows:

Dedicated Network - with a direct cable connection from the PC to the

device

Dedicated Network - making use of a network hub or switch

LAN with a DHCP server

(Local Area Network with a Dynamic Host Configuration Protocol)

LAN without a DHCP server

(Local Area Network with no Dynamic Host Configuration Protocol)

Brief descriptions and illustrations follow.

Dedicated Network - with a direct cable connection from the PC to the device

In this scenario a DaqLab/2000 Series device is connected directly to an Ethernet

jack on a host computer. The following figure could just as easily portray a

DaqScan/2000 Series device.

Dedicated Network using a Direct Cable Connection

6-2 Configuring the System for Operation 947091 DaqLab/2000 Series & DaqScan/2000 Series

Page 37

Some network devices such as a wireless access point may act as a DHCP

server. If this is the case, follow the instructions for the LAN with a DHCP

server. For detailed information consult the documentation that is specific

to your network device.

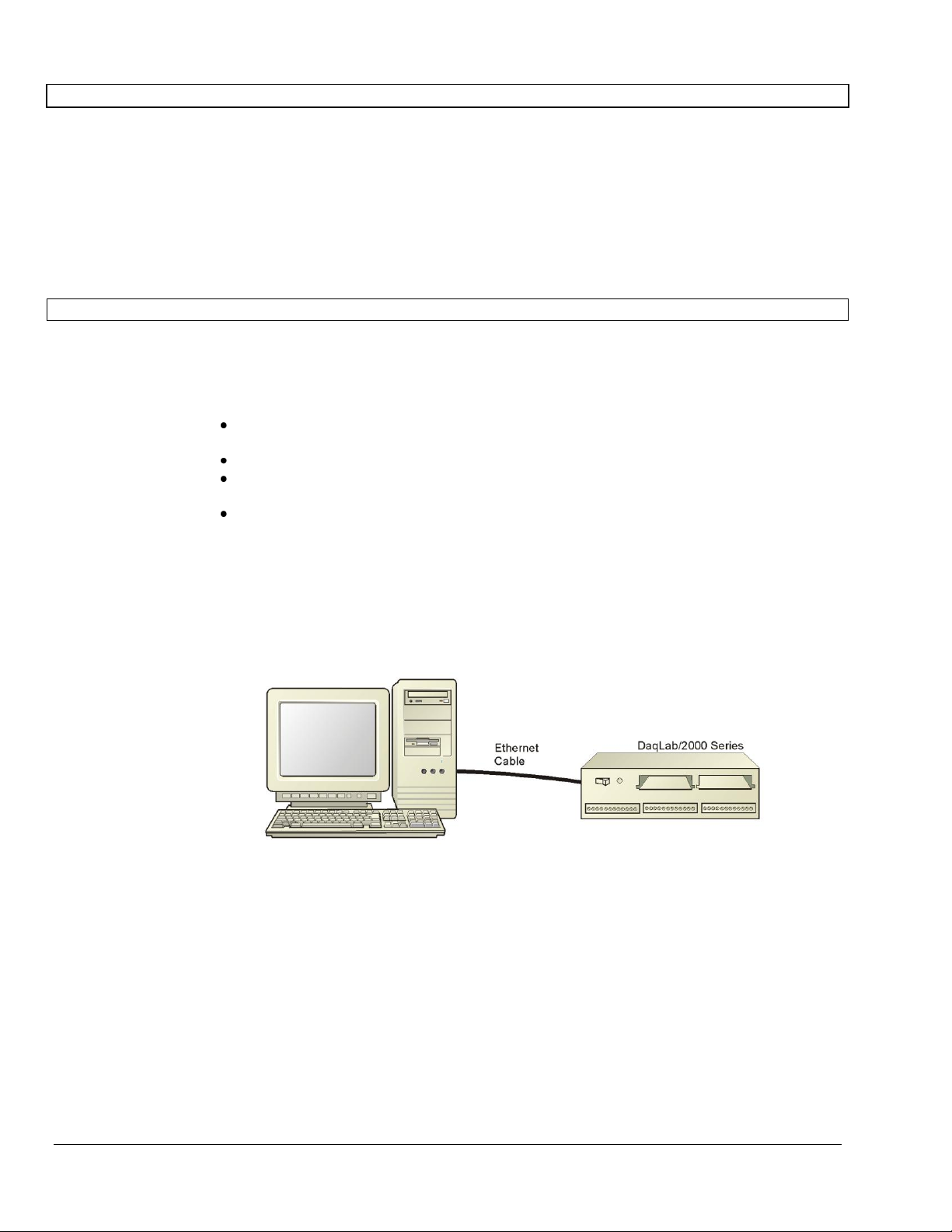

Dedicated Network - making use of a network hub or switch

In the following figure a DaqLab/2000 Series device is connected to the Ethernet through a

network hub/switch. At least one computer is also connected to the hub. DaqScan/2000

series devices can be connected directly to the hub/switch in the same manner.

Dedicated Network using a Hub/Switch

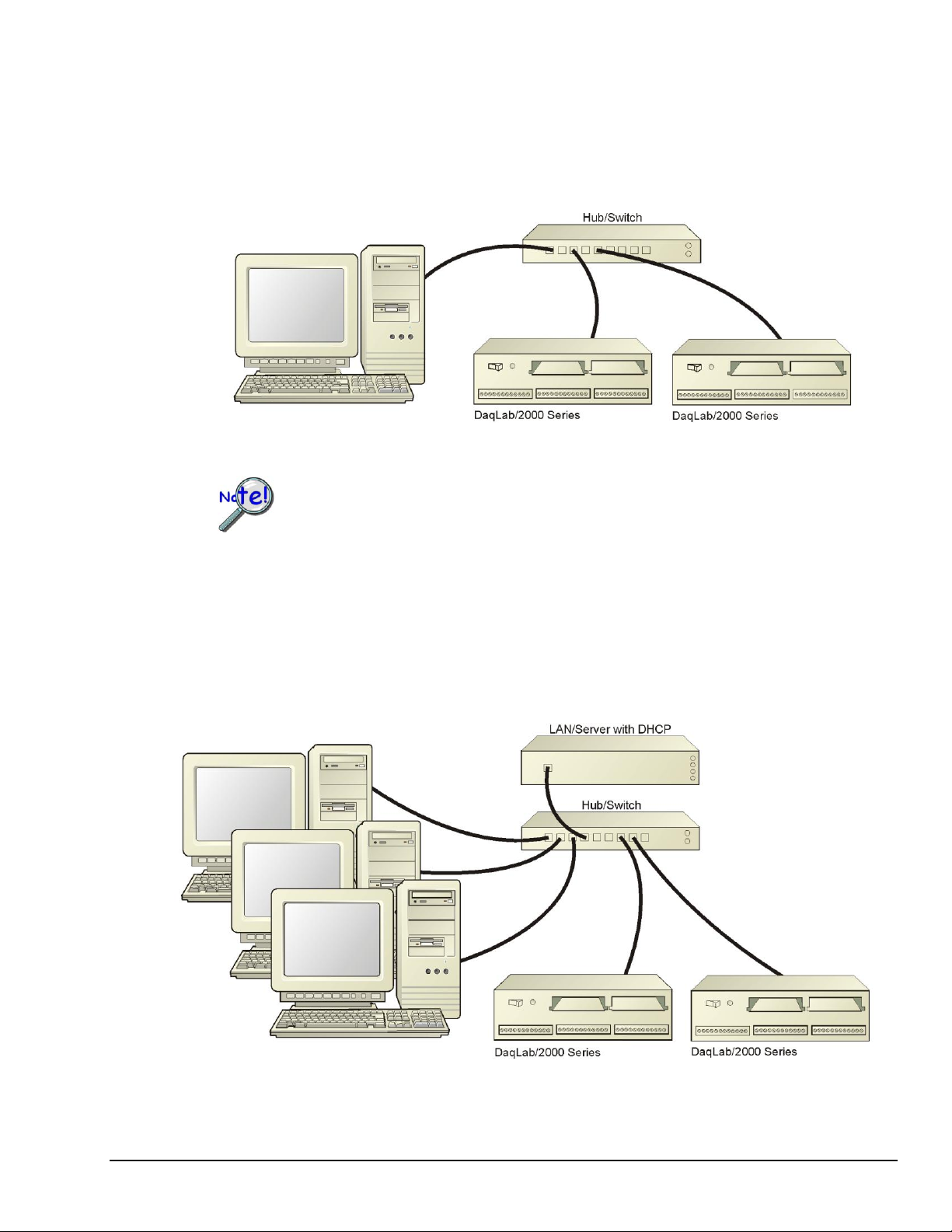

LAN with a DHCP Server

(Local Area Network with a Dynamic Host Configuration Protocol server)

Many corporations use the LAN/Server with DHCP arrangement for their networks. In

this type of setup several computers are typically connected to a network that makes use

of a DHCP server. In addition, the primary data acquisition device, e.g., DaqLab/2001, is

connected to the network hub/switch.

LAN with a DHCP Server

DaqLab/2000 Series & DaqScan/2000 Series 947091 Configuring the System for Operation 6-3

Page 38

Reference Note:

For information regarding connections, refer to Chapter 4, Connectors, Indicators, Cables,

& Pinouts.

Notes:

Using a DaqLab/2000 Series or DaqScan/2000 Series device on a typical LAN may

affect the speed of the network and internet data transfer. Because of this we

recommend adding a network card to the computer and using one of the two

dedicated network configurations.

Contact your network administrator before connecting your device to a corporate

network.

LAN with no DHCP Server

(Local Area Network with no Dynamic Host Configuration Protocol server)

This scenario looks the same as that shown in the previous illustration, except there is no

Dynamic Host Configuration Protocol (DHCP). In this type of setup, one or more computers

are connected to a network; and each computer has a static IP address.

STEP 3 – Connect the System Components

What you will need to connect your DaqLab/2000 Series or DaqScan/2000 Series

device to the Ethernet:

An available connection to the Ethernet. The connection can be either

- an Ethernet jack on a computer or

- an Ethernet jack on a hub that is connected to the Ethernet.

An Ethernet patch cable, e.g., a CA-242 (1.5 foot cable) or a

CA-242-7 (7-foot cable).

1. Connect the Ethernet cable to the Ethernet jack on the Daq device.

2. Connect the other end of the Ethernet cable to the Ethernet jack on the host

computer or network hub.

6-4 Configuring the System for Operation 947091 DaqLab/2000 Series & DaqScan/2000 Series

Page 39

STEP 4 – Power-up the System

What you will need:

A 90 to 240 VAC power supply.

Your unit’s power supply cord.

How to make the connection:

In the following steps we use the term “Daq Device” to mean a DaqLab/2000 Series device or

DaqScan/2000 Series device as applicable to your system.

1. Using the unit’s power switch, turn the Daq device “OFF.” The switch will be in the

“0” position and the power LED will be unlit.

2. Connect the power cord to the Power In connector on the Daq device.

3. Connect the plug to a standard AC outlet, or to the outlet of another reliable 90 to

240 VAC power supply.

4. If your power supply has a switch or breaker, close it to turn power “ON.”

5. Turn ON the Daq device by placing its power switch to the “1” position. The unit’s

power led will light up.

DaqLab/2000 Series & DaqScan/2000 Series 947091 Configuring the System for Operation 6-5

Page 40

If using a LAN (Local Area Network), which has a DHCP server, skip this section

and continue with STEP 7 - Configure and Test the System using the

Daq*Configuration Applet (page 6-10).

If using a LAN (Local Area Network), which has no DHCP server, skip this

section and continue with STEP 6 - Configure Device Network Settings using

DaqIPConfig (page 6-9).

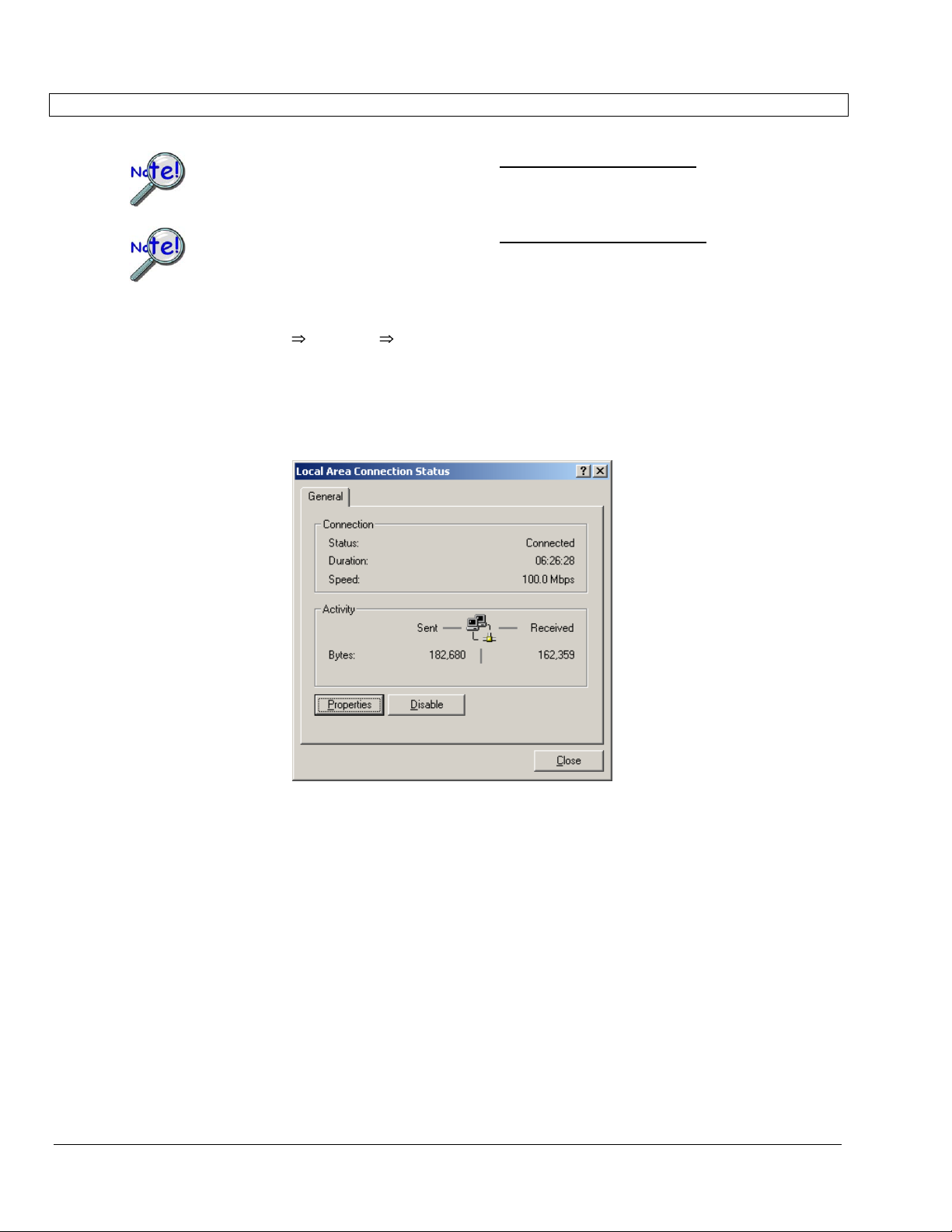

Local Area Connection Status

4. In the “Local Area Connection Status” box (previous figure), click on the <Properties>

button. The “Local Area Connection Properties” box will appear (following figure).

STEP 5 – Configure the Computer’s Network Settings [Applies to “dedicated networks” only]

1. Open the Control Panel by navigating from the Windows Desktop as follows:

Start Menu Settings Control Panel.

2. Double-click the “Network and Dial-up Connections” icon.

3. Double-click the “Network Connection” icon for the network that the Daq device is

connected to.

6-6 Configuring the System for Operation 947091 DaqLab/2000 Series & DaqScan/2000 Series

Page 41

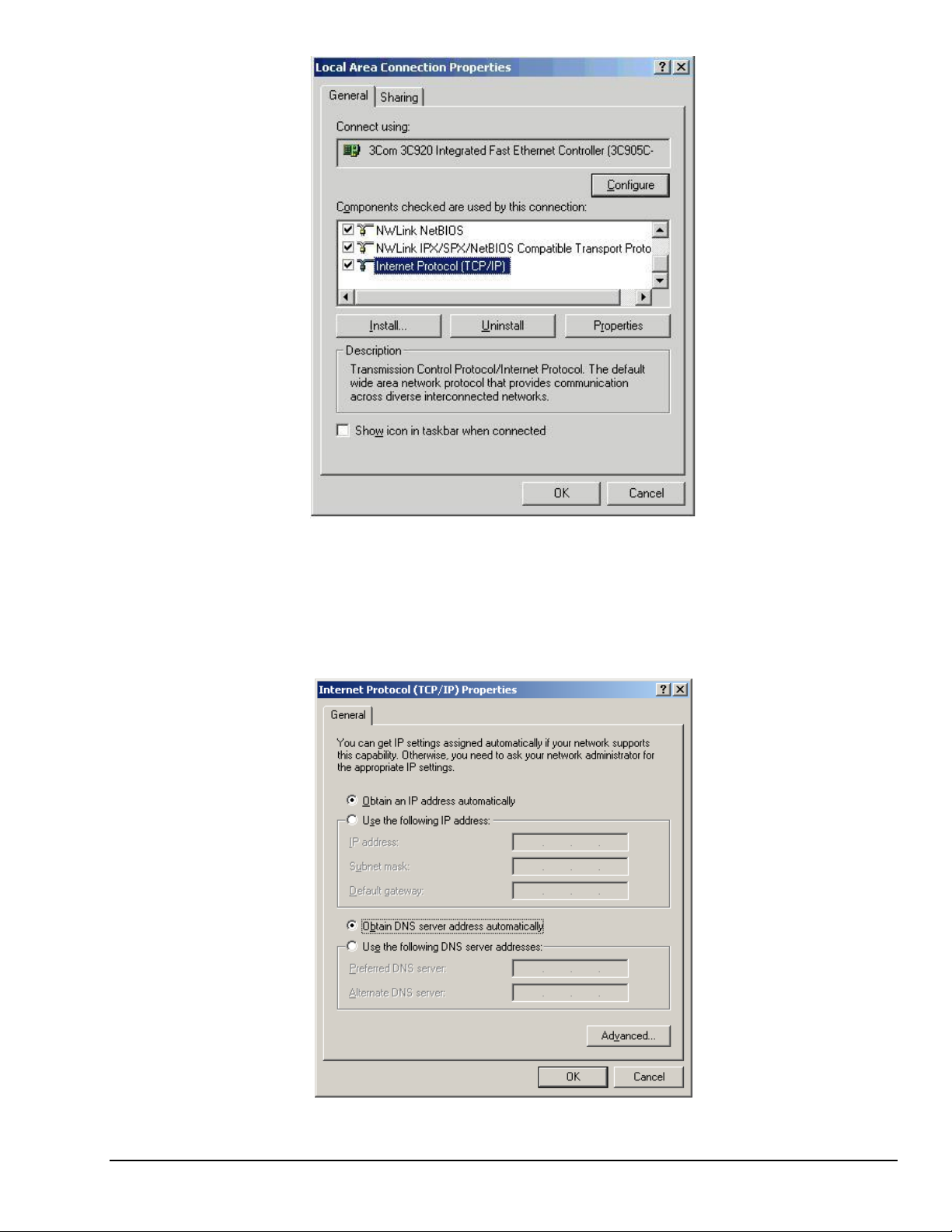

Local Area Connection Properties

5. Double-click the “Internet Protocol (TCP/IP)” component (previous figure).

The “Internet Protocol (TCP/IP) Properties” box will appear (following figure).

Internet Protocol (TCP/IP) Properties

DaqLab/2000 Series & DaqScan/2000 Series 947091 Configuring the System for Operation 6-7

Page 42

Make sure that each computer on the dedicated network has a unique

IP address. Make sure that the IP address of the acquisition device is also

unique. The computer and the device cannot use the same IP address.

Internet Protocol (TCP/IP) Properties

Configure the Computer’s TCP/IP settings as follows.

6. Select the “Use the following IP Address” radio button.

7. Set the IP address field to 10.0.0.x where x is some number from 1 to 255.

Make sure that each computer on the dedicated network has a unique

IP address!

8. Set the Subnet mask to 255.0.0.0. Note that the remaining fields can be left

unchanged.

6-8 Configuring the System for Operation 947091 DaqLab/2000 Series & DaqScan/2000 Series

Page 43

Never set the TCP/IP for the device to be the same as the host computer’s IP address!

Each computer and each device on a dedicated network must have a unique IP address!

If using a LAN (Local Area Network), which has a DHCP server, skip this section and continue

with STEP 7 - Configure and Test the System using the Daq*Configuration Applet (page 6-10).

STEP 6 – Configure Device Network Settings using DaqIPConfig

Applies only to a LAN (Local Area Network), which has a no DHCP server.

The DaqIPConfig applet is designed for 32-bit Windows/2000/XP/Vista systems. You can use DaqIPConfig to

change the IP address of the device to be compatible with networks that require fixed IP addresses. As a

precaution, you should always consult with your IT administrator before using the applet to ensure that each

device and host computer connected to the network maintains a unique IP address. The applet is located in the

program group for the associated device and can be accessed from the Windows Desktop via the start menu.

1. Locate the DaqIPConfig Applet.

Locate the DaqIPConfig applet by navigating from

the Windows’ Desktop as follows:

Start Menu Programs IOtech DaqX

Software DaqIPConfig

2. Open the DaqIPConfig Applet.

Click on the DaqIPConfig selection to open the

applet.

3. Select the device that is to have the address

change.

Note: In the above figure there is only one device

to select, i.e., DaqLab/2001.

4. Set the internet protocol (TCP/IP) settings to

be compatible with host computer.

(a) Select the radio button labeled “Use the

following IP address.”

(b) Enter the new internet protocol settings. If

needed, consult your network administrator

for acceptable numbers.

Do not set the TCP/IP to the computer’s IP address!

(c) Click the <OK> button.

5. Reboot the device.

The new IP address will not take affect until the device has been powered-off, then powered

back on.

6. Repeat steps 3, 4, and 5 for other devices in the system.

After configuring the network settings for all devices, proceed to Step 7.

DaqLab/2000 Series & DaqScan/2000 Series 947091 Configuring the System for Operation 6-9

Page 44

STEP 7 – Configure and test the System using the Daq* Configuration Applet

The Daq* Configuration applet is located in the Windows Control Panel. It allows you to add

or remove a device and change configuration settings. The included test utility provides

feedback on the validity of current configuration settings and performance summaries.

1. Open the Daq* Configuration Applet.

a. Open the Control Panel by navigating from the Windows’ Desktop as follows:

Start Menu Settings Control Panel

b. From the Control Panel, double-click the Daq* Configuration icon.

2. Add the first-level device to the list of installed devices.

The first-level device is the device that will be connected directly to the Ethernet, via a host

computer’s Ethernet jack or a jack on a network hub. DaqLab/2001 is an example of a firstlevel device.

a. Select the Computer image in the Device Inventory configuration tree (following

figure).

b. Click the <Add Device> button. The “Select Device Type” box will appear.

c. Select the device from the list of devices. In our example we are selecting a

DaqLab/2001.

d. Click the <OK> button. The “Properties” box will appear for the selected device.

Using Daq Configuration’s “Device Inventory” and

”Select Device Type” to Add a Device

Note: Although the above figure indicates that a DaqLab/2001 was selected as the

first level device, we could similarly have selected another device, for

example, a DaqLab/2005 or a DaqScan/2004.

3. Set the properties of the first-level device.

In this step you will set the device properties according to one of the following two methods,

depending on whether you have a “Dedicated Network” or a “LAN with DHCP Server Network.”

Illustrations of the network types are provided on page 6-3.

6-10 Configuring the System for Operation 947091 DaqLab/2000 Series & DaqScan/2000 Series

Page 45

Users of Dedicated Networks follow these 2 steps.

Provide your network administrator with the information located on

the device’s MAC label.

Find out from the administrator if the IP Address will be changing. If

so, see if you can obtain a permanent IP Address that will be dedicated

specifically to your device.

For DEDICATED Networks

For LAN with DHCP Server Networks

Daq Configuration, Properties Dialog Boxes

Note: The above images are based on DaqLab/2001. We could similarly have selected another device.

a. Enter the Serial Number of the first-level device, e.g., DaqLab/2001. In the

following screen shots the Serial Number is 800069.

b. Select the “Auto IP Setting” radio button. Note that the IP Address of the

DaqLab/2001 will automatically be calculated and displayed in the IP Address field

as indicated in the following left-hand figure.

c. Click the <OK> button.

Users of LAN with DHCP Server Networks follow these 3 steps.

The DaqIPConfig applet provides the Serial Number and the IP Address of the device.

Users of LAN with DHCP Server Networks will need to enter both numbers in the Daq

Configuration, Properties dialog boxes (previous right-hand figure). Page 6-9 includes

instructions for accessing DaqIPConfig.

If needed, refer to the upper right-hand figure in regard to radio-button and data entry

locations.

a. Enter the base 10 version of the Serial Number of the device, e.g., DaqLab/2001.

b. Select the “Manual IP Setting” radio button.

c. In the IP Address field, enter the IP address.

d. Click the <OK> button.

4. Test the system connections.

a. Make sure the device has been properly installed and is powered-on.

b. Make sure all cables are properly and securely connected.

c. Click the “Test Hardware” tab.

d. Click the <TCP/IP Test> button. This tests the Transmission Control Protocol /

Internet Protocol. The TCP/IP test has two components: Pinging Device and TCP

Connection.

DaqLab/2000 Series & DaqScan/2000 Series 947091 Configuring the System for Operation 6-11

The Pinging Device test is an ICMP (Internet Control Message Protocol) ping test.

In addition to indicating either “Passed” or “Failed,” the test displays the round-trip

Page 46

time of the ping, for example, <10 ms; and Packet Loss expressed as a percent of

When testing a DaqLab/2000 Series or a DaqScan/2000 Series device, if

the unit does not respond within 30 seconds perform the following steps:

1) reboot the system

2) upon power-up, re-open the Daq Configuration applet

3) select another configuration setting

4) reinitiate the test

Reference Notes:

Depending on your application and system setup, related information can be found

in the following sources:

The DBK Options Manual (p/n 457-0905).

The Programmer’s Manual, (p/n 1008-0901).

data lost.

A long ping round trip time, for example, >50 ms and/or any packet loss indicates

a slow network that is not optimized.

If the Pinging Device Test fails a <Details> button will appear just above the

<Resource Test> button. If this is the case, click the <Details> button to

obtain possible causes and possible solutions.

The result of the TCP (Transmission Control Protocol) test will be either

passed or failed. If the TCP test failed a <Details> button will appear just above

the <Resource Test> button. If this is the case, click the <Details> button to

obtain possible causes and possible solutions.

e. Upon completion of the TCP/IP test, click the <Resource Test> button. The

Resource Test consists of two components: Resource Tests and Performance

Tests.

The Resource Test performs a quick communications check. If the host PC can

communicate with the device a message that the test passed is displayed.

The Performance Tests obtain quantitative results using the current

configuration of the acquisition device. The test results represent the maximum

rates at which various operations can be performed, and will vary according to

port hardware capabilities.

The ADC FIFO Input Speed part of the test results in a display of the maximum

rate at which data can be transferred from the tested device’s internal ADC FIFO

to computer memory. Results are given in samples/second, where a sample

(2 bytes in length) represents a single A/D value.

This completes the procedure for connecting a DaqLab/2000 Series or a DaqScan/2000 Series

device to the Ethernet.

Note: You can access PDF documents directly from the opening screen of the data acquisition

CD via the <View PDFs> button.

6-12 Configuring the System for Operation 947091 DaqLab/2000 Series & DaqScan/2000 Series

Page 47

CE Compliance & Noise Considerations 7

Overview

Overview ……7-1

CE Standards and Directives …… 7-1

Safety Conditions ……7-2

Emissions/Immunity Conditions ……7-2

CE Enhancements for DBKs .…… 7-3

CE Compliance for System Expansion …… 7-3

Noise Considerations …… 7-4

CE-compliant products bear the “CE” mark and include a Declaration of Conformity

stating the particular specifications and conditions that apply. The test records and

supporting documentation that validate the compliance are kept on file at the

factory.

The European Union established CE standards in 1985. The standards include specifications

for safety, EMI emissions, and immunity from electromagnetic interference. Products that are

intended for placement in the European Union must meet or exceed the standards and bear

the "CE" mark.

Although not required in the USA, meeting or exceeding the CE standards is considered good

engineering practice, since doing so enhances safety while reducing noise and ESD problems.

In contracted and in-house testing, most Daq products met the required specifications. In

many cases, products that were not originally in compliance were redesigned accordingly. In

noted instances, alternate product versions, shield plates, edge guards, special connectors, or

add-on kits are required to meet CE compliance.

CE Standards and Directives

The electromagnetic compatibility (EMC) directives specify two basic requirements:

1. The device must not interfere with radio or telecommunications.

2. The device must be immune from electromagnetic interference from RF transmitters,

etc.

The standards are published in the Official Journal of European Union under direction of

CENELEC (European Committee for Electrotechnical Standardization). The specific standards

relevant to Daq equipment are listed on the product’s Declaration of Conformity.

The safety standard that applies to Daq products is EN 61010-1:1993 (Safety Requirements

for Electrical Equipment for Measurement, Control, and Laboratory Use, Part 1: General

Requirements). Environmental conditions include the following:

• indoor use

• altitude up to 2000 m

• temperature 5°C to 40°C (41°F to 104°F)

• maximum relative humidity 80% for temperatures up to 31°C (87.8°F) decreasing

linearly to 50% relative humidity at 40°C (104°F)

• mains supply voltage fluctuations not to exceed ±10% of the nominal voltage

• other supply voltage fluctuations as stated by the manufacturer

• transient overvoltage according to installation categories (overvoltage categories) I, II

and III. For mains supply, the minimum and normal category is II.

• pollution degree I or II in accordance with IEC 664

DaqLab/2000 Series and DaqScan/2000 Series 959195 CE-Compliance & Noise Considerations 7-1

Page 48

For clarification, terms used in some Declarations of Conformity include:

• pollution degree: any addition of foreign matter, solid, liquid or gaseous (ionized

gases) that may produce a reduction of dielectric strength or surface resistivity.

Pollution Degree I has no influence on safety and implies: the equipment is at

operating temperature with non-condensing humidity conditions; no conductive particles

are permitted in the atmosphere; warm-up time is sufficient to avert any condensation

or frost; no hazardous voltages are applied until completion of the warm-up period.

Pollution Degree II implies the expectation of occasional condensation.

• overvoltage (installation) category: classification with limits for transient

overvoltage, dependent on the nominal line voltage to earth. Category I implies signals

without high transient values. Category II applies to typical mains power lines with

some transients.

Safety Conditions

Users must comply with all relevant safety conditions in the user’s manual and the

Declarations of Conformity. This manual and Daq hardware make use of the following

Warning and Caution symbols: If you see either of these symbols on a product, carefully read

the related information and be alert to the possibility of personal injury.